Page 1

MoTeC M84 User’s Manual

Contents

Introduction ........................................................................ 1

Additional Documentation ................................................................................... 1

Overview ............................................................................. 3

Options ............................................................................................................... 3

ECU Inputs & Outputs......................................................................................... 4

Calibration & Setup ............................................................................................. 7

ECU Functions .................................................................................................... 8

MoTeC Software ............................................................... 11

PC Requirements ............................................................................................. 11

Connecting a PC to the ECU ............................................................................ 11

Installing the Software ...................................................................................... 11

Starting the Software ........................................................................................ 12

ECU Manager Software .................................................................................... 12

Data Logging .................................................................................................... 12

Installation ........................................................................ 15

Throttle Position or MAP Load Sensing ............................................................ 15

Sensors ............................................................................................................. 15

Wiring................................................................................................................ 19

Fuel System ...................................................................................................... 21

Ignition System ................................................................................................. 25

Auxiliary Valves ................................................................................................ 27

ECU Mounting .................................................................................................. 27

ECU Cleaning ................................................................................................... 27

Initial Setup ....................................................................... 29

Main Setup ........................................................................................................ 29

Sensor Setup .................................................................................................... 30

Input / Output Functions.................................................................................... 30

Other Functions ................................................................................................ 31

Initial Calibration .............................................................. 33

Fuel Tables ....................................................................................................... 33

Ignition Tables .................................................................................................. 34

Initial Starting Procedure ................................................ 37

Pre Start Checks ............................................................................................... 37

Starting ............................................................................................................. 39

After Start Checks ............................................................................................. 40

Page 2

Calibration ........................................................................ 43

Warning Alarms ................................................................................................ 43

Ensure that the engine is “On Site” ................................................................... 43

Site Tables ........................................................................................................ 43

Dyno Calibration ............................................................................................... 44

Fuel - Main Table .............................................................................................. 44

Ignition - Main Table ......................................................................................... 45

Fuel - Injection Timing ...................................................................................... 46

Fuel - Cold Start ................................................................................................ 46

Other Calibration Tables ................................................................................... 46

Data Logging & Road Testing ........................................................................... 47

ECU Manager Software .................................................... 49

Introduction ....................................................................................................... 49

Basics ............................................................................................................... 49

Calibration Files ................................................................................................ 51

Versions & Upgrading ....................................................................................... 51

Screen Layouts ................................................................................................. 53

Making Adjustments ......................................................................................... 55

View Screen ...................................................................................................... 65

Testing the ECU Outputs .................................................................................. 66

Enabling ECU Options ...................................................................................... 66

Keyboard Reference ......................................................................................... 67

Appendices ....................................................................... 69

Appendix A: General Specifications .................................................................. 69

Appendix B: Sensor Supplies ........................................................................... 70

Appendix C: Input Characteristics ..................................................................... 71

Appendix D: Auxiliary Output Characteristics ................................................... 73

Appendix E: Ignition Output Characteristics...................................................... 74

Appendix F: Injector Output Characteristics ...................................................... 75

Appendix H: Wire Specifications ....................................................................... 76

Appendix J: CAN Wiring - Multiple Devices ...................................................... 77

Appendix K: CAN Bus Wiring - Single Device ................................................... 78

Appendix L: Pin list by Function ........................................................................ 79

Appendix M: Wiring Schematic ......................................................................... 81

For racing and off highway use only

Not legal on emissions controlled vehicles unless appropriately certified

© Copyright – MoTeC Pty Ltd 2001-2010

While every effort is taken to ensure correctness, no responsibility will be taken for the consequences of any

The information in this document is subject to change without notice.

inaccuracies or omissions in this manual.

11 April, 2014

Page 3

MoTeC Introduction 1

Introduction

Thank you for purchasing a MoTeC Engine Management System.

This manual will help you understand the installation and calibration

requirements of your MoTeC Engine Management System.

Additional Documentation

Additional documentation is available in the form of Drawings and Tech

Notes. These can be downloaded from the MoTeC website at

www.motec.com.au

Drawing Categories

Accessories

ECUs

Looms

Ignition Modules

Combined Module & Trigger Systems

Trigger Systems

Valves

Sensors

Miscellaneous

. They are also available on the MoTeC Resource CD.

Tech Notes

Traction Control

Boost Control

Idle Speed Control

Closed Loop Lambda Control

Wideband Lambda Sensor

Others

Page 4

2 Introduction MoTeC

Page 5

MoTeC Overview 3

Overview

The MoTeC M84 ECU is a powerful and compact programmable Engine

Control Unit (ECU). The M84 is characterised by the following features:

• 1, 2, 3, 4, 5, 6 and 8 Cylinder/ 2, 3 and 4 rotor operation

• 8 injector outputs

• 6 ignition outputs

• 8 Auxiliary outputs

• Waterproof plastic connector with gold plated contacts

• 512 kByte logging memory

• Single Wideband Lambda input

Data Logging

Allows logging of the ECU sensors and operating parameters to the internal

data logging memory. The logged data may then be analysed in graphical

format using the MoTeC i2 Software.

Wideband Lambda

Allows Wideband Lambda (Air Fuel Ratio) measurement, which may be used

for data logging or closed loop control of the Air Fuel Ratio. The ECU is

compatible with Bosch LSU 4.0, 4.2 and 4.9 or NTK Wideband Lambda

sensors.

Options

A number of options are available which allow the ECU to be configured for a

particular need and can also be updated later if necessary.

The options may be enabled at any time by entering an enable password.

Optional functions include:

• Traction Control

• Boost Enhancement (Anti-lag)

• Hi/Lo Injection

• Gear Change Ignition Cut

• Advanced Functions (Traction Control, Boost Enhancement (Anti-la g),

Hi/Lo Injection, Gear Change Ignition Cut)

• Dual Wideband Lambda Inputs

Page 6

4 Overview MoTeC

ECU Inputs & Outputs

The ECU analyses signals from the sensors, then controls the Fuel Injectors,

Ignition System and other auxiliary devices according to the Calibration and

Setup Data which is stored in the ECU’s programmable memory.

The Inputs and Outputs are shown below.

Main Engine Sensors

The Main Engine Sensors are required for correct operation of the ECU.

The engine RPM is derived from the REF trigger sensor.

The SYNC trigger sensor is required to synchronise the Fuel and Ignition to

the correct engine cycle for sequential injection and correct firing of multicoil

ignition systems.

Page 7

MoTeC Overview 5

The Throttle Position, Manifold Pressure, Air Temp and Engine Temp are

used as inputs to the various calibration tables.

Optional Sensors

The Optional Sensors are not required for basic operation of the ECU.

The Lambda Inputs may be used for Wideband air fuel ratio measurement or

Wideband or Narrowband closed loop Lambda control.

The Digital Inputs may be used for wheel speed measurement or to activate

functions such as Dual RPM Limit.

The other inputs may be used for data logging (e.g. Exhaust Gas Temp, Fuel

Pressure etc.) or for special calibration features.

Fuel Injector Outputs

Up to eight injectors may be driven fully sequentially including very low ohm

types (0.5 ohms).

Ignition Outputs

The Ignition Outputs may be used to drive many different types of ignition

systems, which are detailed in the various ignition system drawings.

Up to six ignition outputs are available for multicoil applications.

• Up to 8 coils may be driven from one Ignition Output using a MoTeC CDI8 or

MoTeC Ignition Expander.

Auxiliary Outputs

The M84 has eight Auxiliary Outputs that may be used for:

Turbo Waste Gate Control, Idle Speed Control, Gear Change Light, Driver

Warning Alarm (plus many others).

CAN Communications

The CAN Communications system is a high speed network comm unications

system that allows multiple devices to be connected and communicate with

each other.

The CAN connection is used for all communications with the PC via the ECU

Manager software which includes calibration, diagnostics checking, retrieving

the logged data, firmware upgrading and enabling options.

Page 8

6 Overview MoTeC

CAN may be used to communicate with the MoTeC ADL & SDL Dash

Loggers, PLM, LTC and SLM.

RS232 Serial Communications

Used for receiving GPS data input and transmitting MoTeC Data Set 1 for use

with dash displays and loggers.

Page 9

MoTeC Overview 7

Calibration & Setup

Calibration Tables

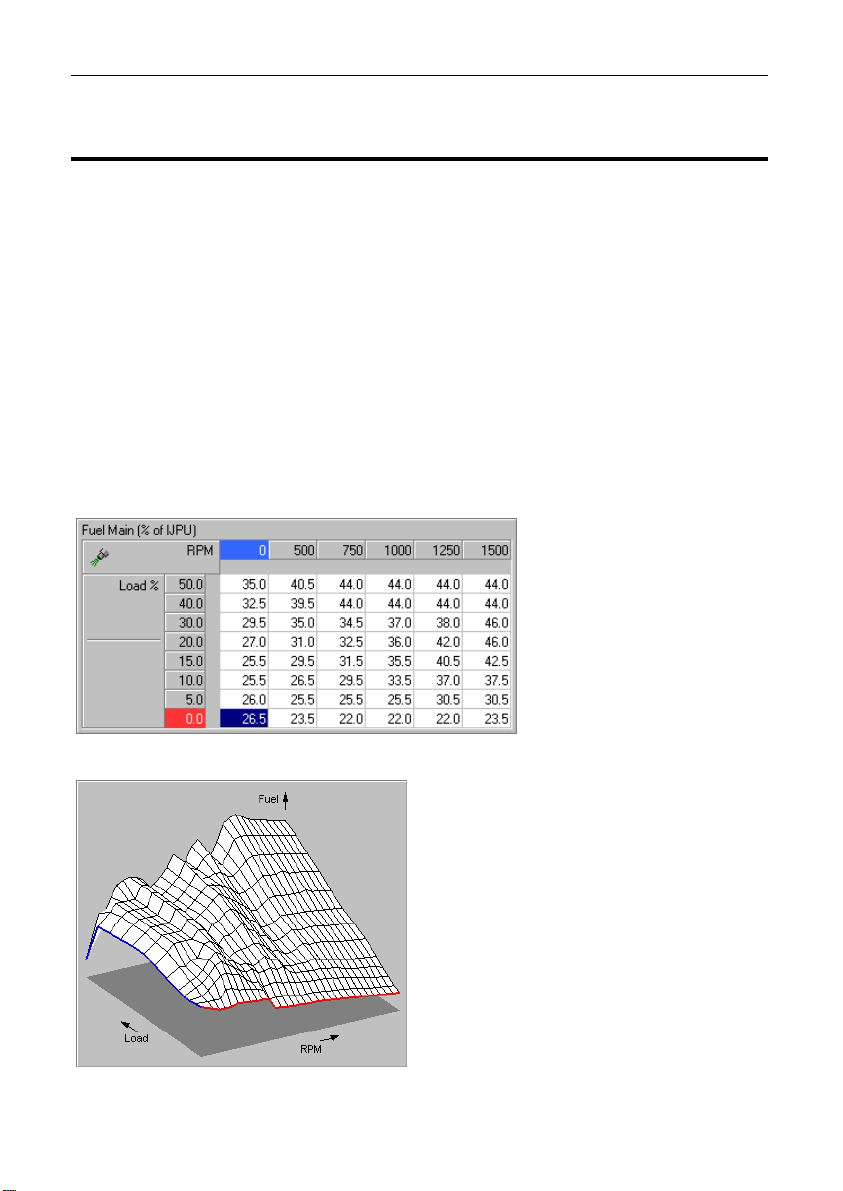

The Calibration Tables determine how the output devices should be controlled

for various sensor readings. For example, the fuel calibration table determines

the base injector pulse width for all combinations of RPM and Load. Other

calibration tables will also affect the fuel injector pulse width such as Air

Temperature compensation and Engine Temperature compensation.

The ECU determines the amount of fuel to inject by first calculating the RPM

and Load then extracting the corresponding value from the table. If the RPM

and Load do not match an RPM and LOAD point exactly then the values from

the closest sites are mathematically interpolated to arrive at an intermediate

value.

A typical 3 dimensional fuel calibration table is shown below.

The calibration tables may also be represented graphically as shown below.

Page 10

8 Overview MoTeC

Setup Parameters

The Setup Parameters allow the ECU to be configured for almost any engine.

The Setup Parameters include Number of Cylinders, Ignition Type, Sensor

Types, Injector Current, Auxiliary Output Functions etc.

• The Setup Parameters must be correct before attempting to start the

engine.

ECU Functions

The ECUs can perform a large number of functions in addition to the normal

Fuel and Ignition control capabilities including; Hi /Lo injection, Individual

Cylinder tables for Fuel and Ignition, Rotary Ignition Split and various sensor

compensations

The functions are setup using ECU Manager either in the Functions menu,

the Digital Input Functions menu or the Auxiliary Output Functions menu.

Help on each function is available from within ECU Manager by pressing the

F1 key when the appropriate screen is shown.

Tech Notes are available from MoTeC on the more complicated functions such

as Traction Control.

The functions are as follows:

Functions

The following functions are setup in the Functions menu

• Boost Control **

• Warning Alarms **

• Gear Detection *

• Overrun Fuel Cut

• Ground Sped Limiting *

• Gear Change Ignition Cut *

• Boost Enhancement (Anti-lag) *

• Lambda Control

• Traction Control *

• Idle Control

* must also be setup in the Digital Input Functions

** must also be setup in the Auxiliary Output Functions

Page 11

MoTeC Overview 9

Digital Input Functions

The following functions are setup in the Digital Input Functions menu

• Speed Measurement

• Period Measurement

• Pulse Measurement

• Dual RPM Limit

• Air Conditioner Request

• Ignition Switch

• Brake

• Logging Enable

• Clutch

• Overrun Boost Enhancement

• Traction Control Enable

• Ground Speed Limiting

• Power Steering

Auxiliary Output Functions

The following functions are setup in the Auxiliary Output Functions menu

• Boost Control

• Idle Speed Control

• Aux Table Controlled Output

• Tacho Signal

• Stepper Idle Speed Control

• Lambda Sensor Heater

• Fuel Pump Control

• Thermatic Fan Control

• Air Conditioner Fan Control

• Air Conditioner Clutch Control

• RPM / Load Table Output

• Gear Change Light Output

• Fuel Used Pulse Output

• Slip Warning Output

• Alternator Control

• Spray Bars Output

• Status Output

• Thermo Pump

Page 12

10 Overview MoTeC

Page 13

MoTeC Software 11

MoTeC Software

The following software is available for the M84 ECU.

ECU Manager: Used for calibration, setup, diagnostics, output testing,

upgrading, unloading the logged data and enabling

ECU options.

i2: Used to analyse the logged data.

PC Requirements

• IBM PC compatible

• 200 MHz Pentium or faster

• Operating System: Windows XP. Windows Vista, Windows 7

Connecting a PC to the ECU

The PC must be connected to the ECU by a MoTeC UTC or CAN Cable. Note

that the ECU must be wired with the mating connector.

MoTeC

Connected to the

Printer Port

CAN Cable

Installing the Software

The MoTeC Software must be installed on to the PC hard disk before it can

be used.

Page 14

12 Software MoTeC

The main software required is the ECU Manager software, if Data Analysis is

required then the i2 software should also be installed.

The software can be downloaded from the MoTeC website at

www.motec.com.au

MoTeC is continually updating the software and newer versions may be

downloaded from the website at no charge.

To install the software after downloading from the web, double click on the

downloaded file and follow the instructions.

Note that a separate folder (directory) is automatically created for each

version of the software. Old versions are kept so that they may be used if

necessary.

• Do not change the MoTeC directory structure or move the software to a

different directory, otherwise the software will not operate correctly.

. It is available on the MoTeC Resource CD.

Starting the Software

To start the MoTeC Software double click the appropriate icon on the desktop

or select the appropriate program from the Start menu. For example: Start /

Programs / MoTeC / M84 / ECU Manager 1.0

ECU Manager Software

The ECU Manager software is covered in more detail later in this manual.

Data Logging

Data Logging allows the ECU operational data to be recorded in a memory

chip inside the ECU. The data may then be extracted for analysis on a PC.

Data logging is extremely useful for checking mixture readings, sensor

readings, diagnostics errors and other operating information.

The items to be logged and the logging rates must be setup using the MoTeC

ECU Manager software. This is done in the Data Logging Setup screens.

The ECU will remember the logged data even if the ECU power is turned off.

• If the logging memory becomes full, the oldest data is overwritten so that

the most recent data is always available.

Page 15

MoTeC Software 13

Unloading the Logged Data

The logged data can be extracted by connecting the MoTeC UTC or CAN

Cable to the ECU and selecting Utilities | Get Logged Data from the ECU

Manager menu.

Data Logging Analysis

The MoTeC i2 software may be used to analyse the logged data.

The i2 software is supplied separately to the ECU Manager software.

The i2 software makes it easy to analyse mixture readings and other sensor

readings by presenting the data in various graphical formats.

Refer to the i2 help screen for more detail.

Page 16

14 Software MoTeC

Page 17

MoTeC Installation 15

Installation

Throttle Position or MAP Load Sensing

The load point for the fuel and ignition calibration tables may be based on any

defined load measuring sensor.

The most commonly used are the Throttle Position sensor or the MAP

(Manifold Pressure) sensor.

Turbo Charged Engines

Normally use Manifold Pressure load sensing (connect the MAP sensor to the

inlet manifold).

A Throttle Position sensor is optional and will be used for acceleration

enrichment if fitted.

Normally Aspirated Engines

Normally use Throttle Position load sensing.

The MAP sensor may be used to compensate for barometric pressure

changes by venting it to atmospheric pressure.

If Idle Speed Control is used then the MAP sensor should be connected to the

plenum or Manifold Pressure load sensing should be used. This is required so

that the fuel is varied as the idle speed control valve opens and closes.

Sensors

Throttle Position Sensor

The Throttle Position sensor must be a potentiometer type, older switch types

are not suitable. The sensor will produce a voltage proportional to the angle of

the throttle plate.

Throttle sensors generally have a dead band at either end and must be preloaded to avoid the dead band.

The Setup Parameters TPHI and TPLO must be set to indicate the fully

closed and fully open positions. These parameters must be set any time the

Page 18

16 Installation MoTeC

sensor is moved or replaced. It is very important to set these parameters with

the butterfly in exactly the same place each time.

The resistance element inside the sensor may wear due to vibration in high

performance engines which can cause erratic readings. It is best to replace

the throttle position sensor periodically.

Avoid high pressure washing as this may penetrate the seals and damage the

sensor.

For wiring details refer to the appropriate MoTeC drawing.

MAP Sensor

The MAP (Manifold Absolute Pressure) sensor measures Absolute Pressure

(i.e. pressure relative to a vacuum).

0 kPa Absolute = Complete Vacuum

100 kPa = 1 Bar = 14.5 PSI

Atmospheric Pressure at sea level is approximately 100 to 102 kPa,

depending on the weather.

MAP sensors normally produce a voltage between 0 and 5V, depending on

the pressure.

The pressure sensor may be used to measure the inlet manifold pressure or

to measure the barometric pressure depending on the Load Sensing

arrangement detailed earlier.

The ECU Sensor Setup parameters must be set to indicate the type and

pressure range of the sensor.

Avoid severe vibration of the sensor as this can cause fluctuations in the

reading. Do not mount rigidly to the engine. Normally the pressure sensor is

mounted to the vehicle body.

If Used for Manifold Pressure Sensing

For normally aspirated engines use a 100 kPa sensor.

For turbo charged engines a 300 kPa absolute sensor will measure up to 200

kPa (29 psi) of boost (above Atmospheric). If higher boost will be achieved, a

sensor with a higher pressure range will be needed.

The sensor should be connected to the inlet manifold plenum via a short hose

(less than 1m). The sensor should be mounted above the level of the plenum

with the port facing down to avoid moisture accumulating on the sensor

element. The hose should run downwards all the way to the plenum.

Page 19

MoTeC Installation 17

The plenum take off point should be at a position that best represents the

average manifold pressure and has minimal pressure pulsations. A small

restrictor may be needed at the manifold end of the hose to help reduce

pressure pulsations. The take off point should not be teed in with other items

such as idle speed control valves as they can affect the pressure reading.

If used for Barometric Pressure Sensing

Use a 105 kPa sensor.

Vent the sensor to the atmosphere with the port facing down.

Avoid mounting at a point where air buffeting occurs Any pressure

fluctuations will directly affect the mixture.

It may be desirable to sense the pressure at the air intake as the pressure

may vary due to aerodynamic effects.

Air Temp Sensor

The Air Temperature sensor is mainly used to correct for air density change

due to air temperature variation.

The sensor contains a temperature dependant resistor and is designed for

high speed response in an air flow.

The Air Temp sensor must be placed to measure the air temperature before

the butterfly (and after the intercooler on turbo charged engines).

Avoid placing the sensor too close to the stand-off vapour in a multi-runner

manifold as this will cool the sensor and give a false reading.

The ECU Sensor Setup parameters must be set to indicate the particular type

of sensor.

Engine Temp Sensor

The Engine Temperature sensor is mainly used for cold start enrichment.

The sensor contains a temperature dependant resistor and is designed for

water immersion.

The ECU Sensor Setup parameters must be set to indicate the particular type

of sensor.

Page 20

18 Installation MoTeC

Trigger Sensors (REF & SYNC)

The trigger sensors supply the necessary timing information to the ECU so

that it knows when to fire the fuel injectors and ignition system. Normally two

sensors are used, REF and SYNC.

Many different types of trigger sensors and chopper patterns may be used.

The wiring and ECU setup information for the trigger sensors are specific to

the particular system. Refer to the appropriate MoTeC drawing.

Home made sensor systems often cause problems. Do not use Chrome molly

for chopper disks as it is a non magnetic material. Runout of the disk,

imperfections and bolt heads are also potential sources of problems. Where

possible it is best to use the manufacturer’s trigger system.

REF Sensor

Supplies the crank position information.

Some sensors supply one pulse per Top Dead Centre (4 pulses per engine

rev on a V8), others supply as many as 360 pulses per engine revolution.

The Engine RPM is derived directly from this signal.

SYNC Sensor

Used to indicate each engine cycle, which is required for sequential injection

and multicoil operation.

Generally supplies one pulse per engine cycle (i.e. once every 2 revs on a 4

stroke engine).

On some special trigger systems the ECU can be synchronised using the

REF sensor only (e.g. Ford Narrow Tooth)

REF / SYNC Alignment

Most modern distributors supply both REF and SYNC signals in which case

the alignment is pre-set.

When using separate REF and SYNC sensors the alignment of the two

sensors relative to one another is critical. Ensure that the sensors are aligned

correctly for the type of trigger system being used. Refer to the appropriate

drawing. Allow for any mechanical play in the distributor drive system if the

SYNC signal is derived from the distributor.

Page 21

MoTeC Installation 19

Exhaust Gas Sensor (Lambda Sensor)

The ECU may optionally use a wideband exhaust gas sensor for data logging

or closed loop control of the Air Fuel Ratio.

The ECU is compatible with the Bosch LSU Wideband sensor and the NTK

Wideband sensor. These sensors are different to the sensors used on

previous model ECUs.

Note that the sensor heater must be connected to these sensors at all times

and must be controlled by the ECU by connecting it to one of the Auxiliary

Outputs.

The sensor should preferably be placed within 0.5 m of the collector pipe on a

normally aspirated engine or 0.5 m of the turbo on a turbo charged engine. If

placed too close to the exhaust outlet, the reading may be affected by the

outside oxygen.

The sensor can be contaminated by exhaust manifold sealant - use an

exhaust gas sensor friendly sealant.

The lifetime of the Sensor will be significantly reduced by leaded fuels.

Refer to the MoTeC Tech Notes and Drawings for more details.

Wiring

Wiring Drawings

For general wiring details refer to the following drawing; M84 Wiring.

The wiring details for the REF and SYNC Trigger Sensors and the Ignition

Module are specific to the type of sensors and Ignition system. MoTeC can

provide wiring diagrams for most Trigger Sensors and Ignition systems.

Wiring details for other sensor types are available from MoTeC.

Wiring Reliability

The wiring is critical for reliable operation of the ECU. The following points will

help to ensure that the wiring is reliable.

Ground Wiring

One of the most common wiring problems is poor ground wiring.

The ground wire must be grounded properly to the engine block. There should

be no paint or anodising between the ground wire and the engine block.

Page 22

20 Installation MoTeC

Temporary wiring is likely to cause problems: use a proper eyelet terminal that

is securely crimped to the ground wire. Studs fixed in place by Loctite® can

also cause a problem as the Loctite® becomes an insulator. These comments

apply to both the ECU ground wire and the Ignition system ground wire.

2

The ground wire must be at least 12# (3.3 mm

possible.

) and must be kept as short as

Power Wiring

The power wire must be wired by the shortest path possible to the battery via

a 30 Amp relay and a 20 Amp fuse. The relay and fuse must be in good

condition and the wires must be crimped securely to the appropriate

terminals. The relay should be activated by the Ignition Switch. The ECU

power must NOT be fed directly from the Ignition switch because it probably

won’t handle the required current.

2

The power wire must be at least 12# (3.3 mm

possible.

) and must be kept as short as

Spark Plug Leads

The spark plug leads can cause interference in the ECU wiring. Keep the

ECU wires away from the plug leads wherever possible (at least 100mm). If it

is necessary to cross the plug leads, cross at right angles.

Terminal Crimping

Use the correct crimping tool for each type of terminal. Do a pull test on a

sample wire and terminal to verify that the crimp is sound. In theory the wire

should break before the wire pulls out of the crimp.

Most crimp tools are only designed for a certain range of wire sizes so be sure

to test the crimp with the particular wire size being used.

Soldering the terminal is a last resort if the correct crimping tool is not

available. Soldering will cause a stress point where the solder wicks up the

wire which is likely to fracture unless all movement is avoided. Solder flux can

also cause corrosion and may affect the contacts.

Terminal Damage

The various connector terminals are easily damaged if probes are inserted

into them. Do not insert probes of any kind into the terminals. If checking a

circuit for continuity, gently touch the side of the terminals only, or preferably

attach a mating connector.

Page 23

MoTeC Installation 21

Wire Splicing

Preferably use a crimp splice. If soldering a wire splice, wire movement near

the joint must be avoided otherwise a fracture may occur at the stress point

created by the solder. Use heatshrink sleeving to insulate and provide support

to the wires.

Wire Strain

Avoid pulling the wires tight at the connectors.

Wire Movement

Avoid wire fatigue by tying the wires down close to the connectors.

Heat

Keep the ECU wires away from the exhaust system.

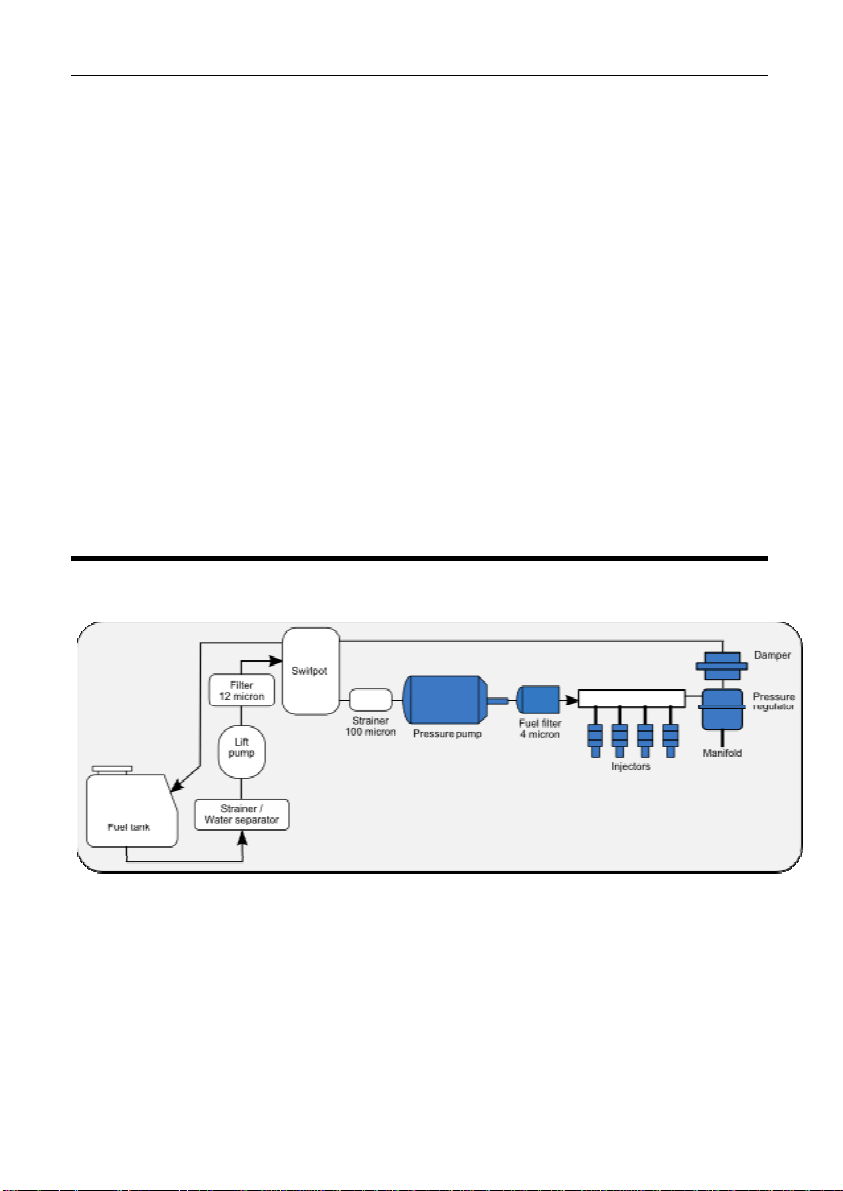

Fuel System

An ideal race fuel system is shown below

Lift Pump

The Lift Pump is a low pressure pump designed to lift the fuel from the fuel

tank to the swirl pot (header tank).

The Lift Pump must be capable of flowing enough fuel for full power operation.

Page 24

22 Installation MoTeC

Swirl Pot

The swirl pot (header tank) maintains a reserve of fuel to avoid fuel starvation

to the engine during cornering and acceleration. Fuel starvation can also

cause damage to the pressure pump as it relies on the fuel for cooling,

lubrication and speed limiting.

The swirl pot also forms a header tank for the pressure pump since the

pressure pump is not capable of lifting the fuel from the tank if the tank is

lower than the pump. Place the swirl pot at the same level, or higher than the

pressure pump.

Pressure Pump

The Pressure Pump is a high pressure pump that must be capable of

delivering the required amount of fuel at the correct pressure at full power.

It is very important that the pump is capable of maintaining the correct fuel

pressure at full power otherwise the engine could be damaged due to a lean

mixture.

A 600 hp engine requires a flow rate of approximately 250 lb/hr for petrol or

gasoline.

Notes

• The pressure pump must be lower than the outlet of the swirl pot.

• Prime the pump with fuel before use.

• The pump’s flow capability is dependant on the required pressure, the flow

capability of the pump will be less at higher pressures. A small pump will

maintain correct pressure at light load but will not maintain correct

pressure as the flow requirement increases.

• On boosted engines the pressure required from the pump increases with

boost pressure because the regulator maintains constant pressure above

manifold pressure.

• Avoid running the pump dry as this may destroy the pump.

Filters

The filters are necessary to ensure that the fuel pump is not damaged and to

ensure that the injectors do not become blocked.

• The strainer before the pressure pump is essential to prevent the pump

from seizing. A strainer is used because the pressure pump won’t suck

through a paper filter.

Page 25

MoTeC Installation 23

Fuel Lines

The fuel feed lines must be high pressure type and should be at least 8mm

(5/16 inch) diameter. The return lines should also be at least 8mm (5/16 inch)

diameter to ensure that the fuel is easily returned to the tank.

Use proper high pressure hose clamps to ensure that the lines do not blow off

under pressure.

Keep the fuel lines as cool as possible to avoid fuel vaporisation. The

temperature of the fuel will also affect the mixture due to the change in fuel

density.

Avoid fire risk by ensuring that all hoses and fittings are in good condition and

installed correctly.

Fuel Rails

The fuel rails must be free of any debris that could block the injectors. Welded

fuel rails can often cause a problem unless they have been properly treated to

remove all scale and debris and even then they may corrode and cause

problems. Aluminium fuel rails mounted directly on the injectors are

recommended as they do not suffer these problems.

The fuel rails must have sufficient volume to minimise fuel pressure pulsation

and resonance problems.

Fuel Pressure Regulator

The fuel pressure regulator maintains constant fuel pressure to the injectors

which is necessary to ensure constant metering of the fuel. Any variation in

the fuel pressure will cause a corresponding mixture change.

The fuel pressure regulator should be mounted at the end of the fuel rail so

that fuel is always flowing through the rail. This helps to avoid vapour locks.

Adjustable pressure regulators are available.

If Using Manifold Pressure Load Sensing

Connect the regulator port to the plenum as this ensures that constant

pressure is maintained across the injectors.

Note that this will cause the fuel pressure required from the pump to increase

as the manifold pressure increases.

Page 26

24 Installation MoTeC

If Using Throttle Position Load Sensing

Leave the regulator port open to the atmosphere, unless the MAP sensor is

connected to the manifold as is recommended when using idle speed control,

in which case the regulator port should be connected to the manifold.

Fuel Injectors

The fuel injectors meter the fuel by opening for a short but defined time once

per engine cycle (sequential operation).

The injectors must be wired in the firing order of the engine.

Sizing

The size of the injector determines the maximum amount of fuel that can be

delivered to the engine.

As a rule of thumb the engine will require about 5 cc per minute per horse

power for petrol or gasoline. For alcohol a higher flow rate is required.

For example: A 600 hp V8 will require each injector to flow at least

600 hp x 5 cc/min/hp/8 injectors = 600 x 5/8 = 275 cc/min.

Note that the flow rate of any particular injector is dependant on the fuel

pressure applied to it.

Sometimes oversize injectors are used to maintain lower duty cycles, since

high duty cycles reduce the effect of sequential injection, because the

injectors are turned on for most of the time. However this can affect idle

fuelling as the injector may have trouble delivering small amounts of fuel.

Flow Rate Matching

The flow rate of injectors can vary between injectors of the same type. It is

advisable to match the flow rates of injectors by testing each injector on a flow

bench.

Fuel Pressure

The fuel pressure applied to the injector will directly affect the amount of fuel

that the injector delivers. Doubling the pressure however only increases the

fuel flow by about 1.4 times.

Most injectors will only operate correctly over a certain range of fuel

pressures. If the pressure is too low then the fuel may not atomise properly. If

the pressure is too high then the injectors may not turn off fully. Many injectors

Page 27

MoTeC Installation 25

will operate correctly at 2.5 bar (29 psi) and some will operate up to 5 bar (73

psi).

Current

Different injectors require different operating currents. The ECU injector drives

must be programmed to suit the injector using the Injector Current setup

parameter.

Pulse Width

The amount of time that the injector spends open during each injection pulse

is called the Injector Pulse Width and is measured in milliseconds

(thousandths of a second), abbreviated as msec.

The injector pulse width is controlled by the ECU according to the ECU,s

calibration data.

Duty Cycle

The Injector Duty Cycle is a measure of the ratio of the time the injector is

open (pulse width) to the available time per engine cycle. For example, if the

injectors were on for half the available time then the duty cycle would be 50%.

The maximum allowable duty cycle is about 85 percent, beyond this the

injector does not have time to open and close and is therefore open

continuously and cannot deliver more fuel.

The ECU will set a Diagnostics Error if the duty cycle exceeds the maximum

allowed duty cycle.

Ignition System

Ignition System Types

Many different types of ignition systems are available with some better suited

to different applications than others.

CDI Distributed

CDI systems are suited to high revving engines with 8 or more cylinders and

are generally capable of at least 12,000 RPM on an 8 cylinder. CDIs are also

good at firing fouled plugs.

Page 28

26 Installation MoTeC

HEI Distributed

High Energy Inductive (HEI) distributed ignition systems are generally limited

to about 8000 RPM on an 8 cylinder engine but will run a 6 cylinder to 11,000

RPM and a 4 cylinder to 15,000 RPM.

Most modern road cars run HEI ignition systems that are equally well suited to

high performance engines as long as the above RPM restrictions are

observed.

Multicoil (HEI or CDI)

HEI or CDI multicoil systems will generally run any engine to 15,000 RPM.

Two types of Multicoil systems are possible:

Coil per plug

One coil for each spark plug, fired sequentially.

Double Ended Wasted Spark

Double ended coils have two high tension towers and fire two plugs at

the same time, one on the compression stroke and the other on the

exhaust stroke. Each coil is fired sequentially twice per engine cycle

and must feed the appropriate two cylinders.

Ignition System Wiring & Setup

The wiring and setup parameters are specific to the particular ignition syste m .

Refer to the appropriate MoTeC Ignition System or Ignition Module drawing.

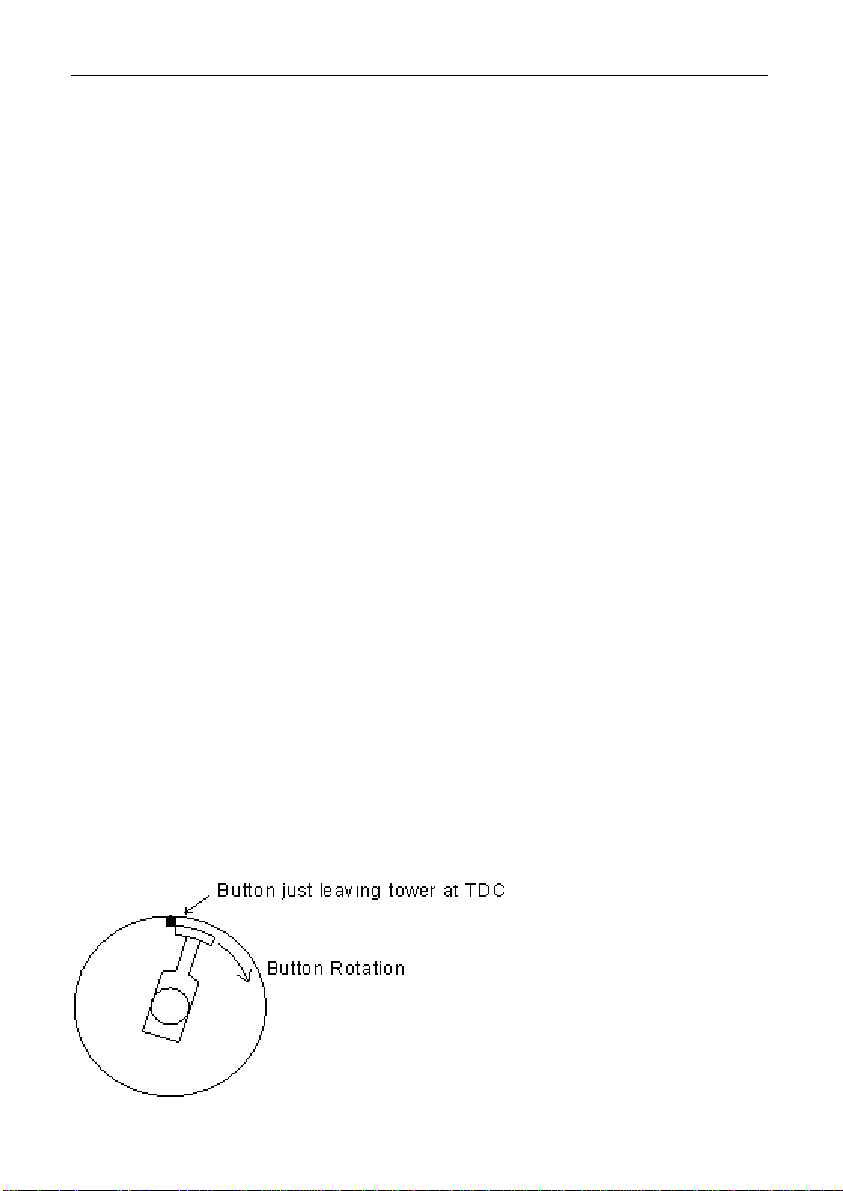

Distributor Button Alignment

If using a distributor, the button must be aligned so that it is leaving the tower

at Top Dead Centre for that cylinder.

Page 29

MoTeC Installation 27

The button must be a wide tip type to cater for a wide range of advance points

since the advance is changed electronically rather than mechanically.

Make sure that the button still overlaps the tower at the maximum advance

point.

The distributor should have no mechanical or vacuum advance as this is

provided by the ECU.

Spark Plug Leads

The spark plug leads should be high quality Inductive Suppression leads such

as Magnicor® leads and must be in good condition.

• Do not use wire leads as they can cause interference.

• Do not use resistive suppression leads as they will reduce the spark

energy.

Auxiliary Valves

The ECU can control various auxiliary devices such as Idle Speed or Turbo

Boost control valves.

Refer to the appropriate MoTeC drawing for setup and wiring details. Refer

also to any relevant Tech Notes.

ECU Mounting

The ECU should be mounted in an area where the internal temperature of the

ECU will not exceed 85 °C. Generally this is in the passenger compartment.

Allow for adequate air circulation around the ECU. The ECU internal

temperature may be viewed using the ECU Manager software or it may be

recorded using the data logging.

Mount so as to minimise vibration, this will help to prolong the ECU’s life.

ECU Cleaning

Avoid high pressure washing or degreasing of the ECU.

Page 30

28 Installation MoTeC

Page 31

MoTeC Initial Setup 29

Initial Setup

Before attempting to start the engine the setup parameters must be correct.

Use the MoTeC ECU Manager software to adjust the setup parameters.

Preferably start with a calibration file from a similar engine as this will make

setup faster and easier.

Main Setup

Injectors

Injector Scaling (IJPU)

Injector Current

Injector Battery Compensation

Refer to the ECU Manager help screens for details.

Calculation Methods

Efficiency Calculation Method.

Load Calculation Method.

Refer to the ECU Manager help screens for details.

Number of Cylinders

CYLS 4 Stroke engines: use positive numbers e.g. 8 for 8 cyl.

2 Stroke engines: use negative numbers e.g. -2 for 2 cyl.

Rotary engines: use -2 for 2 rotor and -3 for 3 rotor.

Trigger Setup

Ref / Sync Mode (REF)

Crank Reference Teeth (CRT)

Crank Index Position (CRIP)

These parameters are dependant on the type of trigger system. Refer to the

appropriate MoTeC Trigger drawing or Ignition System drawing.

Page 32

30 Initial Setup MoTeC

Note that the trigger sensor type (Hall / Mag, Edges etc.) must be setup in the

Sensor Setup screens.

Ignition

Ignition Type (IGN)

Number of Coils (COIL)

Ignition Dwell Table

Ignition Delay Time

These parameters are dependant on the type of Ignition Module. Refer to the

appropriate MoTeC Ignition Module drawing or Ignition System drawing.

Sensor Setup

Throttle Position Sensor Hi / Lo

TPLO Throttle Position LO (Closed Throttle)

TPHI Throttle Position HI (Wide Open Throttle)

The Throttle HI and LO points must be set every time the throttle position

sensor is moved or replaced so that the throttle can be correctly scaled

between 0 and 100%.

REF / SYNC Sensor Setup

The REF/SYNC setup parameters must be set to suit the trigger sensors.

Refer to the MoTeC Trigger drawings for details.

Sensor Calibrations

The sensors calibrations must be set to suit the connected sensors.

Refer to the ECU Manager help screens for details.

Input / Output Functions

Setup any essential Input / Output functions.

It may be best to start with any non essential functions turned off (e.g. Idle

Speed Control, Dual RPM Limit etc.).

Page 33

MoTeC Initial Setup 31

Refer to the ECU Manager help screens for details.

Other Functions

Ensure any other functions such as Boost Control, Traction Control etc. are all

set appropriately.

It may be best to start with any non essential functions turned off (e.g.

Traction Control, Lambda Control etc).

Refer to the ECU Manager help screens for details.

Page 34

32 Initial Setup MoTeC

Page 35

MoTeC Initial Calibration 33

Initial Calibration

Before attempting to start the engine the calibration tables should be

initialised to sensible values.

Use the MoTeC ECU Manager software to initialise the ECU calibration tables.

Preferably start with a calibration file from a similar engine as this will make

initial calibration faster and easier.

Clear any *s from the tables by selecting Clear *s from the ECU Manager

software Tools Menu (Press the F9 key). The *s indicate values that have

been set correctly, which is inappropriate at this stage.

Fuel Tables

Fuel - Main Table

Check the Fuel - Main Table.

The table should be smooth.

In general, turbo tables look quite different from throttle position tables, so it is

wise to start with a table from a similar engine.

Fuel - Air Temp

Check the Fuel - Air Temp compensation table.

Typically the following table can be used :

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80+

10 9 8 6 4 2 0 -2 -4 -6 -8 -10 -12

Fuel - Engine Temp

The Fuel - Engine Temp compensation table may be used instead of the cold

start warm up parameter.

If using Engine Temp compensation the following table can be used :

-10 0 10 20 30 40 50 60 70 80 90 100 110+

60 50 40 30 20 10 5 2 0 0 0 0 5

Page 36

34 Initial Calibration MoTeC

Fuel - MAP

Check the Fuel - MAP compensation table.

The fuel must be increased by 100% every 100 kPa increase in air pressure.

Normally the MAP table should contain the following values, with a straight

line increase between values.

0 kPa 100 kPa 200 kPa 300 kPa 400 kPa 500 kPa

-100 0 100 200 300 400

This table is equally applicable whether the MAP sensor is used for

barometric pressure measurement or for manifold pressure measurement.

Note that the higher pressure sites will only be available if a high pressure

MAP sensor is used.

Fuel - Cold Start

Start with the typical values listed in the help.

Fuel - Acceleration Enrichment

Start with the typical values listed in the help.

Generally acceleration enrichment is not required above 4000 RPM.

Other Fuel Compensation Tables

Typically all other compensation tables should be set to zero.

Ignition Tables

Ignition - Main Table

The table should be smooth.

Make sure that the Ignition - Main Table is initialised with a conservative curve

for the particular engine, not too advanced and not too retarded.

Page 37

MoTeC Initial Calibration 35

Ignition - Air Temp

Check the Ignition - Air Temp compensation table.

Typically the following table can be used :

-20 -10 0 10 20 30 40 50 60 70 80 90 100+

-12 -9 -6 -3 0 0 0 0 -3 -6 -9 -12 -15

Other Ignition Compensation Tables

Typically all other ignition compensation tables should be set to zero.

Page 38

36 Initial Calibration MoTeC

Page 39

MoTeC Initial Starting Procedure 37

Initial Starting Procedure

The ECU Manager software should be used to assist during starting.

The ECU Manager software allows all diagnostic errors and sensor re adings

to be checked and allows the injectors, ignition system and auxiliary outputs

to be tested while the engine is stopped. The calibration tables and setup

parameters should also be checked.

Pre Start Checks

Calibration Tables & Setup Parameters

Check that all setup parameters have been set appropriately.

Check that all calibration tables have sensible values in them.

Check that any advanced functions such as Traction Control are turned off.

Power to the ECU

If the ECU has power then the ECU Manager software should indicate that

the ECU is connected (at the bottom left corner of the screen).

Diagnostic Errors

Before starting the engine check the diagnostic errors on the ECU Manager

Diagnostic Errors screen. Any errors must be rectified before starting the

engine.

To clear any non current errors press the Enter key on the PC while viewing

the Diagnostics Errors screen.

• Note that the diagnostic errors are lost if the ECU power is turned off.

Sensor Errors

If an error is shown for a sensor that is not fitted, the sensor should be

disabled by setting the sensor setup number to zero.

Sensor Errors may be due to bad wiring to the Sensor (either short circuit or

open circuit).

Page 40

38 Initial Starting Procedure MoTeC

Test the Sensors

Before starting the engine, test that all sensors are giving sensible readings

by viewing their values on the ECU Manager : View screen. Vary the sensor

readings if possible to check for correct operation.

Check that the Throttle Position Sensor varies smoothly from 0 to 100% when

moved from fully closed to fully open. Note that the TPHI and TPLO setup

parameters must have been set correctly for correct operation of the Throttle

Position sensor.

The MAP sensor should read barometric pressure when the engine is stopped

(approximately 100 to 102 kPa at sea level depending on the day).

The Engine Temp and Air Temp sensors must give correct readings.

Test the Ignition

Use the ECU Manager : Ignition Test (in the Utilities menu) to ensure that

the Ignition System is functioning correctly.

Notes

• Some special ignition systems do not work in the Ignition Test screen. e.g.

Mazda Series 4 and 5 and other direct fire ignition systems.

• If the Ignition System is wired via the Fuel Pump relay then the ignition test

will not work unless this relay is activated.

• It will be necessary to place a spark plug on the lead from the ignition coil if

the ignition system uses a distributor.

Test the Injectors

Use the ECU Manager : Injector Test (in the Utilities menu) to ensure that

all injectors are working and that they are wired in the correct firing order for

sequential operation.

WARNING: Ensure that the fuel pump is off during this test.

Initial Cranking

Crank the engine without fuel pressure and check the RPM reading.

Check that the RPM reading is sensible, if the RPM is too high or too low or is

erratic then the Setup may be incorrect or there may be a problem with the

REF sensor signal. If there is no RPM reading then the REF sensor is not

working.

Page 41

MoTeC Initial Starting Procedure 39

Check that no REF or SYNC Diagnostic Errors occur during constant

cranking. Diagnostic errors may occur as cranking winds up; this is OK, but

the errors need to be cleared by pressing the Enter key while viewing the

ECU Manager : Diagnostics Errors screen, so that constant cranking may

be checked for errors. Diagnostic errors may occur as cranking winds down,

this is also OK.

Cranking Ignition Timing

Check that the Ignition Timing is correct during constant cranking.

This can best be done in the Crank Index Position setup screen under the

ignition menu. While in this screen the ignition timing will stay fixed at the

value set under ‘Test Advance’. This allows the CRIP to be adjusted if

necessary until the timing matches the Test Advance.

Notes

• Dial back timing lights such as the Snap-On® brand may not work

correctly at cranking - use a traditional timing light.

• For some trigger modes (one tooth per firing) the Ignition Timing is set by

the sensor position only. In this case the ECU only controls the timing

above 500 RPM.

• If the spark is going to the wrong cylinder on a Direct Fire Ignition the

ignition may be wired incorrectly or the CRIP (Crank Index Position) setup

parameter may be out by a multiple of the angle between cylinders.

Starting

Fuel System

Power up the fuel pumps and check the fuel system for leaks before

attempting to start the engine.

Fuel Overall Trim

Use the FUEL - Overall Trim to vary the mixture when trying to start the

engine to see if the engine needs more or less fuel, This ensures that the

mixture is varied equally for all RPM and Load points.

Establish how much trim the engine needs on average then trim this out by

adjusting the setup parameter IJPU (Injector Pulse Width Scaling), or by using

the Overall Trim Table item in the Tools Menu.

Page 42

40 Initial Starting Procedure MoTeC

If the engine won’t start

• Check for correct fuel pressure.

• Check for fouled plugs.

• Re-check for diagnostics errors.

• Re-check the Ignition Timing with a Timing Light.

• Check the setup parameters against the drawings.

• Check that the ignition is wired in the correct firing order.

• Check that the ignition is firing on the compression stroke, not the exhaust

stroke.

After Start Checks

Ignition Timing Check

Check the Ignition Timing with a Timing Light to ensure that the actual Ignition

Timing corresponds to the ECU Ignition Timing as shown on the ECU

Manager : View screen. Check the timing at high and low RPM to ensure that

it is correct at all revs. If the timing is correct at one RPM but incorrect at

another RPM and the REF sensor is a magnetic type then the trigger edge

may be incorrect or the sensor may be wired in the wrong polarity.

Adjust the setup parameter CRIP (Crank Index Position) to correct for small

variations in the REF sensor positioning.

Adjust the Ignition - Individual Cylinder Trim for cylinder number 1 and

verify that it changes the ignition timing for cylinder number 1 rather than any

other cylinder. If not the CRIP is incorrect and needs to be adjusted by

multiples of the angle between cylinders.

Fuel Pressure

Check that correct fuel pressure is maintained under all load conditions.

Operational Diagnostics Errors

After the engine has started check for diagnostics errors.

To clear any non current errors press the Enter key while viewing the ECU

Manager : Diagnostics Errors screen.

The following operational errors may occur in a new installation:

Page 43

MoTeC Initial Starting Procedure 41

Injector Errors

Open The Injector is open circuit - check the wiring.

Short The Injector is short circuit - check the wiring.

Peak The Injector peak current was not reached.

Possible causes:

• The Injector Current Setup Parameter IJCU is set too high.

• The battery voltage is too low.

Over Duty

The injector duty cycle is too high, typically the duty cycle should not exceed

85%.

If the injectors exceed their maximum duty then larger injectors or higher fuel

pressure is needed.

REF / SYNC Errors

The possible causes of the various errors are detailed below:

REF Error

Too many REF pulses have occurred between SYNC pulses.

Possible causes:

• A bad REF signal has caused extra pulses or a SYNC pulse has

been missed - check voltage levels with a scope

• Bad REF / SYNC alignment

• Incorrect Setup

No REF

Two SYNC signals have occurred without a REF signal.

Possible causes:

• If the RPM is 0 then there is no signal - check the wiring and sensor

voltage levels with a scope.

• If RPM is not 0 then a bad SYNC signal has caused extra pulses -

check voltage levels with a scope.

• If RPM is low the REF and SYNC signals may have been swapped.

• Incorrect Setup

Page 44

42 Initial Starting Procedure MoTeC

SYNC Error

The SYNC signal has occurred before expected.

Possible causes:

• A bad SYNC signal has caused extra SYNC pulses - check voltage

levels with a scope.

• A bad REF signal has caused missing REF pulses - check voltage

levels with a scope.

• Bad REF / SYNC alignment.

• Incorrect Setup

No SYNC

Two or more consecutive SYNC pulses are missing.

Possible causes:

• No SYNC signal - check the wiring and SYNC sensor voltage levels

with a scope.

• A bad REF signal has caused many extra pulses - check voltage

levels with a scope.

• Incorrect Setup

Multiple REF / SYNC Errors

Multiple REF / SYNC errors may occur. Often the first error to occur is

the correct error.

Multiple errors may also occur due to incorrect Setup.

Page 45

MoTeC Calibration 43

Calibration

The Calibration Tables determine how the output devices should be controlled

for various sensor readings. For example the Fuel - Main Table determines

the pulse width for the Fuel Injectors for all combinations of RPM and Load.

The ECU Manager software should be used to adjust the various calibration

tables to suit the engine.

Warning Alarms

Set the Warning Alarms to warn if the engine temperature goes too high. (The

warning alarms may be set in the Functions menu).

Ensure that the engine is “On Site”

The engine must be “On Site” for changes to the table values to affect the

tuning. This means that the engine must be operating at the same RPM and

Load as the currently selected site in the calibration table.

Note that when the engine RPM (or Load) is between table sites the current

fuel value (or Ignition value etc.) is affected by the sites to either side. For this

reason, when adjusting the calibration values it is important that the engine

RPM and Load are centred on the current adjustment site to ensure that the

values from the adjacent sites have minimal influence on the value being

adjusted. Use the Target (at the left of the table) to ensure that the engine

operating point is centred on the site being adjusted.

During initial tuning, if large adjustments are required to a particular site

ensure that the sites around it are also adjusted to a similar value so that the

adjacent sites have minimal influence.

Use the SPACEBAR key to quickly move the adjustment cursor to the

engine,s current operating point.

Site Tables

The RPM and Load sites for the various calibration tables may be modified in

the Setup Sites screen.

A number of site tables are available which affect different calibration tables

Use the help to check which calibration tables are affected by which site

tables.

Page 46

44 Calibration MoTeC

To insert or delete sites use the Tools menu (press the F9 key). When sites

are inserted or deleted, the calibration tables may be adjusted so that the new

sites do not affect the tuning.

Dyno Calibration

The alternator should be connected while tuning the engine to ensure that the

injectors are working at normal operating voltage.

The exhaust system should be the same as that in the vehicle as it will affect

the engine tuning.

On multi runner intake manifolds the air box should be fitted as it is an integral

part of the intake system and will affect the engine tuning.

The fuel pressure is critical to the injector flow and should be monitored during

dyno tuning. Incorrect fuel pressure will result in incorrect tuning. Note that on

turbo engines the fuel pressure will vary as the manifold pressure varies

because the regulator maintains a fixed pressure above manifold pressure.

Fuel - Main Table

The Fuel - Main Table allows adjustment of the fuel at various RPM and Load

points.

Work through all the table values systematically so that all points are adjusted

for the correct Air Fuel Ratio reading.

Use extreme caution when adjusting the fuel to ensure that the engine does

not run lean at high loads. It is best to start rich. A temperature compensated

Wideband Air Fuel Ratio Meter is essential to ensure correct air fuel ratio.

Note: If the engine is misfiring for any reason (including over rich) the sensor

may falsely read lean due to the oxygen in the unburnt mixture.

The Air Fuel Ratio should be adjusted according to the engine load and the

desired results, for example, power, economy, emissions etc. At high loads

the mixture should be approximately 0.89 Lambda for maximum power. On

turbo charged engines a richer mixture may be required to reduce exhaust

temperatures and help avoid knocking. At lighter loads the mixture may be

adjusted for best emissions (1.00 Lambda) or best economy (1.05 Lambda).

The cranking (starting) fuel may be changed by adjusting the 0 RPM load

sites. Typically more fuel is required at cranking than at idle RPM.

The Quick Lambda feature may be used to quickly adjust each table value

with one key stroke (Press the Q key). The adjustment is made to the value

Page 47

MoTeC Calibration 45

closest to the current engine operating point. The Quick Lambda feature may

only be used if the ECU is directly measuring the Lambda reading. The

desired Lambda value must be set in the Functions - Lambda Control

Table.

If the maximum value in the table falls below 60 then the setup parameter

IJPU should be decreased to increase the table values. This ensures that the

table has sufficiently fine resolution. Similarly, if the table values reach the

maximum table value then the IJPU setup parameter should be increased to

decrease the table values.

Use the F5 key to change quickly between the Fuel - Main Table and the

Ignition - Main Table.

Use the F6 key to change quickly between the Fuel - Main Table and Fuel Timing Table.

Use the View - Fuel Screens to check that all the fuel trims and

compensations are correct (press the V key).

Refer to the ECU Manager software help for more details (Press F1).

Ignition - Main Table

The Ignition - Main Table allows adjustment of the Ignition Timing at various

RPM and Load points.

Start with a conservative curve for the particular engine, not too advanced and

not too retarded.

Use extreme caution when adjusting the Ignition Timing to ensure that the

engine does not knock due to excessive advance. Re-check the Ignition

Timing with a Timing Light to ensure that what the ECU thinks is the ignition

advance is in fact the actual advance.

The Ignition Timing should be adjusted for maximum torque without knocking,

by increasing the advance until the torque stops increasing. Make sure t here

are at least 3 or 4 degrees margin to the knock limit.

Too much retard will cause excessive exhaust gas temperature.

At idle, a more retarded ignition setting is desirable (approximately 10 to 15

degrees). This makes the idle speed less sensitive to load changes. Also the

ignition should be flat over the idle RPM range so that timing variations do not

cause the engine to hunt, since variations in the timing will vary the engine

torque.

Page 48

46 Calibration MoTeC

The Quick Lambda feature may also be used from the Ignition Main Table,

which allows ignition timing adjustments to be made while also maintaining

correct mixture readings.

Use the View - Ignition Screen to check that all the fuel trims and

compensations are correct (Press the V key).

Refer to the ECU Manager software help for more details (Press F1).

Fuel - Injection Timing

The Fuel - Injection Timing table allows adjustment of the Fuel End of

Injection Timing at various RPM points and optionally at various Load points.

This table is only effective if the injectors are fired sequentially.

Adjusting the Injection Timing ensures that the fuel is injected at the optimum

point in the engine cycle, so that the engine makes best use of the fuel. In

theory the fuel should end injection at a point where all the fuel will be sucked

into the current induction stroke, therefore the end of injection point should be

some time before the intake valve closes. The optimum point depends on the

engine RPM and load.

Torque, economy, emissions and idle quality are all affected by the Injection

Timing.

At high duty cycles the Injection Timing will have minimal influence since the

injectors are on for most of the engine cycle.

Refer to the ECU Manager software help for more details (Press F1).

Fuel - Cold Start

The Cold Start parameters may be adjusted after the Fuel - Main Table has

been tuned and the 0 RPM sites have been set for good hot starting.

Refer to the ECU Manager software help for more details (Press F1).

Other Calibration Tables

The other calibration tables may be adjusted as necessary.

Refer to the ECU Manager software help for more details (Press F1).

Page 49

MoTeC Calibration 47

Data Logging & Road Testing

The calibration must be verified on the road. This is best done by logging the

air fuel ratio and other sensors and checking them using the MoTeC i2

software.

Data Logging is also very useful for identifying unexpected problems such as

an incorrect air temperature reading due to fuel vapour cooling the sensor or

excessive air temperature due to hot air entering the intake system.

Data logging may also be used to verify and fine tune the operation of the

various advanced functions such as traction control.

The light load and overrun calibration must also be completed on the road as

these areas cannot be adjusted on a dyno.

Page 50

48 Calibration MoTeC

Page 51

MoTeC ECU Manager Software 49

ECU Manager Software

Introduction

The following is an overview of the main concepts of the ECU Manager

software. More detailed information is available from the online help.

The ECU Manager software is used for :

• Calibration and Setup

• Sending calibration files to the ECU

• Viewing Sensor readings

• Viewing Diagnostics information

• Testing the Outputs

• Unloading the logged data

• Upgrading the ECU firmware

• Enabling ECU options.

PC Requirements

See the MoTeC Software section.

Connecting a PC to the ECU

See the MoTeC Software section.

Installing the Software

See the MoTeC Software section.

Basics

Starting ECU Manager

To start ECU Manager double click the icon on the desktop or select ECU

Manager from the Start menu, for example: Start / Programs / MoTeC / M84/

ECU Manager 1.0

Note that the desktop icon will start the latest version of ECU Manager.

Page 52

50 ECU Manager Software MoTeC

Online Help

Online help is available in two forms:

Context sensitive help is available by pressing F1 or clicking on the help

button, this shows help that is relevant to the current screen.

General help is available from the Help menu.

Main Men u

The Main Menu is used to access all of the features of the ECU Manager

software.

Select a menu item by using the mouse or use the keyboard by holding down

the Alt key followed by the keys corresponding to the underlined letter of the

menu items to be selected. For example to select File | Exit hold down the Alt

key then press F then X. Alternatively press the F10 key then use the arrow

keys and the Enter key to select the desired menu item.

Unavailable Menu Items

Note that some menu items may be unavailable if the ECU is not connected

or a file is not opened.

Unavailable items appear grey.

Button Bar (Toolbar)

The Button Bar provides an alternative way of activating some of the

commonly used items on the main menu. To find out what each item does

hold the mouse pointer over the button of interest until a hint appears.

Note that some items will not be available depending on whether the ECU is

connected and if a calibration file is open.

Status Bar

The bottom line on the screen is called the Status Bar and shows the

following:

Page 53

MoTeC ECU Manager Software 51

ECU Status: Connected or NOT Connected (if the ECU is connected the ECU

firmware version is also shown). If the ECU is not connected the reason that it

is not connected is shown where the Diagnostics Errors are normally shown.

The number of diagnostics errors (if the ECU is connected)

Calibration Files

ECU Manager records the ECU calibration and setup data in files that are

stored on the PC hard disk, this ensures that a permanent record of the data

is kept. The files also record comments to allow easy identification of each

file. Any file may be sent to any ECU which will totally re-configure the ECU

according the calibration and setup data contained in the file.

Creating a New Calibration File

To create a new calibration file open an existing file and save it to a new file

by selecting Save As from the File menu.

Sending a Calibration File to the ECU

To send a calibration file to the ECU select Send File to ECU from the File

menu. Note that the ECU must be connected to the PC using a MoTeC UTC or

CAN Cable.

Changing the Comments

To change the file comments select Edit Comments from the File menu.

Versions & Upgrading

MoTeC is continually updating the software and newer versions may be

downloaded from the website at no charge www.motec.com.au

The software consists of the ECU Manager software that runs on the PC and

the control software (firmware) that runs inside the ECU.

The ECU firmware may be updated at any time by the user which allows the

latest features to be used.

The ECU Manager version may be viewed by selecting About from the Help

menu.

The ECU firmware version is shown on the ECU Manager status line when

the ECU is connected.

Page 54

52 ECU Manager Software MoTeC

Matching Versions

The version of ECU Manager and the version of the firmware in the ECU

must match in order to be able to communicate with each other.

To communicate with an ECU that has older firmware in it, either the matching

ECU Manager software must be used or the ECU firmware must be upgraded

to match the version of ECU Manager on the PC.

Upgrading the ECU

To upgrade the ECU firmware select Upgrade ECU Version from the

Utilities menu. This will send the new firmware to the ECU and automatically

convert the calibration data in the ECU to ensure it is compatible with the new

firmware.

Calibration File Versions

The calibration files that are stored on the PC must also match the version of

software being used.

To ensure that older version calibration files are not rendered useless, the

older version calibration files may be converted in order to be used with the

new version of the software. To convert older files select Convert from the

File menu.

Minor Version Updates

Minor version updates do not require the calibration data to be converted but

still require the firmware to be sent to the ECU by selecting Upgrade ECU

Version from the Utilities menu.

Minor updates usually contain bug fixes or minor enhancements.

A minor update is one where the number before the decimal point and

immediately after do not change, for example 1.00A, 1.00C, 1.01A are all

minor updates of version 1.0.

Software Version Release Notes

The changes between the various software versions may be viewed by

selecting Release Notes from the Help menu.

Page 55

MoTeC ECU Manager Software 53

Screen Layouts

The screen layouts are completely user definable and may be optimised to

suit the user’s preference, the screen resolution and the task to be performed.

For example it may be useful to have screen layouts to suit different types of

engines or to perform particular tasks such as Idle Control or individual

cylinder tuning.

The image above shows one possible screen layout that suits an 800x600

screen.

Layout Pages

Separate layouts may be defined on separate pages. A number of pages may

be loaded at once and may then be selected by clicking on the tabs at the top

of the pages or by pressing the Tab or the Ctrl+Tab keys.

The layout pages are saved to files. To open, close or create new pages

select the appropriate menu item from the Layout menu.

Layout Objects

To add an object to the layout page select Add from the Layout menu or right

click on an empty space in the layout page and select Add.

Page 56

54 ECU Manager Software MoTeC

To change the properties (settings) of any object, right click on the object and

select Properties.

To delete an object, right click on the object and select Delete.

Adjust Tables and Adjust Graph Objects

In order to make adjustments the layout page must contain an Adjust Table or

an Adjust Graph or both.

Note that only one Adjust Table and one Adjust Graph are allowed per page.

Adjust Tables

Adjust Tables show the values for the currently selected table and allow

adjustments to be made. They also show axis indicators and a target to help

positioning of the engine operating point.

Adjust Graphs

The table values may also be shown graphically in an Adjust Graph.

The graph may be rotated if necessary by clicking on the rotation buttons or

by holding down the Ctrl key while using the arrow keys.

Graph Table

If there is no graph displayed, the table object may be switched between table

mode and graph mode by pressing the G key.

Y Axis Reversing

On certain graphs it may be desirable to reverse the Y axis so that the graph

surface is easier to see.

Page 57

MoTeC ECU Manager Software 55

To do this select Reverse Y-Axis on the Tools menu or press the Y key.

Making Adjustments

On Line / Offline

Changes may be made directly to the ECU (Online) or to a file (Offline).

Online (ECU Connected)

To make changes directly to the ECU, connect the ECU then select Open

ECU from the File menu.

When the ECU is opened the calibration data is first retrieved from the ECU

then matched to a file. If the ECU data does not match an existing file then a

new file will be created, at which point an Engine Description and Comment

should be entered to describe the file.

Changes to the ECU are also saved to this file when the ECU is closed.

Offline (ECU not Connected)

To make changes to a file with the ECU offline, select Open from the File

menu.

The file may be sent to the ECU at a latter date by selecting Send File to ECU

from the File menu.

Closing the ECU or File

When the changes are completed, the ECU or file should be closed by

selecting Close from the File menu. This will ensure that changes are saved

to the associated file.

Warning Alarms

If the Warning Alarms have been set a warning screen will be displayed if any

sensor goes outside its alarm limits. This can be particularly useful for

automatically monitoring engine temperature during a dyno session. The

alarms can be configured in the Functions table.

Help

Context sensitive help is available by pressing F1 or clicking on the help

button. This shows help that is relevant to the current screen.

Page 58

56 ECU Manager Software MoTeC

Selecting the Adjust Table

Once a file or the ECU has been opened, the appropriate table or setup

screen may be selected from the Adjust menu by using the mouse or the