Page 1

MoTeC SKM and OKM User Manual

Contents

Introduction ................................................................................ 2

Getting Started ........................................................................... 4

Installation .................................................................................. 5

SKM ......................................................................................................... 5

OKM ......................................................................................................... 5

Configuration ............................................................................. 6

Knock Detection....................................................................................... 6

Knock Module Configuration ................................................................... 8

Operation .................................................................................. 23

Appendices .............................................................................. 24

Appendix 1 SKM Internal Dip Switch Settings ....................................... 24

Appendix 2 SKM Connector, Pin Out and Wiring .................................. 26

Appendix 3 SKM Tuning Loom #61114 ................................................. 27

Appendix 4 Gold Wave Settings ............................................................ 29

Appendix 5 Detonation Explained ......................................................... 31

ESD - Antistatic

All necessary antistatic precautions must be taken while handling circuit

boards.

Copyright© 2008 – MoTeC Pty Ltd

The information in this document is subject to change without notice.

While every effort is taken to ensure correctness, no responsibility will be taken for the

consequences of any inaccuracies or omissions in this manual.

Version 1.0, 24 October 2008

Page 2

2 Introduction

Introduction

MoTeC’s Knock Modules provide individual cylinder closed loop knock

control, allowing tuners to safely optimise high performance ignition maps.

There is a standalone module compatible with all 'hundred series' ECUs and a

version specifically designed to mount onto an M800 Plug-In ECU. Both

modules work in conjunction with MoTeC’s ECU Manager software (v3.5 and

up)

Standalone Knock Module (SKM)

This module is housed in a robust aluminium casing that can be mounted as

required in any vehicle. It is wired between the ECU and the knock sensor.

Onboard Knock Module (OKM)

This module is fitted onto the board of an M800 Plug-In ECU prior to delivery

and linked to the knock sensor. M800 Plug-In ECUs are available for selected

vehicles. Please check our website at www.motec.com.au

for details.

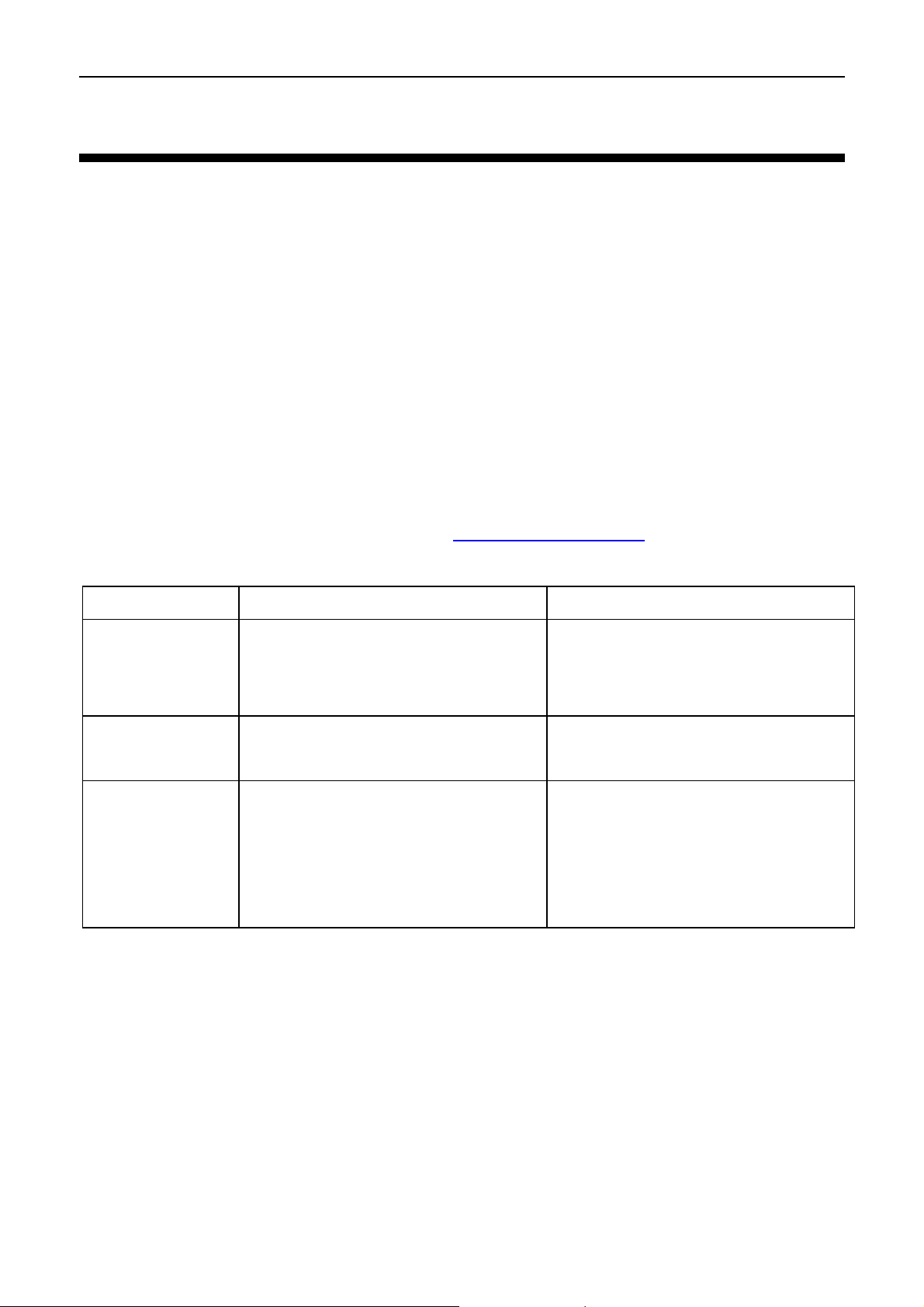

Basic Specifications

SKM OKM

Inputs

Outputs

Physical

y Knock sensor input

y Knock window input

y Power supply 8 V

y Knock sensor out

y Audio

y Case size 38 x 90 x 25 mm

excluding connector

y Weight 100 grams

y 1 x 13 pin Autosport

connector

y Audio

y Fitted onto a M800 Plug-In

ECU

Page 3

MoTeC Introduction 3

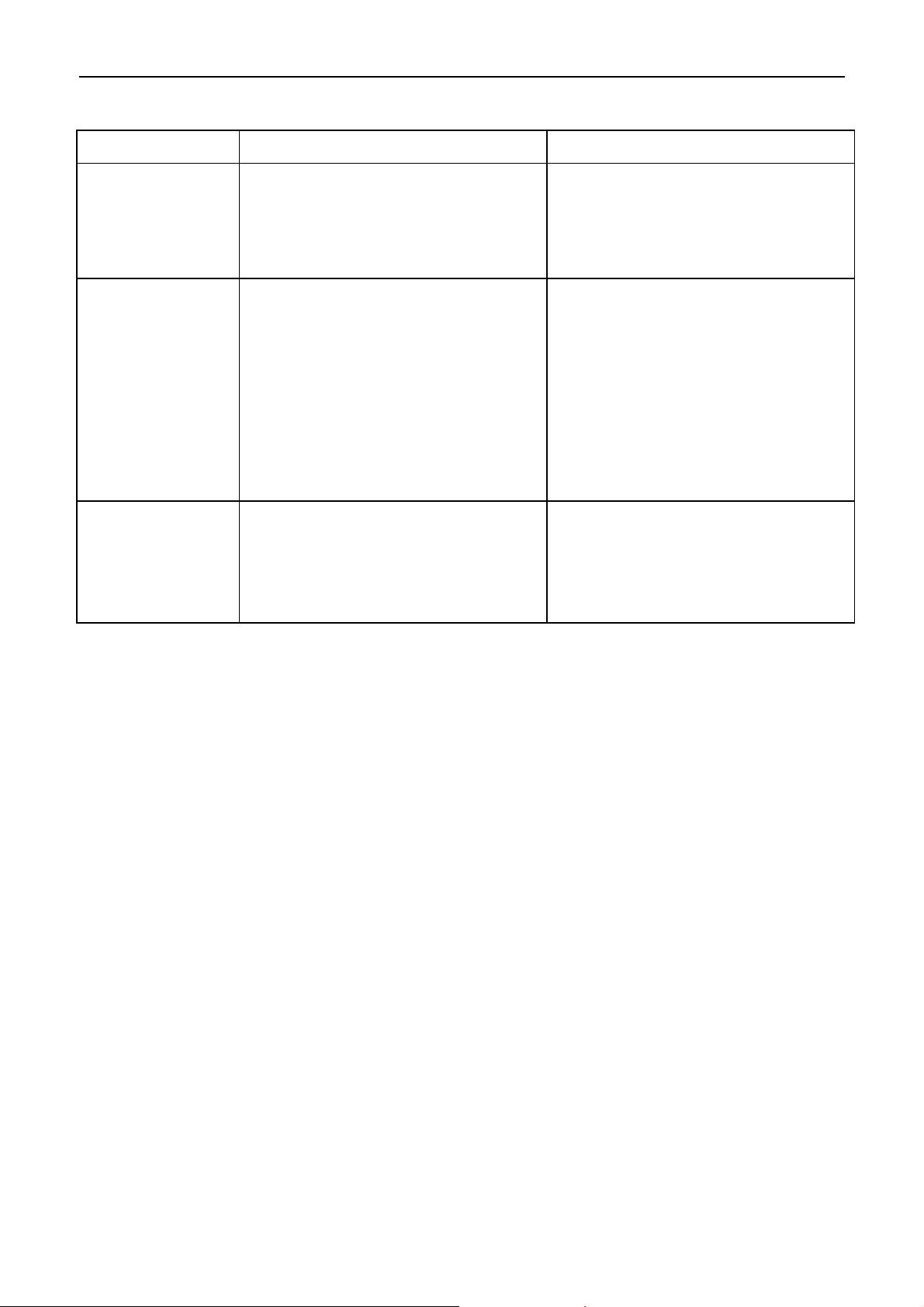

Other information

Compatibility

Related

software

Accessories

SKM OKM

y ‘hundred series’ ECUs;

M400, M600, M800 and

M880

y All knock sensors

y ECU Manager software

v3.5 and up

(software version 2.3

enables monitor only)

y i2 Data Analysis

y Gold Wave Audio

Analysis Software (for

frequency analysis only)

y Stereo headphones

y Knock sensor

y SKM tuning loom #61114

(optional)

y M800 Plug-In ECUs

y ECU Manager software

v3.5 and up

(software version 2.3

enables monitor only)

y i2 Data Analysis

y Gold Wave Audio

Analysis Software (for

frequency analysis only)

y Stereo headphones

Page 4

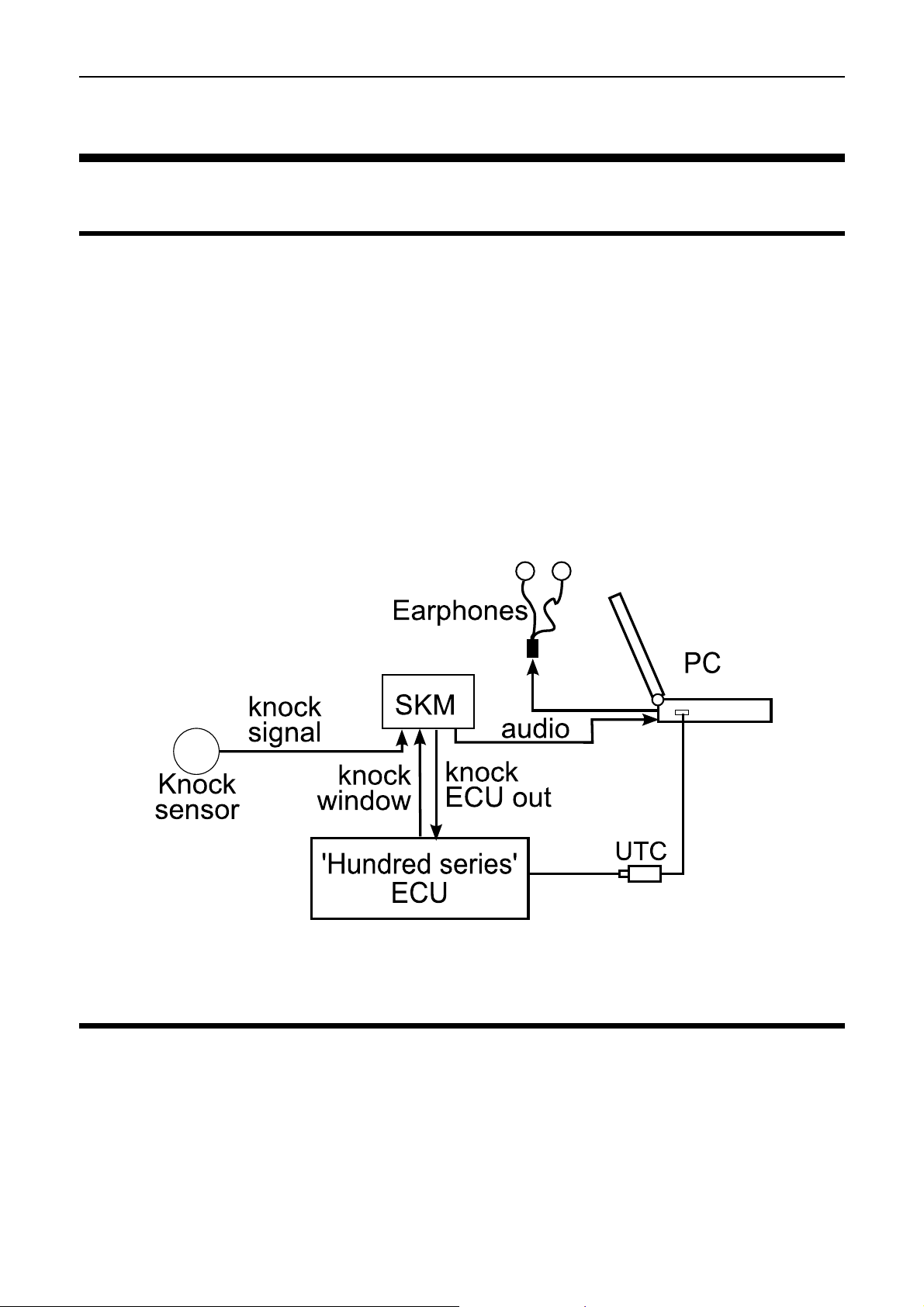

4 Getting Started

Getting Started

The Knock Modules have no stand-alone Manager software.

All knock control configuration is done through MoTeC's ECU Manager

software (version 3.5 or up). This can be downloaded from the MoTeC

website at www.motec.com

can be found in the ECU User Manual

For frequency analysis MoTeC recommends Gold Wave Audio Analysis

Software. A trial version can be downloaded from www.goldwave.com

PC requirements

• Operating System: Windows XP and up

• Audio and USB input

• Sound card capable of simultaneously recording and playing.

Alternatively, an external soundcard or third party device can be used.

. Further information on ECU Manager software

Page 5

MoTeC Installation 5

Installation

SKM

The SKM is connected between the OEM fitted knock sensor and a 'hundred

series' ECU – M400, M600, M800 or M880.

The SKM knock signal output must be connected to the ECU via an available

analogue voltage input, preferable a Lambda sense input. The Lambda sense

input has a slightly higher resolution.

To send the gated window signal to the knock module connect a spare

injector or ignition output on the M800 or M880 ECU to the SKM input. On the

M400 and M600, injector 8 output must be used.

Alternatively the SKM Tuning loom can be used (available separately)

See appendix 2 and 3 for detailed wiring instructions

OKM

The OKM is fitted directly onto the board of an M800 Plug-In ECU.

Most M800 Plug-In ECUs fitted with an OKM are pre-configured to analogue

voltage input AV5 and ignition output 6. WRX9/10 boards use lambda 1 sense

input rather than AV5.

Page 6

6 Configuration

Configuration

When suffering detonation, each engine/chassis combination and associated

accessory package resonates at different frequencies. To configure an

electronic knock control system, the exact combination of engine, engine

mount, exhaust system, alternator and starter etc. must have been fitted.

A reliable electronic knock control system requires detecting knock accurately

and differentiating knock from normal engine noise.

MoTeC’s knock modules use the vehicle’s original, factory-fitted knock

sensors to detect detonation, improving this detection by reducing the

influence of background engine noise using a combination of data gating and

frequency filtering.

The engine sound energy during engine operation will vary for different

frequencies in the spectrum. The knock sound energy will be more prominent

at certain frequencies.

A competent tuner needs to carry out a frequency analysis to determine the

frequency where the difference of the engine sound with and without

detonation is most clear to detect. The centre frequency settings of the Knock

Module must match this frequency.

The Knock Control system in the ECU can then be configured to adjust the

ignition according to measured knock levels.

Knock Detection

Knock Sensor

The knock sensor measures the engine vibrations and turns this into an AC

waveform output.

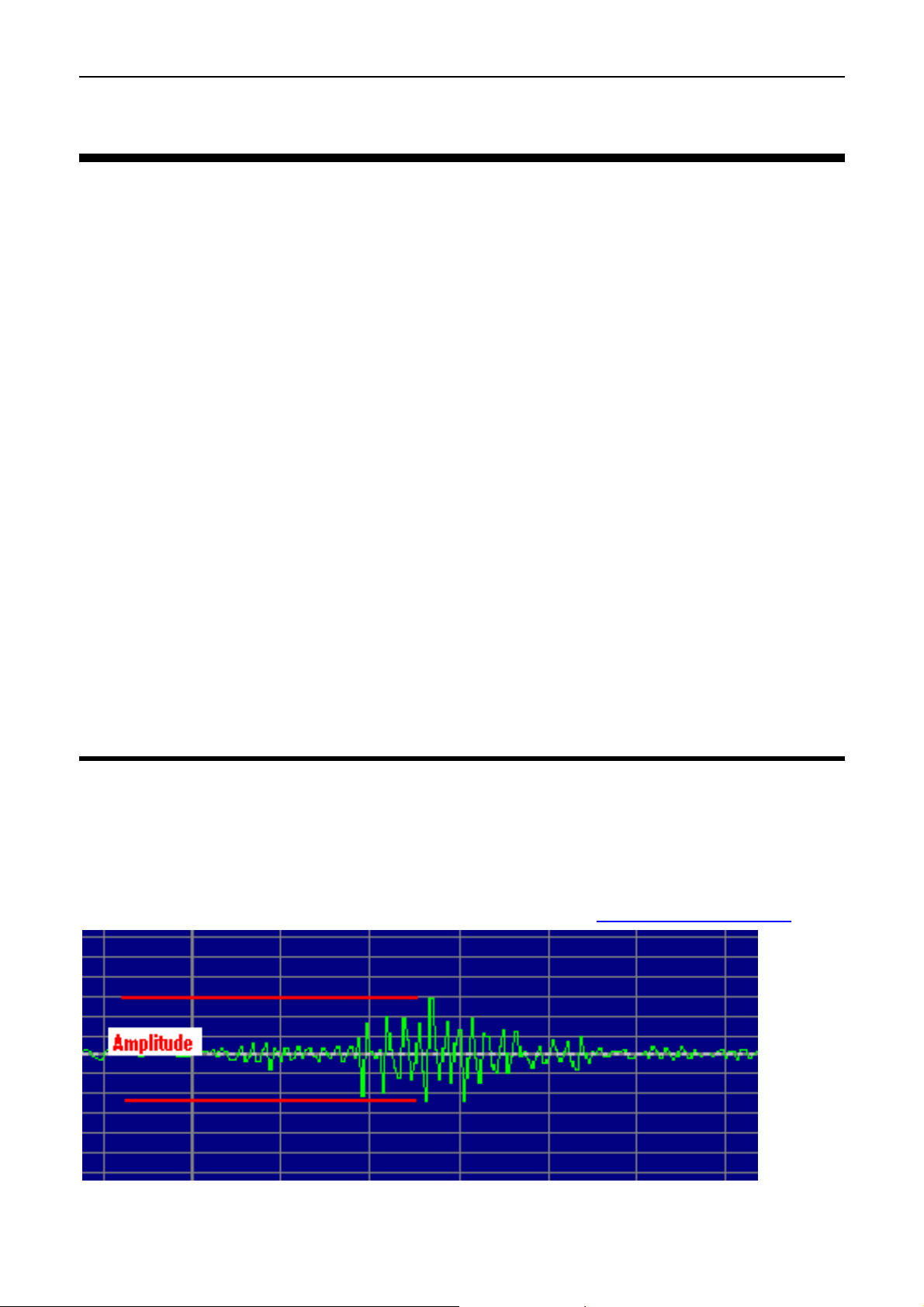

The next figure shows a zoomed in view of typical knock sensor signal

(captured using Gold Wave Audio Analysis Software www.goldwave.com

).

Audio signal output from a knock sensor

Page 7

MoTeC Configuration 7

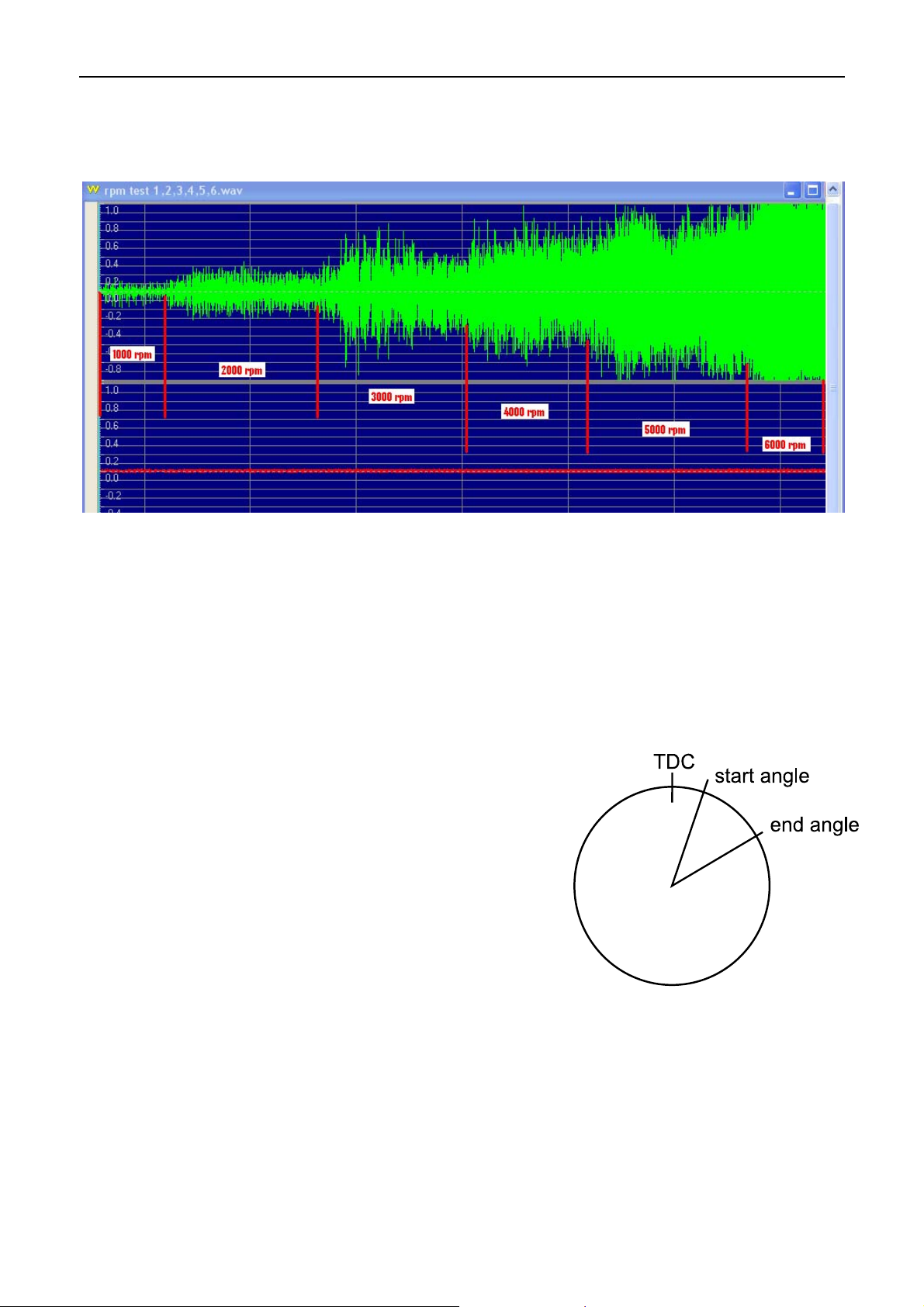

With increasing engine RPM, the higher engine vibrations will result in an

increase in the amplitude of the knock sensor signal. A race engine operating

at high RPM will show high amplitudes making it difficult to detect knock.

Knock sensor signal with increased engine RPM

Knock Modules

The SKM/OKM modules improve knock detection by reducing the influence of

background engine noise using a combination of data gating and frequency

filtering.

Data Gating

The knock window is the period in the

combustion cycle during which knock is likely

to occur, normally between 10 and 50 degrees

after TDC (top dead centre). The ECU sends a

knock window signal to the Knock Module to

mark the start and end angle in the engine

cycle.

The SKM/OKM will measure the knock sensor

signal during this window and sends the

information to the ECU. The ECU uses the

measurement to calculate the knock

percentage for each cylinder of the engine.

Knock window

Frequency Filtering

To correctly identify knock, the SKM switches must be set to match the

theoretical best centre frequency. The centre frequency in the SKM/OKM is

normally set to the frequency of the engine that shows the greatest energy

difference between normal engine operation and active detonation.

Page 8

8 Configuration

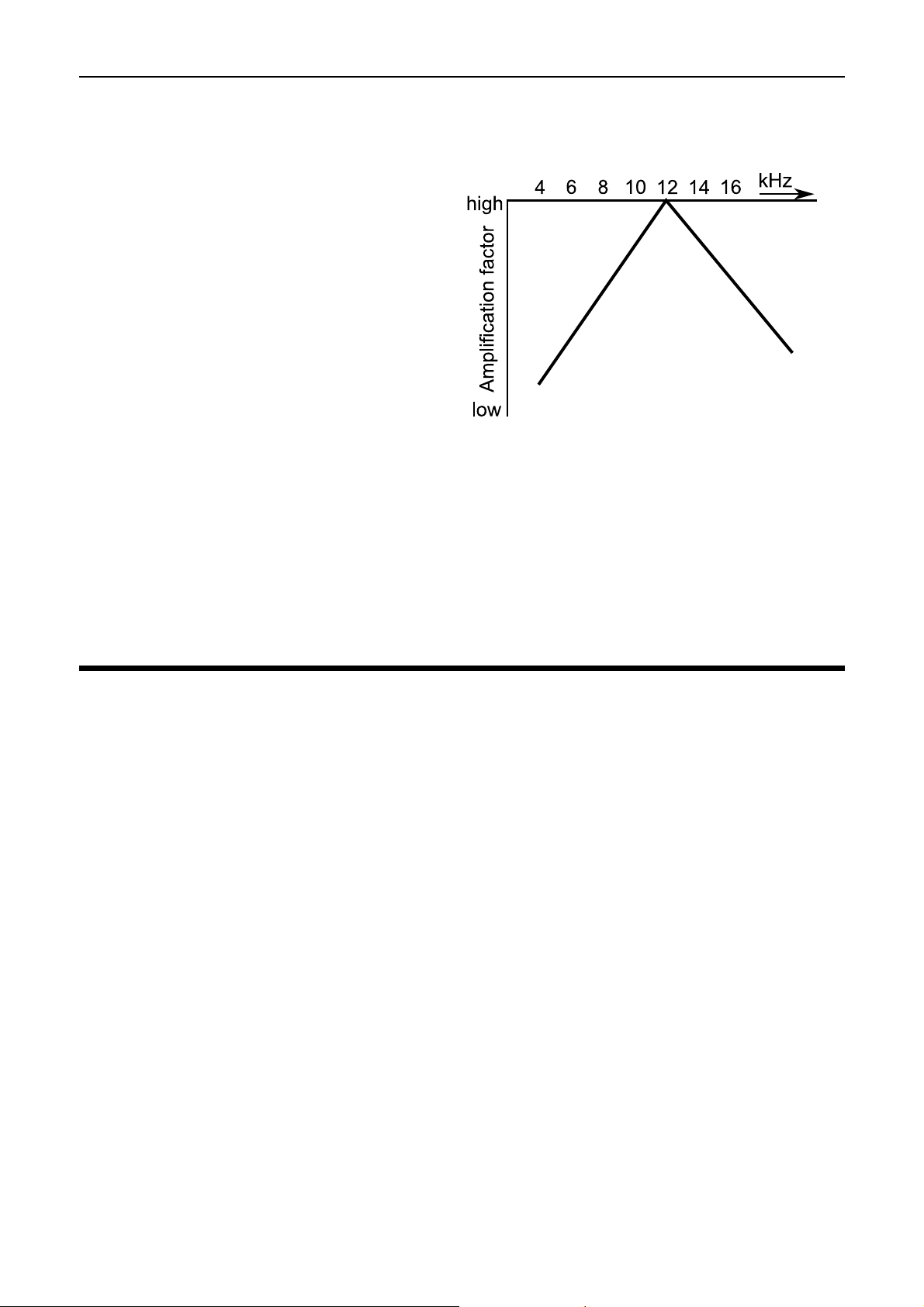

The knock module filters and amplifies the signal transmitted from the knock

sensor based on the centre frequency. Signals of the selected centre

frequency pass the frequency filter

amplified, while signals in other

frequencies will be reduced. The

further away from the centre

frequency, the more the signal will

be reduced. Filtering will reduce the

influence of background engine

noise resulting in improved knock

detection.

The figure shows frequency based

amplification with the centre

frequency set to 12 kHz.

Frequency based amplification

Gain Factor

A gain factor is only required for knock sensors with very low output levels.

The gain factor can be chosen to multiply the raw knock output signal, prior to

frequency filtering. It is also possible to set a gain factor from ECU Manager

software.

Knock Module Configuration

The configuration of the Knock Modules consists of two stages:

Stage 1: Carrying out a frequency analysis of the knock sensor signal to

determine the centre frequency and knock module settings. This needs to be

done by a competent tuner, as incorrect operation can easily result in severe

engine damage

Stage 2: Tuning the knock control system

Note: The OKM settings are preconfigured to suit the standard vehicle. It only

requires the second configuration stage to tune the knock system. If the

vehicle is modified significantly, contact an authorised MoTeC dealer for

further advice.

Before carrying out any stage of the configuration the vehicle needs to be

prepared by setting up the ECU for knock measuring and data logging using

ECU Manager software.

Page 9

MoTeC Configuration 9

Preparation

Configuring the Knock Window

y On the Adjust menu select injector/ignition output functions

y Select injector/ignition out [#]

Select injector or ignition output the SKM//OKM is wired to.

Note: For M400/M600 Inj8 must be used.

y Select Function

y Type Function value 122 (Knock Window)

y Press ESC

y Select Parameters

Start Ref

0: knock window measured after ignition point

1: knock window measured after TDC

Typical value 1

Start Angle

The starting angle of the knock window in the engine cycle where the

knock sensor signal is recorded

Unit: degrees

Typical value 10

Slow End Angle

The end angle of the knock window in the engine cycle when

operating at slow engine RPM (up to 1000 RPM)

Unit: degrees

Typical value 40

Fast End Angle

The end angle of the knock window in the engine cycle when

operating at fast engine RPM (RPM as specified in RPM Limit)

Unit: degrees

Typical value 50

Polarity

0: output high for 0% duty

1: output low for 0% duty

Value 0 is required for SKM/OKM

Page 10

10 Configuration

Configuring the channel Knock Voltage

y On the Adjust menu click Sensor Setup

y Click Input Setup…

this will open the Input Pins Setup screen

y Click the Other tab

y Select Knock Voltage (Knock V)

y Click Change

y In the Input Source list click AV[#] or Lambda[#] (Select the

input the SKM//OKM is wired to)

y In the Calibration area select Predefined and in the list click

#31 Volts(V); x1 (5.000V=5.000V)

Knock Gain Table

y On the Adjust menu click Functions

y Click Knock Control

y Click Gain

This table compensates any sensitivity differences of the sensor to

particular cylinders.

The Knock Gain table should be used in conjunction with the Knock

Offset table to level out any differences between the individual

cylinders.

Typical starting value: 1.00

Note: The values in this table must be non-zero to show any Knock

Percentage values.

Data Logging Setup

Each cylinder's knock input should be logged at 50 Hz or greater.

• On the Adjust menu click Data Logging Setup

• Click Knock Levels

• Select Knock Limit and type 10

• Select Knock 1 and type 50 (or greater)

• Continue the last step for all remaining cylinders in firing order

Follow the same procedure to log other useful channels.

Recommended channels are:

y Knock Retard Short Term for each cylinder

y Knock Retard Long Term for each cylinder

y Individual Ignition Advance channels - to evaluate the

performance of the control system during calibration tuning.

Page 11

MoTeC Configuration 11

Frequency Analysis

A competent tuner with the right equipment can measure and analyse the

knock frequency for the specific engine and associated hardware by

comparing the sound of the engine with and without detonation. Frequency

analysis will determine the theoretical best centre frequency. This is the

frequency where the difference of the engine sound with and without

detonation is most clear to detect.

Surprisingly minor changes to the engine hardware will affect the frequency of

the detonation “ring” throughout the structure. So frequency settings that suit

one car may not be suitable for another car of the identical model but with

slight modifications.

Warning

Knock frequency analysis is a specialised job, to be carried out

by experienced technicians. Incorrect operation can easily cause

severe engine damage.

Setup

1. Using the SKM tuning loom, connect an audio lead to the line in or

microphone in port on the PC.

The PC must be able to record sounds through a line in port and

simultaneously play it to the headphone jack, so the operator can

listen and monitor the engine while recording.

Note: If your computer does not have the ability to record and listen

at the same time an alternative method should be used to listen to the

engine e.g. an external sound card or third party device.

2. Configure the PC to play sound only from the left channel. The right

channel is the knock window signal sent from the ECU.

Tip: You can make an adapter plug for the headphones that joins the

sound from the left and right channel.

3. Connect audio headphones to the PC.

Tip: To block out external engine and car noise, bud type ear phones

with high quality ear muffs used over top can be used.

4. To perform frequency analysis on the recorded audio file requires

dedicated software.

In this document Gold Wave software is used in all examples.

See Appendix 4 Gold Wave Settings

Page 12

12 Configuration

Test

1. Ensure the engine is at normal operating temperature.

2. Run the engine and listen for any irregularities in engine vibrations

like internal component noise.

3. If all sounds normal bring the engine under some load and carefully

introduce light detonation.

Tip: To introduce detonation at as light a load as possible, use a low

octane fuel.

4. Proceed with extreme caution and note where detonation can be

introduced. Return to no detonation.

5. Open a new file in Gold Wave and record the data while running the

engine from a normal operating situation to a situation with detonation

at a similar engine speed.

6. Shut down the engine.

Analysis

1. Configure the Gold Wave Software so that the sound recording can

be viewed on a spectrogram (see appendix 4).

2. Play back the Gold Wave audio file.

The Y-axis on the spectrograms chart is the frequency range, the Xaxis is the playback time.

The colours on the chart represent the energy of the recorded sound.

The key to the colours is underneath the X-axis.

3. Look at the spectrogram chart, while listening for detonation. The

colour in the spectrogram changes at the moment detonation occurs.

4. The colour change occurs at the knock frequency, but there are often

reflections of the detonation at other frequencies.

5. Determine the frequency where the difference of the engine sound

with and without detonation is most clear to detect. This will be the

centre frequency setting.

Page 13

MoTeC Configuration 13

Examples

The following examples show how to interpret the data and choose the centre

frequency.

Example 1

In the next spectrogram, increased energy levels show consistently at

8 kHz. The noise at this frequency is constant even when the engine is not

detonating, therefore we can assume that this is normal engine

background noise. Detonation, introduced via an ignition timing adjustment

in the ECU, can be seen at the 3.5 second mark. Here extra energy levels

are seen throughout all frequencies.

To determine which frequency has the best ratio between little background

noise energy and high detonation intensity compare the areas with and

without detonation.

In the example, at 5 kHz there is little background noise and a touch of

yellow (high energy) at the detonation point. The highest detonation

energy is at 8 kHz, however the background noise is also high here.

To help selecting the best centre frequency, experiment with different

settings while downloading the log files from the ECU. Analyse the log files

using i2 data analysis software.

The log files will show the individual cylinder knock channels. They are

represented as a percentage. The absolute value is at this moment not

relevant.

Important is a low background noise level and a high actual knock

signal.

The log file with a setting of 8 kHz might equal background noise levels of

approximately 60% and mild knock shows peaks of 90%.

A log file with a setting of 5 kHz might equal background noise levels of

approx 25% and mild knock showing peaks of 70%.

Therefore a centre frequency setting of 5 kHz would in this example likely

be the best.

Note: The centre frequency will affect the overall level of the knock voltage

channel.

Page 14

14 Configuration

Frequency spectrogram in GoldWave

Page 15

MoTeC Configuration 15

Example 2

The Mitsubishi Evolution Lancer series has a narrowband knock sensor

that transmits a signal different to wideband knock sensors.

The voltage amplitude is high compared to signals from wideband sensors

for the same level of engine noise, so overall energy levels will be high.

The next spectrogram shows a signal from a narrowband knock sensor. It

shows severe detonation at the 2 seconds mark (yellow energy spikes).

The background noise and detonation is concentrated on one frequency,

in this case13 kHz.

Mitsubishi Evolution Lancer: knock frequency analysis

With an example setting of 13 kHz, the log file from the ECU might show

background noise level at 50%- 70% and mild knock showing peaks of

90%. This makes it difficult to detect severe detonation, so an SKM/OKM

centre frequency setting of 13 kHz would be inappropriate.

The detonation energy is high enough to reflect through other frequencies.

For example at 7 kHz, there is less background noise and still relatively

high detonation intensity.

With a setting of 7KHZ the log file from the ECU might show background

noise level at 30-40% and mild knock at 60%. With this setting larger

detonation events can be measured with appropriate action taken as a

result. This would therefore be a better choice for the correct setting.

Page 16

16 Configuration

Log file from ECU with a centre frequency setting of 13 kHz

Log file from ECU with a centre frequency setting of 7 kHz

This example highlights the complexity involved in determining knock and

appropriate centre frequency settings for each application.

Page 17

MoTeC Configuration 17

Example 3

The car from the previous example has been converted to rally

specifications. This involved fitting a roll cage, larger exhaust etc. Other

than a restrictor the engine remains unchanged.

The knock sensor signal is now concentrated on 12 kHz rather than

13 kHz and the characteristics are different.

In this case a centre frequency of 6 kHz may be more appropriate.

Mitsubishi Evolution Lancer r a lly spec: knock frequency analy si s

Centre Frequency Setting

After the knock frequency has been assessed and a centre frequency chosen

the Knock Module must be setup accordingly.

For instructions on changing the SKM switch settings, see appendix 1.

Note: The OKM settings are preconfigured to suit the standard vehicle.

However, should adjustment be required because the vehicle is modified

significantly, contact an authorised MoTeC dealer for further advice.

Page 18

18 Configuration

Tuning Knock Control System

Note: The following tuning is a specialised job, to be carried out

by experienced technicians. Incorrect operation can easily cause

severe engine damage.

The knock control system will retard the ignition timing depending on the level

of knock. There is an instantaneous setting to reduce the knock levels

immediately and a long term retard setting to prevent knock re-occurring.

i2 data showing the instantaneous (short) and long term retard effect on knock levels

Page 19

MoTeC Configuration 19

The knock control settings are adjusted in ECU Manager software.

• On the Adjust menu click Functions

• Click Knock Control

• Click Setup to enter Knock Control and set the following parameters

Activate Throttle Pos

Specifies the throttle position which must be exceeded to activate

knock control

0: Disabled - knock control always active

Unit: Percentage (%)

Activate Full Throttle Time

Knock control will only activate when the full throttle timer exceeds

this value.

0: Off – Ignore full throttle timer

Units: seconds

Maximum RPM

Knock control is disabled once Engine RPM exceeds this value.

Useful when background noise becomes excessive and clear knock

detection is no longer possible.

Normally set to 50 RPM below the RPM limit as engines running on

the RPM limit may knock intermittently.

Mode

0: Individual cylinder knock control

1: Global knock control. All cylinders will be retarded equally.

Usually set to 0.

If set to 1 the control system will retard all cylinders, regardless of the

cylinder on which the knock was measured.

Error Retard

Specifies the amount of permanent retard that will be applied to all

cylinders if the knock sensor goes into error as defined by the

diagnostic levels in the input setup.

Unit: Degrees

Warning Trigger

Specifies the level above the Knock Target Threshold (value from

Knock Table) which, if exceeded will cause a warning to be

generated.

Page 20

20 Configuration

Note: Requires the Driver Warning Alarm function to be configured on

an auxiliary output.

Note: The knock warning is included in Status Group 3.

Unit: Percentage (%)

Retard Gain (Instantaneous Term)

Defines the amount of retard applied for each percent over the Knock

Target Threshold (value from Knock Table).

Unit: Degrees/Percent

e.g.: Retard gain = 0.5 and knock= 20% over the Knock Target

Threshold would result in 10 degrees ignition retard

Advance Rate

Rate at which ignition retard is advanced back to normal.

Unit: Degrees/Second

e.g.: Advance rate = 2 would result in the ignition to advance back at

a rate of 2 degrees per second.

Retard Limit

Maximum amount of retard from the current ignition timing (from

Ignition Table)

Unit: Degrees

e.g.: Retard Limit = 10 and current ignition timing = 25 degrees BTDC

then the Instantaneous term trim aspect of the Knock Control

Function can retard to 15 degrees BTDC.

Retard Rate Long term

Amount of long term retard applied per second for each degree of

instantaneous term trim retard applied.

Unit: Degrees/Second/Degree

e.g.: Retard Rate Long Term = 0.200 and currently active

Instantaneous Term trim = 8 degrees, then 1.6 degrees/second long

term trim is also applied.

Advance Rate Long Term

Long term rate at which ignition is advanced back to normal.

Unit: Degrees/Second

e.g.: Advance Rate Long Term = 0.050 would result in the ignition to

advance back at a rate of 1 degree in 20 seconds.

Retard Limit Long Term

Maximum amount of long term retard the Knock Control function can

remove from the current ignition timing (from Ignition Table)

Page 21

MoTeC Configuration 21

This is added to the value in Retard Limit for the Instantaneous term

trim.

Unit: Degrees

e.g.: Retard Limit = 10, Retard Limit Long Term = 6 and

current ignition timing = 25 degrees BTDC then the Knock Control

Function can retard to 25 – (10+6) = 9 degrees.

• When all parameter settings are completed, click ESC

• Click Knock Table to enter the Knock Table window

This table sets the Knock Target Threshold (or Knock Limit) for the

Knock Control function.

The ignition will not be retarded unless the measured knock value of

any of the cylinders exceeds the Knock Target Threshold value.

To determine Knock Target Threshold values, run the engine in a non

knocking condition with safe ignition timing. Operate the engine fully

loaded through all RPM levels and note the background noise levels

in the cylinders knock percentage channels.

The Knock Table is configured with RPM as X-axis. As a starting

point, values are to be entered at 5 to 10% above background noise

levels.

• When all Knock Table settings are completed, click ESC

• Click Gain to enter the Knock Gain Table

This table compensates any sensitivity difference of the sensor to

particular cylinders.

The Knock Gain table should be used in conjunction with the Knock

Offset table to level out any differences between the individual

cylinders.

Typical starting value: 1.00

Note: The values in this table must be non-zero to show any Knock

Percentage values.

• When all Gain settings are completed, click ESC

• Click Offset to enter the Knock Offset Table

This table compensates for any offset differences of the sensor to

particular cylinders.

The Knock Offset table should be used in conjunction with the Knock

Gain table to level out any differences between the individual

cylinders.

Typical starting value: 0

Page 22

22 Configuration

Knock Tuning Tips

y Set both Retard Limit and Retard Limit Long Term to 0 degrees.

y Listen for detonation while running the engine.

y Introduce light detonation very carefully and log the knock

percentages.

y Estimate the Ignition Retard required preventing this level of knock

continuing.

y Adjust the Instantaneous Term trim parameters:

Start with values which will cause too much retard.

Work your way back until an appropriate strategy for the type of

engine is found.

y To start, work with Instantaneous Term trim only

y Add the Long Term trim parameters later if required.

Page 23

MoTeC Operation 23

Operation

Once the Knock Control System is tuned, it can be used for continuous

monitoring.

The configuration will generally not need any adjustment. Only major changes

in engine (exhaust, cams, pistons etc) and transmission might require a new

centre frequency setting.

In this case, the vehicle should be returned to the dealer for a new frequency

analysis.

Page 24

24 Appendices

Appendices

Appendix 1 SKM Internal Dip Switch Settings

Dip switches are used to set the gain factor, centre frequency and the

differential mode switch.

To access the switches, remove the 4 lid locating screws. Hold the device as

shown in the photo to see the various switch identification codes.

SKM Dip Switches

Switch down toward the circuit board = on

Switch up away from circuit board = off

Page 25

MoTeC Appendices 25

Differential Mode Switch

DM Function

off normal knock sensor connection (default)

on differential sensors

Gain Switches

G2 G1 G0 Gain

On on on 2 (default)

On on off 4

On off on 8

On off off 16

Off on on 16

off on off 32

off off on 64

off off off 128

Knock Centre Frequency Switches

F3 F2 F1 F0 Frequency

off on on on 5 kHz

off on off on 6 kHz

off on off off 7 kHz

off off on on 8 kHz

on off off on 9 kHz

on on on on 10 kHz (default)

on on off on 12 kHz

on on off off 14 kHz

on off on on 16 kHz

Page 26

26 Appendices

Appendix 2 SKM Connector, Pin Out and

Wiring

Connector

Autosport 13 pin

Mating connector #65041

SKM Connect to

Pin Function Device/connector Input

1 Select 0

2 Select 1

any available AV input,

3

Knock ECU

Out

M400/M600/M800/M800

preferable a Lambda

sense input

4

Knock Audio

Out

5 Audio Ground 3.5 mm stereo connector ring (ground)

6 Sensor 1 Input knock sensor signal

7 Sensor 2 Input

8 Sensor 3 Input

9 Sensor 4 Input

10 Shield knock sensor shield

Knock

11

Window

3.5 mm stereo connector tip (left channel)

M400/M600 injector8 only

M800/M880

3.5 mm stereo connector

any spare ignition or

injector output

via 100 KΩ resistor to

ring

(right channel)

12 8 V M400/M600/M800/M880 8 V

13 Ground M400/M600/M800/M880 ground

Page 27

MoTeC Appendices 27

Appendix 3 SKM Tuning Loom #61114

Optionally the SKM Tuning Loom can be used for wiring.

• Length of the ECU and knock sensor leads is 600 mm

• Length of the audio lead is 1850 mm

Connector 1: Stereo plug

Pin Function

Base Audio Ground

Connect to stereo headphones

Middle right channel Knock Window

Tip left channel Knock Audio Out

Connector 2: DTM 2 pin

Mating connector #68051

Pin Function Connect to knock sensor

1 Shield Shield

2 Knock Signal Signal

Connector 3: DTM 4 pin

Mating connector #68054

Pin Function Connect to M400/M600/M800/M880

1 Ground Ground

2

Knock ECU

Out

Knock

3

Window

4 8 V 8 V

Any available AV input, preferable a Lambda sense

input

Any spare ignition or injector output

Note: on M400/M600 injector8 only

Page 28

28 Appendices

Page 29

MoTeC Appendices 29

Appendix 4 Gold Wave Settings

To set up the side display as a Spectrogram for analysing frequency of

sounds:

On the Options menu click Control Properties (keyboard shortcut F11)

In the Left Visual box, select Spectrogram <GoldWave*>

Page 30

30 Appendices

On the Tool menu click Control

Right click in the screen to open the menu and select Spectrogram

<GoldWave*>

Click Properties to configure the spectrogram.

Choose Fixed frequency range and set range to From (Hz) 3000 To (Hz)

18000

Choose Show Axis

Page 31

MoTeC Appendices 31

Appendix 5 Detonation Explained

Detonation (also called "spark knock") is an erratic form of combustion that

can cause catastrophic engine failure. Detonation occurs when excessive

heat and pressure in the combustion chamber causes the air/fuel mixture to

self ignite. This produces a sudden rise in cylinder pressure accompanied by

a sharp metallic pinging or knocking noise. The hammer-like shock waves

created by detonation subject the head gasket, piston, rings, spark plug and

rod bearings to severe overloading. Mild or occasional detonation can occur in

almost any engine and normally causes no harm. But prolonged or heavy

detonation can be very damaging.

Detonation is the result of an amplification of pressure waves, such as sound

waves, occurring during the combustion process when the piston is near top

dead centre (TDC). The actual "knocking" or "ringing" sound of detonation is

due to pressure waves pounding against the insides of the combustion

chamber and the piston top. It is not due to 'colliding flame fronts' or 'flame

fronts hitting the piston or combustion chamber walls.'

Normal Combustion

This is the burning of a fuel and air mixture charge in the combustion

chamber. It should burn in a steady, even fashion across the chamber,

originating at the spark plug and progressing across the chamber in a three

dimensional fashion. Similar to the ripples spreading out when a pebble is

thrown into a pond with a glass smooth surface, the flame front should

progress in an orderly fashion. The burn moves all the way across the

chamber and quenches (i.e.: cools) against the walls and the piston crown.

The burn should be complete with no, or very little, remaining unburnt fuel-air

mixture. Note that the mixture does not "explode" but burns in an orderly

fashion.

During combustion, the location of peak pressure (LPP) can be measured

with an in-cylinder pressure transducer. When the spark is fired at optimum

timing the burn is initiated at the spark plug and will progress evenly through

the chamber to reach peak pressure shortly after top dead centre depending

on the chamber design and the burn rate. Ideally, the LPP should occur

between 12 and 15 degrees after top dead centre.

Page 32

32 Appendices

Combustion chamber at TDC

Abnormal Combustion – Detonation

If conditions for combustion are not ideal, detonation can occur. This usually

happens first at points of amplification of the pressure waves.

For example at the edges of the piston

crown where reflecting pressure waves

from the piston or combustion chamber

walls can constructively recombine – this

causes very high local pressures. If the

speed at which this pressure build-up to

detonation occurs is greater than the

speed at which the mixture burns, the

pressure waves from both the initial

ignition at the spark plug and the

pressure waves coming from the

problem spots can set off immediate

explosions in the remaining air/fuel

mixture, rather than smooth combustion.

The remaining fuel in the end gas simply

lacks sufficient octane rating to withstand

this combination of heat and pressure.

Combustion Pressure with detonation

Page 33

MoTeC Appendices 33

Detonation causes a very large, very rapid, pressure spike of very short

duration in the combustion chamber. The pressure trace of the combustion

chamber process would show the normal burn as a steady pressure rise, and

then all of a sudden a very sharp spike when the detonation occurred. The

pressure spike creates a force on the combustion chamber causing the

structure of the engine to ring or resonate (much as if it were hit by a

hammer). Resonance, which is characteristic of combustion detonation,

occurs between 4 to 12 kHz resulting in the audible pinging. This noise or

vibration is what the knock sensor detects.

Detonation Indicators

The best indication of detonation is the pinging sound that cars, particularly

old models (pre 1980) make at low speeds and under load. It is very difficult to

hear the sound in the well insulated luxury interiors of today's cars. An

unmuffled engine running straight pipes or a Rally Car racing on a gravel road

can easily mask the sound.

In some cases, the engine may smoke but more often the driver is not aware

detonation is occurring.

Typical results of detonation are broken piston ring lands, broken spark plug

porcelains or broken ground electrodes. However these signs are usually not

spotted externally.

It is also difficult to detect detonation while an engine is running in a remote

and insulated dyno test cell.

To help hear detonation a very elementary technique often proves successful:

run a copper pipe bolted flat to the side of the engine block into the control

room, place a funnel at the end to amplify the sound through the pipe and

listen. This allows the operator to hear all mechanical noises within the engine

and helps to identify detonation should it occur.

Also commonly used for knock detection are electronic amplifiers.

These devices either connect directly to a knock sensor or use an alligator clip

placed on the engine block. The engine sounds are amplified and filtered and

then routed to the operator via headphones.

Detonation Failures

Detonation causes three main types of failure:

1. Mechanical damage (broken ring lands, hammered big end bearings)

The high impact nature of the pressure spike can also cause

fractures; it can break the spark plug electrodes, the porcelain around

the plug, cause a clean fracture of the ring land and in severe cases

can actually cause fracture of valves-intake or exhaust.

2. Abrasion (pitting of the piston crown).

The sandblasted appearance to the top of the piston near the

perimeter the piston is typical if detonation occurs. Examined with a

Page 34

34 Appendices

microscope the small holes are not unlike those found in Swiss

cheese. The detonation actually mechanically erodes material out of

the piston. Typically the sandblasted look can be expected in the part

of the chamber most distant from the spark plug.

3. Overheating (scuffed piston skirts due to excess heat input or high

coolant temperatures).

Because the pressure spike is very severe and of very short duration,

it can actually shock away the boundary layer of gas that surrounds

the piston. Normal combustion temperatures exceed 900 deg Celsius.

An aluminium piston, subjected directly to that temperature, would

melt.

Under normal combustion it does not melt because of its thermal

inertia and because of a boundary layer of air fuel mixture a few

molecules thick next to the piston top. This thin layer isolates the

piston from the flame and causes the flame to be quenched as it

approaches this relatively cold material. This protects the piston and

chamber from absorbing the heat of the combustion.

However, under extreme conditions the shock wave from the

detonation spike can cause the boundary layer to breakdown. Since

pressure waves created during detonation can sweep away these

unburned boundary layers of air-fuel mixture they leave parts of the

piston top and combustion chamber exposed to the flame front. This,

in turn, causes an immediate rise in the temperature of these parts,

often leading to direct failure or at least to engine overheating.

Detonation Causes

The potential for detonation is influenced by chamber design elements

including: shape, size, geometry, plug location, compression ratio, engine

timing, mixture temperature, cylinder pressure and fuel octane rating. Too

much spark advance ignites the mixture too soon, increasing the pressure

resulting in spontaneously combustion.

Preventing Detonation

With the engine configuration set, detonation can be reduced by

y reducing ignition timing

y reducing air/fuel intake temperature (i.e. making the mixture richer

or using a larger intercooler)

y Reducing Coolant Temperature

y Using a fuel with a higher octane rating

Page 35

MoTeC Notes 35

Page 36

36 Notes

Loading...

Loading...