Page 1

MoTeC E888/816 Manual

Contents

Introduction........................................................................ 1

Overview............................................................................. 2

Inputs.................................................................................. 3

Input Pin Configuration (ADL) .............................................................................4

Outputs............................................................................... 7

Output Configuration...........................................................................................7

E8xx Diagnostic Information.......................................... 11

Test Analogue Inputs........................................................................................12

Test Auxiliary Outputs.......................................................................................12

Communications.............................................................. 14

CAN..................................................................................................................14

Firmware Upgrades...........................................................................................14

Appendices....................................................................... 15

Appendix A: General Specifications..................................................................15

Appendix B: Input Characteristics.....................................................................16

Appendix C: Output Characteristics..................................................................18

Appendix D: CAN Wiring – Multiple Device.......................................................19

Appendix E: E8xx to ADL Wiring.......................................................................20

Appendix F: E8xx to M800 Wiring.....................................................................21

Appendix G: E888 Pin List by Pin Number........................................................22

Appendix H: E816 Pin List by Pin Number................................... .....................23

Appendix I: E816 Connector.............................................................................24

© Copyright 2005 – Motec Pty Ltd

The information in this document is subject to change without notice.

While every effort is taken to ensure correctness, no responsibility will be taken for the consequences of any

inaccuracies or omissions in this manual.

16 December, 2005

Page 2

Page 3

MoTeC Introduction 1

Introduction

This manual describes the functions and specifications of the E888/E816

expander modules and their configuration for use with a MoTeC ADL. These

devices offer additional inputs and outputs into the ADL v ia a CAN connection.

ECU Manager software is currently being developed that will allow the M800

family of ECUs to read information from the E888/816.

This manual includes information on connecting a single expander unit to an

ADL or ADL2. The ADL2 along with the ADL2 Dash Manager software has

been designed to easily allow the connection of a second expander.

It is possible to connect a second expander unit to an ADL and a third or even

fourth unit to an ADL2 – please contact your MoTeC dealer for details in these

situations.

The SDL is capable of reading data from 8 thermocouples when connected to

an E888. It cannot read analog voltage inputs.

Page 4

2 Overview

Overview

The E888 has the following inputs and outputs:

• 8 Analog voltage inputs (AV 1-8)

• 8 Thermocouple inputs (TC 1-8)

• 2 Cold junction compensation thermistor inputs (CJC 1-2)

• 4 Digital inputs (DIG 1-4)

• 2 Switch inputs (DIG 5-6)

• 8 PWM outputs (Aux 1-8)

The E816 has the following inputs and outputs:

• 16 Analog voltage inputs (AV 1-16)

• 2 Thermistor inputs (CJC1-2)

• 4 Digital inputs (DIG 1-4)

• 2 Switch inputs (DIG 5-6)

• 8 PWM outputs (Aux 1-8)

The E888 uses the two part 60 pin connector also used by the M400, M600

and M800 ECUs.

The E816 uses a 66 pin Autosport connector, the same as that used by the

M880 ECU.

Page 5

MoTeC Inputs 3

Inputs

E888 Thermocouple Inputs (TC1 – TC8)

The E888 has eight calibrated and compensated type K (-200 to 1250ºC)

thermocouple inputs. Thermocouple inputs are calibrated during production.

Note that the thermocouples numbered TC1 – TC8 correspond to pins AV9 –

AV16 in the Dash Manager Input pins setup.

Cold Junction compensations are performed using external sensors or the

E888 internal temperature sensor, according to the following rules:

• If only one of the two external cold junction compensation sensors (CJC1

or CJC2) is present then that sensor is used for compensations on all

thermocouple inputs.

• If both of the two external cold junction compensation sensors are present

then sensor CJC1 is used for compensations on TC1 to TC4, and sensor

CJC2 is used for compensations on TC5 to TC8.

• If neither of the two external cold junction compensation sensors are

present then the internal temperature sensor is used for compensations on

all thermocouple inputs.

Cold Junction Compensation Inputs (CJC1 and

CJC2)

The cold junction compensation inputs are used to measure thermistor (2 wire

temperature sensor) temperatures for thermocouple input compensation. If the

thermocouple inputs are not in use, or when using the E816, these inputs may

be used as general purpose temperature inputs.

CJC1/2 inputs have internal 1K pull-ups, and are calibrated to use Bosch 0 280

130 023/026 sensors to read from -30ºC to 150ºC.

Analog Voltage Inputs (AV1 – AV8 or AV1 – AV16)

The E888 has eight 0-5V analog voltage inputs (AV1 to AV8), while the E816

has sixteen inputs (AV1 to AV16). These are suitable for Potentiometers,

voltage output sensors and variable resistance (temperature) sensors (these

require an external pull-up resistor to 5V).

Page 6

4 Inputs

Digital Inputs (DIG1 – DIG 4)

DIG1 to DIG4 may be used to measure frequency. The frequency

measurement range is approximately 1Hz to 5000Hz. Digital inputs should be

pulled to ground as the inputs have an internal 2K7 to 12V pull-up resistor.

Note: Digital Inputs 1 – 4 can only be calibrated to measure frequency. If they

are used as On/Off switches, then the status information is available in the

CAN template ‘Expander Diagnostics’ – see below

Switch Inputs (DIG5 – 6)

These can be used to measure and On/Off style switch. The switches should

be wired so that the E8xx input is pulled to ground when the switch is activated.

Note: Digital inputs 5 and 6 are not included in the Input Pins setup. Instead

they are included in the CAN template ‘Expander Diagnostics’ – see below.

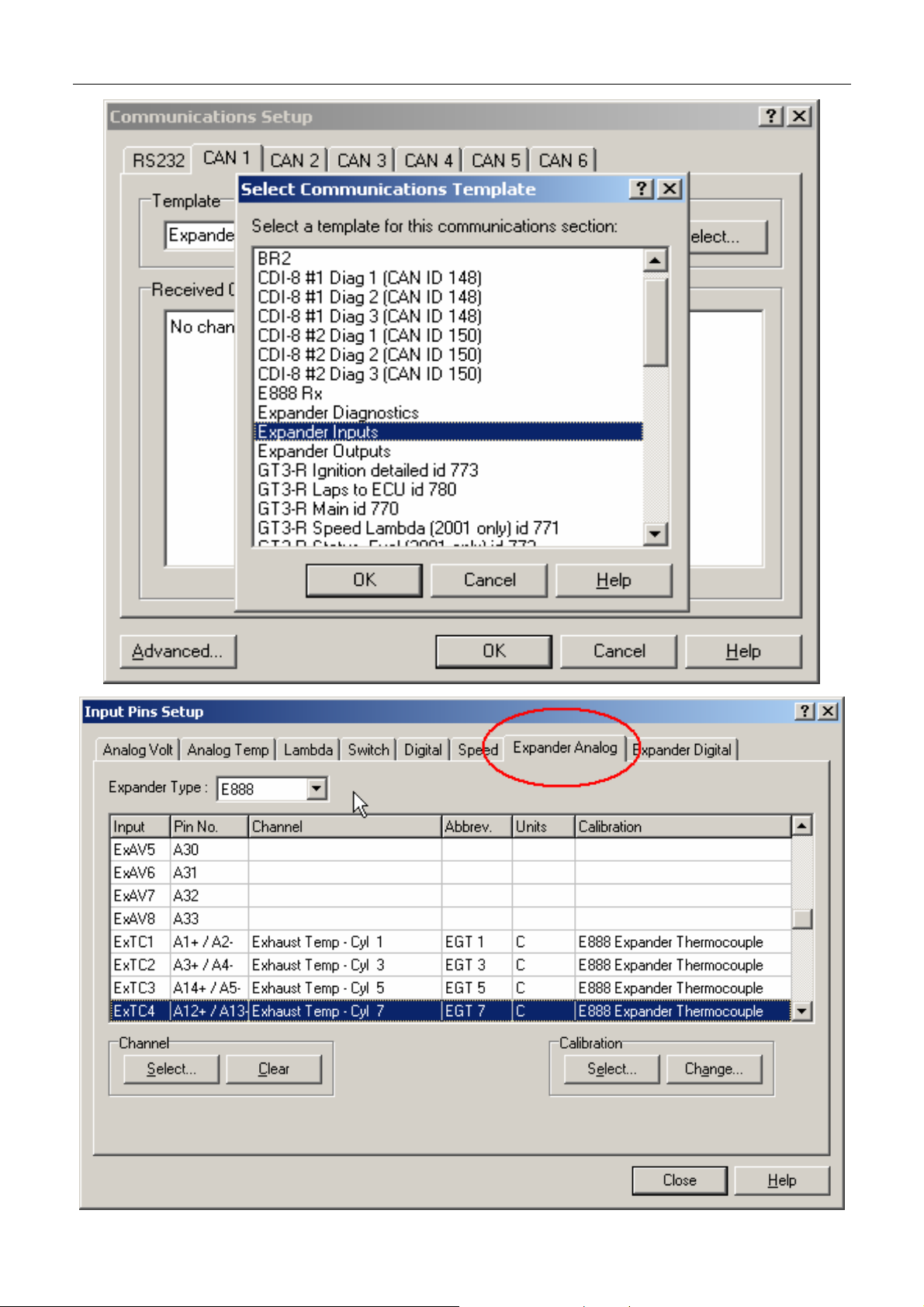

Input Pin Configuration (ADL)

Sensors connected to the E8xx inputs can be configured in the same way as

those connected directly to the ADL. This requires that the ADL is upgraded to

version 3.1 or later.

In Dash Manager, go to ‘Inputs – Communications’ and select an empty CAN

tab. Click on ‘Select’ and choose ‘Expander Inputs’ from the list.

Tabs for Expander Analog Volt and Expander Digital input pin configuration

can be found under the Dash Manager menu item ‘Inputs – Input Pins’.

The Expander type can be selected from the drop down list. The list of inputs

will then show the input name and pin numbers for that particular expander.

The 16 Analogue Volt and 4 Digital Inputs can now be configured the same

way as other ADL inputs by Selecting a channel and then assigning a

calibration. See the ADL Manual for more details on configuring sensor inputs.

Page 7

MoTeC Inputs 5

Page 8

6 Inputs

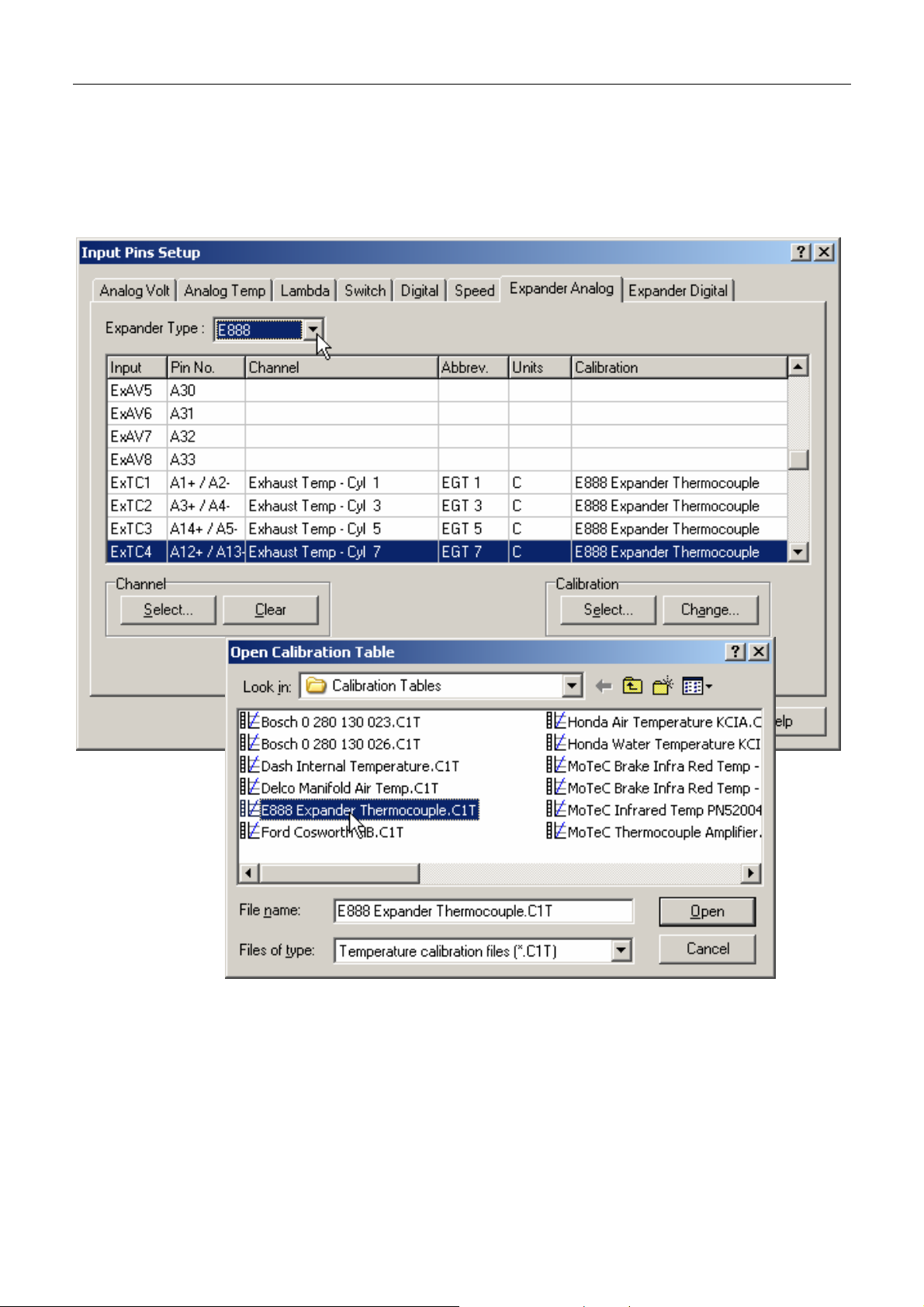

E888 Thermocouples

Thermocouple inputs 1 – 8 correspond to Expander Analog inputs ExTC1 to

ExTC8. The calibration used for these inputs is “E888 Expander

Thermocouple” and can be found in the ‘Select Calibration’ list.

Page 9

MoTeC Outputs 7

Outputs

Both the E888 and E816 include 8 Auxiliary Outputs that are individually

controllable for frequency and duty cycle. They are known as PWM – Pulse

Width Modulated – outputs.

The outputs are in two groups (odd and even) with different characteristics as

follows:

Duty cycle for PWM1/3/5/7 is adjustable from 0 to 100% in 255 steps.

Frequency for PWM1/3/5/7is adjustable from 8Hz to 5kHz.

Duty cycle for PWM2/4/6/8 is adjustable from 0 to 100% in 20 steps.

Frequency for PWM2/4/6/8 is adjustable from 1Hz to 100Hz.

The PWM outputs each have high and low side drivers. A duty cycle sent to the

E888 is the low duty cycle ie:

• an output with 100% duty cycle is pulled low

• an output with 0% duty cycle is pulled high

If the frequency for an output is set to 0, then the output is turned on/off

according to the following rules:

• For a duty cycle of 0%, the output is off (ie: pulled high)

• For a duty cycle greater than 0%, the output is on (ie: pulled low)

All outputs are disabled until the first CAN message is received.

Outputs are disabled after no CAN messages have been received for one

second.

Output Configuration

Auxiliary Devices connected to the E8xx outputs can be configured in the same

way as those connected directly to the ADL. This requires that the ADL is

upgraded to version 3.1 or later.

In Dash Manager go to ‘Inputs – Communications’ and select an empty CAN

tab. Click on ‘Select’ and choose ‘Expander Outputs’ from the list.

Page 10

8 Outputs

Page 11

MoTeC Outputs 9

The tab for Expander Output configuration can be found under the Dash

Manager menu item ‘Functions – Auxiliary Outputs’.

Page 12

10 Outputs

The E8xx outputs can now be configured the same way as the ADL Auxiliary

outputs by select ing an output and then setting the control channels and

parameters.

Ie: Outputs can be on/off, controlled by frequency, duty cycle or a combination

of frequency and duty cycle. Note that appropriate control channels will need to

be generated for these functions. See the ADL Manual for more details on

configuring outputs.

Page 13

MoTeC E8xx Diagnostic Information 11

E8xx Diagnostic Information

Additional status information is available from the E8xx along with the state of

the 2 Switch Inputs and the temperatures measured on the 2 thermistor inputs.

This information can be accessed by selecting an additional CAN template in

the Dash Manager communications setup.

Go to ‘Inputs – Communications’ and click on a blank CAN tab. Then ‘Select’

the template “Expander Diagnostics”.

Page 14

12 E8xx Diagnostic Information

Test Analogue Inputs

It is possible to view the current ‘live’ voltages on the expander’s analogue

inputs using a PC connected to the E8xx via an ADL. In Dash Manager select

the menu item ‘Online – Test – Analogue Inputs’. Then click on the tab

‘Expander Analog’. This is very useful for testing wiring and sensors, and even

determining which sensors are connected to which inputs.

Test Auxiliary Outputs

Similar to the ‘Test Analog Inputs’ function, this screen allows the Auxiliary

Outputs to be tested. In Dash Manager select the menu item ‘Online – Test –

Auxiliary Outputs’ then cl ick on the tab ‘Expander Outputs’.

To test an output select the desired output from the list then enter a suitable

Duty Cycle and Frequency then click the Start button.

Page 15

MoTeC E8xx Diagnostic Information 13

100% duty cycle corresponds to the output fully On (Low Voltage), 0% duty

cycle corresponds to the output fully Off (High Voltage). The frequency should

be chosen to suit the device.

Page 16

14 Communications

Communications

CAN

The CAN bus is used for PC communications during testing, calibration and

firmware upgrades, and for communicating to the ADL or M800.

The following data is transmitted by the E888/E816 at 200Hz:

• Thermocouple temperatures

• Analog input voltages

• Digital input frequencies

The following data is transmitted by the E888/E816 at 50Hz:

• Cold junction compensation temperatures

• Digital input states

• Output driver faults

• Internal temperature

• Internal voltages (-5v, 8vAux, 5vAux, Vbat, 4.5v)

• E888 status flags

• E888 firmware version

The following data is received by the E888/E816 from the ADL:

• PWM outputs frequency and duty cycle

• PWM outputs disable

Firmware Upgrades

At times MoTeC may release Firmware upgrades for the E8xx Expander units.

Upgrades are performed over the CAN bus using the Dashsend utility with a

MoTeC CAN cable.

The Dash Manager installation adds an icon to the Start menu to perform the

E888 firmware upgrade.

See the item under ‘Start – Programs – MoTeC – E888 and E816 Expander

Page 17

MoTeC Appendices 15

Appendices

Appendix A: General Specifications

Physical and Environmental

Case Size 99 x 105mm x 40mm

Weight E888 310g

E816 320g

Temperature Range -10 to 70°C

Power Supply

Operating Voltage 9 – 22V DC

Operating Current 150mA (excluding sensor currents and outputs)

Protection Battery transient protection

Reverse battery protection via external fuse

CAN Communications

CAN bus speed 1Mbit/s

No CAN terminating resistor onboard

Page 18

16 Appendices

Appendix B: Input Characteristics

K-Type thermocouple Inputs (E888)

Range -200 to 1250°C

Resolution 1°C

Accuracy (excluding cold junction errors):

• E888 case temperature 25°C, +/- 2°C Typical

• E888 case temperature -10 to 70°C, +/- 4°C + 2% measured

temperature

Filtering Oversampled for anti-aliasing

Update rate on CAN 100Hz (CAN address 0x0F0 or 0x0F8)

50Hz (CAN address 0x0F4 or 0x0FC)

Analog Voltage Inputs

Range 0 to 5V

Resolution 4.89mV (10bit conversion)

Input Resistance 100Kohms to 0V

Filtering Oversampled for anti-aliasing

Update rate on CAN 200Hz (CAN address 0x0F0 or 0x0F8)

50Hz (CAN address 0x0F4 or 0x0FC)

Internal Cold Junction Compensation sensor-

Resolution 1°C

Accuracy

• E8XX case temperature 25°C, +/- 2°C

• E8XX case temperature -10 to 70°C, +/- 4°C

External Cold Junction Compensation Inputs (Bosch

0 280 130 023/026)-

Range -30 to 150°C

Page 19

MoTeC Appendices 17

Resolution 1°C

Accuracy -10 to 70degC measured temperature, +/- 1°C + Sensor accuracy

Digital Inputs (Schmitt Trigger)

Pullup resistor 2700 ohms to 5V

Voltage range 0 to 15V

Positive trigger threshold 3.5V max

Negative trigger threshold 1.0V min

Hysteresis 0.5V min

Freq Range (for inputs 1-4) 1Hz to 6kHz

Freq Resolution (for inputs 1-4) 0.1Hz

Minimum Pulse Width 0.05mS

Update rate on CAN 200Hz (CAN address 0x0F0 or 0x0F8)

50Hz (CAN address 0x0F4 or 0x0FC)

Page 20

18 Appendices

Appendix C: Output Characteristics

Outputs

Current per output when using the given number of outputs:

• 1 Output 3.2A

• 2 Outputs 2.3A

• 4 Outputs 1.6A

• 8 Outputs 1.1A

Duty cycle resolution (high speed outputs) 255 steps (0-100%)

Frequency Range(high speed outputs) 8Hz to 5kHz

Duty cycle resolution (low speed outputs) 20 steps (0-100%)

Frequency Range (low speed outputs) 1Hz to 100Hz

Page 21

MoTeC Appendices 19

Appendix D: CAN Wiring – Multiple Device

The CAN bus should consist of a twisted pair trunk with 100R (0.25Watt)

terminating resistors at each end of the trunk.

The preferred cable for the trunk is 100R Data Cable but twisted 22# Tefzel is

usually OK.

The maximum length of the bus is 16m (50ft) including the MoTeC CAN Cable

(PC to CAN Bus Communications Cable)

CAN Devices (such as MoTeC ADL, BR2 etc) may be connected to the trunk

with up to 500mm (20in) of twisted wire.

The connector for the CAN Communications Cable may also be connected to

the trunk with up to 500mm (20in) of twisted wire and should be within 500mm

of one end of the trunk. If desired two CAN Cable connectors may be used so

that the MoTeC CAN Cable may be connected to either side of the vehicle.

Both connectors must be within 500mm of each end of the trunk.

100R Terminating

Resistors at each

end of the CAN Bus

CAN-HI

CAN-LO

100R

CAN-LO

CAN-HI

CAN Device

eg BR2

These w ires must be Tw ist ed

Minimum one twist per 50mm (2in)

500mm

<< CAN Bus >>

500mm

Max

CAN-LO

CAN-LO

CAN-HI

CAN Device

eg M800

CAN-HI

CAN Device

eg ADL

Max

CAN Cable

Connector

5

4

3

1

CAN-LO

CAN-HI

500mm Max

0V

8V

100R

Short CAN Bus

If the CAN Bus is less than 2m (7ft) long then a single termination resistor may

be used. The resistor should be placed at the opposite end of the CAN Bus to

the CAN Cable connector.

Page 22

20 Appendices

Appendix E: E8xx to ADL Wiring

E8xx

Ground

Power

CAN-LO CAN-LO

CAN-HI CAN-HI

See pin list

See pin list

B24 / 47

B23 / 54

Bat -

Bat +

7

8

73 or 75

74 or 76

Bat Bat +

ADL

0V

8V

71

72

CAN Cable

Connector

1

0V

2

3

8V

4

CAN-LO

5

CAN-HI

CAN-HI

CAN-LO

100R

See the CAN Bus

Wiring Specification

Any Other

CAN Device

Any Other

CAN Device

100R

for more Detail

E8xx Power and Ground Wiring

E888

E816

Additional Power and Ground pins are provided to simplify wiring and to meet

the current requirements of any devices connected to the PWM outputs.

Bat + Bat -

A17, B8, B9 A10, A11, B15, B16

28, 29, 30, 37, 38, 39 13, 14, 15, 19, 20, 21, 22

As a general principle, if no outputs are being used, then wiring one power and

one ground pin is sufficient. If the expander outputs are used, then all power

and ground pins should be wired up.

Page 23

MoTeC Appendices 21

Appendix F: E8xx to M800 Wiring

Note that this also applies to the M400, M600 and M880 ECUs.

E8xx

Ground

See pin list

Bat -

Bat +

ECU

CAN Cable

Connector

Power

CAN-LO CAN-LO

CAN-HI CAN-HI

CAN-HI

CAN-LO

100R

See pin list

B24 / 47

B23 / 54

See the CAN Bus

Wiring Specification

for more Detail

B24 / 47

B23 / 48

Any Other

CAN Device

E8xx Power and Ground Wiring

Bat + Bat -

71

0V

72

8V

Any Other

CAN Device

1

0V

2

3

8V

4

CAN-LO

5

CAN-HI

100R

E888

E816

A17, B8, B9 A10, A11, B15, B16

28, 29, 30, 37, 38, 39 13, 14, 15, 19, 20, 21, 22

Additional Power and Ground pins are provided to simplify and to meet the

current requirements of any devices connected to the PWM outputs.

As a general principle, if no outputs are being used, then wiring one power and

one ground pin is sufficient. If the expander outputs are used, then all power

and ground pins should be wired up.

Page 24

22 Appendices

Appendix G: E888 Pin List by Pin Number

The E888 uses a 34 + 26 pin connector pair with the following pin-out:

Pin Function Pin Function

A1 TC1+ B1 PWM1

A2 TC1- B2 PWM2

A3 TC2+ B3 PWM3

A4 TC2- B4 PWM4

A5 TC3- B5 PWM5

A6 CJC1 B6 PWM6

A7 CJC2 B7 PWM7

A8 B8 BATTERY +

A9 B9 BATTERY +

A10 BATTERY- B10 DIG2

A11 BATTERY- B11 DIG1

A12 TC4+ B12 DIG5

A13 TC4- B13 PWM8

A14 TC3+ B14 0V COMMS

A15 0V B15 BATTERYA16 8V B16 BATTERYA17 BATTERY+ B17

A18 TC5+ B18 DIG4

A19 TC5- B19 DIG3

A20 TC6+ B20 5V

A21 TC6- B21 0V

A22 AV1 B22 8V

A23 AV2 B23 CAN HI

A24 AV3 B24 CAN LO

A25 AV4 B25 DIG6

A26 TC7+ B26

A27 TC7-

A28 TC8+

A29 TC8-

A30 AV5

A31 AV6

A32 AV7

A33 AV8

A34 5V

Page 25

MoTeC Appendices 23

Appendix H: E816 Pin List by Pin Number

The E816 uses a 66 pin autosport connector with the following pin-out:

Pin Function

(E816B)

1 34 PWM8

2 PWM7 35 CJC1

3 PWM6 36 8V

4 37 BATTERY+

5 AV11 38 BATTERY+

6 AV10 39 BATTERY+

7 PWM5 40

8 41 DIGITAL IN 5

9 AV9 42 DIGITAL IN 6

10 43

11 AV12 44 AV14

12 0V COMMS 45 8V

13 BATTERY- 46 5V

14 BATTERY- 47 CAN LO

15 BATTERY- 48

16 PWM4 49 PWM3

17 CJC2 50

18 0V 51

19 BATTERY- 52 AV15

20 BATTERY- 53 5V

21 BATTERY- 54 CAN HI

22 BATTERY- 55

23 DIGITAL IN 1 56 PWM2

24 DIGITAL IN 2 57 AV16

25 58 AV1

26 AV13 59 AV2

27 0V 60 AV3

28 BATTERY+ 61 PWM1

29 BATTERY+ 62 AV4

30 BATTERY+ 63 AV5

31 64 AV6

32 DIGITAL IN 3 65 AV7

33 DIGITAL IN 4

Pin Function

(E816B)

66 AV8

Page 26

24 Appendices

Appendix I: E816 Connector

Mating Connector

Deutsch : AS6-18-35SN

Wire

Wire to suit connector : 22# Tefzel, Mil Spec : M22759/16-22

Crimp Tool

Crimp Tool : M22520/2-01

Positioner for Crimp Tool : M22520/2-07

• Note that the Crim p Cont acts are type 22D (this is needed to set the crimp

tool correctly)

Wire Stripping Tool

The following tool is recommended

Ideal Industries 45-2133 stripping tool with LB1195 wire stop.

Heatshrink Boots

Straight : Racychem 202K153, Hellermann 156-42-G

Right Angle : Racychem 222K153, Hellermann : 1156-4-G

Page 27

MoTeC Notes 25

Page 28

26 Notes

Page 29

MoTeC Notes 27

Page 30

28 Notes

Loading...

Loading...