Page 1

M oTe C ADL / EDL User’s Manual

Contents

Introduction ........................................................................ 1

Overview ............................................................................. 2

Display ................................................................................................................2

Alarms................................................................................................................. 6

Data Logging.......................................................................................................7

Other Functions ................................................................................................12

Measurement Inputs .........................................................................................13

Auxiliary Outputs............................................................................................... 18

Communications Overview ...............................................................................19

ECU Connection ............................................................................................... 19

Telemetry..........................................................................................................20

Lap Beacon....................................................................................................... 20

Options .............................................................................................................20

Software............................................................................................................ 21

Field Updateable Control Software ................................................................... 22

CAN Cable........................................................................................................22

Installation ........................................................................ 23

Mounting ........................................................................................................... 23

Display Care .....................................................................................................24

Wiring................................................................................................................ 24

MoTeC Supplied Wiring Loom ............................................................................25

Custom Wiring Loom ........................................................................................25

External Buttons................................................................................................25

External Lights .................................................................................................. 26

Thermocouples ................................................................................................. 26

Connecting to a MoTeC ECU ............................................................................. 26

Telemetry..........................................................................................................28

Dash Manager Software .................................................. 29

Introduction ....................................................................................................... 29

Computer Requirements...................................................................................29

Installing Dash Manager ...................................................................................30

Mouse & Keyboard ...........................................................................................30

Main Menu ........................................................................................................ 31

Button Bar (Toolbar) .........................................................................................31

On line / Off line ................................................................................................ 32

Configuration..................................................................................................... 32

Configuration Files ............................................................................................ 32

Changing the Configuration ..............................................................................34

Versions and Updating...................................................................................... 34

Page 2

Channels........................................................................................................... 36

Conditions Overview ......................................................................................... 40

Checking Operation ..........................................................................................41

Sensor Zeroing .................................................................................................42

Details Editor ....................................................................................................42

Windows Keyboard Use .................................................. 43

Main Menu ........................................................................................................ 43

Closing a Window .............................................................................................43

Getting Help......................................................................................................43

Selecting an Item in a Window.......................................................................... 44

Using the Selected Item....................................................................................44

Appendices....................................................................... 48

Appendix A: General Specifications..................................................................48

Appendix B: Options Summary.........................................................................49

Appendix C: Dash Manager Command Line..................................................... 51

Appendix D: Input Characteristics..................................................................... 53

Appendix E: Auxiliary Output Characteristics.................................................... 59

Appendix F: CAN Bus Specification..................................................................60

Appendix G: CAN Wiring - Multiple Device ....................................................... 61

Appendix H: CAN Wiring - Single Device.......................................................... 62

Appendix J: ECU to ADL Wiring (RS232) .........................................................63

Appendix K: Pin List by Function ......................................................................66

Appendix L: Pin List by Pin Number.................................................................. 70

Appendix M: Connector ....................................................................................72

Appendix N: Wire Specifications ....................................................................... 73

Appendix P: Case Dimensions..........................................................................74

Copyright – Motec Pty Ltd – 1998-2003

The information in this document is subject to change without notice.

While every effort is taken to ensure correctness, no responsibility will be taken for the consequences of any

inaccuracies or omissions in this manual.

25 October, 2004

Page 3

MoTeC Introduction 1

Introduction

Thank you for purchasing a MoTeC ADL Dash / Logger and/or EDL Enclosed

Data Logger

ADL

The MoTeC ADL Dash / Logger is a combined LCD dash unit and high

performance data logger.

EDL

The EDL is a model of the ADL that is manufactured without a display screen.

Aside from this, it functions in the same way, using the same software as the

ADL. In the remainder of this manual when reference is made to the ADL, it

also refers to the EDL – except when referring to the display.

This Manual Covers:

• Overview of the ADL/EDLs capabilities

• Installation

• Overview of the MoTeC Dash Manager software

Software Information

For detailed information on using the various software programs refer to the

online help supplied with the program.

Other Manuals

Separate Manuals are available for:

• MoTeC Lap Beacon / BR2

• Interpreter Data Analysis Software

Sensor Details

Drawings are available for all MoTeC sensors. The drawings detail all

mounting and wiring requirements for each sensor.

Page 4

2 Overview

Overview

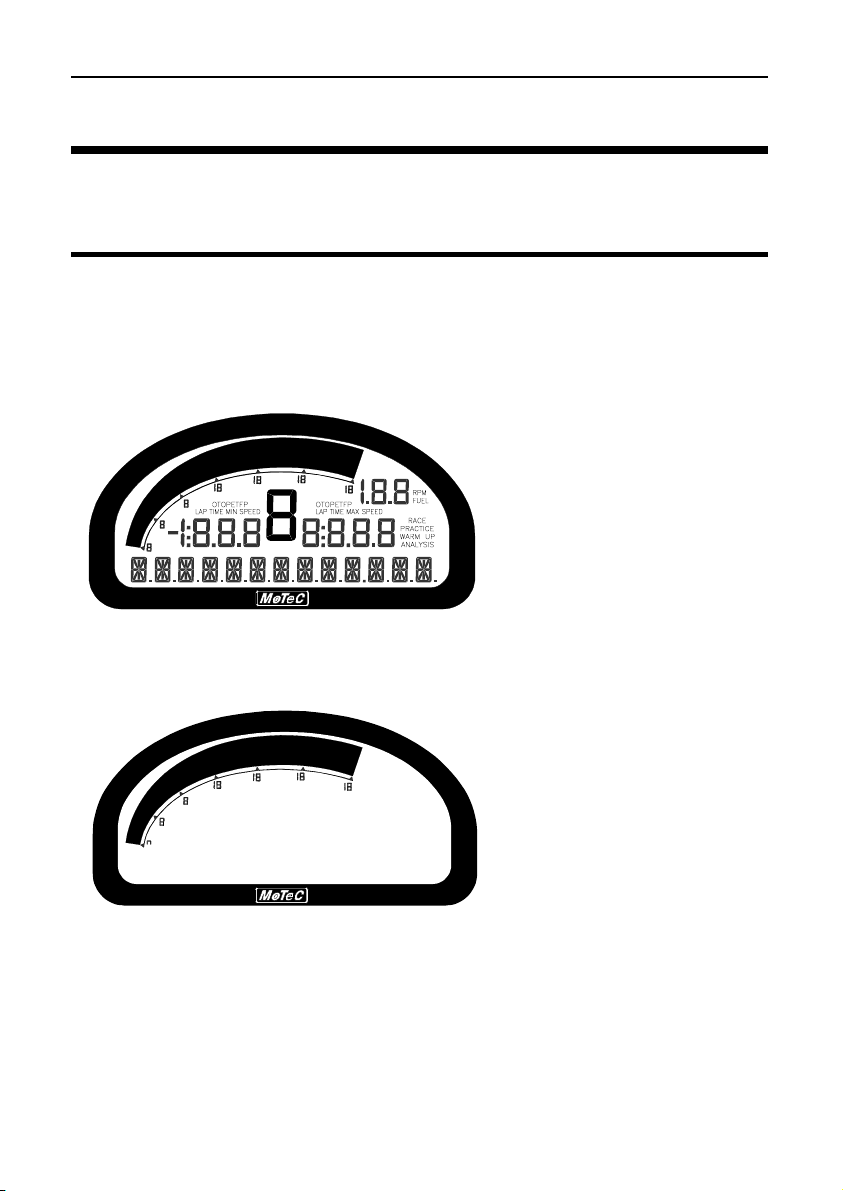

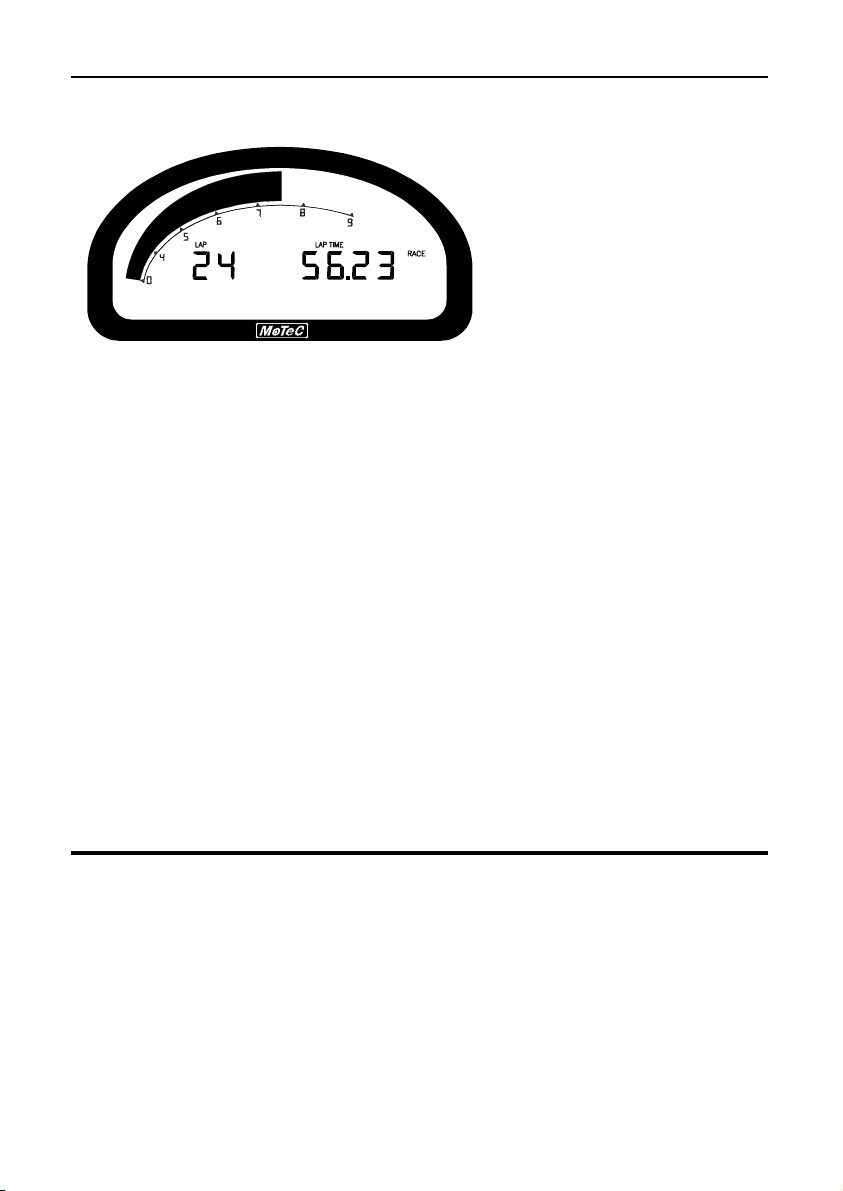

Display

The ADL display is a high contrast, high temperature, custom made LCD

display.

The display contains a Bar Graph, three Numeric Displays, a Centre Numeric

Display and a Bottom Alpha / Numeric Display.

Bar Graph

The 70 segment bar graph has a user definable range and is typically used as

a tacho, however it can be used to display any other value. When used as a

tacho it may be configured for up to 19,000 RPM.

A fully programmable shift point can be displayed, which can also be gear

dependent.

Page 5

MoTeC Overview 3

The operation of the bar graph can be different for each of the display modes

(Race Practice and Warmup), this allows a lower range to be used in Warmup

mode.

Numeric Displays

The three numeric displays (Left, Right and Top Right) can be programmed to

display any value, which may be different for each of the display modes

(Race Practice and Warmup).

Note that each of the three numeric displays has a different number of digits

and are therefore suited to displaying different values. Fox example the Top

Right display can only show values up to a maximum of 199 and is therefore

not suitable for displaying Lap Times, but is suitable for displaying many other

values such as Lap Number of Fuel Remaining, Engine Temperature etc.

The numeric displays can show any channel value plus up to two override

values, which are shown each time their value is updated, this is useful for

values that are updated periodically, for example Lap Time. The override

values are shown for a programmable period of time, for example a numeric

display could normally show the Running Lap Time (which is continuously

updating) then be overwritten by the Lap Time for 10 seconds each time the

Lap Time is updated.

Enunciators for some of the common display values are provided above the

numeric displays, eg. ET (Engine Temperature), OP (Oil Pressure).

Page 6

4 Overview

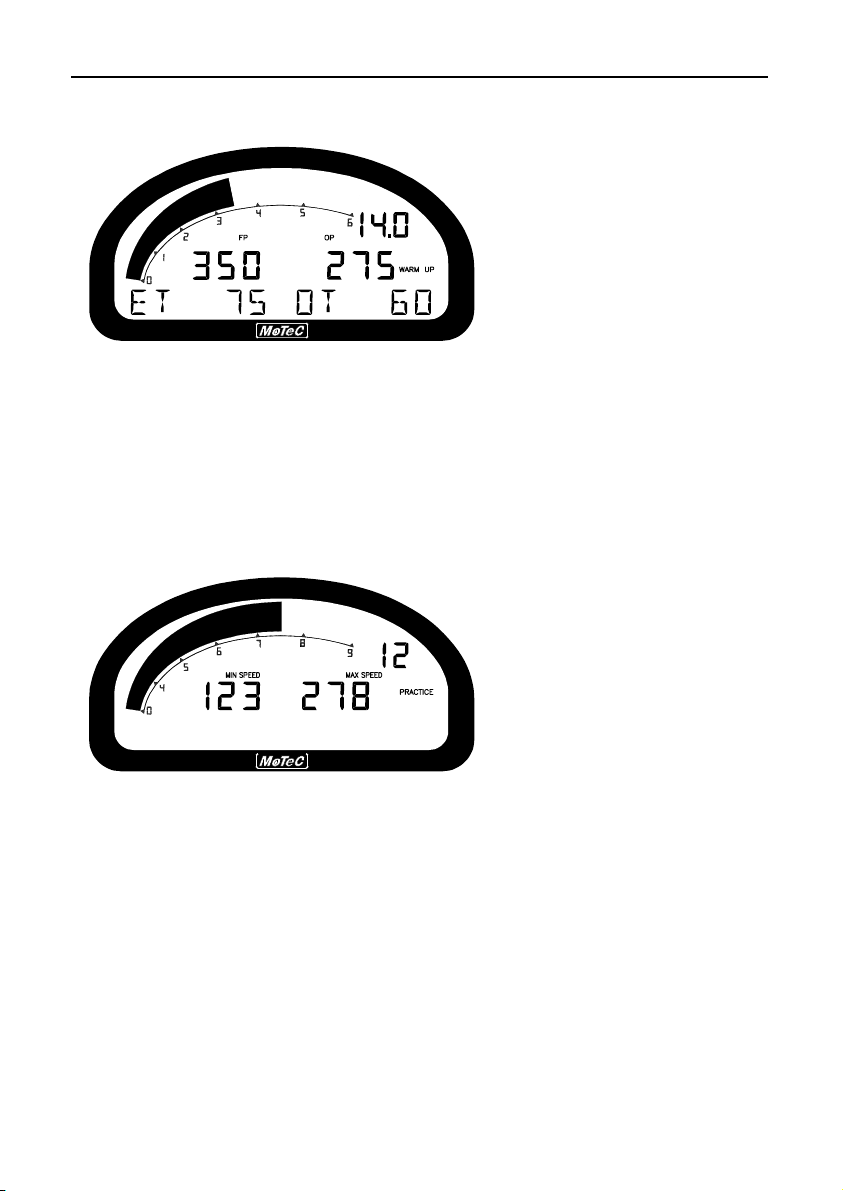

Centre Numeric Display

The Centre Numeric display is incorporated to show the current gear but may

be used for other purposes.

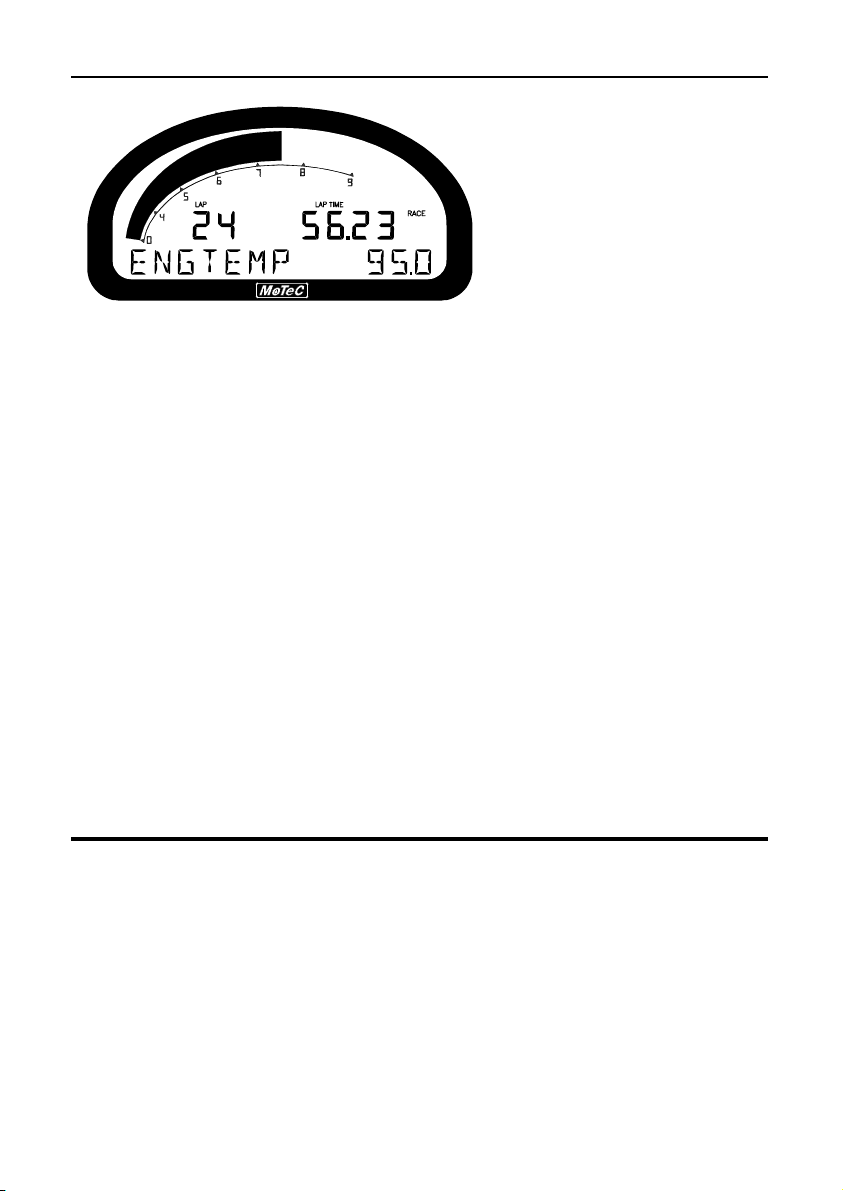

Bottom Display

The 13 digit alpha numeric display can display up to 20 lines of information

that can be scrolled up or down using the external buttons. Each of the 20

lines can display up to 3 channel values at a time.

The values shown may be different for each of the three display modes.

Additionally the bottom display can show up to four override values, similar to

the numeric displays.

The bottom display will also show any active alarm messages, which will

override all other values until the alarm is cleared.

Display Modes

The display has three main modes of operation, Race, Practice and Warm

Up.

Page 7

MoTeC Overview 5

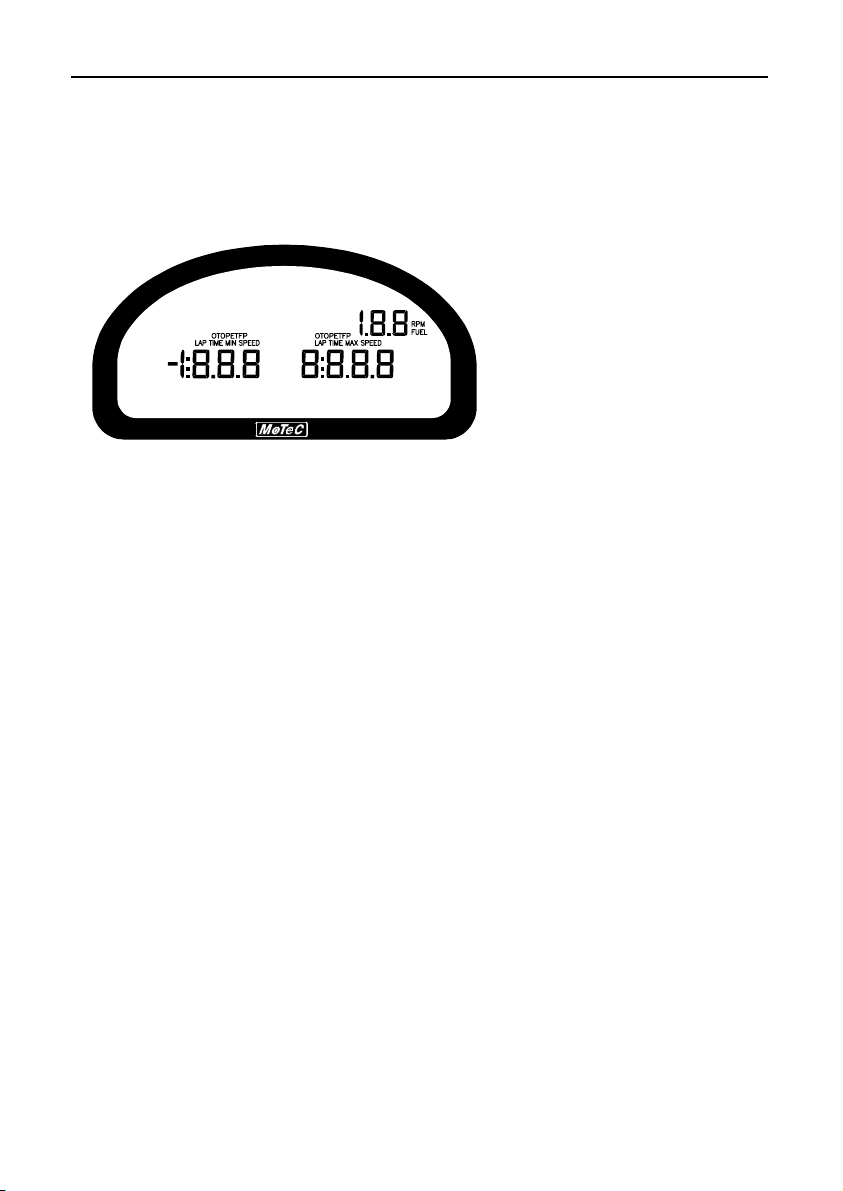

Warm Up

The warm up display is used to display important engine sensor readings

during engine warm up, eg, RPM, Battery Voltage, Engine Temperature, Oil

Pressure, Oil Temperature & Fuel Pressure.

The bottom display may be used display many other values that may need

checking during warm up.

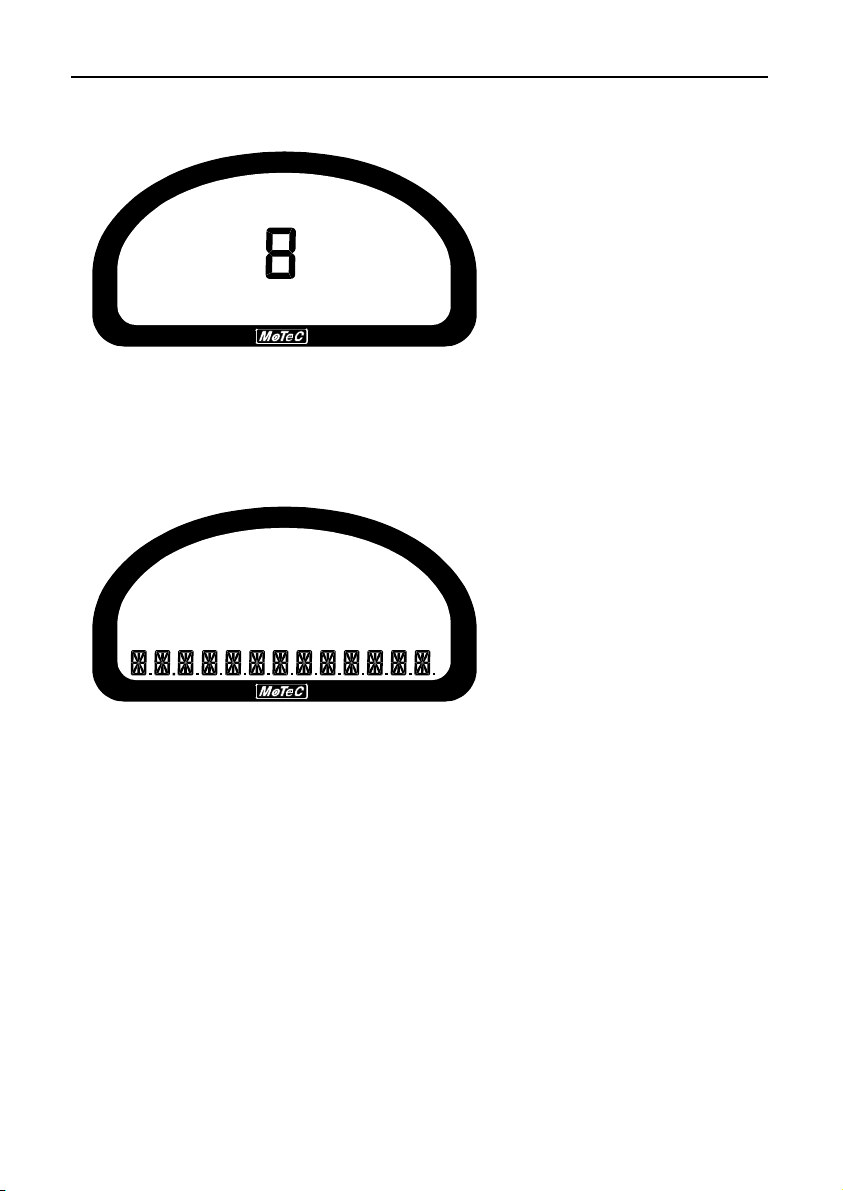

Practice

The practice display is used to display basic information, plus information to

help the driver improve lap times, eg. Lap Time, Lap / Gain Loss, Maximum

Straight Speed, Minimum Corner Speed or Corner Exit Speed.

The bottom display may be used to display additional information as needed.

Page 8

6 Overview

Race

The race display is normally used to display minimal information, eg RPM,

Lap Time, Fuel Remaining or Laps Remaining.

The bottom display may be used to display additional information as needed.

Display Formatting

Units

The display units can be changed to suit the driver, for example the driver

may prefer to see the engine temperature in Fahrenheit rather Celsius. This is

independent of the units used for other purposes.

Decimal Places

The number of decimal places can be reduced for display purposes, for

example the engine temperature is measured to 0.1 °C but is better displayed

with no decimal places. This is normally done automatically.

Alarms

When an alarm is activated a message is shown on the bottom line of the

display, a warning light can also be activated which is recommended to draw

the drivers attention to the display.

The message displayed can be defined and can also include the current

sensor reading or the sensor reading when the alarm was triggered.

Page 9

MoTeC Overview 7

The alarms remain active until they are acknowledged, either by a driver

activated switch or automatically after a defined period of time.

The warning alarm limits are fully programmable and may include up to 6

comparisons to ensure that the alarms are only activated at the correct time.

For example, an engine temperature alarm may activate at 95 °C if the

ground speed has been above 50 km/h for 30 seconds. The speed

comparison avoids the alarm showing during a pit stop due to heat soak.

Additionally another comparison could be set at a higher temperature to cover

all other situations.

The comparison values can be automatically incremented or (decremented)

when an alarm occurs. For example the engine temperature alarm may be set

at 95°C with and increment of 5°C, so that the second time the alarm

activates it activates at 100°C. A limit may be set on the number of times the

comparison value is allowed to increment, also it may return to its original

value after a period of time, in case the alarm condition was temporary.

The alarms can also be dependent on the current display mode (Race,

Practice or Warmup)

Data Logging

Data logging allows the sensor readings (or any calculated value) to be stored

in the ADL for later analysis on a Personal Computer.

Logging Memory

The ADL comes with 8 Mbytes of logging memory. Various options determine

how much of the memory can be used and whether Fastest Lap Logging and

Burst Logging are enabled.

See the Options Summary in the Appendices for details.

Page 10

8 Overview

Power

The ADL power can be turned off at any time without losing the logged data.

The ADL uses FLASH memory which does not require an internal battery to

keep it alive.

Logging Rate

The ADL can store any value at up to 1000 times per second, which can be

individually set for each logged item.

The rate at which the values are logged is very important – the value must be

logged fast enough to record all variations in the reading. If the value is

logged too slowly then the readings can be totally meaningless. For example

suspension position normally needs to be logged at 100 times per second or

more.

Note, however, that if a value is logged faster than necessary it will not

improve the accuracy of the logged data, it will just reduce the total logging

time available. For example, the engine temperature only needs to be logged

at once per second.

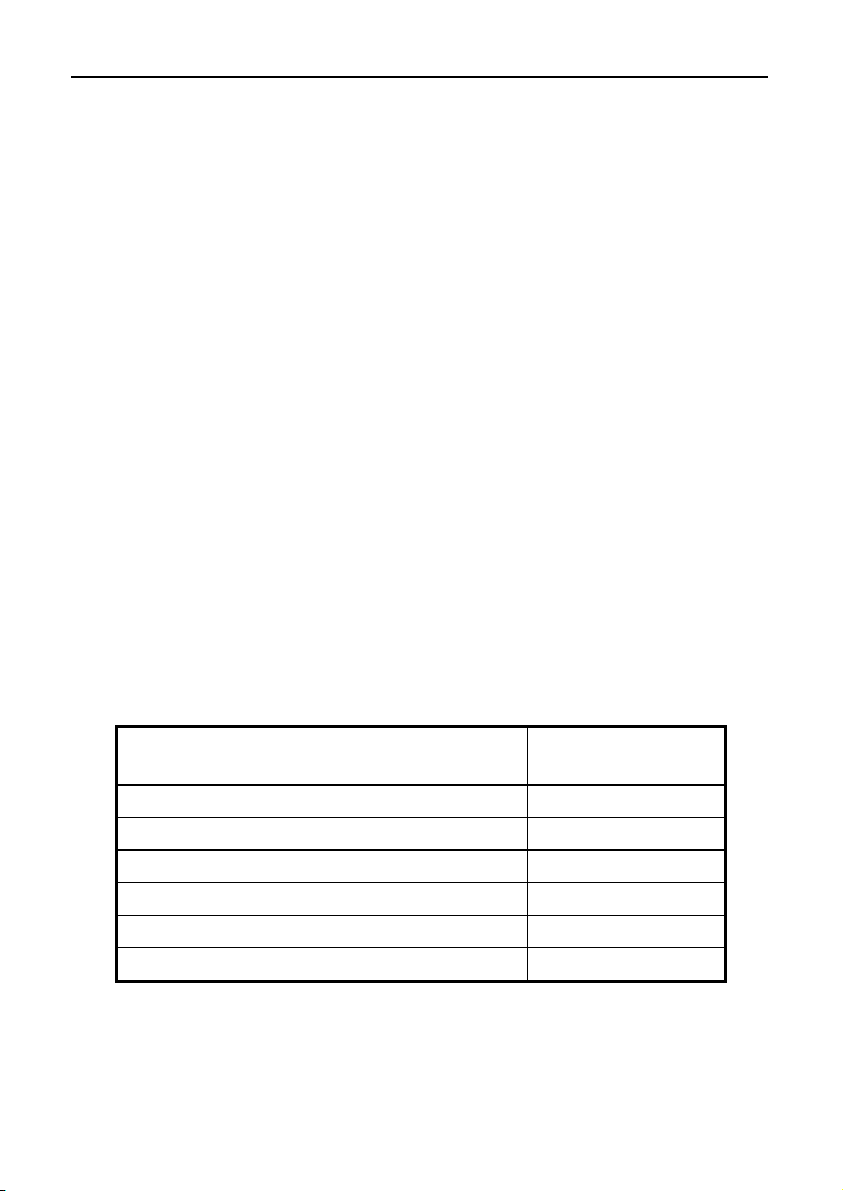

Update Rate

Not all values are updated 1000 times per second, and logging them faster

than their update rate will simply waste memory.

The update rates for all input types are listed below:

Input Type Update Rate

(times per second)

Analog Voltage Inputs 1 to 4 & 11 to 14 1000

Other Analog Voltage Inputs 500

Analog Temp Inputs 500

Lambda Inputs 100

Digital Inputs & Speed Inputs 100

RS232 & CAN Communications 50 max *

* Note that the RS232 & CAN Communications update depends on how

frequently the data is sent from the device. Typically the update rate from an

M4, M48, M8 or M800 ECU is about 20 times per second using RS232, and

about 50 times per second for the M800 using CAN.

Page 11

MoTeC Overview 9

Logging Time

The maximum logging time is dependent on the logging memory size, the

number of items logged and the rate at which they are logged. The

configuration software will report the logging time, taking all these factors into

account.

Logging Types

The ADL provides three ways of logging the data: Normal Logging, Fastest

Lap Logging and Burst Logging.

Normal Logging

Normal Logging continuously logs data to memory whenever the Start

Condition is true (and the Stop Condition is false).

Logging Rates

The logging Rate may be individually set for each value between 1 to 1000

times per second.

Start and Stop Logging Conditions

To avoid logging unnecessary data, logging can be started and stopped by

user definable conditions. For example logging might start when the vehicle

exceeds 50 km/h, and stop when the engine RPM is below 500 RPM for 10

seconds. Note that the Start Condition must be true and the Stop Condition

must be false before logging will start.

Memory Filling Options

When the logging memory is full the ADL may be configured to either stop

logging, or to overwrite the oldest data, which ensures that the most recent

data is always available. This is referred to as cyclic logging.

For most applications it is recommended that cyclic logging is used.

Logging Setup Files

The logging list can be saved and loaded from a file. This allows multiple

logging setups to be used.

Page 12

10 Overview

Fastest Lap Logging

Fastest Lap logging records data for the Fastest Lap since the data was last

retrieved. Normally this is used for items that require fast logging rates, such

as suspension position. This allows the available memory is used more

efficiently.

Note that Fastest Lap Logging requires that a Lap Beacon is connected.

Fastest Lap Logging is in addition to and works concurrently with Normal

Logging.

Up to 50 values may be logged.

Logging Rates

The logging Rate may be individually set for each value between 1 to 1000

times per second.

Maximum Lap Time

Note that a maximum Lap Time must be entered which indicates to the ADL

how much memory to reserve for fastest lap logging. If there are no Lap

Times less than this value then Fastest Lap data will not be available.

Memory Occupied

The amount of memory occupied by Fastest Lap logging depends on how

many items are logged, how fast they are logged and the specified maximum

Lap Time. The effect on normal logging time is shown in the configuration

software.

Logging Setup Files

The logging list can be saved and loaded from a file. This allows multiple

logging setups to be used.

Burst Logging

Burst logging allows data to be captured at high speed without wasting large

amounts of memory.

Two independent burst logging systems are available.

Up to 20 values may be logged for each.

Page 13

MoTeC Overview 11

Logging Rates

The logging rate may be set between 100 and 1000 times per second and is

the same for all logged items.

Trigger Conditions

Burst logging is triggered when a defined condition becomes true.

Note that the normal Start and Stop Logging conditions do not affect burst

logging.

Trigger Position

Burst logging can capture data before and/or after the burst start condition

becomes true (trigger event). This is because the burst logging data is stored

continuously, overwriting the oldest data as necessary. When the trigger

event occurs, a proportion of the old data (before the trigger event) is kept

and the rest of the memory is filled with new data (after the trigger event).

Events and Memory

Up to 8 events can be captured for each of the two burst systems. Each burst

event occupies 64 kbytes of memory (1/16

The number of events may be set by the user. Note that this will affect the

amount of memory available for normal logging.

th

of a Mbyte).

Logging Time

Since each burst event is fixed at 64 kbytes of memory, the burst logging time

is dependent on how many items are logged and how fast they are logged.

The burst logging time is reported by the configuration software.

For example 8 items logged at 500 times per second will last 8.2 seconds.

Retrieving the Logged Data

A personal computer is used to unload the logged data from the ADL. The

logged data is then stored on the computer hard disk.

The logged data may be retrieved at very high speed (approximately 20

seconds per Mbyte).

After each unload the user has the option to clear the logging memory.

The unload may be interrupted part way through if necessary by

disconnecting the computer. The partial unload will contain the most recently

Page 14

12 Overview

logged data and will be stored on the computer hard disk. In this case the

ADL logging memory is not cleared and logging will continue as normal at the

end of the existing data. Next time the logged data is unloaded both the new

data and the previously partly unloaded data will be retrieved.

Track Map Sensor Requirements

In order for the logging analysis software to plot a track map the following

sensors are required and must be logged.

• Lateral G force

• Wheel Speed

• Lap Beacon (Note that the ‘Beacon’ Channel must be logged)

• Longitudinal G force (Optional: See Below)

A Longitudinal G force sensor should be used if the vehicle has only one

wheel speed sensor. This allows the analysis software to eliminate wheel

lockups which is essential when creating or using a track map.

Other Functions

The ADL can perform many other functions and calculations including the

following:

Functions:

• Shift Lights

• Engine Log

Calculations:

The ADL can calculate and display any of the following:

• Lap Time, Lap Speed, Running Lap Time, Split Lap Times, Lap Number,

Laps Remaining.

• Ground Speed, Drive Speed, Wheel Slip, Lap Distance, Trip Distance,

Odometer.

• Lap Time Gain / Loss continuously displays how far behind or ahead the

vehicle is compared to a reference lap.

• Current Gear.

Page 15

MoTeC Overview 13

• Minimum Corner Speed, Maximum Straight Speed and other Min/Max

values.

• Fuel Used, Fuel Usage, Fuel Remaining, Laps Remaining, Fuel Used per

Lap.

General Purpose Calculations:

The ADL also provides a number of general purpose calculations including:

• 2D and 3D Lookup Tables

• User Defined Conditions

• General Purpose Timers

• Mathematics

The user defined conditions or tables can be used to activate items such as a

Thermatic Fan or Gearbox Oil Pump.

Measurement Inputs

The ADL measurement inputs can be connected to a wide variety of sensors.

This allows the ADL to measure vehicle parameters such as: Suspension

Movement, Wheels Speeds, Steering Angle, Engine Temperature etc.

Input Types

The ADL has a number of different input types which are designed to suit the

different types of sensors.

The following inputs are available:

• 20 Voltage Inputs

• 8 Temperature Inputs

• 2 Wide Band Air Fuel Ratio Inputs (Lambda Inputs)

• 4 Switch Inputs

• 4 Digital Inputs

• 4 Wheel Speed

Page 16

14 Overview

Options

The number of inputs that can be used depends on which options are

enabled. See the Options Summary in the Appendices for details.

Internal Sensors

The ADL also includes internal sensors for Battery Voltage and ADL Internal

Temperature.

Sensors

Different types of sensors are available to suit different types of

measurements.

Sensors convert a physical measurement (e.g. Pressure) into an electrical

signal (e.g. Volts). Different types of sensors generate different types of

electrical signals. For example most temperature sensors convert the

temperature into a variable resistance signal which may be measured by the

ADL Temperature inputs, however most wheel speed sensors generate a

variable frequency signal which must be connected to either a Digital input or

a Speed input.

Calibration

Calibration is the process of converting the electrical value, e.g. Volts into a

number that represents the physical value, e.g. Temperature.

All inputs can be calibrated to suit the connected sensor.

The calibrations can be selected from a number of predefined calibrations

provided by M oTe C , or they can be entered by the user.

Analog Voltage Inputs

The 20 Analog Voltage inputs are normally used to measure the signals from

analog voltage type sensors, i.e. sensors with variable voltage outputs, such

as:

• Rotary or linear potentiometers

• Signal conditioned 3 wire pressure sensors

• Thermocouple amplifiers

• Accelerometers

These inputs can also be used to measure two wire variable resistance

sensors if an external pullup resistor is connected from the input to the 5V

Page 17

MoTeC Overview 15

sensor supply. Additionally, on/off switch signals may be connected, which

may also require an external pullup resistor.

Options

Note that the number of inputs that are available depends on which options

are enabled. See Appendix B: Options Summary for details.

Measurement Methods

These inputs can be configured to use several measurement methods to suit

the various types of sensors:

• Absolute Voltage: The sensor voltage is independent of the sensor supply

voltage

• Ratiometric Voltage: The sensor voltage is proportional to the 5V sensor

supply voltage

• Variable Resistance: The sensor resistance can be entered directly.

• On/Off : The voltage for on and off can be defined

Input Voltage Range

The measurable input voltage range is 0 to 15 Volts. This allows selection

from a wide range of sensors.

Specifications

For full specifications see Appendix D: Input Characteristics.

Analog Temp Inputs

The 8 Analog Temp inputs are identical to the Analog Voltage inputs, except

that they contain a 1000 ohm resistor which is connected internally from the

input pin to the 5V sensor supply. This allows the Analog Temp inputs to be

used with two wire variable resistance sensors such as:

• Two wire thermistor temperature sensors

• Two wire variable resistance pressure sensors

Some voltage output sensors can also be used if they can drive the 1000 ohm

resistor without causing an error in their reading (eg M oTe C Thermocouple

Amplifier). Additionally, on/off switch signals may be connected.

Page 18

16 Overview

Options

Note that the number of inputs that are available depends on which options

are enabled. See Appendix B: Options Summary for details.

Measurement Methods

These inputs use the same measurement methods as the Analog Voltage

Inputs.

Input Voltage Range

The measurable input voltage range is 0 to 15 Volts. This allows selection

from a wide range of sensors.

Specifications

For full specifications see Appendix D: Input Characteristics.

Wide Band Lambda Inputs

The two high accuracy, fully temperature compensated Wide Band Air Fuel

Ratio measurement inputs can be used if the Lambda Option is enabled.

These inputs connect directly to a M oTe C 4 wire Wide Band Lambda Sensor

and are accurate to 1.5% up to 1.2 Lambda under all load and temperature

conditions.

Note that this is the Bosch LSM sensor and not the 5 wire Bosch LSU.

Note that NTK Lambda sensors should be connected to an Analog Voltage

input via the appropriate amplifier.

Switch Inputs

The 4 switch inputs are generally used for the external switches required to

operate the ADL display. They can also be connected to a brake switch or

other switch.

These inputs have a 4700 ohm resistor connected internally from the input pin

to the 5V sensor supply so that a switch can be simply connected between

the input pin and 0 volts.

Options

All four inputs are available irrespective of which options are enabled.

Page 19

MoTeC Overview 17

Specifications

For full specifications see Appendix D: Input Characteristics.

Digital Inputs

The 4 digital inputs are identically to the switch inputs except that they include

the following additional measurement methods:

• Frequency: The frequency of the input signal is measured

• Period: The time between successive pulses is measured

• Pulse width: The low time of the pulse is measured

• Count: Counts the number of pulses

• Beacon: For connection of a lap beacon

Options

Note that the number of inputs that are available depends on which options

are enabled. See Appendix B: Options Summary for details.

Specifications

For full specifications see Appendix D: Input Characteristics.

Speed Inputs

The 4 Speed Inputs are identical to the Digital Inputs except that they can

also be configured to suit Variable Reluctance (Magnetic) sensors such as

some wheel speed sensors. Because the amplitude of the signal from these

sensors varies with speed of rotation, variable trigger levels are required,

which must vary with the frequency of the input signal.

The Speed Inputs can also be used with Hall Effect type wheel speed

sensors.

• Note that Inputs 1 & 2 use common trigger thresholds and a common

pullup resistor switch, as do Inputs 3 & 4, therefore the same type of

sensors need to be used on each pair of inputs.

• Note also that the Pulse Width measurement method measures the high

time of the pulse rather than the low time as measured by the Digital

Inputs.

Page 20

18 Overview

Options

Note that the number of inputs that are available depends on which options

are enabled. See the Options Summary in the Appendices for details.

Specifications

For full specifications see the Appendices.

Internal Sensors

The ADL includes internal sensors for battery voltage and internal

temperature.

Electrical Specifications

See the Appendices for more detail on each type of input.

Auxiliary Outputs

The ADL has 8 Auxiliary Outputs which may be used to control various

vehicle functions such as: Gear Change Lights, Warning Lights, Thermatic

Fan, Gear Box Oil Pump, etc.

Items such as Thermatic Fans or Pump Control should be setup using the

User Conditions or the general purpose Tables, there is no specific setup item

for these types of devices.

The Auxiliary Outputs switch to ground and can drive up to 0.5 Amps.

Devices that consume more than 0.5 Amps such as motors should be driven

via a relay.

They Auxiliary Outputs can be configured for switched or pulsed control.

Options

Note that the number of outputs that are available depends on which options

are enabled. See Appendix B: Options Summary for details.

Specifications

For full specifications see Appendix E: Auxiliary Output Characteristics.

Page 21

MoTeC Overview 19

Communications Overview

The ADL has two communications ports which are used to communicate with

other devices.

RS232 Communications Port

The RS232 communications port can be connected to an ECU or similar

device and to a Radio Telemetry device. A M oTe C telemetry kit is available

which provides high quality data transmission and flexible data display.

• Note that when connected to both an ECU via RS232 and to a Telemetry

device, the baud rates of the two devices must be the same (usually 9600

or 19200 baud).

CAN Communications Port

The CAN (Control Area Network) communications port can be connected to

other devices with a compatible CAN port. The advantage of CAN is that

many devices can be connected to the CAN bus at once, which allows all

connected devices to communicate with each other, also the CAN port

communicates at very at high speed.

Other M oTe C products that use CAN for intercommunication include the

M800, BR2, PLM and MDD.

Note that these communicate at 1Mbit/sec, so any other devices connected

on the CAN bus must also communicate at 1Mbit/sec.

The CAN communications port is also used for all PC communications,

including configuration of the ADL and unloading the logged data.

ECU Connection

The ADL can be connected to most Engine Management Systems (ECUs).

This avoids duplication of sensors and allows the ADL to display and log

many ECU parameters.

The ECU may send up to 40 values to the ADL. The update rate of these

values depends on how many values are transmitted, the communications

baud rate and if sent using CAN or RS232. For RS232 the typical update rate

is about 20 times per second and for CAN it is about 50 times per second.

Note that logging the ECU values faster than these rates is unnecessary and

will reduce the total logging time.

Page 22

20 Overview

• Note that if the ADL is connected to a M oTe C M800 ECU the M800

sensors should be calibrated in metric otherwise special scaling will be

required.

Telemetry

The ADL can transmit real time and/or end of lap telemetry data. This allows

monitoring of the current vehicle condition, position on the track, lap times,

fuel remaining, laps remaining etc.

The real time telemetry data is transmitted continuously.

The end of lap telemetry data is transmitted at a specified time after the lap

beacon is detected

• Note that if RS232 ECU communications is used then the telemetry baud

rate must be the same as the ECU communications baud rate (normally

9600 or 19200 baud)

• Note that the Telemetry option is required.

Lap Beacon

A Lap Beacon can be connected to the ADL in order to record Lap Times for

display and to provide lap reference information for the data logging analysis

software.

The M oTe C Lap Beacon consists of a Transmitter which is mounted beside

the track and a Receiver which is mounted in the vehicle.

Multiple beacon transmitters may also be used to generate split times.

For further details refer to the Lap Beacon manual.

Options

Various options allow the ADL to be configured as a simple stand-alone dash

or to be upgraded to a sophisticated data logging, display and control system.

The options can be enabled at any time by entering a password.

Note that the ADL does not require a Software Update Unit (SUU) to enable

the options, as required by the M4 (pre M4e), M48 & M8 ECUs.

Page 23

MoTeC Overview 21

See Appendix B: Options Summary for details.

Software

The ADL comes with software packages for managing the ADL, analysing the

logged data and monitoring the telemetry link.

The software must be run on an IBM compatible personal computer running

Windows 95/98/Me/NT/2000/XP.

The following software programs are provided:

Dash Manager

Dash Manager is used for configuration, testing, retrieving the logged data

and for general management of the ADL.

An overview of Dash Manager is included latter in this manual. For detailed

information use the Dash Manager help system.

Interpreter

Interpreter is used to analyse the logged data.

Data Logging analysis is covered in a separate manual.

Telemetry Monitor

The Telemetry Monitor software is used to monitor the optional Telemetry link

and allows viewing of the telemetry data in various graphical formats such as

Charts, Bar Graphs and Dial Gauges. It can also show the vehicles current

track position on a track map and compare the current vehicle data to

reference data.

Alarms can also be set to indicate when a particular value, such as Engine

Temperature exceeds a user programmable limit.

BR2Config

This program is used to configure the BR2 beacon receiver via a CAN

connection. BR2 configuration is covered in the BR2 Manual.

Page 24

22 Overview

Field Updateable Control Software

The ADL control software (firmware) is field updatable so that new software

features can be used as they become available.

CAN Cable

The CAN Cable allows the computer to communicate with the ADL at high

speed.

The CAN Cable connects between the PC Printer Port (Parallel Port) and the

CAR cable, which is mounted in the vehicle and connects to the ADL.

Be sure that the CAN Cable is connected directly to the PC, do not use an

extension cable or switch box between the PC and the CAN Cable otherwise

incorrect operation may result.

Note that the PC parallel port must be a bidirectional type.

The CAN Cable contains electronics which is powered via the cable from the

ADL.

The CAN Cable can be extended by up to 12 meters. Note that a special 100

ohm data cable is required.

Page 25

MoTeC Installation 23

Installation

Mounting

Mounting Dimensions

Refer to the product dimensions in the Appendices.

Attachment

Use washers between the unit and the mounting panel to ensure that the unit

is mounted only at the mounting points (to avoid twisting the case). The ADL

has three threaded mounting posts, while the EDL has four mounting holes.

Do not over tighten the mounting screws (to avoid twisting the case).

Vibration isolation may be desirable if the vehicle vibrates severely.

ADL Orientation

For best contrast, the display should be viewed at approximately 20 degrees

above normal, however the ADL will give good contrast between 0 and 40

degrees. Display reflections should also be considered when determining the

mounting angle.

20°

Lighting

The ADL display has excellent visibility in a very wide range of lighting

conditions, however for night time use a front light module is required.

Connector Access

Mount so that the connector may be easily accessed.

Page 26

24 Installation

Display Care

Take care when cleaning the display, use a soft cloth to avoid scratching the

display and avoid aggressive solvents.

Wiring

Pin Connection Details

The ADL pin connection list appears at the back of this manual.

Wire

Use 22# Tefzel wire (Mil Spec M22759/16-22) (5 amps max at 100 °C)

Note that the Tefzel wire is difficult to strip unless the correct stripping tool is

used. Be careful not to nick the wires as this may result in wire failure or poor

crimping.

Some sensor connectors may not be available with 22# terminals, in which

case doubling the wire over gives the equivalent of an 18# wire, which is

suitable for many of the common sensor terminals.

For full wire specifications see Appendix N: Wire Specifications.

Crimping

Ensure that the correct crimping tool is used for all contacts to ensure a

reliable connection.

Power

Power the ADL via a separate switch and a 5 Amp fuse. The separate switch

is recommended so that the computer can communicate with the ADL without

needing to turn the rest of the vehicle power on.

Ground

Ground the ADL to a good ground. The ground should have a direct

connection to the vehicle battery.

Page 27

MoTeC Installation 25

Sensor Wiring

M oTe C can supply wiring details for all sensors.

MoTeC Supplied Wiring Loom

M oTe C can supply either partial or complete wiring looms to suit each

application.

Custom Wiring Loom

If creating a custom wiring loom the following important points should be

observed.

Connector

The ADL uses a 79 pin Auto Sport connector, see Appendix M: Connector for

full details.

To ensure that the connector is sealed plug unused holes with filler plugs. A

heat shrink boot may also be used if desired.

Crimp Tool

The correct mil spec crimping tool must be used for the ADL crimp pins. See

Appendix M: Connector for details.

• Note that the Crimp Contacts are type 22D which is needed to set the

crimp tool correctly.

CAN Bus and CAN Cable Wiring

Refer to Appendix G: CAN Wiring - Multiple Device and or Appendix H: CAN

Wiring - Single Device for details.

External Buttons

A number of external buttons are required for various functions of the ADL.

Typically these buttons are used for:

• Display Mode

Page 28

26 Installation

• Display Next Line (and optionally Previous Line)

• Alarm Acknowledge

• Lap Number Reset

• Fuel Remaining Reset

These buttons are normally wired to the ADL Switch Input pins, but may also

be wired to the Digital or Analog Inputs, if the Switch Inputs are occupied.

The buttons should be wired between an ADL input and ADL 0V pins.

Note that if wired to an Analog Voltage input an external pull-up resistor must

be connected between the input pin and the 5V sensor supply.

External Lights

All lights including the Shift Lights & Warning Lights must be wired externally.

This allows a choice of lights and allows the lights to be placed in the

optimum position.

Usually LEDs or LED arrays are used.

The lights must be wired between one of the Auxiliary Outputs and the ADL

Battery Positive.

The lights must not consume more than 0.5 Amps (6 watts at 12Volts) unless

activated via a relay.

Thermocouples

Thermocouples must be wired to the ADL via a thermocouple amplifier.

The M oTe C Thermocouple Amplifier (TCA) may be used with K Type

thermocouples and may be connected to either the Analog Voltage or Analog

Temperature inputs of the ADL.

Connecting to a MoTeC ECU

An ECU may be connected to the ADL which will make information in the

ECU available to the ADL for display or logging or any other purpose.

M oTe C M400/M600/M800/M880 ECUs may be connected via CAN or via

RS232.

Page 29

MoTeC Installation 27

The M oTe C M4, M48 & M8 ECUs must be connected via RS232.

Connection via RS232

The telemetry feature of the M oTe C ECU is used to send data to the ADL via

an RS232 connection.

See Appendix J: ECU to ADL Wiring (RS232) for wiring details.

ECU Setup

The ECU ‘Telemetry Set’ and ‘Telemetry Baud Rate’ should be selected to

suit an RS232 communications template supported by the ADL.

ADL Setup

Setup for the ADL is done in the ‘Inputs | Communications’ setup screen, on

the RS232 tab.

Select a communications template that matches the ECU type and ECU

telemetry set.

In the displayed channel list, check those channels that you wish to receive in

the ADL

Interruption of the Data

Note that the data flow to the ADL will be interrupted while a computer is

connected to the ECU and will not resume for up to 10 seconds after the

computer has been unplugged. During this period any value that comes from

the ECU, such as RPM or Engine Temperature will not be updated and will

normally be displayed as zero. On latter versions of the ECU software the 10

second delay is reduced to 1 second.

Connection via CAN

The ADL and ECU must be connected on the same CAN bus.

See Appendix G: CAN Wiring - Multiple Device for wiring details.

ECU Setup

Set the ‘CAN Data Set’ to a set supported by the ADL (normally set 1).

The ‘CAN Address’ must also be set. Normal value for ADL is 1520. This is a

decimal value that corresponds to a hexadecimal value of 0x5F0 in the ADL.

Page 30

28 Installation

ADL Setup

Setup for the ADL is done in the ‘Inputs | Communications’ setup screen, on

an unused CAN tab.

Select a communications template that matches the ECU type and ECU set.

In the displayed channel list, check those channels that you wish to receive in

the ADL.

ECU Sensor Calibrations

Metric Calibration of the sensors should be used in the ECU otherwise special

scaling is required in the ADL communications setup.

Telemetry

The ADL can transmit telemetry information via a radio link.

• Note that if RS232 ECU communications is used then the telemetry baud

rate must be the same as the ECU communications baud rate (normally

9600 or 19200 baud)

Wiring

Wiring is dependent on the particular telemetry system, please consult the

wiring details supplied with the telemetry system.

ADL Setup

Set the RS232 communications for Telemetry Only, or ECU and Telemetry.

The telemetry channels should then be configured in the separate Telemetry

Setup screen, found under the ‘Functions’ menu.

Page 31

MoTeC Dash Manager Software 29

Dash Manager Software

Introduction

The following is an overview of the main concepts of the Dash Manager

software. More detailed information is available from the online help provided

with Dash Manager. Online help is accessed by clicking on the help buttons

that appear on most Dash Manager screens and by selecting Help from the

main menu.

Note that the EDL uses the same configuration software as the ADL and is

accessed and operated in the same way.

The Dash Manager software is used for:

• Editing the configuration files

• Sending configuration files to the ADL

• Retrieving the logged data from the ADL

• Testing the ADL

• Enabling ADL options

• Upgrading the ADL software version

• Changing event, venue and vehicle details

Computer Requirements

The Personal Computer (PC) must be an IBM PC compatible running

Windows 95/98/Me/NT/2000/XP.

Recommended Minimum Specifications

Pentium II, 32Mb RAM, Parallel Port (for CAN Cable)

Printer Port (Parallel Port)

The CAN Cable connects to the PC parallel port.

Page 32

30 Dash Manager Software

The parallel port must be either an 8 bit bidirectional port or an ECP parallel

port. Single directional parallel ports will not work, these are found on some

older computers and some plug in cards.

Installing Dash Manager

From a CD-ROM

Place the CD-ROM into the CD drive of the pc.

A new window will appear. This can be navigated in the same way as a web

page.

If it does not appear, click on the Windows Start button and select Run. Type

‘D:\Iindex.htm’

Click on the button marked ‘Software Archive’.

Select the version of Dash Manager (or other software) that you wish to install

and click on the name.

When the dialog appears asking you to ‘Open’ or ‘Save’ the selected file,

choose ‘Open’ and then follow the setup program instructions.

From the Internet

Go to the MoTeC web site at www.motec.com.au and select Software

Updates | Current Release Software. Click on one of the Dash Manager links

to start the down load and choose to save the file to a location where it can be

easily located after downloading (such as the desktop). After downloading

double click on the file to start the installation process.

Mouse & Keyboard

The Dash Manager Software may be operated using the keyboard or a

mouse.

On many Notebook PCs the pointing device (mouse substitute) is difficult to

use and in many cases it is much easier and faster to use the keyboard. For

details on using the keyboard refer to the topic on Windows Keyboard Use

latter in this manual.

Page 33

MoTeC Dash Manager Software 31

Main Menu

The main menu is used to access all of the features of the Dash Manager

software. Click the mouse on one of the menu items or press the Alt key

together with the underlined letter, for example press Alt + F to select the File

menu.

Unavailable Menu Items

When Dash Manager is started the items related to changing the

configuration will be unavailable, this is because a configuration file has not

been selected.

Unavailable items appear grey as shown below.

Button Bar (Toolbar)

The Button Bar provides an alternative way of activating some of the

commonly used items on the main menu. To find out what each item does

hold the mouse pointer over the button of interest until a hint appears.

Page 34

32 Dash Manager Software

On line / Off line

All changes to the ADL configuration are performed ‘Off Line’, ie without the

PC communicating with the ADL. Once the configuration changes have been

made and saved to a file, they can be sent to the ADL which is an ‘On line’

process, ie the PC is communicating with the ADL.

Many other functions are also performed ‘On line’, for example, Get Logged

Data, Zero Sensors, Monitor Active channels etc.

To consolidate the Online concept, all on line activities are placed in the

‘Online’ Menu item. All other menu items perform Off Line activities.

Configuration

The configuration of the ADL determines exactly how it operates.

The strength of the ADL lies in its flexibility of configuration. All aspects of the

ADL can be configured including, which sensor is connected to which input,

the calibration of each sensor, what to display and where to display it, what to

log and how fast to log it, tacho range, warning alarms, multi stage shift lights,

etc, etc.

Configuration Files

The ADL configurations are stored in files on the PC hard disk and can be

sent to the ADL at any time.

When changing the configuration, changes are only made to the file on the

PC. The file must be sent to the ADL before the changes take affect.

Creating a New Configuration File

A new configuration file can be created by selecting File | New from the main

menu, this will create a new configuration based on one of a number of

predefined templates.

If using a M oTe C supplied wiring kit there will be a template supplied to suit

that kit. In general this template should be ready to use other than vehicle

dependent calibrations such as wheel speed. Items such as the Alarms and

Display setup should also be checked and modified if necessary to suit the

application.

Page 35

MoTeC Dash Manager Software 33

After a new configuration has been defined, it should be saved with a

meaningful name by selecting File | Save from the main menu, the file may

then be sent to the ADL by selecting Online | Send Configuration from the

main menu.

Alternatively a new file can be created by loading an existing configuration file

and saving it to a new file by selecting File | Save As from the main menu.

Opening an Existing File

Before an existing configuration file can be modified or sent to the ADL it must

first be opened.

To open a configuration file select File | Open from the main menu and select

the desired file.

Note that the most recently used files appear at the bottom of the File menu,

which is often the easiest way to open a recently used file.

Sending the Configuration to the ADL

The currently open configuration file can be sent to the ADL by selecting

Online | Send Configuration from the main menu.

When a configuration file is sent to the ADL any changes are automatically

saved to the file.

Retrieving the Configuration from the ADL

The configuration can be retrieved from the ADL if necessary by selecting

Online | Get Configuration from the ‘Online’ menu. However this is not

normally necessary unless the original file is not available on the PC.

Backups

Whenever a file is saved, the previous contents of the file are saved in the

‘Save Backups’ directory. The total number of files is limited to 100.

When a file is sent to the ADL the existing ADL data is retrieved and stored in

the ‘From Dash Backups’ directory, this is in case the data in the ADL needs

to be restored. The total number of files is limited to 10.

File Management

The configuration files may be Renamed, Deleted, sent to a Floppy Disk etc

by clicking the right mouse button on the desired file when the Open File

screen is displayed.

Page 36

34 Dash Manager Software

Changing the Configuration

Once an existing configuration file has been opened, or a new one created

the various parts of the configuration may be modified by choosing the

appropriate items from the main menu. The configuration setup items are

accessed from the main menu items: Inputs, Calculations and Functions.

Setup Details

For details on each of the Dash Manager setup screens click on the Help

button that is provided on each screen.

Configuration Sequence

The configuration is best setup in the following order:

1. Inputs (Input Pins & Communications)

2. Calculations (Lap Time, Fuel Prediction etc)

3. Functions (Logging, Display, Alarms, Auxiliary Outputs etc)

This simplifies the setup procedure by ensuring that the required channels are

available for the functions that use them.

• Note that channels cannot be used until they have been generated by an

input, calculation or function.

Versions and Updating

Updating

The software inside the ADL can be updated by the user at any time to take

advantage of the latest features offered by M oTe C .

To update the ADL software version select Online | Update Version from the

Dash Manager main menu.

Matching Versions

The version of software inside the ADL must match the version of the Dash

Manager software. If the versions do not match, Dash Manager will show a

warning when it attempts to communicate with the ADL.

Page 37

MoTeC Dash Manager Software 35

To check the version of Dash Manager select Help | About M oTe C Dash

Manager from the main menu.

Configuration File Version

After the ADL version has been upgraded the configuration file in the ADL

must also be updated to match the new version. The display will show a

warning until a new configuration has been sent to the ADL.

From Dash Manager version 3.0 onwards, there is an option to automatically

upgrade the configuration file in the ADL when performing an upgrade.

This eliminates the necessity to manually upgrade the file (see Converting

Older Version Files) and then sending it.

Converting Older Version Configuration Files

An older version configuration file can be converted to the latest version by

selecting the appropriate version in the ‘File of type’ entry box on the File

Open screen. When the file is opened the file is converted to the new version

format and saved with the same file name but with the new version file

extension. The old file is not changed.

Page 38

36 Dash Manager Software

A

A

A

A

Channels

Channels are used to convey information between the various systems of the

ADL. For example an input pin may feed a channel called ‘Engine

Temperature’, this channel may then be used by any other system, such as

the Display or Data Logging systems.

Channel Connection Example

Sensors

nalog

Inputs

Speed

Inputs

ECU

RS232

Comms

Data

Logging

System

Display

System

larm

System

Gear

Detection

uxiliary

Outputs

Logging

Memory

LCD

Display

Warning

Light

Fuel Pressure

Oil Pressure

Wheel Speed Front

Wheel Speed Rear

Engine RPM

Channels

Engine Temperature

larm Warning Light

Gear

Page 39

MoTeC Dash Manager Software 37

Channel List

M oTe C has defined an extensive list of channels. All systems within the ADL

that generate values must choose to feed one of these channels.

General Purpose Channels

Since the use of all channels can not be predetermined, a number of general

purpose channels have been included for occasions when a suitable

predefined channel is not available.

These channels may be required when measuring an uncommon value, or

when a general purpose function needs to generate a special output channel,

for example a 3D table may generate an output channel to control a valve of

some sort, in which case a general purpose channel may be used and

renamed appropriately.

Channel Usage

The ADL channel scheme allows complete flexibility in channel usage, as any

available channel can be used by any other function, i.e. any channel can be

logged, displayed, used in conditions, used in alarms, used as an input to the

user definable tables, etc.

Channel Properties

For each channel the following properties have been defined, some of which

may be modified by the user.

Properties that may be modified by the user:

• Name

• Abbreviation

• Units (eg. Celsius, Fahrenheit etc)

Fixed Details

• Measurement Type (Temperature etc)

• Resolution (eg. 0.1 °C for Engine Temperature)

• Suitable Logging rates

• Suitable Display filtering

• Minimum and Max Range

Page 40

38 Dash Manager Software

Predefining these properties makes the channels easy to use throughout the

rest of the software, for example knowing the measurement type allows the

channels to be displayed in any units suitable for that type, with automatic

conversion between the units. For example all temperature channels can be

displayed in Celsius, Fahrenheit or Kelvin.

Channel Names & Abbreviations

The channels names may be changed if necessary. However name changes

should be limited to name preferences rather than redefining the purpose of

the channel, except for the general purpose channels which may be renamed

to suit the current use.

Channel Units

The units for a channel can be selected from a predefined list, for example

the Engine Temperature channel may have units of Celsius, Fahrenheit or

Kelvin. Conversion between units is automatically handled by the software.

Note that the units are used for display purposes only. This means that the

units can be changed at any time with out affecting the calibration of the

channel.

Channel Resolution

The resolution of all channels is fixed, for example the resolution of the

Engine Temperature channel is fixed at 0.1 °C.

Fixed channel resolutions ensure that the unit conversion system works

properly and that channel comparisons can be performed correctly.

Selecting Channels

There are two methods of selecting channels, either the Category Method or

the Search Method.

Category Method

This method divides all the channels into categories and sub categories, so

that the list can be narrowed down to a small list of channels. For example,

the ‘Engine Sensors / Cooling’ category shows a list of channels associated

with the cooling system of the engine.

When selecting a channel from the complete list of channels, it is usually

easiest to use the category selection method, for example when assigning a

channel to an input pin.

Page 41

MoTeC Dash Manager Software 39

To expand a category click on the + sign next to the category name.

Page 42

40 Dash Manager Software

Search Method

This method lists all channels in alphabetical order and allows a channel to be

found either by typing the first few letters of any word in the channel name, or

by scrolling through the list.

Note that the words may be typed out of order so that ‘Engine Oil

Temperature’ could be found by typing "temp eng oil" or "oil t eng" or "e o t”

This method is most useful when selecting a channel from the available

channels. For example, if ‘Engine Temperature’ has been assigned to an

input pin, it can be easily located in the Search list, since this list normally only

contains 50 to 100 items.

Conditions Overview

Conditions are used extensively throughout the software to define a true /

false condition based on comparing one or more channels to a value. Most

conditions can perform up to 6 comparisons.

Conditions are used to define features such as when to start logging, or when

to activate an alarm.

For example an Engine Oil Pressure alarm may read as: Activate the alarm

when: Engine Oil Pressure < 200 kPa for 1 second AND Engine RPM > 1500

Page 43

MoTeC Dash Manager Software 41

RPM for 2 seconds. Note that this condition could also include a test for when

the engine is greater than 500 RPM but set at a lower pressure, which would

cover the range from 500 to 1500 RPM, which might read as: Engine Oil

Pressure < 50 kPa for 1 second AND Engine RPM > 500 RPM for 5 seconds.

In the case of alarms, the condition can also contain an increment or

decrement amount, which may increase or decrease the test value by a

certain amount each time the alarm is acknowledged. The number of times

this value is incremented can also be limited.

The following shows an example of an Engine Oil Pressure alarm condition.

Checking Operation

Monitor Channels

The currently active channels can be monitored to allow checking of the

operation of all functions and measurements.

To monitor the active channels select Online | Monitor Channels from the

main menu.

Oscilloscope Screen

Any channel may also be shown on an oscilloscope style screen by pressing

the Utilities | Oscilloscope button on the Monitor Channels screen.

Simulate

The Simulate feature allows most input channels to be manually changed so

that the ADL operation can be checked under abnormal conditions, eg High

Engine Temp.

This is extremely useful for checking that the ADL is working as expected.

To activate the Simulate screen select Online | Simulate from the main menu.

Page 44

42 Dash Manager Software

Tests

A number of tests are provided to check the operation of the ADL, such as the

Display Test.

To run one of the tests select the appropriate test from the Online menu.

Sensor Zeroing

Some sensors require regular zeroing, for example Steering Angle,

Suspension Position, Ride Heights, G Force Sensors & Throttle Position.

Dash Manager provides a screen to allow easy zeroing of all these sensors.

To zero the sensors select Online | Zero Sensors form the main menu.

Details Editor

The Details Editor allows details about the Event, Venue, & Vehicle to be

entered.

This data is attached to the logged data file for latter reference.

Some of this data is also attached to the configuration to determine the

operation of some functions, for example, the Track Length is used to

determine Lap Speed, if used.

To change the details select File | Edit Details from the main menu.

Page 45

MoTeC Windows Keyboard Use 43

Windows Keyboard Use

This section gives details on how to use the keyboard with Windows

applications.

Main Menu

The Main Menu can be accessed by holding down the Alt key then pressing

the key corresponding to the underlined letter in the menu name, followed by

the underlined letter of the item in the drop down menu. Eg Alt F, N for F

New.

Alternatively press and release the Alt key then select the desired menu item

using the arrow keys, then press enter to activate it.

Closing a Window

ile

Enter = OK or Close (Only works when the OK or Cancel button has a bold

line around it)

Esc = Cancel or Close

Getting Help

To get help on the current screen or screen item press the F1 key, or press

Alt + H if the screen has a Help button.

To access the main help system select Help from the Main Menu.

Page 46

44 Windows Keyboard Use

Selecting an Item in a Window

To access the various items in a window hold down the Alt key and press the

key corresponding to the underlined letter of the item of interest, for example

to select the ‘Flash Light’ item press Alt F

Alternatively the Tab key may be used to progress from one item to the next

(use Shift Tab to move backwards). The selected control is usually indicated

by a dotted line around it, or by highlighting the text or item selected within the

control.

Using the Selected Item

The method of using the selected item (or control) depends on what type of

control it is. The common controls are detailed below:

Button

Buttons are generally used to show another screen or perform a

particular function.

Page 47

MoTeC Windows Keyboard Use 45

Hold down the Alt key then press the underlined Letter ( S

navigate to the button using the Tab key then press the Enter key or

the Space Bar.

), or

Check Box

A check box is used to tick on or off a particular option.

Hold down the Alt key then press the underlined Letter ( F

navigate to the Check Box using the Tab key then press the Space

Bar.

), or

Radio Buttons

Radio buttons are used to select an item from a group of options.

Hold down the Alt key then press the underlined Letter of the desired

option ( F

Tab key then use the arrow keys to select the desired item.

, A or D), or navigate to the Radio Buttons group using the

Edit

An edit control is used to enter a value or text.

Hold down the Alt key then press the underlined Letter of the text

above the edit box (M

type in the new value or text. Use the Backspace key or Delete key to

remove unwanted characters

) or navigate to the button using the Tab key then

List

Page 48

46 Windows Keyboard Use

A list is used to select from a number of options.

Hold down the Alt key then press the underlined Letter of the text

above the list ( M

select the desired item using the Arrow keys.

Drop down List

A drop down list is used to select from a number of items, but only the

selected item is shown until a new item needs to be selected.

Hold down the Alt key then press the underlined Letter of the text

above the list ( L

select the desired item using the Arrow keys, Press the Enter key to

close the list.

Tabs

) or navigate to the button using the Tab key then

) or navigate to the button using the Tab key then

Tabs are used to select the different tab pages of a screen.

To select the next tab hold down the Ctrl key then press the Tab key.

To select the previous tab hold down the Ctrl key and Shift keys then

press the Tab key.

Page 49

MoTeC Windows Keyboard Use 47

Tree View

A Tree View is used to select items from a hierarchical list

Up Arrow = Move the cursor up (selects the item above)

Down Arrow = Move the cursor down (selects the item below)

Right Arrow = Expand (Expandable branches indicated by a +)

Left Arrow = Collapse (Collapsible branches indicated by a -)

Page 50

48 Appendices

Appendices

Appendix A: General Specifications

Physical

Case Size ADL: 180.5 x 91.5 x 18.0 mm (7.1 x 3.6 x 0.7 inches)

EDL: 194.5 x 98.0 x 14.3 mm (excluding connector)

Weight 385 grams (0.85 lb)

Power Supply

Operating Voltage: 7 to 22 Volts DC

Operating Current: 0.15 Amps Typical (excluding sensor currents)

Reverse Battery Protection

Battery Transient Protection

Operating Temperature

Internal Temperature Range -10 to 80°C

Ambient Temperature Range -10 to 70°C typical

Sensor Supply Current

5V Sensor Supply : 0.2 Amps Max

8V Sensor Supply : 0.3 Amps Max

Internal Sensors

Battery Voltage

Dash Temperature

Page 51

MoTeC Appendices 49

Appendix B: Options Summary

The following options are available :

Standard I/O

The ADL comes standard with the following I/O (Input / Output) capabilities.

6 Analog Voltage Inputs (AV1 to AV6)

4 Analog Temperature Inputs (AT1 to AT4)

4 Switch Inputs (Sw1 to Sw4)

2 Digital Inputs (Dig1 & Dig2)

2 Wheel Speed Inputs (Spd1 & Spd3)

4 Auxiliary Outputs (Aux1 to Aux4)

30 I/O Option

10 Analog Voltage Inputs (AV1 to AV10)

4 Analog Temperature Inputs (AT1 to AT4)

4 Switch Inputs (Sw1 to Sw4)

2 Digital Inputs (Dig1 & Dig2)

4 Wheel Speed Inputs (Spd1 to Spd4)

4 Auxiliary Outputs (Aux1 to Aux4)

2 0 to 1 Volt inputs using the LA1 & LA2 pins

50 I/O Option

20 Analog Voltage Inputs (AV1 to AV20)

8 Analog Temperature Inputs (AT1 to AT8)

4 Switch Inputs (Sw1 to Sw4)

4 Digital Inputs (Dig1 & Dig4)

4 Wheel Speed Inputs (Spd1 to Spd4)

8 Auxiliary Outputs (Aux1 to Aux8)

2 0 to 1 Volt inputs using the LA1 & LA2 pins

384k Memory Option

384k Bytes (0.384 Mbytes) of logging memory.

1M Memory Option

1 Mbyte of logging memory.

Page 52

50 Appendices

2M Memory Option

2 Mbyte of logging memory.

4M Memory Option

4 Mbyte of logging memory plus Fastest Lap and Burst Logging.

8M Memory Option

8 Mbyte of logging memory.

Note that this option is only available on units with serial number greater than

2000.

Pro Analysis Option

Advanced Analysis features in the Interpreter software, including multiple

overlays and user mathematics.

Lambda Option

2 Wide Band Lambda (Air fuel ratio) measurement inputs.

Telemetry Option

Radio telemetry transmission.

Remote Logging Option

Allows logging to an external bulk memory device with removable memory

cards.

Enable Option

Enables the ADL.

The ADL will not function until this option is enabled.

Page 53

MoTeC Appendices 51

Appendix C: Dash Manager Command Line

Usage:

dash.exe -c[connection] -d -x -l -e -t -s [config file name]

[config file name]

(Optional)

Fully qualified path to the configuration file.

(eg "c:\motec\dash\config\bathurst.d30")

Note: the path must included the file extension (eg .d30)

Options :

Each of the following options can be given as "/[character]" or "-[character]".

They are shown here as "-[character]".

-c[Connection Name]

(Optional)

Select a preconfigured connection by name as configured in the dash

connections dialog.

(eg -c"Primary CAN Connection").

Note: There must not be a space between the c and the connection name.

-d

(Optional)

Causes the debug console to be displayed.

Only available for debug builds.

-x

(Optional)

Causes the app to terminate when one the following tasks has been

performed.

Tasks :

One or more of the following may be specified.

-l

(Optional)

Perform a “Get Logged Data” operation.

Page 54

52 Appendices

-e

(Optional)

Perform a “Get Engine Log” operation.

-t

(Optional)

Perform a “ Get Tell-tale Values” operation.

-p

(Optional)

Perform a “Print Summary” operation.

Note: The config file must be specified using a fully qualified path including

the file extension.

(eg -p "c:\motec\dash\config\bathurst.d30")

Note: There must be a space between -p and config name.

-s

(Optional)

Perform a “Send Configuration” operation.

Note: The config file must be specified using a fully qualified path including

the file extension.

(eg -s "c:\motec\dash\config\bathurst.d30")

Note: There must be a space between -s and config name.

-u

(Optional)

Perform an “Upgrade Dash Version” operation.

Page 55

MoTeC Appendices 53

Appendix D: Input Characteristics

Analog Voltage Inputs

Suitable for : Potentiometers, Voltage output sensors & Variable resistance

sensors with a pullup resistor

Measurement Voltage Range : 0 to 15 V

• Note that voltages outside this range may affect the readings on other

inputs.

Input Resistance : 100k ohms to 0V

Resolution : 3.74 mV

Measurement Methods : Ratiometric, Absolute, Variable Resistance, Off/On

Update Rate (Inputs 1 to 4 & 11 to 14) : 1000 times / second

Update Rate (Other inputs) : 500 times / second

Filter: 150Hz 1

Calibration Accuracy

Gain (Ratiometric operation) 0.05% max

st

order

Gain (Absolute operation) 0.15% max

Offset ± 6 mV max

Linearity ± 6 mV max

Temperature Stability 60 ppm/°C max

Calibration Schedule 12 Months

Analog Temp Inputs

Suitable for : 2 wire variable resistance sensors and some voltage output

sensors.

Measurement Voltage Range : 0 to 15 V

• Note that voltages outside this range may affect the readings on other

inputs.

Input Resistance : 1000 ohms pullup to 5V sensor supply + 100k to 0V

Resolution : 3.74 mV

Page 56

54 Appendices

Measurement Methods : Ratiometric, Absolute, Variable Resistance, Off/On

Update Rate: 500 times / second

Filter: 150Hz 1

st

order

Calibration Accuracy

Gain (Ratiometric operation) 0.05% max

Gain (Absolute operation) 0.15% max

Offset ± 6 mV max

Linearity ± 6 mV max

Temperature Stability 60 ppm/°C max

Calibration Schedule 12 Months

Lambda Inputs

Type : Wide Band M oTe C

Measurement Range : 0.75 to 1.50 Lambda (or 0 to 1V)

Accuracy : 1.5 % up to 1.20 Lambda

Update Rate: 100 times / second

Switch Inputs

Suitable for : Switch to 0V, or Off / On Voltage signal

Pullup Resistor : 4700 ohms to 5V

Voltage Range : 0 to 15V

Positive Trigger Threshold : 3.5 V max

Negative Threshold : 1.0 V min

Hysteresis : 0.5 V Min

Measurement Methods : Off/ On only

Filter Time Constant: 22usec

Digital Inputs

Suitable for : Switch to 0V, Logic signal & open collector device (eg Hall

Switch)

Page 57

MoTeC Appendices 55

Pullup Resistor : 4700 ohms to 5V

Voltage Range : 0 to 15V

Positive Trigger Threshold : 3.5 V max

Negative Threshold : 1.0 V min

Hysteresis : 0.5 V Min

Update Rate: 100 times / second

Filter Time Constant: 22usec

Digital Input Measurement Methods

Frequency

Resolution 0.1 Hz

Maximum Frequency : 3200 Hz

Rising Edge Triggered

Period 1 usec

Measures period between rising edges

Resolution : 1 usec

Maximum : 32 msec

Period 100 usec

Measures period between rising edges

Resolution : 100 usec

Maximum : 3.2 sec

Pulse Width 1 usec

Measures pulse low time

Resolution : 1 usec

Maximum : 32 msec

Pulse Width 100 usec

Measures pulse low time

Resolution : 100 usec

Page 58

56 Appendices

Maximum : 3.2 sec

Speed Inputs

Can be used in two modes : Hall or Magnetic.

In Hall mode a 4700 ohm pullup resistor is connected to 5V and the trigger

levels are fixed.

In Magnetic mode the pullup resistor is disengaged and the trigger levels can

be varied depending on the input frequency.

Note that the Hall and Magnetic modes must be activated in pairs, ie inputs 1

& 2 must have the same mode and level settings, similarly inputs 3 & 4 must

have the same mode and level settings.

Update Rate: 100 times / second

Filter Time Constant: 25usec

Speed Input Measurement Methods

Frequency

Resolution 0.1 Hz

Maximum Frequency : 3200 Hz