Motan OPTIMUS MT, C15SPV 24MEFM, MAXOPTIMUS C17 SPV 31 MEF Technical Instructions

KÖBER LTD DUMBRAVA ROSIE - VADURI BRANCH OFFICE

Branch Office:Vaduri, No. 280, Alexandru cel Bun, Neamt District, Postal Code 617511, Romania

Phone : +40.233.24.17.46, 233.24.19.33, Fax : +40.233.24.19.29

E-mail : , www.motan.rooffice.vaduri@kober.ro

TECHNICAL INSTRUCTIONS

FOR INSTALLATION/ USAGE/ MAINTENANCE

Köber LTD

Vaduri Branch Office

1798

OPTIMUS MT

C15SPV 24MEFM

CONTENTS

General presentationof the wall hung gasboiler

Connection for evacuation of theflue gases ...............................................................

Operating mode

.................................................................................

..........................................................

....................................................

General description of the wallhung gas boiler ...........................................................

Description of the boilers types..................................................................................

Symbols ....................................................................................................................

General instructions concerning the safetyof the wall hung gas boiler ........................

Technical characteristics...........................................................................................

Functional and constructive characteristics ..............................................................

Constitutive elements of wall hung gas boiler.............................................................

The heat generator ...................................................................................................

The exhaust gases/water heat exchanger.................................................................

The heating and domestic hotwater circuits Hydrauliccircuits ..................................

The command and control system ............................................................................

The external shell ......................................................................................................

The hydraulic characteristic of circulationpump .........................................................

Mounting/installation instructions ..............................................................................

The location of the unit...............................................................................................

The central heating ...................................................................................................

The gas supply ..........................................................................................................

The electric power supply .........................................................................................

Instructions for the final user(beneficiary) ..................................................................

Operating instructions ..............................................................................................

The control panel .......................................................................................................

The LCD display board inthe user module .................................................................

The LCD display in theuser module ................................................

The pressure checking ..............................................................................................

Additional facilities that may beobtained by ...............................................................

Handing over to the beneficiary.................................................................................

Recommendations for the yearly checking ...............................................................

Marking, documents, packing, storage, transport, quality and warranty conditions .....

Marking ......................................................................................................................

Documents ................................................................................................................

Packing ......................................................................................................................

Storage .....................................................................................................................

Shipment ...................................................................................................................

Quality and warranty conditions .................................................................................

Responsibilities during the warranty period ...............................................................

Malfunctions which refer to themanufacturer's responsibility ....................................

Malfunctions which refer to theresponsibility of the utilities provider ...........................

Malfunctions for which the manufactureris not responsible .......................................

List and plans necessary formounting and putting into service ...................................

Plan 1 ........................................................................................................................

Plan 2 .........................................................................................................................

Plan 3 .........................................................................................................................

Plan 4 .........................................................................................................................

Plan 5 .........................................................................................................................

The domestic hot water module, The heating module, Antifrost function, Auto-checking

and safety functions, The boiler shutting down in safety conditions .....................................

The functioning of the heating unit

Other functions concerning the safety ofthe boiler

Pg

Pg

Pg.

Pg

Pg 4

Pg 5

Pg 5

Pg 6

Pg 6

Pg 7

Pg 7

Pg 8

Pg 8

Pg 9

Pg 10

Pg 10

Pg 10

Pg 11

Pg 11

Pg 12

Pg 13

Pg 13

Pg 13

Pg 13

Pg 13

Pg 15

Pg 16

Pg 17

Pg 17

Pg 18

Pg 19

Pg 19

Pg 20

Pg 20

Pg 20

Pg 20

Pg 20

Pg 20

Pg 20

Pg 21

Pg 21

Pg 22

Pg 22

Pg 23

Pg 23

Pg 24

Pg 25

Pg 26

Pg 27

. 3

. 3

3

. 3

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

INTRODUCTION TO THE BOILER

General description of the boiler

The wall hung gas boiler is a fuel gas-consuming appliance which has the role of

turning the fuel gas power into thermal energy through burning.

This appliance runs unsupervised due to its protection and control systems.

The boiler is made of many parts that we are going to describe in the following

chapters.

The gas enters inside the boiler through the gas feeding circuit made ofa coupling

and a reducing valve which will be set at 20 mbar for G20 A(L) and A(H) subgroups.

The reducing valve will be set at 37 mbar for LPG (propane subgroups and propanebutane mixtures). Thus it gets into the gas valve which has the role of controlling the

gas discharge at the outlet to the burner.

The ignition achieves by flame activating by an ignition electrode, by means of

an ignition transformer.

During the combustion, the flame sensing is made by an ionization sensor.

The boiler type with forced draft is provided with a fan which evacuates the

exhaust gases. In the initiation phase, this evacuates an air volume to provide an

unexplosive ignition. The explosive ignition may occur due to a gas storage from the

non-operating period.

The combustion chamber, as a plate parallelotope, interior ceramics fibre-lined,

is designed to allow the transfer to the exchanger with less heat leakages.

In case of the CH circuit of the two heat exchangers type, the heat resulted from

fuel gas ignition is taken over by the monothermal heat exchanger and sent to the

thermal agent (water) which is delivered by the circulating pump through the heating

installation. In case of on the DHW circuit, a water discharge is detected by the

flowmeter, the 3- way gas valve is energized. The 3- way gas valve achieves the

transition from the central heating circuit on the short circuit through the plate heat

exchanger (the main plate heat exchanger) and the heat transfer is realized by means

of this to the DHW circuit (the secondary plate heat exchanger).

The scavenging is realized by means of the fan.

The running protection andcontrol are performed electronically. The boiler setting

is made from the control board (see the chapter concerning this subject).

DESCRIPTION OF THE BOILER

3

BOILER

TYPE

C15 SPV 24 MEFM

Useful power

Accessories

[kcal/h] The fan The pump

The

expansion

vessel

DHW

instant

production

20670

X X X X

SYMBOLS

S- with instant production of DHW (without cumulation)

P- with pump

V-with closed expansion vessel

24-the maximum power output in kW

M- the burner is supplied by a continuous modulating valve

E- the ignition and the control of the flame are electronically-made

F-the forced scavenging

M-monothermal

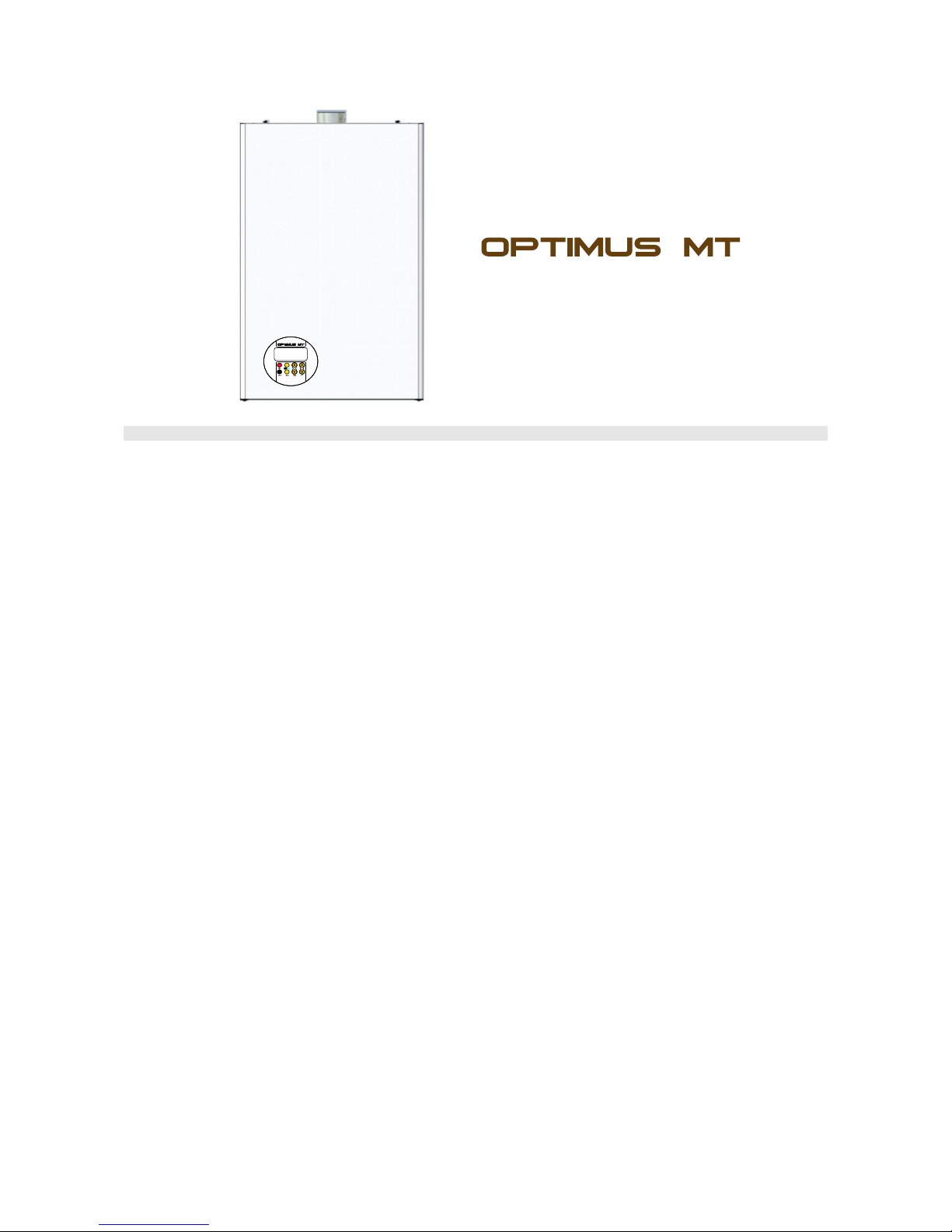

OPTIMUS MT

C 15 SPV 24 MEFM

GENERAL INSTRUCTIONS CONCERNING THE BOILER SAFETY

!

!

!

!

!

!

!

!

!

!

!

!

This manual is part of the product and it has tobe given to the user.

Read this manual carefully and keep it carefully for a further application by the user and by the

mounting and installing authorized personnel.

The installation, the putting into service, the service-repair operations and a periodical

technical checking are performed only by authorized personnel in accordance with the regulations

in force. All the indications of this manual must be respected; any exception may cause damages

and the producer isn`t responsible forthese.

In case of a defective running of the device, shut it down and call up immediately one of the

breakdown services units.

To guarantee the boiler efficiency and its correct running it is recommendable that the boiler be

checked yearly by the qualified personnel,complying with the manufacturer`s conditions.

If the device is sold or given, make sure it is delivered with its technical handbook in order to be

consulted by the new user/ installer.

In case of some components damaging there will be used only the original components. You

must have the manufacturer`s acceptance to use some components from another company, you

must obtain the writtenacceptanceof the producer sothat you may use those components.

This boiler will be used properly. Any other usewill be considered unsuitable.

There is excluded any contractual or extra-contractual responsibility of the producer for the

damages caused by the installing or usage errors and by thenon-observance of his instructions.

The maximum limit of the water hardness inlet is of maximum 5ºF (French degrees) on the

DHW circuit, equal to 50 mg CaCO2 or an equivalent quantity of other salts as Ca and Mg. It is

compulsory to install asoftener filter onthe domestic water circuit, a mechanical impurities filter (Y

filter) on the CH installation return and a pressure controller onthe gas supply circuit.

It is recommendable to use these boilers types presented in this manual to heat areas of 150

mp (at a mediumheight of 2,5 m of the heat volume).

Unsubmitting to these technical manual regulations as to the warranty certificate leads to

warranty loss.

4

RESETMOD

Name

Type OPTIMUS MT - C 15 SPV 24 MEFM

Forced

Sealed

92,7%

93,7%

10 - 23,7 kw

10,9 - 25,49 kw

20 mbar

35 mbar

30 - 37 mbar

230 VAC, 50 Hz

160 W

40 kg

1 L

1,1- 2,6 Nm /h

0,4 - 1,07 kg/h

Draft

Combustion chamber

Efficiency at maximum load

Efficiency at minimum load

Useful power (min/ max)

Burner nominal load (min/ max)

Gas pressure

NG on coupling ( behind the reducer)

NG on maximum admitted output

LPG

Power-supply

Power consumption

Weight

Heat exchanger output

-

0,5 ºi 3 bar

40 - 80°C

3/4"

1/2"

3/4"

275

415

700

850

7 L

Central heating

Minimum and maximum admitted pressure

Temperature on the heating circuit

Connections - inlet outlet central heating

- inlet outlet DHW

- gas supply

Dimensions - depth (mm)

- Width (mm)

- Height (mm)

- With mounted elbow (mm)

Expansion vessel with membrane

NG consumption (8500 kcal/ Nm3)

At useful power (max/ min)

LPG consumption (20425 kcal/ kg)

At maximum output

3

5

TECHNICAL CHARACTERISTICS

CONSTRUCTIVE AND FUNCTIONAL CHARACTERISTICS

30 - 60°C

13,5 l/min

9,7 l/min

7,5l/min

DHW temperature range

Flow values

Ät °C=25

Ät °C=35

Ät °C=45

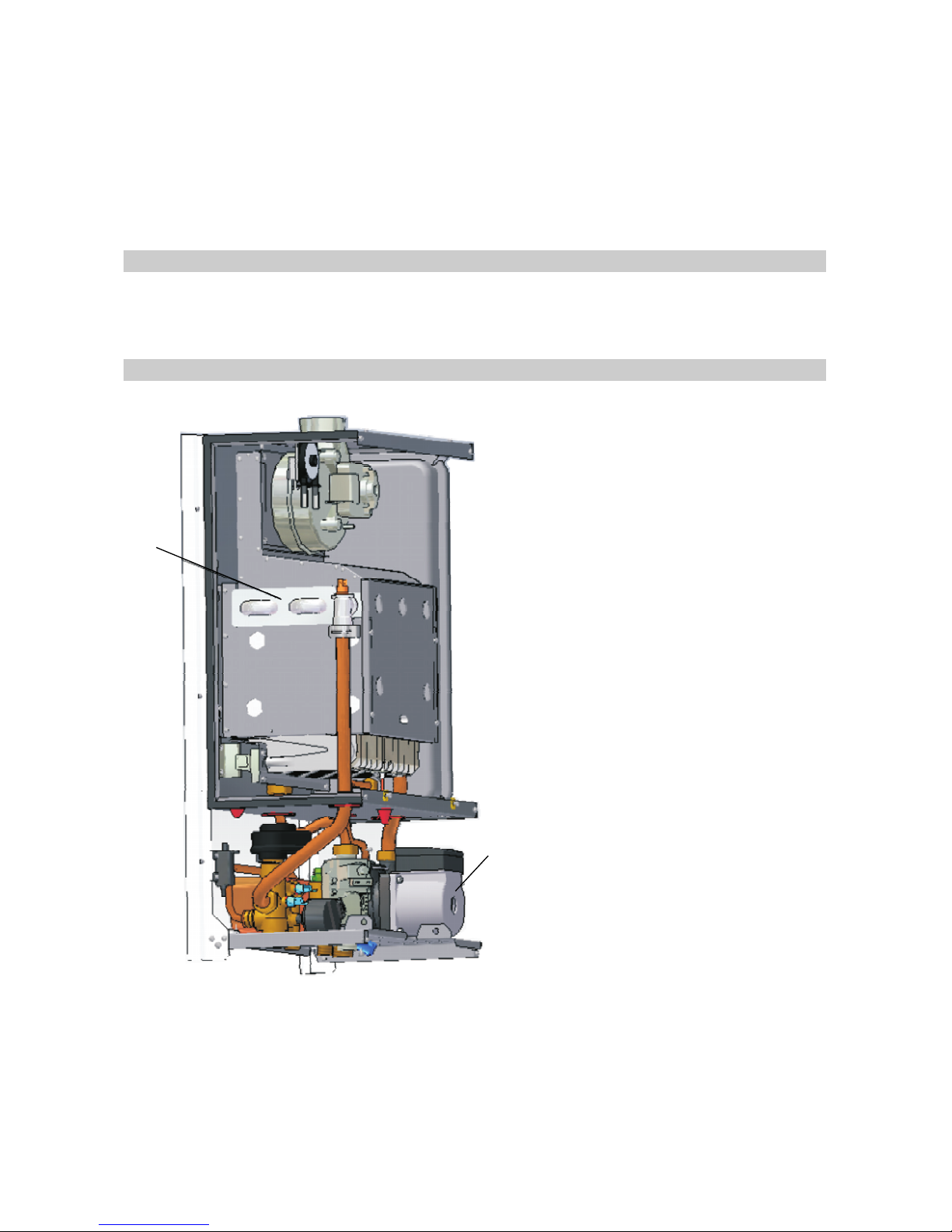

PRINCIPAL COMPONENTS OF THE BOILER

The heat generator

It is designed to supply the necessary heat for the heating exchange withthe heating and DHW

circuits. It is made of the following elements:

The gas feeding circuit will be performed through a reducing valve which will set the inlet

pressure at 20-25 mbar NG,respectively 30-37 mbar for LPG.

It is compulsory to mount a pressure controller on the gas

feeding circuit.

1. The gas valve

2. The burner

is designed to allow a

continuous modulation of combustion,

supplying the minimum, medium and

maximum gas pressures required by the

boiler running at the minimum, medium and

maximum load. The connector between the

gas valve and the burner is the copper pipe

(14x1).

is stainless-made, forced or

atmospherics, with 11 cannularinclines and it

runs with fuel gas (NG or LPG). The burner

output is set in a modulated systemby means

of a gas modulating valve so that it supply a

maximum useful power of 23,7 kW.

3. The combustion chamber is design to

allow the heat transfer to the heat exchanger

with less heat leakages. We chose a simple

constructive solution as a rectangular piping

of 170 mm between the burner and the heat

exchanger. To reduce the heat leakages, the

piping walls are isolated indoor with heat

insulating material (ceramics fibres).

4

3

2

1

Domestic cold water pressure

Exhaust gases temperature at rated output

Burned gases connection ( input- output)

Burned gases connection length

Orientative values

Maximum water content in the installation

Maximum surface of the precinct

0,2 - 8 bar

142,4°C

O 100 / O 60

Max 3 m

150 l

150 m²

6

7

4

The boiler is provided with afan for scavenging.

The flue system and the air supply (for the boiler with forced draft) is made of two concentric

pipes connected to the outside of the room where the boileris mounted.

is monothermal, the domestic water is

heated through the plate heat exchanger.

From the power pointof viewthe rated output is of 24kW and the efficiency over 93%.

-

The fan

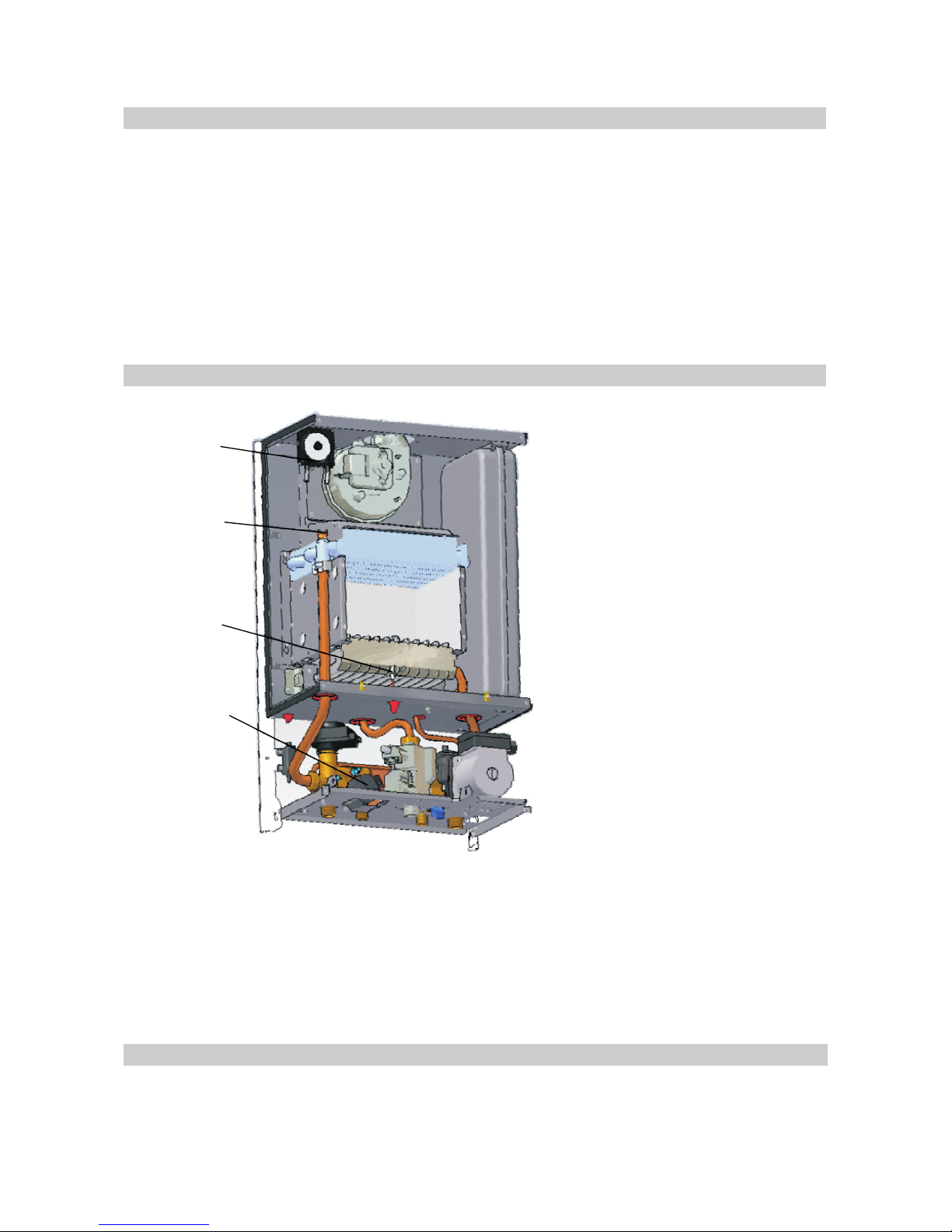

The exhaust gases/ water heat exchanger

The exhaust gases/ water heat exchanger

The heating and DHW circuits - Hydraulic circuits

- DHW circuit is with plateheat exchanger.

5

7

They are designed to allow thethermal

transfer to the external heating

and DHW installations.

- the loading circuit of the installation is

made of the valve and the copper pipe

connected to the domestic cold water

supply line;

- the relief valve of the circuit is designed

to reduce the pressure from the heating

circuit and to open at 3 bars full

pressure;

- the ventilation circuit of the installation

is made of an air-release valve which

allows the air discharge from the heating

circuit, mounted on the circulating pump

shell;

- The heating agent recirculating pump (7)

is designed to supply the output

necessary for the heating agent recycling

through the heating circuit;

- Expansion vessel is designed to allow

the expansion processes from the heat

installation, preventing from hydraulics

overstraining or damaging. This has a

capacity of 7 litres.

- The automatic by-pass circuit is made of

a copper pipe of 14x1 mm fixed between

the heating circuit turn and return and a

safety valve set to open at 0,3 bar to

allow the heat carrier recycling through

the heat exchanger and pump, in case of

some pressure differences,

between the external heat installation

turn and return at over 0,3 bar.

The heating circuit

8

The command and control system of the boiler running performs:

The command and controlsystem is madeof thefollowing components:

- the ignition and the protection when the flame is extinguished, provided by the electronic

ignition;

- the protection when the gas is switched off, provided by electro-valve;

- the water pressure signalling in the boiler, provided by minimum pressure sensor;

- the temperature signalling on the heating and DHW circuits, provided by the electronic board

functions;

- the setting of the heating cycle following the instructions of the temperature control switch;

- the safety of the boiler against excessive temperature, provided by the safety thermostat at

overpressure, through the safety valve and at water leakages through the minimum pressure

switch from the circuit;

- protection against draft deficiency, by the fan derangement or the exhaust piping blockage of

the exhaust gases, provided by the combustion pressure switch .

- the electronic board

-

- heating circuit temperature

sensor

- DHW temperature sensor

- Flowmeter

- Ignition/ ionization electrode

as a

controller of the boiler running

(see the attached drawing).

the measuring and pilot cells

of the functional parameters for the

boiler

which sends the

temperature signal to the electronic

control block of the heating circuit.

which sends the temperature signal

to the electronic control block of the

DHW circuit.

as a detector of

the DHW consumption which sends

the DHW circuit running command

to the electronic control block.

(8) with double role, of combustion

flame activation and sensing.

- Air pressure switch (9)

- Temperature sensors

- Temperature switch (10)

- Programmer ambient sensor

- Water pressure sensor

The external shell

as a detector and controller of the exhaust gases, which

determines the heating and DHW circuits running.

as reading the temperature on the heating circuit (the electronic

board display).

as a detector and controller of the maximum temperature on the

heating circuit which sends the non-running command of the heating circuit in case a maximum

admitted temperature is exceeded.

as setting the ambient temperature from a room (optional).

as a detector of the minimum pressure on the heating circuit.

It has a parallelepipedal shape. It is detachable and electrostatically painted.

The shell covers the pressurized combustion chamber and the enclosed installations.

9

10

8

11

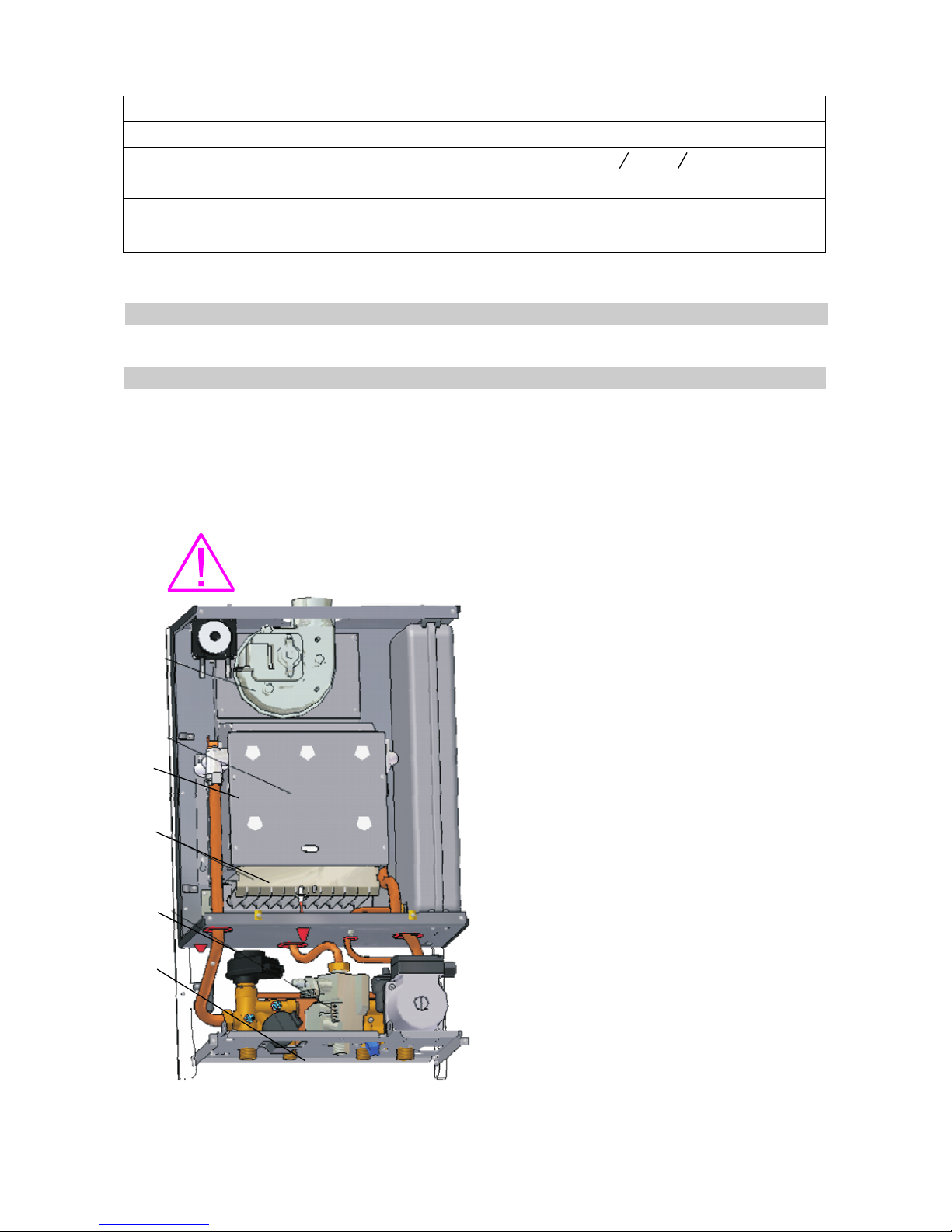

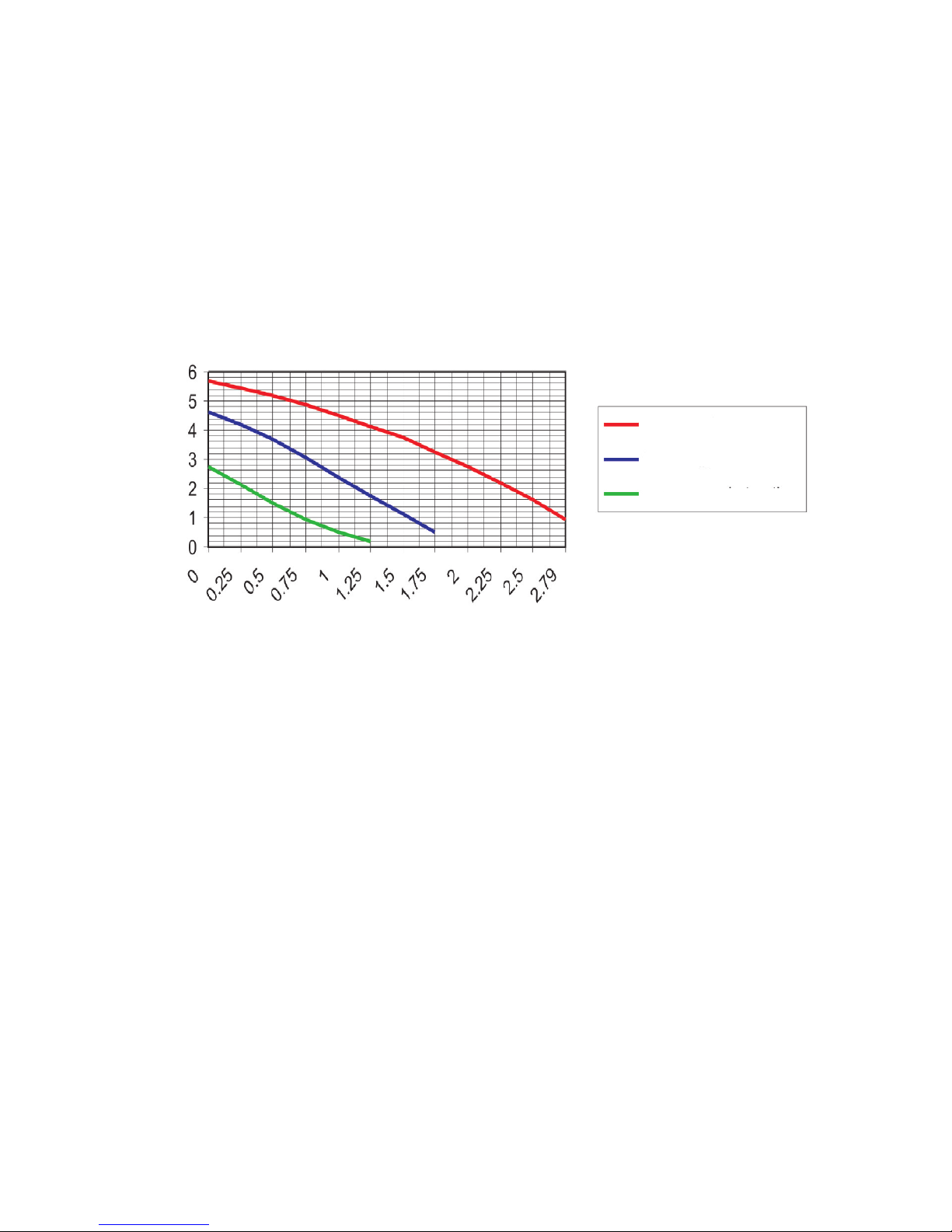

For designing the central heating installation we must be aware of the hydraulic features of the

pump.

9

The hydraulic characteristic of the pump

Pressure pump P[mca]

Pump output Q[mc/h]

the third stage of

the speed

the second stage

of the speed

the first stage of

the speed

Loading...

Loading...