MOTALA HISSAR AB

mc200501

Luxorgatan 1

Box 4029

591 04 Motala

SWEDEN

Tel: +46 (0)141-23 70 50

LOW SPEED LIFT

MC2000

2-6 landings

Automatic/manual doors

Assembly Instruction Manual

Release 2.02 2011-10-20

Safety regulations 3

Wordlist 4

ols 5

To

Preparations before assembly 6

Use the layout drawing for erection site check 6

Lift material 6

Lift well construction planning 6

Assembly 7

Introduction 7

General information on how to erect modules 7

Construction of precision gauge blocks 7

Lift well assembly according to layout drawing. 9

Installation of electric cables and wires 23

Guide rails 24

Driving shafts, gear and motor 27

Connecting pit functions 29

Connecting control panel wiring 30

Connecting drive command box 30

Door panel and removal of work platform 31

Commencing with drive command box 32

Chain jointing rod 32

Platform 33

Fixing lift well 35

Sills 35

Fixing plates 36

Travelling flex cable, panel plate, overload unit and control panel 37

Cancelling drive command box 41

Ceiling 41

Commencing from platform control panel 42

43

Lock arms 43

Highspeed contact and magnet 43

Lubrication 44

Cover plates 45

Finishing work 47

Final inspection and own inspection 47

Layout drawing 48

Checklist 49

Approvals and version history 50

Attachments

MOTALA HISSAR AB

Luxorgatan 1

Box 4029

59104 Motala

SWEDEN

Tel: +46 (0)141-23 70 50

MC2000 – Assembly Instruction Manual

mc200501

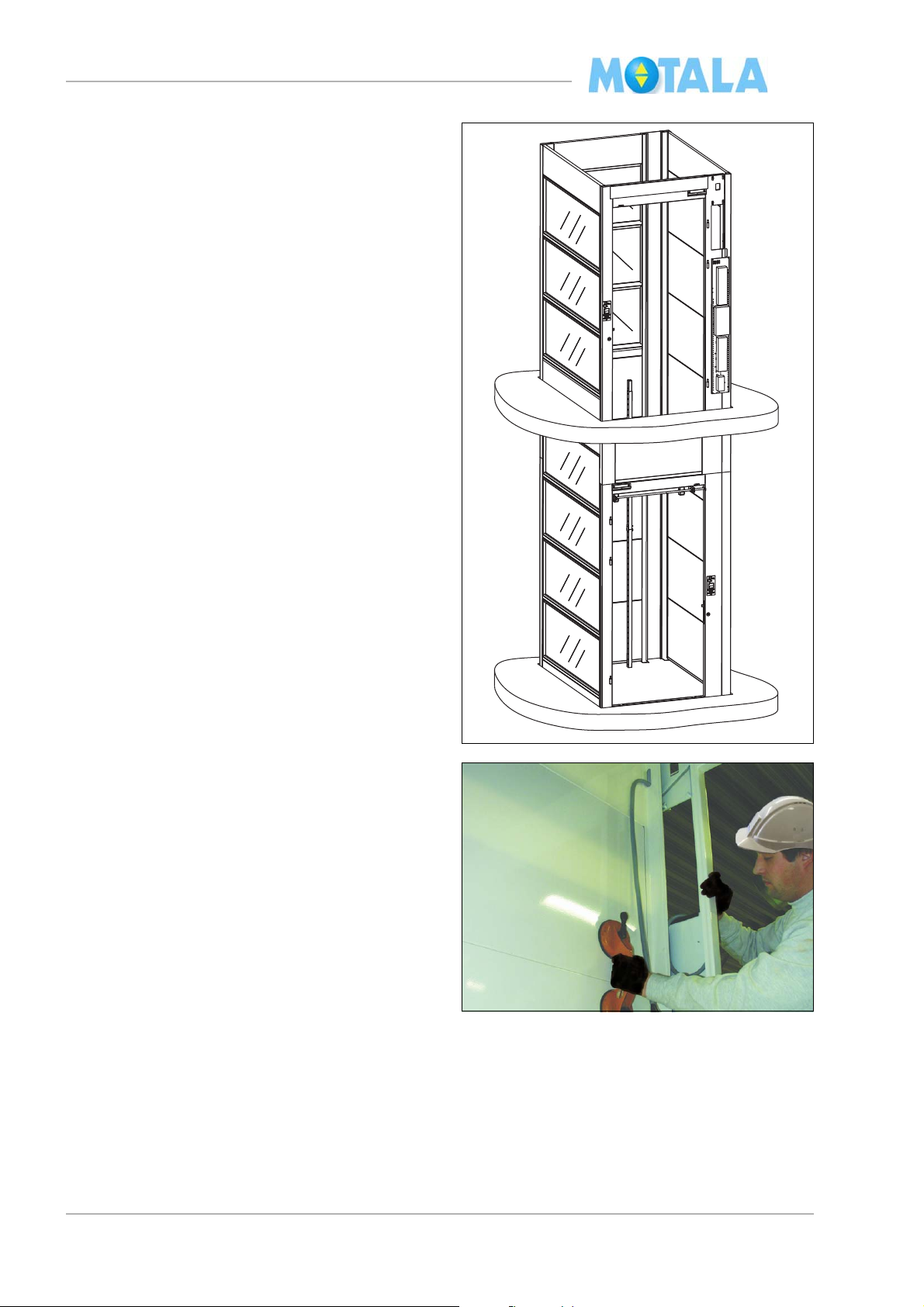

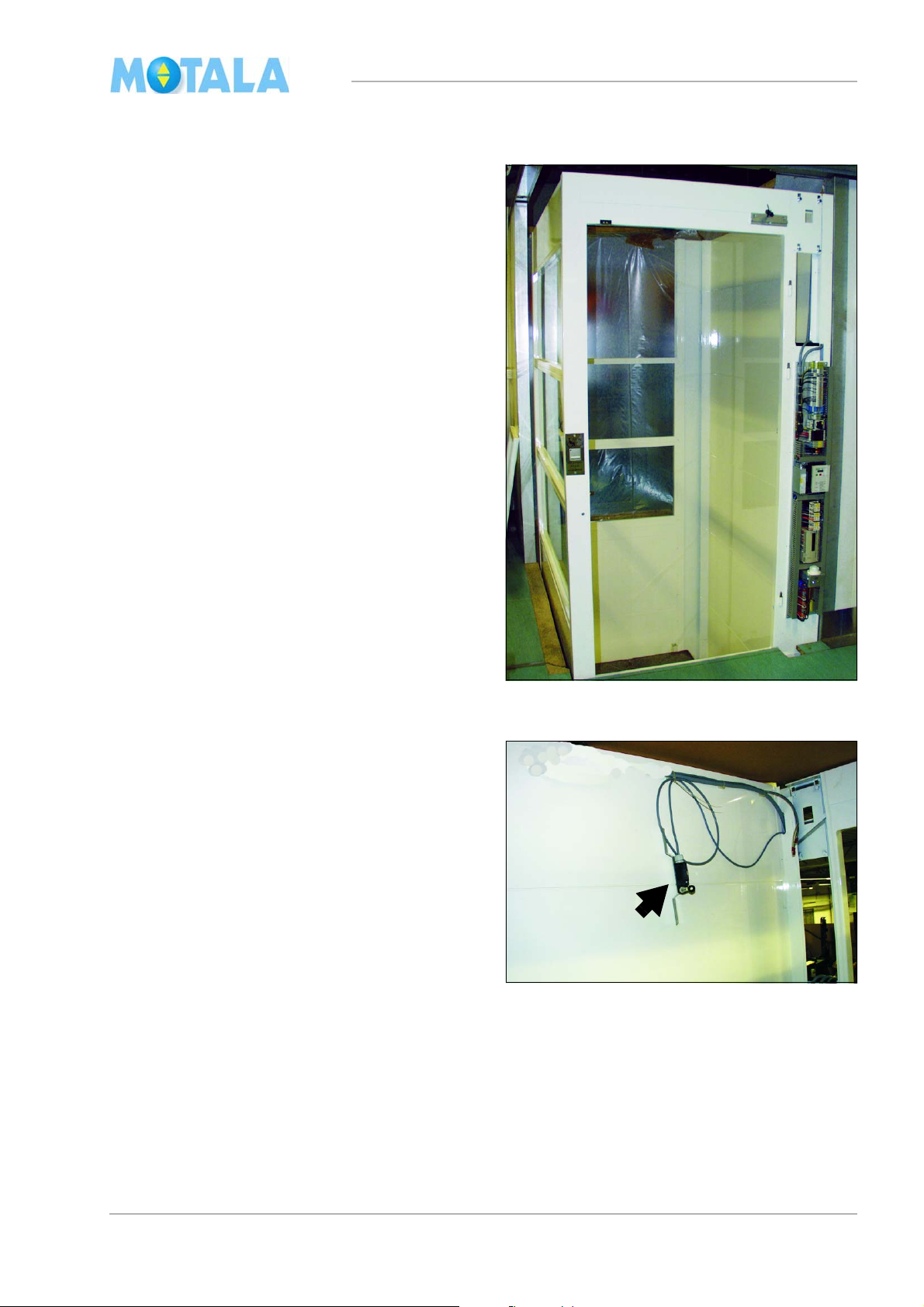

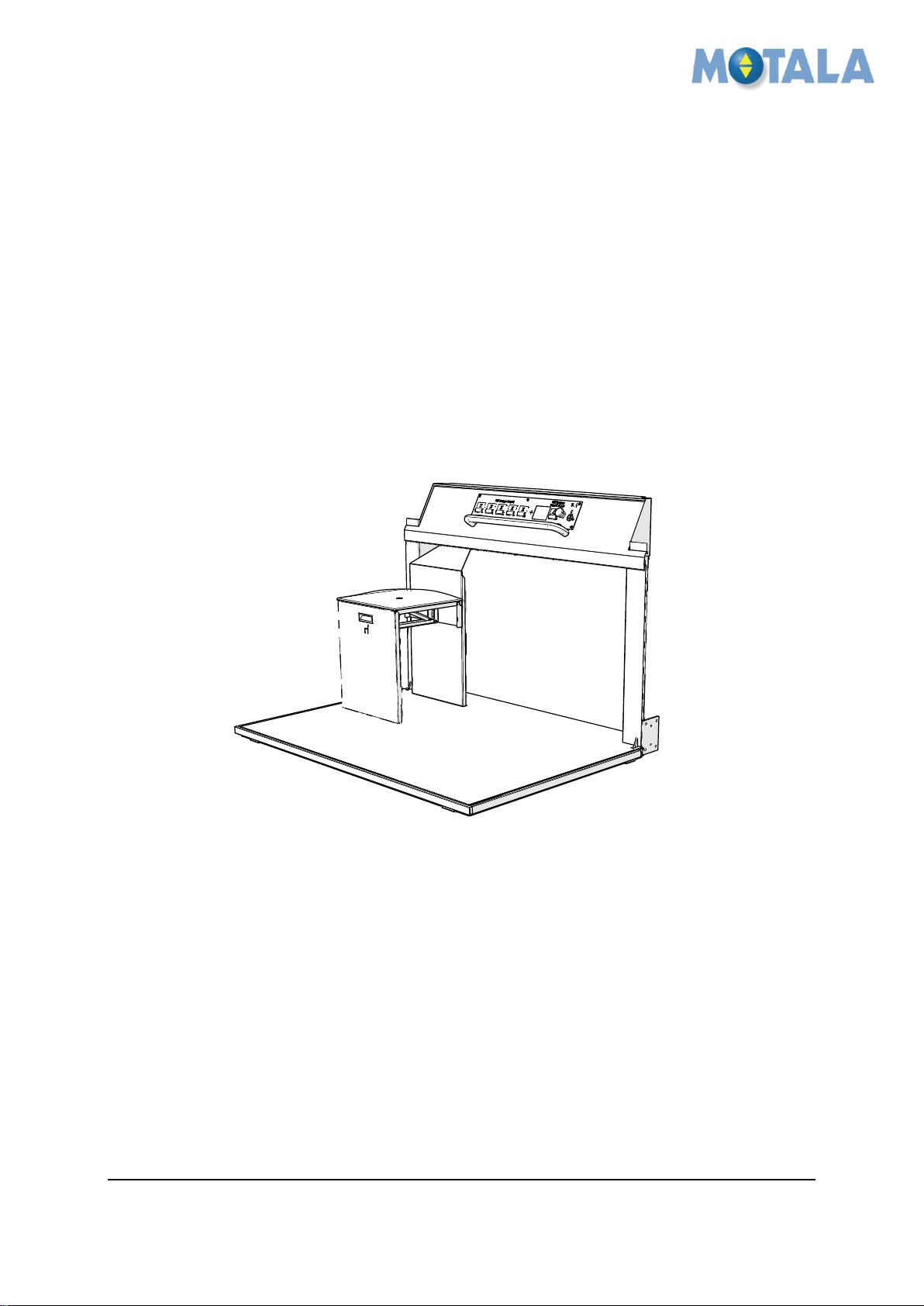

Introduction

This assembly instruction manual shows you

how to erect Motala Hissar MC2000 with 2-6

landings and manual or automatic doors.

The texts

and the illustrations of the manual

show an MC2000 with 2 landings, but are also

valid for lifts with several landings. Note that the

manual also describes the assembly of equipment that is not found in all lifts.

MC2000 can be delivered with straight or

adja-cent two-way entrances. For power

supply, see the current electrical diagram.

The assembly instructions are based on

equip-ment and tools that were accessible

when the manual was written. Because of

continuous product development we reserve

the right to al-terations without further notice.

Safety regulations

Important!

For your own safety and for the safety of others,

follow the existing safety regulations.

Warning! Risc to get jammed! Do not work in

the pit without necissary pre-actions, use the pit

prop, use the stop button, switch off the power!

3

MC2000 – Assembly Instruction Manual

Wordlist

Adjacent lift Lift with door or doors on sides B or D.

Chain joint For connecting the chain between the guide rail sections and

tween the chain and the jointing rod.

be

Clamp coupling For jointing the driving shaft.

Corner profile 100x40 Non-drive side corner.

Corner profile 250x40 Drive side corner.

Door front (With door frame, lock etc).

Drive command box For temporary driving.

Drive command panel Plate with control buttons, attached to the panel shelf and

he panel plate.

t

Drive side The side where the guide rails are placed. This is the wider

ide if you look at the door frame. Can be on the B or D side

s

FF Finished floor.

Glass module Glass module on the long and short sides.

Jointing rod 12x12 mm square rod for adjusting the chain tension.

Jointing sleeve U-section to be put between two corner profiles.

Lift well module Isolamine. Product and expression for 25 to 35 mm thick iso-

lated steel modules.

Non-drive side E.g. side B if the guide rails are on side D.

Panel plate The plate to which the panel shelf and the control panel are

ached.

att

Panel shelf Steel shelf with electric equipment, attached to the panel

ate.

pl

Passage contact Contact which straps across the lock contact when the lift is

the landing zone.

in

Platform Floor frame, floor plate

Pit prop (in the pit) Yellow safety bar that can be raised.

Safety gear test equipment. Attached below the gripping lever. Remote-released by a

ord in the control panel.

c

Side A The side where the motor and gear are placed.

Side B The side placed clockwise next to side A.

Side C The side opposite side A.

Side D The side placed clockwise next to side C.

Slide Flat bar iron with sliding guide shoes where the chain is fas-

tened.

Turning case Cut plastic case where the chain changes direction.

Two-entrance lift. Lift with doors on side A and side C.

Two-metre fixing plate angles. Fixings for the large cover plate above the guide rails.

Work platforms Occasional platforms for building lift wells.

4

MC2000 – Assembly Instruction Manual

Tools

Tools/Equipment with item numbers can be ordered from Motala Hissar AB.

Equipment

Sets of dimension sticks, 1480 mm, 1081

m, 1181 mm.

m

Work platforms, standard set. 705658 For lift well construction. For about three

Drive command box complete with 25 m

ble.

ca

Winch or telpher, min. approx 100 kg. 705867 For lifting guide rails.

Lifting eye bolt with lock, see ill 6 on

page 25.

Fastening rod (telescopic) 705824 For suspending the winch in the well top.

Chain fixing tool. 701268 To prevent the chain from sliding during as-

Glue sprayer. 101428

Structural glue. 100510 Gluing of platform floors.

Grease and lubricating substances. Lubrication of guide rails and lock arms.

Lifting tool (suction cups), 2 pieces 101423 For glass and lift well modules.

Working place illumination

Spirit-level, short, approx, 500 mm

MH item

numbe

705827 For lift well construction, outside dimensions:

705868 For driving the lift during assembly and test-

705826 For lifting guide rails.

r

Notes

depth 1560mm x width 1150 mm/1250mm.

rs. Extra equipment to be ordered

floo

ing.

sembly.

Spirit-level, long, approx, 2000 mm

Measure tape/folding rule, plumb.

Measuring instruments

Tools for electric installation

Jigg saw with long blade “120mm”. For cutting lift well modules “35mm thick”.

Wire shears For cutting wires and wire covers.

Electric screw driver with extender and bits,

pe ph2.

ty

Ratchet with extender and sleeves 13 mm

nd 17 mm.

a

Ring-open-end spanners 7-17 mm.

Plate shears

Riveting tongs

Drill, diameter 3.3, 4.2, 6 and 12 mm For pop rivets and making holes in jointing

ods for drive chains.

r

Hand tools: multi-purpose pliers, screwdrivers, socket wrenches etc.

Hack saw For sawing the joint rod of the drive chain.

Crowbar

5

MC2000 – Assembly Instruction Manual

2

A

D

B

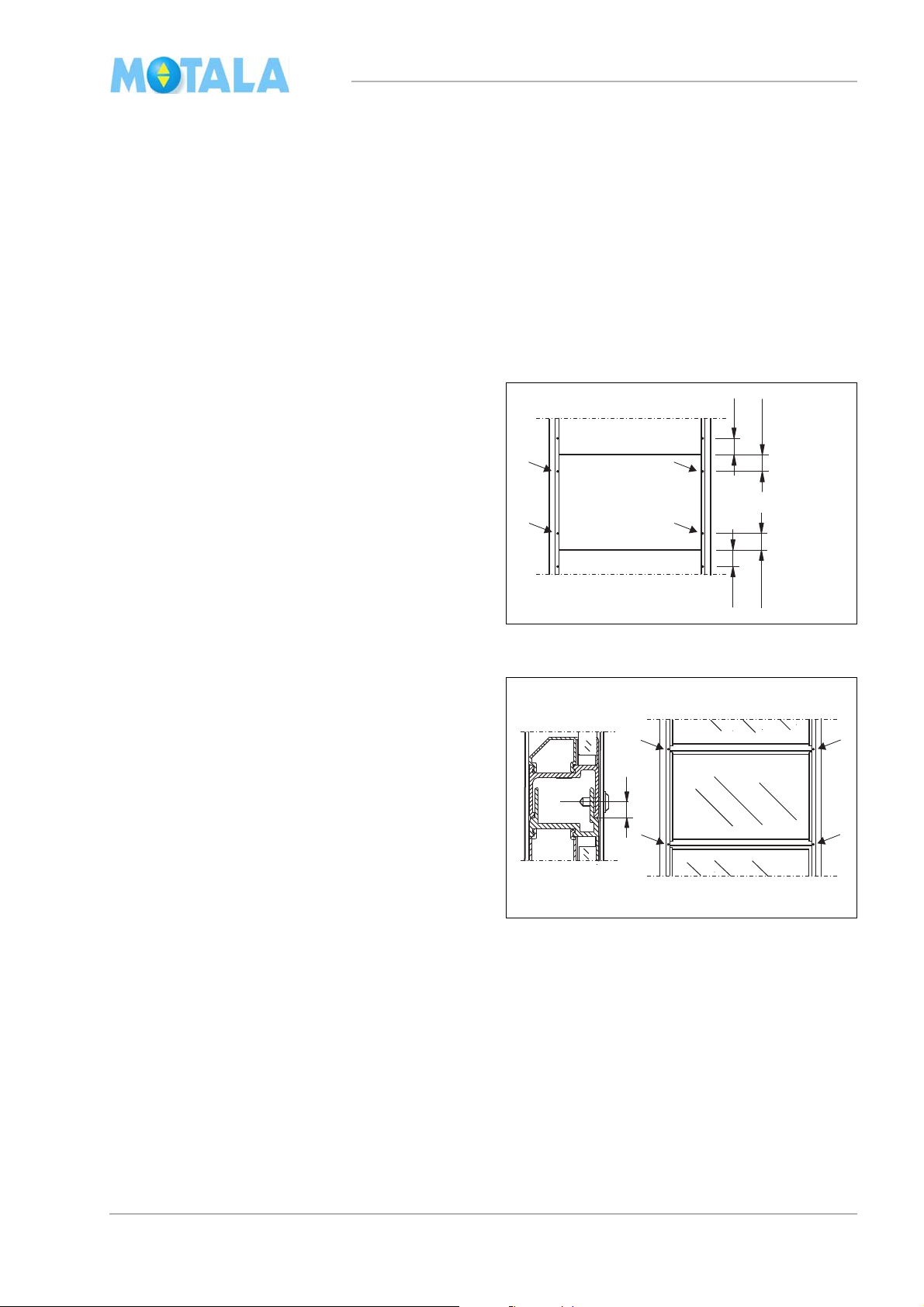

Preparations before assembly

Use the layout drawing for erection site check

Measurments

There is an example under the heading “Layout

awing” on page 48. (The measurments in the

dr

picture are taken from that example.)

Check that the pit:

• has the correct measurments

• is even and level

• is painted.

C

1590

Check the lifting heights (FF-FF). Check that

the floors are completed, i.e. have the correct

height.

Use the plumblines to measure the openings of

e joists. Also check that the diagonal meas-

th

ures of the openings are equal.

Check that the erection space is at least 30 mm

the maximum height of the lift.

above

Check the wall opening dimensions in front of

e door sections according to the layout draw-

th

ing.

Free space for doors

Check the space available for opening doors,

king the inclination of the floors into consider-

ta

ation. Are the doors hung correctly - right or

ft?

le

Free space for the pit prop

Check the space available for the pit prop. See

e layout drawing.

th

Power supply

Check that there is power supply for the lift, the

llumination and the telephone. Compare with

i

the electrical diagram and the layout drawing.

Other facts

Go through and make sure what parts of the lift

e to be powder coated or just primed consid-

ar

ering the framing of joists, walls etc. at the erection site. See the object description enclosed

h the delivery of the lift. Also check the plac-

wit

ing of glass modules, if any.

60

1280

mc20050

Lift material

Check at arrival

Check the number of packages against the

gnment note and the equipment against

consi

the packing list.

Check that nothing is damaged or missing.

Placing

Transport the material to the erection site and

ace it on the appropriate floor. Use the

pl

“checklist”. See example under the heading on

page 49. The door frames are marked on the

bottom side of the profile with an 0, I, II, III or IIII,

dependi

ng for which floor they are intended.

Lift well construction planning

• Where do glass module sections start and

end, if any? The first lift well module might

have to be adjusted so that the glass modules are at the right height above the correct

sts higher up in the lift well. See the lay-

joi

out drawing.

• Where are the channels for lock wires and

es? (These channels can be found in

cabl

adjacent lifts and in two-entrance lifts.)

6

MC2000 – Assembly Instruction Manual

100

100

100

100

mc200553

mc200552

8

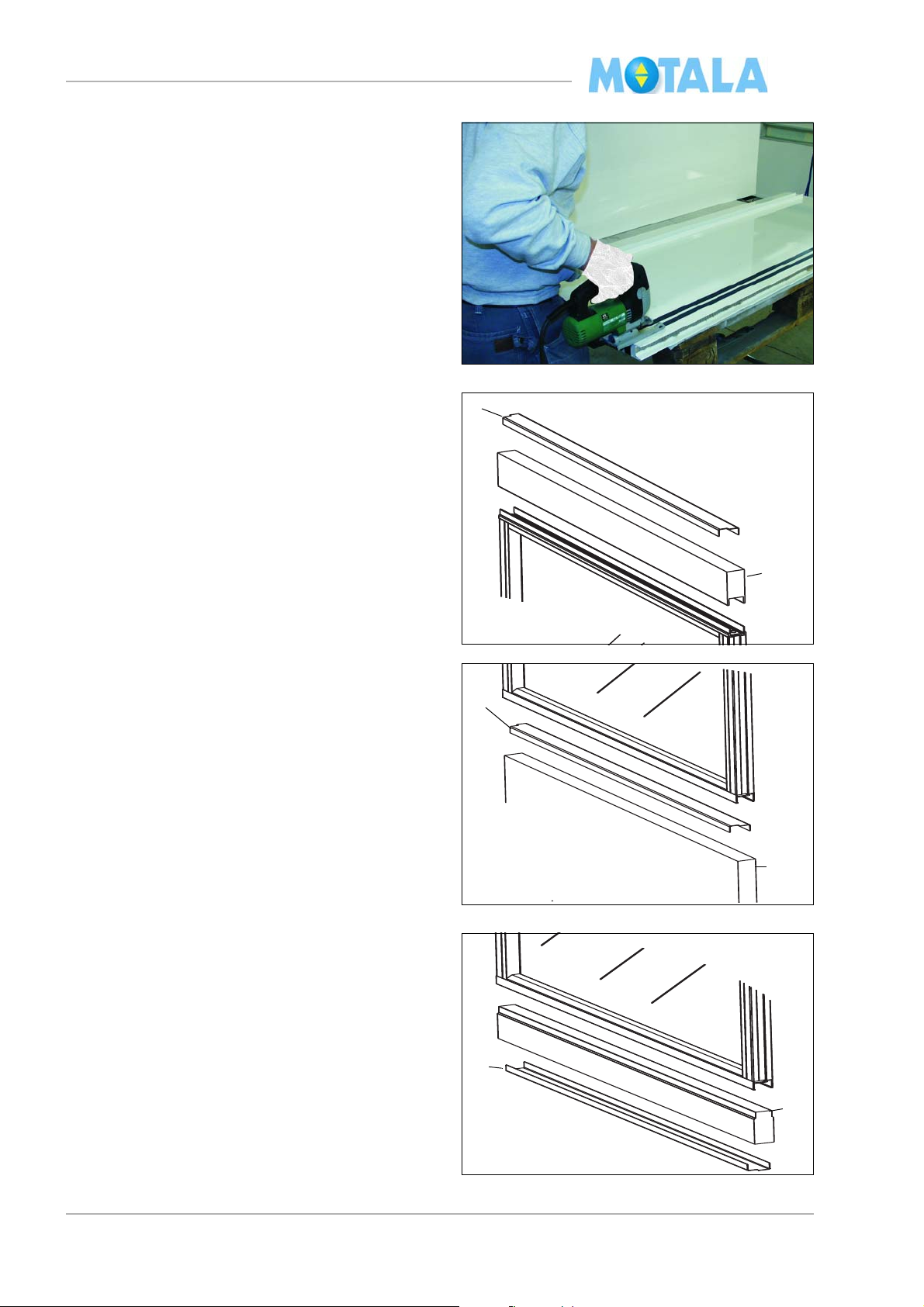

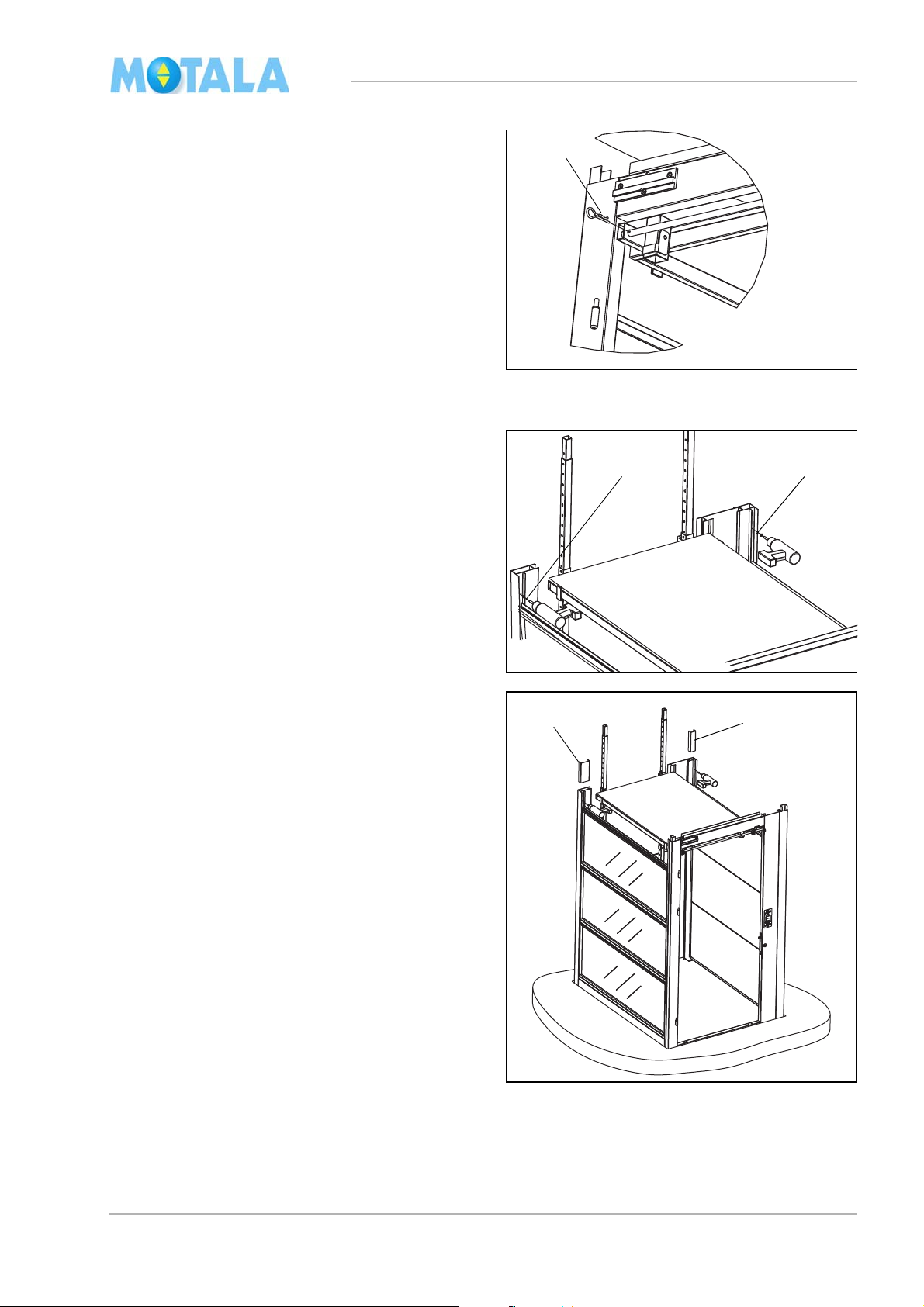

Assembly

Introduction

This section contains general information on

o construct so called precision gauge

how t

blocks and how to erect lift well modules and

glass modules.

General information on how to erect modules

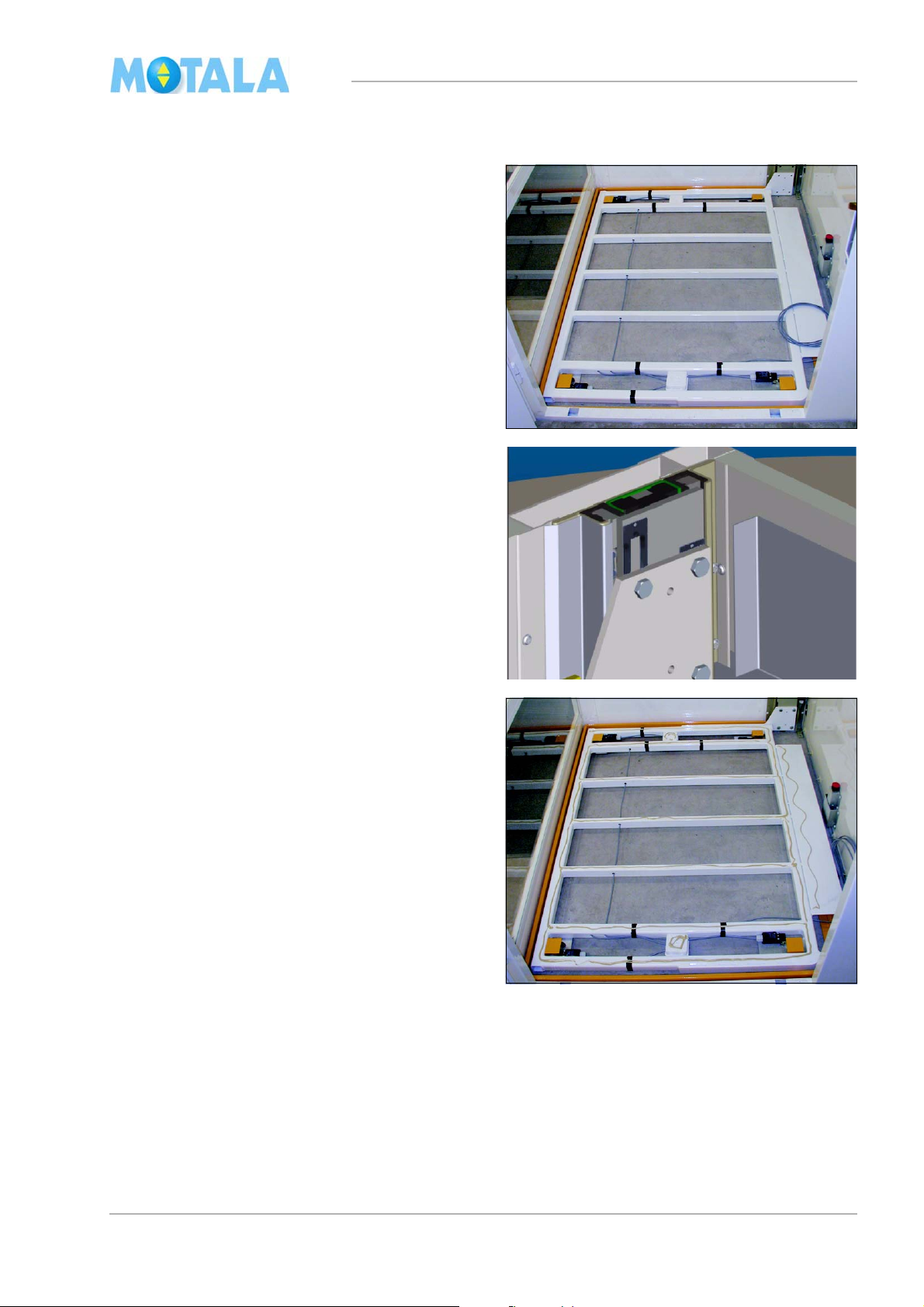

Lift well modules

Generally, each module is assembled with four

ews in the corner profiles. The screws are

scr

placed about 100 mm from the upper and lower

edges.

For a nicer look, the screws can be exchanged

pop rivets (4 mm).

by

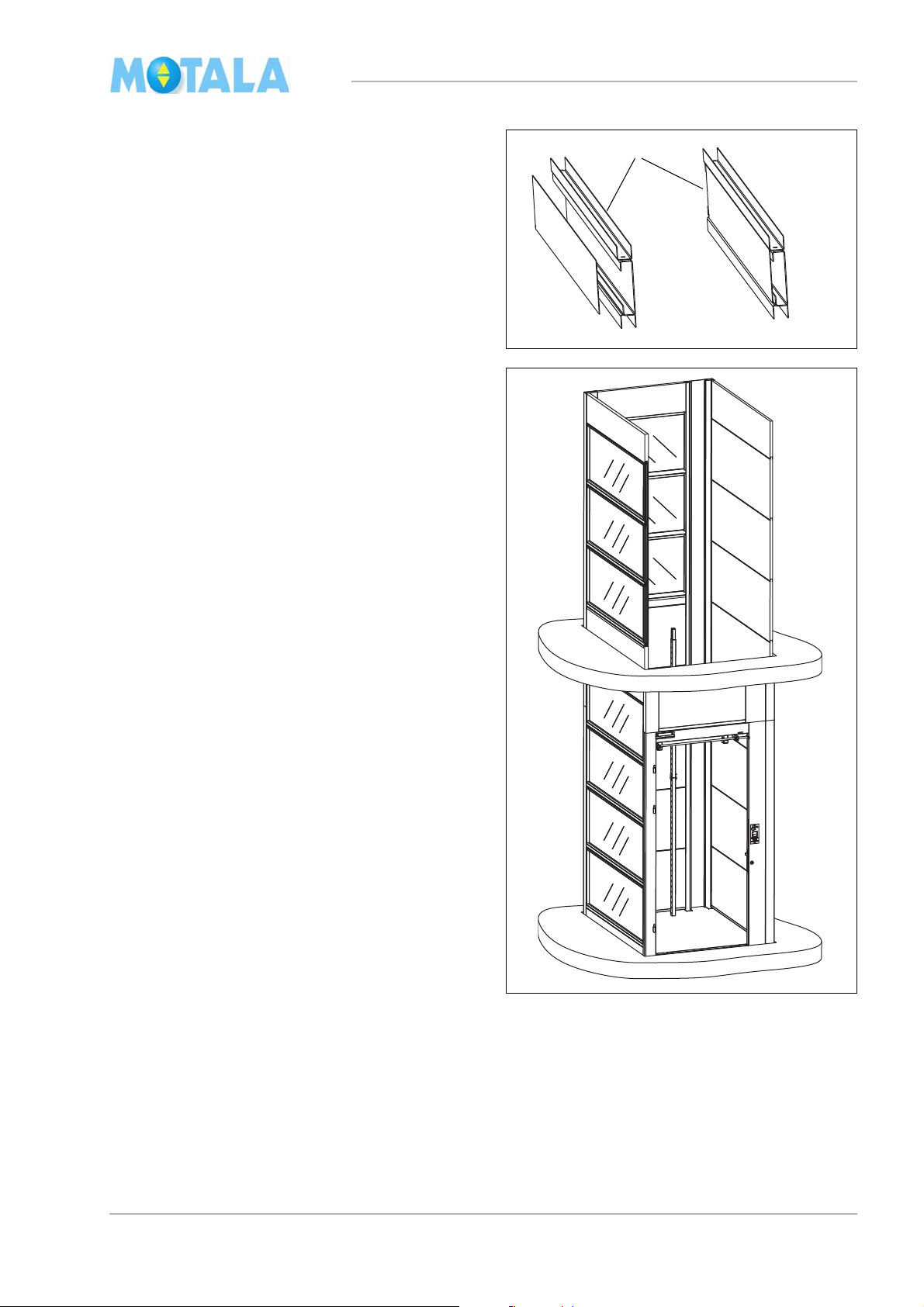

Glass modules

Glass modules are to be placed with the bevelled window moulding on the outside of the lift

. (The flush side on the inside.)

well

The modules are generally put together so that

each modul

e is fastened with four screws in the

corner profiles. You need to pre-drill 3,2mm.

The screws in the splice between two modules

placed about 8 mm from the lower edge of

are

the upper module so that the screw also goes

through the male profile of the lower module.

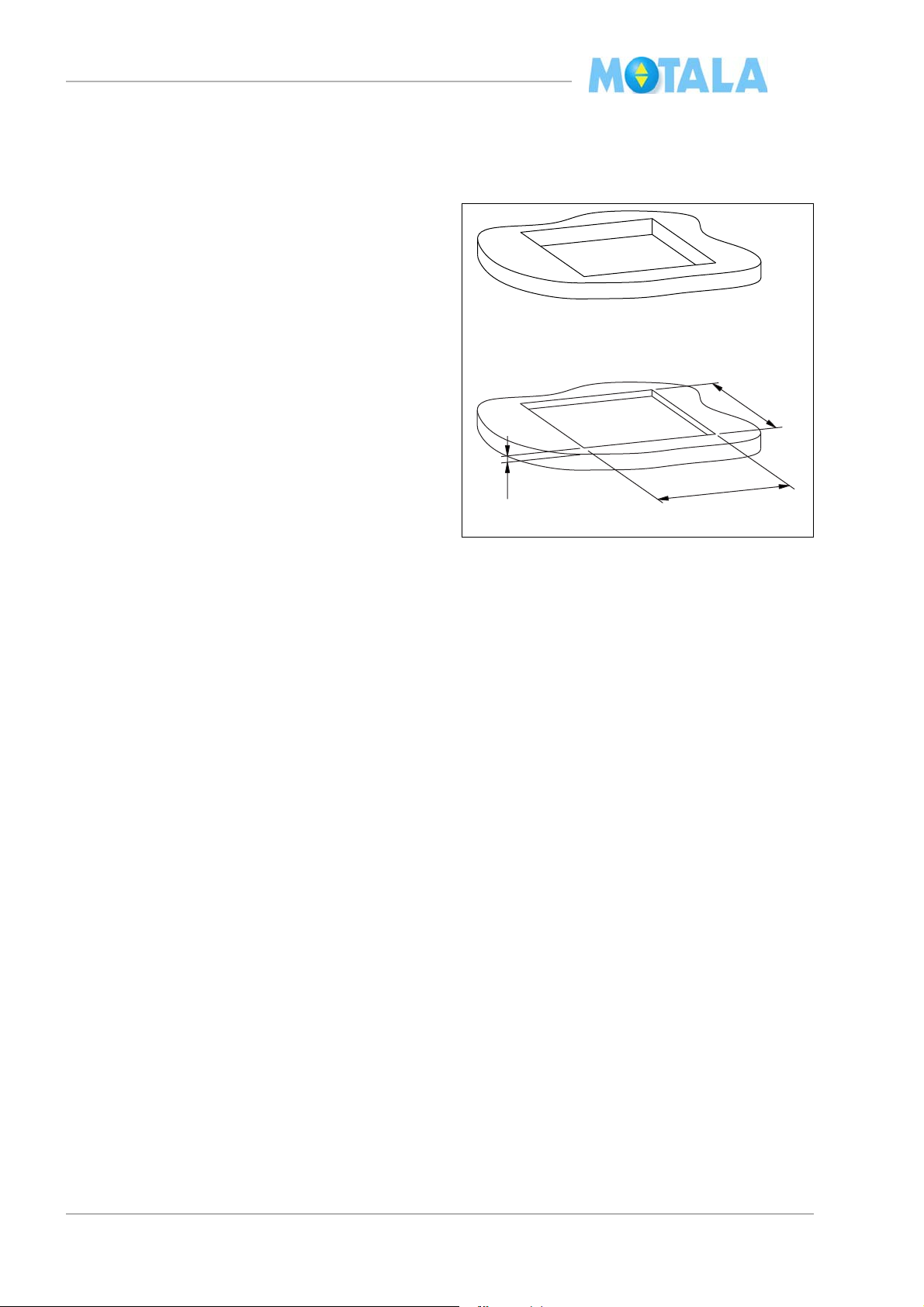

Construction of precision gauge blocks

For glass modules, precision gauge blocks are

used at joist passages and in the pit so that the

glass surfaces are placed at the proper height

according to the layout drawing. Note that the

measurements in the layout drawing apply to

cutting measurements of the precision gauge

blocks. Example: see the heading “Layout

drawing” on page 48

7

MC2000 – Assembly Instruction Manual

1

2

2

1

1

4

1. Cut the lift well modules with a jigg saw.

Protect the surface with insulating tape or

something similar.

2. Remove the sharp edges.

3. Turn the U-profile with notch 1 towards the

side of the lift well. Note that the top U-

out

profile looks different.

Finish (top clearance of lift well)

Use female section 2 of a lift well module.

Joist passage

Use female section 2 of a lift well module.

Pit

For glass modules, for example.

Use male section 4 of a lift well module.

8

MC2000 – Assembly Instruction Manual

mc200505

2

1

3

4

C

A

D

B

100

100

mc200506

8

5

7

6

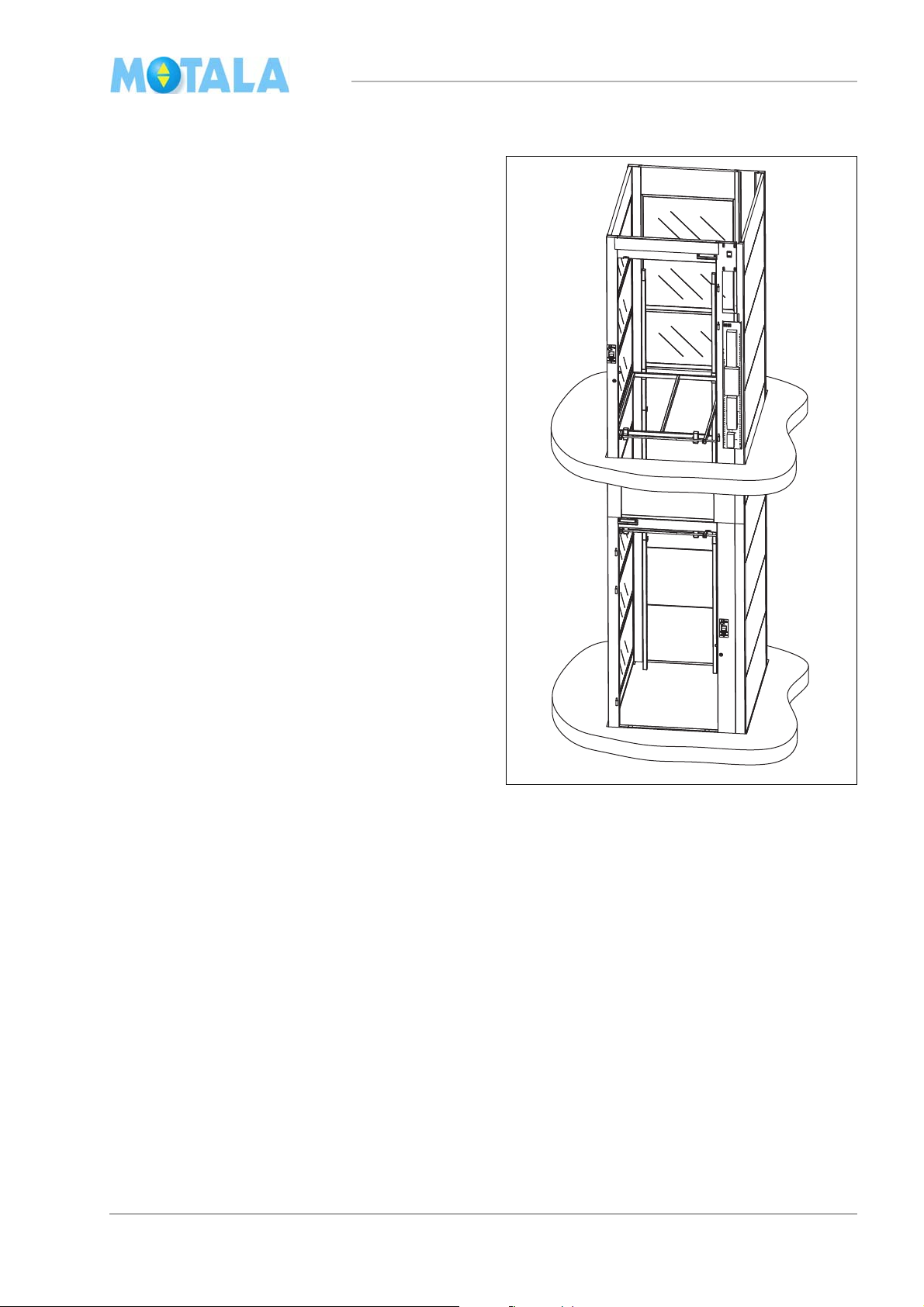

Lift well assembly according to

layout drawing.

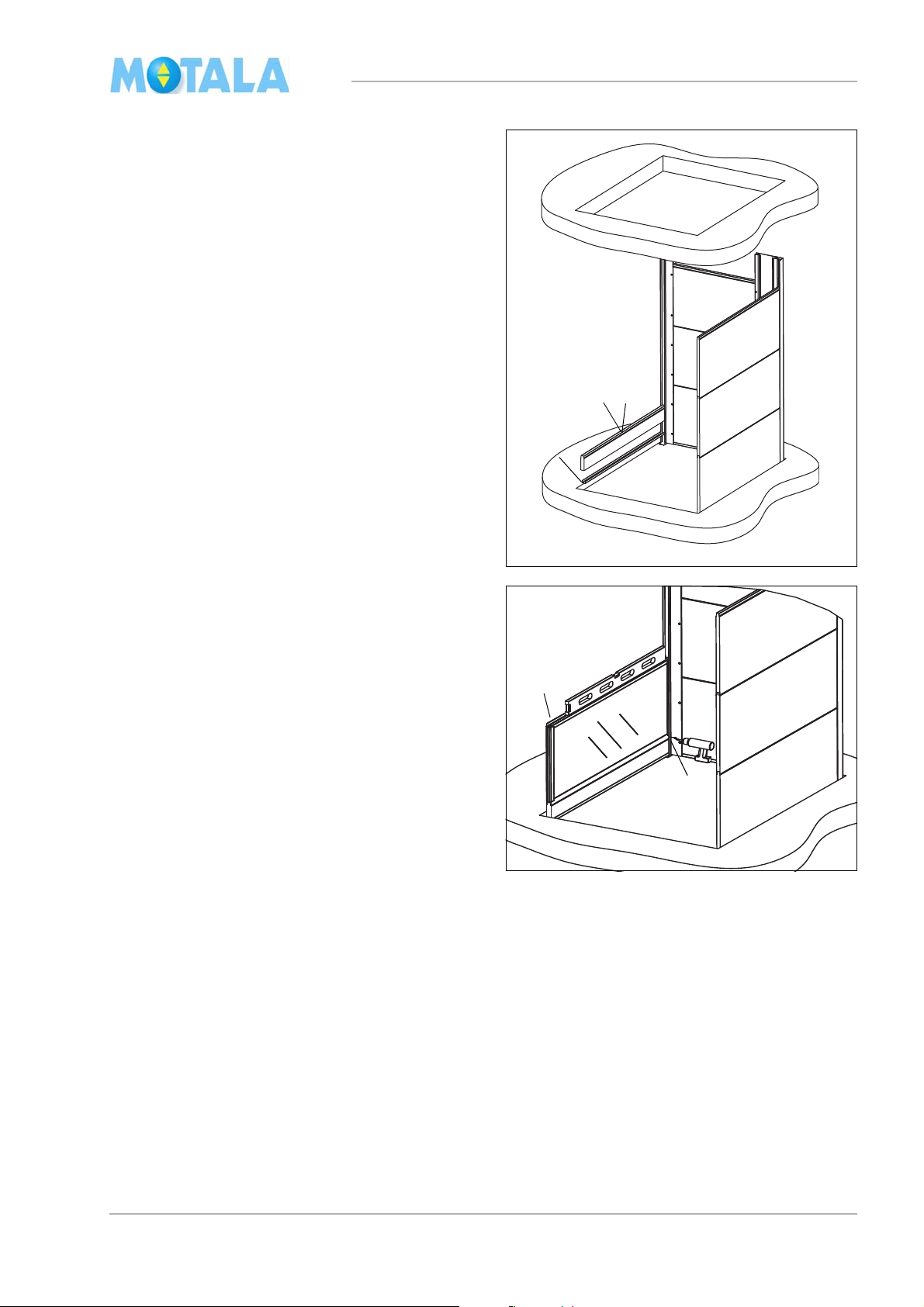

Bottom part of the lift well, landing 0

1. Erect the broad corner profile on side C of

the lift well. Note that the broad profile must

be placed against side D.

2. Erect the thin corner profile.

3. Place a U-profile (35 mm) on the bottom

de, “female side”, at the bottom of the

si

lowest lift well module/glass module. The

notches (ends) of the U-profile should be

turned towards the outside of the lift well.

4. Place three lift well modules/glass modules

ween the corner profiles. Turn the “male

bet

side” upwards. The modules must not

reach the very bottom of the corner profiles. Leave a millimetre or two so that,

ater, you will be able to align the whole

l

side C vertically.

5. Place a short dimension stick between the

ner profiles. Check that the base is

cor

level.

6. If necessary, adjust with a metal shim under the corner profiles. The shim must be

aced under the corner profile and the

pl

module. Note! When plumbing, always

start at the “highest point” of the pit.

7. Fasten the modules in the corner profile by

taching one screw at the top and one at

at

the bottom of each side about 100 mm

from the edges. Use a dimension stick.

(For placing of screws, see the heading

“General information on module assembly”

on page 7).

8. Align vertically by means of a long spirit-

vel.

le

9. Fasten the modules and the corner profiles

th screws.

wi

9

MC2000 – Assembly Instruction Manual

10

mc200508

14

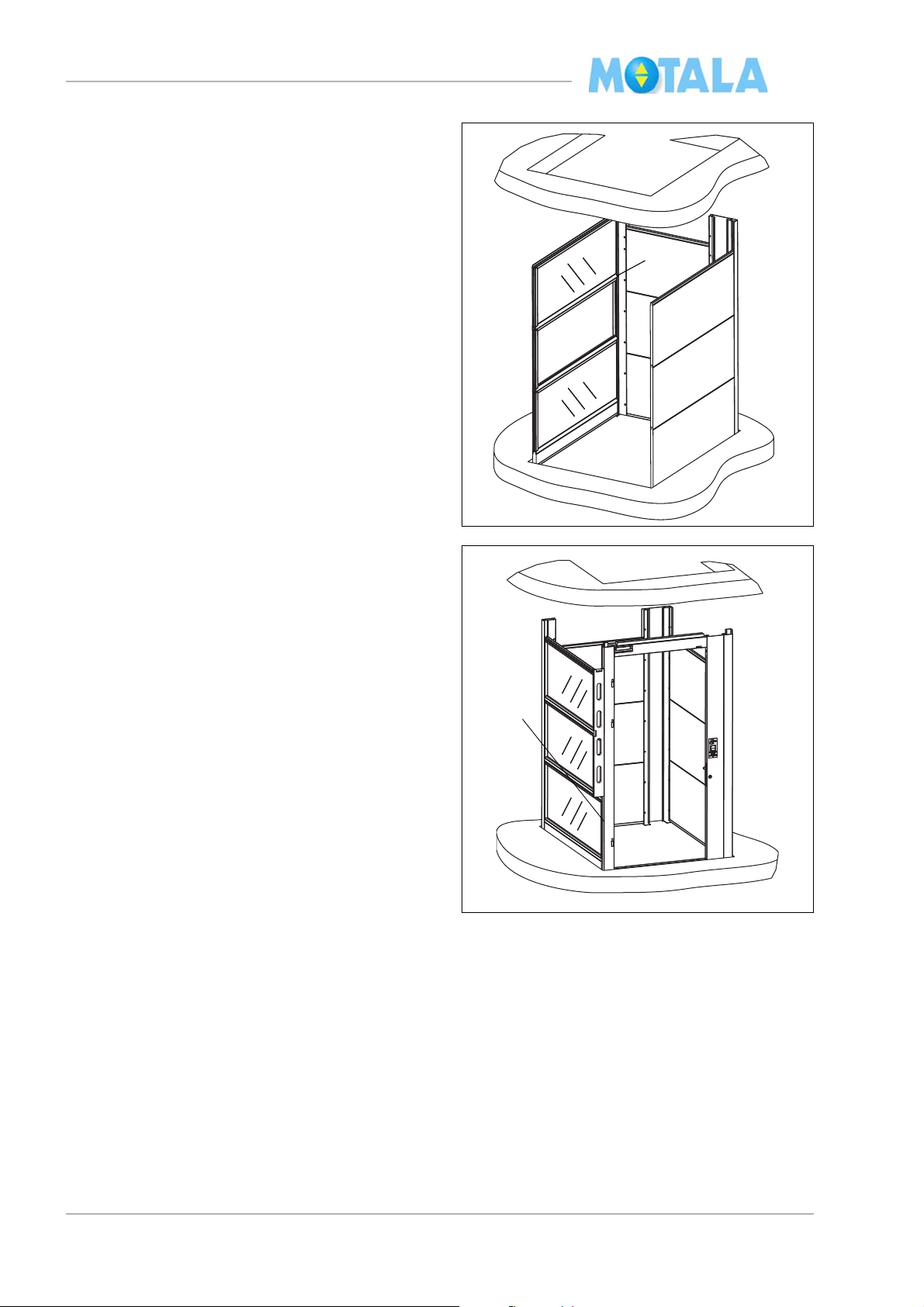

10. Place a U-profile (25 mm) under the lift well

module/glass module on side D. Turn the

notch of the U-profile towards the outside

of the lift well.

11. Place three lift well modules/glass modules

de D. Turn the “male side” upwards.

on si

The modules must not reach the very bottom of the corner profiles. Leave a millimetre or two so that, later, you will be able to

ign the whole side C vertically.

al

12. Fasten the modules in the corner profile by

f

astening one screw at the top and one at

the bottom about 100 mm from the edges.

Note! The screw heads in the corner profile

of the driving side must be placed at least 6

mm from the corner profile to leave room

for the guide rail flange.

13. Align horizontally by means of a spirit-level.

14. If necessary, use metal shims.

10

MC2000 – Assembly Instruction Manual

mc200509

15 17

16

C

D

A

B

18

20

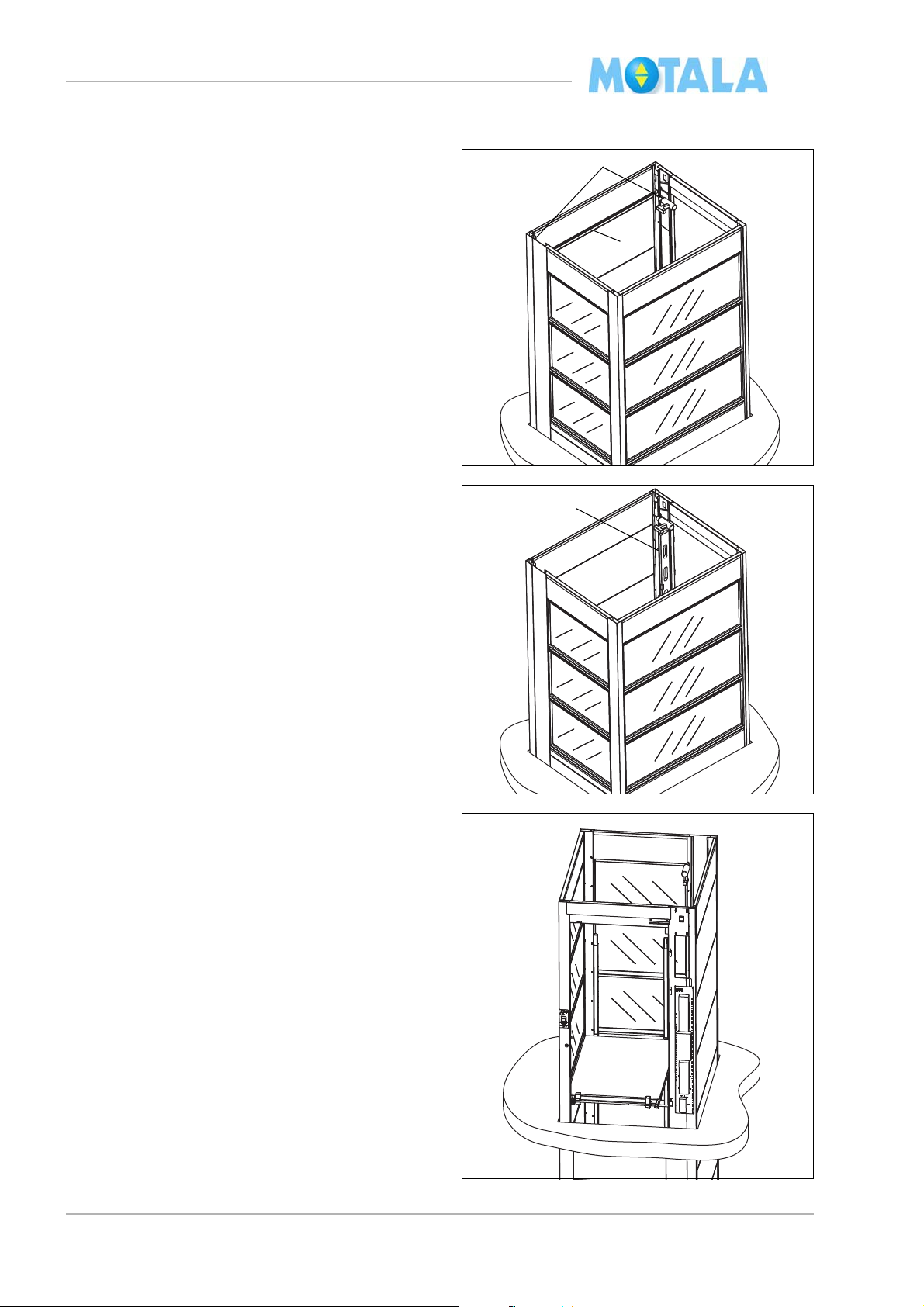

In this example, the lift well side B has glass

modules. The first glass module must not be in

close contact with the pit but should be placed

a little higher up. For measurments, see the layout drawing.

15. Using the male section of a lift well module,

truct a precision gauge block and

cons

place it in close contact with the pit. See

the heading “Construction of precision

gauge blocks” on page 7.

16. Install the U-profile with the notch turned

wards the outside of the lift well.

to

17. Fit the precision gauge block.

18. Place a glass module on top of the preci-

sion gauge block. Turn the “male side” upwards and the level glass side towards the

ift well. Check with a spirit-level that the

l

upper edge of the glass module is horizontal.

19. If necessary, adjust with a metal shim be-

tween the precision gauge block and the

t.

pi

20. Fasten the glass module with a screw in

e longitudinal bottom corner profile. See

th

the heading “Glass module” on page 7.

11

MC2000 – Assembly Instruction Manual

mc200511

22

A

D

C

B

mc200512

23

B

D

C

A

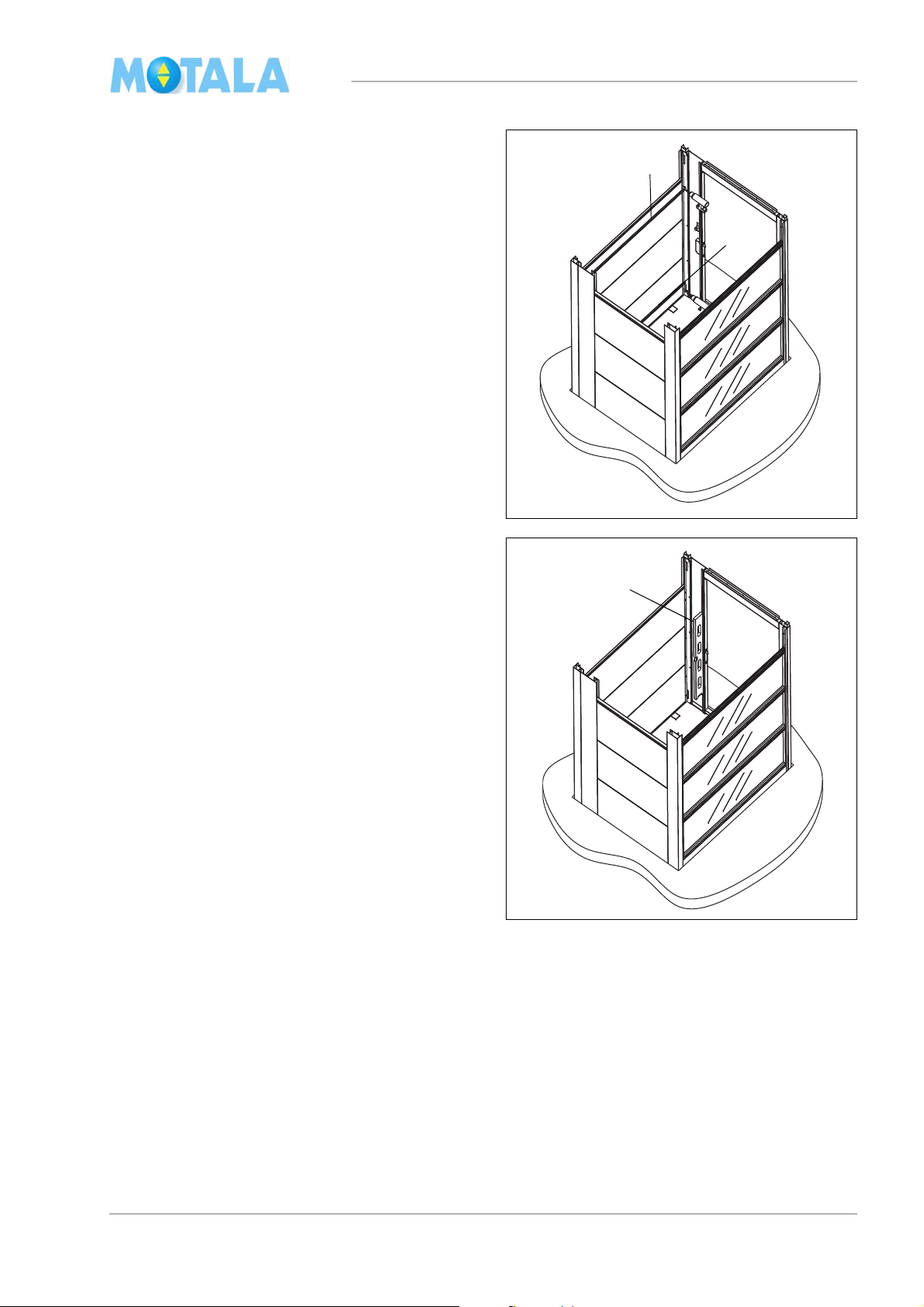

21. Fit three glass modules.

22. Fasten the tops of the glass modules in the

ner profile with a screw through the two

cor

modules.

23. Set up the door frame. Start at the bottom.

Check

is laterally vertical. If necessary, adjust with

metal shims.

with a spirit-level that the door frame

12

MC2000 – Assembly Instruction Manual

mc200513

25

24

A

B

C

D

mc200514

26

24. Use a long dimension stick to check the

correct distance between sides A and C of

the lift well. Fasten the door frame with

screws at the very bottom of the modules

on sides B and D.

25. Move the dimension stick upwards and fasten the door frame with screws in the upper

es of sides B and D.

modul

26. Check with a spirit-level and straighten the

frame vertically against sides A and C.

door

27. Secure the remaining screws in the modules.

13

MC2000 – Assembly Instruction Manual

mc200519A

mc20051

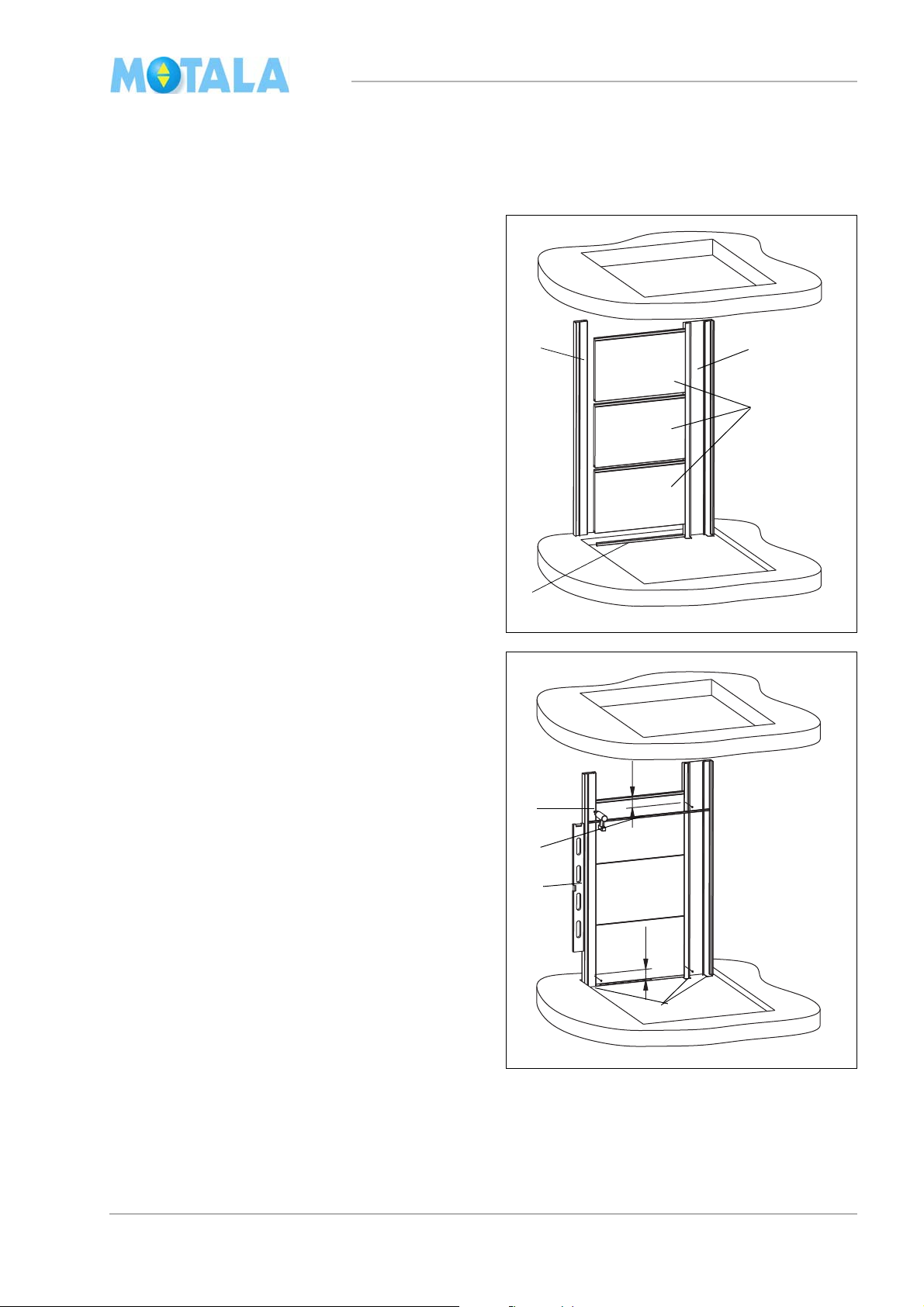

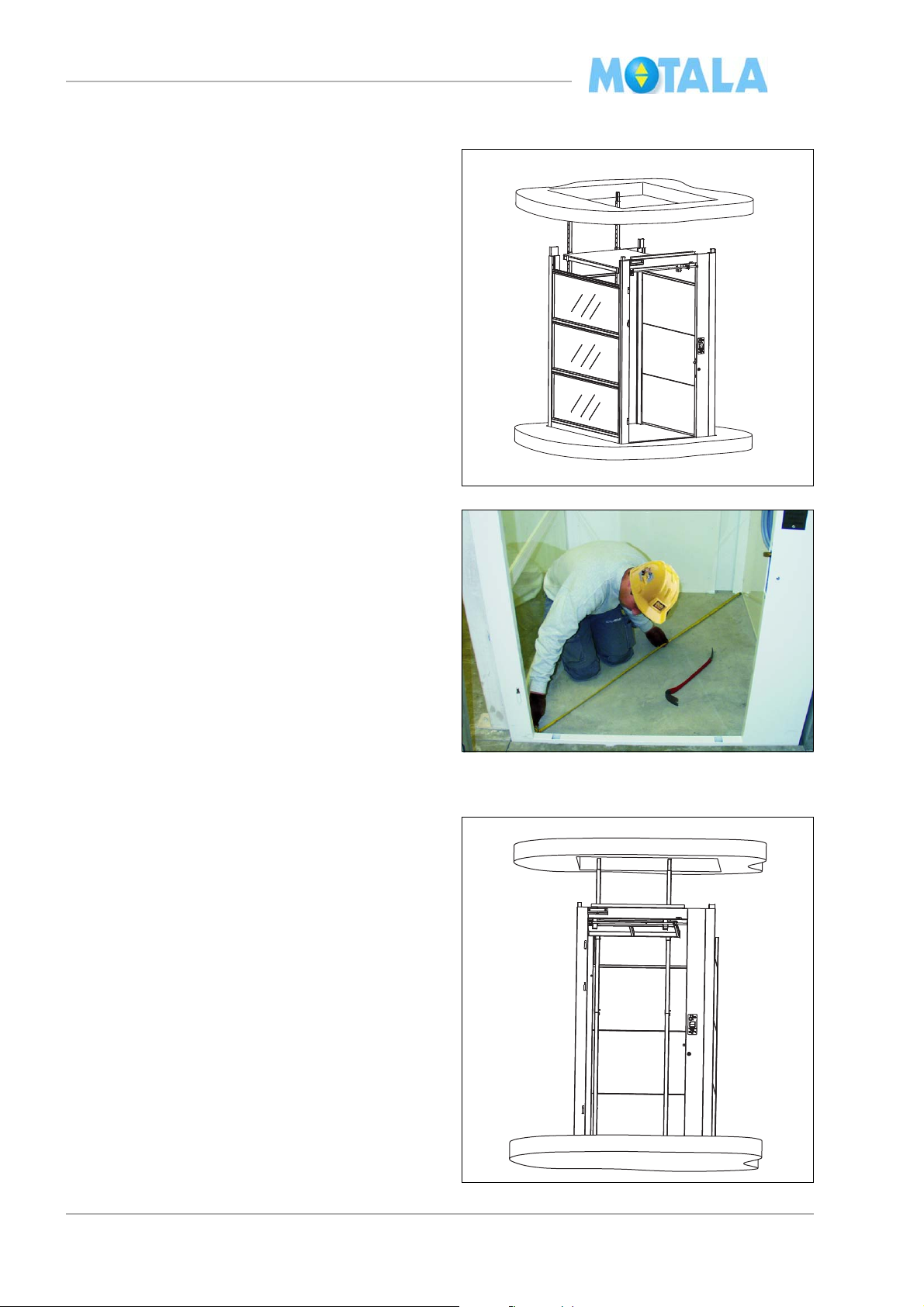

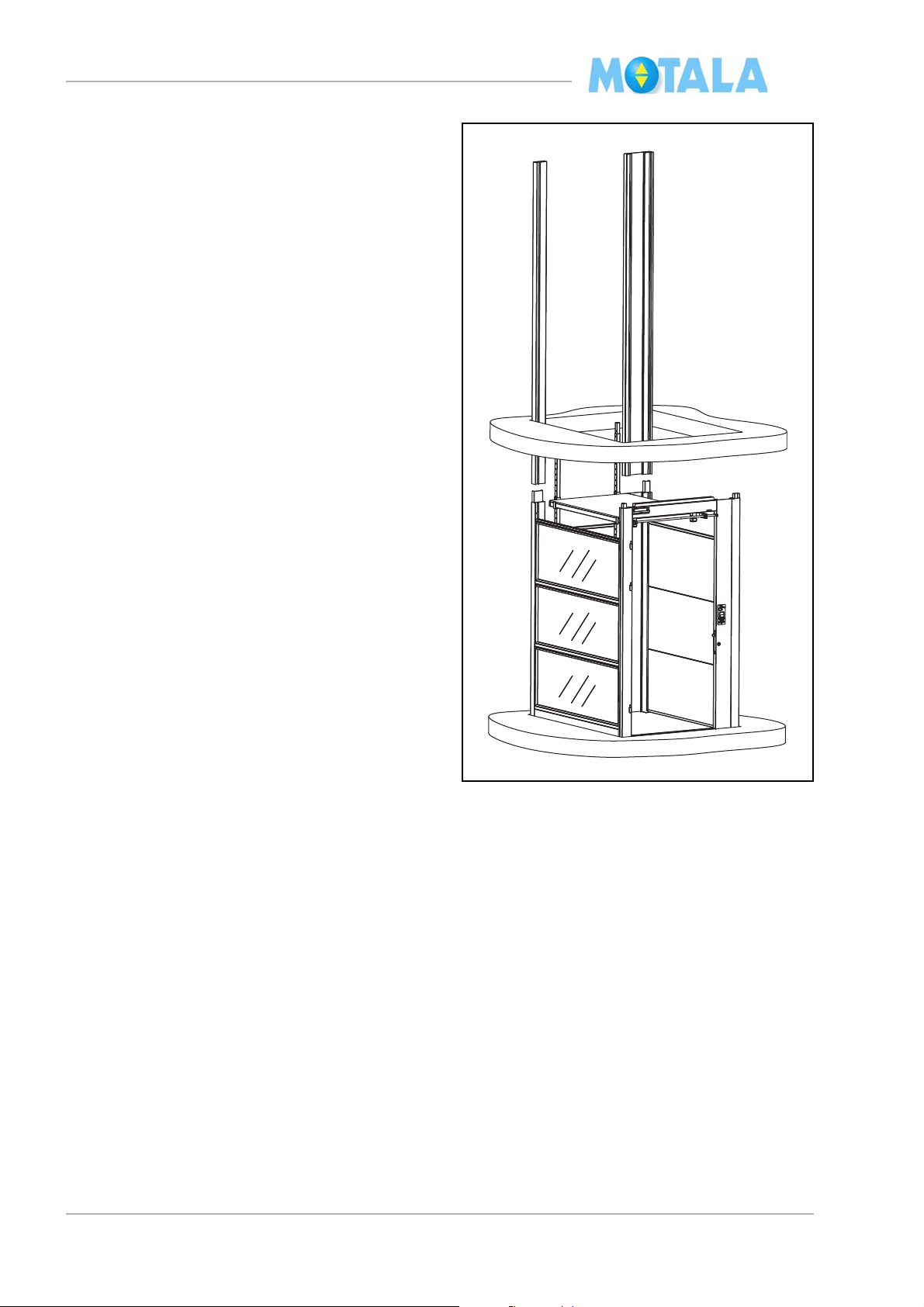

Placing the lift well in the pit

1. Adjust the placing of the lift well in the pit

and chec

k that the lift well can pass freely

upwards through the joists.

2. Measure and adjust the diagonal measurements of the lift well.

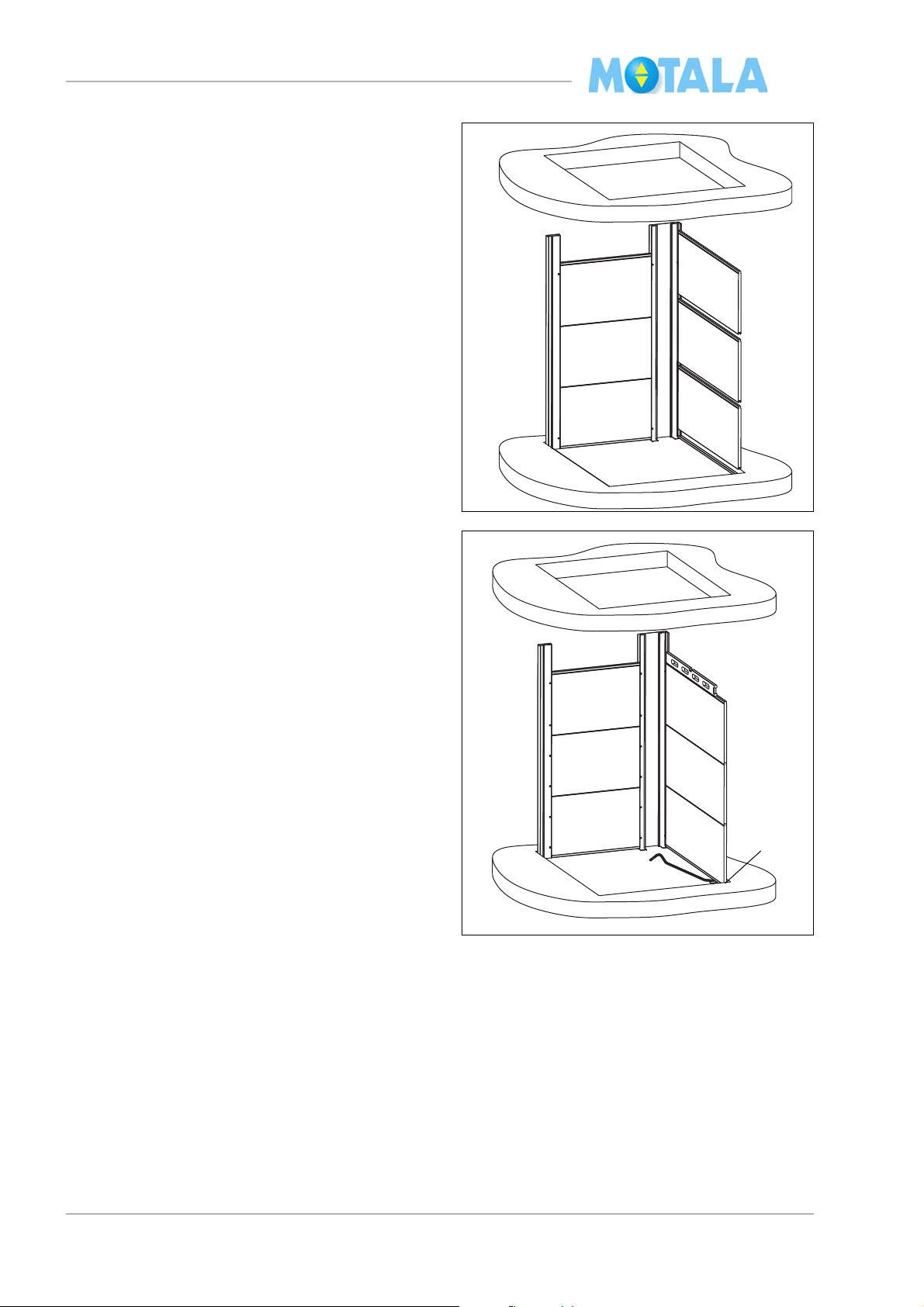

Erecting the work platform, landing 0.

1. Erect the work platform in the two predrilled holes of the door frame. Unfold the

platform and set up two adjustable legs in

the back edge of the platform.

14

MC2000 – Assembly Instruction Manual

mc200517

2

mc200518

11

mc200518

2

2

2. Attach the lock pins.

3. Set up the platform floor.

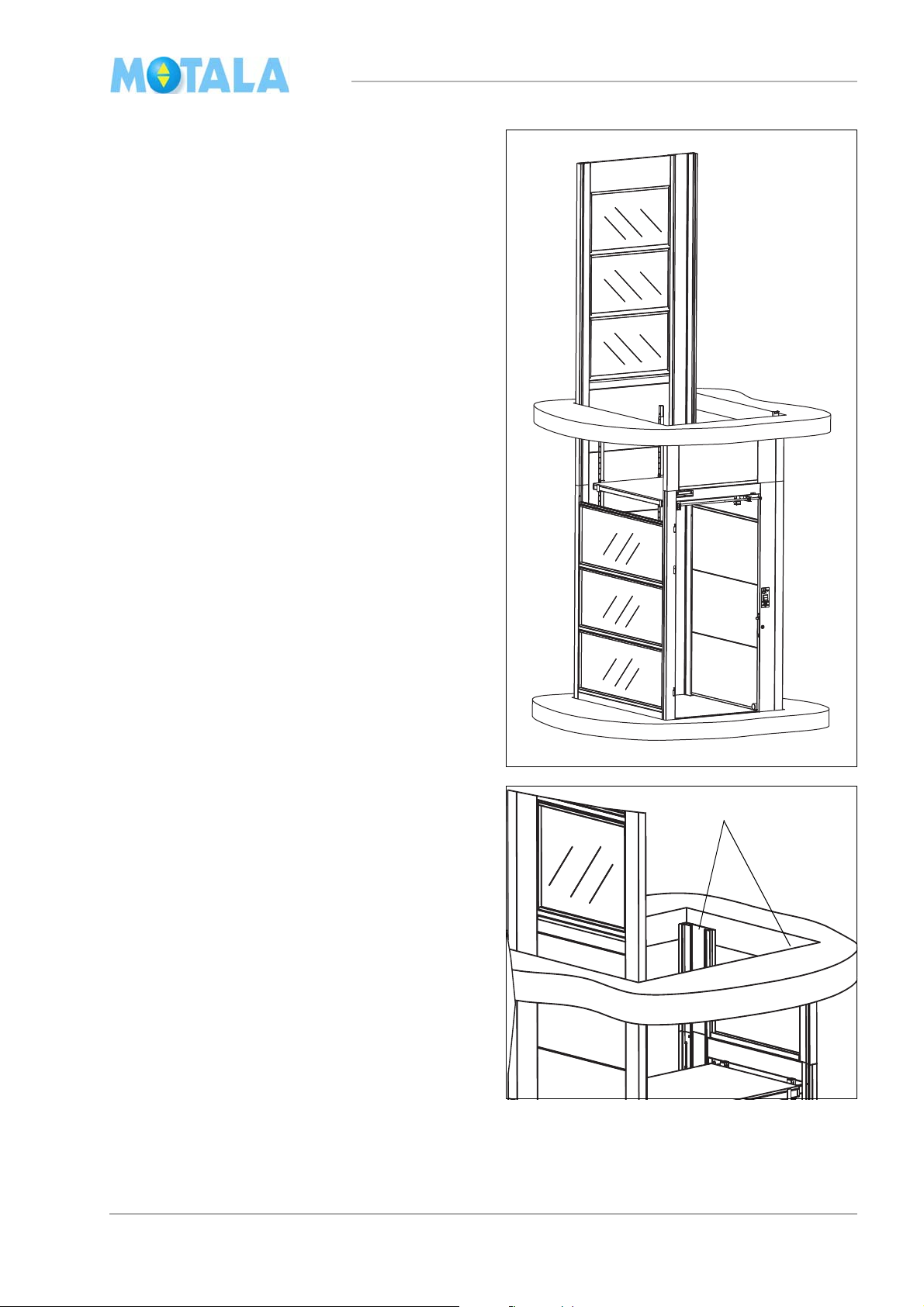

Construction of lift well for remaining floors (1-4)

Corner profiles, side C

1. Fasten a screw in each corner profile of

de C so that half the jointing sleeve de-

si

scends into the profile.

2. Attach the jointing sleeves.

15

MC2000 – Assembly Instruction Manual

mc200519

3. Erect the corner profiles onto the jointing

sleeves

16

MC2000 – Assembly Instruction Manual

mc200521mc200521

7

In this example side C is also fitted with glass

modules and therefore a precision gauge block

is needed for the joist passage and a second

one is needed as a finish at the well top.

4. Construct precision gauge blocks, see the

ng “Construction of precision gauge

headi

blocks”, on page 7.

5. Set up no more than 3 or 4 modules.

6. Align and fasten side C with screws in the

way as you did for landing 0.

same

Corner profiles, side A

7. Push the two corner profiles into the door

ame. For length, see the checklist. (The

fr

corner profiles ascend through the joists so

that the door frame of landing 1 can be

placed on top of these profiles.)

17

MC2000 – Assembly Instruction Manual

A

B

C

D

A

B

D

C

8. Measure and cut the lift well module with a

jigg saw if necessary. The module should

end a few millimetres below the upper ends

of the corner profiles.

9. Assemble the module/modules.

10. Use a short dimension stick and fasten the

modul

of the corner profiles.

11. Use a spirit-level and fasten the remaining

s

e with two screws in the upper edges

crews in lift well wall A.

12. Erect the modules on sides B and D. Use a

ong dimension stick and fasten the mod-

l

ules with two screws in the upper edges of

he corner profiles. Use a spirit-level and

t

fasten the remaining screws in lift well walls

B and D.

18

MC2000 – Assembly Instruction Manual

mc200548

13

mc200545

13. Note! For adjacent lifts and two-entrance

lifts, remember that you need a channel for

cables and wires in the lift well walls. The

retiring ramp is always on the same side as

the motor and the gear, see “Layout drawing” on page 48.

14. Install the modules on sides B and D.

15. Cut the modules about 2 mm shorter than

e corner profiles.

th

16. Set up the U-profiles.

17. Fasten the sides with screws just as you

d on the previous floor.

di

19

MC2000 – Assembly Instruction Manual

mc200525

18. Install the door frame in the two foremost

corner profiles.

19. Unfold and fit the door frame against the

modul

es of sides B and D. Use a glazier’s

lifting tool with suction cups.

20

MC2000 – Assembly Instruction Manual

mc200526

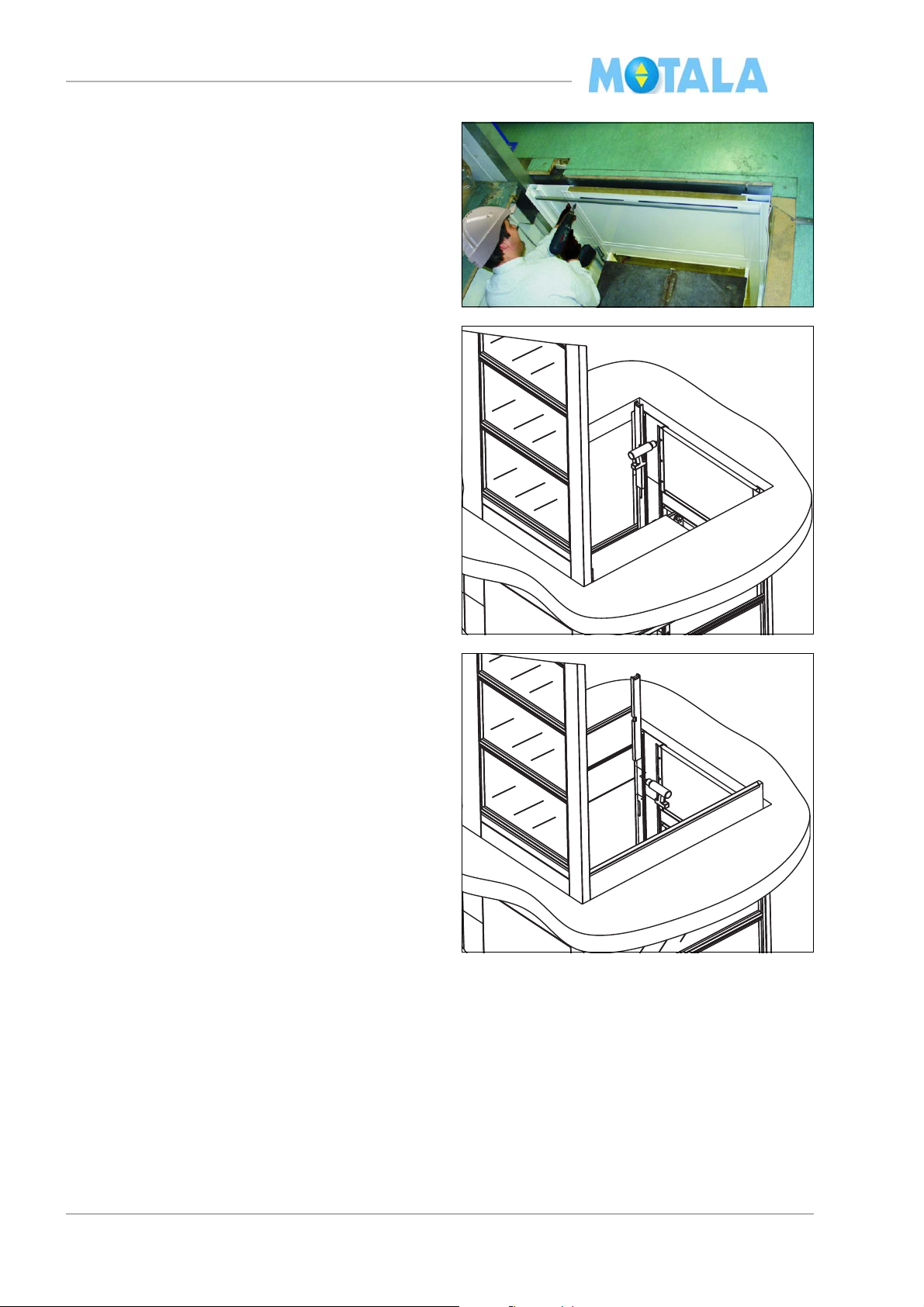

Erecting the work platform, landings 1-4

1. Erect the work platform in the two preilled holes of the door frame. Unfold the

dr

platform and set it up in the two adjustable

legs in the back edge of the platform.

2. Attach the lock pins.

3. Install the platform floor.

21

MC2000 – Assembly Instruction Manual

2

1

3

Finishing the upper part of the lift well

Straightening of sides B and D

1. Place the dimension stick on a level with

he upper edge of the door frame.

t

2. Fasten a screw in the upper part of the

frame and another screw on the same

door

level on side C.

3. Align side A with a spirit-level and fasten

t

he remaining screws.

4. Align and fasten the other side in the same

.

way

5. Erect the remaining modules on side C and

sec

ure them with screws. Use a short di-

mension stick.

In order to place the last lift well modules/glass

es on side C in case of minimal roof

modul

space.

• Unfasten the module screws temporarily.

• Pull the corner profiles apart so that the

module

ner profiles.

• Fasten the modules with screws.

s can be placed in between the cor-

22

MC2000 – Assembly Instruction Manual

127:

Installation of electric cables and wires

Pull all the cables to the control panel, i.e. the

e from the pit and the cables from all the

cabl

door frames.

The illustrations show the standard installation,

e. the control panel is installed on the door

i.

frame on the top floor at the same place as the

motor and the gear.

If the control panel is placed on another floor on

side the lift, cables for the hand wheel

or out

contact 28: must be installed; the motor cable

and the brake cable to the control panel. (The

hand wheel contact is effected by the hand

wheel tool for emergency control of the lift.)

Also see on page 28.

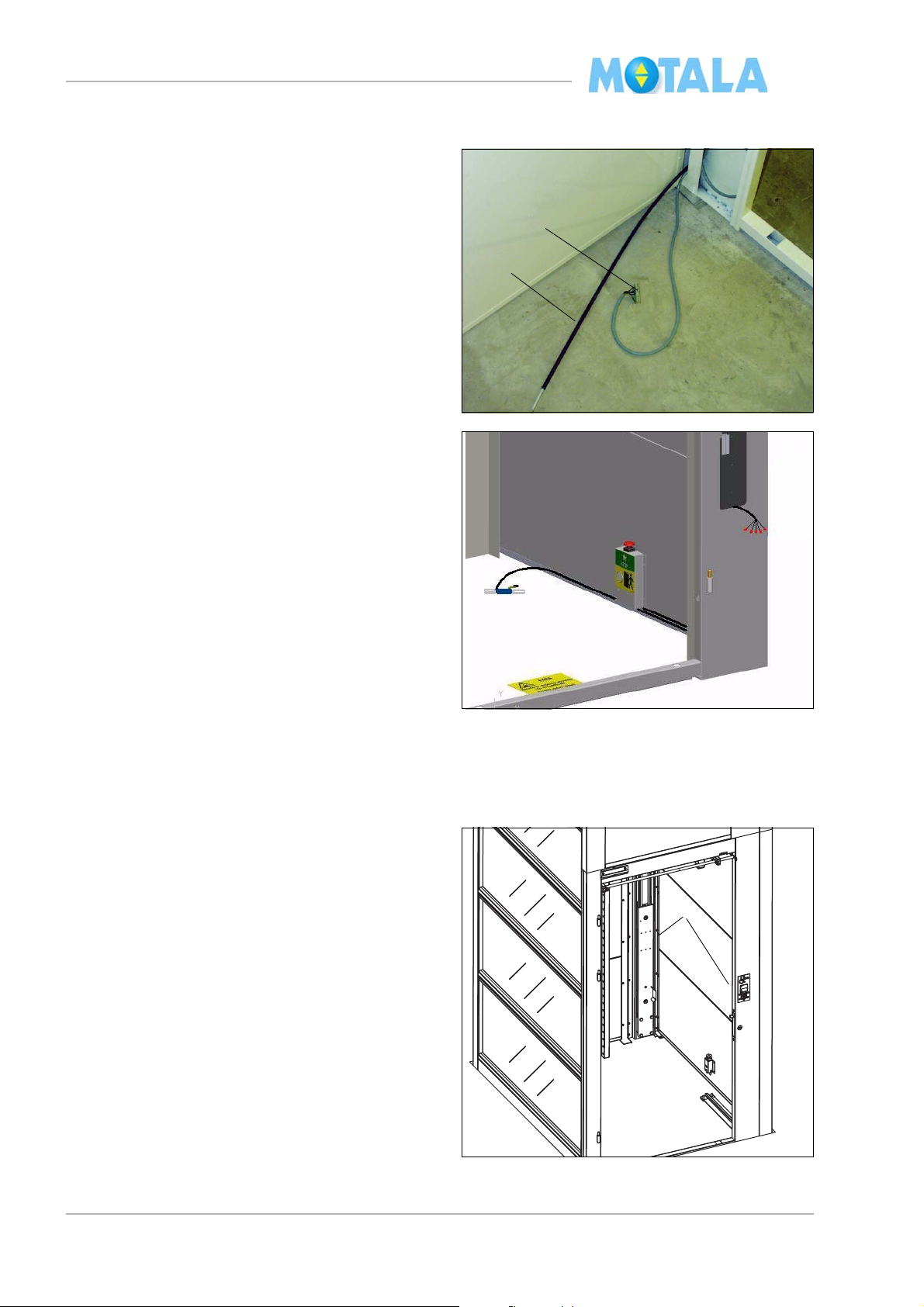

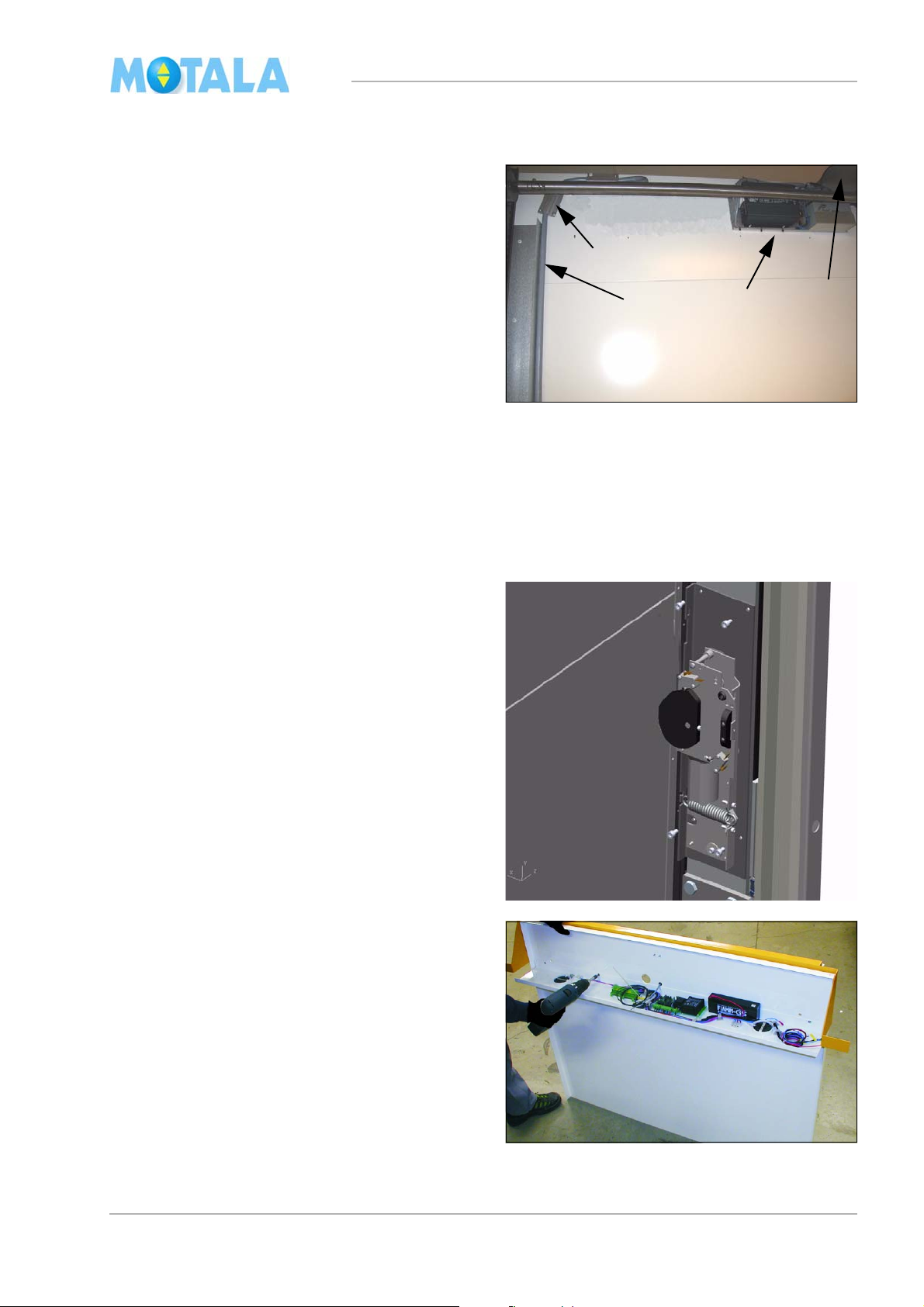

Top landing

1. Route the cable for the safety gear contact

127: to the control panel (to be installed

later) with cable tie

2. .Temporarily fasten the upper end limit

U (marked with an arrow in the photo)

62:

and pull the cable through the door frame

to the control panel.

3. Note where the cables from the door

ames enter the channel so that you do not

fr

screw or drill through them by mistake. Try

to keep the cables in the centre of the door

frame profile and the corner profile.

23

MC2000 – Assembly Instruction Manual

1

2

1

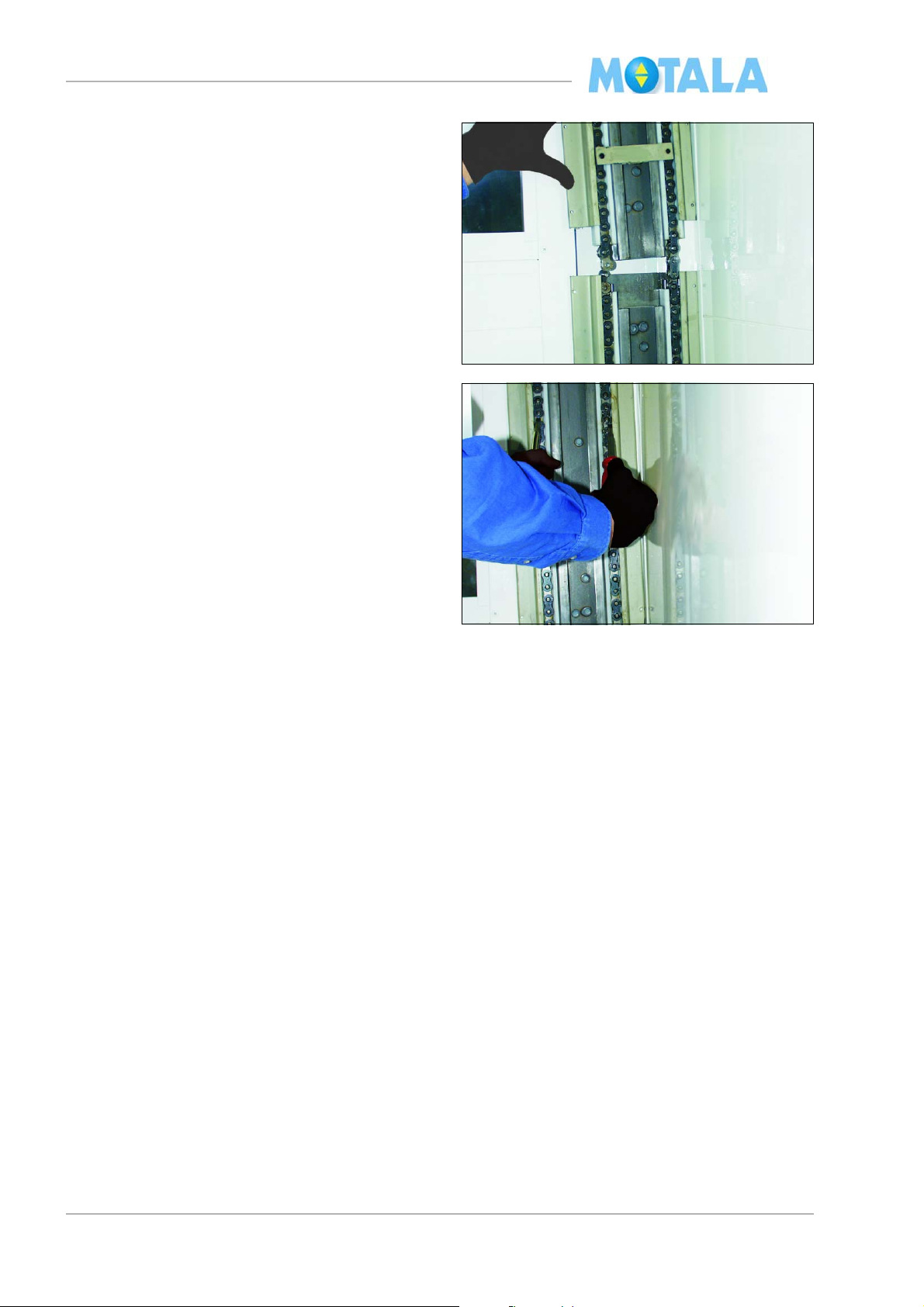

Landing 0, pit

1. Pull the cable with terminal block “control

anel - terminal block pit” through the

p

opening in the door frame. (Length of cable

to the block approx. 0.8 m.)

2. Pull the door lock wire through the same

ing.

open

3. Install “terminal block with the stop button”

and cabe

switch 62:U on the side wall of the driving

side in the lift well. It should be placed in a

position of 100mm from centre nearest

door side, about 50 mm upwards on the

wall.

4. Route the cable for the pit prop into the cor-

ner profile and out where the recess for the

t prop is. The end limit and the pit prop

pi

shall be fitted later.

l for the pit prop and end limit

Guide rails

Lower guide rails

1. Place the lower rails in the lift well. Note the

markings A and C. Side A is always the

side where the motor and the gear are

placed.

24

MC2000 – Assembly Instruction Manual

mc200529

1

2

6

2. Place the guide rails in the very corners

th the mounting brackets turned towards

wi

the lift well wall. Check that the lower end

of the guide rail is on the same level as the

lower edge of the lift well, i.e. take the

shims, if any, into consideration

3. Secure the guide rails with screws. Note!

Use 25

mm screws. Check that you do not

screw through any cable or door lock.

Upper guide rails

1. Install the chain fixing device.

2. Remove the two plate screws (transport

ocking) that keep the chain in place in

l

each guide rail.

3. Erect the adjustable mounti

ng rod between

two of the walls of the lift well.

4. Attach the lifting winch to the mounting rod.

5. Lift the guide rails into the lift well.

6. Install a lifting loop on one of the guide

ils.

ra

7. Lift the guide rail. Check that it is installed

n its correct position, see the marking in

i

the guide rail profile..

25

MC2000 – Assembly Instruction Manual

8. Joint the chains. Lift the guide rail that is to

be jointed high enough above the lower

guide rail so that you can attach the connecting links.

9. Hold the chains in the upper guide rail with

g. two screw drivers and loosen the chain

e.

fixing device at the same time. Lower and

adjust the guide rail. Work carefully and

check that the steering pins enter the top

track properly.

10. Fasten the guide rails in the lift well with

rews. Use 25 mm screws. Check that the

sc

two C-profiles of the guide rails are in a position exactly opposite each other, so that

he lift moves softly past the joint.

t

11. Perform the same operation with the remaining guide rails..

26

MC2000 – Assembly Instruction Manual

mc200530

1

2

mc200531

3

20mm

4

mc200532

7

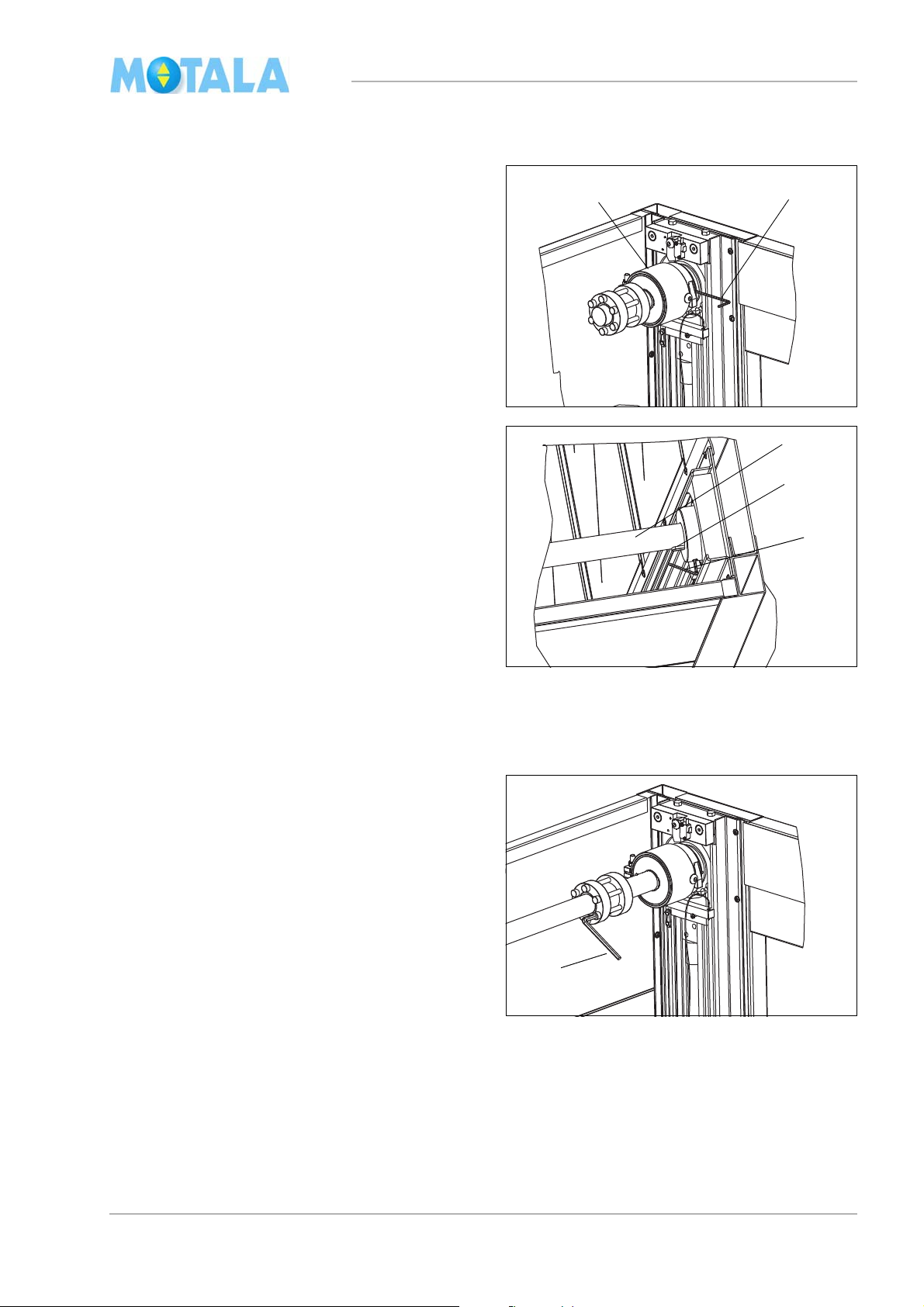

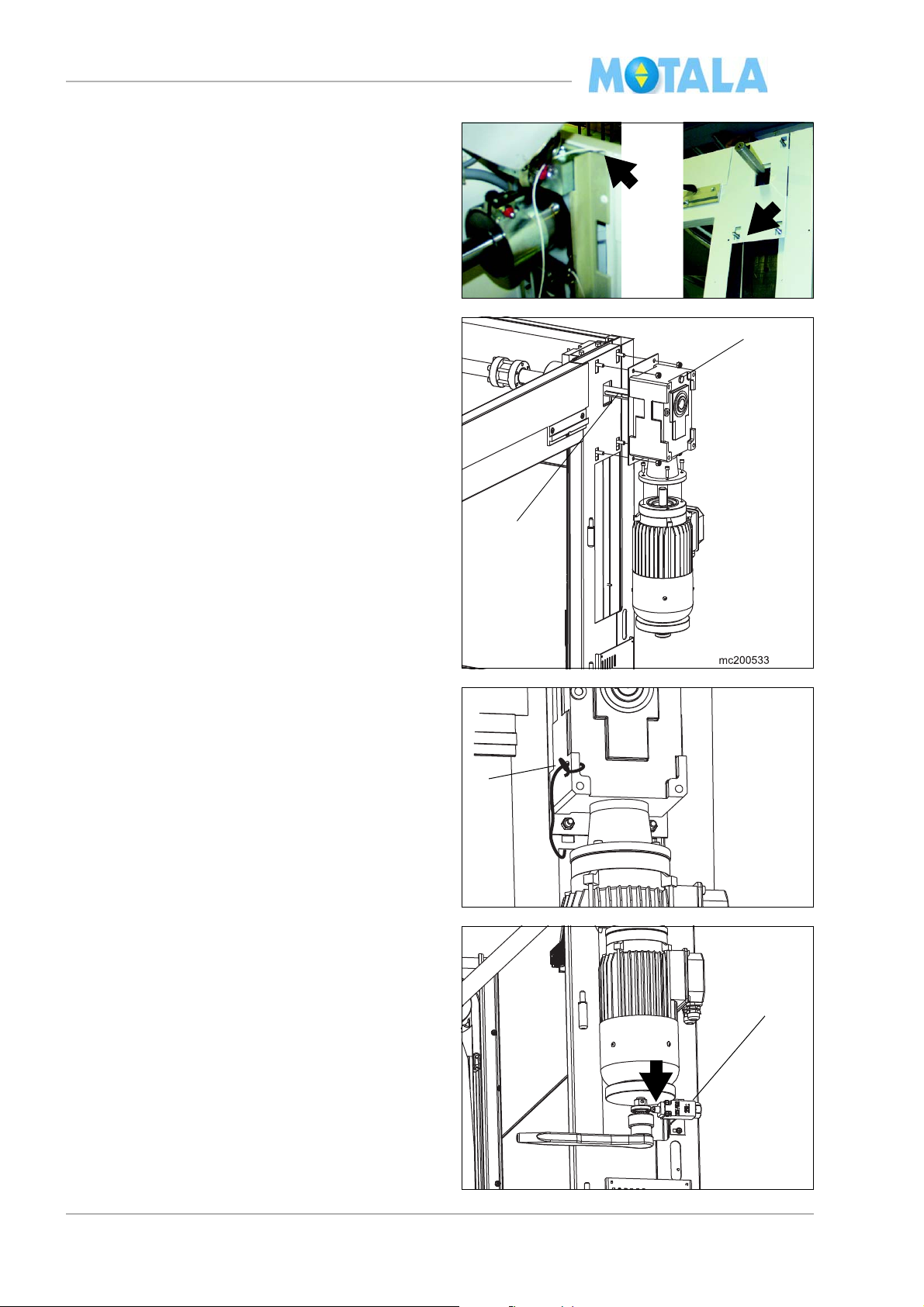

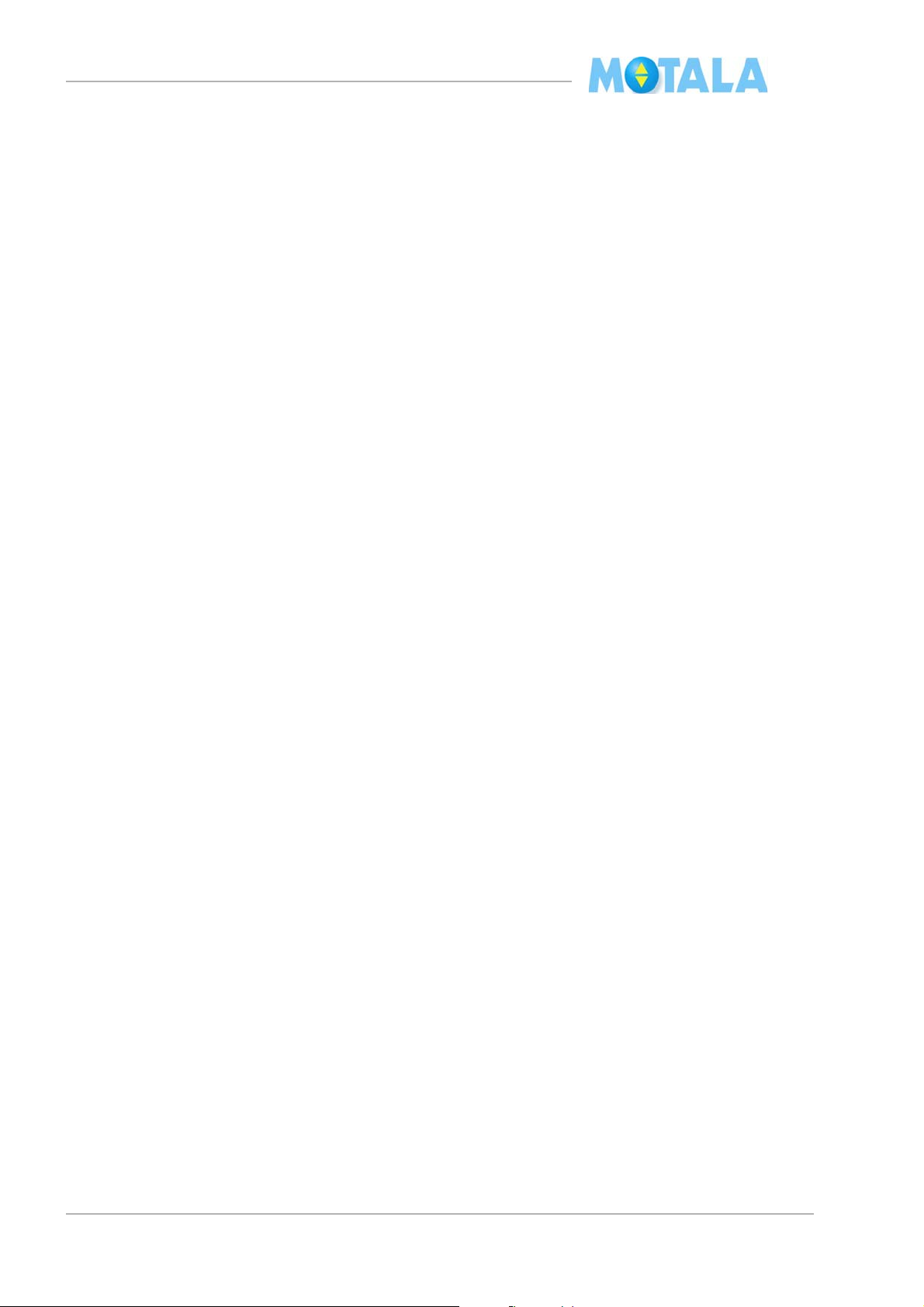

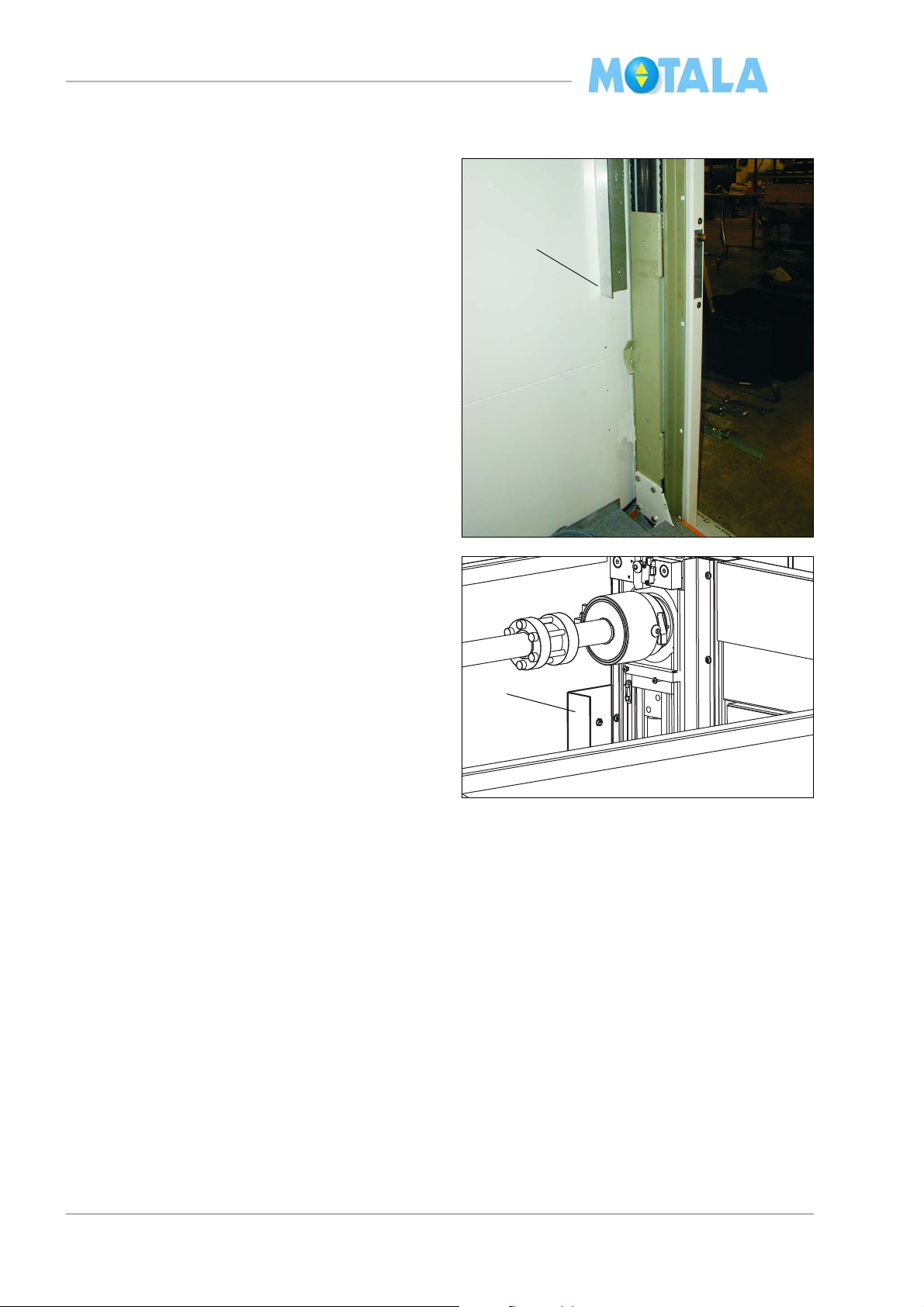

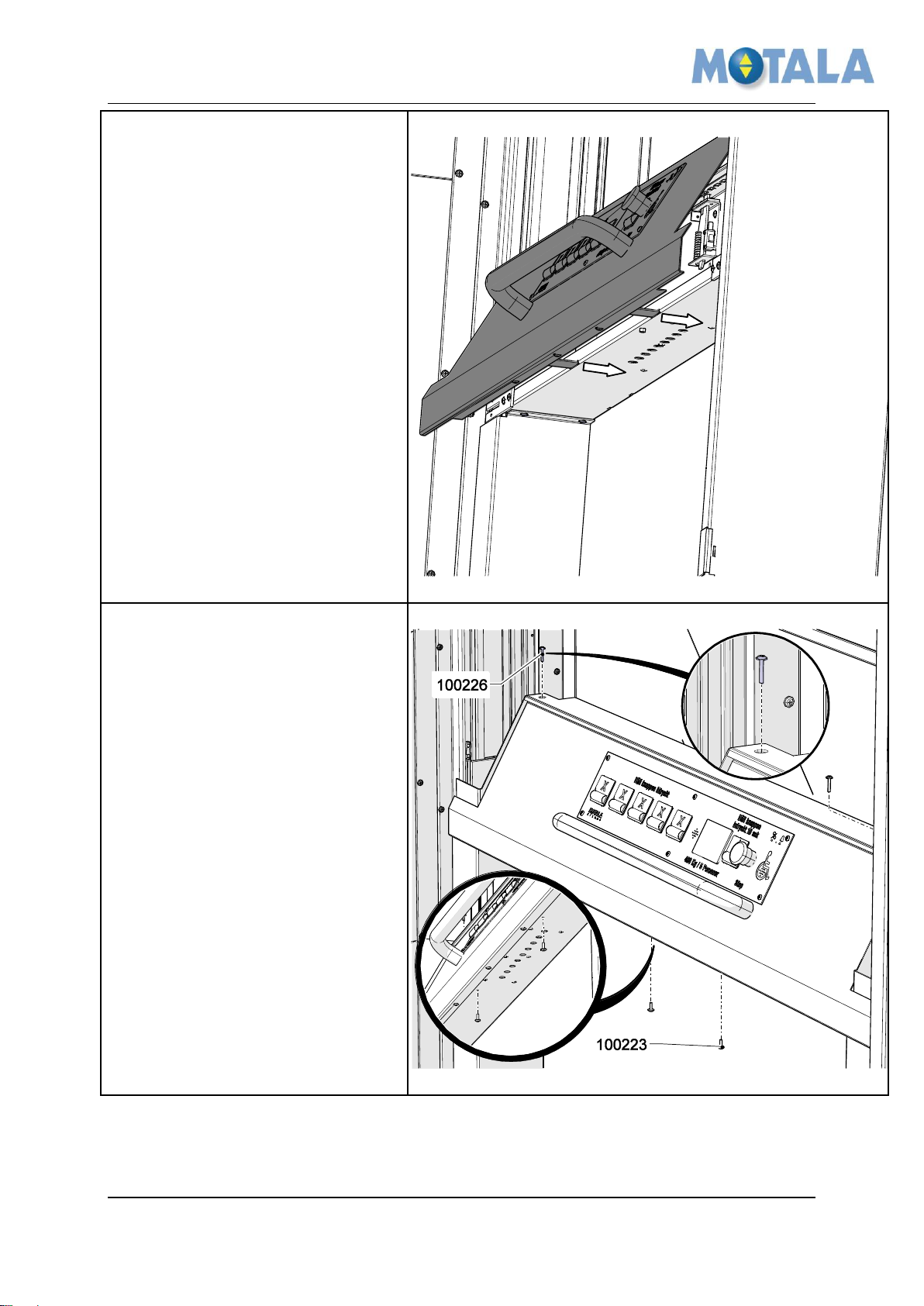

Driving shafts, gear and motor

1. Carefully push the safety gear shaft into the

sprocket wheel on side A of the lift. Note!

Do not use force!

2. Fasten the lock screw (use a 3 mm socket

ch).

wren

3. Carefully insert the long driving shaft into

si

de A. Check that the shaft reaches the

very bottom of the sprocket wheel bearing

in the turning case. Maximally 20 mm of the

keyway should be seen. Note! Do not use

force!

4. Fasten the lock screw (use a 4 mm socket

ch.)

wren

5. Loosen the four M10 screws (transport po-

sition) on each slide so that the shafts can

ned by hand. (Note! These screws

be tur

will be needed later for platform fitting.)

6. Measure and adjust the chain joints of the

two gui

de rails so that they are at the same

distance from the turning case.

7. Pull the shaft coupling tight crosswise (use

6 mm socket wrench 41 Nm).

a

27

MC2000 – Assembly Instruction Manual

10

9

mc200534

11

mc200535

28:

8. Thread on the test device cord of the safety

gear through the hollow space between the

guide rail and the door frame.

9. Fit the two keyways on the short driving

ft before installing the motor package.

sha

10. Change the oil plug at the top of the gear

or the enclosed plug with vent holes.

f

11. Tie the test device cord of the safety gear

n an empty screw hole on the gear.

i

12. Fasten the hand wheel contact 28: with

rews. The contact must be activated be-

sc

fore the hand wheel tool enters the teeth.

28

MC2000 – Assembly Instruction Manual

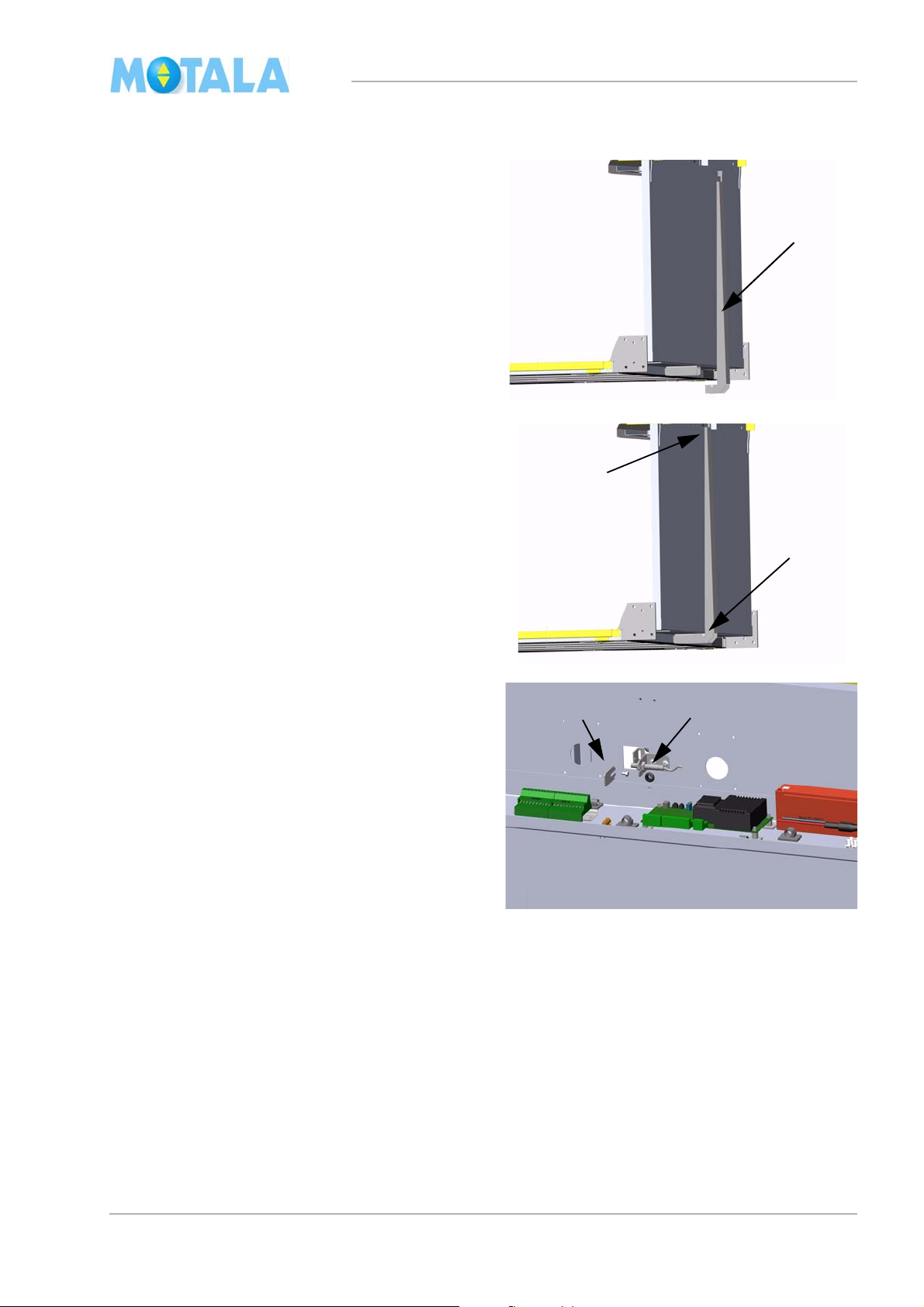

Connecting pit functions

Connect the cables according to the electrical

diagram of the lift. The bottom floor is called

“landing 0” in the diagram.

1. Fit temporarily and connect the terminal

oor switch (marked with an arrow in the il-

fl

lustration). The friction roller should be

aced at least 40 mm from the outer edge

pl

of the guide rail. (The position is to be adjusted later).

2. Fit and connect the pit prop, contact 155:1

and the

electrical drawings

3. Fasten all cables in the side wall of the lift

wel

4. Fit the pit prop cover.

position contact 155:2. See in the

l.

29

MC2000 – Assembly Instruction Manual

Connecting control panel wiring

1. Connect the cables in the control panel according to the electrical diagram.

• Do not cut the cables too short.

• Unload the cables with cable tie.

• Import

ant! Make sure there is no lead

connected to terminal input 15 on the

PLC! Impulse function!

Connecting drive command box

Safety

Use the approved drive command box from

Motal

a Hissar (with emergency stop).

Note! For your own safety and that of other

ons, disconnect the control voltage for

pers

the call buttons, connected to terminals X1/

47 and X1/48. See the electrical drawings.

1. Connect the emergency stop to block X1/3

and X1/

10 in the controlpanel. Important!

This is the same terminals where the

platform safety contacts will be connected later. The command box shall be

sconnected before connect the plat-

di

form safety leads.

2. Connect the lift drive wires. Connect the

ply to terminal X1/24V, upwards drive to

sup

X1/42 and downwards drive to X1/41. See

the electrical drawings.

x

30

MC2000 – Assembly Instruction Manual

mc200536

mc200544

8

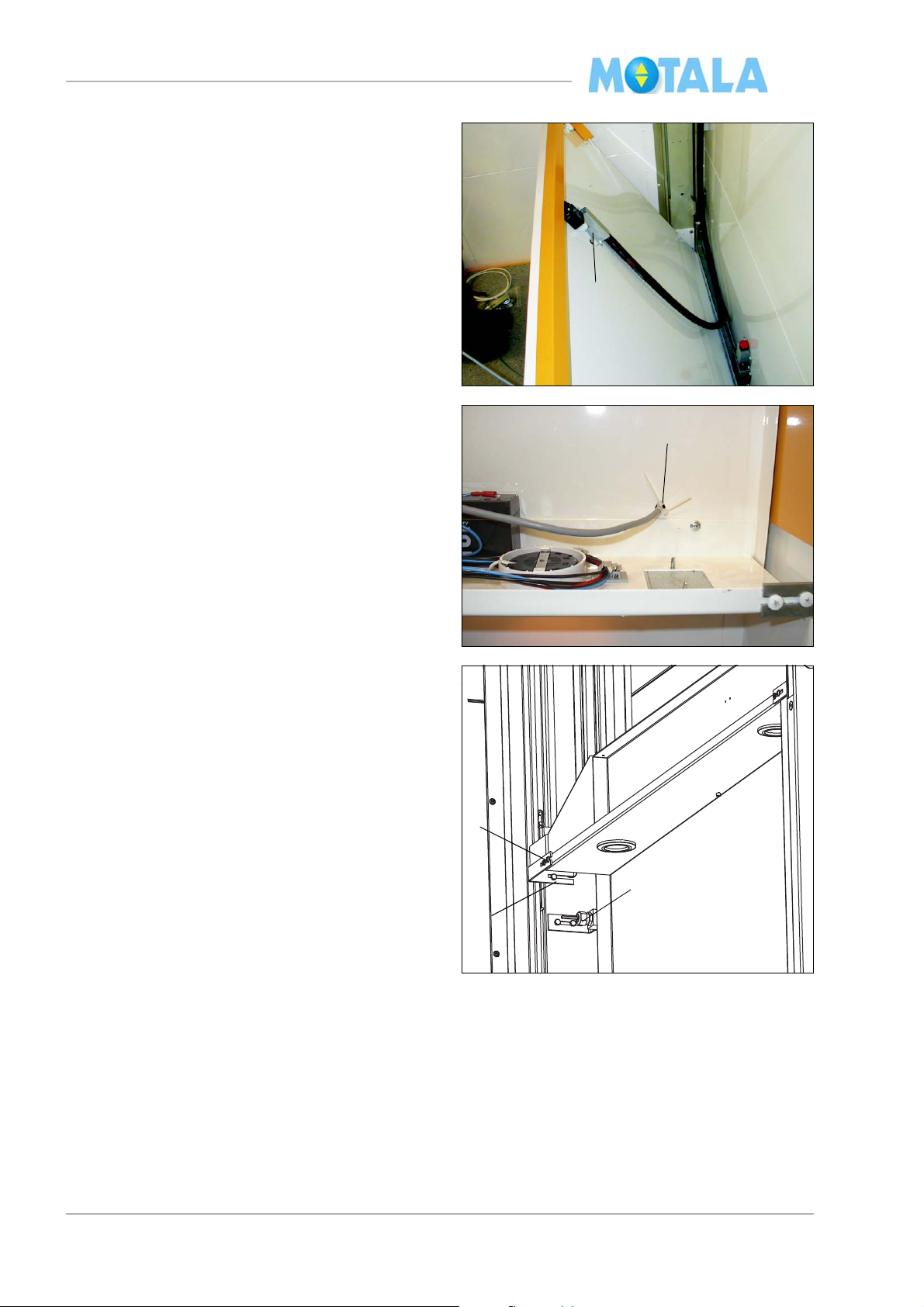

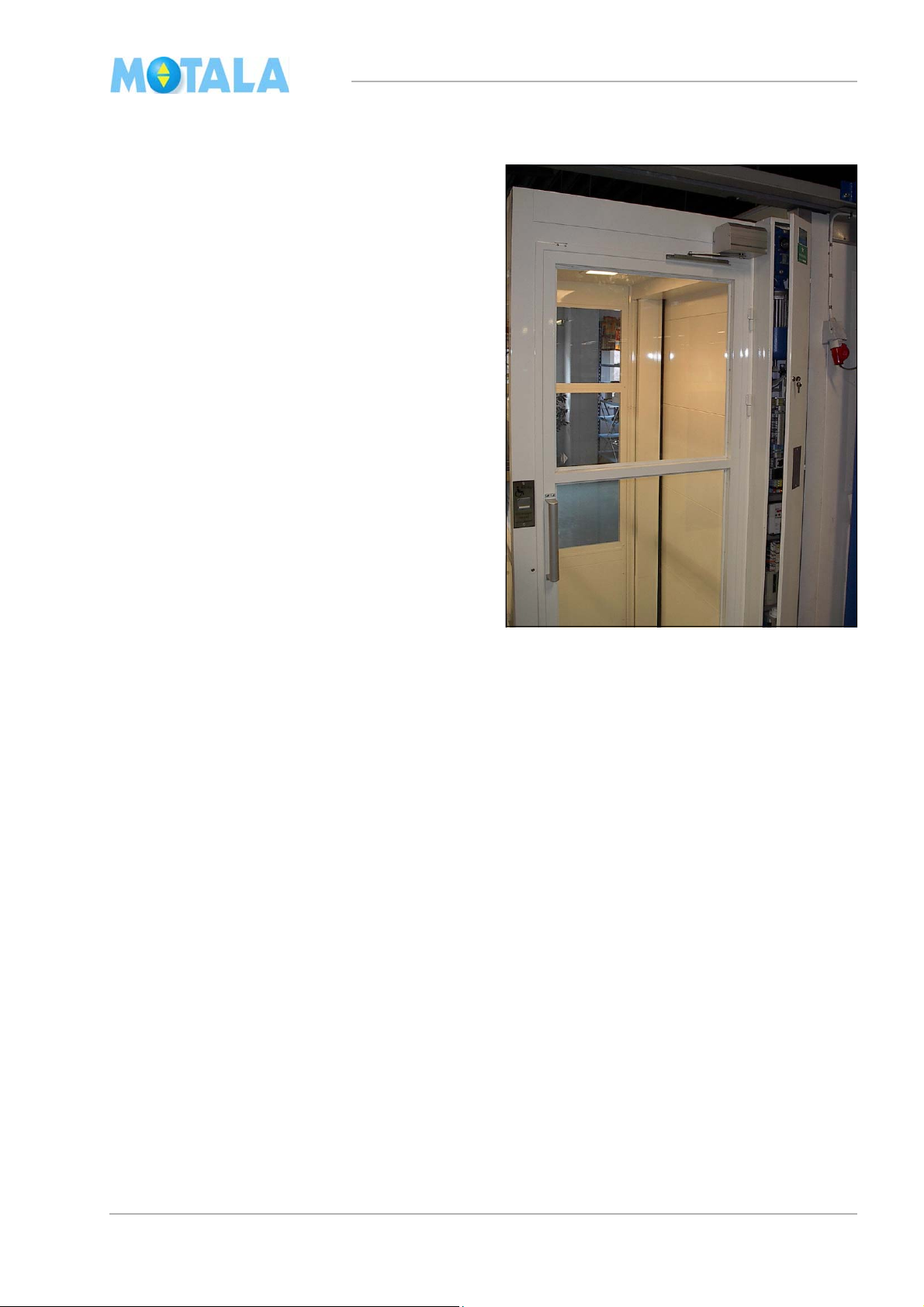

Door panel and removal of work platform

1. Secure the door openings so that nobody

can accidentally fall into the lift well.

2. Install all the sills loosely except on landing

here the sill should be fitted properly af-

0 w

ter fastening the lift well.

3. Hang up the doors.

4. Remove the work platforms and close the

s as the platforms are being removed.

door

5. Adjust the doors and the lock box. (There

d be an approximate play of 1 mm.)

shoul

Adjust by loosening the screw above the

lock box, push the loose wedge upwards or

downwards.

6. Fasten the screw.

7. Install the door closer or electric door

opener

, with the exception of landing 0

where only the door panel should be fitted.

The door closer is fitted after the fastening

of the lift well.

8. The electric door opener moment is factory-set.

The adjustment of door opening times for electric door openers is made later. See separate

tructions in the electrical diagram.

ins

31

MC2000 – Assembly Instruction Manual

2

Commencing with drive command box

1. The safety circuit must be whole in order to

drive, i.e. stop circuit, door circuit, lock circuit etc.

2. Switch on the supply voltage.

3. Check that the slides of the platform goes

n the right direction in relation to the con-

i

tactors. If they go in the wrong direction,

nge motor phase.

cha

The lift will only go down after the current

has been discone

The lift has PLC control, so you can only drive

landing 0 the first time, in order to reset the

to

PLC program after the current has been disconnected. You may need to adjust floor 0 limit

tch now.

swi

cted!

Chain jointing rod

1. With the drive command box, drive the

slides almost to the top so that the chain

ends are reachable from landing 0.

2. With a big screw driver, press the lower

of the chain upwards. Measure the de-

end

sirable length of the jointing rod.

3. Measure and drill a new hole (diameter 6.0

mm) in t

ends.

4. Fit the jointing rod with connecting links.

5. Perform the same procedure on the other

cha

6. Drive the slides down.

he jointing rod. Cut and bevel the

in.

32

MC2000 – Assembly Instruction Manual

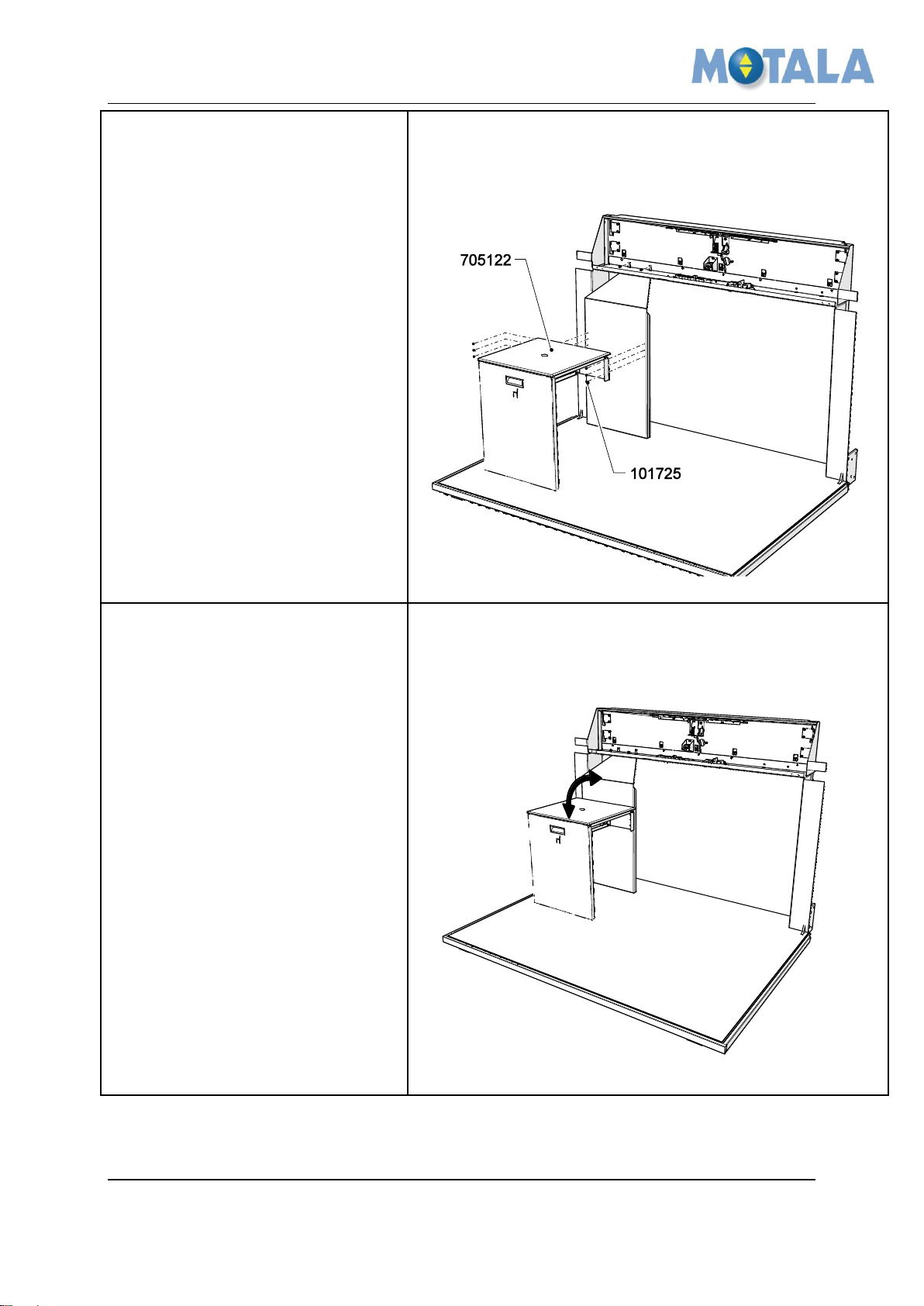

Platform

1. Lift the floor panel from the floor frame.

2. Carry the floor frame into the lift well and

ld it downwards.

fo

1. Fasten the floor frame in the slides, using

ght M10 screws. Lift and adjust the floor

ei

frame into position with a crowbar so that

the screws can be fastened lose by hand.

2. Fit if nesisary schims “in pairs between”

atform fixing and slide. If yo need to put

pl

more than one pair of shims to fill up the

gap, you shall share them equal only in

pairs to both fixings.

3. Fasten the screws with 55 Nm

4. Put an adhesive run on all the floor frame

ossbars.

cr

33

MC2000 – Assembly Instruction Manual

3

4

5

5. Install the floor panel. Check that the bentdown edge of the floor panel is in close

contact with the floor frame.

6. If necessary, fine-adjust the diagonal

measur

e of the lift well so that the platform

can run freely and smoothly through the

whole lift well.

7. Check with a spirit-level that the platform is

izontal. If it needs adjusting, see below.

hor

Fine adjustment of the platform

1. Run to the topmost landing.

2. Push the emergency stop.

3. Place a 12 mm drill steel or a screw be-

tween the sprocket wheel of the driving

ft and the chain.

sha

4. Lock the drill steel/screw by lowering the

atform somewhat with the hand wheel

pl

tool.

5. Loosen the terminal coupling of the driving

ft.

sha

6. Measure with a spirit-level and adjust with

he hand wheel tool to make the platform

t

floor horizontal.

7. Fasten the terminal coupling (41 Nm).

8. Raise the platform somewhat in order to re-

move the drill steel/the screw.

9. Note! Do not forget to remove the drill

eel/the screw.

st

34

MC2000 – Assembly Instruction Manual

3

5

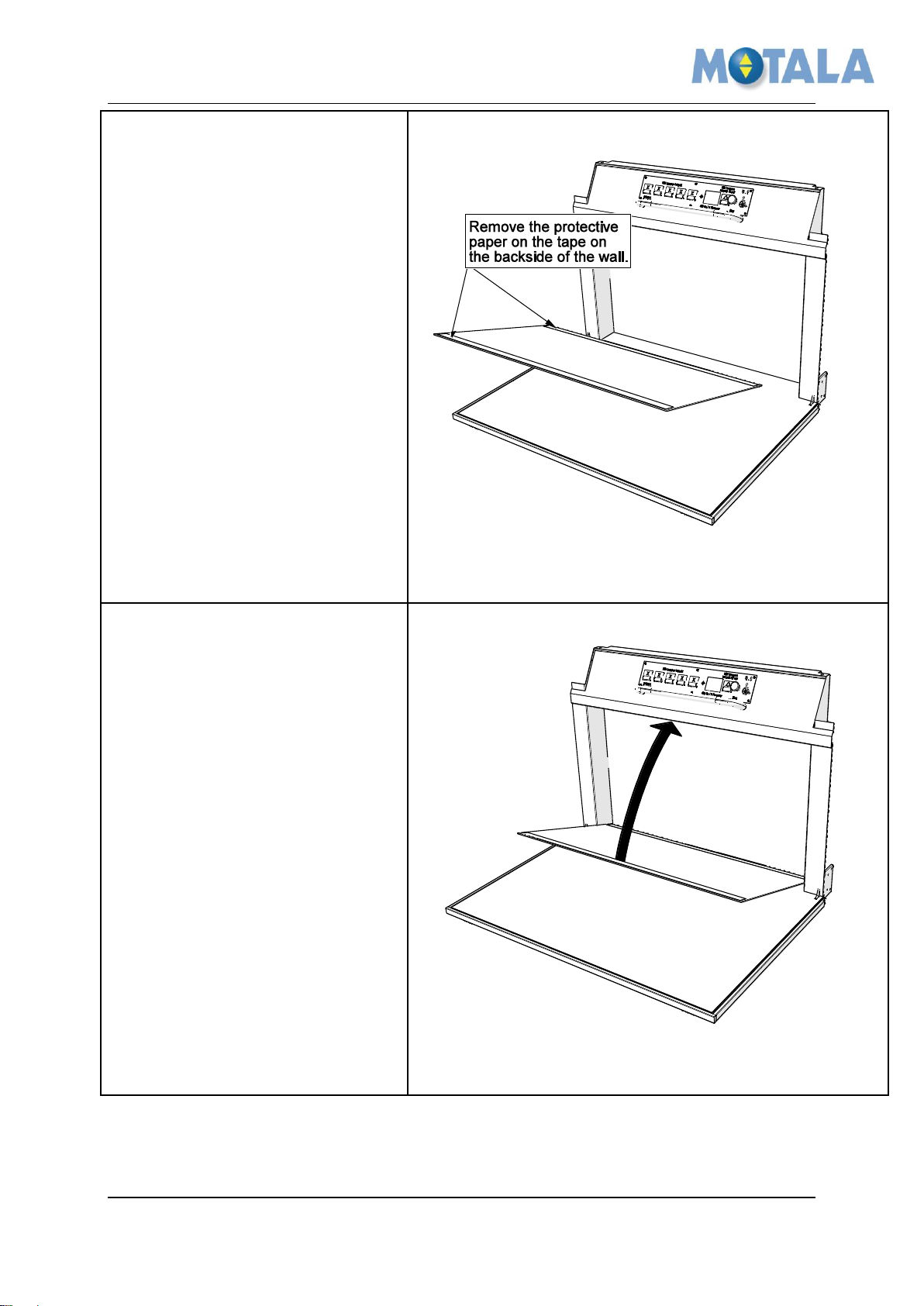

Fixing lift well

1. Fasten the lift well in the pit with bolts. One

bolt for each guide rail and two in the notch

of the door frame.

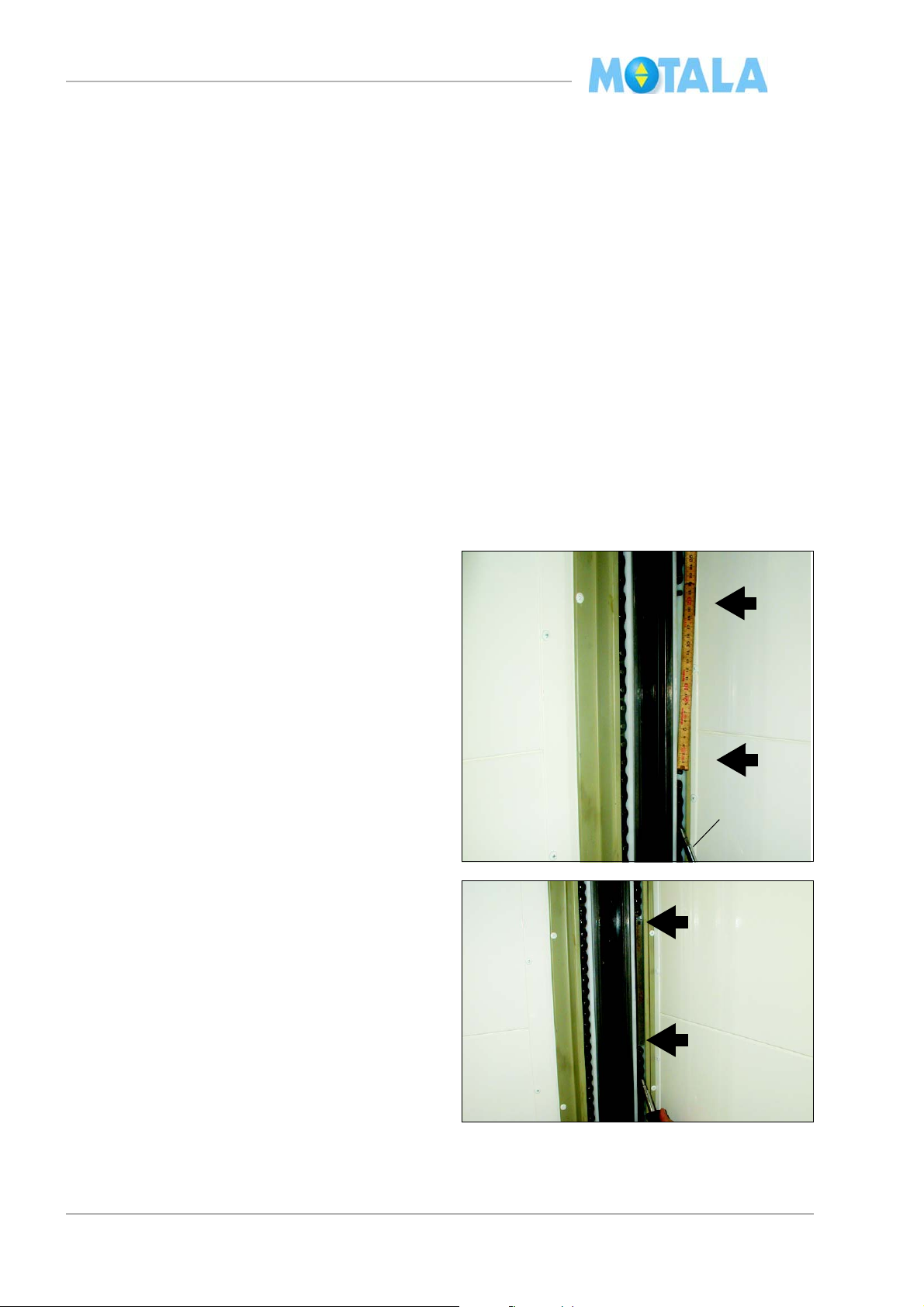

Sills

1. Lift or hang off the lower door (landing 0)

te

mporarily and install the sill.

2. Install the door opener/door closer for landing 0.

3. Secure the sills on all landings with screws.

4. Check that the opening between the sill

and the door

If the opening is wider, fit the door plate

onto the inside of the door. This does not

apply to landing 0.

panel does not exceed 6 mm.

5. Placing of door plate.

35

MC2000 – Assembly Instruction Manual

1

mc200538

3

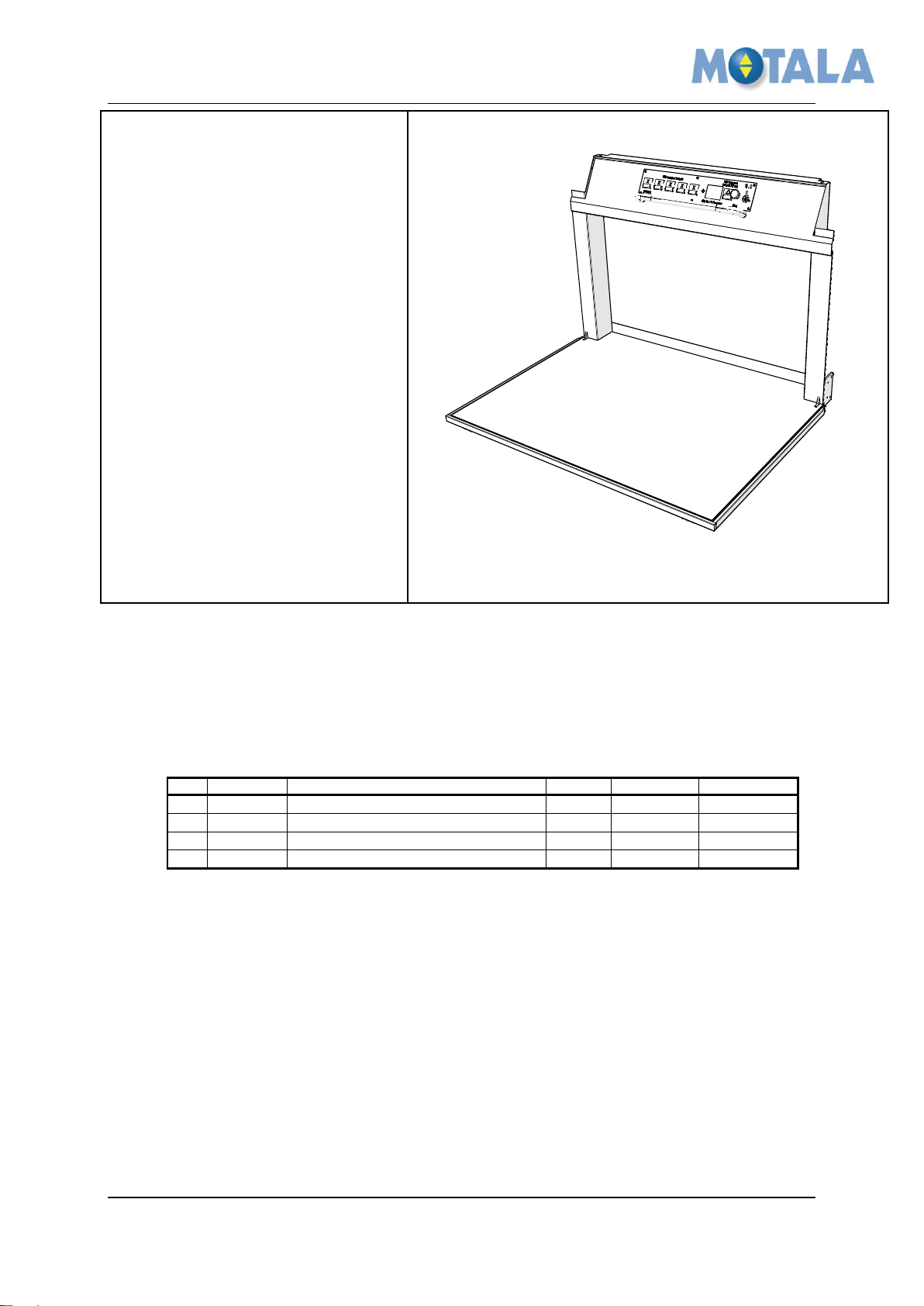

Fixing plates

1. Secure the fixing plates (90x50x2000 mm)

for the “large cover plates” of the guide rails

with screws. The fixing plates must be

edge to edge with the flange of the corner

profiles. Start from the bottom, 50 mm from

the pit. Note! You now have to loose the

62:N switch and re-install it up on the fixing

plate.

2. Make notches for cables and wires, if any.

Applies to two-entrance lifts and open ad-

(

jacent lifts.)

3. The fixing plates must end where the top

urning cases of the guide rails begin.

t

Check that the safety gear can rotate

freely.

36

MC2000 – Assembly Instruction Manual

1

2

3

4

Travelling flex cable, panel plate, overload unit and control panel

1. Run the lift to the topmost landing.

2. Lower the flex cable (1) with the platform

rminals in the end on the opposite side of

te

the door on floor 0. The unpeeled part of

the cable should reach the pit precisely.

Lower the cable another 1150 mm.

3. Secure the travelling cable with U-fasten-

ers (2).

4. Fasten the remaining parts of the travelling

e with U-fasteners. The cable must not

cabl

run down further than 180 mm from the

well top. Check that no cables can touch

the driving shaft. Note! If the lift has an

electrical emergency lowering device (3).

Also leave place for that.

5. Install the protection over the safety gear

).

(4

6. Fit (if any) the electrical emergency lower-

ing device. Route the cables 28 and 29 to

e control panel.

th

7. Switch off the supply voltage of the lift,

ute and connect the travelling cable to

ro

block X1 in the control panel.

8. Switch on the supply voltage of the lift,

ive down to landing 0 and switch off the

dr

power.

9. Fit the retiring ramp on the same side as

e motor is fitted. A-side.

th

10. Attach the panel shelf with electric equip-

ment on the panel plate of the platform.

37

MC2000 – Assembly Instruction Manual

10

11

13

12

15

11. Place the panel plate on the platform.

12. Thread the travelling cable through the

e “nearest the side as the cable hangs

hol

on” in the panel plate and secure the cable

with U-fasteners. Note! Check that the

screws are not placed under the panel

shelf or damage the shelf components.

13. Thread the cable from the floor sensitive

contacts trough the hole. Stretch it

edge

and lock it with cable tie.

14. Fasten the two angle brackets for the panel

lf with hexagon-headed screws, M6x10,

she

and plain washers in each slide.

15. Fasten the angle brackets in the panel

ate with self tapping screws. Adjust the

pl

position of the brackets with the screws so

that the panel plate is in an exact central

position between the slides.

16. Adjust the distance between the sensetive

list of the panel plate and the lift well

edge

wall. The distance should be 10-15 mm,

maximally 15 mm. Adjust the distance by

loosening the hexagon-headed screws.

17. Fasten the fixing with contacts 66:,61: (if

) and 51: in the upper pre-drilled holes

any

in the slide on the opposite side of the side

where the motor is placed.

38

MC2000 – Assembly Instruction Manual

1

2

3

4

5

Overload unit

Bring the platform to the middle of the door

ng so you can reach to fit the overload

openi

arm (1) from underneath.

Fit with screws in the pre-drilled holes nearest

nner corner (2).

the i

Adjust the distance between arm and panel

te to be15mm at the end of the arm (3) when

pla

the platform is unloaded.

Fasten the arm in the holes that remain. Use

f-drilling screws.

sel

Fit the overload flag (4) from inside of the panel.

Pre-adjust the transmitter (5) to a gap of 2mm

between

transmitter and the flag and at the

same time the distance between the edge of

the flag to centre of the transmitter to about

6mm.

Note. Do not

tighten the nuts to hard you may

damaged the transmitter.

Adjustment with load has to be made later.

39

MC2000 – Assembly Instruction Manual

Electric connections on the platform panel

plate

All electric connections are made according to

e electrical diagram of the lift. Fasten all ca-

th

bles from the slide to the panel shelf on the inside of the angle bracket with cable tie (not on

e top or bottom sides).

th

1. Connect the following cables:

• the travelling cable 51.

• the cable from the floor sensitve edge contacts 57.

• the cable from the sensitive edge of the

anel plate 56.

p

• the cables 62-65 from the high speed contact 66:, 59:, 51: and intermediate floor

ector 61:, if any.

det

• the cable 53 from the retiring ramp.

2. Connect alarm and telephone equipment, if

. Do not yet install the battery, as the

any

alarm signal might ring.

3. Push in both the stopbutton on the control

anel and the commission box.

p

4. Connect the control panel.

5. Connect the battery. Im

portant! If the lift

has the electrical emergency lowering

system as an option. The battery on the

panel is replaced with the battery in the

emergency lowering unit, suited at the

top of the shaft. You shall not in any circumstances connect two batteries!

6. Switch on the main power

7. Bring in test load on the platform.

8. Adjust by move the transmitter in or outwards. The transmitter shall light when it’s

ivated. Also check that input 0 on the

act

PLC lights up. Note. Do not tighten the

nuts to hard you may damaged the transmitter.

40

MC2000 – Assembly Instruction Manual

1

mc200542

1

mc200543

2

3

4

9. Fasten the platform panel with four screws

(1). Place the cables so that they cannot be

damaged.

Cancelling drive command box

1. Push the stop button on platform panel.

Warning! In this position, the button is connected in parallel with the emergency stop

the drive command box.

of

2. Disconnect the command box from the

rol panel.

cont

3. Reset the stop button on the platform

nel.

pa

Ceiling

The ceiling should be placed at a height of 2100

m

m above the floor of the topmost landing.

1. Fasten three L-shaped mouldings on all

ls except the wall of the drive side. Turn

wal

the side with the pre-drilled screw holes upwards.

2. Install the ceiling (4). The electric fittings (2)

d be centred in the lift well.

shoul

3. Route and the light cable 18 to the control

anel. Secure the cable on the safety gear

p

cover plate to prevent it from getting dammiged.

arning! There is power on the terminal

4. W

LJ for the light even if the main switch is

set to OFF! Connect if the power is com-

pletely OFF from the main central and also

e F8 fused shall be removed in the con-

th

trol panel.

41

MC2000 – Assembly Instruction Manual 2011-10

5

3

4

5. Important! Fasten the ceiling in the L-

shaped moulding with screws from underneath (5).

Commencing from platform control panel

1. Switch the main switch 220: to ON. Note!

The lift is equipped with PLC control so it

will run down to landing 0 in order to reset

the PLC program, no matter which button

you push.

2. Run to the upper terminal floor, to exactly

correct height.

3. Install the terminal floor stop switch so that

the roller of the arm is in close contact with

the slide. Check that the arm cannot get

stuck against the edge of the guide rail.

Fasten the cable.

4. If the lift has more than two landings, run it

down and install intermediate floor magnets. Switch the supply voltage off and on

and run to landing 0 in order to reset the lift.

• Note! The size of the magnet is15X30 mm

and must be fitted vertical. (Changed from

horizontal to vertical in okt 201 1 from control

panel No 6000 and higher)

42

MC2000 – Assembly Instruction Manual 2011-10

1

1

Lock arms

5. Run the lift to an exact position on each

floor and fit the lock arm. When the lift is on

a certain floor, the roller of the lock arm

should be in the centre of the ramp. Note!

There is an exception for the bottom and

top floors: there, the lock arm should be fitted so that, when the lift reaches the floor,

the roller has just reached the flat part of

the ramp.

6. Adjust the length of the lock wires by cutting the outer cover so that it reaches the

lock arm. Let the inner cover run a short

distance through the lock arm sleeve. Pull it

down and fasten excessive wire in the recess of the arm.

Highspeed contact and magnet

1. Adjust the distance of the floor counting

contact 61: (if any) and highspeed contact

to 7 mm from the lift well wall.

2. Fasten the highspeed contact magnet (1)

at every floor. Adjust the magnet so it

starts and ends 50 mm from the floor in

question.

43

MC2000 – Assembly Instruction Manual

2

3. Fit the final stop ramp (2) for the 51: contact at the top and ground floor. The switch

uld be effected by the ramp if the lift

sho

runs more than 15mm above the top floor

and 15mm below the ground floor. The

ramp shall align against the angle plate

corner.

Lubrication

1. Lubricate the C-profile guide rails. Use Superlube synthetic grease, article item

number

100401.

2. Lubricate the roller of the lock arms where

t

he wire runs.

44

MC2000 – Assembly Instruction Manual

1

2

1

Cover plates

Check before fitting cover plates

Check

• that the lift stops at the landings

+ - 10 mm.

• that the locks open properly, even if you pull

the door

• that the safety gear is placed correctly in relation to the motor position, see illustration,

and t

works.

• Check safety according to document IQ-

K98_10_C

B

Small cover plates

and call the lift simultaneously.

hat the safetygear testing function

1. Fasten the small guide rail cover plates

with pop rivets. Start from the bottom and

work upwards in the lift well. Note! Take

care not to fasten pop rivets in the locks

and cables that might be placed behind the

covers.

Shaft hood

1. Fit the drive shaft cover plate (1). The illus-

tration shows a lift with 2200 mm ceiling

ght.

hei

2. Lose the screws for the ceiling a little, so

you can push th

shaft cover plate (2).

3. Then tighten the screws to the ceiling

n.

agai

e ceiling tight against the

45

MC2000 – Assembly Instruction Manual

2

4

3

On lifts with 1300 mm ceiling height the drive

shaf

t cover plate is fastened in the same way

and is also fastened with screws from the top

side.

Large cover plates

1. Start from the bottom with the lowest cover

plates (they can usually be shorter than the

others) 50mm up from the pit.

2. Fit the next cover plates.

3. Continue with the remaining cover plates

hat measure 2000 mm. The two upper-

t

most cover plates (2) must reach about

10 mm above the edge of the drive shaft

er plate.

cov

4. Check that the safety gear can rotate

reely.

f

Cover plate, platform

5. Run the lift to the bottom position.

6. Fit the cover plates (3) with two short

rews (4). Note! Maximum length 8 mm.

sc

er screws might scratch the large

Long

cover plates of the guide rail while the lift is

running.

46

MC2000 – Assembly Instruction Manual

Finishing work

1. Fit the motor and the electric cabinet top

cover.

2. Put up all necessary signs, taking local demands into consideration.

3. Clean the lift.

4. If necessary, patch damaged paint.

5. Inform customers and working staff about

e lift and its functions.

th

Final inspection and own inspection

Make a final inspection and, at the same time,

fill in the inspection form.

47

MC2000 – Assembly Instruction Manual

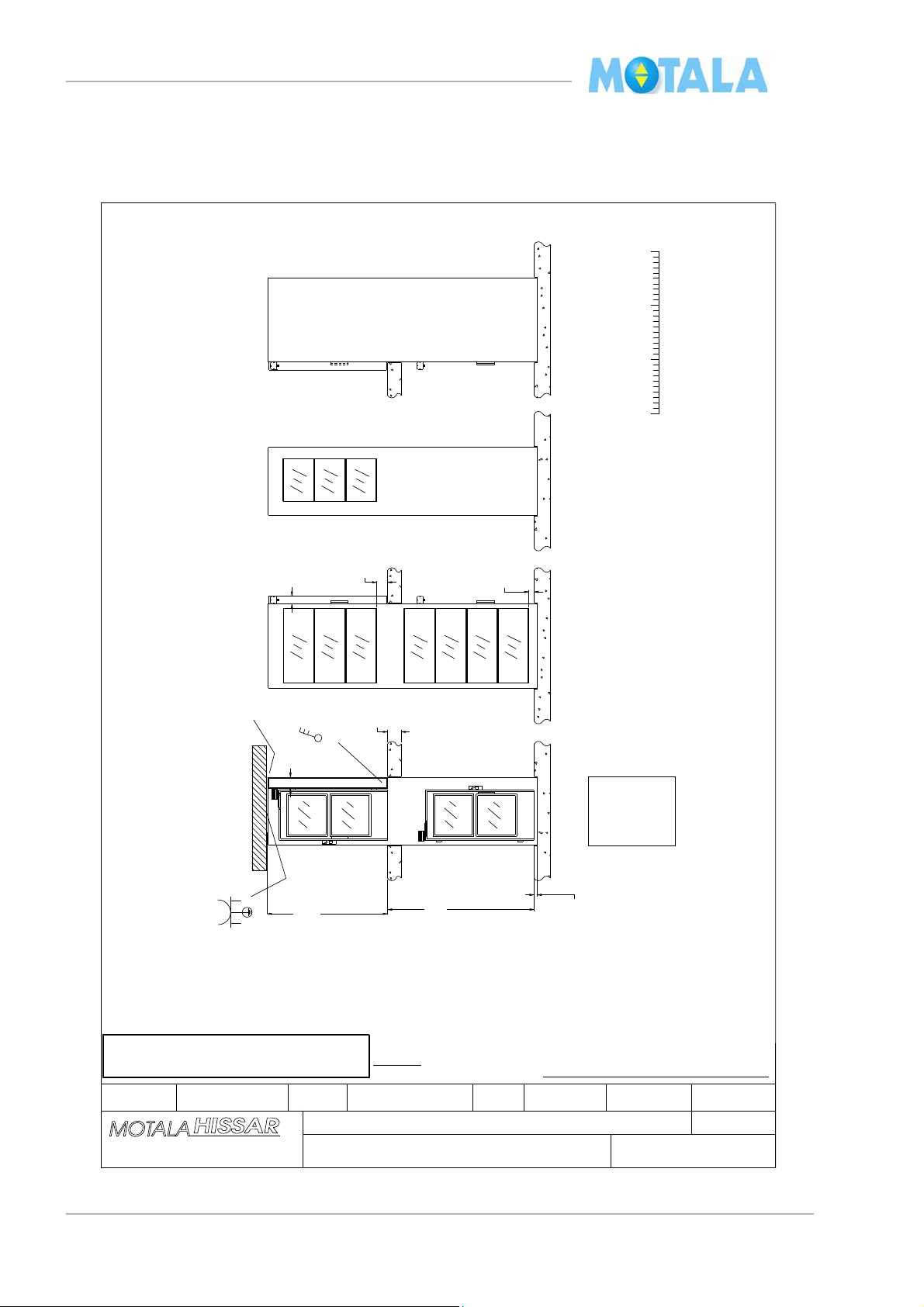

145

Pit depth

60 +5/-0

and painted

Replaces

Drawing/Lift number

Motala Lift MC2000

Object

Lift type

Note! Basic free construction heights.

Floor with automatic doors requires free height min. 2200 mm.

Floor without automatic doors requires free height min. 2150 mm.

Delivery time

Box 4029 591 04 MOT ALA

Tel +46 141 237050 Fax +46 141 237051

Drawn

RMS Produktion

Demo Mo tala Hissar

Check .ApprovedSeller Scale -Not according to scale

APPROVED with registered changes:

Purchaser’s signature:

A

A

030116

9187

Replaced by

Dat.

Scale

0 1

3m2

FF ±0

FF ±0

HIT

HISS

1590

From above

Joist hole

Width 1280

FF ±0

FF ±0

A

B

C

D

30 mm.

HIT

HISS

L1

N

1d

1d

1

Ceiling height

2200

210

FF +2700

+0/-5 mm

100

200

250

400V/10A

A

B

D

C

IMPORTANT! Please check and adjust measures, door hangers etc.

Please return the layout drawing immediately.

Floor 0

Freely plumbed

Should be horizontal

Floor

Fitting space

Depth

Layout drawing

48

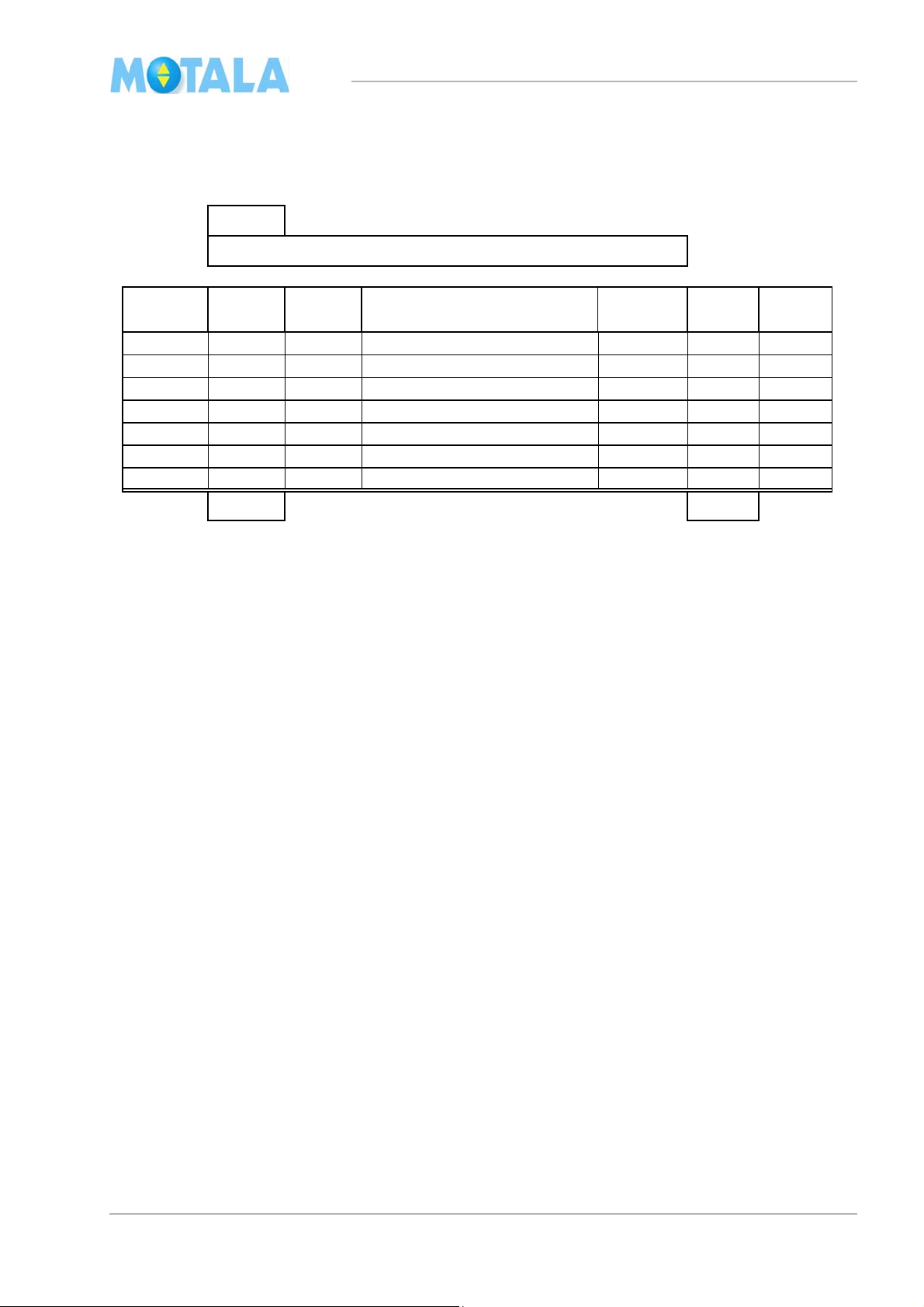

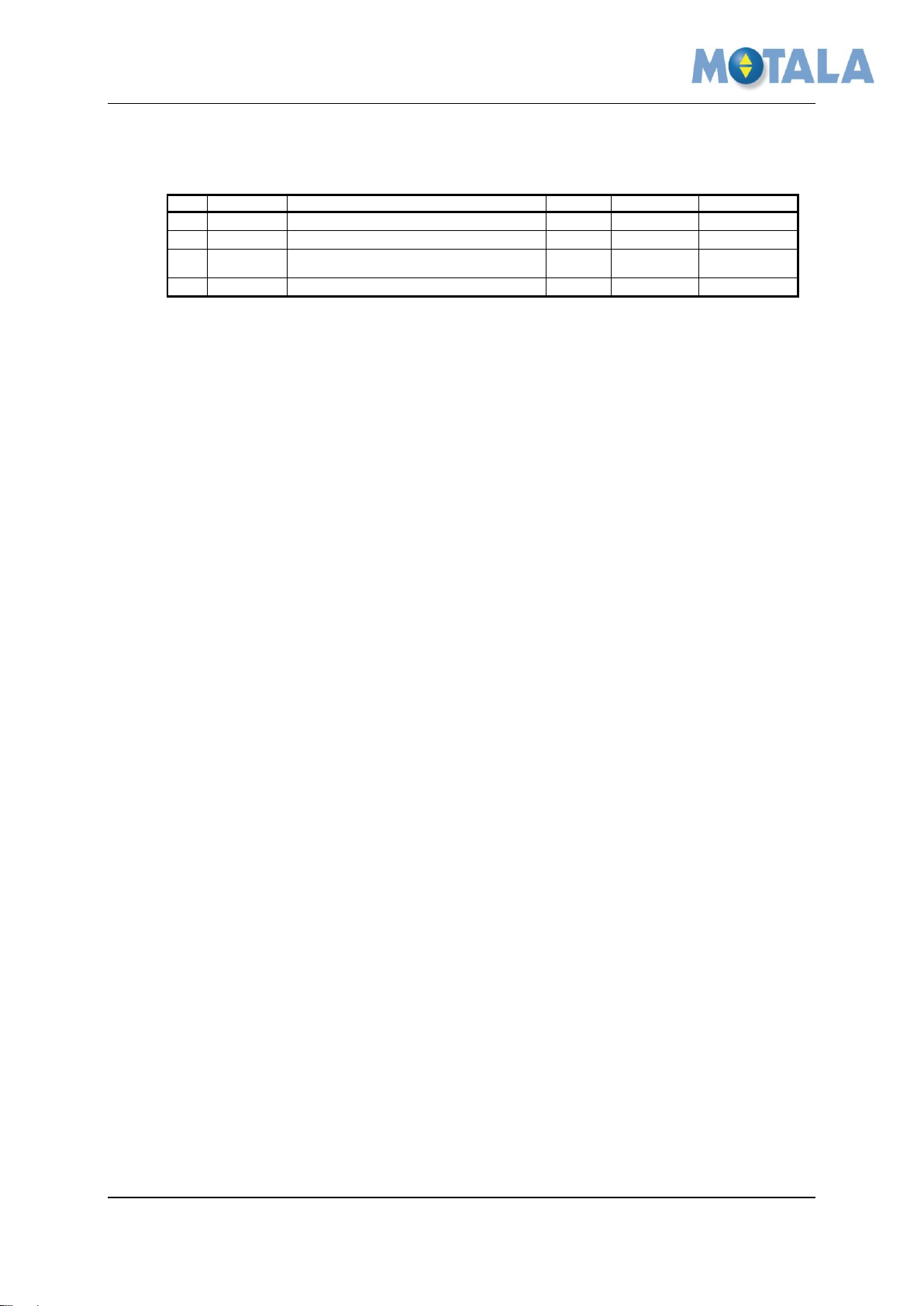

Checklist

Lift number: 9187

Project: MC2/2 Dem o Motal a His s ar

L ength

[mm]

Door

Al-prof.

Length

[mm]

Door

Al-prof.

1 2155 Door 1 2950 Al-prof.

2 535 Al-prof. 2 2010 Al-prof.

3 2270 Door 3

4 4

5 5

6 6

7 7

4960 mm Total height 4960 mm

Side A

Side C

From below

Cable hole

From below

MC2000 – Assembly Instruction Manual

49

MC2000 – Assembly Instruction Manual

Approvals and version history

Table 1:

Issue Date Description of change Ref CR Approve by

Rev.A 2005-05-04

1.01 2007-01-31 Change of version counting. See first page

Adding this side. See “Approvals and version history”

on page 50.

Headline and text modified in step 2 and 10. See

“Travelling flex cable, panel plate, overload unit and

control panel” on page 37.

New steps added for overload unit. See “Overload

unit” on page 39.

Step 3, 6, 7 and 8 added. See “Electric connections

on the platform panel plate” on page 40.

50

MC2000 – Assembly Instruction Manual

Attachments

51

MOTALA HISSAR AB

Hidden hinges

Mounting and adjustment of door with hidden

hinges

2012-04-12

Draft 2 – Method for mounting door with hidden hinges.

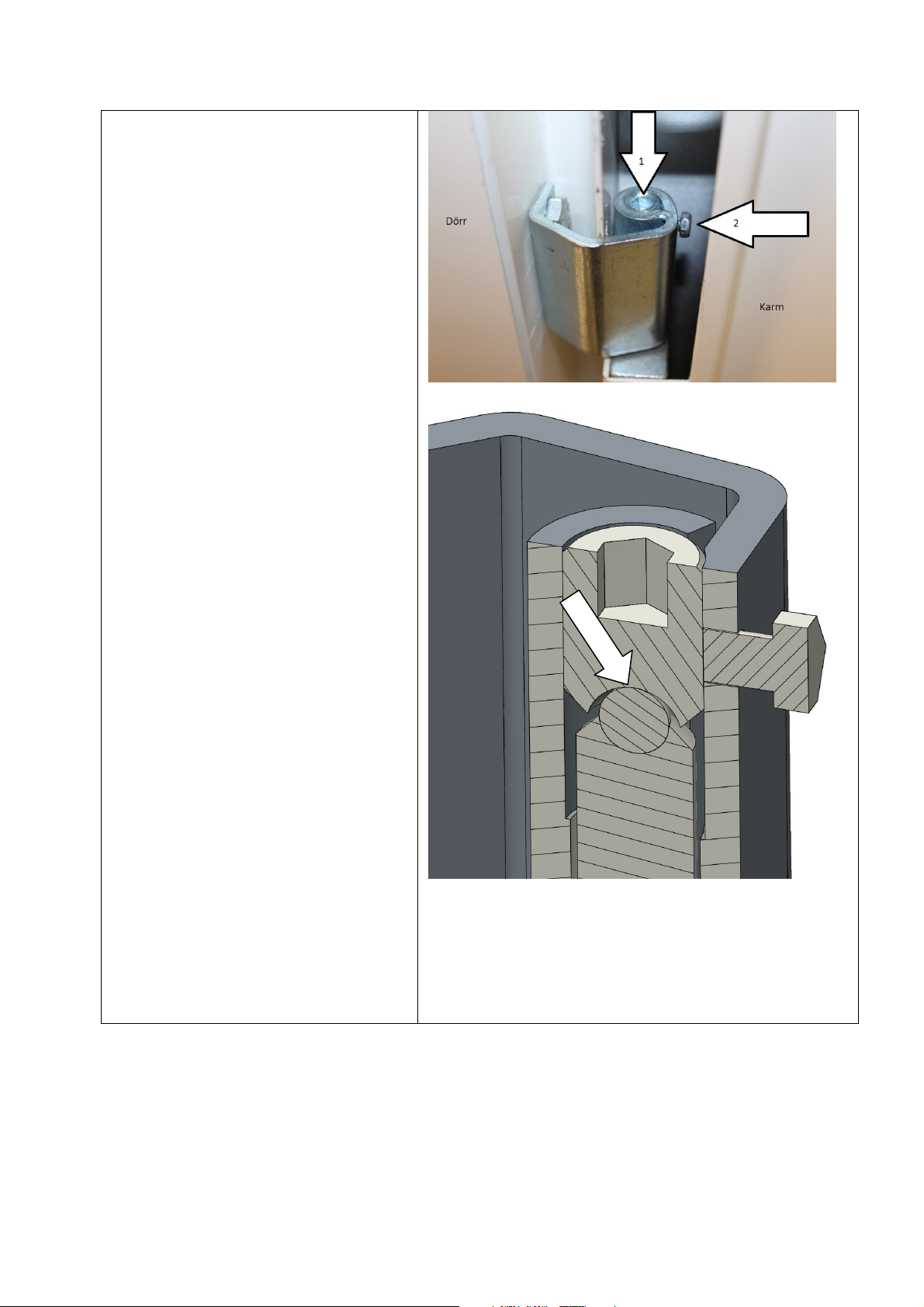

Mounting door leaf

Tips!

Hold the door leaf in about 45 degree

opening angle so that the door part of

the hinge rests against the edge of the

frame as shown, this makes it easier to

steer hinges on the pins that are

hidden inside the frame.

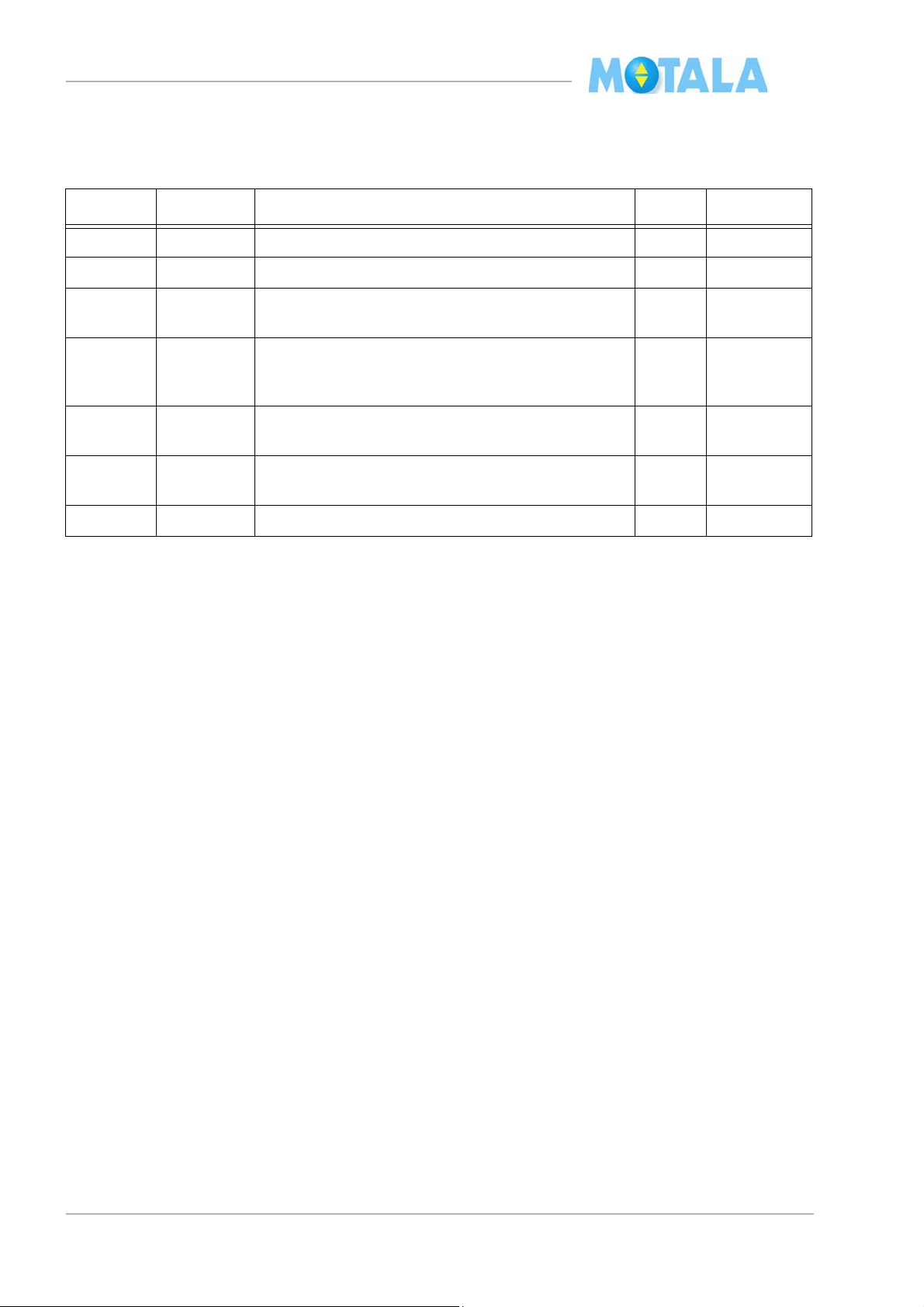

Door stop

Install the door stop (1) so that the door

is not possible to open more than 90

degrees.

Note!

If the door is opened more than 90

degrees there is a risk to damage

hinge or door frame (2).

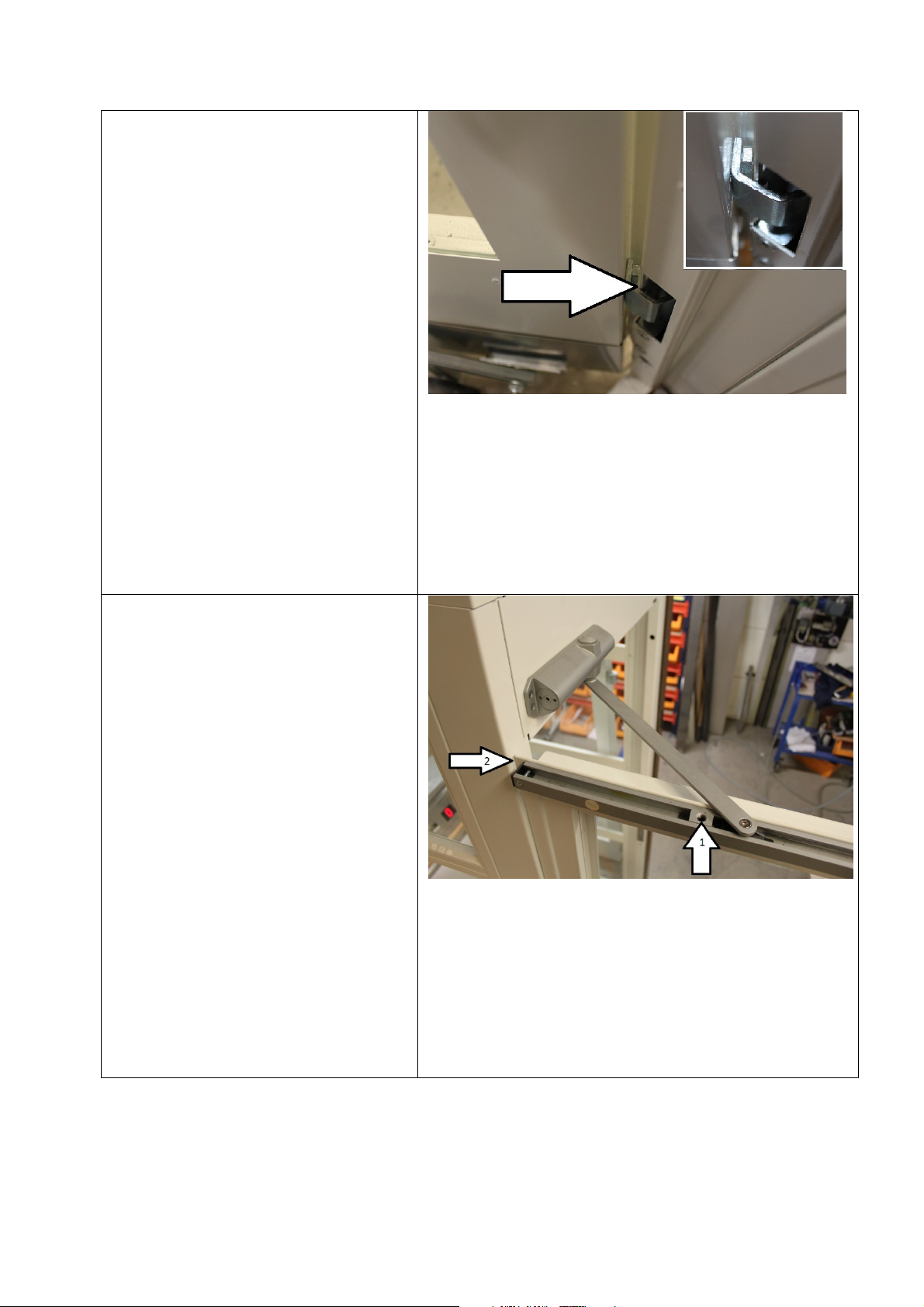

Adjusting the hinges

The hinges can only be adjusted in

height.

1. Adjust the door in height by

turning the Allen screw.

2. Lock Allen screw with hex.

Note! Adjust the upper and

lower hinge equal. The hinges

can only be adjusted in height.

Important!

Both the upper and lower hinge must be adjusted so

that the ball of the hinge rests in the cup in order to

avoid play in the hinges.

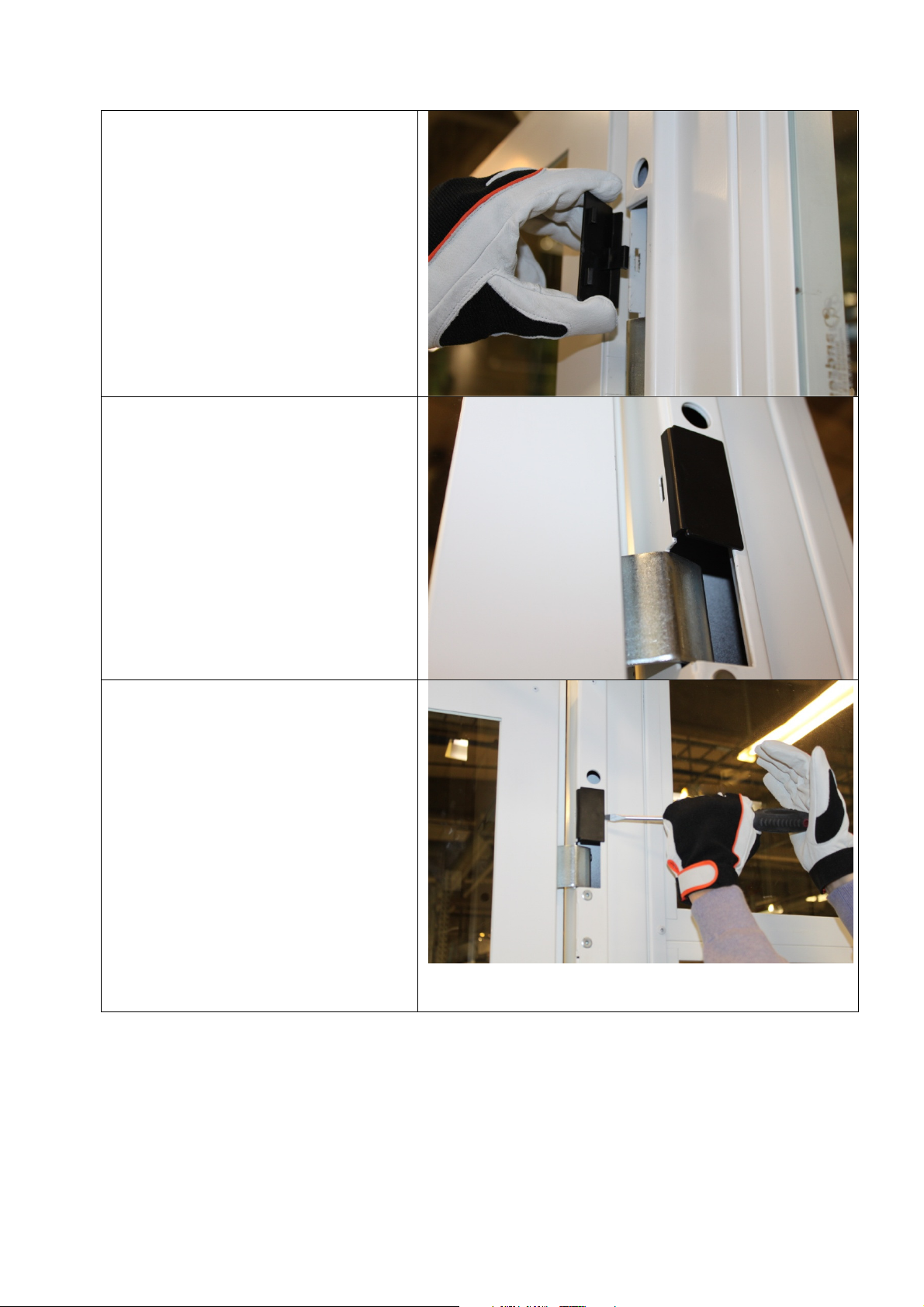

Install the cover at both hinges.

Insert the controller that fits into the

groove of the door frame and snap on

lid.

Done

Removing the cover

Press gently with a screwdriver on the

side as shown until the lid comes off.

MOTALA MC2000 – Mechanical blocking device

Instruction

Mechanical blocking device in the pit MC2000

Rev. B

© 2012 Motalahissar AB 0 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

Instruction

All rights reserved.

No part of the contents of this document may be copied, reproduced or transmitted in any form or by

any means, or translated into another language or format, in whole or part, without prior written

permission of MOTALA HISSAR Corporation.

CONTACT:

MOTALA HISSAR AB

Luxorgatan 1

BOX 4029

591 04 MOTALA

+46 141 23 70 50

www.motalahissar.se

© 2012 Motalahissar AB 1 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

Instruction

TABLE OF CONTENTS

1. GENERAL .................................................................................................................3

RELATED DOCUMENTS ..................................................................................................3

2. SAFETY .....................................................................................................................3

3. FASTENERS USED IN THE INSTALLATION INSTRUCTION ................................3

4. OVERVIEW................................................................................................................4

MECHANICAL BLOCKING DEVICE ....................................................................................4

THE OPERATING HANDLE TO THE MECHANICAL BLOCKING DEVICE ....................................4

5. INSTALLATION ........................................................................................................5

MOUNT THE FIRST BRACKET..........................................................................................5

MOUNT THE COVER PLATE BRACKET ..............................................................................5

MOUNT THE SECOND BRACKET .....................................................................................6

MOUNT THE FIRST PULLEY ............................................................................................6

MOUNT THE SECOND PULLEY ........................................................................................7

EXAMPLE OF PULLEY PLACEMENT ..................................................................................7

MOUNT THE OPERATING HANDLE AND THE WARNING SIGN...............................................8

MOUNT THE WIRE .........................................................................................................8

MOUNT THE PLATFORM FRAME ......................................................................................9

MOUNT THE MECHANICAL BLOCKING DEVICE ..................................................................9

ADJUSTMENT OF THE WIRE ........................................................................................ 10

REMOVE SLACK IN THE OPERATING HANDLE AND WIRE. ................................................ 10

MOUNT THE RETIRING RAMP AND LIMIT SWITCH CAMS .................................................. 11

MOUNT THE LIMIT SWITCHES ...................................................................................... 11

ADJUSTMENT OF THE LIMIT SWITCHES POSITIONS ........................................................ 12

6. APPROVALS AND VERSION HISTORY .............................................................. 12

© 2012 Motalahissar AB 2 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

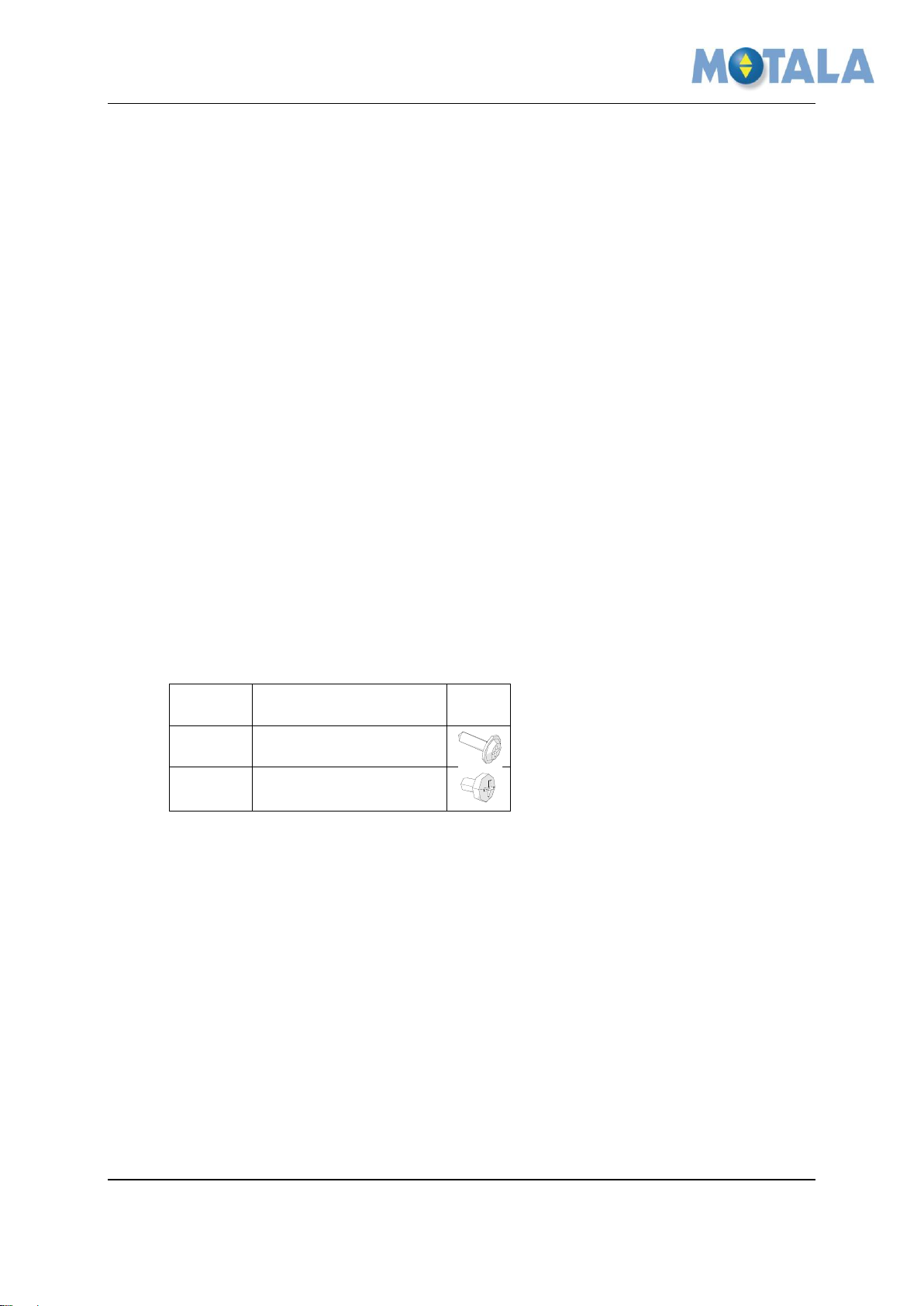

Number

Description

view

100223

Staps 4,2x14 CS Ph2

100197

RXS B8x16

102040

MC6S M4x8

100179

M6S M10x16

100136

MC6S M6x10

Instruction

1. GENERAL

This mechanical blocking device are special designed to be fitted on MC2000. Follow this

instruction carefully to ensure an efficient and trouble-free installation.

Related documents

This instruction is to be used with the MC2000 installation instruction.

2. SAFETY

Personal safety precautions for fitters.

Always use Personal Protective Equipment (PPE). Always use Head protection, Eye

protection, Foot protection, Hand protection, Protective clothing, Face shield and

Safety harness.

Follow the safety precautions in the MC2000 installation instruction.

3. Fasteners used in the installation instruction

© 2012 Motalahissar AB 3 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

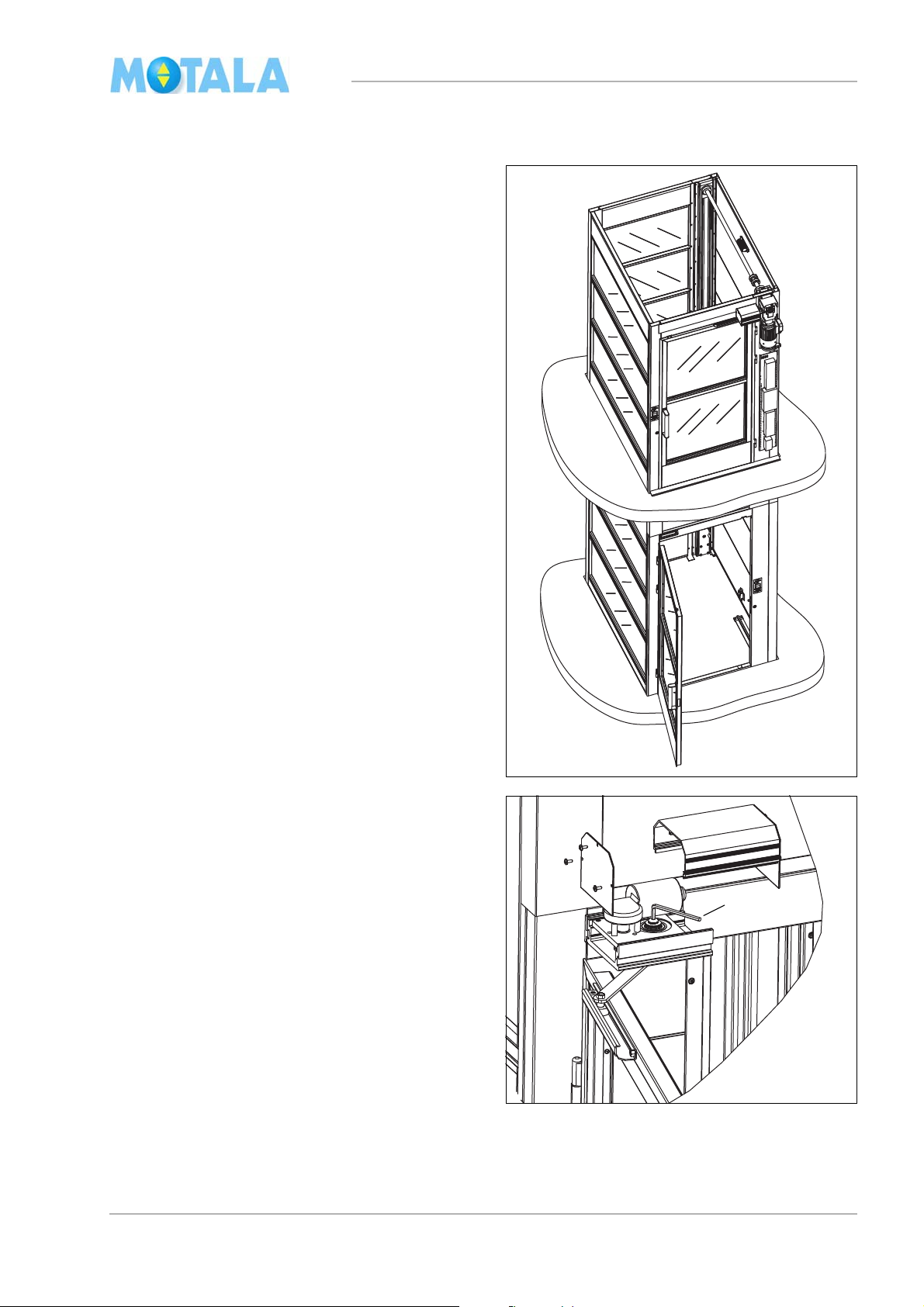

Mechanical blocking device

1. The mechanical blocking

device in the pit is always

placed on the opposite side

from the motor and the retiring

ramp. It is used to provide a

safety space of 500 mm when

working in the pit.

The operating handle to the

mechanical blocking

device

1. Open the bottom floor door,

the operating handle is placed

in the pit just inside the door.

2. Lift up (2.1) and swing out

(2.2) the arm to activate the

mechanical blocking device.

3. The green light on the

emergency stop device must

be switched on before entering

the pit.

4. When entered the pit push the

emergency stop device.

5. When you are leaving the pit

make the steps in reverse

order.

Instruction

4. Overview

© 2012 Motalahissar AB 4 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

Mount the first bracket

1. Mount the bracket 730888 in

the pre-drilled holes in the

guide, use 4x 100197.

Mount the cover plate bracket

1. Mount the cover plate 730624,

use 8x 100223.

2. Make sure that the cover plate

edge rest against the edge of

the door frame (or aluminum)

profile. And its lower end is

100 mm over the pit floor.

Instruction

5. Installation

© 2012 Motalahissar AB 5 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

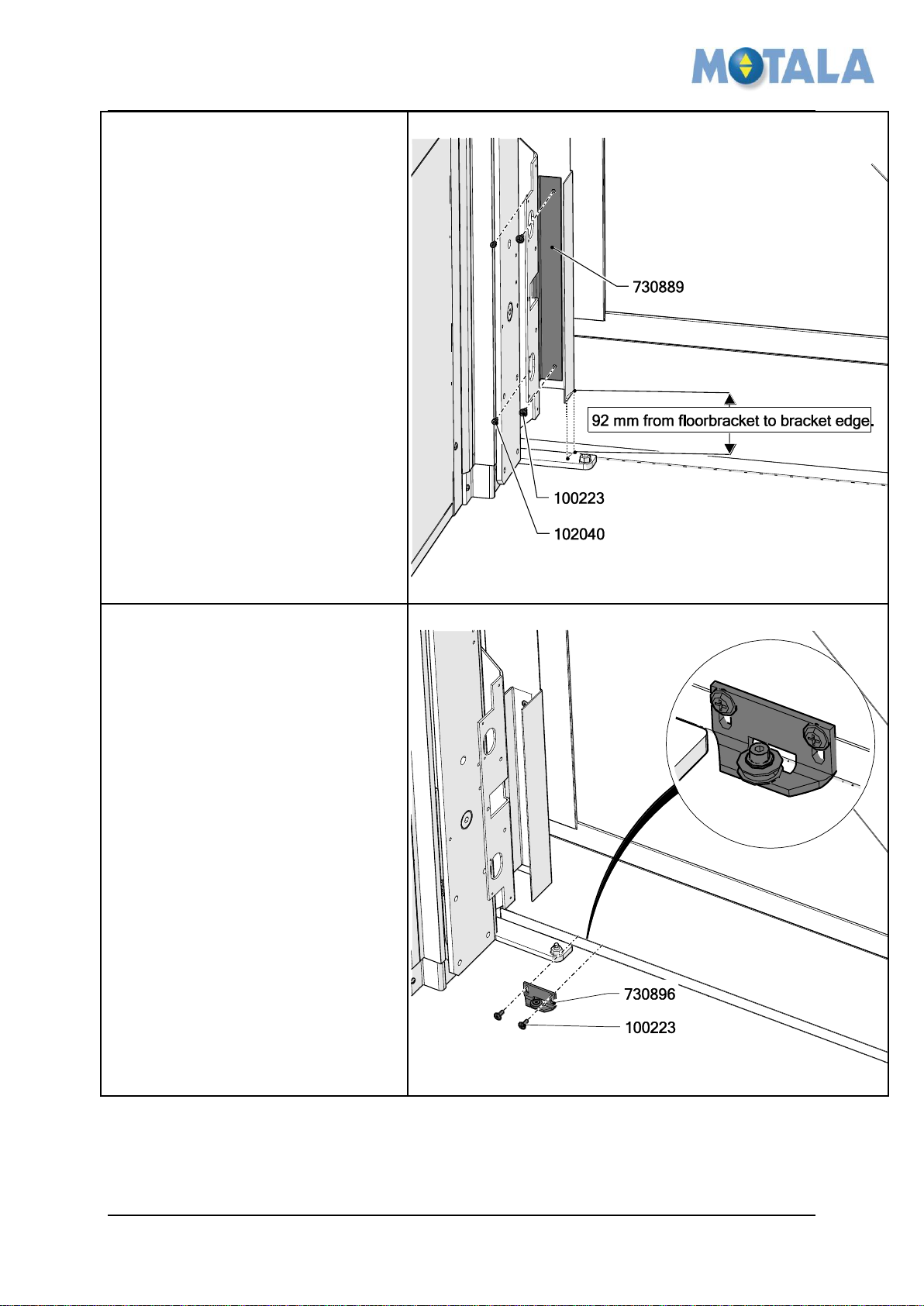

Mount the second bracket

1. Put the second bracket

730889 behind the first

bracket.

2. Use 2x 102040.

3. Use 2x 100223.

Mount the first pulley

1. The first pulley 730896 is

mounted right next to the floor

bracket.

2. Use 2x 100223

Instruction

© 2012 Motalahissar AB 6 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

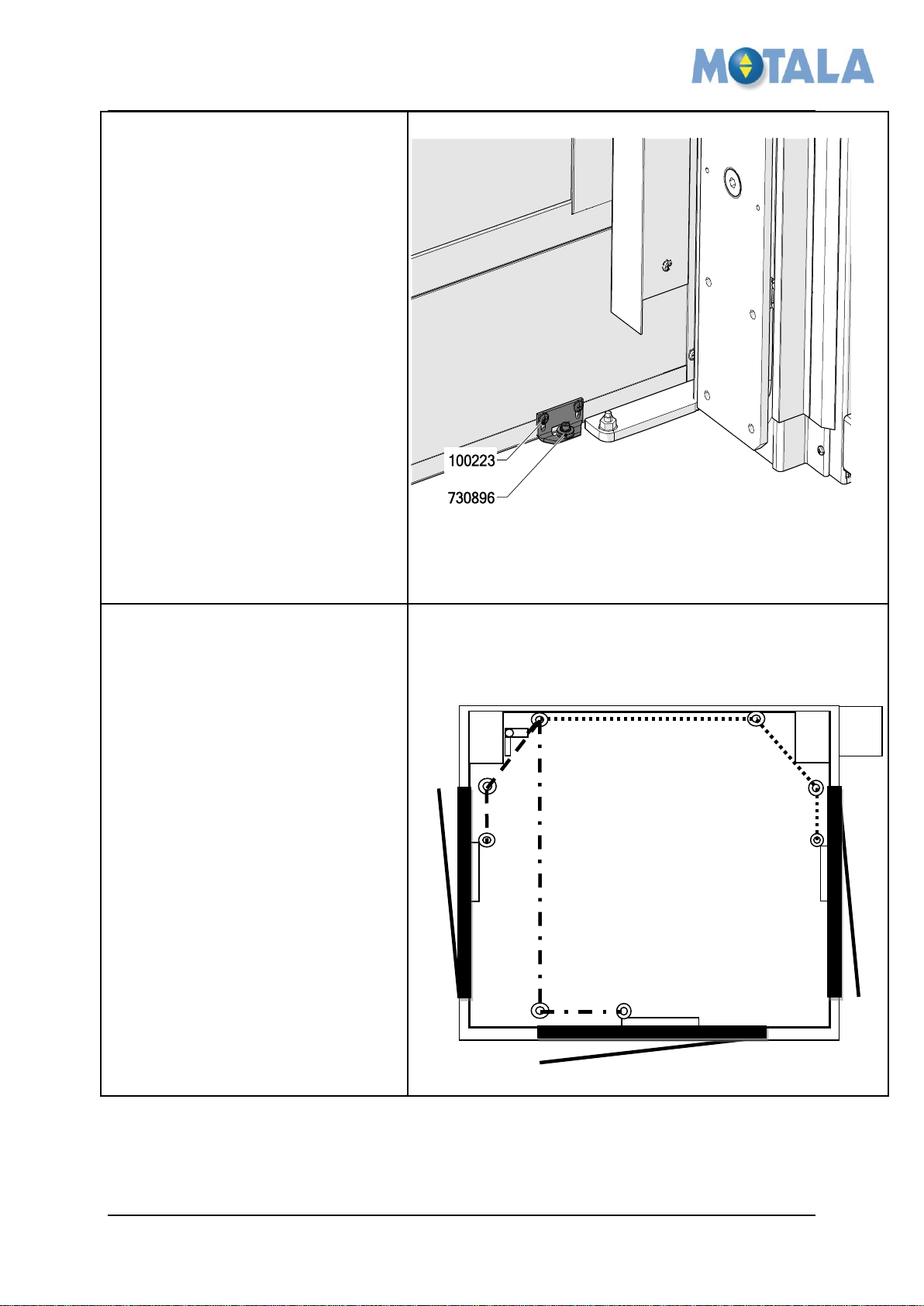

Mount the second pulley

1. The second pulley 730896 is

mounted right next to the floor

bracket.

2. Use 2x 100223.

3. Note that the second pulley

can be placed in a variety of

places depending on the

placement of the mechanical

blocking device and the door

giving access to the pit. See

example below.

Example of pulley placement

1. If the mechanical blocking

device is placed to the left this

is 3 alternative for the pulleys

and the wire. See the picture

for alternative door

placements 1, 2 and 3.

2. If the mechanical blocking

device is place to the right the

alternatives will be mirrored.

1.

2.

3.

Instruction

© 2012 Motalahissar AB 7 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

Mount the operating handle and

the warning sign

1. Place the operating handle

731032 inside of the threshold

on the door giving access to

the pit, use 2x 100223.

2. Place the warning sign on the

floor at the bottom of the pit,

fix it with glue or screws.

Mount the wire

1. Pull the wire from the

mechanical blocking device to

the operating handle.

2. The wire end must not stick

out from the wire lock at the

handle, that would prevent the

handle movement.

Instruction

© 2012 Motalahissar AB 8 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

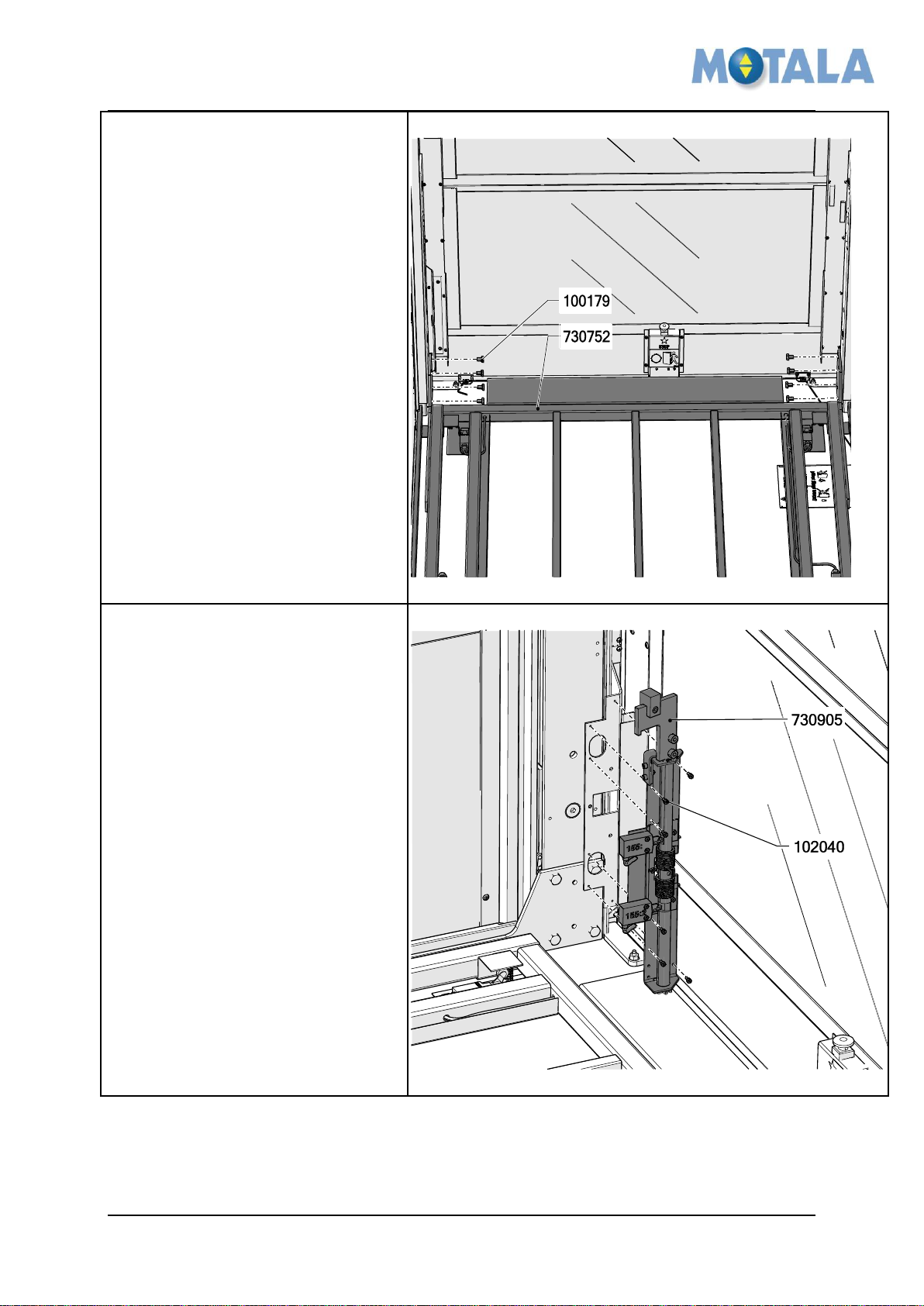

Mount the platform frame

1. Mount the platform frame

730752, use 8x 100179.

2. See the MC2000 installation

instruction for further important

details on mounting the

platform.

Mount the mechanical blocking

device

1. Mount the mechanical

blocking device 730905, use

6x 102040.

Instruction

© 2012 Motalahissar AB 9 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

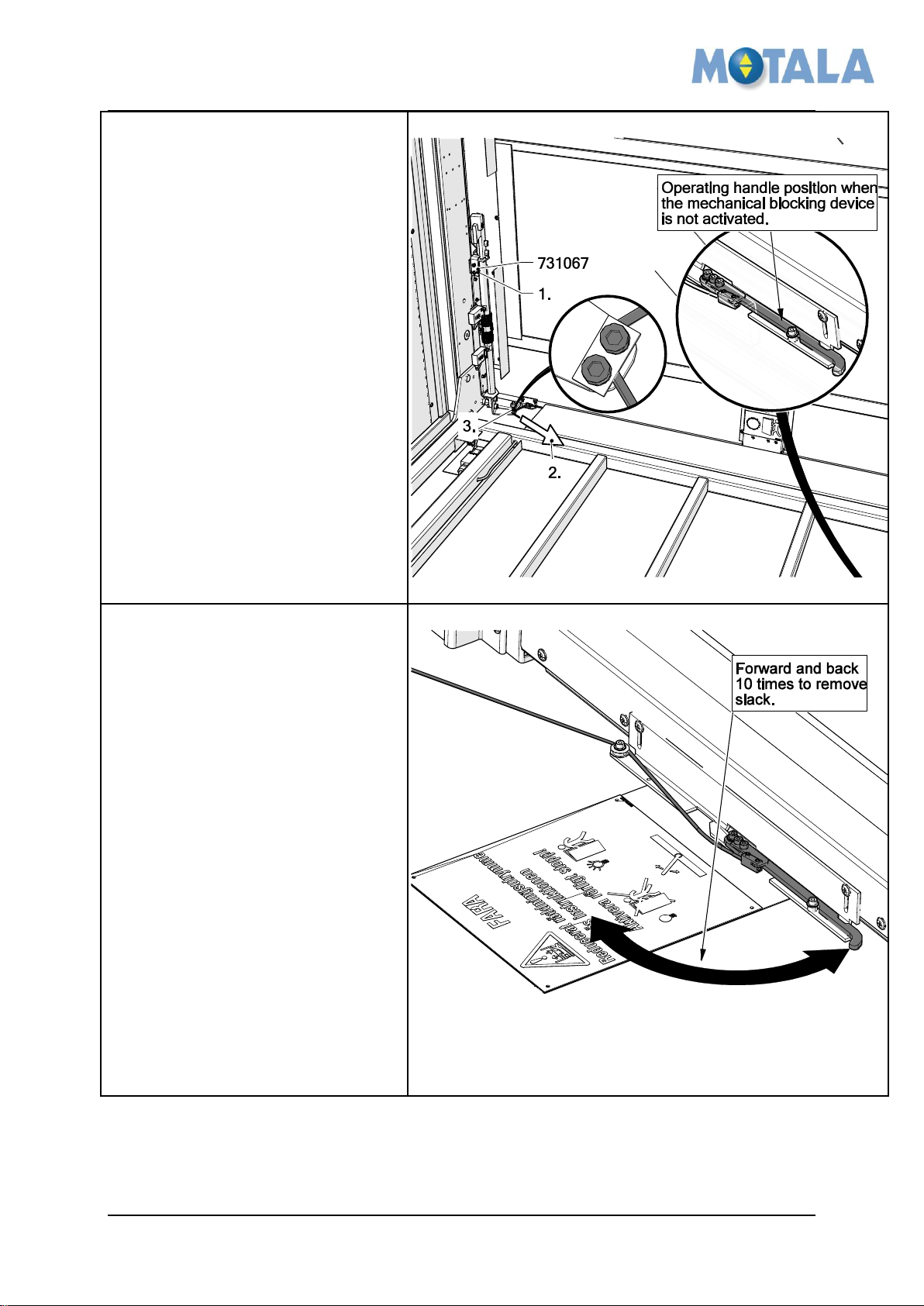

Adjustment of the wire

1. Make sure the red device

731067 is in its position. And

the operating handle is in its

inactivated position.

2. Stretch the wire.

3. Tighten the two screws to lock

the wire.

4. Remove the red device

731067 and check that the

mechanical blocking device is

still in its inactivated position.

5. Test that the wire, stop and

handle function works

properly. (See - 4. Overview)

Remove slack in the operating

handle and wire.

1. To make the mechanical stop

work properly over time the

slack in the operating handle

and the wire must be

eliminated.

2. Turn the handle forward and

back 10 times.

3. Test that the wire, stop and

handle function works

properly. (See - 4. Overview),

if not repeat (adjustment of the

wire 1-5)

Instruction

© 2012 Motalahissar AB 10 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

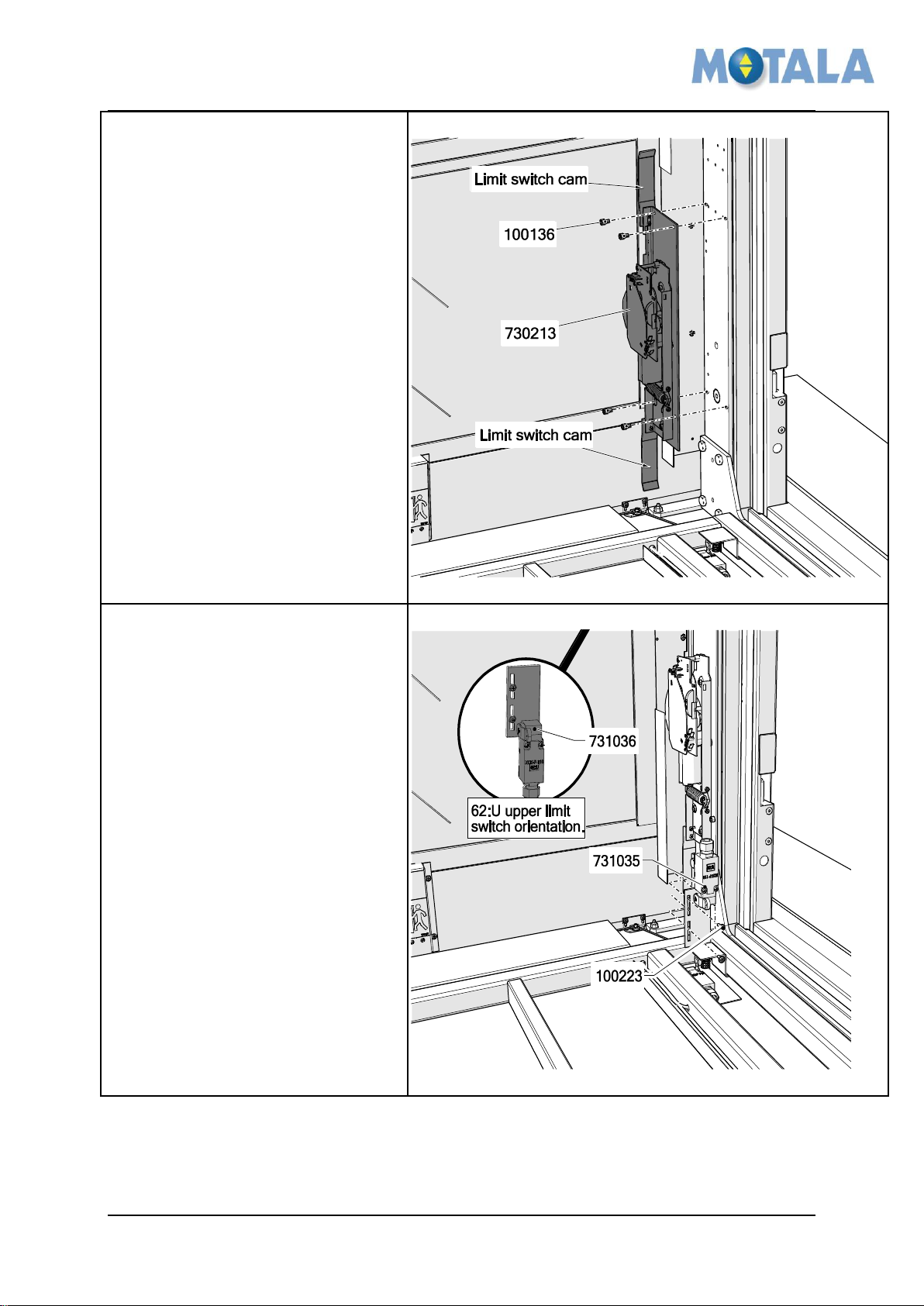

Mount the retiring ramp and

limit switch cams

1. Mount the retiring ramp

730213, use 4x 100136.

Mount the limit switches

1. Mount the retiring ramp

731035 (62:N) and 731036

(62:U), use 4x 100223.

Instruction

© 2012 Motalahissar AB 11 (12) IQ56-03 Rev: B

MOTALA MC2000 – Mechanical blocking device

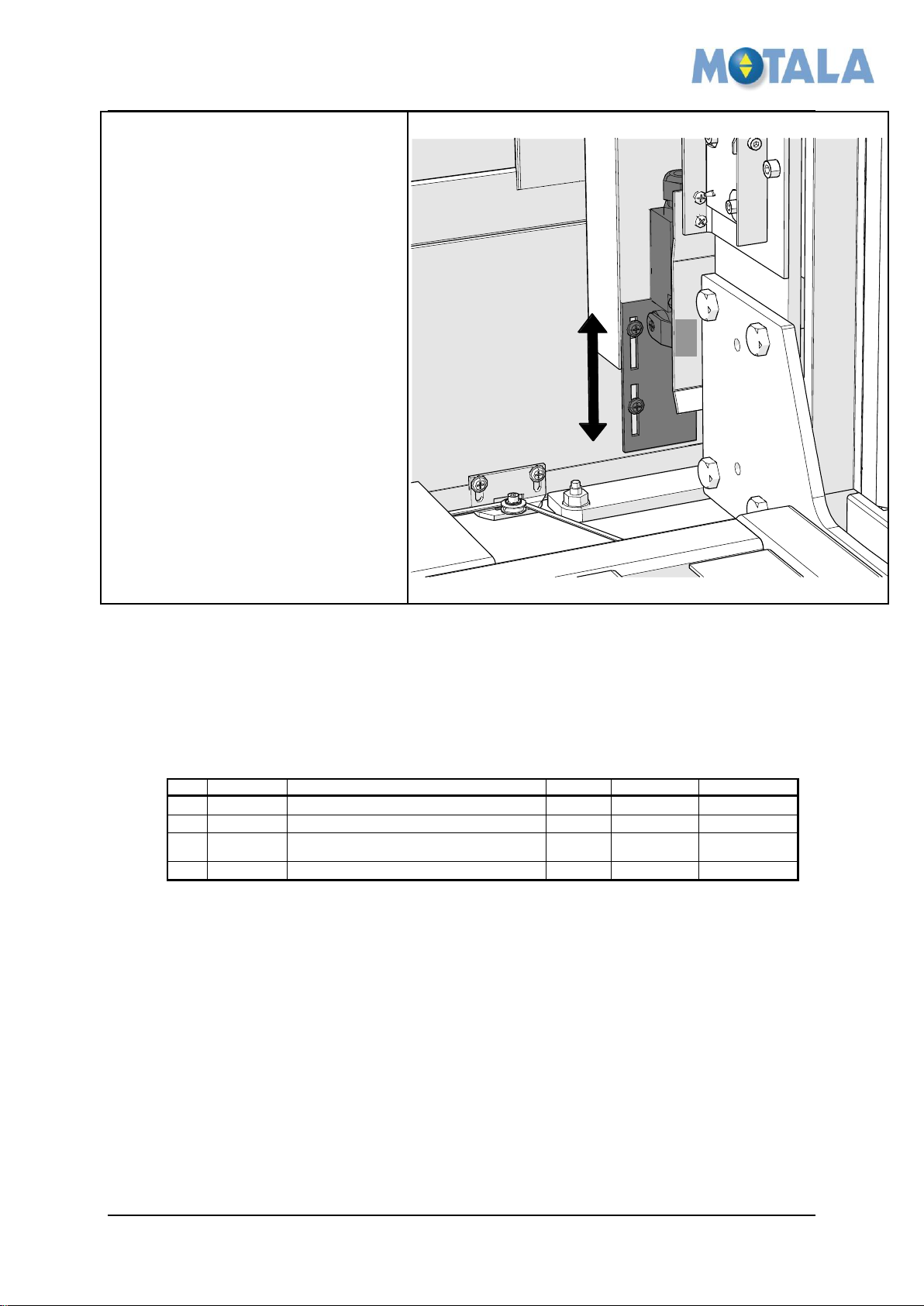

Adjustment of the limit switches

positions

1. Place the lower switch so that

the ridge affects the switch 25

mm before the platform

reaches the lower floor level.

2. Place the upper switch so that

the cam break the switch just

when the platform reaches the

upper floor level.

Rev

Date

Description of change

Ref CR

Checked by

Approved by

-

2012-09-05

Draft 1.0

10521

Niklas Adell

Ari Nieminen

A

2012-09-25

New transport safety device

12629

Niklas Adell

Ari Nieminen

B

2013-02-19

Remove slack in the operating handle and

wire

13536

Niklas Adell

Ari Nieminen

C

Instruction

6. APPROVALS AND VERSION HISTORY

Compiled by: Designer/Ronnie Sundström

© 2012 Motalahissar AB 12 (12) IQ56-03 Rev: B

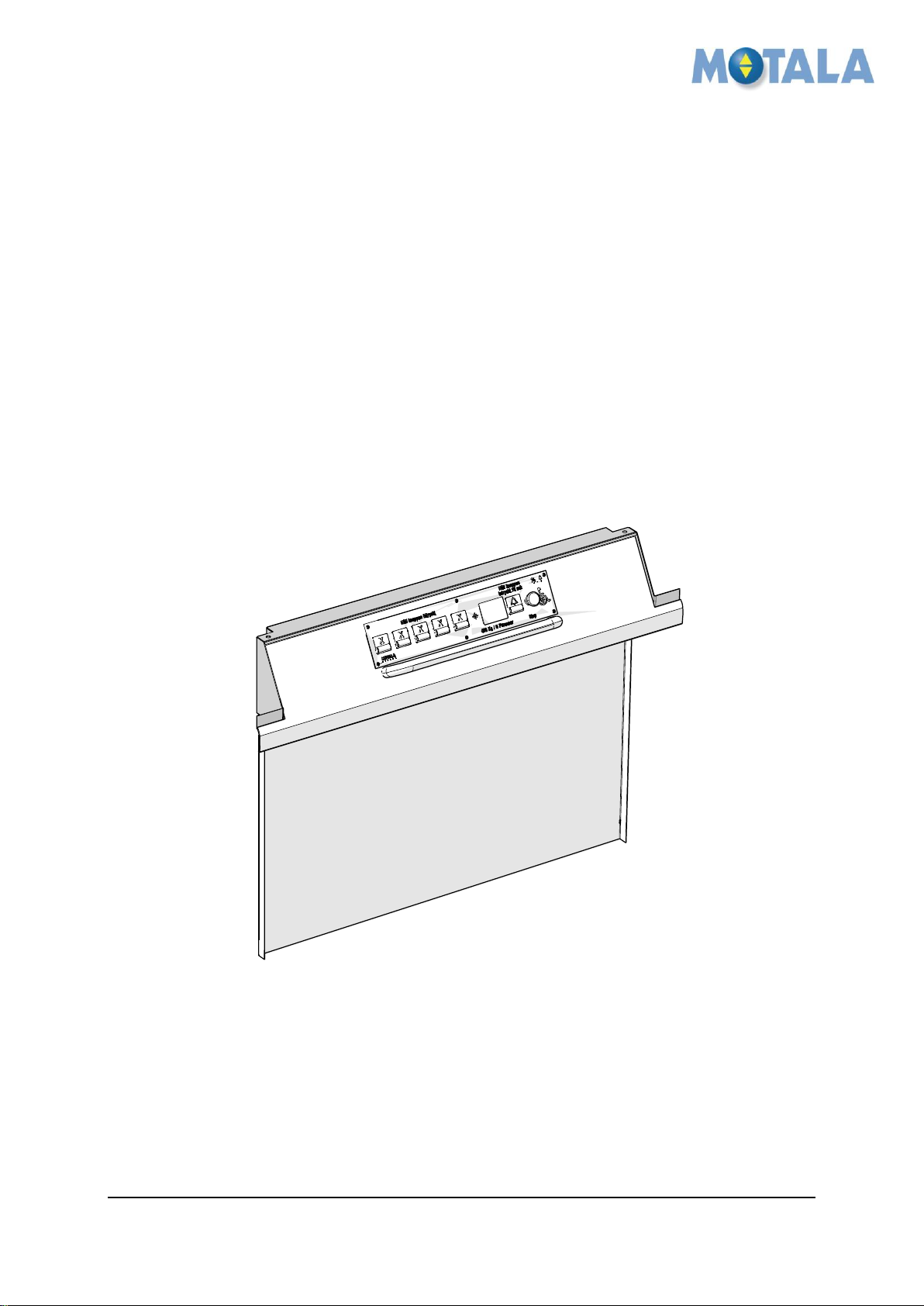

MOTALA MC2000 – Updated version of the platform wall

Instruction

Updated version of the platform wall MC2000

Rev. B

© 2012 Motalahissar AB 0 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Instruction

All rights reserved.

No part of the contents of this document may be copied, reproduced or transmitted in any form or by

any means, or translated into another language or format, in whole or part, without prior written

permission of MOTALA HISSAR Corporation.

CONTACT:

MOTALA HISSAR AB

Luxorgatan 1

BOX 4029

591 04 MOTALA

+46 141 23 70 50

www.motalahissar.se

© 2012 Motalahissar AB 1 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Instruction

TABLE OF CONTENTS

1. GENERAL .................................................................................................................3

RELATED DOCUMENTS ..................................................................................................3

2. SAFETY .....................................................................................................................3

3. FASTENERS USED IN THE INSTALLATION INSTRUCTION ................................3

4. INSTALLATION ........................................................................................................4

INSTALL THE OVERLOAD ARM ........................................................................................4

INSTALL THE PLATFORM WALL .......................................................................................4

ATTACH THE TRAVELING CABLE .....................................................................................5

SENSITIVE EDGE CABLE ................................................................................................5

FIT THE SHELF..............................................................................................................6

FIT THE ANGLE BRACKETS .............................................................................................6

INSTALL THE SWITCH UNIT FOR THE UPPER SENSITIVE EDGE ...........................................7

FIT THE SWITCH FOR THE OVER LOAD DEVICE .................................................................7

FIX THE OVERLOAD ARM ...............................................................................................8

FIT THE EARTH TERMINAL AND CIRCUITS BOARD .............................................................8

FIT THE UPPER SENSITIVE EDGE ....................................................................................9

PLACE THE SIDE PANELS ...............................................................................................9

FIX THE SIDE PANELS ................................................................................................. 10

FIT THE COP AND HANDRAIL ...................................................................................... 10

INSTALL THE COP PANEL STEP 1 ............................................................................... 11

INSTALL THE COP PANEL STEP 2 ............................................................................... 11

INSTALL THE COP PANEL STEP 3 ............................................................................... 12

INSTALL THE COP PANEL STEP 4 ............................................................................... 12

INSTALL THE COP PANEL STEP 5 ............................................................................... 13

INSTALL THE COP PANEL STEP 6 ............................................................................... 13

5. APPROVALS AND VERSION HISTORY .............................................................. 14

© 2012 Motalahissar AB 2 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Number

Description

View

100223

Staps 4,2x14 CS Ph2

100226

Staps 4,2x25 CS Ph2

100132

MC6S M5x14 FZB

100137

M6S M6x10 FZB DIN

100260

AZ 5,3 FZB

102332

SR 2604

101924

Secufast M5x12

100158

M6S M8x20 FZB DIN

Instruction

1. GENERAL

This new platform wall is specially designed to achieve a better and easier installation and

give the platform a better look. Follow this instruction carefully to ensure an efficient and

trouble-free installation.

Related documents

This instruction is to be used with the MC2000 installation instruction and the electrical

drawings.

2. SAFETY

Personal safety precautions for fitters.

Always use Personal Protective Equipment (PPE). Always use Head protection, Eye

protection, Foot protection, Hand protection, Protective clothing, Face shield and

Safety harness.

Follow the safety precautions in the MC2000 installation instruction.

3. Fasteners used in the installation instruction

© 2012 Motalahissar AB 3 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

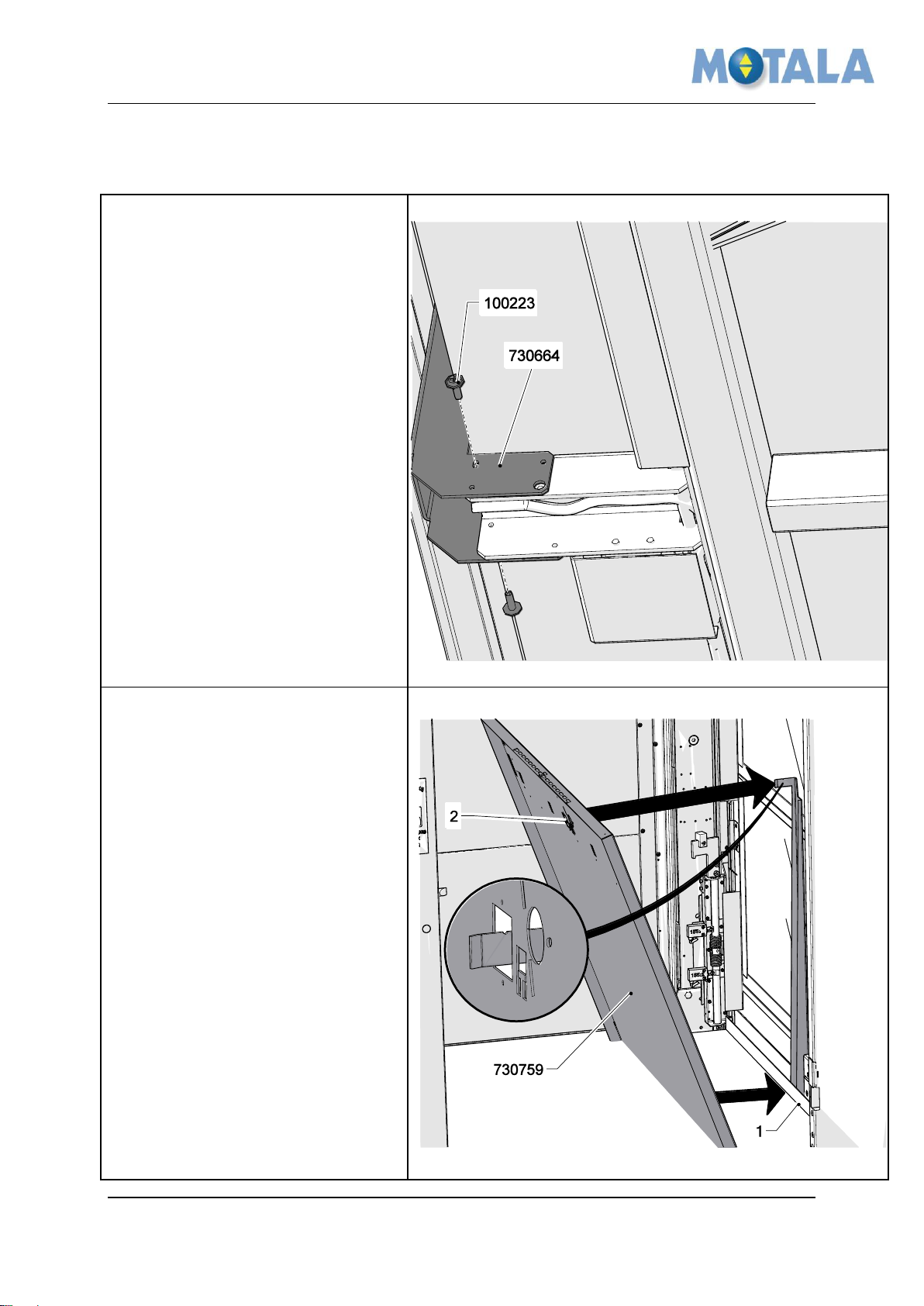

Install the overload arm

1. Fit the overload arm from the

underside of the platform, use 2x

100233 so that it still can be

adjusted.

2. Route the cable from the

sensitive edges inside the arm.

Install the platform wall

1. Fit the lower part of the wall

730759 so it abuts the platform

floor edge (1).

2. Fit the overload arm into the

hole (2) in the platform wall.

Instruction

4. Installation

© 2012 Motalahissar AB 4 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Attach the traveling cable

1. Tread the traveling cable through

the hole (1) and fix it with the

cable clamp 730764, use 1x

100132.

2. Note, no cables are visible in this

illustration.

Sensitive edge cable

1. Thread the cable from the floor

sensitive edge contacts through

the hole. Stretch it and lock it

with a cable tie.

2. Note, no cables are visible in this

illustration.

Instruction

© 2012 Motalahissar AB 5 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Fit the shelf

1. Fit the shelf 731072, use 5x

100223.

Fit the angle brackets

1. Fit the angel brackets 2x 730767,

one on the left and one on the

right side, use 4x100137 and 4x

100223.

2. Route the cables from the

magnet sensors, end limit switch

and retiring ramp together with

the fixings.

Instruction

© 2012 Motalahissar AB 6 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Install the switch unit for the

upper sensitive edge

1. Fit the unit 730781, use 2x

100223.

Fit the switch for the over load

device

1. Fit the switch unit 730669, use 2x

100223.

Instruction

© 2012 Motalahissar AB 7 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Fix the overload arm

1. Fix the overload arm, use 6x

100223.

Fit the earth terminal and

circuits board

1. Fit the earth terminal 100732,

use 1x 100260 and 1x 100938.

2. Fit fasteners for circuit boards, 6x

102332 on the shelf.

3. Fit the circuit board 102475.

4. Connect the cables to the PCB

terminals. See electrical drawings

for connection points.

Instruction

© 2012 Motalahissar AB 8 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

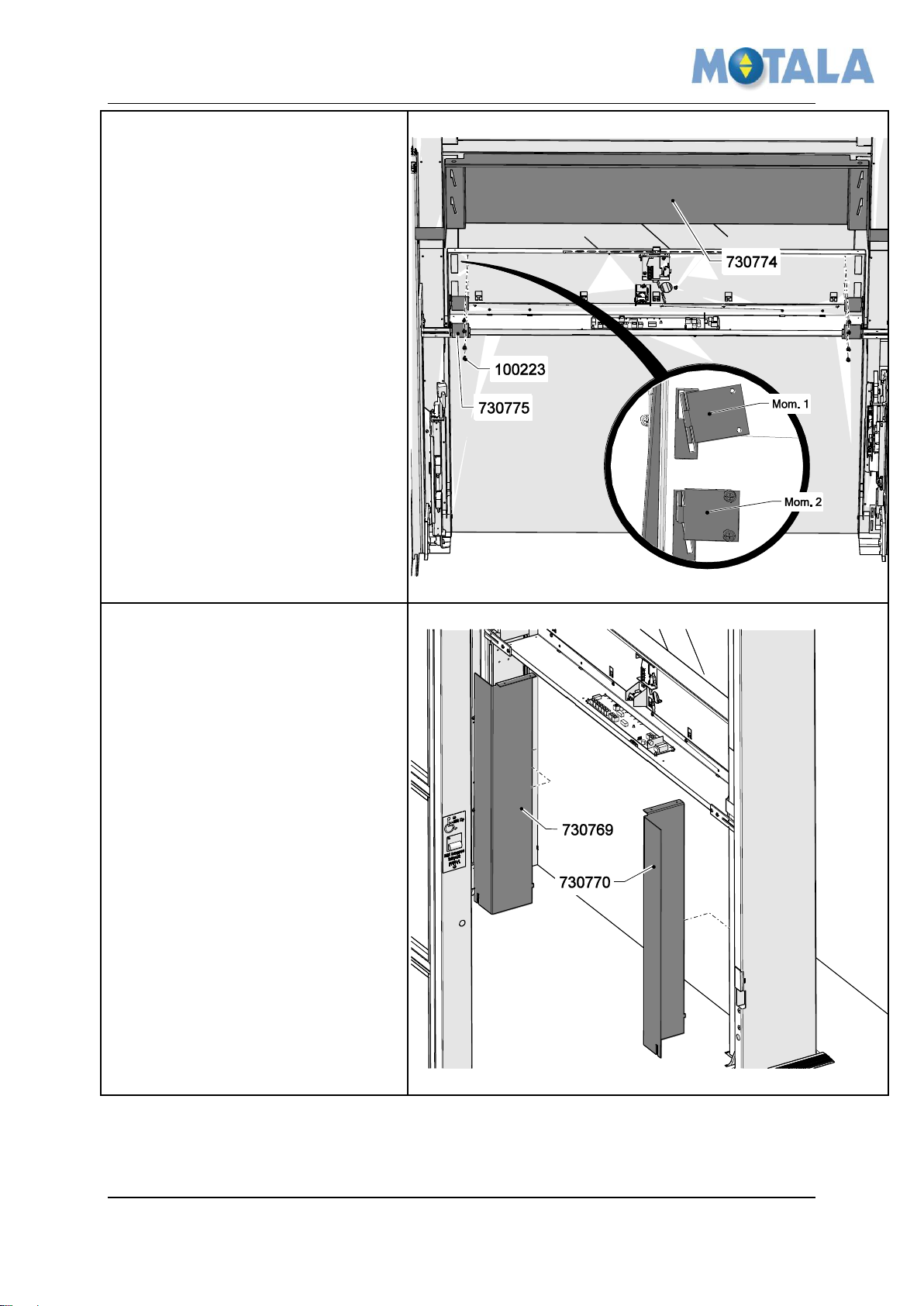

Fit the upper sensitive edge

1. Fit the upper sensitive edge

730774, use 4x 730775 and 8x

100223. Se Mom. 1 and Mom. 2.

Place the side panels

1. Place the left 730769 and right

730770 side panel after that you

are satisfied with floor magnets,

limit and lock arm positions.

Note! If you want to drive and

adjust from the platform COP

you may have to fit these panels

temporary for getting the COP

etc in right place.

Instruction

© 2012 Motalahissar AB 9 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Fix the side panels

1. Insert the hook into the groove.

2. Fasten the side panels, use 4x

100223.

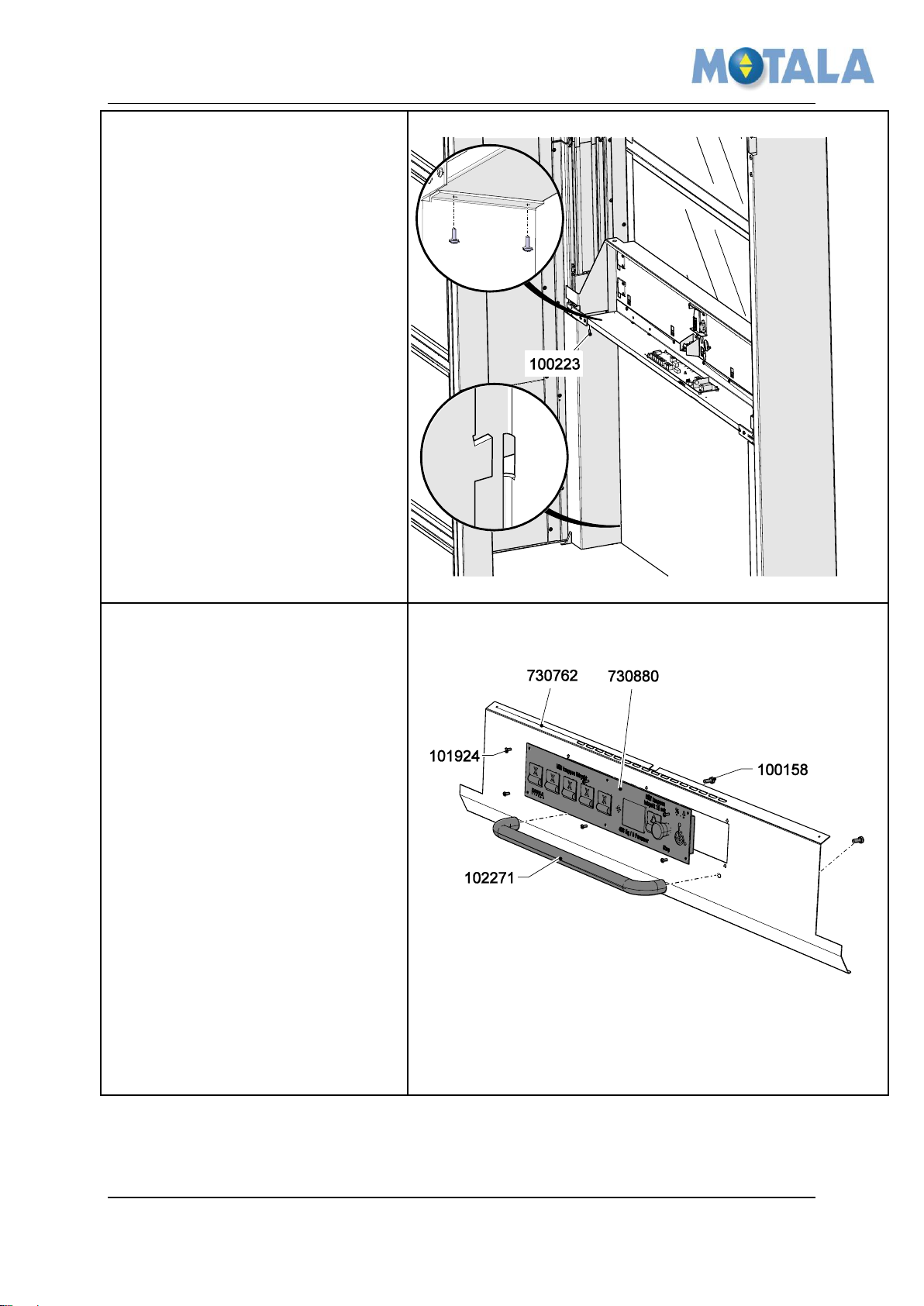

Fit the COP and handrail

1. Fit the COP 730880 on the panel

730762, use 6x 101924.

2. Fit the hand rail 102271, use 2x

100158.

Instruction

© 2012 Motalahissar AB 10 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

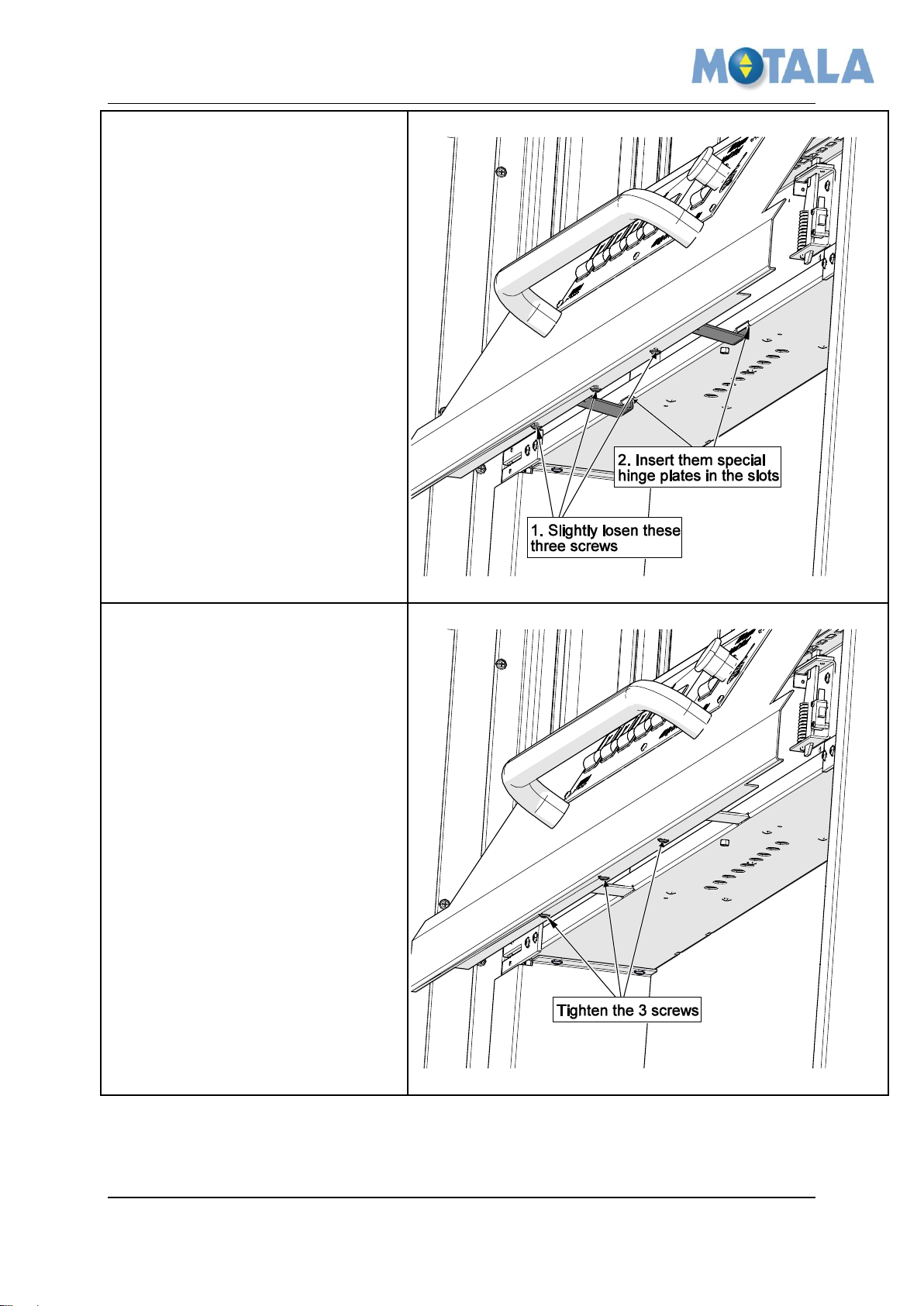

Install the COP panel step 1

1. Slightly loosen the 3 screws

under the COP panel.

2. Insert them special hinge plates

in the slots.

Install the COP panel step 2

1. Tighten the 3 screws.

Instruction

© 2012 Motalahissar AB 11 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

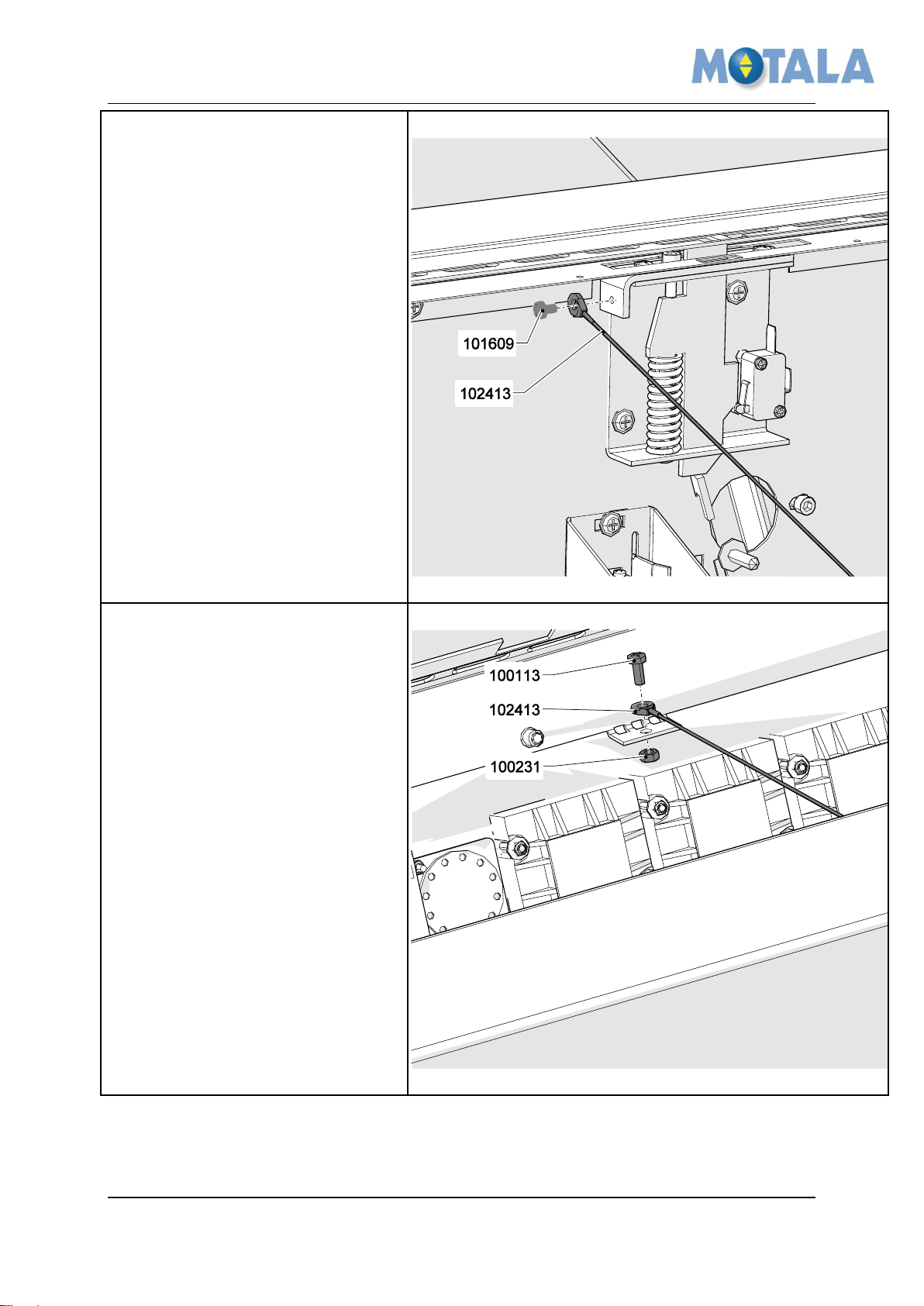

Install the COP panel step 3

1. Apply one end of the wire

102413 to the wall, use 1x

101609.

Install the COP panel step 4

1. Apply the other end of the wire

102413 to the COP, use 1x

100113 and 1x 100231 .

2. Connect the cables from the COP

to the PCB terminals. See

electrical drawings for

connection points.

Instruction

© 2012 Motalahissar AB 12 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Install the COP panel step 5

1. Slide in the COP in until it stops,

let the edge of the plate slide in

under the sensitive edge.

Install the COP panel step 6

1. Fix the COP, use 2x 100226 and

2x 100223.

Instruction

© 2012 Motalahissar AB 13 (14) IQ56-04 Rev: B

MOTALA MC2000 – Updated version of the platform wall

Rev

Date

Description of change

Ref CR

Checked by

Approved by

-

2012-09-26

Draft 1.0

9340

Niklas Adell

Ari Nieminen

A

2013-01-15

Modified to fit Kinds equipment

9340

Niklas Adell

Ari Nieminen

B

2013-02-21

Added information about electrical

connections,

9340

Johan

Strömberg

Ari Nieminen

C

Instruction

5. APPROVALS AND VERSION HISTORY

Compiled by: Designer/Ronnie Sundström

© 2012 Motalahissar AB 14 (14) IQ56-04 Rev: B

MOTALA MC2000 – Flip chair on the platform

Instruction

MC2000 - Flip chair on the platform

Rev. -

© 2012 Motalahissar AB 0 (6) IQ56-06

Rev: -

MOTALA MC2000 – Flip chair on the platform

Instruction

All rights reserved.

No part of the contents of this document may be copied, reproduced or transmitted in any form or by

any means, or translated into another language or format, in whole or part, without prior written

permission of MOTALA HISSAR Corporation.

CONTACT:

MOTALA HISSAR AB

Luxorgatan 1

BOX 4029

591 04 MOTALA

+46 141 23 70 50

www.motalahissar.se

© 2012 Motalahissar AB 1 (6) IQ56-06

Rev: -

MOTALA MC2000 – Flip chair on the platform

Instruction

TABLE OF CONTENTS

1. GENERAL .................................................................................................................3

RELATED DOCUMENTS ..................................................................................................3

2. SAFETY .....................................................................................................................3

3. FASTENERS USED IN THE INSTALLATION INSTRUCTION ................................3

4. INSTALLATION ........................................................................................................4

REMOVE THE COP .......................................................................................................4

FIT THE CONSOL ...........................................................................................................4

MOUNT THE FLIP CHAIR ................................................................................................5

TEST THE FLIP CHAIR ....................................................................................................5

REFIT THE COP AND MAKE A FUNCTION TEST OF THE COP ............................................6

5. APPROVALS AND VERSION HISTORY .................................................................6

© 2012 Motalahissar AB 2 (6) IQ56-06

Rev: -

MOTALA MC2000 – Flip chair on the platform

Number

Description

View

100223

Staps 4,2x14 CS Ph2

101725

RXK B8x9 FZB

Instruction

1. GENERAL

This flip chair is special designed to fit on MC2000 platform. Follow this instruction carefully

to ensure an efficient and trouble-free installation.

Related documents

This instruction is to be used with the MC2000 installation instruction and IQ56-04 Updated

version of the platform wall MC2000 installation instruction.

2. SAFETY

Personal safety precautions for fitters.

Always use Personal Protective Equipment (PPE). Always use Head protection, Eye

protection, Foot protection, Hand protection, Protective clothing, Face shield and

Safety harness.

Follow the safety precautions in the MC2000 installation instruction.

3. Fasteners used in the installation instruction

© 2012 Motalahissar AB 3 (6) IQ56-06

Rev: -

MOTALA MC2000 – Flip chair on the platform

Remove the COP