OWNER’S

MANUAL

TM�

702 and 715T

PLINKSTER

®

.22 CAL

SEMI-AUTOMATIC RIFLE

WITH DETACHABLE MAGAZINE

IMPORTANT “SAFETY WARNINGS” — NOTE THE SYMBOL

THESE SAFETY WARNINGS ARE FOR YOUR PROTECTION AS WELL AS

THE SAFETY OF OTHERS. DISREGARDING INFORMATION IN THIS MANUAL MAY RESULT IN SERIOUS INJURY OR DEATH.

Be certain this ownerʼs manual is available for reference and is kept

with this firearm if transferred to anoth

misplaced, contact the Product Service Center for a free replacement

copy.

After performing any work on your firearm such as cleaning, adjustments,

disassembly or installation of any accessory, the firearm should be

re-checked for proper functioning before firing live ammunition.

Firearms are complex mechanisms. Any modification, alteration, or

improper fitting of par

to the firearm and injury to the shooter and/or other persons. The firearmʼs

owner must accept full responsibility for the correct reassembly and

functioning of the firearm after any disassembly or replacement of parts.

If you do not understand any of the material in this manual or have any

questions, contact the Product Service Center or a qualified gun

ts may result in a dangerous malfunction, damage

er party. If this manual is lost or

smith.

Do not attempt to load, handle or use the firearm until you read and understand the information contained in its ownerʼs manual. Before handling your

firearm, you should learn how it operates and how to maintain it. This includes

knowing its basic parts, how the manual safety and other safety features

operate, how to safely open and close the action and how to safely load and

unload ammunition

ous and could cause serious injury or death to you or those around you. All

users of the firearm must become thoroughly familiar with the instructions in

this manual.

P.O. BOX 497 • 7 GRASSO AVENUE, NORTH HAVEN, CT 06473

Safety and safe firearms handling is everyone’s responsibility.

from the firearm. Improper use and handling is danger-

distributed by

MOSSBERG INTERNATIONAL, INC.

PHONE (800) 363-3555

www.mossberg.com

As the owner of a firearm, you must undertake the full-time responsibility

of safe firearms handling for your own safety and the safety of those

around you:

• Keep all firearms and ammunition out of the reach of children.

• Store your firearms and ammunition separately.

• Never store a loaded firearm.

• Never leave a loaded firearm unattended.

• Never transport a loaded firearm in a vehicle.

• Unloa

d your firearm when you have stopped shooting and when

you have to climb a tree, fence, cross a slippery surface or have

to transport it in a vehicle.

• Do not load your firearm before you are in a place where it is

safe to shoot, and keep your finger off the trigger until you are

on target and have decided to fire.

• Never shoot at water, rocks or any hard surfaces. Bullets may

glance off such surfac

es and cause injuries.

• Do not use alcohol or drugs before or while handling firearms.

• Do not touch the trigger while the safety button is being engaged

or disengaged.

Always point the muzzle of your firearm in a safe direction, regardless

of whether the firearm is loaded or unloaded. You should become

thoroughly familiar with the function and operation of this firearm and the

instructions supplie

d with it.

Always treat every firearm as it is were loaded. Give your firearm to

someone with the action open (bolt fully rearward), and the safety button pushed fully to the right to the “ON” (SAFE) position, after you verify

the firearm is unloaded. Insist on the same procedure when receiving a

firearm from someone else. Learn the location of all the safety features

of your firearm and how they oper

ate.

Wear eye and ear protection when shooting. Shooting without proper ear

protection can cause hearing damage. The use of eye protection during

any type of shooting is important to protect your vision.

When using a firearm with mounted optics, maintain an adequate

distance between the rear of the scope and your face at all times. Be

certain the scope installation does not interfere with access to, o

r the

proper functioning of the safety button.

We specifically disclaim any responsibility for damage or injury

whatsoever occurring in connection with, or as a result of, the use of

faulty, or non-SAAMI standard, or “remanufactured” or hand-loaded

(reloaded) ammunition. Additionally, we disclaim any responsibility

for damage or injury which results from any modifications or

changes that are not a part of

the firearm as delivered from the fac-

tory.

Learn to clean your firearm thoroughly and make certain no oil, grease

or other materials are blocking the barrel. Obstructions of any kind can

cause damage to the firearm resulting in personal injury.

Practice proper firearm maintenance and safety. Make sure all exposed metal

surfaces are coated with a thin film of oil, especially after being exposed to da

mp

weather. (See proper section of this manual for cleaning instructions.) Do not plug

the barrel or store in a fabric-lined case, which will absorb lubricants from the

firearm. Before using after storage, follow complete instructions stated in this

manual for refamiliarization with the firearm. A thorough inspection and

function test should be performed before going into the field. Have your firearm

periodically checked by a qualified gunsmith.

PART NO. 17928 REV. E

2

A note about the warnings and information contained in this manual:

We strongly suggest that you check with your local licensed retailer or state police

for additional information concerning firearms ownership, or hunting or target shooting rules that may be required by local law or regulation. Since such rules and regulations are subject to change, local authorities are in the best position to advise you

on such matters.

TABLE OF CONTENTS

Page

General Information and Mechanical Characteristics . . . . 4, 5

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Magazine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Keeping the Bolt in the “OPEN” Position . . . . . . . . . . . . . . . . . 9

Loading and Unloading the Magazine and Firearm . . . . . 10, 11

Firing the Firearm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12, 13

Disassembly for Cleaning and Lubrication . . . . . . . . . . . . 13-16

Cleaning and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

To Re-assemble the Firearm . . . . . . . . . . . . . . . . . . . . . . . 18, 19

Function Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19, 20

Precautions and Care with

Sight Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20, 21

Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Exploded View for Models without AR Style Stock . . . . . . . . 24

Parts List for Models without AR Style Stock . . . . . . . . . . . . . 24

Exploded View for Models with AR Style Stock . . . . . . . . . . . 25

Parts List Models with AR Style Stock . . . . . . . . . . . . . . . . . . 25

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-28

Basic Rules of Safe Firearms Handling

your Firearm . . . . . . . . . . . . . . . . 20

. . . . . . . . . Back Cover

3

GENERAL INFORMATION AND MECHANICAL CHARACTERISTICS

The 702 Plinkster®(including 715T models) is designed to operate with .22 long

rifle cartridges of sub-sonic, standard, high or hyper velocities only.

When the firearm leaves the factory, its metal parts are protected by a coat of very

adherent oil. This coating, especially inside of the barrel, must be removed before

using the firearm. The oil on the

the packing box has been open because the oil is very sticky and it easily retains

dust and other solid impurities from the air.

The firearm is designed to fire semi-automatically. Finger pressure must be

relieved from the trigger before an additional shot can be fired.

WARNING

Because this firearm can be used as a single shot, it will fire whether

or not a magazine is in the firearm if a cartridge is chambered.

FIREARM WILL FIRE WITH MAGAZINE OUT.

outside surfaces should also be removed when

4

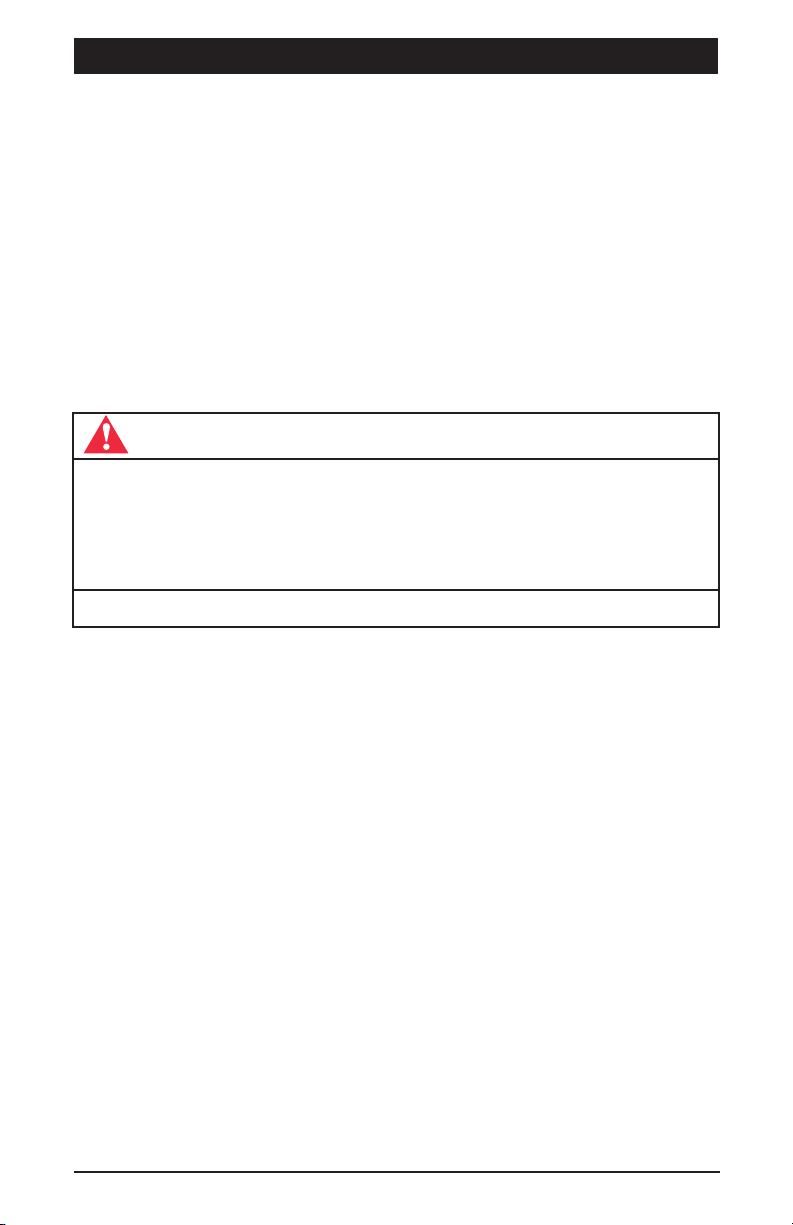

Butt Plate

Fig. 1

Butt Plate

Stock

Rear Sight

Receiver

Operating Handle

Bolt

Muzzle

Clip Magazine

Magazine Lock

Safety

Button

* The chamber is the rearmost part of the barrel. It can only be seen when the

bolt is in the “open” position.

Trigger

Guard

Trigger

Chamber*

Barrel

Front Sight

Receiver

Stock

Operating Handle

Bolt

Chamber*

Rear Sight

Front Sight

Barrel

Muzzle

Trigger

Receiver**

Receiver**

Trigger

Trigger

Guard

Guard

Safety

Button

Operating Handle

Operating Handle

Bolt

Bolt

Safety

Safety

Button

Button

Trigger

Guard

* The chamber is the rearmost part of the barrel. It can only be seen when the

bolt is in the “open” position.

Receiver Shell

Receiver Shell

(Both Sides)

(Both Sides)

Stock

Stock

* The chamber is the rearmost part of the barrel. It can only be seen when the

* The chamber is the rearmost part of the barrel. It can only be seen when the

bolt is in the “open” position.

bolt is in the “open” position.

** The receiver is enclosed in the receiver shells.

** The receiver is enclosed in the receiver shells.

Rear Sight

Rear Sight

Stock

Stock

Bolt

Bolt

Trigger

Trigger

Clip Magazine

Fig. 1

Chamber*

Chamber*

Clip Magazine

Clip Magazine

Magazine Lock

Forearm

Forearm

(Both Sides)

(Both Sides)

Magazine Release

Magazine Release

(Both Sides)

(Both Sides)

Front Sight

Front Sight

Muzzle

Muzzle

Sling Swivel

Sling Swivel

Barrel

Barrel

Fig. 2

5

Read and understand this entire manual and its safety warnings before

firing the firearm.

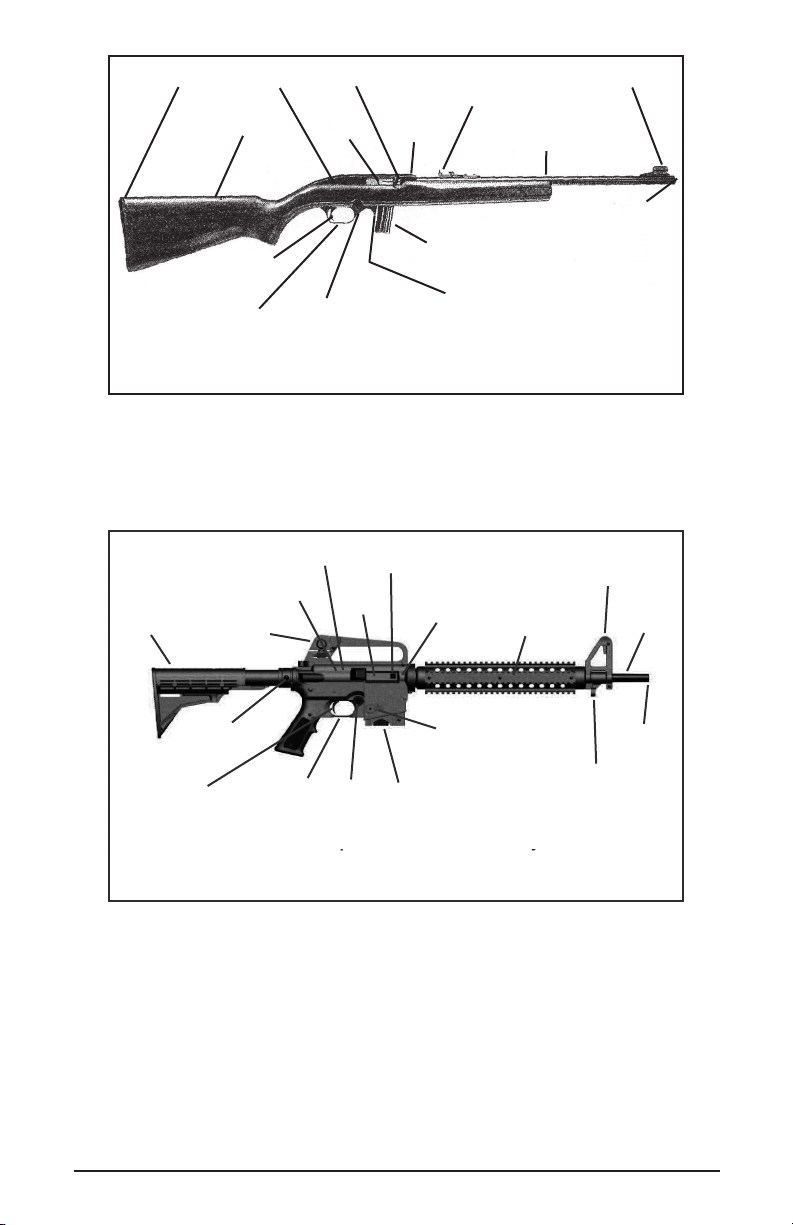

MECHANICAL SAFETY

The safety button is located at the front of the trigger guard (Fig. 3) and must be

manually moved to the desired position by the shooter. The safety mechanism

cannot be engaged unless the hammer is cocked.

The safety is set in the “ON” (SAFE) position by pushing the button from

the left side (side opposite the ejection port) so that it moves all the way

to the right. The button must

always b

e pushed fully to the right until it

moves no further to be in the “ON” (SAFE) position.

Safety

Button

Fig. 3

Remember, a firearmʼs manual safety is a mechanical device which can

never replace safe firearm handling practices.

Because any mechanical device can fail, never

rely on any mechanism

or safety device to prevent the dangers of careless handling or pointing

a firearm in an unsafe direction.

Moving the safety button fully to the left will put the safety in the “OFF” (FIRE)

position. The safety should be in the “ON” (SAFE) position until you are on target and have decided to fire.

The safety button is designed to function only as described above and

should not be

eversed. Do not attempt to remove or reverse the button.

r

Doing so will result in an unsafe condition which can cause serious injury

or death.

The safety button is marked with a red ring for training purposes as a reminder

that moving it to the left with red showing is the “FIRE” position, moving it all the

way to the right with red not showing is the “SAFE” position. The safety button can

only be enga

hen the hammer is cocked.

ged w

6

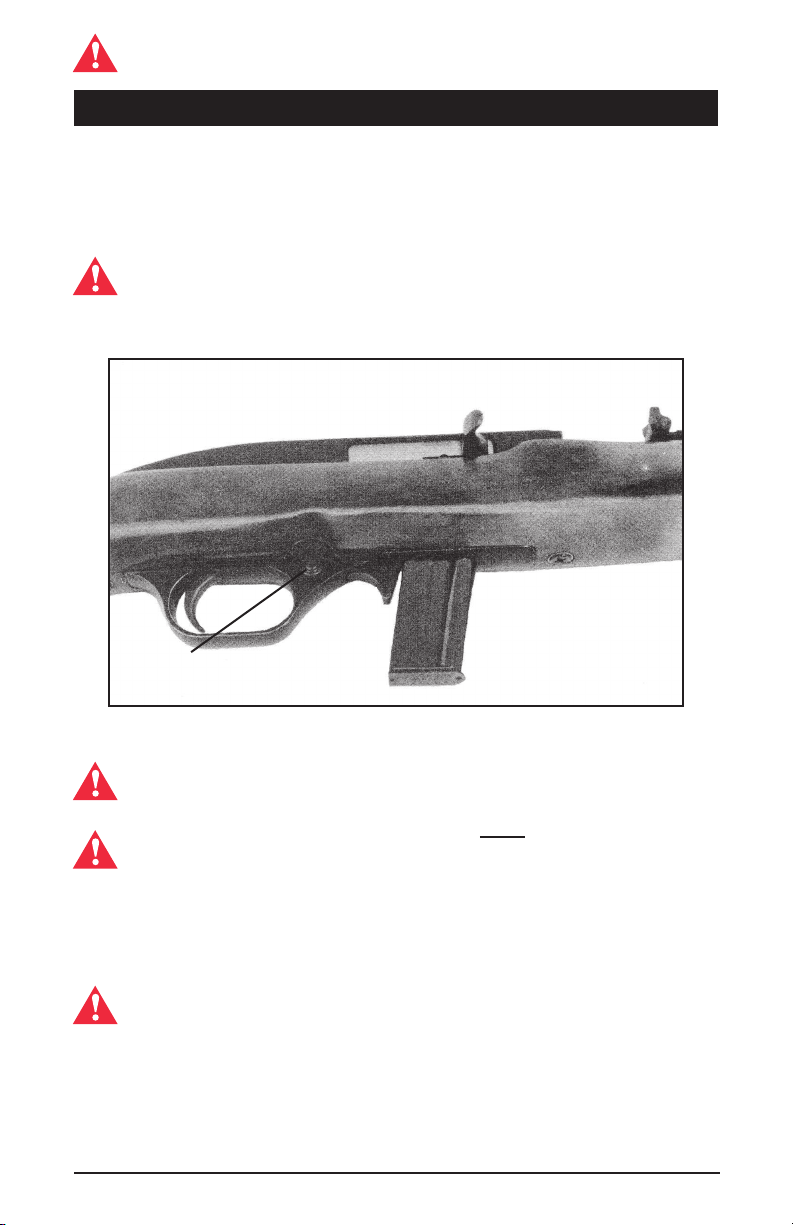

MAGAZINE INSTALLATION

MAGAZINE INSTALLATION

Familiarize yourself with the firearm by installing and removing an unloaded clip

magazine and by learning to keep the bolt in the open position.

Ensure the safety button is fully to the right to the “ON” (SAFE) position

and visually and physically check the chamber and the receiver area to

be certain the firearm is unloaded.

Fig. 4

Bolt

Press

Magazine Lock

Clip Magazine

Operating Handle

Familiarize yourself with the firearm by installing and removing an unloaded

clip

magazine and by learning to keep the bolt in the open position.

Ensure the safety button is fully to the right to the “ON” (SAFE) position

and visually and physically check the chamber and the receiver area to

be certain the firearm is unloaded.

Bolt

Operating Handle

Press

Magazine Lock

Clip Magazine

Fig. 4

Safety Button

Safety Button

Operating Handle

Operating Handle

Bolt

Bolt

Press

Press

Magazine Release

Magazine Release

Fig. 5

7

Clip Magazine

Clip Magazine

TO INSTALL CLIP MAGAZINE

Insert the unloaded clip magazine with the red cartridge follower end first and the

long flat portion of the clip to the rear of the magazine opening. Push the magazine into place until it snaps into its locked position. (Fig. 4 & 5) On models with

AR style stock, be sure that the release lever is returned to its upmost position so

that the magazine will snap into its locked

position.

TO REMOVE CLIP MAGAZINE FROM MODELS WITHOUT AR STYLE STOCK

Press the magazine lock forward toward muzzle and pull the magazine from the

stock with your free hand. (Fig. 4)

TO REMOVE CLIP MAGAZINE FROM MODELS WITH AR STYLE STOCK

Press down on the magazine release on either side of the receiver shell and pull

the magazine from the stock with your free hand. (Fig. 5)

N

OTE: It is easier to install and remove the magazine from the firearm if the bolt is

locked at its most rearward position by its operating handle. (Fig. 6 & 7)

WARNING

Removal of the magazine will not unload the firearm! Removing the

magazine will not remove any cartridge which is in the firearm’s chamber! A cartridge in the firearm’s chamber can still be fired, even after

the firearm’s magazine has been removed! After you remove the magazine always

visually and physically inspect the chamber and receiver

to ensure the firearm is completely unloaded!

FIREARM WILL FIRE WITH MAGAZINE OUT.

8

KEEPING THE BOLT IN THE “OPEN” POSITION

If the magazine is not installed, pull the operating handle fully rearward then push

the handle inward. To release the bolt, pull the end of the operating handle to the

rear and outward to release.

If an empty magazine is installed, the magazine follower will keep the bolt in an

open position. (Fig. 6) To remove the magazine, follow the instructions for your

parti

cular model in “To Remove Clip Magazine” section of this manual.

Magazine Follower

Fig. 6

Fig. 7

9

Fig. 8

TO LOAD AND UNLOAD MAGAZINE AND FIREARM

The magazine should be loaded before installing it to the firearm. Remove it from

firearm as described in “To Remove Clip Magazine” section of this manual.

Load the magazine by inserting one cartridge at a time, pressing against the plastic

follower and rearwards until it is fixed between the lips of the magazine. Repeat

the operation until the magazine is full,

have been loaded. The magazine should be loaded with .22 Long Firearm cartridges only (Fig. 9). For best performance we recommend using Hi-Velocity

ammunition.

or until the desired number of cartridges

10

Fig. 9

Before inserting the magazine into the firearm, point the muzzle in a safe

direction, pull the operating handle fully rearward, release it, and let the

bolt return to its most forward position. Move the safety button fully to the

right to the “ON” (SAFE) position.

Insert the loaded magazine into the magazine opening until it snaps into

its locked position.

Point the muzzle in a safe direction and ensure

positioned fully to the right at the “ON” (SAFE) position. Using the

operating handle, pull the bolt to its most rearward position, release it,

and let the bolt return freely to its forward position. It may be necessary

to pull out on the operating handle when it is in its most rearward position to get it to return to its forward position. The bolt will push one cartri

dge from the magazine into the chamber.FILLER FOR FORMATTING

The firearm is now loaded.

Do not touch the trigger until you are on target and have decided to fire.

Removing the magazine does not unload the firearm! The firearm will fire

if a cartridge is chambered, whether or not a magazine is in the firearm.

11

the safety button is still

FIRING

Discharging firearms in poorly ventilated areas, cleaning firearms, and/or

handling ammunition may result in exposure to lead and/or other

substances known to cause birth defects, reproductive harm, and other

serious physical injury. Have adequate ventilation at all times. Wash

hands thoroughly after exposure.

With the muzzle pointed in a safe direction and held in the proper firing position,

mov

e the safety button fully to the left to its “OFF” (FIRE) position. Pulling the trigger through its full travel to the rear, will fire the firearm. Ensure that the muzzle

is pointed in a safe direction before placing your finger on the trigger.

Should any cartridge fail to fire, keep the muzzle pointed in a safe direction for at least thirty (30) seconds in case the cartridge is a “hangfire”

(dela

yed firing of the cartridge after being struck by the firing pin.) Then,

remove the magazine (as it may still have loaded cartridges), pull the

operating handle fully rearward and lock the bolt in the open position

(Fig. 6 & 7) and extract and eject the misfired cartridge. Move the safety button fully to the right to the “ON” (SAFE) position. Segregate the

misfired cartridge from other ammunition.

fired cartridge.

If at any time during firing, the sound of any cartridge is noticeably louder or softer than previous cartridges fired, STOP! Do not load or fire additional cartridges. Keep the muzzle pointed in a safe direction, remove

the magazine (as it may still have loaded cartridges in it), and while

keeping the ejection port and magazine well opening of the firearm

turned away from your face (to protect your eyes in the event a defective cartridge explodes), pull the operating handle fully rearward and lock

the action open. Visually and physically verify that the chamber is empty.

Move the safety button fully to the right to the “ON” (SAFE) position. After

unloading, inspect your firearm for possible damage or obstructions in

the chamber or bore.

Upon firing, the pressure generated by the powder combustion will push the bolt

to its rearward position, extr

reaching its most rearward position, the bolt will have recocked the hammer, and

the bolt recoil spring will then push the bolt forward, feeding a new cartridge from

the top of the clip magazine and chambering it. The firearm will again be ready

to fire. This cycle will be repeated every time the trigger is pulled until there are

no cartridges remai

will then fire the live cartridge remaining in the firearmʼs chamber. After this last

cartridge has been fired, the clip magazine follower is designed to keep the bolt

in the open position.

As the firearm was designed to fire semi-automatic only, it is mandatory to relieve

pressure on the trigger after each shot in order to allow the d

connect the trigger to the firing mechanism.

After the last cartridge has been fired, the clip magazine follower is designed to

keep the bolt in the open position. (Fig. 6)

Move the safety button fully to the right to the “ON” (SAFE) position and

visually and physically inspect the chamber and magazine to ensure that

there are no live cartridges present.

If the magazine is withdrawn

ier to remove the magazine from the firearm if the bolt is locked at its most rearward position by its operating handle.

ning in the magazine. If the trigger is pulled again, the firearm

acting and ejecting the fired cartridge case. Upon

from the firearm, the bolt will close; however, it is eas-

Do not attempt to refire a mis-

isconnector to again

12

Before inserting a new loaded magazine into the firearm move the safety button fully to the right to the “ON” (SAFE) position.

If the bolt is locked in its open position by the operating handle, to chamber a cartridge, insert a loaded magazine, pull the operating handle to the rear and outward and let the bolt move freely forward.

The firearm is now loaded and will fire if the trigger is pressed.

To interrupt shooting and unload the firearm, keep the muzzle pointed in a safe

direction, move the safety button fully to the right to the “ON” (SAFE) position,

remove the magazine and pull the bolt to its most rearward position, extracting

and ejecting the cartridge in the chamber. Push the operating handle inward to

hold the bolt open. (Fig. 6 & 7)

If desired or necessary, the firearm can be single

into the chamber. Pull the bolt rearwards and lock it to the receiver using the operating handle. Move the safety button fully to the right to the “ON” (SAFE) position

and keeping the muzzle pointed in a safe direction, insert a cartridge directly into

the chamber and close the bolt. It will be easier to single load the firearm if the

magazine is removed from the fire

The firearm is now loaded and will fire when the trigger is pulled with the

safety in the “OFF” (FIRE) position whether or not the magazine is in the

firearm.

As a safety procedure, every time shooting is interrupted or the firearm is

unloaded, move the safety button fully to the right to the “ON” (SAFE) position,

and move the bolt to the open (rearward) position and locked open by pushing

inward on the operating handle.

DISASSEMBLY FOR CLEANING AND LUBRICATION

Remove the magazine.Pull the operating handle fully rearward to extract

and eject any cartridge that might be in the chamber. Push the operating

handle inward to lock the bolt in the open position. Move the safety button fully to the right to the “ON” (SAFE) position.

Visually and physically inspect the chamber and inside the receiver to be

certain the firearm

and cleaning to protect your eyes from oil spatter or spring loaded components.

arm.

is unloaded. Wear eye protection during disassembly

loaded with a cartridge directly

Remove the barrel/receiver assembly from the stock.

MODELS WITH 702 PLINKSTER STOCKS: Using a No. 2 Phillips

screwdriver, remove the two takedown screws located at the front and

back of the trigger guard and pull the barrel/receiver assembly away

from the stock.

MODELS W

both sides of the tactical stock assembly. Remove the stock assembly

from the receiver shells. Remove the nut from the scope mounting rail

and lift the rail from the hole in the top of the carry handle. Insert a 5/32”

Allen wrench into the hole in the pistol grip and the front of receiver shells

ITH AR STYLE STOCKS: First remove the stock bolt from

13

and engage with the heads of the takedown screws. (Fig. 10) Loosen the

Fig. 10

Remove the #2 Plastite

TM

screw and the right magazine release lever.

The left magazine release lever can now be removed. Remove the #4

Plastite

TM

screws from the right halves of the forearm and receiver shell.

(Fig. 11) Remove one side of the forearm, and then the other. The sling

swivel can be slid off of the barrel. Now separate the receiver shells

from one another. The action assembly can now be removed from the

receiver shell.

Rear Takedown Screw

Front Takedown Screw

Stock Bolt

and engage with the heads of the takedown screws. (Fig. 10) Loosen the

takedown screws, but do not fully remove.

#2 PlastiteTMScrew

Right Magazine Release Lever

takedown screws, but do not fully remove.

Stock Bolt

#2 PlastiteTMScrew

Right Magazine Release Lever

Rear Takedown Screw

Front Takedown Screw

Fig. 10

TM

Remove the #2 Plastite

The left magazine release lever can now be removed. Remove the #4

TM

Plastite

screws from the right halves of the forearm and receiver shell.

screw and the right magazine release lever.

(Fig. 11) Remove one side of the forearm, and then the other. The sling

swivel can be slid off of the barrel. Now separate the receiver shells

from one another. The action assembly can no

w be removed from the

receiver shell.

Fig. 11

14

TO DISASSEMBLE THE FIREARM

TO DISASSEMBLE THE FIREARM

With a pin punch or similiar tool, remove the two trigger housing retaining pins

located at the side of the receiver (Fig. 12). Be careful not to damage the black

finish on the parts.

TO DISASSEMBLE THE FIREARM

With a pin punch or similiar tool, remove the two trigger housing retaining pins

located at the side of the receiver (Fig. 12). Be careful not to damage the black

finish on the parts.

While holding the operating handle fully rearward, carefully lift the trigger housing

from the receiver (Fig. 13).

Fig. 12

With a pin punch or similiar tool, remove the two trigger housing retaining pins

located at the side of the receiver (Fig. 12). Be careful not to damage the black

finish on the parts.

Fig. 12

While holding the operating handle fully rearward, carefully lift the trigger housing

from the receiver (Fig. 13).

Allow the operating handle to SLOWLY move fully forward. Remove the bolt buffer

f

rom the rear of the receiver (Fig. 14).

Fig. 13

15

Fig. 14

Fig. 14

Fig. 14

Using the operating handle, pull the bolt rearward until you can insert your fore-

finger in front of the bolt. Be careful not to pinch your finger between the bolt face

and the barrel. Lift up slightly on the bolt with your forefinger and remove the bolt

handle through the ejection port.

Fig. 15

Fig. 14

Using the operating handle, pull the bolt rearward until you can insert your fore-

finger in front of the bolt. Be careful not to pinch your finger between the bolt face

and the barrel. Lift up slightly on the bolt with your forefinger and remove the bolt

handle through the ejection port.

Fig. 15

Continue to lift up on the bolt while slowly letting it come forward to rest against

the barrel. Reposition your forefinger grip and insert a finger through the ejection

port (Fig. 16). Maneuver the bolt assembly completely up and out of the receiver.

Remove the bolt spring and bolt spring guide rod (Fig. 17a).

Fig. 16

Using the operating handle, pull the bolt rearward until you can insert your forefinger in front of the bolt. Be careful not to pinch your finger between the bolt face

and the barrel. Lift up slightly on the bolt with your forefinger and remove the bolt

handle through the ejection port.

Fig. 15

Continue to lift up on the bolt while slowly letting it come forward to rest against

the barrel. Repo

port (Fig. 16). Maneuver the bolt assembly completely up and out of the receiver.

Remove the bolt spring and bolt spring guide rod (Fig. 17a).

sition your forefinger grip and insert a finger through the ejection

Fig. 16

No further disassembly should be done by the owner. If service is required, contact the factory authorized service center or a qualified gunsmith.

16

CLEANING AND LUBRICATION

N

OTE: Semi-automatic firearms require more frequent cleaning than those

manually operated.

With proper care, your Mossberg Intʼl.

TM

rifle will provide you with years of dependable service. Your firearm should be inspected and cleaned after every 200 rounds

to ensure that it remains in good condition. However, unusually dusty, dirty, or

harsh weather conditions, or use of dirty ammunition which leaves sig

nificant powder residue may necessitate more frequent cleaning. Clean your firearm as soon

as possible after use. This is especially important if your firearm has been exposed

to moisture.

Follow the instructions and use the equipment provided in a quality firearm

cleaning kit.

All metal parts should be cleaned with an appropriate firearm cleaning solvent

and lightly lubricated with gun oil. Over lubr

ication should be avoided. Use only

lubricants specifically designed for firearms. Avoid the use of abrasives, which

may damage the metal finish.

Normal use requires only that the mechanisms be free of excessive shooting

residue. Very little lubrication other than a light oiling of external surfaces is needed

to prevent rust.

If the firearm is to be stored for a long period of time it should be thorough

cleaned and oiled. Do not plug the barrel or store the firearm in a case that will

absorb lubricants.

THE TRIGGER HOUSING ASSEMBLY, BOLT ASSEMBLY AND RECEIVER

In the trigger housing, special attention should be given to the bolt sliding surfaces

and to the feeding ramp. The bolt and the receiver must be carefully cleaned and

free of any solid residues. Solid residues in the bolt/receiver areas may pr

event

the bolt from closing properly and a misfire may result.

THE BARREL

As it is not possible to clean the barrel from breech to muzzle, be very careful while

introducing the cleaning rod into the barrel muzzle, thus avoiding any damage to

the barrel crown.

Use a .22 caliber brass cleaning brush, moistened with solvent, scrubbing the barrel several times.

Use a .22 caliber cleaning rod with a clean cl

oth patch to wipe the bore dry. Repeat

several times, using a new patch each time, until the barrel is clean and shows no

signs of residue.

Final wipe with a quality gun oil moistened patch. Do not over-lubricate, a light film

is recommended.

Be sure not to leave cleaning patches or excessive oil or grease in the

bore and make sure the barrel is free of obstructions and excessive lubricant after cleani

ng as they can create dangerous obstructions, resulting

in damage to the firearm and/or serious personal injury to you or those

around you.

ly

17

TO REASSEMBLE THE FIREARM

TO REASSEMBLE THE FIREARM

Assemble the bolt spring and bolt spring guide rod into the bolt assembly (Fig.

17a and 17b).

TO REASSEMBLE THE FIREARM

Assemble the bolt spring and bolt spring guide rod into the bolt assembly (Fig.

17a and 17b).

Fig. 17a Fig. 17b.

Insert the assembly into the receiver, bolt face first (Fig. 18a). Insert the operat-

ing handle through the ejection port to line up with the operating handle slot in the

bolt (Fig. 18a).

TO REASSEMBLE THE FIREARM

Assemble the bolt spring and bolt spring guide rod into the bolt assembly (Fig.

17a and 17b).

Fig. 17a Fig. 17b.

Insert the assembly into the receiver, bolt face first (Fig. 18a). Insert the operat-

ing handle through the ejection port to line up with the operating handle slot in the

bolt (Fig. 18a).

Fig. 18a Fig. 18b

Compress the bolt spring and lower the bolt assembly into the receiver (Fig. 18b).

As the bolt is lowered into the receiver make sure the operating handle does not

move out of position. Compress the bolt recoil spring until the end of the bolt

spring guide pops into the blind hole in the rear of the receiver.

Insert the bolt buffer (Fig. 19). Make sure it is oriented as shown in figure 14.

Assemble the bolt spring and bolt spring guide rod into the bolt assembly (Fig.

17a and 17b).

Fig. 17a Fig. 17b.

Insert the assembly into the receiver, bolt face first (Fig. 18a). Insert the operating handle through the ejection port to line up with the operating handle slot in the

bolt (Fig. 18a).

Fig. 18a Fig. 18b

Compress the bolt spring and lower the bolt assembly into the re

As the bolt is lowered into the receiver make sure the operating handle does not

move out of position. Compress the bolt recoil spring until the end of the bolt

spring guide pops into the blind hole in the rear of the receiver.

Insert the bolt buffer (Fig. 19). Make sure it is oriented as shown in figure 14.

Fig. 19

Fig. 19

18

ceiver (Fig. 18b).

Using the operating handle, push the bolt fully rearward. While holding the bolt

Using the operating handle, push the bolt fully rearward. While holding the bolt

fully rearward, place the trigger housing assembly into the receiver (Fig. 20).

Allow the bolt to SLOWLY come fully forward. Align the holes in the trigger hous-

ing with the holes in the receiver, and insert the two trigger housing retaing pins

(Fig. 12).

fully rearward, place the trigger housing assembly into the receiver (Fig. 20).

Allow the bolt to SLOWLY come fully forward. Align the holes in the trigger housing with the holes in the receiver, and insert the two trigger housing retaing pins

(Fig. 12).

Fig. 20

MODELS WITH 702 PLINKSTER STOCK: Place the action into the stock an

reinstall the two take-down screws located in the stock (one to the rear of the trigger guard and one in front of the magazine).

MODELS WITH AR STYLE STOCK: For models with AR style stocks, reverse the

procedure outlined in the “Disassembly for Cleaning and Lubrication” section of

this manual. Ensure that the sling swivel is in place on the barrel prior to reassembly. Tighten the Plastite

TM

screws until snug. Do not over-tighten the Plastite

TM

screws as this can damage the forend and/or receiver shells. Ensure that the front

and rear takedown screws (Fig. 10) are securely tightened.

Check to ensure the firearm is functioning properly, see “Function

Testing” before using live ammunition.

FUNCTION TESTING

AFTER PERFORMING ANY WORK ON YOUR FIREARM SUCH AS

CLEANING, DISASSEMBLY OR INSTALLATION OF AN ACCESSORY:

a. Keep the muzzle pointed in a safe direction, remove the magazine

and pull the operating handle fully rearward to open the action, and

visually and physically check the chamber and inside the receiver to

be certain the firearm is unloaded.

b. Move the safety button fully to the ri

ght to the “ON” (SAFE) position.

KEEP THE MUZZLE POINTED IN A SAFE DIRECTION AT ALL TIMES

THROUGHOUT THE FOLLOWING STEPS! FAILURE TO DO SO

COULD RESULT IN SERIOUS INJURY OR DEATH IF THE FIREARM

HAS NOT BEEN PROPERLY UNLOADED, AND FIRES WHILE YOU

ARE TESTING ITS FUNCTION!

d

Close the action and leave the safety in the “ON” (SAFE) position. Pull the trigger

rearward fully. The hammer should not fall (No

Fire).

19

Remove your finger from the trigger. Move the safety to the “OFF” (FIRE) position.

The hammer should not fall (No Fire).

Leave the safety in the “OFF” (FIRE) position.

Pull the trigger rearward. The hammer should fall (FIRE).

Open the action by pulling the operating handle fully rearward and push the

operating handle in to lock the bolt in the open position. Move the safety button

fully to the right to

the “ON” (SAFE) position.

IF YOUR FIREARM DOES NOT PERFORM AS DESCRIBED IN ANY OF

THE ABOVE STEPS, CONTACT THE PRODUCT SERVICE CENTER

IMMEDIATELY. DO NOT ATTEMPT TO LOAD OR USE THE FIREARM.

PRECAUTIONS AND CARE WITH YOUR FIREARM

When you store your firearm, make sure that the magazine and the chamber are

empty.

Operation of the firearm and/or repeated disassembly may cause screws to

loosen. Refer to the section of the manual TO REASSEMBLE THE FIREARM

and check all screws including the Takedown Screws (Figure 10), the #4 Plastite

Screws (Figure 11), the #2 Plastite

each cleaning interval to ensure the continued accuracy and safe operation of

your firearm. Care should be taken, especially with the #2 Plastite

TM

Screw, and the Stock Bolt periodically and at

TM

Screw that

TM

attaches the Magazine Release, not to over-tighten any screws as this may cause

screws to strip.

Handling leaves moisture prints that can cause metal parts to rust. Abrupt

changes in temperature cause condensation and mo

isture. Wipe the barrel and

other metal parts with light oil after handling.

SIGHT ADJUSTMENT

BEFORE MAKING ANY SIGHT ADJUSTMENTS:

a. Keep the muzzle pointed in a safe direction, remove the magazine

and lock the operating handle in the open position (Fig 6 & 7), and

visually and physically check the chamber and inside the receiver to

be certain the firearm is unloaded.

b. Move the safety button fully to the right to the “ON” (SAFE) position.

ELEVATION ADJUSTMENT ON MODELS WITH

OUT AR STYLE STOCK: To raise

the point of impact, raise the rear sight by turning the top adjustment screw clockwise. To lower the point of impact, lower the rear sight by turning the top adjustment

screw counter-clockwise.

Windage adjustment: To move the point of impact to the right, turn the side adjustment screw clockwise. To shift the point of impact to the left, turn the side adjustment screw

counter-clockwise.

Remember: Move the rear sight in the same direction you would like the shot to

move. For example, if the point of impact is low and left from the point of aim,

20

move the rear sight upward and to the right. (Fig. 21)

Lower

Raise

Right

Left

Fig. 21

ELEVATION ADJUSTMENT ON MODELS WITH AR STYLE STOCK: To raise the

point of impact, raise the rear sight by turning the elevation knob clockwise. To lower

the point of impact, lower the rear sight by turning the elevation knob counter-clockwise.

Windage adjustment: To move the point of impact to the right, turn the windage

adjustment screw clockwise. To shift the point of impact to t

he left, turn the

windage adjustment screw counter-clockwise.

Remember: Move the rear sight in the same direction you would like the shot to

move. For example, if the point of impact is low and left from the point of aim,

move the rear sight upward and to the right. (Fig. 22)

Left

Raise

Right

Lower

Fig. 22

21

SERVICE INSTRUCTIONS

Should your firearm, or any component of your firearm require service, ship your

entire firearm (please do not send components only), via your chosen carrier,

postage paid (we do not accept C.O.D. shipments), following these instructions:

• Make absolutely certain your firearm is unloaded.

• Do not send ammunition with your firearm.

• Remove all accessories from your firearm such

mounts, etc.

• Ship your firearm in a suitable container, packaging it securely to

prevent parts from shifting and/or harm during shipping.

• Include a note with a clear description of the service you wish us to

perform, your complete return shipping address (no P.O. boxes

please), your daytime telephone number and your e-mail address (if

available). It is advisable to place your c

shipping container when shipping.

SHIPPING ADDRESS

Product Service Center

Maverick Arms, Inc.

1001 Industrial Blvd.

Eagle Pass, TX 78853

Attention: Repair

If you have any questions, please contact the Product Service Center at

(800) 363-3555, or service@mossberg.com

TO ORDER PARTS FROM US

To order parts from the Product Service Center, you can fax, phone,

mail, or e-mail your order to us at one of the below numbers/addresses.

Fax Number: (830) 773-5893

Phone Number: (830) 773-9007

E-mail Address: service@mossberg.com

Mailing Address: Product Service Center

Maverick Arms, Inc.

1001 Industrial Blvd.

Eagle Pass, TX 78853

Attention: Order Department

as scopes, slings,

orrespondence inside your

Please provide your name, address, city, st

and e-mail address. Weʼll need Model #, Serial #, Gauge/Caliber, Finish, Part #

and Part Name. We have a $7.50 (U.S.) minimum parts order charge. We accept

most major credit cards, personal checks, money orders, and bank drafts.

Service outside of the U.S.A.

For Mossberg International firearm parts and service requirements outside of the

United States, customers are r

International stocking dealer/distributor.

equested to contact the closest Mossberg

ate, zip, your daytime phone number

22

MOSSBERG INTERNATIONAL WARRANTY

702/715T™ .22 CALIBER SEMI-AUTOMATIC RIFLE

ONE (1) YEAR LIMITED WARRANTY

Limited Warranty: Mossberg International, Inc. (“Mossberg”) warrants to you, the original retail

purchaser of a new Mossberg Intʼl.

the Mossberg firearm will be free of defects in material or manufacture for a period of one (1)

year from the date of your purchase of the new Mossberg firearm (the “Warranty Period”) in the

United States or Canada. This is

MOSSBERG MAKES NO OTHER WARRANTIES OF ANY KIND OR CONDITIONS, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

This Limited Warranty gives you specific legal rights, and you may have other rights that vary

from State to State.

Purchaserʼs Remedy: During the Warranty Period, Mossberg will, at its sole option, (1) repair

the Mossberg firearm or any part thereof that, upon examination and testing by Mossberg, does

not conform to the Limited Warranty without charge to you for parts or labor, or (2) replace the

Mossberg firearm with a new or similar model. THIS REMEDY SHALL BE YOUR EXCLUSIVE

AND SOLE REMEDY FOR ANY BREACH OF WARRANTY. MOSSBERG S

RESPONSIBLE FOR ANY OTHER EXPENSES, LOSSES OR INCONVENIENCE THAT YOU

MAY SUSTAIN AS A RESULT OF THE PURCHASE, USE, MALFUNCTION OR DEFECTIVE

CONDITION OF THE MOSSBERG FIREARM. Mossberg reserves the right to inspect, examine

and/or test the Mossberg firearm to assess any claim made under the Limited Warranty.

TM

.22-caliber semi-automatic rifle (the “Mossberg firearm”), that

the only express warranty on the Mossberg firearm.

HALL NOT BE

EXCLUSIONS:

THE MOSSBERG FIREARM OR ANY DAMAGE CAUSED BY:

(1) NORMAL WEAR AND TEAR;

(2) FAILURE TO PERFORM PROPER CARE AND MAINTENANCE;

(3) ACCIDENTS, ABUSE OR NEGLECT;

(4) BARREL OR BORE OBSTRUCTIONS;

(5) FAILURE TO FOLLOW THE INSTRUCTIONS AND WARNINGS THAT ACCOMPANY

THE MOSSBERG FIREARM; OR

(6) THE USE OF DEFECTIVE, NON-SAAMI STANDARD, REMANUFACTURED,

LOADED, AND/OR RELOADED AMMUNITION.

IN ADDITION, ANY UNAUTHORIZED REPAIRS, ALTERATIONS OR MODIFICATIONS TO THE

MOSSBERG FIREARM WILL AUTOMATICALLY VOID THE LIMITED WARRANTY.

LIMITATION OF DAMAGES:

BE LIABLE FOR ANY LOSS OR DAMAGE WHATSOEVER ARISING FROM THE USE OF THIS

MOSSBERG FIREARM, WHETHER DIRECT, INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL

OR PUNITIVE, REGARDLESS OF THE LEGAL THEORY ASSERTED, INCLUDING CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. SOME JURISDICTIONS DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, O

DENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

Warranty Service:

found in the “Service Instructions” section of the Ownerʼs Manual and return the Mossberg firearm

to the authorized Product Service Center. You are responsible for all shipping costs to the Product

Service Center. Mossberg will not accept COD shipments of any Mossberg firearm for service.

After repair or replacement, the

postage paid by Mossberg. If we replace the Mossberg firearm, we will keep the firearm that you

returned to Mossberg.

Modification of Warranty:

firearms has any authority to modify the terms or conditions of the Limited Warranty in any way.

The Limited Warranty may only be modified in writing by an authorized officer of Mossberg.

THIS WARRANTY DOES NOT COVER THE COSMETIC APPEARANCE OF

HAND-

EXCEPT WHERE PROHIBITED BY LAW, MOSSBERG WILL NOT

R THE EXCLUSION OF INCI-

To obtain service under this Limited Warranty, you must follow the instructions

Mossberg firearm or a similar model will be returned to you, return

No agent, representative, distributor, or authorized dealer of Mossberg

THIS LIMITED WARRANTY IS EFFECTIVE JANUARY 1, 2003.

23

EXPLODED VIEW

EXPLODED VIEW

14

14

13

12

12

11

11

4

4

10

10

9

9

16

16

13

6

6

7

7

8

8

5

5

1

1

3

15

15

3

2

2

Item No. Description

1 Stock assembly - standard

2 Stock assembly - thumbhole

3 Take down screw (2 pieces)

*4 Receiver and barrel assembly

5 Operating handle

*6 Bolt assembly

7 Bolt recoil spring

8 Bolt recoil spring guide

Items marked with an asterisk (*) are reserved for qualified gunsmiths only.

PARTS LIST

Item No.

9 Bolt buffer

10 Pin 5.0 x 26.0 mm (2 pieces)

11 Rear sight assembly

12 Rear sight screw (2 pieces)

13 Front sight assembly

14 Front sight screw (2 pieces)

*15 Trigger guard assembly

16 Magazine Assembly

24

Description

EXPLODED VIEW

EXPLODED VIEW

702 With AR Shell

702 With AR Shell

14

14

15

15

23

23

8

8

22

22

2

2

5

5

17

17

18

18

19

19

16

16

13

13

12

12

9

11

11

10

10

1

1

4

4

7

7

20

20

21

21

9

3

3

6

6

Item No. Description

1 Receiver shell right

2 Receiver shell left

3 Forearm right

4 Forearm left

5 Tactical stock assembly

6 Accessory rail (2 pieces)

7 Magazine release lever right

8 Magazine release lever left

9 Barrel band sling swivel

10 Rear sight elevation knob

11 Rear sight windage knob

Items marked with an asterisk (*) are reserved for qualified gunsmiths only.

PARTS LIST

Item No.

12 Rear sight elevation base

13 Rear sight aperture

14 Flat washer

15 Wave washer

16 Magazine Assembly

*17 Receiver and barrel assembly

18 Rear take down screw

19 Front take down screw

20 #2 Plastite

21 #4 Plastite

22 Stock bolt (2 Pieces)

23 Scope mounting rail

25

Description

TM

screw

TM

screw (18 pieces)

NOTES

26

NOTES

27

FIREARMS SAFETY DEPENDS ON YOU.

MAKE NO MISTAKE ABOUT IT!

From the time an individual picks up a firearm, that individual shooter

becomes a part of a system over which he has complete control. He is

the only part of the system that can make a gun safe – or unsafe. Hunting

and target shooting are among the safest of all sports. This booklet is

intended to make them even safer – by re-emphasizing and reaffirming

the basics of safe gun handling and storage and b

vidual shooter that he or she is the key to firearms safety. You can help

meet this responsibility by enrolling in hunter safety or shooting safety

courses. You must constantly stress safety when handling firearms,

especially to children and non-shooters. Newcomers in particular must

be closely supervised when handling firearms with which they may not

be acquainted. Don’t be timid

observe anyone violating any safety precautions, you have an obligation

to suggest safer handling practices, such a those in this booklet. Please

read these rules carefully and follow the safety procedures outlined.

Firearms safety is up to you. Make no mistake about it.

1. ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION

2. FIREARMS SHOULD BE UNLOADED WHEN NOT ACT

IN USE

3. DON’T RELY ON YOUR GUN’S “SAFETY”

4. BE SURE OF YOUR TARGET AND WHAT’S BEYOND IT

5. USE CORRECT AMMUNITION

6. IF YOUR GUN FAILS TO FIRE WHEN THE TRIGGER IS PULLED,

HANDLE WITH CARE

7. ALWAYS WEAR EYE AND EAR PROTECTION WHEN SHOOTING

8. BE SURE THE BARREL IS CLEAR OF OBSTRUCTIONS BEFORE

SHOOTING

9. DO NOT ALTER OR MODIFY YOUR GUN, AND HAVE GUNS

SERVICED REGULARLY

10. LEARN THE MECHANICAL AN

OF THE FIREARM YOU ARE USING

when it comes to gun safety. If you

D HANDLING CHARACTERISTICS

y reminding each indi-

UALLY

Courtesy of

Sporting Arms and Ammunition Manufacturers� Institute, Inc.

Sporting Arms and Ammunition Manufacturers Institute, Inc.

Courtesy of

Loading...

Loading...