MosquitoBite Planes Robin Contruction Manual

Construction Manual

Read all Safety notes before proceeding with this Construction

Manual. It is recommended that the builder read this

Construction Manual in it’s entirety before building any portion

of the supplied kit.

A Word About Safety

• The Robin is a highly engineered kit that requires the modeller to follow exact instructions to complete the

kit properly. Failure to follow the instructions provided may result in loss or damage to the kit or to persons

and property. Take your time building this kit. Attention to detail is required in completing each section.

• Do not alter/modify this kit beyond its designed specifications. Over stressing the kit in any way (i.e. too

much power or too much weight), may result in unexpected behaviour when operating. This model kit can

travel very fast; you must operate it with care for the sake of yourself and others.

• Use quality components when installing radio equipment. Do not use damaged or modified servo/radio

equipment as this may result in improper or unsafe operation of this kit.

• Always perform a radio check before operating the engine. Be sure that all radio equipment is in perfect

operating condition. All clevis connections must have safety keepers to prevent loss of control.

• If the modeller building and/or flying this model airplane is not well experienced in how to perform a radio

check or perform any of the functions related to the safe construction and/or operation of this kit, then

he/she should first consult a MAAC/AMA recognized pilot for assistance.

• Note: As the manufacturer, we provide a high-quality product for modellers to build. Great consideration

has been given to the safe operation of this kit when built properly. However, the modeller building this kit is

completely responsible for the quality of the construction. By no means, implied or otherwise, is the

manufacturer responsible for the safe construction and operation of this kit. Safe operation and the safe use

of materials and tools is the responsibility of the builder.

IV

MosquitoBite Planes Robin

Let Us Help You

During the construction or operation of this model airplane, if at

any time you are unclear about any part of the build process or

have questions on flight, CALL US FIRST. We cannot stress this

enough. Building this kit while unsure of any particular aspects of

this kit’s construction or operation may result in unwanted flight

behaviour.

Do not modify or alter this kit beyond what is instructed. If

alterations are attempted, you must consult with the designer

first so that impact to the design can be assessed.

We are always here to help. You may contact us at any time

through email, letter, or by phone (during business hours).

If Things Change

If you find there is a discrepancy in this Construction Manual

compared to information found on the plans, contact us for

clarification.

Shopping List

There are a few items you will need when building this kit:

• Lee Valley 2002 GF Cabinet Maker’s Wood Glue

• Thin CA Glue

• Epoxy Glue (12 min)

• 2 Rolls of UltraCote covering

• Dave Brown 46-50 Engine Mount

• OS .46AX Engine

• Engine Mounting Hardware

• Bisson Custom Muffler #1000

• APC 12x7 Propeller

• Fuel Tubing

• Throttle Cable

• DU-BRO Servo Arm Set

• 8oz Fuel Tank

• 2

1

⁄2" Spinner

• 1⁄8" Fluxless Pipe Solder

• Hangar 9 Remote Glow Plug Adapter (preferred, not required)

• Clear Desk Tape

Definitions of Terms

“Dryfit” means to place a part into its position but not to apply

glue of any sort at this time.

Gluing Note:

Two types of glue will be used in the construction of this model.

When the manual instructs you to “glue", use W

OOD GLUE. When

thin CA GLUE is required, the manual will specify.

Star Icon:

The STAR icon on laser-cut parts, always indicates the starboard

side of the part.

Starboard = Right hand side.

Port = Left hand side.

Important: Read

Read this Construction Manual first before starting. Familiarize

yourself with all aspects of the construction; then begin.

Model Weight

To achieve the target model weight of 112oz is recommended,

but not necessary. Those who wish to add remote glow

equipment, pumps, cameras, large batteries [etc...] can do so

without adverse effects (within reason). The scratch version of the

Robin was built light by design. Some materials used in this kit

differ from the original Robin for the sake of offering a true kit and

not a scratch-build project with ribs cut out. The result: build time

is now a fraction of what was once needed. But to get down to

112oz will take a conscious effort on the part of the modeller.

Below is a list of pointers to help get to that magical number.

Weight Saving List:

• Cover the plane in UltraCote Lite covering, Solarfilm or

equivalent light weight covering - cloth covering not supported.

• Sand the Fuselage and the tips of the tail surfaces round as

shown on the supplied plans. (More material at the rear of the

plane will require more ballast in the nose.)

• Carefully glue the Tail area only with necessary amounts of glue.

• Use the supplied tail wheel or a lighter foam wheel.

• Refrain from applying elaborate graphics to the tail of the plane.

• Use a prop weight inside the spinner to set CG further out.

• Apply ballast inside the lower cowl as instructed.

• Use standard servos in the Fuselage and Wing.

• Sand the undercarriage to the profile shown on the plans.

• Use specified 12x7 APC prop.

• Trim wing and undercarriage bolts 1/4" past threaded opening.

• Use supplied Push-Nuts for all wheel axles.

• Allow 1 week of drying before covering the plane.

• Cover the Wing & Fuselage when humidity is lowest.

• Install battery in forward half of receiver box.

Covering Weight Chart (referencing manufacture’s data)

Monokote - - - - - - - - - - - - - - - - - - - - - - 78.576 g/m

2

(white)

UltraCote/Oracover - - - - - - - - - - - 71.041 g/m2(Cub Yellow)

UltraCote/Oracover Lite - - - - - - - 36.597 g/m2(Trans. Yellow)

UltraCote/Oracover AIR (OD)- - - - - - - - - - - - - - - - - ~33 g/m

2

Solarfilm- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50-65 g/m

2

SolarSpan- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60-80 g/m

2

LiteSpan - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30 g/m

2

1 Roll of Monokote = 13 sqft. or 1.207 sqm (94.84g)

1 Roll of UltraCote = 12.916 sqft. or 1.200 sqm (43.91g)

Example: 2 Rolls of UltraCote Lite saves you 3.59oz (101.86g) over

standard Monokote.

Servo Weight:

Hitec HS-475HB - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40g

Futaba S3004 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37g

JR 537 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45g

Airtronics 94102Z - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45g

Electric conversion is possible but not supported by this manual

at this time. Check our website for developing information

regarding this.

MosquitoBite Planes Robin

V

A Word About Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .III

Let Us Help You IV

If Things Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IV

Shopping List IV

Definitions of Terms IV

Important: Read IV

Model Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IV

Forward VI

A few notes from Andy Lennon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VI

The Wing 1

Wing Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Assembling the Wing Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installing Ribs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Constructing the Leading Edge Spar . . . . . . . . . . . . . . . . . . . . . . . . . .2

Creating the Slot Lip (TE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Creating the Ailerons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Creating the Flaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sheeting the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Flap Hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wing Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Aileron Hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fuselage 9

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pre-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Constructing the Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Main Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Steering Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Elevator Cable Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Rudder Cable Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connecting the Fuselage Sidewalls to the Floor . . . . . . . . . . . . .15

The Tail Gear and Steering Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Setting the Rudder Cable Position . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Creating the Horizontal Stab (H.S.)/Elevator 18

Creating the Horizontal Stab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Creating the Elevator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Elevator Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Main Hatch 22

Forward Hatch Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Aft. Hatch Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Completing the Tail 26

Sheeting the Vertical Stab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

The Rudder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Mass Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Building the Nose 30

The Upper Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

The Lower Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Sheeting the Lower Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Sheeting the Upper Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Main Landing Gear 35

Final Touches 36

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Gluing the Snaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Setting Centre of Gravity (CG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Engine and Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Covering the Nose and Sealing the Lower Cowl . . . . . . . . . . . . .36

Notes 37

Table of Contents

VI

MosquitoBite Planes Robin

Forward

A few notes from Andy Lennon

The Robin is a versatile model airplane, with a wide speed range, that

can take off and land in either of two modes: the conventional mode or

the STOL mode (short take off and landing) – made possible by several

unique features which are described below. It is a “fun” airplane.

The wing features large slotted flaps that cover 65% of its trailing edge

and when extended 40 degrees, virtually double the lift of that 65% of

wing area. The wing’s airfoil is the Eppler E197. It’s aspect ratio (ratio of

span to chord) is 6. It has low profile drag and a gentle stall at 20

degrees AOA (angles of attack) out of ground effect. Its zero lift AOA is

minus 2 degrees.

Ahead of the ailerons, the E197 airfoil is modified to NASA development

leading edge extensions and droop that do three things: the stall is

delayed a further 9 degrees, aileron control at high angles of attack is

effective and there is no tip-stalling, important for STOL landings.

The fuselage, when the model is on its three wheels, is inclined upward

10 degrees. The wing is set at plus 2 degrees to the centreline and is

therefore at 12 degrees angle of attack; moving forward, the wing lift is

close to the maximum, but below the stall. With flaps half extended and

in ground effect, the stall is at 17 degrees. This permits the short take off.

The landing gear in conventional or “tail dragged”. With all three wheels

firmly on the ground, the model is directionally stable and is

maneuvered by the steerable tail wheel, linked to the rudder control.

With the tail wheel off the ground, however, the model is directionally

unstable; this calls for careful rudder action to prevent the model from

veering which it is prone to do!

The recommended power for the Robin is the OS MAX .46AX engine that

turns the recommended APC 12X7 prop at 10,000 rpm. producing thrust

estimated to equal the model’s fuelled weight. This provides a steep

climb. Minimum level flight speed, flaps fully extended, is 20 mph and 80

mph in full speed level flight, flaps up. For low drag, the engine is

enclosed in a ducted cowling. The lower half of this cowl is easily

removed and replaced for engine servicing, such as glow plug changes.

A remote jack permits glow plug lighting safely away from the lethal

prop. Engine cooling has not been a problem.

The horizontal tail is positioned low in the fuselage where it is in the

prop’s powerful slip stream. The elevators are 40% of the tail’s area and

when raised, cause the tail wheel to rest firmly on the ground under slip

stream pressure. To taxi, hold “up-elevator” which provides good steering

and prevents “noseovers” should the main wheels meet an obstruction

like long grass. The flaps, when extended, create considerable

turbulence. The large dorsal fin ahead of the vertical tail provides good

directional control despite the turbulence.

A 6 channel transmitter-receiver is recommended with a 3 position snap

switch for flap control: up, 20 degrees down, and 40 degrees down.

The ailerons have heavy differential (20 degrees up and 10 degrees down)

and are top hinged with modified Frise features that eliminate adverse

yaw. The model turns on ailerons alone without rudder input.

The Robin is spirally stable. Put in 20 degree bank and controls centred, it

will return to level flight on its own. It will fly inverted, but requires a

healthy amount of down elevator (inverted down elevator is up-elevator).

The two modes of take off are conventional and STOL. In the

conventional, the model is pointed upwind, flaps half extended, and the

throttle slowly opened. As the model accelerates, the tail comes up and

the directional instability raises its ugly head. Torque and gyroscopic

precession cause a swing to the left, calling for just the right amount of

rudder. Over control results in a swing to the right and danger of a

ground loop. This is not imaginary – it has happened! At 20 feet of

altitude, raise the flaps, level off, and the plane is up and away.

For the preferred STOL take off, point the model into the wind, lower half

flap, hold enough up elevator to keep the tail-wheel firmly on the

ground and open the throttle wide. On a calm day, take off run is under

4 feet; on a day with wind of 10 to 15 mph, the take off is almost

instantaneous followed by a steep climb. At 20 feet, raise the flaps, level

off and the plane is away. Directional control on the ground is good and

torque and gyroscopic precession are avoided.

There are two types of landing: the low wind STOL landing and the high

wind landing. On a low wind day, do not try to land flaps up. The glide is

fast and flat; overshooting the landing area is probable. Instead throttle

to idle, lower full flap; the added lift and drag permits steep approaches

at relatively low speeds. There is little or no change in the model’s

attitude with flaps lowered fully – just a noticeable reduction in speed.

The objective is to have all three wheels touch down simultaneously at a

speed just above the stall, which is (flaps fully down and in ground

effect) 14 degrees. At an AOA of 12 degrees, the plane is just below the

stall. Ground run 4 feet. This is when the “no tip-stall” feature is so

valuable. The wing area ahead of the flaps may be stalled but the two

outer panels are still lifting with effective aileron control.

On a windy day, land flaps up with a bit of power. A model flying at 30

mph into a wind of 15 mph has a ground speed of 15 mph. Rather than

a full stall landing, land on the main wheels first, closing the throttle to

idle just before touchdown.

The Robin will spin but very reluctantly; the spin has to be forced by full

up-elevator and full rudder offset. After 3 or 4 turns, the spin will convert

to a fast spiral dive, speeds of well over 100 mph are possible - the model

has low drag - so do not omit the mass balancing of the ailerons,

elevators and rudder which will prevent “flutter” at high speeds.

Enjoy the Robin and happy landings!

- AGL

In a later note, Andy offered more information about landing with

full flaps:

Lowering flaps while at altitude will create substantial downwash. The

downwash will hit the horizontal tail and influence it’s attitude. Pilots

must be careful to note that while landing with full flaps, you will

eventually come into ground effect. At that point, the downwash over

the horizontal tail will be reduced due to the pressure from the ground.

The Robin will pitch down slightly as the downwash pressure eases off

the horizontal tail, so pilots should be ready for it when approaching

with full flaps.

MosquitoBite Planes Robin

1

The Wing

Wing Construction

Glue and clamp together Main Centre Spar layers, to create the

laminated Main Centre Spar and Rear Centre Spar. Leave to dry.

The three pieces that make up the Main Centre Spar must be

glued together very precisely. Each of the 3 pieces have a slight

lengthwise curve. Ensure the insides of the curves face each other

(this cancels out any over-all curve) and glue together.

Repeat this method to laminate the two layers of the Rear Centre

Spar and the two layers of the Wing Bolt Beam.

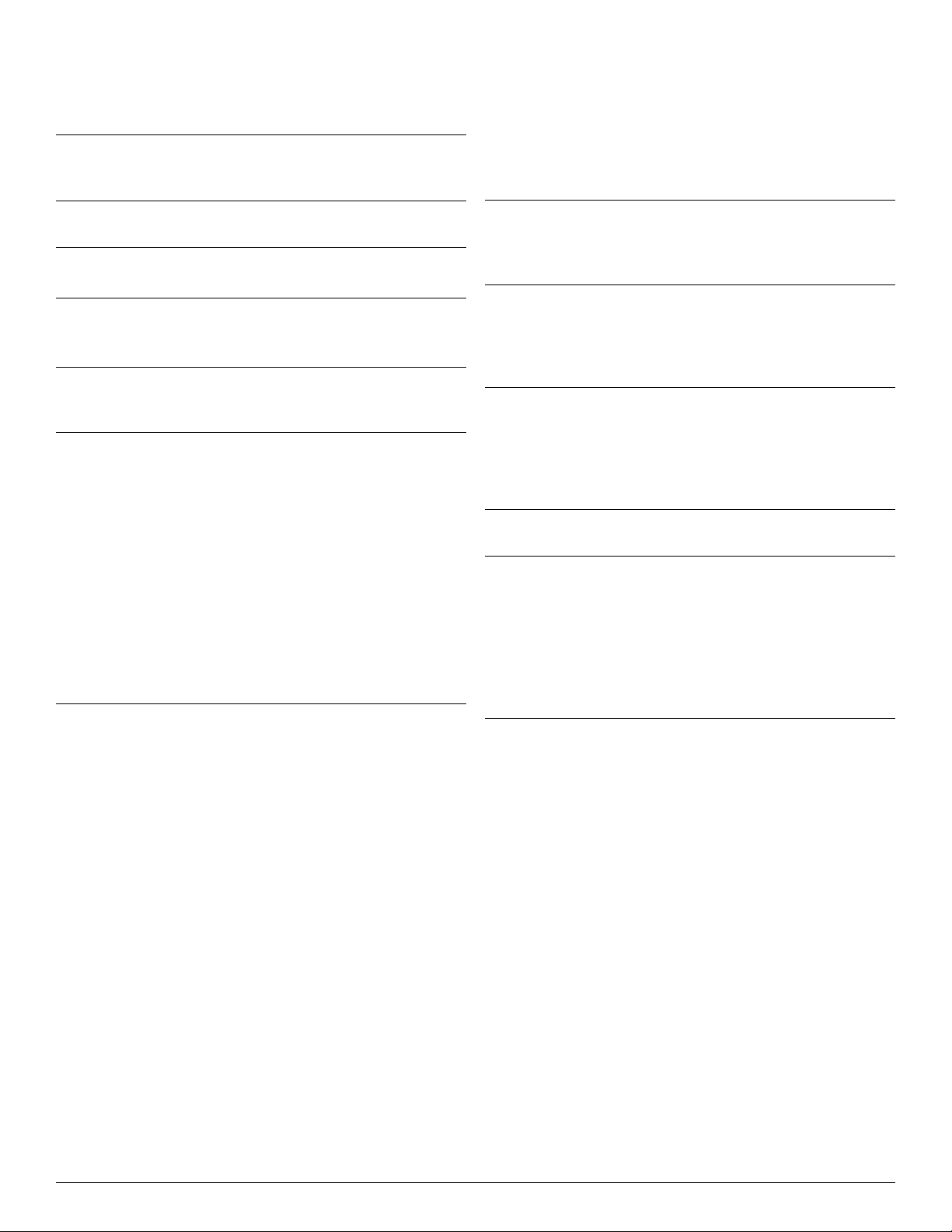

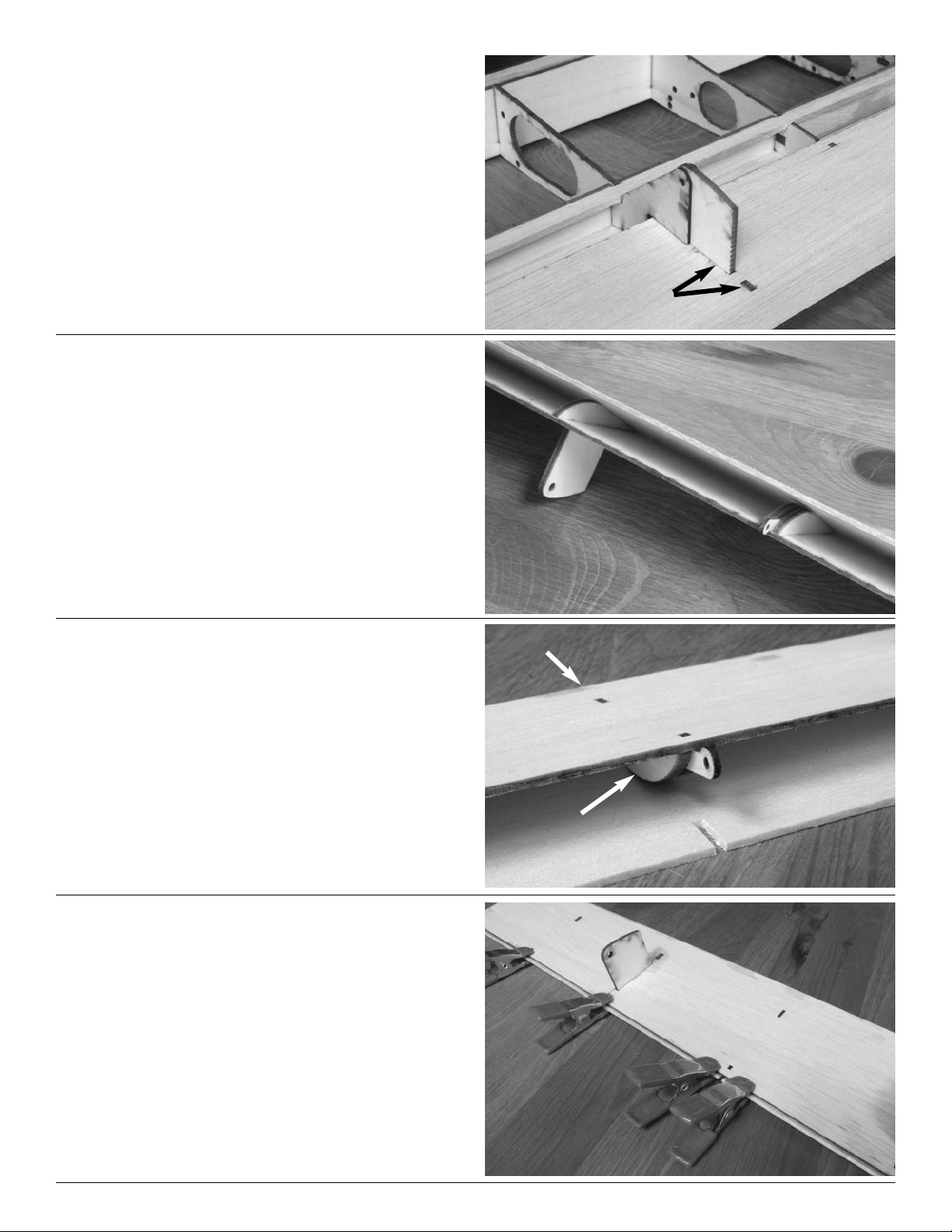

Assembling the Wing Cage

The gluing of the Wing Cage must be done quite rapidly.

Therefore, we suggest you familiarize yourself with the Cage

assembly by dryfitting the following pieces as shown in Figure 1

• Main Centre Spar - 3 parts

• Rear Centre Spar - 2 parts

• Wing Servo Tray

• Rib A (x2)

• Wing Bolt Beam - 2 parts

If any parts are too snug, perform minimal sanding.

Disassemble and continue with these gluing instructions:

Along the front and back edges of the Wing Servo Tray, run a line

of glue. Immediately connect the Main Centre Spar to the Tray’s

front, and the Rear Centre Spar to the Tray’s back.

Glue the rear edge of the Wing Bolt Beam and install in place

along the front of the Main Centre Spar.

Run a line of glue along both side edges of the Wing Servo Tray,

and along the sides edges of the Wing Bolt Beam.

Slide Rib A along the Spars. The letter “A” on each Rib, should both

be facing the Wing Servo Tray. Connect both Rib A parts into the

tabs of the Wing Servo Tray and the Wing Bolt Beam.

Before the Wing Cage cures, place a heavy weight in the centre of

the Wing Servo Tray to ensure all parts dry flat and square.

Fig 1

2

MosquitoBite Planes Robin

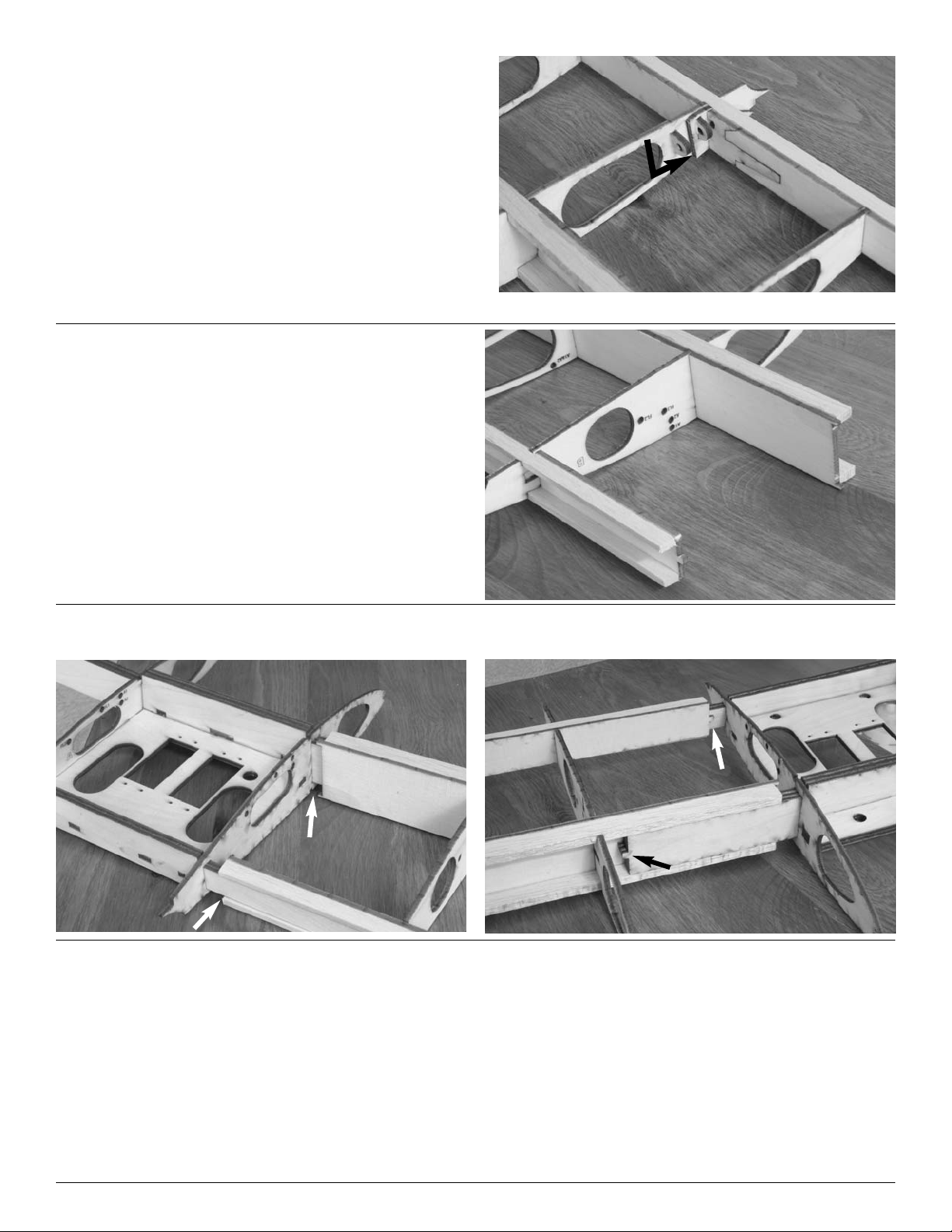

Installing Ribs

Place Main Spar upside down on its top edge. Along side it, place

a

3

⁄8" x 3⁄16" stick - wide side down. Dryfit Rib B into the first slot so

that it holds the balsa stick against the Main Spar. See Figure 2.

Note: In Figure 2, Rib B and the Main Spar are shown upside

down, as constructed. Also note that the end of the stick must

extend slightly past the end of the Main Spar. This will be

trimmed later.

Continue to dryfit Ribs C to J.

Dryfit the remaining

3

/

8" x

3

/

16" stick along the Main Spar. Glue with

thin CA, the upper and lower sticks along the Main Spar. (Using

wood glue here would warp the wing due to its moisture

content.) Watch the Main Spar doesn’t develop a curve.

Repeat instructions to create the opposite side of the wing.

(Be careful not to make two left wings.)

Constructing the Leading Edge Spar

Locate Rib F1. (half a rib)

Install Rib F1 against the forward half of Rib F, between

Ribs F and E.

To install Leading Edge Spar, you must first ensure that all ribs are

evenly spaced. Therefore, use the Rear Spar as a tool and dryfit

the Rear Spar into the rear slots of all ribs. Then place the other

Rear Spar over the leading edge of all Ribs to ensure the spacing

is correct. See Figure 3.

Do note Glue the Rear Spars yet.

Glue (wood glue) a

3

/

16" square stick to the leading edges of Ribs F

to J. Use masking tape to hold the stick in place while glue cures.

Remove the two temporary Rear Spars.

Once the leading edge’s stick has cured, remove the tape.

Repeat for the opposite side of the wing.

Fig 2

Fig 3

F1

MosquitoBite Planes Robin

3

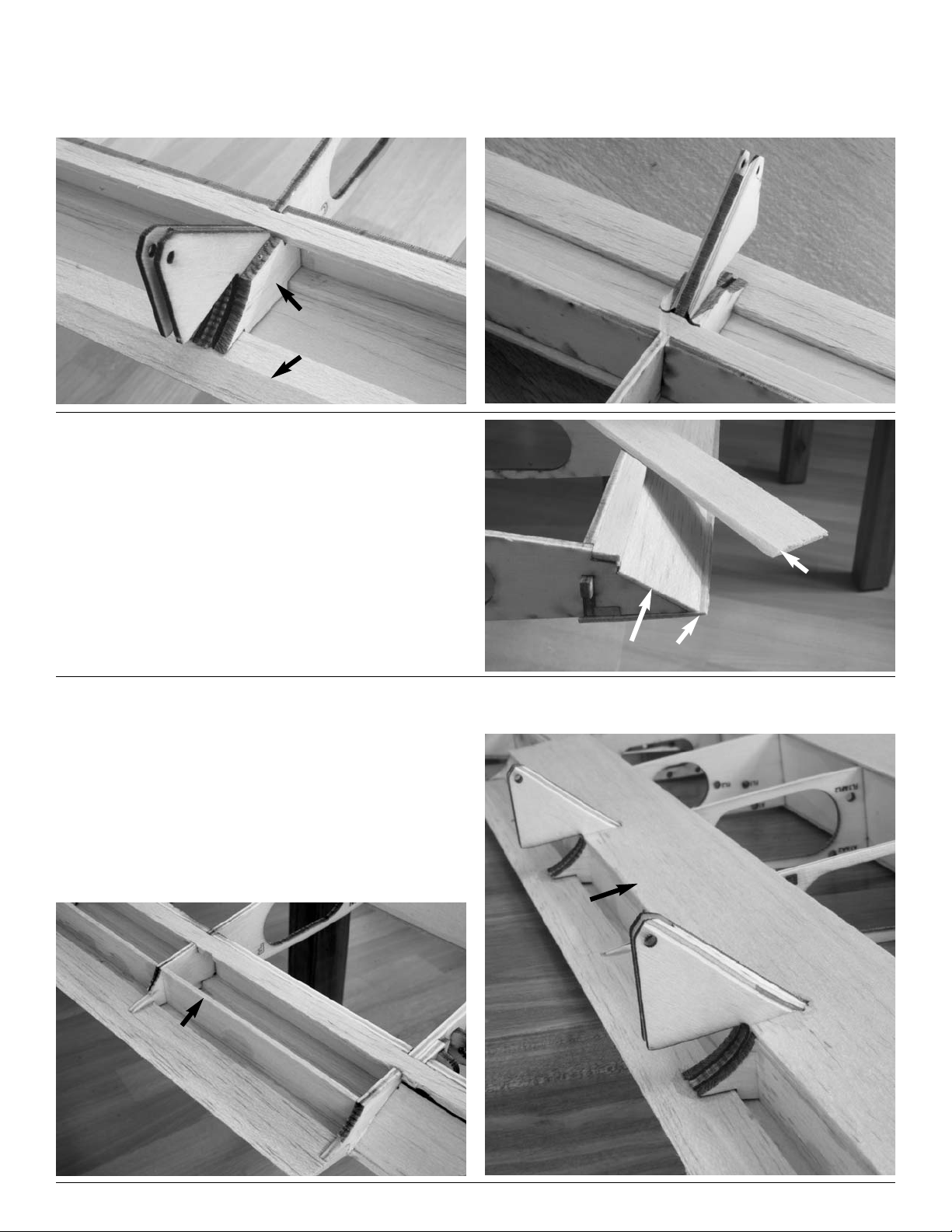

Glue Rib G1 on the outboard side of Rib G.

Dryfit the upper and the lower

1

/

4" x

1

/

8" sticks into the slots of

every Rib behind the Rear Spar. (See Plan Sheet 2)

Glue two Aileron Cable Anchors into the slots of Rib G1 as shown

in Figure 4.

Trim flush the sticks that protrude from the inboard upper and

lower Main Spar and Rear Spar, as shown in Figure 5.

Repeat the “Constructing the Leading Edge Spar” instructions to

create the opposite side of the wing.

Test the connection of each Wing-side to the Wing Cage,

as shown in Figures 6 and 7.

Glue the Wings to the Wing Cage in all places where contact is made.

Using thin CA, glue the Rear Spar and its upper and lower balsa

sticks in place.

Glue both Flap Cable Anchors into Rib D. They line up with the

hole on the Rear Spar. Repeat for the opposite side of the wing.

Apply a bead of glue to the joint of each Rib and Main Spar as

well as to the joint of each Rib and Rear Spar.

Dryfit a

3

/

16" square stick to the leading edge of each Wing from

Rib A to F1(the half-rib). See plan sheet 2 for details.

Use masking tape to hold each stick in place while glue cures.

Slide Rib G1 in

Fig 4

Fig 5

Fig 7

Fig 6

4

MosquitoBite Planes Robin

Locate all eight Flap Support Arms.

Glue two Flap Support Arms to either side of Rib C and to either

side of Rib E as shown in Figure 8.

Before the glue cures, use a

3

/

32" wire to align the hinge holes as

shown in Figure 9. Repeat for the opposite side of the wing.

Fig 8

Fig 9

Fig 10

Aileron Horn

Aileron Rib

Creating the Slot Lip (TE)

Locate the Trailing Edge Stock (

3

/

16" x

3

/

4"). Cut two pieces,

each 22" long.

Apply glue to the trailing edge of Rib A to Rib G on both sides of

the Wing, and install both pieces of Trailing Edge Stock.

Clamp until cured.

Creating the Ailerons

Locate two Aileron Base Sheets, eight Aileron Ribs, two Aileron

Horns, two Aileron Spars and two Aileron Top Sheets.

Build both Ailerons at the same time (facing each other) to

prevent making two left Ailerons.

On the Base Sheets, position the Aileron Ribs and Aileron Horns in

their slots. See Figure 10.

Dryfit the Aileron Spar into the End Slots of all Aileron Ribs and

Aileron Horns.

Making sure not to glue the Spar, apply thin CA to the base of all

the Aileron Ribs and Aileron Horns. (We don’t want to glue the

spar in yet.)

Remove the Spar and apply wood glue to the Aileron Ribs and to

the short edges of the Aileron Horns. Replace the Aileron Spar.

(Note: Ensure that no wood glue contacts the Aileron Base Sheet

to avoid warping.)

MosquitoBite Planes Robin

5

Position each Aileron at the edge of a table and use a sanding

block to sand the edge of the Aileron Base Sheet to a fine point.

Locate the two Aileron Top Sheets.

Dryfit each Top Sheet along the upper tabs of the Aileron

Ribs/Horn.

Wick thin CA glue into the tabs of each Aileron Rib/Horn. (Note:

To avoid a twisted Aileron, hold the assembly down on a flat

surface as CA glue is applied.)

Once the Top Sheet has cured, sand the trailing edge to almost a

fine point. Cover Aileron with Ultracote and install the Mass

Balance along the full width of the Aileron. See Plan Sheet 2.

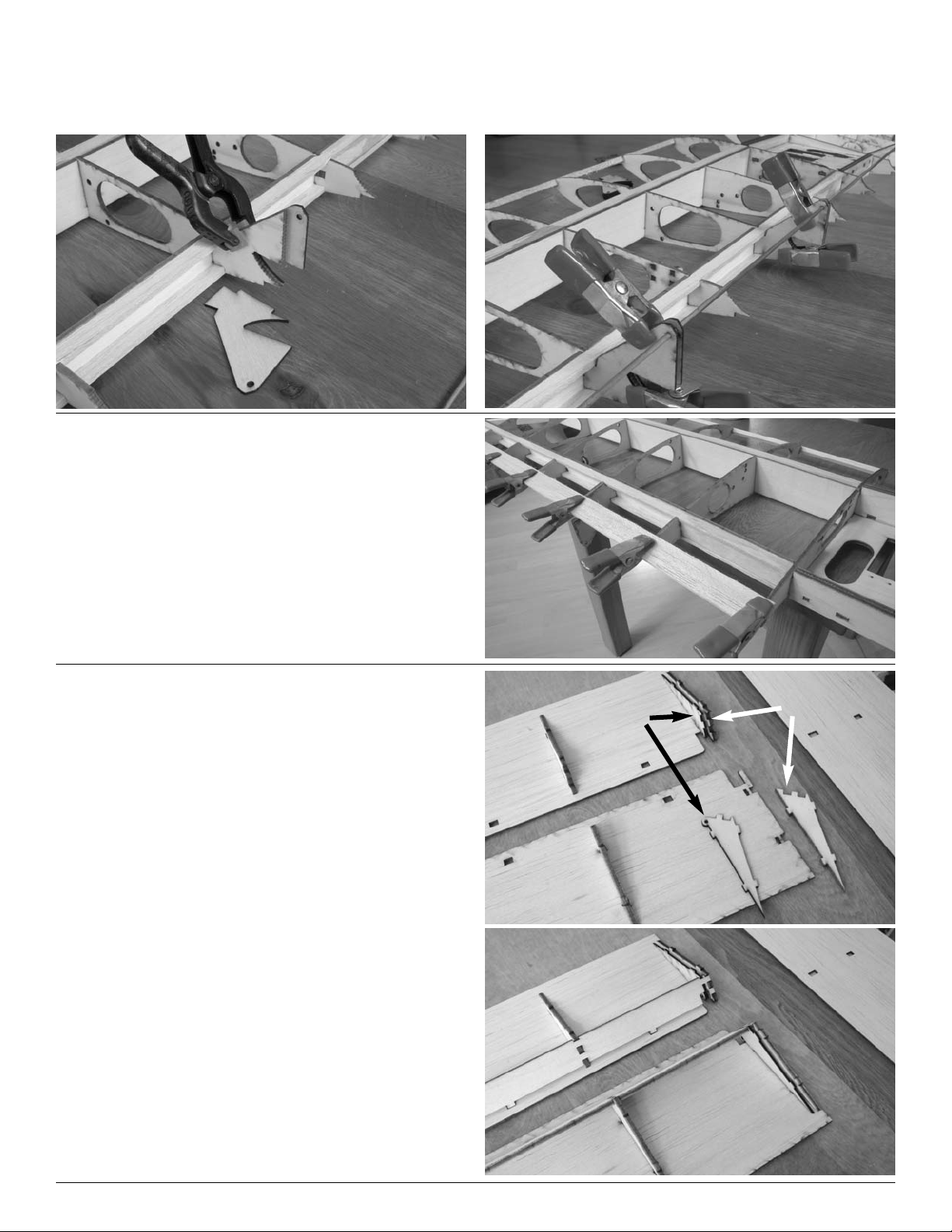

Creating the Flaps

Locate two Flap Base Sheets, eight Flap Ribs, two Flap Horns, four

Flap Horn Supports and four Flap Pivot Ribs.

Build both Flaps at the same time to prevent making two

left Flaps.

On the Base Sheets, dryfit the Flap Ribs in their slots as seen on

Plans Sheet 2. Use thin CA to glue in place.

Into the centre set of slots, dryfit the Flap Horn with Flap Horn

Supports on either side. Use thin CA to glue in place.

Dryfit Flap Pivot Ribs into the two remaining slots, then dryfit

both Flap assemblies into the trailing edge of the Wing so that

the Flap Pivot Ribs drop into the Flap Support Arms, as shown in

Figure 11.

Using thin CA, glue the back tab of each Flap Pivot Rib and just

the rear portion of each Flap Pivot Rib. Be sure no glue contacts

the Flap Support Arms. When glue cures, remove both Flap

assemblies and complete the gluing of each Flap Pivot Rib.

Sand the top side of each Flap trailing edge to a fine point – in

the same fashion as done with the Ailerons. See Plan Sheet 2.

Cut a sheet of

1

/

16" balsa sheeting the length of the Flap, by 3

1

⁄2".

Lay the Flap upside down on top of the

1

/

16" sheeting. Position the

sheeting 1⁄4" past the Flap Base Sheet. Use thin CA to glue along

the trailing edge.

When the trailing edge has cured, sneak a drop of CA on top of

each Rib while still working on a flat surface.

Rock the Flap forward until the Flap Horn contacts the top

sheeting. Mark the sheeting on either side of the Flap Horn to

indicate the Horn Opening.

Cut a small slot (about

1

/

2" long) out of the sheeting to allow the

Horn to emerge. See Figure 12.

Use clamps on the leading edge of every Rib to hold the sheeting

against the Flap Base Sheet.

Now is the time to manually adjust the Flap to remove any

warping caused by handling.

Use thin CA to glue the leading edge of the Flap. Remove clamps

when glue has cured.

Sand the leading edge of each Flap to match the profile on Plans

Sheet 2.

Cover the main Flap Surface with Ultracote. Do not cover the

Pivot Rib.

6

MosquitoBite Planes Robin

Fig 11

CA Glue

CA glue trailing edge

Sneak in CA

Fig 12

MosquitoBite Planes Robin

7

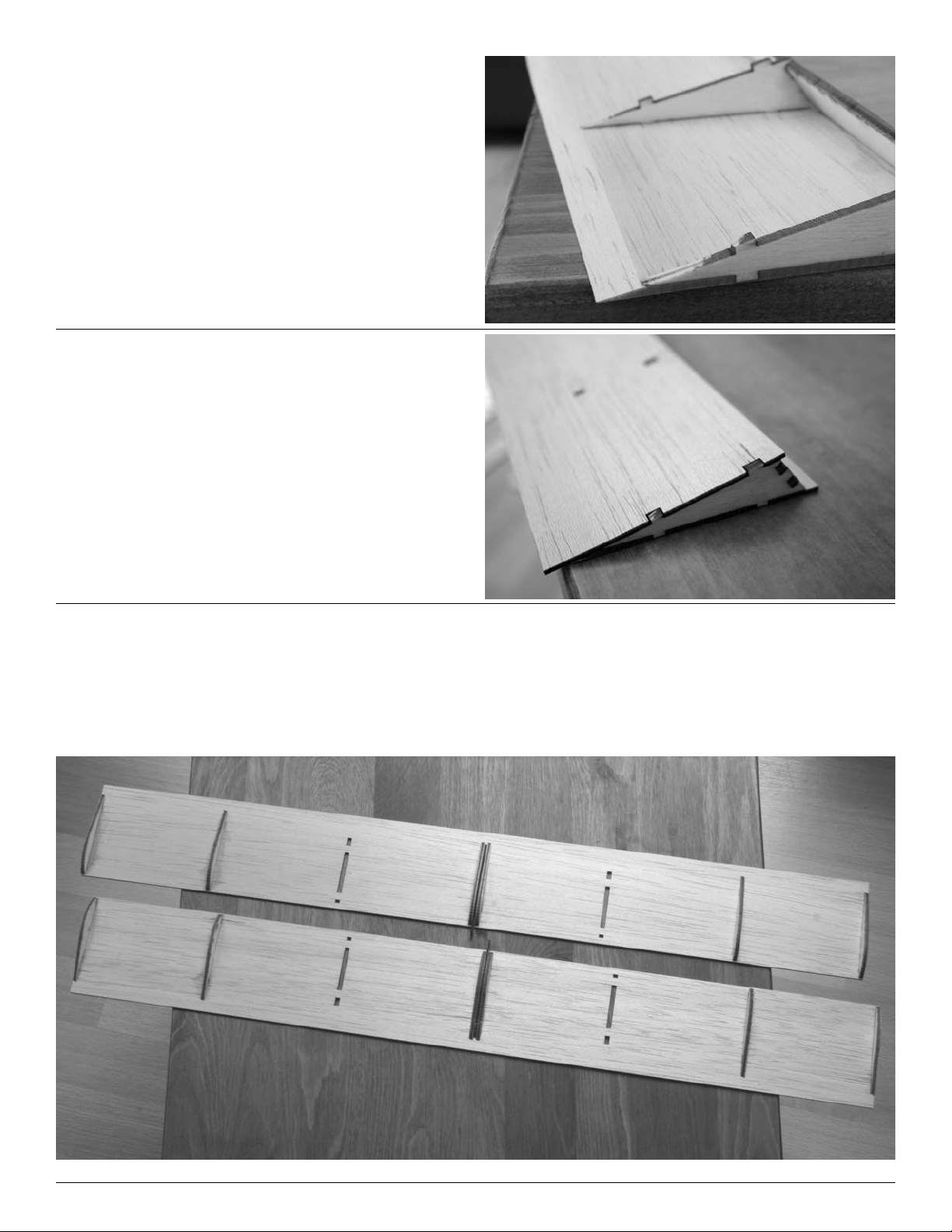

Test fit the Flap in its position on the Wing. If the hole in the Flap

Pivot Rib and the Flap Support Arm do not line up, sand the

underside of the trailing edge stock to allow more room for the

Flap to enter. (See Figure 13)

Sand and profile the Flap Support Arms to match the profile

shown on Plan Sheet 2.

Locate the 8 Sheeting Supports. (See Plan Sheet 2.) Glue them

onto the sides of each Flap Support Arm. (See Figure 13)

Sand Trailing Edge

Sheeting Supports

Fig 13

Sheeting the Wing

The sheeting of the Wing is done using common methods. There

are, however, some details that need addressing. Refer to Plan

sheet 2 for details.

To begin, cut a strip of

1

/

16" sheeting wide enough to cover the top

of the Rear Spar and to butt up against the Slot Lip TE stock. This

goes the full length of each side of the Wing. Let the sheeting

hang over to give support for the Lower Aileron Sheeting (A).

For the Lower Aileron section, cut and glue on a strip of sheeting

(B). Shave the edge of this sheeting to best fit the profile (C).

Before sheeting the Lower Wing (Flap section), we will make

some supports; cut strips of

1

/

16" balsa (the height about

1

/

2 " - see

Plan Sheet 2) to snugly fit between the rear of each Rib. (D) Use

thin CA to glue in place.

To sheet the Lower Wing (Flap section), measure and cut

1

/

16" balsa

to fit around the Flap Supports. See Plan Sheet 2 for sheeting

width. Glue on with thin CA. (See E.)

A small insert is needed for support. Cut a long, thin section of

sheeting. (See Figure 15 on next page.) Glue in with thin CA.

Fig 14

Wing shown inverted.

A

B

C

D

The remainder of the Wing is sheeted in the traditional fashion:

D-tube and cap strips with

1

/

16" balsa, according to Plan Sheet 2.

E

Control Cables

The supplied cables should be distributed as follows: Two 36"

cable/sleeves are for the Rudder and Elevator. Each 48"

cable/sleeve = 1 Aileron and 1 Flap for one side of the Wing.

Install an empty 48" Sleeve into the Aileron cable path, and trim.

The remainder is for the Flap control. Do not cut both 48" cables

the same - the port side of the wing is a longer cable length.

You will have to make an opening in the Lower Aileron section of

the Wing’s sheeting for the Cable to exit. (See Figure. 16)

Flap Hinges

With a hobby rail saw, cut the supplied brass tubing and the 3⁄32"

rod to make the 4 sets of hinges. Each tube length = the width of

the Flap Pivot Rib. (When cutting these tubes, leave a little extra and sand the edges clean - Figure 17.) Each rod length should be

1

⁄4" long. Insert the tube into the Flap Pivot Rib. The rod goes

through the tube, after the Flap is installed.

Install the

1

⁄16" balsa Fairings. Once glued in place, sand to the

profile shown on Plan Sheet 2. To secure the brass tube joints in

place, cover the Flap Support Arms with Ultracote.

Wing Tips

Locate the supplied Wingtips. These are extra deep to allow

trimming. Install the Wingtips over the Wing Tip Ribs and glue

with epoxy. Trim and sand the WTR inside face. Study Plan Sheet

2 for positioning of the WTR and the Wing Tips.

Do not attempt to cover the Wing Tips, they will deform from the

heat. Paint them instead, and then Install.

Install all Wing Servos and test all Flaps and Ailerons. (Temporarily

use desk tape to attach the Ailerons) Make sure everything

operates smoothly. Once everything is in check, cover the Wing.

Aileron Hinges

After the Wing has been fully covered, create the Aileron Hinges.

These will be made of Ultracote. With an Aileron fully deflected

down, iron a long thin strip of covering across the joint of the

Wing and the Aileron. To prevent binding, allow a small gap

between the Aileron and the Wing, remembering that the gap

will shrink when the covering is heated.

Next, fully deflect the Aileron up. Iron a long thin strip of covering

across the inside edge of the Wing and Aileron, making sure this

strip makes contact with the top covering in the middle.

8

MosquitoBite Planes Robin

Fig 15

Fig 16

Fig 17

Flap

Pivot

Rib

Flap

Support

Arm

Fairing

Loading...

Loading...