Mosa TS 300 SC-SXC Maintance Manual

TS 300 SC-SXC

USE AND MAINTENANCE MANUAL

SPARE PARTS CATALOG

219829003 - GB1 2 0 5

21982M00 29/01/98

preparato da UPT

approvato da DITE

Quality system GE_, MS_, TS_, EAS_

M

01

© MOSA 1.2-05/03

UNI EN ISO 9001 : 2000

10/10/02 M01-GB

MOSA has certified its quality system according to

UNI EN ISO 9001:2000 to ensure a constant, high

quality of its products. This certification covers the

design, production and servicing of engine driven

welders and generating sets.

The certifying institute, ICIM, which is a member of

the International Certification Network IQNet,

awarded the official approval to MOSA after an

examination of its operations at the head office and

plant in Cusago (MI), Italy.

This certification is not a point of arrival but a pledge

on the part of the entire company to maintain a level

of quality of both its products and services which

will continue to satisfy the needs of its clients, as

well as to improve the transparency and the

communications regarding all the company’s actives

in accordance with the official procedures and in

harmony with the MOSA Manual of Quality.

The advantages for MOSA clients are:

· Constant quality of products and services at the

high level which the client expects;

· Continuous efforts to improve the products and

their performance at competitive conditions;

· Competent support in the solution of problems;

· Information and training in the correct application

and use of the products to assure the security of

the operator and protect the environment;

· Regular inspections by ICIM to confirm that the

requirements of the company’s quality system

and ISO 9001 are being respected.

All these advantages are guaranteed by the

CERTIFICATE OF QUALITY SYSTEM No.0192

issued by ICIM S.p.A. - Milano (Italy ) -

www.icim.it

INDEX GE_, MS_, TS_, EAS_

M

1

© MOSA 1.0-01/01

11/01/01 M1-GB

INDEX (for all MOSA models)

M 01 QUALITY SYSTEM

M 1.01 COPYRIGHT

M 1.1 NOTES

M 1.4 NOTES

M 2- ... SYMBOLS AND SAFETY PRECAUTIONS

M 2.3 ABBREVIA TIONS LEGEND

M 2.4 SYMBOLS

M 2.5... INSTALLATION AND ADVICE BEFORE USE

M 2.6 INST ALLATIONS AND ADVICE

M 2.7 INSTALLATION

M 3 P ACKING

M 4 TRANSPORT AND DISPLACEMENTS

M 6 ASSEMBLY: CT ........

M 20 SETTING-UP THE UNIT (DIESEL ENGINE)

M 21 ENGINE STAR TING AND USE (DIESEL ENGINE)

M 22 STOPPING THE ENGINE (DIESEL ENGINE)

M 25 SETTING-UP THE UNIT (GASOLINE ENGINE)

M 26 STARTING THE ENGINE (GASOLINE ENGINE)

M 27 STOPPING THE ENGINE (GASOLINE ENGINE)

M 30 CONTROLS LEGEND

M 31 CONTROLS

M 32 CONTROLS (FRONT P ANEL)

M 33 USE AS HYDRAULIC POWER T AKE-OFF only for TS

M 34 USE AS A WELDER only for TS

M 35 USE A S AN ENGINE STARTER only for TS

M 36 USE AS A BATTER Y CHARGE

M 37 USE AS A GENERA TOR

M 38 USE OF THE REMOTE CONTROL

M 39 USE OF THE ENGINE PROTECTION

M 40 TROUBLE SHOOTING

M 43 MAINTENANCE

M 44 PERIODIC MAINTENANCE

M 45 STORAGE

M 46 CAST OFF

M 51 TECHNICAL DAT A

M 52 TECHNICAL DAT A ENGINE DRIVEN WELDER only for TS

M 53 DIMENSIONS

M 55 RECOMMENDED ELECTRODES only for TS

M 60 ELECTRICAL SYSTEM LEGENDE

M 61 ELECTRICAL SYSTEM

M 65 HYDRAULIC SYSTEM

R 1 SPARE PARTS LIST

...... SPARE PAR TS

K... ACCESSORIES

Copyright GE_, MS_, TS_, EAS

M

1.01

© MOSA 1.0-10/02

ATTENTION

ã

All rights are reserved to said Company .

It is a property logo of MOSA division of B.C.S.

S.p.A. All other possible logos contained in the

documentation are registered by the respective

owners.

➠

The reproduction and total or partial use, in

any form and/or with any means, of the

documentation is allowed to nobody without a

written permission by MOSA division of B.C.S.

S.p.A.

T o this aim is reminded the protection of the author’s

right and the rights connected to the creation and

design for communication, as provided by the laws

in force in the matter .

In no case MOSA division of B.C.S. S.p.A. will be

held responsible for any damaga, direct or indirect,

in relation with the use of the given information.

MOSA division of B.C.S. S.p.A. does not take any

responsibility about the shown information on firms

or individuals, but keeps the right to refuse services

or information publication which it judges discutible,

unright or illegal.

!

10/10/02 M1-01-GB

This use and maintenance manual is an important

part of the machines in question.

The assistance and maintenance personel must

keep said manual at disposal, as well as that for

the engine and alternator (if the machine is

synchronous) and all other documentation about the

machine.

We advise you to pay attention to the pages

concerning the security (see page M1.1).

INFORMATION

Dear Customer,

We wish to thank you for having bought from

MOSA a high quality set.

Our sections for Technical Service and Spare

Parts will work at best to help you if it were

necessary.

To this purpose we advise you, for all control and

overhaul operations, to turn to the nearest

authorized Service Centre, where you will obtain

a prompt and specialized intervention.

☞

In case you do not profit on these Services and

some parts are replaced, please ask and be

sure that are used exclusively original MOSA

parts; this to guarantee that the performances

and the initial safety prescribed by the norms in

force are re-established.

☞

The use of non original spare parts will cancel

immediately any guarantee and Technical Ser-

vice obligation from MOSA.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this

manual attentively. Follow the instructions

contained in it, in this way you will avoid

inconveniences due to negligence, mistakes or

incorrect maintenance. The manual is for qualified

personnel, who knows the rules: about safety and

health, installation and use of sets movable as

well as fixed.

You must remember that, in case you have

difficulties for use or installation or others, our

Technical Service is always at your disposal for

explanations or interventions.

The manual for Use Maintenance and Spare Parts

is an integrant part of the product. It must be kept

with care during all the life of the product.

In case the machine and/or the set should be

yielded to another user, this manual must also

given to him.

Do not damage it, do not take parts away, do not

tear pages and keep it in places protected from

dampness and heat.

You must take into account that some figures

contained in it want only to identify the described

parts and therefore might not correspond to the

machine in your possession.

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine

and/or set you will find: the manual for Use

Maintenance and Spare Parts, the manual for

use of the engine and the tools (if included in the

equipment), the guarantee (in the countries where

it is prescribed by law).

Our products have been designed for the use of

generation for welding, electric and hydraulic

system; ANY OTHER DIFFERENT USE NOT

INCLUDED IN THE ONE INDICATED, relieves

MOSA from the risks which could happen or,

anyway , from that which was agreed when selling

the machine; MOSA excludes any responsibility

for damages to the machine, to the things or to

persons in this case.

Our products are made in conformity with the

safety norms in force, for which it is advisable to

use all these devices or information so that the

use does not bring damage to persons or things.

While working it is advisable to keep to the

personal safety norms in force in the countries to

which the product is destined (clothing, work tools,

etc.).

Do not modify for any motive parts of the machine

(fastenings, holes, electric or mechanical devices,

others..) if not duly authorized in writing by MOSA:

the responsibility coming from any potential

intervention will fall on the executioner as in fact

he becomes maker of the machine.

Notes GE_, MS_, TS_, EAS_

M

1-1

© MOSA 1.0-10/02

☞

Notice: this manual does not engage MOSA,

who keeps the faculty, apart the essential

characteristics of the model here described and

illustrated, to bring betterments and modifications

to parts and accessories, without putting this

manual uptodate immediately .

10/10/02 M 1-1 GB

CE MARK GE_, MS_, TS_, EAS_

M

1.4

© MOSA 1.2-06/03

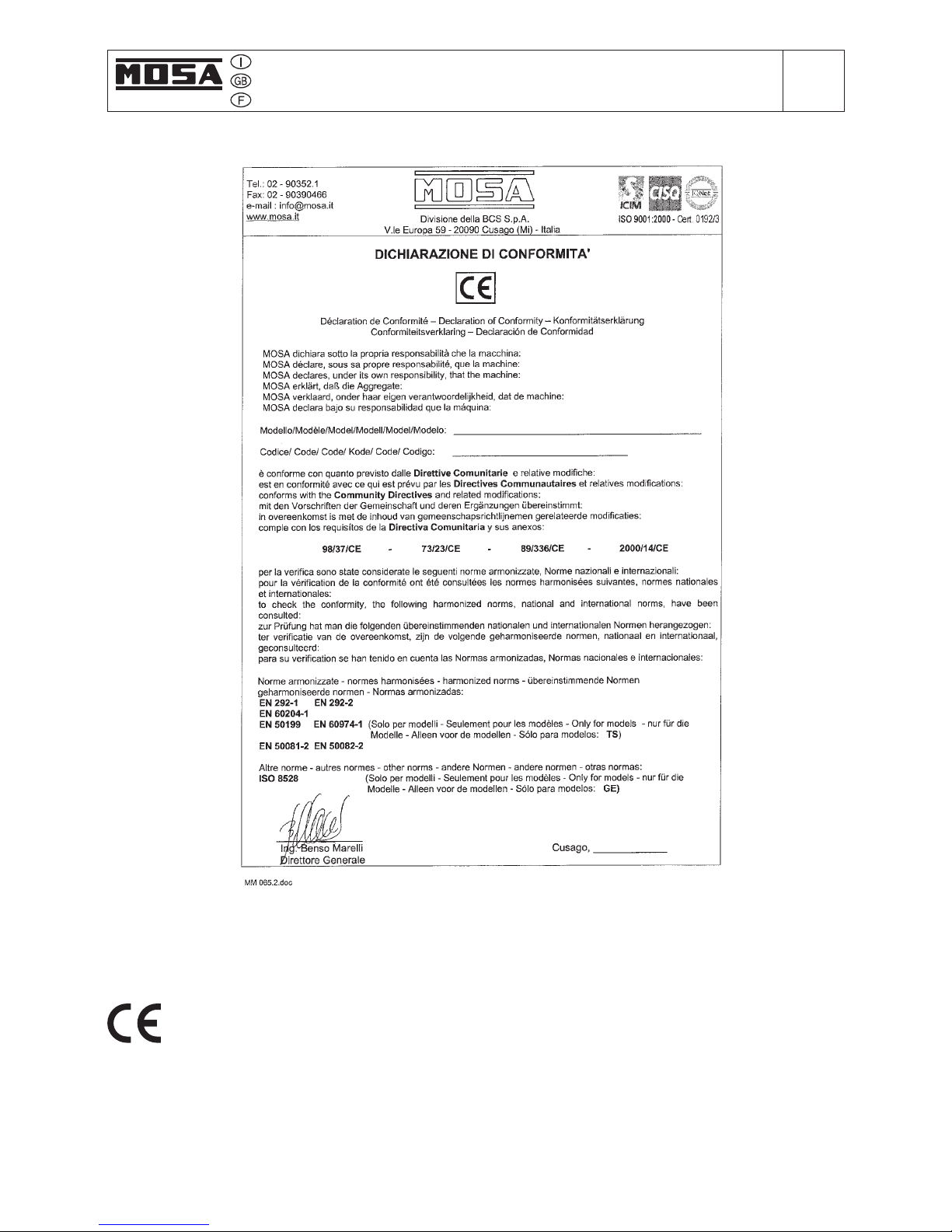

The CE mark (European Community) certifies that the product complies with the essential

safety requirements provided by the applicable COMMUNITY DIRECTIVES. In the Conformity

Declaration are reported the HARMONIZED NORMS and not, used for the checking.

10/10/02 M1-4 GB

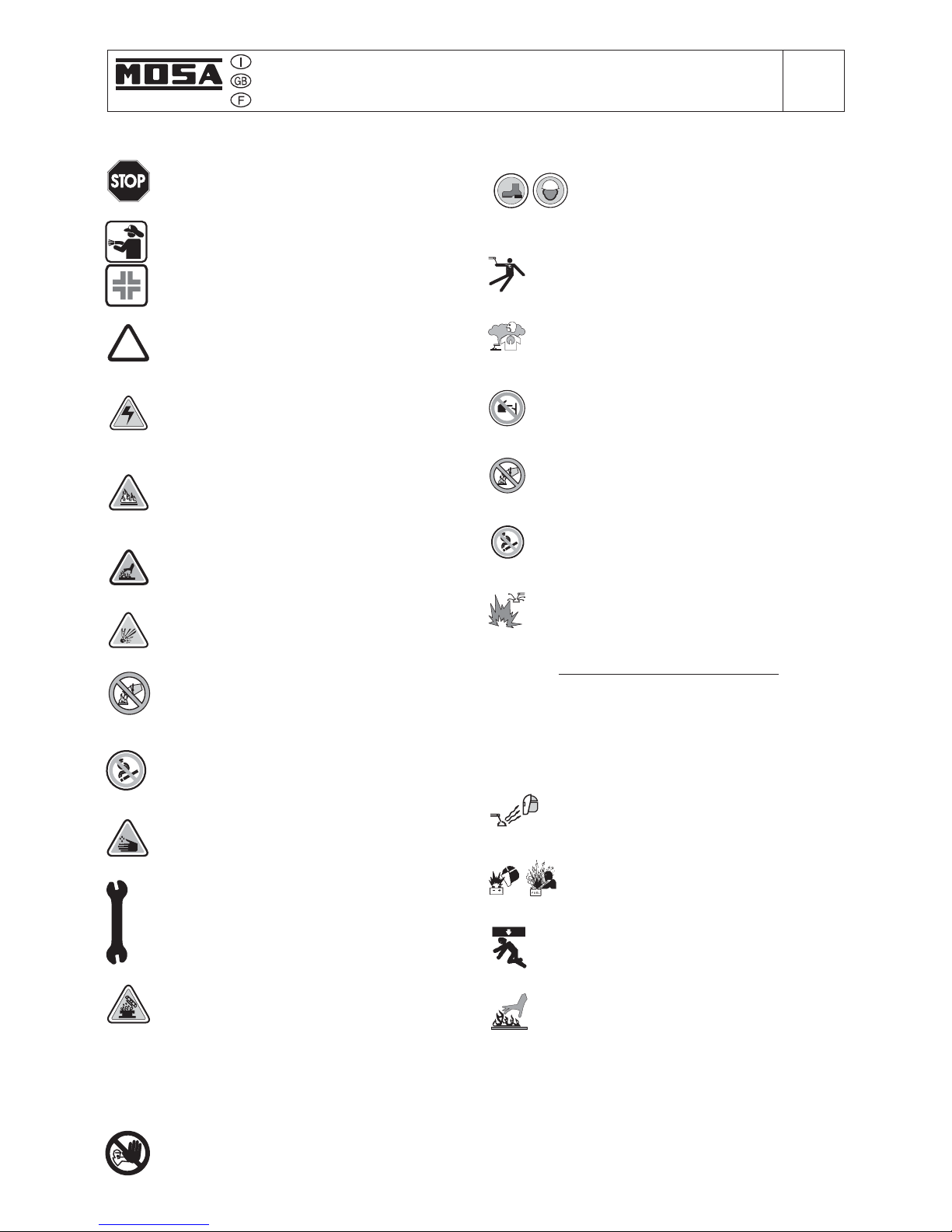

SYMBOLS AND SAFETY PRECAUTIONS GE_, MS_, TS_

M

2

© MOSA 1.0-11/99

SYMBOLS IN THIS MANUAL

- The symbols used in this manual are designed to call

your attention to important aspects of the operation of

the machine as well as potential hazards and dangers

for persons and things.

IMPORTANT ADVICE

- Advice to the User about the safety:

☞

N.B.: The information contained in the manual can

be changed without notice.

Potential damages caused in relation to the use of

these instructions will not be considered because

these are only indicative.

Remember that the non observance of the

indications reported by us might cause damage to

persons or things.

It is understood, that local dispositions and/or laws

must be respected.

WARNING

Situations of danger - no harm to persons

or things

Do not use without protective devices provided

Removing or disabling protective devices on the

machine is prohibited.

Do not use the machine if it is not in good technical

condition

The machine must be in good working order before

being used. Defects, especially those which regard

the safety of the machine, must be repaired before

using the machine.

SAFETY PRECAUTIONS

This heading warns of an immediate danger for persons

as well for things. Not following the advice can result in

serious injury or death.

This heading warns of situations which could result in

injury for persons or damage to things.

T o this advice can appear a danger for persons as well as

for things, for which can appear situations bringing material damage to things.

These headings refer to information which will assis you

in the correct use of the machine and/or accessories.

!

ATTENTION

!

NOTE

!

IMPORTANT

!

CAUTION

!

W ARNING

!

DANGEROUS

!

26/11/99 M2GB

SYMBOLS AND SAFETY PRECAUTIONS GE_, MS_, TS_

M

2-1

© MOSA 1.1-04/03

SYMBOLS (for all MOSA models)

STOP - Read absolutely and be duly attentive

Read and pay due attention

GENERAL ADVICE - If the advice is not

respected damage can happen to persons or

things.

HIGH VOLT AGE - Attention High V oltage.There

can be parts in voltage, dangerous to touch.

The non observance of the advice implies life

danger.

FIRE - Danger of flame or fire. If the advice is

not respected fires can happen.

HEAT - Hot surfaces. If the advice is not

respected burns or damage to things can be

caused.

EXPLOSION - Explosive material or danger of

explosion. in general. If the advice is not

respected there can be explosions.

WATER - Danger of shortcircuit. If the advice

is not respected fires or damage to persons

can be caused.

SMOKING - The cigarette can cause fire or

explosion. If the advice is not respected fires

or explosions can be caused.

ACIDS - Danger of corrosion. If the advice is

not respected the acids can cause corrosions

with damage to persons or things.

WRENCH - Use of the tools. If the advice is

not respected damage can be caused to things

and even to persons.

PRESSION - Danger of burns caused by the

expulsion of hot liquids under pressure.

PROHIBITIONS No harm for persons

Use only with safety clothing -

It is compulsory to use the personal

protection means given in equipment.

Use only with safety clothing -

It is compulsory to use the personal protection

means given in equipment.

Use only with safety protections -

It is a must to use protection means suitable for

the different welding works.

Use with only safety material -

It is prohibited to use water to quench fires on

the electric machines.

Use only with non inserted voltage -

It is prohibited to make interventions before

having disinserted the voltage.

No smoking -

It is prohibited to smoke while filling the tank

with fuel.

No welding -

It is forbidden to weld in rooms containing

explosive gases.

ADVICE No harm for persons and things

Use only with safety tools, adapted to the specific

use -

It is advisable to use tools adapted to the various

maintenance works.

Use only with safety protections, specifically suitable

It is advisable to use protections suitable for

the different welding works.

Use only with safety protections -

It is advisable to use protections suitable

for the different daily checking works.

Use only with safety protections -

It is advisable to use all protections while

shifting the machine.

Use only with safety protections -

It is advisable to use protections suitable for

the different daily checking works.and/or of

maintenance.

!

26/11/99 M2-1GB

ACCES FORBIDDEN to non authorizad peaple.

ABBREVIATIONS LEGEND GE_, MS_, TS_

M

2.3

© MOSA 1.0-06/99

14/06/99 M2-3GB

°C: temperature Celsius grades

10:10 kVA synchronous (wording example)

10000:10 kVA asynchronous (wording example)

A: Ampere

A: ADIM engine

atm: pressure

B: pretrol

BAT: battery

BC: base current

C.A.(c.a.): alternating current

C.B.: battery charger

C.C.(c.c.): direct current

cc: cm³ (volume)

CE: European norm conformity

CF: special for pipe welding

CTL: slow touring trolley

CTM CTV: fast touring trolley: hand touring trolley

D: diesel

D: GFI

D: Deutz engine

E: electric start

EAS: automatic intervention panel for generating sets for

connection to the mains

EL: electronic regulation, allows to use welder and

generating set simultaneausly

EP1: automatic accelerator according to requestedpower,

engine protection, low oil pressure, high temperature

with engine stop, troble warning lights

EP2: engine protection, low oil pressure, hight temperature

with engine stop, trouble warning lights

EP4: engine protection, low oil pressure, high temperature

with engine stop, no battery charge, belt broken, low fuel

level with engine stop, trouble warning lights

EP5: engine protection, low oil pressure, high temperature

with engine stop, no battery charge, belt broken, low fuel

level with engine stop, everspeed, trouble warning lights

EP6: Control and protection unit of generating sets. It

has operating modes OFF – MAN – AUTO It protects the

engine for low oil pressure, high temperature, belt broken,

no battery charge and low fuel level, over peed and

under speed, over and under voltage and no tarting.It

shows besides: voltage, frequency and current generator,

current battery voltage and battery charge, engine rpm.

EP6 disposes of 29 programmable parameters.

ES: oil/temperature engine protection device

EV: electrovalve

g/kwh: grams/kilowatt hour (engine consumption)

GA: asynchronous alternator

GE: generating set

GHF: high frequency alternator

GS: synchronous alternator

h: hour meter (symbol)

H: Hatz engine

H: Honda engine

HI: hydraulic central

Hz: frequency

I: single-phase auxiliary generation (symbol 1~)

IP: protection grads for electric devices against acess to

dangerous parts according to the IEC 529 norm (Internal

Protection)

kg: kilogram (mass)

K: welding cables set

kVA: kilovolt ampere

kW: kilowatt (engine power)

kWh: kilowatt hour (energy)

l: liters (capacity)

L: Lombardini engine

Lwa: maximum acoustic (power level) according to the

regulations in force

mm: millimeter (length) (measure)

m: meter (length)

mA: milliampere

MS-MSG: MOSA engine driven welder with high

frequency alternator

MT: magnetothermic switch

MT: grounding kit

MTD: magnetothermic switch / GFI

OH: heater (engine oil) for generating sets

P: plus

PAC: power electric frame

PAR: device for double

PB: battery holder

PL: „pipe line“ welding

PS: exhaust pipe extension

PW: welder for polyethylene and propylene pipes

QEA: automatic electric panel

QEM: manual electric panel

R: Ruggerini engine

RVT: voltage electronic regulator

S: symbol of EN 60974-1

S: Suzuki mengineotore

SKID: unit assembled on a base with no protection (no

fairing)

S-SC: silenced (faired) - silenced compact (faired

SX-SXC: supersilenced (faired and sound prof) -

supersilenced compact (faired and super sound prof)

T: thermic switch

TC-TCM-TCPL: remote control

TS: welder with asynchronous alternator

V: Volt

Y: Yanmar engine

Y: three-phase auxiliary generation (symbol 3~)

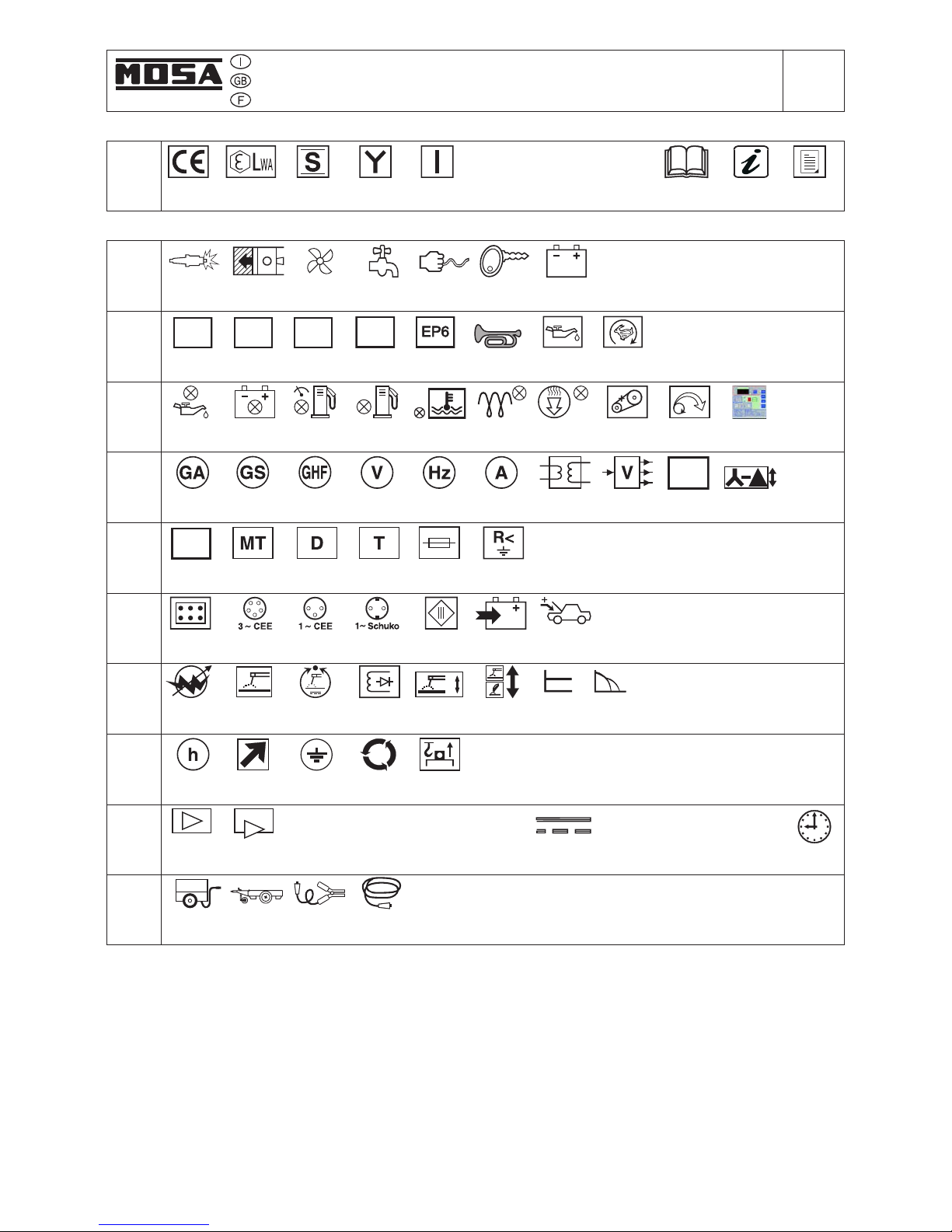

SYMBOLS GE_, MS_, TS_, DSP_

M

2.4

© MOSA 1.1-04/05

Conformity

CE

Singlephase

1 ~

EEC

Sound power

conformity

Triphase

3 ~

EN 60974-1

conformity

Equipment and optional

Engine

Central

lifting eye

Air

cooling

Diesel

engine

Electric

start

Asynchronous

alternator

Socket

400/230V

EEC

Socket

230/110/48V

EEC

Polarity

inverter

Base current

diode bridge

Welding cur-

rent electr.

regulation

Battery

charger

indicator

Air filter

blockage

Hour

counter

Socket

48V EEC

Gasoline

engine

Manual

recoil

Battery

12 V

Battery

charger

Oil level

indicator

Thermal

shut off

Synchronous

alternator

Ground fault

interrupter

Water

cooling

Low fuel

indicator

Warning light

for preheating

glow plugs

Circuit

breaker

Isolation

monitoring

Voltmeter

Arc

control

Engine

booster

Fuse

Generator

high frequency

Welding

cables

Frequency-

meter

Voltmeter

phase

selector

Ammeter Compound

Terminal

strip

Remote

control

Welding with

covered

electrode

Generation

Generation

use

Welding

control

Engine

protection

Socket

230V

Schuko

Various

news

Fuel level

gauge/low

fuel

Engine

alarms

Electric

protection

Information

Switch

CC/CV

selector

Ready for

TC

Ground

connection

point

Emergency

stop button

Options on

request

Standard

equipment

Trolley

Users'

manual

Engine

protection

Engine

protection

Engine

protection

Siren

Engine

speed

Engine shut

down (oil)

Engine

protection

Oil

temperature

Belt

breakage

Over speed

Control unit

QEA

Electronic

Voltage

regulator

Circuit breaker/

Ground fault

interrupter

Various

devices

Optionals

Various

Site tow

Maintenance

Time

+

-~

A.C. Plus MinusD.C.

15/06/98 M2-4GB

EV

E V

ES

EP1

EP5

RVT

MTD

+

-

+

-

Costant

current

Costant

voltage

TIG

Contact

starting

Engine

protection

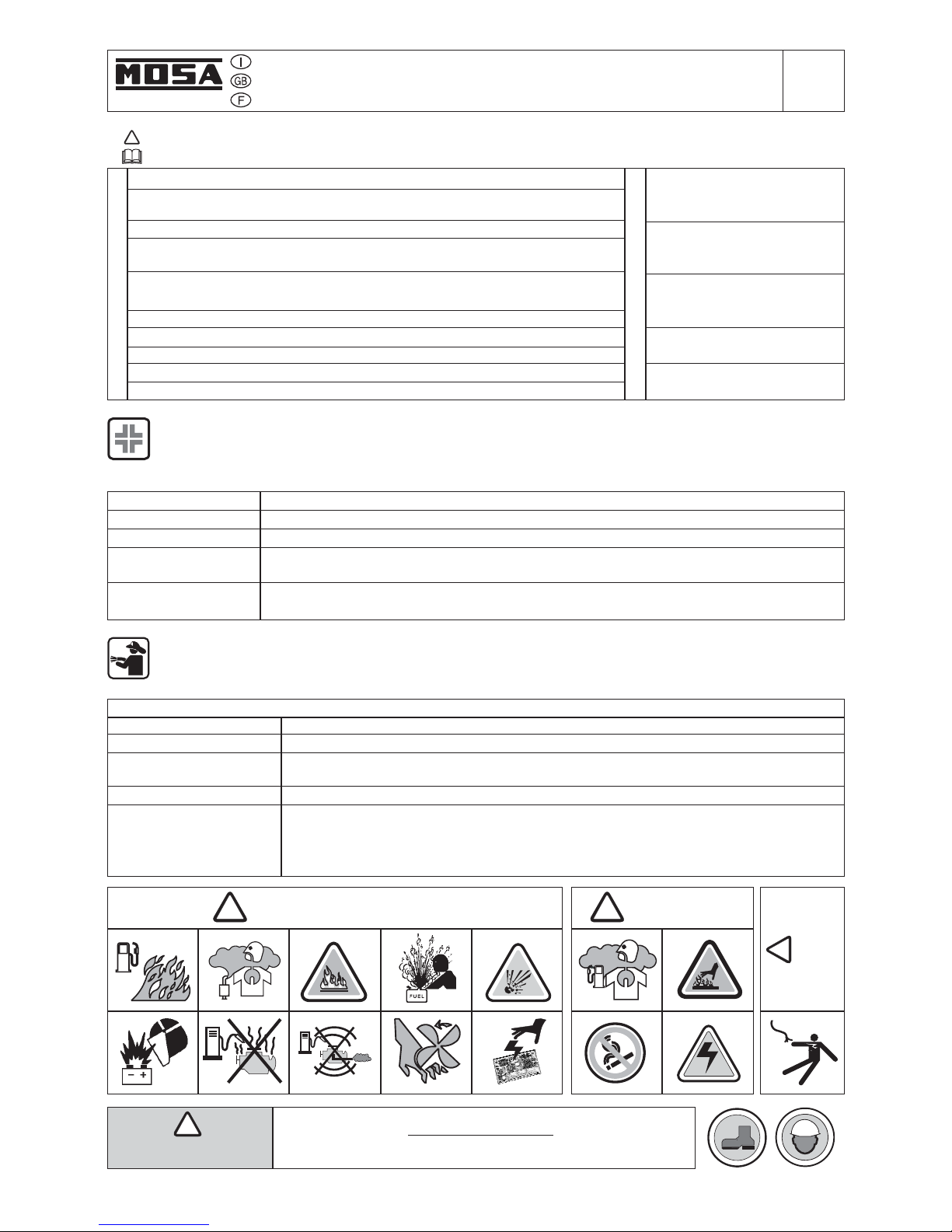

INSTALLATION AND ADVICE BEFORE USE GE_, MS_, TS_

M

2-5

© MOSA 1.0-06/00

Stop engine when fueling

ENGINE

CHECKING BOARD

Do not touch electric devices if you

are barefoot or with wet clothes.

Always keep off leaning surfaces

during work operations

Static electricity can demage the

parts on the circuit.

An electric shock can kill

The installation and the general advice concerning the operations, are finalized to the correct use of the

machine, in the place where it is used as generator group and/or welder.

!

☞

FIRST AID. In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas

or whatever event which may cause serious injuries or death, predispose the first aid in accordance with

the ruling labour accident standards or of local instructions.

Skin contact

Eyes contact

Ingestion

Suction of liquids from

lungs

Inhalation

Wash with water and soap

Irrigate with plenty of water, if the irritation persists contact a specialist

Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

If you suppose that vomit has entered the lungs (as in case of spontaneous vomit) take the

subject to the hospital with the utmost urgency

In case of exposure to high concentration of vapours take immediately to a non polluted zone

the person involved

☞

FIRE PREVENTION. In case the working zone,for whatsoever cause goes on fire with flames liable to

cause severe wounds or death, follow the first aid as described by the ruling norms or local ones.

Appropriated

Not to be used

Other indications

Particular protection

Useful warnings

Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Avoid the use of water jets

Cover eventual shedding not on fire with foam or sand, use water jets to cool off the

surfaces close to the fire

Wear an autorespiratory mask when heavy smoke is present

Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric

contacts (switches,plugs,etc.). In case of oil sprinkling from pressure circuits, keep in

mind that the inflamability point is very low.

EXTINCTION MEANS

W ARNING

!

CAUTION

!

!

DANGEROUS

!

W ARNING

THE MACHINE MUST NOT BE USED IN AREAS WITH

EXPLOSIVE ATMOSPHERE

10/06/00 M2-5I

Do not smoke, avoid flames, sparks or electric tools when fueling.

Unscrew the cap slowly to let out the fuel vapours.

Slowly unscrew the cooling liquid tap if the liquid must be topped up.

The vapor and the heated cooling liquid under pressure can burn face, eyes, skin.

Do not fill tank completely.

Wipe up spilled fuel before starting engine.

Shut off fuel of tank when moving machine (where it is assembled).

Avoid spilling fuel on hot engine.

Sparks may cause the explosion of battery vapours

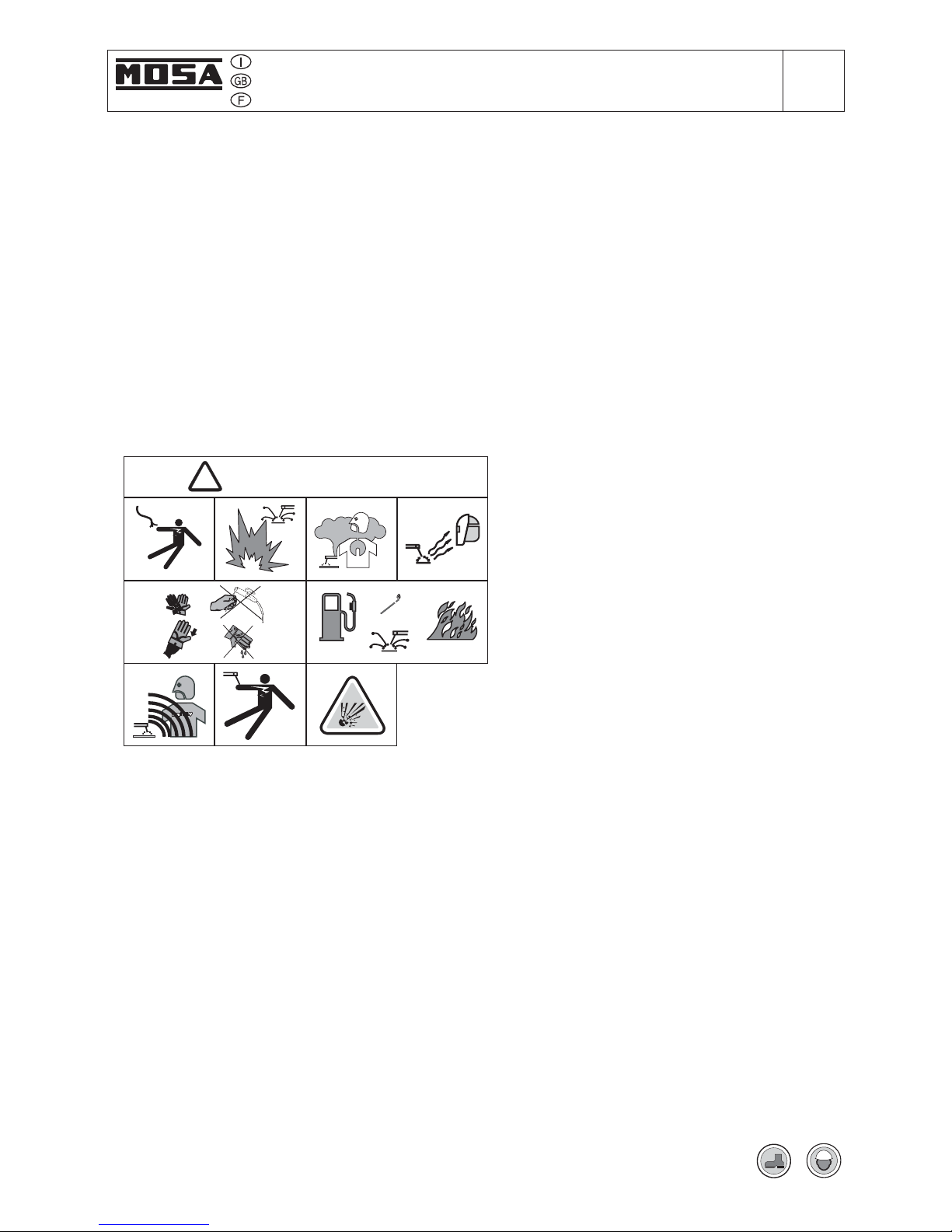

PRECAUTION (ENGINE DRIVEN WELDER) GE_, MS_, TS_

M

2-5-1

© MOSA 1.0-03/00

INST ALLA TION AND ADVICE BEFORE USE

The operator of the welder is responsible for the security of the people who work with the welder and for those in the

vicinity.

The security measures must satisfy the rules and regulations for engine driven welders.

The information given below is in addition to the local security norms.

Estimate possible electromagnetic problems in the work area taking into account the following indications.

1. T elephonic wirings and/or of communication, check wirings and so on, in the immediate vicinity.

2. Radio and television receptors and transmettors.

3. Computer and other checking devices.

4. Critical devices for safety and/or for industrial checks.

5. Peapol who, for instance, use pace-maker, hearing-aid for deaf or something and else.

6. Devices used for rating and measuring.

7. The immunity of other devices in the operation area of the welder. Make sure that other used devices are

compatible. If it is the case, provide other additional measures of protection.

8. The daily duration of the welding time.

A TTENTION

!

+

=

Make sure that the area is safe before starting any welding operation.

➠

Do not touch any bare wires, leads or contacts as they may be live and there is danger of electric shock

which can cause death or serious burns. The electrode and welding cables, etc. are live when the unit is

operating.

➠

Do not touch any electrical parts or the electrode while standing in water or with wet hands, feet or clothes.

➠

Insulate yourself from the work surface while welding. Use carpets or other insulating materials to avoid

physical contact with the work surface and the floor.

➠

Always wear dry , insulating glovers, without holes, and body protection.

➠

Do not wind cables around the body.

➠

Use ear protections if the noise level is high.

➠

Keep flamable material away from the welding area.

➠

Do not weld on containers which contain flamable material.

➠

Do not weld near refuelling areas.

➠

Do not weld on easily flamable surfaces.

➠

Do not use the welder to defrost (thaw) pipes.

➠

Remove the electrode from the electrode holder, when not welding.

➠

Avoid inhaling fumes by providing a ventilation system or , if not possible, use an approved air breather .

➠

Do not work in closed areas where there is no fresh air flow.

➠

Protect face and eyes (protective mask with suitable dark lens and side screens), ears and body (nonflamable protective clothers).

30/03/00 M2-5GB

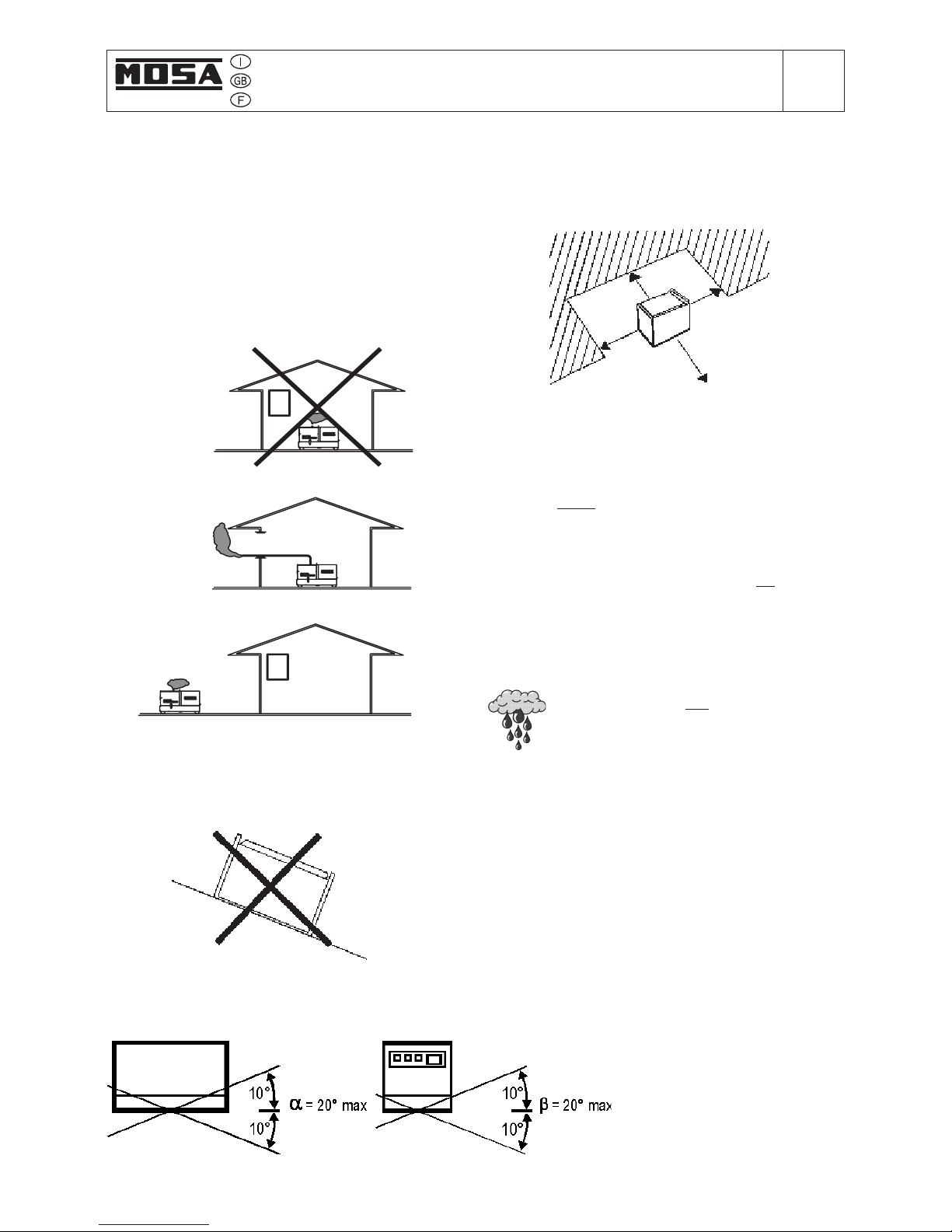

INSTALLATION AND ADVICE GE_, MS_, TS_

M

2.6

© MOSA 1.0-11/99

INSTALLATION AND ADVICE BEFORE USE

GASOLINE ENGINES

■ Use in open space, air swept or vent exhaust gases,

which contain the deathly carbone oxyde, far from

the work area.

DIESEL ENGINES

■ Use in open space, air swept or vent exhaust gases

far from the work area.

POSITION

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other plants.

Check that the air gets changed completely and the hot

air sent out does not come back inside the set so as to

cause a dangerous increase of the temperature.

☞

Make sure that the machine does not move during

the work: block it possibly with tools and/or devices

made to this purpose.

Protect all the electric parts at risk, because water

infiltrations could cause short circuits with damages

at persons and/or things.

The protection degree of the machine is put on the data

plate and in this manual at page "Technical Data".

Maximum leaning of the machine (in case of dislevel)

26/11/99 M2-6GB

1,5 m

1,5 m

1,5 m

GAS DI SCARICO

EXHAUST OUTPUT

MOVES OF THE MACHINE

☞

At any move check that the engine is off, that there

are no connections with cables which impede the

moves.

PLACE OF THE MACHINE

In spots where it often rains and/or there are

flooded areas, do not put the machine:

■

in the bad weather

■

in flooded places.

Installazione

Installation

Installation

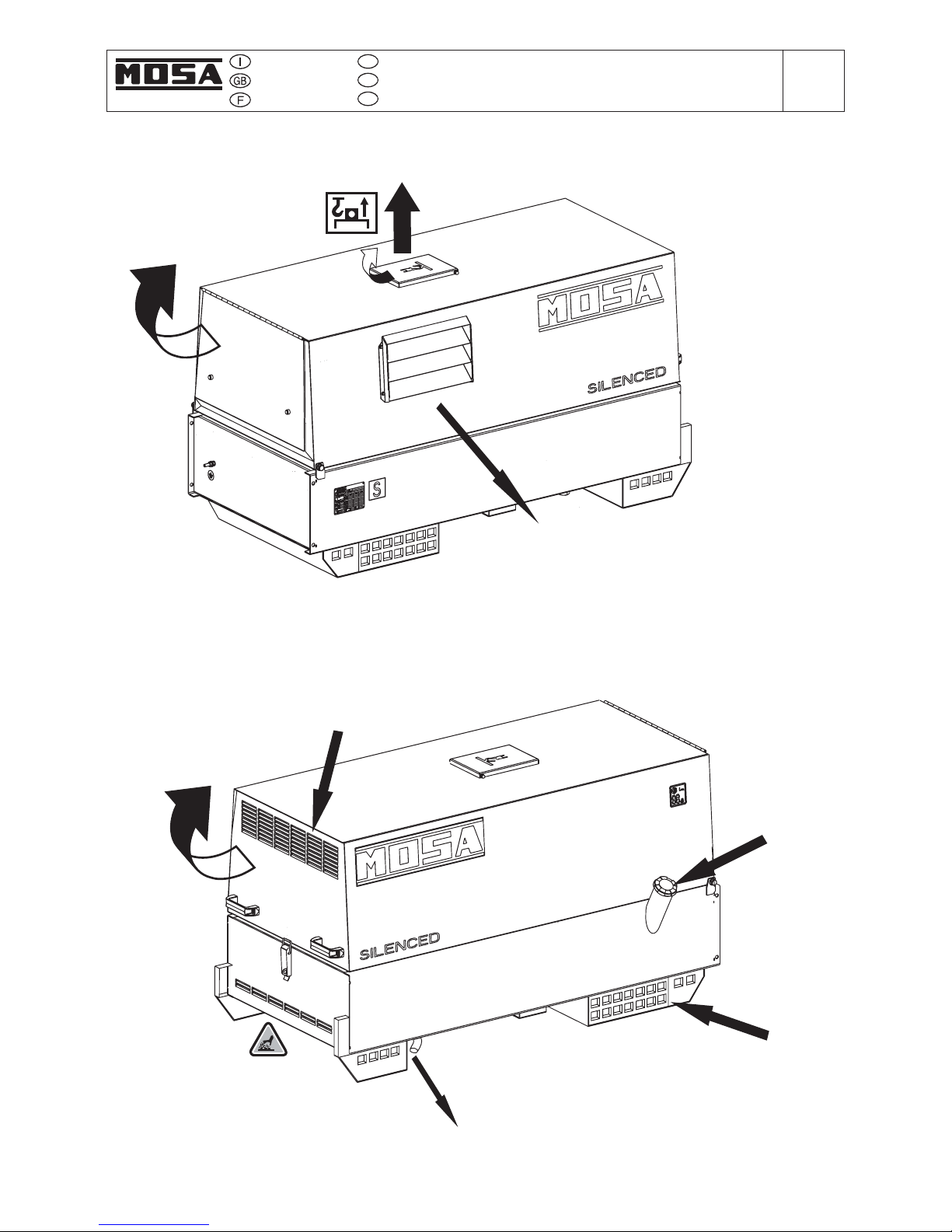

TS 250-300 SC/SXC

M

2.7

© MOSA 1.0-12/05

Luftzirkulation

Instalación

E

D

NL

SUPERFICIE CALDA

HOT SURFACE

SURFACE TRES CHAUDE

HEIßER BEREICH

SUPERFICIE CALIENTE

Scarico silenziatore motore

Gas exhaust pipe

Tuyau d’échappement gaz

Auspuffgase Motor

Tubo de descarga gas

Caricamento carburante

Fuel filling

Remplissage carburant

Tankstutzen

Carga combustible

Entrata aria

Air inlet

Entrée air

Lufteintritt

Entrada aire

Apertura portellone

Cover opening

Overture portillon

Klappe öffnen

Apertura tapa

Apertura pannello frontale

Opening cover front panel

Ouverture couvercle frontal

Frontdeckel öffnen

Apertura tapa

Uscita aria - Air outlet

Expulsion air - Luftausttritt

Salida aire

Gancio di sollevamento - Central lifting eye

Oeillet central de levage - Zentrale Hebeöse

Gancho de elevación

Entrata aria - Air inlet

Entrée air - Lufteintritt

Entrada aire

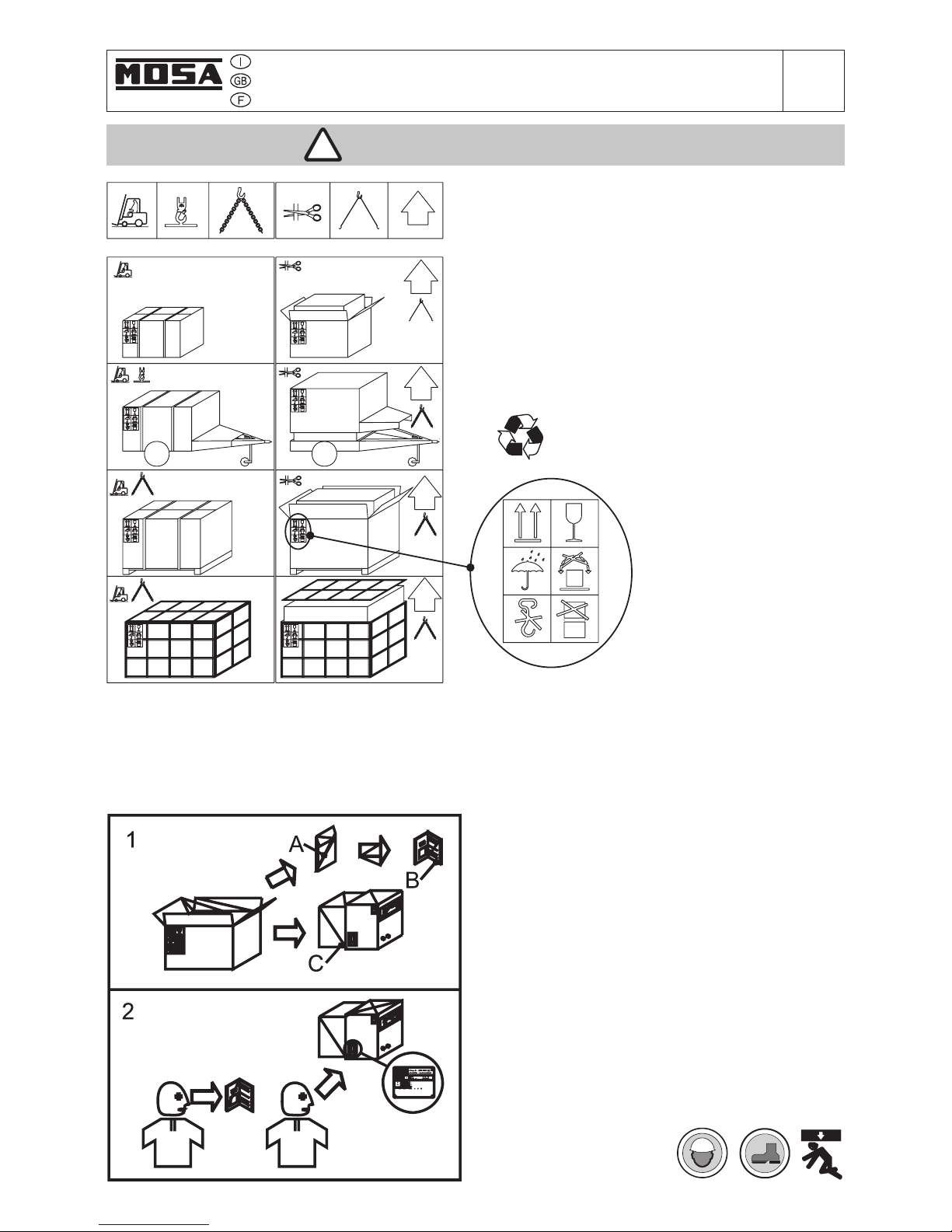

UNPACKING GE_, MS_, TS_

M

3

© MOSA 1.1-02/04

NOTE

!

☞

Be sure that the lifting devices are: correctly mounted,

adequate for the weight of the machine with it’s

packaging, and conforms to local rules and regulations.

When receiving the goods make sure that the product has not suffered damage during the transport,

that there has not been rough handling or taking

away of parts contained inside the packing or in the

set.

In case you find damages, rough handling or absence of parts (envelopes, manuals, etc.), we advise you to inform immediately our Technical Service.

For eliminating the packing materials, the User

must keep to the norms in force in his country.

1) Take the machine (C) out of the shipment packing.

Take out of the envelope (A) the user’s manual (B).

2) Read: the user’s manual (B), the plates fixed on the

machine, the data plate.

30/03/00 M3GB

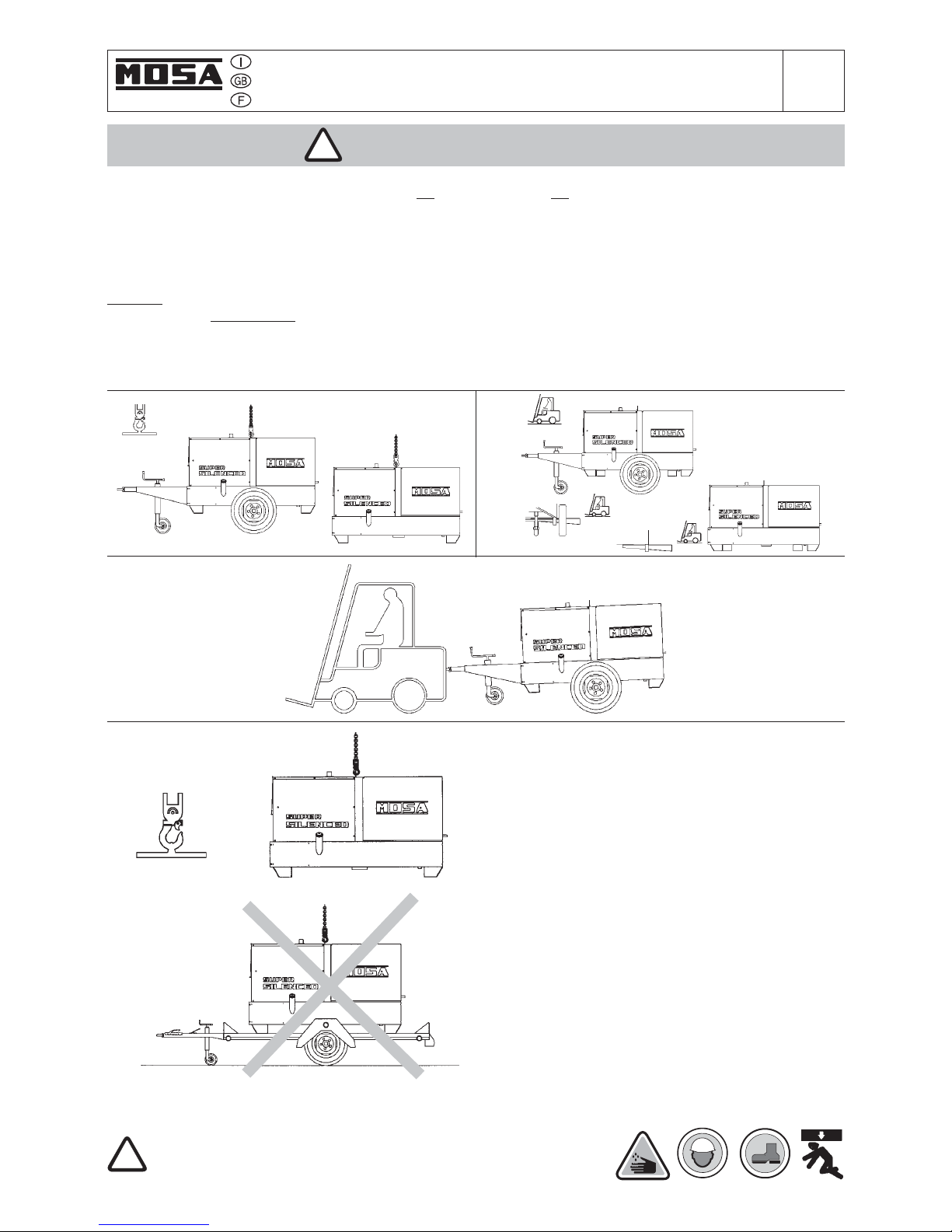

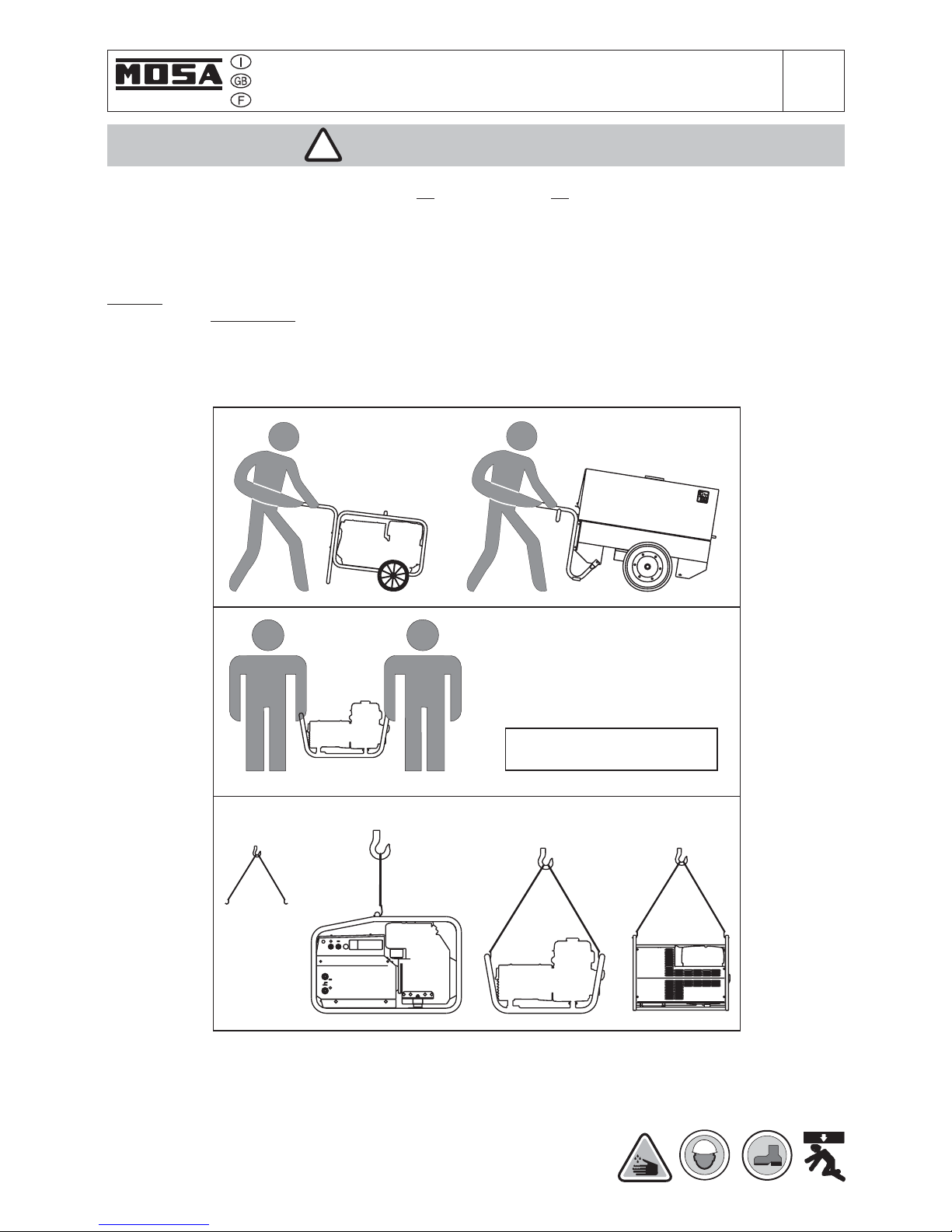

TRANSPORT AND DISPLACEMENTS COVERED UNITS GE_, MS_, TS_

M

4

© MOSA 1.0-03/00

NOTE

!

In case you should transport or move the machine, keep to the instructions as per the figures.

Make the transportation when the machine has no petrol in its tank, no oil in the engine and and electrolyte in the

battery.

Be sure that the lifting devices are: correctly mounted, adequate for the weight of the machine with it’s packaging, and

conform to local rules and regulations.

Only authorized persons involved in the transport of the machine should be in the area of movement.

DO NOT LOAD OTHER P ARTS WHICH CAN MODIFY WEIGHT AND BARICENTER POSITION.

IT IS STRICTL Y FORBIDDEN TO DRAG THE MACHINE MANUALL Y OR TOW IT BY ANY VEHICLE (model with no

CTL accessory).

If you did not keep to the instructions, you could damage the structure of the machine.

DANGER: LIFTING EYE IS NOT DESIGNED TO SUPPORT

ADDED WEIGHT OF ROAD TOW TRAILER

DO NOT LIFT THE MACHINE AND TRAILER

LIFT ONLY THE MACHINE

!

30/03/00 M4GB

TRANSPORT AND DISPLACEMENTS COVERED UNITS GE_, MS_, TS_

M

4-1

© MOSA 1.0-01/01

NOTE

!

In case you should transport or move the machine, keep to the instructions as per the figures.

Make the transportation when the machine has no petrol in its tank, no oil in the engine and and electrolyte in the

battery.

Be sure that the lifting devices are: correctly mounted, adequate for the weight of the machine with it’s packaging, and

conform to local rules and regulations.

Only authorized persons involved in the transport of the machine should be in the area of movement.

DO NOT LOAD OTHER P ARTS WHICH CAN MODIFY WEIGHT AND BARICENTER POSITION.

IT IS STRICTL Y FORBIDDEN TO DRAG THE MACHINE MANUALL Y OR TOW IT BY ANY VEHICLE (model with no

CTM accessory).

If you did not keep to the instructions, you could damage the structure of the machine.

15/01/01 M4GB

Weight max. per person: 35 kg

T otal max. weight; 140 kg

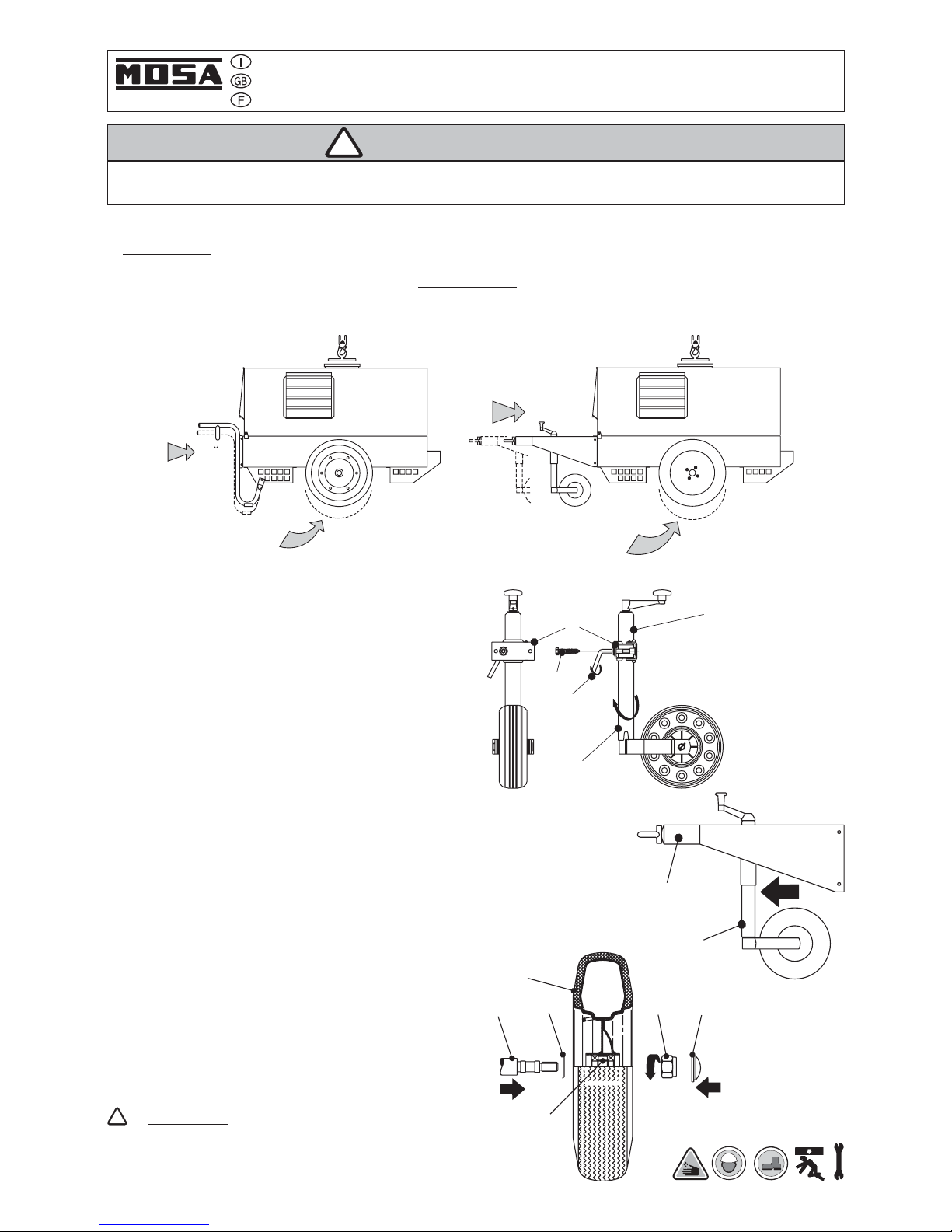

ASSEMBLY

CTM300

CTL300

© MOSA 1.0-09/00

M

6.4

Nota: Lift the machine and assemble the parts as shown in the drawing

The CTL or CTM accessory cannot be removed from the machine and used separately (actioned manually or

following vehicles) f or the tr ansport of loads or anyway for used different from the machine movements.

For assembling the generating set on the trolley CTL300

please keep to following instructions:

1) - Lift the generating set (by means of suitable hook).

2) - Slightly fix the jaw (3) of the parking foot to the bar

with the M10x20 screws, the M10 nuts and the

washers (so as to let the foot sprag go through.

3) - Split (unscrewing them) the tw o parts of the foot (4S4I) to be able later to assemble them on the jaw.

4) - Introduce into the jaw (3) the upper part (4S) of the

foot and screw again the low er part (4I), then tighten

the screws (4V) of the jaw to the towbar and block

momentaneously with the lever (4L) the whole foot.

5) - Assemble on the machine the towbar (5) complete of

foot with the M10x20 screws, nuts and washers (see

fig. page M6.4).

6) - Assemble the axle (7) to the base of the machine

(see fig. page M6.4) with the M 8x20 screws and

relative washers (two per part) so that their supports

coincide.

7) - Introduce on the axle the antidust ring (7A) with

folded edges turned toward the machine.

8) - Insert the wheel (9) on the axle paying attention to

the spacer (8D) which is between the two bearings,

then insert the selfblocking nut (8A) and finally assemble the shutting cap (8C).

9) - Pump the tyre (9) bringing the pressure to three atms.

10)- Lower the machine to the ground and place the

parking foot definitively (regulating at the best height).

ATTENTION

Do not substitute the original tires with other types.

!

ATTENTION

3

4S

4I

4L

4V

!

4

5

7

8D

8A

8C

9

7A

CTM300

CTL300

TRAILERS

The machines provided for assembling the CTL accessory (slow towing trolley) can be towed up to a maximum speed

of 40 Kms/hour on asphalted surfaces.

Towing on public roads or turnpikes of any type IS EXCLUDED, because not in possesion of the requirements by

national and foreign traffic norms.

18/09/00 M6GB

Set-up for operation (Engine diesel)

TS_GE

Air cooled systems

M

20

© MOSA 1.1-09/05

16/07/03 M20-R-A-GB

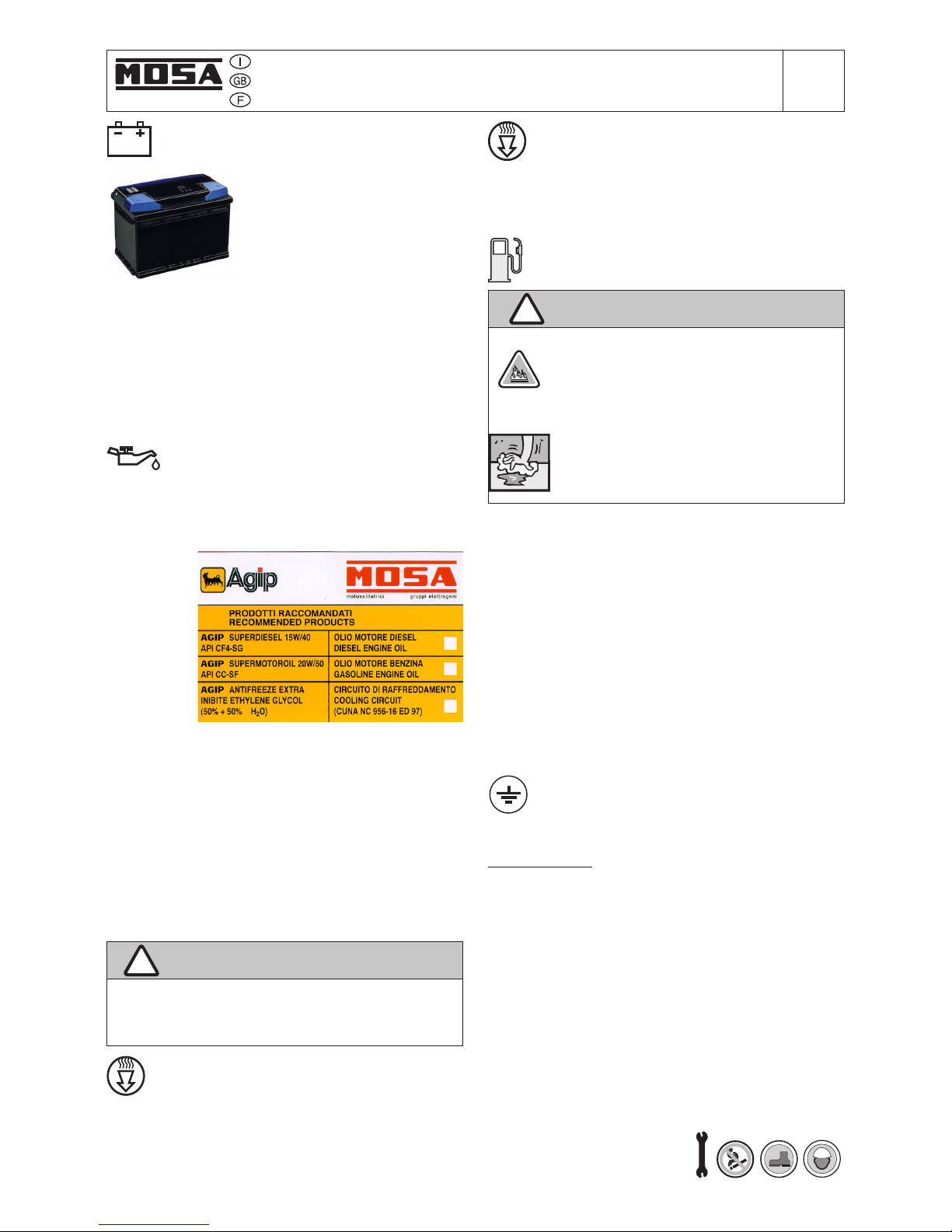

BATTERY WITHOUT MAINTENANCE

Connect the cable + (positive)

to the pole + (positive) of the

battery (after having taken

away the protection), by

properly tightening the clamp.

Check the state of the battery

from the colour of the warning light which is in the

upper part.

- Green colour: battery OK

- Black colour: battery to be recharged

- White colour: battery to be replaced

DO NOT OPEN THE BATTERY.

RECOMMENDED OIL

MOSA recommends selecting AGIP engine oil.

Refer to the label on the motor for the recommended

products.

LUBRICANT

Please refer to the motor operating manual for the

recommended viscosity.

It is dangerous to fill the motor with too much oil,

as its combustion can provoke a sudden increase

in rotation speed.

ATTENTION

!

FUEL

Do not smoke or use open flames during

refuelling operations, in order to avoid

explosions or fire hazards.

Fuel fumes are highly toxic; carry out

operations outdoors only, or in a wellventilated environment.

Avoid accidentally spilling fuel. Clean

any eventual leaks before starting up

motor.

ATTENTION

!

Refill the tank with good quality diesel fuel, such as

automobile type diesel fuel, for example.

For further details on the type of diesel fuel to use,

see the motor operating manual supplied.

Do not fill the tank completely; leave a space of

approx. 10 mm between the fuel level and the wall

of the tank to allow for expansion.

In rigid environmental temperature conditions, use

special winterized diesel fuels or specific additives

in order to avoid the formation of paraffin.

GROUNDING CONNECTION

The grounding connection to an earthed installation

is obligatory for all models equipped with a

differential switch (circuit breaker). In these groups

the generator star point is generally connected to

the machine’s earthing; by employing the TN or TT

distribution system, the differential switch

guarantees protection against indirect contacts.

In the case of powering complex installations

requiring or employing additional electrical protection

devices, the coordination between the protection

devices must be verified.

For the grounding connection, use the terminal

(12); comply to local and/or current regulations in

force for electrical installations and safety.

REFUELLING AND CONTROL:

Carry out refuelling and controls with motor at level

position.

1.

Remove the oil-fill tap (24)

2. Pour oil and replace the tap

3. Check the oil level using the dipstick (23); the oil

level must be comprised between the minimum

and maximum indicators.

DRY AIR FILTER

Check that the dry air filter is correctly installed and

that there are no leaks around the filter which could

lead to infiltrations of non-filtered air to the inside of

the motor.

OIL BATH AIR FILTER

Fill the air filter using the same engine oil up to the

level indicated on the filter.

Loading...

Loading...