Page 1

NEW MAGIC WELD

222629003 - GB1 1 0 8

18/11/08 22262M00

preparato da UPT

approvato da DITE

ENGLISH

Page 2

Page 3

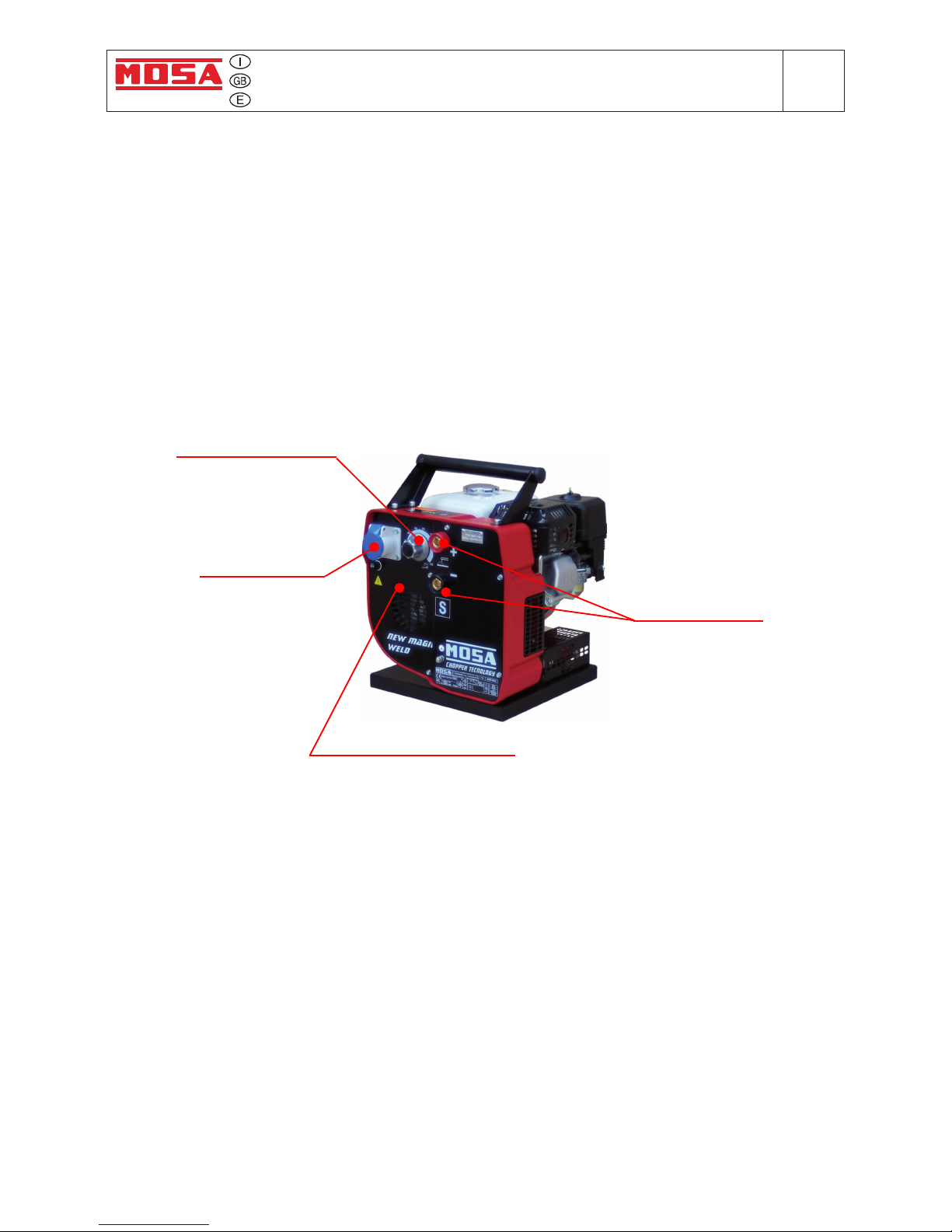

DESCRIPTION OF THE MACHINE

M

0

© MOSA REV.0 - 11/08

18/11/08 22262-GB

The Engine Driven Welder is a block with an engine, an aluminium casting and a front panel. Inside the

c

asting there are all electrical components of the machine: a permanent magnet alternator, a high

frequency chopper diode bridge, an electronic control board and an electromagnet.

Main features:

• D.C. welding current 150A @ 60%

• Continuous regulation of the welding current with "Chopper Technology"

• Suitable for basic and rutile electrodes. A reactance for cellulose electrodes is available as an option

• Antistick function (small arc force)

• Continuous auxiliary output 1600 W/ 230 Vdc (max. power 2000 W)

• Auto idle function

• Weight 34 Kg.

Electrical components of the machine:

• Permanent magnet alternator: the alternator has 2 galvanically separated windings, one for welding

and the other for the auxiliary output.

• Auto idle solenoid: an electromagnet inside the aluminium casting is supplied at no load only and

forces the engine speed at minimum (2000 rpm). When the load is present, welding or auxiliary

output, the electromagnet is not supplied any more and the engine speed goes to the maximum

(4000 rpm rated open circuit).

• High frequency chopper diode bridge: it regulates the welding current using the “Chopper Technology”, which chops the welding D.C. current at high frequency.

• Hall sensor: it measures with high precision the welding current and it’s completely isolated from

the welding circuit.

• Reactance for cellulose electrodes (optional).

• PWM control board: this single board controls the welding process, the auxiliary current and the elec-

tromagnet for the engine accelerator. Three integrated circuits PWM type (Pulse Width Modulation)

have been used. The use of these PWM’s not only for the welding control but also for the supply

control of the electromagnet reduces to the minimum the wasted power on the electromagnet.

• D.C. chopped auxiliary output: the auxiliary output is chopped every 50 msec. in order to prevent

damages to switches of hand tools due to arcing. This special D.C. auxiliary is suitable not only for

universal hand tools with brushes, but also for those with electronic speed control. In this case the

limit is that these tools can run at the maximum speed only, without possibility of speed regulation.

Auxiliary output

Fuse for auxiliary output

Welding sockets

Regulation knob for

welding current

NEW MAGIC WELD

Page 4

Page 5

Quality system

M

01

REV.4-03/12

UNI EN ISO 9001 : 2008

10/10/02 M01-GB

MOSA has certied its quality system according

to UNI EN ISO 9001:2008 to ensure a constant,

highquality of its products. This certication covers

thedesign, production and servicing of engine drivenwelders and generating sets.

The certifying institute, ICIM, which is a member

ofthe International Certication Network IQNet,

awarded the ofcial approval to MOSA after anexamination of its operations at the head ofce

andplant in Cusago (MI), Italy.

This certication is not a point of arrival but a

pledgeon the part of the entire company to maintain

a levelof quality of both its products and services

whichwill continue to satisfy the needs of its clients,

aswell as to improve the transparency and thecommunications regarding all the company’s activesin

accordance with the ofcial procedures and inharmony with the MOSA Manual of Quality.

The advantages for MOSA clients are:

·Constant quality of products and services at thehigh

level which the client expects;

· Continuous efforts to improve the products andtheir

performance at competitive conditions;

· Competent support in the solution of problems;

· Information and training in the correct applicationand use of the products to assure the security

ofthe operator and protect the environment;

· Regular inspections by ICIM to conrm that therequirements of the company’s quality systemand

ISO 9001 are being respected.

All these advantages are guaranteed by the CERTIFICATE OF QUALITY SYSTEM No.0192 issued

by ICIM S.p.A. - Milano (Italy ) - www.icim.it

Page 6

INDEX NEW MAGIC WELD

M

1

© MOSA REV.0 - 11/08

18/11/08 22262-GB

M 01 QUALITY SYSTEM

M 1.01 COPYRIGHT

M 1.1 NOTES

M 1.4 CE MARK

M 2 ADVICE

M 2.1 SYMBOLS

M 2.2 ADVICE ENGINE DRIVEN WELDER

M 2.3 SYMBOLS - ABBREVIATIONS LEGEND

M 2.6 INSTALLATION AND ADVICE

M 2.7 INSTALLATION

M 3 UNPACKING AND TRANSPORT

M 25 SET-UP FOR OPERATION

M 26 ENGINE STARTING

M 27 STOPPING THE ENGINE

M 31 CONTROLS

M 34... USE AS A WELDER

M 37 USE AS A GENERATOR

M 40.2... TROUBLE-SHOOTING

M 43 MAINTENANCE

M 45 STORAGE - CUST OFF

M 51 TECHNICAL DATA

M 55 RECOMMENDED ELECTRODES

M 53 DIMENSIONS

M 60 ELECTRICAL SYSTEM LEGENDE

M 61-….. ELECTRICAL SYSTEM

R1 SPARE PARTS LIST

AG... SPARE PARTS

R1.1 REQUEST FOR ORDER SPARE PARTS

Page 7

Copyright GE_, MS_, TS_, EAS

M

1.01

© MOSA 1.0-10/02

ATTENTION

© All rights are reserved to said Company.

It is a property logo of MOSA division of B.C.S.

S.p.A. All other possible logos contained in the

documentation are registered by the respective

owners.

➠

The reproduction and total or partial use, in any

form and/or with any means, of the

documentation is allowed to nobody without a

written permission by MOSA division of B.C.S.

S.p.A.

To this aim is reminded the protection of the author’s

right and the rights connected to the creation and

design for communication, as provided by the laws

in force in the matter.

In no case MOSA division of B.C.S. S.p.A. will be

held responsible for any damaga, direct or indirect,

in relation with the use of the given information.

MOSA division of B.C.S. S.p.A. does not take any

responsibility about the shown information on firms

or individuals, but keeps the right to refuse services

or information publication which it judges discutible,

unright or illegal.

10/10/02 M1-01-GB

This use and maintenance manual is an important

part of the machines in question.

The assistance and maintenance personel must

keep said manual at disposal, as well as that for

the engine and alternator (if the machine is

synchronous) and all other documentation about the

machine.

We advise you to pay attention to the pages

concerning the security (see page M1.1).

Page 8

INFORMATION

Dear Customer,

We wish to thank you for having bought from

MOSA a high quality set.

Our sections for Technical Service and Spare

Parts will work at best to help you if it were

necessary.

To this purpose we advise you, for all control and

overhaul operations, to turn to the nearest

authorized Service Centre, where you will obtain

a prompt and specialized intervention.

☞

In case you do not profit on these Services and

some parts are replaced, please ask and be

sure that are used exclusively original MOSA

parts; this to guarantee that the performances

and the initial safety prescribed by the norms in

force are re-established.

☞

The use of non original spare parts will cancel

immediately any guarantee and Technical Ser-

vice obligation from MOSA.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this

manual attentively. Follow the instructions

contained in it, in this way you will avoid

inconveniences due to negligence, mistakes or

incorrect maintenance. The manual is for qualified

personnel, who knows the rules: about safety and

health, installation and use of sets movable as

well as fixed.

You must remember that, in case you have

difficulties for use or installation or others, our

Technical Service is always at your disposal for

explanations or interventions.

The manual for Use Maintenance and Spare Parts

is an integrant part of the product. It must be kept

with care during all the life of the product.

In case the machine and/or the set should be

yielded to another user, this manual must also

given to him.

Do not damage it, do not take parts away, do not

tear pages and keep it in places protected from

dampness and heat.

You must take into account that some figures

contained in it want only to identify the described

parts and therefore might not correspond to the

machine in your possession.

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine

and/or set you will find: the manual for Use

Maintenance and Spare Parts, the manual for

use of the engine and the tools (if included in the

equipment), the guarantee (in the countries where

it is prescribed by law).

Our products have been designed for the use of

generation for welding, electric and hydraulic

system; ANY OTHER DIFFERENT USE NOT

INCLUDED IN THE ONE INDICATED, relieves

MOSA from the risks which could happen or,

anyway, from that which was agreed when selling

the machine; MOSA excludes any responsibility

for damages to the machine, to the things or to

persons in this case.

Our products are made in conformity with the

safety norms in force, for which it is advisable to

use all these devices or information so that the

use does not bring damage to persons or things.

While working it is advisable to keep to the

personal safety norms in force in the countries to

which the product is destined (clothing, work tools,

etc.).

Do not modify for any motive parts of the machine

(fastenings, holes, electric or mechanical devices,

others..) if not duly authorized in writing by MOSA:

the responsibility coming from any potential

intervention will fall on the executioner as in fact

he becomes maker of the machine.

Notes GE_, MS_, TS_, EAS_

M

1-1

© MOSA 1.0-10/02

☞

Notice: this manual does not engage MOSA,

who keeps the faculty, apart the essential

characteristics of the model here described and

illustrated, to bring betterments and modifications

to parts and accessories, without putting this

manual uptodate immediately.

10/10/02 M 1-1 GB

Page 9

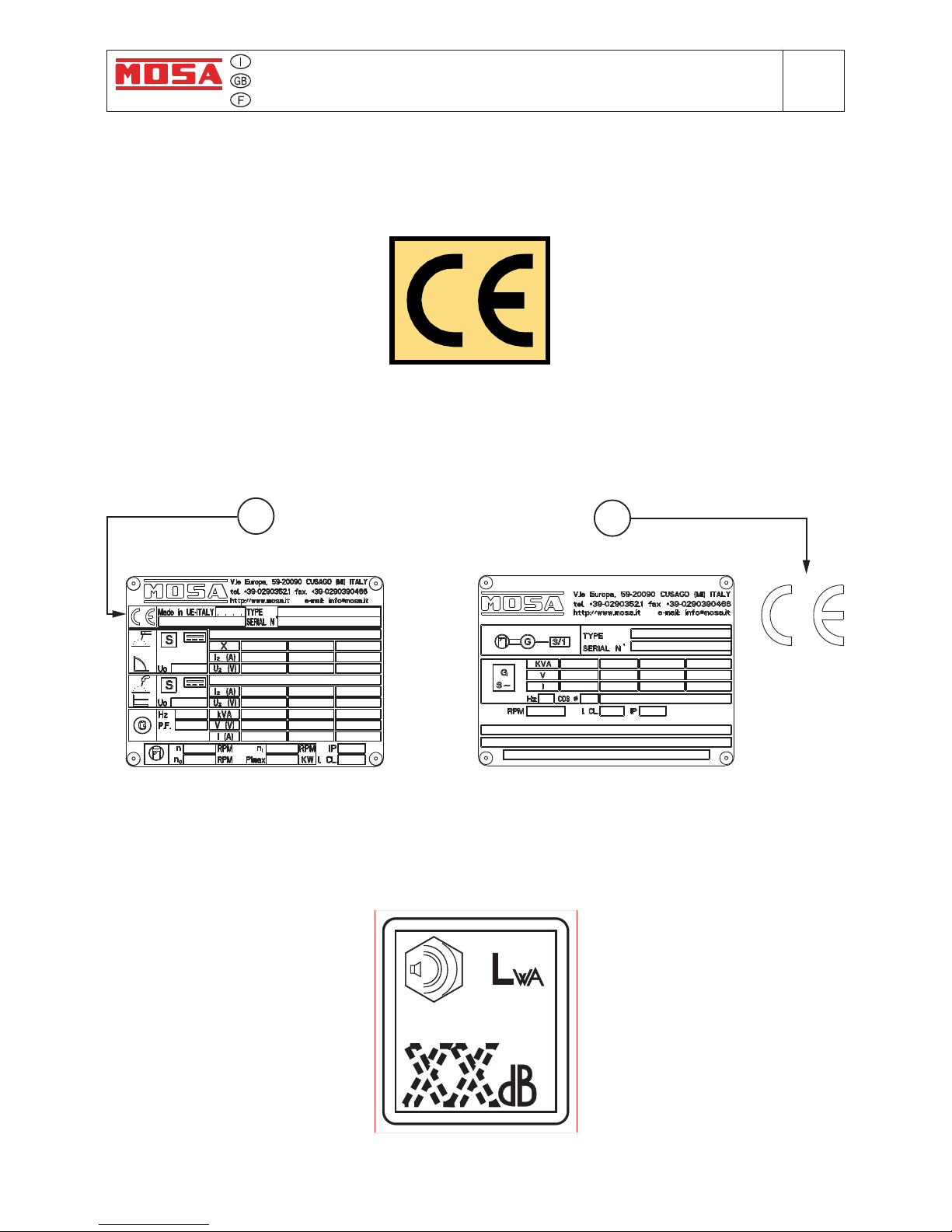

CE MARK

M

1.4

© MOSA REV.4-10/07

10/10/02 M1-4 GB

Any of our product is labelled with CE marking attesting its conformity to appliable directives

and also the fulfillment of safety requirements of the product itself; the list of these directives is

part of the declaration of conformity included in any machine standard equipment.

Here below the adopted symbol:

CE marking is clearly readable and unerasable and it can be either part of the data-plate (A) or

placed as a sticker near the data-plate (B)

A

B

Furthermore, on each model it is shown the noise level value; the symbol used is the following:

The indication is shown in a clear, readable and indeleble way on a sticker.

Page 10

18/11/08 22262-GB

Technical data

M

1.5

© MOSA REV.0 - 11/08

Technical data NEW MAGIC WELD

D.C. WELDING

Current range, continuous 30 - 150A

Open circuit voltage 40-65V

Duty cycle 150 A - 60%

D.C. GENERATION

Single-phase output (max) 2 kW / 230 V / 8.7 A

Single-phase output (continuous) 1.6 kW / 230 V / 6.9 A

Single-phase output (max) (optional) 1.5 kW / 110 V / 13.6 A

Single-phase output (continuous) (optional) 1.2 kW / 110 V / 10.9 A

ALTERNATOR Self-excited, self-regulated, brushless

Type permanent magnet, three-phase

Insulating class H

ENGINE

Mark / Model HONDA / GX 200

Type / Cooling system Gasoline 4-stroke / Air

Cylinders / Displacement 1 / 196 cm

3

Output max 5 kW (6.8 HP)

Speed 4000 rpm

Fuel consumption 313 g/kWh

Engine oil capacity 0.6 l

Starter recoil

GENERAL SPECIFICATIONS

Tank capacity 3.6 l

Running time (at duty cycle 60%) 3.5 h

Protection IP 23

Dimensions max. on base Lxlxh * 430x375x470

Weight (dry) * 34 Kg

Noise level 99 LWA (74 dB (A) - 7 m)

* Dimensions and weight are inclusive of all parts.

NEW MAGIC WELD

POWER

Declared power according to ISO 3046-1 (temperature 25°C, 30% relative hummidity, altitude 100 m above sea level).

It’s admitted overload of 10% each hour every 12 h.

In an approximative way one reduces: of 1% every 100 m altitude and of 2.5% for every 5°C above 25°C.

ACOUSTIC POWER LEVEL

ATTENTION: The concrete risk due to the machine depends on the conditions in which it is used. Therefore, it is up to the end-

user and under his direct responsibility to make a correct evaluation of the same risk and to adopt specific precautions (for

instance, adopting a I.P.D. -Individual Protection Device)

Acoustic Noise Level

(LWA)

- Measure Unit dB(A): it stands for acoustic noise released in a certain delay of time. This is not

submitted to the distance of measurement.

Acoustic Pressure (Lp) - Measure Unit dB(A): it measures the pressure originated by sound waves emission. Its value

changes in proportion to the distance of measurement.

The here below table shows examples of acoustic pressure (Lp) at different distances from a machine with Acoustic Noise

Level

(LWA)

of 95 dB(A)

Lp a 1 meter = 95 dB(A) - 8 dB(A) = 87 dB(A) Lp a 7 meters = 95 dB(A) - 25 dB(A) = 70 dB(A)

Lp a 4 meters = 95 dB(A) - 20 dB(A) = 75 dB(A) Lp a 10 meters = 95 dB(A) - 28 dB(A) = 67 dB(A)

PLEASE NOTE: the symbol when with acoustic noise values, indicates that the device respects noise emission limits

according to 2000/14/CE directive.

2000/ 14 / CE

Page 11

ADVICE NEW MAGIC WELD

MAGIC WELD 200

M

2

© MOSA REV.0 - 11/08

18/11/08 22262-GB

ATTENTION

NOTE

IMPORTANT

CAUTION

WARNING

DANGEROUS

☞ FIRST AID. In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas

or whatever event which may cause serious injuries or death, predispose the rst aid in accordance

with the ruling labour accident standards or of local instructions.

☞ FIRE PREVENTION. In case the working zone,for whatsoever cause goes on re with ames liable to

cause severe wounds or death, follow the rst aid as described by the ruling norms or local ones.

This heading warns of an immediate danger for persons

as well for things. Not following the advice can result in

serious injury or death.

This heading warns of situations which could result in

injury for persons or damage to things.

To this advice can appear a danger for persons as well

as for things, for which can appear situations bringing

material damage to things.

The installation and the general advice concerning the operations, are nalized to the correct use of the machine, in the place where it is used as generator group and/or welder.

!

- Advice to the User about the safety:

N.B.: The information contained in the manual can be changed without notice.

Potential damages caused in relation to the use of these instructions will not be considered because these are

only indicative.

Remember that the non observance of the indications reported by us might cause damage to persons or things.

It is understood, that local dispositions and/or laws must be respected.

Skin contact

Eyes contact

Ingestion

Suction of liquids

from lungs

Inhalation

Wash with water and soap

Irrigate with plenty of water, if the irritation persists contact a specialist

Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

If you suppose that vomit has entered the lungs (as in case of spontaneous vomit) take

the subject to the hospital with the utmost urgency

In case of exposure to high concentration of vapours take immediately to a non polluted

zone the person involved

Appropriated

Not to be used

Other indications

Particular protection

Useful warnings

EXTINCTION MEANS

Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Avoid the use of water jets

Cover eventual shedding not on re with foam or sand, use water jets to cool off the

surfaces close to the re

Wear an autorespiratory mask when heavy smoke is present

Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over

electric contacts (switches,plugs,etc.). In case of oil sprinkling from pressure circuits,

keep in mind that the inamability point is very low.

!!!

!

!

!

These headings refer to information which will assis you

in the correct use of the machine and/or accessories.

Page 12

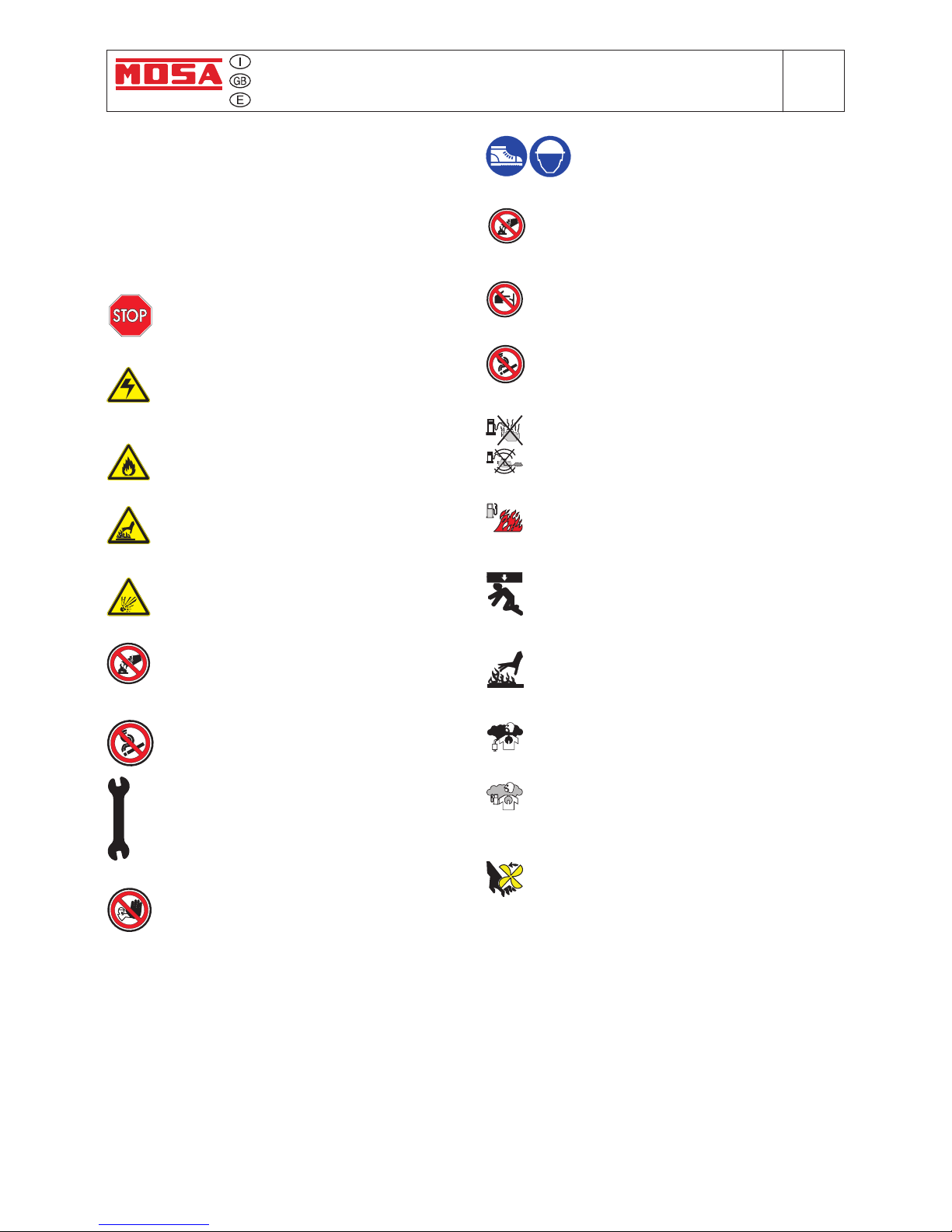

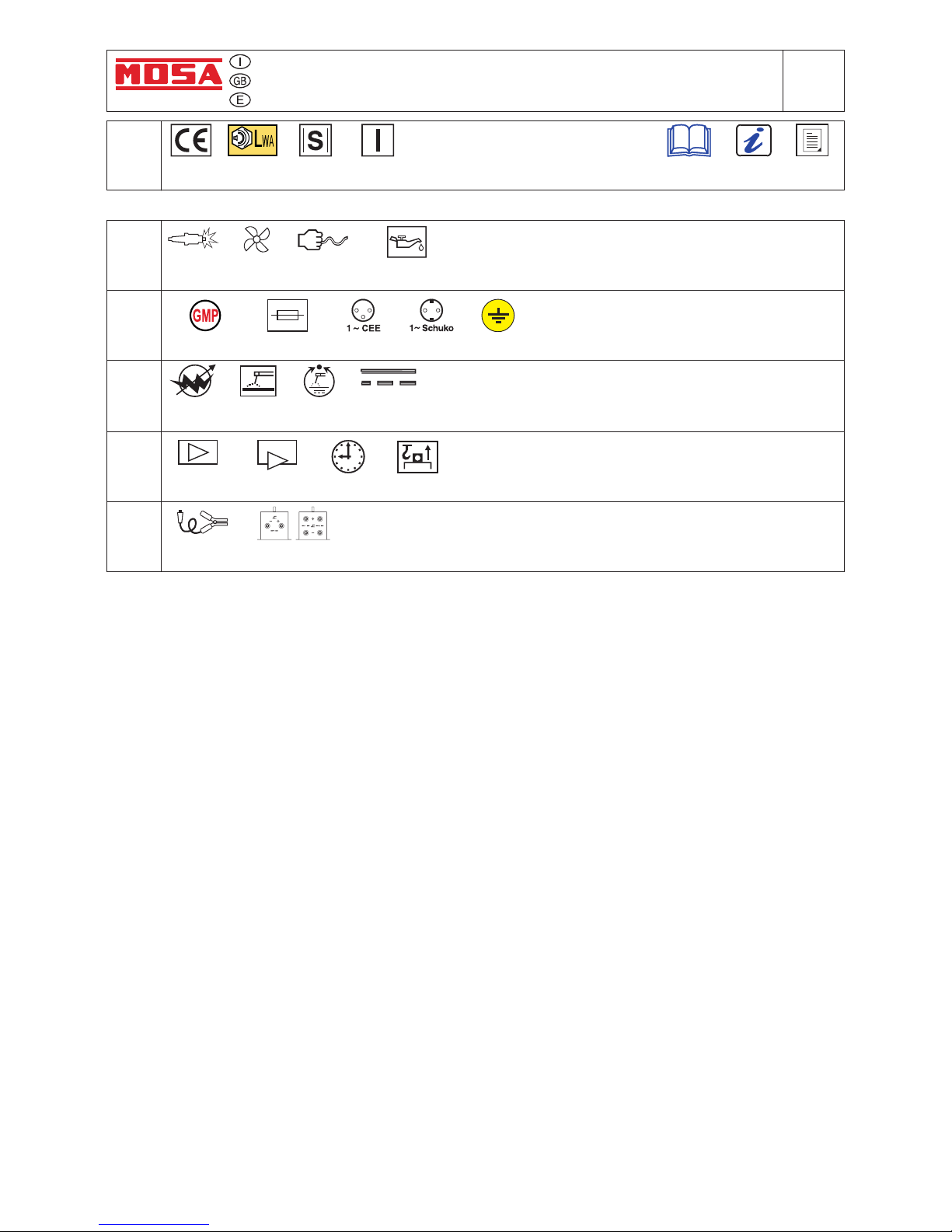

SYMBOLS NEW MAGIC WELD

MAGIC WELD 200

M

2.1

© MOSA REV.0 - 11/08

18/11/08 22262-GB

STOP - Read absolutely and be duly attentive

HIGH VOLTAGE - Attention High Voltage.

There can be parts in voltage, dangerous

to touch. The non observance of the advice

implies life danger.

FIRE - Danger of ame or re. If the advice is

not respected res can happen.

HEAT - Hot surfaces. If the advice is not

respected burns or damage to things can be

caused.

EXPLOSION - Explosive material or danger

of explosion. in general. If the advice is not

respected there can be explosions.

WATER - Danger of shortcircuit. If the advice

is not respected res or damage to persons

can be caused.

SMOKING - The cigarette can cause re or

explosion. If the advice is not respected res

or explosions can be caused.

WRENCH - Use of the tools. If the advice is

not respected damage can be caused to things

and even to persons.

ACCES FORBIDDEN to non authorizad peaple.

SYMBOLS IN THIS MANUAL

- The symbols used in this manual are designed to call

your attention to important aspects of the operation of

the machine as well as potential hazards and dangers

for persons and things.

This symbol is used to draw your attention to the fact

that the welder is being used correctly and that the

machine or equipment used operates perfectly.

Use only with safety clothing -

It is compulsory to use the personal protection means given in equipment.

Use with safe materials only -

Never use water to put out res on electrical

equipment

Use only with non inserted voltage -

It is prohibited to make interventions before

having disinserted the voltage.

No smoking -

It is prohibited to smoke while lling the tank

with fuel.

Do not refuel -

Do not refuel when the engine is hot.

Switch off the engine prior to refuelling.

Fire -

Fuel can cause res.

Use only with safety protections -

It is advisable to use all protections while

shifting the machine.

Use only with safety protections -

It is advisable to use protections suitable for

the different daily checking works.and/or of

maintenance.

Exhaust gases -

Exhaust gases from the engine can kill.

Petrol vapours -

Petrol vapours cause res and can seriously

damage your health.

Moving parts -

Moving parts are dangerous. Avoid touching any

moving parts with your hands or ngers. Never

wear loose clothing which may get trapped by

moving parts.

Page 13

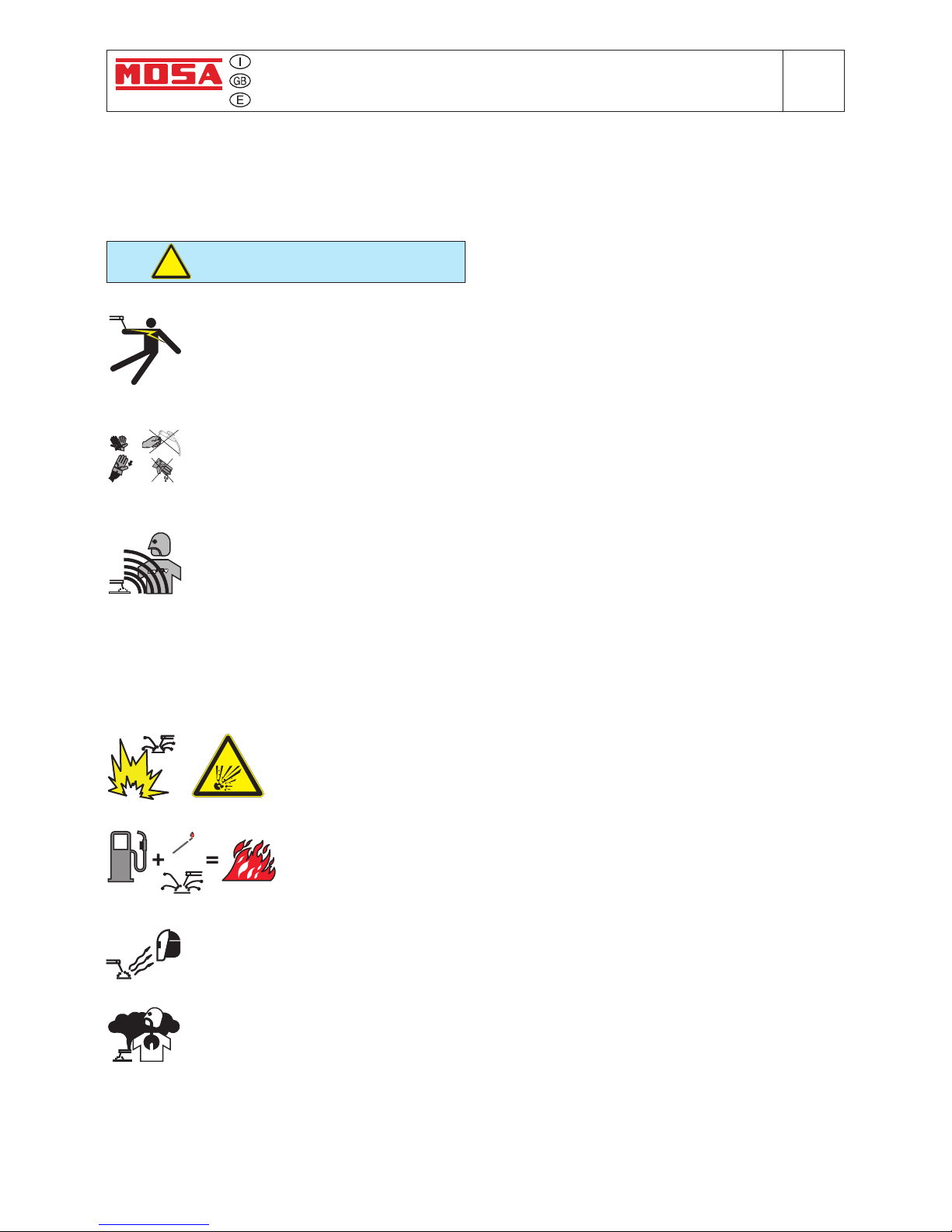

ADVICE ENGINE DRIVEN WELDER NEW MAGIC WELD

MAGIC WELD 200

M

2.2

© MOSA REV.0 - 11/08

18/11/08 22262-GB

ADVICE BEFORE USE

The operator of the welder is responsible for the security of the people who work with the welder and for those in

the vicinity.

The security measures must satisfy the rules and regulations for engine driven welders.

The information given below is in addition to the local security norms.

Do not touch any bare wires, leads or contacts as they may be live and there is danger of electric

shock which can cause death or serious burns. The electrode and welding cables, etc. are

live when the unit is operating.

Do not touch any electrical parts or the electrode while standing in water or with wet hands,

feet or clothes.

Insulate yourself from the work surface while welding. Use carpets or other insulating materials

to avoid physical contact with the work surface and the oor.

Do not wind cables around the body.

Always wear dry, insulating glovers, without holes, and body protection.

Estimate possible electromagnetic problems in the work area taking into account the following indications:

Telephonic wirings and/or of communication, check wirings and so on, in the immediate vicinity.

Radio and television receptors and transmettors.

Computer and other checking devices.

Critical devices for safety and/or for industrial checks.

Peapol who, for instance, use pace-maker, hearing-aid for deaf or something and else.

Devices used for rating and measuring.

The immunity of other devices in the operation area of the welder. Make sure that other used devices

are compatible. If it is the case, provide other additional measures of protection.

The daily duration of the welding time.

It is forbidden to weld in rooms containing explosive gases.

Keep amable material away from the welding area.

Do not weld on containers which contain amable material.

Do not weld near refuelling areas.

Do not weld on easily amable surfaces.

Protect face and eyes (protective mask with suitable dark lens and side screens),

ears and body (non-amable protective clothers).

☞

Avoid inhaling fumes by providing a ventilation system or, if not possible, use an approved air breather

☞

Do not work in closed areas where there is no fresh air ow.

☞

Do not use the welder to defrost (thaw) pipes.

☞

Use ear protections if the noise level is high.

DANGEROUS

Arc welders can be dangerous. Protect yourself and others

from any possible risks which may cause death or serious

injury.

!

Page 14

SYMBOLS - ABBREVIATIONS LEGEND

NEW MAGIC WELDM2.3

© MOSA REV.0 - 11/08

18/11/08 22262-GB

Equipment and optional

Permanent magnet

alternator

Gene ration

2000 / 14 / CE

+

-

~

°C: temperature Celsius grades

A: Ampere

B: pretrol

C.A.(c.a.): alternating current

C.C.(c.c.): direct current

cc: cm³ (volume)

CE: European norm conformity

CF: special for pipe welding

D: GFI

F: Fuse

g/kwh: grams/kilowatt hour (engine consumption)

GMP: permanent magnet alternator

Hz: frequency

I: single-phase auxiliary generation (symbol 1~)

IP: protection grads for electric devices against acess to

dangerous parts according to the IEC 529 norm (Internal

Protection)

kg: kilogram (mass)

K: welding cables set

kVA: kilovolt ampere

kW: kilowatt (engine power)

kWh: kilowatt hour (energy)

Lwa: maximum acoustic (power level) according to the

regulations in force

mm: millimeter (length) (measure)

S: symbol of EN 60974-1

T: thermic switch

V: Volt

PAR

600

Single-phase

1 ~

Engine

Welding

control

Optionals

Conformity

CE

EEC

Sound power

conformity

EN 60974-1

conformity

Various

news

Information

Users'

manual

Air

cooling

Socket

230/110/48V EEC

Welding cur-

rent electr.

regulation

Gasoline

engine

Manual

recoil

Arc

control

Fuse

Welding with

covered

electrode

Socket

230V Schuko

Ground connection point

Engine shut

down (oil)

A.C.

Plus MinusD.C.

Options on

request

Standard

equipment

Maintenance

Time

Central

lifting eye

Welding

cables

Various

Page 15

INSTALLATION AND ADVICE NEW MAGIC WELD

MAGIC WELD 200

M

2.6

© MOSA REV.0 - 11/08

18/11/08 22262-GB

INSTALLATION AND ADVICE BEFORE USE

☞ Use in open space, air swept or vent exhaust gases,

which contain the deathly carbone oxyde, far from

the work area.

POSITION

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other plants.

Check that the air gets changed completely and the hot

air sent out does not come back inside the set so as to

cause a dangerous increase of the temperature.

Make sure that the machine does not move during

the work: block it possibly with tools and/or devices

made to this purpose.

MOVES OF THE MACHINE

At any move check that the engine is off, that there

are no connections with cables which impede the

moves.

PLACE OF THE MACHINE AND/OR EQUIPMENTS

10°

10°

= 20° max

10°

10°

= 20° max

1,5 m

1,5 m

1,5 m

GAS DI SCARICO

Maximum leaning of the machine (in case of dislevel)

EXHAUST OUTPUT

ATTENTION

!

For a safer use from the operator DO NOT

t the machine in locations with high risk of

ood

Please do not use the machine in weather

conditions which are beyond IP protection

shown both in the data plate and on page

named “technical data” in this same manual.

Page 16

NEW MAGIC WELDM2.7

© MOSA REV.O-11/08

18/11/08 22262-I

Installazione

Installation

Installation

Luftzirkulation

Instalación

Page 17

UNPACKING AND TRANSPORT NEW MAGIC WELD

M

3

© MOSA REV.0 - 11/08

18/11/08 22262-GB

NOTE

Be sure that the lifting devices are: correctly mounted, ade-

quate for the weight of the machine with it’s packaging,

and conforms to local rules and regulations.

When receiving the goods make sure that the product has

not suffered damage during the transport, that there has

not been rough handling or taking away of parts contained

inside the packing or in the set.

In case you nd damages, rough handling or absence of

parts (envelopes, manuals, etc.), we advise you to inform

immediately our Technical Service.

For eliminating the packing materials, the User must

keep to the norms in force in his country.

1) Take the machine (C) out of the shipment packing.

Take out of the envelope (A) the user’s manual (B).

2) Fit the handle as shown in the instructions (tting:

screws and spanner are supplied).

3) Read: the user’s manual (B), the plates xed on the

machine, the data plate.

2

B

A

1

C

In case you should transport or move the machine, keep to the instructions as per the gures.

Be sure that the lifting devices are: correctly mounted, adequate for the weight of the machine with it’s packaging,

and conform to local rules and regulations.

Only authorized persons involved in the transport of the machine should be in the area of movement.

!

Page 18

ASSEMBLY

CTM-MW

© MOSA REV.0-06/07

M

6.11

26/06/01 M6GB

Note

: Lift the machine and assemble the parts as shown in the drawing

The CTM accessory cannot be removed from the

machine and used separately (actioned manually

or following vehicles) for the transport of loads or

anyway for used different from the machine movements.

ATTENTION

Page 19

Set-up for operation

M

25

© MOSA REV.0 - 11/08

18/11/08 22262-GB

LUBRICANT

Please refer to the motor operating manual for

the recommended viscosity.

RECOMMENDED OIL

MOSA recommends selecting AGIP engine oil.

Refer to the label on the motor for the recommended

products.

To check the oil level:

1. Remove the oil-ll tap (24) and clean the dip-stick

(23).

2. Insert the dip-stick into the oil ller without

screwing it in.

3. If the oil level is low, ll with recommended oil up

to the top of the oil ller

Oil ll tap / dip-stick

Upper oil level

MOTORS WITH OIL ALERT DEVICE

The “Oil Alert” system is designed to prevent damage to the motor due to an insufcient quantity of oil

in the cup. This system automatically shuts off the

motor before the oil level falls below the safety limit.

If the motor does not start up again after shutting

itself off, check the oil level.

FUEL

ATTENTION

!

Gasoline is highly ammable. Refuel with

motor shut off in a at surfaced well-ventilated area. Do not refuel in the presence

of ames. Avoid spilling fuel.

Any eventual spilled fuel and fumes are

ammable. Clean any dispersions of fuel

before starting up the motor.

AIR FILTER

Check that the dry air lter is correctly installed and

that there are no leaks around the lter which could

lead to inltrations of non-ltered air to the inside

of the motor.

WARNING

Do not use the machine if it is not in good

technical condition

The machine must be in good working order

before being used. Defects, especially those

which regard the safety of the machine, must

be repaired before using the machine.

Do not use without protective devices provided

Removing or disabling protective devices on the

machine is prohibited.

!

NEW MAGIC WELD

MAGIC WELD 200

Fill the tank with gasoline for automobiles (preferably lead free or with low lead content in order to

reduce deposits in the combustion chamber to a

minimum).

For further details on the type of gasoline to use,

see the motor operating manual supplied.

Do not ll the tank completely; leave a space of

approx. 10 mm between the fuel level and the wall

of the tank to allow for expansion.

Page 20

Engine starting

M

26

© MOSA REV.0 - 11/08

18/11/08 22262-GB

check daily

Do not alter the primary conditions of regulation and do not touch the sealed parts.

NOTE

!

1. Turn the fuel cock (87) to ON.

FUEL COCK

2. Switch the choke control (66) to CLOSE

N.B.: Do not use the air valve if the motor is hot

or the air temperature is too high.

CHOKE LEVER

CLOSE

CLOSE

3. Turn the engine switch (28) to the ON position

ENGINE SWITCH

STARTER GRIP

Lightly pull the start-up knob (73) until meeting

resistance, then pull decisively.

ATTENTION:

Allow the start-up knob to re-enter slowly,

avoiding having it knock against the motor and

thereby damaging the start-up system.

4. When the engine is started the machine reaches maximum engine speed immediately

(4000 rpm) for 6/7 seconds, after which the

engine speed automatically decreases to

minimum (2000 rpm). The minimum is set by

the solenoid which acts on the accelerator

lever.

5. The engine reaches maximum speed only

when current is drawn in welding or auxiliary

power mode.

NEW MAGIC WELD

MAGIC WELD 200

Page 21

Stopping the engine

© MOSA REV.0 - 11/08

18/11/08 22262-GB

Before stopping the engine it is compulsory:

- Disconnect or close any power load connected

to the system’s auxiliary generation.

- Interrupt welding.

To shut down the motor:

For shut down the motor in case of emergency,

turn the motor switch (28) to OFF.

In normal conditions, wait for the engine to reach

minimum speed automatically 6/7 seconds after

the load has been excluded. Turn the engine

in these conditions for a few minutes so that it

can cool down and then turn the engine switch

(28) to OFF.

Turn the fuel valve to the OFF position.

ENGINE SWITCH

FUEL VALVE

NEW MAGIC WELD

MAGIC WELD 200

M

27

Page 22

Comandi

Controls

Mandos© MOSA REV.O-11/08

18/11/08 22262-I

Commandes

Pos. Descrizione Description Description

9

10

12

15

22

23

24

26

27

28

31

66

73

87

F

T

Tomas de soldadura (+)

Tomas de soldadura (-)

Toma de puesta a tierra

Toma de corriente en c.c

Filtro aire motor

Aguja nivel aceite motor

Tapón llenado aceite motor

Tapón depósito

Silenciador de descarga

Mando stop

Tapón vaciado aceite motor

Pulsador Choke

Mando manual arranque

Grifo de combustible

Fisible

Regulador corr. de soldadura

Welding sockets (+)

Welding sockets (-)

Earth terminal

d.c. socket

Engine air filter

Oil level dipstick

Engine oil reservoir cap

Fuel tank cap

Muffler

Stop control

Oil drain tap

Choke button

Starting push button

Fuel cock

Fuse

Welding current regulator

Prises de soudage (+)

Prises de soudage (-)

Prise de mise à terre

Prises de courant en c.c.

Filtre air moteur

Jauge niveau huile moteur

Bouchon remplissage huile moteur

Bouchon réservoir

Silencieux d’échappement

Commande stop

Bouchon décharge huile moteur

Bouton Choke

Commande manuelle démarrage

Robinet de l'essence

Fusible

Régulateur courant soudage

Prese di saldatura (+)

Prese di saldatura (-)

Presa di messa a terra

Presa di corrente in c.c.

Filtro aria motore

Asta livello olio motore

Tappo caricamento olio motore

Tappo serbatoio

Silenziatore di scarico

Comando stop

Tappo scarico olio motore

Comando choke

Comando manuale avviamento

Rubinetto carburante

Fusibile

Regolatore corrente di saldatura

Descripción

F

M

31

F15 T 910

12

22 27 26

73

31

23-24

28

87

66

NEW MAGIC WELD

Page 23

Use as a welder

M

34

© MOSA REV.0 - 11/08

18/11/08 22262-GB

Areas for which access by non-authorized

personnel is forbidden are:

- the control panel (at the front) - the endothermic motor discharge.

WARNING

!

PUSH AND

TWIST

CONNECT WELDING CABLES

Insert the welding cable plugs completely in the

sockets, turning clockwise to lock them in place.

Connect the earth clamp to the negative pole

and the electrode holder to the positive.

Pay attention to the two polarities on the

welding circuit, which must not come into

electrical contact with each other.

- Carefully tighten the output cables to the

bushings; if loose, they can cause problems

of overheating and damage the bushings,

cables, etc.

- Make certain the grounding pincer is connected as near as possible to the work station.

ATTENTION

!

To reduce the risk of electromagnetic interference, keep the welding cable length short and

keep them on or near the ground. If possible,

welding operations should not be done near

sensitive electronic devices. If interference

continues to occur, adopt additional measures:

shift the group, use shielded cables, line lters,

shield the entire work area.

If the above solutions do not sufce, consult

our Technical Servicing Department.

ADJUSTING THE WELDING CURRENT

The welding current is regulated by turning knob

“T” continuously. If set to the minimum (turned

fully in an anticlockwise direction) it provides

a current of approximately 30 A; if set to the

maximum (turned fully in a clockwise direction)

it gives a maximum current of approximately

150A.

RECOMMENDED ELECTRODES

All the electrodes on the market can be used,

however for cellulose electrodes we recommend Magic Weld with added reactor.

NEW MAGIC WELD

Page 24

Use as a welder

© MOSA REV.0 - 11/08

18/11/08 22262-GB

AUTO IDLE

Operation

When the engine is switched on it immediately

reaches a maximum speed of 4000 rpm for approximately 6/7 seconds for easy start up, after

which it automatically decreases and idles at

2000 rpm. It remains at this speed until current

is drawn when set to weld or auxiliary power.

When set to weld mode the machine reaches

maximum engine speed as soon as there is minimum contact between the tip of the electrode

and the piece to be welded and also when set to

generation drawing a minimum of 250 – 300 W

The machine returns to minimum 6/7 seconds

later if power is not drawn during welding or

generation.

Checking and adjusting idling speed

- Check idling speed when COLD;

- When the engine is switched on it reaches ma-

ximum speed; after 6/7 seconds it decreases

automatically to idle. Check the speed when

the engine idles;

- The idling speed corresponds to 33-35 Vdc

(only for Italy 42-45 Vdc) at the welding sockets

or the equivalent at 2000-2200 rpm.

Minimum welding voltage TOO LOW

- From Fig. 1 proceed as follows:

• when the machine idles (engine cold)

• Keep pin A locked (8 mm spanner) and un-

screw nut B (7 mm spanner)

• Again with pin A locked, turn nut C clockwi-

se (7 mm spanner) 1 - 3 mm: The more it is

extended the more the idle speed increases

• Tighten nut B on pin A and check the idling

speed.

Minimum welding voltage TOO HIGH

- From Fig. 1 proceed as follows:

• When the machine idles (engine cold)

• tKeep pin A locked (8 mm spanner) and un-

screw nut B 1-3 mm (7 mm spanner)

• Again with pin A locked, turn nut C anticlockwi-

se (7 mm spanner) until nut B touches pin A

• Tighten nut B against pin A and check that the

idling speed is correct.

Adjusting the maximum engine speed

FIG. 1

FIG. 2

To check that the maximum engine speed is

correct simply measure the welding voltage

(under no-load conditions) at maximum engine

speed which must be 49-51 V (only for Italy

66-68 Vdc).

Turn screw (A) to adjust the engine speed Fig. 2.

Turning the screw clockwise increases the idling

speed , screwing it anticlockwise decreases the

maximum engine speed.

M

34.1

NEW MAGIC WELD

Page 25

Checking and adjusting the maximum welding current

© MOSA REV.0 - 11/08

18/11/08 22262-GB

dal ponte chopper

from chopper welding bridge

dal sensore di corrente

from current sensor

taratura corrente max. di sald. (*)

welding max. current adjustment (*)

dall'alternatore

from alternator

dai ponti ausiliari

from aux. bridges

dal frontale

from frontal

dal solenoide

from solenoid

NEW MAGIC WELD

M

34.2

Sol. 1

Sol. 2

Si

Su

Ri

Ru

Y

Ti

Tu

2

1

14

13 7

8

1

2

11

12

2

1

Y

T

R

S

S

R

T

ON

OFF

*) Tutte le volte che viene sostituita o la scheda o il sensore di corrente è necessario procedere ad

una verica della massima corrente di saldatura e eventualmente procedere ad una sua taratura nel seguente modo:

- Lasciare ssato il frontale solo con la vite centrale inferiore e non stringerla in modo che il frontale nella

sua parte superiore rimanga staccato di circa 7-8 cm.

- Ruotare il trimmer sulla scheda tutto in senso antiorario.

- Porre i dip switch secondo la gura

- Vericare che al minimo del potenziometro corrisponda il minimo della manopola.

- Porre la manopola di saldatura al minimo e avviare il motore. Lasciare che la macchina vada al

minimo poi fare un corto circuito tra il + e - tramite i cavi di saldatura.

- Ruotar e la manopola di saldatura al massimo.

- Ruotare lentamente il trimmer in senso orario afnché la corrente di saldatura arrivi a 140A.

*) Every time either the board or the current sensor is changed, it is necessary to check the max. welding

current and, if it is the case, to set it as follows:

- Keep the front panel xed with its lower central screw and don't tight it, so that the front panel in its upper part can

have a gap of 7-8 cm.

- Rotate the trimmer on the board fully anticlockwise.

- Put the dip switch as drawing

- Check that to the minimum of the potentiometer corrisponds the minimum of the knob.

- Put the welding knob to the minimum and start the engine.

- Let the machine idle, then shortcircuit between the + and - welding sockets through the welding cables.

- Rotate the welding knob to the maximum.

- Slowly rotate the trimmer clockwise so that the welding current reaches 140 A.

Dip switch

Dip switch

Dip switch

Page 26

Parallel engine driven welder

M

34.3

© MOSA REV.0 - 11/08

How to put two machines in parallel:

from the front panels of the machines connect the two positives welding sockets(+) between

themselves and the two negative welding sockets bethween themselves.

To effect the connection ask for the accessory K2X150.

ATTENTION: use t cables and tight at the connection point.

How to proceed:

- start the machine putting the two welding handles (T) in the wanted position (half of the total

current);

- put in parallel with the right cables;

- proceed with welding.

18/11/08 22262-GB

NEW MAGIC WELD

Page 27

Use as a generator

© MOSA REV.0 - 11/08

18/11/08 22262-GB

WARNING

!

GENERATION IN C.C. (CONTINUOUS CURRENT WITH MICRO-INTERRUPTION)

Machines with three pin outlets for auxiliary

supply have, at each outlet, isolated active

and neutral sockets, and an earth socket. Only

the earth socket is bonded to the frame of the

machine.

For your safety, all auxiliary equipment, extension cords, appliance cords, plugs, plug sockets

and appliances should be in good condition and

correctly wired and connected. All earthing wires, qhere used, must be continuous. Extension

corde with three wires should be used except

for double insulated appliances.

The frame of the unit should not be connected to the general mass of earth by an earth

spike or by any other means, but should be

isolated from earth.

Note: in line with current practice, a oating

auxiliary power system is used. The auxiliary

power windings are not connected to the frame, hence a "residual current device" is not

required.

- If the generator is used to feed more complex

circuits, or used in special environments, for

example: building sites, it is obligatory to

interpose between the socket and the loads a

small distribution panel complete with electrical

safeties foreseen by regulatory norms in force

in matters of electrical installation.

It is absolutely forbidden to connect the

unit to the public mains and/or another

electrical power source.

Areas for which access by non-authorized

personnel is forbidden are:

- the control panel (at the front) - the endothermic motor discharge.

M

37

NEW MAGIC WELD

Page 28

Trouble-shooting

© MOSA REV.0 - 11/08

18/11/08 22262-GB

The motor does not start up,

or starts up and then stops

immediately

1) Engine switch (28) at position

OFF

2) Lack of or insufcient oil in the

motor

3) Faulty motor stopping device

(oil-alert)

4) Lack of fuel in tank or fuel tap

closed

5) Dirty or faulty spark plug

6) Cold motor

7) Other causes

1) Position switch to ON

2) Rell or top off

3) Replace

4) Rell the tank. Open the fuel tap

5) Clean or check and eventually

replace

6) Hold down the CHOKE button,

after start-up, for a longer period

of time

7) Consult the motor Operating Manual.

Problem Possible cause Solution

No current under no-load

conditions in weld mode

No current under no-load

conditions in auxiliary power

mode

Incorrect minimum voltage

1) Use a multimeter to test that there

are 3 Kohms between pins 1-2; if

NOT replace the bridge

2) Replace

3) Disconnect the welding and

auxiliary power cables. Use a

voltmeter to check that there is

48 Vac at the outputs in weld and

approximately 170 Vac in the 230

V version and 90 Vac in the 110

V version. Carry out the check

when the engine idles (disconnect one of the two wires to the

solenoid)

1) Chopper welding bridge broken

2) Faulty circuit

3) Faulty alternator

1) replace the fuse

10A retarded for version 230V

15A retarded for version 110V

2) Use a multimeter to check the 2

single phase diode bridges on the

auxiliary power

3) Replace

4) Disconnect the welding and

auxiliary power cables. Use a

voltmeter to check that there is

48 Vac at the outputs in weld and

approximately 170 Vac in the 230

V version and 90 Vac in the 110

V version. Carry out the check

when the engine idles (disconnect one of the two wires to the

solenoid).

1) Fuse open

2) Auxiliary power diode bridge

broken

3) Faulty circuit

4) Faulty alternator

under no-load conditions 1) Adjust the solenoid as shown on

page M34.

1) Incorrect solenoid adjustment

M

40.2

NEW MAGIC WELD

Page 29

Trouble-shooting

© MOSA REV.0 - 11/08

18/11/08 22262-GB

M

40.2.

1

Problem Possible cause Solution

RESISTENCE OF WINDING AT 20°C

Ω (ohm)

NOTE

Output in weld mode

Between green / black cable

Between green / red cable

Between black / red cable

0,030

0,030

0,030

All cables of the same colour are

connected in parallel

Auxiliary power outputs 230 Vdc

Between the black cables: R / S

Between the black cables: R / T

Between the black cables: S / T

1,2

1,2

1,2

Auxiliary power outputs 110Vdc

Between the black cables: R / S

Between the black cables: R / T

Between the black cables: S / T

1,0

1,0

1,0

Cable Y is connected to the centro

stella of the three phase circuit

Cable Y is connected to cable T

1) Adjust the maximum engine speed as shown on page M34.

Incorrect maximum voltage

under no-load conditions

Engine always at idle speed

1) Replace

Engine always at maximum

speed

1) Incorrect maximum engine

speed

1) Faulty circuit

1) Replace;

2) Check that the resistance of the

solenoid winding is approximately

10 ohm.

Insufficient power during

welding or generation

1) Dirty petrol lter,

dirty air lter,

dirty carburetor.

See engine instruction booklet.

1) Disconnect all the outputs; 3 for

1) faulty circuit

2) Faulty solenoid

1) Engine

1) a lt er na to r w in di ng s n o t

Irregular or inconsistent welding current

insulated from earth

2) welding chopper bridge not

insulated from earth

3) power cables not insulated

from earth

4) faulty circuit

welding which go to the chopper

bridge and 4 for auxiliary power

which go to the circuit board.

Use a multimeter to check the

insulation of the alternator;

2) disconnect the 3 welding cables,

the + and - for welding, the black

wire and the connector which

go to the circuit board, Use a

multimeter to check that the

bridge is insulated from the earth.

3) check that the cables inside the

aluminium casting, are properly

insulated;

4) Replace

NEW MAGIC WELD

Page 30

MAINTENANCE

© MOSA REV.0 - 11/08

18/11/08 22262-GB

!

!

• Maintenance and repair work should only be done by qualied personnel.

• Stop the engine before doing any work on the machine. If

for any reason the machine must be operated while working

on it, be careful not to touch rotating parts, hot surfaces,

live wires, etc. which may be unprotected.

• Remove protective guards only when necessary to perform

maintenance and replace them immediately after the maintenance is completed.

• Use suitable tools and wear suitable clothes.

• Do not modify the machine without prior authorization

ATTENTION

When carrying out maintenance operations

be careful to avoid polluting the environment

with the materials used during maintenance.

Follow all local health and safety regulations.

IMPORTANT

MAINTENANCE OF THE MACHINE

Maintenance refers to all operations regarding

the control and replacement of mechanical and

electrical parts subject to wear. In addition it

refers to the control and topping up or replacement of uids such as fuel, oil and the regular

cleaning of the machine.

Repairs refers to the substitution of worn or

damaged parts and repairs should be carried

out by Authorized Service Centres.

Refer to the Engine Manufacturer’s Manual for

the maintenance instructions for the engine.

Periodic maintenance should be performed

according to the schedule shown in this manual.

On a regular basis check that there are no

obstructions in the aspiration/exhaust ducts of

the alternator, the engine or the housing which

could restrict the ow of cooling air.

DRY AIR FILTER

Replace the air lter cartridge every 200 hours

under normal conditions and every 100 hours

in dusty environments.

PERMANENT MAGNET ALTERNATOR

No maintenance is necessary, as the alternator

has no brushes or slip rings, and there are no

devices for regulation of the output.

WARNING LABELS AND DECALS

Check warning labels and decals once a year

and replaced if missing or unreadable.

CABLES AND CONNECTIONS

Periodically check the condition of the cables

and tighten the connections.

HOT surface

can

hurt you

MOVING

PARTS

can injure

M

43

NEW MAGIC WELD

MAGIC WELD 200

Page 31

STORAGE - CUST OFF

© MOSA REV.0 - 11/08

18/11/08 22262-GB

M

45

Have qualied personnel prepare the ma-

chine for the cust-off.

STORAGE

In case the machine will not be used for more

than 30 days, it should be stored in a suitable

area where it is protected from the elements to

prevent rusting, corrosion and other damage to

the machine.

ENGINE

Run the engine until it stops from lack of fuel.

For long periods of storage, refer to the engine

manufacturer’s manual.

Clean the machine carefully.

Cover the machine with a plastic cover and store

in a dry place.

CUST-OFF

As cust off we intend all operations to be made,

at utilizer’s care, at the end of the use of the

machine.

This comprises the dismantling of the machine,

the subdivision of the several components for

a further reutilization or for getting rid of them,

the eventual packing and transportation of the

eliminated parts up to their delivery to the store,

or to the bureau encharged to the cust off or to

the storage ofce, etc.

The several operations concerning the cust off,

involve the manipulation of uids potentially

dangerous such as: lubricating oil.

The dismantling of metallic parts liable to cause injuries or wounds, must be made wearing

heavy gloves and using suitable tools.

The getting rid of the various components of the

machine must be made accordingly to rules in

force of law a/o local rules.

Particular attention must be paid when

getting rid of: lubricating oils, inamable

liquids such as fuel.

The machine user is responsible for the observance of the norms concerning the environment

conditions with regard to the elimination of the

machine being cust off and of all its components.

In case the machine should be cust off without

any previous disassembly it is however compulsory to remove:

- tank fuel

- engine lubricating oil

NOTE: MOSA is involved with custing off the

machine only for the second hand ones, when

not reparable.

This, of course, after authorization.

In case of necessity for rst aid and re prevention, see page M2.

In the storage or cust-off operations avoid

that polluting substances, liquids, exhausted

oils, etc. bring damage to people

or things or can cause negative

effects to surroindings, health or

safety respecting completely the laws and/or

dispositions in force in the place.

!

IMPORTANT

NEW MAGIC WELD

MAGIC WELD 200

Page 32

RECOMMENDED ELECTRODES (In accordance with A.W.S Standard)

MS_, TS_

M

55

© MOSA 1.0-10/03

The information here below are to be intended only as indicative since the above norm is much larger.

For further details please see the specific norms and/or the manufacturers of the product to be used in the welding

process.

RUTILE ELECTRODES: E 6013

Easily removable fluid slag, suitable foe welding in all position.

Rutile electrodes weld in d.c. with both polarities (electrode holder at + or -) and in a.c..

Suitable for soft steels R-38/45 kg/mm2 . Also for soft steels of lower quality.

BASIC ELECTRODES: E 7015

Basic electrrodes wels onlu in d.c. with inverse polarity (+ on the electrode holder) ; there are also types for a.c.

Suitable for impure carbon steels. Weld in all position.

HIGH YIELD BASIC ELECTRODES: E 7018

The iron contained in the coating increases the quality of metal added. Good mechanical properties. Weld in all position.

Electrode holder at + (inverse polarity). Wld deposit of nice aspect, also vertical. Workable; high yield.

Suitable for steels with high contens of sulphur (impurities).

CELLULOSIC ELECTRODES: E 6010

Cellulosic electrodes weld only in d.c. with polarity + electrode holder - ground clamp.

Special for steels run on pipes with R max 55 kg/mm2. Weld in all position. volatile slag.

ELECTRODES IDENTIFICATION ACCORDING TO A.W.S. STANDARDS

EX XY Z

2 digits: type of coating

and electric power

conditions.

(see table 3)

1 digits: welding

positions.

(see table 2)

2÷3 digits: tesile strenght of

the weld deposit.

(see table 1)

symbol for

"Coated

electrode"

10 Cellulose electrodes for d.c.

11 Cellulose electrodes for a.c.

12 Rutile electrode for d.c.

13 Rutile electrode for a.c.

14 High yield rutile electrodes

15 Basic electrodes for d.c.

16 Basic electrodes for c.a.

18 High yield basic electrodes for d.c.

(inverse polarity)

20 Acid electrodes for flat or front position welding for

d.c. (- pole) and for a.c.

24 High yield rutile electrodes for flat or front plane

position welding for d.c. and a.c.

27 High yield acid electrodes for flat or front plane

position welding for d.c. (- pole) and a.c..

28 High yield basic electrodes for flat or front plane

position welding for d.c. (inverse polarity)

30 Extra high yield acid electrodes, extra high

penetration if required, for flat position welding only

for d.c. (- pole) and a.c.

N° Descrizione

Number

Strenght

K.s.l. Kg/mm

2

60

70

80

90

100

110

120

60.000

70.000

80.000

90.000

100.000

110.000

120.000

42

49

56

63

70

77

84

for all positions

for plane and verticl

for plane posotion only

1

2

3

Table 1

Table 2 Table 3

10/10/03 M55GB

Page 33

© MOSA REV.O-11/08

18/11/08 22262-I

M

53

Dimensioni

Dimensions

Dimensions

Abmessungen

Dimensiones

375

430

470

510

854

610

402

~

566

NEW MAGIC WELD

Page 34

18/11/08 22262-I

NEW MAGIC WELD

M

60

© MOSA REV.O-11/08

A : Alternatore

F : Fusibile

H : Presa 230V monofase

I : Presa 110V monofase

R : Unità controllo saldatura

T : Regolatore corrente saldatura

Y : Ponte diodi saldatura

F1 : Elettromagnete acceleratore

S2 : Trasmettitore livello olio

F3 : Pulsante stop

G3 : Bobina accensione

H3 : Candela accensione

W6 : Sensore di hall

Legenda schema elettrico Electrical system legende Legende des schemas electriques

Stromlaufplan-Referenzliste Leyenda esquema eléctrico

A: Alternator

F: Fuse

H: 230V 1phase socket

I: 110V 1-phase socket

R: Welding control PCB

T: Welding current regulator

Y: Welding diode bridge

F1: Acceleration solenoid

S2: Oil level transmitter

F3: Stop push-button

G3: Ignition coil

H3: Spark plug

W6: Hall sensor

A : Alternateur

F : Fusible

H : Prise 230V monophasé

I : Prise 110V monophasé

R : Unite contrôle soudage

T : Régulateur courant de soudage

Y : Pont diodes soudage

F1 : Electro-aimant accélérateur

S2 : Transmetteur niveau huile

F3 : Bouton stop

G3 : Bobine allumage

H3 : Bougie allumage

W6: Senseur de hall

A Generator

F Sicherung

H Steckdose 230V 1-phasig

I Steckdose 110V 1-phasig

R Steuerplatine Schweißstrom

T Schweißstromregler

Y Diodenbrücke Schweißstrom

F1 Elektromagnet Motordrehzahl

S2 Ölstandssensor

F3 Taste Stopp

G3 Zündspule

H3 Zündkerze

W6 Hall-Sensor

A :Alternador

F :Fusible

H :Toma 230V monofásica

I :Toma 110V monofásica

R :Unidad control soldadura

T :Regulador corriente soldadura

Y :Puente diodos soldadura

F1 :Electromagnetismo acelerador

S2 :Captador nivel aceite

F3 :Pulsador stop

G3 :Bobina encendido

H3 :Bujía encendido

W6 :Sensor de entrada

Page 35

18/11/08 22262-I

Schema elettrico

Electric diagram

Esquema eléctrico

NEW MAGIC WELD

(110V version)

M

61

© MOSA REV.O-11/08

20090-CUSAGO (MI)-ITALY

http://www.mosa.it

MAGIC WELD

Wiring Diagram 22263.prg

22240.S.060-F

Leporace N.

2

Approvato:

Esp.

Data Dis. Appr.

Modifica

Denominazione:

Macchina:

Data:

Progetto:

di n°

Pag.n°

2

Date Appr.

Approved:

Project:

Denomination:

Machine:

Modification

Date:

Da Pag.

Alla Pag.

To Page

From Page

Designer:

of n°

Desi.

Dis. n°:

Exp.

Page n°

Dwg. n°:

Disegnatore:

La MOSA si riserva a termini di legge la proprieta' del presente disegno con divieto di riprodurlo o comunicarlo a terzi senza sua autorizzazione.

02.07.2004

-

+

KEY COLOR

LEGENDA COLORI

NERO/BLACK

(R)

ROSSO/RED

(B)

(B)

Y

T

S

R

(B)

GIALLO/YELLOW

(B)

(Y)(B)(Y)

(Y)

(B)

(Y)

(B)

(B)

(Y)

(BL)

(BL)

BLU/BLUE

(Y)

(R)

(B)

(B)

(R)

(BL)

+

-

~

~

~

-

+

Z

3~

GS

A

W6

Y

F1

S2G3H3

ONOFF

F3

P1

P3

P2

Sol. 1

Sol. 2

Si

Su

Ri

Ru

Tu

Ti

Y

1

2

3

4

5

6

7

8

9

10

11

12

R

T

A

18.04.2005 N.L.

T

(R)

(B)

S

R

+

-

+

-

F

15A

110V/16A

I

Aggiunto soppressore (Zenamic) a pr

otezione dei ponti diodi ausiliaria.

B Aggiunto ponticello tra pin9e10suc onn. P1 (opzione Arc- Force). 22.03.2006 N.L.

(BL)

N.L.

C

03.04.2006

1Kohm/¼W

Aggiunto resistenza 1Kohm/¼W nel pontic

ellotrapin9e10suconn. P1.

22Kohm/2W

D

27.06.2006 N.L.

Aggiunto resistenza 22Kohm/2W in parallelo uscita ponti diodi ausilaria.

10µH

Aggiunto induttanza 10µH su cavo

1 connettore P1. 23.05.2007 N.L.

E

Aggiunto reattore(W)F

27.10.2008 N.L.

W

Page 36

18/11/08 22262-I

Schema elettrico

Electric diagram

Esquema eléctrico

NEW MAGIC WELD

(EU Version)

M

61.1

© MOSA REV.O-11/08

20090-CUSAGO (MI)-ITALY

http://www.mosa.it

MAGIC WELD

Wiring Diagram

22243.prg

22243.S.060-C

Leporace N.

2

Approvato:

Esp.

Data

Dis.

Appr.

Modifica

Denominazione:

Macchina:

Data:

Progetto:

di n°

Pag.n°

2

Date

Appr.

Approved:

Project:

Denomination:

Machine:

Modification

Date:

Da Pag.

Alla Pag.

To Page

From Page

Designer:

of n°

Desi.

Dis. n°:

Exp.

Page n°

Dwg. n°:

Disegnatore:

La MOSA si riserva a termini di legge la proprieta' del presente disegno con divieto di riprodurlo o comunicarlo a terzi senza sua autorizzazione.

-

+

T

(R)

(B)

KEY COLOR

LEGENDA COLORI

NERO/BLACK

(R)

ROSSO/RED

(B)

(B)

Y

T

S

R

S

R

(B)

GIALLO/YELLOW

(B)

(Y)(B)(Y)

(Y)

(B)

(Y)

(B)

(B)

(Y)

(BL)

(BL)

BLU/BLUE

(BL)

(Y)

(R)

(B)

(B)

(R)

-

+

Z

3~

GS

A

W

+

-

+

-

F

10A

230V/16A

H

W6

Y

F1

S2G3H3

ONOFF

F3

P1

P3

P2

Sol. 1

Sol. 2

Si

Su

Ri

Ru

Tu

Ti

Y

1

2

3

4

5

6

7

8

9

10

11

12

R

A

18.04.2005 N.L.

Aggiunto soppressore (Zenamic) a protezione dei ponti diodi ausiliaria.

02.07.2004

2x15Kohm/2W

N.L.

B Aggiunto n° 2 resistenze da 15Kohm/2W in parallelo uscita ponti diodi ausilaria.

19.09.2006

10µH

C Aggiunto induttanza 10µH su cavo 1 connettore P1.

23.05.2007 N.L.

Page 37

SPARE PARTS LIST

R

1

© MOSA 1.0-03/00

MOSA guarantees that any request for spare parts will be satised.

To keep the machine in full working order, when replacement of MOSA spare parts is required, always

ask for genuine parts only.

When ordering the spare parts, it is recommended to indicate:

1) Y serial number

2) Y model of welder and/or generating set

3) u n. table

4) u n. position

5) quantity

14/12/986Q16M31

TAVOLA RICAMBI - SPARE PARTS - PIECES DE RECHANGE - ERSATZTEILE

ON

OFF

START

*

VE

NULLEITERAUFMASSE

NULVERBONDENMETMASSA

NEUTROCONECTADOAMASA

NEUTRERACCORDEAUBATI

NEUTRALBONDEDTOFRAME

NEUTROCOLLEGATOAMASSA

*

65

60

Hz A

10

50

15

55

500

300

V

ST

RS

0

200

100

TR

0

h

HOURMETER

I

0

EA

1

25

20

125

1-3 13

18

17 16

20-21-22

12

21-22-23

14

11

8

2

19

15

4-5-6

EA

1

12

50 Hz

50 Hz

3

EA

1

4

12

TS 0000 GE

V.le Europa,59 - 20090 CUSAGO (MI) ITALY

Tel. +39-02 90352.1 - fax +39-02 90390466

0987654321

TYPE

SERIAL N°

22/03/00 R1GB

The requested data are to be found on the data

plate located on the machine structure, quite visible

and easy to consult.

Y

ABBREVIATIONS AND SYMBOLS:

(EV) Whenordering,specifytheenginetypeand

theauxiliaryvoltage

(ER) Enginewithrecoilstarteronly

(ES) Enginewithelectricstarteronly

(VE) E.A.Sversiononly.

(QM) Whenordering,specifythelengthinmeters

(VS) Specialversiononly

(SR) Byrequestonly

Page 38

18/11/08 22262-I

© MOSA REV.O-11/08

Ricambi

Spare parts

Piéces de rechange

Ersatzteile

Tabla de recambios

AG

NEW MAGIC WELD 5

1

2

(230V Version)

(110V Version)

3

3a

4

6

5

5a

(110V version)

(230V version)

7

8

9

10

11

12

13

14

15

16

17

18

20

23

24

22

19

21

25

Page 39

18/11/08 22262-I

© MOSA REV.O-11/08

NEW MAGIC WELD

AG

5.1

Ricambi

Spare parts

Piéces de rechange

Ersatzteile

Tabla de recambios

Pos. Rev. Cod. Descr. Note

1 222406020 VENTOLA CENTRIFUGA / FAN

2 222403047 ASSIEME MOZZO/ROTORE /HUB / SHAFT ASSY

3 222413025 STATORE AVVOLTO 230 VAC / STATOR 230V Versione 230V /230V version

3a 222403025 STATORE AVVOLTO 110 VAC / STATOR 110V Versione 110V / 110V version

4 222418263 PIASTRINA FERMA CAVI

5 1270040 PONTE DIODI / DIODE BRIDGE 35A800V Versione 110V / 110V version

5a 1270070 PONTE DIODI / DIODE BRIDGE Versione 230V / 230V version

6 222422200 MOTORE HONDA GX200T - EPA / HONDA ENGINE GX200T

7 102011270 TAPPO MANIGLIA / STOPPER, HANDLE

8 222401226 MANIGLIA DI SOLLEVAMENTO / LIFTING HANDLE

9 222509800 SCHEDA SALDATURA (MAGIC WELD) / WELDING PCB

10 222405400 PONTE CHOPPER / WELDING PCB

11 222405107 SENSORE DI HALL 250A / HALL SENSOR

12 222408065 GRIGLIA USCITA ARIA / AIR OUTLET GRID

13 222403040 CARTER ATT. MOTORE/ALTERN. (LAV.) / BOX

14 222409050 ELETTROMAGNETE ECONOMIZZATORE / ECONOMIZER SOLENOID

15 222402244 MORSETTO PER FUNE COMANDO / COMMAND WIRE CLAMP

16 222409101 SUPPORTO ELETTROMAGNETE / SOLENOID BRACKET

17 222434126 LAMIERA PROTEZIONE REATTORE / REACTOR PROTECTION

18 222401035 ANTIVIBRANTE D.25x30 / VIBRATION DAMPER

19 222402038 RONDELLA DISTANZIALE / WASHER

20 222411050 BASE SUPPORTO MOTORE/ALTERN. / BASE

21 222434100 REATTORE DI LIVELLO / REACTOR

22 222402199 SQUAD.SUPP.LEVA COMAN.GAS MOT.(COMPL.) / ENGINE GAS LEVER BRACKET

23 222408460 FILO RIGIDO COMANDO ACCELER. / ACCELERATOR WIRE

24 222402230 ASSIEME LEVA COMANDO GAS MOT. / ENGINE GAS LEVER

25 208029104 COLONNETTA / SPACER

Page 40

18/11/08 22262-I

© MOSA REV.O-11/08

NEW MAGIC WELD

AG

2

Ricambi

Spare parts

Piéces de rechange

Ersatzteile

Tabla de recambios

110I Version

230I Schuko Version

15

16

230I Version

123 4* 567

8*

9*

10*

11*

12*

13*

(*) 14

FUSE

10

20

30

40

50

60

70

1a

Page 41

18/11/08 22262-I

© MOSA REV.O-11/08

NEW MAGIC WELD

AG

2.1

Ricambi

Spare parts

Piéces de rechange

Ersatzteile

Tabla de recambios

Pos. Rev. Cod. Descr. Note

1 1291180 FUSIBILE Versione 230V

1a 1291090 FUSIBILE Versione 110V

2 103011320 PORTA FUSIBILE fino a REV.2-11/05 Del. 78/06 del 18/05/06

2 873789045 PORTA FUSIBILE da REV.3-06/07 Del.78/06 del 18/05/06

3 307017240 PRESA 220V 16A

4 270009701 POTENZ. LINEARE A FILO 5Kohm (*)

5 102301310 PRESA DI SALDATURA (+)

6 102044400 PRESA DI SALDATURA (-)

7 222427020 FRONTALE

8 1018090 ANELLO OR (*)

9 107799349 BUSSOLA MANOP.POT.REG.UN.SALD. (*)

10 207409751 MANOPOLA REGOLAZ.CORR.SALDAT. (*)

11 107011870 TAPPO (*)

12 6060070 GRANO FILETTATO E.I.M4X8 (*)

13 6060050 GRANO M 4X4 UNI 5923 R45H (*)

14 222440543 KIT MANOPOLA ARCO SALD. COMPL, (* 4+8÷13)

15 307047250 PRESA 110V 16A Versione 110V

16 259107241 PRESA SCHUKO 16A 230V - 2P+T Versione Schuko

Pos. Rev. Cod. Descr. Note

1 1291180 FUSE 230V version

1a 1291090 FUSE 110V version

2 103011320 HOLDER, FUSE up to REV.2-11/05 Del. 78/06 del 18/05/06

2 873789045 HOLDER, FUSE from REV.3-06/07 Del.78/06 del 18/05/06

3 307017240 EEC SOCKET 16A, 220V 2P+T

4 270009701 POTENTIOMETER (*)

5 102301310 WELDING SOCKET (+)

6 102044400 WELDING SOCKET (-)

7 222427020 FRONT PANEL

8 1018090 O RING (*)

9 107799349 SLEEVE (*)

10 207409751 KNOB WELDING CURRENT REGULAT. (*)

11 107011870 CAP (*)

12 6060070 DOWEL (*)

13 6060050 DOWEL (*)

14 222440543 KIT FOR ARC FORCE KNOB (*4+8÷13)

15 307047250 SOCKET 110V 16A 110V version

16 259107241 SOCKET SCHUKO 16A 230V 2P+T Schuko version

Page 42

© MOSA REV.0-06/07

29/06/01 KA

CTM-MW

222420130

KA

18

1

2

3

4

5

6

7

8

9

10

Pos. Rev. Cod. Descr. Descr. Note

1 222421050 BARELLA

PROTECTIVE FRAME

2 222421226 MANIGLIA DI SOLLEVAMENTO

LIFTING HANDLE

3 219861159 MANOPOLA

KNOB

4 222422038 RONDELLA

WASHER

5 222421170 RUOTA

WHEEL

6 222421051 PIEDE DI STAZIONAMENTO

PARKING STAND

7 222421160 ASSALE

AXLE

8 6075020 COPIGLIA

PIN, SPLIT

9 222421356 PIASTRA FISS. BASAMENTO

FIXING PLATE FOR BASE

10 222429359 SPINA DI SICUREZZA

SAFETY PLUG

Page 43

Page 44

MOSA div. della BCS S.p.A.

Stabilimento di Viale Europa, 59

20090 Cusago (MI) Italia

Tel. + 39 - 0290352.1

Fax + 39 - 0290390466

Loading...

Loading...