Mosa NAKED GE 3500 HBM, NAKED GE 3500 KBM Maintance Manual

MADE IN ITALY

CJ6D60109003

• Gruppo Elettrogeno

• Generating Set

• Groupe Electrogene

• Grupos Electrógenos

• Stromerzeuger

• Grupo Gerador

• Генераторная Установка

• Stroomaggregaten

• Skupina generátoru

Codice

Code

Code

Codigo

Kodezahl

Código

Код

Code

Kód

Edizione

Edition

Édition

Edición

Ausgabe

Edição

Издание

Editie

Edice

07.2016

NAKED

GE 3500 HBM

GE 3500 KBM

USE AND MAINTENANCE MANUAL

TRANSLATION OF THE ORIGINAL INSTRUCTIONS – ENGLISH

language

13/11/14 CJ6D6010_EN

ENGLISH

ENGLISH

REV.0-07/16

INDEX

0. GENERAL INFORMATION

M1.1

INTRODUCTION

.....................................................................................................................PAG. 4

M1.4

CE MARK

...............................................................................................................................PAG. 5

M2

SYMBOLS AND SAFETY PRECAUTIONS

..................................................................................PAG. 6

M2.1

WARNINGS

............................................................................................................................PAG. 7

M2.5

SAFETY RULES

......................................................................................................................PAG. 8

1. GENERAL INFORMATION OF THE MACHINE

M0

DESCRIPTION OF THE MACHINE

.............................................................................................PAG. 10

RECORDING DATA

..................................................................................................................PAG. 11

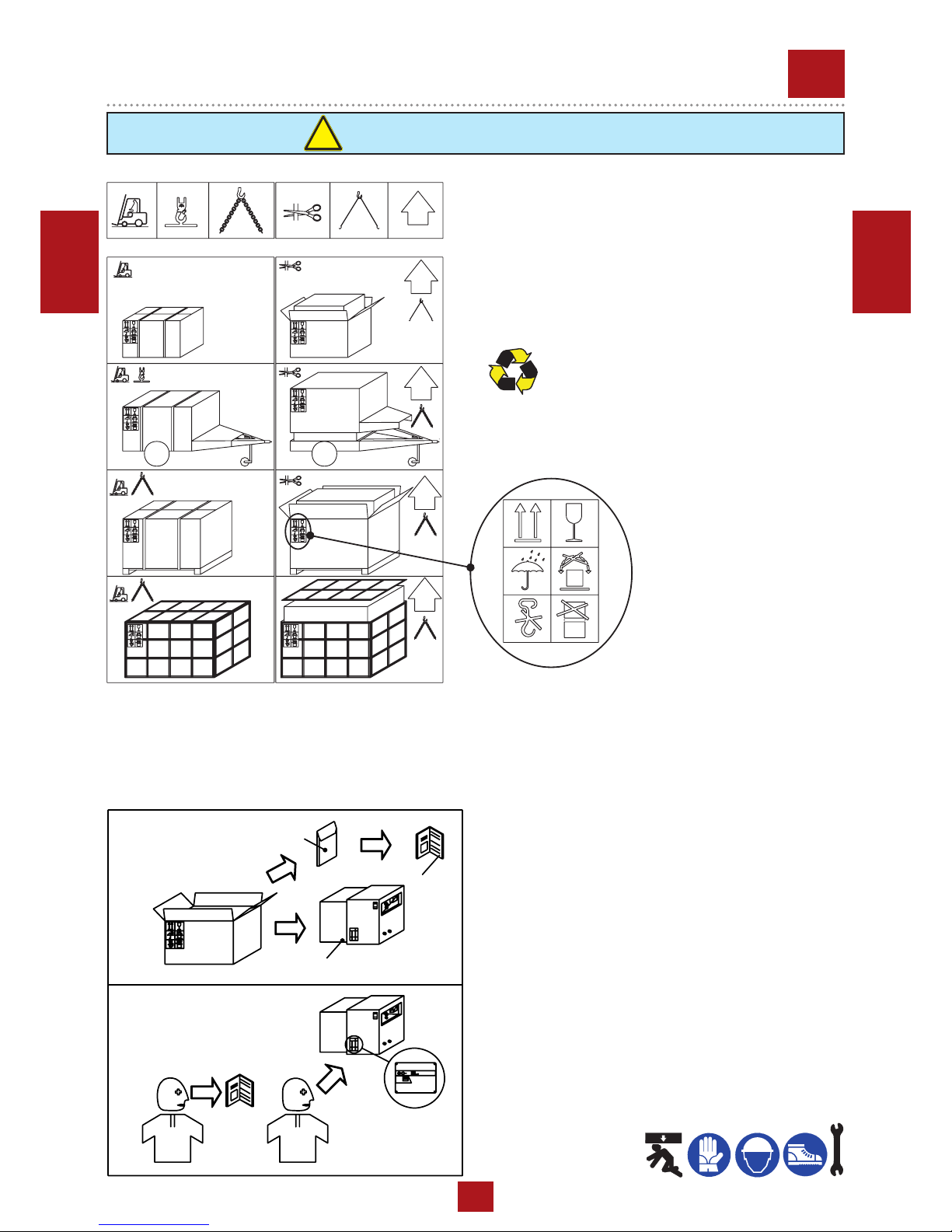

2. DISPLACEMENTS AND TRANSPORT

M3

MACHINE UNPACKING

...........................................................................................................PAG. 12

M4.1

TRANSPORT AND DISPLACEMENTS COVERED UNITS

.............................................................PAG. 13

3. INSTALLATION AND USE

M2.7

INSTALLATION

.......................................................................................................................PAG. 14

M2.6

INSTALLATION AND ADVICE

....................................................................................................PAG. 15

M25

SET-UP FOR OPERATION GASOLINE ENGINE

...........................................................................PAG. 19

EARTHING KIT ........................................................................................................................

PAG. 20

M26.1

STARTING AND STOPPING HONDA GASOLINE ENGINE

............................................................PAG. 21

M26.2

STARTING AND STOPPING KHOLER GASOLINE ENGINE

..........................................................PAG. 22

M31

CONTROLS (GE 3500 HBS)

.....................................................................................................PAG. 23

M31.1

CONTROLS (GE 3500 KBS)

.....................................................................................................PAG. 24

M37...

USE AS A GENERATOR

...........................................................................................................PAG. 25

4. MAINTENANCE

M40.2...

TROUBLE SHOOTING

..............................................................................................................PAG. 29

M43

MAINTENANCE

.......................................................................................................................PAG. 31

M45

STORAGE AND CAST OFF

.......................................................................................................PAG. 32

5. TECHNICAL INFORMATIONS

M1.5

TECHNICAL DATA

...................................................................................................................PAG. 33

M2.7.1

DIMENSIONS

.........................................................................................................................PAG. 34

M60

ELECTRICAL SYSTEM LEGENDE

.............................................................................................PAG. 35

M61...

ELECTRICAL SYSTEM

.............................................................................................................PAG. 36

3

10/10/02 M1-1_EN

ENGLISH

ENGLISH

REV.0-10/02

M

1.1

INTRODUCTION

Dear Customer,

We wish to thank you for having bought a high quality set.

Our sections for Technical Service and Spare Parts will work at

best to help you if it were necessary.

To this purpose we advise you, for all control and overhaul

operations, to turn to the nearest authorized Service Centre,

where you will obtain a prompt and specialized intervention.

+ In case you do not prot on these Services and some arts

are replaced, please ask and be sure that are used exclusively original parts; this to guarantee that the performances

and the initial safety prescribed by the norms in force are

re-established.

+The use of non original spare parts will cancel immediately

any guarantee and Technical Service obligation.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this manual attentively. Follow the instructions contained in it, in this way you will

avoid inconveniences due to negligence, mistakes or incorrect

maintenance. The manual is for qualied personnel, who knows

the rules: about safety and health, installation and use of sets

movable as well as xed.

You must remember that, in case you have difculties for use

or installation or others, our Technical Service is always at your

disposal for explanations or interventions.

The manual for Use Maintenance and Spare Parts is an integrant part of the product. It must be kept with care during all

the life of the product.

In case the machine and/or the set should be yielded to another

user, this manual must also given to him.

Do not damage it, do not take parts away, do not tear pages and

keep it in places protected from dampness and heat.

You must take into account that some gures contained in it

want only to identify the described parts and therefore might

not correspond to the machine in your possession.

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine and/or set you

will nd: the manual for Use Maintenance and Spare Parts,

the manual for use of the engine and the tools (if included in

the equipment), the guarantee (in the countries where it is

prescribed by law).

+ NOTICE: the manufacturer, who keeps the faculty, apart

the essential characteristics of the model here described

and illustrated, to bring betterments and modications to

parts and accessories, without putting this manual uptodate

immediately.

The Manufacturer shall not be liable for ANY USE OF THE PRODUCT OTHER THAN THAT PRECISELY SPECIFIED IN THIS

MANUAL and is thus not liable for any risks which may occur as

a result of IMPROPER USE. The Company does not assume

any liability for any damage to persons, animals or property.

Our products are made in conformity with the safety norms in

force, for which it is advisable to use all these devices or information so that the use does not bring damage to persons or things.

While working it is advisable to keep to the personal safety

norms in force in the countries to which the product is destined

(clothing, work tools, etc.).

Do not modify for any motive parts of the machine (fastenings,

holes, electric or mechanical devices, others..) if not duly authorized in writing: the responsibility coming from any potential

intervention will fall on the executioner as in fact he becomes

maker of the machine.

4

10/10/02 M1-4_EN

ENGLISH

ENGLISH

1

2

17

19

20

21

22

23

24

25

25

18

3

4

5

6

7

8

9

10

11

12

13

14

15

16

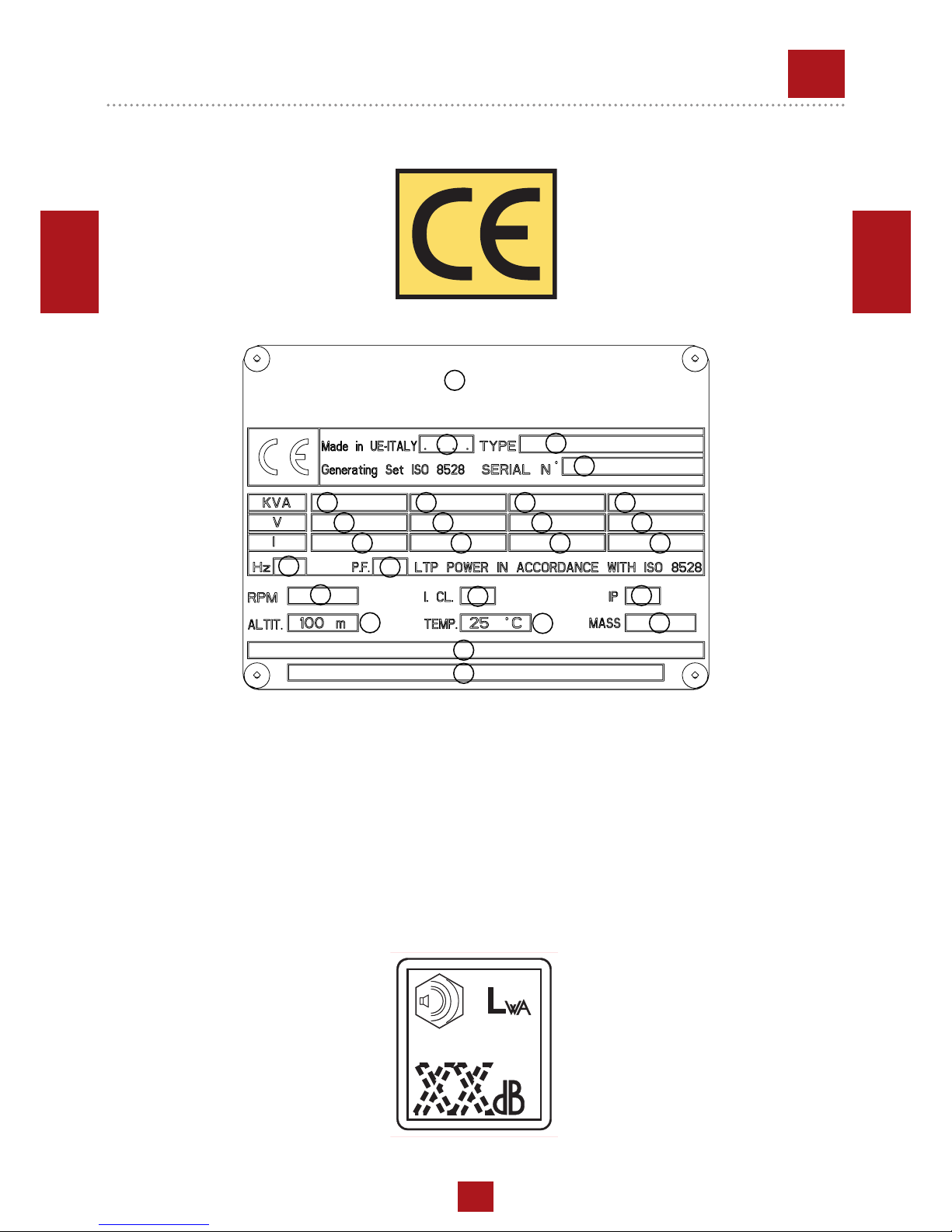

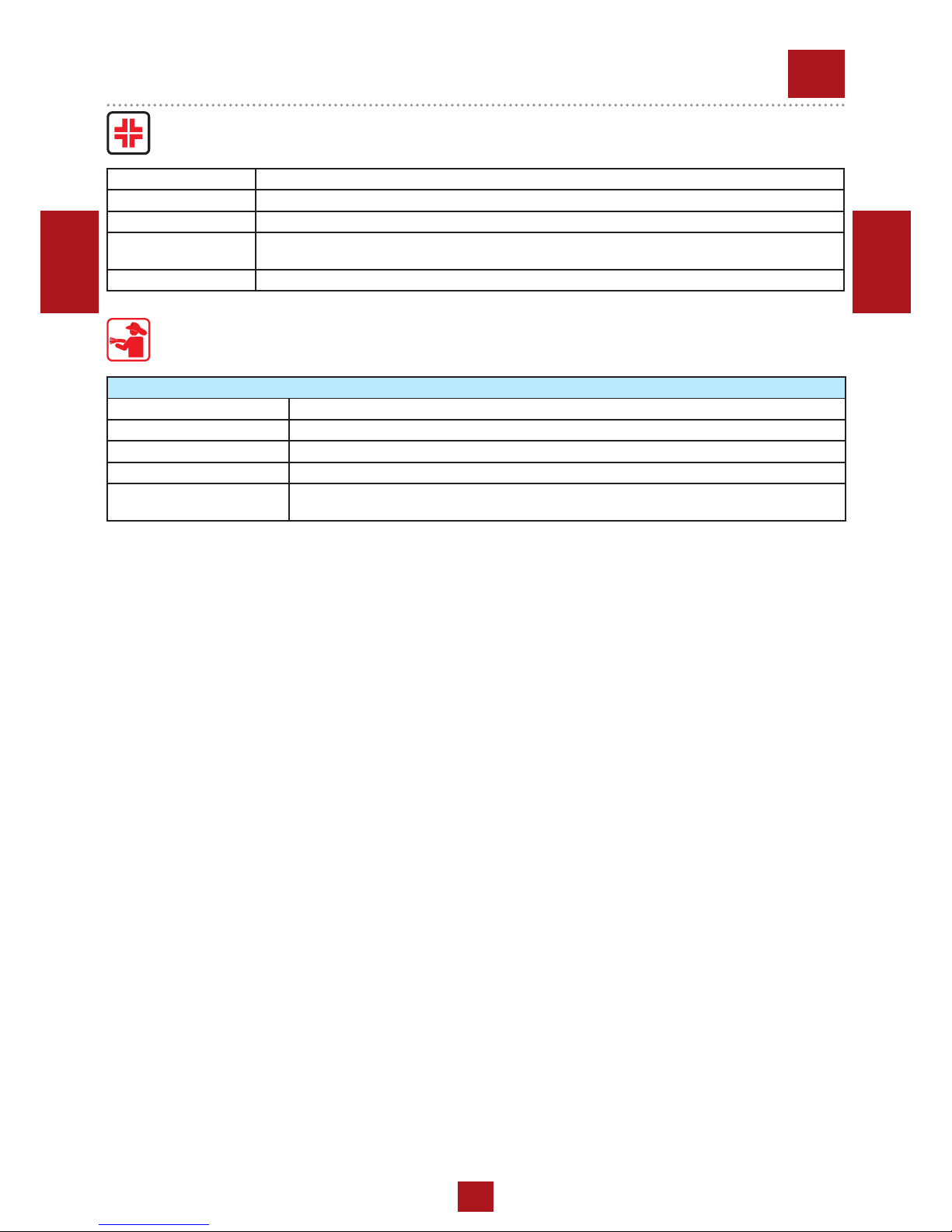

1. Name or brand supplier

2. Year of production

3. Generating Set model

4. Serial number | registration number

5. Power (kVA/kW)

6. Rated voltage (V)

7. Rated current (A)

8. Power (kVA/kW)

9. Rated voltage (V)

10. Rated current (A)

11. Power (kVA/kW)

12. Rated voltage (V)

13. Rated current (A)

14. Power (kVA/kW)

15. Rated voltage (V)

16. Rated current (A)

17. Rated frequency

18. Power factor cosφ

19. Engine rated speed

20. Insulation class

21. IP degree protection

22. Rated altitude (above sea level)

23. Max ambient temperature

24. Dry weight (kg)

25. Any additional information

Any of our product is labelled with CE marking attesting its conformity to appliable directives and also the fulllment of safety

requirements of the product itself; the list of these directives is part of the declaration of conformity included in any machine

standard equipment.

Here below the adopted symbol:

CE marking is clearly readable and unerasable and it can be either part of the data-plate.

Furthermore, on each model it is shown the noise level value; the symbol used is the following:

The indication is shown in a clear, readable and indeleble way on a sticker.

REV.7-02/14

M

1.4

CE MARKING

GENERATING SETS

5

13/11/14 M2_EN

ENGLISH

ENGLISH

REV.2-06/10

M

2

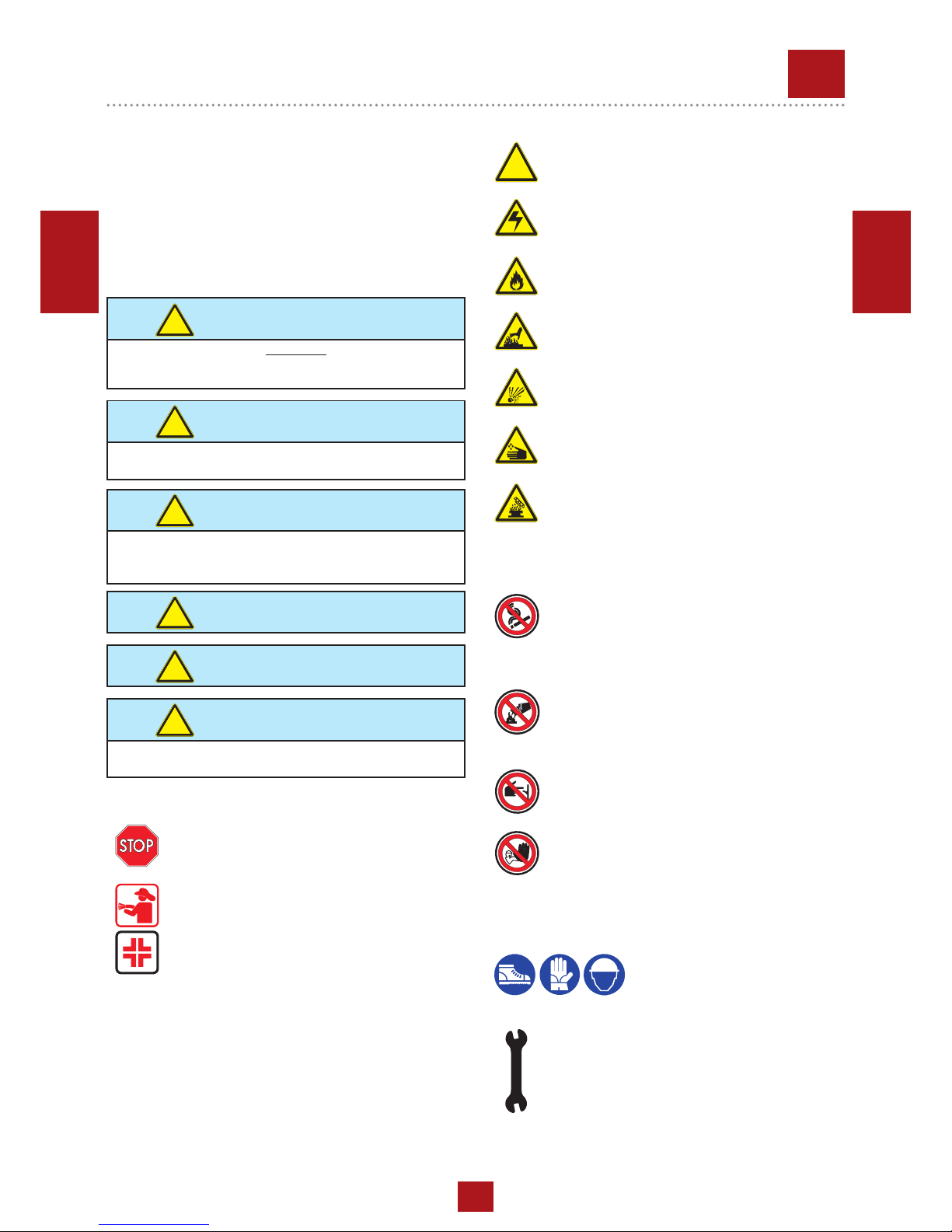

SYMBOLS AND SAFETY PRECAUTIONS

GENERATING SETS - LIGHTING TOWERS

SYMBOLS IN THIS MANUAL

- The symbols used in this manual are designed to call your

attention to important aspects of the operation of the machine

as well as potential hazards and dangers for persons and

things.

Moreover, this symbolism intends to draw your attention

with the aim to give you indications for a correct use and,

as a result, to obtain a good operation of the machine or

equipment used.

SAFETY PRECAUTIONS

WARNING

This heading warns of situations which could result in injury

for persons or damage to things.

DANGEROUS

This heading warns of an immediate danger for persons as

well for things. Not following the advice can result in serious

injury or death.

CAUTION

To this advice can appear a danger for persons as well as

for things, for which can appear situations bringing material

damage to things.

IMPORTANT

NOTE

ATTENTION

These headings refer to information which will assis you in

the correct use of the machine and/or accessories.

!

!

!

!

!

!

SIMBOLS

STOP - Read absolutely and be duly attentive

Read and pay due attention

DANGER

!

GENERAL ADVICE - If the advice is not respected damage can happen to persons or things.

HIGH VOLTAGE - Attention High Voltage.There

can be parts in voltage, dangerous to touch. The

non observance of the advice implies life danger.

FIRE - Danger of ame or re. If the advice is not

respected res can happen.

HEAT - Hot surfaces. If the advice is not respected

burns or damage to things can be caused.

EXPLOSION - Explosive material or danger of

explosion. in general. If the advice is not respected

there can be explosions.

ACIDS - Danger of corrosion. If the advice is not

respected the acids can cause corrosions with

damage to persons or things.

PRESSION - Danger of burns caused by the

expulsion of hot liquids under pressure.

PROHIBITIONS

It is prohibited to smoke while lling the tank with fuel.

The cigarette can cause re or explosion. If the

advice is not respected res or explosions can

be caused.

It is prohibited to use water to quench res on the electric

machine

If the advice is not respected res or damage to

persons can be caused.

Use only with non inserted voltage -

It is prohibited to make interventions before having

disinserted the voltage.

ACCES FORBIDDEN to non authorized peaple.

ADVICE

Use only with safety clothing -

It is compulsory to use the personal

protection means given in equipment.

WRENCH - Use of the tools. If the advice is not

respected damage can be caused to things and

even to persons.

6

13/11/14 M2_EN

ENGLISH

ENGLISH

+ FIRST AID. In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas or whate-

ver event which may cause serious injuries or death, predispose the rst aid in accordance with the ruling labour

accident standards or of local instructions.

+ FIRE PREVENTION. In case the working zone,for whatsoever cause goes on re with ames liable to cause severe

wounds or death, follow the rst aid as described by the ruling norms or local ones.

Skin contact Wash with water and soap

Eyes contact Irrigate with plenty of water, if the irritation persists contact a specialist

Ingestion Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

Suction of liquids from

lungs

If you suppose that vomit has entered the lungs (as in case of spontaneous vomit) take the subject to the hospital with the

utmost urgency

Inhalation In case of exposure to high concentration of vapours take immediately to a non polluted zone the person involved

EXTINCTION MEANS

Appropriated Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Not to be used Avoid the use of water jets

Other indications Cover eventual shedding not on re with foam or sand, use water jets to cool off the surfaces close to the re

Particular protection Wear an autorespiratory mask when heavy smoke is present

Useful warnings Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric contacts (switches,plugs,etc.).

In case of oil sprinkling from pressure circuits, keep in mind that the inamability point is very low.

REV.2-06/10

M

2.1

WARNINGS

GENERATING SETS - LIGHTING TOWERS

7

13/11/14 M2.5 (GE-TF)_EN

ENGLISH

ENGLISH

GENERAL SAFETY INSTRUCTIONS

+ NOTE: the information contained in this manual are

subject to change without notice.

The instructions in this manual are intended as indicative only.

It is the responsibility of the owner/operator to evaluate risks

and potential damages in relation to the use of the product in

the specic conditions of application. Remember that the non

observance of the indications of this manual may result in damage to people or things.

In all cases, however, it is understood that the use shall be in

compliance with the applicable laws/regulations.

• Before operating the machine, read carefully the safety in-

structions contained in this manual and other manuals supplied (engine, alternator, etc.).

• All operations, handling, installation, use, maintenance, re-

pair should be carried out by authorized and qualied personnel.

• When operating, wear personal protective equipment (PPE):

footwear, gloves, helmet, etc..

• The owner is responsible for maintaining the equipment in

safe conditions.

Use only in perfect technical conditions

The machinery or equipment must be used in perfect tech-

nical condition. Remove immediately any defects that may

affect the safe conditions of use.

• Before starting to use this equipment it is important to take

knowledge of all the controls of the machine, all its functions

and its correct installation in order to avoid accidents to people and damage to the machine itself. In particular, it is

important to know how to stop the equipment quickly in case

of emergency.

• Do not allow the use of the machine to people unless pre-

viously instructed with all the information for a proper, safe

use.

• Forbid the access in the operational area to non authorized

personnel, children and pets so as to protect them from possible injury caused by any part of the machine.

SAFETY PRECAUTIONS DURING HANDLING AND TRANSPORTATION

• Lift the machine using only the points allocated for this fun-

ction.

The lifting eye (or eyes) and the correct positioning of the

forks of the forklift are marked with specic adhesives.

• Clear the operational area of possible obstacles and all un-

necessary personnel.

• Always use lifting equipment properly sized and controlled

by enabled bodies.

• It is forbidden to set on the frame of the equipment objects

or accessories that alter weight and center of gravity and

cause stresses not foreseen to the lifting points.

• Do not submit the machine and the lifting equipment to

swinging or shock which may transmit dynamic stress to the

structure.

Equipments with trailers or site tows

• Never drag the machine without trailer (or site tow)

• Check for a correct assembly of the machine to the towing

device.

• Always make sure that the hook of the vehicle is suitable for

towing of the total mass of the trailer.

• Do not tow the trailer if the coupling devices are worn or

damaged.

• Check for proper tire pressure.

• Do not replace the tires with types different from the original

ones.

• Check that the brakes and the optical signaling of the trailer

are working properly.

• Verify that the bolts of the wheels are in place and well

tightened.

• Do not park the machine (on trailer or site tow) on a steep

slope.

For the stops, not followed by a work session, always enga-

ge the parking brake and / or block the wheels by means of

wheel chocks.

• Do not tow the trailer on bumpy roads.

• Do not exceed the maximum permissible speed on public

roads of 80 km/h with the trailer, in any case comply with the

legislation applicable in the country of use.

• Do not use the site tow on public roads, this is intended for

use only in private and delimited areas. The maximum permitted speed is 40 km/h on smooth surfaces (asphalt or concrete), adapt in each case the speed to the type of ground.

SAFETY PRECAUTIONS DURING INSTALLATION AND

USE

• Always locate the machine on a at and solid ground, so as

to avoid tipping, slipping or falling during operation. Avoid

using the machine on slopes greater than 10 degrees.

• Make sure the area immediately surrounding the machine is

clean and free from debris.

• Connect the machine to an earthing system according to

the regulations in force at the place of installation. Use the

ground terminal on the front of the machine.

• Do not use the machine with wet or damp hands and / or

clothing.

• Use plugs suitable for the output sockets of the machine and

make sure that electrical cords are in good condition.

• The machine must always be positioned so that the exhaust

gases are dispersed in the air without being inhaled by people or living beings.

• If you use the machine indoors is necessary that the installation is designed and built by skilled technicians in a workmanlike manner.

• During normal operation, keep doors closed. The access to

the internal parts should be allowed only for maintenance

reasons.

• Do not place objects or obstructions in the vicinity of the air

intakes and air outlets, a possible overheating of the gene-

rator could cause a re.

• Keep area near to the mufer free from objects such as

rags, paper, cardboard. The high temperature of the mufer

could cause the burning of objects and cause re.

• Immediately stop the machine in case of malfunction.

Do not restart the machine without rst having found and

xed the problem.

REV.0-03/15

M

2.5

SAFETY RULES

GENERATING SETS - LIGHTING TOWERS

8

13/11/14 M2.5 (GE-TF)_EN

ENGLISH

ENGLISH

SAFETY PRECAUTIONS DURING MAINTENANCE

• Make use of qualied personnel to carry out maintenance

and troubleshooting.

• It is mandatory to stop the engine before performing any

maintenance on the machine.

• Always use protective devices and suitable equipment.

• Do not touch the engine, the exhaust pipes and the mufer

during operation or immediately after. Allow the engine to

cool before performing any operation.

• With the machine running pay attention to moving parts

such as fans, belts, pulleys.

• Do not remove the protections and the safety devices unless

absolutely necessary, restore them after completion of the

maintenance or repair.

• Do not refuel while the engine is running or hot. Do not smo-

ke or use naked ames when refueling.

• Refuel only outdoors or in well ventilated areas.

• Avoid spilling fuel, especially on the engine. Clean and dry

any leaks before restarting the machine.

• Slowly unscrew the cap of the fuel tank and put it back

always after refueling.

• Do not ll the tank completely to allow for expansion of the

fuel inside.

• Do not remove the radiator cap when the engine is running

or still hot, the coolant may spurt out and cause serious

burns.

• Do not handle the battery without the use of protective gloves, the battery uid contains sulfuric acid, which is very corrosive and dangerous.

• Do not smoke, avoid any naked ames or sparks near the

battery, the vapors exhaled could cause the battery to explode

REV.0-03/15

M

2.5.1

SAFETY RULES

GENERATING SETS - LIGHTING TOWERS

SAFETY PRECAUTIONS DURING HANDLING AND TRANSPORTATION

• Before moving a lighting tower lower the telescopic mast

and block properly all movable parts such as the access do-

ors, the mast, the outriggers, the oodlights.

• Check the fastening of the wheels of the trolley.

SAFETY PRECAUTIONS DURING INSTALLATION AND

USE

• Make sure the area above the lighting tower is free from

overhead cables or other obstacles.

• Before raising the mast extract the outriggers located at

the sides of the machine. Acting on the outriggers level the

lighting tower making use of the bubble, so as to bring the

equipment in a horizontal position. Make sure that the tower rests securely on the outriggers. If the lighting tower is

mounted on road trailer pull the handbrake.

• Do not operate the lighting tower if the wind speed exceeds

the safe speed indicated or if it is expected the arrival of

storms or thunderstorms in the area.

• Lower the telescopic mast when the tower is not used.

• Always check the good condition of the power cable before

connecting the lighting tower to the generating set.

• Do not touch and do not place objects on the lamps during

operation or immediately after use. The lamps become very

hot.

• Do not turn on the lamps without the protective glass or with

the same broken or damaged.

• Make sure all the ropes and the manual winch are in perfect

condition.

• Place the lighting tower in order to avoid that the winch can

receive shocks which may cause damage to the automatic

brake.

SAFETY PRECAUTIONS DURING MAINTENANCE

• Turn off the generating set or unplug the power cable before

carrying out any type of maintenance on the lighting tower.

• Always cut off power to the lamps and wait for their cooling

before performing any maintenance or replacement.

• Before carrying out any type of maintenance or repairs on

the generating set refer to the manual of the generating set

and the other manuals supplied.

ATTENTION

The lighting towers is designed to be used with a generating

set or with a xed mass on its base. The weight and positioning of the generating set on the base are essential for the

safety of the lighting tower.

Failure to comply with this provision causes a serious danger

of tipping or instability during operation and during handling

with site tow If necessary, contact the service.

!

ADDITIONAL PRECAUTIONS FOR LIGHTING TOWERS

9

13/11/14 CJ6D6010_EN

ENGLISH

ENGLISH

M

0

DESCRIPTION OF THE MACHINE

REV.0-07/16

BASE / TANK

FRONT PANEL

FRAME

FUEL TANK

ALTERNATOR

VIBRATION

DAMPER

ENGINE

MUFFLER

The generating set is a unit which transforms the mechanical energy, generated by combustion engine, into electric

energy, through an alternator.

The model GE3500 is a compact diesel generating set, is easily transported using a trolley.

The design incorporates a steel structure with engine and alternator mounted on anti-vibration dampers to increase service life

and reduce noise, whilst a steel frame provides protection for the complete machine.

The recessed control panel houses the sockets and machine controls.

Suitable for a wide range of uses in general construction, equipment rental, events and standby applications.

10

0.1

RECORDING DATA

REV.1-11/14

The manual is for the range of machines indicated on the front cover.

With the scope to facilitate the search of the spare parts and maintain information of the bought machine, is necessary to record

some data.

Please write the requested data inside the squares to side:

1. Model of machine

2. Serial number of the machine

3. Serial number of the engine

4. Name of the dealer where bought the machine

5. Address of the dealer

6. Phone number of the dealer

7. Date of the bought machine

8. Notes

RECORDING DATA

1.

2.

3.

4.

5.

6.

7.

8.

16/10/15 Registrazione Dati_EN

ENGLISH

ENGLISH

11

30/03/00 M3_EN

ENGLISH

ENGLISH

NOTE

!

+ Be sure that the lifting devices are: correctly mounted,

adequate for the weight of the machine with it’s packaging,

and conforms to local rules and regulations.

When receiving the goods make sure that the product has

not suffered damage during the transport, that there has

not been rough handling or taking away of parts contained

inside the packing or in the set.

In case you nd damages, rough handling or absence of

parts (envelopes, manuals, etc.), we advise you to inform

immediately our Technical Service.

For eliminating the packing materials, the User must

keep to the norms in force in his country.

1) Take the machine (C) out of the shipment packing. Take out

of the envelope (A) the user’s manual (B).

2) Read: the user’s manual (B), the plates xed on the machine,

the data plate.

2

B

A

1

C

REV.1-02/04

M

3

MACHINE UNPACKING

12

Loading...

Loading...