Mosa GE 7000 HSX, GE 7500 HSX Maintance Manual

GE 7000 - 7500 HSX

357709003 - GB

1 0 1 1

© MOSA - 01/09/08 35770M00

preparato da UPT

approvato da DITE

USE AND MAINTENANCE MANUAL

SPARE PARTS CATALOGS

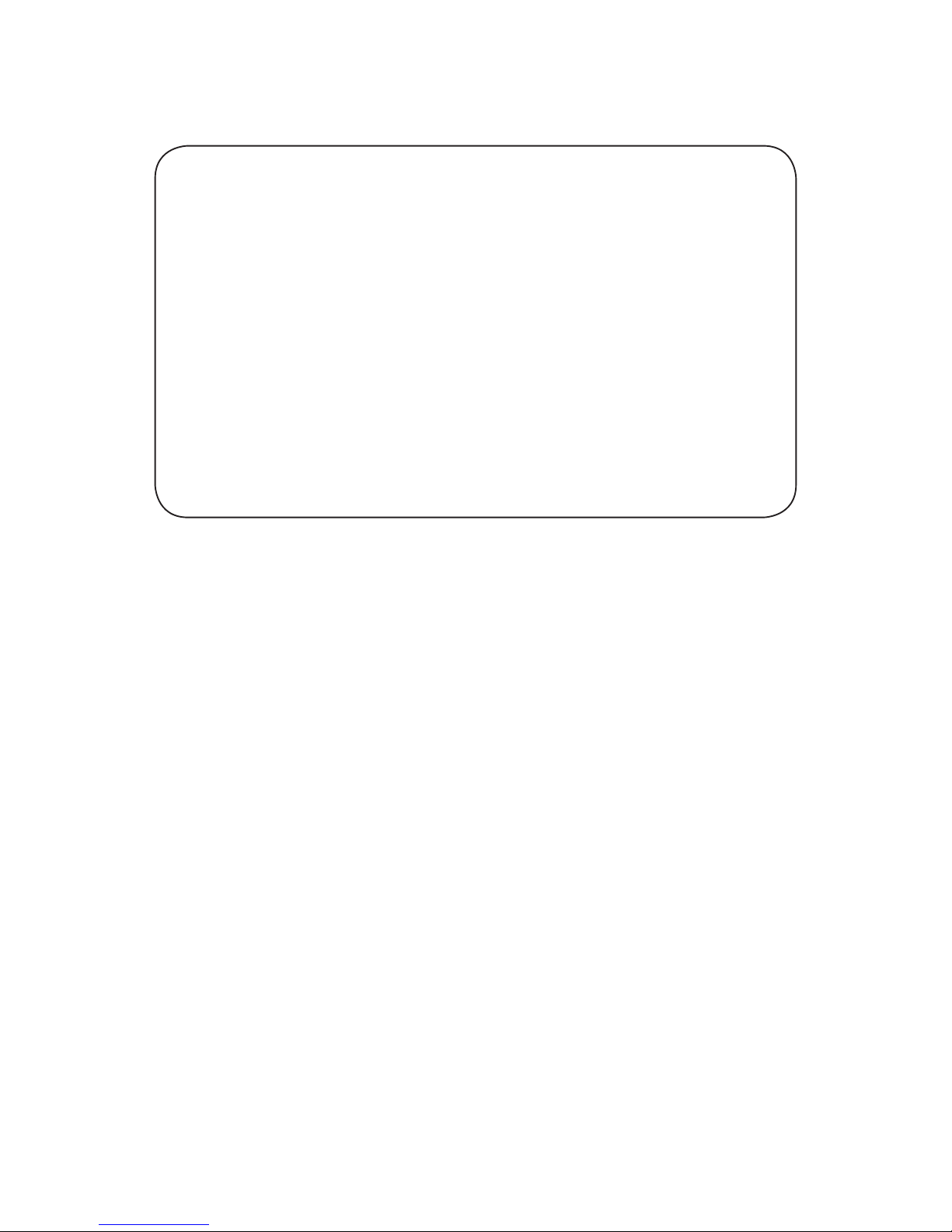

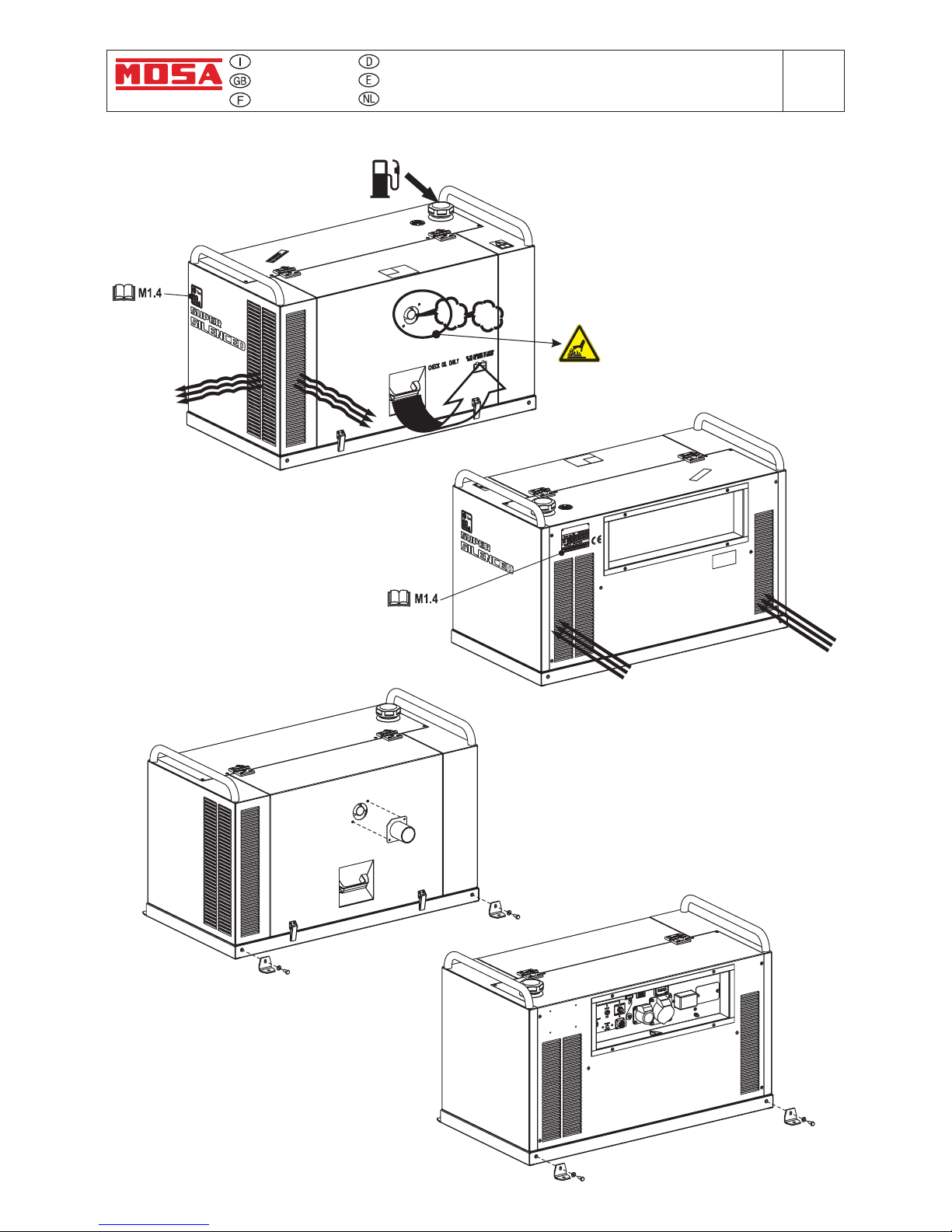

DESCRIPTION OF THE MACHINE GE 7000-7500 HSX

M

0

REV.1-10/11

The generating set GE 7000-7500 is a unit which transforms the mechanical energy, generated by endothermic engine, into

electric energy, through an alternator.

Is meant for industrial and professional use, powered by an endothermic engine; it is composed of various main parts such as:

engine, alternator, electric and electronic controls, the fairing or a protective structure.

The assembling is made on a steel structure, on which are provided elastic support which must damp the vibrations and also

eliminate sounds which would produce noise.

BATTERY

ENGINE

BASE

FRONT

PANEL

CANOPY

ALTERNATOR

HANDLES

VIBRATIONDAMPER

Quality system

M

01

UNI EN ISO 9001 : 2008

10/10/02 M01-GB

MOSA has certied its quality system according

to UNI EN ISO 9001:2008 to ensure a constant,

highquality of its products. This certication covers

thedesign, production and servicing of engine drivenwelders and generating sets.

The certifying institute, ICIM, which is a member

ofthe International Certication Network IQNet,

awarded the ofcial approval to MOSA after anexamination of its operations at the head ofce

andplant in Cusago (MI), Italy.

This certication is not a point of arrival but a

pledgeon the part of the entire company to maintain

a levelof quality of both its products and services

whichwill continue to satisfy the needs of its clients,

aswell as to improve the transparency and thecommunications regarding all the company’s activesin

accordance with the ofcial procedures and inharmony with the MOSA Manual of Quality.

The advantages for MOSA clients are:

·Constant quality of products and services at thehigh

level which the client expects;

· Continuous efforts to improve the products andtheir

performance at competitive conditions;

· Competent support in the solution of problems;

· Information and training in the correct applicationand use of the products to assure the security

ofthe operator and protect the environment;

· Regular inspections by ICIM to conrm that therequirements of the company’s quality systemand

ISO 9001 are being respected.

All these advantages are guaranteed by the CERTIFICATE OF QUALITY SYSTEM No.0192 issued

by ICIM S.p.A. - Milano (Italy ) - www.icim.it

© MOSA REV.3-02/09

INDEX

GE 7000-7500 HSX

M

1

REV.1-10/11

01/09/08 35770-GB

M 0 DESCRIPTION OF THE MACHINE

M 01

QUALITY SYSTEM

M 1.01 COPYRIGHT

M 1.1 NOTE

M 1.4 CE MARK

M 1.4.1 DECLARATION OF CONFORMITY

M 1.5 TECHNICAL DATA

M 2 .... SYMBOLS USED AND SAFETY PRECAUTIONS

M 2.5 INSTALLATION AND ADVICE BEFORE USE

M 2.6 INSTALLATION WARNINGS

M 2.7 INSTALLATION AND DIMENSIONS

M 3 PACKING

M 4.1 TRANSPORT AND HANDLING

M 6.13 ASSEMBLY CTM

M 25 SET-UP FOR OPERATION

M 26 STARTING THE ENGINE

M 27 STOPPING THE ENGINE

M 31 CONTROLS

M 37... USING THE GENERATOR

M 38.5 REMOTE CONTROL

M 40.2... TROUBLE SHOOTING

M 43… MACHINE MAINTENANCE

M 45 STORAGE

M 46 CAST OFF

M 60 ELECTRICAL SYSTEM LEGEND

M 61-….. ELECTRICAL SYSTEM

R1 SPARE PARTS TABLES

GU.. SPARE PARTS

K.. ACCESSORIES

Copyright GE_, MS_, TS_, EAS

M

1.01

© MOSA 1.0-10/02

ATTENTION

© All rights are reserved to said Company.

It is a property logo of MOSA division of B.C.S.

S.p.A. All other possible logos contained in the

documentation are registered by the respective

owners.

➠

The reproduction and total or partial use, in any

form and/or with any means, of the

documentation is allowed to nobody without a

written permission by MOSA division of B.C.S.

S.p.A.

To this aim is reminded the protection of the author’s

right and the rights connected to the creation and

design for communication, as provided by the laws

in force in the matter.

In no case MOSA division of B.C.S. S.p.A. will be

held responsible for any damaga, direct or indirect,

in relation with the use of the given information.

MOSA division of B.C.S. S.p.A. does not take any

responsibility about the shown information on firms

or individuals, but keeps the right to refuse services

or information publication which it judges discutible,

unright or illegal.

10/10/02 M1-01-GB

This use and maintenance manual is an important

part of the machines in question.

The assistance and maintenance personel must

keep said manual at disposal, as well as that for

the engine and alternator (if the machine is

synchronous) and all other documentation about the

machine.

We advise you to pay attention to the pages

concerning the security (see page M1.1).

INFORMATION

Dear Customer,

We wish to thank you for having bought from

MOSA a high quality set.

Our sections for Technical Service and Spare

Parts will work at best to help you if it were

necessary.

To this purpose we advise you, for all control and

overhaul operations, to turn to the nearest

authorized Service Centre, where you will obtain

a prompt and specialized intervention.

☞

In case you do not profit on these Services and

some parts are replaced, please ask and be

sure that are used exclusively original MOSA

parts; this to guarantee that the performances

and the initial safety prescribed by the norms in

force are re-established.

☞

The use of non original spare parts will cancel

immediately any guarantee and Technical Ser-

vice obligation from MOSA.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this

manual attentively. Follow the instructions

contained in it, in this way you will avoid

inconveniences due to negligence, mistakes or

incorrect maintenance. The manual is for qualified

personnel, who knows the rules: about safety and

health, installation and use of sets movable as

well as fixed.

You must remember that, in case you have

difficulties for use or installation or others, our

Technical Service is always at your disposal for

explanations or interventions.

The manual for Use Maintenance and Spare Parts

is an integrant part of the product. It must be kept

with care during all the life of the product.

In case the machine and/or the set should be

yielded to another user, this manual must also

given to him.

Do not damage it, do not take parts away, do not

tear pages and keep it in places protected from

dampness and heat.

You must take into account that some figures

contained in it want only to identify the described

parts and therefore might not correspond to the

machine in your possession.

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine

and/or set you will find: the manual for Use

Maintenance and Spare Parts, the manual for

use of the engine and the tools (if included in the

equipment), the guarantee (in the countries where

it is prescribed by law).

Our products have been designed for the use of

generation for welding, electric and hydraulic

system; ANY OTHER DIFFERENT USE NOT

INCLUDED IN THE ONE INDICATED, relieves

MOSA from the risks which could happen or,

anyway, from that which was agreed when selling

the machine; MOSA excludes any responsibility

for damages to the machine, to the things or to

persons in this case.

Our products are made in conformity with the

safety norms in force, for which it is advisable to

use all these devices or information so that the

use does not bring damage to persons or things.

While working it is advisable to keep to the

personal safety norms in force in the countries to

which the product is destined (clothing, work tools,

etc.).

Do not modify for any motive parts of the machine

(fastenings, holes, electric or mechanical devices,

others..) if not duly authorized in writing by MOSA:

the responsibility coming from any potential

intervention will fall on the executioner as in fact

he becomes maker of the machine.

Notes GE_, MS_, TS_, EAS_

M

1-1

© MOSA 1.0-10/02

☞

Notice: this manual does not engage MOSA,

who keeps the faculty, apart the essential

characteristics of the model here described and

illustrated, to bring betterments and modifications

to parts and accessories, without putting this

manual uptodate immediately.

10/10/02 M 1-1 GB

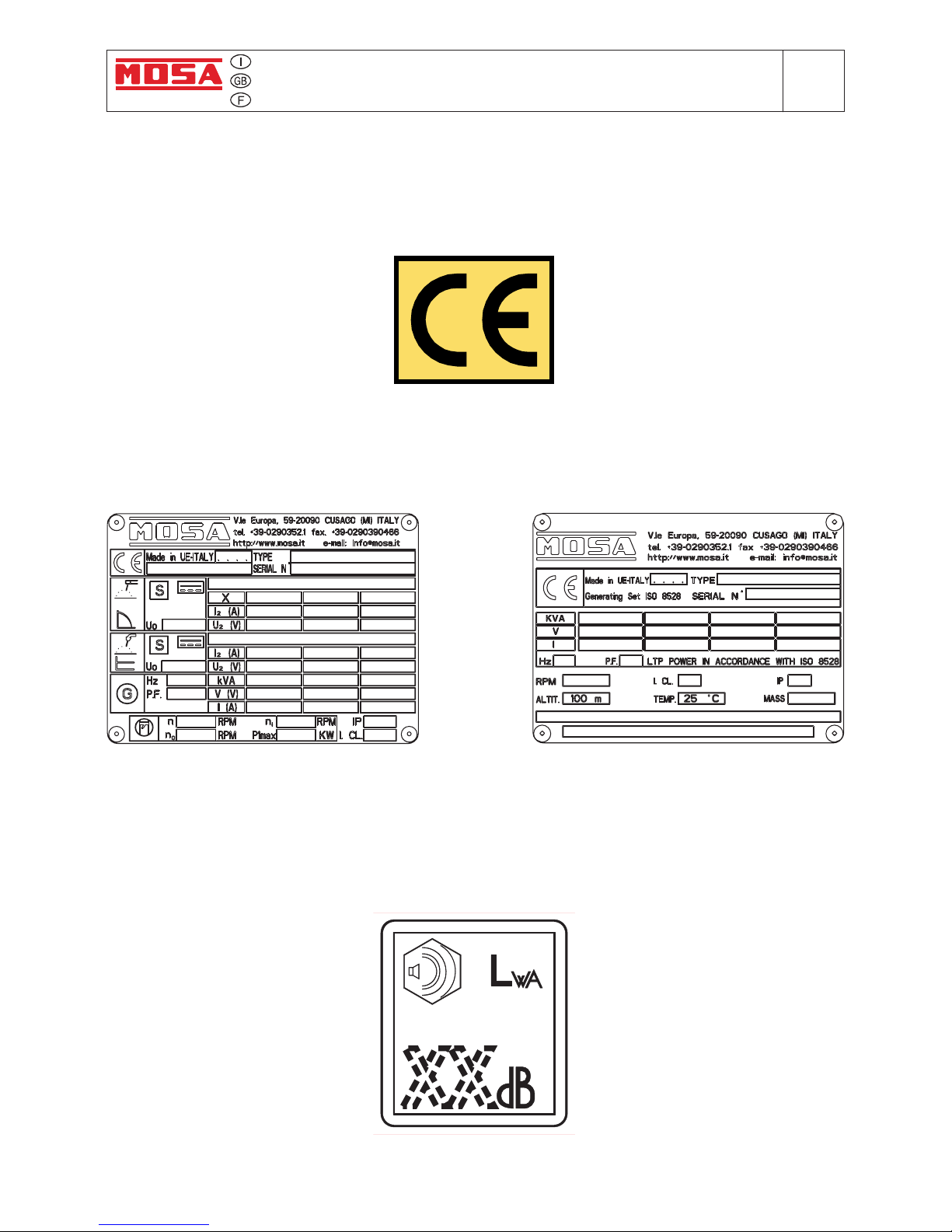

CE MARK

M

1.4

10/10/02 M1-4 GB

Any of our product is labelled with CE marking attesting its conformity to appliable directives and

also the fulllment of safety requirements of the product itself; the list of these directives is part

of the declaration of conformity included in any machine standard equipment.

Here below the adopted symbol:

CE marking is clearly readable and unerasable and it can be either part of the data-plate.

Furthermore, on each model it is shown the noise level value; the symbol used is the following:

The indication is shown in a clear, readable and indeleble way on a sticker.

REV.5-03/11

04/06/10 M1.4.1

Dichiarazione conformità

Declaration of conformity

Déclaration de conformité

M

1.4.1

REV.0-06/10

MM 083.0

BCS S.p.A.

Sede legale:

Via Marradi 1

20123 Milano - Italia

Stabilimento di Cusago, 20090 (MI) - Italia

V.le Europa 59

Tel.: +39 02 903521

Fax: +39 02 90390466

DICHIARAZIONE DI CONFORMITA'

Déclaration de Conformité – Declaration of Conformity – Konformitätserklärung

Conformiteitsverklaring – Declaración de Conformidad

BCS S.p.A. dichiara sotto la propria responsabilità che la macchina:

BCS S.p.A. déclare, sous sa propre responsabilité, que la machine:

BCS S.p.A. declares, under its own responsibility, that the machine:

BCS S.p.A. erklärt, daß die Aggregate:

BCS S.p.A. verklaard, onder haar eigen verantwoordelijkheid, dat de machine:

BCS S.p.A. declara bajo su responsabilidad que la máquina:

GRUPPO ELETTROGENO DI SALDATURA / WELDING GENERATOR

GRUPPO ELETTROGENO / POWER GENERATOR

Marchio / Brand : _MOSA_____________________________________________

Modello / Model : ______________________________________________

Matricola / Serial number : ______________________________

è conforme con quanto previsto dalle Direttive Comunitarie e relative modifiche:

est en conformité avec ce qui est prévu par les Directives Communautaires et relatives modifications:

conforms with the Community Directives and related modifications:

mit den Vorschriften der Gemeinschaft und deren Ergänzungen übereinstimmt:

in overeenkomst is met de inhoud van gemeenschapsrichtlijnemen gerelateerde modificaties:

comple con los requisítos de la Directiva Comunitaria y sus anexos:

2006/42/CE - 2006/95/CE - 2004/108/CE

Nome e indirizzo della persona autorizzata a costituire il fascicolo tecnico :

Nom et adresse de la personne autorisée à composer le Dossier Technique :

Person authorized to compile the technical file and address :

Name und Adresse der zur Ausfüllung der technischen Akten ermächtigten Person :

Persoon bevoegd om het technische document , en bedrijf gegevens in te vullen

Nombre y dirección de la persona autorizada a componer el expediente técnico :

ing. Benso Marelli - Amministratore Delegato / CEO; V.le Europa 59, 20090 Cusago (MI) - Italy

_______________

Cusago, Ing. Benso Marelli

Amministratore Delegato

CEO

Konformitätserklärung

Declaración de conformidad

01/09/08 35770-GB

Technical data GE 7000-7500 HSX

M

1.5

REV.2-10/11

Technical data GE 7000 HSX GE 7500 HSX

GENERATORE

*Stand-by three-phase output - 7.5 kVA (6 kW) / 400 V / 10.8 (8.7) A

**PRP three-phase output - 6.5 kVA (5.2 kW) / 400 V / 9.4 A

*Stand-by single-phase output) 6.7 kVA (6 kW) / 230 V / 29.1 (26.1) A **PRP single-phase output 5.5 kVA (5 kW) / 230 V / 23.9 A 4 kVA (4 kW) / 230 V / 17.4 A

Frequency 50 Hz 50 Hz

Cos ϕ 0.9 0.8

ALTERNATOR self-excited, self-regulated, brushless self-excited, self-regulated, with brush

Type synchronous, single-phase synchronous, three-phase

Insulating class H H

ENGINE

Mark / Model HONDA / GX 390

Type / Cooling system gasoline 4-Stroke, OHV / air

Cylinders / Displacement 1 / 389 cm

3

*Stand-by net power 8.2 kW (11.1 HP)

*PRP net power 6.4 kW (8.7 HP)

Speed 3000 rpm

Fuel consumption (75% of PRP) 2.4 l/h

Engine oil capacity 1.1 l

Starter Electric

GENERAL SPECIFICATIONS

Tank capacity 20 l

Running time (75% of PRP) 8.3 h

Protection IP 23

*Dimensions max. on base Lxwxh (mm) 1060x570x665

*Weight (dry) 155 Kg 165 Kg

Measured acoustic power LwA (pression LpA) 88 dB(A) (63 dB(A) @ 7 m)

Guaranteed acoustic power LwA (pression LpA) 89 dB(A) (64 dB(A) @ 7 m)

* Dimensions and weight are inclusive of all parts.

2000/ 14/ CE

2000 /14 / CE

OUTPUT

Declared power according to ISO 8528-1 (temperature 25°C, 30% relative humidity, altitude 100 m above sea level).

(*Stand-by) = maximum available power for use at variable loads for a yearly number of hours limited at 500 h. No overload is

admitted.

(**Prime power PRP) = maximum available power for use at variable loads for a yearly illimited number of hours. The average

power to be taken during a period of 24 h must not be over 80% of the PRP.

It’s admitted overload of 10% each hour every 12 h.

In an approximative way one reduces: of 1% every 100 m altitude and of 2.5% for every 5°C above 25°C.

ACOUSTIC POWER LEVEL

ATTENTION: The concrete risk due to the machine depends on the conditions in which it is used. Therefore, it is up to the end-

user and under his direct responsibility to make a correct evaluation of the same risk and to adopt specic precautions (for

instance, adopting a I.P.D. -Individual Protection Device)

Acoustic Noise Level

(LWA) - Measure Unit dB(A): it stands for acoustic noise released in a certain delay of time. This is not

submitted to the distance of measurement.

Acoustic Pressure (Lp) - Measure Unit dB(A): it measures the pressure originated by sound waves emission. Its value changes

in proportion to the distance of measurement.

The here below table shows examples of acoustic pressure (Lp) at different distances from a machine with Acoustic Noise Level

(LWA) of 95 dB(A)

Lp a 1 meter = 95 dB(A) - 8 dB(A) = 87 dB(A) Lp a 7 meters = 95 dB(A) - 25 dB(A) = 70 dB(A)

Lp a 4 meters = 95 dB(A) - 20 dB(A) = 75 dB(A) Lp a 10 meters = 95 dB(A) - 28 dB(A) = 67 dB(A)

PLEASE NOTE: the symbol when with acoustic noise values, indicates that the device respects noise emission limits

according to 2000/14/CE directive.

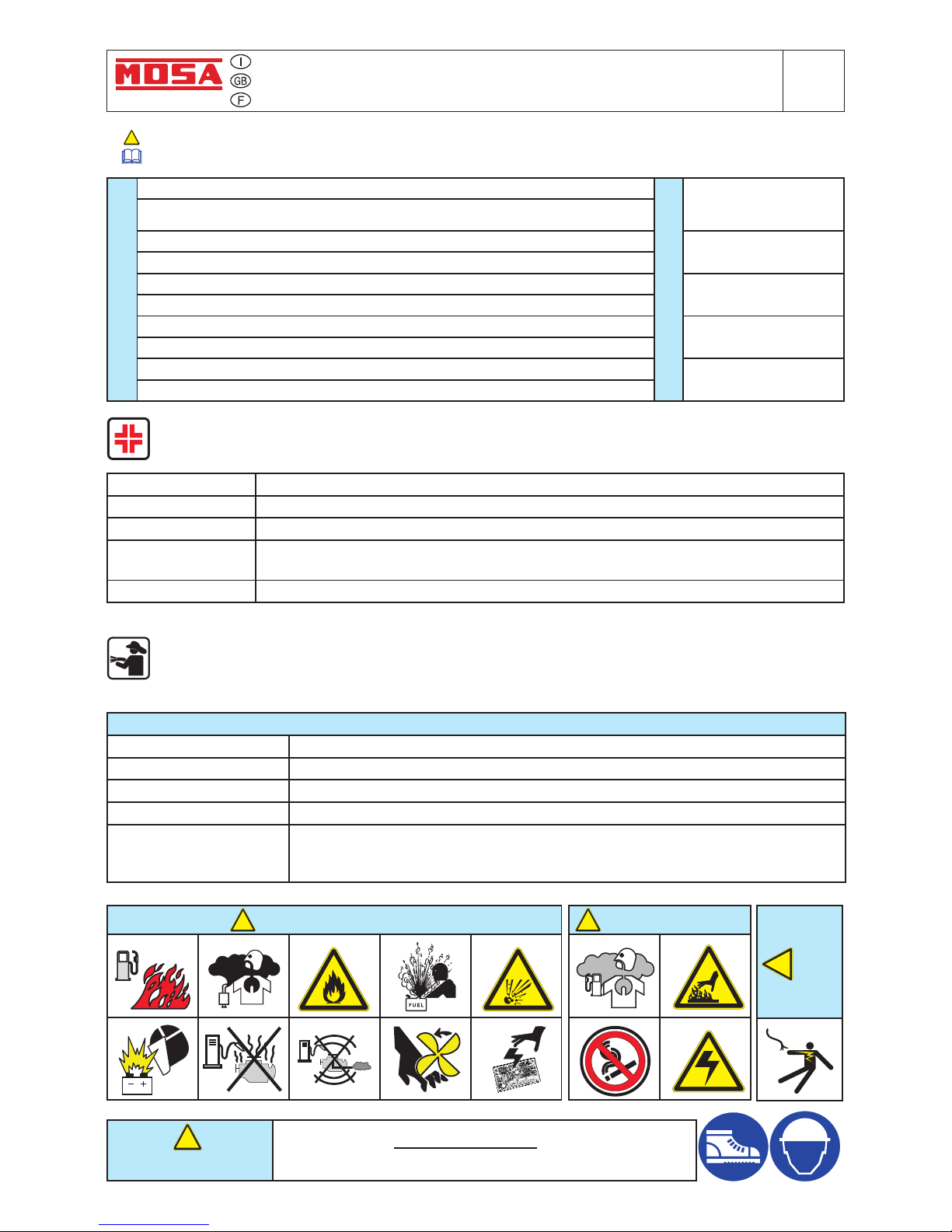

SYMBOLS AND SAFETY PRECAUTIONS

GE_, MS_, TS_

M

2

© MOSA 1.0-11/99

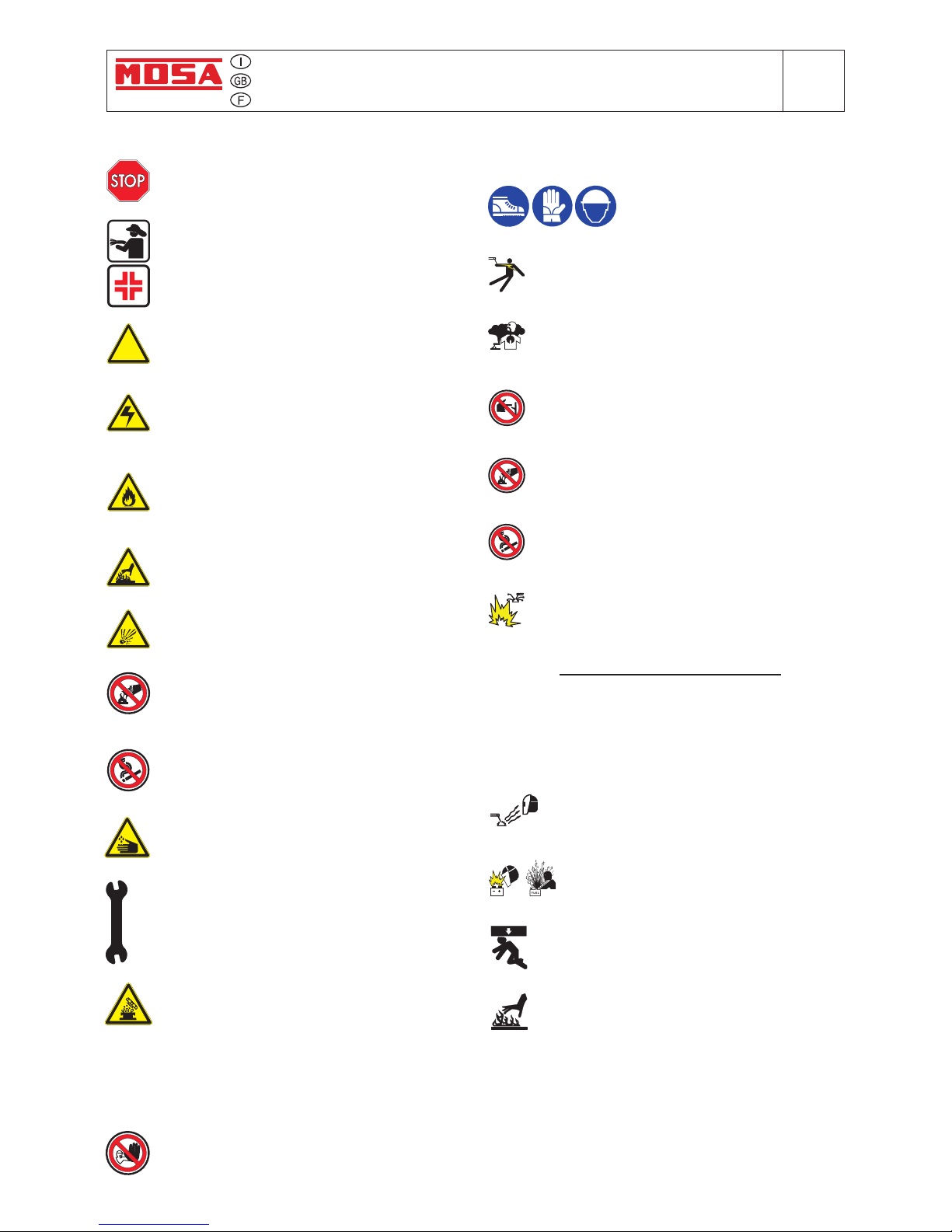

SYMBOLS IN THIS MANUAL

- The symbols used in this manual are designed to call

your attention to important aspects of the operation of

the machine as well as potential hazards and dangers

for persons and things.

IMPORTANT ADVICE

- Advice to the User about the safety:

+ N.B.: The information contained in the manual can be

changed without notice. Potential damages caused

in relation to the use of these instructions will not be

considered because these are only indicative.

Remember that the non observance of the indications

reported by us might cause damage to persons or

things. It is understood, that local dispositions and/or

laws must be respected.

WARNING

Situations of danger - no harm to persons

or things

Do not use without protective devices provided

Removing or disabling protective devices on the

machine is prohibited.

Do not use the machine if it is not in good technical

condition

The machine must be in good working order before

being used. Defects, especially those which regard

the safety of the machine, must be repaired before

using the machine.

SAFETY PRECAUTIONS

This heading warns of an immediate danger for persons

as well for things. Not following the advice can result in

serious injury or death.

This heading warns of situations which could result in

injury for persons or damage to things.

To this advice can appear a danger for persons as well

as for things, for which can appear situations bringing

material damage to things.

These headings refer to information which will assis you

in the correct use of the machine and/or accessories.

!

26/11/99 M2GB

WARNING

DANGEROUS

CAUTION

IMPORTANT

NOTE

ATTENTION

!!!

!

!

!

SYMBOLS AND SAFETY PRECAUTIONS

M

2-1

REV.2-06/10

SYMBOLS

STOP - Read absolutely and be duly attentive

Read and pay due attention

GENERAL ADVICE - If the advice is not

respected damage can happen to persons or

things.

HIGH VOLTAGE - Attention High Voltage.

There can be parts in voltage, dangerous

to touch. The non observance of the advice

implies life danger.

FIRE - Danger of ame or re. If the advice is

not respected res can happen.

HEAT - Hot surfaces. If the advice is not

respected burns or damage to things can be

caused.

EXPLOSION - Explosive material or danger

of explosion. in general. If the advice is not

respected there can be explosions.

WATER - Danger of shortcircuit. If the advice

is not respected res or damage to persons

can be caused.

SMOKING - The cigarette can cause re or

explosion. If the advice is not respected res

or explosions can be caused.

ACIDS - Danger of corrosion. If the advice is

not respected the acids can cause corrosions

with damage to persons or things.

WRENCH - Use of the tools. If the advice is

not respected damage can be caused to things

and even to persons.

PRESSION - Danger of burns caused by the

expulsion of hot liquids under pressure.

PROHIBITIONS No harm for persons

Use only with safety clothing -

It is compulsory to use the personal

protection means given in equipment.

Use only with safety clothing -

It is compulsory to use the personal protection

means given in equipment.

Use only with safety protections -

It is a must to use protection means suitable for

the different welding works.

Use with only safety material -

It is prohibited to use water to quench res on

the electric machines.

Use only with non inserted voltage -

It is prohibited to make interventions before

having disinserted the voltage.

No smoking -

It is prohibited to smoke while lling the tank

with fuel.

No welding -

It is forbidden to weld in rooms containing

explosive gases.

ADVICE No harm for persons and things

Use only with safety tools, adapted to the specic

use -

It is advisable to use tools adapted to the various

maintenance works.

Use only with safety protections, specically suitable

It is advisable to use protections suitable for the

different welding works.

Use only with safety protections -

It is advisable to use protections suitable for

the different daily checking works.

Use only with safety protections -

It is advisable to use all protections while

shifting the machine.

Use only with safety protections -

It is advisable to use protections suitable for

the different daily checking works.and/or of

maintenance.

!

26/11/99 M2-1GB

ACCES FORBIDDEN to non authorizad peaple.

INSTALLATION AND ADVICE BEFORE USE

GE_, MS_, TS_

M

2-5

© MOSA 1.0-06/00

The installation and the general advice concerning the operations, are nalized to the correct use of the machine, in the place where it is used as generator group and/or welder.

!

+ FIRSTAID. In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas

or whatever event which may cause serious injuries or death, predispose the rst aid in accordance

with the ruling labour accident standards or of local instructions.

+ FIREPREVENTION. In case the working zone,for whatsoever cause goes on re with ames liable to

cause severe wounds or death, follow the rst aid as described by the ruling norms or local ones.

10/06/00 M2-5I

ENGINE

Stop engine when fueling

CHECKINGBOARD

Do not touch electric devices

if you are barefoot or with wet

clothes.

Do not smoke, avoid ames, sparks or electric tools when fueling.

Unscrew the cap slowly to let out the fuel vapours.

Always keep off leaning surfaces during work operations.

Slowly unscrew the cooling liquid tap if the liquid must be topped up.

The vapor and the heated cooling liquid under pressure can burn face, eyes, skin.

Static electricity can demage

the parts on the circuit.

Do not ll tank completely.

Wipe up spilled fuel before starting engine.

An electric shock can kill

Shut off fuel of tank when moving machine (where it is assembled).

Avoid spilling fuel on hot engine.

Sparks may cause the explosion of battery vapours

Skin contact Wash with water and soap

Eyes contact Irrigate with plenty of water, if the irritation persists contact a specialist

Ingestion Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

Suction of liquids from

lungs

If you suppose that vomit has entered the lungs (as in case of spontaneous vomit) take the subject to the

hospital with the utmost urgency

Inhalation In case of exposure to high concentration of vapours take immediately to a non polluted zone the person involved

EXTINCTIONMEANS

Appropriated Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Not to be used Avoid the use of water jets

Other indications Cover eventual shedding not on re with foam or sand, use water jets to cool off the surfaces close to the re

Particular protection Wear an autorespiratory mask when heavy smoke is present

Useful warnings Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric contacts

(switches,plugs,etc.). In case of oil sprinkling from pressure circuits, keep in mind that the inamability

point is very low.

WARNING

THE MACHINE MUST NOT BE USED IN AREAS WITH EX-

PLOSIVE ATMOSPHERE

WARNING CAUTION

DANGE-

ROUS

!

!

!

!

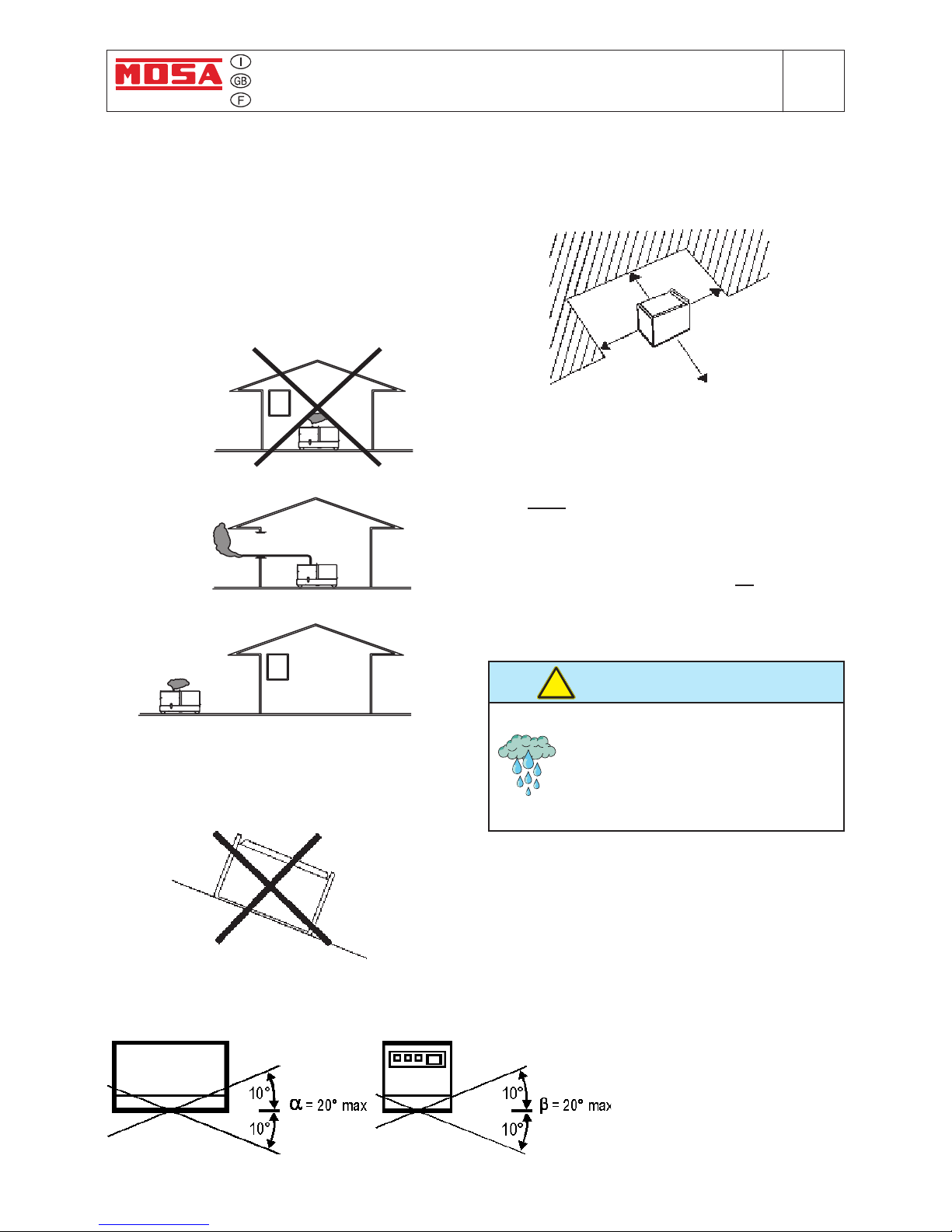

INSTALLATION AND ADVICE

M

2.6

© MOSA REV.1-06/07

INSTALLATION AND ADVICE BEFORE USE

GASOLINE ENGINES

+

Use in open space, air swept or vent exhaust gases,

which contain the deathly carbone oxyde, far from

the work area.

DIESEL ENGINES

+ Use in open space, air swept or vent exhaust gases

far from the work area.

POSITION

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other plants.

Check that the air gets changed completely and the hot

air sent out does not come back inside the set so as to

cause a dangerous increase of the temperature.

+ Make sure that the machine does not move during the

work: block it possibly with tools and/or devices made

to this purpose.

Maximum leaning of the machine (in case of dislevel)

26/11/99 M2-6GB

1,5 m

1,5 m

1,5 m

GAS DI SCARICO

EXHAUST OUTPUT

MOVES OF THE MACHINE

+ At any move check that the engine is off, that there are

no connections with cables which impede the moves.

PLACE OF THE MACHINE

ATTENTION

For a safer use from the operator DO NOT

t the machine in locations with high risk

of ood.

Please do not use the machine in weather

conditions which are beyond IP protection

shown both in the data plate and on page

named "technical data" in this same manual.

!

Installazione

Installation

Installation

Luftzirkulation

Instalación GE 7000-7500 HSX

REV.1-10/11

01/09/08 35770-I

M

2.7

Loading...

Loading...