Page 1

DSP 2x400 PSX

884129003 - GB0 4 0 8

USE AND MAINTENANCE MANUAL

28/11/05 88412M00

preparato da UPT

approvato da DITE

SPARE PARTS CATALOG

Page 2

© MOSA 1.2-05/03

Quality system GE_, MS_, TS_, EAS_

M

01

UNI EN ISO 9001 : 2000

MOSA has certified its quality system according to

UNI EN ISO 9001:2000 to ensure a constant, high

quality of its products. This certification covers the

design, production and servicing of engine driven

welders and generating sets.

The certifying institute, ICIM, which is a member of

the International Certification Network IQNet,

awarded the official approval to MOSA after an

examination of its operations at the head office and

plant in Cusago (MI), Italy.

This certification is not a point of arrival but a pledge

on the part of the entire company to maintain a level

of quality of both its products and services which

will continue to satisfy the needs of its clients, as

well as to improve the transparency and the

communications regarding all the company’s actives

in accordance with the official procedures and in

harmony with the MOSA Manual of Quality.

The advantages for MOSA clients are:

· Constant quality of products and services at the

high level which the client expects;

· Continuous efforts to improve the products and

their performance at competitive conditions;

· Competent support in the solution of problems;

· Information and training in the correct application

and use of the products to assure the security of

the operator and protect the environment;

· Regular inspections by ICIM to confirm that the

requirements of the company’s quality system

and ISO 9001 are being respected.

All these advantages are guaranteed by the

CERTIFICATE OF QUALITY SYSTEM No.0192

issued by ICIM S.p.A. - Milano (Italy ) -

www.icim.it

10/10/02 M01-GB

Page 3

INDEX DSP 2x400 PSX

© MOSA REV.1-04/08

M 01 QUALITY SYSTEM

M 1.01 COPYRIGHT

M 1.1 NOTES

M 1.4 CE MARK

M 1.5 TECHNICAL DATA

M 2 .... SYMBOLS AND SAFETY PRECAUTIONS

M 2.3 -…. ABBREVIATIONS LEGEND

M 2.5 -…. INSTALLATION AND ADVICE BEFORE USE

M 2.6 INSTALLATION AND ADVICE

M 3 UNPACKING

M 4.2 TRANSPORT AND DISPLACEMENTS COVERED UNITS

M 6.8 ASSEMBLY CTL

M 20.... PREPARING THE UNIT

M 21 START-UP

M 22 SHUTTING DOWN THE MOTOR

M 31 CONTROLS

M 32 USE AS A WELDER

M 33... WELDER DSP (USE)

M 37 USING THE GENERATOR

M 38.9 REMOTE CONTROL

M 40.1 TROUBLESHOOTING

M 43… MAINTENANCE

M 45 STORAGE

M 46 CUST OFF

M 52 TECHNICAL DATA

M 55 RECOMMENDED ELECTRODES

M 60 ELECTRICAL SYSTEM LEGENDE

M 61-….. ELECTRICAL SYSTEM

M

1

ED... SPARE PARTS

28/11/05 88412-GB

Page 4

Copyright GE_, MS_, TS_, EAS

© MOSA 1.0-10/02

ATTENTION

This use and maintenance manual is an important

part of the machines in question.

The assistance and maintenance personel must

keep said manual at disposal, as well as that for

the engine and alternator (if the machine is

synchronous) and all other documentation about the

machine.

We advise you to pay attention to the pages

concerning the security (see page M1.1).

© All rights are reserved to said Company.

It is a property logo of MOSA division of B.C.S.

S.p.A. All other possible logos contained in the

documentation are registered by the respective

owners.

M

1.01

The reproduction and total or partial use, in

➠

any form and/or with any means, of the

documentation is allowed to nobody without a

written permission by MOSA division of B.C.S.

S.p.A.

To this aim is reminded the protection of the author’s

right and the rights connected to the creation and

design for communication, as provided by the laws

in force in the matter.

In no case MOSA division of B.C.S. S.p.A. will be

held responsible for any damaga, direct or indirect,

in relation with the use of the given information.

MOSA division of B.C.S. S.p.A. does not take any

responsibility about the shown information on firms

or individuals, but keeps the right to refuse services

or information publication which it judges discutible,

unright or illegal.

10/10/02 M1-01-GB

Page 5

© MOSA 1.0-10/02

Notes GE_, MS_, TS_, EAS_

M

1-1

INFORMATION

Dear Customer,

We wish to thank you for having bought from

MOSA a high quality set.

Our sections for Technical Service and Spare

Parts will work at best to help you if it were

necessary.

To this purpose we advise you, for all control and

overhaul operations, to turn to the nearest

authorized Service Centre, where you will obtain

a prompt and specialized intervention.

In case you do not profit on these Services and

☞

some parts are replaced, please ask and be

sure that are used exclusively original MOSA

parts; this to guarantee that the performances

and the initial safety prescribed by the norms in

force are re-established.

The use of non original spare parts will cancel

☞

immediately any guarantee and Technical Service obligation from MOSA.

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine

and/or set you will find: the manual for Use

Maintenance and Spare Parts, the manual for

use of the engine and the tools (if included in the

equipment), the guarantee (in the countries where

it is prescribed by law).

Our products have been designed for the use of

generation for welding, electric and hydraulic

system; ANY OTHER DIFFERENT USE NOT

INCLUDED IN THE ONE INDICATED, relieves

MOSA from the risks which could happen or,

anyway, from that which was agreed when selling

the machine; MOSA excludes any responsibility

for damages to the machine, to the things or to

persons in this case.

Our products are made in conformity with the

safety norms in force, for which it is advisable to

use all these devices or information so that the

use does not bring damage to persons or things.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this

manual attentively. Follow the instructions

contained in it, in this way you will avoid

inconveniences due to negligence, mistakes or

incorrect maintenance. The manual is for qualified

personnel, who knows the rules: about safety and

health, installation and use of sets movable as

well as fixed.

You must remember that, in case you have

difficulties for use or installation or others, our

Technical Service is always at your disposal for

explanations or interventions.

The manual for Use Maintenance and Spare Parts

is an integrant part of the product. It must be kept

with care during all the life of the product.

In case the machine and/or the set should be

yielded to another user, this manual must also

given to him.

Do not damage it, do not take parts away, do not

tear pages and keep it in places protected from

dampness and heat.

While working it is advisable to keep to the

personal safety norms in force in the countries to

which the product is destined (clothing, work tools,

etc.).

Do not modify for any motive parts of the machine

(fastenings, holes, electric or mechanical devices,

others..) if not duly authorized in writing by MOSA:

the responsibility coming from any potential

intervention will fall on the executioner as in fact

he becomes maker of the machine.

Notice: this manual does not engage MOSA,

☞

who keeps the faculty, apart the essential

characteristics of the model here described and

illustrated, to bring betterments and modifications

to parts and accessories, without putting this

manual uptodate immediately.

You must take into account that some figures

contained in it want only to identify the described

parts and therefore might not correspond to the

machine in your possession.

10/10/02 M 1-1 GB

Page 6

M

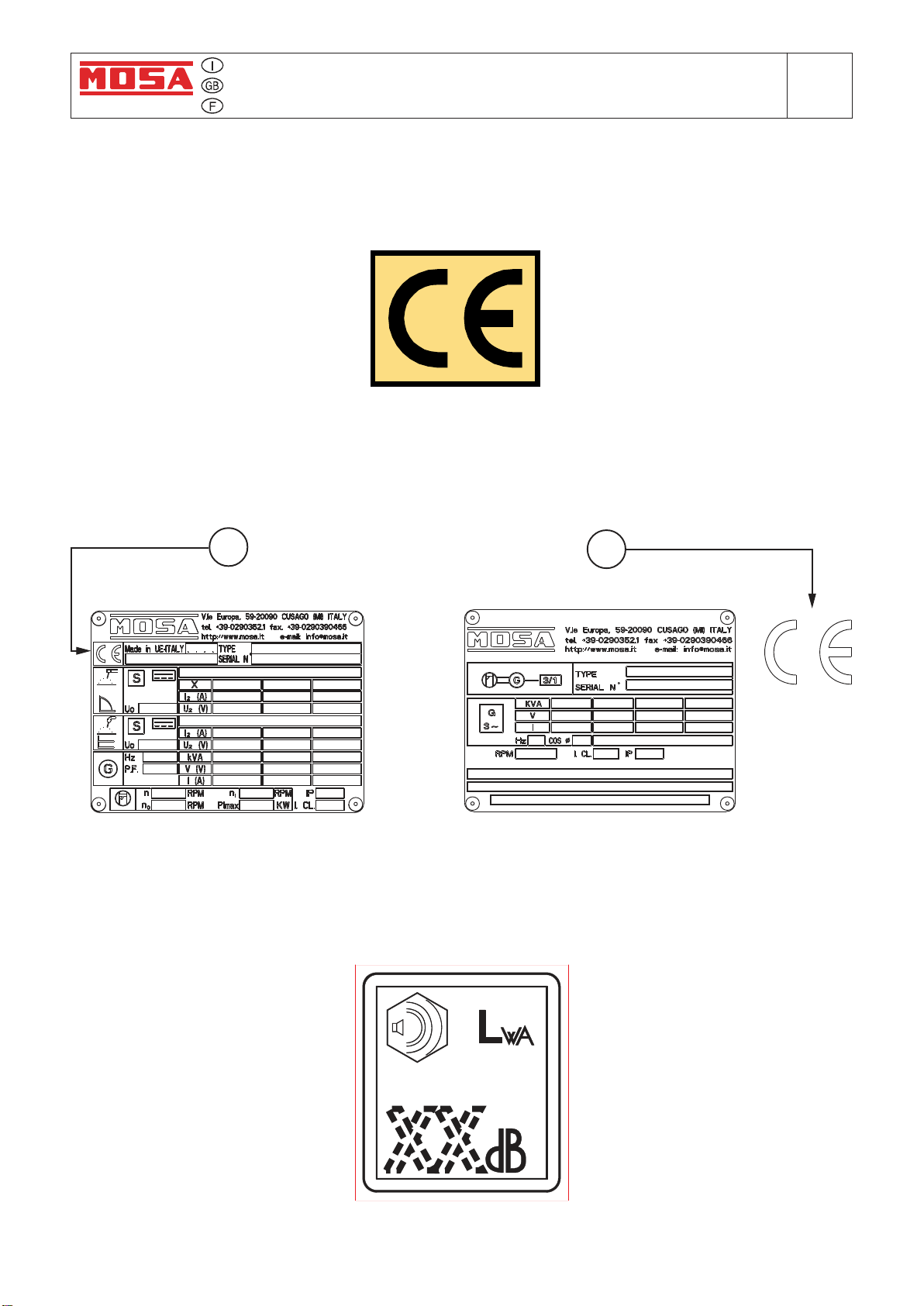

CE MARK

© MOSA REV.4-10/07

1.4

Any of our product is labelled with CE marking attesting its conformity to appliable directives

and also the fulfillment of safety requirements of the product itself; the list of these directives is

part of the declaration of conformity included in any machine standard equipment.

Here below the adopted symbol:

CE marking is clearly readable and unerasable and it can be either part of the data-plate (A) or

placed as a sticker near the data-plate (B)

A

B

Furthermore, on each model it is shown the noise level value; the symbol used is the following:

The indication is shown in a clear, readable and indeleble way on a sticker.

10/10/02 M1-4 GB

Page 7

M

DSP 2x400 PSX

© MOSA REV.1-04/08

The DSP 2x400 engine driven welder ia a unit which ensures the function as:

a) a current source for arc welding

b) a current source for the auxiliary power generation

It is meant for industrial and professional use, powered by an endothermic engine; it is composed of

various main parts such as: engine, alternator, electric and electronic controls, the fairing or a protective structure.

The assembling is made on a steel structure, on which are provided elastic support which must damp the vibrations and also

eliminate sounds which would produce noise.

TECHNICAL DATA

1.5

Technical data DSP 2x400 PS

GENERATOR

Output three-phase 40 kVA / 400 V / 58 A

Output single-phase 20 kVA / 230 V / 87 A

Output single-phase 5 kVA / 48 V / 104 A

Frequency 50 Hz

ϕϕ

Cos

ϕ 0.8

ϕϕ

ALTERNATOR Self-excited, self-regulated, brushless

Type three-phase, asynchronous

Insulating class H

ENGINE

Mark PERKINS

Model 1103A-33TG1

Type 4-Stroke

Displacement 3300 cm

Cylinders 3

Output max 45.6 kW (62.1 HP)

Speed 1500 rpm

Fuel consumption 215 g/kWh

Cooling system water

Cooling system capacity 10.2 l

Engine oil capacity 7.9 l

Starter Electric

Fuel Diesel

GENERAL SPECIFICATIONS

Battery 12V - 100Ah

Tank capacity 102 l

Running time (at duty cycle 60%) 13 h

Protection IP 44

Dimensions Lxwxh (mm) * 2490x1030x1300 (1480)

Weight * 1300 Kg

Noise level 94 LWA (69 dB(A))

* Dimensions and weight are inclusive of all parts without wheels and towbar.

3

OUTPUT

Declared power according to ISO 8528-1 (temperature 25°C, 30% relative hummidity, altitude 100 m above sea level).

(*Stand-by) = maximum available power for use at variable loads for a yearly number of hours limited at 500 h. No overload is

admitted.

(**Prime power P.R.P.) = maximum available power for use at variable loads for a yearly illimited number of hours. The average

power to be taken during a period of 24 h must not be over 80% of the P.R.P.

It’s admitted overload of 10% each hour every 12 h.

In an approximative way one reduces: of 1% every 100 m altitude and of 2.5% for every 5°C above 25°C.

ACOUSTIC POWER LEVEL

ATTENTION: The concrete risk due to the machine depends on the conditions in which it is used. Therefore, it is up to the end-

user and under his direct responsibility to make a correct evaluation of the same risk and to adopt specific precautions (for

instance, adopting a I.P.D. -Individual Protection Device)

Acoustic Noise Level (LWA) - Measure Unit dB(A): it stands for acoustic noise released in a certain delay of time. This is not

submitted to the distance of measurement.

Acoustic Pressure (Lp) - Measure Unit dB(A): it measures the pressure originated by sound waves emission. Its value

changes in proportion to the distance of measurement.

The here below table shows examples of acoustic pressure (Lp) at different distances from a machine with Acoustic Noise

Level (LWA) of 95 dB(A)

Lp a 1 meter = 95 dB(A) - 8 dB(A) = 87 dB(A) Lp a 7 meters = 95 dB(A) - 25 dB(A) = 70 dB(A)

Lp a 4 meters = 95 dB(A) - 20 dB(A) = 75 dB(A) Lp a 10 meters = 95 dB(A) - 28 dB(A) = 67 dB(A)

PLEASE NOTE: the symbol when with acoustic noise values, indicates that the device respects noise emission limits

2000/ 14 / CE

according to 2000/14/CE directive.

28/11/05 88412-GB

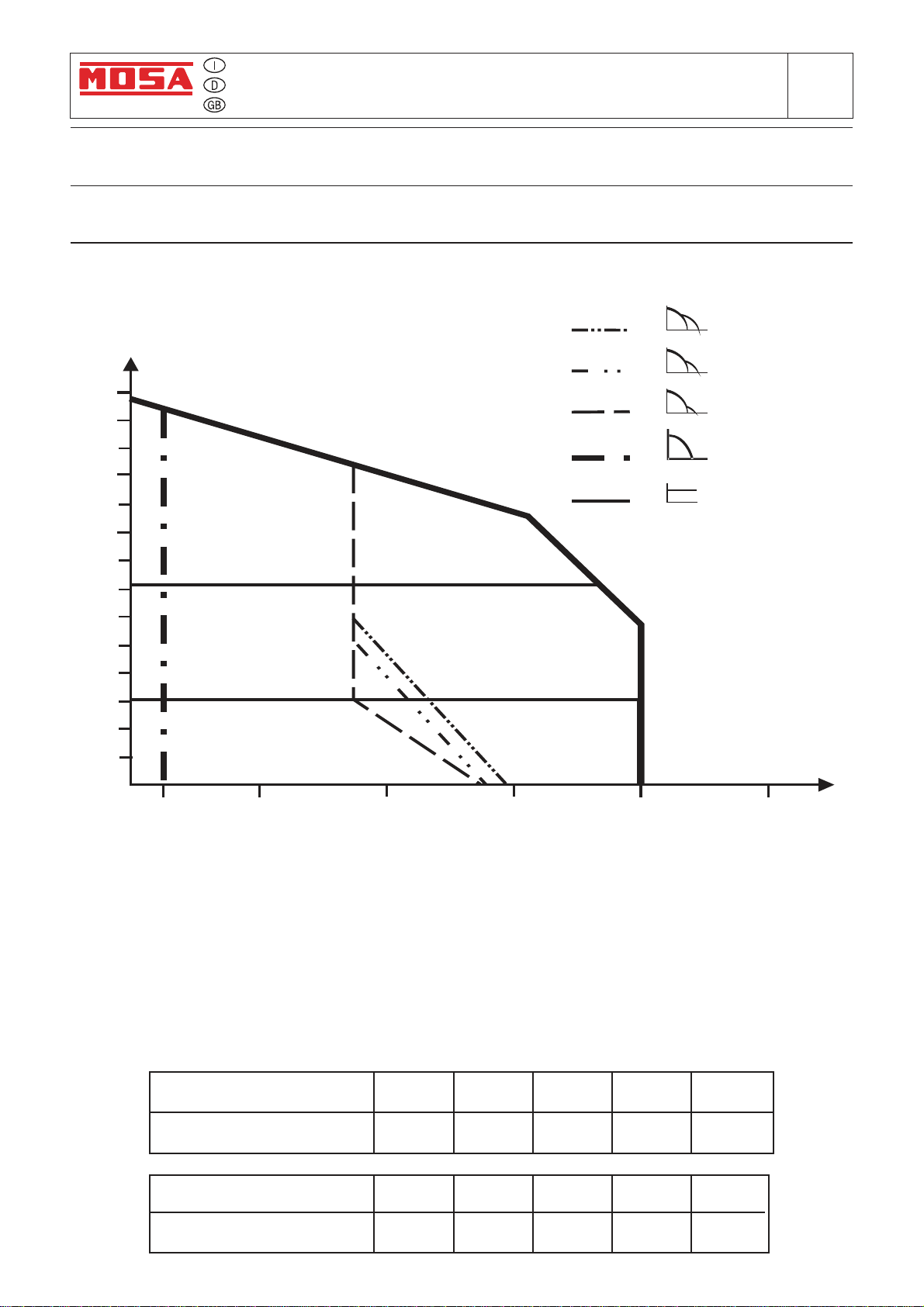

Page 8

© MOSA 1.0-11/05

C.C. WELDING

Welding current 2x400A/35% - 2x360A/60% - 2x330A/100%

Starting voltage 68V

C.V. WELDING

Welding current 2x360A/60% - 2x330A/100%

Welding voltage 16 - 36V

TECHNICAL DATA

DSP 2x400 PSX

C.C.

M

1.5.1

70

60

50

40

30

20

10

STATIC CHARACTERISTIC

V

C.C.

C.C.

C.C. TIG

C.V.

max

min.

A

10

100 200

300 400 500

SIMULTANEOUS UTILIZATION FACTORS

In case Welding and Generation can be used simultaneously, however, the engine cannot be overloaded.

The table below gives the maximum limits to be respected:

WELDING CURRENT

SINGLE POSITION

AUXILIARY POWER

WELDING CURRENT

DOUBLE POSITION

AUXILIARY POWER

300A400A

35 kVA30kVA25kVA

40 kVA 40 kVA

2x300A2x400A 02x200A 2x100A

30 kVA20 kVA10kVA 40 kVA 40 kVA

0200A 100A

28/11/05 88412-GB

Page 9

© MOSA 1.0-11/99

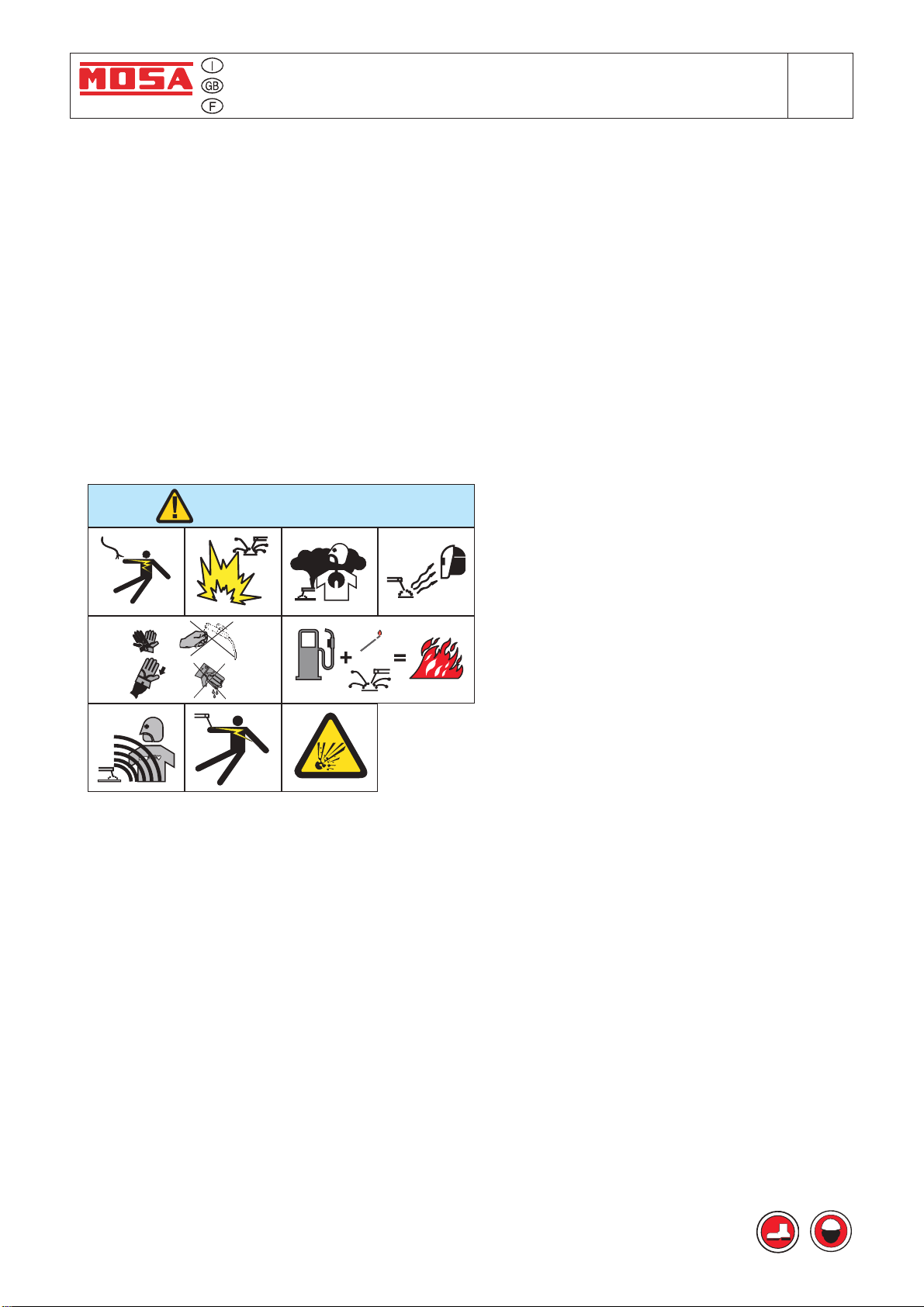

SYMBOLS AND SAFETY PRECAUTIONS GE_, MS_, TS_

M

2

SYMBOLS IN THIS MANUAL

- The symbols used in this manual are designed to call

your attention to important aspects of the operation of

the machine as well as potential hazards and dangers

for persons and things.

IMPORTANT ADVICE

- Advice to the User about the safety:

N.B.: The information contained in the manual can

☞

be changed without notice.

Potential damages caused in relation to the use of

these instructions will not be considered because

these are only indicative.

Remember that the non observance of the

indications reported by us might cause damage to

persons or things.

It is understood, that local dispositions and/or laws

must be respected.

SAFETY PRECAUTIONS

DANGEROUS

This heading warns of an immediate danger for persons

as well for things. Not following the advice can result in

serious injury or death.

WARNING

This heading warns of situations which could result in

injury for persons or damage to things.

CAUTION

To this advice can appear a danger for persons as well as

for things, for which can appear situations bringing material damage to things.

IMPORTANT

WARNING

Situations of danger - no harm to persons

or things

Do not use without protective devices provided

Removing or disabling protective devices on the

machine is prohibited.

Do not use the machine if it is not in good technical

condition

The machine must be in good working order before

being used. Defects, especially those which regard

the safety of the machine, must be repaired before

using the machine.

NOTE

ATTENTION

These headings refer to information which will assis you

in the correct use of the machine and/or accessories.

26/11/99 M2GB

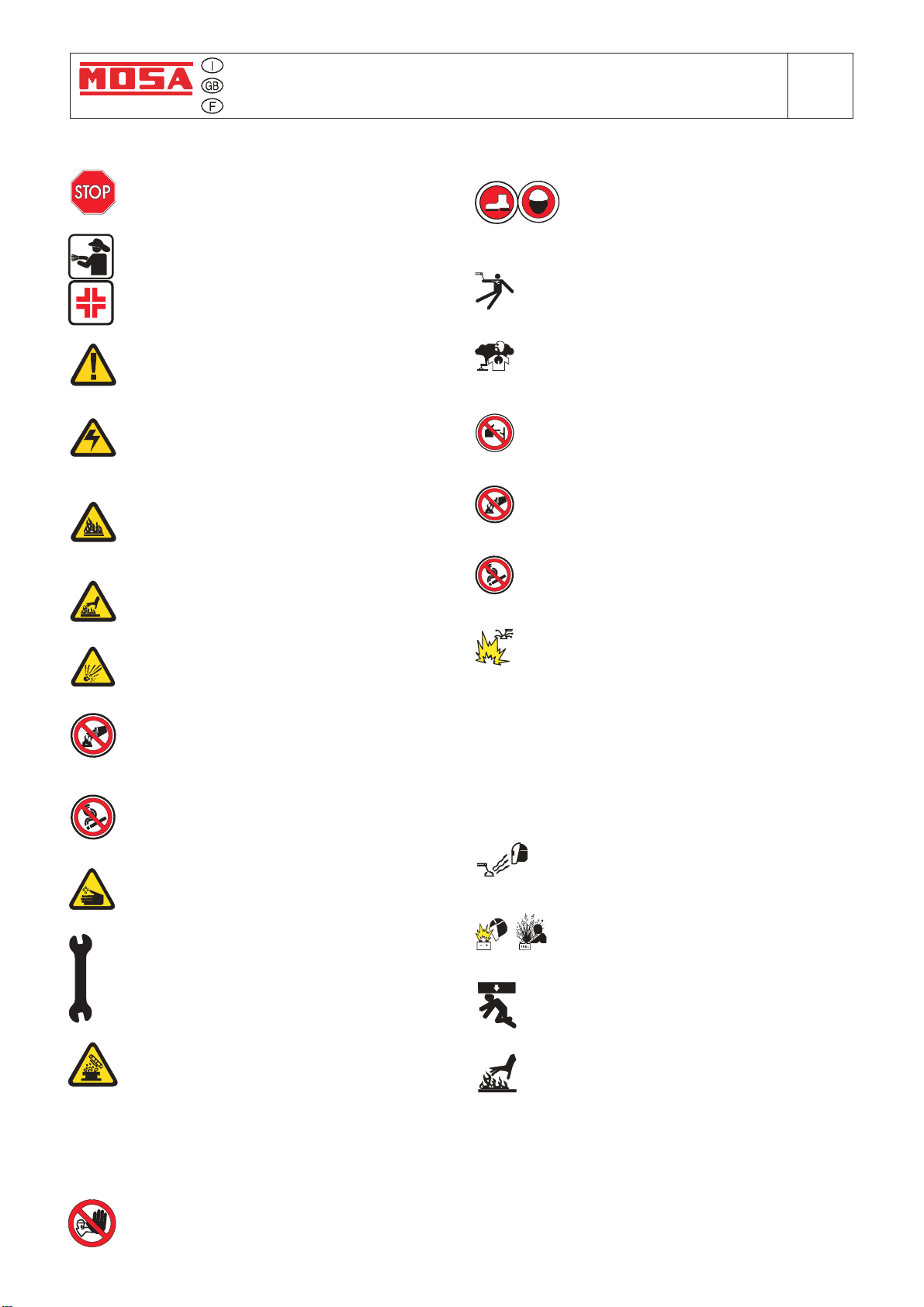

Page 10

© MOSA 1.1-04/03

SYMBOLS AND SAFETY PRECAUTIONS GE_, MS_, TS_

M

2-1

SYMBOLS (for all MOSA models)

STOP - Read absolutely and be duly attentive

Read and pay due attention

GENERAL ADVICE - If the advice is not

respected damage can happen to persons or

things.

HIGH VOLTAGE - Attention High Voltage.There

can be parts in voltage, dangerous to touch.

The non observance of the advice implies life

danger.

FIRE - Danger of flame or fire. If the advice is

not respected fires can happen.

HEAT - Hot surfaces. If the advice is not

respected burns or damage to things can be

caused.

EXPLOSION - Explosive material or danger of

explosion. in general. If the advice is not

respected there can be explosions.

WATER - Danger of shortcircuit. If the advice

is not respected fires or damage to persons

can be caused.

SMOKING - The cigarette can cause fire or

explosion. If the advice is not respected fires

or explosions can be caused.

ACIDS - Danger of corrosion. If the advice is

not respected the acids can cause corrosions

with damage to persons or things.

PROHIBITIONS No harm for persons

Use only with safety clothing -

It is compulsory to use the personal

protection means given in equipment.

Use only with safety clothing -

It is compulsory to use the personal protection

means given in equipment.

Use only with safety protections -

It is a must to use protection means suitable for

the different welding works.

Use with only safety material -

It is prohibited to use water to quench fires on

the electric machines.

Use only with non inserted voltage -

It is prohibited to make interventions before

having disinserted the voltage.

No smoking -

It is prohibited to smoke while filling the tank

with fuel.

No welding -

It is forbidden to weld in rooms containing

explosive gases.

ADVICE No harm for persons and things

Use only with safety tools, adapted to the specific

use -

It is advisable to use tools adapted to the various

maintenance works.

Use only with safety protections, specifically suitable

It is advisable to use protections suitable for

the different welding works.

Use only with safety protections -

It is advisable to use protections suitable

for the different daily checking works.

WRENCH - Use of the tools. If the advice is

not respected damage can be caused to things

and even to persons.

PRESSION - Danger of burns caused by the

expulsion of hot liquids under pressure.

ACCES FORBIDDEN to non authorizad peaple.

Use only with safety protections -

It is advisable to use all protections while

shifting the machine.

Use only with safety protections -

It is advisable to use protections suitable for

the different daily checking works.and/or of

maintenance.

26/11/99 M2-1GB

Page 11

INSTALLATION AND ADVICE BEFORE USE GE_, MS_, TS_

© MOSA 1.0-06/00

The installation and the general advice concerning the operations, are finalized to the correct use of the

machine, in the place where it is used as generator group and/or welder.

M

2-5

Stop engine when fueling

Do not smoke, avoid flames, sparks or electric tools when fueling.

Unscrew the cap slowly to let out the fuel vapours.

Slowly unscrew the cooling liquid tap if the liquid must be topped up.

The vapor and the heated cooling liquid under pressure can burn face, eyes, skin.

ENGINE

Do not fill tank completely.

Wipe up spilled fuel before starting engine.

Shut off fuel of tank when moving machine (where it is assembled).

Avoid spilling fuel on hot engine.

Sparks may cause the explosion of battery vapours

FIRST AID. In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas

☞

or whatever event which may cause serious injuries or death, predispose the first aid in accordance with

the ruling labour accident standards or of local instructions.

Skin contact

Eyes contact

Ingestion

Suction of liquids from

lungs

Inhalation

Wash with water and soap

Irrigate with plenty of water, if the irritation persists contact a specialist

Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

If you suppose that vomit has entered the lungs (as in case of spontaneous vomit) take the

subject to the hospital with the utmost urgency

In case of exposure to high concentration of vapours take immediately to a non polluted zone

the person involved

Do not touch electric devices if you

are barefoot or with wet clothes.

Always keep off leaning surfaces

during work operations

Static electricity can demage the

parts on the circuit.

CHECKING BOARD

An electric shock can kill

FIRE PREVENTION. In case the working zone,for whatsoever cause goes on fire with flames liable to

☞

cause severe wounds or death, follow the first aid as described by the ruling norms or local ones.

Appropriated

Not to be used

Other indications

Particular protection

Useful warnings

EXTINCTION MEANS

Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Avoid the use of water jets

Cover eventual shedding not on fire with foam or sand, use water jets to cool off the

surfaces close to the fire

Wear an autorespiratory mask when heavy smoke is present

Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric

contacts (switches,plugs,etc.). In case of oil sprinkling from pressure circuits, keep in

mind that the inflamability point is very low.

WARNING

CAUTION

DANGEROUS

WARNING

THE MACHINE MUST NOT BE USED IN AREAS WITH

EXPLOSIVE ATMOSPHERE

10/06/00 M2-5I

Page 12

M

PRECAUTION (ENGINE DRIVEN WELDER) GE_, MS_, TS_

© MOSA 1.0-03/00

INSTALLATION AND ADVICE BEFORE USE

The operator of the welder is responsible for the security of the people who work with the welder and for those in the

vicinity.

The security measures must satisfy the rules and regulations for engine driven welders.

The information given below is in addition to the local security norms.

Estimate possible electromagnetic problems in the work area taking into account the following indications.

1. Telephonic wirings and/or of communication, check wirings and so on, in the immediate vicinity.

2. Radio and television receptors and transmettors.

3. Computer and other checking devices.

4. Critical devices for safety and/or for industrial checks.

5. Peapol who, for instance, use pace-maker, hearing-aid for deaf or something and else.

6. Devices used for rating and measuring.

7. The immunity of other devices in the operation area of the welder. Make sure that other used devices are

compatible. If it is the case, provide other additional measures of protection.

8. The daily duration of the welding time.

2-5-1

ATTENTION

Make sure that the area is safe before starting any welding operation.

Do not touch any bare wires, leads or contacts as they may be live and there is danger of electric shock

➠

which can cause death or serious burns. The electrode and welding cables, etc. are live when the unit is

operating.

Do not touch any electrical parts or the electrode while standing in water or with wet hands, feet or clothes.

➠

Insulate yourself from the work surface while welding. Use carpets or other insulating materials to avoid

➠

physical contact with the work surface and the floor.

Always wear dry, insulating glovers, without holes, and body protection.

➠

Do not wind cables around the body.

➠

Use ear protections if the noise level is high.

➠

Keep flamable material away from the welding area.

➠

Do not weld on containers which contain flamable material.

➠

Do not weld near refuelling areas.

➠

Do not weld on easily flamable surfaces.

➠

Do not use the welder to defrost (thaw) pipes.

➠

Remove the electrode from the electrode holder, when not welding.

➠

Avoid inhaling fumes by providing a ventilation system or, if not possible, use an approved air breather.

➠

Do not work in closed areas where there is no fresh air flow.

➠

Protect face and eyes (protective mask with suitable dark lens and side screens), ears and body (non-

➠

flamable protective clothers).

30/03/00 M2-5GB

Page 13

© MOSA 1.0-11/99

INSTALLATION AND ADVICE GE_, MS_, TS_

M

2.6

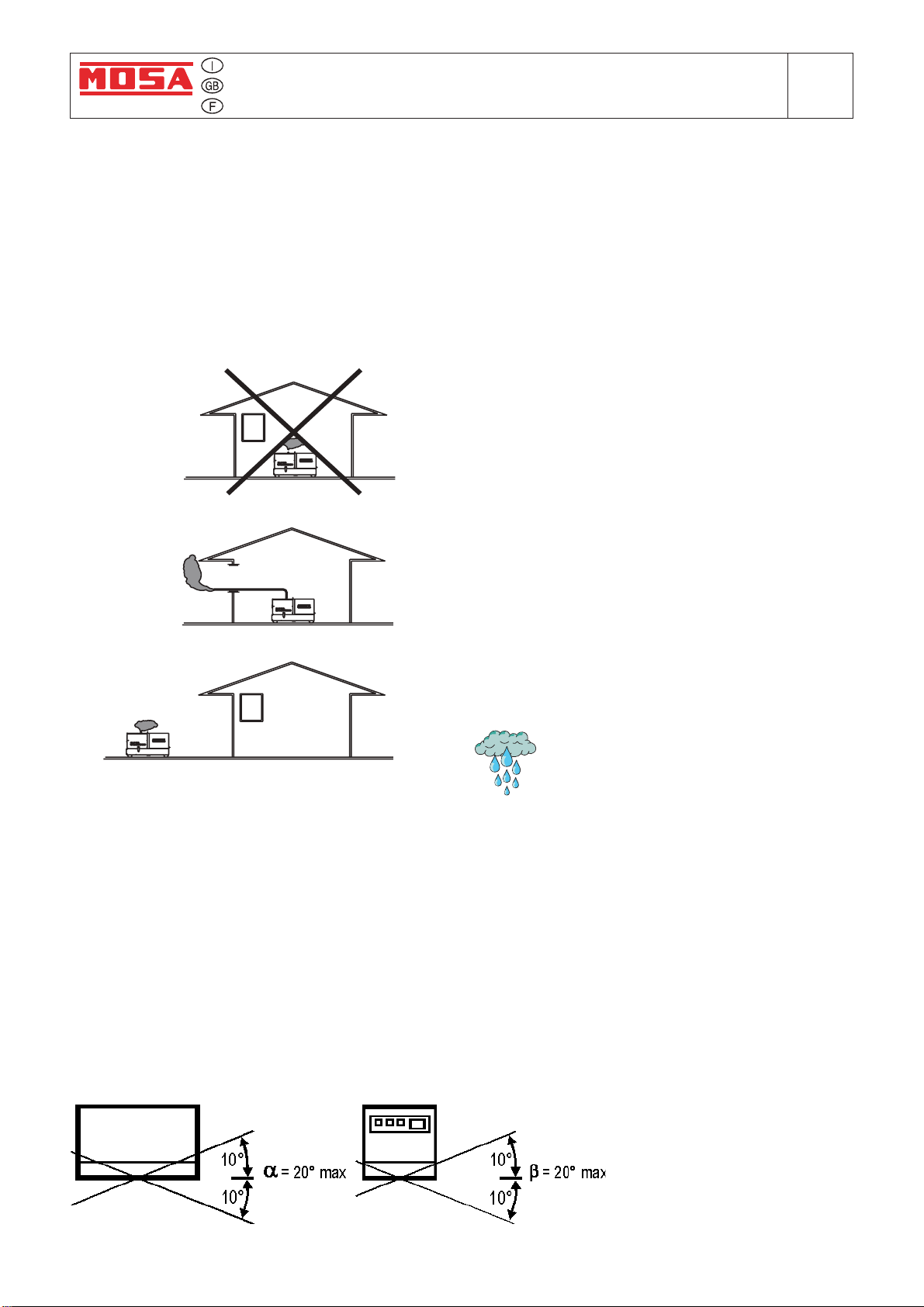

INSTALLATION AND ADVICE BEFORE USE

GASOLINE ENGINES

■ Use in open space, air swept or vent exhaust gases,

which contain the deathly carbone oxyde, far from

the work area.

DIESEL ENGINES

■ Use in open space, air swept or vent exhaust gases

far from the work area.

Check that the air gets changed completely and the hot

air sent out does not come back inside the set so as to

cause a dangerous increase of the temperature.

1,5 m

1,5 m

1,5 m

GAS DI SCARICO

EXHAUST OUTPUT

Make sure that the machine does not move during

☞

the work: block it possibly with tools and/or devices

made to this purpose.

MOVES OF THE MACHINE

At any move check that the engine is off, that there

☞

are no connections with cables which impede the

moves.

POSITION

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other plants.

Maximum leaning of the machine (in case of dislevel)

PLACE OF THE MACHINE

In spots where it often rains and/or there are

flooded areas, do

■ in the bad weather

■ in flooded places.

not put the machine:

Protect all the electric parts at risk, because water

infiltrations could cause short circuits with damages

at persons and/or things.

The protection degree of the machine is put on the data

plate and in this manual at page "Technical Data".

26/11/99 M2-6GB

Page 14

© MOSA 1.0-11/05

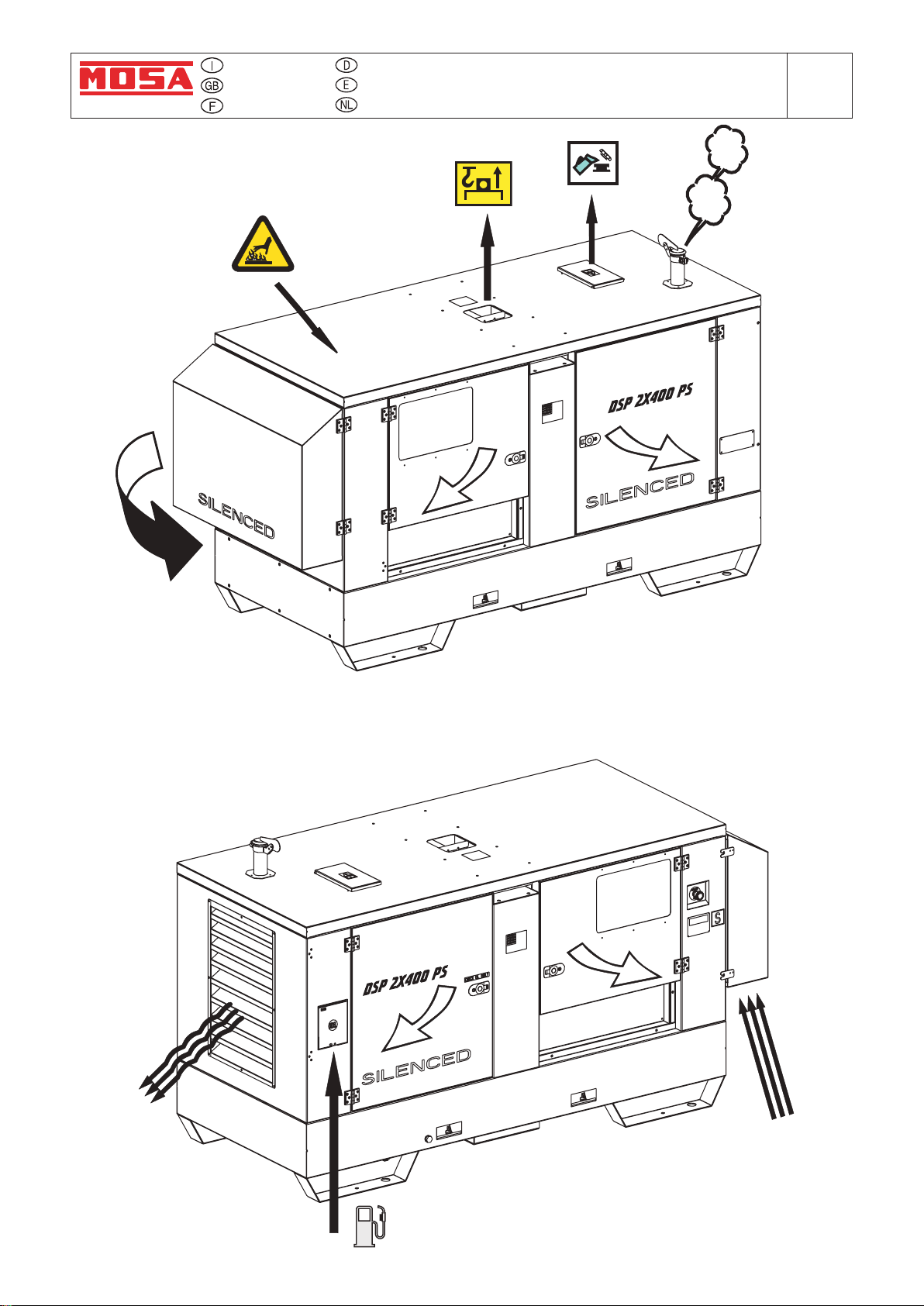

Installazione

Installation

Installation

Luftzirkulation M

DSP 2x400 PSX

2.7

18/11/05 88412-I

Page 15

© MOSA 1.1-02/04

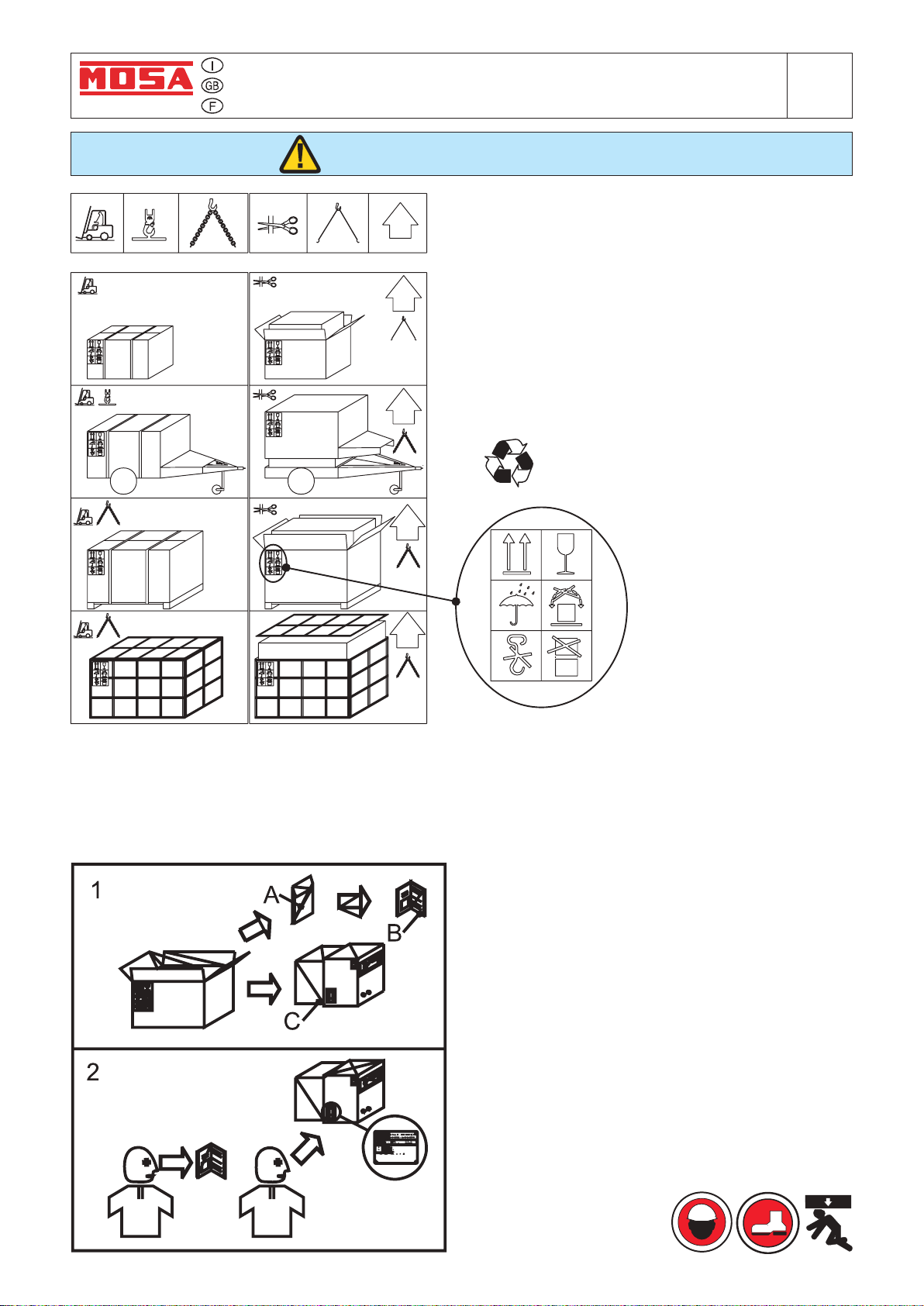

UNPACKING GE_, MS_, TS_

NOTE

Be sure that the lifting devices are: correctly mounted,

☞

adequate for the weight of the machine with it’s

packaging, and conforms to local rules and regulations.

When receiving the goods make sure that the product has not suffered damage during the transport,

that there has not been rough handling or taking

away of parts contained inside the packing or in the

set.

In case you find damages, rough handling or absence of parts (envelopes, manuals, etc.), we advise you to inform immediately our Technical Service.

For eliminating the packing materials, the User

must keep to the norms in force in his country.

M

3

1) Take the machine (C) out of the shipment packing.

Take out of the envelope (A) the user’s manual (B).

2) Read: the user’s manual (B), the plates fixed on the

machine, the data plate.

30/03/00 M3GB

Page 16

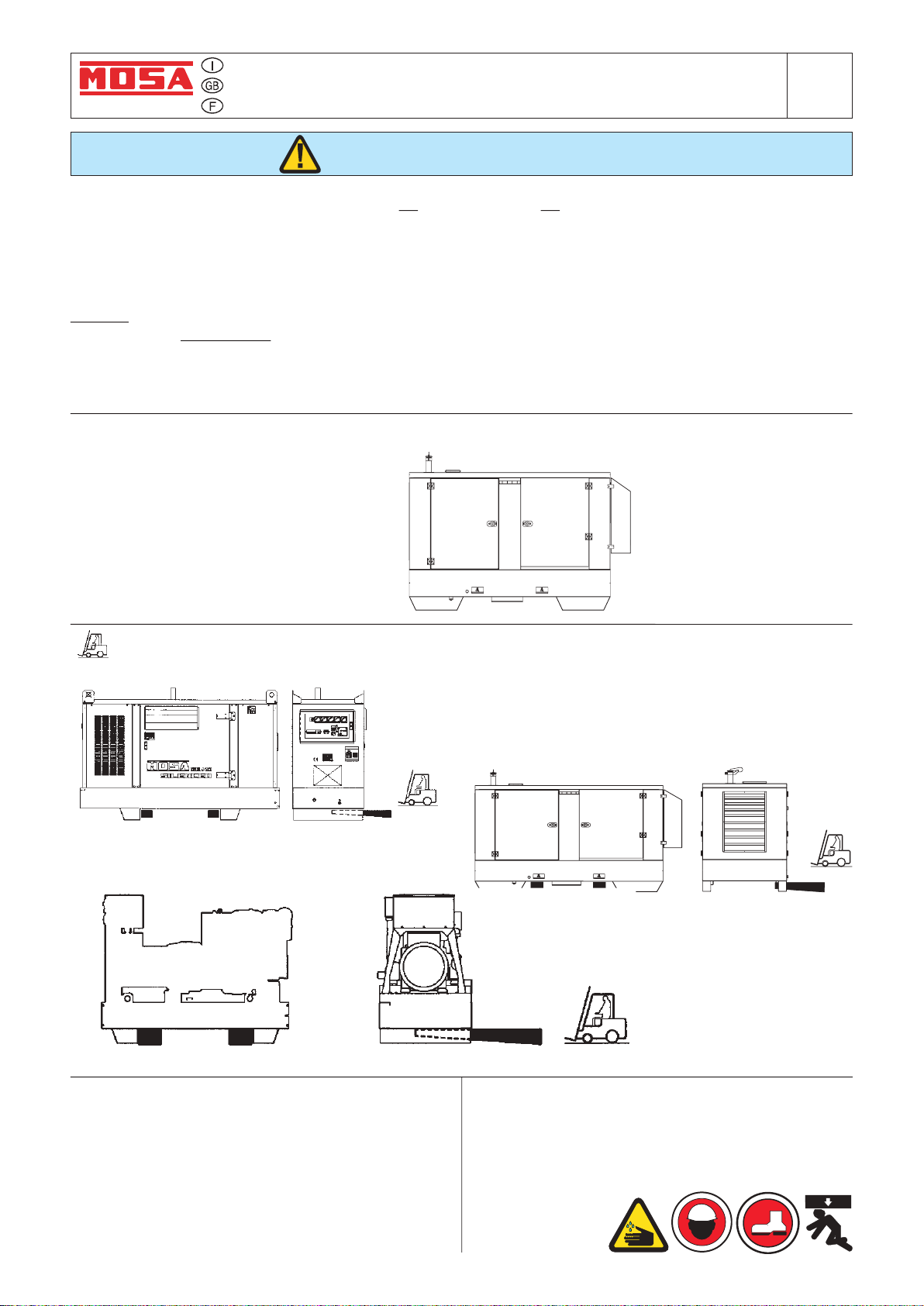

TRANSPORT AND DISPLACEMENTS COVERED UNITS AND SKID GE_, MS_, TS_M4-2

© MOSA 1.0-03/00

NOTE

In case you should transport or move the machine, keep to the instructions as per the figures.

Make the transportation when the machine has

battery.

Be sure that the lifting devices are: correctly mounted, adequate for the weight of the machine with it’s packaging, and

conform to local rules and regulations.

Only authorized persons involved in the transport of the machine should be in the area of movement.

DO NOT LOAD OTHER PARTS WHICH CAN MODIFY WEIGHT AND BARICENTER POSITION.

IT IS STRICTLY

CTL accessory).

If you did not keep to the instructions, you could damage the structure of the machine.

FORBIDDEN TO DRAG THE MACHINE MANUALLY OR TOW IT BY ANY VEHICLE (model with no

no

petrol in its tank,

no

oil in the engine and and electrolyte in the

30/03/00 M4GB

Page 17

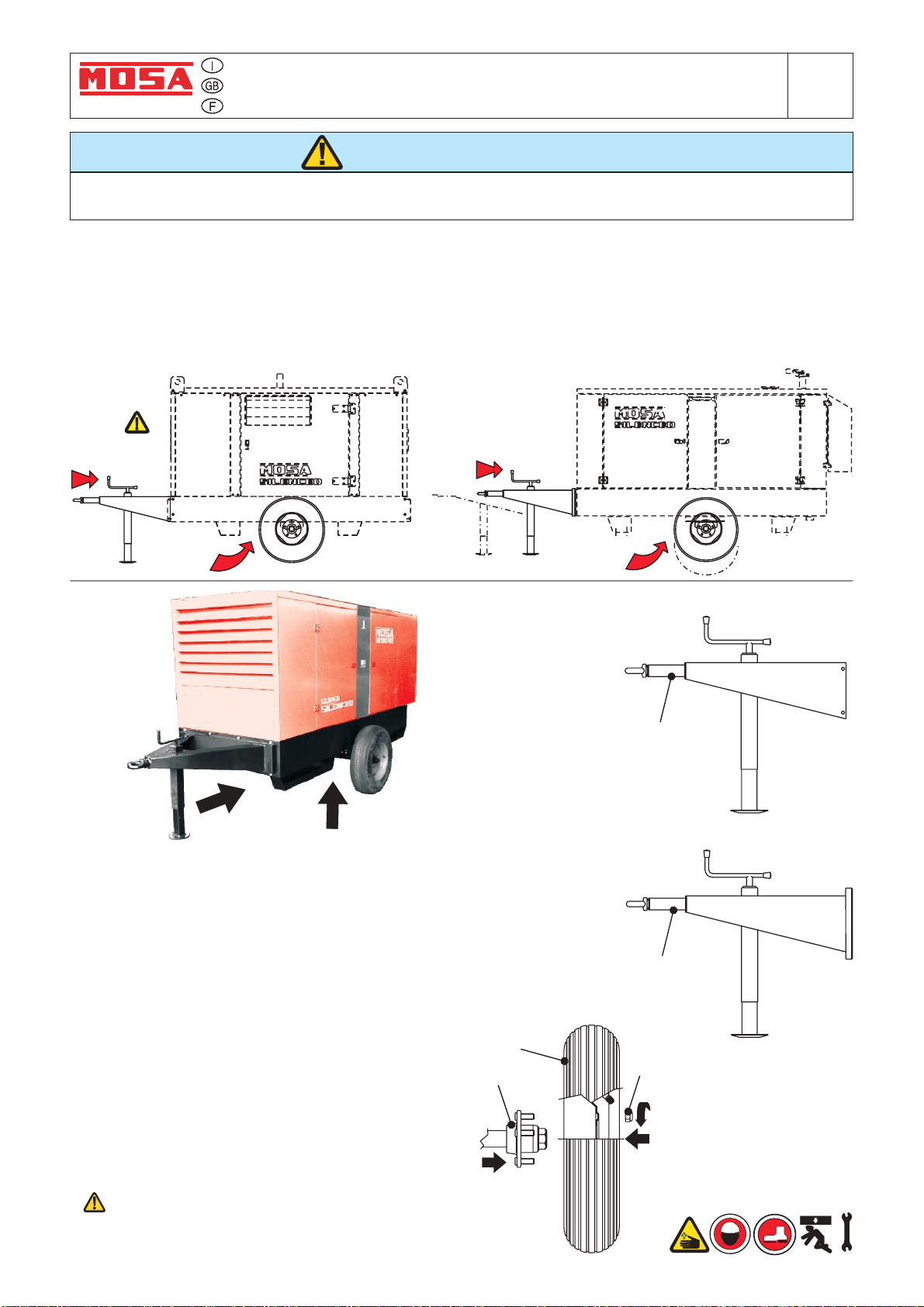

CTL 35 -45 - 50 - 95

5

5

ASSEMBLY

© MOSA 1.1-04/06

M

6.8

ATTENTION

The CTL accessory cannot be removed from the machine and used separately (actioned manually or

following vehicles) for the transport of loads or anyway for used different from the machine movements.

TRAILERS

The machines provided for assembling the CTL accessory (slow towing trolley) can be towed up to a maximum speed

of 40 Kms/hour on asphalted surfaces.

Towing on public roads or turnpikes of any type IS EXCLUDED, because not in possesion of the requirements by

national and foreign traffic norms.

Nota: Lift the machine and assemble the parts as shown in the drawing

CTL 35-50

COMANDS

CTL 95

CTL 45

CTL 35-50

For assembling the generating set on the trolley CTL 35-45 50 - 95 please keep to following instructions:

1) - Lift thr generating set (by means of suitable hook)

6) - Assemble on the machine the towbar (5) complete of

foot with the M10x20 screws,nuts and washers.

7) - Assemble the axle (7) to the base of the machine with

the M10x20 screws and relative washers (two per

part) so that their supports coincide.

8) - Insert the wheel (9) on the axle then twist the

selfblocking nut (8).

9) - Pump the tyre (9) bringing the pressure to 4 atms for

the CTL 35-45-50 and 5/6 for the CTL 95.

10) - Lower the machine to the ground and place the parking

foot definitively (regulating at the best height).

ATTENTION

Do not substituite the original tires with other types.

CTL 45-95

9

7

8

30/03/04 M6GB

Page 18

© MOSA 1.1-09/05

Set-up for operation TS_,DSP_,GE

Water cooled systems

M

20

BATTERY WITHOUT MAINTENANCE

Connect the cable + (positive)

to the pole + (positive) of the

battery (after having taken

away the protection), by

properly tightening the clamp.

Check the state of the battery

from the colour of the warning light which is in the

upper part.

- Green colour: battery OK

- Black colour: battery to be recharged

- White colour: battery to be replaced

DO NOT OPEN THE BATTERY.

LUBRICANT

RECOMMENDED OIL

MOSA recommends selecting AGIP engine oil.

Refer to the label on the motor for the recommended

products.

AIR FILTER

Check that the dry air filter is correctly installed and

that there are no leaks around the filter which could

lead to infiltrations of non-filtered air to the inside of

the motor.

FUEL

ATTENTION

Do not smoke or use open flames during

refuelling operations, in order to avoid

explosions or fire hazards.

Fuel fumes are highly toxic; carry out

operations outdoors only, or in a wellventilated environment.

Avoid accidentally spilling fuel. Clean

any eventual leaks before starting up

motor.

Please refer to the motor operating manual for the

recommended viscosity.

REFUELLING AND CONTROL:

Carry out refuelling and controls with motor at level

position.

Remove the oil-fill tap (24)

1.

2. Pour oil and replace the tap

3. Check the oil level using the dipstick (23); the oil

level must be comprised between the minimum

and maximum indicators.

Refill the tank with good quality diesel fuel, such as

automobile type diesel fuel, for example.

For further details on the type of diesel fuel to use,

see the motor operating manual supplied.

Do not fill the tank completely; leave a space of

approx. 10 mm between the fuel level and the wall

of the tank to allow for expansion.

In rigid environmental temperature conditions, use

special winterized diesel fuels or specific additives

in order to avoid the formation of paraffin.

ATTENTION

It is dangerous to fill the motor with too much oil,

as its combustion can provoke a sudden increase

in rotation speed.

12/06/03 M20-R-HO2-GB

Page 19

Set-up for operation TS_,DSP_,GE

© MOSA 1.0-06/03

COOLING LIQUID

ATTENTION

Do not remove the radiator tap with the

motor in operation or still hot, as the liquid

coolant may spurt out and cause serious

burns. Remove the tap very carefully.

Remove the tap and pour the liquid coolant into the

radiator; the quantity and composition of the liquid

coolant are indicated in the motor operating manual.

Replace the tap, ensuring it is perfectly closed.

After refilling operations, allow the motor to run for

a brief time and check the level, as it may have

diminished due to air bubbles present in the cooling

circuit; restore the level with water.

To replace the liquid coolant, follow the operations

described in the motor operating manual.

Water cooled systems

M

20.

1

GROUNDING CONNECTION

The grounding connection to an earthed installation

is obligatory for all models equipped with a

differential switch (circuit breaker). In these groups

the generator star point is generally connected to

the machine’s earthing; by employing the TN or TT

distribution system, the differential switch

guarantees protection against indirect contacts.

In the case of powering complex installations

requiring or employing additional electrical protection

devices, the coordination between the protection

devices must be verified.

For the grounding connection, use the terminal

(12); comply to local and/or current regulations in

force for electrical installations and safety.

12/06/03 M20-R-HO2-GB

Page 20

© MOSA 1.0-11/05

ENGINE STARTING AND USE

DSP 2x400 PSX

DSP 600 PS/PSX

M

21

Check daily

NOTE

Do not alter the factory adjustment of the

engine and do not touch the sealed parts.

1500 / 1800 RPM ENGINES

These engines start their normal operating speed.

IGNITION KEY

OFF

ON

START

STARTING THE ENGINE

Introduce the key (Q1), turn it clockwise completely,

leaving it as soon as the engine starts.

for safety reason the key must be kept by

NB.:

qualified personel.

Let the engine run for some minutes before drawing

the load.

ENGINE PROTECTION (EP5)

The EP5 device monitors the engine oil pressure,

the engine water temperature and the rpm of the

engine. If the oil pressure is too low, the water

temperature too high or the speed too high, the

device shuts-down the engine. For a few seconds

after the engine is started the shut-down function is

inhibited to allow the engine to start.

The ingnition key is a part of the EP5

engine protection device and has

three positions.

M5.1 (yellow) Fuel

reserve

M5.2 (yellow)

M5.3

c

M5.2

M5.1

Battery charge

M5.3 (red)

Overspeed

M5.4 (red) High

temperature

M5.5 (red) Low oil

M5.6

M5.5

OFF

M5.4

a

b

M

pressure

STOP

M5.6 (green)

Protection unit on

LOW OIL PRESSURE (M5.5)

In the event of low oil pressure the LED lights and

the engine is shut-down.

HIGH TEMPERATURE (M5.4)

If the water temperature is too high the LED lights

and the engine is shut-down.

OVERSPEED (M5.3)

If the engine speed goes over the preset value the

LED lights and the engine is shutdown. The nominal

frequency (50 or 60 Hz) is monitored .

FUEL RESERVE (M5.1)

If the fuel level reaches the reserve level the LED

lights and the sirene sounds and the engine is shutdown.

BATTERY CHARGE (M5.2)

It the battery is not being charged the LED light but

the engine does not stop.The visual signal will stay

on until until the charging system is repaired.

STOP BUTTON

The stop button can be used to stop the engine at

any time. Push and hold the button until the engine

stops.

CAUTION

RUNNING-IN

During the first 50 hours of operation, do not use

more than 60% of the maximum output power of

the unit and check the oil level frequently, in any

case please stick to the rules given in the engine

use manual.

28/11/05 88412-GB

Page 21

© MOSA 1.0-11/05

STOPPING THE ENGINE

Before stopping the engine it is compulsory to:

- disconnect or shut off any loads which are

connected to the unit auxiliary outputs.

- stop welding

DSP 2x400 PSX

DSP 600 PS/PSX

M

22

To stop the engine:

OFF

ON

START

Turn the starter key to the off position.

28/11/05 88412-GB

Page 22

© MOSA 1.0-11/05

Comandi

Controls

Commandes

Bedienelemente

DSP 2x400 PSX

M

31

Pos. Descrizione Description Description Referenzliste

Presa di saldatura (+)

9

Presa di saldatura (-)

10

Presa di messa a terra

12

Presa di corrente in c.a.

15

Protezione termica motore

59A

Protezione termica corrente aux

59B

Prot. termica alim. 42V trainafilo

59C

Protezione termica elettropompa

59F

Indicatore livello combustibile

C2

Interruttore differenziale (30mA)

D

Presa di corrente 48V (c.a.)

I2

Contaore

M

Unità controllo motore EP5

M5

Voltmetro

N

Selettore modalità saldatura

Q7

Amperometro di saldatura

S

Regolatore corrente di saldatura

T

Voltmetro tensione saldatura

V

Comando invertitore di polarità

V4

Presa per comando a distanza

X1

Welding socket ( + )

Welding socket ( - )

Earth terminal

A.C. socket

Engine thermal switch

Aux current thermal switch

Supply thermal switch wire

feeder-42V

Fuel injection pump thermal

switch

Fuel level light

G.F.I.

48V A.C. socket

Hour counter

Engine control unit EP5

Voltmete

Welding selector mode

Welding ammeter

Welding current regulator

Welding voltage voltmeter

Polarity inverter control

Remote control socket

Prise de soudage ( + )

Prise de soudage ( - )

Prise de mise à terre

Prises de courant en c.a.

Protection thermique moteur

Protection thermique courant aux.

Protection thermique alimentation 42V fil

Protection thermique électro-pompe

Indicateur niveau carburant

lnterrupteur différentiel

Prise de soudage 48V (c.a.)

Compte-heures

Protection moteur EP5

Voltmètre

Sélecteur madalité soudage

Ampéromètre de soudage

Régulateur courant soudage

Voltmètre tension soudage

Commande inverseur polarité

Prise pour télécommande

Schweißbuchse (+)

Schweißbuchse (-)

Erdanschluß

Steckdose AC

Thermoschutz Motor

Thermoschutz Hilfsstrom

Thermoschutz Drahtvorschub

Thermoschutz elektropumpe

Anzeige Kraftstoffpegel

FI-Schalter (GFI)

Steckdose 48V AC

Stundenzähler

Motorschutz EP5

Voltmeter

Schweissschalter

Amperemeter Schweißstrom

Schweißstromregler

Voltmeter Schweißspannung

Polwendeschalter

Steckdose Fernbedienung

18/11/05 88412-I

Page 23

USE AS A WELDER DSP

© MOSA 1.0-04/02

ATTENTION

Access to non qualified personnel is prohibited

in proximity of these areas:

- the control panel (front-end) - the engine exhaust

fumes - the welding process.

This symbol (regulation EN 60974-1 on safety

requirements for arc welding apparatus)

indicates that the engine driven welder is

suitable for use in environments with an

increased risk of electrical shock.

WELDING CABLE CONNECTION

Fully insert the welding cable plugs into the

corresponding sockets turning them clockwise to

lock them in position.

M

32

PUSH AND

TWIST

Make sure that the ground clamp, whose cable

☞

must be connected to the + or - terminal,

depending on the type of electrode, makes a

good connection and is near to the welding

posítion.

Pay attention to the two polarities of the welding

circuit, which must not come in electric contact

between themselves.

21/04/04 M32_DSP_GB

Page 24

© MOSA 1.0-04/02

USE WELDING DIGITAL CONTROLM33.1

GETTING STARTED

1) After having prepared the machine (charged the

battery, put in oil and fuel) the machine is ready

for operation.

Before starting the engine please note the following:

- The welder should only be operated by qualified

personnel with experience in working with engine

driven welders.

- Check the oil level daily. Fuel should be put in

before starting the engine.

- Before using the welder or the auxiliary power let

the engine warm up and before stopping the engine

let it run without load to cool down.

Refer to the following instructions regarding the

function of the various controls on the front panel.

OFF

ON

START

Start the engine of the welder

2)

3) Turn the welding current/voltage

adjusting knob to the minimum

setting.

SETTING THE WELDING PROCESS

There is a manual switch for selecting the various

welding processes on the welding control panel.

There are 5 processes to choose from:

1 for TIG welding

3 for STICK welding (electrode)

1 for MIG/MAG welding (continuous wire).

The switch can also be set to “stand-by” (first

position). In this position there is no current at the

welding connections; led “ON” off.

The process can be selected either before or after

starting the motor powered welder.

After selecting the mode, the “ON” LED lights up

except for the MIG/MAG mode which can only be

selected when the button on the torch is pressed.

11/10/04 M33_WDC_GB

Page 25

USE WELDING DIGITAL CONTROLM33.2

© MOSA 1.0-10/04

TIG MODE

Contact starting TIG

This position is specifically for TIG welding. To create the arc simply place the tip of the TIG electrode

on the piece that requires welding then gently move

the tip away. The arc starts automatically and at the

same time the welding current rises to the preset

value, first using the welding current adjustment

knob which is on the lower part of the control panel.

The welding current can be adjusted continuously

from a minimum of 10 A to a maximum which

depends on the power of the machine 400 A, 500 A,

600 A.

Inversion of polarity (Optional, available on

request)

In order to invert polarity, press the switch on the

remote control unit.

By selecting “inversion” the “ON” LED switches off

and the voltage at the welding socket becomes

zero. The power contactor is witched inside the

electrical box and the voltage reappears at the

welding sockets. The “ON” LED switches back on

at the same time.

The “Invert polarity” LED on the front panel near the

welding current adjuster switches on .

You cannot invert polarity in “MIG/MAG” mode.

WARNING

For EP1 version it is compulsory to accelerate

the engine manually.

STICK MODE (Electrode)

Features C.C. (Constant Current)

There are three stick modes which feature

increasing “arc forces” so that the arc has different

levels of penetration according to the electrode

and/or welding position.

MIG/MAG MODE (continuous wire)

Features C.V. (Constant Voltage)

All wire type welding processes can be carried out,

naked or coated.

The voltage can be adjusted using the same knob

which adjusts the current in STICK mode.

Adjustment is continuous and goes from a minimum

of 15 V to a maximum of 36V, 40 V.

Optional remote control

The welding current can also be set from a distance

using the optional remote control. Once the remote

control is connected to the connector (X1), the

current is controlled by the remote control. To return

to front panel control remove the connector.

Optional VRD program (Voltage Reduction Device

VRD)

When you choose the program stick or stick arc

force the Open Circuit Voltage (OCV) go up bat

only for about 3”, than the OCV go down about 11V

and stop there, until the welder start welding.

When you make a short circuit with the stick the

OCV immediately go up, so you can start to welding.

VRD don’t work with the program MIG-MAG.

PROTECTIONS

The Welding Digital Control features 3 protections

for the control and chopper.

1) “ON” LED blinking

When the engine of the welder is

started the control unit automatically

goes to the stand by mode for few istants (stand-by

LED on) and performs a self-diagnosis of the current

sensor connector and power source voltage + 15V;

than the last process is loaded (on led turned ON).

In case of malfunction the “ON” LED blinks.

2) Red LED blinking

The chopper has a thermal protection,

which intervenes in case the operating

temperature exceeds 85°C.

If the protection intervenes, the red LED begins to

flash and the welding current/voltage goes to zero.

In this case do not switch off the welder, since the

alternator fan will help cool down the chopper more

quickly.

After a few minutes, the LED will automatically

switch itself off and the welding voltage/current will

once again be available at the plugs.

3) Red LED continuously lit

If an anomalous current is detected in

the chopper, the control blocks the

conversion immediately, the output

welding current/voltage goes to zero and the red

LED lights up. To reset everything, it is necessary

to switch off the machine.

If the protections 1) and 3) should intervene, it is

best to immediately contact the nearest authorised

Service Centre.

11/10/04 M33_WDC_GB

Page 26

USE WELDING DIGITAL CONTROLM33.3

© MOSA 1.0-10/04

WIRE WELDING with constant voltage (C.V.)

“Wire welding” can be performed in two modes:

”short arc” or “spray arc.”

TERMS

1) “Short” refers to the way of transferring the

material (wire) to the work piece.

In this case, each time a drop of molten material

is formed at the tip of the wire, assuming that the

rod continues to advance, the tip touches the

molten weld pool and is combined with it,

provoking a very brief short circuit - hence the

term “Short” is commonly used.

“Spray” refers to the transfer of material in the

2)

form of tiny molten droplets which, by means of

the arc itself, pass into the molten weld pool as if

they were sprayed by the arc.

“Short arc” welding requires a much lower arc

voltage than “spray arc,” on the order of 25% less.

The passage from “short arc” to “spray arc” occurs

automatically by setting a higher operating voltage,

if using inert gases or a mixture of gases, but not

with pure CO

. With pure CO2 the “spray arc” occurs

2

only in part and, in any case, over a wide area

resulting in excessive splatter.

“Short arc” welding can be performed with low

currents, in relation to the diameter of the wire and

is, therefore, especially suitable when working with

thin material or in cases where the welding heat

could create warping problems.

“Spray arc” welding requires higher arc voltages,

which also imply higher currents for an equal size

of wire in respect to “short arc” and is used with

medium/high sheet thicknesses.

For high currents with thick materials, it is preferred

with respect to “short arc”.

“Spray arc” welding is ideal for welding aluminium

or magnesium.

11/10/04 M33_WDC_GB

Page 27

USE WELDING DIGITAL CONTROLM33.4

© MOSA 1.0-10/04

WIRE FEEDER CONNECTION

Model WF4

Connect the wire feeder to the welder with the

welder turned off:

- Welding cable between the machine’s (9) welding

plug (+) and the wire feeder.

- Welding cable between the machine’s (10) welding

plug (-) and the piece to be welded.

- Control/power cable between the machine’s

connector (X1) and the corresponding connector

on the wire feeder.

Start the machine welder

The “ON” LED will be off and will turn on only when

there is voltage at the welding plugs (and therefore

at the wire).

The voltage is only present when the welding torch

button is pressed.

The setting of the welding voltage is done using the

knob on the wire feeder.

The adjusting knob on the welder is automatically

inhibited.

WARNING

The connection of other brands of 42V AC wire

feeders to the front panel connection can be

done ONLY if wire feeder connector has the

same configuration as showed below.

NAME OF

CONTACT

A (electric ground)

B

C (5 V d.c.)

D

E

F (5 V d.c.)

G

H (welding ground)

I (44 - 48V a.c.)

J (44 - 48V a.c.)

DESCRIPTION

To potentiometer RC1 "terminal

a"

To potentiometer RC1"central b"

To potentiometer RC1 "terminal

c"

short circuit with contact "C"

To switch "Polarity Inverter"

(Close for negative polarity)

Return from switch on CV welding

gun, 1-phase (44 - 48V a.c.)

Welding ground for d.c. voltmeter

on wire feeder

Voltage supply for wire feeder

11/10/04 M33_WDC_GB

Page 28

USE AS A GENERATOR

© MOSA 1.0-04/02

WARNING

It is strictly forbidden to connect the group to

the public mains and/or to any other source

of electric power.

GENERATION IN AC (ALTERNATING CURRENT)

Make certain of the efficiency of the ground

connection (12) - See page M20 -.

Position the G.F.I. switch to ON.

Voltage is now immediately available to the AC

☞

sockets.

Verify that the voltmeter displays the nominal voltage

value + 10%.

Connect the electric devices to be powered to the

AC sockets, using suitable plugs and cables in

good condition.

Verify that the electrical characteristics (voltage/

☞

frequency/power) of the device being powered are

compatible with those of the generator.

Low frequency and/or voltage can irreparably

damage some electrical devices.

Verify that the ground lead of the electrical appliance/

tool to be powered is correctly connected to the

terminal of the plug.

For double insulation devices with the symbol

☞

, the plug’s ground terminal does not need

to be grounded.

THERMAL PROTECTION

The monophase outputs are protected against

overloads by the thermal protection (59B).

When the rated current is exceeded, the protection

intervenes to cut off the voltage to the AC socket.

. Note: the intervention of the thermal protection is

not instantaneous, but reacts according

to an overcurrent/time characteristic, whereby the

greater the overcurrent the quicker the intervention.

In case of intervention by the protection device,

verify that the total power for the loads connected

does not exceed the declared rating and decrease

if necessary. Disconnect the loads and wait a few

minutes to allow the thermal protection to cool down.

WELDING DIGITAL CONTROL

DSP

M

37

Before resetting by pressing

the central button and then

PUSH TO

RESET

connect the load again.

If the protection should

intervene again, replace it with another one with

matching intervention current specifications and/or

contact the Service Department.

. Note: do not forcibly hold the central button of the

thermal protection device to prevent its intervention,

as this could irreparably

damage the unit’s

alternator.

Note: the three phase output does not require

☞

any protection against overcurrents, since it uses

a self-protecting asynchronous type alternator.

GROUND FAULT INTERRUPTOR SWITCH

The high-sensitivity ground fault interruptor switch

[G.F.I.] (30mA) (D), guarantees protection against

indirect contacts due to faulty ground currents .

When the G.F.I. switch picks up a faulty ground

current that is higher than 30mA, it intervenes by

immediately cutting off voltage to the AC sockets.

In case of intervention by this protection

device, reset the G.F.I. switch by moving

the lever to the ON position. In case of

another intervention, verify that there are

no faults in the tools connected, or

replace the G.F.I. switch with another

one of matching specifications and/or contact the

Service Department.

Notes: Verify the operation of the G.F.I. switch

☞

at least once a month by pressing the TEST button.

The generator must be running and the G.F.I. lever

in the ON position.

SIMULTANEOUS USE

The welder’s alternator permits the simultaneous

use of auxiliary power and welding current. The

auxiliary power available to the AC plugs (15)

diminishes as the welding current drawn increases.

The table on page M52 TECHNICAL

SPECIFICATIONS shows the amount of auxiliary

power available as the welding current varies.

COMBINED USE

The output available from the various auxiliary power

sockets is limited, not only by the declared output of

the unit but also by the capacity of each individual

socket.

09/04/02 M37DSP-GB

Page 29

© MOSA 1.0-04/02

RC1 REMOTE CONTROL

DSP

M

38.9

Is it possible to connect the RC1, to all DSP engine driven

welders.

The remote control RC1, which regulates the welding current

in the CC mode and the welding voltage in the CV mode, is

connected to the front panel by means of a multipole connector.

When the remote control is connected to the remote control

connector (8), it is functional and automatically excludes the

front panel regulation. The remote control can also be

connected to the connector on the wire feeder front panel but

in this case it is necessary to switch the wire feeder commutator

so it can operate.

The polarity inverter (64A), if installed, can be operated from

the remote control.

PUSH AND

SCREW TIGHT

Adjust the welding current control knob to the correct current

for the diameter and type of electrode being welded.

ATTENTION

When the RC1 is not used, it is necessary to disconnect

the multipole connector

09/04/02 M38GB

Page 30

TROUBLE SHOOTING DSP - EP5

© MOSA 1.0-05/05

PROBLEM POSSIBLE CAUSE WHAT TO DO

WELDING

P1 All functions performed

by the WDC are regular,

but there is no tension

on the welding sockets

selection of welding

processes or in their

confirmation on other

functions performed

by the WDC

1) Position of regulation potentiometer incorrect knob

1) Adjust the position of the WDC regulation knob on the

potentiometer spindle so that the potentiometer is not

completely at the end of its travel when the knob reaches its

minimum position. Idem for the RC1 remote control knob.

1) Replace the WDC.1) WDC defectiveP2 Malfunction in the

M

40.1

Blinking “ON” LED 1) Current sensor connector

P3

P3

2)Aux power voltage value

(±15V) too high or too low

P4 Blinking red LED 1) The chopper thermic

protection is intervening

2) Temperature sensor situated

on chopper (NTC resistor)

short circuited or open.

3) WDC defective

P5 Red LED always on

1) WDC defective

2) Chopper defective

3) Current sensor defective

1) Connector P3 not inserted or defective - see drawing 5

2) Check the aux trasformer, see drawing 1

1) The output is inhibited automatically; let the motor continue

to run to cool down the chopper, and after a few minutes the

LED will automatically switch off and there will be current/

voltage once again at the welding sockets.

2) Check chopper connector, drawing 2, from pin 1-2. The

resistor must be bigger than 1800 Ω and less than 25 KΩ,

otherwise the led blinking.

Replace the chopper.

In the meantime you can work cutting the wire which arrives

to pin 1 - pin 2 and put on it one resistor 10 KΩ.

In this case the thermic protection don’t work but you can

use the machine.

3) Replace the WDC.

1) Switch off the machine and start it up again; if the LED remains

off try to weld, verifying that the welding is regular; if the LED

lights up again. Replace the WDC.

2) Check the chopper as shown on drawing 2.

3) Replace the sensor.

P6 PHG1 remote does not

operate.

P7 The welding current

is always at max or

always at minimum

P8 No voltage at the

welding sockets in

CV mode

P9

No welding or

generation output

1) Remote control (or cable)

defective.

2) WDC defective.

1)Potentiometer on WDC

defective

2) WDC defective

3)Welding current sensor

defective

1) Defective wire feeder cable

2) Defective wire feeder

3) Defective WDC

1) Short circuit of chopper.

2) Short circuit of generation

unit.

3) Alternator defective.

1) Check the remote control as drawing 4

2) Replace the WDC

1) Check from pin 1-12 connector P4 (pin 1 - ground see

drawing 3)

2) Replace the WDC

3) Replace the current sensor

1) Check the connections pin to pin of the wire

2) Check the wire feeder

3) Without wire feeder cable put the pin I in short circuit with G

on remote control connector, the led ON must be light - WDC

ok otherwise change WDC

1) Disconnect the chopper and re-start the machine; if there is

now an output present, replace the chopper

2) Disconnect the auxiliary output circuit and re-start the machine;

if there is now an output present, there is a short circuit in the

auxiliary output circuit or in one of the components

3) Disconnect all outputs on the alternator (welding and

12/05/05 M40DSP/EP5-GB

Page 31

© MOSA 1.1-11/05

TROUBLE SHOOTING DSP - EP5

M

40.2

PROBLEMS

P10The welding tension after

3 sec isn’t less enough

(plus in 12V dc)

P1 Voltmeter shows no voltage

or low voltage but actual

voltage at the sockets is OK.

P2 No three-phase voltage

present at the socket(s).

P3 No single phase voltage one

socket but voltmeter reading

is normal and there is

voltage on the other sockets.

POSSIBLE CAUSE WHAT TO DO

generation unless the output going to the condensers)

and check the capacity of the condensers. Restart the

machine, if there is still no output, replace the alternator.

WELDING WITH V.R.D.

1)Net R.C. defective or

1) Check the net R.C. Check the connections.

disconnected from + or welding socket

2) WDC defective.

2) Replace the WDC.

GENERETING

1) Voltmeter malfunction 1) Replace the voltmeter.

1)Differential switch not

1)Turn on the switch.

inserted

2)Differential switch

2)Replace the switch.

malfunction

1)Intervention of thermal

1)Push in the thermal switch.

switch due to excessive

current.

2) Thermal switch malfunction.

2) Replace the thermal switch.

P4 No voltage present.

(See problem P9)

1) Short circuit present on the

generator outputs.

MOTOR

P1 The engine does not start

or stops immediately after

startup.

1) Low battery voltage, battery

dead or defective.

2) Presence of air in the fuel

supply circuit.

3)Starting system thermal

switch

4) Fuel injection pump thermal

switch

5) Engine solenoid

P2 Engine stops due to

intervention of EP5/ES.

1) Engine temperature too high

or insufficient oil pressure.

2) High temperature sensor or

oil pressure defective.

3) EP5/ES protection defective.

P3 The battery is not charged. 1) Battery charger alternator

defective.

2) Battery charger warning light

defective.

1)Disconnect all outputs on the generator except for

those on the condensers and re-start machine; check

for voltage on condensers.

1) Check the level of the electrolyte. Fill or replace the

battery.

2) Carry out de-aeration on the fuel system. See engine

operating manual.

3) Push in the thermal switch. In case the problem persists,

check the electrical circuit and eliminate the problem.

Call an authorised service centre.

4) Push in the thermal switch. In case the problem persists,

check the electrical circuit and eliminate the problem.

Call an authorised service centre.

5) See engine manual

1)Check oil level.

2)Replace the malfunctioning sensor.

3)Replace the protection.

1)Replace

2)Replace

P4 For other problems, refer to

the attached engine manual

18/11/05 M40DSP/EP5-GB

Page 32

© MOSA 1.0-05/05

TROUBLE SHOOTING DSP - EP5

CHECK THE CHOPPER FROM THE

CONNECTOR

CHOPPER CONNECTOR

CHECK MOSFET ON CHOPPER

M

40.3

OUTPUT

OUTPUT

OUTPUT

Check the transformer in this way:

18 Vca

18 Vca

25 Vca

input: 220 Vac

output: 18 Vac, 25 Vac, 10 Vac

10 Vca

OUTPUT

2

4

6

8

10

12

14

FOR THE CHECK HOLD THE CONNECTOR AS SHOWED ABOVE

WITH A TESTER CHECK THERE ARE

Pin 1-2 1,8 ÷ 25 KΩ

Pin 3-4 (open)

Pin 5-6 (open) (open) 3,3 KΩ

Pin 7-8 (open) 3,3 KΩ 3,3 KΩ

Pin 9-10 3,3 KΩ 3,3 KΩ 3,3 KΩ

Pin 11-12 3,3 KΩ 3,3 KΩ 3,3 KΩ

Pin 13-14 3,3 KΩ 3,3 KΩ 3,3 KΩ

DSP 400 - 415

1

3

5

7

9

11

13

DSP 2x400 - 500

DSP 600-615

DRAWING 1

DRAWING 2

How to check the potentiometer put on WDC

1)Start the welding without load (at max RPM)

2)Take the voltage from pin 1 - pin 12 on

connector P4

3)

Position

Knob

Minimum

Max

Voltage

from pin 1 - pin 12

on P4

0 Vdc

4,5 - 4,7 Vdc

DRAWING 3

12/05/05 M40DSP/EP5-GB

Page 33

© MOSA 1.0-05/05

TROUBLE SHOOTING DSP - EP5

Put the knob on RC1 at minimum/max, put one ohmmeter

from pin A - B and measure the resistance.

M

40.4

P1 Supply connector

P2 Chopper connector

P3 Current sensor connector

P4 - P5 Free

DRAWING 4

Knob

Minimum

Max

Resistance

50 ÷ 100 Ω

4,5 - 4,7 KΩ

P1

P2

P5

P3

P4

DRAWING 5

12/05/05 M40DSP/EP5-GB

Page 34

© MOSA 1.0-09/05

MOVING

PARTS

can injure

MAINTENANCE

WARNING

● Have qualified personnel do maintenance and troubleshooting work.

● Stop the engine before doing any work inside the machine. If for any

reason the machine must be operated while working inside, pay

attention moving parts, hot parts (exhaust manifold and muffler,

etc.) electrical parts which may be unprotected when the machine

is open.

● Remove guards only when necessary to perform maintenance, and

replace them when the maintenance requiring their removal is

complete.

● Use suitable tools and clothes.

● Do not modify the components if not authorized.

- See pag. M1.1 -

M

43

HOT surface

can

hurt you

NOTE

By maintenance at care of the utilizer we intend all the

operatios concerning the verification of mechanical parts,

electrical parts and of the fluids subject to use or

consumption during the normal operation of the machine.

For what concerns the fluids we must consider as

maintenance even the periodical change and or the refills

eventually necessary.

Maintenance operations also include machine cleaning

operations when carried out on a periodic basis outside

of the normal work cycle.

The repairs cannot be considered among the

maintenance activities, i.e. the replacement of parts

subject to occasional damages and the replacement of

electric and mechanic components consumed in normal

use, by the Assistance Authorized Center as well as by

MOSA.

The replacement of tires (for machines equipped with

trolleys) must be considered as repair since it is not

delivered as standard equipment any lifting system.

The periodic maintenance should be performed according

to the schedule shown in the engine manual. An optional

hour counter (M) is available to simplify the determination

of the working hours.

ENGINE and ALTERNATOR

PLEASE REFER TO THE SPECIFIC MANUALS

PROVIDED.

VENTILATION

Make certain there are no obstructions (rags, leaves or

other) in the air inlet and outlet openings on the machine,

alternator and motor.

ELECTRICAL PANELS

Check condition of cables and connections daily.

Clean periodically using a vacuum cleaner, DO NOT

USE COMPRESSED AIR.

DECALS AND LABELS

All warning and decals should be checked once a year

and replaced if missing or unreadable.

STRENUOUS OPERA TING CONDITIONS

Under extreme operating conditions (frequent stops and

starts, dusty environment, cold weather,extended periods

of no load operation, fuel with over 0.5% sulphur content)

do maintenance more frequently.

BATTERY WITHOUT MAINTENANCE

DO NOT OPEN THE BATTERY

The battery is charged automatically from the battery

charger circuit suppplied with the engine.

IMPORTANT

In the maintenance operations avoid that

polluting substances, liquids, exhausted oils,

etc. bring damage to people or things or can

cause negative effects to surroindings, health

or safety respecting completely the laws and/

or dispositions in force in the place.

Check the state of the battery from the colour of the

warning light which is in the upper part.

- Green colour: battery OK

- Black colour: battery to be recharged

- White colour: battery to be replaced

NOTE

THE ENGINE PROTECTION NOT WORK WHEN THE

OIL IS OF LOW QUALITY BECAUSE NOT CHARGED

REGULARLY AT INTERVALS AS PRESCRIBED IN

THE OWNER’S ENGINE MANUAL.

05/09/05 M43GB

Page 35

STORAGE GE_, MS_, TS_

© MOSA 1.0-06/00

In case the machine should not be used for more than 30

days, make sure that the room in which it is stored

presents a suitable shelter from heat sources, weather

changes or anything which can cause rust, corrosion or

damages to the machine.

Have qualified personnel prepare the machine for

☞

storage.

GASOLINE ENGINE

M

45

In case of necessity for first aid and of fire prevention,

see page. M2.5.

Start the engine: lt will run until it stops due to the lack of

fuel.

Drain the oil from the engine sump and fill it with new oil

(see page M25).

Pour about 10 cc of oil into the spark plug hole and screw

the spark plug, after having rotated the crankshaft several

times.

Rotate the crankshaft slowly until you feel a certain

compression, then leave it.

In case the battery, for the electric start, is assembled,

disconnect it.

Clean the covers and all the other parts of the machine

carefully.

Protect the machine with a plastic hood and store it in o

dry place.

DIESEL ENGINE

For short periods of time it is advisable, about every 10

days, to make the machine work with load for 15-30

minutes, for a correct distribution of the lubricant, to

recharge the battery and to prevent any possible bloking

of the injection system.

IMPORTANT

In the storage operations avoid that

polluting substances, liquids, exhausted

oils, etc. bring damage to people or

things or can cause negative effects to

surroindings, health or safety respecting

completely the laws and/or dispositions

in force in the place.

For long periods of inactivity, turn to the after soles

service of the engine manufacturer.

Clean the covers and all the other parts of the machine

carefully.

Protect the machine with a plastic hood and store it in a

dry place.

30/00/00 M45GB

Page 36

CUST OFF GE_, MS_, TS_

© MOSA 1.0-03/00

Have qualified personnel disassemble the

☞

machine and dispose of the parts, including the

oil, fuel, etc., in a correct manner when it is to

be taken out of service.

M

46

As cust off we intend all operations to be made, at

utilizer’s care, at the end of the use of the machine.

This comprises the dismantling of the machine, the

subdivision of the several components for a further

reutilization or for getting rid of them, the eventual

packing and transportation of the eliminated parts

up to their delivery to the store, or to the bureau

encharged to the cust off or to the storage office,

etc.

The several operations concerning the cust off,

involve the manipulation of fluids potentially

dangerous such as: lubricating oil and battery

electrolyte.

The dismantling of metallic parts liable to cause

injuries or wounds, must be made wearing heavy

gloves and using suitable tools.

The getting rid of the various components of the

machine must be made accordingly to rules in force

of law a/o local rules.

Particular attention must be paid when getting

rid of:

lubricating oils, battery electrolyte, and

inflamable liquids such as fuel, cooling liquid.

In case of necessity for first aid and fire prevention,

see page M2.5.

IMPORTANT

In the cust-off operations avoid that

polluting substances, liquids, exhausted

oils, etc. bring damage to people or

things or can cause negative effects to

surroindings, health or safety respecting

completely the laws and/or dispositions

in force in the place.

The machine user is responsible for the observance

of the norms concerning the environment conditions

with regard to the elimination of the machine being

cust off and of all its components.

In case the machine should be cust off without any

previous disassembly it is however compulsory to

remove:

- tank fuel

- engine lubricating oil

- cooling liquid from the engine

- battery

NOTE: MOSA is involved with custing off the

machine

reparable.

This, of course, after authorization.

only for the second hand ones, when not

30/03/00 M45GB

Page 37

© MOSA 1.0-11/05

Dimensioni

Abmessungen

Dimension

DSP 2x400 PSX

M

53

18/11/05 88412-I

Page 38

© MOSA 1.4-02/06

ELECTRICAL SYSTEM LEGENDE GE_, MS_, TS_

M

60

A: Alternator

B: Wire connection unit

C: Capacitor

D: G.F.I.

E: Welding PCB transformer

F: Fuse

G: 400V 3-phase socket

H: 230V 1phase socket

I: 110V 1-phase socket

L: Socket warning light

M: Hour-counter

N: Voltmeter

P: Welding arc regulator

Q: 230V 3-phase socket

R: Welding control PCB

S: Welding current ammeter

T: Welding current regulator

U: Current transformer

V: Welding voltage voltmeter

Z: Welding sockets

X: Shunt

W: D.C. inductor

Y: Welding diode bridge

A1: Arc striking resistor

B1: Arc striking circuit

C1: 110V D.C./48V D.C. diode bridge

D1: E.P.1 engine protection

E1: Engine stop solenoid

F1: Acceleration solenoid

G1: Fuel level transmitter

H1: Oil or water thermostat

I1: 48V D.C. socket

L1 : Oil pressure switch

M1 : Fuel warning light

N1: Battery charge warning light

O1: Oil pressure warning light

P1: Fuse

Q1: Starter key

R1: Starter motor

S1: Battery

T1: Battery charge alternator

U1: Battery charge voltage regulator

V1: Solenoid valve control PCBT

Z1 : Solenoid valve

W1: Remote control switch

X1: Remote control and/or wire feeder

socket

Y1: Remote control plug

A3: Insulation moitoring

B3: E.A.S. connector

C3: E.A.S. PCB

D3: Booster socket

E3 : Open circuit voltage switch

F3: Stop push-button

G3: Ignition coil

H3: Spark plug

I3: Range switch

L3: Oil shut-down button

M3: Battery charge diode

N3: Relay

O3: Resistor

P3: Sparkler reactor

Q3: Output power unit

R3: Electric siren

S3: E.P.4 engine protection

T3 : Engine control PCB

U3: R.P.M. electronic regulator

V3: PTO HI control PCB

Z3 : PTO HI 20 l/min push-button

W3: PTO HI 30 l/min push-button

X3: PTO HI reset push-button

Y3: PTO HI 20 l/min indicator

A4: PTO HI 30 l/min indicator

B4: PTO HI reset indicator

C4: PTO HI 20 l/min solenoid valve

D4: PTO HI 30 l/ min solenoid valve

E4 : Hydraulic oil pressure switch

F4: Hycraulic oil level gauge

G4: Preheating glow plugs

H4: Preheating gearbox

I4: Preheating indicator

L4 : R.C. filter

M4: Heater with thermostat

N4: Choke solenoid

O4: Step relay

P4: Circuit breaker

Q4: Battery charge sockets

R4: Sensor, cooling liquid temperature

S4: Sensor, air filter clogging

T4 : Warning light, air filter clogging

U4: Polarity inverter remote control

V4: Polarity inverter switch

Z4: Transformer 230/48V

W4: Diode bridge, polarity change

X4: Base current diode bridge

Y4: PCB control unit, polarity inverter

A6: Commutator/switch

B6: Key switch, on/off

C6: QEA control unit

D6: Connector, PAC

E6: Frequency rpm regulator

F6: Arc-Force selector

G6: Device starting motor

H6: Fuel electro pump 12V c.c.

I6: Start Local/Remote selector

L6: Choke button

M6 : Switch CC/CV

N6: Connector – wire feeder

O6: 420V/110V 3-phase transformer

P6: Switch IDLE/RUN

Q6: Hz/V/A analogic instrument

R6: EMC filter

S6: Wire feeder supply switch

T6 : Wire feeder socket

U6: DSP chopper PCB

V6: Power chopper supply PCB

Z6 : Switch and leds PCB

W6: Hall sensor

X6: Water heather indicator

Y6: Battery charge indicator

A7: Transfer pump selector AUT-0-MAN

B7: Fuel transfer pump

C7: „GECO“ generating set test

D7: Flooting with level switches

E7: Voltmeter regulator

F7: WELD/AUX switch

G7: Reactor, 3-phase

H7: Switch disconnector

I7: Solenoid stop timer

L7: "VODIA" connector

M7: "F" EDC4 connector

N7: OFF-ON-DIAGN. selector

O7: DIAGNOSTIC push-button

P7: DIAGNOSTIC indicator

Q7: Welding selector mode

R7: R.C. net

S7: 230V 1-phase plug

T7: V/Hz analogic instrument

U7: Engine protection EP6

V7: G.F.I. relay supply switch

Z7 : Radio remote control receiver

W7: Radio remote control trasnsmitter

X7: Isometer test push-button

Y7: Remote start socket

A2: Remote control welding regulator

B2: E.P.2 engine protection