MORTEX G17, G18 Owner's Manual

SEALED COMBUSTION

DOWNFLOW

GAS FURNACE

This heavy duty furnace will provide you with reliable and efficient operation if maintained. Please read the entire

booklet. It contains information on furnace operation and maintenance needed to keep it operating safely and

efficiently. Thank you for choosing our product.

Keep this manual for future reference

FOR YOUR SAFETY – Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information consult a qualified

installer, service agency or the gas supplier.

FOR YOUR SAFETY- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbors phone. Follow the gas suppliers

instructions.

• If you cannot reach your gas supplier, call the fire department.

Never attempt to modify this furnace. Fire, explosion, or asphyxiation may result. If

malfunction occurs, obtain the assistance of a qualified service agent.

If not installed, operated, and maintained in accordance with the manufacturer’s

instructions, this product could expose you to substances in fuel or from fuel combustion which

are known to the State of California to cause cancer, birth defects or other

reproductive harm.

Use of furnace or air conditioning components that are not included in the Underwriters

Laboratories certification of this appliance may create a hazard, will invalidate the

certification, and will in many states make installation illegal. UL listed air conditioning

components are specified on the furnace label.

Before placing furnace in service, it must be checked to ensure it is equipped for the type of

gas being used. Failure to observe this caution may result in unsafe operation, explosion,

and/or fire or asphyxiation. Use of other components not tested in combination with this

furnace may make the equipment in violation of State Codes, may create a hazard, and may

ruin the equipment.

IMPORTANT:

If your home is located at an elevation above 2,000 feet, the gas input to the furnace should be derated (reduced). The dealer or the Gas

Company may already have applied the necessary deration to the furnace burner. They will be able to advise you if this is the case. If not,

the deration of the burner should be accomplished only by a qualified service company or the Gas Company. Deration will insure continued

use of the unit; failure to derate properly may create a hazard and will eventually render the unit inoperable.

This furnace was shipped from the factory with a gas burner orifice installed for Natural gas. If the furnace will be operating on LP gas, the

furnace burner orifice must be converted. The LP gas orifice for conversion is stored in a bag on the gas valve. It is the correct size for

operation to 2,000 feet. If the furnace will be operating on LP gas above 2,000 feet, the orifice supplied is too large to allow proper

operation. Contact your gas supplier for help to have the proper size derated orifice installed. Note: Deration of the unit is not covered by

the manufacturers warranty. This procedure is considered a part of the installation process and required to make the furnace operate properly.

Do not use this appliance if any part

has been under water. Immediately call

a qualified service technician to inspect

the appliance and to replace any gas

control which has been under water.

OWNER’S MANUAL

WARNING

WARNING

CAUTION

14

Mortex Products, Inc. / FT. WORTH, TX 76106 G17 / G18 Owner’s Manual Printed 04/04Mortex Products, Inc. / FT. WORTH, TX 76106 G17 / G18 Owner’s Manual Printed 04/04

will lock out. It will remain in lock out for one hour, at which

time the furnace will try for ignition again.

7. About 60-90 seconds after the burner lights, the furnace

blower will run.

8. When the thermostat is satisfied, the electrical circuit to the

control board is opened. At the same time the circuit to the

combustion blower and the gas valve is opened and the

burner flame will be extinguished.

The control board keeps the furnace blower running for 1-2

minutes to allow additional heat to be drawn from the heat

exchanger.

OBSERVING BURNER OPERATION

1. Observe burner to make sure it ignites and to observe the

flame color. With Natural gas, the flame will be blue with

yellow tips; with Propane gas, a yellow flame can be expected.

2. Allow furnace to heat up until the blower cycles on. (2-1/2 min.)

3. Turn wall thermostat down.

4. Observe main burner flame to make sure it shuts off.

5. Let furnace cool and blower turns off.

6. If any abnormalities should occur, such as the burner failing to

light or to turn off, the flame looks sooty or it seems to be

“floating” around inside the heat exchanger, call a qualified

service technician for service.

IF FURNACE FAILS TO OPERATE PROPERLY

1. Check setting of the wall thermostat and position of the

heat/cool switch if air conditioning is installed.

2. Check to see that electrical power is “ON”.

3. Check to see that lever on gas valve is in the “ON” position.

4. Make sure that air filters are clean, supply registers are open

and return air grilles are not obstructed.

5. Be sure that furnace flue and inlet air pipes are open and

unobstructed.

6. On Automatic Ignition furnaces only, observe the Diagnostic

Light. This light is visible through a slot on the control panel

cover and flashes when there is a service problem. The

diagnostic codes are:

Steady On: Normal Operation

One Flash: Ignition Failure

Two Flashes: Pressure switch failed closed.

Three Flashes: Limit switch open.

Five Flashes: Gas valve energized with no call for heat

Six or Rapid Flash: Reversed polarity.

If the cause for failure to operate properly is not obvious, call a

service technician or your gas supplier.

THE FURNACE CONTROLS AND THEIR FUNCTION

• Auto Ignition & Standing Pilot Units with “ONOFF” System Switch

- The switch is on the right side of the

furnace control box and turns electrical power to the furnace

on or off. It must be “ON” for the furnace to operate.

•

Standing Pilot, Heat Model with “ON-OFF-FAN”

System Switch

-The switch turns electrical power to the

furnace on or off. The switch must be set to “ON” for the

furnace to operate. To run the blower continuously without

heating, set the switch to “FAN”.

•

Limit Switch - All furnace models are protected by two (2)

temperature limit safety switches. The lower limit switch (inside

furnace control box) is an automatic reset type. The limit switch

by the furnace blower is a manual reset type.

•

Vent Limit Switch - Standing Pilot furnaces without a

combustion blower are additionally protected by a manual

reset safety switch located on the vertical combustion air inlet pipe.

•

Fan Switch - Standing Pilot furnaces have a temperature

sensing device that turns on the blower when sufficient heat

has built up inside the furnace. During warm weather, the

blower may come on periodically or operate continuously due

to heat from the pilot and the warm weather. -This is normal. If

blower operation is not desired during this time, the “ON-OFFFAN” switch may be set in the “OFF” position to cut electrical

power to the furnace.

•

Gas Valve - The gas valves for all models are 100% shut-off

type and will fail safe if, for some reason, the gas is turned off .

INSPECTION AND MAINTENANCE BY THE HOMEOWNER

•Make a visual inspection of the furnace every 30 days. Do the

following:

•

Filters - Clean filters at least every (3) months and replace as

needed. Size; 16”x20”x1”

•

Motor Lubrication - None: The combustion and air

circulator motors are permanently lubricated.

•

Return Air - On some closet installations, the return air opening

may be in the floor. DO NOT cover or obstruct these floor

openings or any other return air opening to the closet.

•

Heat Exchanger - under normal conditions, no cleaning is

needed. If cleaning becomes necessary, only a service

technician should do so. Chemicals should not be used to

clean the heat exchanger.

•

Furnace Vestibule - periodically remove furnace panels

and clean the vestibule area to remove dust and lint. Shut off

all electrical power to the unit before cleaning.

•

When you’re away - the furnace has safety controls to

shut the unit down if there is a malfunction. Therefore do not

assume it can operate unattended for prolonged time

periods. If there is a damage possibility to your home due to

freezing weather, have a neighbor check your home daily.

INSPECTION AND MAINTENANCE BY A SERVICE TECHNICIAN

Annual furnace maintenance and inspection is recommended.

• Replace air filters, and clean dust and lint from furnace and

area.

• Remove blower assembly and clean blower wheel and motor.

•Inspect the combustion chamber, flue collar and roof jack.

• Check the gas valve and gas line connections for leaks.

•Make adjustments as needed for good operation.

SEASONAL SERVICE INFORMATION

In regions where there is heavy snow accumulation, a roof jack crown

extension is recommended to prevent blockage of the roof jack

combustion air openings.

During extreme cold weather, ice may form on the furnace roof jack.

Small amounts of ice on the roof jack will present no problem to proper furnace operation. Excessive ice formation could restrict the combustion air supply to the burner causing inefficient burner operation. If

excessive ice has formed on the inlet or exhaust portions of the

roof jack, it must be carefully removed.

OWNER’S MANUAL

P/N : 61GF0010

32

Mortex Products, Inc. / FT. WORTH, TX 76106 G17 / G18 Owner’s Manual Printed 04/04Mortex Products, Inc. / FT. WORTH, TX 76106 G17 / G18 Owner’s Manual Printed 04/04

WARRANTY AND OWNERS RESPONSIBILITIES

The furnace manufacturer warrants the furnace to be free from defects

in material or workmanship for the time period stated in the warranty.

The home owner has the sole responsibility to make certain the gas

furnace has been correctly set up and converted to use the proper fuel

(LP or Natural Gas) and adjusted to operate properly.

The furnace manufacturer is not responsible for any repair costs to

correct problems due to improper setup, improper installation, furnace

control damage at installation, furnace adjustment, improper operating

procedure by the user, etc.

Some specific examples of parts or service charges incurred not

covered by the furnace manufacturers warranty are:

a) Cracked gas valve body due to over tightening at installation.

b) Converting the furnace to use another type of gas.

c) Correcting problems caused by improper gas supply pressure

to the furnace.

d) Furnace problems due to faulty installation of the furnace

venting system (roof jack).

e) Addition of a roof jack extension due to unusual wind

conditions or snow conditions.

f) Adjustments to furnace or wall thermostat.

Gas Supply

The gas supply to the home will be either Natural or Propane gas. The

furnace is factory equipped to operate on one of these gases. A tag

adjacent to the furnace gas valve specifies the type of gas your furnace

is equipped to use.

If gas to the home is different from that specified on the tag, the

furnace can be converted by following instructions on the furnace

Safety Label. Conversion parts are in the small bag attached to the

gas control valve. Make sure the proper size gas orifice is used.

The orifice size is printed on the furnace model-data label.

Natural Gas Operation

The furnace is designed for 7” WC inlet gas pressure. Pressure is

reduced to 3.5” WC by the pressure regulator in the gas valve.

LP-Propane Gas Operation

The furnace is designed for 11” WC inlet gas pressure. Pressure is

reduced to 10.0” WC by the pressure regulator in the gas valve.

SAFETY INFORMATION

For your safety, read before lighting.

The first lighting of the furnace after any home setup must be

performed by a qualified service technician.

A. If this furnace has a pilot, it must be lighted by hand. When

lighting the pilot, follow the LIGHTING INSTRUCTIONS FOR

STANDING PILOT FURNACE exactly. If this furnace does not

have a pilot, it is lighted with an ignition device which

automatically lights the burner. Do NOT try to light the burner

by hand. Follow the LIGHTING INSTRUCTIONS FOR

AUTOMATIC IGNITION FURNACE.

B. BEFORE LIGHTING, smell all around the furnace for gas.

Smell next to the floor because some gas is heavier than air

and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch and

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions. If you cannot reach

your gas supplier, call the fire department.

C. Use only your hand to move the gas lever. NEVER USE

TOOLS. If the lever will not move by hand, don’t try to repair

it. Call a service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect the

furnace and to replace any part of the control system and any

gas control which has been under water.

Lighting Instructions for Standing Pilot Furnace

1. STOP! Read the safety information.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the furnace.

4. Remove control access panels.

5. Move gas control lever to "OFF" position. Do not force. Turn

system switch on control panel to "OFF" position.

6. Wait (5) minutes to clear out any gas. Then smell for gas

including near the floor. If you smell gas, STOP! Follow "B"

in the safety information in this manual. If you don't smell

gas, go to the next step.

7. Locate the hinged pilot access door. Find pilot, follow metal

tube from gas control. The pilot is located inside the burner

compartment-adjacent to the main burner.

8. Move gas control lever to the "SET" position and hold.

Insert match in wire holder and immediately light the pilot.

Continue to hold the gas control lever for about one (1)

minute after the pilot is lit. Release lever and it will return to

the pilot position. Pilot should remain lit. If pilot goes out,

repeat steps 5 thru 8. If lever does not release or if the pilot

will not stay lit after several tries, move the gas control lever

to "OFF" and call your service technician or gas supplier.

9. Move gas control lever to "ON" position. Turn system switch

to "ON" position.

10. Replace control access panels.

11. Turn on all electric power to the furnace.

12. Set thermostat to desired setting.

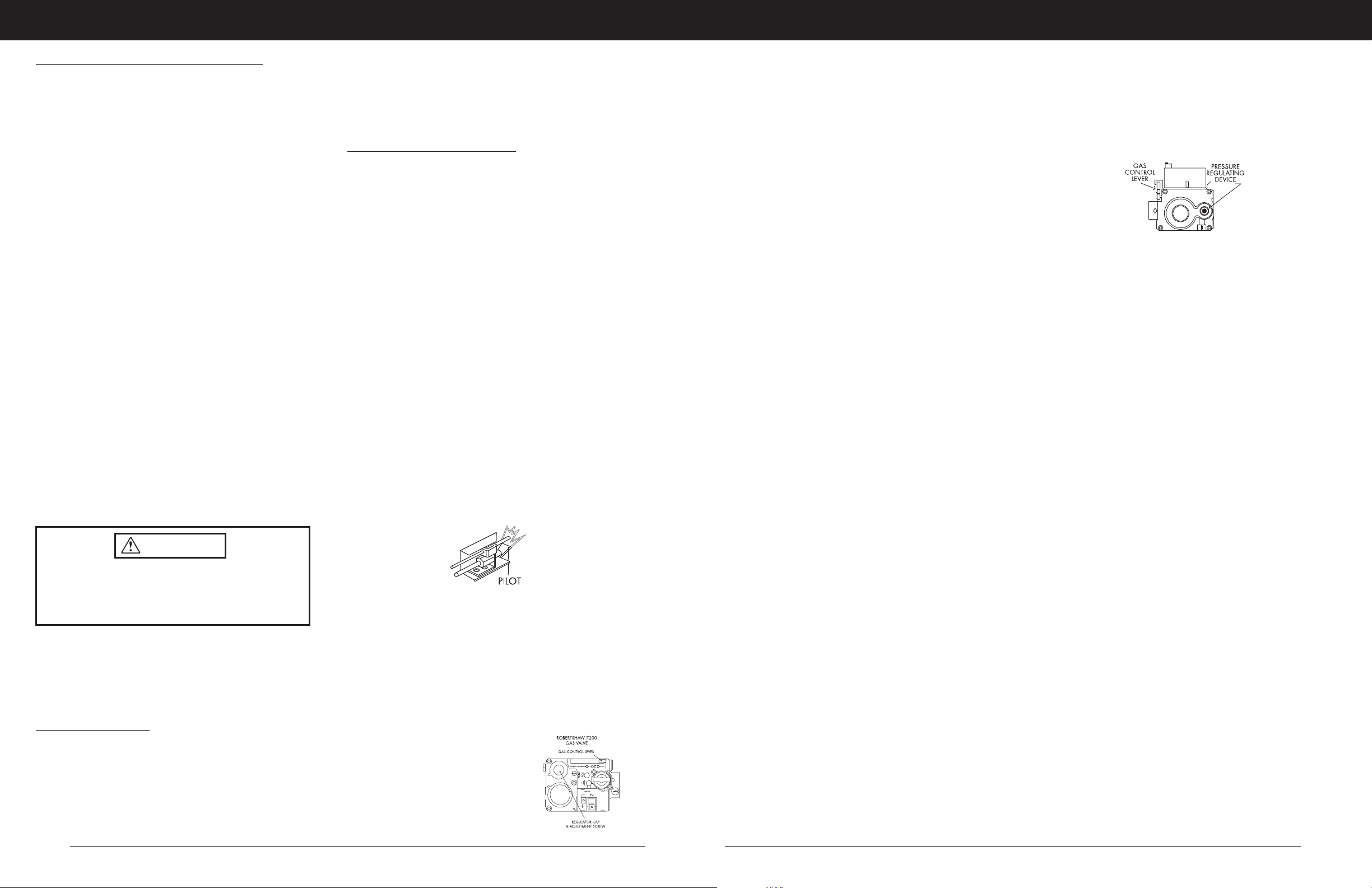

FIG.1 STANDING PILOT GAS VALVE

SEQUENCE OF OPERATION

Standing Pilot- no Combustion Blower

1. On a call for heat, the thermostat contacts close supplying

24VAC to the gas valve.

2. When the gas valve is energized it initially opens at a reduced

flow and opens fully about 30 seconds later.

3. About 1-2 minutes after the burner lights, the furnace air

circulator blower comes on.

4. When the call for heat is satisfied, the thermostat contacts open

and the gas valve shuts off the gas flow.

5. After the burner shuts off, the blower continues to run for 2-4

minutes until the furnace has cooled.

SEQUENCE OF OPERATION:

Standing Pilot-with Combustion Blower

1. On a call for heat, the thermostat contacts close and supply

24VAC to a relay.

2. The relay contacts close and energize the 120V combustion

blower motor.

3. The inlet vacuum pressure from the combustion blower closes a

set of contacts in the air pressure switch energizing the 24VAC

gas control valve.

4. When the gas valve is energized it initially opens at a reduced

flow and opens fully about 30 seconds later.

5. About 1-2 minutes after the burner lights, the furnace air

circulator blower comes on.

6. When the call for heat is satisfied, the thermostat contacts

open, the gas valve shuts off gas flow and the combustion

blower stops.

7. After the burner shuts off, the blower continues to run for 2-4

minutes, until the furnace has cooled.

TO TURN OFF GAS TO FURNACE

Standing Pilot Models

1. Set thermostat to the lowest setting.

2. Turn off all electric power to the unit if service is to be performed.

3. Remove control access panels.

4. Move gas control lever to "OFF" position. DO NOT FORCE

5. Replace control access panels.

LIGHTING INSTRUCTIONS FOR

AUTOMATIC IGNITION FURNACE

1. STOP! Read the safety information on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the burner. Do not try to light the burner by

hand.

5. Remove control access panels.

6. Push in gas control knob slightly. Valve will snap to "OFF"

position.

7. Turn system switch to "OFF" position.

8. Wait (5) minutes to clear out any gas. If you smell gas, STOP!

Follow "B" in the safety information on this label. If you don't

smell gas, go to the next step.

9. Turn gas control knob to "ON" position. Set system switch to

"ON" position.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting. Appliance will automatically

begin an ignition sequence which may take up to 60 seconds

before burner ignition is initiated.

12. After three (3) trials for ignition, if the furnace will not operate,

follow the instructions, "TO TURN OFF GAS TO APPLIANCE" and

call your service technician or gas supplier.

13. Replace control access panels.

FIG. 2 AUTO IGNITION GAS VALVE

TO TURN OFF GAS TO FURNACE

Automatic Ignition Models

1. Set thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is to be

performed.

3. Remove control access panels.

4. Push in gas control knob slightly - Valve will snap to "OFF"

position. NOTE: Knob cannot be turned to "OFF" unless knob

is pushed in slightly. DO NOT FORCE.

5. Replace control access panels.

SEQUENCE OF OPERATION

Automatic Ignition Furnace Model

This furnace has an electronic control system which automatically

supervises burner and fan operation. A green indicator light in the

control panel is lit during normal operation. The indicator light also

informs when certain basic services are needed.

In a call for heat from the room thermostat, the electronic control

system initiates an operational cycle. This results in ignition of the gas

at the burner with a hot glowing igniter. The burner will continue to

operate until the thermostat is satisfied at which time the burner flame

is extinguished.

A normal furnace cycle is:

1. When the room temperature falls below the thermostat setting,

the thermostat contacts close and activate the electronic control

board.

2. When the control board is activated, the combustion blower

turns on.

3. When the combustion blower reaches it’s normal speed, the

vacuum produced on the blowers inlet activates a switch

completing the ignition circuit to the control board.

4. For the next (1) minute, the combustion blower brings in out-

door air into the heat exchanger and the igniter begins to

glow. Then the gas valve opens and the burner lights.

5. After the burner lights, a sensor in front of the burner acts as a

flame probe to check on the presence of flame. As long as

there is a flame, the sensor will monitor it and hold the gas

valve open.

6. If the burner fails to light within 6-8 seconds after the gas valve

opens, the valve will close and the igniter will turn off. After a

short pause, the system will recycle and try again for ignition.

If the burner fails to light after three tries, the ignition system

CAUTION

The furnace must be converted by a qualified technician.

Improper conversion can cause unsafe operation,

explosion, and/or fire and asphyxiation. DO NOT

re-drill a burner orifice. If the orifice size must be

changed, use only a new orifice.

OWNER’S MANUAL

Loading...

Loading...