MORTEX DOWNFLOW ELECTRIC FURNACE Installation Instructions Manual

MORTEX

INSTALLATION INSTRUCTIONS

DOWNFLOW ELECTRIC FURNACE

A. Introduction

Mortex Downflow Electric Furnaces are specifically

designed for Manufactured Housing applications. The

furnaces are rated at 240 volts, 60 Hz, single phase. 10, 12,

15, 17 and 20Kw models are available. All models have

multi-speed blowers capable of handling a wide range of

BTUs of cooling.

These instructions are primarily to assist qualified

individuals trained and experienced in the proper installation

of this type of equipment. Refer to authorities having

jurisdiction for additional guidance.

B. Rules For Safe Installati on And Operation

1. This unit has been designed and manufactured to

comply with National Codes, it is the installers responsibilit y

to install this unit to comply with National Codes and/or

prevailing local codes and regulations. Mortex assumes no

responsibility for units installed in violation of any code or

regulation.

2. Access for servicing is an important factor in the

location of the furnace. A minimum of 24 inches should be

provided in front of the furnace for access to the heating

elements and controls.

3. This electric furnace is approved for zero (0)

clearance to combustible material on all or any part of the

furnace exterior and the inlet or outlet duct work.

4. Duct work must be installed in accordance with the

standards of the National Fire Protection Association (NFP A)

for the installation of Air Conditioning, Warm Air Heating

and Ventilating Systems (NFPA 90A and 90B). See National

Environment al S ys t e ms Co nt ra cto r s Asso ci ati on M a nua l K for

duct sizing recommendations.

5. Ground the unit to prevent electric shock. All

electrical wiring should be in accordance with the National

electrical Code.

6. The safety testing agency label appearing on these

units covers the unit only. It does not cover any other

equipment.

7. The unit should be unpacked on receipt and if

damage is found, a claim should be made immediately by the

receiver upon the shipping carrier.

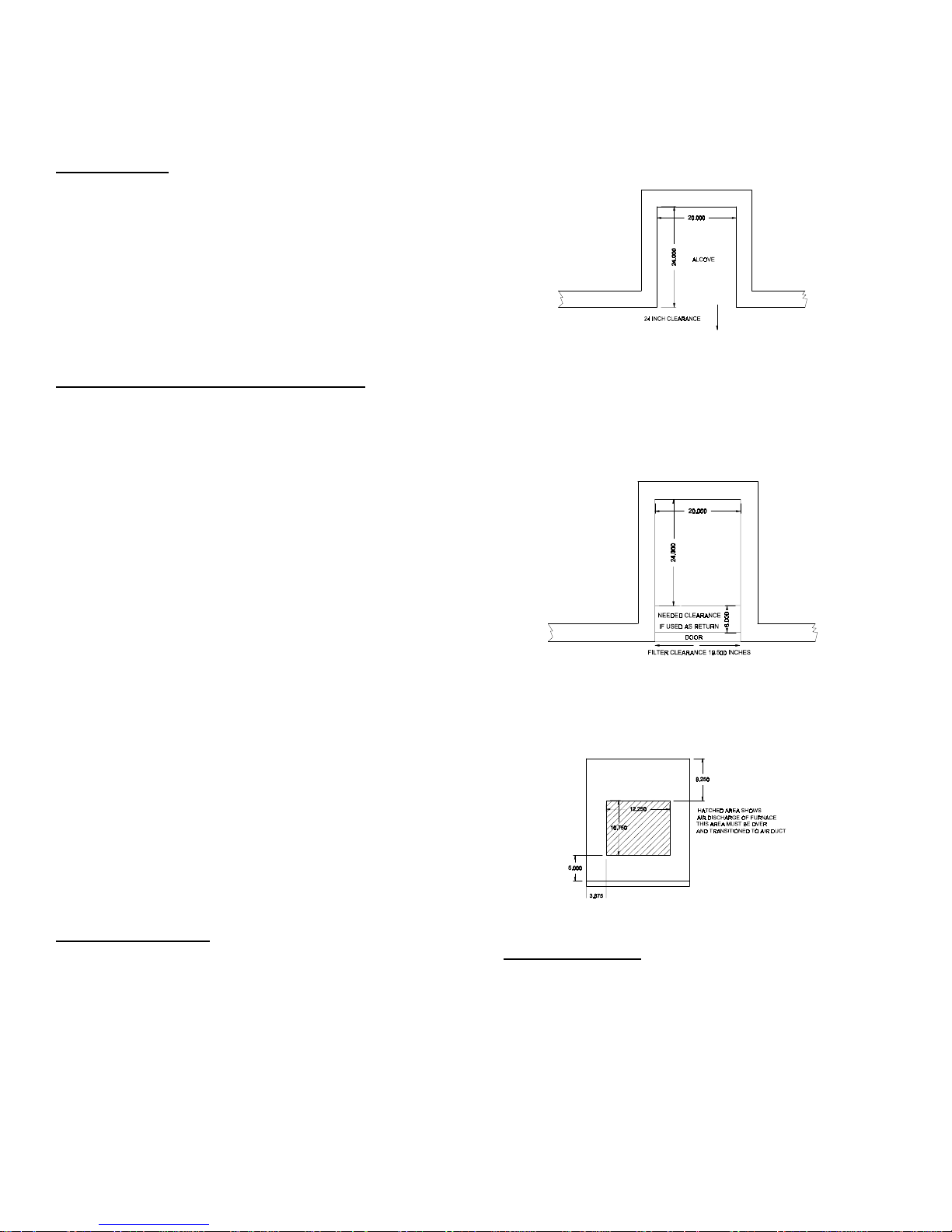

Closet: Must be of sufficient size to allow removal of air filter

and maintenance of the blower in the furnace. If return is in

door or wall below the furnace casing height a minimum of 6

inches clearance must be allowed on that side of furnace to

allow proper air flow to top of the furnace. Return air

openings must be as stated in alcove installation.

Furnace must be positioned to allow the discharge air to flow

unrestricted into the duct below. A metal transition should be

used. Be sure to seal the joints to prevent air leakage.

C. Physical Installation

Alcove: Must be a minimum of 24 inches deep by 20 inches

wide. Electrical connections are on right side. Door makes

overall depth of unit 25 inches. 24 inches must be clear in

front of the unit to nearest wall or partition. A return air

opening must be provided to allow return air to enter top

opening of furnace. Opening must be a minimum of 200

square inches for heating. Increase to a minimum of 300

square inches for A/C operation. For large A/C or HP

applications a larger opening may be required.

D. Electrical Wiring

Refer to the units nameplate for specific electrical data.

Caution: Disconnect power at main fuse or circuit breaker

distribution panel before wiring furnace to prevent shock

or fire hazard.

Power wiring

Unit is suitable for use with copper conductors. Tighten all

wire connectors. Take care not to damage heater ceramic

insulators. For correct field wire size see unit nameplate and

field wiring table inside electrical compartment. Use 75

degree C minimum wire if wire must be replaced. Circuit

29may98 61BH0001

breakers are provided and supply circuits are to be connected

directly to the marked circuit breaker terminals.

Caution: Furnace is equipped with a protective shield

over field wiring connection. When field wiring is

completed, shield must be replaced to prevent hazard of

electrical shock when servicing furnace.

Note: See unit for complete wiring diagram attached to

back of electrical compartment door.

Control wiring

Field connections to the low voltage leads are made using

appropriate field supplied wiring connectors. Consult

installation instructions provided with accessory items for

specific information on control wiring. Do not use two

separate thermostats for operation of heating and cooling. If

two class two circuits are used, use a thermostat with isolating

contacts to prevent inter-connection of two circuits. Set

thermostat heat anticipator at 0.15 amps for furnaces 10KW or

smaller, 0.30 amps for larger furnaces.

D. Blower Motor

Units are equipped with a three speed blower motor. Two

factory selected motor speed leads are connected to the blower

relay to provide automatic speed change for heating and

cooling airflow volume s.

E. Air Filter

Air handlers are factory equipped with an air filter. If the

return grille has its own filter, a filter installed in the air

handles is not recommended.

F. Check Test and Start

The unit should be tested after the system has been co mpletely

installed to determine proper operation. Unit is equipped with

heater time delay controls. All heating ele ments should turn

on within one minute.

G. Periodic Maintenance

The filter must be changed at least twice a year to permit

proper airflow for safe and efficient operation.

H. Contact us for Help or for Any Comments on Our

Products

As we strive to better serve our customers like you, we are

always ready to help you. We also welcome any comments

from our customers concerning quality and improvements that

could be made to our products. Please feel free to call or write

us. Thank you for the purchase of our product.

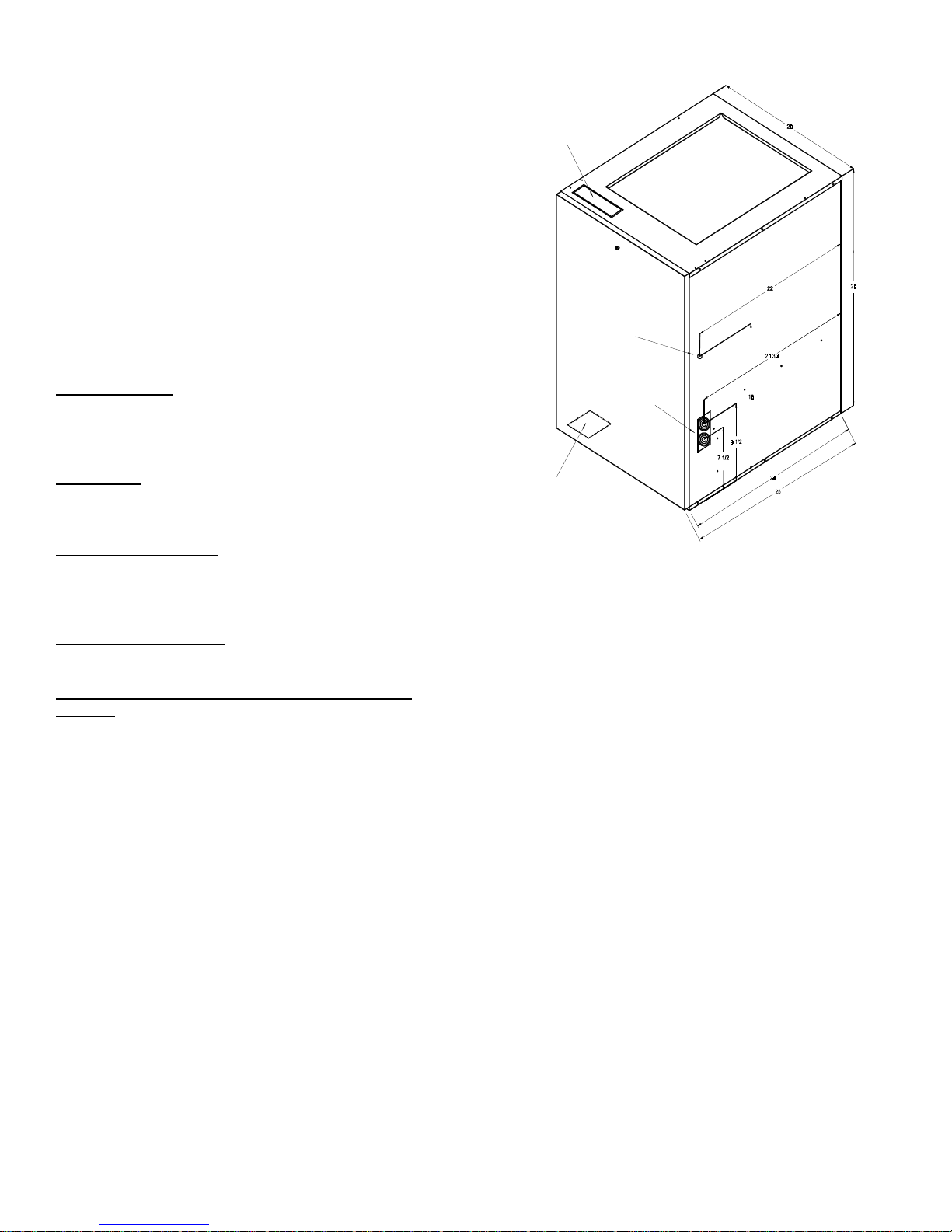

2 X 6 LINE AND DRAIN OPENINT

14 X 18 RETURN AIR OPENING

9/16 THERMOSTAT WIRE OPENING

TWO 1 3/4 LINE VOLTAGE K. O.

3 1/4 X 3 1/2 LINE AND DRAIN OPENING

Mortex Products

P.O. Box 9380

Ft. Worth, Texas 76147

Office (817) 624-0820

Fax (817) 624-8581

61BH0001/2

Loading...

Loading...