Mortex 96-8Z3-0P, 98-8W7-0P, 96-8Z4-0P, 98-8W8-0P, 98-8Z6-0P Installation Manual

...

Mortex

INSTALLATION INSTRUCTIONS

AIR CONDITIONING & HEAT PUMP INDOOR COILS

INTRODUCTION

Please note that HUD Manufactured Home Construction and Safety Standard Section 3280.714, paragraph (a) and subparagraph

(4) and (5) clearly specifies when a cooling or heat pump coil and air conditioner blower are installed with a furnace or heating

appliance they shall be tested and listed in combination for heating and safety performance by a nationally recognized testing

agency(ies). Additionally, the cooling or heat pump systems to be installed in Manufactured Housing shall be certified, listed and

rated based on US Department of Energy test procedures which are listed by AHRI and shall be tested and listed in combination

for heating and safety performance by a nationally recognized testing agency(ies).

Mortex coils are designed specifically for use with various models of manufactured housing gas or electric furnaces in both down-flow

and up-flow applications. A different pan will be required on up flow oil furnaces.

These instructions are primarily intended to assist qualified individuals trained and experienced in the proper installation of this type of

equipment. Some state codes require installation and service personnel to be licensed. Refer to authorities having jurisdiction for

additional guidance. Remember that the Clean Air Act of 1990 requires technician certification for handling refrigerant.

NOTE: EFFICIENCY AND CAPACITY RATINGS ARE LISTED IN CURRENT AHRI UNITARY DIRECTORY [UNDER SUMMIT

MANUFACTURING] FOR MORTEX COIL MODEL NUMBERS MATCHED WITH OUTDOOR CONDENSING OR HEAT PUMP UNITS.

AIR CONDITIONING COIL MATCHES ARE LISTED IN INDOOR COIL MANUFACTURER AIR CONDITIONING SECTION. HEAT

PUMP COIL MATCHES ARE LISTED IN INDOOR COIL MANUFACTURER HEAT PUMP SECTION. INCORRECTLY MATCHED

SYSTEMS MAY NOT WORK PROPERLY AND MAY VOID MANUFACTURER LIMITED WARRANTY.

Model Nomina

l

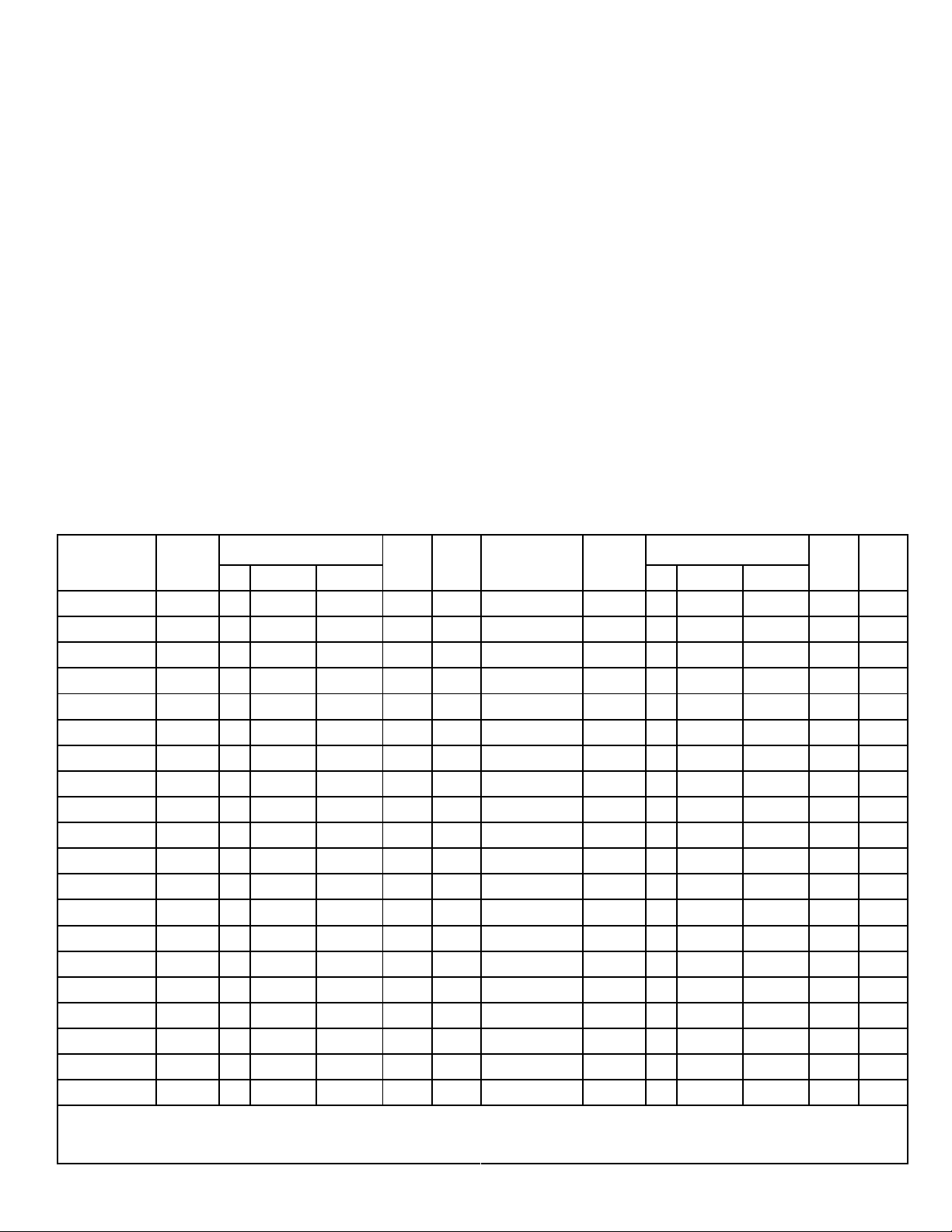

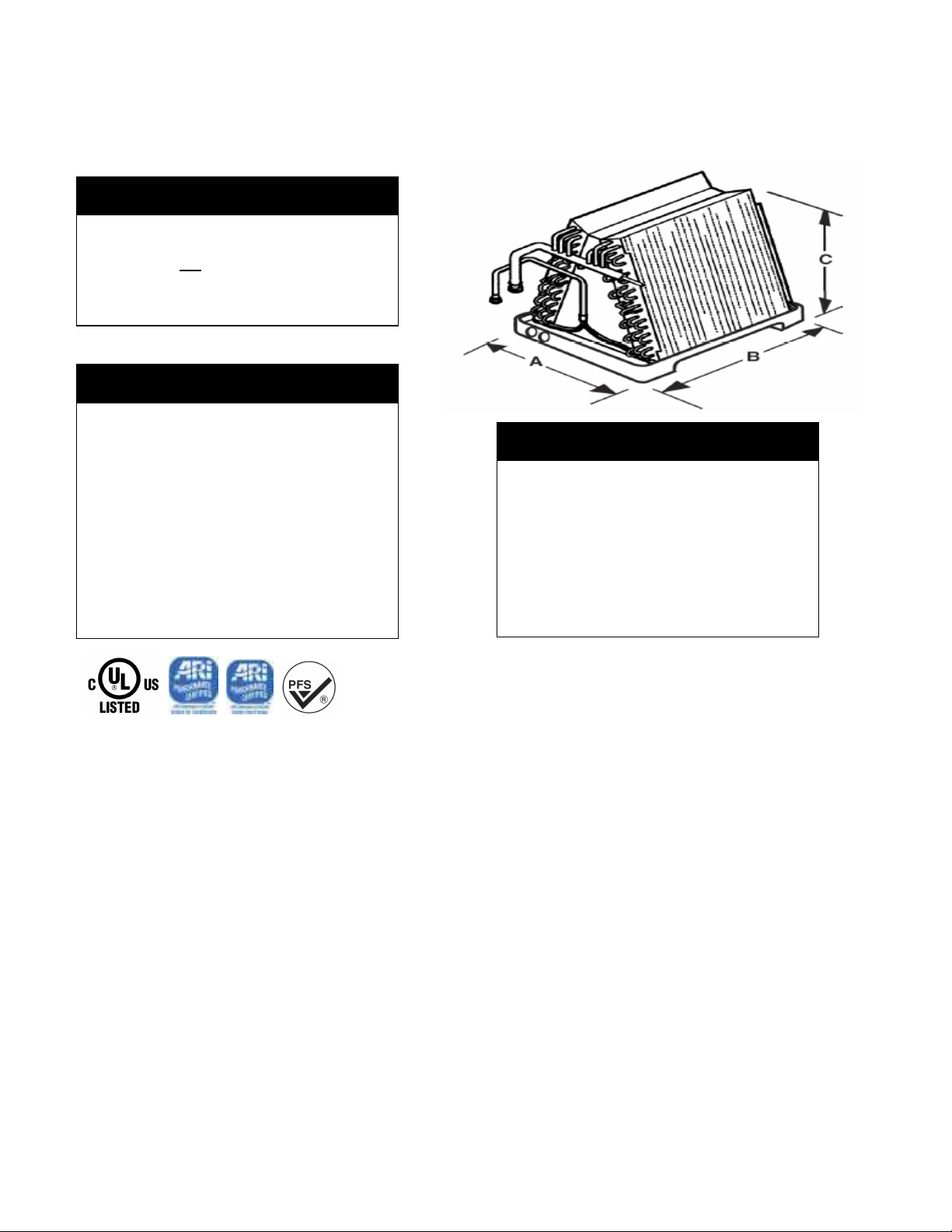

No. Tons A B C Wt. Qty. No. Tons A B C Wt. Qty.

96-8Z3(*)-0P 1.5-2.0 18 19 5/8 16 30 20 98-8W7(*)-0P 2.5-5.0 18 19 5/8 24 1/2 48 12

96-8Z4(*)-0P 1.5-2.5 18 19 5/8 18 32 16 98-8W8(*)-0P 2.5-5.0 18 19 5/8 26 1/2 50 8

98-8Z6(*)-0P 1.5-3.5 18 19 5/8 22 34 12 98-8W9(*)-0P 2.5-5.0 18 19 5/8 28 1/2 52 8

98-8Z7(*)-0P 1.5-3.5 18 19 5/8 24 35 12 98-8W11(*)-0P 2.5-5.0 18 19 5/8 32 1/2 56 8

98-8Z9(*)-0P 1.5-3.5 18 19 5/8 28 37 8 98-8W12(*)-0P 2.5-5.0 18 19 5/8 34 1/2 58 8

96-8G2(*)-0P 1.5-3.0 18 19 5/8 14 30 20 97-9E5(*)-0P 2.5-5.0 18 20 1/2 20 1/2 50 16

96-8G3(*)-0P 2.0-3.5 18 19 5/8 16 31 20 98-9E7(*)-0P 2.5-5.0 18 20 1/2 24 1/2 53 12

96-8G4(*)-0P 2.0-3.5 18 19 5/8 18 33 16 98-9E9(*)-0P 2.5-5.0 18 20 1/2 28 1/2 57 8

97-8G5(*)-0P 2.0-4.0 18 19 5/8 20 34 16 96-R33(*)-0P 1.5-2.0 18 19 5/8 13 29 20

98-8G6(*)-0P 2.0-4.0 18 19 5/8 22 35 12 96-R34(*)-0P 1.5-2.0 18 19 5/8 14 30 20

98-8G7(*)-0P 2.0-4.0 18 19 5/8 24 36 12 96-R36(*)-0P 2.5-3.0 18 19 5/8 18 33 16

98-8G8(*)-0P 2.0-4.0 18 19 5/8 26 43 8 96-R46(*)-0P 3.5-4.0 18 19 5/8 18 38 16

98-8G9(*)-0P 2.0-4.0 18 19 5/8 28 46 8 97-L46(*)-0P 3.5-4.0 18 20 1/2 18 40 16

98-8G11(*)-0P 2.0-4.0 18 19 5/8 32 52 8 98-R49(*)-0P 3.5-4.0 18 19 5/8 28 52 8

98-8G12(*)-0P 2.0-4.0 18 19 5/8 34 52 8 98-R28(*)-0P 1.5-2.0 18 19 5/8 21 1/2 36 8

96-893(*)-0P 2.0-4.0 18 19 5/8 16 1/2 36 20 98-R210(*)-0P 1.5-2.0 18 19 5/8 24 3/4 38 8

96-8W4(*)-0P 2.0-5.0 18 19 5/8 18 1/2 38 16 98-R213(*)-0P 2.5-3.0 18 19 5/8 29 3/4 41 8

97-9E4(*)-0P 2.0-5.0 18 20 1/2 18 1/2 38 16 98-R311(*)-0P 3.5-4.0 18 19 5/8 26 1/2 56 8

97-8W5(*)-0P 2.5-5.0 18 19 5/8 20 1/2 45 16 98-R313(*)-0P 3.5-4.0 18 19 5/8 29 3/4 58 8

98-8W6(*)-0P 2.5-5.0 18 19 5/8 22.5 47 12

Dimensions Coil Pallet Model Nomina

l

Dimensions Coil Pallet

(*) Designates Piston Size or TXV Current Production Models

CAUTION!

ATTENTION!

NOTE!

All sweat and quick connect coils are

shipping from factory pressure with nitrogen.

They do not

HFC410A. Relieve nitrogen pressure before

opening the refrigerant circuit.

contain any HCFC22 or

Some Mortex coils have a TXV as the metering

device. However, the sensor bulb is not mounted

due to potential heat damage and / or proper bulb

location. Therefore, after the suction and liquid

line have been properly connected to the coil the

bulb can be mounted on the suction. Many times,

due to space limitations in the manufactured

housing applications it will require the sensor

bulb to be mounted vertically. If that is the case

the bulb should be located at least 6” away from

and bend (elbow) and fastened on the tubing side

opposite the plane of the bend. The bulb should

be insulated using the thermal insulation to

protect it from the effects of the surrounding

ambient temperature. (SEE PAGE 7)

GENERAL COIL INSTALLATION NOTES

1.

On a quick connect coil, test for pressure by pushing

against the diaphragm located inside the quick connect

fitting on the suction manifold. If you are not able to

depress the diaphragm, the coil contains a Nitrogen

holding charge.

To test for pressure on a sweat connect coil, remove

the cap or flare nut on the Schrader fitting and depress

the core valve located on the suction manifold.

2. The blower and duct system must be properly

All Mortex coils are shipped pressurized with

Nitrogen. Coils with sweat or quick connect

fittings are shipped with a nitrogen holding

charge.

ALL COILS SHOULD BE CHECKED FOR

PRESSURE BEFORE LEAVING THE

DISTRIBUTOR OR BEFORE INSTALLATION!

IF THERE IS NO PRESSURE PRESENT, THE

COIL MAY HAVE DEVELOPED A LEAK

DURING SHIPMENT AND SHOULD BE

RETURNED TO THE POINT OF PURCHASE

FOR EXCHANGE.

Sized in order to provide adequate cooling and

heating performance. Select the correct motor

speed tap on the furnace blower to give the

Mortex coils and other accessories installed when

air conditioning is added to manufactured

housing furnaces will comply with HUD

regulations requiring third party approvals.

Efficiency and capacity ratings as required by

HUD are listed in the current AHRI directory for

Mortex [see Summit Manufacturing] matched with

the outdoor units. These coil ratings are based on

air quantities consistent with those that are

encountered in typical manufactured housing air

condition and heat pump applications.

required CFM needed for rated cooling capacity

or upgrade the blower assembly to attain the

proper CFM. Return air filters of generous size

must be provided, in order to avoid contaminating

the coil, blower and ductwork, or restricting

necessary airflow. Failure to deliver the proper air

flow across the indoor coil will cause system

and/or component problems, i.e. TXV

performance problems.

3. It is essential that the indoor coil and outdoor

unit be properly matched and charged with

the proper amount of refrigerant. Incorrect

charge levels will result in inefficient operation.

See more details in installation instructions for the

outdoor unit.

4. For optimum performance and efficiency of air

conditioning or heat pump coils, adjust system

charge and/or superheat/subcooling as

recommended by outdoor unit manufacturers.

Procedures will differ between manufacturers.

5. It is recommended that the coil be sprayed with

liquid detergent thoroughly and rinsed thoroughly

before installation to assure proper drainage of

condensate from the coil fins to eliminate water

blowoff and to assure maximum coil

performance. If not sprayed, approximately 50

hours of break in time is required to achieve the

same results.

Loading...

Loading...