Buy A Morley. And Step On It.

SPRING REPLACEMENT INSTRUCTIONS FOR:

GLW, GLW2, MARK 1, MARK PW, VAI-1, VAI-2, VAI-LW, PBA, PBA-2, NSW, TMW or WAH-SP

(wound spring style)

Follow the below instructions to replace a broken or fatigued spring on any of the above

mentioned pedal models.

Tools you will need:

- 12 mm nut driver

- 5/16” nut driver

- 1/4” nut driver

- Phillips Screwdriver (medium tip)

- Long tip Needle-nose pliers (2” long tip)

- 3/8” Wrench (Open end or Box end)

DISASSEMBLY

1) Remove four bottom cover screws using Phillips screwdriver.

2) Remove bottom cover.

3) Remove two Chrome jack nuts and black plastic rings from 1/4” input and output jacks.

4) Remove four 1/4” nuts that hold down circuit board.

5) Slip battery snap out from battery foam slit.

6) The circuit board can now be removed from base.

7) Remove four 5/16” nuts, four 6-32 x 1/2” Phillips pan head screws and three washers that

attach base to treadle.

8) The base, treadle and spring will be completely disassembled at this point. Discard old spring.

CAUTION: Coiled spring steel version may have sharp edges especially where a break has

occurred!

ASSEMBLY

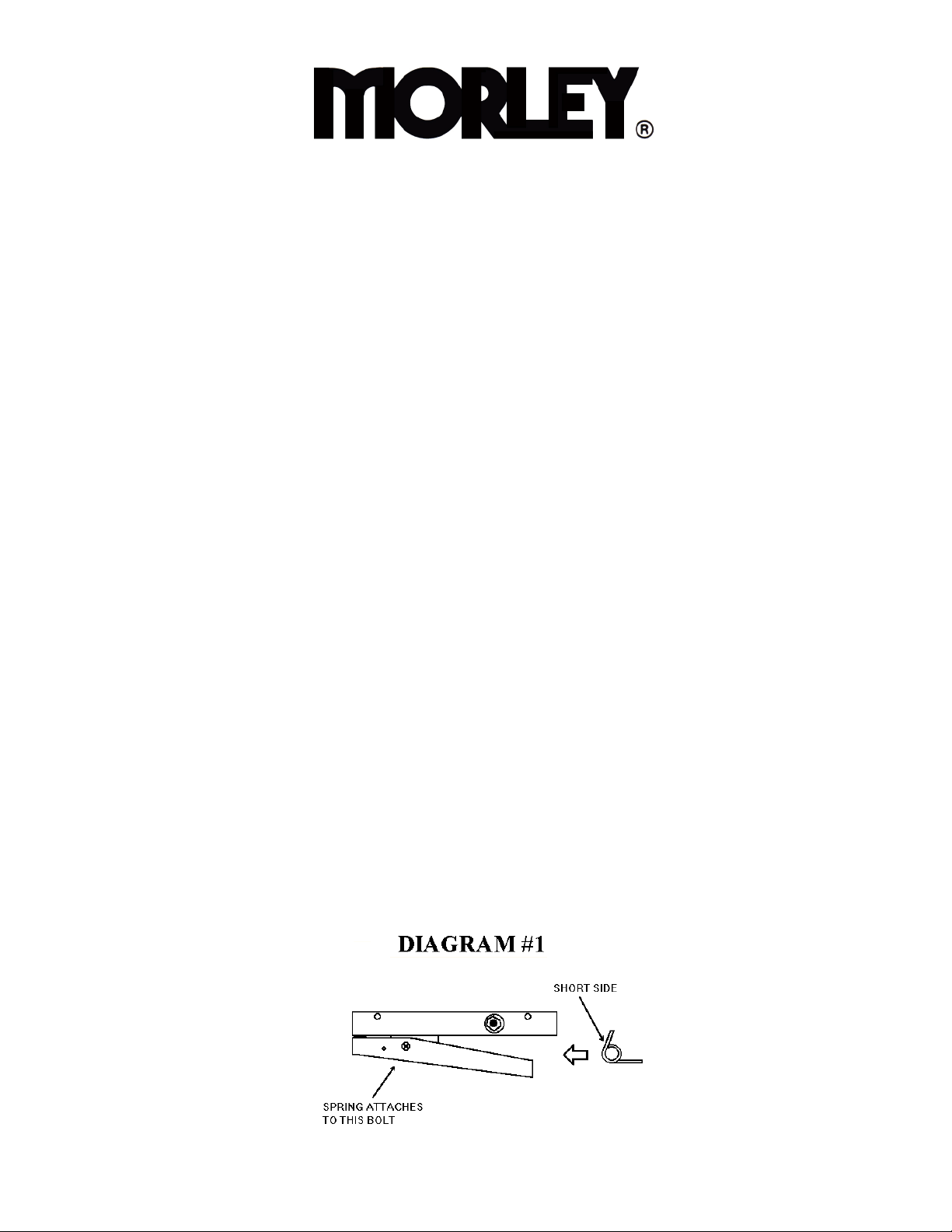

1) Diagram 1 indicates the direction in which the spring should when assembled. The short side of

the spring (also indicated in diagram #1) should rest on the surface of the bracket. Although the

diagrams show a pedal with a base, the spring is to be assembled to the treadle/treadle bracket

first.

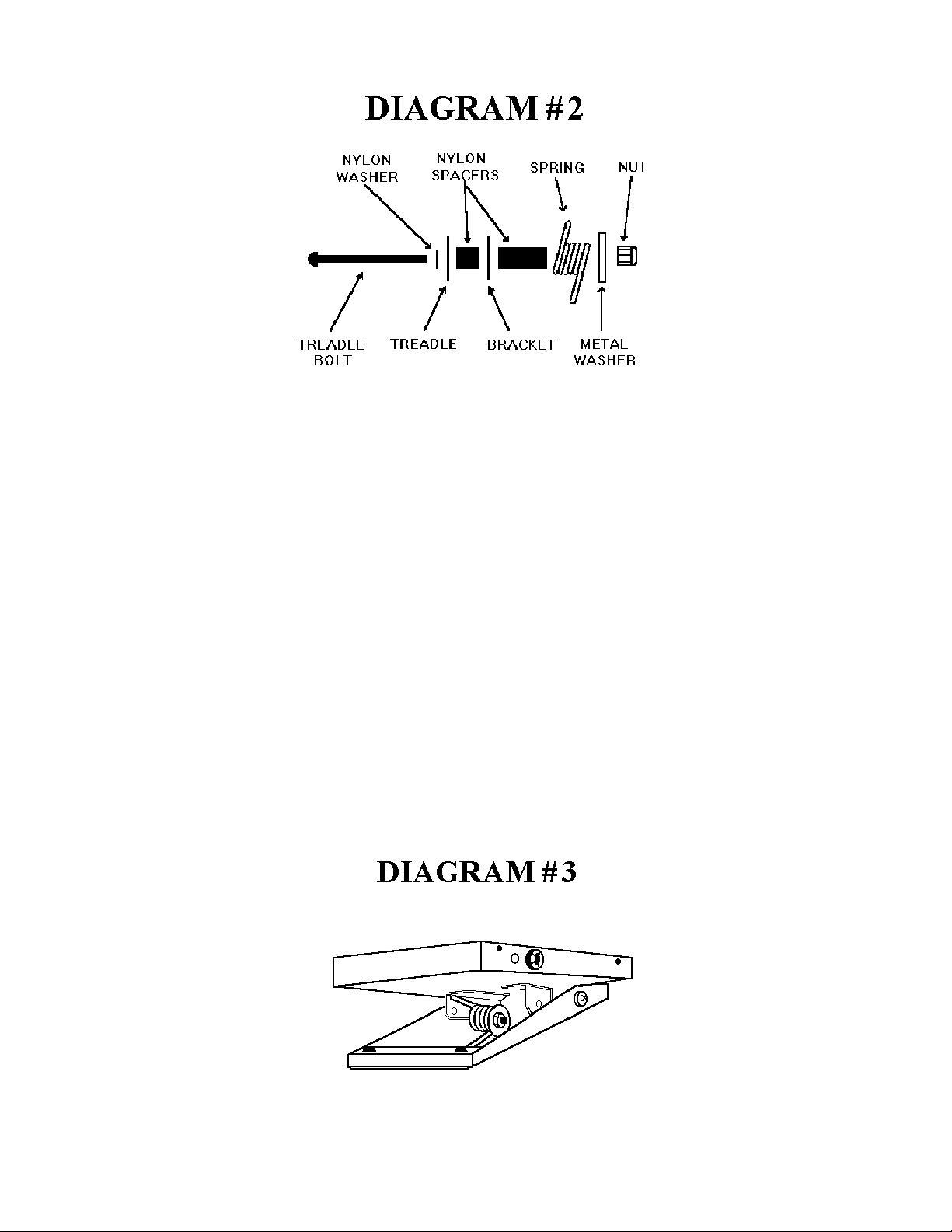

2) Diagram #2 shows the proper assembly order of spring and associated components.

3) Place all components (per diagram #2) into place.

4) Place base onto treadle and align screw hole openings in base to line up with holes in treadle

bracket.

5) Place a int. tooth washer on 6-32 a 1/2” screw. Using the needle-nose pliers, hold the 6-32 x

1/2” Phillips pan head screw by the head and insert from underside of treadle bracket. (The thread

should stick up in the inside of the pedal base) Replace washer and 5/16” nut. Repeat for three

remaining mounting locations. Do not tighten any of the four nuts yet.

6) Align and center treadle to base. This can be accomplished by setting the pedal assembly on

its heel end to push treadle as far toward the toe end as possible and visually centering the

treadle (so it is not cocked right or left). This is important so the shutter is located properly

between the optics.

7) Tighten the four 5/16” nuts thoroughly.

8) Set the screw tightness on each side of the treadle. To accomplish this, place the 3/8” wrench

on the nut located on the inside of the treadle/bracket assembly. Tighten bolt all the way down

and loosen it one half turn to allow treadle to move freely. Repeat for opposite side.

9) Replace circuit board, four 1/4” nuts, two black plastic rings & two chrome jack nuts.

10) Insert battery snap through the slit in battery foam.

11) Perform sound test to verify wah setting is still within acceptable range.

12) Replace bottom cover and bottom cover screws.

13) Diagram #3 shows the assembled spring.

If you need further assistance, please contact Scott Flesher

at 1-800-284-5172 ext 15 or scott@morleypedals.com

Loading...

Loading...