MORIWAKI MD250H Service Manual

MORIWAKI MD250H

SERVICE MANUAL

GENERAL INFORMATION

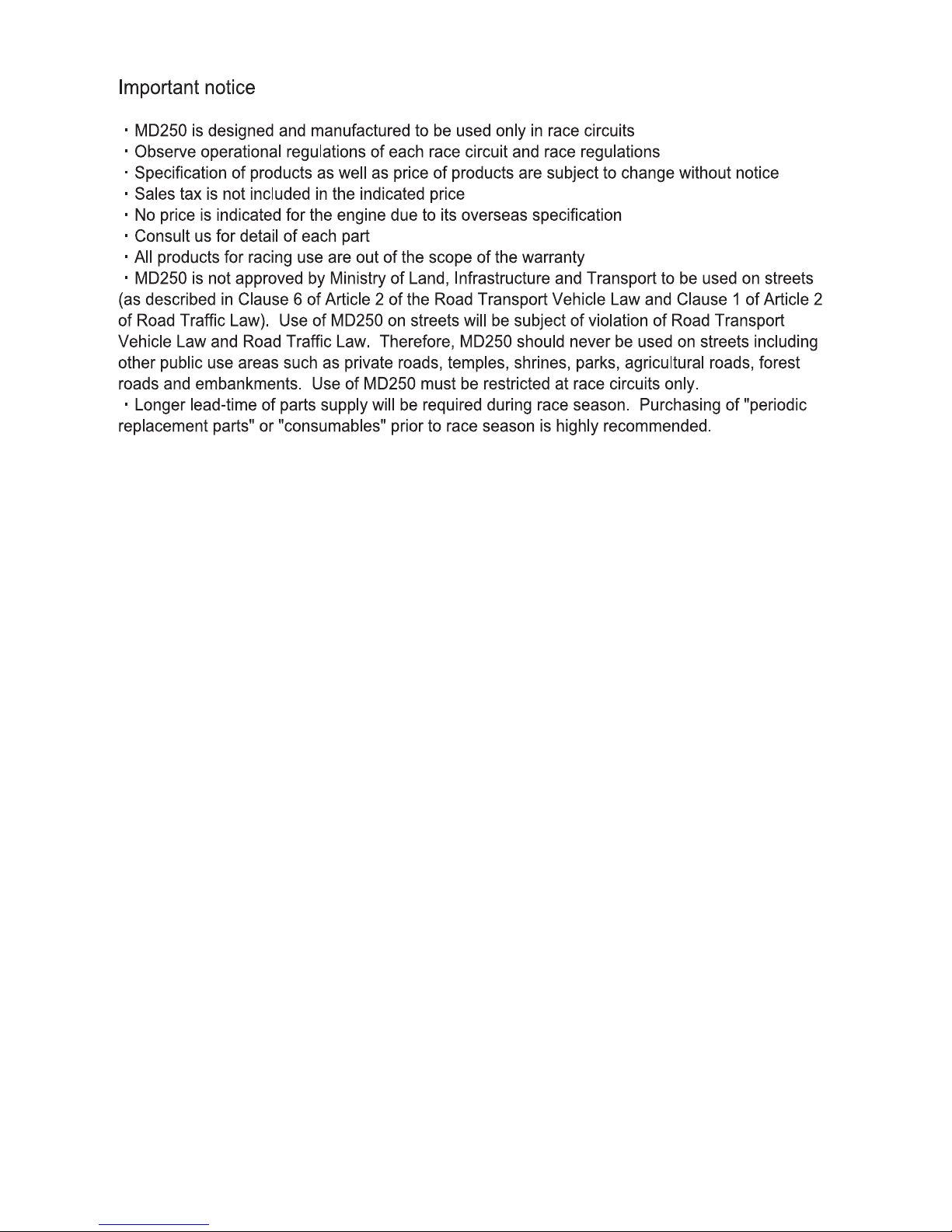

Refueling

Remove the tank cover.

PRINT EDITION 2.1

1-1

Remove the fuel tank cap.

Fuel tank capacity: 7.0 liter

Fuel: Unleaded high-octane gasoline

Be sure to install the fuel tank cap and breather tube before ride.

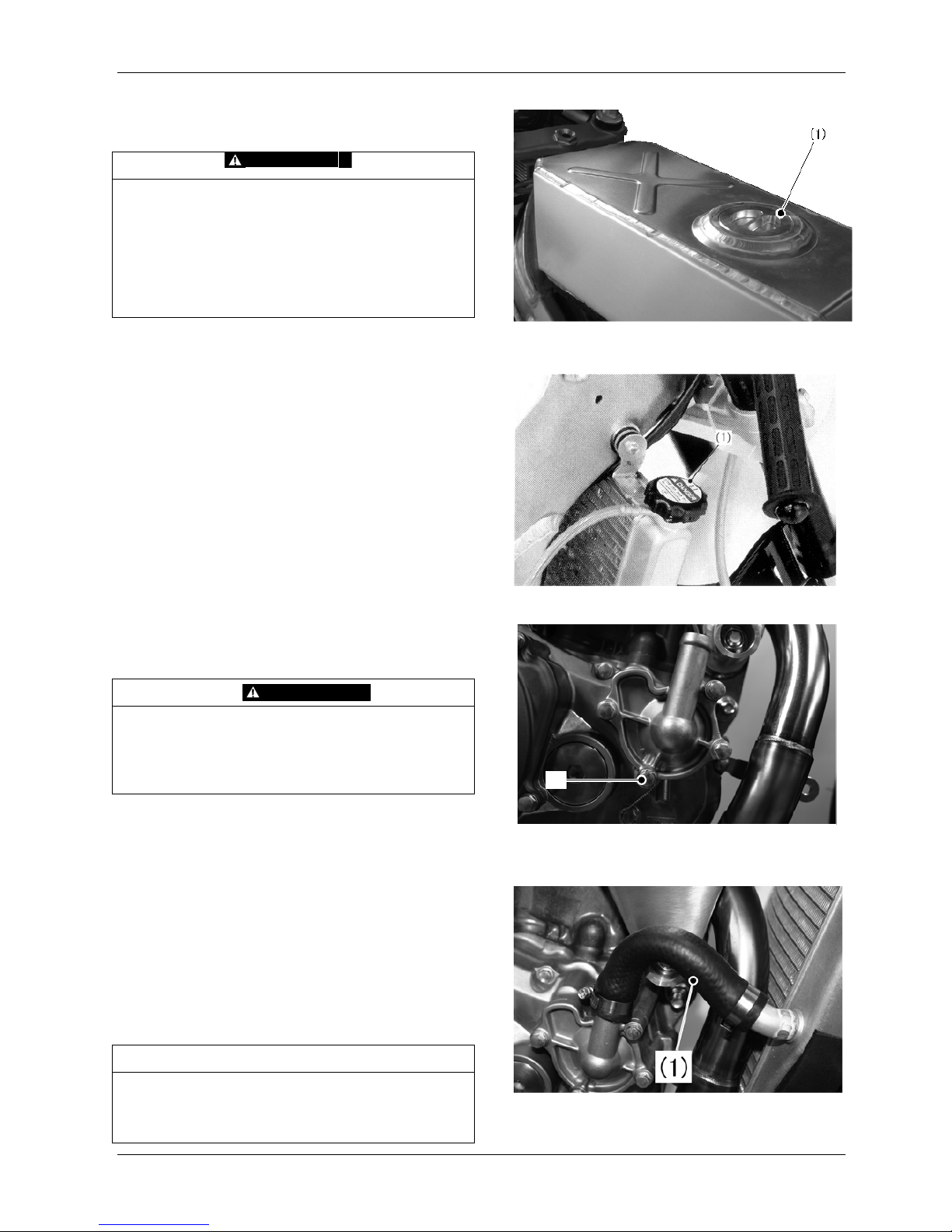

Coolant

MD250H uses water for its engine cooling system.

Remove the radiator cap and fill the radiator with coolant water up to

the filler neck.

Coolant: Tap water (soft water) or drinking water

The “DANGER” label on the top of the radiator cap indicates

potential danger.

Be sure to bleed any air trapped in the coolant system after refilling

the coolant. Remaining air may cause the engine over heating.

Air bleeding procedure:

1. Remove the radiator cap and fill the radiator with coolant slowly

up to the filler neck.

2. Loosen the drain bolt and release any trapped air.

3. Hold the handle bars and lean the bike left to right for a few times

to release air. If the coolant level drops, add more coolant.

4. Repeat above procedure until the coolant level doesn’t drop.

5. Reinstall the radiator cap and fasten it securely.

Gasoline is explosive. It can cause you to be burned or

seriously hurt due to explosion.

When you handle gasoline;

・ Engine must be stopped. The work area must be free form

flames, sparks or heat source.

・ Work in a well ventilated area.

・ If you spill gasoline, wipe and remove it immediately.

WARNING

Removing the radiator cap while the engine is hot can allow the

coolant to spray out, seriously scalding you.

Always let the engine and radiator cool down before removing

the radiator cap.

Notice

The radiator cap has a double-lock fasten system.

Be sure to fasten the radiator cap completely, otherwise the system will

not hold the required pressure and cause coolant leakage and serious

troubles.

(1) Fuel tank cap

DENGER

DANGER

(1)

Radiator ca

p

(1)

(1)

Drain bolt

(1)

Radiator hose

GENERAL INFORMATION

(1)

(2)

6. Remove the radiator cap and start the engine when it is cold.

Check the coolant flow at the filler neck (coolant will not flow if

there is trapped air in the system). Stop the engine and re-check

the coolant level. Add more coolant if necessary, then reinstall

the radiator cap.

Drain any coolant in the catch tank before ride.

Drain coolant from the cooling system after finish riding to avoid

troubles in the system such as corrosion or clogging.

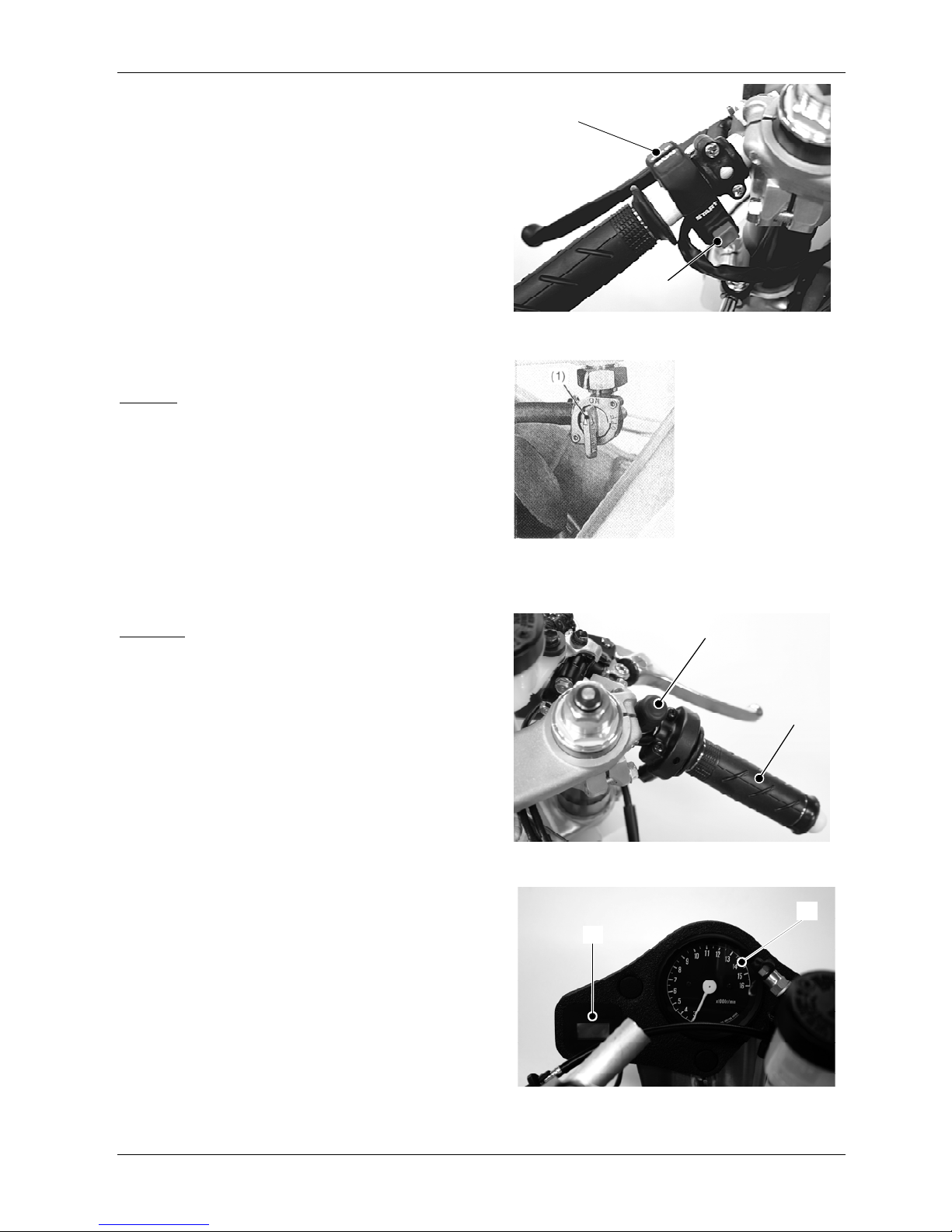

Riding

(1)

Main switch (2) Starter button

Starting

Check the coolant level before start the engine. (→1-1)

Cold start:

1. Switch the main switch to “RUN”.

Tachometer and water temp. indicator start operating

(Power ON)

Tachometer: Indicator goes all the way and back to the minimum

value; 3000rpm and the back light turns on.

Water temp. indicator: Start indicating the coolant temperature.

2. Turn the fuel valve to “ON”.

3. Open and close the throttle 2 to 3 times in quick motion.

(1) Fuel valve

4. Push the starter button to start the engine.

(1)

(2)

War m s ta rt :

Follow the “Cold start” procedure above except #3 and start the engine.

Stopping

1. Shift the transmission into neutral.

2. Turn the fuel valve to “OFF”.

3. Push the engine stop button when the engine rev drops and keep

until the engine stops completely.

4. Switch the main switch to “OFF”.

Leaving the fuel valve “ON” may cause starting difficulty especially

when the carburetor overflow the gasoline.

(1) Throttle grip (2) Engine stop button

(1)

(2)

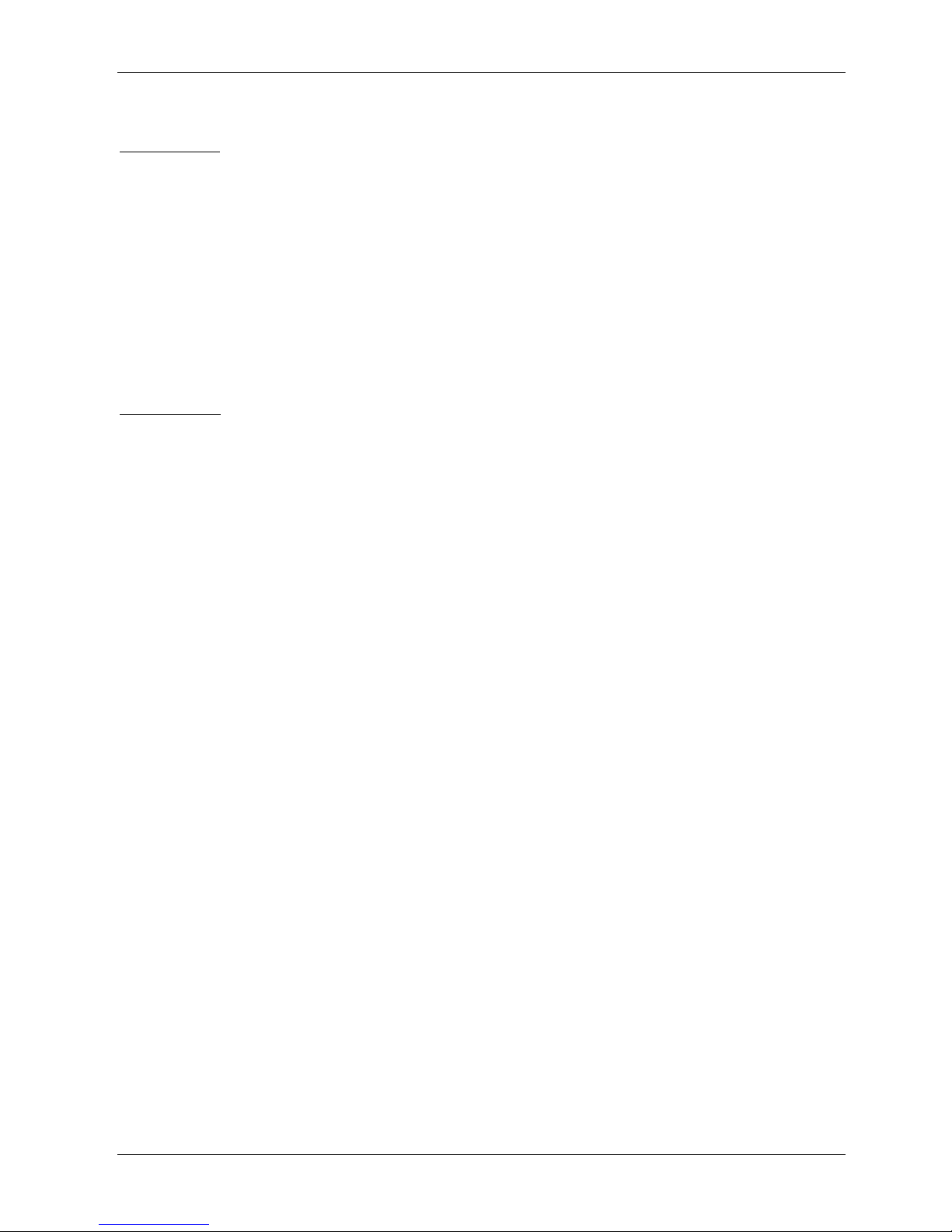

Engine warm up

Do not run the engine at high rev idle for too long during the warming

up.

1. Start the engine, then open the throttle instantaneously while

obtaining 5,000rpm~6,000rpm until the coolant temperature

rises to 40~50℃.

2. Then, open the throttle further in same instantaneous motion up

to 8,000rpm until the temperature rises to 70℃, and stop the

engine.

3. To stop the engine, close the throttle and push the engine stop

button until the engine stops.

(1) Tachometer (2) Water temp indicator

PRINT EDITION 2.1

1-2

GENERAL INFORMATION

PRINT EDITION 2.1

1-3

Break-in ride

First break-in ride

Keep the engine rev constant at the specified rpm during break-in ride. Shift speed up and down below the specified rpm. Use

relatively high gears and observe function of each part. Use 4 to 5 speed gears when riding through straight section of circuit tracks.

Up to 7,000rpm…………… about 50km (approx. 30min)

Up to 8,000rpm‥………… about 15km

Up to 9,000rpm…………… about 15km

Up to 10,000rpm ………… about 15km

Total: approx. 1hr or 95km

After parts change

・ Perform same amount of break-in ride as first break-in when cylinder or crankshaft is replaced: approx. 1hr (95km)

・ In case of replacement of engine parts such as piston, piston rings and gears:

Up to 7,000rpm………… about 20km

Up to8,000rpm………… about 10km

Up to 9,000rpm………… about 10km

Up to 10,000rpm……… about 10km

Total: approx. 30min or 50km

・ Replace the transmission oil(⇒3-6) after break-in rides. Check the contamination and foreign substances in used oil.

GENERAL INFORMATION

(1) Lock nut (2) Adjuster

(A) Increase the free play (B) Decrease the free play

Operation system

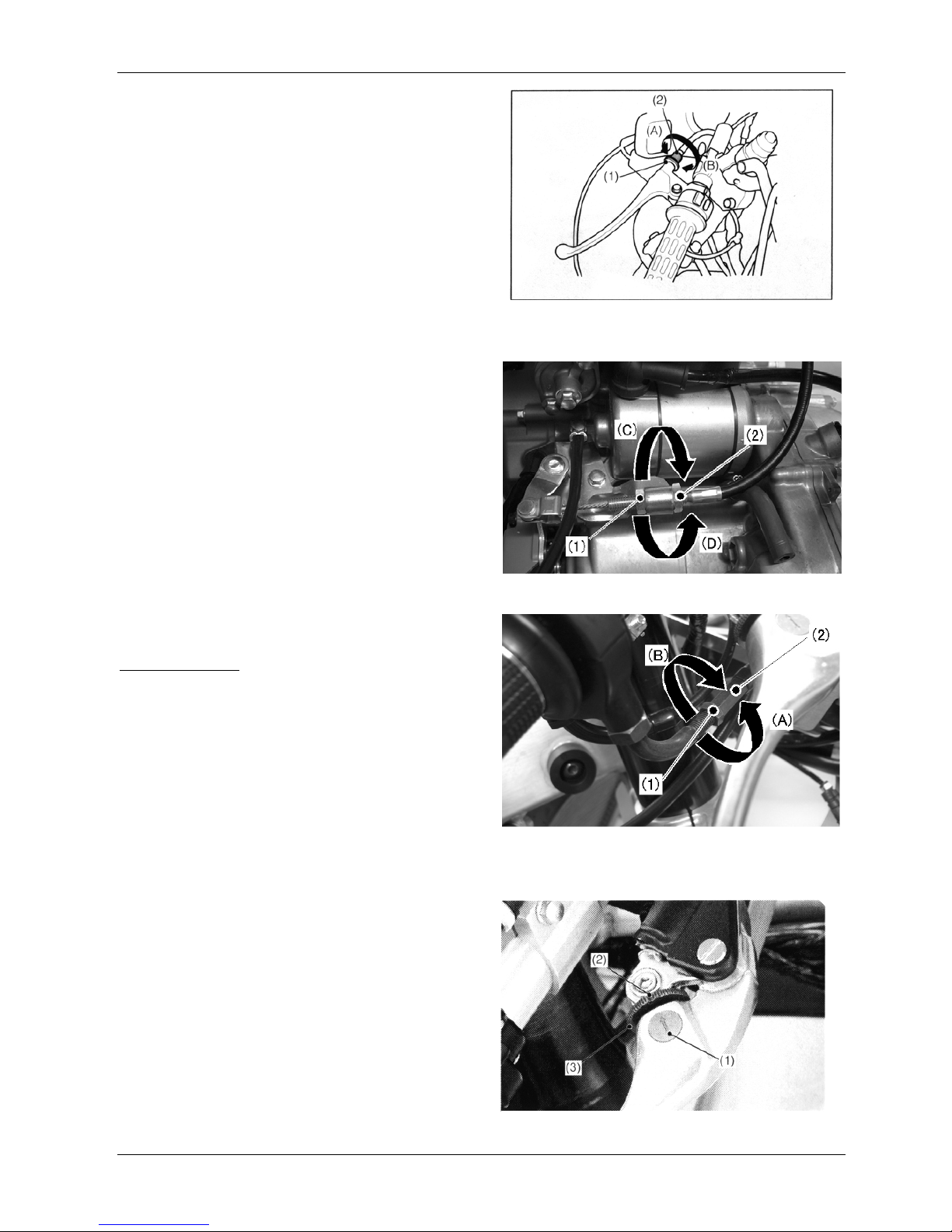

Clutch

Check the clutch lever free play at the lever end.

Free play: 10 – 20mm

Minor adjustments can be made at the cable end adjuster on the

lever.

・ Turning the cable end adjuster in direction A will increase free

play

・ Turning the cable end adjuster in direction B will decrease free

play.

Major adjustments can be made with the in-line cable adjuster

located behind the starter motor.

・ Turning the adjuster in direction C will increase free play

・ Turning the adjuster in direction D will decrease free play

Start the engine and check the clutch for disengaging or slips.

(1) Lock nut (2) Adjuster

(C) Increase the free play (D) Decrease the free play

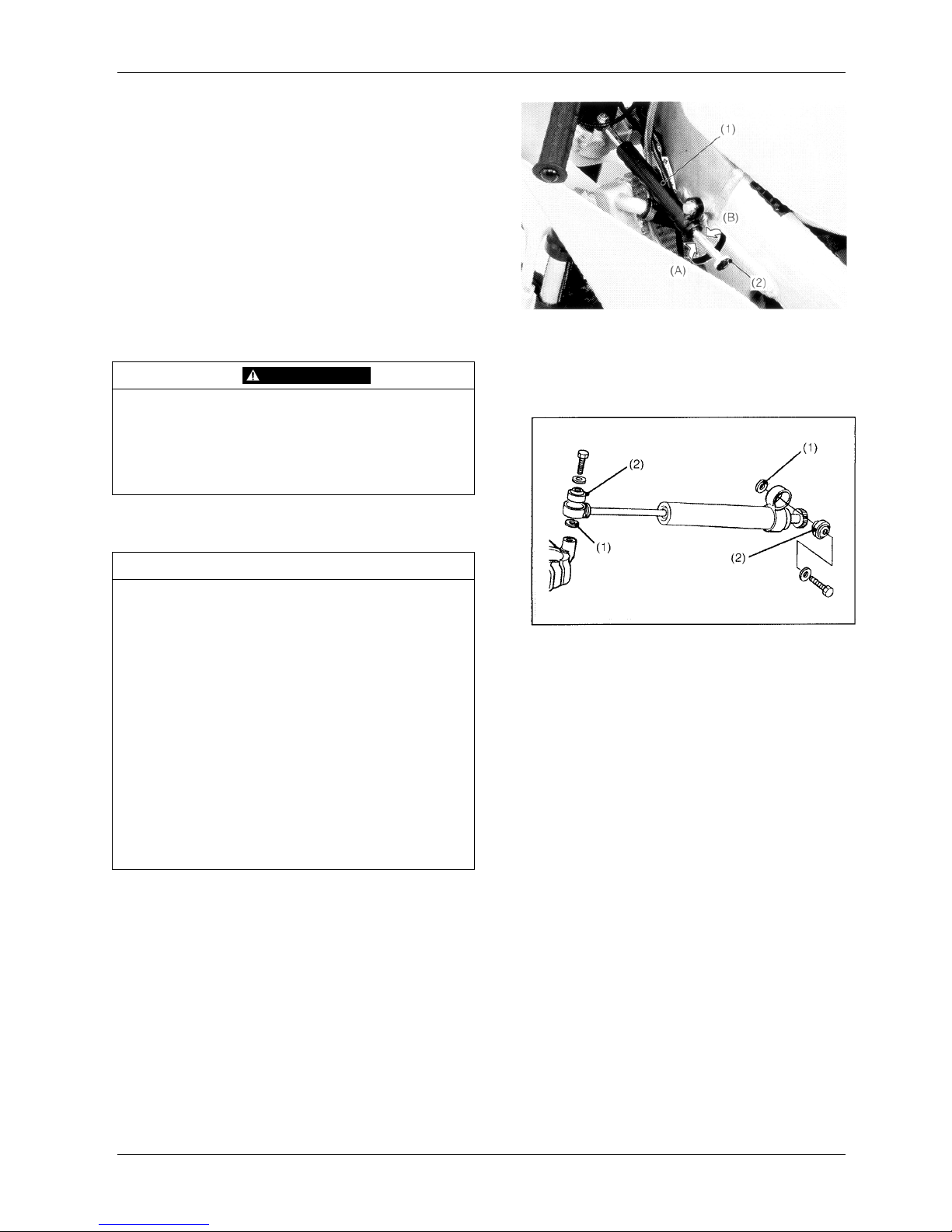

Throttle grip

Throttle grip free play

Check the free play at the throttle grip flange.

Free play: 3mm

Minor adjustments are made with the throttle grip side adjuster.

・ Turning the adjuster in direction A will increase free play

・ Turning the adjuster in direction B will decrease free play

Tighten the lock nut after adjustment.

Check the throttle grip for its operation.

(1) Lock nut (2) Adjuster

(A) Increase free play (B) Decrease free play

(1)

Arrow mark (2) Alignment mark (3) Adjuste

r

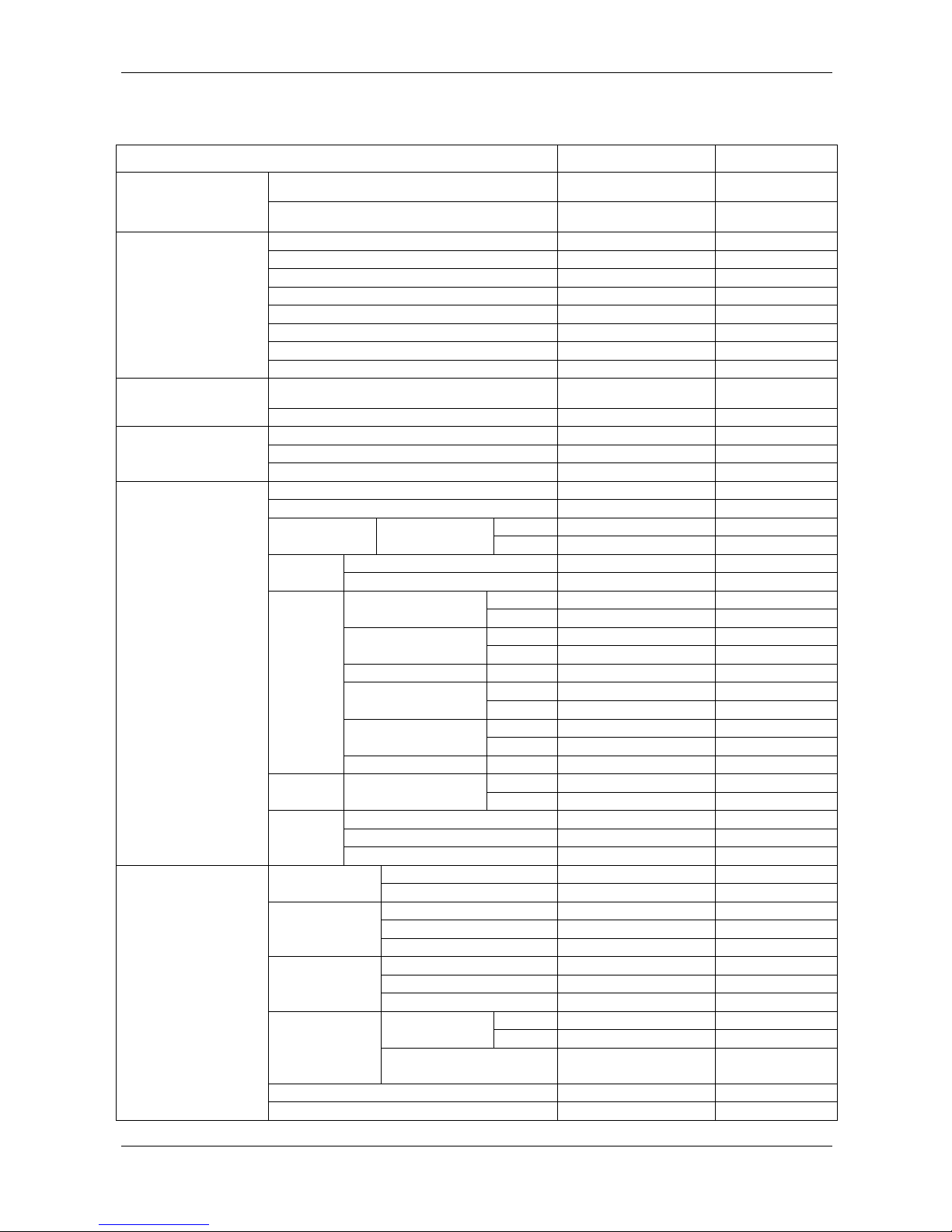

Front brake lever adjustment

The brake lever position can be adjusted by adjuster.

Adjust the brake lever to appropriate position by using the arrow and

alignment marks as reference.

PRINT EDITION 2.1

1-4

GENERAL INFORMATION

Brake pedal height

Adjust the brake pedal to the desired height by loosening the lock nut

and turning the push rod.

Apply grease to the brake pedal axle at every ride.

(1) Lock nut (2) Adjuster

(A) Pedal goes higher (B) Pedal goes lower

Gear shift linkage

(1)

(2)

(1)

The change pedal height can be adjusted by changing the length of the

change rod.

Loosen the lock nuts at both ends and turn the change rod to adjust

the change pedal height. Measure the distance between 2 pillow b

as a reference to the pedal height.

alls

Change rod adjustable length (between the pillow balls)

minimum length: 311mm

maximum length: 332mm

One of 2 ends of the change rod had reverse threads.

Shift pattern: 1 up 4 down

(1)

Lock nut (2) Change rod

1 UP 4 DOWN

(1) Change arm (2) Change rod

(3) Change pedal

PRINT EDITION 2.1

1-5

GENERAL INFORMATION

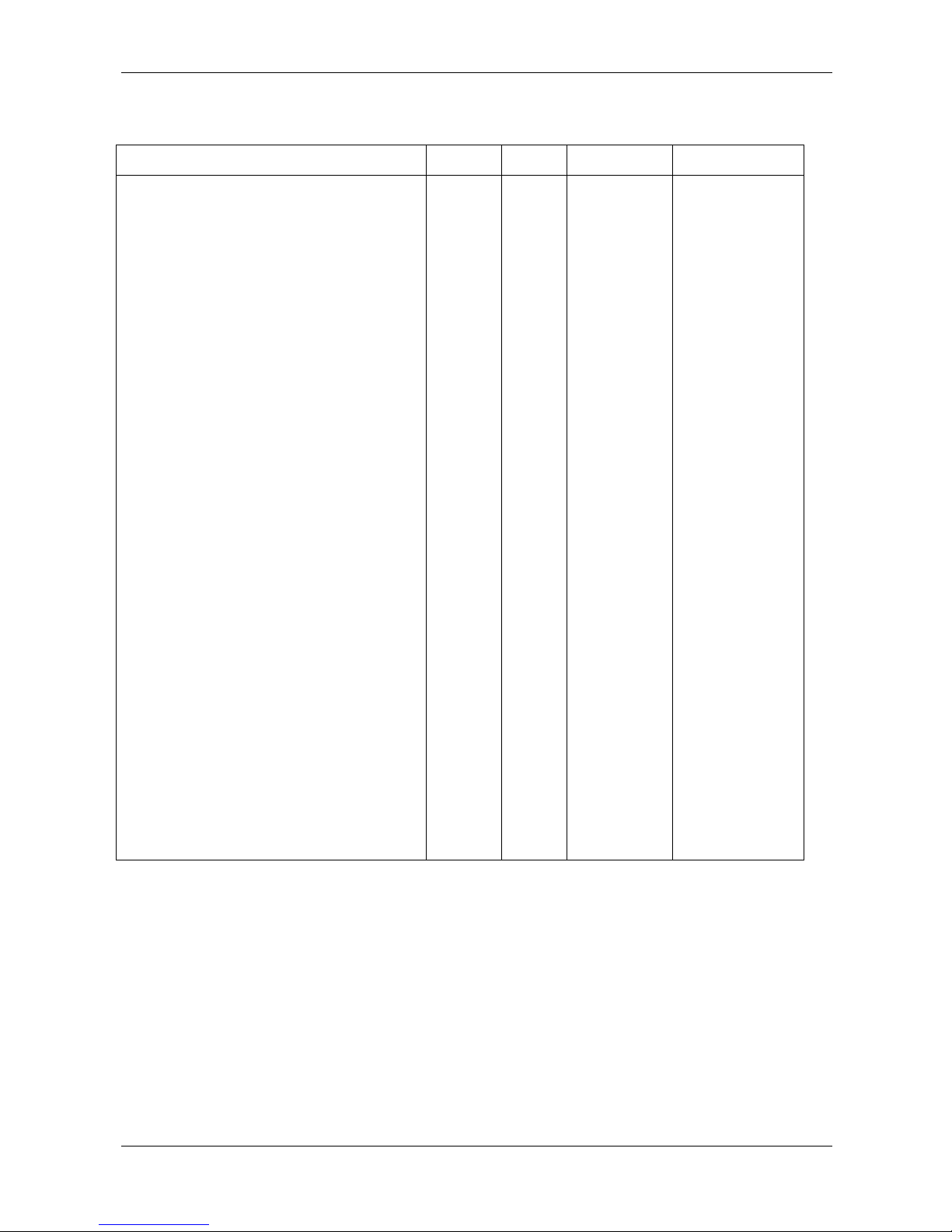

Steering damper

The steering damper damping force can be adjusted by its adjuster.

The damping force is adjusted in 7steps. The damping force increases

as turning the adjuster clockwise and obtain the maximum damping

force at the turning end.

The damping force decrease as turning the adjuster counter-clockwise.

Standard setting: Minimum damping force

(1) Steering damper (2) Adjuster

(A) Increase damping force (B) Decrease damping force

CAUTION

Do not start the steering damper setting from its maximum

damping force position. It will cause problem in handling of the

motorcycle.

Always start the steering damper setting from its minimum

damping force position.

Note

・Do not turn the adjuster to clockwise further than its turning

end. It will break the stopper in the steering damper and

cause damping force adjustment malfunction.

・Be sure to install the steering damper within the tolerance of 2

spherical bearings movement. Inappropriate installation will

create unnecessary stress on the piston rod and disturb

steering movement.

・Do not damage the sliding surface of the piston rod. Score

marks or hitting marks cause damper oil leaks.

・Make sure that the steering damper is not fully stretched at

both steering ends. Also check the steering damper for

interference with the frame or other parts of the motorcycle.

・Do not disassemble the steering damper unit

・Make sure to use the thick washers (2.3mm) between the frame

and spherical bearing, and bottom bridge and spherical

bearing, then tighten the bolts.

(1)

Washers(2.3mm) (2) Spherical bearings

PRINT EDITION 2.1

1-6

SERVICE INFORMATION

Service specification

Unit: mm

ITEM STANDARD SERVICE LIMIT

Recommended transmission oil

HONDA Ultra-G1 (4-stroke

motorcycle oil)

LUBRICATION

SYSTEM

SPECIFICATIONS

Recommended engine oil

HONDA Ultra-G1 (4-stroke

motorcycle oil)

Venturi diameter 40

Carburetor identification number FCR12C A

Float level 6.0

Main jet #160

Slow jet #42

Jet needle NCYR

Pilot screw initial opening 1-1/4 turns out

FUEL SYSEM

SPECIFICATIONS

Jet needle clip position(Standard)

4th groove from top

Coolant

Tap water (soft water) or

drinking water

COOLING SYSEM

SPECIFICATIONS

Radiator cap relief pressure

1.1-1.4kgf/c ㎡

Clutch spring free length 38.8 38.0

Clutch disc thickness 2.92-3.08 2.85

CLUTCH

SPECIFICATION

Clutch plate warpage

- 0.10

Cylinder compression 392kPa(0.95-1.25kgf/c ㎡) -

Cylinder head warpage - 0.05

IN 35.580-35.660 35.44 Camshaft Cam lobe height

EX 25.081-25.161 24.98

Valve lifter O.D. 22.478-22.493 22.47 Valve lifter

Valve lifter bore I.D. 22.510-22.526 22.54

IN 0.12±0.3 - Valve clearance

EX 0.28±0.3 -

IN 4.975-4.990 - Valve stem O.D.

EX 4.965-4.980 4.955

Valve guide I.D. IN/EX 5.000-5.012 5.052

IN 0.010-0.037 - Stem-to-guide

clearance

EX 0.020-0.047 -

IN 14.8-15.0 - Valve guide projection

above cylinder head

EX 19.9-20.1 -

Valve and

valve guide

Valve sea t w idth IN/EX 0.90-1.10 1.7

IN 39.47 38.5 Valv e

spring

Valve spring free

length

EX 43.07 42.1

Rocker arm I.D. 12.016-12.034 12.07

Rocker arm shaft O.D. 11.977-11.985 11. 93

CYLINDER

HEAD/VALVE

SPECIFICATION

Rocker

arm

Rocker arm-to-shaft clearance 0.031-0.057 0.11

War pa ge - 0.05 Cylinder

I.D. 78.00-78.015 78.025

Circularity / Cylindricity - 0.010

O.D. (7mm from the bottom of skirt) 77.970-77.980 77.940

Piston

Cylinder-to-piston clearance 0.020-0.045 0.085

Piston pin bore I.D. 16.002-16.008 16.03

Piston pin O.D. 15.994-16.000 15.98

Piston pin

Piston-to-piston pin clearance 0.002-0.014 0.04

Top ring 0.15-0.25 0.39 Piston ring end

gap

Oil ring 0.20-0.70 0.90

Piston ring

Piston ring-to ring groove

clearance (Top)

0.065-0.100 0.08

Connecting rod small end I.D. 16.016-16.038 16.04

CYLINDER/PISTON

SPECIFICATIONS

Connecting rod-to-piston pin clearance 0.016-0.044 0.06

PRINT EDITION 2.1

2-1

SERVICE INFORMATION

ITEM STANDARD SERVICE LIMIT

FRONT 1.8kgf/c ㎡ - Cold tire pressure

REAR

1.9kgf/c ㎡ -

Axle runout - 0.5mm

Radical - 0.3mm Wheel rim runout

Axial - 0.3mm

Drive chain slack 20mm±2mm -

WHEEL/TIRE

SPECIFICATION

Drive chain slider thickness

- 2.0mm

Fork tube runout - 0.20mm

Fork oil (type) HONDA Ultra Cushion Oil

Special (SAE5W), SHOWA

SS05 or equivalent

-

R L

(Std) 111mm 106mm -

(Upper) 92mm 87mm -

Fork oil level

(Lower) 152mm

147mm -

(Std) 233c㎥ -

(Upper) 257c㎥ -

Fluid capacity

(Lower) 210c㎥ -

Compression damping adjuster standard position 10 clicks out from full in -

FRONT

SUSPENSION

SPECIFICATION

Rebound damping adjuster standard position

6 clicks out from full in -

Damper gas pressure 10.0-13.0kgf/c ㎡ -

Damper rod compressed force (at 10mm compressed) 15.4-20.0kgf -

Spring installed length 147mm -

Compression damping adjuster standard position 6 clicks out from full in -

REAR

SUSPENSION

SPECIFICATION

Rebound damping adjuster standard position 10 clicks out from full in -

Brake fluid DOT4 -

Brake disk thickness 4.0mm 3.5mm

Brake disc runout - 0.3mm

Master cylinder I.D. 12.700-12.743mm 12.755mm

Front

Master piston O.D. 12.657-12.684mm 12.650mm

Brake disk thickness 4.0mm 3.5mm

Brake disc runout - 0.3mm

Master cylinder I.D. 12.700-12.743mm 12.755mm

Master piston O.D. 12.657-12.684mm 12.650mm

Caliper cylinder I.D. 27.000-27.005mm 27.06mm

HYDRAULIC

BRAKE

SPECIFICATION

Rear

Caliper piston I.D. 26.900-26.950mm 26.85mm

PRINT EDITION 2.1

2-2

SERVICE INFORMATION

Tightening torque values

Engine

ITEM

THREAD

DIA.(mm) QTY

TORQUE

N・m(kgf・m)

REMARKS

Engine oil drain bolt

Transmission oil drain bolt

Timing hole cap

Crankshaft hole cap

Rocker arm shaft cap

Spark plug

Throttle drum cover bolt

Needle jet

Main jet

Slow jet

Starter jet

Leak jet

Maintenance cover bolt

Carburetor top cover bolt

Throttle shaft screw

Float chamber screw

Diaphragm cover screw

Carburetor drain plug

SE valve lock nut

Hot start cable nut

Needle holder

Throttle position sensor mount torx screw

Water pump impeller

Cylinder head cover bolt

Camshaft holder bolt

Cylinder head nut

Cam chain tensioner bolt

Decompressor cam stopper bolt

Shift drum center bolt

Shift drum stopper arm bolt

Clutch center lock nut

Clutch spring bolt

Gear shift return spring pin

Crankshaft bearing set plate torx screw

Countershaft bearing set plate screw

Mainshaft bearing set plate bolt

Shift drum bearing set plate bolt

Drive sprocket bolt

Primary drive gear bolt

Balancer shaft nut

Oil jet mounting bolt

Flywheel nut

Pulse generator mounting bolt

Stator mounting screw

Clutch cover bolt

8

8

14

30

14

10

5

7

5

6

5

4

4

4

4

4

4

18

12

-

8

5

7

6

7

9

6

5

8

6

18

6

8

6

6

6

6

8

12

14

6

12

5

4

6

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

4

3

1

1

1

1

1

1

2

4

4

1

1

1

1

1

5

1

2

2

2

2

1

1

1

1

1

2

3

5

16 (1.6)

16 (1.6)

6.0 (0.6)

15 (1.5)

6.0 (0.6)

16 (1.6)

3.4 (0.3)

1.8 (0.2)

1.5 (0.2)

1.5 (0.2)

1.5 (0.2)

0.3 (0.03)

2.1 (0.2)

2.1 (0.2)

2.1 (0.2)

2.1 (0.2)

2.1 (0.2)

4.9 (0.5)

2.1 (0.2)

2.1 (0.2)

2.1 (0.2)

3.9 (0.4)

12 (1.2)

10 (1.0)

16 (1.6)

39 (4.0)

12 (1.2)

10 (1.0)

22 (2.2)

12 (1.2)

69 (7.0)

12 (1.2)

22 (2.2)

20 (2.0)

10 (1.0)

10 (1.0)

10 (1.0)

31 (3.2)

108 (11.0)

44 (4.5)

10 (1.0)

64 (6.5)

5.2 (0.5)

2.6 (0.3)

10 (1.0)

Apply engine oil

Apply engine oil

Apply grease

Apply grease

Apply locking agent

Apply locking agent

Reverse thread

Apply engine oil

Apply engine oil

Apply locking agent

Apply locking agent

Apply locking agent

(TB1373N or equivalent)

Apply locking agent

Apply locking agent

Apply locking agent

Apply engine oil

Apply locking agent

Apply engine oil

Apply locking agent

Apply locking agent

PRINT EDITION 2.1

2-3

SERVICE INFORMATION

FRAME

ITEM

THREAD

DIA.(mm) QTY

TORQUE

N・m(kgf・m)

REMARKS

Engine mounting bolt (1 crankcase bolt)

Steering thread

Steering stem bolt

Top / bottom bridge pinch bolt

Axle nut

Axle holder bolt

Fork bolt

Fork damper rod lock nut

Fork socket bolt

Swingarm pivot adjusting bolt

Swingarm pivot adjusting bolt lock nut

Swingarm pivot nut

Chain guard bolt

Rear cushion spring lock nut

Upper joint lock nut

Front brake caliper mounting bolt

Rear caliper pad pin

Rear caliper pad pin plug

Front brake hose oil bolt

Rear brake hose oil bolt

Front brake bleeder bolt

Front caliper bleeder screw

Brake bleeder screw

Front brake disc bolt

Rear brake disc bolt

Torque rod end nut

Fuel valve lock nut

Handle holder pinch bolt

Clutch cable nut

Clutch lever holder screw

Step holder socket bolt

Tw s ensor

10

26

18

8

14

8

39

20

10

30

30

18

6

50

16

10

10

10

10

10

8

10

8

6

8

8

18

8

8

5

8

12

3

1

1

6

2

4

2

2

2

1

1

1

2

1

1

2

2

2

2

2

3

1

1

6

3

2

12

1

1

2

4

1

41.2(4.2)

6(0.6)

59(6.0)

23(2.3)

69(7.0)

22(2.2)

34(3.5)

34(3.5)

34(3.5)

15(1.5)

44(4.5)

95(9.7)

8(0.8)

49(5.0)

64(6.5)

49(5.0)

18(1.8)

1(0.15)

24(2.4)

24(2.4)

24(2,4)

7(0.7)

7(0.7)

12(1.2)

42(4.3)

18(1.8)

19(1.9)

23(2.3)

10(1.O)

4(0.40)

15(1.5)

11(1.1)

Apply grease

Apply oil

Apply grease

Apply grease

Apply grease

Apply grease

Apply grease

Apply grease

・Do not apply oil or grease to fasteners unless otherwise specified in the table.

STANDARD TORQUE VALUES

FASTENER TYPE

TORQUE

N・m(kgf・m)

5mm bolt and nut

6mm bolt, SH flange bolt and nut

8mm bolt and nut

10mm bolt and nut

12mm bolt and nut

5mm screw

6mm screw

6mm flange bolt (NSHF type) and nut

8mm flange bolt and nut

10mm flange bolt and nut

5 (0.5)

10 (1.0)

22 (2.2)

34 (3.5)

54 (5.5)

4 (0.40)

9 (0.9)

12 (1.2)

26 (2.7)

39 (4.0)

PRINT EDITION 2.1

2-4

SERVICE INFORMATION

LUBRICATION & SEAL POINTS

ENGINE

ITEM LOCATION MATERIAL

Camshaft

Rocker arm

Valve stem

Valve lifter

Crankshaft

Clutch outer guide

Clutch lifter lever

Connecting rod

Mainshaft

Countershaft

Shift fork

Shift fork shaft

Each gears

Cam lobe, journal

Shaft, slipper surface

Valve guide sliding surface, stem end

Outer surface

Big end, small end

Sliding surface

Cam area

Small end inner surface

Spline area, sliding surface

Spline area, sliding surface

Claw, guide pin, sliding surface

Outer surface

Groove

Molybdenum oil solution

(mixture of the engine oil and

molybdenum grease with the ratio

1:1)

Engine oil drain bolt

Transmission oil drain bolt

Camshaft holder bolt

Crankshaft

Cylinder

Cylinder head nut

Decompressor cam

Balancer shaft nut

Piston

Piston pin

Piston ring

Clutch outer

Clutch lifter

Clutch disc / plate

Clutch center lock nut

Primary drive gear bolt

Flywheel nut

Shift drum

Shift spindle

Oil pump rotor

Seal ring

Each bearings

Each O-rings

Threads

Threads

Threads

Oil seal outer surface

Bore

Threads, seating surface

Sliding area

Threads, seating surface

Outer surface, pin hole

Outer surface

Whole surface

Sliding area

Needle bearing contact area

Lining surface

Threads, seating surface

Threads, seating surface

Threads, seating surface

Guide groove

Serration area

Sliding area

Whole surface

Rolling contact area

Whole surface

Engine oil

Crankshaft hole cap

Timing hole cap

Rocker arm shaft cap

Camshaft set ring

Oil filter spring

Dust seal

Wat er se al

Oil seals

Threads

Threads

Threads

Whole surface

Contact area

Lips

Lips

Lips

Multi-purpose grease

PRINT EDITION 2.1

2-5

SERVICE INFORMATION

ITEM LOCATION MATERIAL

Shift drum center bolt

Stator screw

Pulse generator bolt

Mainshaft bearing set plate bolt

Countershaft bearing set plate screw

Shift drum bearing set plate bolt

Oil jet mounting bolt

Breather plate bolt

Cam chain tensioner pivot bolt

Throttle shaft screw

Throttle position sensor torx bolt

Brake pedal pivot bolt

Decompressor cam stopper plate bolt

Oil guard plate bolt

Threads(Coating width: 6.5±1mm/ from 1~2mm off tip)

Threads(Coating width: 3.0±1mm)

Threads(Coating width: 4.5±1mm)

Threads

Threads(Coating width: 3.5±1mm)

Threads

Threads(Coating width: 6.5±1mm/ from 1~2mm off tip)

Threads(Coating width: 6.5±1mm/ from 1~2mm off tip)

Threads(Coating width:6.5±1mm/ from 1~2mm off tip)

Threads

Threads

Threads

Threads(Coating width: 6.5±1mm/ from 1~2mm off tip)

Threads

Locking agent

Crankshaft bearing set plate torx screw Threads(Coating width: 6.5±1mm) High strength locking agent

(TB1373N or equivalent)

AC generator wire grommet

Cylinder head

Seating surface

Semi-circular portion

Liquid sealant

FRAME

LOCATION MATERIAL REMARKS

Handle lever pivot bolt sliding area

Cable adjuster bolt threads

Axle shaft outer surface

Driven sprocket washer seating surfaces

Driven sprocket collar O-ring

Steering head bearing / race

Steering stem bolt threads / seating area

Caliper bracket both surfaces

Brake pedal pivot sliding area

Shift pedal pivot sliding area

Swingarm pivot ball bearing / needle bearing

Swingarm pivot dust seal lip

Swingarm pivot adjuster bolt threads / seating area

Cushion arm needle bearing

Cushion arm dust seal lip

Tw sensor threads

Multi-purpose grease

Master cylinder pivot sliding area / piston contact area

Rear brake caliper pin bolt

Rear brake caliper piston seal

Silicone grease

Silencer joint area Heat resistant sealing agent (ME30) MORIWAKI

Drive chain slider screw threads Locking agent

Steering thread Honda Ultra U

Handle grip / Throttle pipe Honda Bond A The material must not come

out more than 3mm

※Heat resistant sealing agent (ME30) Part number: 860-806-0600

PRINT EDITION 2.1

2-6

MAINTENANCE

PRINT EDITION 2.1

3-1

・Fuel leak, oil leak and coolant leak

・ Coolant level

・ Engine oil level

・ Transmission oil level

・Spark plug burning condition, coloration, tightening, cap loose

・Clutch lever play, clutch operation

・Throttle grip free play, throttle valve operation

・Steering head operation, loose, deformation or damages

・Frame damages, cracks

・Tire pressure, wear

・Front and rear suspension operation, oil leak

・Brake lever and pedal free play, brake performance, fluid level

・Drive chain slack, lubrication

・Drive chain slider damage, wear

・Exhaust spring fatigue, damage

・Nuts, bolts, fasteners tightening, loose (oil drain bolt wire-lock, specially)ock, specially)

Pre-ride inspection

Perform maintenance operation according to following chart to obtain performance of your MD250H. The maintenance

schedule may differ depending on condition of use. Machines subjected to severe use require more frequent servicing.

I: Inspect and Clean, Adjust, Lubricate or Replace if necessary. C: Clean. L: Lubricate

MAINTENANCE SCHEDULE

ITEMS

FREQUENC

Y

Inspection Replace Note

Throttle operation I

Carburetor box C

Breather tube I Bend, Break

Cooling system I

Engine oil I 500 km

Engine oil filter I 1,000 km

Transmission oil I 500 km Replace every after wet race

Camshaft 1,000 km 4,000 km Score, wear

Valve, Intake 1,000 km 2,000 km Bend, seat damage, Do not lap the intake valve

Valve, Exhaust 1,000 km 4,000 km Bend, seat damage

Cylinder head 1,000 km 4,000 km Valve seat face damage

Valve spring 1,000 km 2,000 km Break, Valve spring fa tigue

Piston 1,000 km 2,000 km Score, wear, Replace in case of a collision with valves

Piston rings 1,000 km 2,000 km Score, wear

Crankshaft 2,000 km 4,000 km Runout check, Service limit: L 0.05, R 0.03

Clutch I Every race Clutch spring fatigue

Spark plug 1,000 km 2,000 km

Drive chain I・L

Drive chain slider I

Drive / Driven sprocket I

Brake fluid I Replace every 3 races (Replace every after wet race)

Brake syste m I

Control cables I・LClutch, Axel

Exhaust silencer I

Suspension I

Overhaul operation is recommended after every

2,000km or every 4 races

Swingarm / Cushion linkage C

Fork oil I

Replace after the first 100km, then replace after every

3 races

Wheels / Tires I

Nuts, Bolts, Fasteners I

WARNING

Improper inspection or maintenance service can be a

cause of unpredictable troubles or serious accidents.

・Be sure to perform inspection and maintenance

service correctly

・Perform Pre-ride inspection before use

・All defectives or abnormalities must be repaired

before use

MAINTENANCE

During engine warm-up

・Thermometer, rev counter operation

・Fuel leak, oil leak and coolant leak

During running

・Thermometer, tachometer indicating value

・Carburetor setting

・Gear ratio setting

・Control system (shift pedal, throttle or others) operation

・Brake performance

Post-ride inspection

・Fuel leak, oil leak and coolant leak

・Nuts, bolts, fasteners tightening, loose or fall

Note

Periodic replacement parts and consumables must be

checked every after riding and replaced if necessary.

・Parts replacement schedule is based upon sprint race conditions and therefore, it is reference for your use. Machines subjected to severe use

require more frequent replacement operation. MORIWAKI ENGINERRING is not responsible for lifetime of any periodic replacement

parts or consumables.

ITEMS REMARK

Engine

Clutch disc, plates

Clutch springs

Drive sprocket

Spark plug

Thickness, discoloring, wear

Fatigue

Wear, damage

Wear on electrode, gap, insulator damage

Frame

Tires

Brake pads

Drive chain slider

Driven sprocket

Exhaust spring

Silencer glass wool

Wear

Wear

Wear

Wear, damage

Fatigue, damage

Exhaust noise increase

PRINT EDITION 2.1

3-2

MAINTENANCE

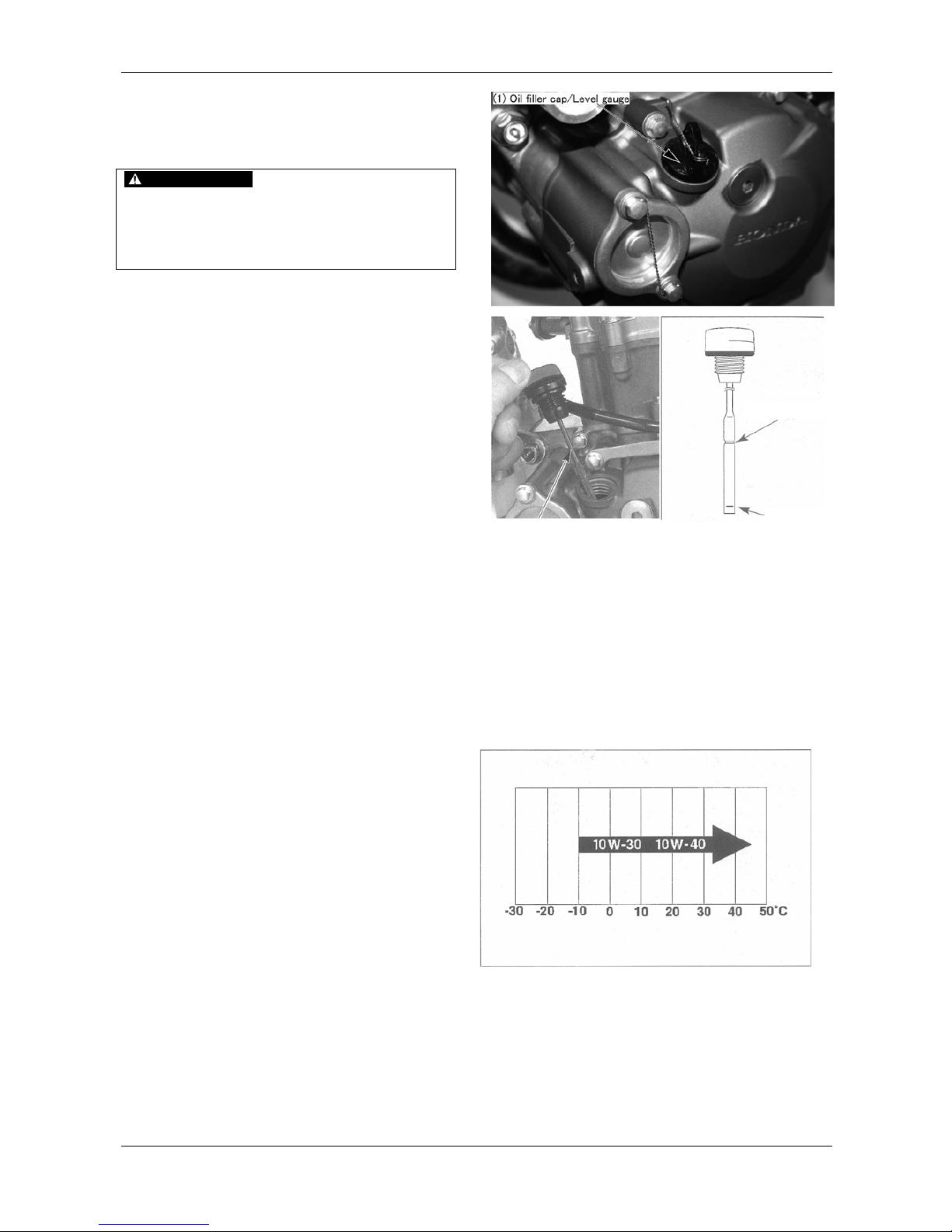

Engine oil / Oil filter

Oil level inspection

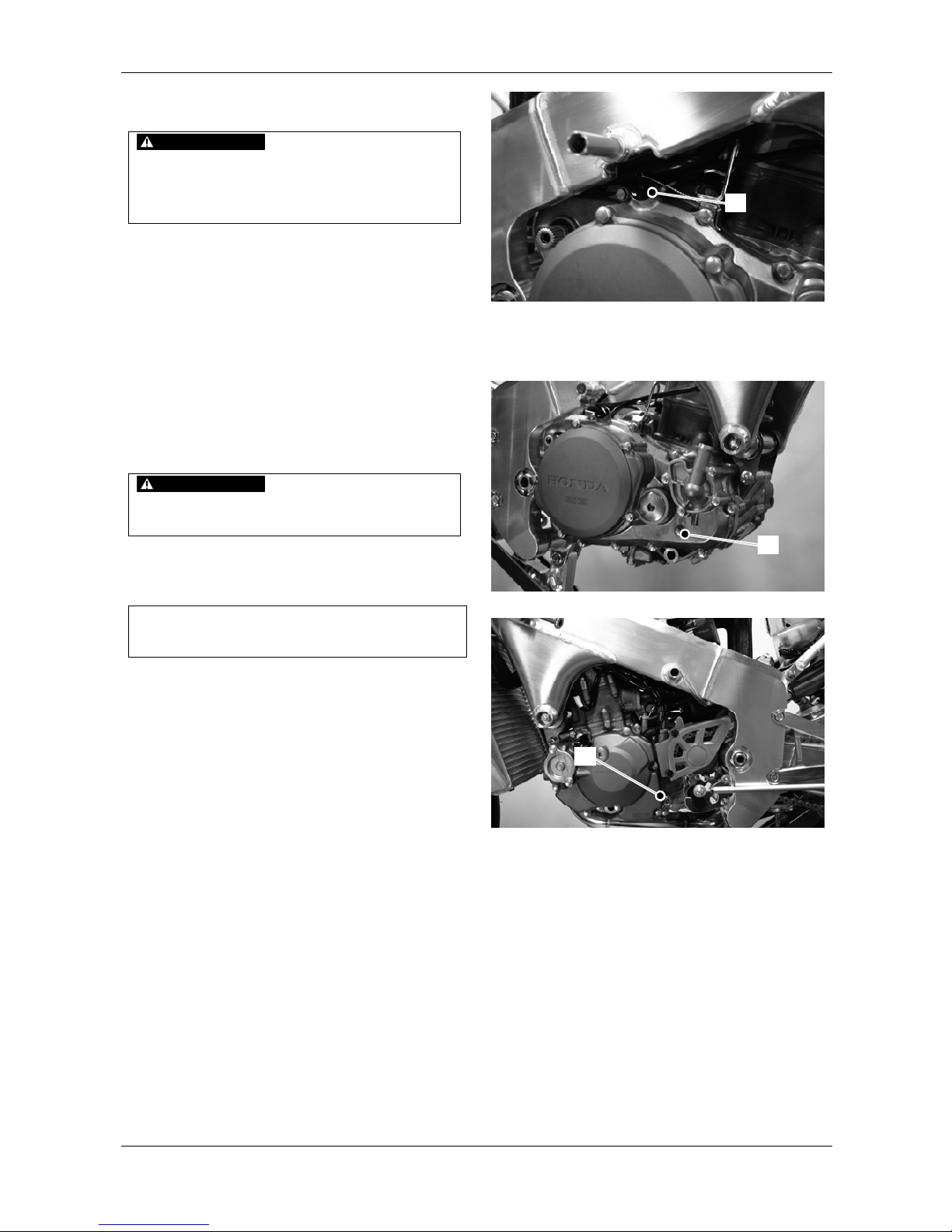

CAUTION

・Support the machine upright on a level surface when you

perform oil level inspection or adding oil.

・Be aware that the engine and the transmission have

individual lubrication systems.

Start the engine and let it idle for 3 minutes.

Stop the engine and wait 3 minutes.

Remove the oil filler cap / level gauge and wipe the oil with a

clean cloth.

Insert the level gauge without screwing it in, remove it and

check the oil level.

Oil level must be within upper and lower level lines.

Lower level line

(1) Oil filler cap / Level gauge

Upper level line

If the oil level is below or near the lower level line on the

level gauge, add the recommended engine oil to the upper

level line

SUGGESTED OIL:

・Honda Ultra G1 (4-stroke motorcycle oil)

SAE10W-30

Or an equivalent oil with following specifications.

・API classification: SG, SH or SJ

・JASO standard: MA

・SAE viscosity: Refer to the chart

Oils with API classification specified above may not be

suitable to your machine due to slight difference in

characteristics.

PRINT EDITION 2.1

3-3

MAINTENANCE

PRINT EDITION 2.1

3-4

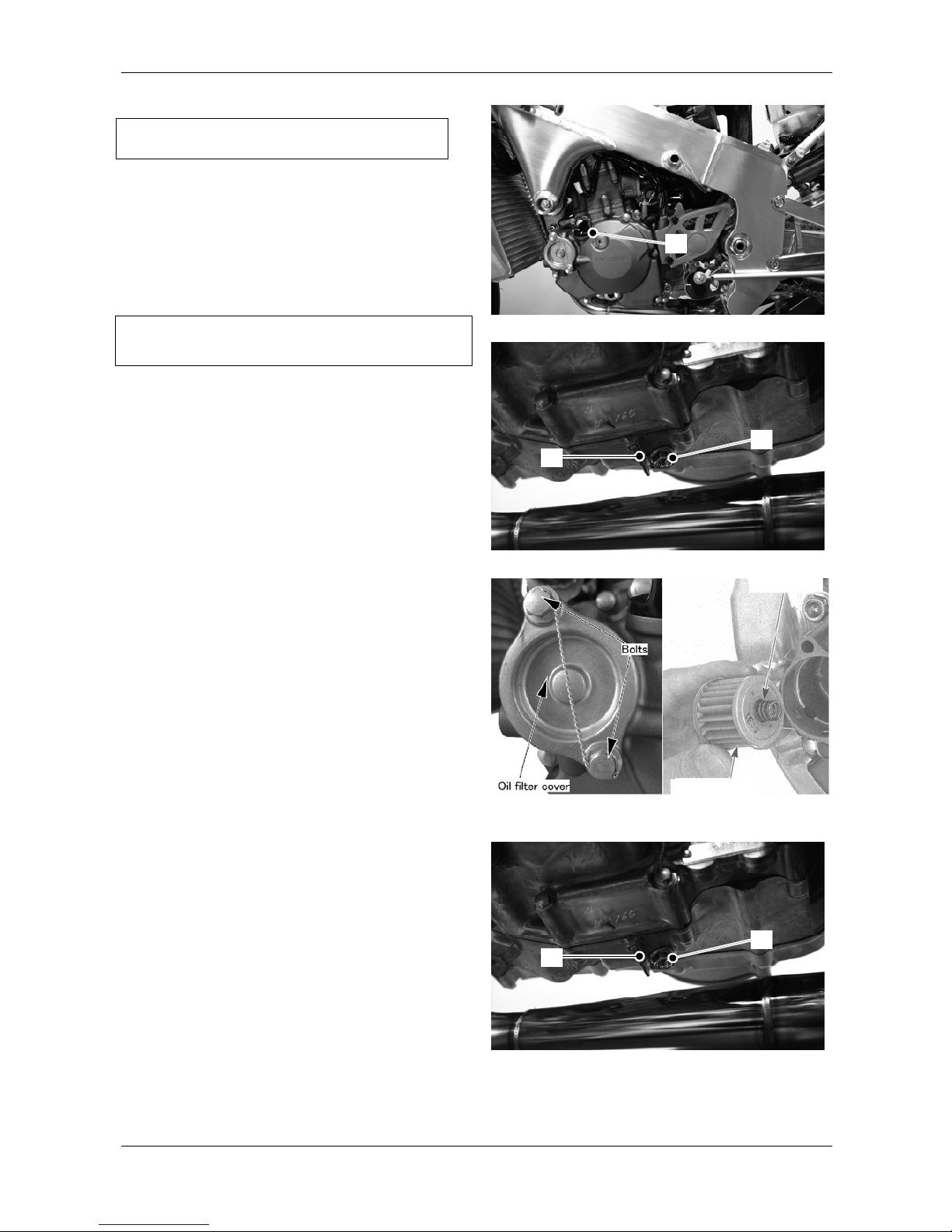

Engine oil / Oil filter change

Note

It is easier to drain the engine oil when it is warm.

Start the engine and let it idle for 3 minutes. Stop the

engine and support the machine upright on a level surface.

Remove the oil filler cap / level gauge.

Remove the bolts and oil filter cover.

Remove the oil filter and spring.

Install the engine oil drain bolt with a new sealing washer after

engine oil completely drains.

Tighten the drain bolt to the specified torque.

Torque: 1 6N ・m (1.6 kgf・m)

Wire-lock the drain bolt with the engine case.

Remove the engine oil drain bolt and sealing washer, and drain the

engine oil.

Note

Operate the starter motor for a few seconds while pushing the

engine stop button, so the engine oil completely drains.

(1)

(1)

(2)

(1)

Drain bolt / Sealing washer (2) Wire-lock

(1) Oil filler cap / Level gauge

Oil filter

Spring

(1)

Drain bolt / Sealing washer (2) Wire-lock

(1)

(2)

MAINTENANCE

PRINT EDITION 2.1

3-5

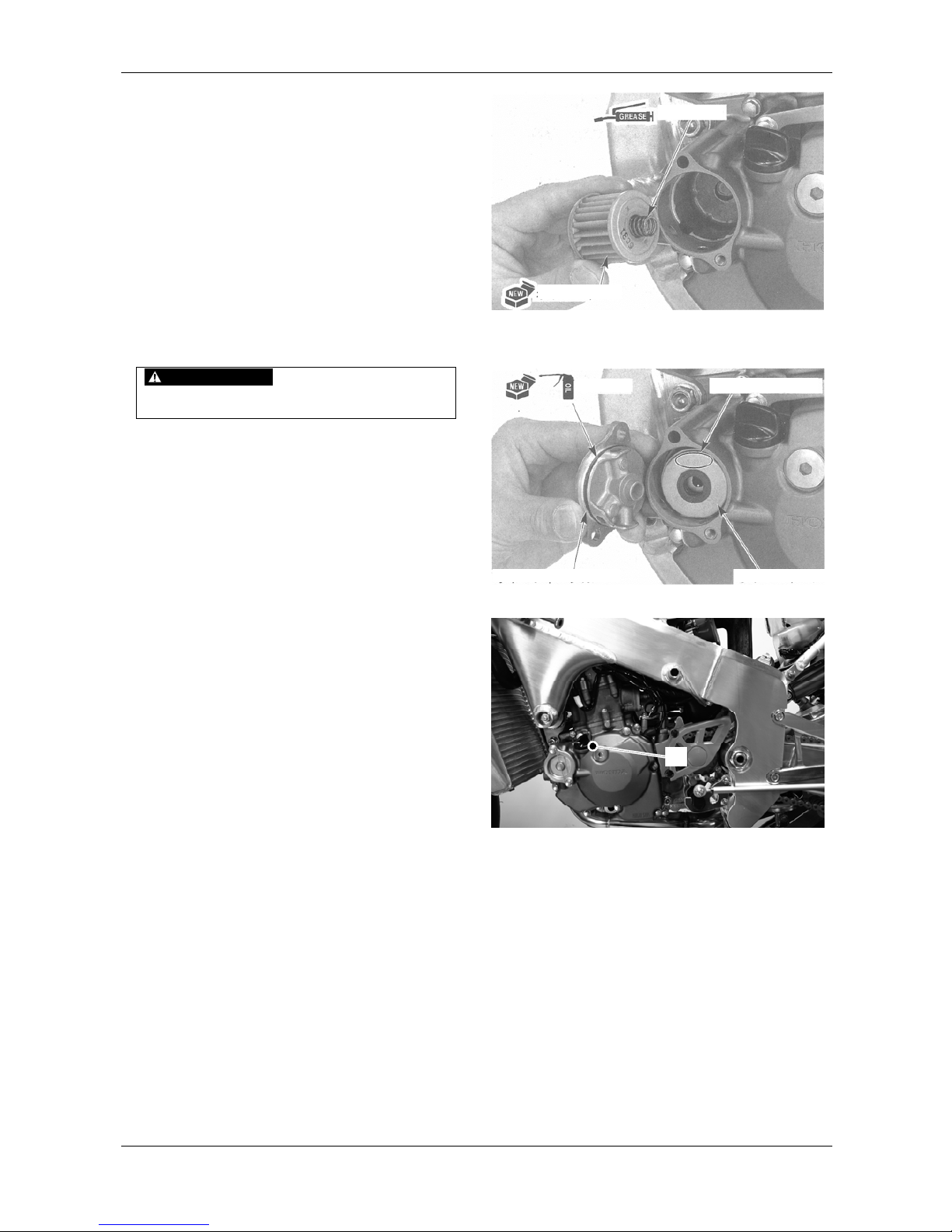

A

pply grease to the filter side of the spring end, then install the

spring into the new oil filter.

Install the oil filter assembly.

CAUTION

Be sure to install the oil filter with the “OUTSIDE”

mark facing out

A

pply engine oil to a new O-ring and install it to the oil filter

cover.

Install the oil filter cover and tighten the bolts securely.

Torque: 1 0N ・m (1.0 kgf・m)

Wirelock the bolts to each other.

Fill the engine with the recommended oil.

Oil capacity:

0.66 liter (at draining)

0.69 liter (at oil filter change)

0.85 liter (at engine disassemble)

Install the oil filler cap / level gauge and tighten it securely.

Start the engine and make sure there are no oil leaks.

Stop the engine and check the oil level.

Wirelock the bolts to each other.

(1)

(1) フィラキャップ/レベルゲージ

Oil filter

Spring

“OUT SIDE” mark

O-rin

g

Oil filter cove

r

Oil filte

r

(1) Oil filler cap / Level gauge

MAINTENANCE

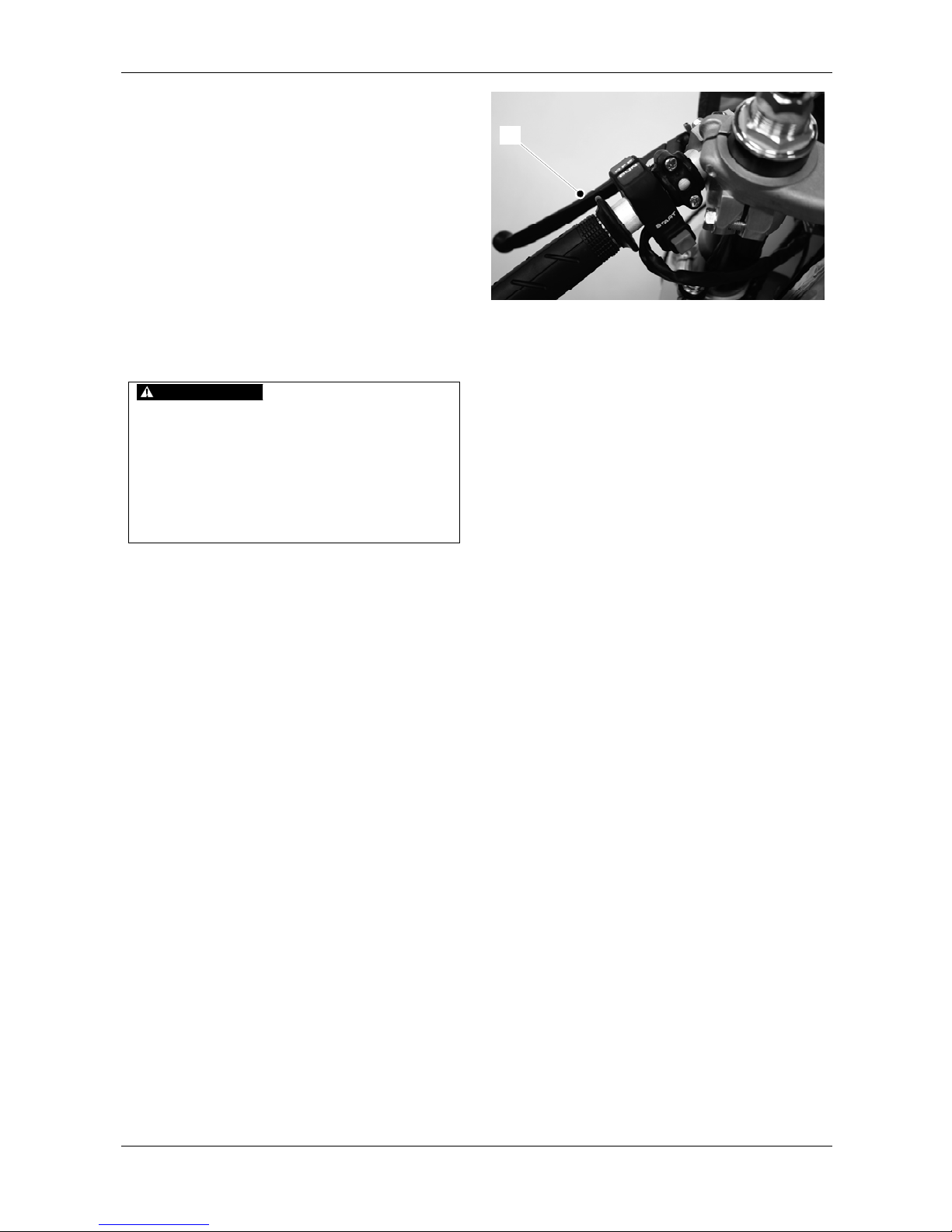

CAUTION

・Support the machine upright on a level surface when you

perform oil level inspection or adding oil.

・Be aware that the transmission and engine have

individual lubrication systems.

Start the engine and let it idle for 3 minutes.

Stop the engine and wait 3 minutes.

Support the motorcycle upright on a level surface, and remove

the oil filler cap, oil check bolt and sealing washer. A small

amount of oil should flow out of the check bolt hole. If a large

amount of oil come out from the hole, let it drain until stops.

If no oil flows out of the check bolt hole, add oil slowly through

the oil filler hole until oil starts to flow out of the check bolt

hole. Install the oil filler cap and oil check bolt with a new

sealing washer, then restart the engine and repeat the

procedures above.

CAUTION

After checking the oil level or adding oil, tighten the oil

check bolt and oil filler cap securely. And make sure

there are no oil leaks.

Transmission oil change

Note

Warm-up the engine before draining the oil. Support the

motorcycle upright on a level surface to drain the oil.

Remove the oil filler cap from the right crankcase cover and

the oil drain bolt from the left crankcase to drain oil.

A

fter the oil has drained completely, apply transmission oil

to the drain bolt threads and install the drain bolt with a

new sealing washer. Tighten the transmission oil drain bolt

to the specified torque.

Torque: 16 N・m (1.6 kgf・m)

A

dd the recommended transmission oil.

Recommended transmission oil:

・Honda Ultra G1 (4-stroke motorcycle oil)

SAE10W-30

Or an equivalent oil with following specifications.

(1)

(1) Oil check bolt / Sealing washer

(1)

(1) Drain bolt / Sealing washer

Wir-lock the oil filler cap.

・API classification: SG, SH or SJ

・JASO standard: MA

Oils with API classification specified above may not be suitable

to your machine due to slight difference in characteristics.

Transmission oil

Transmission oil level inspection

(1)

(1) Oil filler cap

Transmission oil capacity: 0.67 liter (at draining)

: 0.75 liter (at disassembly)

Check the oil level after performing the oil change operation.

Wire-lock the transmission oil drain bolt.

PRINT EDITION 2.1

3-6

MAINTENANCE

PRINT EDITION 2.1

3-7

A

fter the oil has drained completely, tighten the drain bolt

securely and wire-lock it.

(1) Overflow tube

Cooling system

Cooling system inspection

1. Check on coolant leak

2. Inspect the radiator houses for cracks or deterioration, or

loose of bands

3. Inspect the radiator installation

4. Check the overflow tube for its installation status and

clogging.

5. Check the radiator air passages for clogging.

6. Inspect the telltale hole for signs of coolant leakage

- If there is coolant leakage, the water pump sealing is

defective and it must be replaced.

- If there is oil leakage, the oil seal is defective and it

must be replaced.

WARNING

Removing the radiator cap while the engine is hot can

allow the coolant to spray out, seriously scalding you.

Always let the engine and radiator cool down before

removing the radiator cap.

(1) Telltale hole

(1)

Oil catch tank is build-in to the left hand side of the main

frame.

Insert the breather tube of the crankcase to the carburetor

box attachment.

Remove the drain bolt to drain any oil left in the oil catch

tank before ride.

Oil catch tank

(1) Drain bolt

(1)

(1)

MAINTENANCE

PRINT EDITION 2.1

3-8

(1) Overflow tube

(2) Overflow catch tank

Coolant overflow catch tank is attached on right hand side

of the main frame with tei-wraps.

Make sure to put an end of the overflow tube into the catch

tank.

Drain any coolant in the catch tank by taking it off from

the frame before ride.

Coolant overflow catch tank

(1) Spark plug

Spark plug

Recommended spark plug

NGK: R0409B-10 (Standard)

A

lways use spark plug with correct thermal value.

Remove the spark plug and measure its gap.

Standard: 0.6―0.7mm

If the spark plug gap is out of specification, replace the plug

with a new one.

In case a spark plug with incorrect thermal value is used, it

may cause engine malfunctions.

Spark plug gap

(1)

MAINTENANCE

PRINT EDITION 2.1

3-9

Fuel tank / Fuel strainer

Check the fuel tube for bend or crack.

Make sure there is no gasoline leaks.

Gasoline is explosive. It can cause you to be burned or

seriously hurt due to explosion.

When you handle gasoline;

・Engine must be stopped. The work are must be free

form flames, sparks or heat source.

・Work in a well ventilated area.

・If you spill gasoline, wipe and remove it immediately.

Fuel strainer cleaning

Install the fuel tank and refill it with gasoline. Again,

make sure there is no gasoline leaks.

Torque: 1 9N ・m(1.9kgf・m)

(1)

(1) Clutch lever

The fuel strainer is installed inside of the fuel valve which

is located below the fuel tank.

Perform the fuel strainer cleaning operation as follows;

1. Remove the seat cowl

2. Turn the fuel valve to OFF position and remove the

fuel tank

3. Drain gasoline from the fuel tank

4. Remove the fuel valve and clean the strainer screen

with treated oil

5. Open the fuel valve and air-blow it from outlet

6. Inspect the O-ring condition, then reassemble the

O-ring and the strainer screen into the fuel valve

7. Install the fuel valve with the outlet facing left.

Check the smooth operation of the clutch lever. Apply

grease to the pivot bolt and the clutch cable if necessary.

Inspect the clutch cable for damage.

Clutch

DENGER

DANGER

MAINTENANCE

PRINT EDITION 2.1

3-10

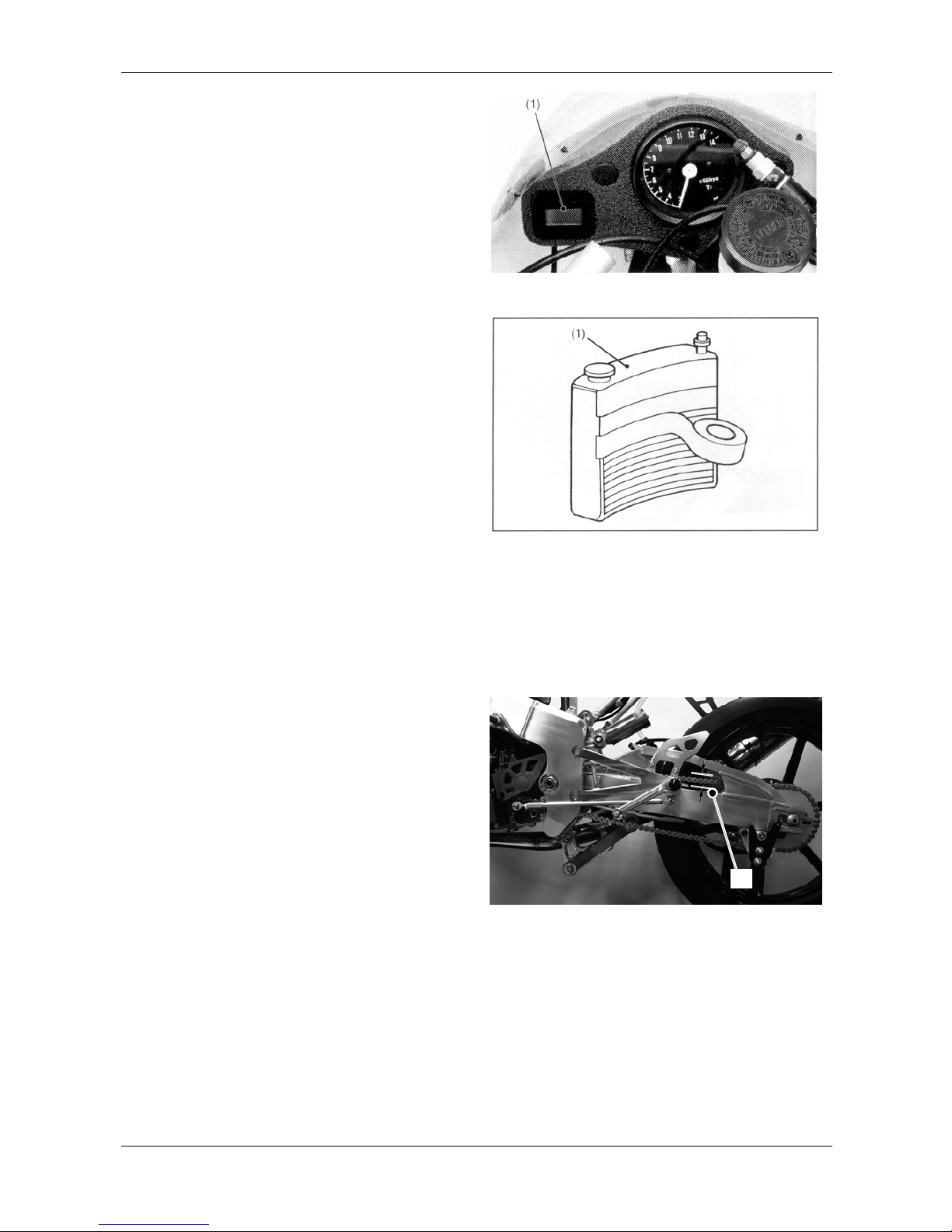

“888” will comes on for 3sec on the water temperature indicator

when you turn on the main switch to “RUN”, then it will start

indicating actual water temperature.

If the indicator shows “‐‐‐”, there will be the thermometer or

cable malfunctions.

(1) Water temperature indicator

Thermometer

Cover a part of radiator front with packing tape in case the

water temperature gets too low during running

A

ppropriate temperature: 70-80℃

(1) Radiator

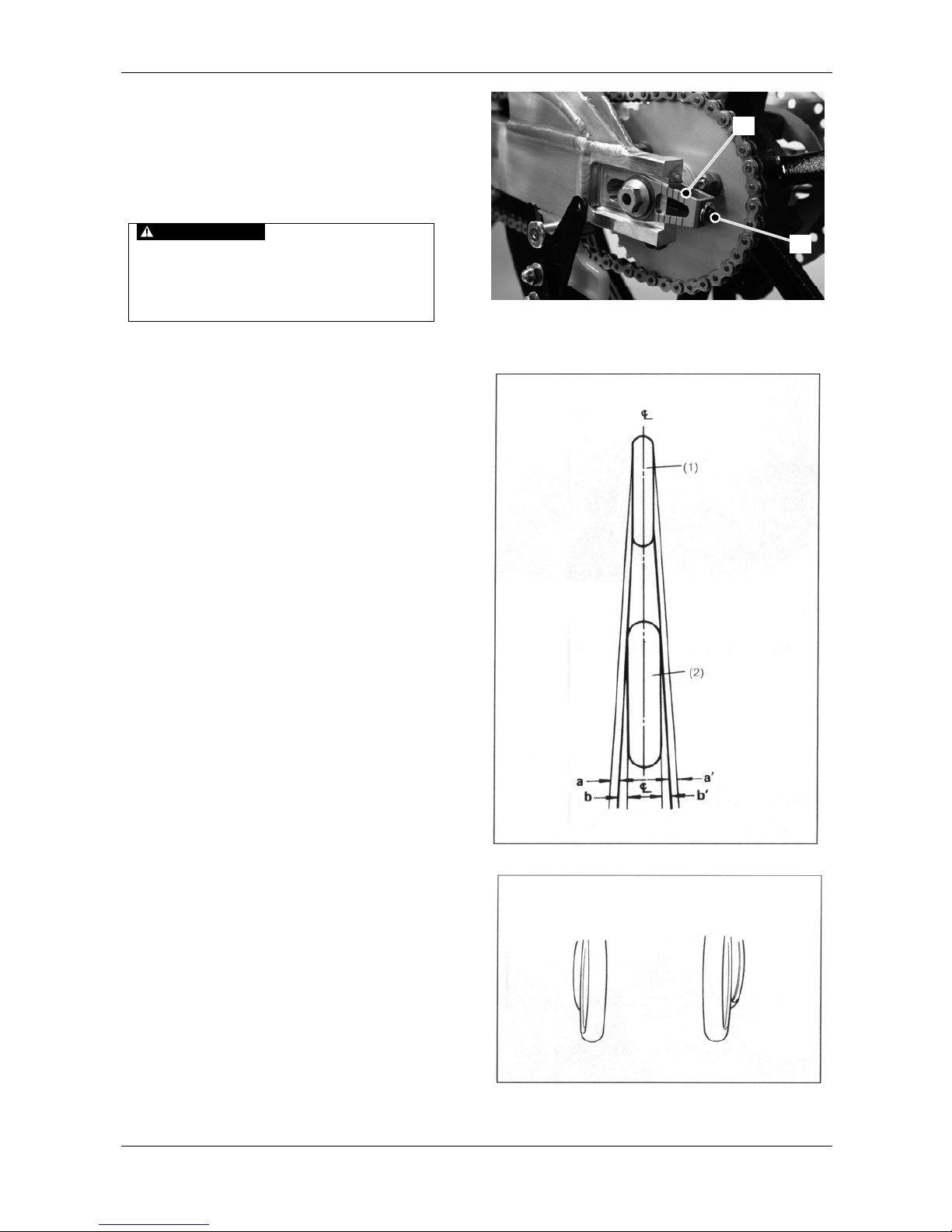

(1) Drive chain slack

At the first break-in ride or after replacing the drive chain with

new one, inspect the initial slack and adjust the chain slack.

A

lways be careful not to catch your fingers between the drive

chain and sprockets.

Stop the engine and raise the motorcycle with the maintenance

stand.

Put the gear in neutral position, then measure the chain slack at

upper side of the chain run near the chain slider

Rotate the rear wheel and measure drive chain slack at a few

different areas.

If there is one or more areas have larger chain slack than other

areas, replace the drive chain with new one.

Drive chain slack inspection

Drive chain slack: 20±2mm

(1)

※Indicated chain slack value is out-of-factory value.

The value may differ depending on the chassis setting.

MAINTENANCE

PRINT EDITION 2.1

3-11

(1) Adjust bolt (2) Alignment mark

Loosen the rear axle nut.

Turn the drive chain adjust bolt and adjust the chain slack.

Turn the adjust bolt counter-clockwise to reduce the

amount of chain slack

CAUTION

Improper drive chain slack will lose not only the

engine power but also the motorcycle running

performance. Make sure to check the chain slack

before ride.

A

dvice

Inspect the drive chain slack again, and check if the wheel

rotate smoothly. Then, lubricate the drive chain.

A

fter performing the drive chain slack adjustment, check

alignment of wheels and adjust it if necessary.

Drive chain slack adjustment

Torque: 6 9N ・m(7.0kgf・m)

Tighten the axle nut to the specified torque.

(1) Front tire (2) Rear tire

Wheel alignment

Inspect the alignment of wheels after performing the drive

chain slack adjustment.

1. Support the motorcycle upright on a level surface

2. Sit 1-2m behind the motorcycle and see both sides of the

wheels from axle down.

The handle is steered to the right

3. Steer the handle to left and right until the front wheel

becomes straight. Align the front edge of the rear tire

and rear edge of the front tire, then equalize the amount

of visible area of both side of the front tire.

Loose the axle nut and adjust the wheel adjustment by

adjusting the drive chain adjust bolts.

(1)

(2)

Straighten up the front wheel.

MAINTENANCE

PRINT EDITION 2.1

3-12

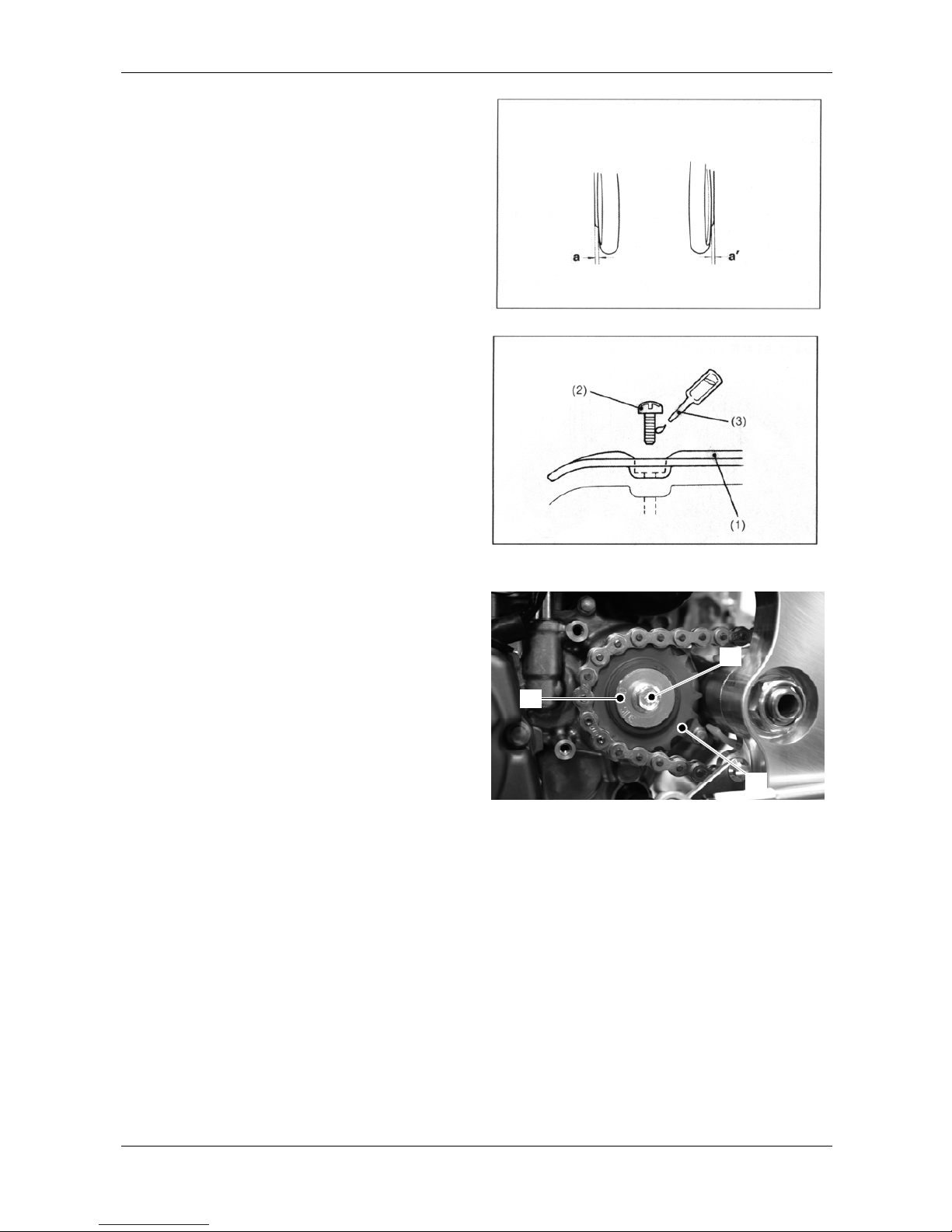

Equalize the [a] and [a’] appearance

(1) Drive chain slider (2) Screw (3) Locking agent

Drive chain slider

Check the chain slider for wear or damage.

Replace with new one if 2mm or more wear is noticed.

When you install a new drive chain slider, apply locking

agent to the screw and tighten it.

Re-tighten the screw after the first break-in ride.

Inspection

(1) Drive sprocket bolt (2) Spring washer (3) Drive sprocket

Drive / Driven sprocket

Drive sprocket change

Remove the lower front cowling.

Loosen the drive chain .

Put the motorcycle into the low gear and put the rear brake

on.

Remove following parts;

- Drive sprocket cover and chain guide

- Drive sprocket bolt

- Spring washer

- Drive sprocket

If inner surface of the spring washer has scratches, replace

it with new one.

Put the motorcycle into the low gear and put the rear brake

on.

Apply transmission oil to the thread and seating face of the

drive sprocket bolt.

Tighten the drive sprocket bolt to the specified torque.

Torque: 39 N・m (4.0kgf・m)

(1)

(2)

(3)

Handle is straight.

MAINTENANCE

Driven sprocket change

Remove the rear wheel.

Remove the driven sprocket collar, driven sprocket and

washer.

Reverse sequence to install the driven sprocket.

※It may require shim adjustment at installation.

A

djust the drive chain slack.

Check the alignment of the wheels.

(1) Driven sprocket (2) Sprocket washer

Advice

・Make sure to check the driven sprocket nut tightening

after riding.

・The sprocket nuts must be replaced with new ones after

every 3 detaching and attaching operation.

・Always use the specified driven sprocket nuts

(1) Oil cup cap (2) Lower level line

Open the oil cup cap to release remaining pressure in the

reservoir and check the brake fluid level.

Remove the screws and oil cup cap.

If the level is near the lower level line, check the brake pads

for wear, and replace them if necessary.

Check the brake system for brake fluid leaks.

Front master cylinder

Brake fluid

・Replace the brake fluid every after 3 races.

・The brake fluid has high hygroscopicity. Performing the

brake fluid replacement on high humidity day is not

recommended.

・Replace the brake fluid every time after riding in wet

condition.

Brake fluid type: DOT4

Open the oil reservoir plug to release remaining pressure in the

reservoir and check the brake fluid level before ride.

A vinyl tube is used for the remaster cylinder reser voir.

Measure the brake fluid level from the top of the vinyl tube.

Rear master cylinder

Fluid level: 40-50mm

If the level is near the lower level line, check the brake pads for

wear, and replace them if necessary.

Advice

・The vinyl tube may get smeared with brake fluid. Clean the

vinyl tube regularly.

・Do not change the handling of the vinyl tube. Changing the

handling may damage the vinyl tube and cause brake fluid

leaks.

The vinyl tube deteriorates naturally. Replace it every 6 months.

PRINT EDITION 2.1

3-13

MAINTENANCE

PRINT EDITION 2.1

3-14

(1) Rear brake torque rod

Rear brake torque rod

The rear brake is floating type.

The rod length must be adjusted around the standard length.

The length is measured between the center of pillow balls.

Standard length: 160mm

(1)

(1) Brake pads

V

isually check the brake pads for wear.

Replace the brake pads if either pad is worn to the bottom

of the wear limit groove.

Use genuine HRC brake pads.

Brake pads

(1)

Brake disc

Brake system

(1) Floating amount

(2) Brake disc

(3) Hub

Brake lever position adjustment. (⇒1-4)

Brake pedal height adjustment. (⇒1-5)

Measure the brake disc thickness with a micrometer.

Service limits: Front: 3.5mm

Rear: 3.5mm

Measure the rear brake disc warpage with a dial indicator.

Replace the brake disc if one or more of above measurements

exceeds the service limits.

Relace the front brake disc.

Replace the rear brake disc.

Brake disc

Service limit: 0.3mm

Service limit: 0.5mm

Measure the floating amount of the front brake with a

feeler gauge.

Maximum length: 167mm

MAINTENANCE

PRINT EDITION 2.1

3-15

(1) Flange bolts

Handle bar / Head pipe bearings

Handle bar

Check the handle bars for bend, crack and damage.

Confirm that the handle bars are on appropriate position.

Make sure that the flange bolts of handle holder and fork

top bridge are securely tightened.

Torque: 2 3N ・m(2.3kgf・m)(8mm bolt)

Torque: 1 0N ・m(1.0kgf・m)(6mm bolt)

Handle bar position: Touching the fork top bridge bottom

(1) Head pipe bearings

Remove the steering damper.

Raise the front wheel off the ground and check that the

handle bar moves freely from side-to-side.

Check the head pipe bearings for play by grabbing the bottom of fork

legs and attempting to move the fork toward to engine.

If the movement isn’t smooth or excessive play has detected, check

the head pipe bearings and make adjustment.

Head pipe bearings

(1) Wheel (2) Tire

Wheels / Tires

・Choose suitable wheels and tires for race condition.

・Tire pressure influences the motorcycle controllability and

durability of the tires. Tire pressure should be checked

and adjusted before ride.

・Tire pressure should be checked when the tires are cold.

Check the cold tire pressure.

Tire pressure: Front: 1.8 kgf/c ㎡

Rear: 1.9kgf/c ㎡

Inspect the wheels for damage.

Check wheels for loose. If excessive play has detected,

replace with new one. (⇒2-2)

Check the axle runout and wheel bearing for damage.

(1)

(2)

(1)

MAINTENANCE

Front suspension

1. Inspect slide pipes and oil seals for dirt.

2. Check the entire assembly for signs of fork oil leaks. Replace the

oil seals with new ones before ride in case oil leak is detected.

3. Check the action of the forks by operating the front brake and

compressing the front suspension several times.

Advice

Damage on suspension components will cause severe problems on

the machine controllability, therefore, make sure to inspect them

before ride..

(1) Rebound adjuster (2) Pre-load adjuster

The front suspension is adjustable. Suitable settings for different

condition can be obtained by performing following adjustment

procedure.

・Rebound adjuster

The rebound adjuster is located in the center of the fork bolt.

Turn the rebound adjuster to change rebound damping force

(extending).

・Compression adjuster

The compression adjuster is located at behind the axle holder.

Turn the adjuster to change compression damping force

(compressing).

・Turn the pre-load adjuster to change initial pre-load of the fork

springs.

・Change the amount of fork oil contained in the fork to change fork

travel.

・Different springs can be chosen (harder or softer) to adjust the

front suspension.

Fork

Grease is applied to the slide pipes at shipping. This is not a sign

of oil leaks.

・Perform the first break-in ride for suspension.

・The first break-in ride must be performed under Out-of-factory

suspension setting.

・To sustain the performance of the suspension, overhaul at HRC

service shop at every 2,000km is recommended.

(1)

Compression adjuste

r

・To obtain maximum performance of the front fork, disassembly

and inspection operation is recommended every after 3hrs of

riding.

・Fork oil should be changed every 3 races or after 7.5hrs of

riding. See Chapter5 for oil change and oil level check

operation.

・Honda Ultra Cushion Oil Special or equivalent oil is

recommended to obtain maximum performance.

・Regularly inspect and clean the front suspension components.

Check the oil seal for dirt or foreign substance. Deterioration

of the fork oil should also be inspected.

・For suspension setting operation, only turn 1 step at a time

when you adjust the compression or rebound adjuster.

Always set the both fork legs simultaneously, and perform test

run after change the settings.

・Always go back to standard setting when you have trouble

getting wishful settings, then re-try the setting

PRINT EDITION 2.1

3-16

Loading...

Loading...