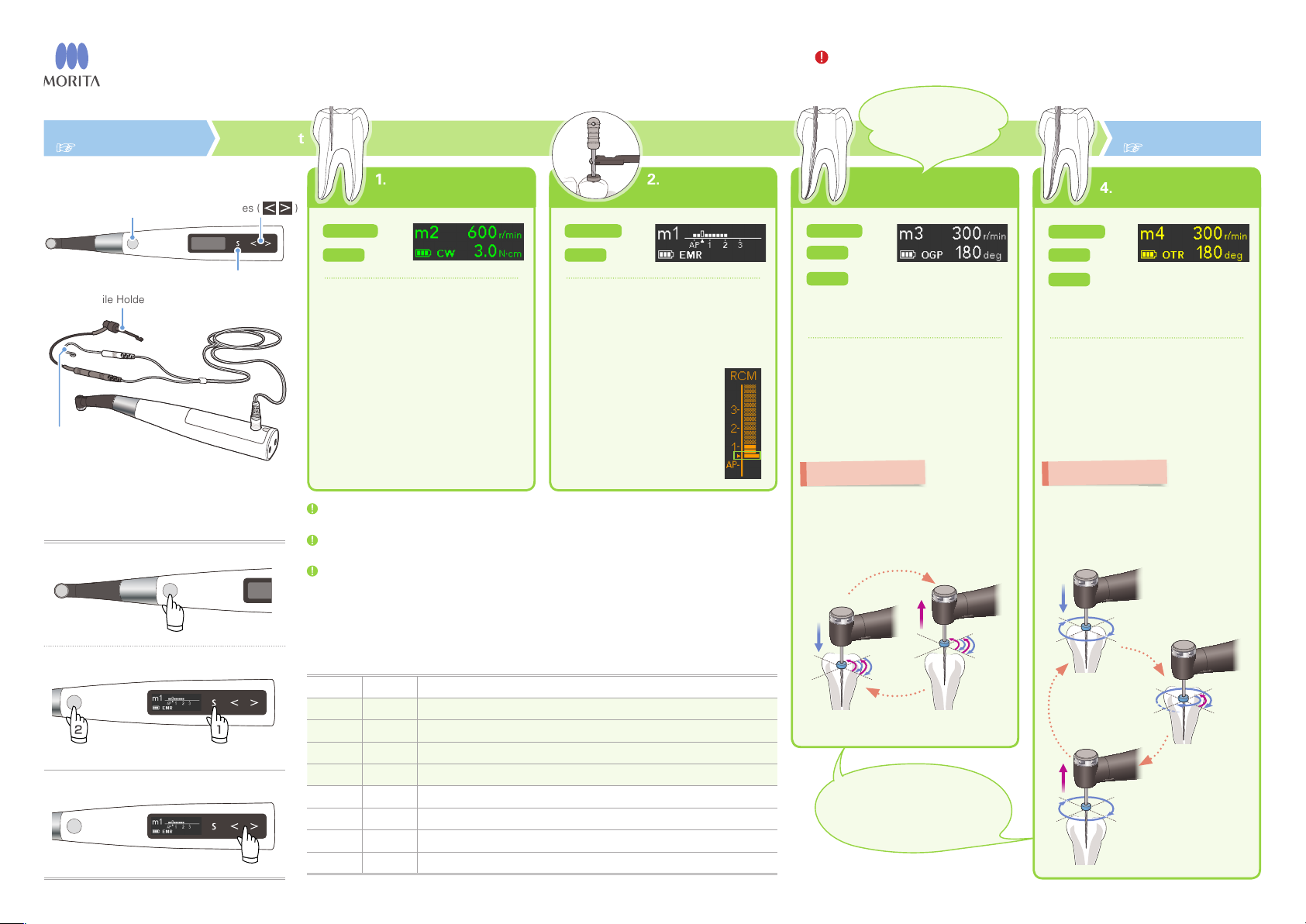

Morita Tri Auto ZX2 Quick Manual

Tri Auto ZX2 Quick Guide

Preparation

see back page

Treatment

Do not fail to read the Operation Instructions before using this instrument.

To create a smooth path

for canal shaping.

Maintenance

see back page

⹅Parts Identification

Main Switch

File Holder

Contrary Electrode

⹅Basic Operations

●Turn Power On

●Turn Power Off

●Memory Selection

Set Switches ( )

Select Switch

Hold down

1. Shape Upper Part

of Canal

Memory

Mode

1. Turn power on.

2. Select memory “m2”.

3. Install a file.

4. Shape upper part of the canal.

m2

CW

The Main switch is used to start and stop

the motor.

Memory

Mode

1. Select memory “m1”.

2. Hook the contrary electrode in

the corner of the patient’s mouth.

3. Clip the file in the file

holder.

4. Advance the file to 0.5

meter bar, and then po-

2. Canal

Measurement

m1

EMR

sition a rubber stopper.

For canals that are hard to measure, refer to “Canal Shaping (for

Instructions.

Use only files that are designed for clockwise filing. Use files very carefully and follow all the recom-

mendations of the manufacturer.

These instructions are for the default settings. If you change the settings, use the instrument accord-

ing to your own treatment procedures.

canals)” in the Operation

complex

⹅Default Settings

Almost all canals can be treated with the memories from m1 to m4.

●Default Memory Settings and Main Uses

Memory Mode Main Uses

m1 EMR

m2 CW

m3 OGP

m4 OTR

m5 OGP

m6 OGP

m7 OTR

m8 CCW

Canal measurement

Shape the upper part of canal.

Negotiation and making a glide path for a normal canal.

Canal shaping for a normal canal.

Negotiation and making a glide path for a complex canal

Making a glide path for a complex canal

Canal shaping for a complex canal.

Injection solutions such as calcium hydroxide, etc.

3. Glide Path 4. Canal Shaping

Memory

Mode

Files

• Nickel-Titanium: #10 – 20(t02)

• Stainless Steel: #10 – 15(t02)

• Glide path files

1. Select memory “m3”.

2. Install a file.

3. Hook the contrary electrode in

4. Make the glide path.

Repeat pressing lightly for 1 second and then pulling back.

Press lightly Pull back

m3

OGP

the corner of the patient’s mouth.

Hint

●Pecking Motion (for OGP)

Thoroughly wipe off all debris

stuck to the file.

Memory

Mode

Files

m4

OTR

• Nickel-Titanium:

#20 and larger shaping files

1. Select memory “m4”.

2. Install a file.

3. Hook the contrary electrode in

the corner of the patient’s mouth.

4. Perform canal shaping.

Hint

●Pecking Motion (for OTR)

Pull back when OTR action is triggered and then repeat.

Inserted in canal

With light load

(normal CW rotations)

With heavy

load, OTR action

is triggered.

Pull back quickly

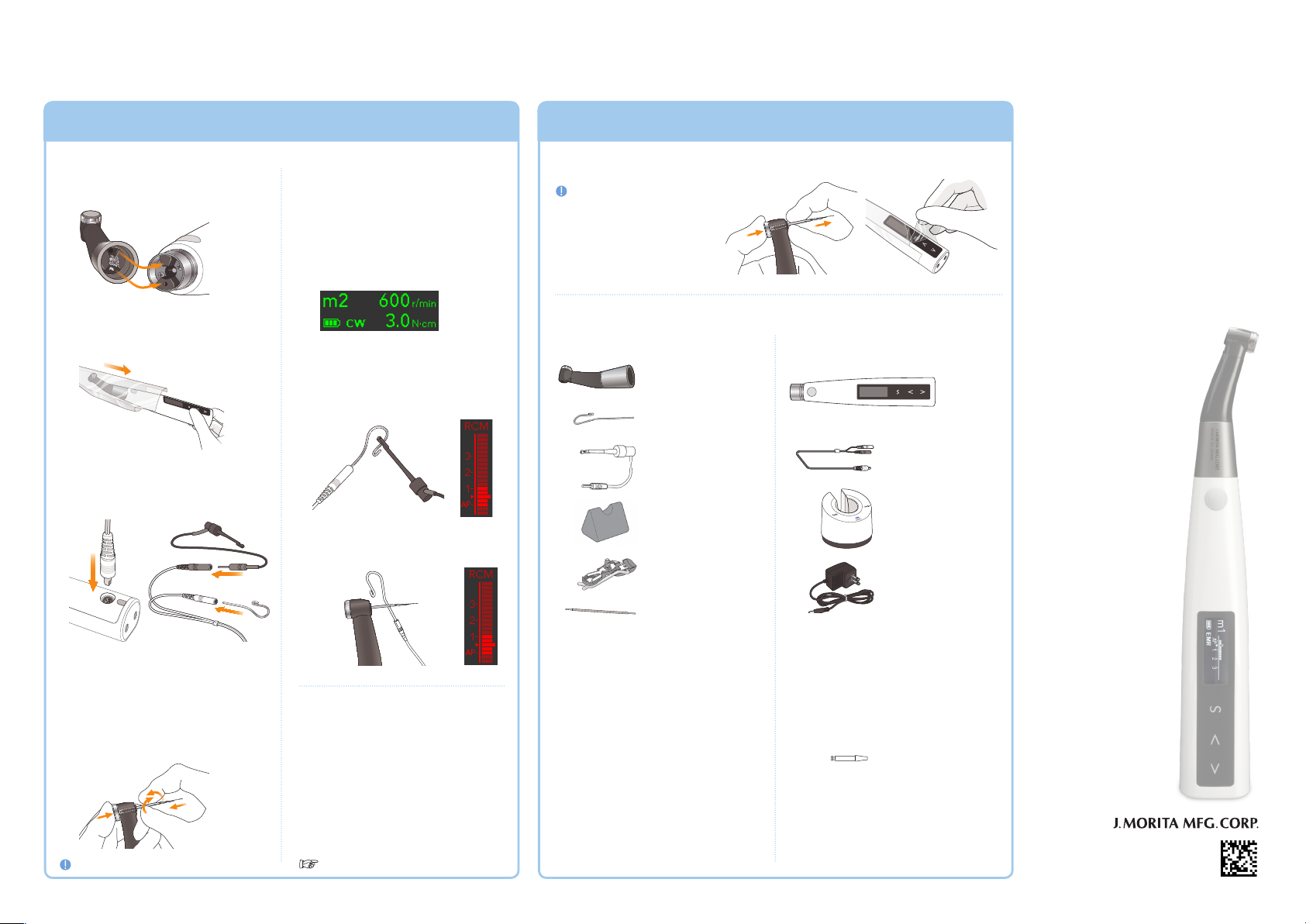

Tri Auto ZX2 Quick Guide

Preparation After Use and Maintenance

⹅Component Assembly ⹅Checking the Function

1. Connect the contra angle.

2. Put on a HP protective sleeve.

A new sleeve must be used for each

patient.

3. Connect the probe cord.

Connect the file holder to gray connector and the contrary electrode to

white one.

1. Turn power on.

2. Select memory “m2”.

Press the Main switch and make

sure the motor runs smoothly.

* Any memory except EMR mode may

be used.

3. Touch the contrary electrode

with the clip on the end of the

file holder and check that all the

indicator bars on the meter in

the LCD display light up.

4. Touch the contrary electrode

with the file and check in same

way.

⹅After Use

Always turn the instrument off.

1. Remove the file.

2. Take off the HP protective

sleeve.

3. Charge the battery.

⹅Maintenance

●Autoclavable Components

Contra Angle

Contrary Electrode

File Holder

Handpiece Holder

External File Electrode

(with cap)

Long File Holder

●Components Sterilized with Ethanol for Disinfection

Motor Handpiece

Probe Cord

Battery Charger

AC Adapter

4. Install a file.

Hold down the push button on the

contra angle and insert the file. Turn

the file back and forth until it is lined

up with interior latch groove and slips

into place.

Release the button to lock the file into

the contra angle.

2

1

Make sure the file will not come out.

3

⹅Calibration

Calibrate the instrument at the following

times:

• Right after purchase.

• Whenever the contra angle has been

replaced.

• Whenever, in OTR mode, the instrument

always alternates between forward and

reverse rotation and never rotates forward

continuously.

“Calibration” in the Operation Instructions.

1. Wash with running water and dry.

2. Use a threeway syringe etc. to blow

dry all moisture.

3. Wipe the components with a piece

of gauze that has been dampened

with Ethanol for Disinfection (Ethanol 70 to 80 vol%) and wrung out

thoroughly.

4. Lubricate only the contra angle with

the LS spray (LS oil).

5. Put components in individual autoclave pouches.

6. Autoclave the components.

* 134°(273.2° F) for at least 6 minutes or

121°(249.8° F) for at least 60 minutes.

1. Wipe the components with a

piece of gauze that has been

dampened with Ethanol for Disinfection (Ethanol 70 to 80 vol%)

and wrung out thoroughly.

●Component Washed and Sterilized with Ethanol for Disinfection

Guide Bur

1. Wash with running water and dry.

2. Wipe the components with a piece

of gauze that has been dampened

with Ethanol for Disinfection (Ethanol 70 to 80 vol%) and wrung out

thoroughly.

Man ufa ctu red by

Pub. No. : K316-80009-500

Printed i n Japan

Loading...

Loading...