Page 1

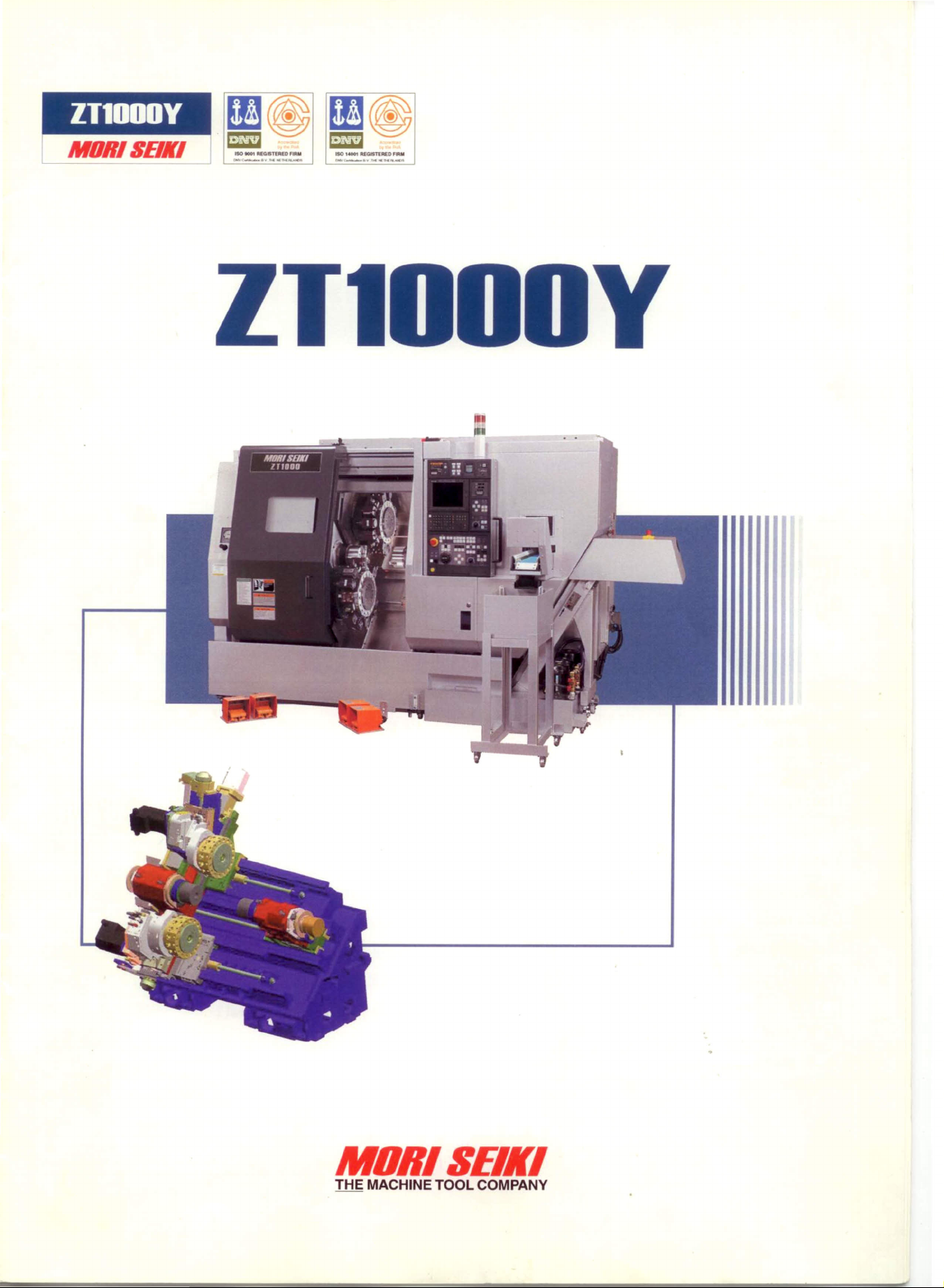

lTl000Y

MORI SElli

., ••• ~1nDlLDAUI 1:10,--.

_c-."......-__ _c- ....

1IIlGISTl1IIUI,....

M...-N ••.-

MORISElli

THE MACHINE TOOL COMPANV

Page 2

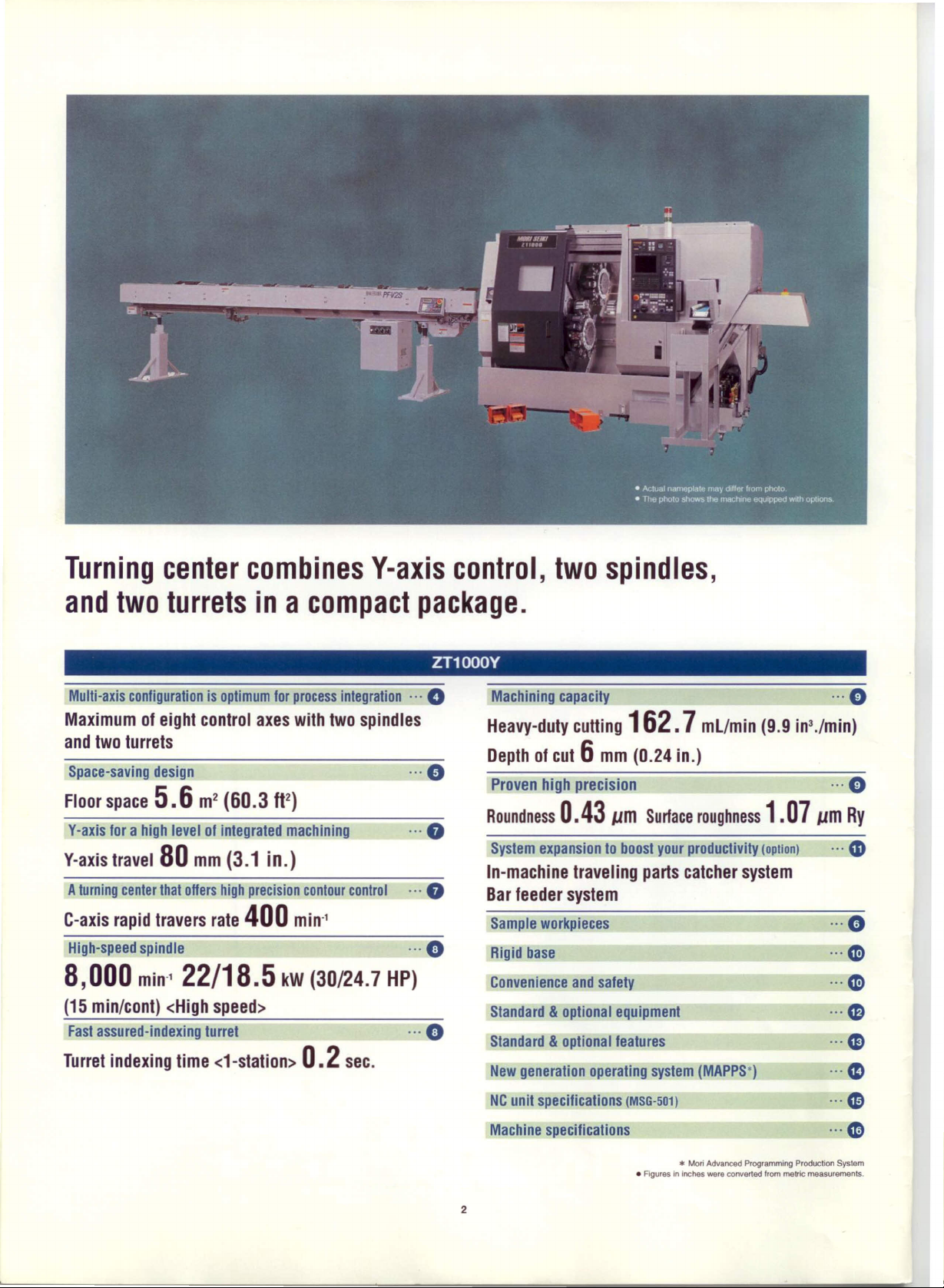

Turning center combines Y-axis control, two spindles,

and two turrets in a compact package.

ZT1000Y

Multi-axis configuration is optimum for process integration ...

Maximum01eight control axes with two spindles

and two turrets

Space-saving design ...

Floor space

Y-axis for a high level of integrated machining ...

Y-axis travel

Aturning centerthat offers high precision contour control ...

C-axis rapid travers rate

High-speed spindle ...

8,000

(15 mìn/com) <High

Fast assured-indexing turret ...

Turret indexing time et-statlon»

5.6

80

min·

2

m

(60.3 It

mm

(3.1 in.)

1

22/18.5

speens

2

)

400

mln'

kW (30/24.7 HP)

0.2

sec.

o

e

O

O

O

O

Machining capacity ...

Heavy-duty cutting

Depth01cut6mm (0.24 in.)

Proven high precision ...

Roundness

System expansion to boost your productivity

In-machine traveling parts catcher system

Bar leeder system

Sample workpieces

Rigid base

Convenience and safety

Standard&optional equipment

Standard&optional features

New generation operating system (MAPPS*)

NCunit specifications

Machine specifications ...

0.43

162.7

,.,m

Surface roughness

(MSG·501) •••

mL/min (9.9 in3./min)

1.07

(oplion) ...

,.,m

O

O

Ry

CD

O

O

O

G

eD

CD

CD

G

*

• Agures In inches were converted tram metrk: measurements.

2

Mori Advanced Programmlng Production System

Page 3

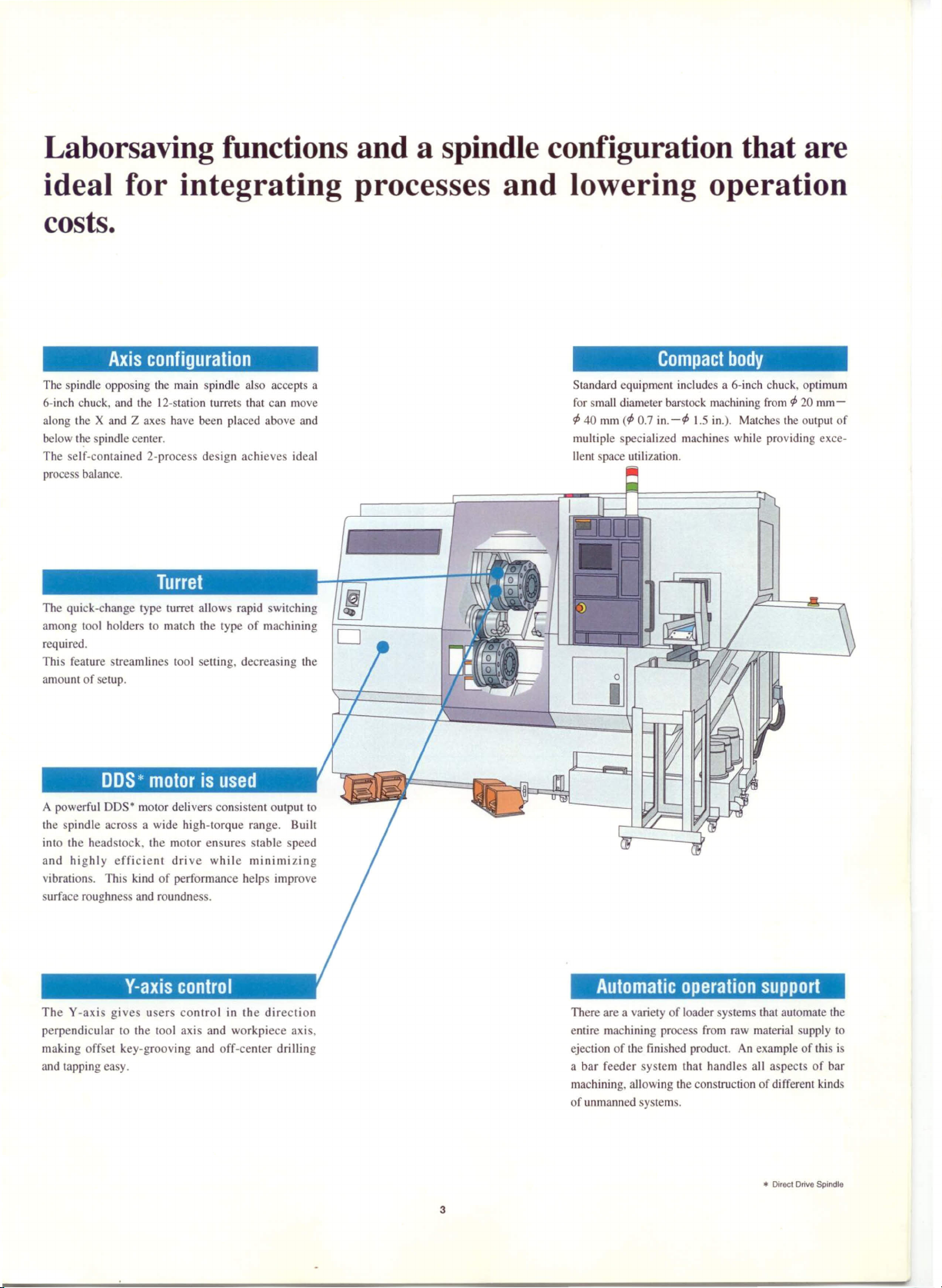

Laborsaving functions and a spindle configuration that are

ideai for integrating processes and lowering operation

costs.

Axis configuration

The spindle oppo ing the main spindle al o accepts a

6-inch chuck, and the 12-station turret that can move

along the X and Z axes have been placed above and

below l~e spindle center.

The seI f-contained 2-process de ign achieves ideaI

proces balance.

lurret

The quick-change type turret allows rapid switching

among 1001 holders to match the type of machining

required.

Thi feature treamlines 1001 euing, decreasing the

amount of setup.

DDS*motor is used

A powerful DDS· motor delivers consistent output to

the spindle across a wide high-torque range. Built

into the headstock, the rnotor ensure stable peed

and highly efficient drive while minimizing

vibralions. This kind of performance helps improve

urface roughnes and roundnes .

Compact body

Standard equipment includes a 6-inch chuck, optimum

for small diameter barstock machining from<P20 mm+

<P

40 mm

(<p

0.7 in.

-<P

1.5 in.). Matches the output of

multiple specialized machines while providing exce-

llent space utilizalion.

o

The Y-axi gi ves users control in the direction

perpendicular lO the 1001 axi and workpiece axi ,

making off et key-grooving and off-center drilling

and tapping easy.

Automatic operation support

There are a variety of loader y tems that automate the

entire machining process from raw material supply to

ejection of the fini hed producI. An example of this i

a bar feeder ystem that handles ali a pects of bar

machining. allowing the construction of different kinds

of unmanned y tem .

*

Direct Orfva Spindle

3

Page 4

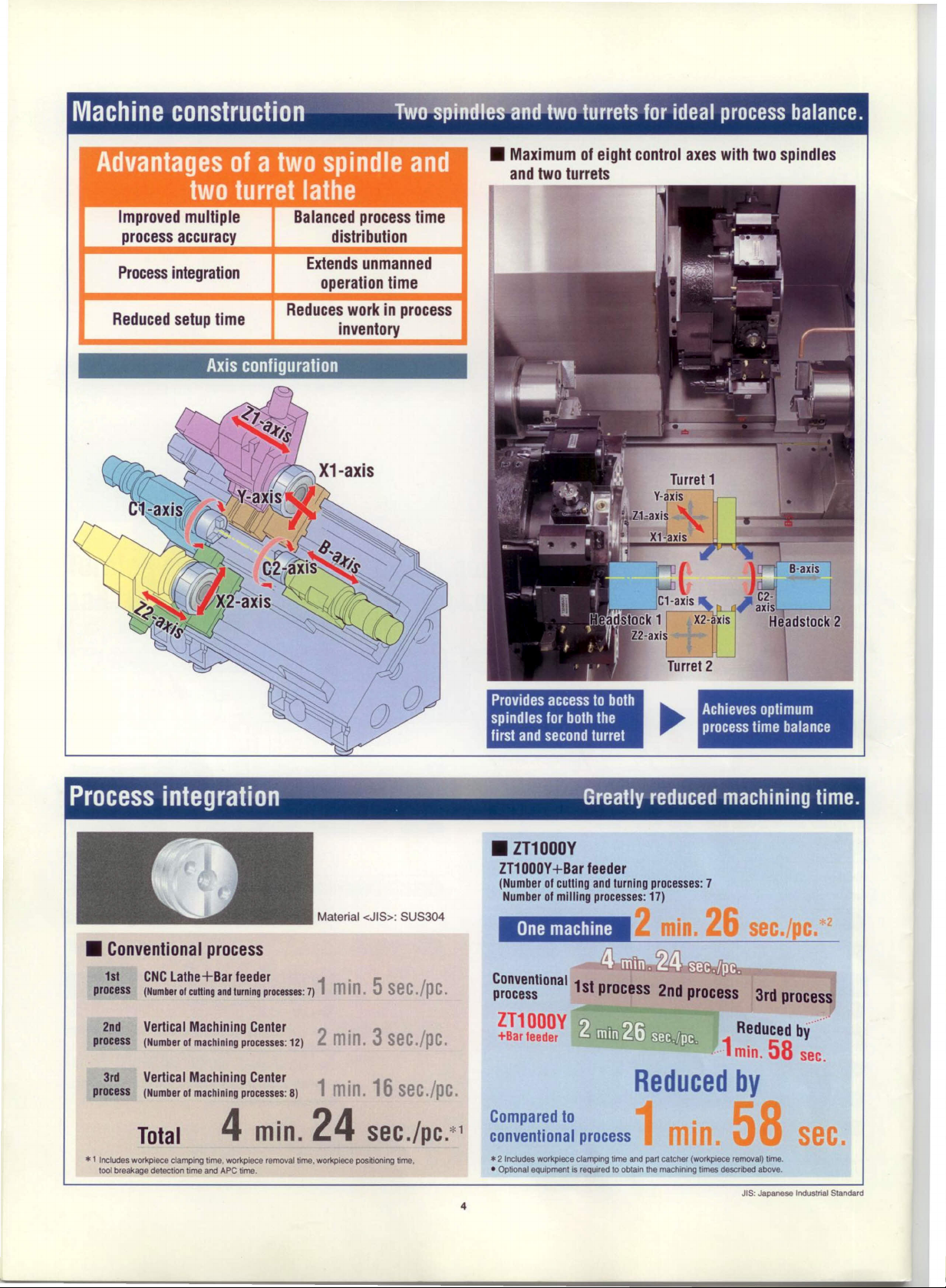

of a two spindle and

Improved multiple

process accuracy

turret lathe

Balanced process time

distribution

Processintegration

Reduced setup time

Axis configuration

Extends unmanned

operation time

Reduces work in process

inventory

Provides access lo bolh

spindles for bolh Ihe

first and second turret

Achieves optimum

process time balance

Material

<JIS>: SUS304

1s1 CNCLatha+Bar feeder

process (Number01cuttlngandlurningprocesses:7)

2nd Vertical Machining Center

process (Number 01machlnlng processes: 12)

3rd Vertical Machining Center

process (Numberolmachlnlngprocesses:8) 1

4

Total

• 1 Includes workptece clamping lime. workpiece removal lime. workpiece positioning tlme.

1001breakage detection lime and APe time.

min.

l'

mIn.5sec./pc.

2

min.3sec./pc.

min.16sec./pc.

24

sec./pc.*l

• ZT1000Y

ZT1OOOY+Bar feeder

(Number 01culling and turning processes: 7

Number 01milling processes: 17)

Onemachine

~~~::S~ional

1st process 2nd process 3rd process

ZT1000Y

+Bar leeder

Reduced

Compared to

conventional process

.2

Includes workplece clamping lime and part catcner (worl<plece removal) lime .

• Optional equipment is

4

reqUl1ed

lo obtain the machining limes descnbed above.

ec./pc.

Reducedby······

·1

min.

58

sec.

by

sec.

JIS: Japanese Industriai Standard

"'2

Page 5

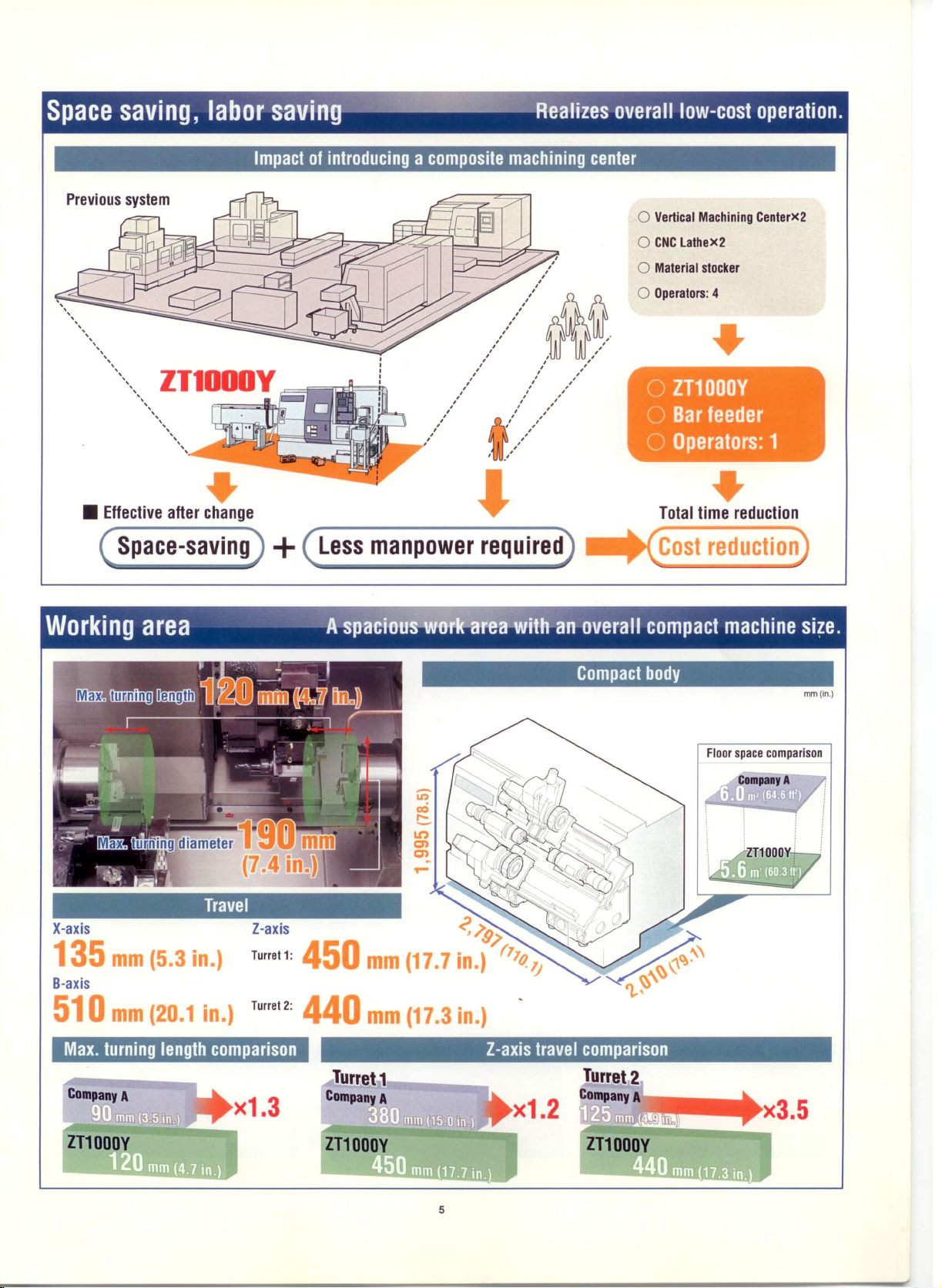

Space saving, labor saving'-Rèalizes overalllow-cosioperalion.

Impact01introducing a composite machining center

o

Vertical Machining Centerx2

o

CNClathex2

o

Material stocker

O

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

-,

Operators: 4

o

ZT1000Y

O

Barfeeder

O

Operalors:

•

1

• Effective after change

•

Space-saving

+

Less manpower required

Total time reduction

•

Cosl reduclion

Working area -':~òverall compaclmachinesìze.

Compact body

mm(ln.)

Floor space comparison

Travel

X-axis

135

B-axis

mm

(5.3

in.)

Z-axis

Turre! 1:

450

mm

(17.7

<';>9;>

in.)

(77Q lJ

510

Max. turning length comparison

mm

(20.1

in.)

Turre!2:

440

ZT1000Y

mm

j ,

(17.3

5

in.)

Z-axis travel comparison

Page 6

Sample workpieces .

• Sample workpiece machined with the ZT1000Y

~k

al whal precision machining can do.

Sample workpiece with Y-axis control

Sample workpiece with Y-axis control

Sample workpiece with Y-axis control

Sample workpiece with Y-axis control

6

Page 7

Y-axis control

_otary toolsforintegratedmachining.

l7

-aXis '---

-...-..,--::.=-----'

Largest of ali o e

Y-axis travellathes

mm

Y-axis machining range

Spindle cantar

(2.0)

50

(3.

in.)

3S 75

(1.4) (3.0)

mm(in.)

• Circurnferentialgroovingon a turningcenter with Y·axis

Milling without

It is hard to match the width of

outer (a) and inner (b) grooves.

~

Y-axis

b

control

Milling on the ZT1000Y

Groove width can be matched

•

using Y-axis control.

contro

• Comparison between polar coordinate interpolation

and Y-axis control

On a conventional turning center, polar coordinate interpolation is used for tool

motion control during grooving and contouring, as illustrated in the left figure.

In this control mode, however, the X-axis travel direction is reversed at points

"a", the intersections between the workpiece center line and the profile to be

machined. This reversal changes cutting conditions and subsequently effects

profile accuracy. Machining with v-axìs control, on the other hand, is Iree of

such changes and ensures a high level 01profile accuracy.

X·ax~

(-)

I

• Points -0-, inlerseclions belWeeo the wor!<piace center ine ard the prome IObe

C-axis rapid travers rate

Polar coordinate interpolation

Y-axìs control

machined.

C·axis exchangingtime

0.52 sec.

Milling is possible during spindle rotation. High preci-

sion contour control is delivered Irom a DDS· motor

acting as the c-axìs indexing servo.

(The pholo shows

*

Direct Drive Spindle

• The cutting test results indlcated in thls catalog are provided as an example. The results indicated In this catalog may not be

ZT2500Y.)

7

0.54 sec.

0.56 sec.

cotalned

due to differences in cutting conditions and environmental conditions durlng measurement.

Page 8

Spindle

'-~;-'a~e specificationsfor bothspindles.

High-output spindle for machining

diverse types of workpieces.

• For5-/6-inch chuck

• Through spindle holediameler49mm

(1.9

in.)

• Headstock 1

• Headstock 2

Oil cooler included as standard equiprnent

• Both spindles (headslock 1 spindle and headslock

2

spindle) are wrapped in an oil jackel lo minimize

I~

Di!

jacket

011

cooler

• Headstock 1 shown here.

11/7.5 kW (15/10 HP)

6,000 min·

1

<10 min/30 mln/cunt»

• I. 1

6,000

mln

100 .

80· . .

~ 60 TaS5.2N·m4Q.7ft· <ooob

~ 40 •.421 N'm 31.1h' <3OmJn>

30 T:3IJ9N'm 22.8fHb

{!

~

2O~----h~'+-

7.5/5.5 kW (10/7.5 HP)

<30 min/conl>

>

<CXlI'Ib

0433ISAOl

l'' I

8,000 min'l 22/18.5 kW (30/24.7 HP)

<15 min/cnnt»

~r-----.--==~~

=r-----t--~~~

E1100

~ Tz:42

N'm

f!

40

~ 5O~'~5~min~>~~~~~~~;E

(:!.

30 T-:35N'm

20 ~~~'lbf,L....,.4L-+---;........c>~

(31.0 tt-tbt)

04331'801

• Oplion

• Quick-change type turret head

(VOI)

O,

'.

,

Oual lurrets come standard including a quick-change type

turret for VOI tools. This draslically shorlens

lime.

(The photo snows ts-toot specification.)

1001

change

Indexing time

(1-station)

Number of tool stations

0.2 sec.

32

(16+16)*

t

I

(turret 1+2) 00 S

=

Opticn

• Bolt-tightened turret head

(option)

3.7/2.2 kW (5/3 HP)

6,000 min'

l

<15 mln/eunt»

40t~=;;;~=.:;;==tA3=.7=kW=<='5~m=1ln>

rl:

=23.5

N'm

17.3ft'lbf : 2.2

i

=14N'm (10.3fHbf); S

g

con :

>-

IO [

5

100

Rotary tool spindle

speed

(mio

kW

l)

<COnI> :

043S11AOl

4

§'~

S

,O

8

Page 9

Processing speed

~'''''--';rl~rmance

in ali machining ranges.

Tapping (O.D.): M12XP1.75

Material <JIS> S45C"

Rotarytool 398 min

spindle speed

Feedrate 1.75 mm/rev (0.069 ipr)

Cutting speed 15 m/min (49.2 fpm)

Drilling

Material <JIS> S45C"

R~tarytool 612 rnln'

spindle

speed

Cutting speed 25 m/mln (82.0 fpm)

Feedrate 0.24 mm/rev (0.009 ipr)

Machining rate 19.5 mUmin

per minute (1.2 in'Jmin)

End mill

Material <JIS> S45C"

R~tarytool 530 min

splndle

speed

Cutting speed 20 m/min (65.6 fpm)

Feedrate 0.2 mm/rev (0.008 ipr)

Machlning rate 12.7 mUmin

per minute (0.8 in'.!min)

Throw-away drill

Heavy-duty cutting

• Headstock 1, Turret 1

I

Making fuI! use of the high output DDS" motor, heavy-duty 0.0. cutting is powerful and

precise evenwilh large workpieces.

Machining rate per minute

162.7

(9.9

i 3./min)

Depth 01 cut

6

mm

Material<JIS> S45C"

Outerdiameter

Cutting speed

Feedrate

I

• Headstock 1

Turrels 1 and 2 move synchronously in 0.0. cutting lo ensure high precision balanced

cutting.

Balanced cutting

mUmin

(0.24

in.)

80 mm (3.1in.)

120 m/min (393.7 fpm)

0.2 mm/rev (0.008 ipr)

High precision

lO

jJm

/

-----

Tool

Material

Outerdlameter

Spindlespeed

Feedrate 0.05 mm/rev (0.002 ipr)

Diamondtool

enose

Brass

40mm(1.6 in.)

1,000 rnìrr

(filter:

radius0.4mm (0.02

Material<JIS> S45C"

Spindlespeed 1,091 min

Cutting speed 120 m/min (393.7fpm)

Feedrate 0.22 mm/rev (0.009 ipr)

Machining rate230.9 mUmin

per minute (14.1 in'Jmin)

I

*

l Carbon steel

*2 Dlrect D,lvo Splndlo

~-precision

1-50)

Roundness

ln.)

0.43

l'm

Turning precision

(/.lm

2.0

r:...

l=j...+=..+t..+ ..+t.+. '+'f'+' .=+..!,=I.. =i...j=1...IH=...j...,I=..f;::::... I=..+,..+=..+f..

0.0~·1tI.·.~.~.

-1"''T' .....

j

-2.0 ..

..

-+-+.-+-

Tool

Material

Outerdiameter 40mm(1.6 in.)

Splndlespeed

Feedrate

'M"'~"~"~~'

"'1

'i"

Diamond tool

enoseradius0.4 mm (0.02in.»

Brass

3,000 min

0.05 mm/rev (0.002 ipr)

~''-R'~~'~.~.

"'T-~~4:'

T'

,or

-1---+-t'. ~- ..~...

I

'T"'T"-r"'r'

JIS: Japanose Induslrial Standard

can be seen in the data.

+...

+.t +...+++... +-+=1.. =i,.t=1.. ::J.ff=.. I=...l=f.. +=...l=f._+..++.+..+.j +... +1+_

~'-~·~~M.iOO·

'"i"o

-j- T

-t' ••

-+..

+..

'--l-'

+-.+

"i"o

T-

.+- .--i-.

M.J,~.,.;.l,'"

oO

Surface roughness

1.07

lIm

Ry

O":

.y

4.0mm

(0.02

in.)

• The cutUng test resutts indicated in thlS cataJog SfO prov;ded as an example. The results indicated in this catalog may noi be obtained due to differenoos in cutting conditions and environmental condrtions during measurement

9

Page 10

High rigidity is ensured with slideways.

Ribbing was optimized by FEM' analysis.

*

Finite Elamenl Method

• Carefully designed ribbing

Achieves excellent chip removal by using a

45° slant construction.

Operability, Safety

Adjustable

operating panel

Swinging the operation panel reduces

eyestrain and improves operability.

device~rgonornic

Built for safety

Door interlock system

Footswitch with lock device Chuck jaw stroke end

e

Full covereCylinder check valve"eLow air pressure detecting switch

e

Low hydraulic pressure detecting switch

e

Danger sensing device interlace

e

Earth leakage breaker(opllon)eWorkpiece holding detector(option}

.1 Featured only when optional

*

2 Recommended whon

chucklcylinderIsselected.

oìt-based

coolanlls used or durlng unmanned operatlon.

Impact resistant viewing window Smaller maintenance area since the coolant

check-

'2

(optlon)

operating environrnent.

Operability

tanks both pull lorward, thereby allowing a

shorter right-side pull-out distance.

High maintainability

Allows the lubricating oillevel to be checked

at one glance by opening the cover 01 the

control pane!.

10

Page 11

Extended unrnanned

oper~"

Unmanned systems for

need greater efflclency.

us~r~

who

In-machine traveling parts catcher system

Parts catcher can receive workpieces trom both spindles. And,

unmanned operation is possible when coupled with a workpiece trans-

porting

conveyor.

• Receiver type

Headstock 1 side

(The p~oto shows ZT2500Y.)

In-machine traveling

Hand model

Max. transler weighl 1.2 kg (2.6Ib.)

Max. speed<Z-axis>

Applicable

workpiece

Ouler diameler

Lenglh 20-120 mm (0.8-4.7 in.)

parts catcher

Recelver typeISingle-hand

40 mm (1.6 in.)

specificalion

100 m/min (328.1 fpm)

10-40 mm

I

(0.4-1.6 in.)

type

• Single-hand type

~

----

(option)

In-machine traveling parts catcher (receiver type)

Workpiece transporting conveyor

Bar feeder system

Complele bar machining is possible on a single machine when coupled with

a parts catcher. You won't needa work loader/unloader or

• Recommended accessories

for bar feeder specification

• Bar feeder

• Signal tower

• Work stopper

• Multi counter

• Guide bushing

turnover

unit.

(option)

In-machine traveling parts catcher

(receiver type)

/

Workpiece transporting

conveyor

Slandard fealures

Toollife management lunction B (monitor)

Load monitoring function (monitor)

Work counter (monitor)

Total counter (monitor)

Optional fealures

Work counter

Tolal counler

x1.2

CompanyB

x1.1

*

Depending on tha chucklcylinder used and Il'5 restrlctions, il may noi be posslble lo reach

lun

bar work capacity.

11

Page 12

I

Standard&optional equipment

Automatic

operation support

o

Coolant

Spindle

Safetv features

Operation support

device/function

Turret 2

Collet chuck

Chip disposal, Automatic operation support

• Chip

Oil mist collector

*

Chip

conveyor

conveyors are

Tool presetter

(eptlcn)"

avallable in various types lor handllng chips of dlNerent shape and materìar.

• Far details contact Mori

Guide bushing

Guide bushing

Sand.

[ 5 3 I

Yr:'

(r--

ç,--

-

~Rr--' ,....--.

Work counter

~r

Chuck air blow

Dii skimmer

• The cotors and configuration shown in the photographs may differ 'rom Ihose of Ihe aclual product.

12

Coolant float switch

Page 13

Standard & optional features

e:

Standard features

Spindle Improved accuracy

Max. spindle speed eheadstock 1>

Max. spindle speed eneadstock 2>

Dii cooler

Spindle orientation

Turret

Quick-change type turret head

Bolt-tightened turret head

Max. rotary tool spindle speed 6,000 rnln: <3.7/2.2 kW (513HP)">

Workpiece holding device

Hydraulic chuck

Collet chuck

Chuck higMow pressure system

Index chuck eheadstock 1>

Soft jaws

Coolant

Coolant system

High-pressure coolant system

Coolant cooling unit

Coolant floal switch

011

sklmmer

Automal/c operal/on support

In-machlne traveling pans catcner

Workpiece transporting conveyor

Workpiece bucket

Workpiece push-out equipmenl

Work pusher

Bar leeder

Gantry-type loader

Work stocker

Pull-out finger

Guide bushing

Work stopper

Operal/on support device/funcl/on

Work counter

Total counter

Multi counter

Automatic door

Automatic power

011

system

6,000min' <7.515.5kW

6,000 min' <11fl.5 kW (15/10HP)">

8,000min"<22/18.5kW(30/24.7HP)">

6,000min' <7.515.5kW

6,000 min' <11fl.5 kW (15/10HP)">

8,000min' <22/18.5kW(30124.7HP)">

12-station cshank diameter

25 mm (1 ìn.)

16-station cshank diameter

25 mm (1 ìn.)

12-station <metric speciticatlons

16-station <metri c specììlcatlor»

12-slation «ncn specìfìcatior»

16-station cinch specificaìior»

5-inch eheadstock 1>

6-inch cheadstock 1>

5-inch eneadstock 2>

6-inch eheadstock 2>

Nominai diameler 40 mm (1.6 in.)

Interface 0.75 kW (1 HP)

Interface 1.5 kW (2 HP)

325/520 W <50/60 Hz>

635/1,040 W <50/60 Hz>

Receiver

Single-hand type

(1017.5

(1017.5

HP)">

HP)">

O

O

O

O

O

O

O

O

O

•

O

O

-(:

O

O

O

O

O

O

-((

O

-((

-(:

-((

-(:

O

O

O

*

O

O

•

o

-tt

•

O

-tt

•

O

•

O

-(:

-(:

-(:

-(:

•

o:

Options

*:

Please contact Mori Seiki

Direct scale leedback

Measurement

Automatic measuring system Dptical touch sensor

Manualtype in-machinetool presetter

Automatic in-machine tool preselter

Chip disposal

Chip conveyor coutsìde rnachìnes

Chip removable coolant system-

Alr blow system In-machine tool presetter

Chip bucket

Coolant gun

Oil mìst collector

Others

Built-in worklight

T

001

holders

Hand tools

Signaltower 3-stage

Chuck

1001

switch

Work stop per <in spindles

Safety features

Door inlerlock system

Impact resistant viewing window

Chuck jaw stroke end cneck-

Low hydraulic pressure detecting switch

Footswitch wlth lock device

Full cover

Cylinder cneck valve"

Low aìr pressure detecting switch

Danger sensing device interface"

Earth leakage breaker

Workpiece holding detector

• 130minlconl

.2

15 minlconl

• 3 For

rear

extIaction

.4

Headslock2is standard.

.5 Featured only when optional

• 6 Recommended when

• The det811s given abava and lhe spec:dications are subject lo change Wlthout

• Specirlcations.

• Some options are noi available in particutar regions. For details contact Moti Seiki.

accessories,

type chip conveyor.

chucklcytinderisselected.

ca-besee coolant

safety device. 800 function

G-axis

x-axìs

Y-axis

Z-axis

Removable

Hinge type <righI>

Seraper type <righI>

Hlnge type

crear»

Scraper type

Interface

Chuck" eheadstock 1>

Tool tip

2 loot switches

RighI extraclion s1yteis optional.

is used or dunng unmanned operation.

crear»

are avallable

upon

notee.

request.

o

o

O

O

O

•

-(:

O

-(:

O

-(:

-(:

•

O

-(:

-(:

O

O

-(:

•

•

•

O

O

-(:

•

•

•

•

•

•

•

•

O

O

-(:

13

Page 14

N

ew gene rati on op erati n

irsyStemriVi~pps~r\"~'~'

• Conversationalautomaticprogramming

By inputting the linal shape 01the workpiece, the

MAPPS can automatically select the necessary

tools, cutting conditions and the most efficient

machining sequence, thus minimizing the amount

01input.

• Program editing

.

~ :llfi.m-cu2

io,

rJnl4:.:

,. t.t •••.• ,,,,",

J :

Two programs can be opened at the same ti me

and data copied&pasted between thern.

04321 N00000

",

.••.

01111

0,

r:,

rFII(t):

1t:!02'

'-,

Sl3l1G

klK..n.

ti:

~l•. r.25 :

i.e r.n .

XIM.U:

'.:tU;

l"! Il' I • "\

~~[

• Simulation

OUI. ~'lItI

j"lnn

""

..

r.l...••#1J'

'''\/LtLl

..•.

tu·!It.~

QIl!l.Z*'l

...

A simulated image 01 the machining workpiece

can be displayed to check proçrarnrnlnp.v

• Network

(oplion)

*

1 Mori Advanced Programmlng Production system*2 Some machinlng programs cannot be graphically simulated.

ConversationalAutomatic ProgrammiiffilS~pjo~l~two-turret Turning Centers

CAPS-ZT

• Automatic programming software

Supports complex multi-axis programming,

such as turning, C-axis and Y-axis machining,

sub-spindles, and balance cutting,

Y-axìs machining menu

• Detailed setup possible

(option)

-------]t'

PC·'

• 2 turrets machining

requiremenls

lIem Requlrement

PCIAT compatible

OOSN

Pentium'm1 GHz or more

NC processor

SVGA

128 MB or more

50 Ma or more avaliable area requlred

Wlndows' 95/98/Me/NT 4,0 Wor1<stationl

2000 ProfessionaliXP

CD-ROM drlve,

Paraliel pori D-SUa 25 pin", Serial port

.,.. , t~

e

~, • 1.1111 $U

'l'CI~~~

:uo .nUII,"U."

oIoJ"..lfuu.r •••.II.1

...."nu'\<l.o' •••

".:.t,

41aO_IU; :n

"

Jao. _

_ .••,U.I':'

_lI:l\1Ct.r:U.IIIlJ.·

;::l:!I:' I!:I

\ti':.

I ••

Easy creation 01 programs tor balance cutting and syn-

chronizing the No, 1 and No, 2 turrets.

Hardware

CPU

Graphics

Memory

Hard dlsk

OIS

Other

(min. 800X600 resolution and 65,536 colors)

J

-------1

--------------- ----o-or

------

~

-------l\

Bydelayingthe position where the cutting

begins,we doubled the amount 01material cut.

By synchronizing tool movement, we

raised the amount 01teed.

14

*

1 Personal Computer

*

2 USB

conversion

• The producI names indicated In this catalog are ali trademarks or registered

trademarks of tha individuai companies.

ls not posslble .

Page 15

Ne

unit specifications

(MSG-501)

Standard

Controlled axes

Controlled axes

Simultaneously controllable axes

Least tnput increment 0.001 mm (0.0001 In.)

Least command Increment

Max. command valua

InctVmetric converslon G20/G21

Inlerlock·'

Machine lock

Emergency stop

Stored stroke IImlt 1

Programmable mlrror lmage

FOllow-UP

Chamfering ON/OFF

Backlash compensation ±9.999

Rapld traverse/cuttlng feed backlash compensation

Stored pitch error compensation

Abnormalload detectlon

Cutling feedrate

Operallon

Search function

Manual intervenlionlrBturn

Dry run

Singie block

Jog feedrate 0-1,260 mmlmln (0-50.0 Ipm) <15 stepss

Manual zero return

Zero polnt setting without dog

Manual pulse handle leed

Interpotation funcllons

Posltioning GOO(Llnear Interpolatlon type positloning Is possible)

Llnear Interpolation

Circular Interpolation G02/G03

Dwell

Polar coordinate Interpolatlon G12.1, G13.1 (Gl12, G113)

Cylindrlcallnterpolation G7.1 (Gl07)

Helical interpolation

Thread culling/Synchronous leed

Multl-start thread culling

Retraet during thread cUlling cycle

Continuous thread cunìnç

Sklp G31

Zero retum G28

Zero retum check G27

2nd zero retum

Balance cut

Feed functlons

Rapid traverse rate override FO.25/100

Feedper minute G98

Feedper revolution

Constant tangenllal velocity control

Cutting feedrate cìamp

Feedrateoverride 0- t 50%(lO%increments)

Jog feedrate override

Overrlde cancel M48, M49

Program Input

Tape code EIA RS244/1S0 840 code automatic recognHion

Label sklp

Optional block skip 1 block

Max. command value ±8 digits

Program number

sequence number 5-dlgit N code

Absolute (incrementai) programmlng

Decimai polnt programmlng/

Eleetrical calculator type decimai point programming

Piane seleetlon

Coordinate system selting

Work coordinate system G52, GS3. G54-G59

Manual absolute onloff PCparameter

Drawlng dimenslon dlrectlnput

sua-prouram cali Up to 4 nestlngs

Single repetitive cycle

Multiple repetmve cycle

Multiple repetitive cycle il Pocket profile, zigzag thread culting

Hole machlnlng canned cycle

Circular arc radlus command

F15 format

H 1: X, Z,c,Y H 2: X, Z, C, B

H 1: X. Z. C.Y H2: X. Z.

0.001 mm (0.0001 In.)

±99,999.999 mm (±9,999.9999 in.)

M code

pulses

Used for sottware damper and load monitor B

Workpiece number, seqeence number

1 unit per control systern:

G01

(CW/CCW)

G04

G30

%

G99

0-1.260 mmlmln (0-50.0 Ipm)

4-dlgit Ocode

x

(U), Z (W), Y (V), C (H)

Electrical calculator type decimai polnt programming is

changeable using parameter

G17, G18, G19

G50

c

xt.xto.xioo

Miscellaneous funcllon/Splndle speed funcllon

Miscellaneous funetlon

Auxillary lunetlon lock

Spindle

speed

Constant surface speed control

Spindle speed override 50 120 % (10% Increments)

Synchronlzed tapping

Splndle synchronlzed control

Tool function/Tool ottset funcllon

Tool funetlon (T function)

Number 01tool offsets 64+64 sets

Tool posltlon offset

Y-axls onset

Tool nose radius otìset G40-G42

ToOIgeometry onseVTool wear onset

Toollile management B

Ediling

Part program storage 80+80 m (262+262 h) <4kB':"10 m (33 ") in tape length>

Number 01stored programs 63+63 programs

Tape editing

Program protect

Background editing

Expanded tape edlting

Selling and dlsplay

Status display

Clock lunetion

Actual posltion display

Program dlsplay

Parameter selting display

Sen-diagnosls funetlon

Alarm display

Afarm history display

Operator's message hlstory display

Running time display/NO. of parts dlsplay

Actual leedrate display

Display 01 actual spindle speed and T code

Operation panel: Display section 10.4-inch TFTcolor LCD

Data fnpul/Output

Reader/puncher Interface

lunetlon

3-digit M code

S-dlgit S code

Wlth rotary tool splndle

4-dlgit T code

Program name: 48 characters

Page 16

Machine specifications

lIem

Max. swing of workpiece mm(in.)

Max. distance betweencenters mm(in.) 750 (29.5)

Capaclty

Max. turning diameter mm(in.)

Standard turning diameter

Max. turning length mm(in.) 120 (4.7)

Bar work capacity°'

X-axis travel mm(ln.) NO.1: 135 (5.3) NO.2: 135 (5.3)

Travel

Z-axls travel mm(in.)

Y-axis travel mm(in.)

Headstock 2 travel <B-axls> mm(in.) 510 (20.1)

Spindle speed rangeo,

Number of spindle speed ranges 1

Splndle

Type of spindle nose

Through spindle holediameter mm(in.)

Spindle bearing inner dlameter mm(in.) 80 (3.1)

Min. spindle indexing angle 0.0010eleast input incremenl>

Number of tool stations 12 [16J

Shank height far square tool

Turrel

Shank diameter far boring bar mm (in.) 25 (1)

Turret Indexing lime

Max. rotary tool spindle speedo,

Feedrale

Rapidtraverse rate

Jog feedrate mm/min (Ipm)

Spindle drive motor <30 min/conl> kW(HP)

Molor

Rotary tool spindle drive motor <15 min/cont> kW(HP) 3.7/2.2 (5/3)

Feedmotor <X1/X2/Z1/Z2/Y!B>

Coolant pump motor

Power sources

Tank capacily

Machine size

Electrical power supplyoJ

Compressed air supply MPa (psi), Umin (gpm)

Coolant lank capacity

Machine height <lrom

nooo

Floor space cchip conveyor not Included> mm(ln.)

Mass of machlne

I l Option

NO.1: Turrel I NO.2: Turrel 2 JIS: Japanese Induslnal Siandard

*

1

Depending on

• 2 Depending on restrictions imposed by lha workplece clamplng

• 3 LoaderlParts cetcner

*

4 AI

*

5 15

.6 Hlgh-output specifications for headstock 1

*

7 High-speed specif)eations far headstock 1 and headstock 2.

• 8 ANR refers to a standard atmospheric state:i.e., temperature al 20t(68 •

8,000

minlcont

min'

tha

chucklcylinder

used and It's resmctlons, il may not be

noI Included.

The

eectrcer

and headstock 2.

power

devce.

reculrements

fixture and tool used, Il may noI be possible lo rotate al tha maximum spindla speed .

vary depending on tha opnoo comblnat!ons.

.

possible

F); absokne

to reach full bar

work capacity .

pressure a1101.3 kPa (14.7

ZT1000Y

250 (9.8) <iRterferencewith turret

190 (7.4)

mm(in.) 170 (6.6)

mm(in.) 40 (1.5)

No. 1: 450 (17.7) NO.2: 440 (17.3)

±40 (±1.6)

mirr

60-6,000 [80-8,ooOJ

JIS A2-5

49 (1.9)

mm(in.)

minI

mm/min (ipm)

s

X1, X2: 18,000 (708.7) Z1, Z2: 24,000 (944.9) Y: 6,000 (236.2)

B: 24,000 (944.9) C: 400 min'

20

0.2

6,000

X, Z, B: 0-1,260 (0-50.0)

7.515.5(10n.5)

[11n.5 (1511O)J[22/18.5 (30/24.7)0"'J

kW(HP) 3/2/3/3/1.5/3 (412.7/4/4/2/4)

kW(HP) 0.52x2 (0.70X2)

kVA 46.0 [52.7"l[92.7 o'J

0.5 (72.5), 100 (26.4) <ANR°,>

L (gai.)

mm(in.)

200 (52.8)

1,995 (78.5)

2,797x2,010 (110.1

kg (Ib.) 5,000 (11,000)

psì): and

relative humk1ìty at 65

%.

(3/.)

X79.1)

coveo

.

.

--

I

194215A02

--

-

-

!

• The information In Ihls catalog Is valid as of August 2002. Deslgn and specifications subject lo ehange Wlthout notlce.

• MOri Seiklls not

responsiote

for differences between tha Information in tbe eatalog and tha aetual maehlne.

MORI SEIKI CO., LTD.

Head Office&Nera Pian'

D .362 ldono-cho. Yamato-Konyama CII)'. Naro 6:\9-11 IO, Japan

Nara No.2 O 106 KIIIl Kortynma-cho. Ynrnato-Konyama eh)'. Naro 6:\9·1160. Japan

Plonl l'hone: (0743) 53-1125

lga Piani O 20) Midal. lga-cho. Ayama-gun, Milo! 519-1-1)-1. Japan

• The export of

Check Wllh the governmenl agency tor authorization.

Phonc: (074~) 53-1121

l'hom: (11595) 45-4151

this prodoct is

subject lo an aulhonzation 'rom the governmenl of the exporting country.

www.moriseiki.com

ZTHJQOY ·EBOl

0209 CDr 0000

Crealed in Japan

Loading...

Loading...