Page 1

MAINTENANCE MANUAL

The manuals for maintenance are comprised of the following

three manuals including this manual:

MAINTENANCE MANUAL, MAINTENANCE INFORMATION,

and INSTALLATION MANUAL.

Applicable Model

NC LATHES

Applicable NC Unit

MSC-500 MSX-511 MSC-801

MSG-500 MSX-511III MSC-802

MSX-500 MSC-515 MSC-803

MSX-500III MSD-515 MSG-803

MSC-501 MSC-516 MSX-803

MSD-501 MSD-516 MSX-803III

MSD-501II MSD-516II MSG-805

MSG-501 MSC-518 MSX-805

MSX-501 MSD-518 MSX-805III

MSX-501III MSD-518II MSG-806

MSG-502 MSC-521 SEICOS Σ21L

MSX-502 MSC-700

MSX-502III MSC-701

Before starting operation, maintenance, or programming, carefully read the

manuals supplied by Mori Seiki, the NC unit manufacturer, and equipment

manufacturers so that you fully understand the information they contain.

Keep the manuals carefully so that they will not be lost.

MM-CENL-H2EN

Page 2

• The contents of this manual are subject to change without notice due to

improvements to the machine or in order to improve the manual.

Consequently, please bear in mind that there may be slight discrepancies

between the contents of the manual and the actual machine. Changes to

the instruction manual are made in revised editions which are

distinguished from each other by updating the instruction manual number.

• Should you discover any discrepancies between the contents of the

manual and the actual machine, or if any part of the manual is unclear,

please contact Mori Seiki and clarify these points before using the

machine. Mori Seiki will not be liable for any damages occurring as a

direct or indirect consequence of using the machine without clarifying

these points.

• All rights reserved: reproduction of this instruction manual in any form, in

whole or in part, is not permitted without the written consent of Mori Seiki.

The product shipped to you (the machine and accessory

equipment) has been manufactured in accordance with the laws

and standards that prevail in the relevant country or region.

Consequently it cannot be exported, sold, or relocated, to a

destination in a country with different laws or standards.

The export of this product is subject to an authorization from the

government of the exporting country.

Check with the government agency for authorization.

990730

Page 3

CONTENTS

SIGNAL WORD DEFINITION

FOREWORD

A: DAILY INSPECTION

B: REGULAR INSPECTION

C: OUTLINE OF SYSTEMS

INDEX

HOW TO ORDER THE MACHINE PARTS

Page 4

SIGNAL WORD DEFINITION

A variety of symbols are used to indicate different types of warning information and advice.

Learn the meanings of these symbols and carefully read the explanation to ensure safe operation

while using this manual.

<Symbols related with warning>

The warning information is classified into three categories, DANGER, WARNING, and CAUTION.

The following symbols are used to indicate the level of danger.

DANGER

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or damages to the machine.

The information described following the caution symbol must be strictly observed.

<Other symbols>

Indicates the items that must be taken into consideration.

NOTE

Indicates useful guidance relating to operations.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

The information described in the DANGER frame must be strictly

observed.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

The information described in the WARNING frame must be strictly

observed.

Indicates the page number or manual to be referred to.

Page 5

FOREWORD

This maintenance manual describes the daily inspection procedure and regular inspection

procedure.

Since the daily and regular inspections to be carried out by machine operators are very important

in maintaining machine accuracy, operators are required to carry out proper inspection and

maintenance in accordance with the details given in this manual.

For machine specifications, inspection, maintenance and installation information, specific to

individual models, refer to the MAINTENANCE INFORMATION manual, DRAWINGS, PARTS

LIST and INSTALLATION MANUAL published separately.

<Assumed machine operation methods>

NC lathes are machine tools intended to be used to cut blank workpieces of a machinable

material, shape and mass, in a shop or plant which is suitable for the cutting operation.

Use of the NC lathe under criteria other than those stated above is considered inappropriate.

Mori Seiki is not responsible for any danger or damage arising from improper operation of the

machine. Some examples of improper machine usage are indicated below.

(1) Adding any part to, or modifying, the machine without consulting Mori Seiki.

(2) Operating the machine outside the machining range.

(3) Improper use of a workpiece holding device or peripheral.

(4) Using the machine with interlocks or machine protection covers removed, or while the

machine is in an unusable state.

(5) Carrying out machine operation, programming, or maintenance and inspection work without

thoroughly understanding the caution information; i.e. without having read the instruction

manuals carefully.

<Protection for machine operators>

Machine operators are responsible to the following.

(1) Carry out machine operation, programming, and maintenance and inspection work in

accordance with the details in the instruction manuals supplied with the machine.

(2) Only operators who have received proper training and have sufficient understanding of the

caution information are allowed to operate or program a machine tool or carry out inspection

and maintenance on it. With regard to safety related measures, operators must receive

training at least once a year.

(3) Develop a thorough understanding of, and strictly observe, the local regulations relating to the

prevention of accidents and environment conservation.

The illustrations in this manual are used as example. Depending on machines, shapes of

NOTE

systems may differ from the illustrations in this manual.

For details, refer to the DRAWINGS published separately.

Page 6

CHAPTER A

DAILY INSPECTION

Page 7

CONTENTS

A : DAILY INSPECTION

1. THE IMPORTANCE OF DAILY INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

2. NOTES ON INSPECTIONS AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

2.1 Work in General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

2.2 Work Inside the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

2.3 Machine Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

2.4 Oils Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

3. LUBRICATING AND HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

3.1 Storing Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

3.2 Cautions When Replenishing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

4. SUPPLYING OIL IN DAILY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

4.1 Supplying Oil to the Lubricating Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

4.2 Supplying Coolant to the Coolant Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

4.3 Greasing the Chuck Master Jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

5. INSPECTION OF THE CHUCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

6. CLEANING MACHINING CHAMBER/SETUP STATION . . . . . . . . . . . . . . . . . . . . . . . A-8

6.1 Cleaning the Front Cover of the Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

6.2 Cleaning the Front Cover of the Tailstock (with Built-in Tailstock Spindle). . . . . . A-9

6.3 Cleaning the Slideway Protection Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

6.4 Cleaning the Front Door Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

6.5 Cleaning the Rear of the Cylinder (Hollow Chuck). . . . . . . . . . . . . . . . . . . . . . . A-10

7. CLEANING THE DRAIN OIL RECEIVER FOR THE LUBRICATING OIL . . . . . . . . . . A-11

8. CLEANING RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

9. PRECAUTIONS WHEN USING CHIP CONVEYOR . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

9.1 Cleaning Chip Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

10. OPENING/CLOSING THE ELECTRICAL CABINET DOOR . . . . . . . . . . . . . . . . . . . . A-15

10.1 Opening the Electrical Cabinet Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

10.2 Closing the Electrical Cabinet Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

10.3 Main Power Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

11. PREPARATION FOR MACHINE OPERATION AFTER

PROLONGED IDLE PERIOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Page 8

DAILY INSPECTION A-1

1. THE IMPORTANCE OF DAILY INSPECTION

In order to operate the machine correctly and make the most of the machine's functions and

performance, all operators must thoroughly understand the machine.

Daily lubrication and inspection by the operator and inspection by maintenance personnel at

regular intervals maintain the accuracy of the machine over the long term.

If an abnormality is discovered during daily inspection, it must be reported to the supervisor and

the person responsible for machine maintenance. Quick action should be taken.

If a problem that cannot be remedied by the user or whose cause cannot be determined occurs,

contact Mori Seiki and the equipment manufacturers.

Page 9

A-2 DAILY INSPECTION

2. NOTES ON INSPECTIONS AND MAINTENANCE

Pay adequate consideration to safety and hygiene when performing work such as machine

inspections, setup, and cleaning, and implement appropriate safety and hygiene measures.

Some points that require attention are cited below but note that other necessary measures must

also be taken and the necessary training given to ensure the safety of the operator, before (s)he

uses the machine.

2.1 Work in General

DANGER

WARNING

CAUTION

Protective circuits and protective covers are provided in order to - in all

conceivable circumstances - prevent the operator from touching moving

parts and live parts while power is supplied to the machine, but these

devices cannot guarantee 100% safety. Exercise due care while operating

the machine.

Always shut off the main power supply to the machine before cleaning the

machine or the vicinity of the machine. Otherwise the machine could

suddenly start operating during cleaning and the operator could be

entangled or crushed in its moving parts, or lose balance and fall over.

When cleaning inside the machine, the operator could suffer injuries such as trauma,

lacerations, contusions or broken bones, caused by tools or fixtures, workpieces, or

projections, corners, or joints in the machine construction, or chips. Take care not to

touch chips, tools, fixtures, workpieces, or the structural parts of the machine with bare

hands. Wear appropriate protective gear for each kind of work, and ensure safety

before starting work.

Page 10

2.2 Work Inside the Machine

DAILY INSPECTION A-3

WARNING

(1) Confirm that the main power supply to the machine is shut off before

entering the machine to do work inside it. Be aware that if you close

the machine door after entering the machine, it may not be possible to

open the door from the inside. If the machine model used is equipped

with a door lock prevention mechanism, take the door lock prevention

key inside the machine when doing the work. At the same time, fit a

padlock through the hole at the end of the lever of the door lock

mechanism, and take steps to ensure that the door lock mechanism is

not released by mistake. If the machine model used does not have a

door lock prevention mechanism, avoid entering the machine as far

as possible. If it is absolutely necessary to enter the machine,

implement measures to ensure that the door will not be closed before

starting the work.

(2) When entering the machine, make sure of your footing: take care that

you will not slip or stumble. Also select and wear appropriate safety

gear, such as a helmet, safety shoes, protective goggles, and so on,

as necessary, so as to ensure safety while working.

(3) If an operator is shut inside the machine, press the EMERGENCY

STOP button regardless of whether the power is ON or OFF, insert the

key into the external key hole in the door lock device fitted to the

machine cover, and turn the key to unlock the door and let the

operator out.

2.3 Machine Management

CAUTION

(1) The customer must take responsibility for managing the keys that are provided

with the machine (for the operation panel, control panel, peripheral devices, etc.).

(2) Keys that do not have to be used on a regular basis, such as the control panel key,

must be removed from the lock and stored elsewhere. If the machine is operated

with the key in the lock, people walking by could brush against the key, breaking it

or injuring themselves.

2.4 Oils Used

CAUTION

The customers themselves must receive an MSDS (safety data sheet for e.g. chemical

substances) for oils such as coolant (cutting fluid) and the various lubricants and

cooling oils, and the customer must take responsibility for securing and managing the

working environment, and for managing disposal of the oils. Take careful note of the

effects on the human body described in the MSDS.

Page 11

A-4 DAILY INSPECTION

3. LUBRICATING AND HYDRAULIC OIL

CAUTION

1. Always use oil types specified by Mori Seiki.

2. The customers themselves must receive an MSDS (safety data sheet for e.g.

For the type of oil to be used and tables comparing the oils produced by different

manufacturers, refer to the OILING CHARTS and the Oil Recommendations in the

MAINTENANCE INFORMATION published separately.

3.1 Storing Oil

If obtaining large amounts of oil for storage, observe the following points to prevent oil

degradation. Obtaining limited amounts of oil only as required is strongly recommended.

Do not mix different brands of oil even when identified as being of "equivalent"

quality. When changing to a different brand of oil, drain all original oil from the tank

completely, clean the inside of the tank, and add replacement oil.

Mori Seiki is not responsible for problems arising from the mixture of different

brands of oil or the use of non-specified oils.

chemical substances) for oils such as coolant (cutting fluid) and the various

lubricants and cooling oils, and the customer must take responsibility for securing

and managing the working environment, and for managing disposal of the oils.

Take careful note of the effects on the human body described in the MSDS.

Obtaining limited amounts of oil only as required is strongly recommended.

(1) Store oil in locations free from direct sunlight or rain.

(2) Keep oil clean. Foreign matter or water should not be allowed to enter the oil storage tank.

(3) Never use degraded oil or oil contaminated by foreign matter or water.

(4) If a storage tank is used, remove foreign matter and water from the tank at least once a year.

3.2 Cautions When Replenishing Oil

When replenishing oil, observe the following points:

(1) Always use the same oil can for specific oil brands. Never use a can used for a different

brand of oil.

(2) Never remove the filter from the filter port of each tank when supplying oil.

CAUTION

If oils other than those specified by Mori Seiki are used mistakenly or different brands

of oil are mixed, clean the tank and flush piping immediately.

Page 12

4. SUPPLYING OIL IN DAILY MAINTENANCE

4.1 Supplying Oil to the Lubricating Oil Tank

If the oil level in the lubricating oil tank drops, an alarm indication is given. If this low lubricating oil

level alarm is given, supply lubricating oil.

<Procedure>

(Example: Showa Yuki 2 L)

1) Check the volume of oil in the lubricating oil tank with

the oil level gage installed on the lubricating oil tank.

2) Remove the cap on the oil supply port.

3) Supply the specified lubricating oil by using the oil jug

while checking the oil level with the oil level gage.

DAILY INSPECTION A-5

4.2 Supplying Coolant to the Coolant Tank

If the coolant level drops, an insufficient amount of coolant is supplied to the cutting tool. If cutting

is continued under such conditions, accuracy will be impaired and tool life shortened. If coolant

level drops, supply coolant to the coolant tank.

<Procedure>

1) Turn OFF the main power.

2) Wait until the coolant level is stabilized after all of the

remaining coolant inside machine is returned to the

coolant tank.

3) Check the volume of coolant in the coolant tank using

the oil level gage.

For the name and volume of the cooling oil,

refer to the OILING CHARTS in the

MAINTENANCE INFORMATION published

separately.

4) When coolant level is close to the red line on the oil

level gage

Supply coolant to the red line on the oil level gage.

NOTE

Do not fill above the red line.

For the capacity of the coolant tank, refer to the

OILING CHARTS in the MAINTENANCE

INFORMATION published separately.

Page 13

A-6 DAILY INSPECTION

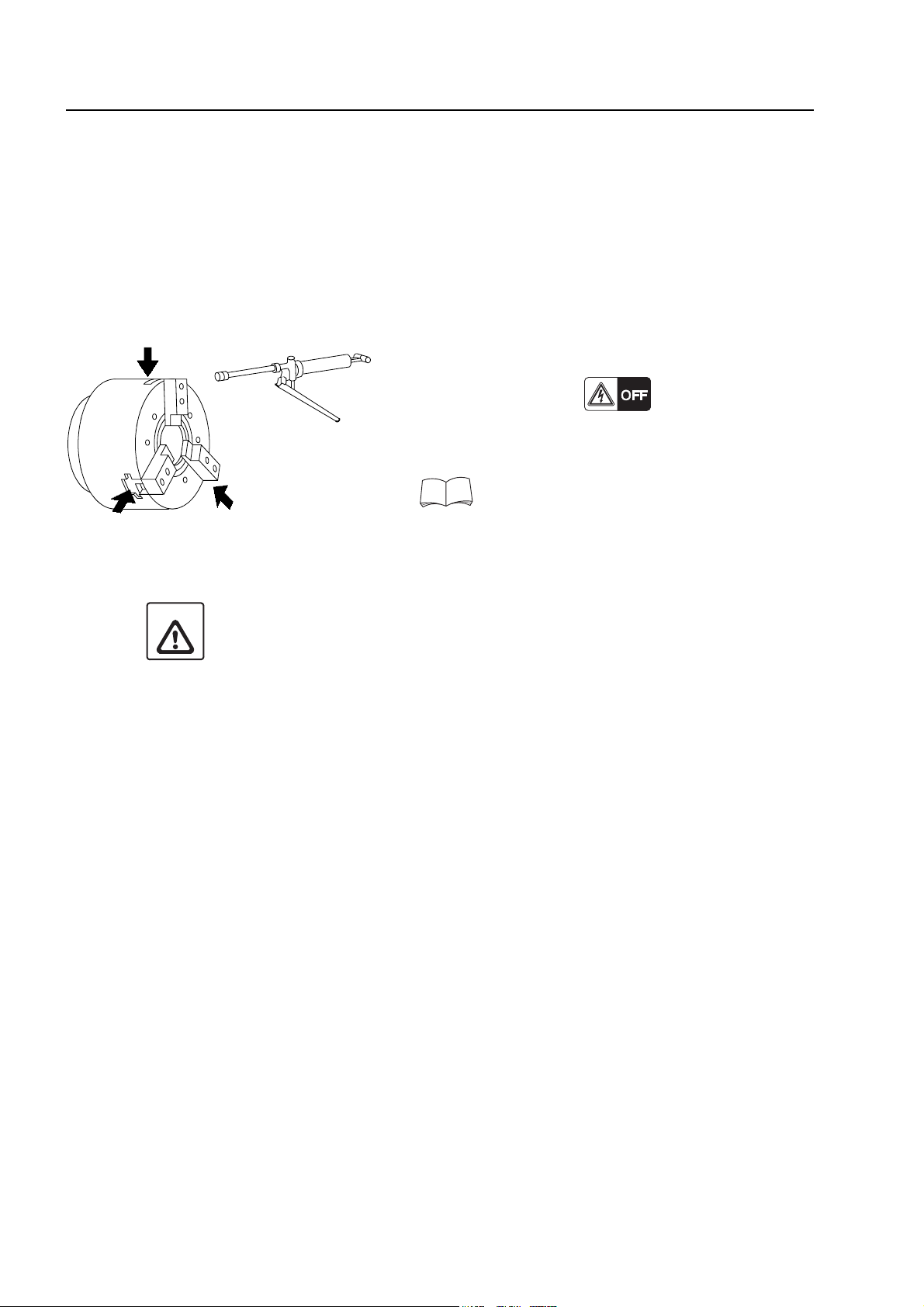

4.3 Greasing the Chuck Master Jaws

If the master jaws are not lubricated properly with grease, the gripping force of the chuck will be

reduced. If the spindle is rotated while the master jaws are not properly greased, the workpiece

will fly out of the chuck, causing injuries and machine damage.

Apply grease to the master jaws at least once a day, before starting the day's operation.

<Procedure>

1) Stop the spindle.

2) Turn off the power.

3) Supply grease from the grease cup around the

chuck.

For the name and volume of the cooling oil,

refer to the OILING CHARTS in the

MAINTENANCE INFORMATION published

separately.

CAUTION

Coolant splashed on the chuck will wash away the grease. Therefore, supply grease

as often as possible.

Page 14

5. INSPECTION OF THE CHUCK

<Daily oiling>

To maintain high chuck accuracy over a prolonged period, it is necessary to supply lubricating oil.

Improper lubrication will cause the following problems.

• Faulty operation at low hydraulic pressure

• Insufficient gripping force

• Low gripping accuracy

• Abnormal wear

• Seizure

To avoid those problems, be sure to supply lubricating oil properly.

The diagram below indicates how greasing influences chuck gripping force by showing the

relationship between the chuck gripping force and the spindle speed.

DAILY INSPECTION A-7

Example) SL-25MC, Chuck HOIMA10A6 (Howa), Cylinder HH4C-125 (Howa)

44.1

39.2

34.3

29.4

24.5

Gripping Force (kN (lbf))

19.6

14.7

0 500 1000 1500 2000 2500

Spindle Speed (min−1)

The diagram above is for reference purposes only. The actual gripping force will vary

NOTE

Greasing after

disassembling and cleaning

After greasing

Before greasing

depending on the machine model, chuck and cylinder used by the customer. In any case,

however, the chuck gripping force is reduced if the chuck is not greased properly. To

obtain the correct chuck gripping force, it is necessary to grease the chuck at least once a

day, before starting operation.

<Daily cleaning>

At the end of each day, when operation is completed, clean the chuck body and slideways.

Page 15

A-8 DAILY INSPECTION

6. CLEANING MACHINING CHAMBER/SETUP STATION

To maintain machining accuracy for the optimum length of time, always clean the machining

chamber and setup station daily following completion of machine operations.

DANGER

CAUTION

When inspecting and cleaning the machining chamber and setup station,

turn OFF the main power and disconnect the plant-side power supply

(breaker).

Do not use compressed air to clean the machining chamber and setup station.

If compressed air is used inside the machining chamber and setup station, chips and

coolant may enter the spindle tapered section and bearings resulting in serious

damage.

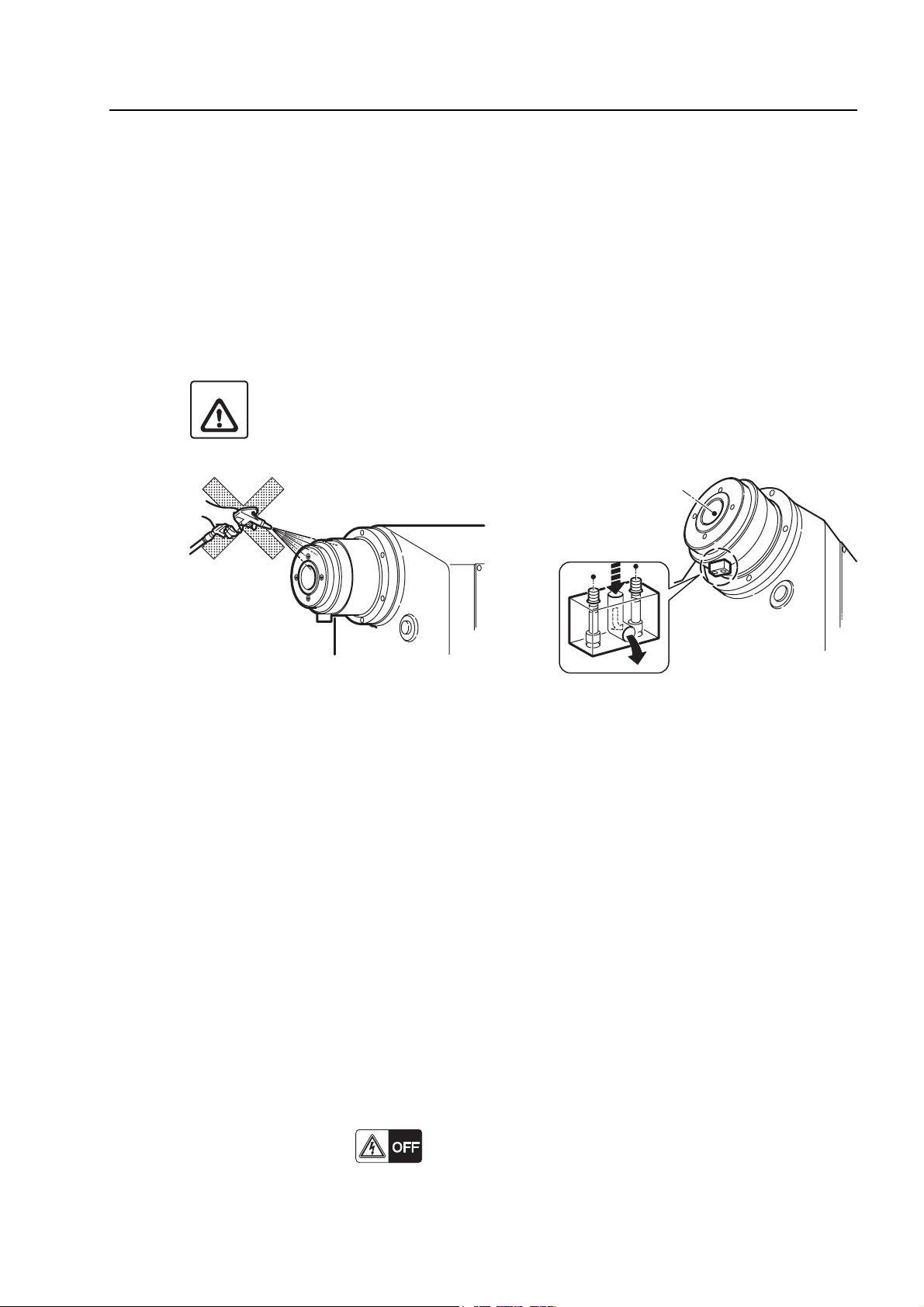

6.1 Cleaning the Front Cover of the Spindle

Dust and foreign matter will accumulate in the coolant holes on the front cover of the spindle

allowing coolant to enter the bearings. This will cause the bearings to seize.

Clean the coolant holes in the front cover of the spindle at least once a week.

<Cleaning interval>

Every 50 hours of operation

CAUTION

Do not use compressed air to remove dust and foreign matter from the coolant holes.

If compressed air is used, dust and foreign matter will enter the bearings.

Coolant discharging hole

Page 16

DAILY INSPECTION A-9

6.2 Cleaning the Front Cover of the Tailstock (with Built-in Tailstock Spindle)

Dust and foreign matter will accumulate in the coolant holes on the front cover of the tailstock

allowing coolant to enter the bearings. This will cause the bearings to seize.

Clean the coolant holes in the front cover of the tailstock at least once a week.

<Cleaning interval>

Every 50 hours of operation

CAUTION

Do not use compressed air to remove dust and foreign matter from the coolant holes.

If compressed air is used, dust and foreign matter will enter the bearings.

6.3 Cleaning the Slideway Protection Covers

During dry cutting or when machining cast workpieces, carefully remove chips from the machine

so that they do not accumulate.

Be aware that any chip accumulation on moving parts, such as the slideway protection covers, will

interfere with proper operation and lead to mechanical problems.

6.4 Cleaning the Front Door Rail

If chips accumulate on the front door rail, the door will not open/close smoothly.

Clean the front rail regularly.

<Cleaning interval>

Every 50 hours of operation

<Procedure>

1) Turn off the power.

2) Remove the chips that have accumulated on the front door rail.

Page 17

A-10 DAILY INSPECTION

6.5 Cleaning the Rear of the Cylinder (Hollow Chuck)

Coolant and chips flow to coolant pan at the rear of the cylinder via the through hole in the draw

pipe.

The coolant returns to the coolant tank via the drain hose.

Chips accumulate on the punched-metal sheet at the rear of the cylinder.

CAUTION

Remove chips from the punched-metal sheet every day. If chips are left to accumulate,

coolant will overflow and spill onto the shop floor.

Coolant will flow into the hydraulic oil tank via the cylinder drain, inhibiting proper

machine operation.

<Procedure>

1) Turn off the power.

2) Remove the cylinder cover at the left side of the machine.

3) Remove the chips that have accumulated on the punched-metal sheet at the rear of the

cylinder.

CAUTION

NOTE

Do not touch the chips bare handed.

Remove coolant and chips that have accumulated in the cylinder at regular intervals by

detaching the rear cover of the cylinder.

Page 18

DAILY INSPECTION A-11

7. CLEANING THE DRAIN OIL RECEIVER FOR THE

LUBRICATING OIL

If the drain oil receiver for the lubricating oil is at the rear or the side of the machine, dispose of the

waste oil before the drain oil receiver becomes full.

The drain oil receiver is provided to prevent lubricating oil being mixed into the coolant. It is

effective when water-soluble coolant is used to prevent deterioration of the coolant due to mixing

of lubricating oil.

(1) Because impurities are contained in the drain oil, do not reuse the oil in the lubrication

NOTE

tank. Always use fresh lubricating oil when replenishing the lubrication tank.

(2) Entrust the disposal of waste oil and coolant to a party qualified to dispose of

industrial wastes or a gas station with the appropriate facilities.

(3) The drain oil receiver is not available for some models.

These models collect the drain oil in the coolant tank.

For details on the disposal of waste oil, refer to FOREWORD in this manual.

Page 19

A-12 DAILY INSPECTION

8. CLEANING RADIATOR

If the radiator on the hydraulic tank is clogged, the oil temperature rises resulting in unit failure.

Clean the radiator at regular intervals.

<Cleaning interval>

As required

<Necessary tools>

• Air gun

Radiator

<Procedure>

1) Turn OFF the main power.

2) Remove dust adhering to the radiator with a compressed air gun.

CAUTION

Protective glasses must be worn to prevent eye damage from dust or foreign matter

(those who are wearing glasses included).

Page 20

DAILY INSPECTION A-13

9. PRECAUTIONS WHEN USING CHIP CONVEYOR

WARNING

CAUTION

(1) Do not operate the chip conveyor or perform maintenance and

inspection tasks without reading and obtaining a thorough

understanding of the contents of the chip conveyor instruction

manual "COOLANT FILTER MANUAL" published separately.

(2) Keep the chip conveyor instruction manual "COOLANT FILTER

MANUAL" on hand to enable immediate reference when operating the

chip conveyor and performing maintenance and instruction tasks.

(3) Do not place hands or feet inside the chip conveyor during operation

to prevent serious injury due to entanglement in rotating components

or by being crushed between moving parts.

(1) Do not operate the chip conveyor intermittently.

Intermittent operation causes fine chips to accumulate between the belts and/or on

the conveyor bottom plates, resulting in conveyor malfunction such as tripping of

the thermal relay.

Always operate the chip conveyor continuously.

(2) The chip conveyor cannot carry materials larger than cutting chips.

If tools and other such materials are mistakenly placed on the conveyor during

operation, the chip conveyor will be damaged.

(1) Close the operator panel-side door before operating the chip conveyor.

NOTE

(2) The chip conveyor cannot discharge all types of chips. Carefully consider appropriate

cutting conditions to generate chips which can be removed from the machining

chamber.

Page 21

A-14 DAILY INSPECTION

9.1 Cleaning Chip Conveyor

<Cleaning interval>

Once or twice daily.

<Necessary tools>

• Rags

<Procedure>

CHIP CONVEYOR

FOR STOP BACK

1) Press the CHIP CONVEYOR [FOR] button on the

operation panel.

The [FOR] button is illuminated.

The chip conveyor moves forward to discharge chips

from machine.

2) Press the CHIP CONVEYOR [STOP] button.

The [STOP] button is illuminated.

The chip conveyor stops.

3) Place an adequate quantity of rags on the conveyor

belt.

WARNING

Before placing rags on the conveyor

belt, disconnect power to prevent

entanglement of fingers and hands in

the rotating unit or between moving

parts, which may result in death or

serious injury.

4) Press the CHIP CONVEYOR [BACK] button. The

[BACK] button is illuminated.

Keep pressing the [BACK] button. The chip

conveyor moves backward to discharge chips and

rags out of the machine only when the button is

pressed.

This completes the chip conveyor cleaning procedure.

For further details on the cleaning procedure,

refer to the chip conveyor instruction manual

"COOLANT FILTER MANUAL" published

separately.

Page 22

DAILY INSPECTION A-15

10. OPENING/CLOSING THE ELECTRICAL CABINET DOOR

DANGER

Before attempting maintenance and inspection inside the electrical

cabinet, be sure to turn OFF the plant-side power supply (circuit breaker).

Even when the main power switch on the electrical cabinet is turned OFF,

parts of the cabinet may still hold residual current and give an electric

shock if accidentally touched.

Do not touch devices installed inside the electrical cabinet at heights of 2 m or greater

NOTE

above the ground as these devices do not require maintenance or inspection.

10.1 Opening the Electrical Cabinet Door

<Procedure>

1) Turn OFF the main power.

CONTROL BOX

DOOR INTERLOCK

ON OFF

CAUTION

Place the control box door interlock switch

installed in the electrical cabinet door in the

[OFF] position when opening the electrical

cabinet door with the main power ON.

2) Insert the key into the keyhole below the lever on the

electrical cabinet.

3) Turn the key to release the electrical cabinet door

lock. The lever is pushed outward when the key is

inserted.

4) Turn the lever 90° counterclockwise.

Page 23

A-16 DAILY INSPECTION

5) Open the electrical cabinet door.

10.2 Closing the Electrical Cabinet Door

1) Close the left side of the electrical cabinet door.

2) Close the right side of the electrical cabinet door.

3) Rotate the lever downward.

4) Push the lever inward.

5) Turn the key below the lever to lock the door.

6) Pull out the key.

The customer is responsible for supervising usage

NOTE

and safe storage of the key.

CONTROL BOX

DOOR INTERLOCK

ON OFF

7) Place the CONTROL BOX DOOR INTERLOCK

switch installed on the electrical cabinet door in the

[ON] position.

Page 24

10.3 Main Power Switch

DAILY INSPECTION A-17

WARNING

When electrical over-current occurs in the machine, the breaker is actuated, the power supply is

automatically turned OFF, and the main power switch automatically moves to the [TRIP] setting.

To reset, return the handle to the [OFF] setting and then turn the handle back to the [ON] setting.

<How to Lock the Main Power Switch>

Lock the main power switch using the following procedure when performing maintenance

procedures considered dangerous if the power is ON.

Type A

1) Place the main power switch in the [OFF] position.

2) Attach a padlock.

When the main power switch is locked, maintenance procedures are

performed. Do not place the main power switch in the [ON] position.

Refer to the OPERATION MANUAL published separately for details on turning the

power ON and OFF.

Type B

1) Place the main power switch in the [OFF] position.

2) Pull out the lock plate.

3) Attach a padlock.

Lock plate

Page 25

A-18 DAILY INSPECTION

Type C

1) Place the main power switch in the [OFF] position.

2) While pushing the shutter plates in the direction of arrows, attach a padlock.

Type D

Shutter plate

1) Place the main power switch in the [OFF] position.

2) Put a driver into the release screw.

When the release screw is not prepared, just pull out the lock plate.

NOTE

3) While turning the driver CCW, pull out the lock plate.

4) Attach a padlock.

Driver

Lock plate

Page 26

DAILY INSPECTION A-19

11. PREPARATION FOR MACHINE OPERATION AFTER PROLONGED IDLE PERIOD

Perform the following operations in the order specified after the machine has been idle for a

*

prolonged period of time

(1) Forced lubrication of ball screws and spindle bearings.

(2) Full stroke travel of all axes.

(3) Spindle warm-up

.

NOTE

*

Prolonged period of time: Two days or more

<Forced lubrication of ball screws and spindle bearings>

Press the manual lubrication button on the lubrication tank for more than 10 seconds. Lubricant is

supplied to the nuts on the ball screws and the spindle bearings.

Manual lubrication button

Page 27

CHAPTER B

REGULAR INSPECTION

Page 28

CONTENTS

B : REGULAR INSPECTION

1. IMPORTANCE OF INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

2. CHECKS PRIOR TO MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

3. PRECAUTIONS TO BE OBSERVED BY TECHNICIANS . . . . . . . . . . . . . . . . . . . . . . . B-3

4. CLEANING THE ELECTRICAL CABINET AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . B-5

5. CLEANING THE COOLANT TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

6. CLEANING THE LUBRICATING OIL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

6.1 Lubricating Unit Tank/Suction Filter/Fill Port Filter Cleaning . . . . . . . . . . . . . . . . B-7

6.2 Inspection Items for the Lubricating Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

6.3 When the Lubricant Pressure does not Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

6.4 Disassembling/Cleaning the Relief Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

6.4.1 Relief Valve Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

6.4.2 Relief Valve Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

6.4.3 Relief Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

7. CLEANING THE SUCTION STRAINER IN THE HYDRAULIC OIL TANK . . . . . . . . . B-12

8. CLEANING THE FANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

9. CLEANING INSIDE THE ELECTRICAL CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

10. REPLACING THE MACHINING CHAMBER OBSERVATION WINDOW . . . . . . . . . . . B-16

11. INSPECTION AND REPLACEMENT OF SLIDE SEALS . . . . . . . . . . . . . . . . . . . . . . B-18

12. TIMING BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-19

13. CHANGING FLUID OF HYDRAULIC TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

14. CHANGING THE BATTERY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-22

14.1 Replacing CNC Memory Back-up Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-24

14.1.1 Type 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-24

14.1.2 Type 2 (Electrical Cabinet Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

14.1.3 Type 2 (Operation Panel Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-26

14.1.4 Type 3 (2CR5 Type Lithium Photo Battery) . . . . . . . . . . . . . . . . . . . . . B-28

14.1.5 Type 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-29

Page 29

14.2 Replacing the Servo Absolute Position Sensing Battery . . . . . . . . . . . . . . . . . . B-30

14.2.1 Type 1 (Alkaline Battery/Manganese Battery). . . . . . . . . . . . . . . . . . . . B-30

14.2.2 Type 1 (Lithium Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

14.2.3 Type 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-33

14.2.4 Type 3 (2CR5 Type Lithium Photo Battery). . . . . . . . . . . . . . . . . . . . . . B-35

14.2.5 Type 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-36

15. ADJUSTING THE SETTING PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

15.1 Adjusting Hydraulic Unit Main Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38

15.2 Adjusting Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-39

16. ADJUSTING THE OIL SKIMMER SEPARATION TANK DRAIN (OPTION) . . . . . . . . . B-40

Page 30

REGULAR INSPECTION B-1

1. IMPORTANCE OF INSPECTIONS

Daily lubrication and inspection by operators and regular inspection by maintenance engineers

are the keys to long-lasting machine accuracy.

Prior to inspection, confirm the following points:

(1) Any abnormality discovered during daily inspections must be reported to maintenance

engineers. If necessary, repair or replacement is to be performed immediately.

(2) Maintenance engineers must take immediate and proper action in compliance with the

instructions of operators who are in charge of daily inspection.

(3) For queries or concerns related to the contents of the instruction manuals, circuit diagrams,

and ladder diagrams, contact Mori Seiki Service Department for assistance.

(4) If the cause of a problem cannot be determined or remedied, contact Mori Seiki Service

Department and/or parts manufacturers for assistance.

<Maintenance/inspection sequence>

Daily oil replenishment and inspection by machine operator

Maintenance and repairs by maintenance engineers

Service request call to Mori Seiki and/or parts manufacturer

For details on checks to be performed, refer to "REGULAR INSPECTION LIST" published

NOTE

separately.

Page 31

B-2 REGULAR INSPECTION

2. CHECKS PRIOR TO MAINTENANCE

DANGER

WARNING

(1) Never close the operator door when working inside the machine with

the main power switch ON. When closed, the operator door is

automatically locked and the power supply to servomotors

connected. Rapid machine operations may start unexpectedly.

(2) When working inside the machine with the main power switch ON,

carry the door lock prevention key at all times. Removing the key

prevents the door from closing by mistake.

(3) Ensure that the main power is turned OFF and locked when

connecting the power.

(4) Provide clear warning that the machine is being maintained and

operations cannot be performed.

(1) Ensure only parts specified by Mori Seiki are used during parts

replacement. Mori Seiki does not accept responsibility for problems

arising from the use of non-specified parts. Use of non-specified

parts not only impairs machine performance but also leads to unsafe

operating conditions that may result in serious injury or machine

damage.

(2) Wear clothing appropriate to the type of maintenance operation to be

performed.

Approaching the machine with loose clothing may lead to serious

injury due to entanglement in rotating parts or by being crushed by

moving parts.

CAUTION

(3) When two or more persons are working on the machine

simultaneously, awareness of procedures being performed and clear

communication between personnel must be maintained at all times.

Operating the machine or a crane in the surrounding area without

adequate checks to determine if other personnel are working inside or

around the machine may result in serious injury.

(1) Listen to operators in charge of machine operation to understand the problem

accurately.

(2) Study the actual conditions of machine and plan the scope of repair procedures.

(3) Study the specifications, construction, and functions of the part of the machine to

be repaired.

(4) If two or more maintenance technicians or personnel from other sections must

work on the machine, discuss the repair procedure with all personnel in advance

so that everyone can understand the problem accurately.

(5) Prepare spare parts and consumables to be used in advance.

Page 32

REGULAR INSPECTION B-3

3. PRECAUTIONS TO BE OBSERVED BY TECHNICIANS

DANGER

(1) Electrical wiring work must be entrusted to a licensed electrical

technician. If a person without knowledge of electrical safety

practices attempts this work, he or she could be electrocuted.

(2) Always lock out the power to the machine before carrying out

inspections, repairs, or maintenance work. In addition, set the main

switch to the OFF position and lock it, and place "UNDER

MAINTENANCE" signs around the machine to stop anyone from

switching on the power or operating the machine while the work is in

progress. If inspection or maintenance work is carried out with the

power switched on, machine elements could be moved, and the

inspection or maintenance personnel could be seriously injured by

being entangled in the rotating parts or crushed by the moving parts

of the machine.

For details on locking the main power switch, refer to 10.3 "Main

Power Switch".

(3) Never touch a switch, button, or key with wet hands.

If it is not properly grounded or is leaking current, you could receive

an electric shock.

WARNING

(1) Machine operators and authorized personnel working inside the plant

and in the vicinity of the machine must put their clothing and hair in

order so that there is no danger they will be entangled in the machine.

If you have uncontrolled long hair or loose clothing and it gets caught

in the machine, you will be seriously injured by being entangled in the

rotating parts of the machine or crushed by its moving parts. Always

wear safety shoes, eye protectors and a helmet.

(2) The parameters are set on shipment in accordance with the machine

specifications; do not change them without first consulting Mori Seiki.

If the parameters are changed without consultation, the machine may

operate in an unexpected manner, causing accidents involving

serious injuries or damage to the machine.

(3) The machine specifications are set before shipping so that the

machine can deliver its full performance. Changing the settings

without consultation may lead to accidents involving serious injuries,

impaired machine performance, and considerable shortening of the

machine service life. If the specifications and/or settings have to be

changed or the machine has to be modified to meet new machining

requirements or due to changes in the operating conditions, consult

Mori Seiki.

Page 33

B-4 REGULAR INSPECTION

WARNING

CAUTION

(4) When two or more people are involved in maintenance work, they

must cooperate carefully, communicating as fully as possible.

If one worker moves the machine without noticing that there is

another worker inside or near the machine, he could seriously injure

that worker or damage the machine.

(5) When changing parts, be sure to use genuine parts specified by Mori

Seiki. Mori Seiki cannot accept responsibility for any trouble arising

from the use of parts not specified by Mori Seiki. Using parts that are

not specified will not only impair the performance of the machine; it

will also make the machine unsafe and could lead to serious injuries

or damage to the machine.

(6) When using equipment such as wires, ropes, and cranes, make sure

that they can bear the mass to be hoisted. If they cannot bear the load

it will fall and could cause serious injuries or damage the machine.

(1) Use service tools appropriate for the intended work. If the tools are not

appropriate, parts could be broken or bolts not tightened properly, leading to

machine failure.

(2) Do not place service tools or parts directly on the slideways. This could cause

scratches or other damage to the slideways, adversely affecting machine life.

(3) Do not climb on top of the machine. If you lose your balance, you could fall off and

injure yourself. Use a ladder or service platform when you have to work in high

places.

(4) When moving a heavy object, always carry it with the help of at least one other

person or use a crane. If you attempt to carry a heavy object by yourself, you

could be injured.

Page 34

REGULAR INSPECTION B-5

4. CLEANING THE ELECTRICAL CABINET AIR FILTER

The electrical cabinet is not cooled directly by outside air; it is cooled indirectly through heat

exchange between outside air, taken into the cabinet through the duct, and inside air.

Therefore, if the air filter at the air suction port is clogged, the inside of the electrical cabinet will

not be cooled satisfactorily.

<Cleaning interval>

Every 50 hours of operation

<Procedure>

1) Turn off the power.

2) Remove the filter cover from the electrical cabinet.

Air filter

Filter cover

3) Clean the filter using neutral detergent.

4) Dry the filter.

5) Mount the filter cover in the electrical cabinet.

6) Turn on the power.

The shape of the electrical cabinet air filter may

NOTE

differ depending on the machine model.

Page 35

B-6 REGULAR INSPECTION

5. CLEANING THE COOLANT TANK

If fine chips and other foreign matter accumulate in the coolant tank, the specified coolant supply

cannot be maintained and coolant supply to the cutting point is insufficient.

In addition, if contaminated coolant is pumped from the coolant tank, the service life of the pump is

reduced.

Clean coolant tank periodically.

<Cleaning interval>

Every 500 hours of operation

(1) When machining cast iron or similar material that generates fine chips, clean coolant

NOTE

tank more frequently.

(2) A certain amount of lubricant also runs into the coolant tank. Even if no coolant is

used in machining, clean the coolant tank at regular intervals.

(3) The cleaning interval may differ depending on the machine model. Refer to the

REGULAR INSPECTION LIST in the MAINTENANCE INFORMATION published

separately.

<Procedure>

1) Press the coolant switch (off) to stop coolant supply.

2) Turn off the power.

3) Loosen the connector and remove coolant motor pipe and wiring.

4) Remove the drain plug and discharge the coolant of the coolant tank.

5) Pull out the coolant tank.

Some models have the coolant tank integrated with the bed, making it impossible to

NOTE

remove the coolant tank.

6) Clean the inside of the coolant tank and the coolant filter.

7) Wind seal tape onto the drain plug and fit it to the coolant tank.

8) Mount the coolant tank to the machine.

CAUTION

When installing the machine, mount the coolant tank and the chip bucket by pushing

them into an appropriate position. Otherwise, coolant may be splashed around the

machine causing the operator or persons around the machine to fall and injure

themselves.

9) Connect the coolant motor pipe and wiring.

10) Supply coolant in the tank.

For the capacity of the coolant tank, refer to the OILING CHARTS in the

MAINTENANCE INFORMATION published separately.

Page 36

REGULAR INSPECTION B-7

6. CLEANING THE LUBRICATING OIL TANK

6.1 Lubricating Unit Tank/Suction Filter/Fill Port Filter Cleaning

<Cleaning interval>

Tank: Every 1000 hours of operation.

Suction filter/fill port filter: Every 500 hours of operation.

<Necessary tools>

• Screwdriver

• Neutral detergent/kerosene (for cleaning)

<Procedure>

Terminal box

Manual

lubrication

button

Two screws

Four screws

Fill port filter

1) Turn OFF the main power.

2) Remove the tank as described below:

a) Loosen the two screws using a phillips head

screwdriver and open the terminal box.

b) Loosen the four screws on the bottom of the

terminal box.

c) Remove the tank.

Take care not to spill lubricant when removing the

NOTE

tank.

3) Clean the inside of the lubricating unit tank using a

neutral detergent.

4) Remove the suction filter from the suction port.

5) Clean the suction filter with kerosene.

Blow compressed air to dry.

6) Reinstall the suction filter in the suction port.

7) Loosen the two screws to remove the fill port filter.

8) Clean the fill port filter.

9) Reinstall the fill port filter.

Suction filter

Tank

Oil level gage

10) Remount the tank.

11) Using an oil can, add lubricant to the maximum level

in the lubricating unit tank while checking the oil level

gage.

12) Turn ON the main power.

Page 37

B-8 REGULAR INSPECTION

13) Press the manual lubrication button for more than 10

seconds to supply lubricant to the slideways.

14) Make sure that lubricating oil is supplied to the

slideway surfaces.

6.2 Inspection Items for the Lubricating Oil Tank

Periodic inspection items for the lubricating oil tank are indicated below.

By referring to the inspection items, carry out inspection and maintenance work at the specified

inspection intervals.

WARNING

No. Inspection Item Contents

1 Fill port filter

2 Oil in the tank Check for deterioration, oxidation, and dirt.

3 Inside of the tank Check for chips, foreign matter and sludge.

4

5 Piping tube Check the piping tube for damage.

6

(7) Always turn the power OFF before performing inspection and

cleaning the lubricating oil tank. When the power is turned ON, the

internal fan starts to rotate. If the fan is rotating during the cleaning

procedure, hands or clothing may become entangled, resulting in

serious injury.

(8) Use only kerosene for cleaning the lubricating oil tank and the fill port

filter. Do not use volatile fluid such as gasoline or thinner.

Check that the fill port filter is properly installed, that the filter is

not damaged and that foreign matter does not adhere to the filter.

Tightness of piping

connections

Oil consumption in

the tank

Check for oil leakage from all joints.

Check that oil consumption in the tank is appropriate.

7Pump

8 Distributor Check that oil is supplied from the distributor properly.

Turn on the lubricating oil pump and check that the lubricant

pressure rises to the setting pressure properly.

Page 38

6.3 When the Lubricant Pressure does not Rise

When the lubricant pressure does not rise, the lubricating oil pump may be malfunctioning, or

lubricant leakage is occurring. Disconnect the piping according to the following procedure to

locate the cause and solve the problem.

<Procedure>

1) Remove the line filter piping from the lubricating oil pump.

2) Place a plug over the line filter discharge outlet.

3) Press the manual lubrication button for more than 10 seconds. Check that the lubricant

pressure rises to between 1.0 MPa - 1.2 MPa during pump operation.

<Cause>

This problem may be caused by the following two factors.

• When the lubricant pressure does not rise: The lubricating unit may be malfunctioning.

REGULAR INSPECTION B-9

• When the lubricant pressure rises: The piping or the distributor may be

malfunctioning.

Refer to the following table to solve the problem.

<Troubleshooting>

Condition Cause Action

Suction filter clogging Cleaning or replacement

When the lubricant

pressure does not rise

(lubricating unit

malfunction)

Relief valve clogging or damage

Pump malfunction

Disassembly/cleaning or

replacement

Air bleeding

Replacement

Piping damage Replacement

When the lubricant

pressure rises (piping or

distributor malfunction)

NOTE

*1

Following air bleeding from the piping, ensure that the pressure rises to between

Failure in air bleeding from the

piping

Distributor malfunction

Air bleeding from the piping

Replacement

1.0 MPa - 1.2 MPa.

*1

*2

*1

*2

*2

Contact Mori Seiki Service Department for assistance.

Page 39

B-10 REGULAR INSPECTION

Manual lubrication button

Relief valve

Line filter piping

Line filter discharge outlet

(plug insertion point)

Suction filter

Page 40

6.4 Disassembling/Cleaning the Relief Valve

If the lubricating unit abnormal pressure is caused by a relief valve malfunction, disassemble and

clean the relief valve.

6.4.1 Relief Valve Disassembly

Remove the adjusting screw to disassemble the relief valve as indicated below.

REGULAR INSPECTION B-11

Adjusting screw

6.4.2 Relief Valve Cleaning

Clean the disassembled relief valve with compressed air and kerosene.

• Take care to check for dust contamination of the tapered section. If scratches are visible on

the tapered section of the relief valve, replacement is necessary.

• Cover the tapered threaded section with seal or sealing tape.

Following disassembly and cleaning of the relief valve, press the manual lubrication button

NOTE

to bleed air from the piping.

Lock nut

Valve

Tapered threaded section

Relief valve disassembly

6.4.3 Relief Valve Adjustment

Following disassembly and cleaning, adjustment of the relief valve is required. Bleed air from the

piping properly prior to adjustment.

• Press the manual lubrication button.

• Set the pump discharge pressure to 1.2 MPa using the relief valve adjusting screw.

If unable to set the pressure to 1.2 MPa, the pump is malfunctioning. Contact Mori Seiki

NOTE

Service Department for assistance.

Page 41

B-12 REGULAR INSPECTION

7. CLEANING THE SUCTION STRAINER IN THE HYDRAULIC OIL

TANK

If the suction strainer becomes clogged, pumps and piping may be damaged, resulting in

hydraulic unit failure. Clean the suction strainer at regular intervals.

<Cleaning interval>

Every 1000 hours of operation.

<Necessary tools>

• Spanner, monkey wrench

• Kerosene (for cleaning)

• Compressed air gun

<Procedure>

1) Turn OFF the main power.

2) Drain oil in the tank.

Refer to steps 3) - 6) in 13. "CHANGING FLUID OF HYDRAULIC TANK".

3) Loosen the hose band.

4) Disconnect the piping.

5) Remove the tank upper plate.

Hose band

Page 42

6) Clean the suction strainer using the following procedure:

a) Remove the suction strainer.

REGULAR INSPECTION B-13

CAUTION

Clamp the suction pipe with a pipe wrench and turn the suction strainer to the left with a

monkey wrench. If the suction strainer is turned without clamping the suction pipe, the

suction pipe will turn with it, causing an oil leak.

b) Clean the suction strainer with kerosene.

c) Dry the suction strainer using compressed air.

CAUTION

Protective glasses must be worn to prevent eye damage form dust or foreign matter

(those who are wearing glasses included).

d) Apply sealing tape to the threaded section of the suction pipe and reattach the suction

strainer.

7) Clean the inside of the tank with kerosene.

8) Remove foreign matter form around the drain plug using a brush.

× 4

× 8

Suction pipe

Monkey wrench

Suction strainer

9) Remount the tank upper plate.

10) Remount the hydraulic unit on the machine.

11) Connect the piping.

12) Remove the fill port cap.

13) Supply oil while checking the oil level gage.

14) Turn ON the main power.

15) Confirm pump pressure and suction noise are normal.

If the suction sound is louder than prior to oil replacement, check the oil level again.

NOTE

Page 43

B-14 REGULAR INSPECTION

8. CLEANING THE FANS

<Battery position>

• Electrical cabinet

• Machine side cover

• Hydraulic pump

<Cleaning interval>

Every 1000 hours of operation

<Procedure>

1) Turn off the power.

2) Remove the fan cover.

3) Blow the fan with compressed air.

The temperature inside the cabinet must be lower than 45°C; measure the temperature

periodically.

If it is higher than 45°C, check the ambient temperature, cooling fan, etc. Eliminate the cause of

the high temperature.

Page 44

REGULAR INSPECTION B-15

9. CLEANING INSIDE THE ELECTRICAL CABINET

Although the electrical cabinet is constructed to shut off external air, foreign matter such as dust

and dirt may enter the cabinet through the gap or when the door is opened.

Accumulation of foreign matter on the printed circuit boards or other electronic components could

cause machine malfunction.

Clean the inside of the electrical cabinet at regular intervals.

<Cleaning interval>

Every 1000 hours of operation

<Procedure>

1) Turn off the power.

2) Open the electrical cabinet door.

3) Remove dust inside the electrical cabinet with a

vacuum cleaner.

CAUTION

4) Close the electrical cabinet door.

Never touch printed circuit boards or parts

around the connector.

Also avoid subjecting them to shock.

Otherwise, the machine may be damaged.

Page 45

B-16 REGULAR INSPECTION

10. REPLACING THE MACHINING CHAMBER OBSERVATION WINDOW

The machining chamber observation window consists of polycarbonate and tempered glass.

Polycarbonate effectively resists strong impact. Tempered glass prevents the window becoming

opaque due to repeated cutting chip impacts. The machining chamber observation window is a

consumable part. Replace the window at regular intervals, or when it becomes necessary, by

following the instructions below.

WARNING

1. Window safety is guaranteed for a maximum of 2 years due to

strength reduction and must therefore be replaced at specified

intervals (once every 5 years). Replace the window immediately if it

becomes cracked or when the operator's field of view is restricted.

2. Replace the window immediately in case a strong impact was made

to the window even though the window may appear unaffected.

Once a window has been subjected to a strong impact, the strength of the

window will decrease remarkably.

3. Due to the hardness of the window, high-speed chip impacts can

cause cracks. Small initial fractures may allow the entry of coolant

which will degrade the polycarbonate and substantially weaken the

window.

4. Even small initial cracks caused by impact may spread across the

window due to the nature of the tempered glass.This is not a fault.

5. To carry out maintenance or inspection work inside the machine,

make the door lock device invalid by turning the door lock

prevention key; remove the key and bring it with you when you enter

the machine. To prevent the door being locked by mistake, lock a

padlock in the hole at the end of the door lock hasp. If the door is

closed by mistake while the door lock device is valid, the door is locked

and you may be cooped up in the machine. If the machine is started while

you are inside the machine, you will be entangled with the rotating part or

crushed between sliding parts to be seriously injured.

<Replacement Interval>

5 years

<Necessary Tools>

• Impact resistant viewing window

• Oil- and heat-resistant silicon

• wrench

Page 46

REGULAR INSPECTION B-17

(1) When replacing the machining chamber observation window, contact Mori Seiki

NOTE

Service Department and use a window of the specified type. Mori Seiki does not

accept responsibility for problems arising from the use of a non-specified window

type.

(2) The machining chamber observation window is a consumable part and is not covered

by the warranty.

(3) Check the mounting direction of the window with the sticker affixed to the window that

indicates the outer side of the window pane.

<Procedure>

1) To secure the space where you can work safely, remove tools from the spindle and

workpieces and fixtures from the table.

2) Turn OFF the main power.

3) Step inside the machining chamber and remove bolts from the rear plate securing the window

on the backside of the door.

(1) Take care not to slip and fall in the machining chamber.

NOTE

(2) Hold the window securely being careful not to drop the window.

4) Remove the old window.

In case the window pane is damaged, take sufficient care not to be injured by touching the

NOTE

damaged part of the pane.

5) Remove silicon from the window frame of the door.

6) Install a new window according to the following procedure:

a) Check the mounting direction (inner or outer side) of the window with the sticker affixed to

the window. Apply silicon around the window frame on the outer side.

b) Install the window.

c) Fix the window by tightening bolts on the rear plate.

7) Set the replacement date on the periodical inspection 1 screen.

This screen may not displayed depending on the machine model.

NOTE

Operation Manual (FUNCTION SELECTION KEYS AND DISPLAYS SCREENS:

Regular Interval Maintenance Screen)

This completes the machining chamber observation window replacement procedure.

Page 47

B-18 REGULAR INSPECTION

11. INSPECTION AND REPLACEMENT OF SLIDE SEALS

Slide seals are used on each slideway. The slide seals are used to prevent the entry of chips

beyond them and to maintain an oil film of uniform thickness.

Check the slide seals periodically.

Pay careful attention to abnormal wear on the lip or scratches or damage due to chips.

If you find any abnormality on a slide seal, replace it immediately.

WARNING

CAUTION

<Cleaning interval>

Every 1000 hours of operation

Be sure to shut off the power before inspecting or replacing the slide seal.

Before changing the slide seals, clean the inside of the machine and remove foreign

matter and chips completely. Chips or foreign matter sticking to the slideway faces will

cause machine faults.

Page 48

12. TIMING BELT REPLACEMENT

Some gravity axes are driven by a timing belt turned by a motor shaft. If the machine employs a

timing belt to drive the gravity axis, replace the timing belt periodically.

REGULAR INSPECTION B-19

WARNING

If the same timing belt is used without replacement, the axis could drop

due to damage and wear of the belt, causing damage to the machine.

Contact the Mori Seiki Service Department for assistance when replacing timing belts.

NOTE

<Replacement Interval>

Once every 5 years

CAUTION

Stop machine operation immediately and contact the Mori Seiki Service Department for

assistance in the event of any abnormality, even if replacement is not due yet.

Page 49

B-20 REGULAR INSPECTION

13. CHANGING FLUID OF HYDRAULIC TANK

Change the hydraulic fluid in the hydraulic unit tank at regular intervals while paying attention to

the following considerations.

CAUTION

(1) Maintain the oil level of hydraulic fluid in the tank at the correct level; make sure

that the pump unit does not suck in air.

(2) Keep the hydraulic fluid clean.

(3) Clean the strainer periodically to avoid clogging which will lower the pump flow

rate.

<Changing interval>

Every 1000 hours of operation

<Procedure>

1) Turn OFF the main power.

2) Remove the fill port cap.

3) Place a drain pan beneath the drain plug.

4) Remove the drain plug and drain oil in the tank.

Place a drain pan beneath the drain plug on the oil pan and remove both drain plugs on

NOTE

the hydraulic unit and oil pan.

5) Wrap sealing tape around the threaded section of the plug.

6) Replace the drain plug.

7) Supply oil while checking the oil level gage.

Fill port cap

Oil level gage

Drain pan

Drain plug

Sealing tape

Page 50

8) Replace the fill port cap.

Turn ON the main power.

9)

10) Confirm pump pressure and suction noise are normal.

If the suction noise is louder than prior to oil replacement, check the oil level again.

NOTE

REGULAR INSPECTION B-21

Page 51

B-22 REGULAR INSPECTION

14. CHANGING THE BATTERY

The machine or gantry-type loader has two types of batteries: for memory backup and for

absolute position sensing. If the battery voltage is low, the battery alarm message is displayed on

the screen. If this alarm indication is given, change the batteries by following the procedure

indicated below.

For MSC-801, refer to the MAINTENANCE INFORMATION published separately.

<Battery to be used>

Type NC Unit Memory Back-up Battery

MSC-515

MSD-515

MSC-500

MSC-501

MSD-501

MSD-501II

MSG-500

MSG-501

MSC-516

MSD-516

MSD-516II

Alkaline battery/Manganese

Type 1

MSC-518

MSD-518

battery × 2 pcs.

(Size R20, products on the

market)

MSD-518II

MSC-521

Absolute Position Sensing

Battery

Alkaline battery/Manganese

battery × 4 pcs.

(Size R20, products on the

market)

*2

Lithium battery

E67028 [A06B-6073-K001]

*2

SEICOS Σ21L

MSX-501

MSX-501III

MSX-502

MSX-502III

MSX-500

MSX-500III

MSX-511

MSX-511III

Page 52

REGULAR INSPECTION B-23

Type NC Unit Memory Back-up Battery

• Electrical cabinet side

Battery unit × 1 set

E30027

MSC-803

*1

[ER6 BKO-NC2157H01]

• Operation panel side

Type 2

Battery unit × 1 set

E03031 [ER3V]

Type 3

Type 4

MSG-803

MSX-803

MSX-803III

MSC-803

MSG-805

MSX-805

MSX-805III

MSC-700

MSC-701

*1

*1

*1

Battery unit × 1 set

E30027

[ER6 BKO-NC2157H01]

Regular lithium photo battery

× 2 pcs.

*2

2CR5 (6 V 1300 mAh)

*1

Lithium battery

E30001 [A02B-0200-K102]

Absolute Position Sensing

Battery

Battery unit × 1 set

E30028 [ER6-B4D-01]

Regular lithium photo battery

× 2 pcs.

*2

2CR5 (6 V 1300 mAh)

Lithium battery

E30234 [A06B-6114-K504]

NOTE

(1) The type of the battery used in the NC depends on the machine model.

(2) [ ]: Part number of the NC unit manufacturer

*1

(3)

Type and number of batteries may vary depending on machines models. See

the actual machine for details.

*2

The number of batteries to be used varies depending on the machine model.

Check the number by looking at the number of battery cases.

Page 53

B-24 REGULAR INSPECTION

14.1 Replacing CNC Memory Back-up Batteries

Change the Memory Back-up Battery by following the procedure indicated below.

The type and mounting position of the Memory Back-up Battery vary depending on the

NOTE

model of NC unit.

14.1.1 Type 1

CAUTION

Change batteries while power is being supplied to the NC. If batteries are changed

with the NC power supply shut off, the data stored in the memory will be lost.

To avoid the danger of lost data, you is recommended to save the memory data to an

external I/O device or a memory card.

Mori Seiki can accept no responsibility if data in the memory such as parameters and

programs is lost.

<Battery position>

The batteries are installed in the electrical cabinet door or the rear cover of the operation panel.

<Changing interval>

Once a year

When the battery alarm message is displayed on the screen.

<Procedure>

1) Turn on the power.

2) Press the NC power switch (on).

3) Rotate the mounting screws in the CCW direction

+

−

with a flat screwdriver to remove the cover.

When the cover is removed, 2 alkaline cells (D) are

visible as shown in the figure on the left.

4) Change the batteries.

Always make sure the polarity of the batteries is

NOTE

correct. The polarity varies depending on the

machine type.

5) Mount the cover.

Page 54

14.1.2 Type 2 (Electrical Cabinet Side)

REGULAR INSPECTION B-25

CAUTION

Change the battery with the power supply shut off.

Be sure to change the battery in less than 30 minutes.

The data stored in the memory will be lost if the power supply is shut off for 30 minutes

or more.

To avoid the danger of lost data, you are recommended to save the memory data to an

external I/O device.

Mori Seiki does not have any responsibility for the loss of memory data.

<Battery position>

The batteries are installed in the electrical cabinet door.

<Changing interval>

Every 5 years

When the battery alarm message is displayed on the screen.

<Procedure>

1) Press the NC power switch (off).

2) Turn off the power.

3) Remove the screws of the battery unit.

4) Pull out the battery unit.

Page 55

B-26 REGULAR INSPECTION

5) Remove the screws of the battery holder.

6) Remove the connector attached to the battery.

Do not pull the battery cable.

NOTE

7) Pull the battery out.

8) Fit a new battery.

14.1.3 Type 2 (Operation Panel Side)

CAUTION

Change the battery with the power supply shut off.

Be sure to change the battery in less than 30 minutes.

The data stored in the memory will be lost if the power supply is shut off for 30 minutes

or more.

To avoid the danger of lost data, you are recommended to save the memory data to an

external I/O device.

Mori Seiki does not have any responsibility for the loss of memory data.

<Battery position>

The battery unit is installed inside the operation panel.

Holder

Screw A

Operation panel

<Changing interval>

Every 10 years

When a battery symbol is displayed on the screen.

Page 56

<Procedure>

1) Turn on the power.

2) Press the NC power switch (on).

3) Press the NC power switch (off).

4) Turn off the power.

5) Open the operation panel door.

6) Remove the connector attached to the battery.

Do not pull the battery cable.

NOTE

7) Hold the battery by hand and loosen screw A.

REGULAR INSPECTION B-27

8) Remove the battery by pulling it sideways.

9) Place a new battery in the holder.

10) Hold the battery by hand and tighten screw A.

Page 57

B-28 REGULAR INSPECTION

14.1.4 Type 3 (2CR5 Type Lithium Photo Battery)

CAUTION

Change batteries while power is being supplied to the NC. If batteries are changed

with the NC power supply shut off, the data stored in the memory will be lost.

To avoid the danger of lost data, you is recommended to save the memory data to an

external I/O device or a memory card.

Mori Seiki can accept no responsibility if data in the memory such as parameters and

programs is lost.

<Battery position>

The batteries are installed in the electrical cabinet door.

<Changing interval>

Once a year

When the battery alarm message is displayed on the screen.

<Procedure>

1) Turn on the power.

2) Press the NC power switch (on).

3) Rotate the mounting screws in the CCW direction

with a driver to remove the cover.

When the cover is removed, 2CR5 type lithium photo

batteries are exposed.

4) Change the batteries.

Always make sure the polarity of the batteries is

NOTE

correct.

5) Mount the cover.

Page 58

14.1.5 Type 4

REGULAR INSPECTION B-29

CAUTION

Change batteries while power is being supplied to the NC. If batteries are changed

with the NC power supply shut off, the data stored in the memory will be lost.

To avoid the danger of lost data, you is recommended to save the memory data to an

external I/O device or a memory card.

Mori Seiki can accept no responsibility if data in the memory such as parameters and

programs is lost.

<Battery position>

The batteries are installed in the electrical cabinet door.

<Changing interval>

Once a year

When the battery alarm message is displayed on the screen.

<Procedure>

1) Turn on the power.

2) Press the NC power switch (on).

3) Remove the battery from the back of the power supply unit.

Hold the battery at the top and bottom faces and pull it toward you.

4) Disconnect the battery connector.

Do not pull the battery cable.

NOTE

5) Change the battery and connect the battery connector.

6) Mount the battery case.

Page 59

B-30 REGULAR INSPECTION

14.2 Replacing the Servo Absolute Position Sensing Battery

Change the Absolute Position Sensing Batteries by following the procedure indicated below.

The type and mounting position of the Absolute Position Sensing Batteries vary depending

NOTE

on the machine.

14.2.1 Type 1 (Alkaline Battery/Manganese Battery)

CAUTION

Change the batteries while power is being supplied to the NC. If the batteries are

changed with the NC power supply turned OFF, the absolute position data in the

memory will be lost.

<Battery position>

Battery box installed in the electrical cabinet door

<Changing interval>

Once a year

When the battery alarm message is displayed on the screen.

<Procedure>

1) Turn on the power.

2) Press the NC power switch (on).

+

−

3) Rotate the mounting screws in the CCW direction

with a flat screwdriver to remove the cover.

When the cover is removed, 4 alkaline cells (D) are

−

+

visible as shown in the figure on the left.

4) Change the batteries.

Always make sure the polarity of the batteries is

NOTE

correct.

5) Mount the cover.

Page 60

14.2.2 Type 1 (Lithium Battery)

REGULAR INSPECTION B-31

WARNING

Since the battery is located in the electrical cabinet, carry out battery

change very carefully. If you touch live parts by mistake, you could

sustain an electric shock.

CAUTION

Change the batteries while power is being supplied to the NC. If the batteries are

changed with the NC power supply shut off, the absolute position data in the memory

will be lost.

<Battery position>

The battery is installed in the servo inverters of individual axes.

<Changing interval>

Once a year

When the battery alarm message is displayed on the screen.

<Procedure>

1) Press the NC power switch (off).

Battery

case

Connector

2) Turn off the power.

3) Place the electrical cabinet door interlock key-switch

in the OFF position.

4) Open the electrical cabinet door.

Refer to Chapter A 10. "OPENING/CLOSING

THE ELECTRICAL CABINET DOOR".

5) Turn on the power.

6) Press the NC power switch (on).

7) Remove the battery case.

Hold the battery case at the top and bottom faces as

shown in the illustration and pull it toward you.

8) Disconnect the battery connector.