Page 1

Page 2

II

III

1

11

12

13

13

14

16

17

19

20

21

23

24

26

27

27

28

29

30

32

39

43

44

44

46

50

51

54

55

59

60

60

62

63

65

67

69

71

I

Page 3

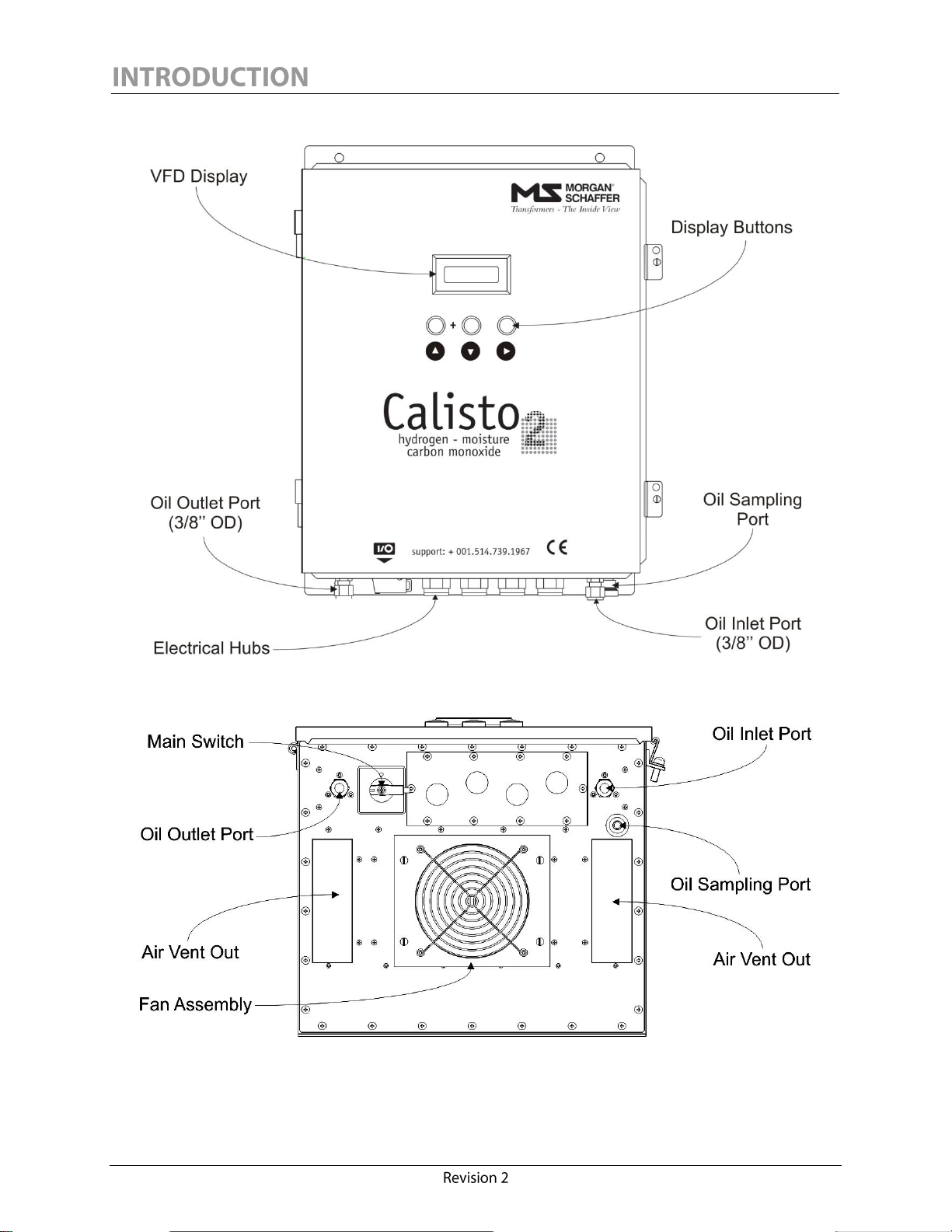

Figure 1: Front View (Calisto 2 model shown) ................................................................................................................................... 6

Figure 2: Calisto/Calisto 2 - Bottom View .......................................................................................................................................... 6

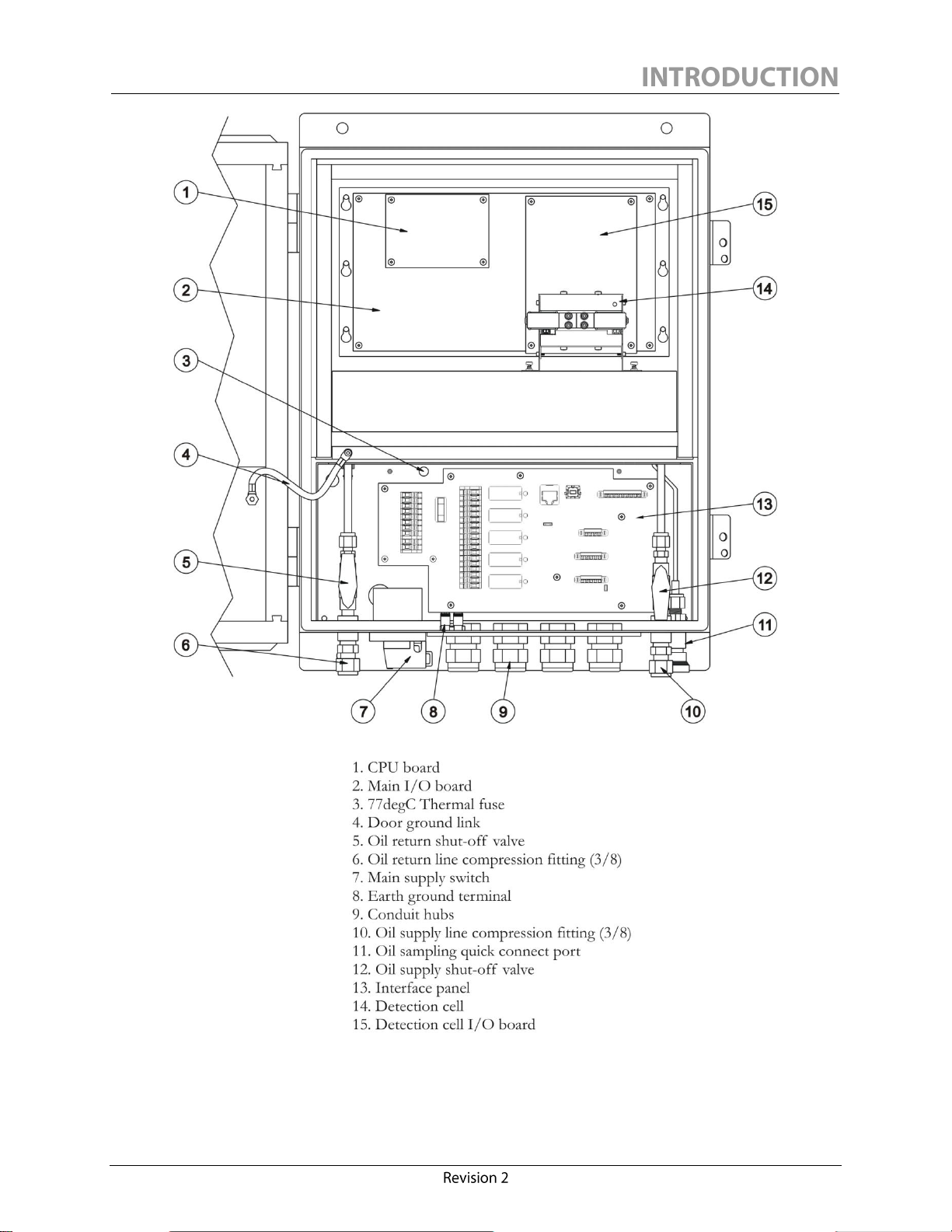

Figure 3: Calisto/Calisto 2 - Main Internal Components ................................................................................................................. 7

Figure 4 : Calisto/Calisto 2 - Mounting Diagram............................................................................................................................. 12

Figure 5: Calisto/Calisto 2 - Interface Board Components ........................................................................................................... 15

Figure 6: Calisto/Calisto 2 - Power Connections ............................................................................................................................. 16

Figure 7: Calisto/Calisto 2 - Alarm Relays and Connections ......................................................................................................... 17

Figure 8: Calisto/Calisto 2 - Analog Output Connector ................................................................................................................. 19

Figure 9: Calisto/Calisto 2 - 4-20 mA Analog Input Connector ................................................................................................... 21

Figure 10: Calisto/Calisto 2 - RS-485 Connection ........................................................................................................................... 22

Figure 11: Calisto/Calisto 2 - RS-232 Connection ........................................................................................................................... 24

Figure 12: Calisto/Calisto 2 - RJ45 Ethernet port ........................................................................................................................... 25

Figure 13: Ethernet Outdoor Connectivity Kit Patchcord ............................................................................................................. 25

Figure 14: Tee Fitting Assembly for the Precision Oil Temperature Probe Option ................................................................. 29

Figure 15: Transformer Valve Elbow Fitting .................................................................................................................................... 29

Figure 16: Adapting the Transformer Valve ..................................................................................................................................... 29

Figure 17: Attaching the Copper Tubing to the INLET Port ....................................................................................................... 30

Figure 18: Attaching the Copper Tubing to the OUTLET Port ................................................................................................... 31

Figure 19: Monitor with Both Valves Closed .................................................................................................................................... 32

Figure 20: Quick Connect Oil Sampling Tube ................................................................................................................................. 33

Figure 21: Connecting the Quick Connect Oil Sampling Tube to the monitor ......................................................................... 33

Figure 22: Flushing the Oil RETURN Tube ..................................................................................................................................... 34

Figure 23: Flushing the Oil SUPPLY Tube ....................................................................................................................................... 35

Figure 24: Disconnecting the Quick Connect Oil Sampling Tube from the Monitor .............................................................. 35

Figure 25: Monitor with both Valves Open ...................................................................................................................................... 36

Figure 26: Calisto/Calisto 2 Display Interface Structure ................................................................................................................ 42

Figure 27: 6-Feet Long A/B Type USB Cable.................................................................................................................................. 43

Figure 28: Calisto Access Status Tab with an Error Code .............................................................................................................. 47

Figure 29: Error Code Interpretation Chart ...................................................................................................................................... 48

Figure 30: Calisto Access Settings Tab ............................................................................................................................................... 51

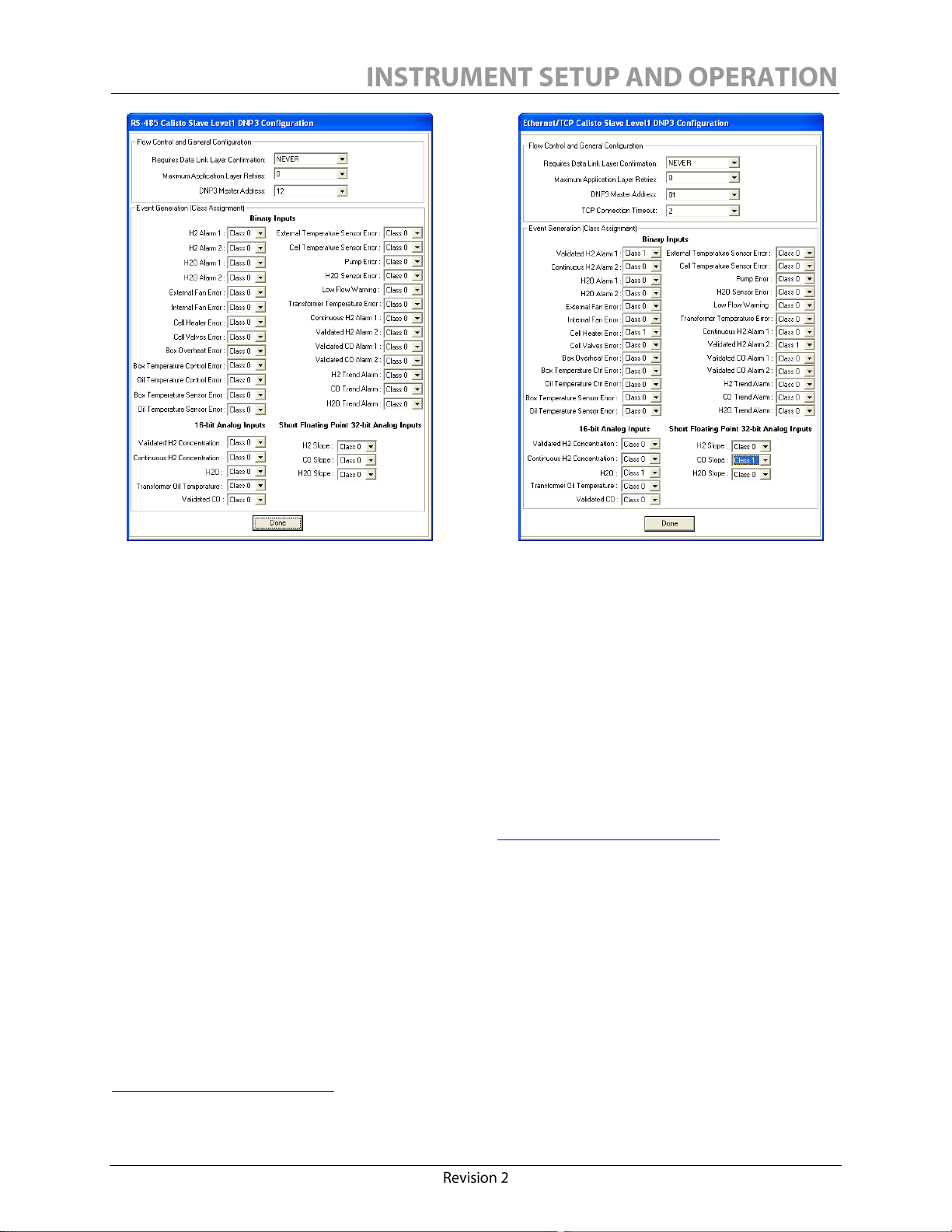

Figure 31: DNP3/RS485 ...................................................................................................................................................................... 53

Figure 32: DNP3/TCP ......................................................................................................................................................................... 53

Figure 33: Calisto/Calisto 2 Access Default Set-Up ........................................................................................................................ 56

Figure 34: Oil Types Selection ............................................................................................................................................................. 61

Figure 35: Calisto Access External Input Settings ........................................................................................................................... 62

Figure 36: Calisto Access Graphic Plotting Panel– H2 ................................................................................................................... 66

Figure 37: Calisto Access Graphic Plotting Panel – CO for Calisto 2 only ................................................................................. 66

Figure 38: Calisto Access Graphic Plotting Panel – H2O .............................................................................................................. 66

Figure 39: Quick Connect Oil Sampling Tube Connected to a 30cc Syringe ............................................................................. 67

Figure 40: 30cc Syringe Connected to the Monitor SAMPLING Port ........................................................................................ 67

II

Page 4

DISCLAIMER

The Calisto/Calisto 2 IED (Intelligent Electronic Device) has been carefully designed

and engineered to provide maximum accuracy while continuously monitoring the

concentration of dissolved gases in transformer oil.

It is assumed by Morgan Schaffer that users will read this Installation & Operation Manual

and will understand the operation of the instrument prior to installation of the IED.

All results obtained using the Calisto/Calisto 2 monitor are based upon material and

equipment under the responsibility of the client. Morgan Schaffer assumes no

responsibility and makes no warranty or representation, expressed or implied, as to the

condition, productivity or proper operation of any equipment or other property for

which the Calisto/Calisto 2 monitor may be used or relied upon for any reason

whatsoever.

The Calisto/Calisto 2 monitor is designed to be permanently installed on critical transformers for

continuous measurement of dissolved fault gases in dielectric insulating fluids. Calisto and Calisto 2

monitor hydrogen and moisture. Hydrogen is a reliable indicator of a recent or existing fault, as all

fault types produce it to a greater or lesser extent.

Calisto 2 also monitors carbon monoxide. Carbon monoxide and moisture levels may highlight

undesirable deterioration of the paper/oil system, and conditions conducive to such deterioration.

Calisto 2 provides the key measurements required to monitor the health of the insulation system, in

order that informed service decisions may be taken, and major transformer problems may be

avoided.

III

Page 5

Page 6

NOTICE

This manual applies to both Calisto and Calisto 2 monitors. Always consider which one

you are working with. Some sections of this manual apply to Calisto 2 only and are

expressly marked “for Calisto 2 only”. If not stated, the section applies to both Calisto

and Calisto 2 monitors.

An electronic version of this manual is available on the Calisto/Calisto 2 CD supplied with your

monitor and at Morgan Schaffer’s web site www.morganschaffer.com. To access this manual on the

website, click Instruments under Products. Then click either Calisto or Calisto 2 and then

Downloads under the Menu (on the right). In order to use the electronic manual efficiently,

proceed as follows after opening Acrobat Reader®:

1. Click Window, Show Bookmarks.

2. Click View, Fit Width.

3. Click View, Continuous.

When necessary, use the Zoom command to view drawing or picture details.

This Installation & Operation Manual provides the required information for installing and setting up a

Calisto monitor version C76-00000 or a Calisto 2 monitor version C85-00000 for operation. All

types of signals, alarm relays and communications are also covered. Users should visit Morgan

Schaffer’s website regularly at www.morganschaffer.com or contact us directly for documentation,

firmware and software updates.

1

Page 7

A 3-year warranty covers each new Calisto/Calisto 2 IED. In order to activate this warranty, the user

must fill out the Warranty Registration Form located in the documentation included with each

instrument and fax it to Morgan Schaffer at 001.514.739.0434. An electronic version of this form is

also available on the Calisto/Calisto 2 CD and can be e-mailed to support@morganschaffer.com

once it has been filled out. Upon receiving the registration form, Morgan Schaffer will confirm the

validity period of the warranty. End users may also visit our website and electronically register their

monitor. In the main menu, under Products, click Instruments and then Calisto or Calisto 2. On

the right side of the menu, click Registration. The warranty can be activated at any time within the

6-month period following the shipping date from Morgan Schaffer. Additional information must be

provided by the end-user if registration of the warranty is performed after the activation period.

Extended warranties are available from Morgan Schaffer. Extended warranty confirmations will be

provided at the time of their purchase or when the standard Warranty Registration Form is received.

2

Page 8

Precise, accurate and continuous hydrogen readings allow detection of transformer incipient

faults at their earliest stage. Hydrogen is a reliable indicator of a recent or existing fault as all fault

types produce it to a greater or lesser extent. Hydrogen’s low solubility in oil and high diffusibility

facilitate its early detection at low concentrations thus providing the earliest warning of the presence

of a fault.

Precise, accurate and continuous moisture readings allow correlations to be established

between moisture in oil and transformer load. They also provide key information on long term

trends of the insulation conditions. In combination with polar products and acids, dissolved water

can significantly affect the dielectric properties of insulating fluids and materials. Monitoring

dissolved water over an extended period of time and undertaking proper action following sudden or

abnormal increases in dissolved water content extends the life expectancy, performance and

serviceability of oil-filled equipment.

Additional continuous measurement of dissolved carbon monoxide in oil differentiates the

Calisto 2 from the Calisto monitor. Carbon monoxide readings can help transformer specialists

assess the remaining life of transformers. Carbon monoxide is often generated in large quantities

when transformer cellulose overheats.

Built-in oil circulation and flow monitoring assure reliability of the readings. Effective on-line

monitoring of dissolved fault gases requires that sensors be in continuous contact with

representative oil from the transformer, in order to react quickly to variations in gas concentrations.

To guarantee accuracy and fast response to developing faults, Calisto/Calisto 2 features an oil

circulation system based on an anti-cavitation reciprocating pump with an outstanding reliability

record. In addition, an integrated oil flow monitor, also designed for maintenance-free operation and

long-term reliability, provides a low-flow warning if the flow drops below a pre-set threshold, as may

occur if a valve is inadvertently closed.

Continuous enclosure and oil conditioning is essential for accurate readings. The most important

source of interference on dissolved gas sensors comes from environmental temperature variations.

Varying ambient and oil temperatures significantly affect the solubility and diffusion rates of

dissolved fault gases, leading to baseline drift and signal variation. This often limits the ability of

IEDs to monitor low levels of fault gases. Calisto/Calisto 2 features passive and thermo-electric

temperature conditioning modules which continuously maintain both enclosure and oil temperatures

constant to pre-set levels. This results in unequalled sensitivity, repeatability and long-term stability,

independent of the environment where the instrument is installed.

Reliable gas extraction and detection technologies are both crucial to produce reliable readings.

As the oil within the Calisto/Calisto 2 is conditioned to a precisely regulated temperature, it is

pumped past a bundle of PTFE capillary tubes which together form the gas probe. Dissolved gases

permeate through the walls of the tubing to form a representative gas sample within the probe.

Gases then diffuse along the capillary tubes to form a gas sample inside the detection cell. Any

change in gas concentrations in the oil will modify the equilibrium within the probe and the cell.

The Calisto/Calisto 2 detection cell uses an enhanced version of Morgan Schaffer’s proprietary

high-accuracy thermal conductivity detection (TCD) technology, to provide accurate gas

3

Page 9

measurements, without any field calibration, for the lifetime of the instrument. The Calisto and

Calisto 2 detection cells take validated measurements for hydrogen and carbon monoxide (Calisto 2

only) every three hours. Validated measurements are continuously zeroed to guarantee long-term

stability and low-level detection accuracy. A continuous measurement of the hydrogen concentration

is also performed for both monitors, to indicate any variation in hydrogen concentration which may

occur between validated readings.

Vacuum tolerance is made possible because of the intrinsic properties of the capillary tubing used

to form the gas sample and because the oil circulating and conditioning systems inside the

Calisto/Calisto 2 can both sustain vacuum. As a result, no action is required to protect the monitor

if the transformer is put under vacuum for degassing purposes.

Precise moisture measurement is achieved using a capacitive thin-film sensor immersed directly

in circulating oil to continuously measure dissolved moisture. Moisture content can be reported in

parts per million (ppm), %RS at 25oC (77°F) or %RS at a specific transformer temperature using the

Expert Series Calisto Precision Oil Temperature Probe.

4

Page 10

The complete technical specifications of the two instruments are included in Appendix I of this

manual. Prior to installing or commissioning the IED, users should understand the basic principles

of operation of the instrument and identify the main components of the built-in systems. Both

Calisto and Calisto 2 monitors feature substantially the same internal components and user interface

hardware. The detection cells are calibrated differently and are specific to each monitor type.

The instrument is usually installed permanently on a transformer or a pedestal-style mounting stand.

The system requires that oil from the transformer be brought to the IED and then returned to the

transformer. To accomplish this, Calisto/Calisto 2 features separate oil inlet and outlet ports. Oil

circulation is achieved with the use of a small reciprocating pump (nominal flow of 60 ml/min. or

0.95 US gal/hr) located inside the instrument.

Figure 1 on the following page shows the general front view of a Calisto/Calisto 2 which features a

vacuum fluorescent display (ultra bright at day and night) and the three-button display interface.

Figure 2 illustrates the main features visible on the bottom view of a Calisto/Calisto 2, including the

oil inlet/outlet ports and the quick-connect oil sampling port.

Figure 3 illustrates the main components inside a Calisto/Calisto 2.

Calisto/Calisto 2 IED controls the oil temperature and the air temperature inside the enclosure

using heat exchangers and thermo-electric elements. A waterproof long-life cooling fan, located at

the bottom of the enclosure, provides the primary heat removal from the system. A small fan,

located inside the enclosure, provides temperature stability to the electronics and the gas

measurement cell.

When the system is in operation, date and time stamped measurements are stored in the

instrument’s memory at a factory set storage frequency of one reading every 3 hours. This data can

be retrieved and viewed graphically using Morgan Schaffer’s Calisto Access software. Data can also

be viewed at any time on the door display, which provides the most recent validated hydrogen and

carbon monoxide (Calisto 2 only) measurements, in addition to the real-time dissolved moisture

measurements. Other instrument operation and manufacturing parameters can be viewed on the

display. Section 3.3 describes the operation of the display buttons in detail.

5

Page 11

Figure 1: Front View (Calisto 2 model shown)

Figure 2: Calisto/Calisto 2 - Bottom View

6

Page 12

Figure 3: Calisto/Calisto 2 - Main Internal Components

7

Page 13

QTY.

DESCRIPTION

1

Standard Calisto/Calisto 2 monitor

1

6-foot male A/B USB 2.0 cable for local connection

1

Calisto Access interface software CD-ROM

1

Quick Connect Oil Sampling Tube

4

Stainless steel vibration mount assembly

2

Copper tubing – 3/8 O.D. × 25 ft (7.6 m)

1

Thermal cut-off fuse (spare)

2

Brass elbow – ½ NPT (M) – 3/8" Tube

4

Brass nut – 3/8 Tube

4

One-lokTM brass ferrule – 3/8 Tube

1

Shipping box

1

Installation & Operation Manual (softcopy, also available on our website)

1

Factory Test Certificate

1

Declaration of Conformity

8

Page 14

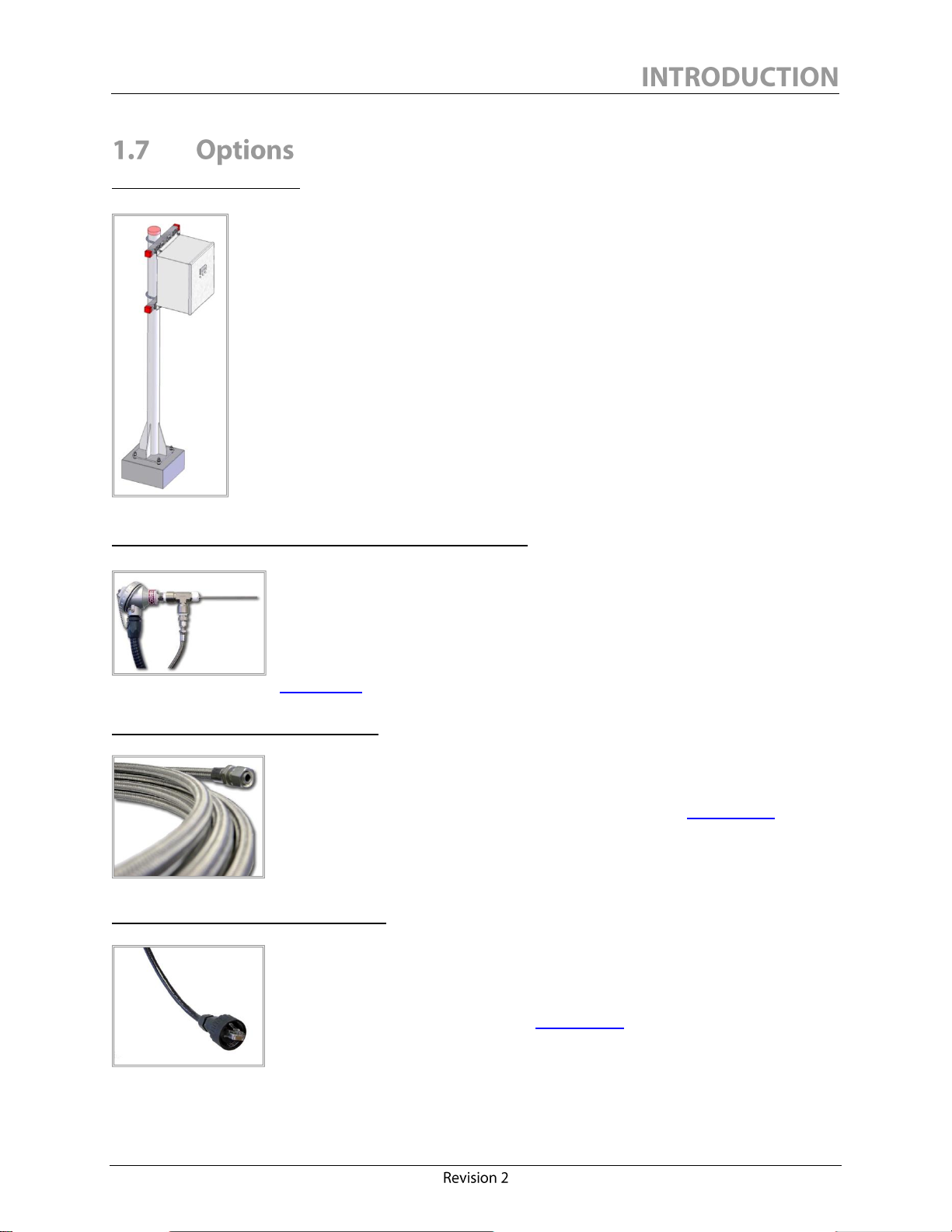

Calisto Mounting Stand

For a fast and easy installation, Morgan Schaffer has designed a pedestal-style

mounting stand for Calisto/Calisto 2. This stand is highly corrosion resistant

and includes all required hardware to perform the installation in less than one

hour.

Precision Oil Temperature Probe – Standard Edition

The Precision Oil Temperature Probe was specifically developed to meet

client demands to report the %RS in oil at a specific transformer temperature

in a truly accurate and reliable way. The 610 mm (24 in.) temperature probe is

customized at the moment of the installation of the monitor and does not

require any specifications from the client at the time of the order. Refer to

Appendix I for the complete technical specifications.

Stainless Steel Braided Flex Lines

The Stainless Steel Braided Flex Lines are a popular customizable option for

the Calisto/Calisto 2 configuration that has the advantage of being highly

resistant to corrosion and easy to install. Refer to Appendix I for the

complete technical specifications.

Ethernet Outdoor Connectivity Kit

Calisto/Calisto 2 features an Ethernet port isolated to 1500 V. The Ethernet

Outdoor Connectivity Kit includes all the necessary parts to bring a

communication cable from the monitor to a control box switch/hub in an

easy and reliable way. Refer to Appendix I for the complete technical

specifications.

9

Page 15

Other available options:

Insulation kit (for -50 to 55°C [-58 to 131°F] operation)

IEC 61850 Ethernet communication kit

900 MHz radio modem over RS-485

2.4 GHz radio modem over RS-485

Quick-connect dust plug

Calisto MultiTrack software

Extended warranty up to 5 years

On-site commissioning assistance

10

Page 16

Page 17

WARNING

IED’s should only be installed by qualified personnel familiar with their operation and

associated hazards. Improper electrical or hydraulic circuitry may result in personal

injury and/or instrument damage and may void the warranty.

Two persons are recommended for lifting the equipment.

NOTICE

Calisto/Calisto 2 is designed for industrial use and shall not be connected to the public

low-voltage distribution system.

Section 2.0 Installation applies to both Calisto and Calisto 2 monitors.

CAUTION

All IEDs are filled with new transformer mineral oil when shipped. DO NOT OPEN

INLET AND OUTLET VALVES PRIOR TO INSTALLATION.

The following steps must be undertaken to properly install a Calisto/Calisto 2 IED on a

transformer:

Mounting of the monitor on a transformer or structure

Electrical connections: power, alarms, signals and communication

Attachment of oil circulation lines between transformer valves and IED

Flushing of the oil lines with oil to remove air

The following tools are usually required for a standard installation:

Pipe cutter (for copper oil lines only)

Pipe wrench, 5/8 and 11/16 wrenches (or adjustable wrenches)

Knife

Small screwdriver (flat)

Large screwdriver (flat)

Installation kit for Calisto/Calisto 2

11

Page 18

This section will provide guidelines on where to install the monitor on the transformer. Two

different scenarios will be discussed. One will be based on the Calisto/Calisto 2 being shipped

directly from a new transformer manufacturer or transformer rewinder (Factory Installed) and the

other is based on a field retrofit.

Calisto/Calisto 2 must be solidly bolted to a suitable support approximately 1.2 m (4 ft) above

ground level to allow easy access to the internal oil sampling valves. A minimum of 60 cm (24 in.) is

required for air circulation under the unit.

The mounting structure should be positioned to protect the monitor from extreme vibrations. A

typical location would be the side of the transformer control box. Vibration mounts (4) are provided

with each monitor and should be used to provide the instrument with additional protection against

possible vibrations. If the monitor is field installed, the use of a post bolted to the concrete base of

the transformer is an ideal configuration. The Calisto/Calisto 2 mounting hole locations are shown

in Figure 4. Standard dimensions are in inches and dimensions in brackets are in millimetres.

Figure 4 : Calisto/Calisto 2 - Mounting Diagram

12

Page 19

NOTICE

The IED is designed to be installed vertically (as shown in this manual). The unit

MUST NOT BE MOUNTED IN ANY OTHER ORIENTATION.

Electronic mounting and installation drawings are included in the CD provided.

In most cases the factory will install the monitor on Unistrut® brackets that are welded to the main

transformer tank. Calisto/Calisto 2 is generally installed at eye level and two additional ½ inch valves

are welded directly to the main tank near the monitor for the oil supply and return.

In most cases the top oil fill valve and the main drain valve are located on the same side of the main

tank. It is best to install the monitor near the bottom drain valve. Of course this location will vary as

needed based on the oil line requirements discussed later in this section.

Typically Unistrut® brackets are used to make a base for mounting the Calisto/Calisto 2. The

mounting structure can be designed to clamp on to various components of the transformer tank, on

the main control cabinet, on a post installed in the ground or on a concrete base. A Morgan Schaffer

Calisto Mounting Stand is available as an optional accessory. Contact Morgan Schaffer for more

information.

A complete Installation Manual is included with the Morgan Schaffer Calisto Mounting Stand

accessories. Refer to this manual when mounting a Calisto/Calisto 2 on the stand.

13

Page 20

WARNING

Electrical shock hazard. Only persons with electrical safety training and certification

should install the equipment or open the enclosure once the equipment has been

installed.

NOTICE

It is recommended to select a shielded cable suitable for outdoor use for all

communication and signal wiring. For any configuration, the installer must follow these

guidelines:

Minimize the length of cable from the hub to the interface board (avoid loops).

Protect against mechanical stress on wires and connectors attached to the

interface board.

The following section explains in detail the monitor interface board and how to connect the mains

power, safety ground, alarm relays, analog signals, and communication cables to a Calisto/Calisto 2

monitor.

The Calisto/Calisto 2 monitor features a 4-hub detachable electrical entry plate made of stainless

steel. All entry holes are 22 mm (7/8 in.) in diameter and can accept most ½ in. entry hub fittings.

Four waterproof rubber entry hole plugs are provided with the instrument to cover unused holes.

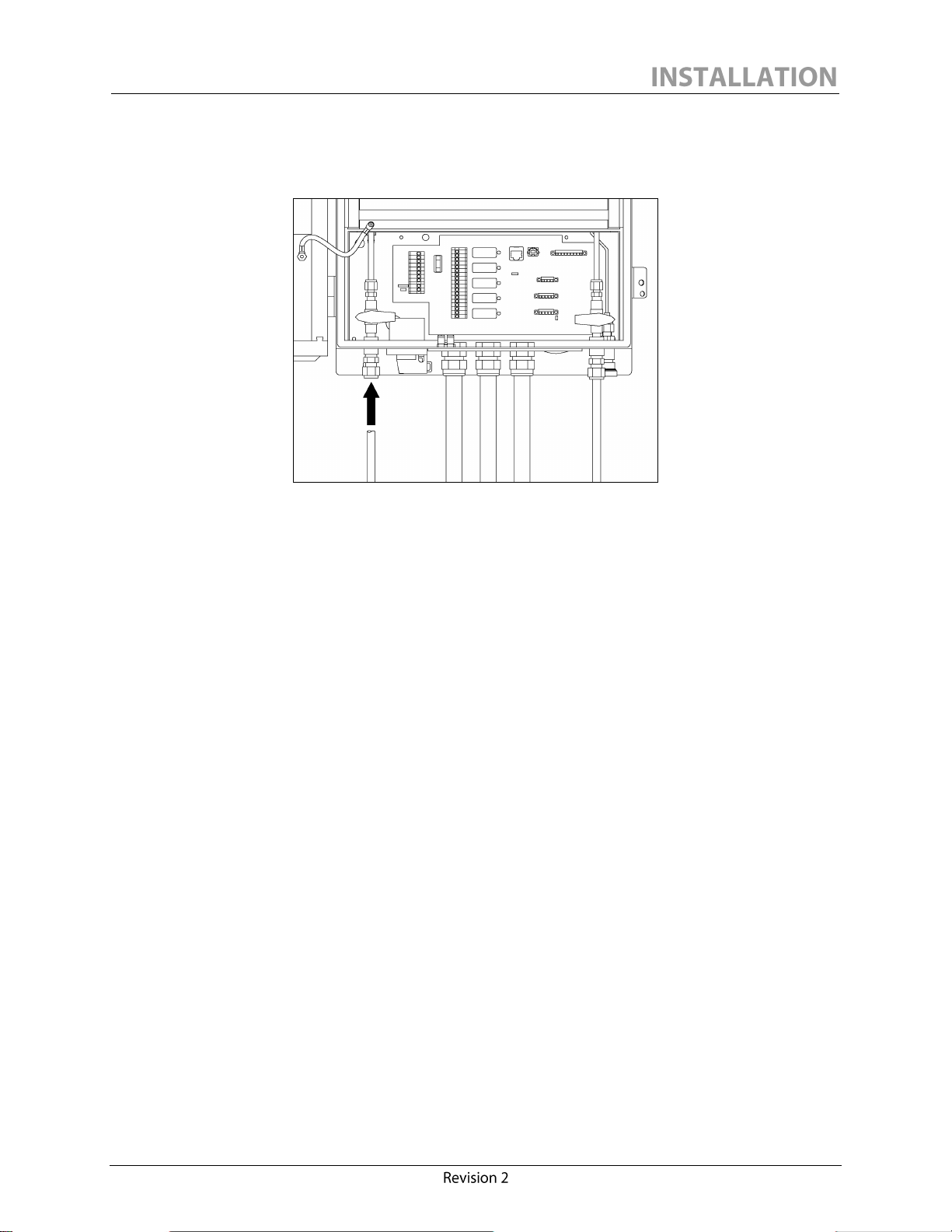

Opening the Calisto/Calisto 2 enclosure door will provide access to the monitor interface board.

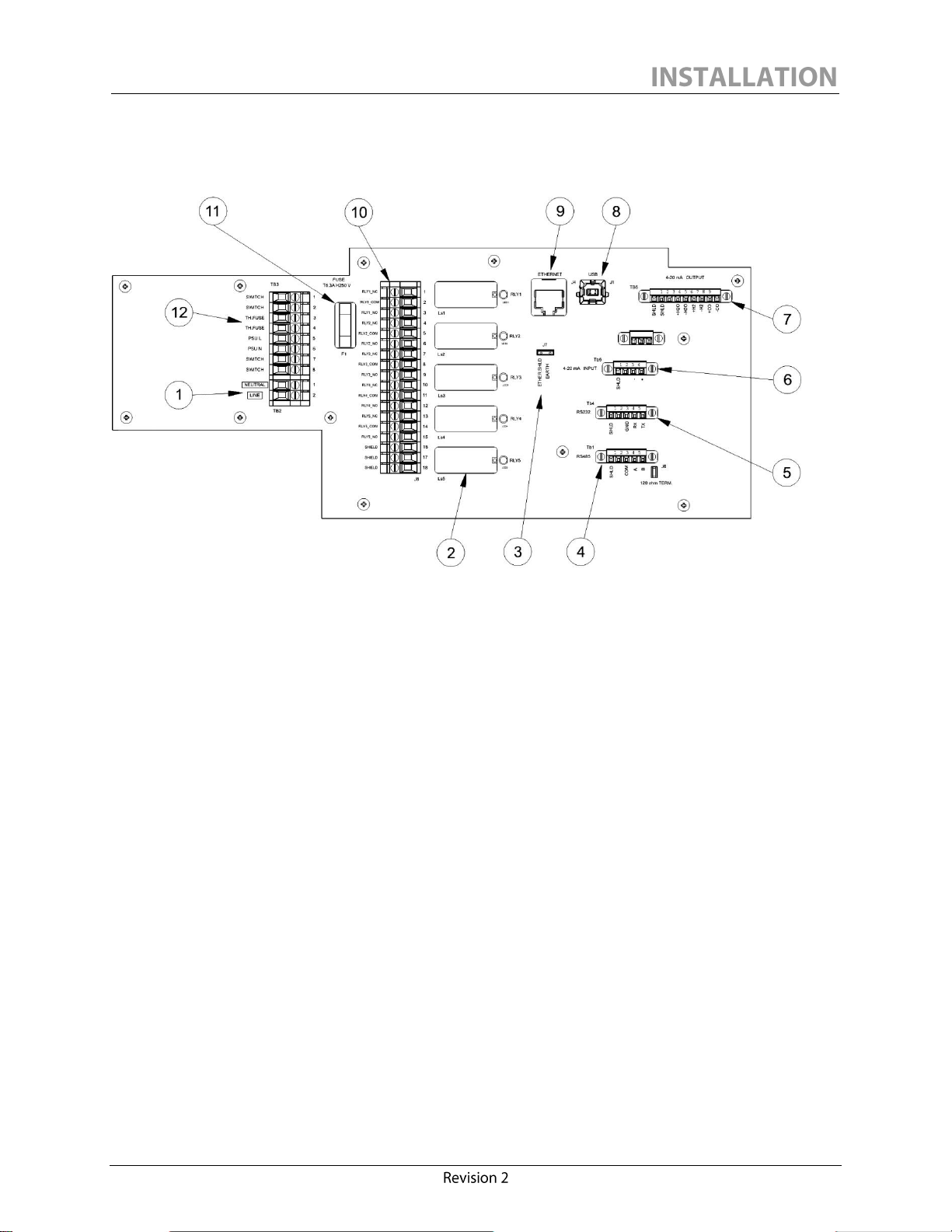

Figure 5 shows the main components of the Calisto/Calisto 2 interface board. All connections to

the monitor are made using this board.

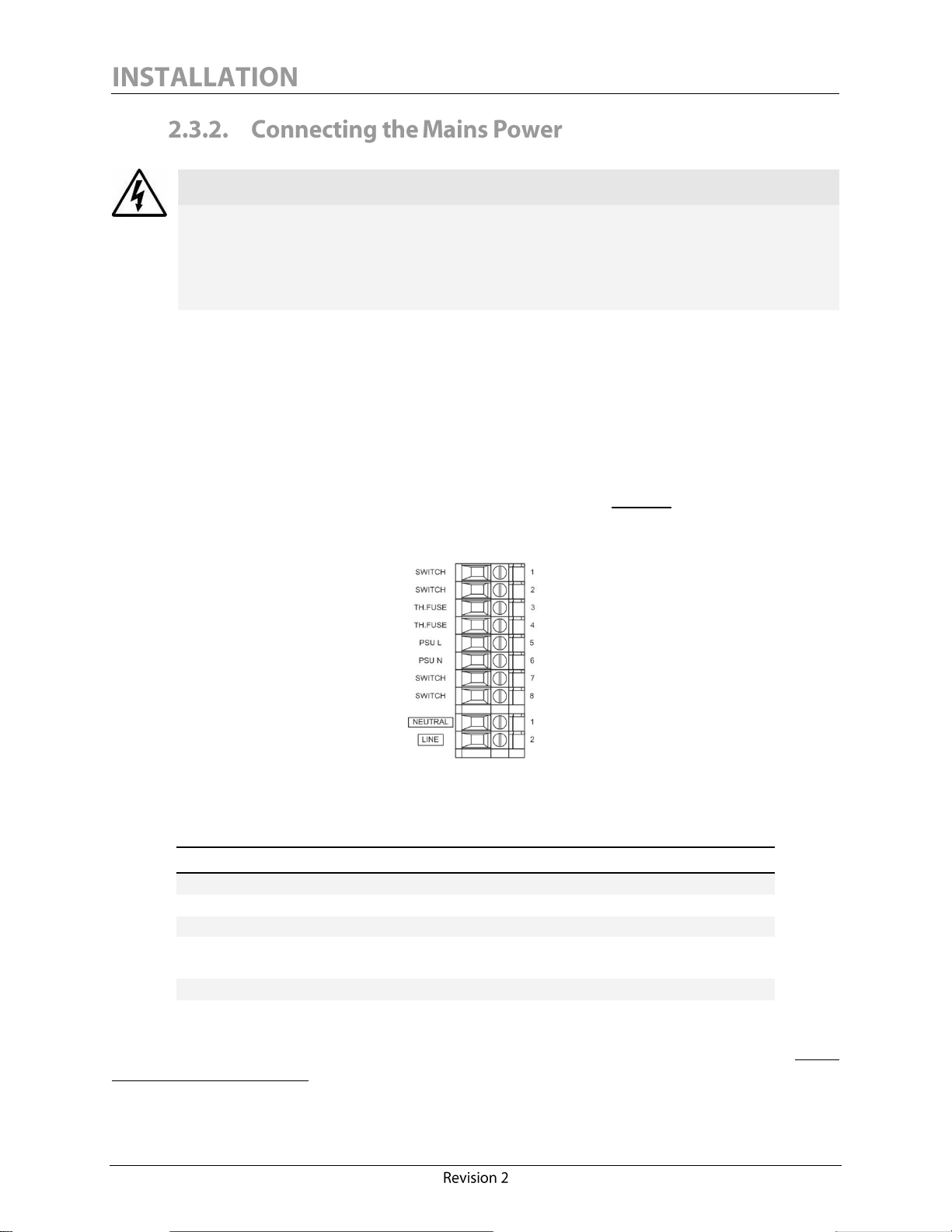

Items 1, 12 and 11 are respectively the mains power connectors, the thermal cut-off fuse and the

over-current fuse.

Items 10 and 2 are the programmable NO/NC dry-contact relays with their respective connectors.

Items 4, 5, 6 and 7 are respectively the RS-485, RS-232, 4-20 mA analog input and 4-20 mA analog

output connectors.

14

Page 21

Calisto Interface Board Components:

12. Thermal cut-off fuse terminals

Items 8, 9 and 3 are respectively the USB type B port, the Ethernet port and the Ethernet shield

earth jumper. The USB port is for local connection only, used during servicing or maintenance of

the instrument.

1. Main supply terminals

2. Programmable relays with activity LEDs (5)

3. Ethernet shield earth jumper

4. RS-485 communication port

5. RS-232 communication port

6. 4-20mA analog input terminals

7. 4-20mA analog output terminals (3rd channel is for

Calisto 2 only)

8. Local USB type B port

9. Ethernet communication port

10. Programmable relay terminal block

11. Main supply fuse (5HT 6.3-R)

Figure 5: Calisto/Calisto 2 - Interface Board Components

15

Page 22

RATING

NOMINAL VALUE/RANGE

Connection range

2.50 – 4.00 mm2 solid

Connection range (UL/CSA)

14 – 12 AWG

Wire strip length

9 mm (~3/8 in.)

Wire insulation ratings

300V,

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.5

WARNING

Install the protective earth conductor to the earth ground terminal before making any

other connections. When uninstalling the unit, remove all other connections before

removing the protective earth connection.

Protective earth connection is essential to guarantee client safety. To install the protective earth

conductor to the earth ground terminal, secure the protective earth conductor tightly using the two

screw terminals provided. It is the client’s responsibility to ensure the integrity of the ground cable

and client-side ground connection.

The Calisto/Calisto 2 monitor is designed to accept any supply voltage from 100 to 240 VAC with

frequencies in the range of 50 to 60 Hz. Mains power connections are made to connector 1 (neutral)

and connector 2 (line) using either solid or stranded conductors (See Figure 6). Connections must be

made in accordance with the connector ratings provided in the table below.

Figure 6: Calisto/Calisto 2 - Power Connections

To connect the mains power, loosen completely each screw terminal, insert the conductor to the

bottom of the terminal slot, and then tighten the screw.

16

Page 23

The Calisto/Calisto 2 nominal power is 320W. The main supply switch may be used to turn the unit

WARNING

Electrical shock hazard. Alarm relays may be connected to hazardous live voltage even

if the mains power is OFF or disconnected.

ON or OFF. A circuit breaker must also be dedicated to the unit for this purpose. Although the

Calisto/Calisto 2 is equipped with an internal over-current fuse, it is strongly recommended that a

suitable fuse or breaker be installed in the mains supply external to the unit, with rating appropriate

to the supply voltage and nominal power.

Calisto/Calisto 2 features 5 programmable dry-contact relays. Each relay can be connected in a

normally open (NO) or normally closed (NC) configuration.

All 5 relays are located on the monitor interface board as shown in Figure 7.

Figure 7: Calisto/Calisto 2 - Alarm Relays and Connections

17

Page 24

The table below describes the alarm relay connections pinout assignment:

CONNECTOR NO.

MARKING

CONNECTION TYPE

1

RLY1_NC

Relay 1 normally closed (NC)

2

RLY1_COM

Relay 1 common

3

RLY1_NO

Relay 1 normally open (NO)

4

RLY2_NC

Relay 2 normally closed (NC)

5

RLY2_COM

Relay 2 common

6

RLY2_NO

Relay 2 normally open (NO)

7

RLY3_NC

Relay 3 normally closed (NC)

8

RLY3_COM

Relay 3 common

9

RLY3_NO

Relay 3 normally open (NO)

10

RLY4_NC

Relay 4 normally closed (NC)

11

RLY4_COM

Relay 4 common

12

RLY4_NO

Relay 4 normally open (NO)

13

RLY5_NC

Relay 5 normally closed (NC)

14

RLY5_COM

Relay 5 common

15

RLY5_NO

Relay 5 normally open (NO)

16

SHIELD

Shield to earth ground

17

SHIELD

Shield to earth ground

18

SHIELD

Shield to earth ground

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 2.5 mm2 stranded

Connection range (UL/CSA)

22 – 141 AWG stranded

Wire strip length

9 mm (~3/8 in.)

Wire insulation ratings

300V,

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.5

1

Connectors 2, 5, 8, 11 and 14 are all commons and can be looped together into one single common

if all signals must route to the same location.

Connectors 16, 17 and 18 can be used to terminate an alarm cable shield to the earth ground.

The relay connections must be made in accordance with the following connector ratings:

To connect the relay connections, loosen completely each screw terminal, insert the conductor in

the terminal slot until the bottom is reached, and then tighten the screw.

Using gauge 14 conductors to wire the relays may dictate the use of a larger diameter protective conduit, thus enlarging

one of the electrical entry holes. Two entry holes can also be dedicated to the alarm relay wiring as an alternative.

18

Page 25

Recommended use of the alarm relays:

AC CONNECTIONS

Characteristic

Nominal value/range

Min./Max. switching voltage

5V/400VAC

Rated resistive load

16A/250VAC

Min switching current

5mA

Coil-contact dielectric strength

5000VAC

DC CONNECTIONS

Characteristic

Nominal value/range

Min./Max. switching voltage

5V/300VDC

Rated resistive load

16A/24VDC

1A/48VDC

0.4A/100VDC

0.3A/(150-300)VDC

Min switching current

5mA

Coil-contact dielectric strength

5000VAC

For more information on how to configure the alarm relays, refer to Section 4.2.6 Setting Alarm

Limits and Section 4.2.7 Relay Output Configuration of this manual. The factory default alarm relay

configurations can also be found at Section 4.2.7.

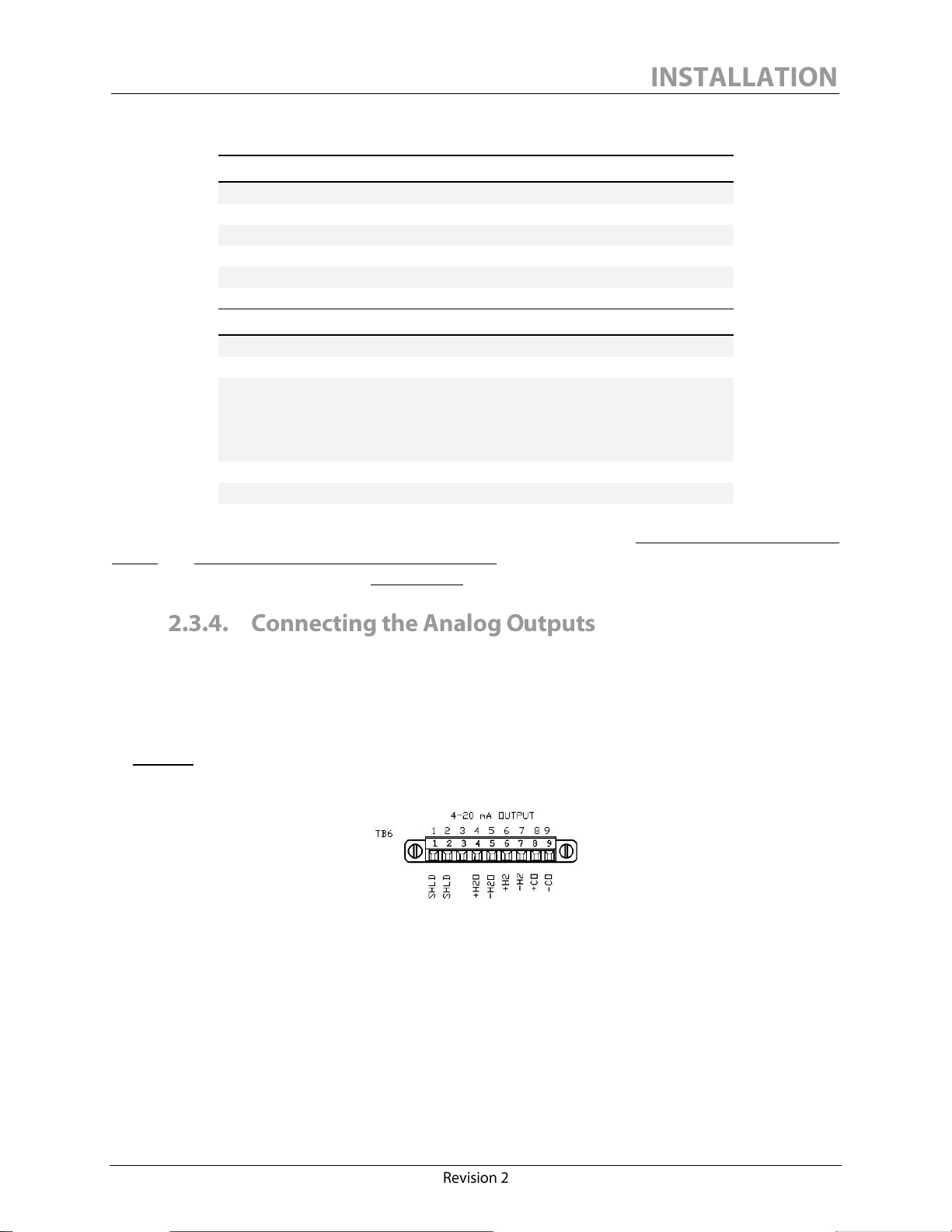

The Calisto monitor features two 4-20 mA analog outputs, one for dissolved hydrogen and one for

moisture. Calisto 2 features one additional 4-20 mA analog output dedicated to carbon monoxide.

All analog outputs are isolated to 1500 V.

The analog output screw-terminal plug-in connector is located on the monitor interface board (Refer

to Figure 8). Although pin 8 and 9 are present in a Calisto monitor, no signal from this output can

be used as Calisto does not report carbon monoxide.

Figure 8: Calisto/Calisto 2 - Analog Output Connector

It is recommended to un-plug the connector to simplify wiring the connections, and to screw the

connector in place after the connections are made.

19

Page 26

The analog output connector pinout has the following configuration:

PIN NO.

OUTPUT

DESCRIPTION

1

SHLD

Shield to earth ground

2

SHLD

Shield to earth ground

3

N/A

Unused 4 Moisture (H2O)

Positive (+)

5

Moisture (H2O)

Negative (-)

6

Hydrogen (H2)

Positive (+)

7

Hydrogen (H2)

Negative (-)

8

Carbon monoxide (CO)

Positive (+) (Calisto 2 only)

9

Carbon monoxide (CO)

Negative (-) (Calisto 2 only)

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 1.5 mm2 solid/stranded

Connection range (UL/CSA)

22 – 16 AWG

Wire strip length

6.5 mm (~1/4 in.)

Wire insulation ratings

150V (300V preferred2),

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.0

2

NOTICE

The analog input can only be used with self-powered 4-20 mA devices and must not be

powered by an external source.

The analog output connections must be made in accordance with the following connector ratings:

The load resistance can be anywhere from 0 Ohm to a maximum of 500 Ohms including resistance

of the wires. The maximum length of the wires depends on the overall resistance of the load and the

acceptable noise level.

The setup of the analog outputs is done using the Calisto Access software. Refer to Figure 33:

Calisto Access Default Set-Up for more information.

Calisto/Calisto 2 features one 4-20 mA analog input that can be used to provide a reading of the

transformer oil temperature to the unit. The 4-20 mA analog input is loop-powered to +13.5 VDC

and isolated to 1500 V.

To preserve 1500V functional I/O isolation, 300V rated voltage is preferred.

20

Page 27

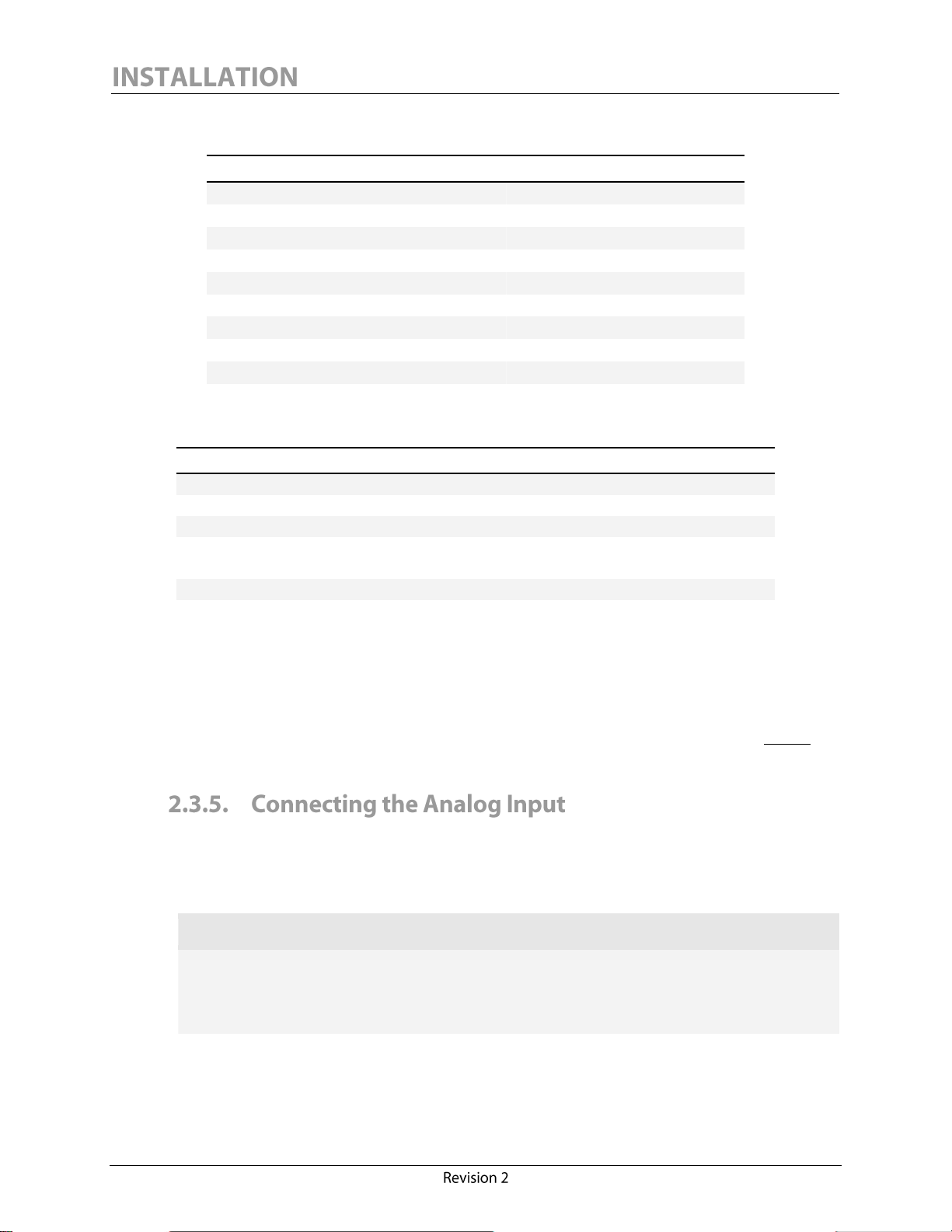

The analog input screw-terminal plug-in connector (Refer to Figure 9) is located on the monitor

PIN NO.

MARKING

DESCRIPTION

1

SHLD

Shield to earth ground

2

Unused 3 -

4-20 mA negative (-)

4

+

4-20 mA positive (+)

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 1.5 mm2 solid/stranded

Connection range (UL/CSA)

22 – 16 AWG

Wire strip length

6.5 mm (~1/4 in.)

Wire insulation ratings

150V (300V preferred3),

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.0

3

interface board.

Figure 9: Calisto/Calisto 2 - 4-20 mA Analog Input Connector

It is recommended to un-plug the connector to simplify wiring the connections, and to screw the

connector in place after the connections are made.

The 4-20 mA analog input connector pinout has the following configuration:

The 4-20 mA analog input connections must be made in accordance with the following connector

ratings:

If the Precision Oil Temperature Probe option for Calisto/Calisto 2 was purchased with your

instrument, refer to the Precision Oil Temperature Probe Manual. An electronic version of this manual

can be found on our website www.morganschaffer.com.

The analog input temperature range is configured via the Calisto Access software.

Calisto/Calisto 2 features one RS-485 communication port isolated to 1500 V. The RS-485 uses a

differential balanced line over twisted pair and can thus span relatively large distances, up to 4000 ft

(1200 m). It is highly recommended to select an industrial grade shielded twisted pair cable of

minimum 0.34 mm2 (22 AWG) to set up a communication via RS-485.

To preserve 1500V functional I/O isolation, 300V rated voltage is preferred.

21

Page 28

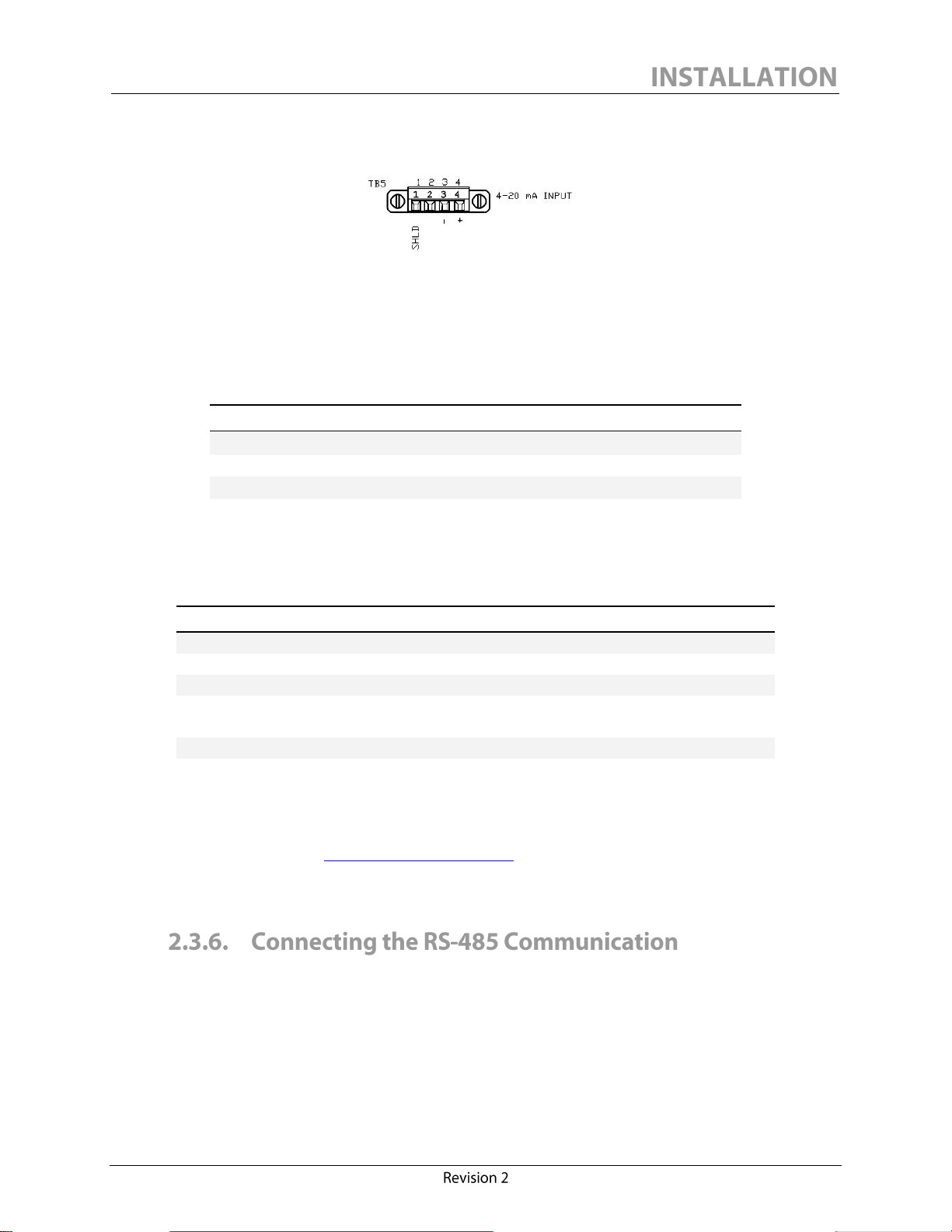

The RS-485 screw-terminal plug-in connector is located on the monitor interface board (See Figure

PIN NO.

MARKING

DESCRIPTION

1

SHLD

Shield to earth ground

2

Unused 3 COMM

Common signal ground

4

A

Line A 5 B

Line B

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 1.5 mm2 solid/stranded

Connection range (UL/CSA)

22 – 16 AWG

Wire strip length

6.5 mm (~1/4 in.)

Wire insulation ratings

150V (300V preferred4),

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.0

4

10).

Figure 10: Calisto/Calisto 2 - RS-485 Connection

It is recommended to un-plug the connector to simplify wiring the connections, and to screw the

connector in place after the connections are made.

The RS-485 connector pinout has the following configuration:

The RS-485 connections must be made in accordance with the following connector ratings:

The RS-485 common signal ground (pin 3, marked “COMM”) should always be wired properly to

ensure a reliable connection. The signal ground of an RS-485 cable must not be connected to the

chassis ground or “SHLD” when optical or galvanic isolation is used at both ends. Since

Calisto/Calisto 2 provides 1500 V isolation, it is recommended to use RS-485 devices that also offer

good isolation. The signal ground conductor should be connected to pin 3 (COMM) and should be

connected at all ends.

To preserve 1500V functional I/O isolation, 300V rated voltage is preferred.

22

Page 29

CAUTION

Morgan Schaffer cannot be held responsible for a monitor communication malfunction

if the RS-485 cable shield is not properly attached to pin 1 (SHLD). For RS-485

communication, the common signal ground is not a shielding/earthing ground.

The monitor interface board provides a 120 Ohm terminating resistor which may be used to

terminate the RS-485 cable shield. The value of the terminating resistor is designed to match the

characteristic impedance of the cable, and may be useful in cases where the monitor is on the end of

an RS-485 network. Termination resistors are generally not required when communicating with a

Calisto/Calisto 2 monitor at the standard speed of 9600bps. To connect the terminating resistor,

install the jumper provided across J6 on the monitor interface board, just below the RS-485

connector.

However, to determine whether or not termination resistors should be used, the cable length and

data rate must be taken into account. If the propagation delay of the data line is less than one bit

width, termination should not be required. Reflections would dampen out in several trips up and

down the data line. Since the receiving device will sample the data in the middle of the bit, it is

important to have a good signal level at that point. The propagation delay can be calculated by

multiplying the cable length by the propagation velocity of the cable (usually specified by the cable

manufacturer, typically between 66% and 75% of the speed of light).

For example, in a system with 2000 feet of wire a round trip would cover 4000 feet. Using a

propagation velocity of 66% of the speed of light, a round trip would be completed in about 6.2µs.

If we assume the reflections dampen out in three round trips, the signal would stabilize 18.6µs after

the leading edge of a bit. At 9600bps one bit is 104µs wide: the reflections would be dampened out

before the center of the bit, and therefore termination resistors would not be required.

Calisto/Calisto 2 supports several protocols over RS-485:

MSSP (Morgan Schaffer Systems Protocol)

DNP3 (widely used protocol specific to the electric utility industry)

ModBus (widely used protocol in general automation industry).

Refer to Section 4.2.5 Communication Settings of this manual for more information on the above

protocols.

Calisto/Calisto 2 features one RS-232 communication port isolated to 1500 V. The maximum

recommended range for RS-232 communication is 15m (50 feet).

23

Page 30

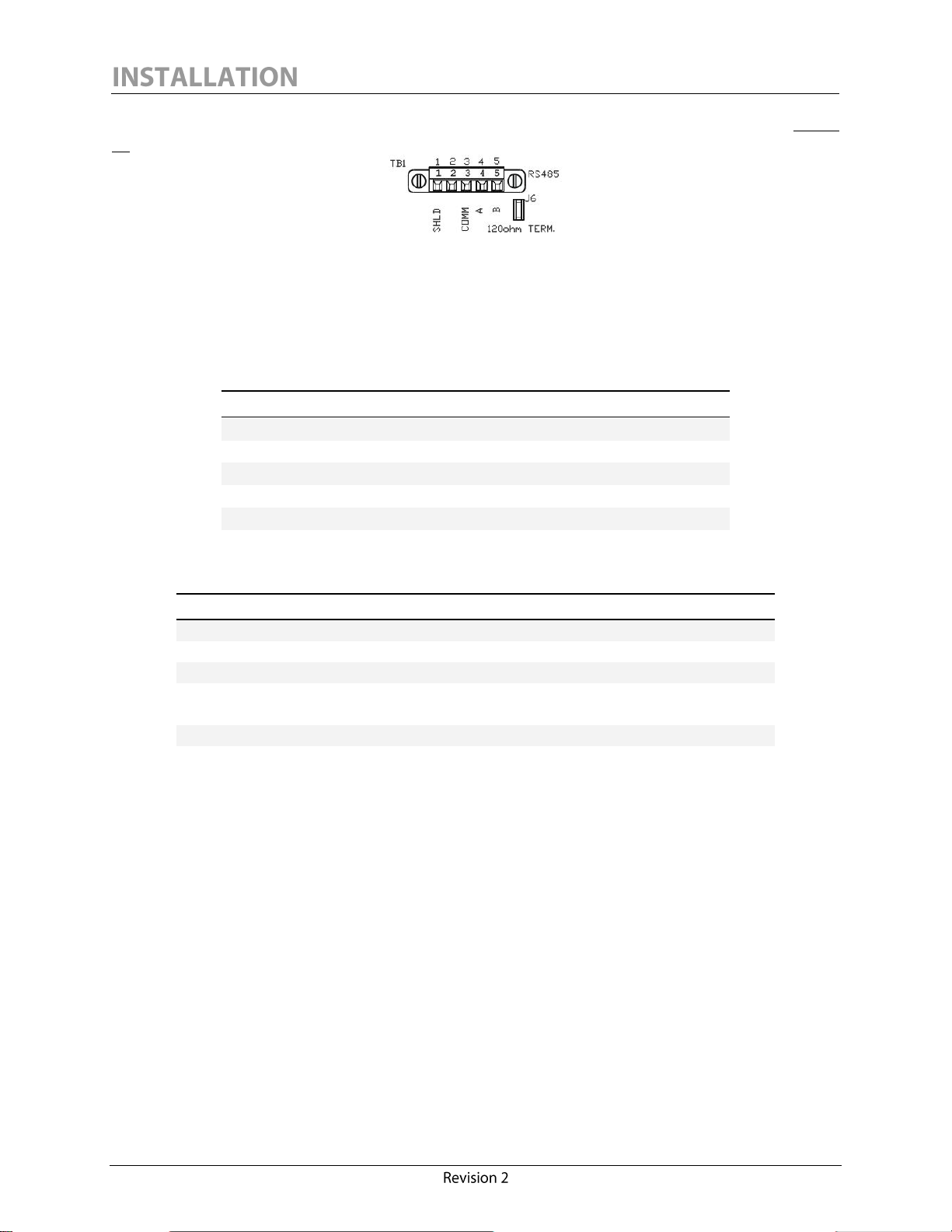

The RS-232 screw-terminal plug-in connector is located on the monitor interface board (see

PIN NO.

MARKING

DESCRIPTION

1

SHLD

Shield to earth ground

2

Unused 3 GND

Signal ground

4

RX

Received data

5

TX

Transmitted data

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 1.5 mm2 solid/stranded

Connection range (UL/CSA)

22 – 16 AWG

Wire strip length

6.5 mm (~1/4 in.)

Wire insulation ratings

150V (300V preferred5),

90ºC (194ºF) or better

Flammability

VW-1 or better

Screw type

M2.0

5

Figure 11).

Figure 11: Calisto/Calisto 2 - RS-232 Connection

It is highly recommended to select an industrial grade shielded twisted pair cable of minimum 0.34

mm2 (22 AWG) to set up a communication via RS-232.

The RS-232 connector pinout has the following configuration:

The RS-232 connections must be made in accordance with the following connector ratings:

The RS-232 signal ground (pin 3, marked “GND”) should always be wired properly to ensure a

reliable connection.

The Calisto/Calisto 2 RS-232 communication port does not support any protocol other than our

proprietary MSSP.

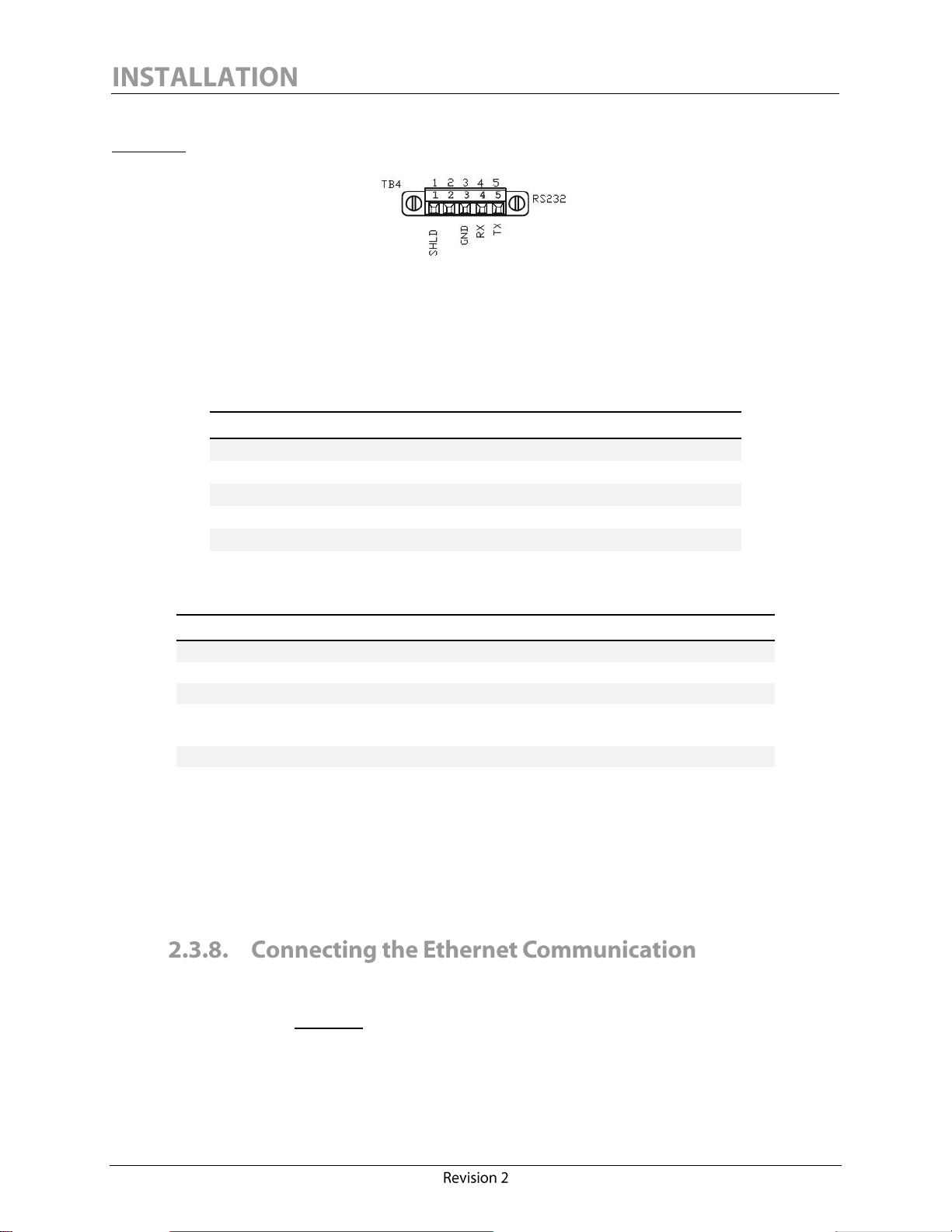

Calisto/Calisto 2 features one Ethernet port which allows the unit to be connected to a computer or

a corporate LAN or WAN. The port is isolated to 1500 V. The port connector is located on the

monitor interface board. Figure 12 illustrates the onboard RJ45 receptacle that can be shielded using

jumper J7 (Ethernet shield to earth ground).

To preserve 1500V functional I/O isolation, 300V rated voltage is preferred.

24

Page 31

RATING

NOMINAL VALUE/RANGE

Connection range

0.34 – 1.5 mm2 solid/stranded

Connection range (UL/CSA)

22 – 16 AWG

Wire strip length

6.5 mm (~1/4 in.)

Screw type

M2.0

Figure 12: Calisto/Calisto 2 - RJ45 Ethernet port

For installing an Ethernet link, it is recommended to use an industrial FTP or ScTP cable suitable

for outdoor use (oil and sun resistant), even if a protection conduit is used. Proper connectors and

fittings must be used to preserve the ingress protection of the monitor. This type of connection

should not span over 30 m (100 ft).

The Ethernet connection must be made in accordance with the following connector ratings:

An FTP or ScTP shield must be connected to earth ground at only one end. Jumper J7 should only

be connected if the cable shield remains disconnected on the client’s side. Grounding at both ends

may lead to poor communication and/or damage to the instrument.

IEC61850 protocol (optional)

Calisto/Calisto 2 supports the IEC61850 substation protocol. This option can be selected at the

moment of the order and can also be retrofitted to any Calisto version C76-00000 or Calisto 2.

Ethernet Outdoor Connectivity Kit (optional)

For an easy and reliable connection, the Calisto/Calisto 2 monitor can be installed with the Morgan

Schaffer Ethernet Outdoor Connectivity Kit. This kit includes an IP68 industrial Ethernet shielded

patchcord (custom length, refer to Figure 13) fitted with screwable end connectors and all required

hardware to interconnect the monitor to a control panel. No protective conduit is required for this

highly abrasion-, oil- and UV-resistant cable.

Figure 13: Ethernet Outdoor Connectivity Kit Patchcord

25

Page 32

INSTALLATION NOTES

Below are guidelines for the installation of the Ethernet Outdoor Connectivity Kit:

The RJ45 pass-through bulkhead provided requires a 1-inch hole and must be

installed on a control cabinet.

UV stabilized cable ties are provided to secure the Ethernet patchcord.

Avoid installing the patchcord in any working or walking area.

The patchcord shield must be connected to the ground for interference

immunity. A Calisto/Calisto 2 monitor ordered with an Ethernet Outdoor

Connectivity Kit will have jumper J7 linking the onboard RJ45 receptacle shield

to the earth ground. Thus, the client has no need to connect the shield on his

side.

Avoid sharp bends to the cable.

Morgan Schaffer cannot guarantee protection from an external surge (such as lightning or electrical

arc) over 1500 V that could infiltrate the Ethernet line. It is the client’s responsibility to isolate the

Ethernet line on the client side.

Calisto/Calisto 2 supports several protocols over Ethernet:

MSSP (Morgan Schaffer Systems Protocol)

DNP3/TCP (widely used protocol specific to the electric utility industry)

Modbus (widely used protocol in general automation industry).

Refer to Section 4.2.5 Communication Settings of this manual for more information on the above

protocols.

The Calisto/Calisto 2 interface board includes a Type B USB jack. The USB connection does not

provide high voltage isolation and is therefore only suitable for local connection using a laptop

computer. This connection is convenient for the initial configuration of communication and other

settings. Driver installation is required in order to communicate over USB. Refer to 4.2.1 Installing

Calisto Access Software.

26

Page 33

NOTICE

When installing a Calisto/Calisto 2 monitor with a Precision Oil Temperature Probe, a

special probe fitting must be attached to the transformer valve before installing the oil

SUPPLY line. Refer to the Precision Oil Temperature Probe Manual.

To ensure representative sampling of the transformer oil, it is important that the oil inlet and outlet

valves on the transformer be distant as stated in the following section, to prevent oil re-circulation.

The valves should have a minimum diameter of 1.3 cm (½ in.), and be located near the

monitor.

Optional shutoff valves (preferably ball valves) are recommended below the monitor on the

oil RETURN and SUPPLY lines to isolate the monitor if unmounting is required.

Female, ball or gate type valves with a minimum diameter of ½ NPT are recommended for

the transformer valves.

The inlet and outlet valves must not be close to a pump.

The oil RETURN line must not exceed 11 m (35 ft).

The oil SUPPLY line must be longer than 1 m (3 ft) to reduce mechanical stress.

The distance between the two transformer valves should be a minimum of 1 m (3 ft).

The inlet valve should be at least 0.45 m (18 in.) above the main tank bottom.

Do not make straight lines between the transformer tank and the monitor. Include one loop

or bend in the oil line.

In very hot conditions, it is strongly recommended not to insulate the oil lines.

In very cold conditions, it is strongly recommended to permanently insulate the oil lines.

Most transformer manufacturers will install two 1.3 cm (½ in.) oil valves directly on the main tank

close to the location where the monitor will be installed. Both of these valves will generally be

accessible from the ground level.

27

Page 34

Calisto/Calisto 2 requires two oil valves from the transformer. Typically the top oil fill valve and the

bottom main drain valves are used. The preferred method is to draw oil from the top fill valve and

return the oil through the bottom main drain valve. This can only be done if the top oil fill valve is

below the top oil level. If the top oil valve is above the top oil level it will be necessary to draw oil

from the bottom main drain valve and return it through the top oil fill valve. Drawing oil from the

bottom main drain valve can pose some problems if there is an excessive amount of sludge from oil

decomposition in the bottom of the transformer. Also, condensed water may accumulate at the

bottom of very wet transformers.

Here are some suggestions for determining whether the top oil valve is below the top oil level:

Contact the transformer manufacturer.

Contact the responsible party within your organization.

Review the Outline drawings of the transformer and look for notes or review the instruction

book supplied with the transformer.

Some transformers have a conservator tank. A conservator tank is a large cylindrical or

rectangular tank that sits above the transformer main tank. A pipe connects the conservator

tank to the main transformer tank. If this is the case, the top oil valve on the main tank will

be below the top oil level.

Compare the location of the oil level gauge to the location of the top oil fill valve. If the

location of the oil level gauge is above the location of the top oil fill valve, most likely the

top oil fill valve is below the top oil level. If the top oil valve is higher than the location of

the oil level gauge, most likely the top oil fill valve is NOT below the top oil level.

Review the small print on the transformer nameplate. Often there is a statement indicating

that the top oil level is X below the highest manhole cover on the top of the transformer.

Compare this measurement to the location of the top oil fill valve.

Refer to Figure 1 and Figure 2 to view the oil inlet and outlet ports of the Calisto/Calisto 2 monitor.

28

Page 35

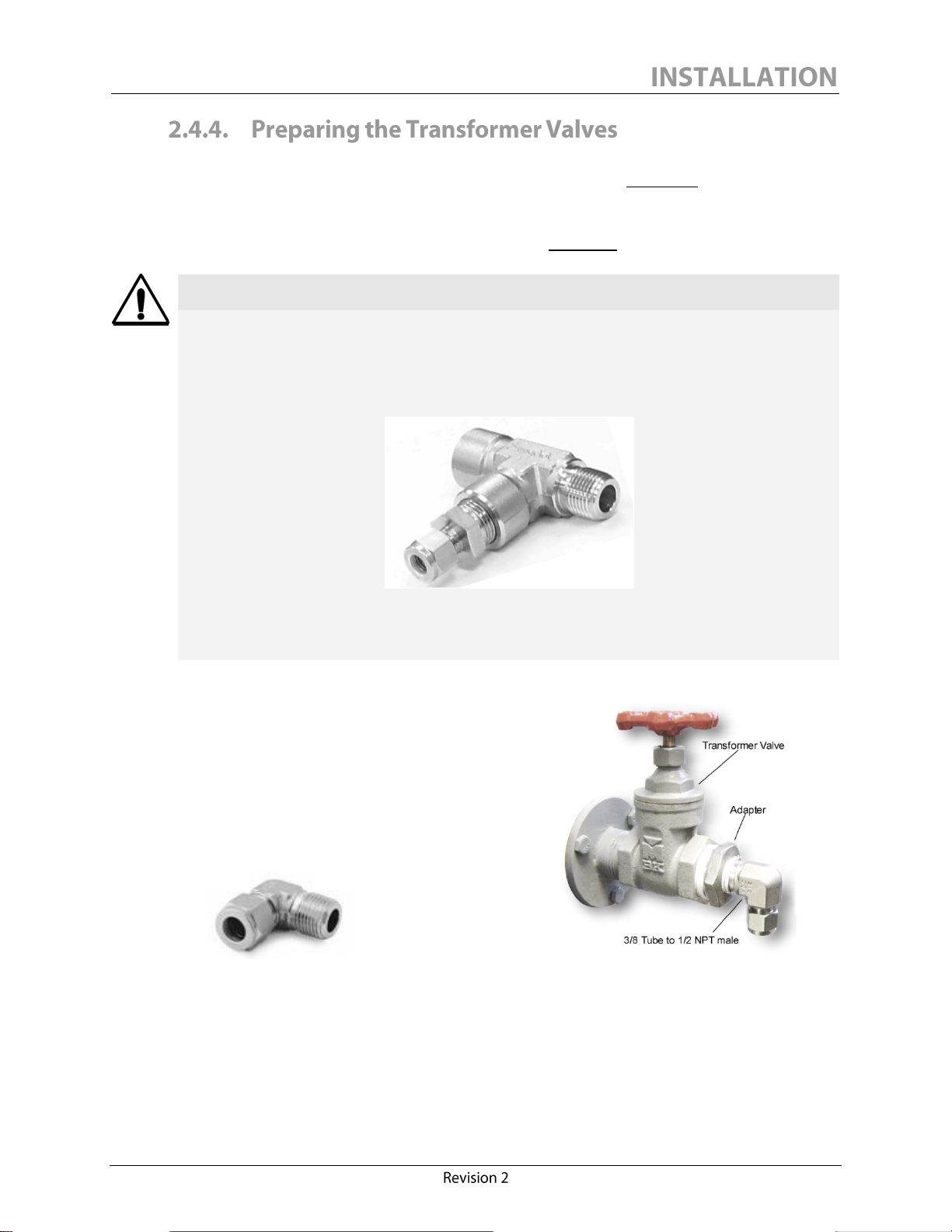

CAUTION

If a Precision Oil Temperature Probe is to be installed with the monitor, a provided tee

fitting must be installed instead of an elbow on the oil SUPPLY valve. Refer to the

Precision Oil Temperature Probe Installation Manual.

Figure 14: Tee Fitting Assembly for the Precision Oil Temperature Probe Option

Prior to installing the oil lines, both transformer valves selected to circulate oil to the monitor must

be prepared to accept the tube fittings included in the accessories. Figure 15 shows one of the

supplied brass elbow fittings 3/8″ tube to ½″ NPT male (stainless steel 316 if stainless steel flexible

oil lines were ordered with the monitor). If required, use a pipe adapter to fit the ½″ NPT male end

to the transformer SUPPLY and RETURN valves (Refer to Figure 16).

Figure 15: Transformer Valve Elbow Fitting

29

Figure 16: Adapting the Transformer Valve

Page 36

CAUTION

When attaching oil lines to the Calisto/Calisto 2, use a counter-torque wrench to avoid

damaging the INLET and OUTLET ports on the monitor. The torque and the

counter-torque wrenches must be aligned one over the other as much as possible to

cancel induced forces. A pipe-cutter must be used to cut the oil lines. Other tools must

be avoided as they can leave burrs, debris and scratches on the surface to be swaged.

1. Install the first oil line as follows: Unroll a few inches of one of the supplied coils of 3/8″

copper tubing and insert one end firmly into the monitor INLET port (See Figure 17). Using

an 11/16 wrench and a 5/8 counter-torque wrench, tighten the compression nut 1¼ turns

from finger tight for proper sealing. Route the tubing properly to the transformer SUPPLY

valve and cut off the excess length using a pipe cutter. Deburr the inside of the tube to

prevent flow restriction. Both ends of the tubing should be straight for several inches where

they enter the fittings. Incorporate at least one shallow bend somewhere in the tubing to aid

installation. Tighten the tubing at the transformer SUPPLY valve (or at the tee fitting

assembly when installing a Precision Oil Temperature Probe option) to complete the oil

SUPPLY line installation.

Figure 17: Attaching the Copper Tubing to the INLET Port

2. Install the second oil line as follows: Unroll a few inches of the second supplied coil of 3/8″

copper tubing and insert one end firmly into the monitor OUTLET port (See Figure 18).

3. Using an 11/16 wrench and a 5/8 counter-torque wrench, tighten the compression nut 1¼

turns from finger tight for proper sealing. Route the tubing properly to the transformer

RETURN valve and cut the excess length of tubing using a pipe cutter. Deburr the inside of

30

the tube to prevent flow restriction. Both ends of the tubing should be straight for several

Page 37

inches where they enter the fittings. Incorporate at least one shallow bend somewhere in the

tubing to aid installation. Tighten the tubing at the transformer valve to complete the oil

RETURN line installation.

Figure 18: Attaching the Copper Tubing to the OUTLET Port

4. Secure all oil lines against excessive vibration.

31

Page 38

CAUTION

Before continuing, Section 5.1 of the Precision Oil Temperature Probe Installation Manual

must now be followed when the option is to be installed with a Calisto/Calisto 2.

NOTICE

The Calisto/Calisto 2 monitor is equipped with a proprietary gas accumulator which

will vent any air bubbles present in the incoming oil, once the monitor is in operation.

1. Once all connections are made, the lines and the monitor must be flushed with oil to remove

any air present in the assembly and to replace the shipping oil inside the monitor with oil

from the transformer. To do so, ensure that both monitor valves are still closed (valve

handles in the horizontal position, refer to Figure 19), then slowly open both transformer

valves.

Figure 19: Monitor with Both Valves Closed

2. Firmly push the supplied Quick Connect Oil Sampling Tube (fitted with ¼" yellow plastic

tubing, refer to Figure 20) into the monitor’s oil SAMPLING port located at the bottom of

the enclosure (beside the oil INLET port, refer to Figure 21).

32

Page 39

Figure 20: Quick Connect Oil Sampling Tube

Figure 21: Connecting the Quick Connect Oil Sampling Tube to the monitor

3. Using a container to collect the flushed oil, slowly turn the OUTLET valve (left side)

counterclockwise ¼ turn (the handle will then be pointing down) to flush the RETURN line

with oil (Refer to Figure 22: Flushing the Oil RETURN ). To avoid injecting trapped air in

the transformer, flush a minimum of 500 cc of oil and then close the OUTLET valve by

turning it clockwise to the horizontal position.

33

Page 40

NOTICE

Before proceeding with Step 5, the following checks should be made:

The earth ground is properly connected.

The mains power is protected by a circuit breaker.

The main supply switch is in the “O” position (OFF).

Both transformer oil supply and oil return valves are open.

Both monitor oil INLET and oil OUTLET valves are closed.

Figure 22: Flushing the Oil RETURN Tube

4. Slowly turn the INLET valve (right side) counterclockwise ¼ turn to the vertical position to

flush the SUPPLY line with oil. Now, turn the main supply switch to the <I> (ON) position

to start the internal oil circulation pump to enable flushing (See Figure 23). To avoid

injecting trapped air into the transformer, wait until a minimum of 500 cc of oil is flushed

again and turn the main supply switch to the <O> position (OFF).

34

Page 41

Figure 23: Flushing the Oil SUPPLY Tube

5. While maintaining the INLET valve open, remove the Quick Connect Oil Sampling Tube

from the oil SAMPLING port by pushing the locking ring up and pulling the fitting (with

yellow hose) down (See Figure 24).

Figure 24: Disconnecting the Quick Connect Oil Sampling Tube from the Monitor

6. Open the OUTLET valve (left side). At this stage, both transformer valves and both

monitor valves should be open as shown in Figure 25.

35

Page 42

Figure 25: Monitor with both Valves Open

7. The monitor is now ready for configuration. Refer to Section 3.0 POWER UP.

36

Page 43

Before starting the installation, ensure that the monitor main supply switch is in the <O> position

(OFF), and that the INLET and OUTLET valves inside the monitor are closed (horizontal

position).

1. Bolt the IED to a proper structure or a Morgan Schaffer Calisto Mounting Stand using the

provided vibration mounts.

2. Connect the earth ground and mains power.

3. Connect the alarm relays (if required).

4. Connect the analog 4-20mA outputs (if required).

5. Connect the analog 4-20 mA input (if required).

6. Connect the RS-485 or RS-232 or Ethernet line (if required).

7. Prepare the transformer SUPPLY and RETURN valves.

8. Connect the copper tubing (or stainless steel braided hoses) to the transformer valves and to

the corresponding oil INLET and OUTLET ports.

9. Connect the supplied Quick Connect Oil Sampling Tube to the sampling port and use a

container to purge the oil RETURN line.

10. Open both transformer valves.

11. Open the OUTLET valve and purge 500 cc of oil from the monitor RETURN line.

12. Close the OUTLET valve.

13. Open the INLET valve and power ON the monitor to pump oil through the SAMPLING

port. Purge 500 cc and power OFF the monitor.

14. Disconnect the Quick Connect Oil Sampling Tube from the SAMPLING port (do not close

the INLET valve).

15. Open the OUTLET valve.

16. The monitor is ready to be configured. Refer to Section 4.0 INSTRUMENT SETUP AND

OPERATION.

37

Page 44

Page 45

The following checks should be made before providing power to the monitor:

Verify that no tools or other equipment are present in the enclosure.

The earth ground is properly connected.

The mains power is properly connected.

All signal, relay and communication wiring is installed.

The monitor is protected by an appropriate circuit breaker.

Both transformer oil SUPPLY and RETURN valves are open.

Both instrument oil INLET and OUTLET valves are open.

All conduit fittings are fully tightened (rubber plugs are present on unused entry holes).

Verify that the instrument has a 0.6 m (24 in.) minimum clearance from the ground.

Verify that there are no excessive vibrations on the complete system.

Verify that the oil line connections have no leaks.

39

Page 46

NOTICE

If the instrument temperature is below -35oC (-31°F) at start-up, the IED will enter

into a pre-heating mode where only the enclosure heaters will be activated. The

instrument on-board computer will start once the enclosure temperature has

reached -5oC (41°F). Reaching the computer start-up temperature could take several

minutes or even hours in extremely cold environments.

Once the instrument has been properly installed and the checks in Section 3.1 have been made, the

instrument can be started by providing power to the unit and placing the main supply switch to the

<I> position (ON). A delay of approximately 5 seconds will occur before a reading is displayed on

the door display. This time is required by the instrument for firmware initialization.

When the Calisto/Calisto 2 is powered on or reset, the unit first enters an initialization and poweron self-test sequence. The purpose of this mode is to allow the on-board computer to evaluate

temperature conditions and to allow the detection cell and moisture sensor to reach equilibrium with

the surroundings. The duration of the initialization is 3 hours or one complete measuring cycle.

During the entire time of this mode of operation, the door display will indicate <H2= INIT> to

inform the user of this normal condition.

After completing this initialization sequence, the unit will then enter into its normal mode of

detection and measurement, thereby displaying the last validated measurement for hydrogen

<H2=000>. Carbon monoxide (Calisto 2 only) and moisture measurements can also be viewed on

the display using the 3-button display interface. Refer to Section 3.3 for a complete description of

the display interface operation. All readings will then be updated after the next measurement cycle,

and subsequently time-stamped and stored as new validated measurement records in the on-board

databank.

40

Page 47

The 3-button display interface provides access to three different “sections” of information: Realtime

<REALTIME>, Manufacturer <MANUFACT> and Database <DATABASE>. Buttons 1 and 2

pushed simultaneously are used to toggle between sections. Button 3 is used to scroll between fields

within the same section. Refer to Figure 26 for a complete overview of the display interface

structure. Data are shown as examples only.

Realtime Section

By default, the instrument will show the last validated concentration of hydrogen <H2=000> under

the section <REALTIME>. For a quick overview of all current measurements, button 3 must be

pressed three times to see consecutively the carbon monoxide <CO=000>, the moisture

<WRS=00> and the oil temperature <OTT=00>. With a Calisto version C76-00000, <CO=N/A>

will be displayed while trying to access the carbon monoxide measurement. By default, moisture is

displayed as <WRS=00> for % relative saturation at 25oC (77°F), and the oil temperature will

display <OTT=NONE> (inactive by default). Using the Calisto Access software provided, the

moisture can be set up to show a % relative saturation at user selectable temperature <WST=00> or

a concentration in ppm <WWC=00>. Note that user selectable temperature requires a Calisto

Precision Oil Temperature Probe connected through the 4-20mA analog input. Refer to Section

4.2.11 External Input Sensor Configuration.

Manufacturer Section

To browse the monitor’s Manufacturer section, press once on buttons 1 and 2 simultaneously from

the default display to access all the instrument information. Press Button 3 to access each field of

the Manufacturer section (refer to Figure 26). This section provides useful information about the

instrument such as the Serial Number, the firmware version and the date of manufacturing. The unit

will return to the default section <REALTIME> after 10 seconds of inactivity.

Database Section

To browse the monitor’s database, press buttons 1 and 2 simultaneously twice from the default

display to access all recorded data. Press Button 3 to access the record number and then press

Button 1 to scroll down all data one by one, starting from the most recent record to the oldest

record: example <REC=299> to <REC=001>. Press Button 2 to scroll up to the newest record.

At any time, at any record number, Button 3 can be pressed to scroll through the fields of a specific

record. For more information, refer to Figure 26 which shows the structure of the display interface

for Calisto/Calisto 2. For a Calisto model C76-00000, the same structure applies, except that CO

will be shown as <CO=N/A>. The unit will return to the default section <REALTIME> after 10

seconds of inactivity.

Trends cannot be seen via the display.

At any time, the user may get back to the current readings by pressing buttons 1 and 2

simultaneously until <REALTIME> is displayed. <H2=000> will be displayed after a few seconds.

41

Page 48

Figure 26: Calisto/Calisto 2 Display Interface Structure

42

Page 49

Page 50

WARNING

Electrical shock hazard. Only persons with electrical safety training and certification

should install the equipment or open the enclosure once the equipment has been

installed.

Calisto/Calisto 2 can be set up for local, remote (hard wired) or wireless communication (not part of

this manual).

Calisto/Calisto 2 is supplied with a 1.8 m (6 ft) A/B type USB cable (Refer to Figure 27). The USB

port is dedicated to the monitor configuration, setup and maintenance.

Before connecting the USB cable to the monitor, open the door and access the monitor interface

board. Connect the USB cable to the interface board port (type B) and to your portable computer

port (type A).

Figure 27: 6-Feet Long A/B Type USB Cable

43

Page 51

6

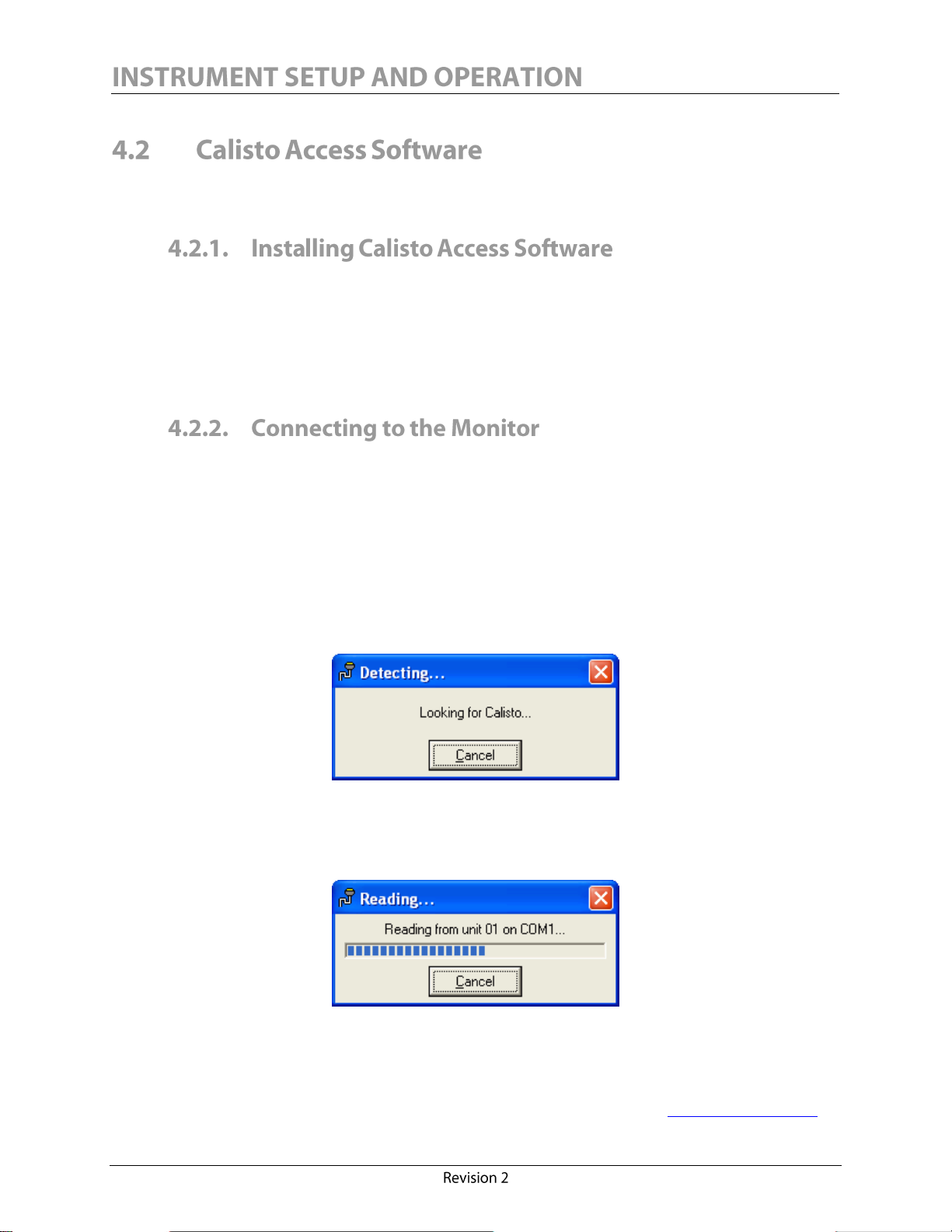

This section describes the use of the Calisto Access software to quickly configure and commission a

Calisto/Calisto 2.

To install Calisto Access, insert the Calisto/Calisto 2 CD-ROM and wait for the Setup window to

appear. Follow the on-screen instructions. At the Choosing Components step of the Calisto

Access installation, make sure to check the USB Drivers box. A notification window may appear;

choose the Continue Anyway option. At the end, Calisto Access setup will give the choice to

immediately launch Calisto Access, or not. Refer to the next section before performing the first

startup.

Prior to starting Calisto Access, your computer should be properly connected to the monitor using

the supplied USB cable and proper drivers should be installed when asked by the operating system6.

Press the Start button, select Programs, choose the Morgan Schaffer group and press on the

Calisto Access icon. The software will automatically try to locate the proper communication port

that is linked to the monitor.

The screen shown below will appear if no problems are encountered during the communication

initialization sequence.

Once a Calisto/Calisto 2 unit has been detected, the following screen will indicate the progression of

the initial information readings from the unit. These readings are necessary to retrieve the basic

settings of the monitor.

After a one minute timeout, the following message will appear if Calisto Access cannot find the port

currently used for communication with the IED.

If you have issues with the USB connection or material, refer to the help document on the Morgan Schaffer website.

44

Page 52

Click OK, check the cable connections at both computer and IED ends and try to initiate

communication manually. To do so, in the Communication/Configuration menu, click Modify.

Be sure that in the Communication Link window the configuration is as follows:

RS232 None None RS232.

Click

Use this configuration.

Select the serial COM port value from the Computer Port combo-

box. It must be the same COM port as the one you selected to communicate with.

To confirm which port is used, see My Computer / Properties / Hardware / Device Manager /

Ports (COM & LPT). The path for accessing Device Manager may differ, depending on your

system. The line representing the Calisto/Calisto 2 is: IAR Virtual COM port, IAR STR912-SK

board.

45

Page 53

COM4 in this example

Different connection steps may appear depending on your selected communication link. In the

event that the error message reappears, close and re-start the application. If the issue is still not

resolved, please contact Morgan Schaffer for assistance, either by e-mail at

support@morganschaffer.com or by phone at 001.514.739.1967.

The Calisto Access Status tab displays information about the currently connected unit. This screen

appears once communication is established with that specific unit. In the first subdivision of the

Status tab, the Unit Description information is found: the Calisto Model, Serial Number and Firmware

Version.

46

Page 54

Figure 28: Calisto Access Status Tab with an Error Code

The Current Readings subdivision contains various measurements and trend values. The Validated H2

(ppm) field displays the last saved hydrogen value while the Continuous H2 (ppm) field shows the actual

continuous hydrogen concentration. Also, for Calisto 2 only, the Validated CO (ppm) field displays

the last saved carbon monoxide concentration. The H2O (ppm) field displays the actual ppm

concentration or the calculated moisture relative saturation, according to the current water

measurement mode set in the Measurements tab under H2O Measurements Mode section.

In case of malfunction, an error message will appear in the Status tab, see Figure 28. An error code

will be displayed along with the instrument components involved.

The Error Code Interpretation Chart, found in Figure 29, explains the hexadecimal-based error

code. This chart lists all possible error bits, their position and description. For example, the 8002

error code shown in Figure 29 is only an illustration of an error combination that could occur. This

error code will also appear on the monitor’s external LCD display. Refer to Table 1 for a description

of individual error codes.

47

Page 55

Figure 29: Error Code Interpretation Chart

48

Page 56

ERROR CODE

(HEXADECIMAL)

ERROR

NAME

DESCRIPTION

1

Outside

Fan

This error only occurs when heat sink temperature (ST

on display or OUTT in Calisto Real Time) is higher than

27°C (81°F) and the external fan is not running. In that

case, the fan is disconnected or has failed. Please contact

Morgan Schaffer for assistance, either by phone at

001.514.739.1967 or by e-mail at

support@morganschaffer.com.

2

Inside Fan

This error occurs when the internal fan is no longer

running. Open the door and manually check the air

flow. If no air circulation is found, the fan must be

replaced. Please contact Morgan Schaffer for assistance.

4, 8, 400, 4000

Detection

Cell

Please contact Morgan Schaffer for assistance.

10, 20, 40, 80, 100, 200

Thermal

Regulation

Please contact Morgan Schaffer for assistance.

1000

Moisture

Sensor

Please contact Morgan Schaffer for assistance.

2000

External

Input

This error occurs when analog input is not properly

connected or missing.

- Verify the current in the 4-20mA circuit with a

multimeter.

- Verify connections for 4-20mA input pinout; refer

to Figure 9.

- Validate the 4-20mA generator functionality.

If all the above are correct, please contact Morgan

Schaffer for assistance.

8000

Oil Flow

This error occurs when the oil flow is below the pre-set

threshold.

- Verify that all valves are open (transformer and

Calisto/Calisto 2).

- Take an oil sample using the Quick Connect Oil

Sampling Tube as described in Section 5.0, and

validate oil viscosity value.

If all the above are correct, please contact Morgan

Schaffer for assistance.

Table 1: Individual Error Code

49

Page 57

The Current Alarm States subdivision contains the H2, H2O and Trend alarm states. Calisto 2 also

NOTICE

Fields can be accessed using the mouse pointer or using the TAB key. New data will

only be sent to the IED if the ENTER key is pressed. Moving to the next field

without pressing the ENTER key will cancel changes made to the previous field.

features alarm states for CO. An alarm state is <ON> when the current reading exceeds the

corresponding alarm level. Alarm levels are configured in the Outputs tab, as discussed in Section

4.2.6.

The Current Relay States subdivision shows the actual state of the five output relays. A red LED

icon turns on when a relay is ENERGIZED. Hardware LEDs with the same functions can be seen

on the entry panel. The relationship between alarm and relay states is configured in the Outputs tab,

as discussed in Section 4.2.7.

New Calisto/Calisto 2 units are shipped with numerous operating parameters configured to Morgan

Schaffer factory defaults. Most of these parameters do not require client modification. However, to

take full advantage of the Calisto/Calisto 2 communications, alarms and analog I/Os, it is necessary

to adjust some settings to suit the specific transformer and installation.

To modify the unit information parameters, establish communication using Calisto Access (refer to

Section 4.2.2 Connecting to the Monitor) and edit the information in the Owner, Location,

Transformer ID, Date and Time fields.

50

Page 58

Figure 30: Calisto Access Settings Tab

The preferred method of adjusting the communication settings is through a local connection

between a laptop PC and the Calisto/Calisto 2 USB port. A few simple steps are required to

configure the communication settings, as discussed below.

Calisto/Calisto 2 units have three available ports that can be accessed and set to different baud rates

simultaneously and independently of each other. If a unit reboots, all ports will keep their baud rate

setting if it has been changed.

51

Page 59

RS-485 Communication

CAUTION

To ensure reliable operation in the face of possible security threats, the Calisto/Calisto

2 should not be connected to the Internet without encryption or password protection.

If there is a concern about the security of the LAN, a VPN router may be used to

connect the Calisto/Calisto 2 to the LAN with encryption security.

To communicate with other devices on an RS-485 network, each monitor must be assigned an RS485 ID (range 01 to 99) which is specific to that network. In a RS-485 network consisting of

multiple Calisto/Calisto 2 units, every unit is then available for connection. The RS-485 ID is used

as the monitor ID for all protocols: DNP3/RS485, DNP3/TCP, Modbus, MSSP (Morgan Schaffer

Systems Protocol).

Ethernet Communication

Each Calisto/Calisto 2 unit has an Ethernet interface, which requires a specific IP address, subnet

mask and gateway. Note that the IP address is normally specific, and that the subnet mask is

normally common to a group of Calisto/Calisto 2 units. The subnet mask defines your local

network boundaries. To obtain an appropriate IP Address and Subnet Mask for your monitor, contact

your network administrator.

DNP3 Protocol

If you are using RS-485 communication, select the DNP3 protocol in the RS-485 protocol field and

press the Configure button which appears. If you are using Ethernet communication, press the

Configure DNP3/TCP button. In both cases, a DNP3 Configuration window will appear; refer to

Figure 31 for RS-485 and to Figure 32 for Ethernet.

The Requires Data Link Confirmation parameter can be set to <ALWAYS> or <NEVER>. In the first

case, Request Link Reset is enabled, while in the second case it is disabled. Also, set the Maximum

Application Layer Retries parameter to the desired value [0 to 6]. Set the DNP3 Master Address