ISSUE 8

JULY

2009

DOCUMENT CREASING & AUTOMATIC

BOOKLET MAKING MACHINE

(Creasing Unit)

OPERATORS MANUAL (Part 1)

FROM SERIAL No. 780156 ONWARDS.

Documaster MK3

Website: www.morgana.co.uk

70-111

Morgana Systems Limited United Kingdom

Telephone: ( 01908 ) 608888 Facsimile: ( 01908 ) 692399

Page 2

INDEX

CREASING / BOOKLET MAKING

SAFETY Do’s & Don’ts 6

THE CREASING UNIT

9

THE CONTROL PANEL

10

11

SETTING THE MACHINE UP AS A CREASER

12

12

13

13

13

13

13

13

15

17

17

18

18

19

20

20

20

20

SETTING THE MACHINE UP AS A BOOKLET MAKER

22

22

23

24

24

25

25

25

26

26

28

28

29

30

31

Labelled Photograph

Detailed diagram and description

Features on the control panel

Adjusting the Paper Gate

Setting the Suction Slot

Setting the Vacuum Bleed

Setting the Adjustable Side Lay

Setting the Back Stop

Setting the Air Seperation Pressure

Setting the Roller Tilt Mechanism

Setting the position of the Drive Wheels and Hubs

Setting the Stacker Assembly

Programming the machine for Creaser Operation

Setting the Feed

Setting the Batch Quantity

Setting the Crease Positions

Storing the Crease Positions

Running the machine

Reading Stored Programs

Paper Jamming

Setting the Machine to Run in Manual Mode

Adjusting the Paper Guides

Adjusting the Sliding Back Stop

Programming the machine for Booklet Maker Operation

Setting the Feed

Setting the Page Length

Setting the Book Centre

Setting the Sheet Width

Setting the number of Sheets in the Book

Setting the Crease Style

Setting the Cover Crease

Setting the Stitch Position

Setting the Machine to Edge Stitch

Setting the Set Knock

Setting the Trimmer

Setting the Batch Quantity

Setting the Air Distribution 13

INTRODUCTION

PAGE 4The Morgana Documaster Mk3

Page 3

SYSTEM

INDEX

31

31

32

32

33

34

37

PERFORATING

39

40

THE BLADE ASSEMBLY

42

43

REPLACING CREASING BLADE SETS

44

45

TROUBLE SHOOTING 46

ERROR MESSAGES 49

DISPATCH KIT 50

ACCESSORIES AND OPTIONS 51

RECOMMENDED SPARES 52

MACHINE CALIBRATION HISTORY 54

PRODUCT RECYCLING & DISPOSAL 55

Storing the Program

Running the Machine

Reading Stored Programs

Clearing Booklet Sheets from the Booklet Maker Infeed Tray

Using the Booklet Maker in Manual Mode (Hand Feed)

Using the Optional Camera Recognition System (Fixed Data)

Using the Optional Camera Recognition System (Variable Data)

Equipment, spares

Setting the machine

Setting the blade pressure

Setting the blade alignment

Installing new blade sets

Spares

DocuMaster MK3

Page 4

CREASING / BOOKLET MAKING

INTRODUCTION

The crease is programmed from the leading edge of the sheet using the

controls on the front panel.

The blade and anvil are mechanically controlled over their entire length

and can be adjusted to accommodate various weights of media

.

Maximum sheet size:- 630mm x 330mm (24.8” x 13”)

Minimum sheet size:- 210mm x 140mm (8.27” x 5.5”)

Maximum sheet weight:- 400 gsm

Minimum sheet weight:- 80 gsm (160 gsm when creasing and folding).

Maximum number of creases:- Nine

Minimum distance between creases:- 4.0mm

Minimum incremental adjustment:- 0.1mm

Minimum crease distance from leading edge:- 30.0mm (1.2”)

Minimum crease distance from trailing edge:- 30.0mm (1.2”)

Production up to 5000 sheets / hour, (one crease on A4 sheet).

CREASER UNIT SPECIFICATION

The Morgana DocuMaster MK3 is a fully automatic, suction feeding, creasing

/ booklet making system; designed for use with both conventional litho and

digital printers.

the operating environment should be controlled to a temperature

between 10

The system comprises a creasing unit linked to a fully automatic booklet

making machine, the creasing unit and booklet maker can be used

separately to give optimum flexibility.

The feed system incorporates an ultrasonic detector system to ensure

complete booklet integrity.

The feed on the Documaster MK3 can also be manually operated for use with

heavy stock, very small or very large sheets, embossed or even irregular

sheets.

IMPORTANT

°°C and 30 C and at 35 - 85% relative humidity.

DocuMaster MK3

Page 5

SYSTEM

BOOKLET MAKER UNIT SPECIFICATION

Maximum sheet size:- 460mm x 320mm (18.1” x 12.6”)

Minimum sheet size:- 210mm x 140mm (8.27” x 5.5”)

Maximum staple pitch:- 138mm (5.4”)

Minimum staple pitch:- 115mm (4.5”)

Maximum number of sheets in book:- 20 sheets (80 gsm)

Maximum cover weight :- up to 350 gsm

Minimum inside sheet weight:- 80 gsm

Maximum trim:- 25mm (1”)

For optimum performance the difference between the cover and the

inside sheet should be no more than 110 gsm.

Production up to 1560 books / hour, (dependant on number of sheets in book).

DocuMaster MK3

Page 6

CREASING / BOOKLET MAKING

Safety Do’s & Don’ts

Safety Do’s & Don’ts

Do - read this operator manual fully before operating the machine.

Do - operate with the designated AC current only. Use an exclusive outlet, as

overloading may cause fire or an electric shock.

Do - install the power cord out of the way to avoid a tripping hazard.

Do - make sure that the mains inlet connector is always easily accessible.

Do not - install the machine in an unstable place such that it tilts or shakes.

Do not - unplug the plug or unplug the power cord from the outlet with a wet hand,

this can cause an electric shock.

Do not - unscrew and remove any covers from the machine, as it can cause an

electric shock or injury.

Do not - place receptacles containing liquids on any surface.

Do not - adjust any part of the machine whilst rollers are running

Do not - operate the machine with loose or trailing clothing or loose hair.

Do not - under any circumstances adjust the paper gate when the machine is

switched on.

REGLES DE SECURITE : « A FAIRE » ET « A NE PAS FAIRE »

Lire ce mode d'emploi avant d'utiliser la machine.

Respecter l'alimentation électrique indiquée. Brancher sur une prise séparée

car une surcharge peut entraîner un incendie ou un choc électrique.

Installer le cordon d'alimentation de manière à ne pas pouvoir

trébucher par dessus.

Ménager un accès libre à la prise de courant.

Ne pas installer la machine sur une surface non plane, afin d'éviter

qu'elle ne penche ou ne vibre.

Ne pas installer la machine sur une surface non plane, afin d'éviter

qu'elle ne penche ou ne vibre.

Ne démonter et enlever aucun carter de la machine, par crainte de décharge

électrique ou de blessure.

Ne pas placer de récipient contenant un liquide sur la machine.

N'effectuer aucun réglage pendant que les rouleaux fonctionnent.

Ne pas porter de vêtements flottants et rassembler les cheveux longs

lors de l'utilisation de la machine.

En aucune circonstance, régler le séparateur de papier lorsque la

machine est branchée.

Safety Do’s & Don’ts

Page 7

SYSTEM

Warning Labels

Do - be aware of any finger traps and rotating parts when operating

the machine.

Do - read this operator manual fully before operating the machine.

Do not - operate the machine with loose or trailing clothing.

Do not - operate the machine with loose hair.

Do - be aware of any finger traps and rotating parts when operating

the machine.

Do - be aware of sharp points and blades.

Do - be aware of rotating rollers.

Do - be aware of low current anti-static shock.

Attention au risque de se coincer les doigts, et aux pièces en

mouvement lors du fonctionnement de la machine.

Ne pas porter de vêtements flottants lors de l'utilisation de la machine

Rassembler les cheveux longs lors de l'utilisation de la machine.

Attention au risque de se coincer les doigts, et aux pièces en

mouvement lors du fonctionnement de la machine.

Attention aux éléments tranchants et aux couteaux.

Attention aux rouleaux en fonctionnement

Attention aux faibles chocs d'électricité statique

Lire ce mode d’emploi avant d’utiliser la machine.

DocuMaster MK3

Page 8

CREASING / BOOKLET MAKING

BLANK

PAGE

Page 9

SYSTEM

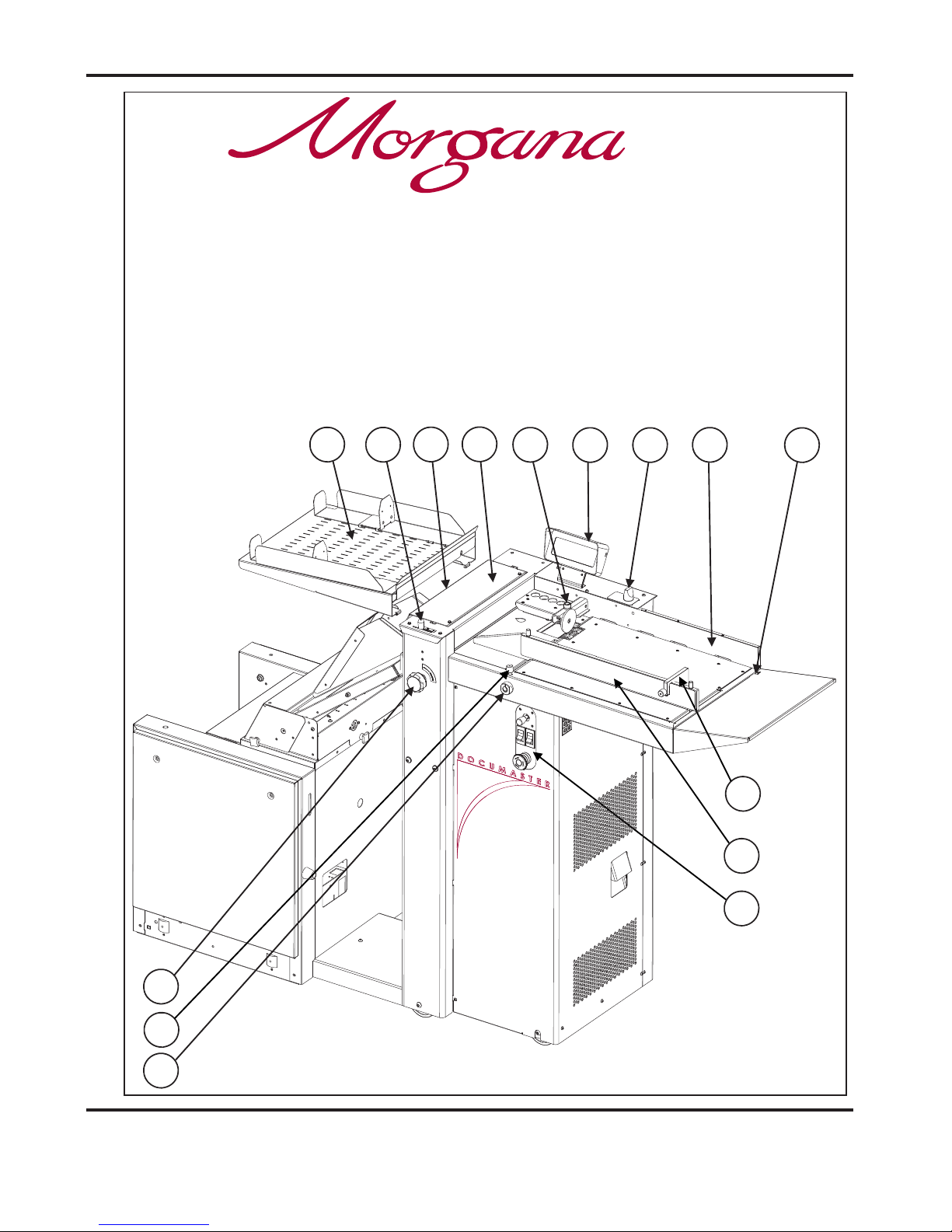

THE CREASING UNIT

5

2

1

15

12

11

6

9

14

8

7

4

3

10

13

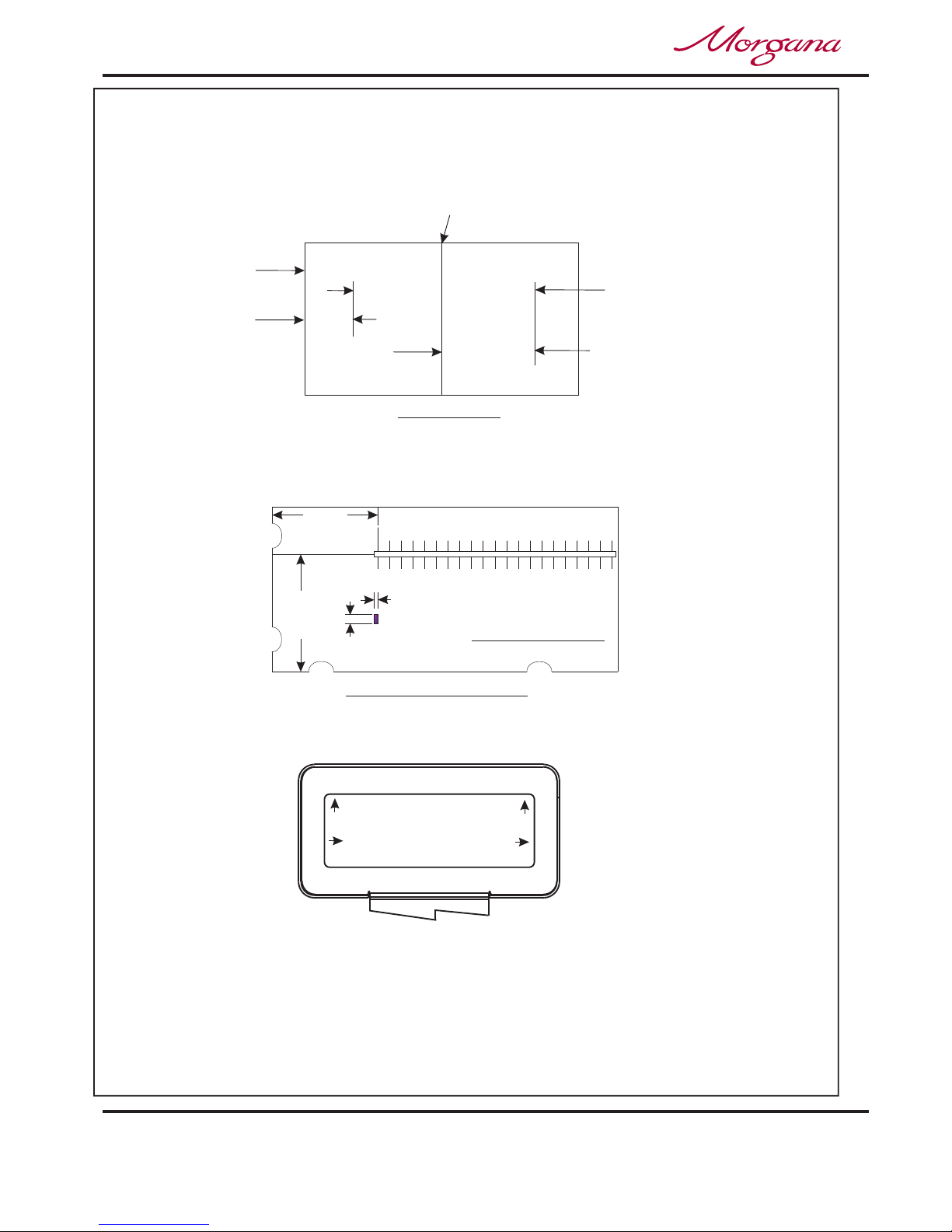

Key to photograph below

1 Roller tilt handle 6 Air separation knob 11 Paper Gate

2 Stacker assembly 7 Adjustable side lay 12 Exit Guard

3 Suction slot knob 8 Back stop 13 Vacuum Bleed Knob

4 The control panel 9 Fixed side lay 14 Display

5 Air distribution knob 10 Roller tilt knob 15 Anti-Static Unit

DocuMaster MK3

DocuMaster MK3

Page10

CREASING/BOOKLETMAKING

THECONTROLPANEL

SystemSwitch

CompressorSwitch

EmergencyStopSwitch

SelectionSwitch

THECONTROLS

TheDisplayUnitandtheSwitchesontheControlPanelallowthe

operatortoread,edit,createandinitiatenumerouscreasingprogramswithin

thememory.

TheControlPanelhousestheSelectionSwitch,Compressorswitch,

Systemswitch,andanindustrystandardEmergencyStopswitchwhich

willstopallpowergoingtothemachinewhenactivated.

Page 11

THE CONTROLS

SYSTEM

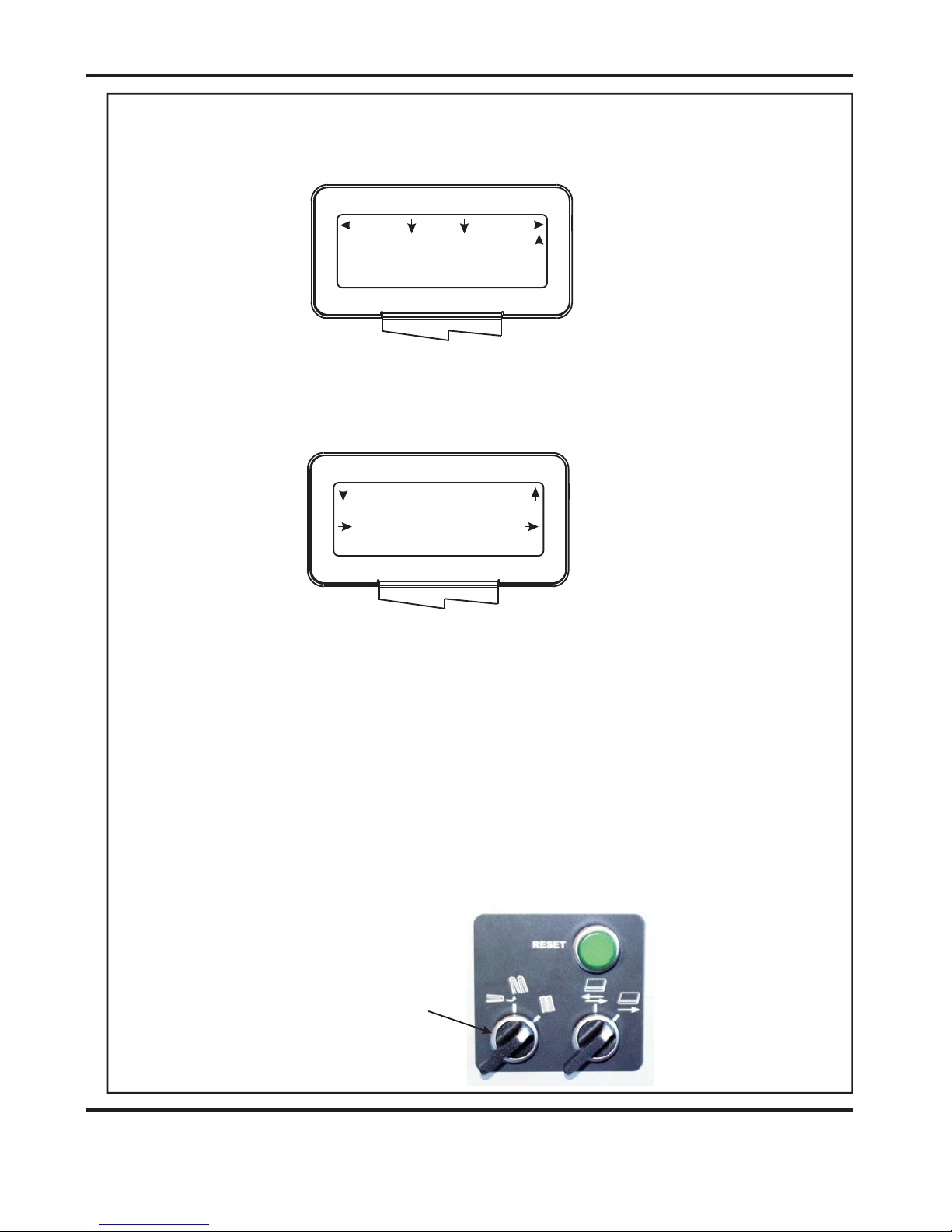

Features on the Control Panel

Selection Switch

System switch

Compressor switch

Allows the operator to scroll through stored addresses and programs, increase or

decrease the batch quantity and set a crease position.

When activated the system switch will operate the motors in order to begin the

creasing sequence.

Allows the operator to switch off the compressor unit in order to utilise the machine

to manually feed sheets.

DocuMaster MK3

Page 12

Adjustable

Side Lay

J

K

6.5mm (1/4")

TWO THICKNESSES

OF PAPER

Suction

Slot Knob

IMPORTANT:-

To avoid possible damage to the suction drum,

when adjusting the paper gate height, ensure that

drum and not over a slot in the drum.

the disc is located over a solid section of the suction

Do not adjust the paper gate while the machine is

running.

CREASING / BOOKLET MAKING

Vacuum

Bleed Knob

Setting the Machine up as a Creaser

Adjusting the Paper Gate

The standard setting for horizontal adjustment of the paper gate is 6.5mm (1/4") away

from the mounting block. Turn disc J to make this adjustment. This setting is only intended

as a guide, for instance, sheets with an upward curl will require this setting to be increased. Set the height of the Paper Gate to approximately two thicknesses of paper, by

turning knob K. An excessive gap is a most likely cause of double sheet feeding.

Setting the Suction Slot

The suction slot is located inside the vacuum roller and can be adjusted by releasing and

moving the suction knob horizontally in either direction to the required position.

For light stocks set the knob to the left and for heavier stocks set the knob to the right.

FIG 8.1

Page 13

SYSTEM

Setting the Machine up as a Creaser

Setting the Vacuum Bleed

Setting the Adjustable Side Lay

Setting the Back Stop

Setting the Air Distribution

Setting the Air Separation Pressure

Place the paper stack on to the loading table and slide up to the fixed side lay and paper

Gate. Release the clamps located at each end of the side lay and slide up towards the

paper stack as demonstrated in FIG 8.1. Allow a gap of approximately 0.5mm (1/64 inch)

between the paper and the side lay.

When using heavy stocks or large paper stacks, the feeding of the sheets may be improved

by fitting the Clamp Plates to the Adjustable Side Lay, as shown in FIG 8.2 below; but

please be aware that they may cause double feeding when using light stocks.

Position the backstop and slide up towards the paper stack allowing a gap (as specified

in the above step).

Depending on the length of the sheet to be creased, the air distribution knob can be

rotated to various positions in order to supply air to different ports. Position 1 is

recommended for most sheet sizes. However, a better result may be obtained by using

the settings below or by experimentation.

For A5 sheets or 8 inches long, front port and port 1 open.

For A4 sheets or 11 inches long, front port and port 2 open.

For A3 sheets or 17 inches long, front port and port 3 open.

For longer sheets in order to supply air to the centre of the stack, port

1 and port 2 open.

To control the amount of air supplied to the ports, the air separation knob can be adjusted

by first rotating the knob to unlock its position, then push the knob down to the required

position and rotate the knob to re-lock its position.

NOTE.

Position 1 -

230-

Situated on the front of the feed table, the Vacuum Bleed Knob is used to allow more

control of the suction on the vacuum drum.

When light weight paper of 90gsm and lower is being fed through the machine turn the knob

clockwise to reduce the possibility of marking, or damage to the leading edge of the paper.

FIG 8.2

Clamp Plates

DocuMaster MK3

Page 14

FIG 10.1

CREASING / BOOKLET MAKING

Setting the Machine up as a Creaser

Setting the Roller Tilt Mechanism

Setting the positions of drive wheels and hubs

The roller tilt mechanism has been designed to compensate for when the creasing

position on the sheet is not square. This could be due to an inaccuracy in the media or if

the roller tilt mechanism has been incorrectly set. The mechanism will be set to zero

(square) when the machine is supplied.

To set the mechanism, unlock the roller tilt knob located below the roller tilting handle by

turning anti- clockwise. Move the roller tilt handle left or right in order to compensate for

any inaccuracy. When the position is set, ensure to lock the roller tilt knob before

operating the machine. Repeat the above procedure until the creasing position is square.

It is important that the drive wheels and drive hubs on the roller shafts are arranged evenly

across the width of the media being creased. This is done to ensure that the media is

accurately driven and supported through the rollers.

The drive wheels and hubs are fixed to the rollers by means of a grub screw. To locate

this grub screw the rollers can be rotated by operating the motor manually.

To operate the motors manually, switch the machine ‘on’ at the Emergency Stop switch.

Following the arrows on the display unit, move the selection switch to the left to select

, the display will now show the Tools sub-menu. Press the system switch down and

then move the selection switch to the left or to the right, to rotate the rollers in short pulses.

Lift the exit guard to see if the grub screws in the drive wheels and hubs can be seen. If the

grub screws cannot be seen, lower the exit guard and rotate the rollers by moving the

selection switch to the left or to the right. Loosen the drive wheels and hubs with a 2mm

allen key. Arrange the drive wheels and hubs as shown in FIG 10.1. In order to avoid

marking on some types of media ensure a gap between the drive wheels and hubs.

This procedure should be repeated when installing perforating blades and anvils onto the

drive wheels and hubs.

DO NOT ROTATE THE DRIVE ROLLERS BY HAND

.

Tools

Page 15

SYSTEM

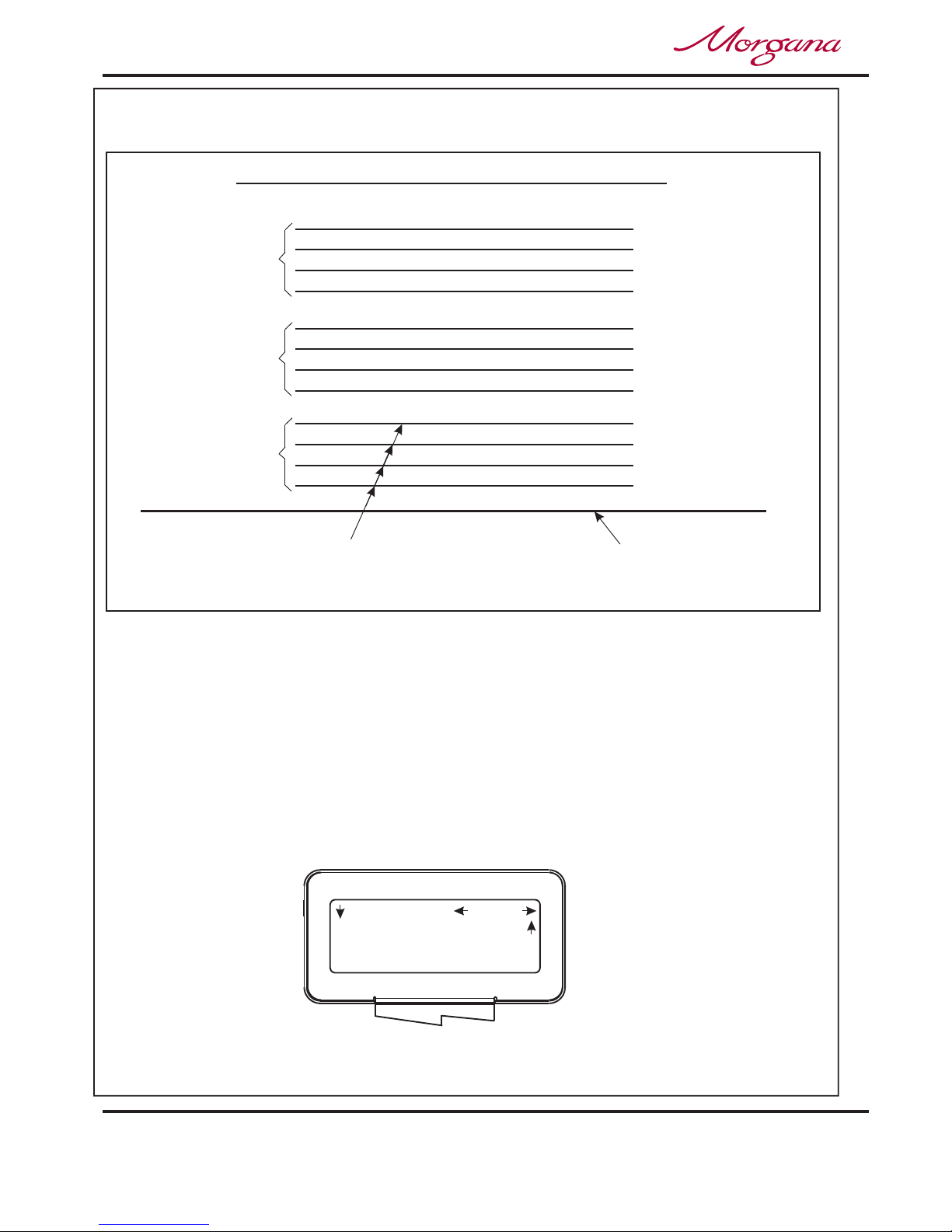

Setting the Machine up as a Creaser

LEFT HAND

SIDE GUIDE

FIG 13.1

RIGHT HAND

SIDE GUIDE

LEFT HAND

BACK STOP

RIGHT HAND

BACK STOP

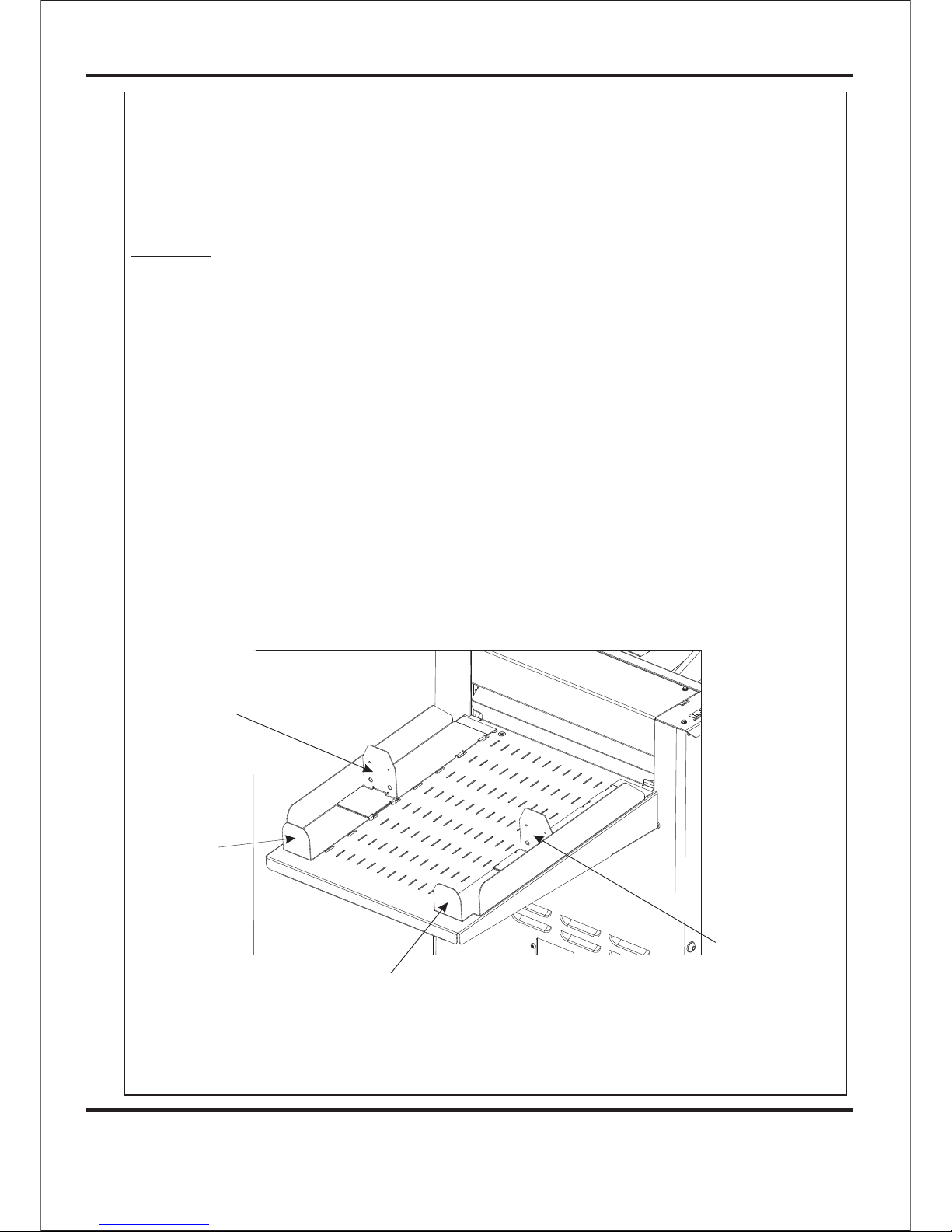

Setting the Stacker assembly

The stacker unit on the machine is used to catch the sheets once they have been

creased or perforated.

NOTE:- This stacker unit is not fitted when the machine is being used as a Booklet maker.

1. Assemble the stacker unit to the machine as shown in fig 13.1 below.

There are two side guides on the stacker unit; a left handed guide and a right handed

guide. The guides will control the way in which the paper is collated by setting their

positions on the stacker bed.

2. Place a single sheet (from the stack to be creased / perforated) on to the stacker bed

against the ‘left hand’ guide.

3. Position the ‘right hand’ side guide on to the stacker bed leaving a minimum

clearance of approximately 1mm each side of the sheet.

Important

Ensure that the stacker unit has been assembled to the machine properly. However,

if it has not, the connection on the magnetic switch will be broken and the machine

will not operate (see Trouble shooting pages for details).

DocuMaster MK3

Page 16

CREASING / BOOKLET MAKING

Setting the Machine up as a Creaser

4. Whilst the sheet is between the two guides on the stacker bed, set the distance .

between the top of the sheet and the backstop flanges to approximately 5mm.

5. For shorter sheets, the back stop can be used (as shown in FIG 13.1 to adjust the

position of the paper stack.

TIPS

! The magnetic back stop supplied with the machine

can also be used as a tool holder as demonstrated

In the photograph (left).

Page 17

SYSTEM

Setting the Machine up as a Creaser

1 Creases

Program 1

To ta l 2 0

Reset

Setup

Tools

Feed

Batch Off

Autocreaser

Operate This Machine

No

Yes

Are You Trained To

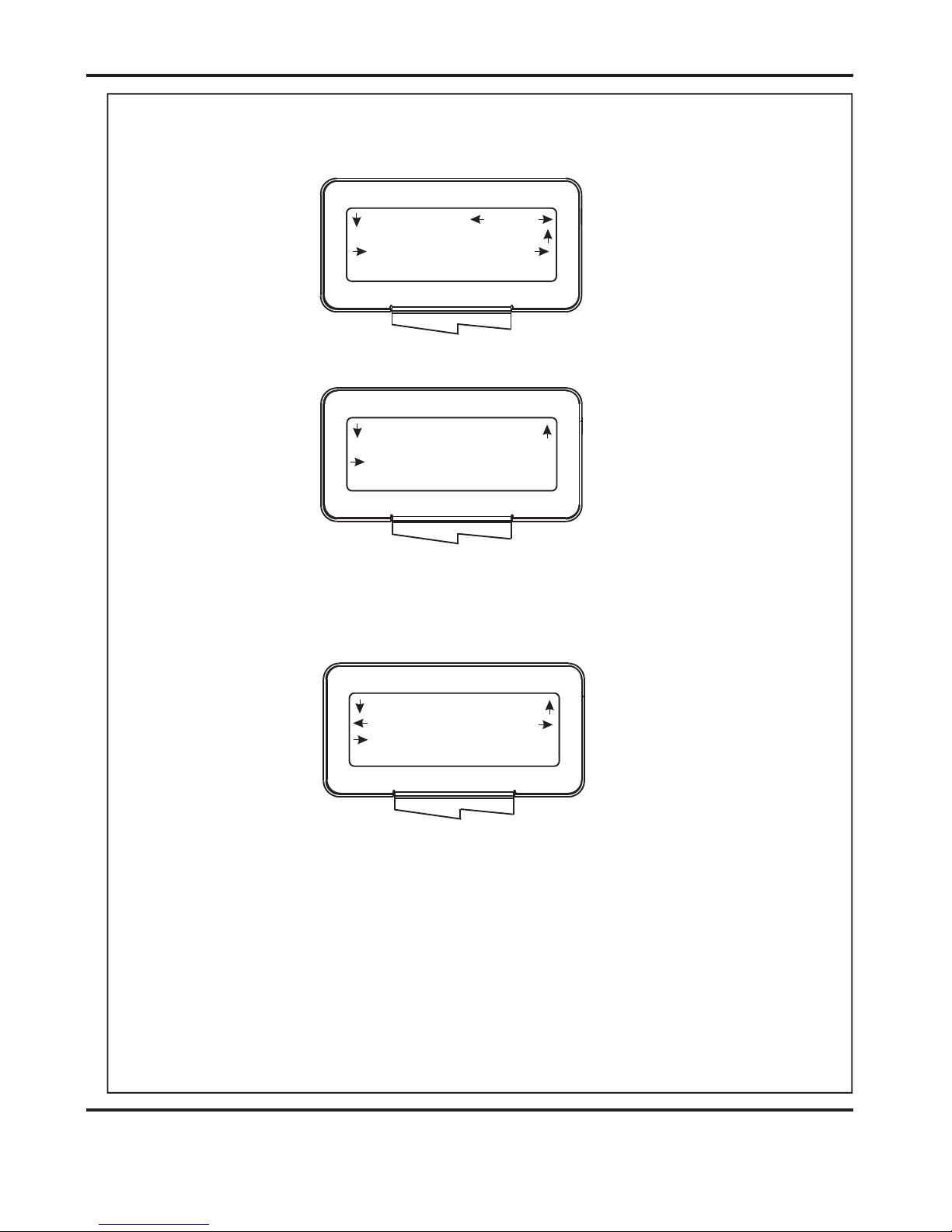

2. If the text on the display contains the word the machine is in the

Booklet Maker mode of operation.

To change to the Creaser mode of operation proceed as follows:-

(i) Move the selection switch up to select .

(ii) Move the selection switch down to .

(iii) Move the selection switch to the right to select .

3. The length of suction on the sheet of paper being fed can be adjusted by setting the

feed type as follows:-

(i) Move the selection switch to the right to select .

(ii) Move the selection switch down to select the required feed type ( ,

, , or )

(iii) Move the selection switch to the right to select .

‘Book’

Set Feed

Reset

Mode to Autocreaser

Mode to Autocreaser

Setup

Long Pulse

Medium Pulse Short Pulse Stream Feed

Select

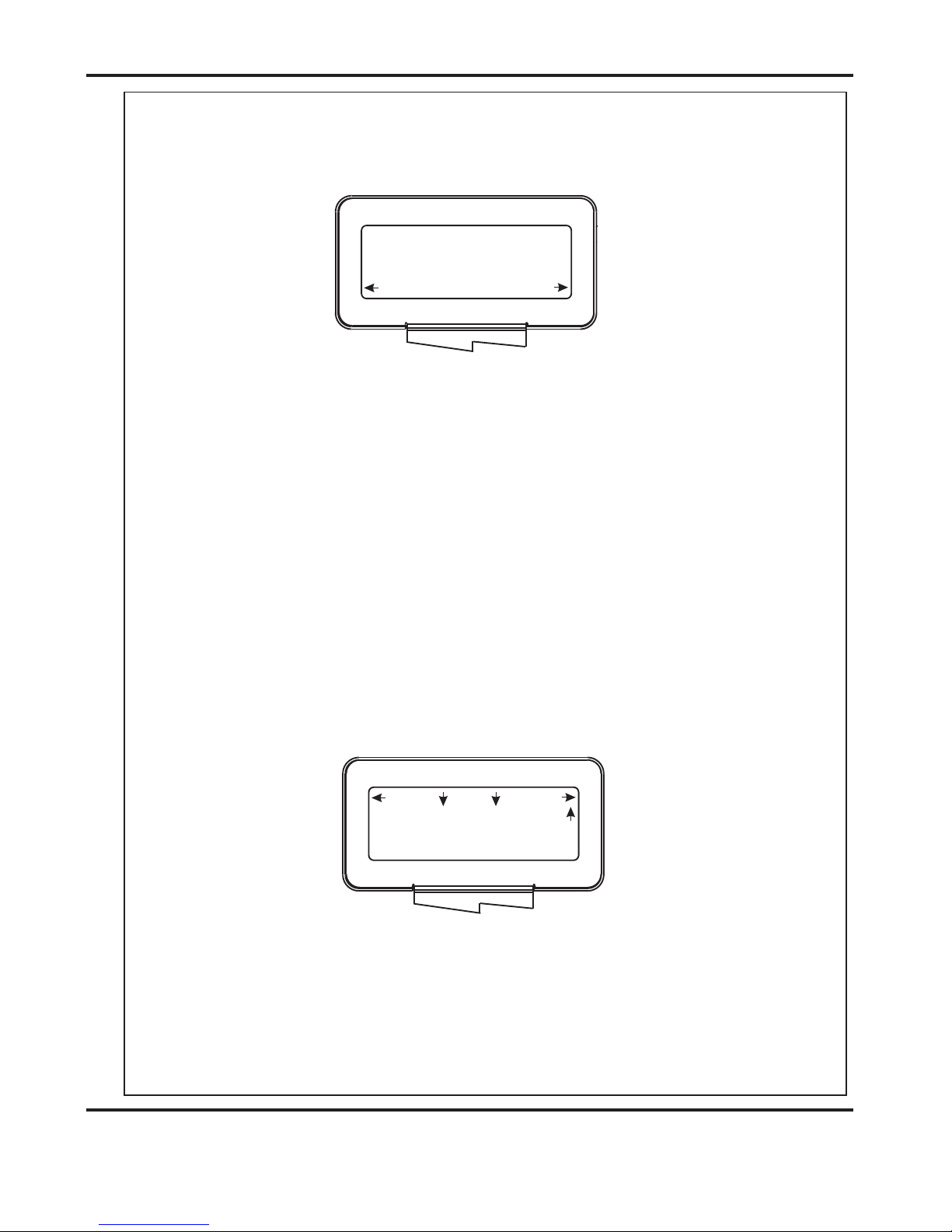

A typical Autocreaser display menu is shown below.

IMPORTANT.

Programming the machine for Creaser operation

1. Switch the power ‘on’ by turning the Emergency stop button clockwise to release the

safety latch. The display is now switched on and will be as shown below.

If you have not been trained to operate this machine, we strongly advise that you move the

selection switch to the right to select . We recommend that you either seek training or

ask a trained operator to run the machine for you.

Move the selection switch to the left to select only if you have been trained to operate

this machine. If you have not been trained to operate this machine and you select ,

Morgana Systems Ltd accept no responsibility for personal injury, damage to the

machine or damage to materials being processed by the machine.

No

Yes

Yes

MORGANA

DocuMaster MK3

Page 18

CREASING / BOOKLET MAKING

Setting the Machine up as a Creaser

0 Creases

Program 3

To ta l 2 0

Reset

Setup

Tools

Feed

Batch Off

Autocreaser

2nd Crease 0.0

1st Crease 297.0

Home

More

Set Creases

Use for all standard size sheets, general purpose.

Use for short non-standard sheets.

Use for very short sheets.

Use for high throughput, see note below.

Do not use stream feed for creases less than 32mm from the leading edge of the paper.

4. (ii) Move the selection switch to the right to select .

(iii) Move the selection switch down to select .

(iv) Rotate the selection switch clockwise or anti-clockwise to adjust the batch quantity

in increments of 5.

5. Move the selection switch up, one click at a time, until the start up menu is displayed,

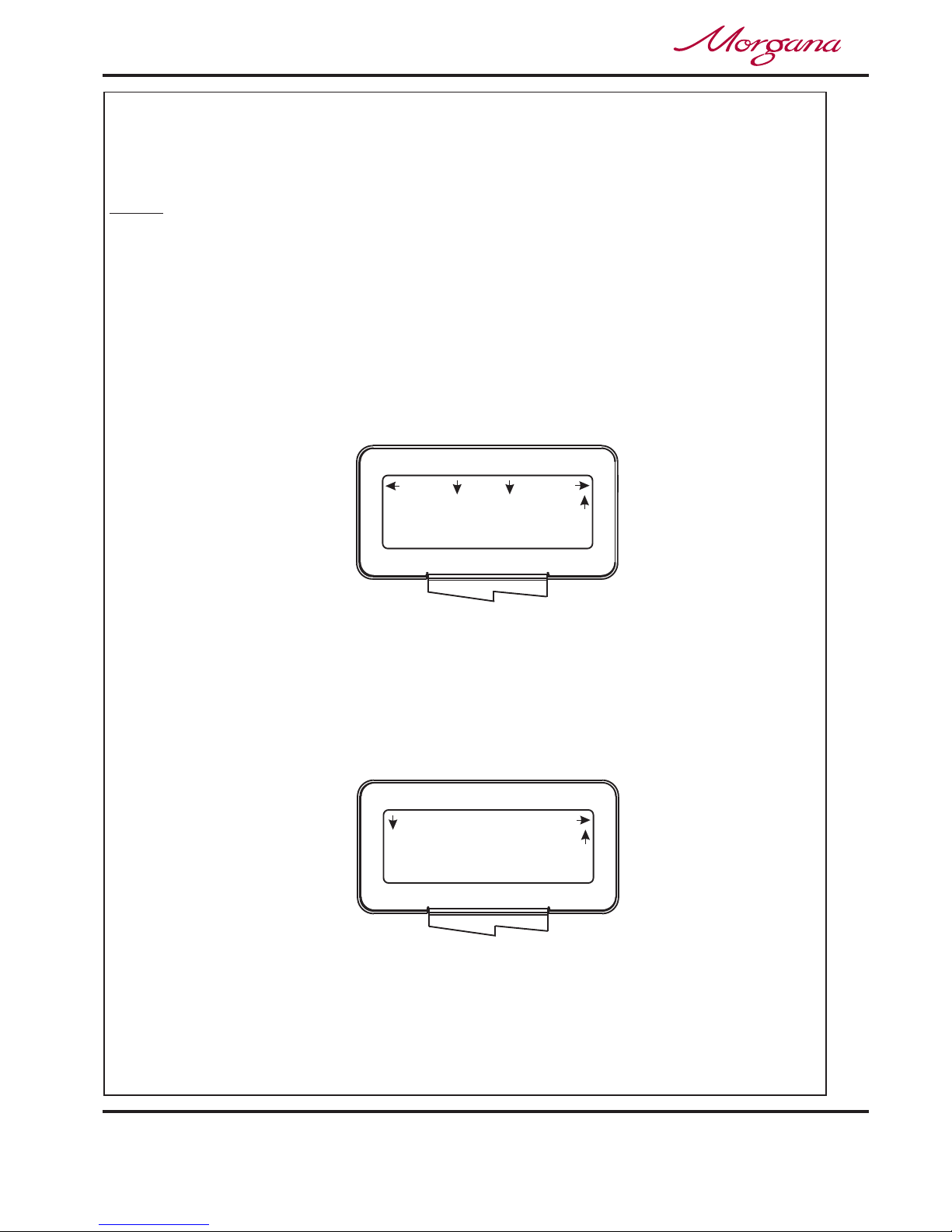

(A typical start up display menu is shown below).

(i) Move the selection switch to the right to select .

(ii) Move the selection switch to the right, one click at a time, selecting ;

until the display shows as shown below.

(iii) Following the arrows on the display unit; move the selection switch down to set the

creases. The 1st Crease is now selected.

Long Pulse

Medium Pulse

Short Pulse

Stream Feed

More

Batch Quantity

Setup

More

Set Creases

NOTE.

Setting the batch quantity

Setting the crease positions

NOTE:-

The arrows on the display denote the direction in which the selection

switch must be moved in order to access the various sub-menus.

Page 19

SYSTEM

Setting the Machine up as a Creaser

Back

Tens Decimals

2nd Crease 0.0

( 1st Crease 297.0 )

Set Creases

Back

Tens Decimals

3rd Crease 0.0

( 2nd Crease 0.0 )

Set Creases

Batch 20

To ta l 8 0

No Program

Reset

Setup

Tools

Feed

2 Creases

Autocreaser

(iv) Move the selection switch to the left to select Tens, or to the right to select Decimals.

(v) The Tens or Decimals (whichever has been selected) can then be adjusted by

rotating the Selection Switch, (clockwise to increase or anti-clockwise to decrease).

(vi) Adjust all other digits for the 1st Crease position as described in steps (iv) and (v),

(i.e. move the selection switch to the left to select the Tens or to the right to select

Decimals and then rotate the Selection Switch to adjust its value.

(vii) To set the 2nd Crease position move the selection switch down; the 2nd crease is

selected and can be set as described in steps (iv) to (vi) above.

Crease positions can be set in increments of 0.1mm. Further creases can be set in

this way, up to a maximum of nine creases.

(viii) When the required creases have been set, move the selection switch up, one click

at a time, until the display contains the word , see below.

6. Once the crease positions are correctly entered, they can be stored as follows.

(i) Move the selection switch to the right to select .

(ii) Move the selection switch to the right, one click at a time, (selecting ) until the

display contains the word .

(iii) Move the selection switch down to select

(iv) Rotate the Selection Switch to select the Program number (1 to 9).

(v) Move the selection switch to the right to select .

(vi) Move the selection switch to the left to select or to the right to select

Feed

Setup

More

Programs

Save Settings.

Select

Yes No.

Storing the crease positions

DocuMaster MK3

Page 20

CREASING / BOOKLET MAKING

Setting the Machine up as a Creaser

Running the machine

In order to manually feed sheets see instructions below.

Reading stored programs

Paper jamming

Setting the machine to operate in manual mode

7. To run the job with the selected settings.

(i) Press the Compressor Switch down.

(ii) Press the System Switch down.

(iii) Move the selection switch down to begin feeding the sheets.

To stop feeding the media at anytime during the program, flick the selection switch up.

The machine will complete its creasing operation if a sheet has already been fed

through the paper gate.

Any of the nine stored programs can be accessed and read as follows:-

(i) From the start up menu, move the selection switch to the right to select .

(ii) Move the selection switch to the right, one click at a time, until the display contains

the word .

(iii) Move the selection switch down to select, .

(iv) Move the selection switch to the right to select, .

(v) Rotate the selection switch clockwise or anti-clockwise to select, to

and view the program settings.

In the event of a paper jam occurring whilst the machine is operating the display will

read In order to remove the paper causing the jam, move the selection switch

to the left or to the right to drive the paper forwards or backwards in short pulses.

In order to feed heavy stock, very small or very large sheets, embossed or even

irregular shaped sheets, it may be required to operate the machine manually.

The machine can be programmed and set up in exactly the same way as explained

when operating the machine automatically. However, when setting up the machine the

paper gate must be raised to its highest position for the sheets to be fed freely.

Operating the machine manually will also require the suction length to be continuous in

order to accommodate various types of stock. Therefore, the feed should be set to

see page 17.

The machine can now be started by activating the System switch to ‘on’.

Move the selection switch down to select and

begin to slide the sheets individually through the paper gate until they are driven by the

drive belts. To stop feeding the sheets, move the selection switch up and then the System

Switch up.

Setup

Programs

Retrieve Program

Select

Program 1

Program 9

Paper Jam.

Long Pulse

Do not

activate the Compressor switch. Feed

Page 21

SYSTEM

BLANK

PAGE

DocuMaster MK3

Page 22

CREASING / BOOKLET MAKING

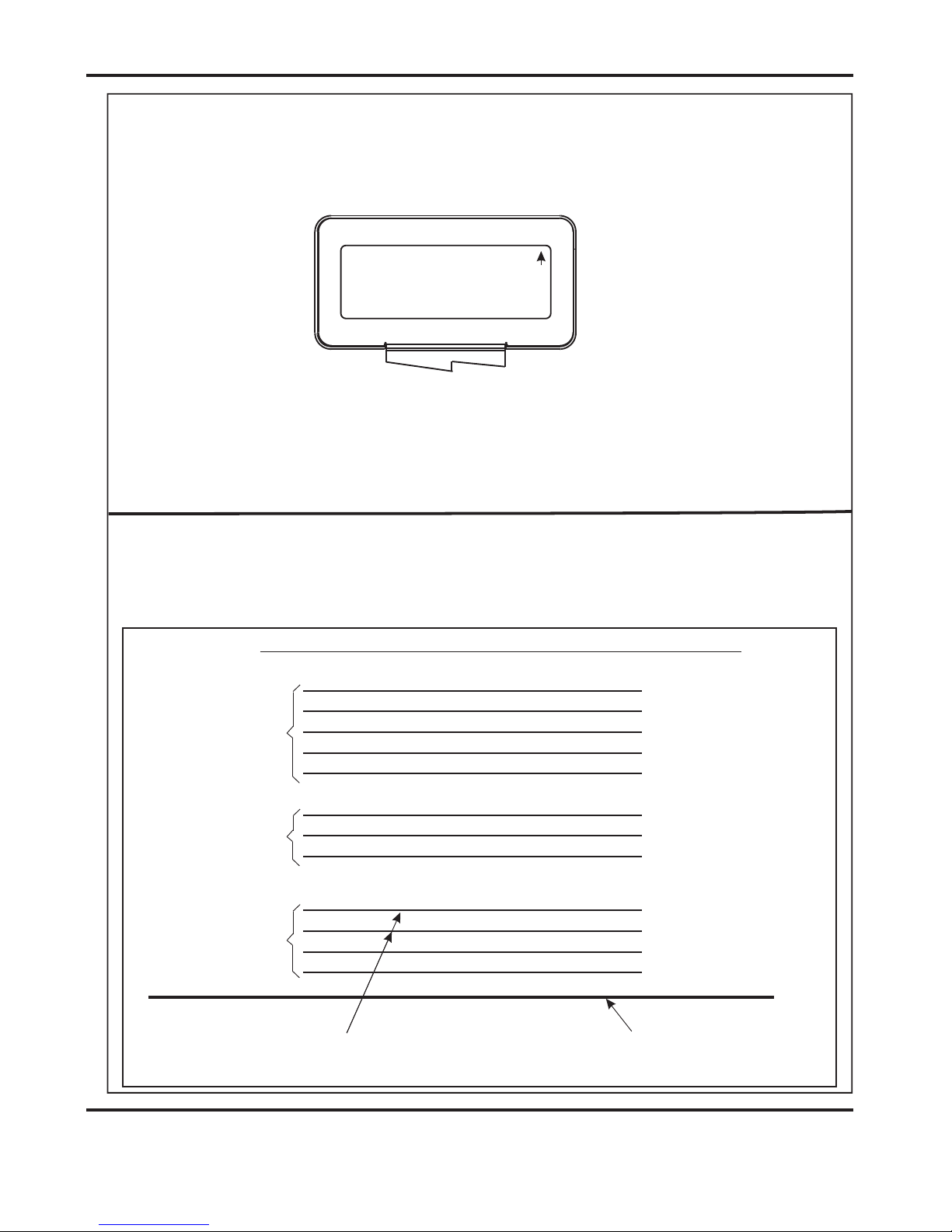

Rear Paper Guide

Sliding Back

Infeed Tray

Front Paper Guide

Setting the Machine up as a Booklet Maker

Paper Guide Adjustment Lever

Stop

(On Underside Of Infeed Tray)

Adjusting the Paper Guides

Adjusting the Sliding Back Stop

Inse he infeed tray of the Booklet Maker. Adjust the width

of the paper guides, by sliding the lever (on the underside of the infeed tray)

forwards or backwards until the sample sheet slides freely in the guides.

With the sample sheet in its downward resting position, adjust the sliding back

stop until it is approximately 5mm to 10mm clear of the back edge of the sample

sheet.

rt a sample sheet into t

Page 23

SYSTEM

Variable Data

Prog 3

Books 9

Reset

Setup

Tools

Feed

Image Rec on

Operate This Machine

No

Yes

Are You Trained To

Programming the machine for Booklet Maker operation

1. Switch the power ‘on’ by turning the Emergency stop button clockwise to release the

safety latch. Allow the booklet maker to run through its program, it will confirm a ready

signal with two blips and a constant flashing of its light. If the light does not constantly flash

and the optional Square Back System is fitted, make sure that the Square Back System

mains switch is switched on. The display is now switched on and will be as shown below.

IMPORTANT.

If you have not been trained to operate this machine, we strongly advise that you move the

selection switch to the right to select . We recommend that you either seek training or

ask a trained operator to run the machine for you.

Move the selection switch to the left to select only if you have been trained to operate

this machine. If you have not been trained to operate this machine and you select ,

Morgana Systems Ltd accept no responsibility for personal injury, damage to the

machine or damage to materials being processed by the machine.

2. If the text on the display contains the word the machine is in the

Creaser mode of operation.

To change the mode of operation to Booklet Maker mode proceed as follows:-

No

Yes

Yes

‘Autocreaser’

MORGANA

DocuMaster MK3

(i) Move the selection switch up to select .

(ii) Move the selection switch down to .

(iii) Move the selection switch to the right to select .

3. Adjust the Paper Gate, Adjustable Sidelay etc, as described on pages 12 to

14 (Setting the Machine up as a Creaser).

Reset

Mode to Documaster

Mode to Documaster

A typical Booklet Maker display menu is shown below.

Page 24

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

Back

Tens Decimals

Book Centre 130.5

Sheet Length 295.5

Set Booklet

Set Feed

Set Booklet (Standard Sheet Sizes).

Set Booklet (Custom Sheet Sizes).

4. The length of suction on the sheet of paper being fed can be adjusted by

setting the feed type as follows:-

(i) Move the selection switch to the right to select .

(ii) Move the selection switch down to select the required feed type ( ,

, , or )

(iii) Move the selection switch to the right to select .

Use for all standard size sheets, general purpose.

Use for short non-standard sheets.

Use for very short sheets.

Use for high throughput, see note below.

Do not use stream feed for creases less than 32mm from the leading edge of

the paper.

Once set, these sizes can be adjusted as required; by following steps 5B to 11.

Setup

Long Pulse

Medium Pulse Short Pulse Stream Feed

Select

Long Pulse

Medium Pulse

Short Pulse

Stream Feed

NOTE.

NOTE.

(ii) Move the Selection Switch down to select the required sheet size, and then

move the Selection Switch to the right to select.

(as described on pages 24 to 32)

5A. A quick setup for a standard size sheet can be set as follows:-

For example A4/A5 - settings will be sheet size 297 x 210, trim size is 145

and number of sheets in book will be 1.

(i) From the Booklet Maker start up menu, move the Selection Switch to the

left to select , the display will now read .

5B. Custom sheet sizes are setup as follows:-

(i) Move the selection switch to the right to select .

(ii) Move the selection switch down to select .

Tools Quick Sizes

More

Set Booklet

Page 25

SYSTEM

Back

Tens Decimals

Sheet Width 180.0

Length 50.0

Set Booklet

Back

Tens Decimals

Sheet Width 180.0

Book Centre 130.5

Set Booklet

(iii) The can now be set as follows:-

Move the Selection Switch to the left to select or to the right to

select . The or (whichever has been selected)

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

(v) The can now be set as follows:-

Move the Selection Switch to the left to select or to the right to

select . The or (whichever has been selected)

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

(vii) The can now be set as follows:-

Move the Selection Switch to the left to select or to the right to

select . The or (whichever has been selected)

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

Sheet Length

Tens

Decimals Tens Decimals

Book Centre

Tens

Decimals Tens Decimals

Sheet Width

Tens

Decimals Tens Decimals

NOTE.

(iv) Move the selection switch down.

(vi) Move the selection switch down.

It is important to set the correctly. This will ensure that the Creaser

and Booklet Maker units are aligned for Booklet Making operation. The Creasing

unit automatically aligns with the Booklet Maker when the sheets are fed.

(viii) Move the selection switch down.

Sheet Width

DocuMaster MK3

Page 26

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

3 Sheet Book

Prog 3

Books 9

Reset

Setup

Tools

Feed

Back

(Variable Data)

Set Booklet

Sheets in Book ?

(ix) The number of can now be set by

rotating the Selection Switch, (clockwise to increase or anti-clockwise to

decrease). Range:- 1 to 20 sheets (including cover).

Sheets in Book (Including Cover)

NOTE:If the selection switch is turned fully anti-clockwise the display will show

‘Sheets in Book ?’ ‘(Variable Data)’ as shown on next page. This setting is

used when the optional ‘Camera Recognition System’ is fitted and the

number of sheets in the Booklet are variable.

Setting the Crease Style.

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the words .

More

Crease Style

6. From the Booklet Maker start up menu, the can be set as

follows:-.

(i) Move the selection switch to the right to select .

Crease Style

Setup

Back

(Including Cover)

Set Booklet

Sheets in Book 3

Back

(Including Cover)

Set Booklet

Sheets in Book 3

Documaster

Page 27

SYSTEM

FIG. 1

Hinge Crease Hinge Crease

Centre Crease

Cover Crease (With Hinges).

Hinge Size: 6.0

Hinges are ON

Home

More

Cover Crease

4 to 10mm

(iii) Move the selection switch down to select the ( ,

,or).

(iv) Move the selection switch to the right to select

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the words .

(iv) Move the selection switch to the right, to toggle between

and .

(v) If has been selected, move the selection switch down and

then rotate the selection switch to adjust the hinge position.

Crease Style Cover Only

Cover & Centre All Sheets None

Select.

More

Cover Crease

Hinges are ON

Hinges are OFF

Hinges are ON

Setting the Cover Crease.

(iii) Move the selection switch down.

7. From the Booklet Maker start up menu, the can be set as

follows:-.

(i) Move the selection switch to the right to select .

Cover Crease

Setup

Cover & Centre

(Cover Only)

Home

More

Crease Style

DocuMaster MK3

Page 28

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

Setting the Stitch Position.

NOTE.

Setting the Machine to Edge Stitch.

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the words .

(iii) Move the selection switch down to select

This adjusts both the stitch and the fold.

(i) Set the to double the length of the finished document. i.e. If the

finished document is 210mm, (see FIG.2 below), set the sheet length to

420mm. (See page 24 for setting the sheet length).

More

Stitch Pos

Stitch Pos.

Sheet Length

(iv) The Offset (From Booklet Centre) can now be adjusted by rotating the

Selection Switch, (clockwise to increase or anti-clockwise to decrease).

.

8. From the Booklet Maker start up menu, the can be set as

follows:-.

(i) Move the selection switch to the right to select .

Stitch Position

Setup

210mm

FIG. 2

Offset - +3.0

Home

More

Stitch Pos

Page 29

SYSTEM

Added Pre-Knock

(Normal Knock)

Home

More

Set Knock

Edge or Centre Staple Selection

Lever Up For Centre Stapling

Lever Down For Edge Stapling

(ii) Set the to . (See page 26 for setting the crease style).

(iii) Set the lever on the Booklet Making Unit to the position,

(Lever in down position).

Crease Style None

Edge Stapling

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the words .

(iii) Move the selection switch down to select the ype (

).

(iv) Move the selection switch to the right to select

Setting the Set Knock.

More

Set Knock

Set Knock t Long

Knock, Double Knock, PreStitch Delay & Pre-Fold Delay

Select.

9. From the Booklet Maker start up menu, the can be set as

follows:-.

(i) Move the selection switch to the right to select .

.

Set Knock

Setup

DocuMaster MK3

Page 30

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

Trimmer is Off

Set Trimmer

Home

More

NOTE.

Definitions of Set Knock types.

Setting the Trimmer.

the set during both stapling and folding without releasing. This is

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the words .

(iii) Move the Selection Switch down to select .

(iv) Move the Selection Switch to the right to turn the Trimmer On (if required)

More

Set Trimmer

Set Trimmer

Long Knock:-

Double Knock:-

PreStitch Delay:-

Pre-Fold Delay:-

Set Trimmer

Setup

Selects long side-knock which causes the infeed sidelays to hold

useful if the booklet is not being folded square, however it is

essential that the sheet width is set accurately.

Selects double knock which causes the infeed sidelays to

actuate twice prior to stapling. This ensures that the booklet

is jogged into a uniform book.

This adjusts the time delay between the side knock and

stapling; this is sometimes useful in ensuring a tidy set.

The default setting is 200ms, but the setting can be adjusted

between 200ms and 900ms.

This adjusts the time delay before folding. The default setting

is 300ms, but the setting can be adjusted between 300ms

and 900ms. Reducing the value will increase the book making

Speed

10. From the Booklet Maker start up menu, the can be set as

follows:-.

(i) Move the selection switch to the right to select .

Page 31

SYSTEM

3 Sheet Book

Prog 3

Books 9

Reset

Setup

Tools

Feed

Trimmer is On

Back

Set Trimmer

Trim Length: 7.285

Back

Set Trimmer

Tens Decimals

Trim Length 7.285

(Trimmer is On)

(v) If the Trimmer has been set to On, Move the Selection Switch down to

set the .

(vi) Move the Selection Switch down to select .

Trim Length

Set Trimmer

(vii) The can now be set as follows:-

Move the Selection Switch to the left to select or to the right to

select . The or (whichever has been selected)

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

11.

Trim Length

Tens

Decimals Tens Decimals

Setting the Batch Quantity.

Storing the Program.

Feed

Setup

This function is not available in the Booklet Maker Mode of operation.

12. The booklet maker settings can now be stored as follows:(i) Move the selection switch up, one click at a time, until the display contains

the word ; see below.

(ii) Move the selection switch to the right to select .

Documaster

DocuMaster MK3

Page 32

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

(iii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the word .

(iv) Move the selection switch down to select

(v) Rotate the Selection Switch to select the Program number (1 to 9).

(vi) Move the selection switch to the right to select .

(vii) Move the selection switch to the left to select or to the right to select

To run the job with the selected settings.

(i) Press the Compressor Switch down.

(ii) Press the System Switch down.

(iii) Move the selection switch down to begin feeding the sheets.

To stop feeding the media at anytime during the program, flick the selection

switch up.

Any of the nine stored programs can be accessed and read as follows:-

(i) From the start up menu, move the selection switch to the right to select

.

(ii) Move the selection switch to the right, one click at a time, until the display

contains the word .

(iii) Move the selection switch down to select, .

(iv) Move the selection switch to the right to select, .

(v) Rotate the selection switch clockwise or anti-clockwise to select,

to and view the program settings.

More

Programs

Save Settings.

Select

Yes No.

1. For Settings and Adjustments to the Booklet Maker Unit see the

Booklet Maker operators manual 70-114.

2. If your machine is fitted with the optional ‘Camera Recognition’ system

see the instruction details on pages 34 To 38.

Running the machine

Reading stored programs

Setup

Programs

Retrieve Program

Select

Program 1

Program 9

Clearing Booklet sheets from the Booklet Maker Infeed Tray.

NOTES.

13.

If for any reason the Feed switch is turned off, during booklet making operation,

booklet sheets may remain in the Booklet Maker infeed tray.

To clear the sheets through into the Booklet Maker, (to be folded and stapled),

follow steps (i) and (ii) on next page.

Page 33

SYSTEM

Set Switch in

this Position

3 Sheet Book

Prog 3

Books 9

Reset

Setup

Tools

Feed

Hand Feed is On

Back

Select Tools

Set Blade Pressure

Using the Booklet Maker in Manual Mode (Hand Feed).

Single Sheet Booklet.

IMPORTANT.

1.

If producing a single sheet booklet without stitch it will be necessary to set the

Creasing Style to or or .

2. If the ‘Square Back System’ is installed with the Booklet Maker ensure that the switch

on the ‘Square Back System’ is set in the position shown below.

All Sheets Cover & Centre Cover Only NoneNOT

(i) From the Booklet Maker start up menu, move the selection switch to the

left to select .

(ii) Move the selection switch down, one click at a time, selecting

until is selected. If the display reads move

the selection switch to the right to change it to .

(iii) Feed the booklet sheets, by hand, into the infeed tray of the Booklet Maker.

The booklet sheets will automatically feed into the Booklet Maker and be

folded and stapled.

Tools

Select Tools

Hand Feed Hand Feed is Off

Hand Feed is On

Documaster

DocuMaster MK3

Page 34

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

Recognition Off

Recognition

Home

More

Cover (Sheet 1)

Cover (Sheet 1)

Cover (Sheet 1)

Sheet 2

Sheet 3

Sheet 4

Feed Bed

4 Sheet Booklet

Image To Be Captured Can Be On The

Underside Of Any Sheet Of The Book

Sheet 2

Sheet 3

Sheet 4

4 Sheet Booklet

TYPICAL BOOKLET STACK (FIXED DATA)

Sheet 2

Sheet 3

Sheet 4

4 Sheet Booklet

Using The Optional Camera Recognition System (If Fitted), and the number

of sheets in each book are the same. (i.e. Fixed Data)

Programme the machine for Booklet Maker operation as described on

pages 22 to 32, and then operate the Camera Recognition System as

follows:-

NOTE:-

(ii) Move the selection switch to the right, one click at a time, (selecting )

until the display contains the word .

More

Recognition

1. From the Booklet Maker start up menu, the camera can be set

as follows:-.

(i) Move the selection switch to the right to select .

Recognition

Setup

Page 35

SYSTEM

Recognition On

Recognition

Home

More

Back

Tens Decimals

Position: 90.0

Capture Image

Recognition

Location: (Cover) -

Back

Position: 90.0

Recognition

Location: (Cover) -

(iii) Move the selection switch down, (selecting ). If the display

reads , move the selection switch to the right to change

it to .

(iv) Move the selection switch down.

(vi) Move the selection switch down.

Recognition

Recognition Off

Recognition On

(v) The that contains the image to be captured can now be set by

rotating the Selection Switch, (clockwise to increase or anti-clockwise to

decrease).

(vii) The of the image to be captured (from the leading edge of the

sheet) can now be set as follows:Move the Selection Switch to the left to select or to the right to

select . The or (whichever has been selected)

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

The default position, (of the image capture position), from the leading edge of

the sheet is 90mm.

Page

Position

Tens

Decimals Tens Decimals

NOTE:-

Limitations of the position of the Image, to be captured, on the sheet.

DocuMaster MK3

Page 36

CREASING / BOOKLET MAKING

Setting the Machine up as a Booklet Maker

Back

Capture Image Now

Recognition

Leading Edge

Crease

90mm

+70 mm No Hinge

IMAGE TEMPLATE

90

100

120110 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270

280

290

Camera Recognition Assistant

Paper Gate

Fixed Rear Lay Edge

Image Area

Part No. 70-113

90 mm

102.5 mm

7mm

3mm

Viewed From Underneath

Image Can Only Be

Within This Band

Of Sheet

+60 mm 10 mm Hinge

FIXED DATA

If there is no image on the sheet, at 90mm from the leading edge of the sheet,

then another position greater than 90mm must be set.

Limitations to the positions of the captured image are pre set in the software

and cannot be exceeded. See Below.

An Image template is provided with the camera recognition system kit to assist

in showing the possible area of the image that can be captured. The Template is

shown below.

(viii) Move the selection switch down.

(ix) Place the sheet, that has the required image, onto the feed bed with the

image face down.

(x) Press the Compressor Switch down.

(xi) Press the System Switch down.

Page 37

SYSTEM

OK

Image Capture

Completed

Cover (Sheet 1)

Sheet 2

Sheet 3

Sheet 4

Feed Bed

4 Sheet Booklet

Cover (Sheet 1)

Sheet 2

Sheet 3

3 Sheet Booklet

Cover (Sheet 1)

Sheet 2

Sheet 3

Sheet 4

5 Sheet Booklet

Sheet 5

TYPICAL BOOKLET STACK (VARIABLE DATA)

Image To Be Captured Can Only Be On The

Underside Of The Cover (Sheet 1) or Sheet 2.

(xii) Move the selection switch to the right to select .

The sheet will be automatically fed into the machine and the camera will

be activated to capture and store the required image.

(xiii) The display will show that the image has been captured, as shown below.

(xiv) Move the selection switch up, one click at a time, until the display contains

the word .

(xv) Load the booklet stack onto the feed bed; and then run the job by switching

the Compressor and System Switches on, and then move the selection

switch down to select .

Capture Image Now

Feed

Feed

Using The Optional Camera Recognition System (If Fitted), and the number

of sheets in each book are different. (i.e. Variable Data)

Do not use ‘Stream Feed’ when running variable data jobs.

NOTE:-

DocuMaster MK3

Page38

CREASING/BOOKLETMAKING

VariableData

Prog?

Books?

Reset

Setup

Tools

Feed

ImageRecOn

LeadingEdge

Crease

90mm

+70mmNoHinge

ImageCanOnlyBe

WithinThisBand

OfSheet

+60mm10mmHinge

-20mmNoHinge

-30mm10mmHinge

IfisSelected

Cover

IfisSelectedSheet2

ImageCanOnlyBe

WithinThisBand

VARIABLEDATA

1.ProgrammethemachineforBookletMakeroperationasdescribedon

pages22to32,settingthetoasdescribed

onpage25.

2.OperatetheCameraRecognitionSystemasdescribedonpages34to36.

Whentheselectionswitchismovedupuntilthedisplaycontainstheword

thedisplaywillreadasshownbelow.

3.Loadthebookletstackontothefeedbed;andthenrunthejobbyswitching

.theCompressorandSystemSwitcheson,andthenmovetheselection

switchdowntoselect.

SheetsinBookVariableData

LimitationsofthepositionoftheImage,tobecaptured,onthesheet.

Feed

NOTE:-

NOTE:-

Thedefaultposition,(oftheimagecaptureposition),fromtheleadingedgeof

thesheetis90mm.Ifthereisnoimageonthesheet,at90mmfromtheleading

edgeofthesheet,thenanotherpositiongreaterthan90mmmustbeset.

Limitationstothepositionsofthecapturedimagearepresetinthesoftware

andcannotbeexceeded.SeeBelow.

Feed

Page 39

SYSTEM

Perforating

Notes

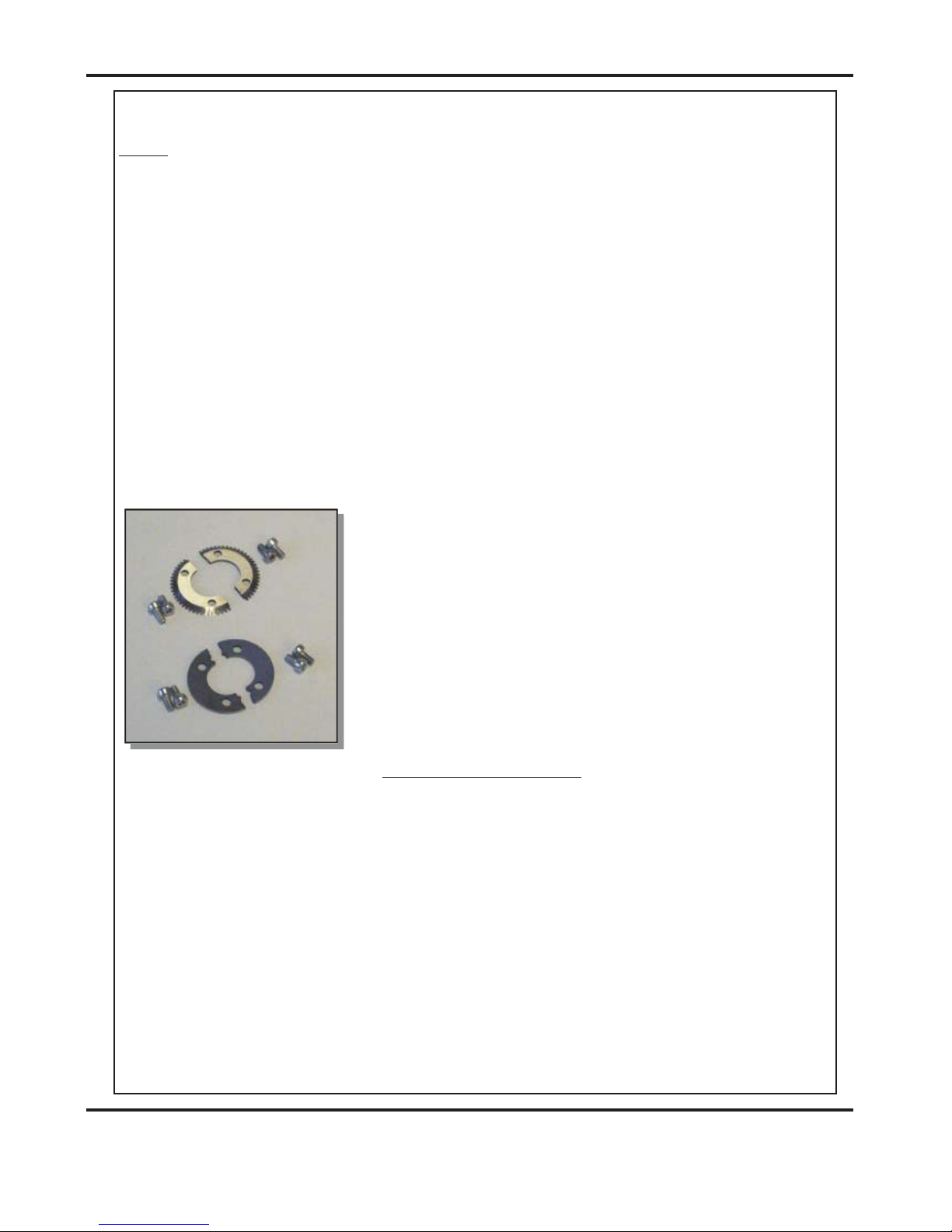

Perforating ‘Spares’ kits

1. Perforating and creasing can be carried out simultaneously. However, if any

adjustment is made to the roller tilt mechanism in order to compensate for the

perforation line being ’out of square’, this may effect the accuracy of the crease. If

this occurs creasing and perforating must be carried out as separate operations.

2. By adjusting the outfeed drive tyres relative to the drive hubs it is possible to stear

the sheet, (i.e. By placing the tyre on top of the hub one side of the paper will stear

faster on that side).

Important: The perforator blades are very sharp and

care must be taken whilst handling.

Do not mix the matching pairs of blades or anvils.

Perforating blades 1-99-41

1-99-12

1-99-10

Anvils 1-99-35

The components and tools required to install the perforator are contained in the despatch

kit supplied with the machine, they are listed below.

1 off Set of standard perforation ‘56 tooth’ blades.

1 off Set of standard hardened anvils.

1 off Perforator stripper.

1 off Scoring wheel

1 off 3mm bondhus wrench / allen key

1 off 2mm bondhus wrench / allen key

The perforator blades are split into two matching halves and

are fitted to the drive wheels as shown in the photograph

using the four screws supplied.

A hardened anvil is fitted to the drive hub as shown in the

photograph also using the four screws supplied. Again the

anvils are made from matching halves.

For perforating and other types of paper, various spares kits are available which can be

assembled to the machine in the same fashion. They are listed below along with a range

of scoring wheels,

56 teeth Part Number - Standard stock /

fine perforations.

28 teeth Part Number - Medium stock /

Medium perforations.

20 teeth Part Number - Heavy stock /

coarse perforations.

Standard Part Number - For all blade types

DocuMaster MK3

Once the machine is set-up, the Documaster Mk3 can be used to perforate or crease.

Page 40

Perforating

CREASING / BOOKLET MAKING

FIG 16.2

FIG 16.1

*Perforator stripper 78-013

All of the blades and anvils are supplied with fixings.

Standard Part Number

*It is recommended that for multiple perforations, a separate perforator stripper is used for

every perforating blade set fitted in the creasing unit.

1. Turn the mains supply to the machine ‘off’.

2. Remove the stacker unit and open the exit guard.

3. Locate and remove the blades / anvils from the despatch kit supplied with the

machine.

4. Using the 2mm allen key (supplied), loosen the drive wheel that is to accommodate

the blades.

5. Slide the drive wheel away from any obstructing drive wheels or hubs in order to

mount the blades.

6. Using the 2.5mm allen key (supplied), take one

half of the matching pair of blades and mount on

to the drive wheel. Do not secure the blade.

7. Mount the other half of the blade to the drive

wheel as shown (fig 35.1). Secure the blades to

the wheel ensuring not to over tighten grub screw.

8. Mark on a single sheet the desired perforating

position. Feed the sheet through the machine

manually until the mark can be seen. Use this

mark to assist in fixing the position of the

perforating drive wheel to the roller drive shaft.

9. Using the 2mm allen key, loosen the drive hub

nearest the perforating drive. Slide the drive hub

away from any obstructing drive wheels or hubs

in order to mount the anvils.

10. Using the 2,5mm allen key, take one half of the

matching pair of anvils and mount to the drive

hub. Do not secure the anvil.

Setting the machine

Page 41

5

2

1

3

4

FIG 17.1

SYSTEM

Perforating

11. Mount the other anvil ensuring that they have matched on the drive hub. Secure the

anvil to the hub ensuring not to over tighten grub screw as shown in fig 16.2.

12. Slide the drive hub towards the perforating drive wheel until there is a clearance

of 0.5mm.

13. To prevent damage to the blades or the anvils, do not force the drive wheel against

the hub.

14. Fix the perforator stripper adjacent to the drive wheel and blade as shown.

15. Operate the machine and test the perforations for form.

For multiple perforations repeat the above procedure.

Demonstrates a typical set-up for perforating sheets.

- Perforating drive wheel with mounted blades - Drive hub with mounted anvils

- Perforator stripper - Standard drive hub

- Standard drive wheel

It is important that the drive hubs are arranged evenly across the width of the paper

in order to reduce the risk of jamming.

Fig 17.1

14

25

3

Always remove blades and anvils once the perforating operation has been

completed to avoid marking on digital or delicate media.

DocuMaster MK3

Page 42

The Blade Assembly

2 Creases

Program 3

To ta l 2 0

Zero

Setup

Tools

Feed

Batch Off

CREASING / BOOKLET MAKING

Tools

Set Blade Pressure

Blade is moving to TOP DEAD

CENTER Blade Pressure May Now Be Adjusted See

Operators Manual

Adjusting the blade pressure (no paper required)

1. (i) Switch the power ‘on’ by turning the Emergency stop button clockwise to release the

safety latch. The display is now switched on and will show the start up menu as

shown below.

(ii) Move the selection switch to the left to select .

(iii) Move the selection switch down to select .

(iv) Press the system switch down.

(v) Move the selection switch to the right, the machine will activate and the blade will

move to top dead center. The display will now read

and then change to read

.

2. Raise the exit guard

3. Using a 6mm allen key, unlock the shoulder bolts (labelled with scale transfer)

positioned at each end of the creasing blade.

4. Turn the adjustment cam to adjust the blade pressure. Increasing the gradient on the

scale will increase the blade pressure.

5. Ensure that the shoulder bolts are locked after setting.

The diagram below demonstrates the adjustment of the blade pressure

Page 43

The Blade Assembly

SYSTEM

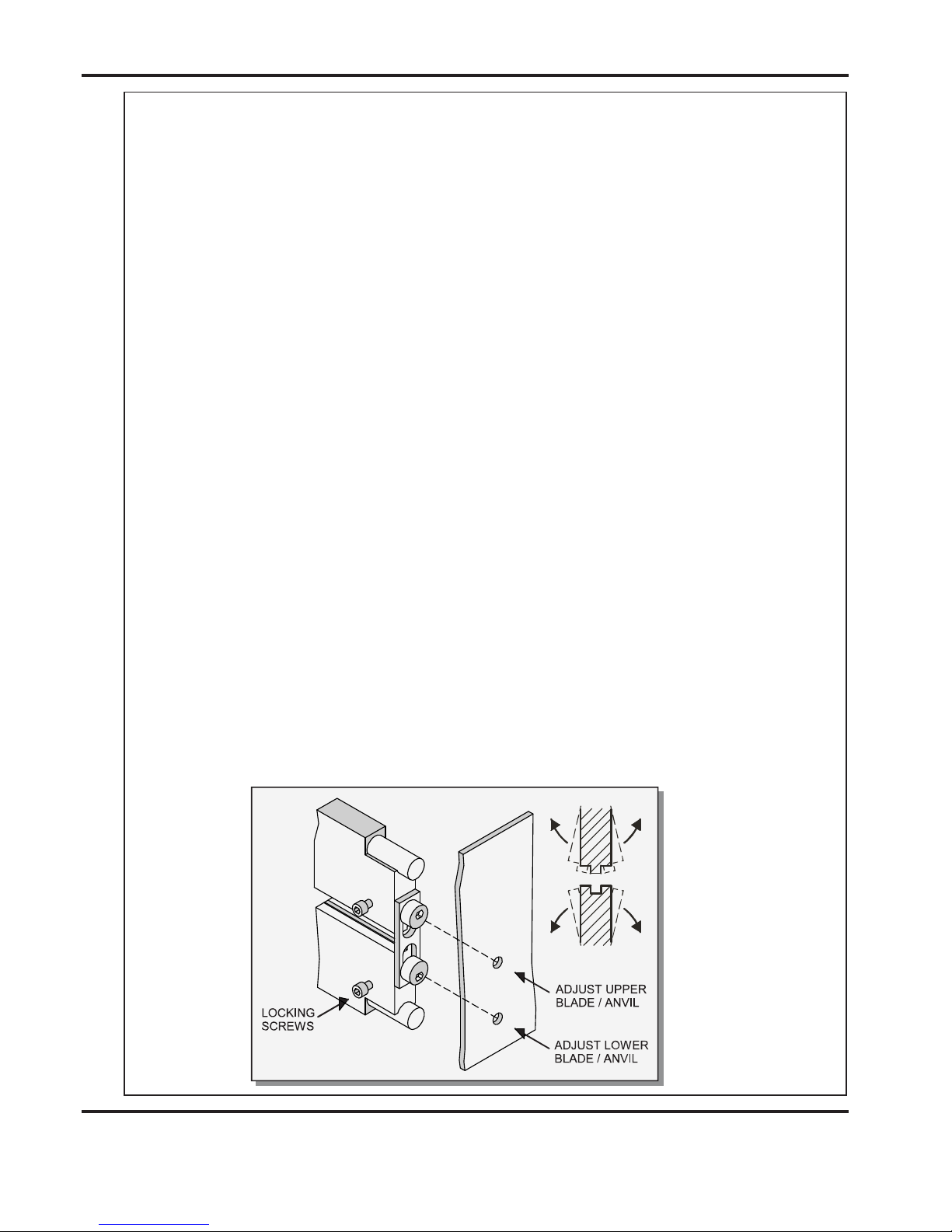

Adjusting the blade alignment

It is extremely important that the blade and anvil assembly within the creasing unit is

correctly aligned. Misalignment of the blade or anvil can lead to damaged profiles and

subsequently poor quality creasing so it must, therefore, be corrected immediately.

If the blade set is misaligned, the media being driven will be subject to scoring or even

tearing at any point along the crease line.

The below sketch

demonstrates how the blade alignment can be carried out.

Adjustment can be made at either of the blade or anvil. The two clearance holes positioned above the roller tilt mechanism are the front alignment (one for blade, one for anvil).

The two holes are repeated on the back of the machine for the back alignment.

1. Remove the stacker unit from the machine.

2. Unlock and centralise the roller tilt mechanism in order to locate the heads of the

front alignment screws.

3. Using a 3mm allen key, loosen the cap head type locking screws located on the

front face at both ends of the blade /anvil as shown below.

4. Using a 4mm allen key, locate the two front or back alignment screws in the side

frame in order to adjust the blade / anvil.

5. The upper screw of the two, will adjust the upper blade / anvil whereas the

lower screw will adjust the lower blade / anvil both in very small increments.

6. In order to obtain the required position, adjust either the blade or the anvil by a

small amount and then operate the machine to test the form of the crease.

Repeat the exercise until centralisation is located.

7. Using a 3mm allen key, lock the cap head type screws (as per step 3) on both the

upper and lower blade / anvil.

Please note that to avoid damage to the

blade set, adjustment should only be made in small increments.

DocuMaster MK3

Page 44

Replacing Blade Set

Blade Extractor Tools

FIG 20.1

CREASING / BOOKLET MAKING

1. Before removing the blade assembly, ensure that the lower blade / anvil is NOT

at ‘top dead centre’, Switch the machine off.

2. Remove the stacker unit and lift the exit guard.

3. Using a 6mm allen key, loosen the socket

head screws located inside the blade

adjustment cams. Remove the screws and

the blade adjustment cams.

4. Insert the blade extractor tools (70-055-01 &

70-055-02) into the holes in the adjustment

links, as shown. Push downwards on the

handles of the blade extractor tools to

release the blade assembly from the power

links.

5. Slide the blade assembly out of the creasing

unit and lay it on a flat surface.

6. Slide the adjustment links away from the

dowels located in the ends of the blades /

anvils as shown in the photograph (left)

7. Place the new blade set into position.

Check that the eccentric shoulder bolts on

the link plates have been positioned as

shown in fig 20.1.

8. (Upper blade / anvil only)

Slide the adjustment links onto the dowels.

9. Slide the new blade set into the slots of the

creasing unit as shown in fig. 21.1.

Locate the blade extractor tools into the holes in

the adjustment links as shown. Pull the handles

of the blade extractor tools upwards to engage

the blade assembly back into the power links.

10. Set the cam graphics for both ends of the blade /

anvil to their lowest point on the scale (ie. When

the mark on the scale reaches the mark on cam

holder) Fasten the socket head screws on the

adjustment cams until they are tight.

Page 45

Replacing Blade Set

FIG 21.1

SYSTEM

11. Push the exit guard down and replace the stacker assembly before operating the

machine.

12. Switch the machine on and test the crease for form.

In the event of any damaged or lost components within the blade assembly, spares kits

are available on request. However, components within the blade set can not be ordered

separately ie single blade or anvil.

Consisting of a standard blade and anvil, blade brushes, blade links and alignment bolts.

Consisting of a narrow blade and anvil, blade brushes, blade links and alignment bolts.

If the pressure and the alignment of the crease is not to a satisfactory level,

see pages 42 - 43 to adjust the creasing line.

Standard Blade set Part number 76-213-01

Extra Narrow Blade set Part number 76-213-03

‘Spares’ kits

DocuMaster MK3

Page 46

Trouble Shooting

CREASING / BOOKLET MAKING

Paper crease out of square

Paper jamming

Machine will not start

Paper not feeding

l Check that the sheets are all square and exactly the same size before loading the

stack on to the table.

Check that the roller tilt mechanism is correctly set and locked in position.

Check that the adjustable side lay has been correctly positioned ie. No further than

0.5mm from the paper stack.

Check that the leading edge of the paper is not being damaged by the paper gate. If

this is occurring, check that the suction slot and the paper gate have been correctly

set.

Check that the first crease position is not too close to the leading edge of the paper.

A minimum distance of 32mm is recommended.

Check the power supply to the machine.

Check that the emergency stop button has been released.

Check that the exit guard is down.

Check that the stacker unit is located correctly and has not been disconnected from

the magnetic switch.

Check that the lower blade / anvil is connecting to the home switch (mounted below

the lower blade / anvil).

Check that the paper stack is not too high or too heavy for the feeder. The height of

the paper stack should be defined by the weight and the size of the stock being

creased.

Ensure that the adjustable side lay is not pressed against the paper stack. However,

if the clearance between the adjustable side lay and the paper stack is too great, the

air supply will escape instead of blowing through the paper thus making it difficult to

feed.

Check that the clearance between the paper gate and the suction roller is not set too

low.

On digital media, the feeding performance may be improved if the leading edge of

the stack is trimmed before loading onto the machine.

l

l

l

l

l

l

l

l

l

l

l

l

l

Page 47

Trouble Shooting

SYSTEM

l

l

l

l

Check that the air distribution has been correctly set.

Check that the air separation has been set high enough to feed the sheets.

For heavy stocks, very small or very large sheets, embossed or even irregular stock,

it may be required to feed the sheets manually - see page 20 for instructions.

Open the exit and remove the blade set

(see pages 44-45) to access the dual

sensor post located in between the drive

rollers. Using a soft brush, clean the

visible sensor on the end of the post.

Use the brush to clean the sensors

between the post and the bottom paper

guide which are not visible.

Photograph (left) shows the dual sensor

post containing the sensors.

If the suction drum is not rotating, check all of the drive belts for cleanliness and

splits (including the bottom in-feed roller drive belt).

.

If at any time during the creasing process the control panel reads it

is indicating that the lower blade / anvil has not made contact with the HOME switch ie.

blade still in top position. Switch the machine off and remove the blade set and ensure

that the area is free from obstructions. Return the blade set to the creasing unit

and switch the machine on. Operate the machine in the normal sequence, if the

display continues to read it is advised to contact a Service Engineer

immediately.

If before operating the machine the display reads this

indicates that there is an obstruction between the upper sensor assembly and the

paper guide sensor (as shown in the above photograph). If there is no obvious

obstruction in the paper path, switch the machine off and repeat the same procedure as

explained above.

Machine not counting

No suction

Control panel reads

Blade Not Home

The Paper Path is not clear

l

l

Blade Not Home

Blade Not Home

The Paper Path is not clear

DocuMaster MK3

Page 48

Trouble Shooting

CREASING / BOOKLET MAKING

Recommended weekly operator maintenance

Technician Maintenance

• Clean all sensors

• Clean in feed rollers and output drive hubs using the cleaning kit supplied.

(Cleaning kit part number 90-018)

• Remove and clean the blade assembly

• With the blade assembly removed, clean the slots and surrounding area

within the creasing unit.

It is recommended that your machine is fully serviced at least once every six months

by a factory trained Service Engineer.

To

To

Re-register the Booklet Maker Unit.

Reset The Booklet Maker Unit Back To Factory Default Settings.

NOTE:-

The Booklet Maker Unit can be re-registered as follows:-

This function will adjust all motor settings to a known start position. It will also display the

version of software loaded into the Interface Module (housed within the motorised infeed unit),

and the version of software fitted on the Main Control board of the Booklet Maker Unit.

This will reset the Booklet Maker Unit back to default factory settings and should only be used

as a last resort.

1. From the Booklet Maker start up menu, move the Selection Switch to the left to select .

2. Move the Selection Switch down to select .

3. Move the Selection Switch to the right to select.

1. From the Booklet Maker start up menu, select move the Selection Switch to the left to .

2. Move the Selection Switch down to select

3. Move the Selection Switch to the right to select.

Minor sideways misalignment, caused by uneven floor or machine build tolerances, can be

adjusted as follows:-

1. From the Booklet Maker start up menu, move the Selection Switch to the left to select .

2. Move the Selection Switch down to select .

3. Rotate the Selection Switch to adjust, a positive value will move the Creaser Unit away

from the operator.

Values of less than 3 may not be enough to adjust the position.

Tools

Re-register BMP

Tools

Set BMP ‘DEF’.

Tools

BMP Alignment

To Adjust Misalignment Between Creaser Unit and Booklet Maker Unit.

Page 49

SYSTEM

Error Messages

‘Warning Sheets not cleared from Bookmaster infeed’

‘BookMaster Error’

‘Double Sheet Feed - Detected’

‘Bookmaster Error - Trim Out Of Range’

‘Warning Vario Trim Guard Open’

‘Warning Vario Stitch Guard Open’

‘Warning Sheet Failed to Arrive’

‘Bookmaster Error - Bad Status Response’

‘Warning Image Out of Sequence’

‘Warning Vario Jam Detected’

Remove sheets from the infeed tray of the Booklet Maker.

Check all Doors and Access Panels are shut correctly

Check Mains Power is Switched on and also Communication Cable is Plugged in.

Check Waste Bin is Empty.

Remove any sheets from the infeed tray of the Booklet Maker and also the Suction Drum area.

Ensure integrity of the remaining booklets in the feed stack.

Check that the trim length is less than half the sheet length.

If no Spinemaster (Square Back) is in line, check that the bridge plug is in place.

Check that the Stitch Guard is shut correctly

Check paper feeding is adjusted correctly, (see page 46).

Check yellow light on Booklet maker (see Booklet maker operators manual

70-114).

Check number of sheets is set correctly.

Check image is captured correctly, reset if necessary.

Check Booklet maker for jams and remove (see Booklet maker operators manual

(70-114).

DocuMaster MK3

DISPATCH KIT

ITEM PART NUMBER QTY DESCRIPTION

1

1 OPERATORS MANUAL(Part 1) (Creasing Unit)

3 90-018 1 ROLLER CLEANING KIT

4

5

650-040 1 POWER CORD

C19-3Pin-UK

650-016 1 L6 - 15P Re-Wirable Plug (Used on USA Only)

11

12

13

620-028 1 BONDUS L WRENCH 3mm

16

620-033 1 BONDUS L WRENCH 6mm

14

624-018 1 DISPATCH BOX

9

620-007 1 HEXAGON BALL DRIVER 2mm

620-026 1 BONDUS L WRENCH 4mm

620-020 HEXAGON BALL DRIVER 2.5mm

10

1

15

70-055-01 1 BLADE EXTRACTION TOOL - OP SIDE

70-055-02 1 BLADE EXTRACTION TOOL - LAY SIDE

WARNING......

THE BLADES FOR ANVIL AND PERFORATING SETS ARE SUPPLIED AS

MATCHING PAIRS AND SHOULD NOT BE MIXED OR LEFT

UNPROTECTED OR SERIOUS DAMAGE MAY RESULT.

8

17

94-087-01 1 CLAMP PLATE - SIDELAY

18

94-087-02 2 CLAMP PLATE WIDE - SIDELAY

7

2

1 OPERATORS MANUAL

(Part 2) (Booklet Making Unit)

650-041 1 POWER

C19-3Pin-USACORD

6

617-004 4 GLASS BALL - Ø20

7-99-01 1 ANVIL SET - Perforator

1-99-12 1 PERFORATOR BLADE SET - 28T

Page 50

CREASING / BOOKLET MAKING

70-114

70-111

7-95-13

ITEM PART NUMBER DESCRIPTION

ACCESSORIES AND OPTIONS

1-99-10 PERFORATING BLADE SET 20T (Card)1

1-99-12 PERFORATING BLADE SET 28T (Single sheets)2

1-99-41 PERFORATING BLADE SET 56T (Fine perforations)3

1-99-35 ANVIL SET USED WITH ABOVE BLADE SETS4

76-213-03 BLADE SET - EXTRA NARROW5

Page 51

SYSTEM

79-052-01 FA45 OBJECT CAMERA KIT6

ACCESSORIES.... OPTIONS....

....May be obtained from ....May also be obtained and

your dealer and fitted to your fitted by your dealer. You should

machine using the instructions not attempt to fit options as

supplied, or by reading your specialist tools and knowledge are

operators manual. required.

75-407 ETHERNET KIT7

DocuMaster MK3

RECOMMENDED SPARES

PART NUMBER DESCRIPTION

93-021 FEED BELT

93-022 DRIVE BELT - Vacuum Roller

609-011 ‘O’ RING Ø20

609-014 ‘O’ RING Ø15

94-028 LOCK PIN ASSEMBLY - Side Lay

75-365

75-366 HOSE - Vacuum Blow

75-367 HOSE - Separation Air

HOSE - Vacuum

613-137 PLUNGER AND SPRING

613-255 SOLENOID COIL

609-013 ‘O’ RING Ø25

613-365 EMERGENCY STOP SWITCH

652-011 SYSTEM SWITCH

75-378-01 DOCUMASTER CONTROL PCB ASSY + CHIP

125-21-02 DUAL STEPPER DRIVE PCB ASSEMBLY

655-011 PSU UNIT 5V/24V

655-015 PSU UNIT - SWITCH MODE - 24V

76-230-03 PAPER GUIDE ASSEMBLY - Bottom Sensor

76-242 PAPER JAM SENSOR ASSEMBLY

76-154 UPPER SENSOR ASSEMBLY

98-013

ANTI-STATIC BRUSH

609-022

‘O’ RING Ø32

606-035 KNOB - Roller Tilt

76-109

POWER LINK BEARING

76-213-01 BLADE SET - Standard

76-042 DRIVE BELT - FEED BED

607-042 TIMING BELT 160XL

607-048 TIMING BELT TWIN GRIP - 200 DXL 050

608-019 SHOULDER BOLT

75-352 POT & LEAD ASSEMBLY

652-009

75-210-05 LCD DISPLAY UNIT-4LINE

144-04-02 JOYSTICK AND LEAD ASSEMBLY

652-010

COMPRESSOR SWITCH (UK)

COMPRESSOR SWITCH (USA)

655-016 PSU UNIT - SWITCH MODE - 48V

76-156 BLADE POSITION SENSOR

Page 52

CREASING / BOOKLET MAKING

RECOMMENDED SPARES

PART NUMBER DESCRIPTION

76-175-01

INPUT ROLLER - Lower

76-177-01

INPUT ROLLER - Upper

76-250-01

UPPER OUTPUT SHAFT ASSY

613-351 MICRO SWITCH - Guard Circuit

613-191 MICRO SWITCH - Home Circuit

78-071-01 ACTUATOR ASSY. - STACKER

602-056 BEARING-DRAWN CUP NEEDLE ROLLER - Ø15XØ21X12

602-085 BEARING-DRAWN CUP NEEDLE ROLLER - Ø10XØ14X10

PERFORATOR STRIPPER ASSEMBLY

78-013

78-251-01

LOWER OUTPUT SHAFT ASSY

613-023

681-011

FUSE 3.15A - Fast Blow

FUSE 315ma - Anti-surge

FUSE 4A - Anti-surge

681-015

175-082-01

RELAY PCB Assy

INTERFACE CABLE

75-388

76-042

DRIVE BELT - FEED BED - Polycord

STACKER SWITCH Assy

75-040

654-014

ULTRASONIC RECEIVER

ULTRASONIC TRANSMITTER

654-015

626-004

STATIC ELIMINATOR BAR

ANTISTATIC TRANSFORMER

75-258

610-029

DOGA MOTOR

Page 53

SYSTEM

NOTE.....

The items listed above represent parts which are subject to wear, loss, or accidental

damage, and is included for your guidance only.

Replacement of parts fitted to your machine require specialist knowledge and should

therefore be entrusted to your dealer.

DocuMaster MK3

Page 54

CREASING / BOOKLET MAKING

MACHINE CALIBRATION HISTORY

Stretch

Lead Edge Trim

Width Trim

Date:-

Total Count:-

Serial Number:-

Camera Fitted

Page 55

SYSTEM

PRODUCT RECYCLING & DISPOSAL

European Union

Disposal Information for Commercial Users

Disposal Information for Domestic Users

Other Countries

DocuMaster MK3

Loading...

Loading...