ISSUE 9 JULY

2006

120-101

DOCUMENT

CREASING/FOLDINGMACHINE

MorganaSystemsLimited UnitedKingdom

Website:www.morgana.co.uk

Telephone: (01908)608888 Facsimile:(01908)692399

OPERATORS MANUAL

Page2

INDEX

INTRODUCTION&SPECIFICATION

PAGE4

THEDIGIFOLD

5

THECONTROLPANEL

6

7

QUICKSTARTGUIDE8

17

17

17

18

18

18

18

19

20

21

21

22

22

22

23

THEDELIVERYUNIT

24

THEBLADEASSEMBLY

25

25

TheMorganaDigifold

LabeledPhotograph

Detaileddiagramanddescription

Featuresonthecontrolpanel

AdjustingthePapergate

SettingtheSuctionSlot

SettingtheAdjustableSideLay

SettingtheBack-Stop

SettingtheAirDistribution

SettingtheAirSeparationPressure

SettingthePositionsofDriveWheelsandHubs

SettingtheExtensionTable

SettingtheDeliveryConveyorSystem

AdjustingtheBatchCount

AdjustingtheRollerGap

StoringPrograms

ReadingStoredPrograms

ClearingStoredProgram

FeedingSheetsManually

SettingtheDeliveryConveyorSystem

Adjustingthebladepressure

Adjustingthebladealignment

OPERATINGTHEDIGIFOLD

10

12

14

16

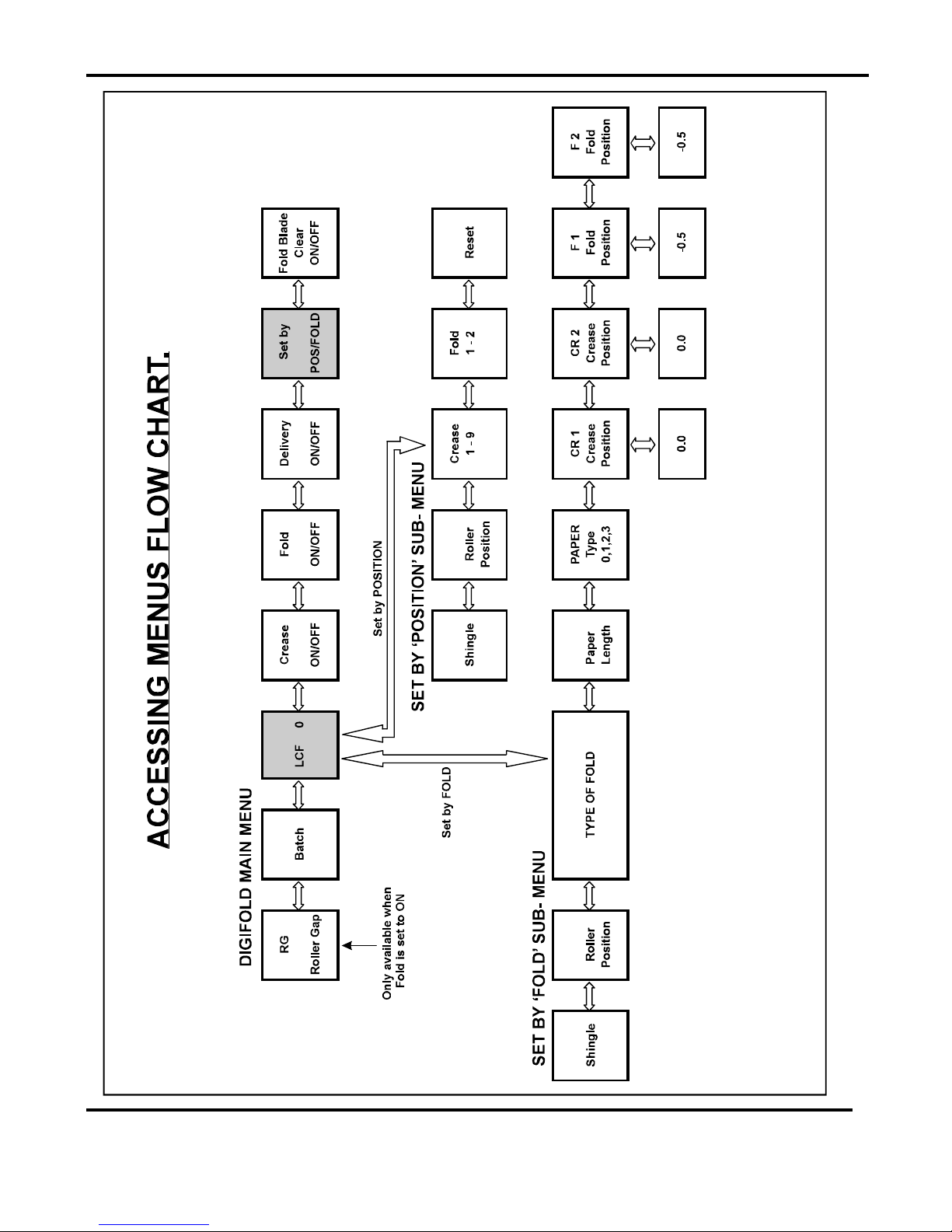

AccessingMenus.

SetbyFold

SetbyPosition

ExampleofSetbyPosition

CREASING/FOLDING

Page3SYSTEM

INDEX

Digifold

REPLACINGCREASINGBLADESETS

PAGE27

28

‘Crunch’32

32

DISPATCHKIT(120-95-01)34

ACCESSORIESANDOPTIONS35

RECOMMENDEDSPARES36-38

Installingnewbladesets

SpareBlades

Displayreads

FoldBladerelocation.

TROUBLESHOOTING

29

29

29

29

30

30

30

31

31

‘h’31

‘ClipP’32

‘Clip1’32

‘Clip2’32

33

MACHINECALIBRATIONHISTORYSHEET39

Papercreaseoutofsquare

Paperfoldoutofsquare

PaperJamming

Machinewillnotstart

Papernotfeeding

Machinenotcounting

Crackingoftheprintedmaterialalongthecrease

Papermarkingorscratching

Nosuction

Displayreads

Displayreads

Displayreads

Displayreads

Recommendedweeklyoperatormaintenance

INTRODUCTION

INTRODUCTIONANDSPECIFICATION

must

DigiFold

DigiFold

IMPORTANT

isaregisteredtrademarkofMorganaSystemsLtd.Theuniquepatented

creasingandfoldingsystem,makesitpossibletofoldmostdelicatestocksfrom90gsm,

uptoandoftenabove300gsm.Thereducesthepossibilityofscratching,marking

orcrackingappearingonthesubstrate,asisoftenassociatedwithconventionalfolding

machinemethods.Amaximumpaperweightcannotbespecified,asthiscanbegoverned

bythehardnessofthesubstrateorthetypeoffoldrequiredtobeproduced.

Itistonotethattopreventcracking,whenusingdryinkortonerbasedprint

engines,thematerialbefullyacclimatisedforatleast48hoursbeforeputtingan

imageontothepaper.

FeedingSystem................................................Bottomsuctionfeed

Max.SheetSize................................................630mmx330mm

Min.SheetSize.................................................140mmx160mm(dependantonstiffness

ofpaperandtypeoffold).

Max.PaperWeight...........................................300gsm(variesaccordingtohardness,

typeoffold,andsubstrate).

Min.PaperWeight............................................120gsm

Max.No.CreasesperSheet............................9

Max.No.FoldsperSheet..................................2

Max.No.StoredProgrammes...........................6

Min.RepeatCreaseDistance...........................4mm(dependingonpaperweight)

Min.RepeatFoldDistance................................70

Min.CreaseDistancefromLeadingEdge........25mm

Min.FoldDistancefromLeadingEdge.............70mm(dependingonpaperweight)

SpeedperHour(A4Material)OneCreaseorOneFold..........1800sheets

SpeedperHour(A4Material)TwoCreasesorTwoFolds......1400sheets

IMPORTANT

Note:

theoperatingenvironmentshouldbecontrolledtoatemperaturebetween

16°Cand27°CMaximum.

mm(dependingonpaperweight)

Min.CreaseDistancefromTailEdge...............25mm

Min.FoldDistancefromTailEdge....................70mm(dependingonpaperweight)

Max.FoldLength..............................................560mm

Min.FoldLength...............................................70mm

SpeedperHour(A4Material)OneCrease&OneFold..........1800sheets

SpeedperHour(A4Material)TwoCreases&TwoFolds.......1400sheets

SpeedperHour(A3Material)OneCreaseorOneFold.........1440sheets

SpeedperHour(A3Material)OneCrease&OneFold..........1440sheets

SpeedperHour(A3Material)TwoCreasesorTwoFolds......1200sheets

SpeedperHour(A3Material)TwoCreases&TwoFolds......1200sheets

Dimensions.......................................................L:1830mmH:1185mmW:555mm

Weight...............................................................180Kgs(+50Kgspacking)

PowerRequirement..........................................1phase220/240v

+

Specification

Theproductionspeedvariesaccordingtothematerialsizeand

thenumberofcreasesorfoldsonthesheet.

Page4

CREASING/FOLDING

DOCUMENTCREASING/FOLDINGMACHINE

Keytophotographbelow

6Airdistributionknob11PaperGate

2Deliveryassembly7Adjustablesidelay12ExitGuard

3Suctionslotknob8Backstop13HighLevelDisplay

4Controlpanel9Fixedsidelay14Extensiontablefixing

5Airseparationknobscrews

Page5SYSTEM

14

6

7

11 13

5

4

3

2

12

9

8

Digifold

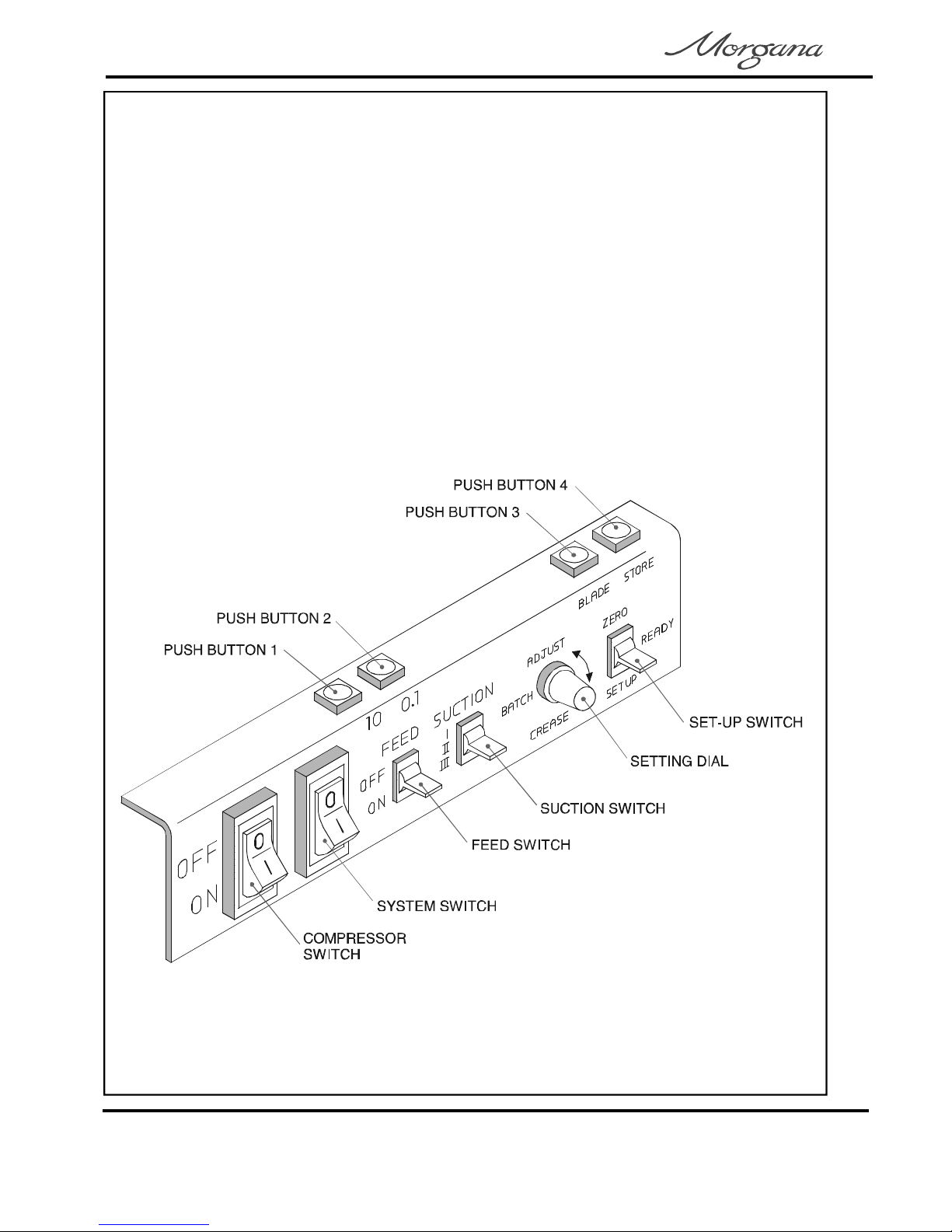

TheControlPanel

TheControlPanelontheDigifoldallowstheoperatortoread,edit,create

andinitiatenumerouscreasing/foldingprogramswithinthememory.

Thetopfaceofthecontrolpanelhousesfourpushbuttonsasshowninthe

diagrambelow.Forthepurposesoftheinstructionsthesebuttonswillbe

describedas.

ThefrontfaceofthecontrolpanelhousestheCompressorswitch,

Systemswitch,Feedswitch,Suctionswitch,SettingdialandSet-upswitch.

UnderthecontrolpanelisanindustrystandardEmergencyStopswitch

whichwillstopallpowergoingtothemachinewhenactivated.

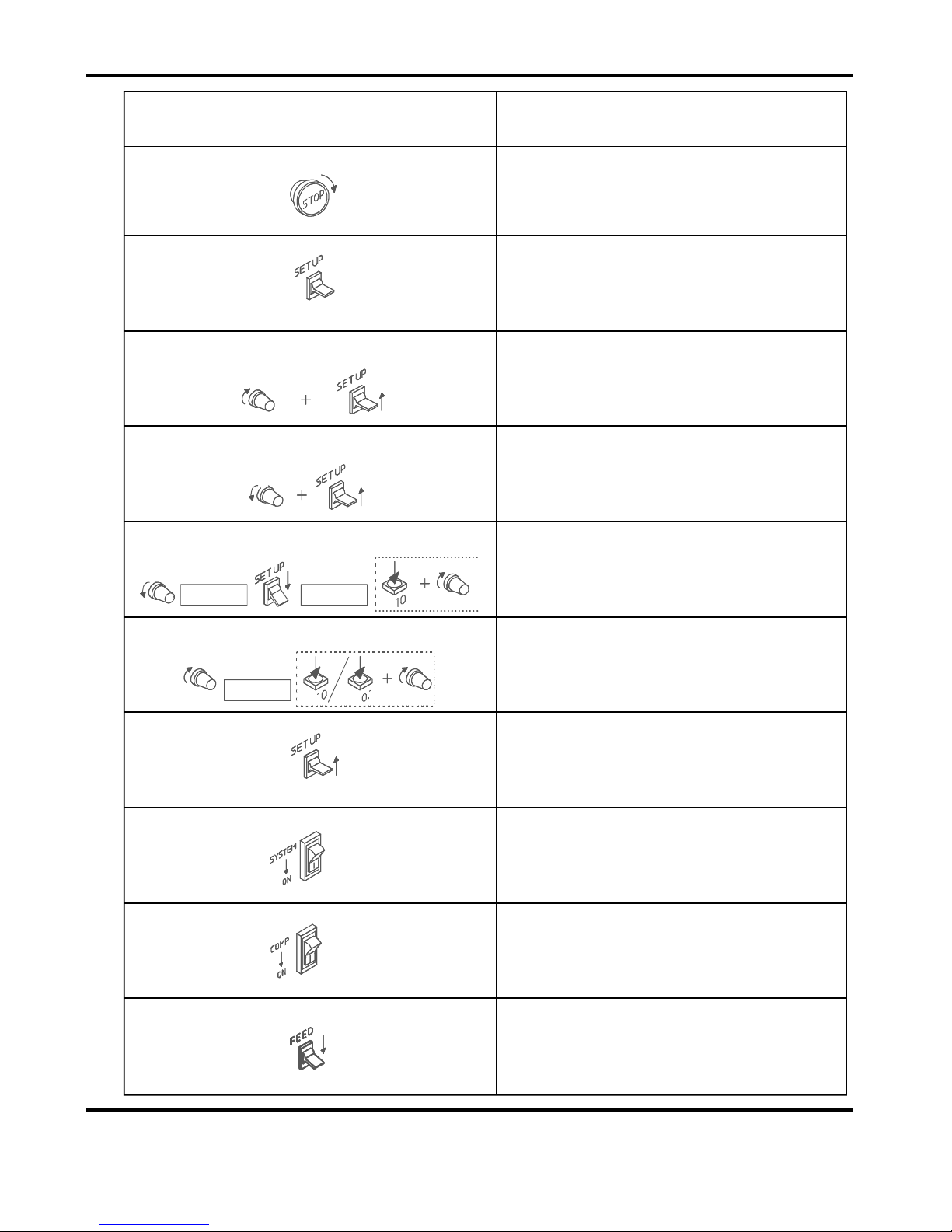

PushButtons1,2,3,4

Page6

CREASING/FOLDING

FeaturesontheControlPanel

PushButton1

PushButton2

PushButton3

PushButton4

Set-upswitch

Settingdial

Suctionswitch

Feedswitch

Systemswitch

Compressorswitch

Usedforadjustingacrease/foldpositioninincrementsof10mmwhenusedwith

thesettingdial.

Alsousedforinchingfeedforwardwheninhandleorcrunch/Clip1orClip2

situation.

Usedforadjustingacrease/foldpositioninincrementsof0.1mmwhenusedwith

thesettingdial.

Usedforlocatingthebottombladeoranviltoits‘TopDeadCenter’positioninorder

tosetthebladepressure(whilstthesystemswitchison).

Alsousedtoreturnthecreaserbladetothe‘Home’positionaftera‘Crunch’if

required.

Allowstheoperatortosaveacreatedprogram.Whenalsousedwiththesetting

dialtheoperatorcanscrollthroughthestoredmemoryaddresses.

Alsousedforcyclingthefolderblade/feedforward.

Allowstheoperatortoenterandsubsequentlyeditorreadastoredprogram.Also

resetsthebatchquantity.

Allowstheoperatortoscrollthroughstoredmemoryaddressesandprograms,

increaseordecreasethebatchquantityandsetacrease/foldposition.

Allowstheoperatortovarythelengthofsuctiononthesheetofpaperbeingfed.

PositionIForveryshortsheets.

PositionIIForshortnon-standardsheets.

PositionIIIForallstandardsizesheets,generalpurpose.

Allowstheoperatortostartandstopfeedingsheets.

Whenactivatedthesystemswitchwilloperatethemotorsinordertobeginthe

creasing/foldingsequence.

Allowstheoperatortoswitchoffthecompressorunitinordertoutilizethemachine

tomanuallyfeedsheets.

Alsousedforinchingfeedinreversewheninhandleorcrunch/Clip1orClip2

situation.

TheControlPanel

Page7SYSTEM

Digifold

QuickStartGuide

Settingthemachinetooperateinautomaticmode.

(i.e.,SetbyFold’)

Tomanuallyfeedsheetsseeinstructionsonpage23.

T

1.Setthegapbetweenthepapergateandthevacuumrollerto

approximatelytwicethethicknessofthestocktobecreased.

(Seepage17)

2.Placethestocktobecreasedontotheloadingtableagainstthe

fixedsidelay.(Seepage17)

3.Releasetheclampsontheadjustablesidelayandslideuptothe

paperstackallowingagapofapproximately0.5mm(1/64inch)

betweenthepaperandthesidelay.(Seepage17)

4.Placethebackstopontotheadjustablesidelayandslideupto

thepaperstack,alsoallowingagap(asstatedintheabovestep)

beforeclamping.(Seepage19)

5.Nowfollowthestepbystepinstructionsshownonpage9.

o‘SetbyPosition’seeinstructionsonpage14.

Page8

CREASING/FOLDING

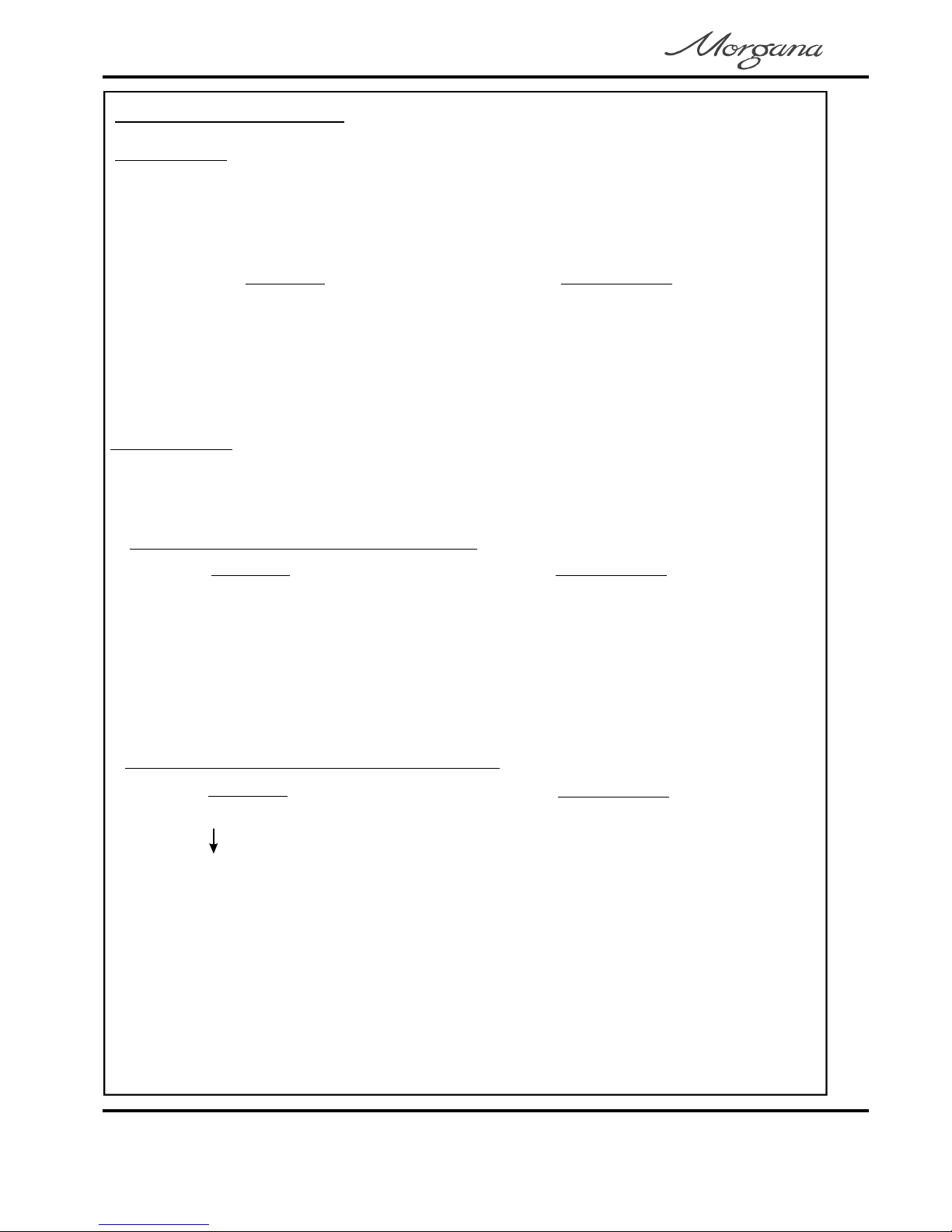

Step1

Step4

SETFOLD&CREASE

(’on’or‘off’)

Mid-Posn.

Step3

SETMACHINETO‘SETBYFOLD’

(’SEtFoLd’or‘SEtPos’)

SETPAPERLENGTH

Step8

Step9

Step10

Step6

Step5

SETFOLDTYPE

Step7

QuickStartGuide

TurntheEmergencyStopbuttonclockwise

toswitchthepoweron.

SettheSetUpswitchtoitsMid-position.

TurntheSettingDialclockwiseuntilthe

displayreads‘SEtFoLd’or‘SEtPos’,flick

theSetUpswitchupwardstochangefrom

onetotheother.

TurntheSettingDialanti-clockwiseuntilthe

displayreads‘CrEES’or‘FoLd’,flicktheSet

Upswitchupwardstoselect‘on’or‘oF’for

eachasrequired.

TurntheSettingDialanti-clockwiseto

selecttheMaindisplay,flicktheSetUp

switchdown,pressthepushbuttonandturn

theSettingDial.

FlicktheSetUpswitchuptoitsMidposition

SwitchtheSystemswitchon.

SwitchtheCompressorswitchon.

SwitchtheFeedswitchontobeginfeeding

sheets

Step2

OPERATION

INSTRUCTIONS

SelectTypIcal

MainDisplay

LcF10 tYPEL

Typical

Display

ToChangeFoldType

LEn100.0

Typical

Display

ToChangePaperLength

TurntheSettingDialclockwisetoselect

‘LEn’,pressthepushbuttonandturnthe

SettingDialtosetthepaperlengthin10mm

or0.1mmincrements.

Page9SYSTEM

Digifold

AccessingMenus.

MainMenu.

1.Themainsswitchonthemachinemustbeoff.

2.Setthetoitsmidpositionandthenturnthemainsswitchon.

3.Thefunctionscanthenbeaccessedbyturningthe

clockwiseoranti-clockwiseasshown.

Set-upSwitch

MainMenuSettingDial

CrEESon/oF=creaseonoroff

FoLdon/oF=foldonoroff

dELrYon/oF=deliveryonoroff

SEtPoS/FoLd=setbypositionorsetbyfold

bAt=batch

rG.00.00=rollergap

Sub-menus.

Set-upswitch

SettingDial

Toaccessthesub-menusflickthetothedownpositionandturnthe

clockwiseoranti-clockwise.

1Cr=creaseposition1

9Cr=creaseposition9

F1=fold1position

F2=fold2position

rPoS=deliveryrollerposition

Shin=shingle(amountdeliverywheelturns)

rESEt=reset

Sub-MenuinSetbymode(setbyposition).PoS

tYPEL=typeoffoldi.e.L=letterfold

Len100=paperlength

PAPEr3=typeofpaper(0=light3=heavy)

Cr10.0=crease1position

rPoS150=deliveryrollerposition

Shin41=shingle(amountdeliverywheelturns)

Cr20.0=crease2position

Sub-MenuinSetbymode(setbyfold)FoLd

F10.0=fold1position

F20.0=fold2position

Clockwise

Anti-clockwise

Clockwise

Anti-clockwise

Clockwise Anti-clockwise

OperatingtheDigifold

Page10

CREASING/FOLDING

F_cLron/oF=foldbladeclearofpapertoreducethepossibilityofmarkingor

scratchingsensitivepaper,onoroff

Page11SYSTEM

OperatingtheDigifold

Digifold

SETBYFOLD

1.TurntheEmergencyStopbuttonclockwisetoswitchthepoweron,andselectthe

maindisplayscreen.

2.SettheSetUpswitchtoitsMid-position.

3.TurntheSettingDialclockwiseuntildisplayreads‘SEtFoLd’or‘SEtPos’,flickthe

SetUpswitchupwardstochangefromonetotheother.(select

4.TurntheSettingDialanti-clockwiseuntilthedisplayreads‘CrEES’or‘FoLd’,flickthe

SetUpswitchupwardstoselect‘on’or‘oF’foreachasrequired.

5.TurntheSettingDialanti-clockwisetoselectthemaindisplay,flicktheSetUp

switchdown,pressandholddownthepushbuttonPB1andturn theSettingDialto

selectfoldtypei.e.hCGetc.ReleasepushbuttonPb1.

6.TurntheSettingDialclockwisetoselectpaperlength‘LEn’.

7.HolddownPB1orPB2,andturntheSettingDialclockwisetoadjustthepaper

lengthin10.0mmor0.1mmincrements.ReleasePB1orPB2.

8.TurntheSettingDialclockwisetoselectpapertype‘PAPEr’,i.e.stiffnessofpaper,

notnecessarilythepaperthickness.

9.HolddownPB1andturntheSettingDialtoadjustthepapertype.ReleasePB1.

i.e.PAPEr0isforlighteststock

PAPEr1isforlightstockof120gsmupwards

PAPEr2isforheavystockof180gsmupwards

PAPEr3isforheavieststockof200gsmupwards

‘SEtFoLd’)

10.SettheDeliveryConveyorSystemasdescribedonpage20.

11.AdjusttheBatchCountasdescribedonpage21,ifrequired.

12.Theprogramsettingscannowbestored,ifrequired,asdescribedonpage22.

NOTE: Thesepapertypesareaguideonly,allfoursettingsshouldbetried

beforeadjustingthecreaseorfoldpositions.

LcF0

foldtype

L=letter

creaseon

foldon

count

OperatingtheDigifold

TypicalmaindisplayscreenSetbyFold

Page12

CREASING/FOLDING

13.RunthejobbyswitchingtheSystemandCompressorswitcheson,then

switchtheFeedswitchon.

14.Viewtheresults,the‘microadjust’functioncanbeusedtoadjustpositions.

15.To‘microadjust’thecreaseposition,turntheSettingDialclockwiseuntilCr1is

displayed.Thiswillbethecalculatedlengthofthecreaseposition.

PressandholdPB1andthedisplayshows0.0

To‘microadjust’,holddownPB1andturntheSettingDialtoadjustineitherdirection

ie+3.1mmto-3.1mmMax.

ReleasePB1.

16.To‘microadjust’thefoldposition,turntheSettingDialclockwiseuntilF1isdisplayed.

Thiswillbethecalculatedlengthofthefoldposition.

PressandholdPB1andthedisplayshows0.0

ToadjustholddownPB1andturntheSettingDialtoadjustineitherdirection

ie+3.1mmto-3.1mmMax.

ReleasePB1.

NOTES:Ifacreasepositionis‘microadjusted’,thefoldwillmovewithit.

Ifafoldpositionis‘microadjusted’,thenonlythefoldwillmove.

‘Microadjust’afoldonlyifthefoldappearstobegivinganoutofsquareresult

orcrackingappears.

Thefoldisprobablytooclosetothecenterofthecreaseandwillbetryingto

foldfromonesideofthecreasetotheoppositesideofthecrease(seepage14

forexplanation).

OperatingtheDigifold

Page13SYSTEM

Digifold

OperatingtheDigifold

SETBYPOSITION

IMPORTANTNOTES.

1.Ifthefoldistoonear,oronthecenterlineofthecrease;thefoldwilltrytofold

diagonallyacrossthecreaseprofileandpullthefoldoutofsquaretothepaper.

Thebestfoldsquarenessisachievedwhenthefoldisonthecenterlineofthe

crease,itshouldbetoonesideofthecreasecenterlineasshownbelow.

ThusforacreasesettingofCr1=100forexample,thefoldshouldbesettoafigure

slightlysmallerorgreaterthan100.

2.Whenusingalldimensionsarefromtheleadingedgeofthepaper

asshownintheexampleonpage16.

not

SetByPosition,

centerlineofcrease

idealfoldline

idealfoldline

TypicalmaindisplayscreenSetbyPosition

2cF0

creases

creaseon

foldon

countnumberof

1.TurntheEmergencyStopbuttonclockwisetoswitchthepoweron,andselectthe

maindisplayscreen.

2.SettheSetUpswitchtoitsMid-position.

3.TurntheSettingDialclockwiseuntildisplayreads‘SEtFoLd’or‘SEtPos’,flickthe

SetUpswitchupwardstochangefromonetotheother.(select‘SEtPos’)

4.TurntheSettingDialanti-clockwiseuntilthedisplayreads‘CrEES’or‘FoLd’,flickthe

SetUpswitchupwardstoselect‘on’or‘oF’foreachasrequired.

5.TurntheSettingDialanti-clockwiseuntilthemaindisplayscreenisdisplayedand

switchdowntheSet-upswitch

Page14

CREASING/FOLDING

OperatingtheDigifold

6.TurntheSettingDialclockwisetoselect

7.HolddownPB1orPB2andturntheSettingDialtoadjustthecreasepositionin

10.0mmor0.1mmincrements.ReleasePB1orPB2.

(thiscanbedoneonallfurthercreasepositions)

11.SettheDeliveryConveyorSystemasdescribedonpage20.

12.AdjusttheBatchCountasdescribedonpage21,ifrequired.

13.Theprogramsettingscannowbestored,ifrequired,asdescribedonpage22.

14.RunthejobbyswitchingtheSystemandCompressorswitcheson,then

switchtheFeedswitchon.

to0.5forPAPEr

type1,1.0forPAPErtype2and1.5forPAPErtype3.

‘1cr’

IfthefoldoptionF2isnotrequiredforthejobbeingsetup,itmustbesetto‘0’

F1

8.TurntheSettingDialclockwisetoetc.(thereare9creasepositionsintotal)

Note:-thecreasepositionsincreaseupwards.(i.e.mustbelessthan

,mustbelessthanetc)

9.ContinueturningtheSettingDialclockwiseto.

10.HolddownPB1orPB2andturntheSettingDialtoadjustthefoldpositionin10.0mm

or0.1mmincrements.ReleasePB1orPB2andturntheSettingDialclockwise.

isthelastfoldposition.

Note:-thefoldpositionsmaybeinanyorder.(i.e.canbelargerthan)

Oncethehasbeenselected,ifreturnedtothedefault

lengthof100willbefoundandanyprevioussettingswillbe lostunlessstored.

If“foldoff”isselectedthenbothkniveswillgotothedoubledeflectsettingswhich

aredeterminedbythepapertypesetting.

Ifin“setbyfold”anddoingaHalffoldthenthe1stknifewillbesettothedeflect

positionwhichisdeterminedbythepapertypesetting.

Whenusingifonlyonefoldisrequired,setthisonand

setat0.0.Iftheleadingedgeofthesheetbucklesup,adjust

‘2cr’

‘1cr’

‘2cr’‘2cr’‘3cr’

Ifanyofthenineavailablecreaseoptions(’1cr’to‘9cr’)arenotrequiredfor

thejobbeingsetup,theymustbesetto‘0’

‘F1’

‘F2’

‘F1’‘F2’

SetbyPositionSetbyFold

SetbyPositionalwaysF2

F1

must

NOTES:-

Deflectknifeposition.

Page15SYSTEM

Digifold

PaperLength=350mm

FeedDirection

LeadingEdge

Cr1 Cr2 Cr3

F1

F2

Cr1=97.0mm

Cr2=179.0mm

Cr3=260.0mm

F1=179.0mm

F2=260mm

Alldimensionsarefromtheleadingedgeofthepaper

ExampleofSetbyPosition.

Cr2

F1

9mm

FirstFold

SecondFold

LeadingEdge

Cr3

F2

=179.0

=260.0

FinishedDocument

9mm

LeadingEdge

9mm

LeadingEdge

SETTINGS

OperatingtheDigifold

Page16

CREASING/FOLDING

OperatingtheDigifold

AdjustingthePaperGate

Thestandardsettingforhorizontaladjustmentofthepapergateis6.5mm(1/4")away

fromthemountingblock.TurndiscJtomakethisadjustment.Thissettingisonlyintended

asaguide,forinstance,sheetswithanupwardcurlwillrequirethissettingtobe

increased.SettheheightofthePaperGatetoapproximatelytwothicknessesofpaper,by

turningknobK.Anexcessivegapisamostlikelycauseofdoublesheetfeeding.

J

K

6.5mm(1/4" )

T WO T HICKNESS E S

OF PAPER

WAR NIN G.

DO NOT AD JUS T T HE

PA P E R GAT E WHILE THE

MA CHINE IS RUNNING OR

T HE SUCT I ON DRUM MAY

BECOME DA MAGE D.

Setingthesuctionslot

.

t

SettingtheAdjustableSideLay

Thesuctionslotislocatedinsidethevacuumrollerandcanbeadjustedbyreleasingand

movingthesuctionknobhorizontallyineitherdirectiontotherequiredposition.

Forlightstockssettheknobtotheleftandforheavierstockssettheknobtotheright

Placethepaperstackontotheloadingtableandslideuptothefixedsidelayandpaper

gate.Releasetheclampslocatedateachendofthesidelayandslideuptowardsthe

paperstackasshowninFIG16.1.Allowagapofapproximately0.5mm(1/64inch)between

thepaperandthesidelay.

Adjustable

SideLay

Page17SYSTEM

Digifold

OperatingtheDigifold

SettingtheBack-Stop

SettingtheAirDistribution

SettingtheAirSeparationPressure

Settingthepositionsofdrivewheelsandhubs

Placetheback-stopontotheadjustablesidelayandslideuptowardsthepaperstack

allowingagap(asspecifiedintheabovestep)beforeclamping.Whentheextensiontable

isusedforfeedinglongersheets,removeclamptypebackstopandusethemagnetic

typebackstopasshowninfig.18.2.

Dependingonthelengthofthesheettobecreased,theairdistributionknobcanbe

rotatedtovariouspositionsinordertosupplyairtodifferentports.Position1is

recommendedformostsheetsizes.However,abetterresultmaybeobtainedbyusing

thebelowsettingsorbyexperimentation.

1-ForA5sheetsor8incheslong,port1open.

2-ForA4sheetsor11incheslong,frontportandport2open.

3-ForA3sheetsor17incheslong,frontportandport3open.

0-Forlongersheetsinordertosupplyairtothecentreofthestack,port

2open

Tocontroltheamountofairsuppliedtotheports,theairseparationknobcanberotated

clockwisetodecreasethepressureoranti-clockwisetoincreasethepressure..

Itisimportantthatthedrivewheelsanddrivehubsontherollershaftsarearrangedevenly

acrossthewidthofthemediabeingcreased.Thisisdonetoensurethatthemediais

accuratelydrivenandsupportedthroughtherollers.

Thedrivewheelsandhubsarefixedtotherollersbymeansofagrubscrew.Tolocatethis

grubscrewtherollerscanberotatedbyoperatingthemotormanually.

Position

DONOTROTATETHEDRIVEROLLERSBYHAND.

Page18

CREASING/FOLDING

OperatingtheDigifold

Tooperatethemotorsmanually,switchthemachine‘on’attheEmergencyStopswitch.

WhilstholdingdownPushButton1,flicktheSet-upswitchto‘setup’.

ThedisplaywillnowreadPresstheSystemswitchto‘on’andusePushButton

1(forward)andPushButton2(reverse)tomanuallyrotatetherollersinshortpulses.

Rotatetherollersuntilthegrubscrewislocated.Lifttheexitguardandthemachinewill

switch‘off’automatically.Loosenthedrivewheelsandhubsbyusinga2mmallenkey.

ArrangethedrivewheelsandhubsasshowninFIG18.1.Inordertoavoidmarkingon

sometypesofmediaensureagapbetweenthedrivewheelsanddrivehubs.

‘hAndLE’.

Settingtheextensiontable

Theextensiontablecanbefixedtothemachineinordertofeedthroughlongersheets.

Thetablecanbesupportedbythetwofixingscrewsasshownonpage4.

ThebackstopcanbeusedtosupportthepaperstackasshowninFIG18.2below.

Theotherbackstopsuppliedwiththemachinecanbeusedasatoolholderasshownin

FIG18.3below.

Page19SYSTEM

Digifold

OperatingtheDigifold

SettingtheDeliveryConveyorSystem.

WARNING:-

TheDigifoldwillstartifthedeliveryunitisnotfittedontothemachine.not

Turningthedeliverysystem‘on’or‘off’

AdjustingtheRollerPositionandShingleLength.(SeeFIG19.1)

1.SettheSetUpswitchtoitsmid-position.

2.TurntheSettingDialuntilthedisplayreads‘dELrY’onoroff.

3.FlicktheSetUpswitchupwardstotogglebetween‘on’and‘off’.

Ifthedeliveryisturnedofftherollerwillfeedtothefarendofthebeltconveyorandpark

thereuntilturnedonagain.

Ifthedeliveryisturnedonwhenusingthe‘SetbyFold’modeofoperation;theRoller

Position(rPoS)andShingleLength(Shin)areautomaticallyset,relativetothepaper

lengthandtypeoffoldselected.

1.FlicktheSetUpswitchdown.

2.TurntheSettingDialanti-clockwiseto‘rPoS’(rollerposition),or

‘Shin’(shinglelength)asrequired.

3.PressandholdpushbuttonPB1andturntheSettingDial,thenumbers

displayedarepreselectedlengthsinmillimeters(toreducesettingtimes).

4.Whentheoptimumsettingsfor‘rPoS’and‘Shin’areachievedtheycanbe

storedwiththejob(seeStoringProgramsonpage22).

Whenusingthe‘SetbyPosition’modeofoperation;theRollerPosition(rPoS)andShingle

Length(Shin)mustbeadjustedmanuallytosuitthejob,asdescribedbelow.

‘Shin’

(ShingleLength)

‘rPoS’

(RollerPosition)

FIG19.1

Page20

CREASING/FOLDING

OperatingtheDigifold

AdjustingtheBatchCount

TheBatchCountercontrolsthefeedofthemachine.

IfforexampletheBatchCountissetto10;themachinewillfeed10sheetsofpaper,pause

forapproximately5seconds,theconveyorbeltwillfeedthe10sheetsforward(toallowthe

removalofthesheetsfromtheconveyor)andthenfeedthenext10sheetsofpaper.

Thebatchcountissetasfollows:-

1.SettheSetUpswitchtoitsmid-position.

2.TurntheSettingDialuntilthedisplayreads‘bAt’.

3.PressandholdpushbuttonPB1,andturntheSettingDialtosetthebatch

quantityrequired.(thebatchquantitychangesinmultiplesof10)

Beware, ifpushbuttonPB1isnothelddown,thedisplaywillregisterthe

adjustmenttothebatchquantitybutwillnotchangewithintheprogram.

4.TheBatchCountcanbestoredwiththejobifrequired(seeStoringPrograms

onpage22)

TheRollerGapadjuststhegapbetweenthelargefoldrollers,(seeFIG20.1).

TheRollerGapmayrequireadjustmentifthickpaperisbeingfolded,orifcrackingofthe

printisnoticeable.

TheRollerGapisadjustedasfollows:-

1.SettheSetUpswitchtoitsmid-position.

2.TurntheSettingDialuntilthedisplayreads‘rG0000’.

3.TheRollerGapsareadjustedbyturningthe‘FoldGap1’or‘FoldGap2’knobs

ontopofthefolderunit.(theRollerGapchangesinincrementsof0.05mm)

NOTE.

AdjustingtheRollerGap

RollerGap2

RollerGap1

INFEED

FIG20.1

Page21SYSTEM

Digifold

OperatingtheDigifold

StoringPrograms

ReadingStoredPrograms

ClearingStoredPrograms

Amaximumof6programs,ofcrease/foldsettings,canbestoredinthemachine.

Whenthecrease/foldsettingshavebeencorrectlyentered,theprogramcanbe

storedasfollows:-

1.FlicktheSetUpswitchdownandthenbackuptoitsmid-position,thedisplay

reads

2.TurntheSettingDialineitherdirectiontocyclethroughthe6memoryaddresses

available.

3.Tostoreaprogramtothedisplayedaddress,pressthepushbuttonPB4.

Thedisplayreads

‘StorE1’

‘StorEd’

HolddownpushbuttonPB4andturntheSettingdialineitherdirectiontocyclethrough

thememoryaddresses.Whenanyoneofthe6addressesaredisplayedreleasePB4to

viewthestoredprogramatthatmemoryaddress.

Atypicalprogramwillshowseepage14forexplanation.

Tovieworeditanyofthecreasesorfoldswithintheprogram,refertosteps4.to9.on

the‘SetByPosition’instructionsonpages14and15.

Whilstviewinganyofthestoredprograms,settheSetUpswitchdownandturnthe

SettingDialclockwiseuntilthedisplayreads

PresspushbuttonPB4toclearthestoredprogram.

‘rESEt’.

3cF100

Page22

CREASING/FOLDING

OperatingtheDigifold

Inordertofeedheavystock,verysmallorverylargesheets,embossedoreven

irregularshapedsheets,itmayberequiredtooperatethemachinemanually.

Themachinecanbeprogrammedandsetupinexactlythesamewayasexplained

whenoperatingthemachineautomatically.However,whensettingupthemachinethe

papergatemustberaisedtoitshighestpositionforthesheetstobefedfreely.

Operatingthemachinemanuallywillalsorequirethesuctionlengthtobecontinuousin

ordertoaccommodatevarioustypesofstock.Therefore,thesuctionlengthswitch

mustbepositionedat‘III’.

ThemachinecannowbestartedbyactivatingtheSystemswitchto‘on’.

FlicktheFeedswitchto‘on’andbegintoslidethe

sheetsindividuallythroughthepapergateuntiltheyaredrivenbythedrivebelts.

Tostopfeedingthesheets,flicktheFeedswitchto‘off’andthentheSystemswitchto

‘Off’.

FeedingSheetsManually

Donot

activatetheCompressorswitch.

Page23SYSTEM

Digifold

ThedeliveryunitontheDigifoldisusedtocatchthesheetsoncetheyhavebeen

creased,orfolded.

1.Hookthedeliveryunitontotheshaftinthepositionsshownbelow,beingcarefulto

alignthematingconnectors.

2.LocatetheSupportHoopintothechannelontheundersideofthedeliveryunit.

WARNING:-

TheDigifoldwillstartifthedeliveryunitisnotfittedontothemachine.not

AssemblethedeliveryunitasshowninFIG23.1.

TheDeliveryUnit

FIG23.1

DeliveryUnit

LocationHooks

HookstobeLocatedontoshaft

inthesepositions

SupportHoop

Connector

Page24

CREASING/FOLDING

Adjustingthebladepressure(nopaperrequired)

1.TurntheEmergencyStopbuttonclockwisetoswitchthemachine‘on’.

2.Activatethesystemswitchandthemotorswillbegintooperate.

3.Flickthe‘Feed’switchto‘on’andthenbackto‘off’toensurethatthelowerblade/

anvilisatitsbottomposition.

4.PressPushButton3,themachinewillautomaticallyswitchoffandthelowerblade/

anvilissettoitstoppositionwherethepressurecanbeadjusted.Raisetheexitguard.

5.Usinga6mmallenkey,unlocktheshoulderbolts(labelledwithscaletransfer)

positionedateachendofthecreasingblade.

6.Turntheadjustmentcamtoadjustthebladepressure.Increasingthegradientonthe

scalewillincreasethebladepressure.

7.Ensurethattheshoulderboltsarelockedaftersetting.

Thediagrambelowdemonstratestheadjustmentofbladepressure

Adjustingthebladealignment

Itisextremelyimportantthatthebladeandanvilassemblywithinthecreasingunitis

correctlyaligned.Misalignmentofthebladeoranvilcanleadtodamagedprofilesand

subsequentlypoorqualitycreasingsoitmust,therefore,becorrectedimmediately.

TheBladeAssembly

Page25SYSTEM

Digifold

TheBladeAssembly

Ifthebladesetismisaligned,themediabeingdrivenwillbesubjecttoscoringoreven

tearingatanypointalongthecreaseline.

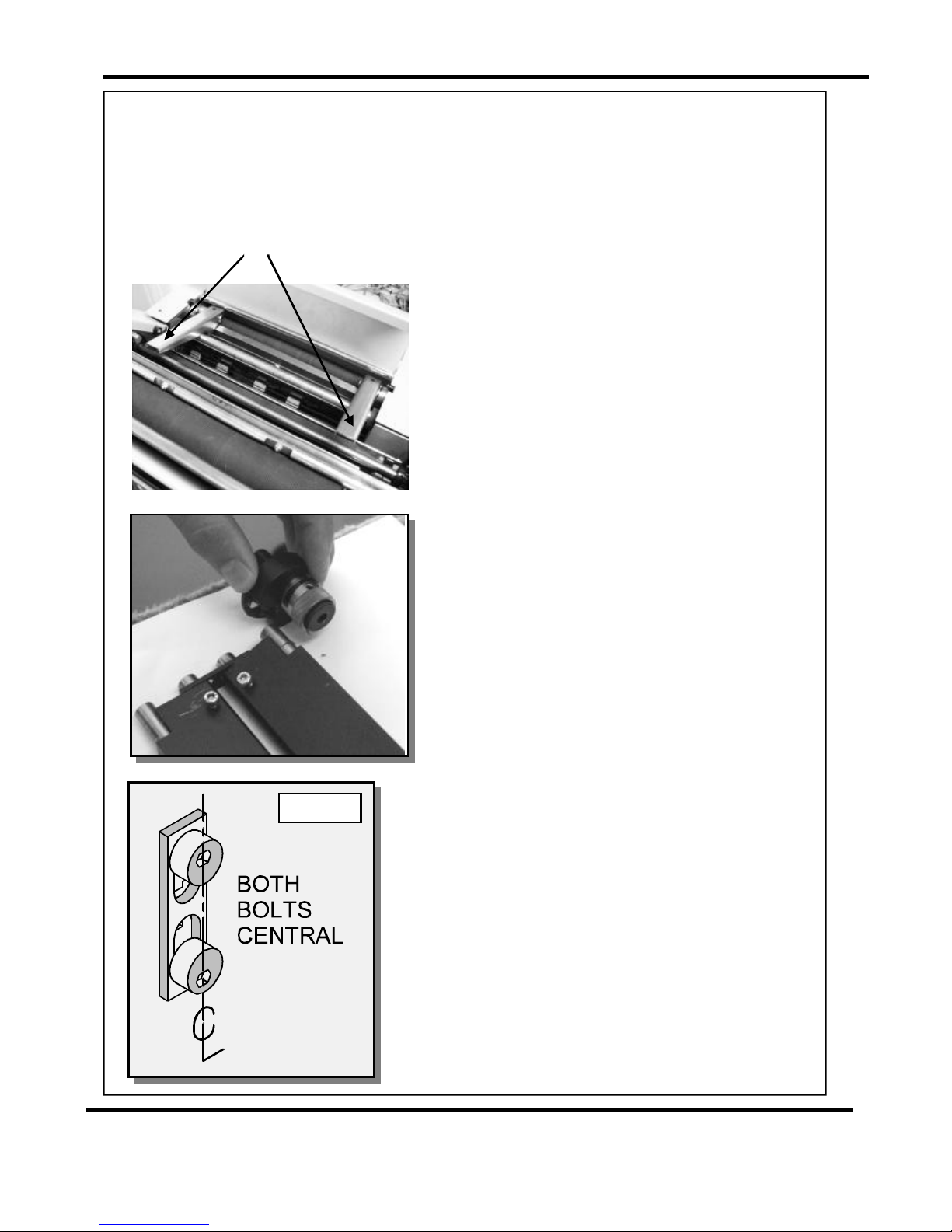

Thesketchbelow

demonstrateshowthebladealignmentcanbecarriedout.

Adjustmentcanbemadeateitherofthebladeoranvil.Thetwoclearanceholes

positionedabovetherollertiltmechanismarethefrontalignment(oneforblade,onefor

anvil).Thetwoholesarerepeatedonthebackofthemachineforthebackalignment.

1.RemovethestackerunitfromtheDigifold.

2.Usinga3mmallenkey,loosenthecapheadtypelockingscrewslocatedonthe

frontfaceatboth endsoftheblade/anvilasshownbelow.

3.Usinga4mmallenkey,locatethetwofrontorbackalignmentscrewsintheside

frameinordertoadjusttheblade/anvil.

4.Theupperscrewofthetwo,willadjusttheupperblade/anvilwhereasthe

lowerscrewwilladjustthelowerblade/anvilbothinverysmallincrements.

5.Inordertoobtaintherequiredposition,adjusteitherthebladeortheanvilbya

smallamountandthenoperatethemachinetotesttheformofthecrease.

Repeattheexerciseuntilcentralisationislocated.

6.Usinga3mmallenkey,lockthecapheadtypescrews(asperstep3)onboththe

upperandlowerblade/anvil.

Pleasenotethattoavoiddamagetothe

bladeset,adjustmentshouldonlybemadeinsmallincrements.

Page26

CREASING/FOLDING

FIG26.1

1.Beforeremovingthebladeassembly,ensurethatthelowerblade/anvilis

at‘topdeadcentre’,ie.PushButton3hasnotbeenpressed.Switchthemachineoff.

2.Removethedeliveryunitandliftthetopguard.

NOT

3.Usinga6mmallenkey,loosenthesocket

headscrewslocatedinsidetheblade

adjustmentcams.Removethescrewsand

thebladeadjustmentcams.

4.Insertthebladeextractortools(70-055-01&

70-055-02)

5.Slidethebladeassemblyoutofthecreasing

unitandlayitonaflatsurface.

6.Slidetheadjustmentlinksawayfromthe

dowelslocatedintheendsoftheblades/

anvilsasshowninthephotograph(left).

7.Placethenewbladesetintoposition.

Checkthattheeccentricshoulderboltson

thelinkplateshavebeenpositionedas

showninfig26.1.

8.(Upperblade/anvilonly)

Slidetheadjustmentlinksontothedowels.

intotheholesintheadjustment

links,asshown.Pushdownwardsonthe

handlesofthebladeextractortoolsto

releasethebladeassemblyfromthepower

links.

9.Slidethenewbladesetintotheslotsofthe

creasingunitasshowninfig.27.1.

Locatethebladeextractortoolsintotheholesin

theadjustmentlinksasshown.Pullthehandles

ofthebladeextractortoolsupwardstoengage

thebladeassemblybackintothepowerlinks.

10.Setthecamgraphicsforbothendsoftheblade/

anviltotheirlowestpointonthescale(ie.When

themarkonthescalereachesthemarkoncam

holder)Fastenthesocketheadscrewsonthe

adjustmentcamsuntiltheyaretight.

ReplacingBladeSets

BladeExtractorTools

Page27SYSTEM

Digifold

ReplacingBladeSets

11.Pushtheexitguarddownandreplacethedeliveryassemblybeforeoperatingthe

machine.

12.Switchthemachineonandtestthecreaseforform.

Intheeventofanydamagedorlostcomponentswithinthebladeassembly,spareskits

areavailableonrequest.However,componentswithinthebladesetcannotbeordered

separatelyi.e.singlebladeoranvil.

Consistingofastandardbladeandanvil,bladebrushes,bladelinksandalignmentbolts.

Ifthepressureandthealignmentofthecreaseisnottoasatisfactorylevel,

seepages25and26toadjustthecreasingline.

StandardBladeset(fittedtoDigifoldasstandard)Partnumber76-213-01

‘Spares’kits

ExtraNarrowBladeset(optional)Partnumber76-213-03

Consistingofaspecialextranarrowanvil,astandardblade,bladebrushes,bladelinks

andalignmentbolts.

Page28

CREASING/FOLDING

Papercreaseoutofsquare

Paperjamming

!

!

!

!

!

Checkthatthesheetsareallsquareandexactlythesamesizebeforeloadingthe

stackontothetable.

Checkthattheadjustablesidelayhasbeencorrectlypositionedie.Nofurtherthan

0.5mmfromthepaperstack.

Checkthatthebladeisaslidefitinthesideplateslots,adjustifnecessary,see

adjustingbladealignment.

Checkthattheleadingedgeofthepaperisnotbeingdamagedbythepapergate.If

thisisoccurring,checkthatthesuctionslotandthepapergatehavebeencorrectly

set.

Checkthatthefirstcrease/foldpositionisnottooclosetotheleadingedgeofthe

paper.Aminimumdistanceof40mmisrecommended.

Paperfoldoutofsquare

Machinewillnotstart

Note:-thebestfoldsquarenessisachievedwhenthefoldisnotonthecenterofthe

crease,buttoonesideortheother.

Checkthatthefoldistoonesideofthecreasecenterline.

Checkthattherollergapisnottootightandsquashingthecrease.

Checkthattherollergapisnottoolargeandallowingthepapertoslide(especially

soonglossypaper).

Checkthattherollersarenotwornononeend.

Ifjammingisoccurringintheoutfeedrollers,openuptherollergap.(Seepage21)

Checkthepowersupplytothemachine.

Checkthattheemergencystopbuttonhasbeenreleased.

Checkthatthetwotopguardsaredown.

Checkthatthedeliveryunitisfitted,andlocatedcorrectly,(themachinewillnotstart

ifthedeliveryunitisnotfitted).

Checkthatthelowerblade/anvilisconnectingtothehomeswitch(mountedbelow

thelowerblade/anvil).

!

!

!

!

!

!

!

!

!

!

TroubleShooting

Page29SYSTEM

Digifold

TroubleShooting

Papernotfeeding

!

!

!

!

Checkthatthepaperstackisnottoohighortooheavyforthefeeder.Theheightof

thepaperstackshouldbedefinedbytheweightandthesizeofthestockbeing

creased.

Ensurethattheadjustablesidelayisnotpressedagainstthepaperstack.However,

iftheclearancebetweentheadjustablesidelayandthepaperstackistoogreat,the

airsupplywillescapeinsteadofblowingthroughthepaperthusmakingitdifficultto

feed.

Checkthattheclearancebetweenthepapergateandthesuctionrollerisnotsettoo

low.

Ondigitalmedia,thefeedingperformancemaybeimprovediftheleadingedgeof

thestackistrimmedbeforeloadingontotheDigifold.

!

!

!

Checkthattheairdistributionhasbeencorrectlyset.

Checkthattheairseparationhasbeensethighenoughtofeedthesheets.

Forheavystocks,verysmallorverylargesheets,embossedorevenirregularstock,

itmaybenecessarytofeedthesheetsmanually-seepage23

Machinenotcounting

! Openthetopandremovethebladeset

(seepages27-28)toaccessthedual

sensorpostlocatedinbetweenthedrive

rollers.Usingasoftbrush,cleanthe

visiblesensorontheendofthepost.

Usethebrushtocleanthesensors

betweenthepostandthebottompaper

guidewhicharenotvisible.

Photograph(left)showsthedualsensor

postcontainingthesensors.

CrackingofthePrintedMaterialalongtheCrease.

Crackingofthematerialalongthecreasemaybecausedbythefollowing:Pressuretooheavyonthetopblade-reducepressure.

Creasetoonarrowforheavystock-changethebladetothestandardbladeset(part

number).

Crackingononeedgecausedbymisalignmentoftheanvilandblade-realignblades

usingcamsatsides(seeFIG26.1onpage27).

!

!

!

76-213-01

Page30

CREASING/FOLDING

TroubleShooting

CrackingofthePrintedMaterialalongtheCrease.(continued)

Papermarkingorscratching.

Setting‘F_cLr’tothe‘on’position.

Nosuction

DisplayWindowReads

!

!

!

!

Whenusingdryinkortonerbasedprintengines,thematerialbefully

acclimatisedforatleast48hoursbeforeputtinganimageontothepaper.

s

must

IMPORTANTNOTE.

Ifthepaperismarkingorscratchingset‘F_cLr’to‘on’,asdescribedbelow.

Thisfunctionisusedtowithdrawthetopfoldbladefromthenipposition,whenpaper

isinthefoldroller.Thisreducesthepossibilityofmarkingorscratchingsensitive

paper.Oncertainfolds,gatetypesforinstance,‘F_cLr’shouldbesetto‘off’because

thetrailingedgeofthepaperwillcatchonthewithdrawnblade.

IfF_cLr’hasbeensetto‘on’,anysubsequentchangetotheprogrammesettingswill

automaticallyreturn‘F_cLr’backtoitsdefaultsettingof‘off’;anditmustthereforebe

etbackto‘on’again.

1.Selectthemaindisplayscreen(seepages11and13toidentifymaindisplay).

2.SettheSetUpswitchtoitsMid-position.

3.TurntheSettingDialclockwiseuntilthedisplayreads‘F_cLr’.

4.FlicktheSetUpswitchupwardstoselect‘on’.

Iftherollersaremarkingthemedia,opentherollergap(seepage21).

Ifthesuctiondrumisnotrotating,checkallofthedrivebeltsforcleanlinessandsplits

(includingthebottomin-feedrollerdrivebelt).

! ‘h’

Ifatanytimeduringthecreasing/foldingprocessthedisplaywindowreads,itis

indicatingthatthelowerblade/anvilhasnotmadecontactwiththeHOMEswitch.

i.e.Bladestillintopposition.Switchthemachineoffandremovethebladeset,

ensurethattheareaisfreefromobstructions.Returnthebladesettothecreasing

unitandswitchthemachineon.Operatethemachineinthenormalsequence,ifthe

lettercontinuestoappearitisadvisedtocontactaServiceEngineerimmediately.

‘h’

’h’

Page31SYSTEM

Digifold

TroubleShooting

!

!

!

!

’Crunch’(PaperJamming)

Intheeventofapaperjamoccurringwhilstthemachineisoperatingthedisplay

windowwillread

Inordertoremovethepapercausingthejam:PushButton1andPushButton2canbeusedtomanuallyoperatethemotor.

PushButton1willdrivepaperforward,inshortpulses.

PushButton2willdrivepaperinreverse,inshortpulses.

PushButton4willcyclethefoldknivesanddrivetherollerforward.

Whenpressed,thepushbuttonwillactivatetherollersforashortmovement.For

continuousmovement,pressandreleasethepushbuttonrepeatedly.

Ifthesheetremainsjammed,checkthatthelower blade/anvilisnotclampingthe

sheet.Ifso,pressPushButton3tolowertheblade/anviltoreleasethejammed

sheet.Whenthepaperjamhasbeenremoved,makesurethefeedswitchisoffand

thenpresstheSetUpswitchuptoclearfromthedisplaywindow.

Whenthepaperjamhasbeen

removed,makesurethattheFeedswitchisoffandthenpresstheSetUpswitchup

toclearfromthedisplaywindow.

Whenthepaperjamhasbeenremoved

makesurethattheFeedswitchisoffandthenpresstheSetUpswitchuptoclear

fromthedisplaywindow.

Whenthepaper

jamhasbeenremoved,makesurethattheFeedswitchisoffandthenpresstheSet

Upswitchuptoclearfromthedisplaywindow.

‘crunch”.

‘crunch’

‘cLiPP’

‘cLiP1’

‘cLiP2’

Note.-Asasafetydevicetooverloading,thefoldkniveswillbeejectedfromtheirdrive/

locationlugs.

usingtworedhandledallenkeys(2.5mmassupplied)

aligntheholesinthebladedrivegears(blackluggedgears)withthebrackets

attachedtothemechanismsideplates,eachside.Thegearsmaybeturnedby

hand.Inserttheallenkeythroughtheslotsinthetopcovertolockthemechanism

andalignthebladedrivepinsbothsideswiththelugsonthegears,withasmall

amountofpressureontherearfaceofthebladeitwillclipintoposition.

IftheFeedswitchisturnedoffwhileapieceofpaperisstillfeeding(buthasnot

reachedthefirstfoldroller),themachinewillstopandthedisplaywindowwillread

.UsePushButtons1,2,and4toremovethepapercausingthejam;as

describedaboveundertheheading.

Ifthemachinestopsandthedisplaywindowreadsthisindicatesthatpaper

hasjammedintherollers.UsePushButtons1,2,and4toremovethepaper

causingthejam;asdescribedaboveundertheheading.Ifthejammed

papercanonlyberemovedbyinchingthepaperforward,thejammedpaperwillbe

foundontheundersideofthedeliveryunit.

Ifthemachinestopsandthedisplaywindowreadsthisindicatesthatpaper

hasjammedintherollers.UsePushButtons1,2,and4toremovethepaper

causingthejam;asdescribedaboveundertheheading.

Toreplacefoldknives.-

‘cLiPP’

‘crunch’

‘cLiP1’

‘crunch’

‘cLiP2’

‘crunch’

‘cLiPP’

’cLiP1’

’cLiP2

Page32

CREASING/FOLDING

Recommendedweeklyoperatormaintenance

TechnicianMaintenance

!

!

!

!

Cleanallsensors

CleaninfeedrollersandoutputdrivehubsusingtheMorganacleaningkit

(Morganacleaningkitpartnumber90-018)

Removeandcleanthebladeassembly

Withthebladeassemblyremoved,cleantheslotsandsurroundingareawithinthe

creasingunit;addasmallamountofgreasetotheslideways.

ItisrecommendedthatyourMorganaDigifoldisfullyservicedatleastonceeverysix

monthsbyafactorytrainedServiceEngineer.

TroubleShooting

Page33SYSTEM

Digifold

DISPATCHKIT

120-95-01

ITEM PART NUMBER QTY DESCRIPTION

1

120-101 1 OPERATORSMANUAL-DIGIFOLD

2 90-018 1 ROLLER CLEANING KIT

3 121-006 1 TILTLEVER

4 613-316 1 POWER CORD CE UK 3Pin

5 617-004 4 GLASSBALL-Ø20

8

9

10 620-004 1 ALLENKEY4mm

11

12 620-028 1 BONDUS L WRENCH 3mm

13 620-033 1 BONDUS L WRENCH 6mm

14 624-018 1 DISPATCH BOX

6

620-007 1 HEXAGONBALLDRIVER2mm

620-026 1 BONDUS L WRENCH 4mm

620-020 HEXAGONBALLDRIVER2.5mm

7

403-01-030-006

409-01-040-004

12 SCREW-SOCKETCAPHEAD-M3x6LG

1 SCREW-SKT.SETFLATPT.-M4x4LG

2

15 70-055-01 1 BLADEEXTRACTIONTOOL-OPSIDE

16 70-055-02 1 BLADEEXTRACTIONTOOL-LAYSIDE

Page34

CREASING/FOLDING

ACCESSORIES....

your dealer and fitted to your

machine using the instructions

supplied, or by reading your

operators manual.

OPTIONS....

....Mayalsobeobtainedand

fittedbyyourdealer.Youshould

not attempttofitoptionsas

specialist tools and knowledge are

required.

....Maybeobtainedfrom

ITEM PART NUMBER DESCRIPTION

1 76-213-03 BLADESET-320Wide-ExtraNarrow

ACCESSORIESANDOPTIONS

Page35SYSTEM

Digifold

RECOMMENDEDSPARES

PARTNO.QUANTITY DESCRIPTION

607-1461TimingBelt-132XL037

607-0401TorqueDisk-White

607-0421TimingBelt160XL

607-0381TwinGripTimingBelt-200DXL

607-0412TimingBelt-110XL037

607-046 2TimingBelt-540XL037

607-047 2TimingBelt-564XL037

606-0281Foot-Black

607-0451MultiBeamCouplerSize13

608-0191ShoulderBolt-AdjustmentCams

609-0111‘O’RingØ20

609-0141‘O’RingØ15

609-0131‘O’RingØ25

613-1371PlungerandSpring

613-2551SolenoidCoil

613-2371Cap-Ø15

613-3651EmergencyStopSwitch

613-3851KnobØ15

609-0221‘O’RingØ32

606-0351Knob-RollerTilt

613-3511MicroSwitch-GuardCircuit

613-1911MicroSwitch-HomeCircuit

652-0111SystemSwitch

681-0071Fuse-3.15A-Time-Delay-(20x5mm)

75-1001SwitchAssembly-Set-up

75-0981SwitchAssembly-Feed

75-1011SwitchAssembly-RotarySettingDial

75-0771ControlPCBAssembly-Digifold

76-0581Anti-StaticBrush-Autocreaser

76-1091PowerLinkBearing

75-0821DisplayPCBAssembly

75-0401StackerSwitchAssembly

76-0421DriveBelt-FeedBed-Ø4Polycord

76-0821Perforator-DriveHubAssembly

76-0831Perforator-DriveWheel

Page36

CREASING/FOLDING

PARTNO.QUANTITY DESCRIPTION

RECOMMENDEDSPARES

124-01-271RollerPotLead

76-203-011InputRollerAssy-Upper

76-203-021InputRollerAssy-Lower

76-2041OutputShaftAssembly

76-2301PaperGuideAssembly-BottomSensor

76-2291PaperJamSensorAssembly

76-2281UpperSensorAssembly

76-213-011BladeSet-320Wide-Standard

93-0211FeedBelt

93-0221DriveBelt-VacuumRoller

94-0281LockPinAssembly-SideLay

95-0171Hose-Vacuum

95-0181Hose-SeperationAir

95-0311Hose-Evacuation

95-0321Hose-Exhaust

95-0201Lens-Display

124-01-011Pot&LeadAssy-GapSet1

124-01-081Pot&LeadAssy-GapSet2

124-01-021KnifePositionSensor

124-01-161ToroidalTransformerAssembly

124-01-171ToroidalTransformerAssembly

125-01-081BlackBox-StepperDriver+DaughterBoard

125-05-011RuntimePCBAssembly

125-12-021StepperDriver+DaughterBoard

126-06-011AccessUnit-1stFold

126-02-011FoldInputRoller

126-03-013FoldRoller-Standard

126-06-031AccessUnit-3rdFold

126-06-041AccessUnit-2ndFold

126-07-011SupportUnit-1stFold

126-07-021SupportUnit-2ndFold

126-07-031SupportUnit-3rdFold

126-12-0111stBladeAssembly

126-12-0212ndBladeAssembly

126-17-011InputRoller-Upper

126-17-041InputRoller-Lower

Page37SYSTEM

Digifold

RECOMMENDEDSPARES

PARTNO.QUANTITY DESCRIPTION

NOTE.....

The items listed above represent parts which are subject to wear, loss, or accidental

damage, and is included for your guidance only.

Section and item numbers refer to the illustrations and tables in this manual.

Replacement of parts fitted to your machine require specialist knowledge and should

therefore be entrusted to your dealer.

128-026-021Belt-PaperTransport

126-0594Link-PaperGuide

126-0532BladeGuide

126-053-022BladeGuide-Long

126-060-011PaperSensor-EdgeDetectRX

126-060-021PaperSensor-EdgeDetectTX

126-060-031PaperSensor-Sync2RX

126-060-041PaperSensor-Sync1RX

126-063-011SensorBar-Sync2TX

126-063-021SensorBar-Sync1TX

Page38

CREASING/FOLDING

MACHINECALIBRATIONHISTORY

Etch

dEtr

FECh

dEtF

gAPF

cEn

Date:-

TotalCount:-

SerialNumber:-

Date:-

TotalCount:-

Date:-

TotalCount:-

Etch

dEtr

FECh

dEtF

gAPF

cEn

Etch

dEtr

FECh

dEtF

gAPF

cEn

Page39SYSTEM

Digifold

Page40

CREASING/FOLDING

Loading...

Loading...