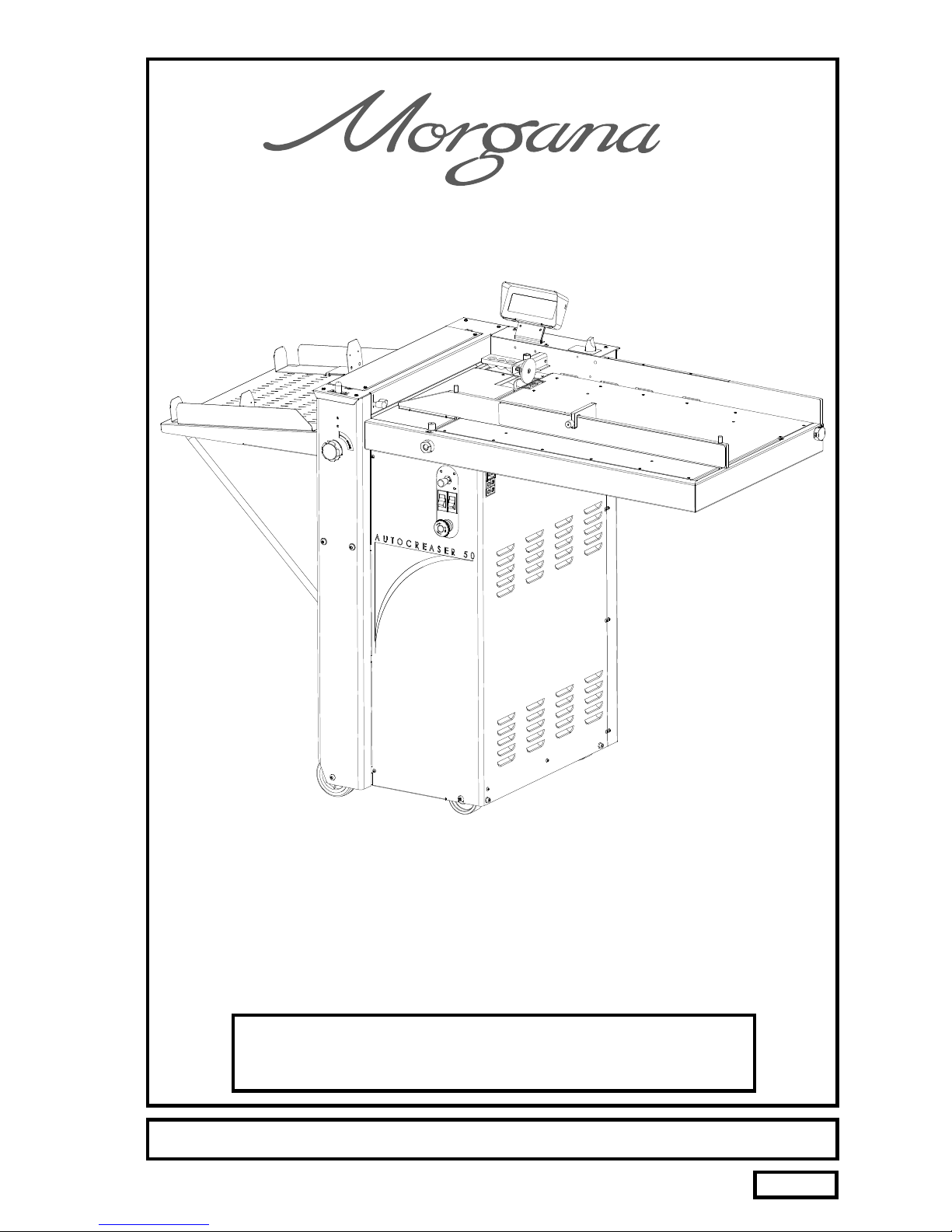

Morgana AutoCreaser 50 Operator's Manual

AutoCreaser 50

CREASING MACHINE

OPERATORS MANUAL

Morgana Systems Limited United Kingdom

Telephone: ( 01908 ) 608888 Facsimile: ( 01908 ) 692399

SERIAL No. 710386LBAD ONWARDS

DOCUMENT

Website: www.morgana.co.uk

ISSUE 7

January

2008

70-069

INDEX

INTRODUCTION

The Morgana Autocreaser 50 PAGE 3

SAFETY Do’s & Don’ts

THE AUTOCREASER 50

Labelled Photograph 6

THE CONTROLS

The control panel 7

Features on the control panel 8

QUICK START GUIDE 9

OPERATING THE AUTOCREASER 50

Setting the machine

Programming the machine

Reading stored programmes 17

Paper jamming 17

THE STACKER ASSEMBL Y

Setting the Stacker unit 18

4

12

16

PERFORATIN G

Equipment, spares 20

Setting the machine 21

THE BLADE ASSEMBLY

Setting the blade pressure 23

Setting the blade alignment 24

REPLACING CREASING BLADE SETS

Installing new blade sets 25

Spares 26

TROUBLE SHOOTING 27

DISPATCH KIT 30

ACCESSORIES & OPTIONS 31

RECOMMENDED SPARES 32

Page 2

CREASING

AutoCreaser 50

The Morgana Autocreaser 50 is a fully automatic suction feeding creasing

system designed for use with both conventional litho and digital printers.

The feed on the Autocreaser 50 can also be manually operated for use with

heavy stock, very small or very large sheets, embossed or even irregular

sheets.

The Autocreaser 50 is capable of creasing sheet sizes to a maximum of

700mm x 500mm (27.5” x 19.7”) and weights in excess of 350gsm.

The minimum sheet size when the machine is used in automatic mode is

140mm x 210mm (5½ “x 8½”).

INTRODUCTION

AutoCreaser 50

Up to sixteen creases can be programmed to a single sheet.

The crease is programmed from the leading edge of the sheet using the

controls on the front panel.

A minimum distance between creases is 0.1mm

The Autocreaser 50 has up to nine available memory addresses for

programmed creasing operations.

The blade and anvil are mechanically controlled over their entire length

and can be adjusted to accommodate various weights of media.

IMPORTANT

The operating environment should be controlled to a temperature between

16° C and 27° C Maximum

SYSTEM

Page 3

Safety Do’s & Don’ts

Safety Do’s & Don’ts

Do - read this operator manual fully before operating the machine.

Do - operate with the designated AC current only. Use an exclusive outlet, as

overloading may cause fire or an electric shock.

Do - install the power cord out of the way to avoid a tripping hazard.

Do - beware of finger traps when replacing roller cassette and fold plates.

Do not - install the machine in an unstable place such that it tilts or shakes.

Do not - unplug the plug or unplug the power cord from the outlet with a wet hand,

this can cause an electric shock.

Do not - unscrew and remove any covers from the machine, as it can cause an

electric shock or injury.

Do not - place receptacles containing liquids on any surface.

Do not - adjust any part of the machine whilst rollers are running

Do not - operate the machine with loose or trailing clothing or loose hair.

Do not - under any circumstances adjust the paper gate when the machine is

switched on.

Page 4

CREASING

AutoCreaser 50

BLANK

PAGE

SYSTEM

Page 5

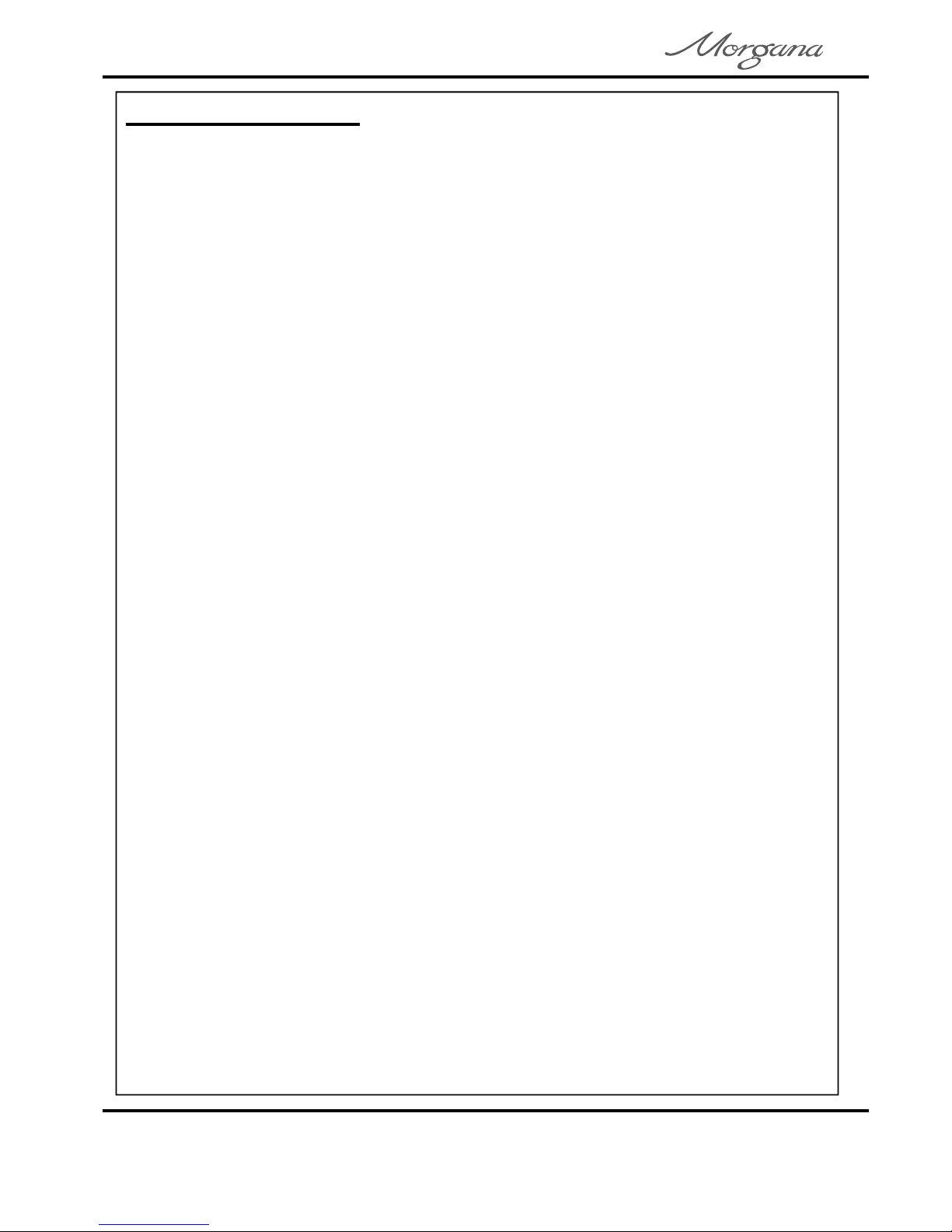

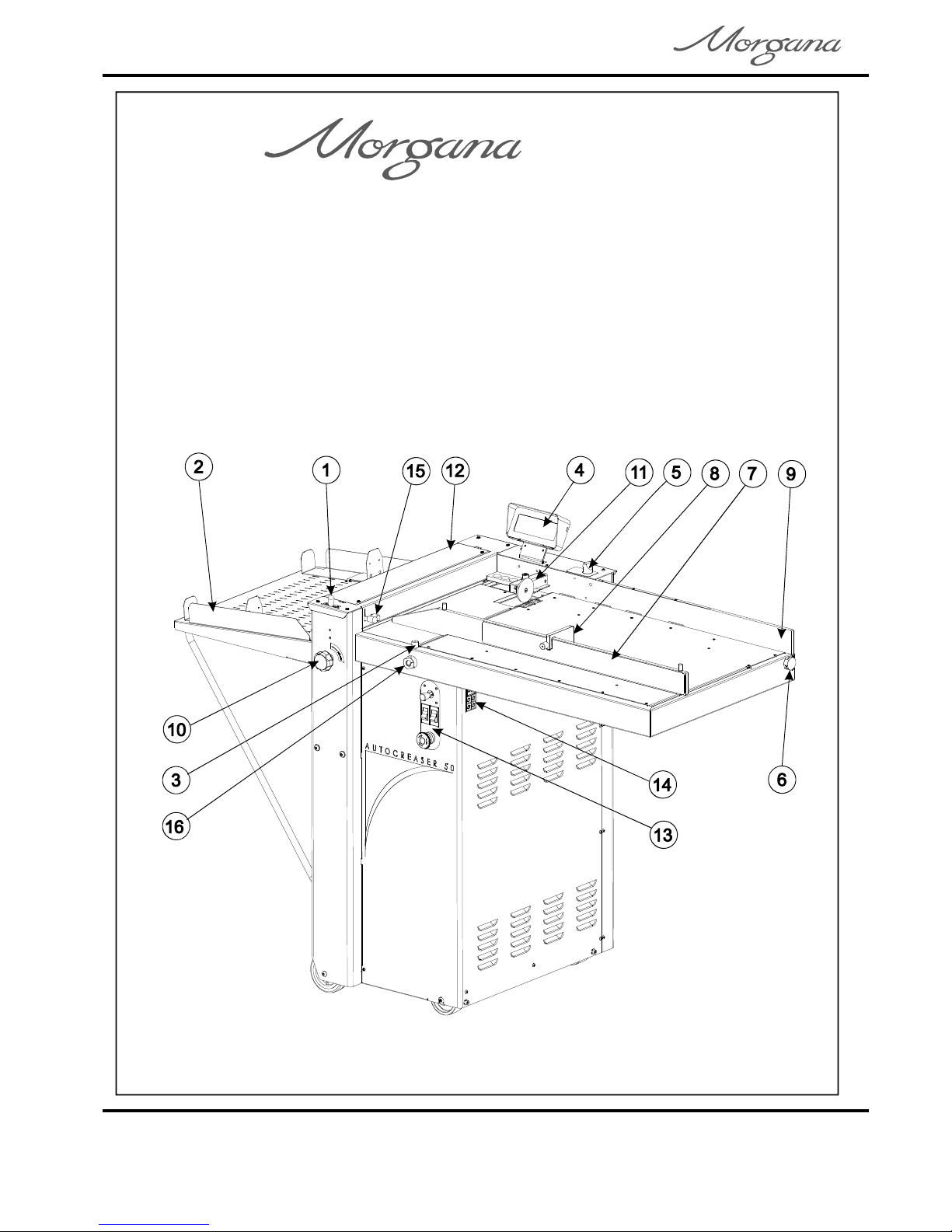

DOCUMENT CREASING MACHINE

Key to photograph below

Roller tilt handle

1

2 Stacker assembly

3

Suction slot knob

4 The display unit

5

Air separation knob

6 Air distribution knob

AUTOCREASER 50

AutoCreaser 50

7 Adjustable side lay

8BackStop

9 Fixed side lay

10 Roller tilt knob

11

Paper Gate

12

Exit Guard

Control Panel

13

14

Fuses

Gap Set Knob and Lever

15

Vacuum Bleed Knob

16

Page 6

CREASING

AutoCreaser 50

The Display Unit and the Switches on the Control Panel allow the

operator to read, edit, create and initiate numerous creasing programs

within the memory.

The Control Panel houses the Selection Switch, Compressor switch,

System switch, and an industry standard Emergency Stop switch which

will stop all power going to the machine when activated.

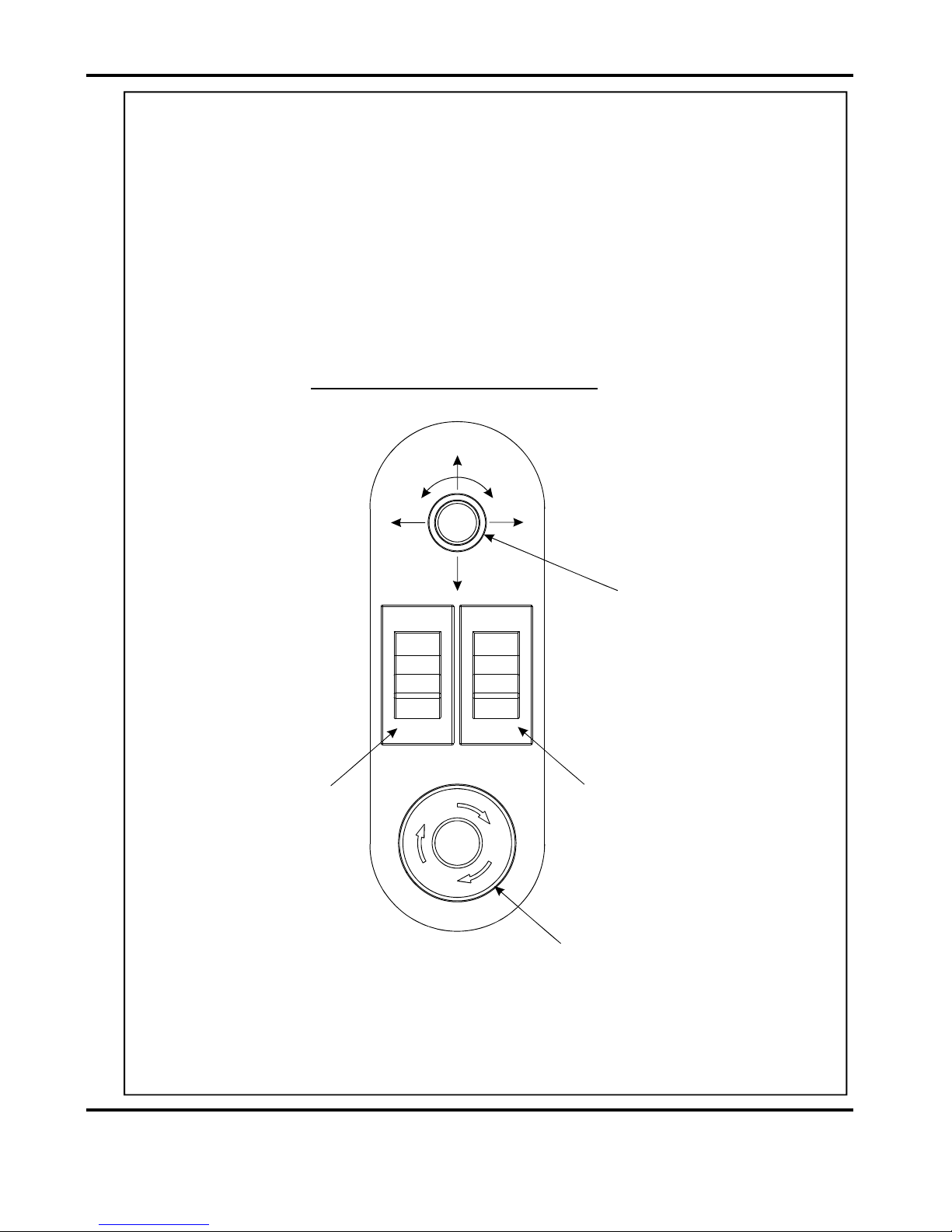

THE CONTROLS

THE CONTROL PANEL

Compressor Switch

Selection Switch

System Switch

Emergency Stop Switch

SYSTEM

Page 7

THE CONTROLS

Features on the Control Panel

Selection Switch

Allows the operator to scroll through stored addresses and programs, increase or

decrease the batch quantity and set a crease position.

System switch

When activated the system switch will operate the motors in order to begin the

creasing sequence.

Compressor switch

Allows the operator to switch off the compressor unit in order to utilise the machine

to manually feed sheets.

Page 8

CREASING

AutoCreaser 50

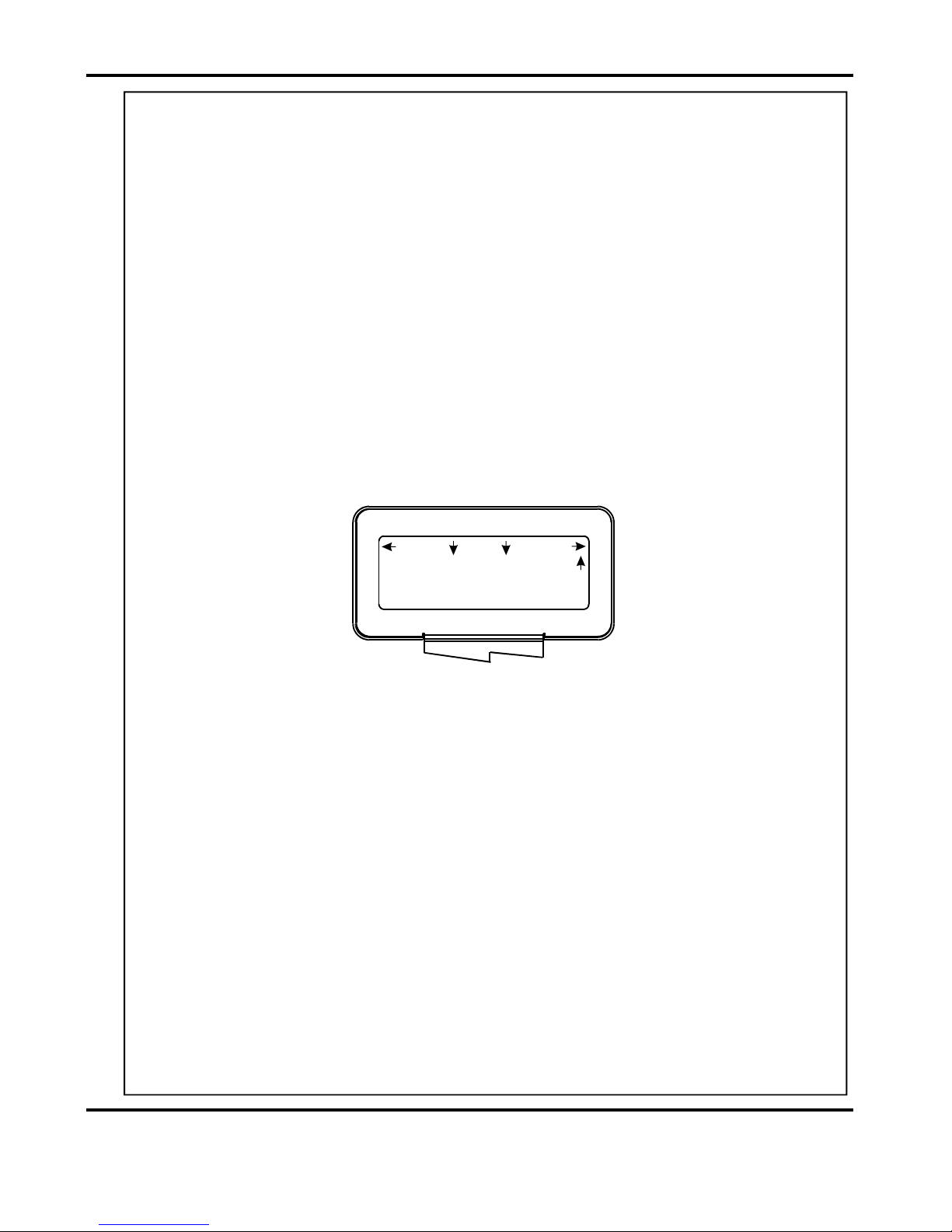

Setting the machine to operate in automatic mode

1. Set the gap between the paper gate and the vacuum roller to

approximately twice the thickness of the stock to be creased.

Place the stock to be creased onto the loading table against the

2.

fixed side lay.

Release the clamps on the adjustable side lay and slide up to the

3.

paper stack allowing a gap of approximately 0.5mm (1/64 inch)

between the paper and the side lay.

4.

Position the backstop and slide it up to the paper stack, also allowing a

gap (as stated in the above step).

5.

Turn the Emergency Stop button clockwise to switch the power on.

The display unit is now illuminated, a typical start up display menu is

shown below.

Quick Start Guide

Tools

Batch Off

2 Creases

NOTE:The arrows on the display denote the direction in which the selection

switch must be moved in order to access the various sub-menus.

Feed

Setup

Zero

Total 20

Program 3

SYSTEM

Page 9

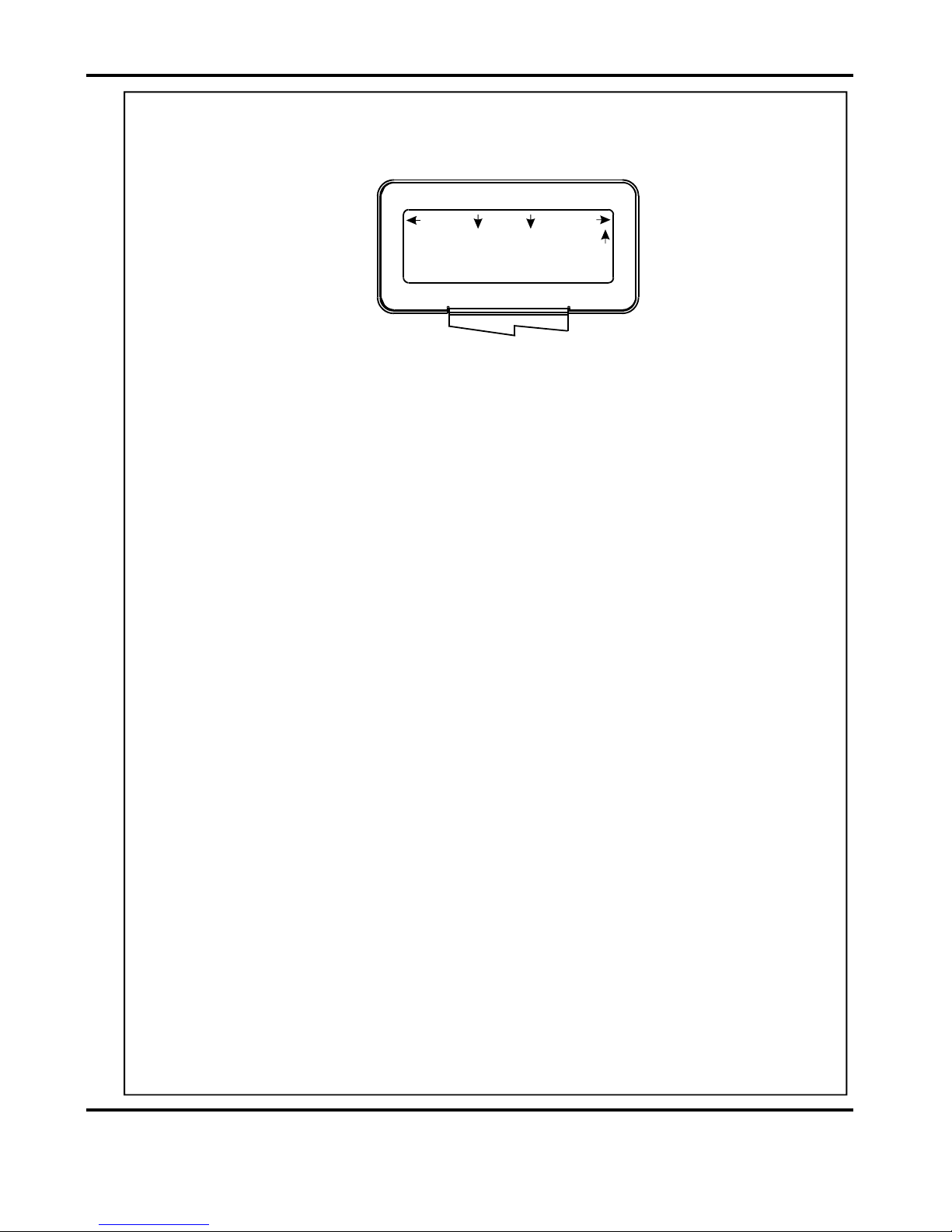

Quick Start Guide

6. Following the arrows on the display unit; move the selection switch to

the right to select (i.e. Setting the crease positions), a typicalSetup

display is shown below .

Set Creases

1st Crease 148.0

2nd Crease 0.0

More

Home

7. Following the arrows on the display unit; move the selection switch down

to set the creases. The 1st Crease is now selected.

Set Creases

Tens Decimals

( 1st Crease 148.0 )

2nd Crease 0.0

8.

Move the Selection Switch to the left to select or to the right toTens

Back

select . The or (whichever has been selected)Decimals Tens Decimals

can then be adjusted by rotating the Selection Switch, (clockwise to

increase or anti-clockwise to decrease).

9. To set the 2nd Crease position move the selection switch down; the 2nd

Crease is selected and can be set as described in step 8. above.

Set Creases

Tens Decimals

( 2nd Crease 000.0 )

3rd Crease 0.0

Back

10. Further creases can be set in this way, up to a maximum of sixteen

creases.

Page 10

CREASING

AutoCreaser 50

11 . When the required creases have been set, move the selection switch up

step by step until the display contains the word , see below.Feed

Quick Start Guide

Tools

Batch Off

2 Creases

12. Press the Compressor Switch down.

13. Press the System Switch down, the display will momentarily read Please

Wait Initiating Feed.and then return to show

14. Move the selection switch down to begin feeding the sheets.

In order to manually feed sheets see instructions on page 17.

Feed

Setup

Zero

Total 20

Program 3

SYSTEM

Page 11

Loading...

Loading...