Morgan MSPro14 Profiler User Manual

Advanced Electrical Materials

DISCLAIMER

Please note that all product, product specifications and data detailed in this brochure are subject to change

without notice to improve reliability, function, design or otherwise. Morgan AM&T B.V. and its affiliates does

not assume any responsibility for the correctness of this information nor for damages consequent to its use.

Statements regarding the suitability of products for certain types of applications are based on knowledge of

typical requirements that are often placed on Morgan products in generic applications

CONTENTS PAGE

Introduction

Recommendations

...................................................................................................................... 1

........................................................................................................... 4

First time Use ..................................................................................................................... 5

Minimum PC requirements: ........................................................................................................................ 5

Registration of software on 1st use ............................................................................................................ 6

Software update procedure ...................................................................................................................... 11

Using the MSPro14 Measuring Box................................................................................ 12

Welcome Screen ........................................................................................................................................ 13

Home Screen .............................................................................................................................................. 14

Settings ..................................................................................................................................................... 15

Date & Time .......................................................................................................................................... 15

Units & Language ................................................................................................................................. 16

Alarms ................................................................................................................................................... 16

Display .................................................................................................................................................. 17

Power Management .............................................................................................................................. 17

Sensor Settings ..................................................................................................................................... 18

Start Measurement ................................................................................................................................... 19

Commutator .......................................................................................................................................... 19

Setting the Sensor ............................................................................................................ 21

Completing one Recording ................................................................................................ 24

Slip-ring ................................................................................................................................................. 31

Setting the Sensor ............................................................................................................ 32

Completing one Recording ................................................................................................ 33

View Data ................................................................................................................................................. 38

Standby Screen .......................................................................................................................................... 40

PC Analysis Software

DASPro14

General ..................................................................................................................................................... 43

User Interface ........................................................................................................................................... 43

Using DASPro14 for the first time ............................................................................................................ 46

Using DASPro14 ...................................................................................................................................... 46

.................................................................................................................................................. 43

.................................................................................................. 43

Adding Datasets.................................................................................................................................... 46

Printing

................................................................................................................................................. 48

Reading and Comparing Values

Adjusting Profiles

Zooming behaviour ............................................................................................................................... 50

Alarms ................................................................................................................................................... 50

Downloading .Mas files ......................................................................................................................... 50

............................................................................................................................... 49

Appendix A: Specifications

Appendix B: Warranty & Repairs

Warranty ...................................................................................................................................................... 52

Repairs & Calibration ................................................................................................................................. 52

........................................................................................................ 49

......................................................................................... 51

............................................................................... 52

INTRODUCTION

The primary object of maintaining or reconditioning a commutator or slip ring (Collector) is to remove those

irregularities which lead to impaired brush efficiency and reduced brush and collector life. Collectors should,

in an ideal world, be smooth and true. A collector that is in bad condition should be either re-ground or

turned.

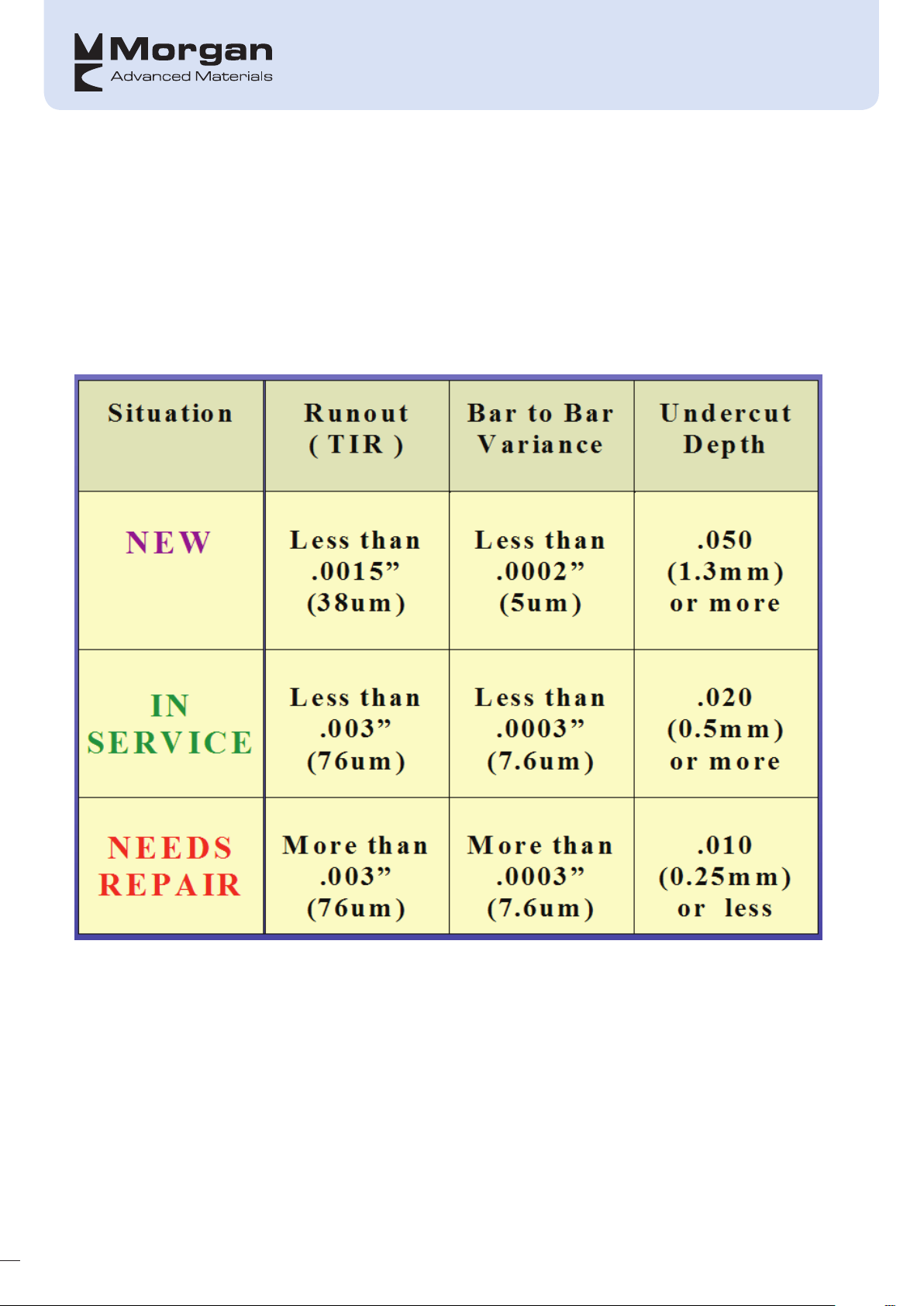

In general, collectors with a Total Indicated Runout (TIR) of 76µm (3 mil) or greater and on a commutator

with a Maximum Bar-to-Bar Height (MBTB) of 7.6 µm (0.3 mil) or greater needs to be re-ground or turned:

Regular use of a profiling device such as the MSPro14 will help to confirm whether there is a problem with

the collector and this should be done at least every six months and if possible every 2 months. Trending this

information will help better plan maintenance schedules.

1

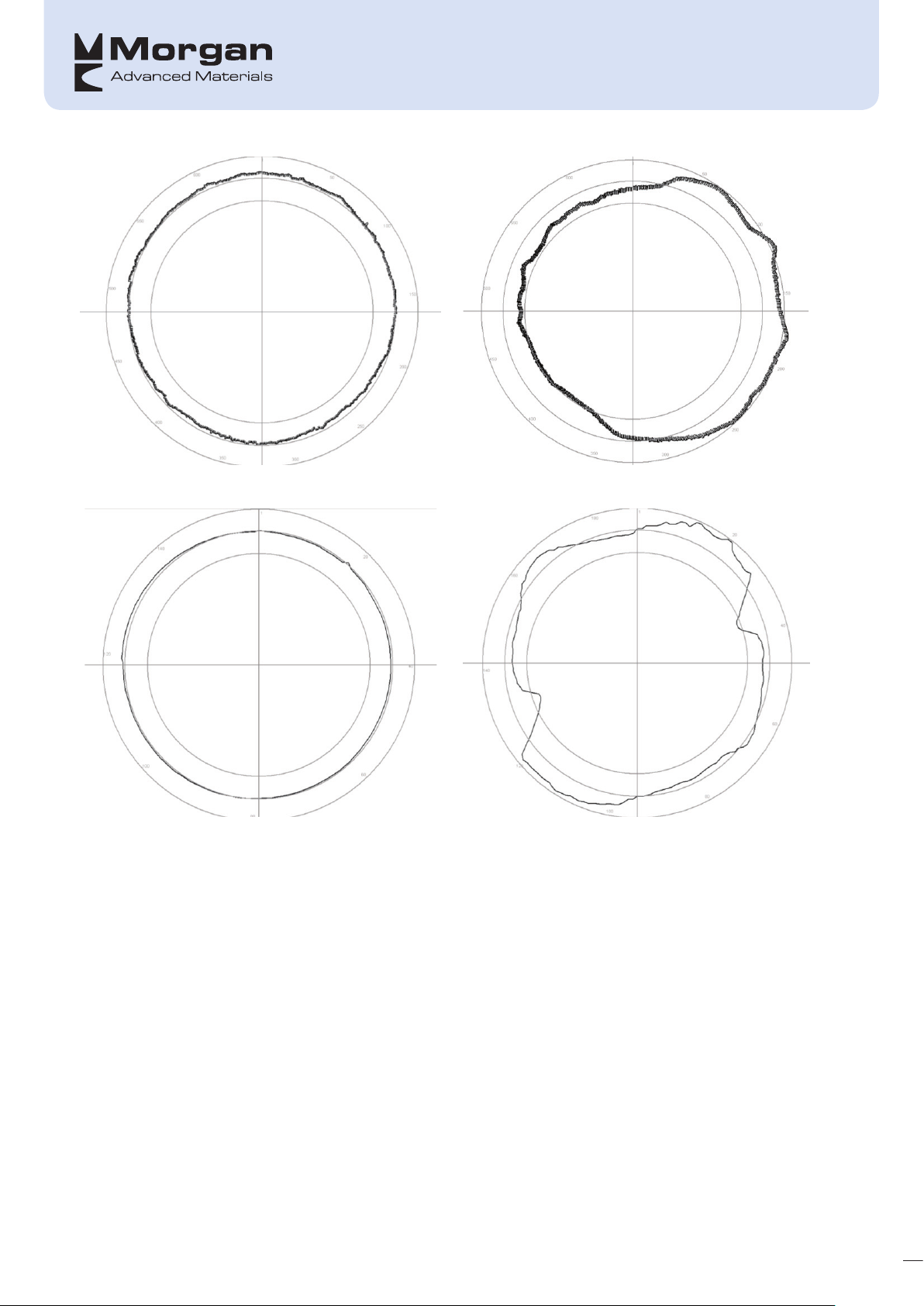

An acceptable slip ring profile

An unacceptable slip ring profile

An acceptable commutator Profile

Therefore congratulations on purchasing the MSPro14 – the new and improved Surface Profiler from Morgan

Advanced Materials. The MSPro14 is used for:

• Collector surface profiling and measures TIR, MBTB as well as collector diameter

• The TIR for collectors is the difference between the minimum height and the maximum height. The TIR is

also referred to as the ‘runout’ or 'out of roundness'.

• The MBTB Height for commutators is the maximum height difference between two adjacent bars. The

MSPro14 can also determine when there are high micas present on Commutators. High Micas occur

when there appears to be no gap between two consecutive bars. High Micas will be indicated as a bar

number in the edit recordings dialog window.

• The MSPro14 takes recordings in what the industry knows as ‘shape’ mode. Shape mode takes readings

as the sensor moves over the collector surface and using these values it is able to generate a shape of

the collector. Shape mode records a large number of samples, thus enabling a profile to be recorded

allowing wear patterns and irregularities to be inspected.

An unacceptable commutator profile

2

• Peak height mode can be selected (in the DASPro14 software) and is where one value per bar is

displayed – this being the peak height of multiple samples taken across the entire bar.

1

2

3

• Collected data can be transferred to a PC where it can be analysed in detail using the DASPro14

Windows based software supplied in the kit.

The MSPro14 also offers:

• A solid easy to mount sensor that can be fitted to a vast range of holder sizes, and is rugged enough to

cope with extreme environments including vibration

• Easy to use responsive industrial colour touch screen

• Optimised sensor head that is not negatively affected by Helically Grooved Slip Rings

• Zero setting light indicators for easy set up

• Previous Morgan supplied profiler measurements (.mas files) can be stored and combined

• Extra extensive memory for storing information and editable on the data acquisition box

• Comes in a robust carrying case including all attachments

4

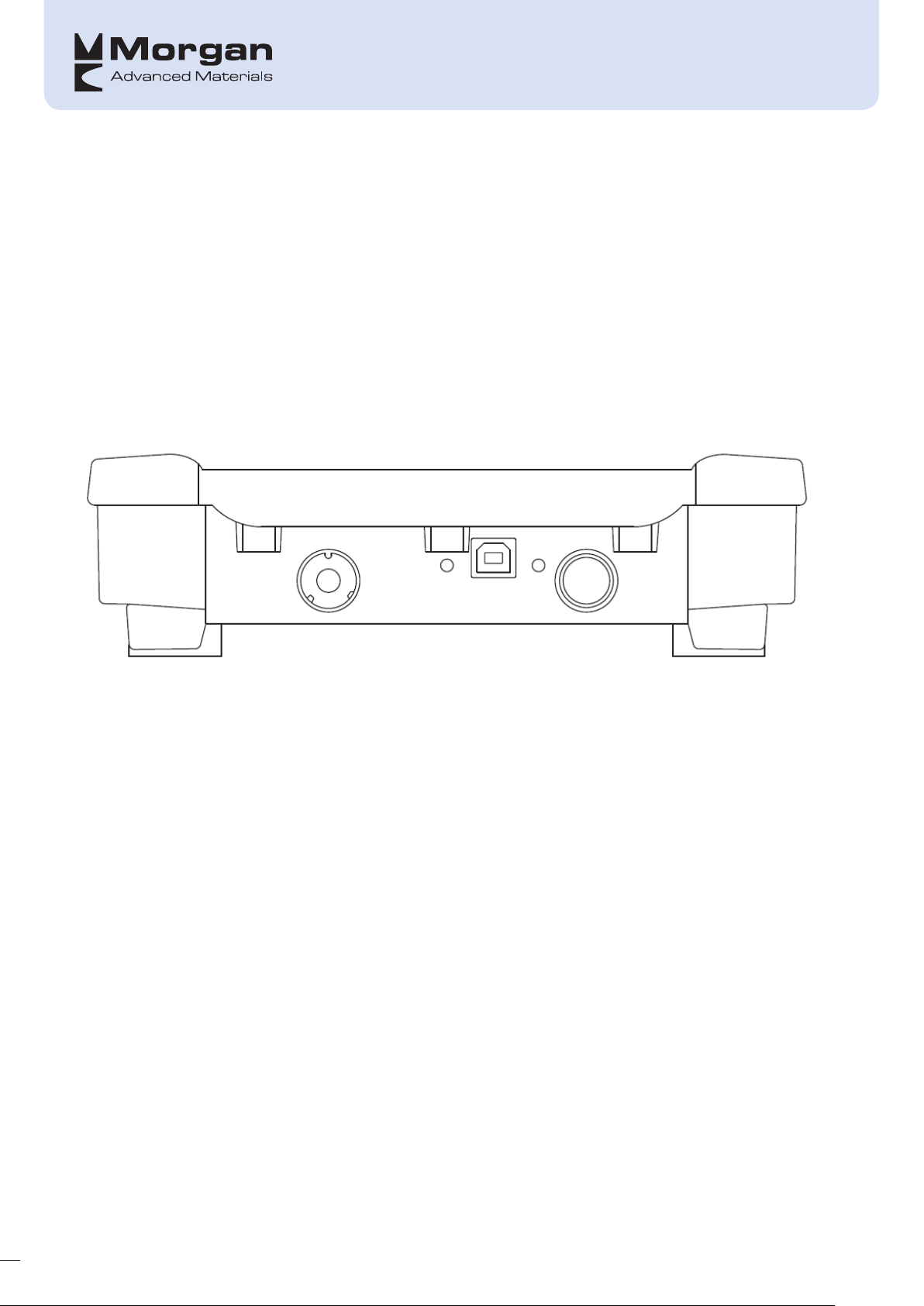

On/off button (1)

Sensor lead port (2)

USB port (3)

LED display showing 3 different colours: (4)

• Green = Device is on

• Orange = Device is on and charging

• Red = Device is off and charging

Standard Kit Items:

Included in the MSPro14 package which is supplied in a robust lightweight case including:

• Data Acquisition Unit (the measuring box)

• USB stick containing this manual and latest PC software (DASPro14 - Data Analysis Software)

• Sensor

• Protective Sensor sleeve and sensor spacer set

• USB cable

• AC power adaptor

• External Battery

• G (or C)-Clamp

• Flashlight & pen

3

RECOMMENDATIONS

Read this manual prior to installing the software and using the device for the first time. All instructions

included in the manual must be followed.

Remove any loose dirt/debris from the collector surface prior to taking a profile and always ensure that the

sensor head is clean before taking any readings as this could affect the results of the profile severely. Use a

clean, lint free cloth for this, for example, spectacle lens cleaning cloths

The sensor head is a highly accurate piece of equipment, and although constructed to withstand normal

handling, it should be treated with care at all times. The sensor should always be stored in its supplied

sleeve when not in use.

When recording a profile, the results will be more consistent when the sensor is mounted as radially as

possible (ideally ±1°) and when rotated in the direction as indicated in the figure below.

Under no circumstances should the sensor be clamped directly – it should always be fitted in a holder or

sleeve and the sleeve held in place with a clamp.

It is recommended that the sensor is calibrated every 12 months – this can either be done by sending your

MSPro14 to your local Morgan Sales office or directly to Morgan Advanced Materials Netherlands.

4

FIRST TIME USE

Minimum PC requirements:

• Operating system: Windows XP or higher

• Minimal 100MB of free disk space

• Minimum of 1GB RAM memory

• One free USB 2.0 port

Once connected to a PC using the USB-cable, the Measuring Box reports itself as new USB-device. The

Measuring Box may be accessed using a Windows File Explorer standard program. This enables the user to:

• Access files stored in the Flash memory of the Measuring Box (note that each measurement results in

one file)

• update the Measuring Box software

5

Registration of software on 1st use

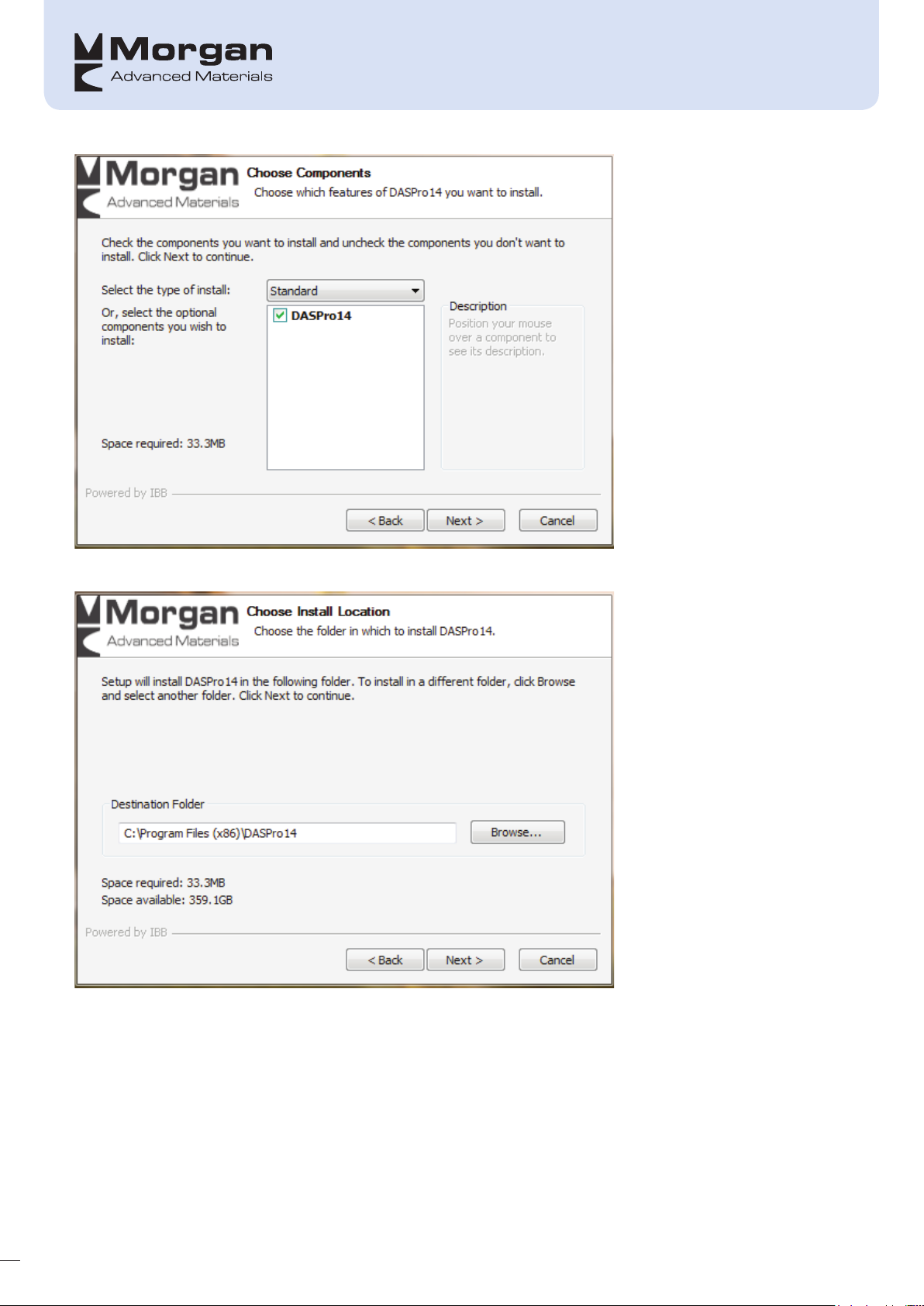

Insert the supplied USB Memory stick into the PC and open the file; double-click on the software link which

looks like:

Follow the on-screen instructions; if there are any warnings displayed regarding the software installation

which could depend on your PC configuration, then press “Yes”, however, if in doubt always contact your IT

administrator.

Press “I agree” to continue

6

Click Next

The default file location is selected; however, change if you require and click “Next” to continue

7

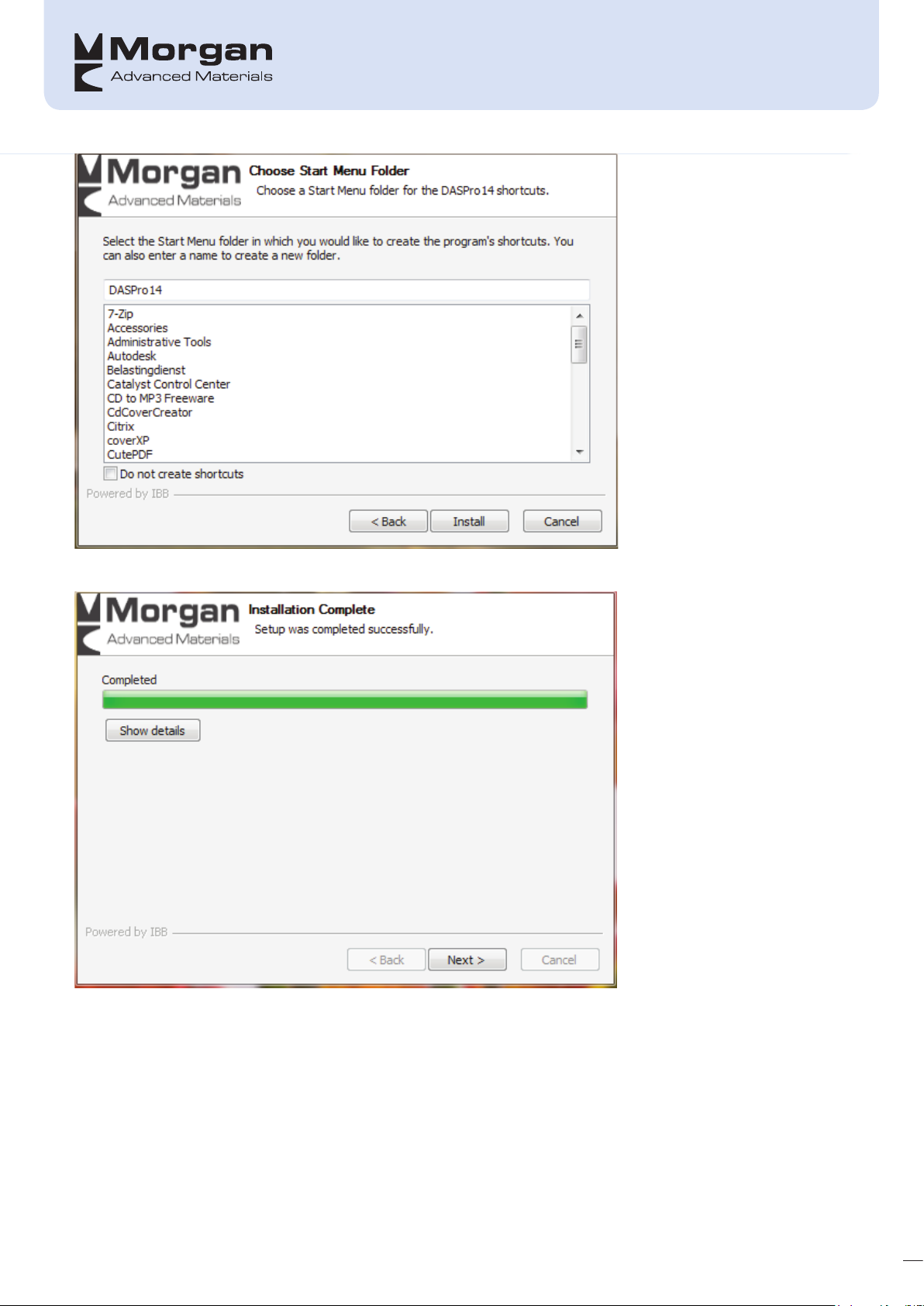

Once details are correct, press “Install”

Once installation is complete, press “Next”

8

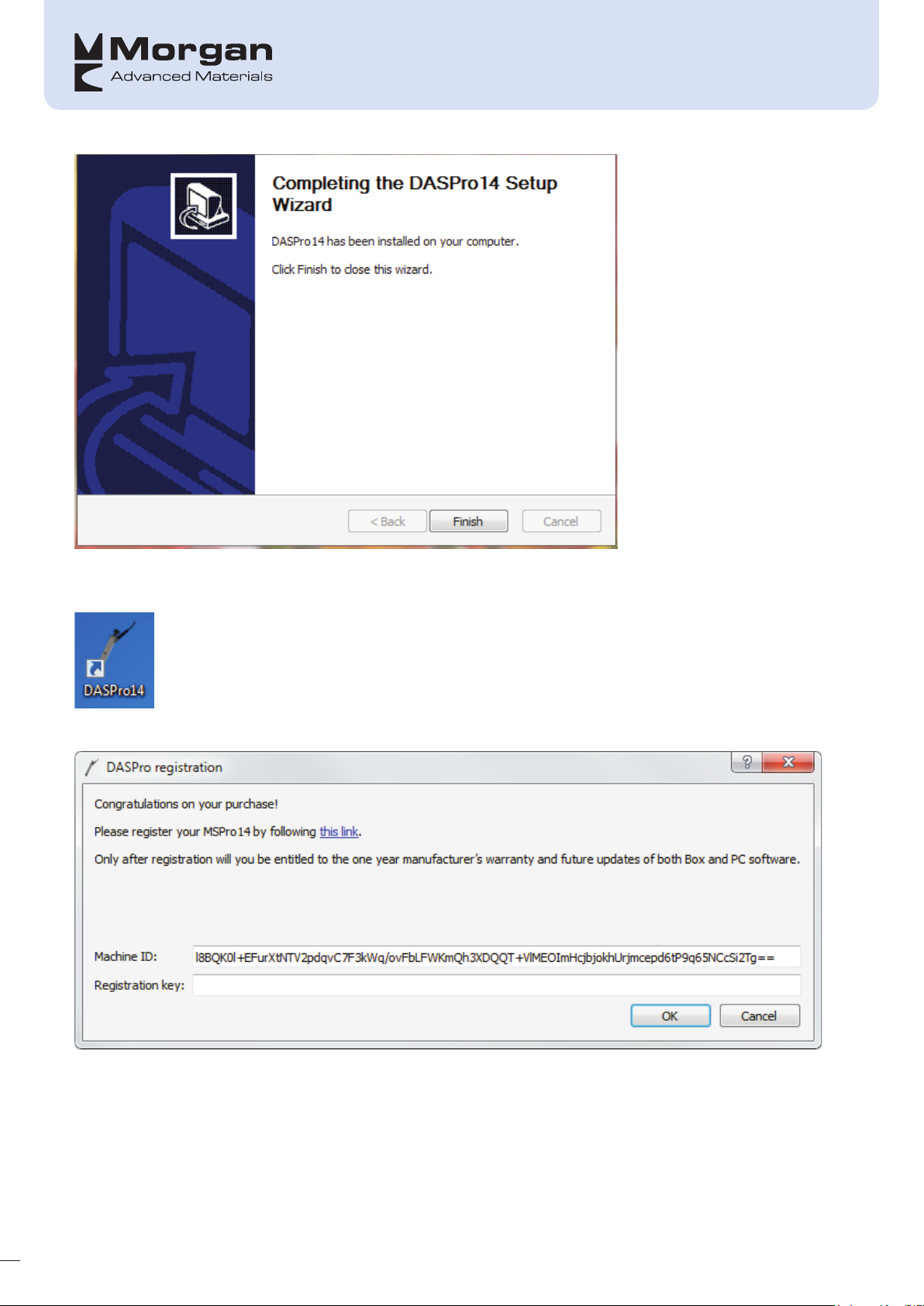

The DASPro14 software is now ready to be registered prior to first use and can be done as follows:

Double-click the link shown below which should be on your PC desktop:

This will then open the following screen:

If a registration key is already known, enter it in the appropriate field, else click the link which opens a

webpage:

9

http://www.morganelectricalmaterials.com/mspro14-registration-form

Once the necessary fields have been completed the submit button should be pressed and this will

automatically send an email to: MSPro14.register@morganplc.com so that a registration key can be sent

back to the user.

Once the registration key is received enter it in the appropriate field and press “OK” and the software will

open accordingly.

10

Software update procedure

Software updating will not be done automatically. The procedure for doing this on both PC-software and

MSPro14 Box is as follows:

• The user will receive an attachment in an email sent to the address used for registering the PC software

or is instructed to download it from a specific server.

• Measuring Box:

– Connect the measuring box to the PC or Laptop.

– Copy the update file to a specific folder on the measuring box.

– Disconnect the box from the PC or Laptop.

– Restart the box to perform the update.

• PC software

– Follow on-screen instructions as in the initial installation

11

USING THE MSPRO14 MEASURING BOX

First, connect the sensor to the MSPro14 measuring box then turn the unit on; wait for it to start-up at which

point you will see the following screen:

The status bar will show how the loading is progressing and once loaded the Welcome Screen will be

displayed.

12

Welcome Screen

This screen shows both the MSPro14 product ID and box software version.

The symbols on the top of the screen mean the following:

The size of the memory will be at least 30 Mbyte. This should be enough to store at least 250

datasets

Sensor position

Units currently set on box – either metric or imperial

Battery life

Press ok to continue

Help

.

13

Loading...

Loading...