Mor Electric Heating Salamander Technical Manual

Salamander

Ceramic Infrared Emitters

Technical Manual

Mor Electric Heating Assoc., Inc.

5880 Alpine A ve. NW, Comstock Park, MI 49321, USA

Tel: 616-784-1121, 800-442-2581, Fax: 616-784-7775

E-Mail: sales@infraredheaters.com

1

Table of Contents

Introduction.............................................................................................................

Agency Approvals....................................................................................................

Comparing Different Forms of Infrared Heat......................................................

Radiant Emission Patterns of Ceramic Emitters...................................................

Ceramic Infrared Panel Design..............................................................................

Infrared Heating Basics..........................................................................................

Infrared Energy ........................................................................................................................

Emissivity................................................................................................................................

Electromagnetic Radiation......................................................................................................

Infrared Spectrum....................................................................................................................

Stefan-Boltzmann Law .............................................................................................................

Planck's Law ...........................................................................................................................

Wien's Law ..............................................................................................................................

Surface T emperature and Radiation Emissions.......................................................................

2

2

3

4

5

6

6

6

7

7

7

8

9

10

Emitter Surface Temperature.................................................................................

Spectral Absorption Curves....................................................................................

Physical Properties of Materials.............................................................................

Reference Data........................................................................................................

Estimating Power Requirements............................................................................

Thermoforming........................................................................................................................

W ater Evaporation...................................................................................................................

11

12

13

14

15

15

18

2

Introduction

In focus with our Mission Statement, we constantly strive to maintain a

communication level with our customers. In this revised, second issue of our technical manual, we hope

to educate the public on the technical aspects of ceramic infrared emitters. Devised, not as a selling tool

but an informational source, there comes a time where selling becomes secondary to informing, and by

this process, informing becomes the primary source for selling. It has been proven that what we know

and understand best is what we sell and utilize most. It is in this exchange of information that we hope to

create a better understanding of our product, the benefits it offers, and heighten awareness to its potential

for the future.

Agency Approvals

Salamander ceramic infrared emitters, manufactured by Mor Electric Heating Assoc., Inc.,

have been tested by Underwriters Laboratories of Northbrook, Illinois, USA. Emitters rated up to 240

volt are UR and C-UR recognized to the standard for safety of electric appliances UL-499 and C-22-2

number 72-M-1984 for electric heating elements.

Reference: Project No. 95NK17113A

File No. E-181581

EC Declaration of Conformity

This is to certify that the:

Salamander Ceramic Infrared Emitters Comprising of:

FTE, FFE, HTE, HFE, HSE, L TE, ESE, and Associated Sheet Metal Fixings and Reflectors

Manufactured By:

Mor Electric Heating Assoc., Inc.

5880 Alpine N.W .

Comstock Park, Michigan 49321

USA T el: 1-616-784-8997

Is in Compliance With all Implemented EU Requirements:

EU Directive 89/336/EEC Electromagnetic Compatibility

EU Directive 73/23/EEC Low V oltage Safety

EU Directive 93/68/EEC CE Marking

3

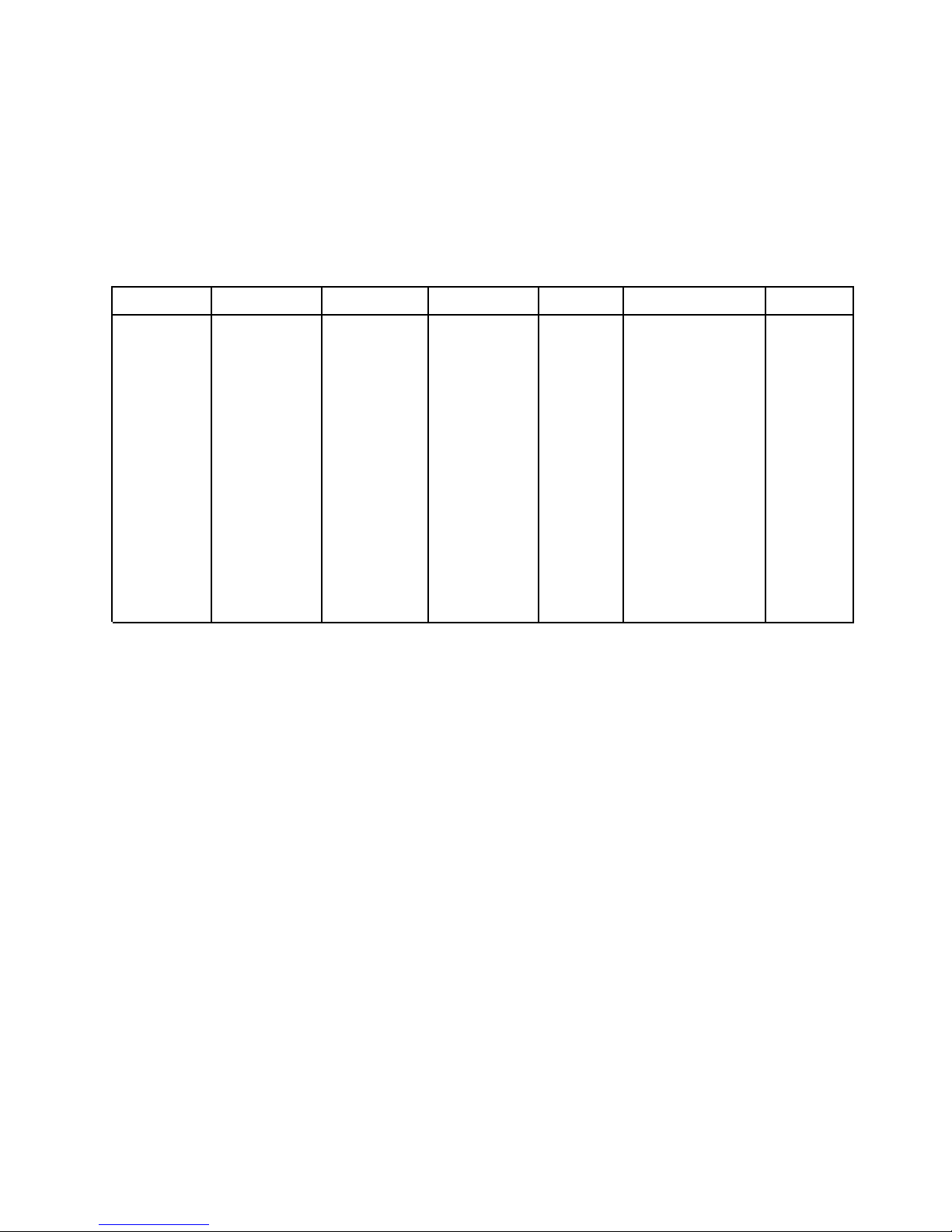

Comparing Different Forms of Infrared Heat

Throughout the years many different forms of infrared heat sources have been developed. Some

of the more familiar forms seen today are metal sheathed tubular heaters, quartz tubes, quartz lamps, gasfired catalytic, flat faced panels, and ceramic emitters. Each source has its own distinctive set of

properties:

Metal Sheath Quartz Tube Quartz Lamp Catalytic Flat Faced Panels Ceramic

Radiant

Efficiency 56% 61% 86% 80% 88% 96%

Physical

Strength High Low Very Low High Medium Medium

Heat-Up

Cool Down Slow Fast Very Fast Very Slow Slow Slow

Max. Temp. 1400 ° F 1600 ° F 4000 ° F 800 ° F 1600 ° F 1292 ° F

Color

Sensitivity Low Low High Low Low Low

Radiant Efficiency: The total amount of energy that is emitted from the source as

infrared radiation. The balance of heat energy from the sources

are transferred via convection and conduction.

Physical Strength: The physical strength of each source. A high rating indicates a

very durable source that can withstand physical abuse such as

dropping a wrench on the source.

Heat-Up/Cool Down: The amount of time required for the source to come up to

operating temperature and cool back down to room temperature.

Maximum Temperature: Maximum operating temperature of the source.

Color Sensitivity: Refers to the ability of a typical load to absorb the spectral

radiation emitted from a source based on the color of the load.

The shorter the wavelength emitted from a source the more color

sensitive a load will be to the sources spectral radiation.

4

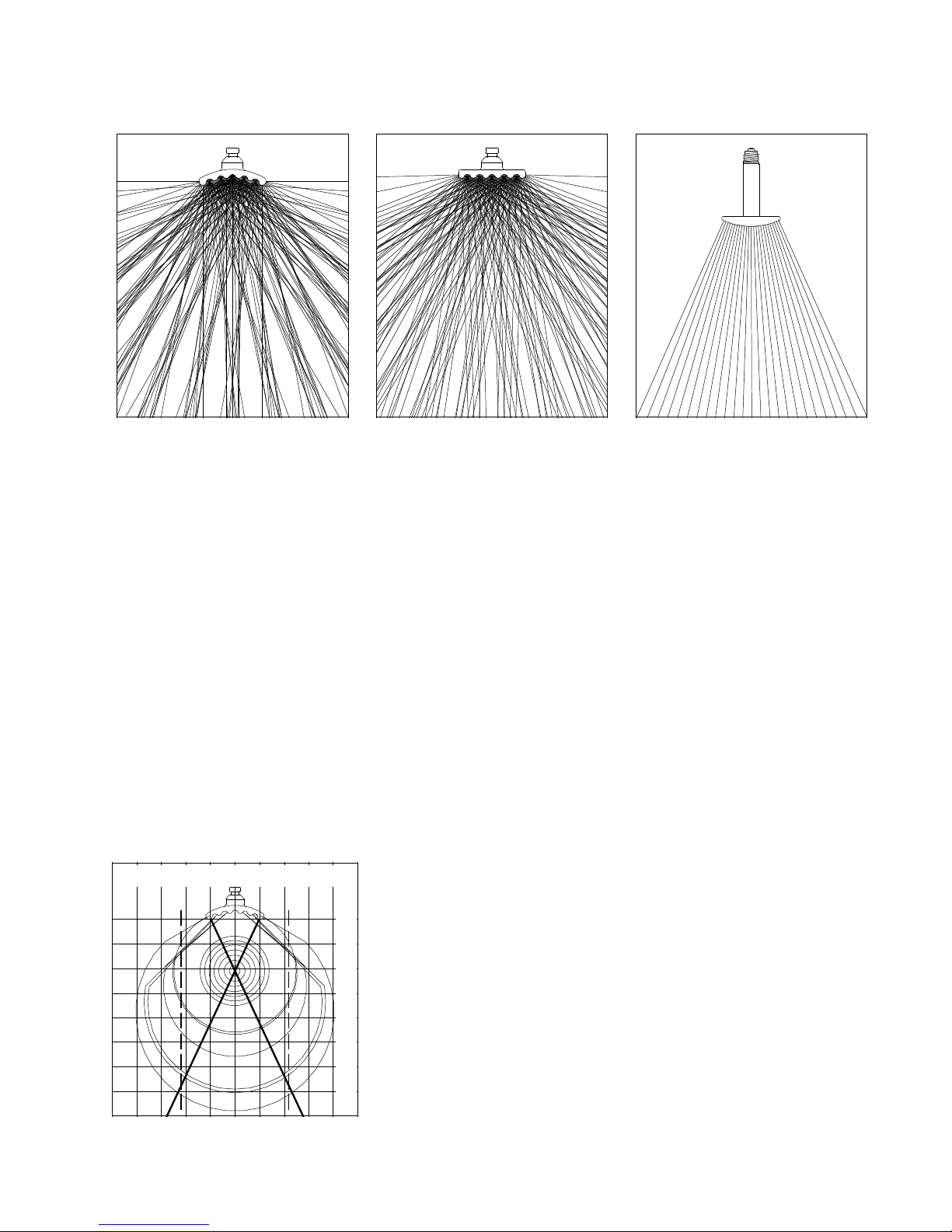

Radiant Emission Patterns of Ceramic Emitters

Concentrated Uniform

Salamander ceramic emitters are manufactured with three basic emitter faces: concave, flat,

and convex. These emitter face styles will result in the specific radiant emission patterns as shown

above. Note: Infrared radiation is emitted at right angles to the emission surface.

Wide Area

Concentrated: The concave surface will emit a "concentrated" radiant pattern which is highly

effective when zone heating is desired as well as radiant heating in general.

Uniform: The flat surface will produce a "uniform" pattern for even heating at a close

proximity between the emitter and the target being heated.

Wide Area: The convex shape gives off a "wide area" pattern which is desirable in

comfort heating or other applications that require a dispersed radiant emission

pattern.

Salamander Radiant Emission Grid

The Salamander radiant emission grid can be used to

Emitter Spacing

01"2"3"4" 1" 2" 3" 4"

Click to add title

Click to add sub-title

0

1"

2"

3"

4"

5"

6"

7"

determine the proper ceramic emitter spacing when used in an

application such as an infrared panel. In order to achieve an

even heat pattern it is critical that the emitters are spaced so that

their radiant emission patterns overlap when reaching the target.

The more overlap that occurs, the more even the heat will be

across the face of the product being heated. The area of highest

radiant emission intensity for a single emitter is shown within

the two dark crossed lines on the grid. In order for element

emissions to overlap, the dashed line shows an intersection point

at a distance of 7" will occur if the emitters are placed a distance

of 2" apart from edge to edge. This same concept should be used to

Distance From Emitter

either determine the distance to place the product if using an existing

panel, or placement of emitters if building a panel to guarantee

radiant emission overlap.

5

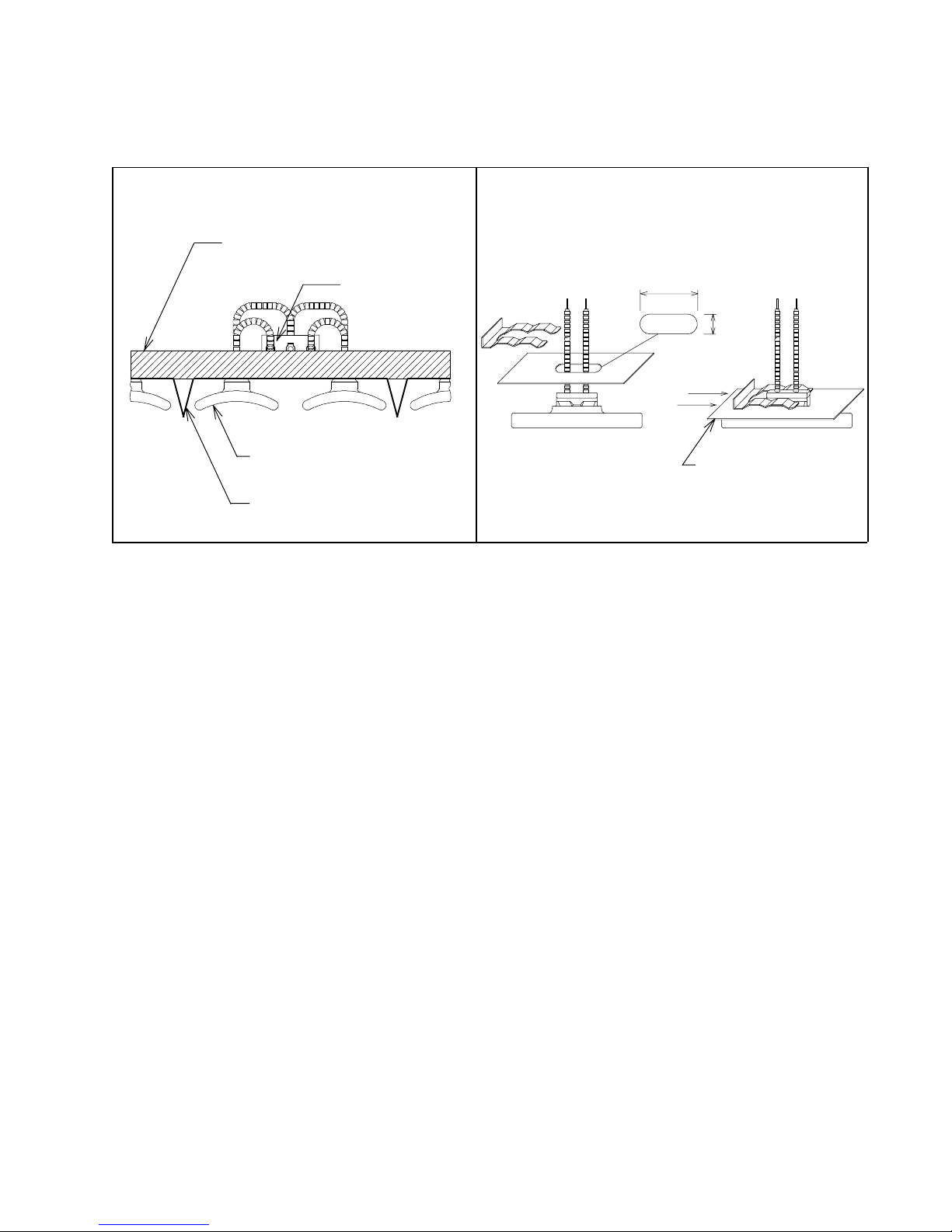

Ceramic Infrared Panel Design

Typical Panel Configuration Ceramic Emitter Mounting

1" Ceramic Fiber Insulation

Click to add title

Ceramic Emitter

Polished Aluminized Steel

or Stainless Steel Reflector,

20 to 24 Gauge

Wiring Specifications:

* High temperature 842 °F (450°C) MG or similar style wire (with a suitable

temperature and amperage rating) should be used for all electrical connections made

within the terminal area of the infrared panel. The high temperature wire must be run

on top of (or above) the ceramic fiber insulation.

3 Pole Ceramic

T erminal Block

1.63"

(41mm)

.59"

(15mm)

Reflector

* Ceramic terminal blocks are recommended to allow for quick emitter replacement,

flexibility in zoning, and "touch safe" design.

* The terminal cover for the infrared panel should be louvered or made out of expanded

metal to minimize the temperature within the terminal area.

Emitter Spacing:

The spacing of the emitters should be such that the resulting infrared emissions incident on the

target will be even and maximized.

* Emitters that are tightly spaced in an array will allow the target to be positioned close

to the emitters and still result in even heating. The intensity and efficiency of the

infrared radiation will be maximized and heat losses will be minimized.

* Emitters that are loosely spaced in an array will force the target to be positioned

further away in order to achieve even heating. This style of panel would typically

result in a lower intensity infrared emission.

6

Infrared Heating Basics

This section of the technical manual is a summary of the physics involved in all infrared heating

systems. The information can be used as an aid in calculating system power requirements as well as

determining the feasibility of a given infrared heating application.

Infrared Energy:

When infrared energy strikes an object it may be absorbed, transmitted, or reflected from the

surface. The sum of the amount of energy absorbed, transmitted, and reflected must equal 100% of the

total incident energy. An object is called a "blackbody" if it absorbs (or emits) 100% of incident

infrared radiation.

1 = ρ + α + τ

Where: ρ = reflectivity

α = absorptivity

τ = transmissivity

Example: Infrared energy strikes an object that is 30% reflective, and 20%

transparent, how much infrared energy is absorbed by the object?

1 = .30 + α + .20

α = 1 - .30 -.20 = .50 (or 50% )

The term "blackbody radiation" was derived from an experiment in cavity radiation. A small

hole was drilled into an object and light was focused into the hole. The hole (cavity) appeared to be

black. Light that entered the cavity is trapped and absorbed into the object allowing no light to escape.

Radiant energy emitted from a "blackbody" source is dependent only on the temperature of the cavity

walls and is not at all dependent on any other characteristic of the source such as color .

Emissivity:

A true "blackbody" source for industrial applications has not yet been developed. However,

various radiant heating elements are available with a wide range of radiant efficiencies. The efficiency

of a radiant heater is given by its emissivity value. Emissivity is defined as the ratio of the radiant

energy emitted by an object at a given temperature and the radiant energy emitted by a "blackbody" at the

same temperature.

Where: e = emissivity of source

Ws = Total radiant energy emitted from a source at temperature T

W

= T otal radiant energy emitted from a blackbody at temperature T

bb

e =

W

W

s

bb

1

1

7

Loading...

Loading...