Serial No.s 3592 and Higher

Part No. 76347-292

Manufactured by:

320 Operator’s Manual

Phone: Morbark®, LLC

Sales - 800-831-0042 8507 S. Winn. Rd., P.O. Box 1000,

Parts and Service - 800-255-8839 Winn, Michigan 48896

www.boxerequipment.com www.morbark.com

Revised: 09/18/2018

BIG POWER IN ALL PLACES

®

Your machine’s Model, Weight, and Power Rating along with Serial Number and Date of

Manufacture of your machine are located on the right side panel at the top.

The Engine information is located on a decal on your engine. Refer to your Engine OEM

Manual for decal location.

i

Boxer Product Warranty

Morbark, LLC (Morbark) warrants to the original purchaser that this product will be free

from defects in materials and workmanship under normal use and operating conditions

subject to the conditions and exclusions stated below. No representative, agent or dealer of

Morbark or any other person is authorized to modify, expand or extend this warranty in any

manner or make any representation on Morbark’s behalf in connection with the sale of any

product covered by this warranty. The warranty period starts with the start-up in-service date.

See the Warranty Period Chart for information on the warranty period.

EXCLUSIONS

This warranty shall not apply to:

1. Product which has been subject to misuse, neglect, modication,

alteration, accident or lack of normal maintenance or service.

2. Fire damage.

3. Labor, unless provided by an authorized Morbark dealer.

REMANUFACTURED PARTS

Morbark reserves the right to use remanufactured parts, when available, for warranty

replacement parts. The remanufactured component has the same warranty as if it was new.

PURCHASER’S EXCLUSIVE REMEDY

The exclusive remedy of the purchaser in the event the product does not conform to this

Warranty shall be repair or replacement of the product (at the option of Morbark) without

charge to the purchaser, when the product is returned to Morbark’s factory at 8507 South

Winn Road, Winn, Michigan, 48896 or at such other locations as may be designated by

Morbark. Morbark shall have sole discretion to determine whether and to what extent the

product is defective in material or workmanship. The acceptance by Morbark of any product

returned is not an admission that the product is defective and if Morbark determines the

product is not covered by this Warranty, the product may be returned to the purchaser at

purchaser’s expense.

DISCLAIMER OF WARRANTY

This warranty is in lieu of all other warranties express or implied. Morbark makes no

other warranties regarding the equipment and in particular, makes no implied warranty of

merchantability or tness for a particular purpose, which are expressly disclaimed.

LIMITATION OF DAMAGES

Morbark shall not be liable for any incidental or consequential damages, directly or by

subrogation, including, but not limited to, any claims for re damage, lost prots, downtime

or loss of use in the event the product is defective.

ii

Morbark, LLC

8507 S. Winn Rd., P.O. Box 1000, Winn, Michigan 48896

Phone: Sales - 800-831-0042,

Parts and Service - 800-255-8839

www.morbark.com

LIMITATION OF DAMAGES

Product Description

Morbark

Manufactured

Components

Vendor Purchased

Components

Extended Coverage

New Boxer Compact

Utility Loaders

One (1) year/1,000

hours; whichever comes

rst

Warranty from vendor

applies, minimum of one

(1) year

Can purchase prior to

start-up

Used Equipment As stated on equipment

order

N/A N/A

New Engines N/A See Engine Warranty

Statement

Can purchase prior to

start-up or possibly up to

two (2) years after startup depending on the

programs offered by the

engine supplier

Wear Items including

but not limited to such

items as, lubricants,

anti-freeze, uids, lters,

belts, bearings, hoses

and ttings, etc…

Manufacturer’s limited

warranty extended to

the original purchaser to

cover conditions that are

reasonably considered

to have been within the

manufacturer’s control.

Conditions not within the

manufacturer’s control

such as irregular wear,

lack of maintenance,

damage due to accidents

or vandalism are not

covered.

Manufacturer’s limited

warranty extended to

the original purchaser

to cover conditions that

are reasonably considered to have been within the manufacturer’s

control. Conditions not

within the manufacturer’s control such as

irregular wear, lack of

maintenance, damage

due to accidents or vandalism are not covered.

N/A

iii

Boxer Warranty Registration

Dear Customer,

Morbark, LLC, manufacturer of the Boxer Compact Utility Loader, would like to thank

you for your purchase. Morbark is committed to providing unsurpassed products and

product support to our customers. To accomplish this, we need to update our database with

information regarding your purchase. Currently the warranty start date (in-service date) is

listed as the date the Boxer Compact Utility Loader left Morbark, LLC, which may be several

months before you received and placed your new Boxer product into service.

To ensure you get the full warranty coverage for your purchase, Morbark, LLC, will restart

the warranty start date (in-service date) if you complete the information below and return this

form to us with a copy of the equipment invoice (bill of sale) verifying the in-service date of

your Boxer Compact Utility Loader. Without receipt of this form, we will continue to use the

original equipment ship date as the warranty start date (in-service date) and not returning this

form may result in denial of warranty entitlements.

To restart the equipment in-service date, simply complete the form below and mail, e-mail or

fax the completed form and bill of sale to:

Morbark, LLC

P.O. Box 1000

8507 S. Winn Road.

Winn, MI 48896-1000

E-mail:anonymous@boxerequipment.com

Fax: (989) 866-2280

Please take the time to complete and return this warranty form.

Fold

Company Name:___________________Contact Name:________________

Address:______________________________________________________

City:____________State/Province:_________Zip/Postal Code:__________

Phone:___________________E-mail address:________________________

Model No._________Serial No.___________Engine S/N_______________

Location Purchased:_______________Date Purchased_________________

I, (the purchaser) have read and fully understand the operator’s manual,

safety instructions and warranty conditions provided with this equipment.

In-service date restart will only be accepted if this form and a copy of the bill

of sale is completed and returned within 30 days of the in-service date.

Customers Signature:_____________________Date:__________________

iv

Ax

Stamp

Here

Morbark, LLC

8507 S. Winn Rd.

P.O. Box 1000

Winn, MI 48898

v

Safety Introduction

Be Prepared - Get to Know All Operating and Safety Instructions

This is the Safety Alert Symbol.

Wherever it appears, either in this manual or on safety signs on the machine, you should be

alert to the potential for personal injury or accidents. Always observe safety precautions and

follow recommended procedures.

Learn the Signal Words Used with the Safety Alert Symbol

The words “DANGER”, “WARNING”, and “CAUTION” are used throughout this manual

and on labels on the machine to indicate hazards or unsafe practices. All three statements

indicate that safety is involved. Observe the precautions indicated whenever you see the

Safety Alert symbol no matter which signal word appears next to the Safety Alert symbol.

INDICATES A HAZARDOUS SITUATION THAT, IF NOT AVOIDED, IS VERY

LIKELY TO CAUSE DEATH OR EXTREMELY SERIOUS INJURY. IT MAY

ALSO BE USED TO ALERT AGAINST EQUIPMENT THAT MAY EXPLODE OR

DETONATE IF HANDLED OR TREATED CARELESSLY.

Indicates a hazardous situation that, if not avoided, could result in serious injury or

death. It may also be used to alert against a highly unsafe practice.

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury. It may also be used to alert against a generally unsafe practice.

This type of statement is used to draw attention to a procedure that needs to be followed to

prevent machine damage.

DANGER

WARNING

CAUTION

NOTICE

vi

Table of Contents

Boxer Product Warranty ....................................................................................i

Safety Introduction ............................................................................................ v

Be Prepared - Get to Know All Operating and Safety Instructions ........ v

Learn the Signal Words Used with the Safety Alert Symbol .................. v

Section 1 – Safety Precautions ....................................................................1–1

GENERAL SAFETY .................................................................................. 1–1

OPERATING SAFETY .............................................................................. 1–2

SERVICE & MAINTENANCE SAFETY ....................................................1–4

ELECTRICAL SYSTEM HAZARDS ..........................................................1–4

Battery Hazards .................................................................................1–5

Jump Starting/Battery Charging Hazards ..........................................1–5

Hydraulic System Hazards ................................................................1–6

Fueling Hazards ................................................................................. 1–7

Section 2 – Operating Controls .................................................. 2–1

Component Locations ............................................................................... 2–1

Right Front View ................................................................................2–1

Left Rear View ...................................................................................2–2

Operating Controls ............................................................................. 2–3

Safety Decals ..................................................................................... 2–4

Operating Controls Description .......................................................... 2–6

Section 3 – Pre-Start Inspection and Operation ....................... 3–1

Pre-Start Inspection .................................................................... 3–1

Daily Service Checks .................................................................. 3–1

Cylinder Lock Installation ........................................................... 3–7

Cylinder Lock Removal ...................................................................... 3–7

Operating Instructions ................................................................ 3–8

Machine Start-up ...............................................................................3–8

Machine Shut-down .........................................................................3–10

Transportation .................................................................................. 3–11

Lifting Procedures ............................................................................ 3–12

Machine Travel Controls ..................................................................3–13

Attachment Installation and Removal ..............................................3–17

Attachment Lock Pins ......................................................................3–17

Installation of Non-Hydraulically Powered Attachments ..................3–19

Removal of Attachment ....................................................................3–21

Installation of Hydraulically Powered Attachments ..........................3–22

Operating Instructions for a Hydraulic Attachment ..........................3–27

Removal of Hydraulically Powered Attachments .............................3–29

vii

Section 4 – Routine Service and Maintenance ...........................................4–1

Daily Maintenance Procedures ................................................................. 4–2

Air Filter Replacement ..............................................................................4–4

Hydraulics Inspection and Service ..................................................... 4–5

New Machine Brake-in Maintenance Procedures ....................................4–9

Weekly Maintenance Procedures ........................................................... 4–11

Monthly Maintenance Procedures ..........................................................4–12

Annual Maintenance Procedures ...........................................................4–17

General Maintenance .............................................................................4–19

Draining Fuel Tank ...........................................................................4–19

Track and Tension System Installation ............................................4–20

Section 5 – Troubleshooting .....................................................................5–1

Section 6 – General Specications ........................................................... 6–1

Vibration Data ...........................................................................................6–2

Noise Data ................................................................................................ 6–2

1.1

Section 1 - Safety Precautions

Since Morbark, LLC has no direct control over machine application or operation, following

the proper safety practices is the responsibility of the owner and/or operator. Remember that

this unit is only as safe as those who operate it. The safety practices described throughout this

Operator’s Manual must be followed at all times.

GENERAL SAFETY

• Never operate the Boxer without first completely reading and understanding this Owner’s

Manual.

• Only authorized, qualified, and trained personnel are allowed to operate this machine.

• Never operate the machine under the influence of alcohol, awareness altering drugs or

medications that would affect your ability to operate safely.

• KEEP CHILDREN CLEAR FROM THE WORK SITE AREA AT ALL TIMES!

• NEVER ALLOW A CHILD TO OPERATE OR RIDE ON THE MACHINE!

• Serious injury or death involving children can occur. Stay ALERT and be aware of your

surroundings at all times. Stop operations if children wander onto the job site. Resume

work only when the operating area is clear.

• Keep all non-operating personnel away from the machine during operation.

• Passengers must never be allowed to ride on the machine or any attachment.

• Wearing protective clothing and gear, such as hard hats, safety glasses, safety shoes,

hearing protection, breathing protection, and long pants and shirts is highly recommended.

Do not operate in clothing or shoes which will expose skin or feet to possible flying debris.

• Clothing should be relatively close fitting. Loose clothing, rings, and other jewelry should

be avoided because of the danger of catching them on machine parts or controls or on any

rotating parts, either on the machine or any attachment.

• Keep hands/fingers clear from all rotating parts.

• Never touch engine parts or machine components while they are hot.

• Always perform the “Standard Shut Down Procedure” shown in this manual, if the unit

will be left unattended for any length of time.

• Use only original Morbark, LLC or approved replacement parts and attachments. Imitation

parts may lead to unit damage and/or injury to personnel. The machines warranty may be

voided if unauthorized parts and attachments are used.

Safety Precautions

1.2

OPERATING SAFETY

• Plan ahead and learn as much as possible about your job-site area before beginning any

work.

• Know the exact location of overhead power lines or obstructions.

• Have all buried lines such as gas, electric, water, telephone, and cable TV, marked by the

proper authorities.

• Prior to use, perform the “Pre-Start Inspection” and “Daily Maintenance” to make sure that

the unit is in safe operating condition.

• Never operate a malfunctioning unit!

• Keep hands, gloves, shoes, control knobs, and operator platform clean. Slippery controls

can cause you to lose control, which may result in an accident.

• Always keep a firm grip on the hand rails located at the operator’s platform during travel

and operation to prevent falling off the unit.

• When working on an unfamiliar construction site, review, understand, and follow job site

safety rules.

• Keep the work site clear of all non-operating personnel. Should a person enter the work

area, stop machine operation until the work area is clear.

• Prior to unloading the unit and starting to work, inspect the path you will travel and work

site area for potential hazards. Some of the hazardous conditions you may encounter are:

- Holes

- Deep ditches or excavations

- Drop-os

- Soft un-compacted soil

- Culverts

- Deep mud/Standing Water

- Large rocks

- Slippery surfaces

- Steep slopes

- Tall grass, trees or shrubs

If any of these conditions exist, correct the hazard or obstruction. If any of these conditions

can not be corrected, avoid operating or traveling near them.

• Be extremely cautious traveling through or near trees, brush, shrubs or any obstacles which

might obscure your vision. These might hide potential hazards, such as the edge of a steep

slope, deep holes, large rocks, etc.

• Never operate near a ditch or embankment where loose or soft ground conditions could

cause the surface to give way under the machine causing it to become unstable.

• Never exceed the rated capacity of the machine. When using attachments, know their

capacity ratings and unit limitations. Unit specifications can be found in the Operator’s

Manual.

Safety Precautions

1.3

• Never attempt to operate any attachment without first understanding proper installation

and operating procedures. The center of gravity, stability, and operating characteristics of

the entire machine will change with the use of different attachments.

• Operate all controls slowly and smoothly and never abruptly stop any function. This can

cause the machine to become unstable.

• Always look in the direction of travel.

• Come to a complete stop prior to reversing travel directions.

• Reduce speed and proceed with caution when traveling in reverse or turning.

• Never travel with the loader boom or attachment raised. Lower the boom or attachment as

soon as possible and travel with the boom at the lowest safe height.

• When traveling with a loaded bucket or forks, the load should be level and the bucket or

forks tilted back to reduce spilling or losing the load.

• Approach corners slowly, turning too fast or sharp may cause the machine to tip over.

• Stay alert when operating near traffic or roadways.

• If the unit should begin to tip or become unstable, DO NOT try to stabilize the unit with

your legs or arms.

• If the unit is involved in an accident or inadvertently damaged during operation, stop and

perform a thorough inspection. Make sure the unit is in safe operating condition prior to

resuming work.

• Be alert to any unusual reaction to any of the controls. If anything unusual is noticed, shut

the machine down and thoroughly inspect it to determine the cause of the problem. Do not

operate the machine until all required repairs have been made.

• If the unit must be left unattended, shut the machine down and make sure that it can not be

started by an unauthorized individual.

• Operating on steep slopes can be dangerous and there is a greater risk of the machine

tipping over or becoming unstable. The list of rules below must be understood and

followed for maximum safety:

- Avoid excessively steep slopes or unstable surfaces. If travel on a slope is

necessary, keep the load low and proceed with extreme caution.

- DO NOT travel ACROSS excessively steep slopes under any circustances.

- Travel straight up and down slopes with the heavy end of the machine

pointing up the incline. When the machine has no load, the operator’s platform end

of the machine is considered the heavy end. When the machine is loaded or has an

attachment on the front of the machine, the front is considered the heavy end.

- Turning on slopes is not a recommended practice, however if you must turn on slopes;

reduce travel speed to as slow as possible, and exercise extreme caution. Avoid sharp

turns or sudden movements.

- Wet or slick ground conditions should be avoided as reduced traction could cause the

machine to slide down the slope.

- Do not attempt to install or remove attachments on a slope.

- Never park the unit on a slope.

Safety Precautions

1.4

SERVICE & MAINTENANCE SAFETY

Maintenance work can be hazardous if not done in a careful manner. All personnel should

realize the hazards and strictly follow safe maintenance practices. Failure to comply with

these safety precautions may result in serious personal injury and/or death.

• Use only Morbark, LLC supplied or approved replacement parts and attachments.

Imitation parts may lead to unit damage and/or injury to personnel. Warranty may be

voided if unauthorized parts and attachments are used.

• Wear the proper protective clothing and personal safety equipment necessary to perform

the maintenance or service required.

• Keep the machine free of grass, leaves or other debris build-up.

• Clean up oil or fuel spillage.

Fuel, oil leaks or spills can create a re or explosion hazard.

• Prior to performing maintenance or service, park the unit in a level area away from

obstructions and/or work site hazards.

• Be sure the area has adequate light and is well ventilated. NEVER operate the machine

inside a closed area.

• Clean-up any oil, grease, mud, water or snow which might cause the floor surface to

become slippery.

• If the machine requires maintenance, take the machine out of service and attach a “Do Not

Operate” tag at the control panel and remove the ignition key.

• If maintenance or repairs require the boom to be raised, the “Hydraulic Cylinder Lock”

must be installed.

• Know where all pinch points and rotating parts on the unit are. These areas must be

avoided to prevent serious injury.

• Remove only those guards or covers on the component being serviced and replace them

immediately upon completion of the work.

• Never attempt to adjust or service engine or machine components while they are hot.

ELECTRICAL SYSTEM HAZARDS

• Prior to working on the electrical system:

- Disconnect battery cables, removing the battery ground cable rst.

- When re-connecting the battery, connect the battery ground cable last.

- Never allow battery cables to contact hydraulic lines or rub against sharp

edges.

WARNING

Safety Precautions

1.5

Battery Hazards

Before working with batteries, the following are important points about battery safety that

you should be aware of:

• Batteries are always surrounded by extremely explosive gases. This is especially true when

the battery is being charged. To avoid explosion:

- Do not smoke near batteries.

- Keep arcs, sparks, and open ames away from batteries.

- Perform battery service work only in a well ventilated area.

• Make sure to dispose of batteries according to local regulations.

• Electrolyte Hazards:

NOTE: The batteries on the machine may be either be “wet cell” or “gel cell”. It is still

important to know and follow these warnings and cautions.

Battery electrolyte in standard “wet cell” batteries contains sulfuric acid which is poisonous

and can cause severe chemical burns. To avoid personal injury:

- Wear a face shield to prevent sulfuric acid contact with your eyes.

- Wear chemical resistant gloves and clothing to keep acid o your skin and

clothing.

- Since wet cell batteries give o explosive gases, use a ashlight to check the electrolyte

level, not an open ame such as a match.

- Never check the battery by placing a metal object across the battery posts. The resulting

spark could ignite anything ammable, causing re or an explosion.

- If electrolyte is splashed into your eyes, ush them immediately with clean water and

seek medical attention.

- If electrolyte is swallowed, seek medical attention immediately.

- If electrolyte is splashed onto exposed skin or clothing, ush and clean the area

immediately with clean water and seek medical attention if necessary.

Jump Starting/Battery Charging Hazards

Follow the instructions for jump starting or battery charging in the engine owner’s manual.

You must be at the operator’s platform when attempting to start the unit with booster batteries

and jumper cables so that you are at the controls when the engine starts.

Here are some general safety rules you must follow for jump starting the machine:

• Make sure to connect the positive jumper cable to the positive (RED) remote starter lug on

the right side of the machine chassis.

• Connect the negative cable to the engine, machine chassis or the furthest ground point

away from the battery. Never make the final connection at the starter or dead battery.

Sparks may ignite the explosive gases surrounding the battery.

• When disconnecting cables after jump starting, remove the negative cable first and then the

positive cable. IMPORTANT: DO NOT let the cable clamps touch when disconnecting

them. Severe damage can occur to the booster battery or machine.

• Never charge a battery or attempt to jump start a frozen battery. The sudden surge in

electrical power could cause the battery to explode.

Safety Precautions

1.6

Hydraulic System Hazards

The hydraulic system is under pressure whenever the engine is running and may hold

pressure even after the engine is shut o. Cycle all hydraulic controls after the loader boom

is resting on the ground. Some components will retain residual or trapped pressure. Use

extreme caution when removing any hydraulic component.

During inspection of the hydraulic system:

• Cycle all hydraulic controls to release residual pressure.

• Wait for the hydraulic fluid to cool down before disconnecting any hydraulic lines. Hot

hydraulic fluid can cause severe burns.

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use

cardboard or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are

injected with hydraulic oil or any other uids, immediately seek treatment by a doctor

trained in the treatment of penetrating uid injuries.

• Hydraulic fluid can cause permanent eye injury. Wear safety glasses or a full face shield to

provide appropriate eye protection.

• When venting or filling the hydraulic system, loosen the filler cap slowly to allow any

pressure in the hydraulic tank to be released and remove the cap gradually.

WARNING

Safety Precautions

1.7

Fueling Hazards

Most fuels are highly ammable. Observe the following precautionary practices to reduce the

possibility of a serious accident:

• Always refuel the unit in an open, well ventilated area away from sparks or open flames.

Gasoline Engines:

• Shut the engine o before attempting to fuel the machine. Never refuel a unit

while it is running.

• Allow engine to cool before re-fueling.

• Always use a funnel or pour spout when lling the tanks.

• Under certain circumstances a static charge can develop and ignite the fuel.

Make sure that you are standing on the ground when lling the fuel tanks.

• If you are lling the fuel tanks from a service vehicle, make sure to connect

the service vehicles ground cable to the machine before beginning the fueling

process. Keep the fuel nozzle in constant contact with the rim of the machines

fuel tank.

• When lling a portable gas container, always place it on the ground. Never ll

a portable fuel container while it is inside a vehicle, truck, pick-up bed or any

surface.

• To avoid static sparks when using a portable fuel container, only ll the

container when it is positioned on the ground and keep the fuel container nozzle

in contact with the tank opening during lling.

• Make sure to move the unit from the transport truck or trailer and only refuel

the unit on the ground, using an approved container.

• Keep sparks and ames away from fuel.

• Do not smoke while refueling or when handling the fuel container.

• Never cut or weld on or near fuel lines, tanks or containers.

• Never overll the tank.

• Clean up spilled fuel immediately.

• Store fuel in an approved container and keep out of the reach of children.

DANGER

Safety Precautions

1.8

Boxer Brush/Sweeper Attachment Silica Dust Caution

An OSHA ruling has established new permissible exposure limits (PEL) for occupational exposure to respriable crystalline silica. OSHA standard 29 CFR 1926.1153

covers the construction industry, and 29 CFR 1910.1053 covers the general and

maritime industries. The rules also requires employee protections such as performing exposure assessments, using exposure control methods, using respiratory protections, offering medical surveillance, developing hazard communication information, and keeping silica-related records.

Under the new standard the employer shall not allow dry sweeping or dry brushing

where such activity could contribute to employee exposure to respirable crystalline

silica unless wet sweeping, HEPA-ltered vacuuming or other methods that minimize

the likelihood of exposure are not feasible. The employer bears the burden of showing the alternative methods are not feasible.

-The use of non-grit, oil, or waxed based sweeping compounds are an acceptable

dust suppression housekeeping method.

-The use of compressed air for cleaning is allowed where the compressed air is

used in conjunction with a ventilation system that effectively captures the dust cloud

created by the compressed air, or where no alternative method is feasible.

-The employer’s exposure control plan must include the description of the housekeeping measures.

2.1

Section 2 - Operating Controls

Component Locations

Right Front View

Item No. Description

1 Attachment mounting plate

2 Loader arms

3 Lift cylinder

4 Fuel tank

5 Left track assembly

6 Right track assembly

7 Hydraulic uid level check

8 Remote air cleaner assembly

9 Hydraulic cooler

10 Ignition switch and hour meter

1

10

7

5

3

2

4

6

8

9

Operating Controls

2.2

Left Rear View

Item No. Description

1 Attachment mounting plate

2 Operating controls

3 Hand grip

4 Service access panel

5 Operator’s platform

6 Fuel tank

7 Manual holder

8 Fuel ller cap/fuel gauge

9 Safety support

10 Loader arms

11 Attachment hydraulic quick connects

12 Tilt cylinder

1

2

3

4

5

6

7

8

9

10

11

12

Operating Controls

2.3

Operating Controls

Item No. Description

1 High/Low selector control

2 Hand grip

3 Attachment tilt control

4 Right travel motor control

5 Left travel motor control

6 Loader arm lift control

7 Engine throttle

8 Auxiliary attachment activation control/Operator presence

1

2345627

8

Operating Controls

2.4

Safety Decals

Item No. Description

1 Crush hazard

2 Model number decal

3 Boxer decal

4 Burn hazard

5 Small Boxer decal

6 ISO 46 decal

7 Danger zone

8 Tie down decal

9 Lifting point decal

10 Morbark decal

11 Boxer internet decal

1

1

4

5

3

7

6

10

9

2

11

8

Operating Controls

2.5

Safety Decals (Continued)

Item No. Description

1 Crush hazard decal

2 Model number decal

3 Burn hazard decal

4 Cylinder lock installation decal

5 Small operating warning decal

6 Gasoline only decal

7 Allow unit to cool warning decal

8 Read operator’s manual warning decal

9 Small boxer decal

10 Danger zone decal

11 Safety instructions decal

12 Operating controls decal

13 Shutdown instruction decal

14 Attachment security decal

1

2

3

4

5

1

6

7

8

9

10

14

13

12

11

Operating Controls

2.6

Operating Controls Description

1. High/Low Selector Lever – Moving this lever either fully forwards or fully backwards

selects the machine function speed. When the lever is in the Low position, all control and

travel functions will be in the slower speed range. With the lever in the High position, all

control and travel functions will be in the high speed range.

2. Ignition Switch and Key – Rotating the key switch one position to the right turns on the

engine ignition and the low oil pressure warning. Rotating the key switch fully to the right

activates the engine starter.

3. Engine Hour Meter Gauge

4. Hand Grip

5. Attachment Tilt – Pushing the lever forwards tilts the attachment plate forwards, lowering

the attachment. Pulling the lever backwards tilts the attachment plate backwards, raising

the attachment.

6. Right Travel Motor Control – Pushing the lever forward rotates the right side wheels for

forward travel. Pulling the lever backwards rotates the right side wheels for reverse travel.

7. Left Travel Motor Control – Pushing the lever forward rotates the left side wheels for

forward travel. Pulling the lever backwards rotates the left side wheels for reverse travel.

8. Boom Raise and Lower – This lever controls the raising and lowering of the boom

assembly.

9. Hand Grip

10. Engine Throttle – Moving the control lever upwards increases the engine speed and

moving the lever downwards slows the engine to idle speed.

11. Attachment Activation Lever/Operator Presence Control – With your left hand,

squeeze the AUXILIARY attachment control lever towards the hand hold to activate the

attachment in the FORWARD motion.

NOTE: The lever is spring loaded and when released, will automatically move from the

FORWARD motion position to the NEUTRAL position, stopping attachment motion.

If you want to reverse the operation of the attachment, move the auxiliary control lever to the

REVERSE position. The control lever will remain in the REVERSE position detent until it is

moved to the NEUTRAL position.

11

10

9

8

7

6

5

4

3

2

1

Operating Controls

2.7

DO NOT attach an auxiliary hydraulic cylinder to the hydraulic circuit controlled by

the Attachment Activation Lever/Operator Presence control. Hydraulic pressure will

not be held in the system when this control is returned to the NEUTRAL position.

CAUTION

Operating Controls

2.8

3.1

Section 3 - Pre-Start Inspection and Operation

IMPROPER USE OF THE COMPACT UTILITY LOADER COULD CAUSE

SERIOUS INJURY OR DEATH. BEFORE OPERATING THE MACHINE

OR PERFORMING MAINTENANCE, THE OPERATOR MUST READ AND

UNDERSTAND THE ENTIRE OPERATOR’S MANUAL, REVIEW MACHINE

CONTROLS, LOCATE AND REVIEW ALL WARNINGS AND SAFETY PLACARDS

AND RELEVANT OPERATOR SAFETY MATERIALS INCLUDING WRITTEN,

VISUAL, VIDEO OR VERBAL INSTRUCTIONS.

Pre-Start Inspection

It is very important to do a visual inspection of the machine before beginning operation. This

inspection should include:

• Check all decals and warning signs for damage.

• Check engine oil.

• Check and rell fuel tanks.

• Check hydraulic lines and hoses for signs of damage or leaks.

• Inspect the machine for any signs of damage or loose fasteners.

• Check uid levels and any signs of leaking uids.

• Do all Daily Service Checks.

• Check machine controls to make sure that they automatically return to the neutral

position.

The following information presents details on these inspection points and service checks

Daily Service Checks

Table 3-1: Service Cycle Table

Activity Daily (10 Hours)

Fuel 3 and R

Engine Oil 3 and A

Engine Oil Filter

Air Filter

Fuel Filter

Engine Idle Speed

Battery

Hydraulics

- Hydraulic Filter

- Hydraulic Fluid

- Hydraulic Hoses

3

3

3

Grease 3***

Tracks 3

Visual Check for Loose/Missing Fasteners 3

Battery

Check and Adjust Track Tension 3

Service Cycle - R = Replace 3 = Check A = Add

***Under very wet, muddy, dusty or dirty working conditions more frequent lubrication may

be required.

DANGER

Pre Start Inspection and Operation

3.2

Do the following pre-start service checks:

1. Check condition of all warning and instructional decals. Replace any damaged decals with

genuine Morbark replacement decals.

2. Check engine oil:

• Make sure that the engine is OFF.

• Pull out the dipstick and look for both the full and add oil lines (Item 1, Figure 3–1)

indicated by the letters “F” and “A”. The correct oil level is between those two lines.

Figure 3-1 Engine Oil Level Check

• If the engine oil level is below the add line, indicated by the letter “A” on the dipstick,

carefully add the proper amount of oil through the engine oil filler (Item 1, Figure 3–2). It is

important to add the correct type of engine oil as stated in the engine manual.

NOTE: Make sure to reinstall and secure the oil ller cap.

Figure 3-2 Filler Cap

OK

1

Pre Start Inspection and Operation

3.3

NOTE: Extremely dusty or dirty working conditions may require more frequent checking,

lling and/or changing of engine oil.

• After filling the oil, wait a few minutes and check the oil level again.

Make sure to securely reinstall the dipstick into the dipstick tube before starting the engine.

Check engine fuel and ll as needed - be sure engine is OFF.

3. The Boxer has one saddle fuel tank (Item 1, Figure 3–3). Remote lter cap (Item 2, Figure

3–3) and insert a clean tank level gauge into tank and remove. This will show you the level

of gas remaining in the tank. Make sure that the tank has been lled on a daily basis.

Figure 3-3 Fuel Level Check

• Carefully pour the fuel into the tank, not exceeding the max fill on your gas tank.

• Allow engine to cool before lling fuel tank.

• Do not overll because fuel could spill onto hot engine parts and ignite or

explode.

NOTICE

CAUTION

E

F

2

1

Pre Start Inspection and Operation

3.4

4. Check all hydraulic hoses, lines, and ttings.

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use

cardboard or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are

injected with hydraulic oil or any other uids, immediately seek treatment by a doctor

trained in the treatment of penetrating uid injuries.

• Visually inspect all of the hydraulic hoses, lines, and fittings for signs of damage, wear or

leaking.

• If any signs of damage are visible, do not operate the machine until repairs have been made.

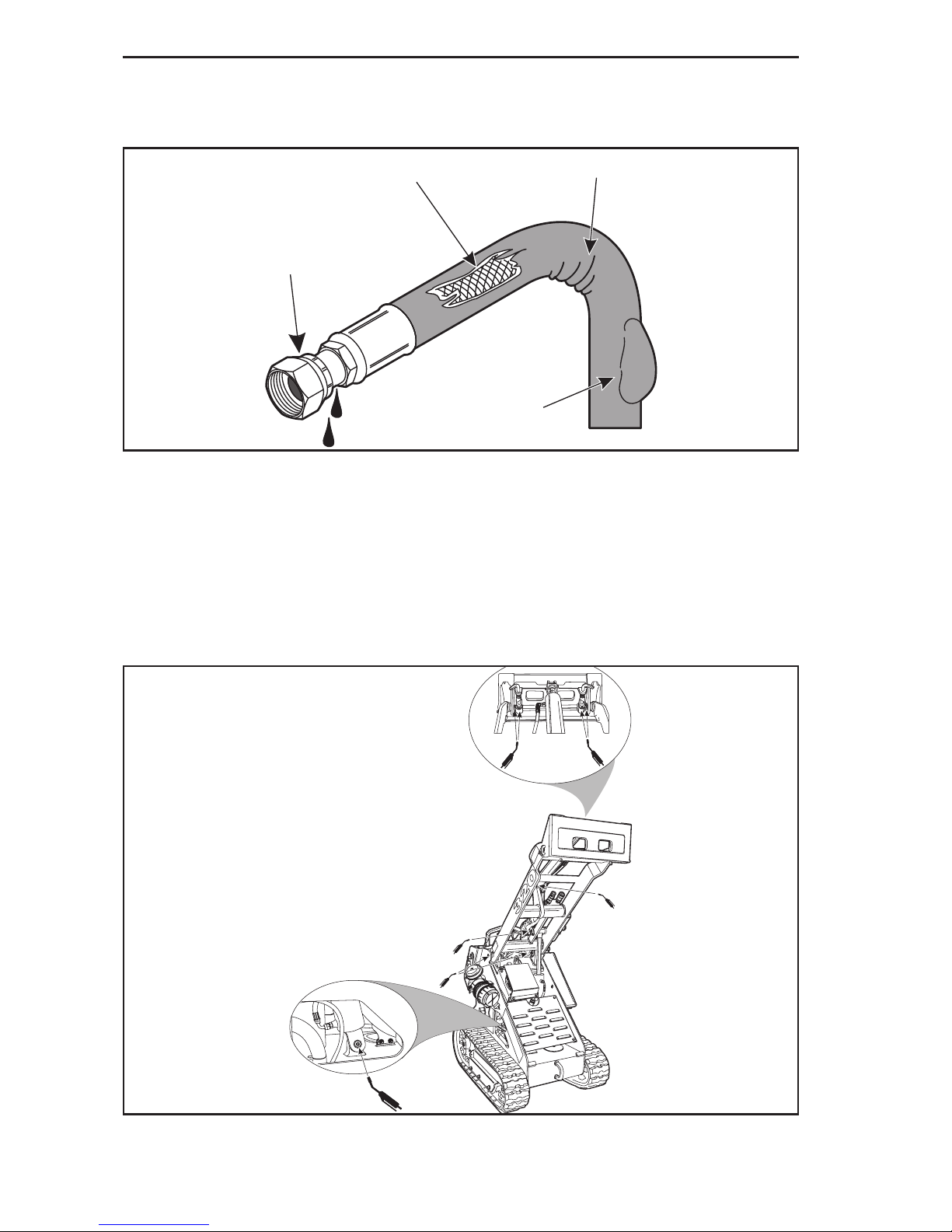

• Some examples of common hydraulic hose damage are shown in Figure 3–4.

Figure 3-4 Hydraulic Hose Damage

5. Check for loose or missing fasteners:

• Inspect for any loose or missing bolts.

• Tighten or replace any missing bolts immediately.

6. While you are performing the daily maintenance, inspect the machine for any signs of

damage, such as missing or damaged components, cracked welds, etc.

7. Check the track assemblies to make sure that:

• The tracks are in good condition and are not showing any signs of wear.

• Track tension is properly set.

• Track drive motors are not leaking oil or hydraulic uid.

1. End ttings damaged or leaking.

2. Outer covering chafed or cut, and wire reinforcing is exposed.

3. Hose shows signs of kinking or crushing.

4. Outer covering ballooning.

1

3

4

2

WARNING

Pre Start Inspection and Operation

3.5

8. Grease pivot shafts with proper type of grease. There are 9 grease points on this machine,

see Figure 3–5.

Before starting the engine:

• Move all hydraulic control levers forward and release the lever. Make sure that

each lever automatically returns to the Neutral position.

• Move all hydraulic control levers rearward and release the lever. Make sure that

each lever automatically returns to the Neutral position.

• The Auxiliary Control Lever will remain in the Reverse position until it is

manually moved to the Neutral position.

• If any of the levers, other than the Auxiliary Control Lever, does not

automatically return to the Neutral position, DO NOT use the machine until

repairs have been completed.

CAUTION

Pre Start Inspection and Operation

3.6

Figure 3-5 Lubrication Points

Extremely dusty or dirty working conditions may require more frequent service/replacement.

NOTICE

Pre Start Inspection and Operation

3.7

1

2

3

4

5

Cylinder Lock Removal

1. Start the engine and raise the loader arm to its full height.

2. Shut o the engine.

3. Pull the safety lock pin (Item 4, Figure 3–6) fully outwards.

4. Return the cylinder lock to the storage position (Item 1, Figure 3–6) on the loader arm.

5. Fully insert the safety lock pin (Item 2, Figure 3–6) and the lock knob (Item 3, Figure 3–6)

to secure the cylinder lock in the storage position.

Cylinder Lock Installation

Make sure to install the cylinder lock before performing any service work underneath

the raised loader arm assembly.

1. Start the engine. (See Machine Start-up in this section for engine starting instructions).

2. Fully raise the loader arm.

3. Shut o the engine.

4. Release the cylinder lock from its storage position (Item 1, Figure 3–6) by removing the

lock knob (Item 3, Figure 3–6) and pulling the safety lock pin (Item 2, Figure 3–6).

5. Place the cylinder lock (Item 5, Figure 3–6) onto the cylinder rod.

6. Fully reinsert the safety lock pin (Item 4, Figure 3–6), securing the cylinder lock in the

support position.

NOTE: Make sure that the safety lock pin goes behind the loader arm cylinder rod.

7. Lower the loader arm assembly until it is supported by the cylinder lock.

Figure 3-6 Operator’s Platform

WARNING

Pre Start Inspection and Operation

3.8

Operating Instructions

Machine Start-up

To start the machine, the operator must:

1. Stand on the operator’s platform (Item 1, Figure 3–7).

Figure 3-7 Operator’s Platform

2. Move the throttle lever (Item 1, Figure 3–8) to about half way between fast and idle engine

speeds.

Figure 3-8 Throttle Settings

1

1

Pre Start Inspection and Operation

3.9

3. Pull the chock knob (Item 3, Figure 3–9) outwards to set the engine choke.

4. Rotate and hold the start switch (Item 1, Figure 3–9) in the START position until the

engine starts.

Figure 3-9 Engine Keyswitch

5. As soon as the engine starts, release the starter key. The key will automatically return to

the RUN position.

6. Slowly push the choke knob inwards. If the engine begins to sputter, pull the choke knob

outwards slightly until the engine smoothes out. As soon as the engine warms up and

begins to run rough, push the choke knob inwards to the normal operating position.

7. Leave the throttle setting at about the halfway position and allow the engine to idle. This

will begin warming the hydraulic oil.

When warming the hydraulic oil, the operator must cycle all functions every 5 minutes.

This will assist in warming the hydraulic oil in all systems evenly and more rapidly.

Failure to do this can cause the control systems to stick creating a run-away situation.

8. In cold weather (32º F [0º C]) after about 5 minutes of engine idling, operate all of the

main hydraulic controls to cycle warmed hydraulic oil through the hydraulic lines into

the cylinders and hydraulic motors. Allow the engine to idle for another 5 minutes before

beginning any machine operations.

WARNING

1

2

3

Pre Start Inspection and Operation

3.10

Machine Shut-down

To safely shut the machine down, the operator must:

1. Park the machine on a solid, level area.

2. Lower the loader arm and attachment to the ground.

3. Idle the engine for 5 - 10 minutes to allow the machine to cool down.

4. Shut o the engine.

5. Clean o any accumulated mud and/or dirt from the machines operating surfaces, i.e.

operator’s platform, both track assemblies, etc.

Pre Start Inspection and Operation

3.11

Transportation

1. Move the throttle control lever to the mid-range engine speed and set the transport speed to

the LOW range. Raise the attachment so that it will clear the ramp of the transport trailer.

NOTE: The longer the attachment, like the trencher, the more the attachment needs to either be

tilted or raised. It is recommended to back the machine onto the transport trailer and position

the machine so that the heaviest weight (center of balance) is towards the front (hitch end) of

the trailer. See Figure 3–10.

The Boxer is designed for maximum working balance. When traveling on an incline,

always have the heaviest portion of the machine pointing uphill.

2. Follow general load carrying safety. Always carry the heaviest load pointing uphill.

NOTE: When operating without an attachment, the operator becomes the load.

Figure 3-10 Transport Position on Trailer

3. When the machine is positioned on the trailer properly, lower the attachment to the trailer deck.

4. Shut the engine o and remove the key.

5. Secure the unit to the transport vehicle with DOT (Department of Transportation) approved

chains, binders (Items 1 and 2, Figure 3–11), and DOT guidelines. Make sure to use the

appropriate tie-down locations (Items 3 and 4, Figure 3–11) on the machine and trailer.

NOTE:

• Never tow or pull the machine. Damage to the hydraulic motors could result.

• If the machine is totally in-operable, using lifting straps or cables and a machine that

can safely lift 4,000 lbs (1820 Kg), lift the machine and place on a trailer. See “Lifting

Procedures” on page 3-12.

When transporting the machine, make sure to use DOT approved chains and binders

(Item 1, Figure 3–12) to secure the machine to the “D” rings (Item 2, Figure 3–12) on the

trailer. NOTE: It is recommended to secure the machine through the ring on the front of

the machine (Item 2, Figure 3–12) and through the two rings on the Operator’s Platform

(Item 4, Figure 3–11).

CAUTION

WARNING

Pre Start Inspection and Operation

3.12

Figure 3-11 Travel Chains and Binders

Lifting Procedures

When it becomes necessary to lift the machine

1. Use a lifting device that can safely lift 4,000 lbs (1820 Kg).

2. Use appropriate lifting chains (Item 1, Figure 3–12) that can safely lift 4,000 lbs (1820

Kg).

3. Route the chains through the lifting eye (Item 2, Figure 3–12) located directly in front of

the operating controls.

• Lift the machine approximately 12” to make sure that the machine is balanced

before completing the lift.

• If lifting the machine with an attachment installed, the overall machine may not

be balanced from front to back.

CAUTION

3

4

2

1

3

Pre Start Inspection and Operation

3.13

Figure 3-12 Machine Lifting

Machine Travel Controls

• Levers and controls should return to the neutral position when they are released.

• Make sure that all of the controls are in the neutral (middle) position before starting the

engine.

• Operate the controls gradually and smoothly. Excessive speed and quick control

movements without regard for working conditions could cause an unsafe situation.

• Make sure to maintain your grip on both of the hand grips any time the machine is in

motion.

Due to the spring tension system built into the track drive system as a safety mechanism, the

machine can be put into an extreme situation during which the drive sprocket will bypass the

rubber track guide holes causing a popping noise, called “cogging”. This situation is part of

the track drive systems safety design, and indicates that this portion of the safety system is

functioning properly. Drive system damage can be caused by excessive cogging.

The “cogging” condition is most likely to occur while operating in a reverse direction pulling

a heavy load, and during the rst 50 hours of track usage. It is caused by the tension spring

being fully compressed due to high track load.

If a cogging condition occurs, immediately stop machine travel and auxiliary functions and

reverse travel direction slightly to de-compress track tension. Continued cogging will cause

the track drive sprocket to seat into the rubber track incorrectly, and cause damage to the

track. If cogging occurs, stop travel function and check for and remove any debris or foreign

matter in the drive system, check track for proper tension as shown in Section 4 of this

manual and resume operation.

WARNING

NOTICE

1

2

Pre Start Inspection and Operation

3.14

Forward Travel Reverse Travel

Push both control

levers forward

to travel straight

forward. The

farther these are

moved, the faster

the machine will

travel. See Figure

3–13.

Figure 3-13

Forward Travel

Pull both control

levers backward

to travel straight

backwards. The

farther these are

moved, the faster

the machine will

travel. See Figure

3–14.

Figure 3-14

Reverse Travel

Right Turn During Forward Travel Left Turn During Forward Travel

To turn to the

right, move the

left hand control

lever farther

forward than

the right control

lever. The farther

forward the left

control is moved,

the faster the right

turn will be made.

See Figure 3–15.

Figure 3-15

Right Hand Turn

in Forward

To turn to the left,

move the right

hand control lever

farther forward

than the left

control lever. The

farther forward

the right control is

moved, the faster

the left turn will

be made. See

Figure 3–16.

Figure 3-16

Left Hand Turn

in Forward

Pre Start Inspection and Operation

3.15

Right Turn During Reverse Travel Left Turn During Reverse Travel

Move the left

hand control lever

farther backward

than the right

control lever. The

farther forward

the left control is

moved, the faster

the right turn will

be made. See

Figure 3–17.

Figure 3-17

Right Hand Turn

in Reverse

Move the right

hand control lever

farther backward

than the left

control lever. The

farther forward

the right control is

moved, the faster

the left turn will

be made. See

Figure 3–18.

Figure 3-18

Left Hand Turn

in Reverse

Spin Turn

Make sure to use the machine hand holds while doing a spin turn to maintain your

balance.

CAUTION

Move the travel control levers in opposite

directions to spin the machine on it axis.

To spin left, move the right control lever

forward while pulling the left control lever

backwards; to spin turn to the right, push

the left control lever forward and while

pulling the right control lever backward.

See Figure 3–19.

Figure 3-19

Spin Turn

Pre Start Inspection and Operation

3.16

• Do not travel up or across a slope steeper than 15°. See Figure 3–20.

• Make sure that the tracks are extended to their widest position, providing the

broadest stance for the machine.

• Keep attachments as low as possible when traveling on slopes or rough terrain.

Figure 3-20 Slide Slope Travel

• Keep the heavy end of the machine towards the uphill direction when traveling

up or down a slope. NOTICE: When the machine has no attachment or load, the

heavy end is the operator’s platform end of the machine. See Figure 3–21.

Figure 3-21 Uphill/Downhill Travel

WARNING

16

15°

>15°

15°

>15°

Pre Start Inspection and Operation

3.17

Attachment Installation and Removal

Attachment Lock Pins

The mounting plate located at the front of the machine provides for the easy installation

and safe use of the wide variety of available attachments. This system is very easy to use,

but requires the proper use of the attachment lock pins. There are two positions for the

attachment lock pins, the unlocked position and the locked position.

Once the machine has picked up an attachment, shut o the engine and rotate the attachment

locks into the “locked” position (Item 1, Figure 3–22). As you rotate the lock pin, it will drop

downwards, securing the attachment to the machine. If the lock pin does not drop into the

locked position, start the engine and tilt the attachment slightly forwards or backwards until

the lock pins snap into place.

Figure 3-22 Attachment Locks in Locked Position

Until the attachment lock pins are fully in the locked position, the attachment has not

been safely secured to the machine. Do not stand near the attachment until it is fully

secured to the machine.

To release an attachment, rotate the attachment locks to the “unlocked” position (Item

1, Figure 3–23). The lock pins will automatically rise, releasing the attachment from the

machine. If the pins do not release the attachment or are very hard to rotate, start the engine

and tilt the attachment slightly forwards or backwards until the pins can be rotated.

CAUTION

11

Pins Locked

Pre Start Inspection and Operation

3.18

Make sure to keep your hands and feet away from the attachment during the unlocking

process. As the attachment becomes free from the machine, it may move.

Figure3-23 Attachment Locks in Unlocked Position

CAUTION

1

1

Pins Unlocked

Pre Start Inspection and Operation

3.19

Installation of Non-Hydraulically Powered Attachments

There are many available attachments that are very easy to install. To install any of the nonhydraulically powered attachments:

1. Position the attachment on a level surface.

Clean the inside lower edge of the female attachment mounting plate to remove any debris

that might interfere with the attachment installation.

2. Start the machines engine, lower the loader arm and tilt the mounting plate forwards.

Make sure that both of the attachment lock pins (Item 1, Figure 3–23) are in the “unlocked”

position. See Attachment Lock Pins earlier in this section.

3. When the top of the attachment mounting plate (Item 1, Figure 3–24) is rmly seated in

the attachment mounting bracket (Item 2, Figure 3–24), tilt the attachment mounting plate

backward slightly to allow the lower edge of the attachment mounting bracket to slide into

place on the attachment mounting plate.

Figure 3-24 Non-powered Attachment Installation

4. When the machines mounting plates top edge is seated in the attachment mounting plate,

curl the machines mounting plate backwards slightly to allow the lower edge of the

machines mounting plate to slide into position. See Figure 3–25.

NOTICE

NOTICE

1

2

Pre Start Inspection and Operation

3.20

Figure 3-25 Attachment Installed

5. Shut the engine o.

6. Rotate the attachment lock pins (Item 1, Figure 3–25 and Item 1, Figure 3–26) into the

locked position, securing the attachment to the machine.

Figure 3-26 Attachment Locks in Locked Position

DO NOT go underneath the attachment when it is raised.

7. Start the engine and raise the attachment o the ground. Visually inspect the bottom edge

of the attachments mounting plate to make sure that both of the attachment lock pins are

securely holding the attachment in position.

CAUTION

1

11

Pins Locked

Pre Start Inspection and Operation

3.21

Removal of Attachment

1. Lower the attachment onto a rm, level surface.

2. Shut o the machine engine.

3. Rotate the attachment lock pins to the UNLOCKED position (Item 1, Figure 3–27).

Figure 3-27 Attachment Locks in Unlocked Position

4. Start the engine and rotate the mounting plate downwards.

5. Back away from the attachment.

It may be necessary to lower the loader arm assembly slightly to fully disengage from

the attachment.

NOTICE

1

1

Pins Unlocked

Pre Start Inspection and Operation

3.22

Installation of Hydraulically Powered Attachments

There are many hydraulically powered attachments available that are very easy to install. To

install any of these attachments:

1. Position the attachment on a level surface.

Clean the lower edge of the female attachment mounting plate to remove any debris that

might interfere with the attachment installation.

2. Start the machine engine, lower the loader arm and tilt the mounting plate forwards.

Make sure that both of the attachment lock pins (Item 1, Figure 3–28 and Item 3, Figure

3–29) are in the “unlocked” position.

Figure 3-28 Attachment Locks in Unlocked Position

3. Slowly drive towards the attachment and align the top edge of the male mounting plate (Item

1, Figure 3–29) and the upper lip of the female attachment mounting plate (Item 2, Figure

3–29).

Make sure to position the attachments hydraulic hoses (Item 4, Figure 3–29) so that they are

not damaged during the installation process. Tuck the upper edge of the male mounting plate

into the upper lip of the female attachment mounting plate.

NOTICE

NOTICE

NOTICE

1

1

Pins Unlocked

Pre Start Inspection and Operation

3.23

Figure 3-29 Hydraulically Powered Attachment Installation

4. When the machines mounting plates top edge is seated in the attachment mounting plate,

curl the machines mounting plate backwards slightly to allow the lower edge of the

machines mounting plate to slide into position. See Figure 3–30.

Figure 3-30 Hydraulically Powered Attachment Installed

5. Shut the engine o.

DO NOT go underneath the attachment when it is raised.

6. Rotate the attachment lock pins (Item 1, Figure 3–30, Item 1, Figure 3–31) into the locked

position securing the attachment to the machine.

1

3

4

2

1

CAUTION

Pre Start Inspection and Operation

3.24

Figure 3-31 Attachment Locks in Locked Position

7. Start the engine and raise the attachment o the ground. Visually inspect the bottom edge

of the attachments mounting plate to make sure that both of the attachment lock pins are

securely holding the attachment in position.

8. Shut the engine o.

Make sure that the engine has been shut o before beginning this procedure.

9. Move any of the main hydraulic controls forward and backward to release any stored

hydraulic pressure.

10. Attach the hydraulic hoses to the quick connects. See Figure 3–33.

a. Move the AUXILIARY control lever (Item 1, Figure 3–32) either towards the hand

grip or backwards into the REVERSE detent position. This will release the hydraulic

pressure locked in the auxiliary hydraulic lines. Leave the control lever in the detent

position.

Figure 3-32 Auxiliary Control Lever

WARNING

1

11

Pins Locked

Pre Start Inspection and Operation

3.25

b. Remove the protective covers (Items 3, Figure 3–33) from the attachment quick

connectors.

c. Wipe o the end of each of the connectors (Items 1, 2, 4, 5, Figure 3–33) to remove any

dirt or debris.

Figure 3-33 Auxiliary Hydraulic Quick Connects

d. Insert the attachments male coupling (Item 2, Figure 3–33) into the female bulkhead

quick connect coupling (Item 1, Figure 3–33) on the machine and push until the

connector locks into position.

e. Repeat the above process to connect the attachments’ female quick connect (Item 4,

Figure 3–33) on the other hose to the male bulkhead connector (Item 5, Figure 3–33) on

the machine.

f. Check the security of both connections by gently tugging on the attachment hoses to

make sure that the quick connects are seated properly.

1

2

3

5

4

3

Pre Start Inspection and Operation

3.26

11. Make sure that the hydraulic hoses are routed so that they will not be in the way or

damaged during machine operation. Figure 3–34 shows how the hoses might be routed to

keep them out of the way during operation and prevent them from being damaged.

Figure 3-34 Attachment Hydraulic Hose Routing

12. The attachment is now ready to use.

Before starting the engine, make sure that the Auxiliary control lever is in the

NEUTRAL position. If this control is left in either the forward or reverse position and

the engine is started, the attachment will begin to function.

CAUTION

Pre Start Inspection and Operation

3.27

Operating Instructions for a Hydraulic Attachment

1. Move the engine throttle to the full speed setting. Raise the attachment o the ground and

position it for use.

2. Move the HI/LOW selector lever (Item 2, Figure 3–35) to either the high speed or low

speed setting depending on the attachment to be used. This setting will control both the

functional speed of the attachment as well as machine travel speed.

Figure 3-35 Auxiliary Attachment Controls

3. With your left hand, squeeze the OPERATOR PRESENCE control lever (Item 1, Figure

3–35) towards the hand grip to activate the FORWARD motion of the attachment.

NOTE: The OPERATOR PRESENCE lever is spring loaded and when released, will

automatically move from the FORWARD motion position to NEUTRAL, stopping the

attachments motion. The engine will continue to run.

When using an attachment that will require the machine to move, such as with a trencher or

tiller, it is recommended to set the HI/LOW selector lever to the LOW speed position.

4. Lower the attachment to begin work.

NOTE: If you want to reverse the operation of the attachment, move the OPERATOR

PRESENCE lever (Item 1, Figure 3-32) to the REVERSE position. The control lever will

remain in the REVERSE position detent until it is moved to the NEUTRAL position.

• Make sure not to travel to fast for operating conditions when using a trencher,

tiller or other attachment that requires the machine to move.

• Stop all machine travel before releasing the OPERATOR PRESENCE lever.

1

2

NOTICE

CAUTION

Pre Start Inspection and Operation

3.28

5. When using a trencher, tiller or other attachment that requires the machine to move while

the attachment is in operation, move the travel control levers slightly in either the forward

or reverse position. Using too fast a travel speed can create an unsafe operating condition

or cause damage to the machine. If the engine begins to labor or stalls, release the travel

controls completely until the engine returns to full operating power.

Pre Start Inspection and Operation

3.29

Removal of Hydraulically Powered Attachments

After use, the quick couples and hydraulic uid will be very hot. Wear gloves when

disconnecting the auxiliary hydraulic lines.

To remove a hydraulically powered attachment;

1. Lower the attachment to the ground and shut o the engine.

2. Move the hydraulic control lever forward or backward to release any stored hydraulic

pressure.

3. Some of the female couplings will have a lock button preventing accidental disconnection.

To release this type of quick connect, rotate the collar on the female quick connect (Item 1,

Figure 3–36) to align the notch on the collar with the lock button (Item 2, Figure 3–36).

4. Slide the collar backwards on the female quick connect (Item 4, Figure 3–36) until it stops

against the lock button. The male connector will be released. Move the attachment hose

away from the bulkhead tting.

5. If the female connector does not have the lock pin type collar, just slide the collar

backwards until the male connector is released.

Figure 3-36 Quick Connect Locking Collar

6. Repeat this procedure on the other hydraulic line.

7. Cover the hose connections with the dust caps (Item 5, Figure 3–36) and store the

hydraulic hoses to prevent damage.

8. Follow the instructions in “Removal of Attachment” earlier in this section to complete the

attachment removal.

CAUTION

2

1

3

4

5

Pre Start Inspection and Operation

3.30

4.1

Section 4 - Routine Service and Maintenance

The following information presents the routine service and maintenance required to make

sure that the machine functions safely and properly. More detailed service information is

contained in the Service Manual.

Table 4-1: Service Cycle Table

Activity

Daily

(10 Hours)

New

Machine

(20 Hours)

Weekly

(50 Hours)

Monthly

(200 Hours) Annual

Safety Placards 3 and R

Fuel 3 and A

Engine Oil 3 and A R* R**

Engine Oil Filter R* R**

Air Filter 3 R** R**

Fuel Filter R**

Engine Idle Speed 3

Check and Clean Battery Ter-

minals and Battery

3 3

Hydraulics

- Hydraulic Filter R* R**

- Hydraulic Fluid Level 3, A, and **** R**

- Hydraulic Hoses 3

Grease 3***

Tracks 3

Visual Check for

Loose/Missing Fasteners

3

Check and Adjust

Track Tension

3

Service Cycle - R = Replace 3 = Check A = Add

* First 20 operational hours, then follow normal service cycle.

** Extremely dusty or dirty working conditions may require more frequent service/replacement.

*** Under very wet and muddy conditions, more frequent lubrication may be required.

*** Check when cold, ll to 1/4” below ll mark.

Routine Service and Maintenance

4.2

Daily Maintenance Procedures

Do the following procedures daily or every 10 operating hours:

1. Check condition of all warning and instructional decals. Before operating the machine,

replace any missing or damaged decals.

Make sure to read and understand all WARNING and SAFETY decals before

operating the machine.

• Allow engine to cool before lling fuel tanks.

• Do not overll because fuel could spill onto hot engine parts and ignite or

explode.

• Make sure engine is turned o.

2. Check engine fuel and ll as needed - be sure engine is OFF.

a. The Boxer has one saddle tank (Item 1, Figure 4–1), on the left side of the machine.

Figure 4-1 Fuel Level Check

b. The fuel tank has a fuel gauge located in the ller cap (Item 2, Figure, 4-1). Remove cap

and visually inspect fuel level to make sure that the indicator is showing the proper fuel

level. Make sure that the tank has been lled on a daily basis.

Carefully pour gas into the tank, not exceeding the max ll indication shown by the

gauge in the fuel cap.

NOTICE

CAUTION

E

F

2

1

Routine Service and Maintenance

4.3

3. Check engine oil -

a. Make sure that the engine is OFF.

b. Pull out the dipstick (Item 1, Figure 4–2) and look for the “FULL” line.

Figure 4-2 Oil Level Check

c. If the engine oil level is below the add line, indicated by the lower line on the dipstick,

carefully add the proper amount of oil through the engine oil ller (Item 1, Figure 4–3).

The correct SAE viscosity grade of oil is determined by the minimum ambient

temperature during cold engine start-up, and the maximum ambient temperature during

operation. The engine is lled at the factory with Chevron Delo 400 Multigrade SAE

15W-40. The recommended ambient temperature range for this oil is 14° F (-10° C)

minimum to 122° F (50° C) maximum. Refer to the engine Operation and Maintenance

Manual for additional information on the proper selection of engine oil.

NOTE:Make sure to reinstall and secure the oil ller cap.

Figure 4-3 Engine Oil Fill

1

2

1

Routine Service and Maintenance

4.4

Air Filter Replacement

1. Check air lter and replace paper elements if they are extremely dirty or plugged.

2. Replace the outer paper element* (Item 3, Figure 4–4) and check inner element* (Item 2,

Figure 4–4).

a. Unhook the two retaining clips and remove the end cap (Item 1, Figure 4–4) from the air

cleaner housing.

b. Pull the outer air cleaner element (Item 3, Figure 4–4) out of the housing.

c. After the main element is removed, check the condition of the inner element (Item 2,

Figure 4–4). It should be replaced whenever it appears dirty, typically every other time

the main element is replaced. Clean the area around the base of the inner element before

removing it, so dirt does not get into the engine.

d. Do not wash the paper element and inner element or use pressurized air, this will

damage the elements. Replace dirty, bent or damaged elements with new genuine

Morbark, LLC repair parts as required.

e. Handle new elements carefully; do not use if the sealing surfaces are bent or damaged.

f. Check all parts for wear, cracks, or damage.

g. Replace any damaged components.

h. If needed, install the new inner element, followed by the outer element. Slide each fully

into place in the air cleaner housing.

i. Reinstall the end cap (Item 1, Figure 4–4) so the dust ejector valve is down and secure

the end cap with the two retaining clips.

*In extremely dusty or dirty operating conditions, this service cycle may need to be

shortened.

Figure 4-4 Air Filter Assembly

NOTE: Extremely dusty or dirty working conditions may require more frequent checking,

lling and/or changing of engine oil.

d. After lling the oil, wait a few minutes and check the oil level again.

Make sure to securely reinstall the dipstick into the dipstick tube before starting the engine.

1

2

1

3

NOTICE

Routine Service and Maintenance

4.5

Hydraulics Inspection and Service

If you are checking the uid level after a period of use, the hydraulic system and

hydraulic uid will be very hot. Wear gloves when inspecting the hydraulic uid level.

1. Check hydraulic oil level, ll as needed with the proper hydraulic oil - be sure engine is

OFF

a. The hydraulic dipstick is located under the large nut (Item 1, Figure 4–5) on the

hydraulic tank ller port (Item 2, Figure 4–5) located on the right side of the machine.

b. Unscrew the dipstick assembly and remove from the machine. (Item 1, Figure 4–5).

c. Make sure that the hydraulic uid is 1/4” below the marker hole in the dip stick.

Figure 4-5 Hydraulic Fluid Level Dip Stick

d. Add the proper hydraulic uid (Chevron Rykon Premium ISO 46 hydraulic uid or

equivalent).

Do not over ll the hydraulic system. Damage to the hydraulic system might result.

CAUTION

1

2

NOTICE

Routine Service and Maintenance

4.6

2. Check hydraulic hoses.

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use

cardboard or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are

injected with hydraulic oil or any other uids, immediately seek treatment by a doctor

trained in the treatment of penetrating uid injuries.

a. Fully raise the loader arm, install and secure the safety support.

b. Follow all of the hoses, line and tubes from the control valve to their end (Items 1, 8

and 9, Figure 4–6). It will be necessary to remove the service access cover (Item 5,

Figure 4–6). Remove the four bolts and washers (Items 6 and 7, Figure 4–6) and then

the service cover. Inspect the connections and look for signs of leaking hydraulic uid,

wear or damage.

c. Carefully inspect both sets of quick couples (Item 2, Figure 4–6) to make sure that they

are not damaged or leaking.

d. Make sure to check for signs of leakage or damage to the drive motors (Item 4,

Figure 4–6) and to their hydraulic connections.

Figure 4-6 Inspect Hydraulic Lines and Fittings

1

1

2

4

8

8

9

9

5

3

6

7

WARNING

Routine Service and Maintenance

4.7

e. If any signs of damage are visible, do not operate the machine until repairs have

been made.

f. Some examples of common hydraulic hose damage are shown in Figure 4–7:

Figure 4-7 Hydraulic Hose Damage

3. Outer covering ballooning.Lubricate pivot shafts with grease. There are 9 lubrication

points on this machine, see Figure 4–8.

Figure 4-8 Lubrication Points

1

3

4

2

1. End ttings damaged or leaking

2. Outer covering chafed or cut, and wire reinforcing is exposed

3. Hose shows signs of kinking or crushing

4. Outer covering ballooning

Routine Service and Maintenance

4.8

NOTE: Extremely dusty or dirty working conditions may require more frequent service/

replacement.

4. Check both track assemblies for:

a. The proper tension. Too little or too much tension can cause premature track wear and

travel motor damage.

b. Make sure that the tracks are not worn or damaged.

5. Check for loose or missing fasteners.

a. Inspect for any loose or missing bolts or fasteners.

b. Tighten or replace any missing bolts or fasteners before operating the machine.

6. Check for proper track tension.

a. Raise the machine o the ground and support it using a device capable of safely

supporting 4000 lbs. See Figure 4–9 for suggested location of the support devices, as an

example, place a concrete or solid wooden block under the operators platform and solid

supports under the bucket.

b. Tilt the bucket downwards until the cutting edge is touching the ground. See Figure 4–9.

c. Lower the loader arm assembly, pushing the front of the machine upwards. Continue

raising the machine until the rear drive sprocket is o the ground. Shut o the engine.