Mopec BF400, BF450, BF500, BF550, BF510 User Manual

USER MANUAL

www.mopec.com

BF Series

Down/Back Draft Workstations

BF400, BF450, BF500, BF510, BF550

Rev 10-28-16 ©

P a g e | 2

P a g e | 3

TABLE OF CONTENTS

UNPACKAGING YOUR PRODUCT..…………………………………………………4

INSTALLATION………..…………………………………………………………….……..5

PRODUCT DRAWINGS

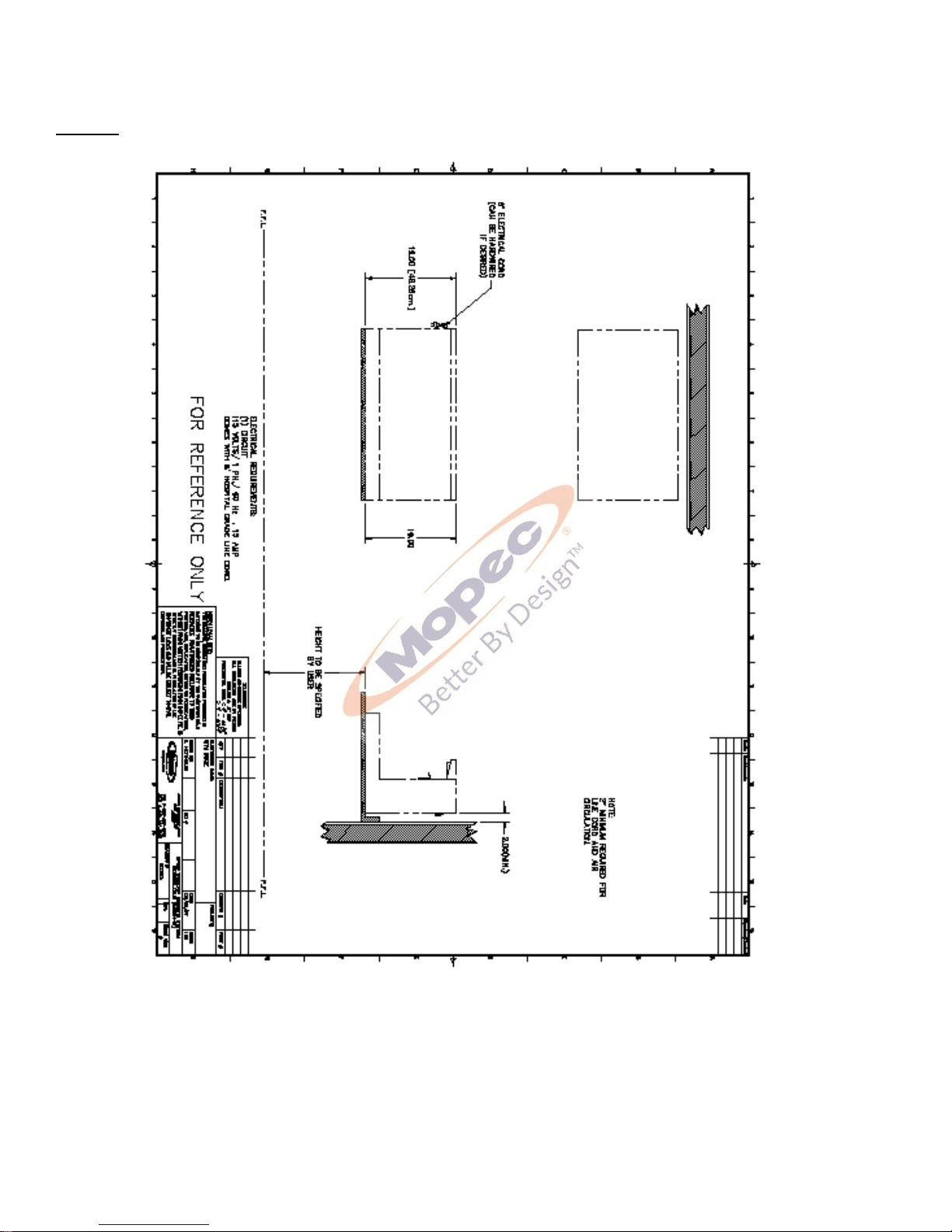

BF400 ROUGH IN……………………………………………………………..7

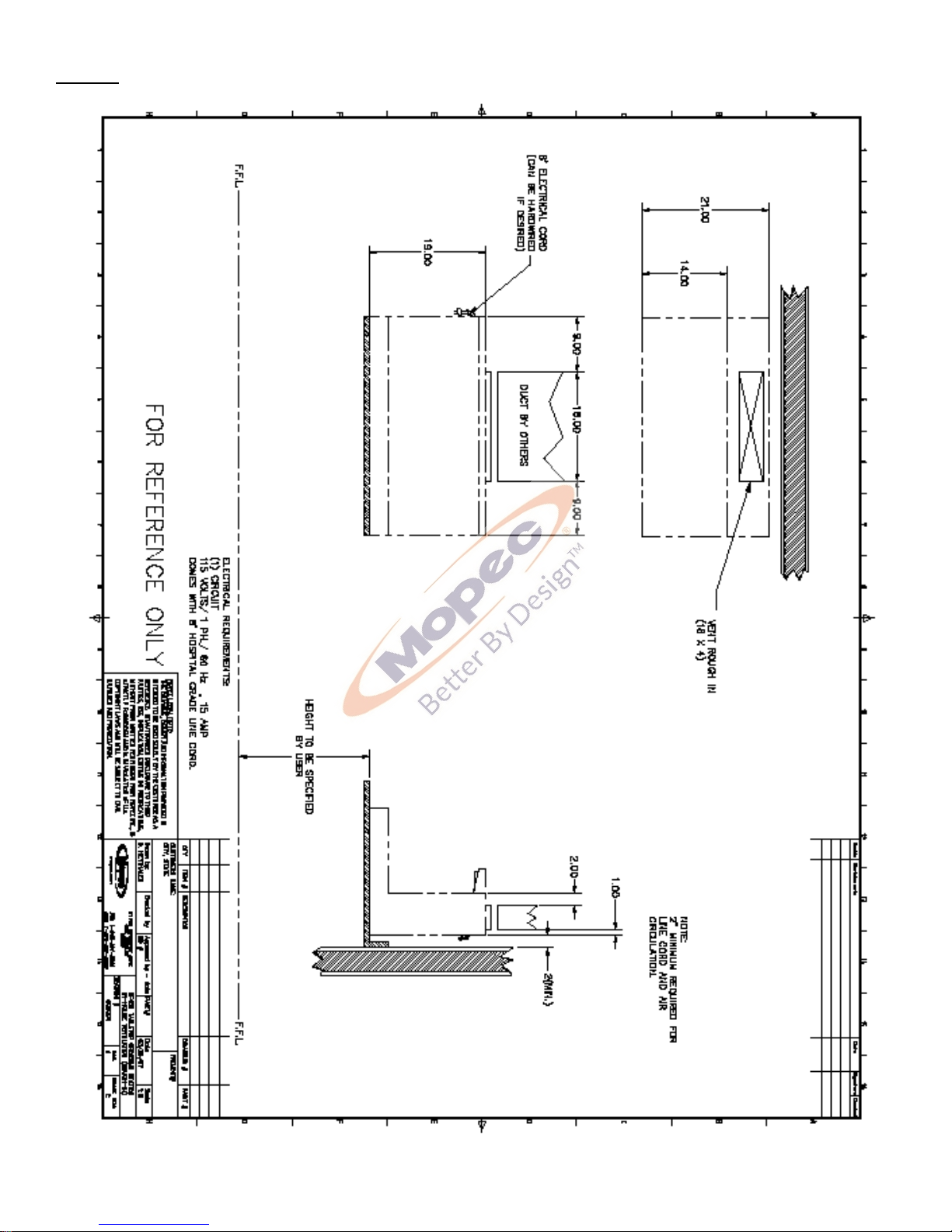

BF450 ROUGH IN……………………………………………………………..8

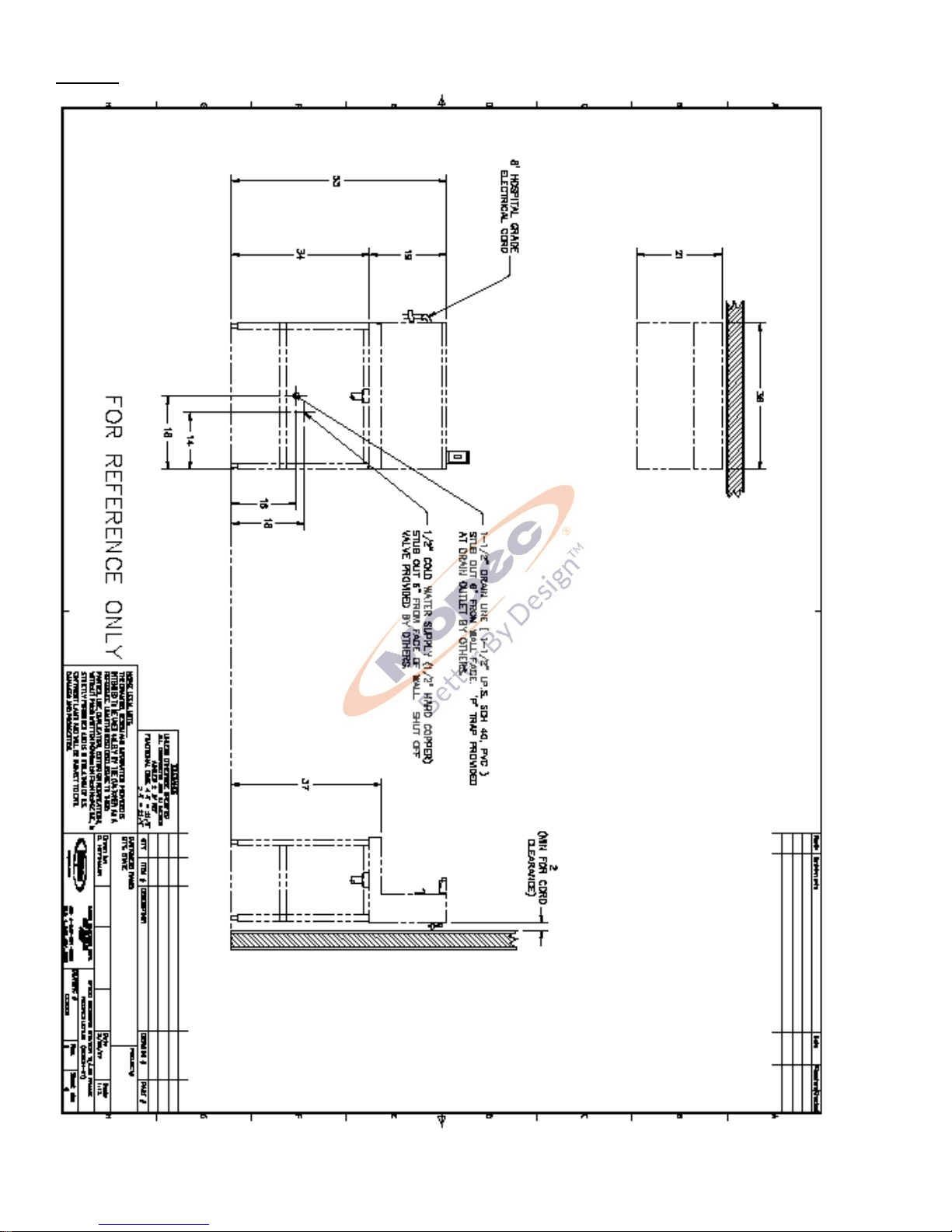

BF500 ROUGH IN (w Optional Leg Frame)..……………………..9

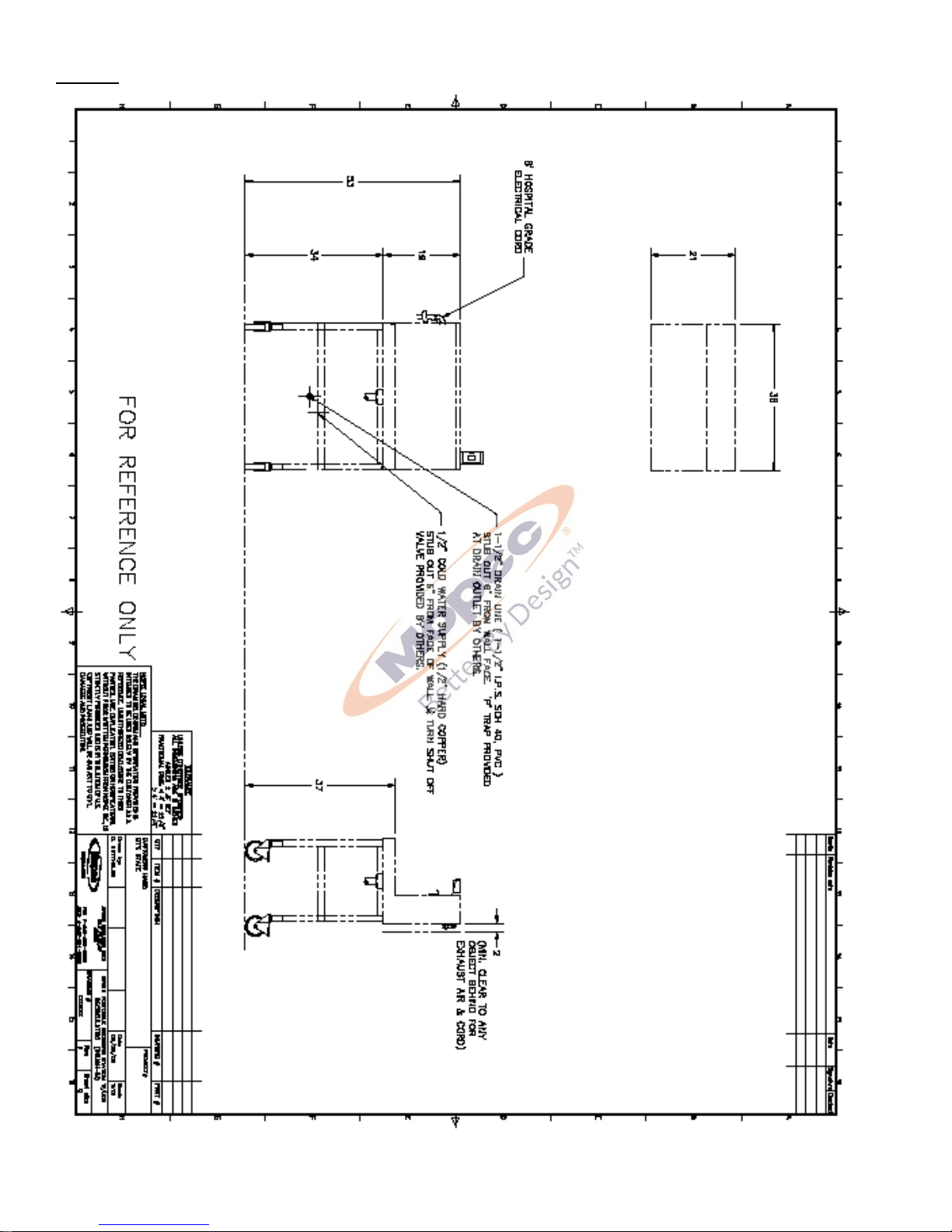

BF510 ROUGH IN…………………………………………………..………..10

BF550 ROUGH IN ………………………………………………..………….11

INTRODUCTION ……………………………………………………..…………………..12

PRODUCT DRAWINGS

BF400 …………………………………………………….……………………..13

BF450 …………………………………………………….……………………..14

BF500 …………………………… ……….…………….………………………15

BF510 ……………………………………………………………………………16

BF550 ……………………………………………………………………………17

FEATURES………………………………………………………………………………….18

AIR HANDLING………………………………………………..………………………..19

CLEANING AND MAINTENANCE

Filter information and evaluation………….……………..……….20

Stainless Steel Care and Maintenance………………………......21

Parts……………………………………………………..…………………..….24

Preventive Maintenance……………………….………………..…….25

WARRANTY……………………………………………………….………………..…….26

SAFETY LABELS……………………………………………………..…………..………27

TROUBLE SHOOTING GUIDE…………………………………………………..….28

ELECTRICAL DIAGRAM………………………………………….……………..…...29

CERTIFICATES……………………………………………………….……………..……30

P a g e | 4

UNPACKING

1) Carefully inspect the exterior of the shipping container before opening. If the crate is damaged and the

product has sustained damage, then immediately contact Mopec and the freight carrier. Never discard the

shipping container even if it is damaged beyond recognition.

2) Have the delivery driver note any suspected damage on the Bill of Lading and sign it. Mopec will help assist in

filing a claim for product repair and/or replacement.

3) Carefully open the containers and inspect the equipment for concealed damage. If visible damage is noticed

(i.e. broken welds, dented stainless, scratches, etc.) follow through as noted above. Do not discard the

shipping material. They are important in settling claims.

CAUTION: There are loose components in the packaging of your product. Be very careful in examining the

packaging material as it may contain installation parts and/or product components.

INSPECTION

1) After carefully unpacking your Mopec workstation please inspect the items in the list below prior to installing

the unit. The workstation should be thoroughly checked for loose screws, defects, or damage that may have

occurred during shipping or packaging.

P a g e | 5

INSTALLATION

BF Series Down and Back Draft Workstation Installation Instructions

Locate package of smaller items (dissection board, tissue boxes, or filters)

When removing from the shipping platform, be careful if the unit has a foot pedal. The unit should be removed from

the shipping platform as to not cause damage to the copper plumbing attached to the foot pedal

Leveling and Setting Unit in Place

The unit should be off the floor and resting on the leveling pads. The unit should be leveled to ensure proper drainage.

This allows water to evaporate or dry in case of a leak without getting trapped by the base of the unit Ensure there is a

Minimum of 6.5” from the wall to the back of the unit. This allows for elevating units to move freely without any

obstructions to the wall.

Utility Connections

The only connections necessary are the Electric, Cold and Hot water supply, the drain connection and the HVAC

connections if in house ventilation. The unit is already pre-wired and plumbed for the options ordered.

Electrical Connection

All electrical, water and ventilation stubs should be prepared in accordance with our rough-in dimensions shown on

rough in diagram from your approval process.

The electrical service provided for the MB600 must include:

1) A switch or circuit breaker for each circuit to which the wiring harnesses from the workstation will be

connected.

Each BF Series Workstation has a eight-foot line cord with a hospital grade plug. It is possible to order with a 3 foot

whip to permanently hard wire the unit to the electrical connection. The whip leads are labeled L1 and C1 for the unit

electrical options such as lights and fans if a recirculation unit.

There are three wires:

Black Labeled as L1

White Labeled as C1

Green w Yellow Stripe Ground

Flexible water tight conduit and connections are the preferred conduit and is not provided with the unit. This is due to

an unknown length needed and variances possible in the rough in process.

Drain Connection

The BF500, BF510 and BF550 workstations are equipped with 1.5” Diameter drain and connections. DO NOT modify

the drain line or connections without contacting MOPEC first. The Units are built in accordance with the rough in

drawings specific to the unit. The height is per the rough in drawings provided at the time of the order.

Water Supply Connection

The water supply connections are ½” DIA copper pipe. The unit has been cleared of water and debris during the

manufacturing and testing of the unit. The rough in drawing for the unit suggests a 1/4 turn valve to be connected to

the wall. This is to allow the water to be localized and disconnected should the need arise to work on plumbing in the

future. Before connecting the unit to the facility water supply, check the lines in the facility for debris by flushing the

lines for a moment. After the connections are made remove the aerator from the faucet and turn the water on and

open the faucet and other water options after the faucet to allow any debris to evacuate the system. This is the time

to look for leaks or other plumbing issues. The plumbing is tested for leaks and function at the facility and is put under

pressure for 45 minutes to check for leaks. However, the plumbing is hard copper and soldier connections. During

transport a unit may experience a failed soldier joint. Contact MOPEC immediately if there is a leak.

P a g e | 6

Ventilation Connection

Ventilation is one of two types for the BF Workstations; In House Ventilation or Recirculation. For in house the unit is

connected to the facility ventilation system via duct work.

In House

BF450 the connection is a 4” x 18” rectangular stub on the top back of your unit. The duct work is not provided by

Mopec unless specifically ordered.

MB550 the connection is a 4” x 18” rectangular stub on the top back of your unit. The duct work is not provided by

Mopec unless specifically ordered.

Recirculation

BF400, BF500 and BF510 the filters will need to be installed. You should have a minimum of 2 inches or more behind

the workstation for the filtered air to discharge. Air flow is generated by multiple fans in the recirculation models. They

are controlled by a rheostat to control volume/speed.

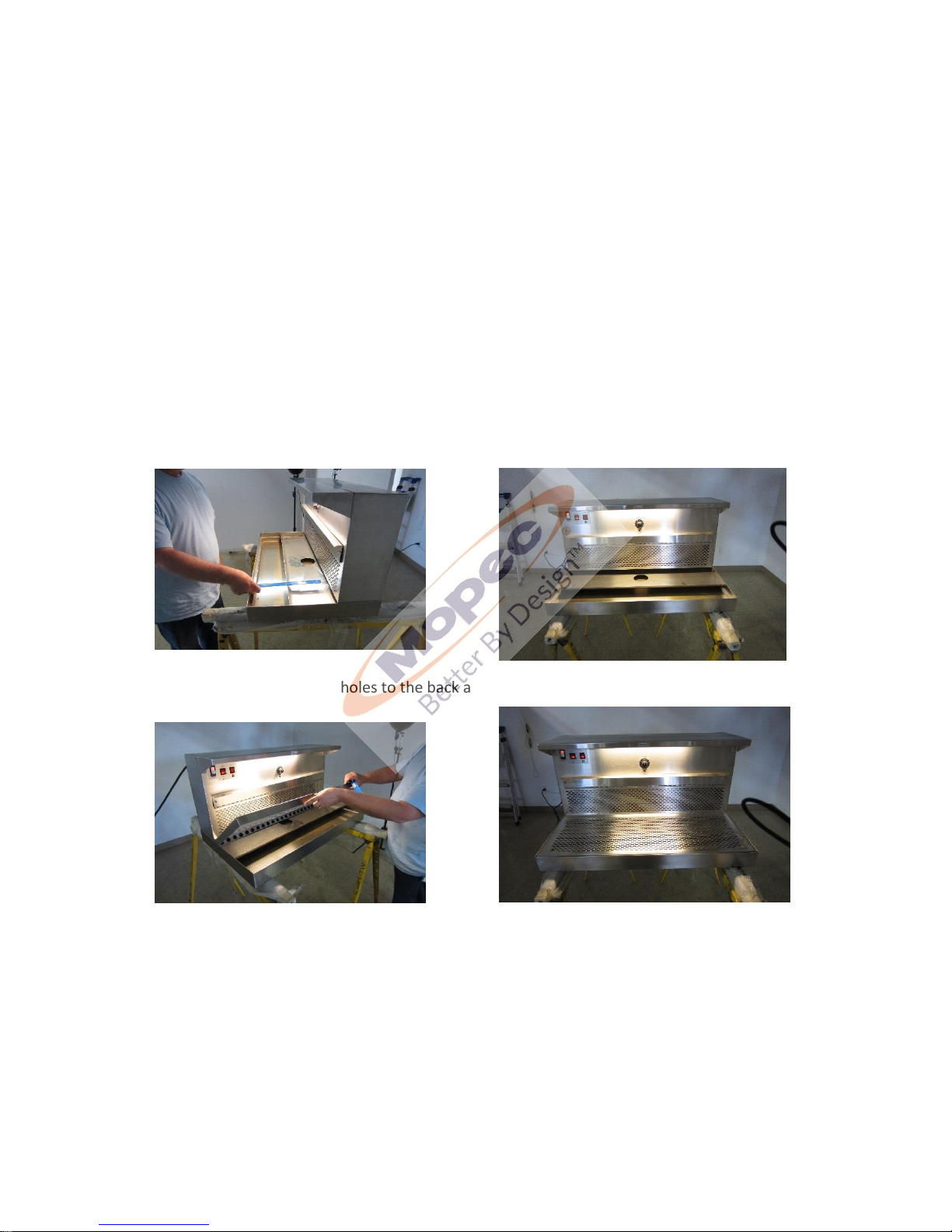

The ventilation diverter should be placed no more than 15CM (Approx 6” from the front/ Please see the photo below.

The grid plate must be installed with the holes to the back and the finger holes to the front as shown below

The next step is to open filter access door (it the unit is a recirculating air unit) by unlatching both side latches pivoting

the access door open and removing filters.

Each filter can be removed simply by pulling it toward you and out of the module. Both the activated charcoal filters

are wrapped in plastic and must be removed before installation. You may notice some loose charcoal particles due to

transportation which is normal.

Once the plastic is removed slide the filter in the slot and close the door.

** Caution ** These are general guidelines and installation is specific for each of the BF Series units. Professional

installation is recommended.

P a g e | 7

Rough In Drawings

BF400

P a g e | 8

BF450

P a g e | 9

BF500

P a g e | 10

BF510

Loading...

Loading...