Page 1

May 2016

149-733-00 D

Programmable Isolated

RTD Transmitter

RIY

Programmable Isolated

RTD Transmitter

RIY

Page 2

Table of Contents

Introduction 1

Description 1

Calibration 3

Installation 13

Operation 14

Maintenance 19

Page 3

RIY

Introduction

Moore Industries’ Programmable Isolated RTD

Transmitter (RIY) is a 2-wire, microprocessor-based

instrument that converts an RTD or ohms input into a

4-20 mA output. The output is field-configurable to be

linear with temperature or linear with an ohms input.

The highly accurate RIY features easy-to-use push

buttons, a rotary switch, and a SIP switch for field

calibration and configuration.

This manual contains descriptive, calibration, installation, and operation information for the RIY. Also

included in this manual is a quick reference page

containing often referred to setup and hookup information (see appendix A).

Notes and cautions are provided throughout this

manual to help you avoid minor inconveniences

(NOTES) and equipment damage (CAUTIONS).

Description

The RIY is a loop-powered, RTD transmitter that

accepts an input from 2-, 3-, or 4-wire RTD’s, or a

resistance source. The RIY processes the input

signal using digital technology and produces a

proportional 4-20 mA output.

• Readouts in degrees Celsius or Fahrenheit, or

ohms (only on units with LCD’s)

• Sensor type and number to be input to the RIY

• Upscale/downscale drive

• Quick/standard ranging

• Keyboard lockout/enable

The RIY is available in two housing styles; a hockeypuck (HP) housing and a DIN-style housing. Both

housing styles have the same operational features

and offer the same options. The intended application

of the RIY must be clearly identified to determine

which housing style is most suitable.

The standard HP-style housing is equipped with

spring clips for mounting in explosionproof enclosures. An RIY packaged in an HP-style housing and

equipped with flange plates (FL Housing option) is

designed to mount on a flat surface or on relay tracks.

The configuration switches for HP-style units are

accessible through a removable panel at the rear of

each unit.

The all-aluminum DIN-style housing snaps directly

onto standard G-type or Top-hat DIN rails. The

configuration switches for DIN-style units are accessible through a removable panel on the upper rightside panel of the unit. The physical layout of the

configuration switches in DIN-style units is identical to

that of HP-style units.

Tactile push buttons, located on the front panel, are

used to set the zero and span (full-scale). The values

entered are stored in an EEPROM and remain, even

when power is removed, until the values are changed

by the user. The push buttons provide greater

calibration accuracy and stability than do potentiometer adjustments of non-microprocessor-based

instruments.

A 4-digit, liquid crystal display (LCD) is standard on

the RIY. (The RIY is available without the LCD.) This

display provides readouts of the applied input (either

in temperature or ohms), and it displays problem

codes. (The LCD is required for

Switches are used to configure several functional

characteristics of the RIY. Each of these switches is

accessible without disassembling the unit. The

switch-selectable features include:

quick ranging

Table 1 contains the operational and performance

specifications for the RIY.

Options

The RIY is available with several optional features.

The following is a brief description of the most

popular options:

DD Option — Downscale drive on loss of input

(upscale drive is standard)

.)

ND Option — No display (LCD)

For availability of other options, including intrinsic

safety approvals, contact your local Sales Representative or Moore Industries’ directly.

The Interface Solution Experts

1

Page 4

RIY

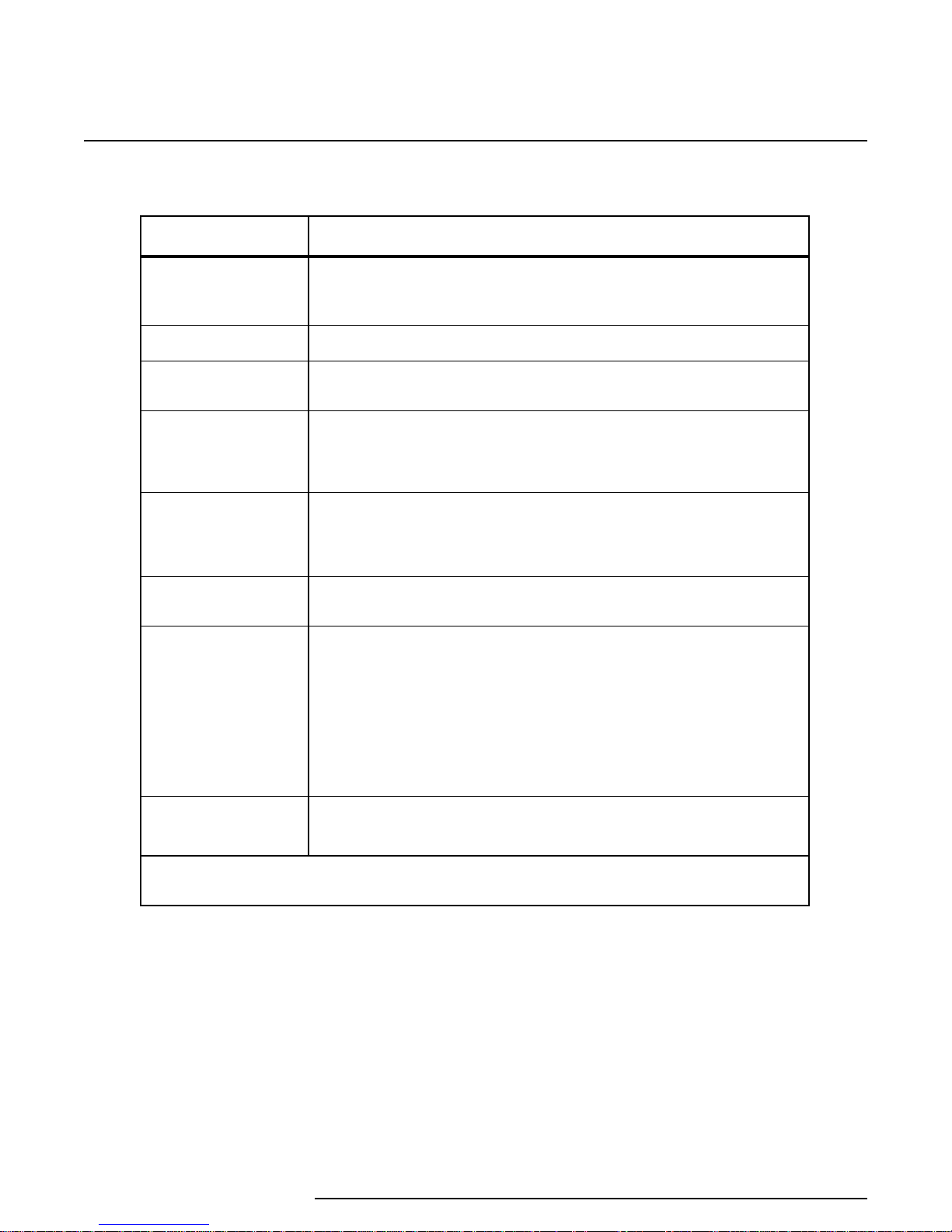

Table 1. RIY Operational and Performance Specifications

Characteristic

Input

Output

Power

Controls

Indicators

Fault

Response

Performance

Specification

RTD’s, 2-, 3-, or 4-wire (single, dual, or triple sensors)

Ohms, 0-4000Ω

(refer to the Calibration Section for ranges)

4-20 mA – linear with temperature or ohms input (switch-selectable)

12-42 Vdc loop-power, standard

12-30 Vdc, I.S. version

Four front panel push buttons: used to set zero and span; SAVE

function (2 'up' buttons); and CANCEL function (2 'down' buttons)

Switches: Used to set the unit’s operating configuration (see Calibration

Section for application of switches)

Liquid Crystal Display: 4-digit LCD; diaplays input values; zero and

full-scale values; problem codes; and high and low table limit warnings

(RIY available without LCD)

LCD Accuracy: ±0.1% of maximum span, ±1 digit

On Loss of Input: Upscale drive to 21.4 mA; downscale drive to 3.6 mA

(switch-selectable)

Accuracy: ±0.05% of span (refer to table 2 for accuracy by input type)

Isolation: Galvanic isolation between input and output up to 1000 Vdc

Stability: ±0.1% of calibrated span for 6 months

Ripple: <10 mV P/P, maximum (up to frequencies of 120 Hz) measured

across a 250Ω load resistor

RFI/EMI Susceptability: 30 V/m – abc -0.1% of ohms reading as

defined by SAMA 33.1 (HP and DIN units)

Ambient Temperature Effect: All combined effect, ±0.006% of span/°C

±10 ppm of ohms reading/°C

Environmental

Ratings

NOTE: Refer to the Installation Section of this manual for housing dimensions.

Unit Data Tracking – Model/Serial Numbers. Moore

Industries keeps a record of configuration information

on every unit it sells or services. This information is

keyed to the unit model and serial numbers.

The serial and model number for the HP-style RIY is

located on the back panel of the unit. The serial and

2

The Interface Solution Experts

Ambient Operating Temperature: –40 to 82 °C (–40 to 180 °F)

Storage Temperature: –40 to 100 °C (–40 to 212 °F)

model number for the DIN-style unit is located on

the right-side panel of the unit.

If product information is ever required, make a note

of the unit model number before contacting the

factory. For fastest assistance, also note the unit

serial number, and the job number and purchase

Page 5

RIY

order number under which the unit was shipped. This

information assists our factory representative in

providing you with the answers you need as efficiently

as possible.

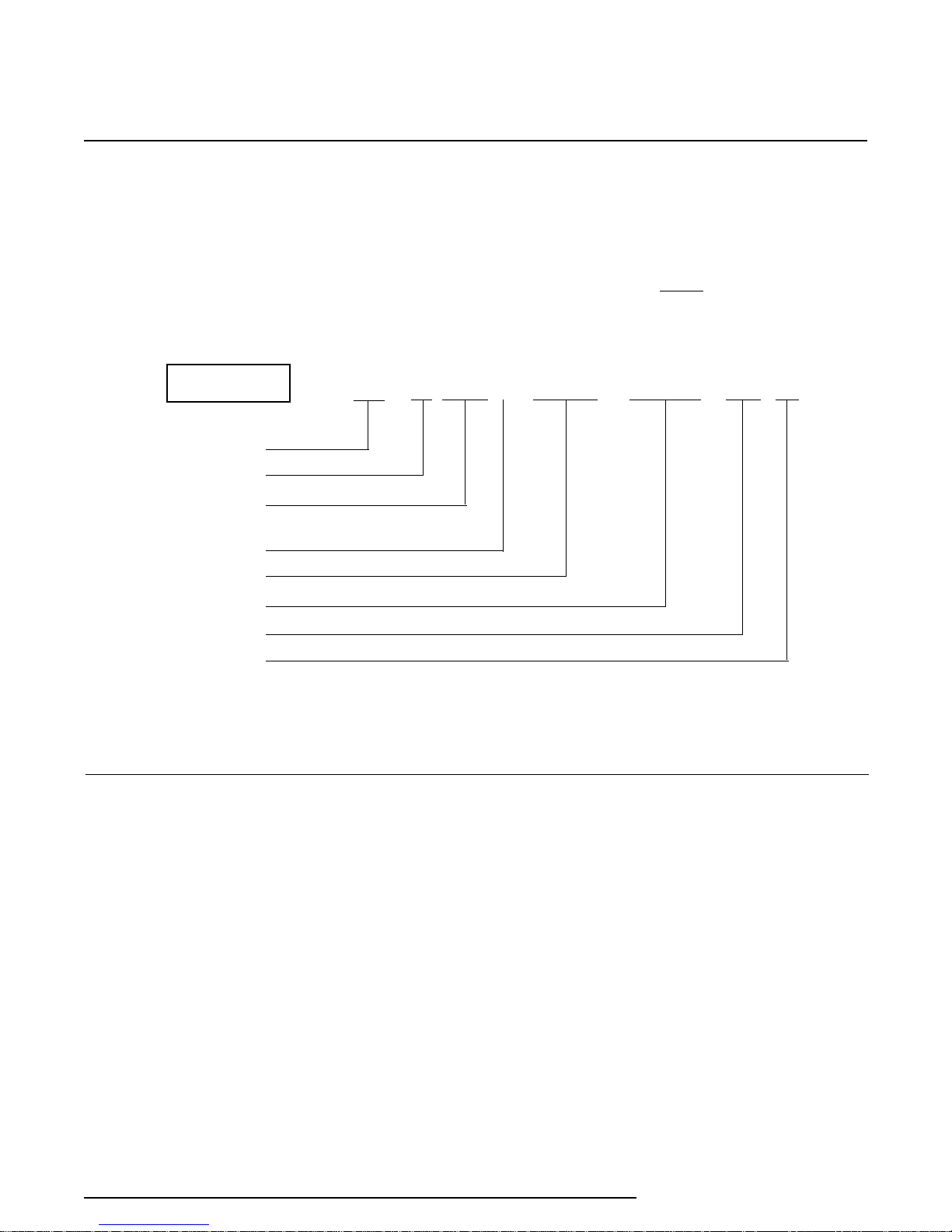

EXAMPLE

Unit Type

Input Code

Calibration Value

Input Units of

Measure

Output

Power

Option(s)

1

2

3

RIY / R0-0-100 C / 4-20MA / 12-42DC / -ND [HP]

The following example identifies the significance of

each field of the RIY model number. Refer to this

example in deciphering the model number of your

RIY.

NOTE

Consult the factory for availability of

specific configuration options.

Housing

1

Table 2 lists the input range for each model number Input Code.

2

Indicates the input range used for factory calibration.

3

F, Fahrenheit; C, Celsius; OHMS, ohms

Calibration

Prior to shipment, every RIY is factory-checked using

automated test equipment. Duplication of the factory

check is not expected nor intended for the field.

However, field calibration procedures involving use of

the front panel push buttons and the configuration

switches are described in this section for field applications.

Both the HP- and DIN-style housings are available

with the same options, and they have the same push

button and switch arrangements. The following

descriptions of the push buttons and configuration

switches pertain to both housing styles.

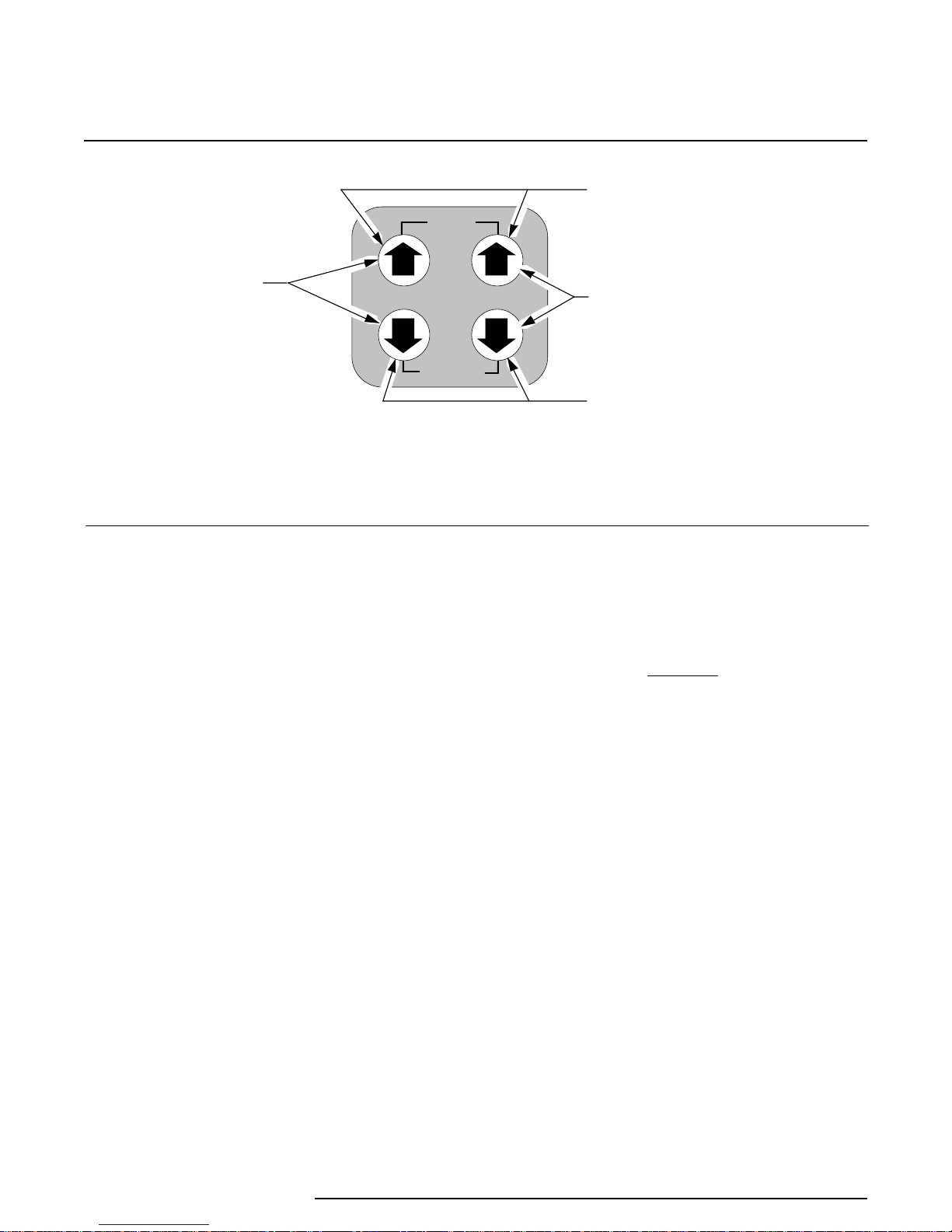

Using the Push Buttons

The RIY is equipped with a membrane panel that

contains four tactile push buttons used to set zero

and span (full-scale). Figure 1 shows the layout of

the membrane panel for both the HP- and DIN-style

units. Each push button is labeled with an Up or

Down arrow inside a circular background that is

contoured to the membrane-panel surface.

The functions of the push buttons are labeled

“ZERO”, “SPAN”, “SAVE”, and “CANCEL”. When the

arrows are pressed individually or in certain simultaneous combinations, one of these four functions is

affected.

The Interface Solution Experts

3

Page 6

RIY

USED TO SET

OR TRIM ZER O

SAVE

ZERO SPAN

CANCEL

Figure 1. RIY Front Panel Push Buttons

USED TO SAVE

CALIBR ATION VALUES

USED TO SET OR

TRIM FULL SCALE

USED TO D ISREGARD LAST

ENTRY AND RETURN TO

OPERATE M OD E

The Up arrows:

• display the latest calibrated setting for zero or

span, respectively, when pressed individually

during normal operation (units with LCD’s

only); does not affect the output of the RIY

• increment zero or span values, respectively,

when pressed individually while in

ranging

• increment the ‘trim’ value for the zero- and 100percent output levels in

• save the calibration setting for zero or span

while in the calibrate mode, then returns the

unit to normal operation, when both are

pressed simultaneously

(units with LCD’s only)

standard ranging

quick

The Down arrows:

• display the latest calibrated setting for zero or

span, respectively, when pressed individually

during normal operation (units with LCD’s

only); does not affect the output of the RIY

• decrement zero or span values, respectively,

when pressed individually while in

ranging

• decrement the ‘trim’ value for the zero- and

100-percent output levels in

• cancel the calibration mode and returns the unit

to normal operation when both are pressed

simultaneously; retains previous values

(units with LCD’s only)

quick

standard ranging

Pressing the ZERO or SPAN Up and Down arrows

simultaneously sets the unit to the calibrate mode (if

enabled through switch settings) for that particular

setting.

CAUTION

The push buttons are not designed to be

actuated with sharp, pointed objects.

Using a pen, screwdriver, or other sharp

object will damage the push buttons.

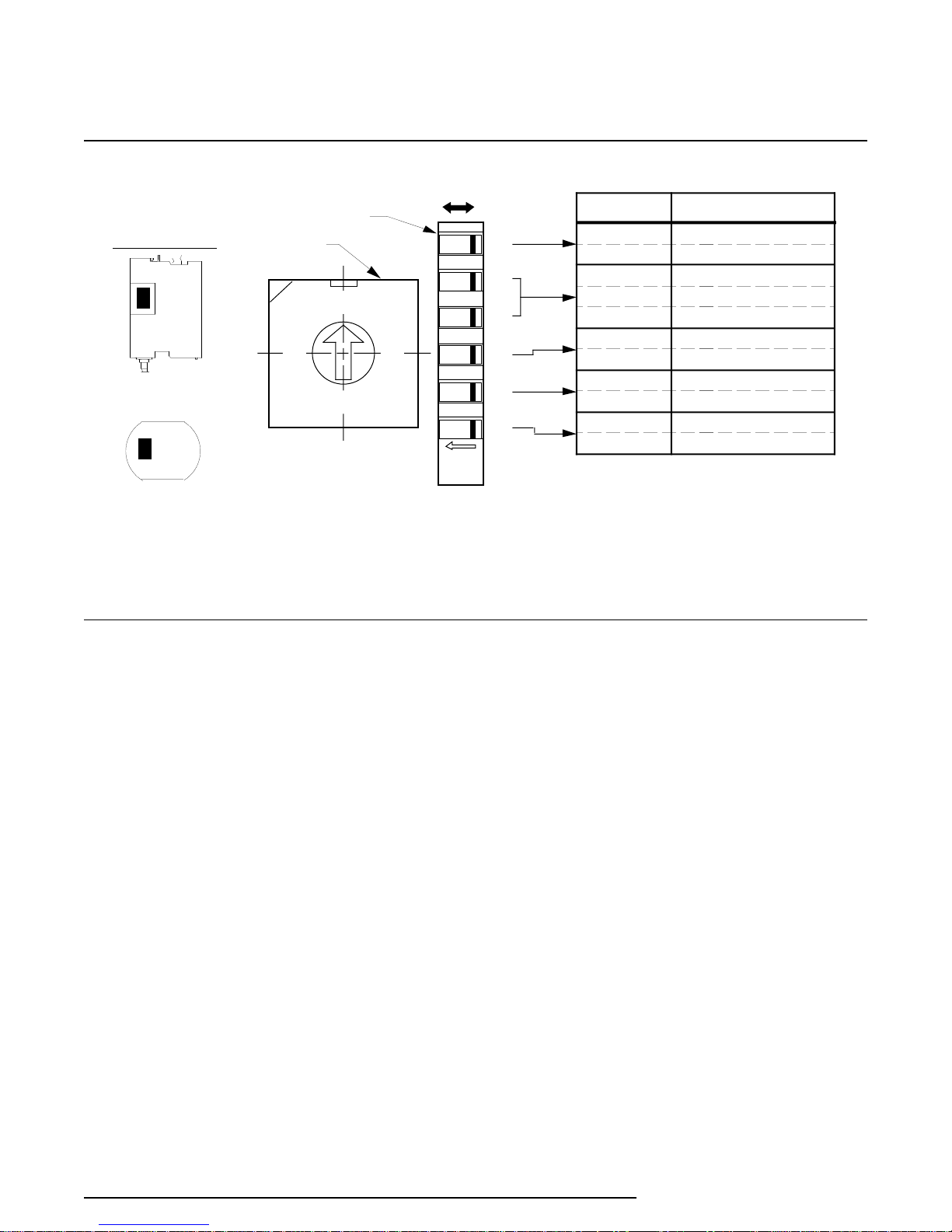

Using the Configuration Switches

A rotary switch and a single in-line package (SIP)

switch are used to configure the RIY for user-selectable operating and calibration parameters.

Figure 2 shows the layout of the configuration

switches and the switch setting options for SW301.

The switch settings for rotary switch SW302 are listed

in table 2. The reference designators and physical

layout of the switches in the HP- and DIN-style units

are identical.

The switches for HP-style units are accessed through

a cutout at the rear of the unit. The cutout is filled

with a small, removable panel. A narrow, slottedhead screwdriver may be used to gently pry the panel

off the unit to access the switches.

4

The Interface Solution Experts

Page 7

RIY

ORIENTATION

DIN

HP

3

4

5

6

ON OFF

-1

-2

-3

-4

-5

-6

SW 301

SW 302

0

1

F

E

2

D

C

B

A

NOTES: 1. Refer to table 2 for SW 302 swi tch setti ng us es.

2. The relative posi ti on of SW 301 and SW 302 i s identi cal for HP- and D IN - s tyle units.

3. SW 301- 6 m ay be inacti ve in earlier units. In thes e units, the s w itch setti ng can be disr egar ded.

Figure 2. Internal Switches, Layout, Designations, and Settings

7

8

9

SETTINGS FEATURES

ON

OFF

-2 OFF /-3 OFF

-2 OFF /-3 ON

-2 ON/-3 ANY

ON

OFF

ON

OFF

ON

OFF

DISPLAYS CELSIUS

DISPLAYS FAHRENH EIT

2-WIRE, DUAL 2-WIRE

3-WIRE, DUAL 3-WIRE

4-WIR E, TR IPLE 2- W IR E

DOWNSC ALE DRIVE

UPSC ALE DRIVE

QUICK RANGING

STANDARD RANGING

KEYBOARD LOC KOU T

KEYBOARD EN ABLE

Switches for DIN-style units are accessed by removing a small, L-shaped panel from the upper right-side

of the unit. This panel is bent over the top, right-side

edge of the unit and is secured with a single screw on

top. A Phillips-head screwdriver is required to

remove one screw securing the small L-shaped panel

to the housing frame.

The configuration switches are used to set the

following features:

SW301-1 — Displayed Temperature Type

ON – Sensor input displayed in Celsius

OFF – Sensor input displayed in Fahrenheit

This switch determines the type of temperature

units that will be displayed on the LCD. If an

ohms range is selected, the display will show

OHMS and this switch is ignored.

SW301-2 & -3 — Number of Wires or Sensors

These two switches determine the number of

wires for a single sensor input, or the number of

sensors of a multi-sensor input configuration.

Refer to table 2.

SW301-4 — Upscale/Downscale on Fault

ON – Downscale Output Drive on Fault

OFF – Upscale Output Drive on Fault

This switch determines the reaction of the RIY

output when an error is detected (during poweron diagnostics) or when an input or sensor lead is

physically open.

SW301-5 — Ranging Method

ON – Quick Ranging (for units with LCD’s only)

OFF – Standard Ranging

Quick Ranging

with an LCD. To set the 4-20 mA output with this

ranging method, dc power is the only input

needed for the unit. The pushbuttons are used to

set the zero and full-scale inputs.

Standard Ranging

output monitoring device, and dc power. The

push buttons are used to capture the zero and

full-scale input values and to trim the zero- and

100-percent output settings.

can only be performed on units

requires an input source, an

The Interface Solution Experts

5

Page 8

RIY

1

Input

Code

SW302

Setting

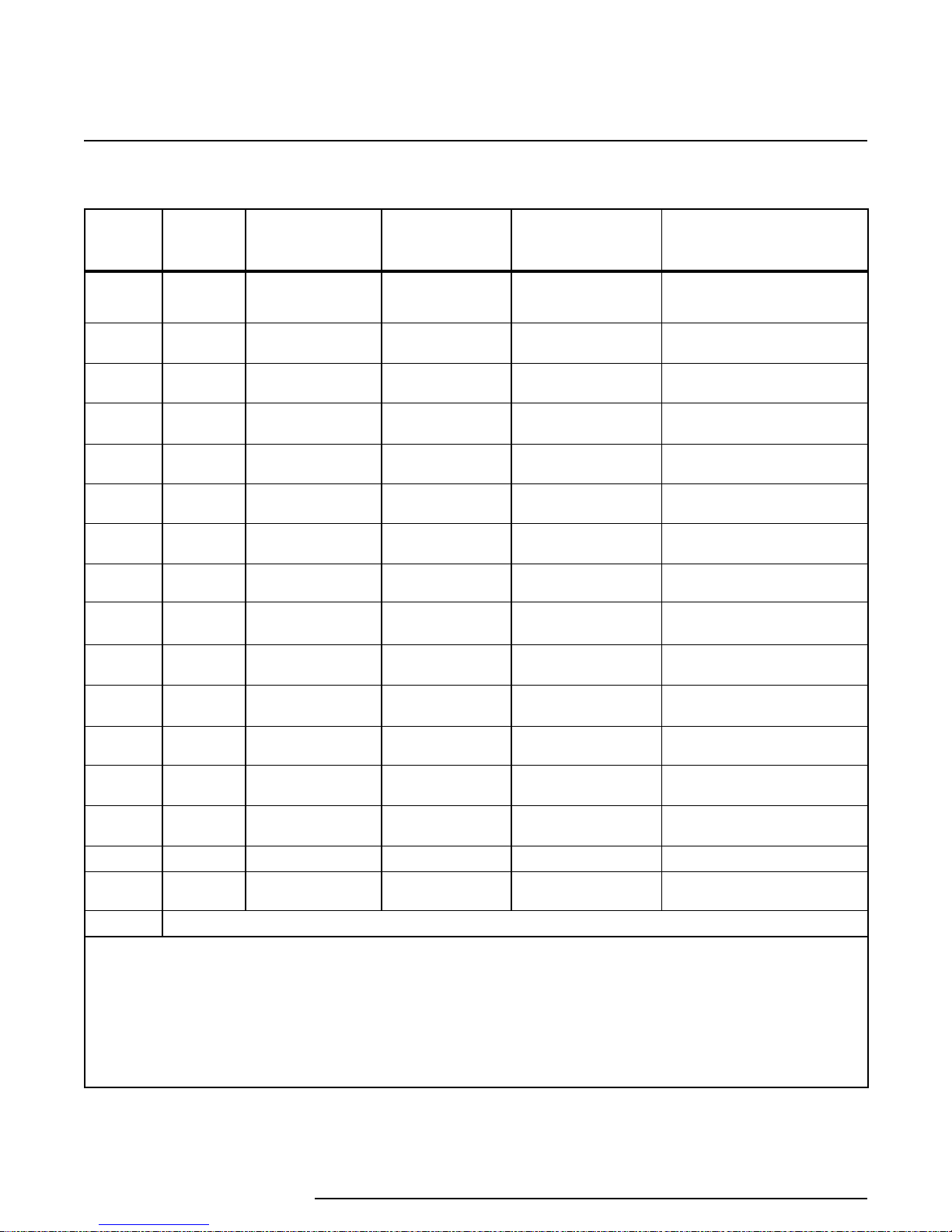

Table 2. RTD and Ohms Input by Input Code (SW302 Settings)

Input

Type

Description

Range

2,3

Accuracy Adjustments

±0.05% of Span, ±

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

PRG

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Programmable input, unspecified at time of order; factory default of R0, -300 to +267 °F (see model number).

Pt 100Ω

385 RTD

Pt 100Ω

3923 RTD

Pt 100Ω

3916 RTD

Pt 100Ω

3902 RTD

Pt 200Ω

385 RTD

Pt 500Ω

385 RTD

Pt 1000Ω

385 RTD

Pt 1000Ω

375 RTD

Two Pt 100Ω

385 RTD’s, Ave.

Two Pt 100Ω

3923 RTD’s, Diff.

Two Pt 100Ω

385 RTD’s, Diff.

Two Pt 500Ω

385 RTD’s, Diff.

NI 120Ω

RTD

CU 10Ω

RTD

Ohms

FLEX-SOR

TM

100Ω at 0 °C,

α = 0.003850

98.129Ω at 0 °C,

α = 0.003923

100Ω at 0 °C,

α = 0.003916

100Ω at 0 °C,

α = 0.003902

200Ω at 0 °C,

α = 0.003850

500Ω at 0 °C,

α = 0.003850

1000Ω at 0 °C,

α = 0.003850

1000Ω at 0 °C,

α = 0.003750

2 or 3 of R0

Averaged

2 of R1

Differential

2 of R0

Differential

2 of R5

Differential

120Ω at 0 °C,

α = 0.00672

9.035Ω at 0 °C,

α = 0.00427

0-4000Ω

1000Ω at 0 °C,

α = 0.00285

–200 to 850 °C

(–328 to 1562 °F)

–200 to 600 °C

(–328 to 1112 °F)

–200 to 510 °C

(–328 to 950 °F)

–200 to 650 °C

(–328 to 1202 °F)

–200 to 630 °C

(–328 to 1166 °F)

–200 to 630 °C

(–328 to 1166 °F)

–200 to 630 °C

(–328 to 1166 °F)

–185 to 540 °C

(–301 to 1004 °F)

–200 to 850 °C

(–328 to 1562 °F)

–550 to 800 °C

(–990 to 1440 °F)

–550 to 1050 °C

(–990 to 1890 °F)

–550 to 830 °C

(–990 to 1494 °F)

–80 to 320 °C

(–112 to 608 °F)

–50 to 250 °C

(–58 to 482 °F)

0-4000Ω

–90 to 175 °C

(–130 to 347 °F)

0.20 °C

(0.36 °F)

0.20 °C

(0.36 °F)

0.20 °C

(0.36 °F)

0.20 °C

(0.36 °F)

0.13 °C

(0.23 °F)

0.10 °C

(0.18 °F)

0.10 °C

(0.18 °F)

0.10 °C

(0.18 °F)

0.20 °C

(0.36 °F)

0.40 °C

(0.72 °F)

0.40 °C

(0.72 °F)

0.20 °C

(0.36 °F)

0.14 °C

(0.25 °F)

1.6 °C

(2.9 °F)

0.2Ω

0.08 °C

(0.14 °F)

NOTES: 1. This column contains the Input Code for the model number of each RIY.

2. The lower table limit extends 5%, or more, of maximum span below the listed value. When this limit is

exceeded, the RIY will clamp at the limit value and the display will read “–LO–”. For ohms ranges, 0Ω is

the lower table limit.

3. The upper table limit extends 10%, or more, of maximum span above the listed value. When this limit is

exceeded, the RIY will clamp at the limit value and the display will read “–HI–”. For ohms range, 4095Ω

is the upper table limit.

6

The Interface Solution Experts

Page 9

RIY

SW301-6 — Keyboard Lockout/Enable

ON – Lockout

OFF – Enable

In some units

dard ranging when it is set to the ‘on’ position.

When set to the ‘off’ position, quick or standard

ranging can be performed. Even with this switch

in the ‘on’ position (lockout), the zero and span

settings of the unit can be viewed on units with an

LCD.

If you are uncertain of the functionality of

SW301-6 for a particular RIY, set it to

‘on’ and try to change the settings. If

you can change the settings, this switch

DOES NOT provide keyboard lockout.

SW302 — Range Select Switch

This is a 16-position rotary switch that is used to

configure the unit for a particular input range.

Refer to table 2 for switch settings.

Anytime a switch setting is changed while power is

applied, one of the front panel push buttons must be

pressed to ensure that the RIY accepts and acknowledges the configuration change.

, this switch inhibits quick or stan-

NOTE

Reading the LCD

The 4-digit, liquid crystal display (LCD) of the RIY

displays:

• the currently applied input in degrees Celsius

(°C), degrees Fahrenheit (°F), or ohms (Ω)

• the calibrated zero or span settings when called

for during normal operation

• zero and span input values during calibration

• “–LO–” or “–HI–” when the input value exceeds

the lower or upper range table limits for a

particular input range, as determined by the

setting of the Range Switch

• problem codes discovered by the self-diagnostics during power-up, calibration, or normal

operation (refer to the Operation Section for

code definitions)

The LCD is also used to perform

feature allows you to calibrate the RIY using predetermined representative zero and span (full-scale) input

values. However, quick ranging can only be performed on units with an LCD.

The LCD operates independently from the highly

accurate conversion circuits of the RIY. Field calibration of the LCD itself is typically not required, as the

performance of the LCD does not affect the accuracy

of the output. However, if the LCD readings drift

beyond the accuracy ratings stated in table 1, you

should consult the factory for LCD calibration requirements. To check the LCD’s accuracy in the field, the

RIY must be supplied a highly accurate and controllable input signal, and then the input device and the

RIY’s LCD readings compared.

The LCD on the RIY displays the input readings in

degrees Celsius, degrees Fahrenheit, or Ohms. The

values displayed in various functional modes are

either rounded off to the nearest whole digit or they

are exact values.

When the RIY is in any display mode other than quick

ranging, such as the operate mode, standard ranging,

or display zero or span values, the LCD displays input

values that are electronically rounded to the nearest

whole unit (e.g., 121, 1143, 237). Because the actual

input to the RIY includes temperature or resistance

values that are not exactly whole units (e.g., 120.6,

1142.91, 237.4), the RIY rounds off the input to the

nearest whole unit for display purposes. However,

the electronics process the exact input value.

When the RIY is in quick ranging, the values displayed are exact to the least significant whole unit

(e.g., 121.0, 1143.0 237.0), because these values are

computed internally.

Labels denoting the unit-of-measure that the display

reading indicates are provided with the RIY. These

adhesive-backed labels are marked “°F”, “°C”, and “Ω”.

These labels are sized to fit in the lower, angled

portion of the LCD frame. Figure 3 shows all three

labels at actual size.

quick ranging

. This

The Interface Solution Experts

7

Page 10

RIY

˚C

˚F

Figure 3. Units-of-Measure Labels for the LCD

‘Ranging’ the RIY

Ranging

features two methods of ranging;

To use either method, configuration switch SW301-5

must be set to the desired setting and SW301-6 must

be set to the ‘off’ position (see figure 2).

is a method of field calibration. The RIY

standard

and

quick

In standard ranging, input values for zero and span

must first be

Then, the output can be

percent output of 4 mA and a 100-percent output of

20 mA. But to effect any range changes, switch

SW301-6 must be set to the ‘off’ position (keyboard

enable).

Reverse Output. The RIY can also be set up for

reverse output

mA and the 100-percent output is 4 mA. To setup the

RIY for reverse output operation, the zero and span

settings must cross over one another. These

settings are made by capturing the

scale, input with the ZERO push buttons as described

in step 7 of the upcoming standard ranging procedure. Then, the span is captured in step 10 with the

.

SPAN push buttons when the input is zero percent for

a 100-percent output. When the zero output setting is

greater than the span output setting, the unit is

configured for reverse output operation.

captured

, where the zero-percent output is 20

by the RIY’s microprocessor.

trimmed

further for a zero-

greater,

or full-

Before ranging (or calibrating) the RIY, you should

verify all switch settings to ensure that the unit will

operate in a predictable manner. Refer to the subsection titled “Using the Configuration Switches”

presented earlier in this section for switch setting

options.

Standard Ranging Overview

Standard ranging is used to set the zero- and 100percent output settings of the RIY based on userselected input values. The input values are simulated

by calibration equipment to represent actual RTD or

resistance input values. Refer to a resistancetemperature table for ohm values representative of

RTD temperature values.

Standard ranging is the only field calibration possible

for units without an LCD. Whether your RIY has an

LCD or not, you should rely on the readings from the

calibration equipment while performing standard

ranging.

By setting switch SW301-5 to the ‘off’ position, the

unit is configured for standard ranging (see figure 2).

Trimming. ‘Trimming’ is a feature of standard

ranging that allows the user to vary the zero- and

100-percent output values using the ZERO and SPAN

push buttons, respectively.

Trimming the zero-percent setting varies the zero

reference point and the 100-percent output value,

proportionally. For this reason, when a new zero

input value is captured, all previously set trim values

are eliminated. The

constant while trimming the zero-percent output.

Trimming the 100-percent output with the SPAN push

buttons varies only the full-scale output value; the

zero reference point remains at the level it was last

set to. The zero-percent output should always be

trimmed before trimming the 100-percent output.

span

of the output remains

Standard Ranging Setup

To perform standard ranging you need an input

source, dc power source, and an output monitoring

device. Table 3 lists the calibration equipment and

the equipment accuracy required to perform this

method of ranging.

8

The Interface Solution Experts

Page 11

RIY

Figure 4 illustrates the calibration setup required to

perform standard ranging.

To monitor the output, a dc voltmeter and a precision

load resistor are called for. Volmeter readings of 1-5

Vdc read across a 250 ohm resistor represent 4-20

mA, proportionally. An output reading of 3 Vdc is

equal to a 12 mA output with a 250 Ohm resistor.

Similar calculations can be made over the 1-5 Vdc

range with the following conversion formula: V

(voltage reading)/250Ω = mA.

Table 3. RIY Calibration Equipment (Standard Ranging)

Equipment

Decade Resistance

Box

Voltmeter and

Precision Resistor

Specifications

Accuracy of ±0.01%, or better

Digital voltmeter, accuracy of ±0.005% or better; 250Ω precision

resistor, tolerance of ±0.01%

Standard Ranging Procedure

1. Set range and other configuration switches for the

required RTD or ohms input, as necessary (refer

to figure 2 and table 2).

NOTE

Switch SW301-5 must be set to the ‘off’

position to perform standard ranging,

and set switch SW301-6 to the ‘off’

position for units with this switch

functional for keyboard enable.

NOTES:

DC Power Source

DECADE

RESISTANCE

BOX

1. Terminals 1 and 4 are the primary connection terminals.

2. To simulate a 3-wire input, use terminal 3 for lead length

compensation

3. To simulate a 4-wire input, use terminals 2 and 3 for lead

length compensation.

(SEE NOTES)

Figure 4. Calibration Hookup Diagram (Standard Ranging)

12-42 Vdc

1

2

3

4

RIY

+PS

–PS

250

+

DC VOLTMETER

–

+

–

12-42 VDC

POWER

SOURCE

The Interface Solution Experts

9

Page 12

RIY

2. Connect RIY as shown in figure 4. Apply power.

3. Press and hold either the Up

or Down ZERO push button.

Note zero value displayed.

ZERO

4. Press and hold either the Up

or Down SPAN push button.

Note span (full-scale) value

SPAN

displayed.

5. To enter zero calibrate mode,

press the Up and Down

ZERO push buttons simulta-

ZERO

neously.

NOTE

In standard ranging, the LCD will

continually flash while in the calibrate

mode.

6. Set input device for zero-percent input to RIY.

7. To capture zero input value,

press (slowly) the Up and

Down ZERO push buttons

ZERO

simultaneously, twice.

NOTE

If the input value being captured

exceeds the upper or lower programmed

table limits for a particular input (refer to

table 2), the LCD will flash -HI- or -LO-,

respectively. The input value must be

within programmed table limits to be

displayed or captured.

Vdc (4 mA), repeat steps 6 and 7 until 5 Vdc

reading is obtained.

9. Set input device for full-scale input to RIY.

10. To capture full-scale input

value, press (slowly) the Up

and Down SPAN push

SPAN

buttons simultaneously,

twice.

11. Verify that voltmeter reading is 1 Vdc (4 mA).

This indicates that full-scale value was captured

successfully. If voltmeter reads 5 Vdc, repeat

steps 9 and 10 until 1 Vdc reading is obtained.

12. To trim zero-percent output,

while monitoring output,

press the Up or Down ZERO

ZERO

push button until desired

output reading is obtained

(e.g., 1.000 Vdc).

13. Press the Up and Down

SPAN push buttons simultaneously.

SPAN

14. To trim 100-percent output,

while monitoring output, press

the Up or Down SPAN push button until desired

output reading is obtained (e.g., 5.000 Vdc).

15. When desired values are

SAVE

captured and outputs

trimmed, press both Up

ZERO

SPAN

arrows simultaneously to

save latest settings.

16. Check zero and full-scale settings as described in

steps 3 and 4. If settings are correct, standard

ranging is complete. If not, repeat entire procedure.

8. Verify that voltmeter reading is 5 Vdc (equivalent

to 20 mA). This indicates that zero input value

was captured successfully. If voltmeter reads 1

10

The Interface Solution Experts

17. When procedure is complete, set SW301-6 to the

‘on’ position for keyboard lockout (for units with

SW301-6 functional).

Page 13

RIY

The settings entered during calibration are stored in an

EEPROM when the SAVE push buttons are pressed.

These setting are retained until a subsequent calibration (quick or standard ranging) is performed. If the

latest settings are not saved before removing power, or

if the CANCEL push buttons (both Down arrows) are

pressed simultaneously, the unit will revert to the

previously saved values.

Quick Ranging Overview & Setup

Quick ranging is a unique feature that allows the user

to calibrate an RIY equipped with an LCD, without the

use of an input source or an output monitoring device.

With switch SW301-5 set to the ‘on’ position and

SW301-6 is set to the ‘off’ position, a 12-42 Vdc

power source applied to the +PS and –PS terminals

of the RIY is all that is required to perform quick

ranging. The front-panel push buttons are used to set

zero and span (full-scale) values to user-selected

input settings that yield the desired zero- and 100percent outputs. The user selected values are

displayed on the unit’s LCD.

When quick ranging is selected, the RIY ignores any

input applied to the input terminals. The zero-percent

output will be 4 mA for whatever value zero is set to

with the ZERO push buttons, and the 100-percent

output will be 20 mA for whatever the full-scale value

is set to with the SPAN push buttons.

The RIY can be set up for reverse output using quick

ranging. To do this, simply increase the zero setting

beyond the full-scale setting, and decrease the fullscale setting below the zero setting. When the zero

and span output settings cross one another, reverse

output is achieved. The reverse output setup is

accomplished while selecting the zero and span

settings in the upcoming procedure.

Figure 5 illustrates the dc power hookup required to

perform quick ranging of the RIY.

If the unit is configured for standard ranging, the

display will continually flash the applied input value

when the Up and Down arrows are pressed simultaneously to enter the calibrate mode. Pressing the Up

or Down arrows will have no affect on the displayed

value. This reaction indicates that the unit is NOT

configured for quick ranging.

Quick Ranging Procedure

1. Set range and other configuration switches for the

required RTD or ohms input, as necessary (refer

to figure 2 and table 2).

NOTE

Switch SW301-5 must be set to the ‘on’

position to perform quick ranging, and

set SW301-6 to the ‘off’ position for units

with this switch functional for keyboard

enable.

12-42 VDC

POWER

SOURCE

NOTES: 1.

2.

+

–

The R IY must be equipped with an LCD to per for m quick r anging.

The i nput is i gnor ed w hen the uni t is confi gur ed for qui c k ranging.

Figure 5. Quick Ranging Hookup Diagram

+PS

–PS

RIY

(with LCD)

(SEE NOTES)

1

2

3

4

The Interface Solution Experts

11

Page 14

RIY

2. Apply dc power as shown in figure 5. (Ignore any

problem codes that appear on the LCD, they will

be cleared in the next step.)

3. Press and hold either the Up

or Down ZERO push button.

Note zero value displayed.

ZERO

4. Press and hold either the Up

or Down SPAN push button.

Note span (full-scale) value

SPAN

displayed.

5. To change zero setting,

press the Up and Down

ZERO push buttons simulta-

ZERO

neously. Value displayed on

LCD will change.

NOTE

If the display begins to flash after

pressing the Up and Down push buttons

simultaneously, the RIY is configured for

standard ranging. Check SW301-5.

If there is no change in the LCD, the RIY

is configured for keyboard lockout.

Check SW301-6.

7. To change span (full-scale)

setting, press the Up and

Down SPAN push buttons

simultaneously.

8. Set 100-percent (full-scale)

input value shown on LCD

to desired setting using the

Up or Down SPAN push

button to increment or

decrement displayed value.

9. When 100-percent input

value is obtained, press both

Up arrows simultaneously to

save the new zero and span

(full-scale) settings.

NOTE

The RIY will take a moment to store the

new value and reset itself. It will return

to the operate mode and display the

currently applied input value.

10. Press and hold the Up or

Down ZERO push button to

verify zero setting.

ZERO

ZERO

SPAN

SPAN

SAVE

SPAN

6. Set zero input value shown

on LCD to desired setting

using the Up or Down ZERO

push button to increment or

decrement displayed value.

NOTE

When the value entered exceeds the

upper or lower programmed table limits

for a particular input (refer to table 2), the

LCD will display -HI- or -LO-,

respectively. The value entered must be

within programmed table limits to be

displayed.

12

The Interface Solution Experts

ZERO

11. Press and hold the Up or

Down SPAN push button to

verify full-scale setting.

SPAN

12. Remove dc power, quick ranging is complete.

For units with SW301-6 functional, set it to the ‘on’

position to avoid inadvertent changes to the settings

after calibratrion. This will allow for viewing of the

zero and span settings, but will not allow for changes

to any range settings.

Page 15

RIY

Ranging the RIY for a Differential Input

Some applications require a differential input, which

consists of two sensors connected to the RIY where

the difference between them influences the 4-20 mA

output of the RIY. For example, when resistance of

one sensor (RTD) increases while the other remains

constant the output of the RIY may also increase

toward 20 mA. If both inputs are varying, increasing

and decreasing in value, the output will vary proportionally with the difference of the two inputs.

Although the RIY

inputs

, the following procedure allows you to verify

the response of the RIY as you vary the inputs.

To range an RIY for differential input operation, you

must determine the minimum and maximum differential input values for the intended application. The

lower differential value will be used to set the zero

output level and the higher differential value will be

used to set the span output level. The following

examples show how to determine the zero-percent

and full-scale differential values based on known

(substitute your own values) minimum and maximum

input temperature ranges.

may be quick ranged for differential

Example 2:

• For zero-percent differential input

• R10 Range (Input Code)

• Pt 100Ω 385 RTD

• –50 °C differential

Input #1 (box #1): -50 °C (80.30Ω)

Input #2 (box #2): 0 °C (100.00Ω)

Differential: -50 °C

Selecting a 100-percent Differential Input. The

following examples show how to determine a 100percent differential input setting that produces a 100-

percent (full-scale) output.

Example 1:

• For 100-percent differential input

• R10 Range (Input Code)

• Pt 100Ω 385 RTD’s

• 100 °C differential

Input #1 (box #1): 100 °C (138.50Ω)

Input #2 (box #2): 0 °C (100.00Ω)

Differential: 100 °C

Selecting a Zero-percent Differential Input. The

following examples show how to determine a zeropercent differential input that produces a zero-percent

output. The RIY responds to negative (–), zeropercent differential input values, as determined in

example 2.

Example 1:

• For zero-percent differential input

• R10 Range (Input Code)

• Pt 100Ω 385 RTD

• 0 °C differential

Input #1 (box #1): 0 °C (100.00Ω)

Input #2 (box #2): 0 °C (100.00Ω)

Differential: 0 °C

Example 2:

• For 100-percent differential input

• R10 Range (Input Code)

• Pt 100Ω 385 RTD’s

• 50 °C differential

Input #1 (box #1): 50 °C (119.39Ω)

Input #2 (box #2): 0 °C (100.00Ω)

Differential: 50 °C

Figure 6 illustrates the hookup required to range a

unit for a differential input. Notice that an additional

decade resistance box is required over the standard

ranging procedure. Refer to the Standard Ranging

Subsection earlier in this section for information

regarding zero and span settings and trimming.

The Interface Solution Experts

13

Page 16

RIY

DECADE

RESISTANCE

BOX #2

DECADE

RESISTANCE

BOX #1

NOTES: 1. Noti ce that terminal 2 on the RIY i s not used for thi s hookup.

2. The specifi cations of both decade resi s tance boxes m ust

meet or exceed those gi ven in table 3.

1

2

3

4

Figure 6. Differential Input Ranging Setup

Differential Input Ranging Procedure

1. Set range and other configuration switches for the

required RTD or ohms input range as determined

by the combined minimum and maximum values

of the intended application (refer to figure 2 and

table 2; choose from ranges R9, R10, or R11).

NOTE

Switch SW301-5 to the ‘off’ position to

perform the following procedure, and set

SW301-6 to the ‘off’ position for units

with this switch functional for keyboard

enable.

+PS

RIY

–PS

DC VOLTMETER

5. To capture zero input value,

press (slowly) the Up and

Down ZERO push buttons

simultaneously, twice.

If the input value being captured

exceeds the upper or lower programmed

table limits for a particular input (refer to

table 2), the LCD will flash -HI- or -LO-,

respectively. The input value must be

within programmed table limits to be

displayed or captured.

250 ohm

+

–

NOTE

+

–

12-42 VDC

POWER

SOURCE

ZERO

2. Connect RIY as shown in figure 6. Apply power.

3. To enter zero calibrate

mode, press the Up and

Down ZERO push buttons

simultaneously.

4. Set both decade resistance boxes (#1 and #2) to

required zero-percent differential input to RIY.

(Refer to examples prior to this procedure.)

14

The Interface Solution Experts

ZERO

6. Verify that voltmeter reading is 5 Vdc (equivalent

to 20 mA). This indicates that zero input value

was captured successfully. If voltmeter reads 1

Vdc (4 mA), repeat steps 4 and 5 until 5 Vdc

reading is obtained.

7. Set decade resistance box #1 to full-scale differential value as determined earlier. Do not change

resistance box #1 setting. (Refer to examples

prior to this procedure.)

8. To capture full-scale input

value, press (slowly) the Up

and Down SPAN push

SPAN

buttons simultaneously, twice.

Page 17

RIY

9. Verify that voltmeter reading is 1 Vdc (4 mA).

This indicates that full-scale value was captured

successfully. If voltmeter reads 5 Vdc, repeat

steps 7 and 8 until 1 Vdc reading is obtained.

10. To trim zero-percent output,

while monitoring output,

press the Up or Down ZERO

push button until desired

output reading is obtained

(e.g., 1.000 Vdc).

11. Press the Up and Down

SPAN push buttons simultaneously.

12. To trim 100-percent output,

while monitoring output, press

the Up or Down SPAN push button until desired

output reading is obtained (e.g., 5.000 Vdc).

13. When desired values are

captured and outputs

trimmed, press both Up

arrows simultaneously to

save latest settings.

14. When procedure is complete, set SW301-6 to the

‘on ’ position for keyboard lockout.

ZERO

ZERO

SPAN

SAVE

SPAN

The HP Housing. Figure 7 is an outline dimension

drawing of the HP-style unit with the FL housing

option. The spring clips on standard HP-style units

have no dimensional significance, so they are not

shown here.

The standard HP-style housing is equipped with

spring clips, which hold the unit in place when

mounted in an explosionproof enclosure. The spring

clips are squeezed inward to allow for positioning of

the unit in the base of the enclosure. When released,

they recoil to an extended position slightly over the

outer edge of the unit, providing adequate outward

force to hold the unit in place.

For other applications, an HP-style unit equipped with

flange plates (the FL Housing option) can be mounted

on relay tracks or a sturdy flat surface. While for

other applications, the DIN-style housing that mounts

on standard DIN rails is more suitable.

The DIN-style Housing. Figure 8 is an outline

dimension drawing of the DIN-style RIY. The all

aluminum DIN-style units mount directly onto standard G-type (DIN EN50035) or Top-hat (DIN

EN50022), DIN rails. This packaging is ideal for highdensity mounting of DIN-style packages on a common DIN rail.

Making the Electrical Connections

Installation

Installing the RIY consists of physically mounting the

unit and completing the electrical connections.

Before installing the RIY, you should perform a bench

check and calibration, if needed, to confirm that the

configuration of the unit is appropriate for the intended application.

Mounting the RIY

The RIY is available in an HP- or DIN-style housing.

Mounting considerations differ for each of these

housing style.

The RIY is a loop-powered instrument. The terminals

for the loop-power connections are marked “+PS” and

“–PS”. The loop-power connections and the input

connections marked “1”, “2”, “3”, and “4” are the only

electrical connections to be made to the RIY. These

terminals are clearly marked on the front panel of

each unit.

Electrical connections for HP-style units are made at

the front panel to individual compression screw

terminals; one for each connection. Each terminal

has a slotted-head screw that is used to terminate

electrical wires.

On DIN-style units, the sensor input and loop-power

connections are made to removable terminal blocks.

Wires are connected to these blocks through openings in the top, and secured by compression screws

on the front of each block.

The Interface Solution Experts

15

Page 18

RIY

82.5 m m

(3.25 in)

72.6 m m

(2.86 in)

61 mm

(2.40 in)

75.4 m m

(2.97 in)

37.8 m m

(1.50 in)

SAVE

ZER O SPAN

CANCEL

+PS 4321-PS

Figure 7. RIY, HP-style Outline Dimension (FL Housing shown)

67 mm

(2.63 in)

63 mm

(2.46 in)

80 mm

(3.15 in)

35 mm

(1.38 in)

4321 + PS –PS

SAVE

ZERO SPAN

CANCEL

128.5

mm

(5.06 in)

Figure 8. RIY, DIN-style Outline Dimensions

16

The Interface Solution Experts

Page 19

RIY

Shielded, twisted wire should be used for input signal

connections. The shield of the wire set should be

grounded to an earth ground potential as close to the

RIY as possible. The HP-style unit has a grounding

lug on its top that may be used for this purpose.

1

2

3

4

2-WIRE RTD

1

2

3-WIRE RTD

(SEE NOTE 1)

Figure 9 is an installation hookup diagram showing

the connections necessary to operate the RIY.

NOTE

It is strongly recommend that you use

shielded, twisted wire for low-level

signals.

1

2

3

4

4-WIRE RTD

1

2

1

2

3

4

1

2

3

4

DUAL SENSOR:

NO LEAD LENGTH

COMPENSATION

3

4

DUAL SENSOR:

NO LEAD LENGTH

COMPENSATION

TRIPLE SENSOR:

NO LEAD LENGTH

COMPENSATION

3

4

(SEE NOTES 1 & 2)

1

2

RTD

3

4

NOTES: 1. For 3-wire RTD's and dual sensors with lead length compensation, all leads

RIY

should be of the same gauge and length, and kept at the same temperature.

2. The single lead length compensation wire used for dual sensor hookups is

effective for both sensors.

+PS

–PS

–

12-42 VDC

Figure 9. RIY Installation Hookup Diagram

+

POWER

SOURCE

–

+

CURRENT

DRIVEN

DEVICE

The Interface Solution Experts

17

Page 20

RIY

Operation

Operating the RIY is limited to viewing the LCD for

input values, zero or span reading, or problem codes;

and performing quick ranging using the push buttons.

Units that are not equipped with an LCD have no

definitive operating procedures.

The LCD

The LCD also displays problem codes resulting from

the RIY’s self-diagnostics. Codes indicate malfunctions or discrepancies detected by the RIY’s microprocessor at power-up, during calibration, or in the

operate mode. Table 4 contains these codes, the

problem indicated, and the remedy for each.

The LCD is the only visual indicator on the RIY;

without it, the user has no on-the-spot, visual indication as to the settings or operational status of the RIY.

When a non-LCD unit is calibrated with standard

ranging methods, it can be reliably installed in a

process loop, but it can not be quick ranged and must

be removed from the loop for subsequent calibrations.

Table 4. Self-diagnostic Problem Codes

Code

P1

P2

P3

P4

P5

Failed RAM test on power up

Failed ROM checksum on power up

Failed EEPROM checksum on power up

EEPROM did not write properly

EEPROM RTD table is bad

Problem

During normal operation, the LCD typically displays

the applied input value. As the input changes, the

read-out of the LCD changes accordingly.

The LCD can also display the zero and span settings

during normal operation when the appropriate front

panel push button is pressed.

Remedy

Cycle dc power; if problem persists,

return unit per instructions on the

back cover of this manual

If power is lost during calibration,

repeat calibration; otherwise, cycle

dc power; if problem persists,

return unit per instructions on the

back cover of this manual

Cycle dc power; if problem persists,

return unit per instructions on the

back cover of this manual

P6 (or EL1)

P7 or L4

P8 or L3

P9 or L2

P10 or L1

P11 or EL1

P12 or EL2

P13 or EL3

18

The Interface Solution Experts

Lead # 1 or 4 is open (2-wire sensor)

Repair sensor or wiring

Lead #4 is open

Lead #3 is open

Lead #2 is open

Lead #1 is open

RTD/Element #1 is open

RTD/Element #2 is open

RTD/Element #3 is open

Page 21

RIY

If zero or span settings need to be changed, the unit

can be quick ranged using loop-power and the LCD.

(SW301-5 must be set to ‘on’ and SW301-6 set to 'off'

to perform quick ranging.) The front panel push

buttons and the LCD are used to set these values to

the desired settings.

The Push Buttons

During normal operation, the push buttons are used

to call-up and display the zero and full-scale settings.

Pressing either of the ZERO push buttons during

normal operation displays the most recent zero

setting. When either of the SPAN push buttons are

pressed during normal operation, the most recent fullscale setting is displayed.

If a switch, or combination of switches, is changed

during normal operation, one of the front panel push

buttons must be pressed to acknowledge the new

settings. After making the desired switch setting

changes, pressing any one of the four push buttons

(or by cycling the power) causes the unit to reset and

the microprocessor will register the switch change(s).

The push buttons are also used in conjunction with

the LCD to perform quick ranging. (Refer to the

Calibration Section for the quick ranging procedure.)

Maintenance

The RIY is designed to operate reliably with a minimum of field maintenance.

Field maintenance is limited to keeping the unit clean

and the wire terminals free of oxidation. Periodic

visual inspections should be performed to ensure the

unit is clean and the electrical connections are in

good condition. The frequency of these inspections is

based on the environment in which the unit is operated. But, it is recommended that inspections be

conducted at least once every six months.

If the RIY is mounted in an explosion-proof enclosure,

the unit will remain much cleaner for a longer period

of time than if it is openly exposed to changing

environmental conditions.

To perform a thorough calibration of the RIY, the unit

must be removed from the process loop and checked

out using the standard ranging method described in

the Calibration Section.

Should performance problems arise, or for technical

assistance, you should contact your local Moore

Industries’ Customer Service Department. In the

U.S.A. call toll-free 1-800-999-2900.

The Interface Solution Experts

19

Page 22

Page 20

RIY

RIY

Appendix A

RIY Quick Reference Sheet

SW301

-2 & -3

SW302

Table A1. SW301 Switch Settings

Settings

-1

-4

-5

-6

NOTE: SW301-6 is not active on all units.

Table A2. SW302 Switch Settings

ON

OFF

-2 OFF/-3 OFF

-2 OFF/-3 ON

-2 ON/-3 ANY

ON

OFF

ON

OFF

ON

OFF

Input Code

Features

Displays Celsius

Displays Fahrenheit

2-wire, Dual 2-wire

3-wire, Dual 3-wire

4-wire, Triple 2-wire

Downscale Drive

Upscale Drive

Quick Ranging

Standard Ranging

Keyboard Lockout

Keyboard Enable

Input Type

1

2

RIY

3

4

SINGLE-SEN SOR

HOOKUPS

1

2

RIY

3

4

DU AL-SENSOR

HOOKUPS

Figure A1. Sensor Hookups

Table A3. LCD Displayed Problem Codes

1

2

3

4

TR IPLE-SENSOR

HOOKUP

RIY

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

Pt 100Ω, 385 RTD

Pt 100Ω, 3923 RTD

Pt 100Ω, 3916 RTD

Pt 100Ω, 3902 RTD

Pt 200Ω, 385 RTD

Pt 500Ω, 385 RTD

Pt 1000Ω, 385 RTD

Pt 1000Ω, 375 RTD

2 or 3 Pt 100Ω, 385 RTD’s (Ave.)

2 Pt 100Ω, 3923 RTD’s (Diff.)

2 Pt 100Ω, 385 RTD’s (Diff.)

2 Pt 500Ω, 385 RTD’s (Diff.)

NI 120Ω RTD

CU 10Ω RTD

Ohms

FLEX-SOR

TM

Code

P1

P2

P3

P4

P5

EL1 (or P6)

L4 or P7

L3 or P8

L2 or P9

L1 or P10

EL1 or P11

EL2 or P12

EL3 or P13

Failed RAM test on power up

Failed ROM checksum on power up

Failed EEPROM checksum on power up

EEPROM did not write properly

EEPROM RTD table is bad

Lead # 1 or 4 is open (2-wire sensor)

Problem

Lead #4 is open

Lead #3 is open

Lead #2 is open

Lead #1 is open

RTD/Element #1 is open

RTD/Element #2 is open

RTD/Element #3 is open

NOTE: For expanded switch setting information refer to the Calibration Section of the RIY User’s

Manual. For expanded hookup information refer to the Installation Section. For expanded

problem code information refer to the Operation Section.

20

The Interface Solution Experts

Page 23

Appendix B

RIY

Intrinsic Safety

This page contains the installation diagram for the RIY

carrying the intrinsically safe option. It also includes

guidelines for setting up zener barriers necessary in

these types of applications.

These diagrams must be used to augment the installation instructions earlier in this manual for units that are

to operate in areas requiring intrinsically safe instrumentation.

The Interface Solution Experts

21

Page 24

RIY

22

The Interface Solution Experts

Page 25

RIY

The Interface Solution Experts

23

Page 26

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.© 2007 Moore Industries-International, Inc.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...