Page 1

April 2016

170-701-00 F

Current to Pressure

Transmitter

IPT

Current to Pressure

Transmitter

IPT

All product names are registered trademarks of their respective companies.

Page 2

Table of Contents

Introduction 1

Description 1

Instrument Air and Filtration Information 3

Application Information 5

Calibration 7

Installation 11

Theory of Operation 12

Maintenance 14

Troubleshooting 16

Drawings 16

i

Page 3

Page 1

IPT

Introduction

This manual contains calibration and installation

information for the Moore Industries' Current-toPressure Transmitter (IPT). Along with a description

of the IPT, this manual contains information

regarding instrument air, filtration, applications and

recommendations. Related tables and illustrations

are provided for reference purposes.

This manual contains notes and cautions that must be

observed to prevent equipment damage or minor

inconveniences during calibration or installation of the

IPT. The following definitions describe these captions:

A

NOTE

shall contain technical or literary information

of a helpful nature. This information is intended to aid

the reader's understanding of the subject being

discussed and/or minimize inconveniences while

performing technical tasks.

A

CAUTION

serious nature that if ignored may cause equipment

damage.

shall contain technical information of a

Description

Individual IPTs consist of two parts: the transmitter

section and an interlocking pneumatic mounting

block, which snaps onto a rail. Units that are ordered

without a mounting block will clip onto an RIR or SIR

(rack or surface mounted header), which supplies air

to each unit using only one pneumatic supply pipe.

Both mounting blocks and supply headers contain

self-sealing valves. Therefore, the IPT can be

removed and replaced without disturbing the pneumatic connections or causing accidental venting of

the supply or output air.

Operation can be montiored or calibration performed

by using the electrical input and optional pneumatic

output test jacks. A red LED display, which indicates

the presence of an electrical input signal, is also

provided.

Table 1 contains the IPT equipment specifications,

including inputs, outputs, power requirements, and

performance characteristics.

Model Number. The IPT model number describes

the equipment type, functional characteristics, operating parameters, any options ordered, and housing. If

all other documentation is missing, this number is

used to identify equipment characteristics. The model

number for the IPT is located on a label on the side

of the unit.

The IPT is a compact 2-wire current-to-pressure

transmitter that converts a standard process current

signal to a pneumatic output. In its compact aluminum housing, the IPT snaps onto standard mounting

rails or optionally onto a header (RIR or SIR). Because of the extremely low dynamic mass of the

transducer element, the unit can be mounted in any

position and it is also very insensitive to shock and

vibration.

Serial Number. Moore Industries maintains a

complete history on every unit it sells and services.

This information is keyed to the serial number. When

service information is required on the IPT,

it is necessary to provide the factory with this number.

The serial number is located near the model number.

Page 4

Page 2

IPT

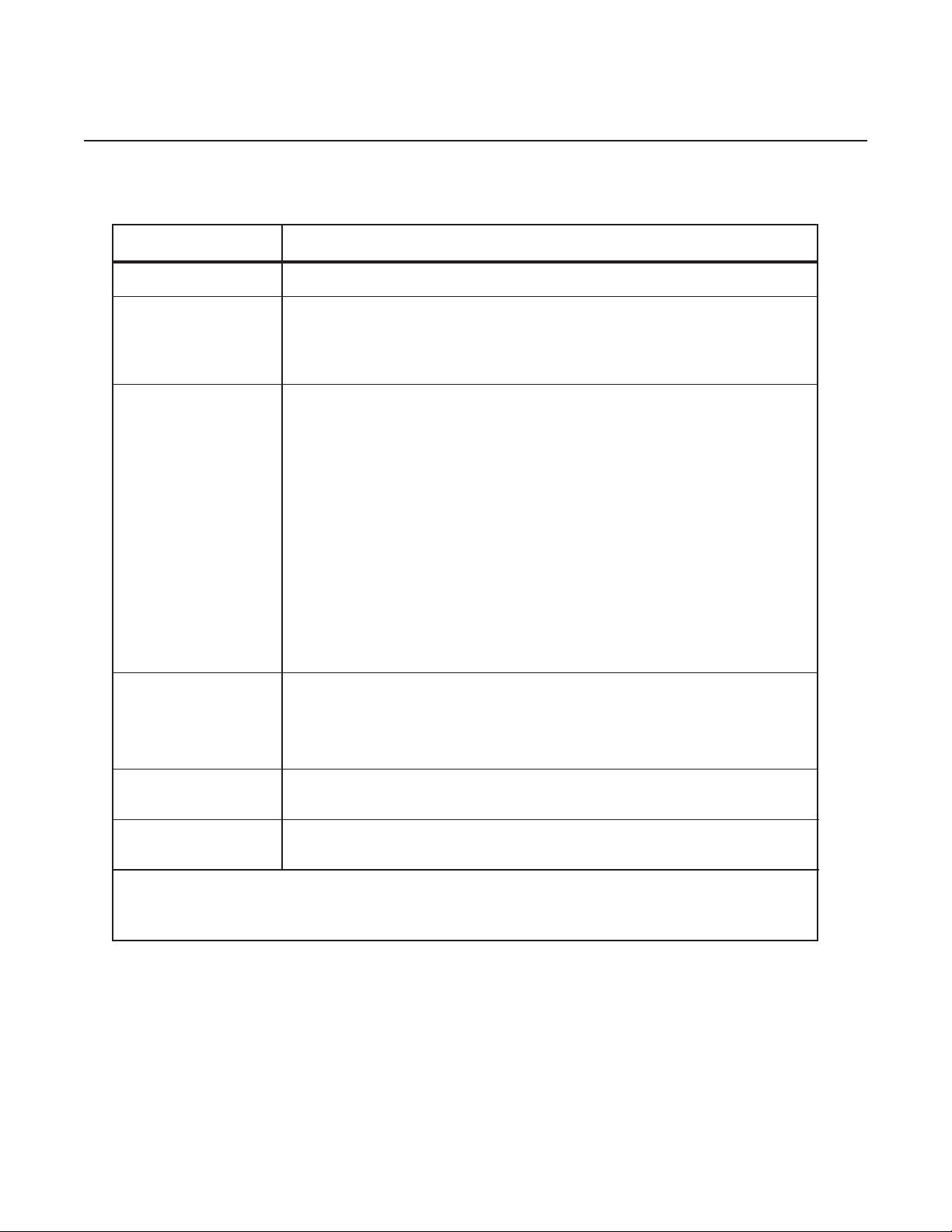

Characteristic Specification

Performance Accuracy: Less than 0.5% of span including the combined effects of

Table 1. IPT Equipment Specifications

Input Current: 4-20mA or 10-50mA

Output Pressure: 0.2-1 BAR, 1-0.2 BAR, 3-15 psig, 3-27 psig,

15-3 psig, 20-100 kPa, or 100-20 kPa

Zero: Adjusts zero to ±3% of span

Span: For 20mA input, adjusts 3-15 psig output to 15 psig ±1%

linearity, hysteresis and repeatability -- defined as independent linearity

per SAMA standard PMC 20.1 - 1973. (For 3-27 psig or 10-50 mA,

error not to exceed 1% of span).

Step Response: 0.3 seconds into 100 ml (6 cu. in.) at 90% of span

Supply Pressure Effect: Maximum 0.3% / 1.4 psig (0.3% / 0.1 Bar)

Mounting Position Effect: Negligible, unit can be mounted in any position

but should be calibrated in final orientation

Shock and Vibration Effect: Less than 0.5% for acceleration up to 10 g's

and frequency up to 80 Hz

RFI Effect: Negligible

Air Capacity: 1.6 SCFM, minimum

Air Supply: Instrument air only, filtered and regulated, 20 psig nominal,

30 psig without damage. For 3-27 psig output, 35 psig nominal, 40 psig

without damage.

Air Consumption: Dead ended 0.1 SCFM (0.18 kg/hr)

Front Panel LED: Red light emitting diode indicates presence of electrical input signal

Zero and Span: Multiturn potentiometers

+T, -T: Electrical test jacks for calibration; accepts 2mm (0.080 in) dia. x 12.7mm

(0.50 in) long phone tip plugs (handles should be less than 8mm or 0.32 in.

in diameter

Operating Range:

Temperature Effect: Less than 0.055%/°F (0.1%/°C)

Weight 20 oz. (0.57 grams)

Note: See Installation Section for physical dimensions.

–40°C to +85°C (–40°F to +185°F).

Page 5

Page 3

IPT

Instrument Air and Filtration Information

NOTE

For optimum performance, the selection and

use of a good quality air filtration system is

essential. Most users find that it is much less

expensive and troublesome to design a system

that includes good air filtration than deal with

downtime and repairs later.

To assure the maximum service life of an IPT, two

things are important: a clean, dry air supply and a

closed-loop application. Good air quality involves

removing solids, oil and water from the air after

compression. The cleaner the air, the longer the

time before servicing is needed.

Oversizing elements avoids performance abberations

and reduces maintenance time. Redundancy should

be used where possible to avoid shutdown during

maintenance.

Solids: Random solid dirt, such as pipe scale and

rust, is rarely a problem in compressed air instrument

systems. A good filter removes these solids. However, if there is a desiccant dryer in the line, a highefficiency sub-micron filter is recommended to

remove the highly abrasive sub-micron particles

produced by the dryer. A high-efficiency filter is

desirable in any system, and is often a feature of

coalescing-type filters.

Liquid Oil: Liquid oil is the most common problem in

compressed air instrument systems. A coalescing

filter removes sub-micron liquid droplets from the air,

and is usually supplied with an automatic drain.

A coalescing filter works by trapping oil and water

droplets in a bed of microfibers. The droplets run

together at fiber cross-over points, form large liquid

drops, and are forced by air flow to a drain. A filter

system consisting of a general purpose first-stage

filter (about 5 micron) and a high-efficiency coalescing final filter is recommended to obtain contaminantfree air.

The exact location of the first-stage filter is not

important; it can be located just ahead of each final

filter, or a single first-stage filter can be located on a

main line to protect a number of final filters on branch

lines. Each final filter (coalescing) should be located

just ahead of each pressure regulator. In a new plant

installation, an oilless compressor may be used to

eliminate this problem.

Water: The amount of water in an air system de-

pends on temperature, pressure and the relative

humidity of the air. Therefore, this amount varies

widely with geographical location and weather.

Sufficient water must be removed to lower the dew

point of the air to a temperature below ambient. The

dew point (at line pressure) is expressed as the

temperature at which any moisture in the system

begins to condense.

Water may be removed using a number of techniques, including coalescing filters, refrigeration

dryers and desiccant dryers. In addition, a variety of

combinations and modular systems may be used for

special circumstances.

Care must be taken in the selection and location of

the filter, because cooling downstream of the filter can

cause more condensation of water. A coalescing

filter should be installed immediately upstream of the

pressure regulator. This type of filter removes most

of the water before the air enters the regulator. Air

leaving the regulator continues to dry due to the

expansion of the air.

For systems subjected to freezing temperatures, the

portion of the system that runs outdoors should have

a dryer installed. The dryer reduces the dew point

below the lowest expected outdoor temperature. A

desiccant dryer is used with a coalescing filter upstream to keep the desiccant dryer from being

damaged by oil or being overloaded with excessive

condensed water. Another high-efficiency coalescing

filter is recommended downstream of the dryer, to

remove the desiccant fines.

Page 6

Page 4

IPT

ISA Specifications: The Instrument Society of

America standard ISA-S73, 1975 (ANSI MC11.1-

1975) covers the air quality requirements for instrument grade air for use in pneumatic installations.

The dew point in outdoor installations must be at least

7.8°C (18°F) below the minimum local ambient

temperature. For indoor installations, the dew point

must be at least 7.8°C (18°F) below the minimum

interior temperature or 2°C (35°F), whichever is

greater. Although the ISA standard calls for a 35°F

dew point, this is often unnecessary indoors, and may

be unsatisfactory outdoors under freezing conditions.

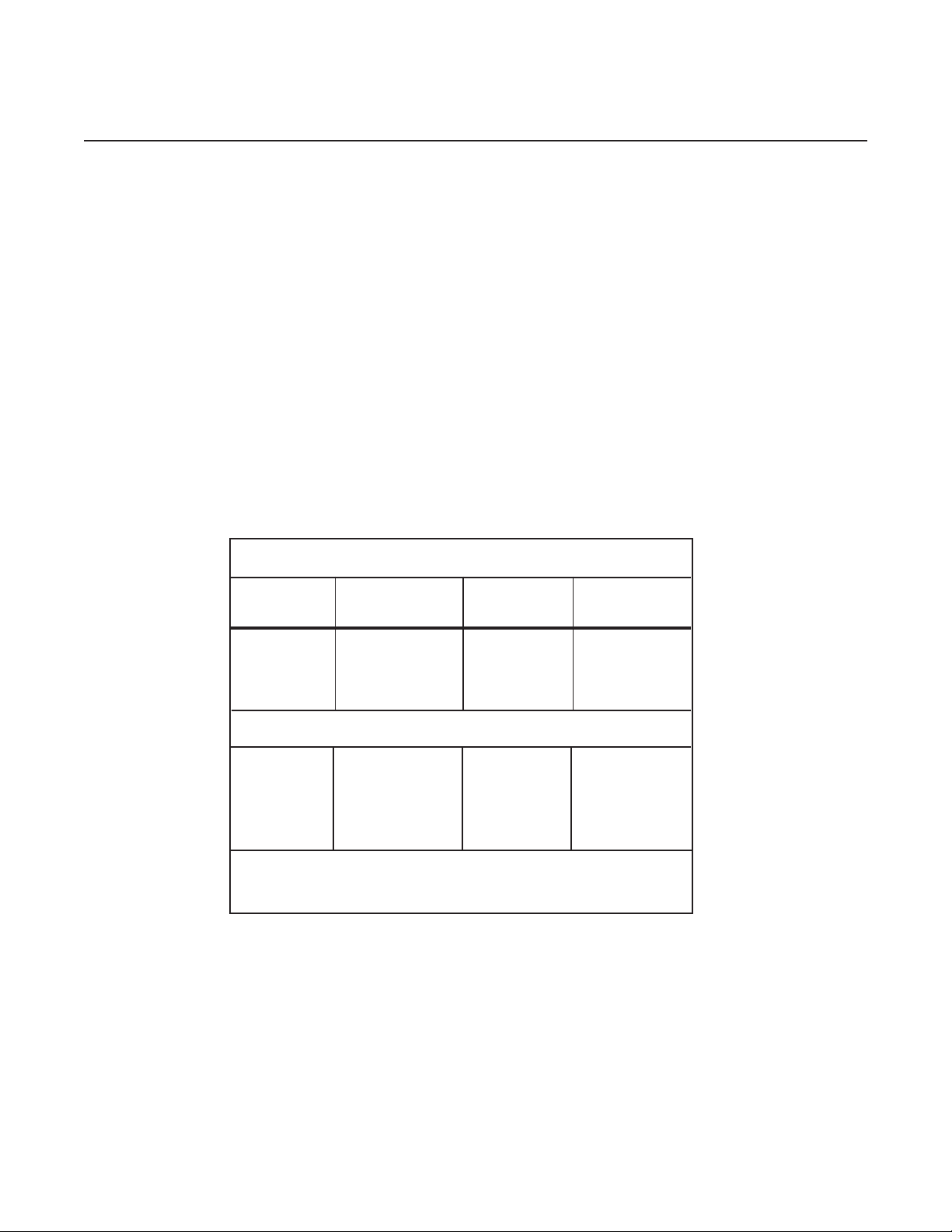

Table 2. Recommended Filters for the IPT Air Supply

5 MICRON GENERAL PURPOSE PRE-FILTERS*

Max. No. MII Part No. Port Size Max. Flow

of IPTs Female NPT @ 100 PSIG

Filters that exceed the ISA specification provide very

inexpensive protection. Although the ISA specification calls for particle size not to exceed 3 microns

and oil content not to exceed 1ppm, most filter

manufacturers supply a line of coalescing filters that

remove particles down to sub-micron sizes (often

0.01 micron) while also removing oil to below ISA

1ppm specification (often to 0.01ppm).

2 800-802-42** 1/4 18

7 800-803-42 3/8 50

17 800-804-42 1/2 50

30 800-805-42 1/2 150

0.01 MICRON COALESCING FINAL FILTERS*

2 800-806-42** 1/4 4

7 800-807-42 3/8 15

17 800-808-42 1/2 35

30 800-809-42 1/2 60

62 800-810-42 1 125

* All filters are based on maximum (full) air flow from the IPT.

** These filters do not have sight glasses on the bowls.

Page 7

Page 5

IPT

Application Information

The IPT

properly. In a closed loop, it is possible to measure

the controlled variable, to determine if a deviation

from the desired value exists, and to automatically

provide feedback for actuator loading pressure.

The IPT cannot operate in an open loop. An open

loop has inherent limitations that are not consistent

with precise control, such as: long term drift of the

loop dynamics, load fluctuations that require constant

adjustments of the actuator loading pressure, and

quality variations because of inconsistencies between

operating personnel. A controlled variable cannot be

directly measured in an open loop; this prevents

compensating adjustments to the system input. If an

IPT is installed in an open loop, it appears to drift due

to the lack of corrective feedback.

Recommendations

Any approach to providing good instrument air quality

should evaluate the worst case air flow and ambient

temperature of the location. This is required to

determine sizing of the air system elements. A

knowledge of yearly humidity cycles is also important

for this evaluation.

must be

installed in a closed loop to operate

The IPT requires periodic maintenance. The frequency of the service depends on the environment in

which the unit operates and the quality of the instrument air supplied. Service in the field is limited to

visual inspection and cleaning of the input nozzle filter

screen on the IPT and servicing of the compressed

instrument air filtration system. The unit may be

returned to the factory for complete

disassembly, cleaning, and servicing on a periodic

basis.

The use of coalescing filters with retention of 0.01

micron particles and droplets is recommended; they

remove all undesirable traces of oil and water droplets. Proper placement with respect to the

regulator(s) may eliminate the need for dryers, except

when coalescing filters are exposed to freezing

(keeping in mind that the dew point of the purified air

must be kept below worst case ambient).

Figures 1 and 2 illustrate typical non-redundant

systems with multiple branch lines. They both work in

any environment above freezing and differ only in the

placement of the general purpose first-stage filter.

Gages, valves, and differential pressure indicators

(for filter service monitoring) are not shown. It is

recommended that filters with integral service life

indicators or differential pressure indicators be used

to help ensure proper servicing, as well as redundancy to avoid shutdown during servicing.

CAUTION

Before placing IPTs in service, all pneu-

matic lines and mounting blocks or headers

(SIRs or RIRs) should be "blown down" to

purge contamination and condensation

deposited during piping and installation.

Also blow down lines to loads, since all

output air vents back through the IPT, and

there are never filters installed to trap these

contaminants (normally only present at

start-up). It is recommend this be done for

at least an hour, longer if there is evidence

of water or oil coming through.

Figures 1 and 2 differ in the method used to remove

water. The use of a desiccant type dryer (figure 2)

requires upstream filtration to prevent oil contamination of the dessicant, as well as downstream filtration,

to prevent desiccant fines from introducing new

contamination.

The service life of an IPT is directly proportional to the

cleanliness and dryness of its air supply. The small

additional cost of providing high-qulaity air ensures a

longer, more trouble-free service life for the unit.

Page 8

Page 9

Page 7

IPT

Calibration

This section provides information necessary to adjust

and calibrate the IPT. Each unit is calibrated and

checked at the factory prior to shipment. Before

installation, every IPT should be checked by the user

for proper operation. Generally, these checks, which

are specified under Calibration Procedures, require

little or no adjustment.

Adjustments

The IPT has Zero and Span adjustments located on

the front panel of the unit. They are represented

symbolically on the front panel by the following

markings:

represents Zero

represents Span

The type of potentiometer used with these adjustments usually require 22 turns of the shaft to move

the wiper from one end of its range to the other. It is

equipped with a slip clutch at each end to prevent

damage if the adjustment is turned beyond the wiper

stop. Usually a slight change can be felt when the

clutch is at the end of a range (i.e., it is slipping).

However, if this change is not felt, either end can be

reached by turning the shaft 22 turns in the desired

direction. Turning these potentiometers clockwise

causes the related output to increase in quantity or

become more positive; while turning them counterclockwise causes the related output to decrease in

quantity or become more negative.

The Span potentiometer provides an adjustment

range of ±1 percent of full scale.

The Zero adjustment consists of a conical-tipped

machine screw that displaces a torque arm on the

flapper pivot. This controls the gap between the

flapper and the nozzle to establish the zero-air bleed

rate. The adjustment screw provides a control range

of ±3 percent of full scale.

Page 10

Page 8

IPT

Calibration Equipment

Table 3 lists the equipment required to calibrate the

IPT. This equipment is not supplied with the unit and

must be provided by the user.

Table 3. Calibration Equipment

Equipment Characteristics Purpose

Adjustable current source 0-50mA output Simulate input signal

Dc milliammeter Accurate to ±0.05% Measure input signal

Instrument air supply Filtered Air supply

Air pressure gauge Accurate to ±2% Measure air supply pressure

Air pressure gauge Accurate to ±0.1% Measure output pressure

Phone tip probes (2) Must have 2,03mm (.080 in.) Easy access to input

diameter tips, .5 inch long signal (optional)

Pneumatic test coupler For IPTs with optional test Easy monitoring of output

MII P/N 163-202-00 jacks pressure (optional)

Pneumatic load Volume of 7.5 cubic inches Provide standard load for

(approx. 120 milliliters) test purposes (per IEC

specification #770)

Page 11

Page 9

IPT

Calibration Setup

Figure 3 is an illustration of a typical calibration setup,

including optional equipment. To check or calibrate

the IPT, connect the unit as shown in this illustration.

Refer to Calibration Procedures.

Calibration Procedure

There are two options shown in figure 3 for monitoring

the output of the IPT. The input current may be

measured by placing a milliammeter in series with the

input terminals as indicated by M1 or connected

across the electrical test jacks (+T and -T) as indicated by M2.

CAUTION

When measuring the input current using the

electrical test jacks, the milliammeter used

must have an internal impedance of less than

10ý. Even with 10ý internal impedance, the

readings can have a variation of as much as

±.02% of full scale.

1. For zero adjustment, connect an adjustable

current source to the electrical input terminal

block. Set the current input signal to zero percent

(e.g., 4mA for a 3-15 psig unit, 20mA for a 15-3

psig unit or 10mA for 3-15 psig unit with 10-50mA

input).

NOTE

Observe that the red LED indicator on the

front panel is illuminated at 4mA input

current and glows somewhat brighter with

increasing current.

2. Using an air pressure gauge to measure the input

air supply pressure, connect a filtered air supply

to the pneumatic supply port located on the

bottom or rear of the unit.

CAUTION

Coupler must be kept lubricated to prevent

damage to O-rings in test jacks. Teflon lubri-

cant is recommended. If grease is used, keep

out of air passage.

If the unit is not supplied with the output test

jacks, use an air pressure gauge to measure the

output air supply pressure (e.g., read 3 psig for a

3-15 psig unit or 15 psig for a 15-3 psig unit).

CAUTION

To avoid damaging their housings, use a

screwdriver with a head no wider than

0.1 inch (2.54mm) to adjust the Zero-

adjustment screw and Span potentiometer.

CAUTION

The Zero-adjustment screw must not be

backed out to the point where the slotted head

presses against the underside of the front

panel. It can put an excessive stress on the

transducer frame and may disengage the

screw from the flapper tension arm. If this

happens, the IPT must be returned to the

factory for realignment.

4. Any deviation in the output pressure can be

corrected by using the Zero-adjustment screw in

a range of ±3 percent.

5. For the Span adjustment, increase the input

signal to 100 percent (20mA or 50mA).

6. Any deviation in the output pressure (e.g., 15 psig

for a 3-15 psig unit or 3 psig for a 15-3 psig unit),

can be corrected by the Span potentiometer over

the range of ±1 percent.

7. Repeat steps 1 through 6 (as applicable) until no

further adjustments are required.

3. If the unit is supplied with the optional frontaccess pneumatic-output test jack, insert the

pneumatic coupler into the receptacle. This

avoids having to disturb any operating connections or fittings.

Page 12

Page 13

Page 11

IPT

Installation

Installation of the IPT is divided into three phases:

mounting, electrical connections, and pneumatic

connections. In most cases, it is easier to mount the

IPT before completing the electrical and pneumatic

connections.

Mounting

Individual IPTs consist of two parts: the transmitter

and the mounting block. Units without a mounting

block snap onto a header. IPTs with a mounting

block are rail mounted. When mounting the IPT,

ensure that the unit is mounted in an area free of

dust, moisture, and corrosive elements. Figure 4

shows the mounting dimensions for both mounting

styles.

CAUTION

It is recommended that mounting blocks and

headers be purged of any debris prior to

mounting the IPT. Insert a small diameter,

blunt tip probe into the fitting and unseat the

ball-check valves for a few minutes with the

filtered instrument air supply in operation.

Rack- or surface-mounted IPTs should be ordered

with a Moore Industries' rack-mounted header (RIR)

or a surface-mounted header (SIR). This eliminates

the need for an interlocking mounting block and rail.

5, 10 or 15 units can be snapped onto one header,

allowing multiple units to receive supply air from one

supply pipe. To mount an IPT onto a header, push

the unit into place until the retaining lever snaps up

flush beneath the handle. To remove an IPT, press

down on the retaining lever and lift the unit out by the

handle.

NOTE

Check valves in the headers prevent the loss of

supply or output air during mounting or removal

of IPTs.

Rail-mounted IPTs must use a pneumatic mounting

block. Pneumatic mounting blocks are 1.39 inches

wide. Using a 0.17 inch wide gage between blocks

provides a uniform spacing in a minimum rail length.

Electrical Connections

There are two terminals on the IPT for connecting

input current. The connections can be front access

or rear access.

Both the front and rear access electrical terminals are

compression screw sockets that accept 22 to 14

AWG hookup wire. To complete these connections,

use a slotted screwdriver with a head approximately

0.125 inch (3mm) in width to secure the wire leads to

the IPT. The screws tighten down, which provides

electrical contact between the wire and the terminal.

Loosen each screw prior to inserting the wire being

terminated. Strip and then tin the end of each wire

with 60/40 solder. Then, while holding the uninsulated end of the wire in place, tighten the screw of the

corresponding terminal.

The Removable Terminal Block (RTB) option adds a

2-piece wire connector to the IPT. This alows the

input wiring to be unplugged without the use of tools,

while maintaining polarity. The plug has screw-clamp

connections and accepts 22 to 14 AWG wire. The

wire should be stripped 0.5 inch (12.7mm).

Pneumatic Connections

Supply air must be clean, dry instrument air. It is

recommended that all particles larger than 1 micron

be removed. Use of 1/4 inch tubing allows sufficient

air for one unit. When using RIR or SIR headers, up

to 30 IPTs may be run from a 3/4 inch NPT pipe

without degrading performance, provided the air

supply pressure is sufficient. Output tubing should be

1/4 inch, though larger tubing may be desirable for

exceptionally long runs. Purge the output tubing and

the controlled device before connecting to the IPT or

RIR/SIR.

CAUTION

Output air cycles back through the IPT.

Contamination in the output line or

controlled device may easily enter and

damage the IPT.

Page 14

Page 15

Page 16

Page 14

IPT

Maintenance

Because instrument air continuously flows through

IPT passageways, the air lines must be kept clean.

Depending on the purity of the air supply, the filter

and two internal orifices of the IPT assembly must be

cleaned at regular intervals to maintain specified

performance. The two orifices should be cleaned at

least once a year. Initial random checks can help

establish a satisfactory maintenance interval geared

to the user's air supply purity.

The supply air filter screen should be removed and

flushed with trichloroethance (TCE) and then air dried

before replacement.

1. Remove the IPT from the mounting block by

pressing down on the locking lever and pulling

straight out to disengage the pneumatic fittings.

2. To remove the supply air filter screen, first slide

the nozzle retainer clip to the right and then pull

the nozzle out of the main body.

3. Remove the filter screen and flush with TCE and

air dry before reinstalling.

4. Slide the nozzle back into the main body.

3. Without pulling the wires loose on the printed

circuit board attached to the front panel, slide out

the front panel.

4. Remove the screw on the bottom of the front

panel to free the printed circuit board.

5. Insert a blade screwdriver between the rear panel

and the IPT. Separate the rear panel from the

IPT.

6. Squeeze and slide back the clamp from the

tubing barb and pull the tubing from the tubing

barb (only on units with optional test jacks).

To access the orifices in the IPT, remove the bottom

mounting screw and the two screws at the rear of the

unit. The orifices are located in the subassembly.

See figure 6.

CAUTION

Use care not to damage the rubber

gaskets between the subassemblies.

Clean the orifices with a 0.004 - 0.005 inch diameter

steel wire. Push the wire through the hole. Refer to

figure 7 for orifice locations.

To clean its orifices, the IPT assembly must be

removed from the extruded aluminum case. To

remove the assembly, proceed as follows:

1. Remove the 6 screws securing the right side

cover and remove the cover.

2. Remove the bottom 4 screws securing the left

side cover and remove the cover. Turn the unit

over. The test point connector and the test point

jack are now free.

Page 17

Page 18

Page 19

Page 17

IPT

Troubleshooting

Many components of the IPT have been thermally

aged, tested, and selected using a computer-aided

design program. This usually makes field repair

unnecessary. It is therefore recommended that any

unit found to be performing below specifications be

returned to the factory in accordance with the instructions found on the back cover of this manual.

If a problem is suspected with the IPT, review the

following steps:

1. Make sure that all connections are clean and

tight.

2. Verify that bench instruments used to take

measurements have the proper range and

accuracy and are currently certified.

3. Check that the bleed-air port (located in a slot on

the left side panel) is not restricted.

4. Using a test jumper, connect one end to the metal

case and the other end to an "IN" terminal while

observing the output pressure. The output

pressure should not change.

5. If a change in the relationship between the input

and the output occurs, try to correct it by readjusting the Zero and Span controls.

6. If the response time lengthens or if the span

drops, this may indicate a blockage due to air

supply contamination. Clean the orifices and the

supply air filter as described in the Maintenance

section.

Drawings

The current revision of the IPT schematic is shown in

figure 8.

Page 20

Page 21

Page S-1

P/N 170-730-01 A

This supplement contains information about the IPT

with the -EPS option. If your unit does not have this

option, please disregard this supplement.

snoitacificepS

ecnamrofreP:ycaruccA napsfo%1.0±

)ni.uc6(

:tceffE:tceffE

:tceffE:tceffE .nimGrep/%52.0

:tceffE

:tceffEIFR nahtsseL

C°08+dnaC°0neewteb

)F°671+otF°23+(

erutarepmettneibma

denibmocehtgnidulcni

,ytiraenilfostceffe

dna,siseretsyh

sadenifed–ytilibataeper

repytiraeniltnednepedni

-1.02CMPdradnatsAMAS

napsfo%51.0±(3791

)C°04–otC°0neewteb

:esnopseRpetS 2.0<

).ni.uc6(.lm001otni.ces

fo%01-09dna%09-01rof

)1erugiFeeS(naps

:esnopseRycneuqerF

lm001otniBd3–tazH5

:tceffEerusserPylppuS

gisp04-02morfelbigilgeN

:tceffEnoitisoPgnitnuoM

ebnactinu;elbigilgeN

,noitisopynanidetnuom

noitarbiVdnakcohS

zH51ot5revo

m/V05tanapsfo%520.0±

ecnamrofreP

)deunitnoC()deunitnoC(

)deunitnoC()deunitnoC(

)deunitnoC(

tneibmAtneibmA

tneibmAtneibmA

tneibmA

snoitidnoCsnoitidnoC

snoitidnoCsnoitidnoC

snoitidnoC

lenaPtnorFlenaPtnorF

lenaPtnorFlenaPtnorF

lenaPtnorF

stnemtsujdAstnemtsujdA

stnemtsujdAstnemtsujdA

stnemtsujdA

IPT

Supplement

The specifications and ordering information for the

IPT with the -EPS option are shown below.

:tfirD deecxeottoN

2erugiF

shtnom

:egnaR:egnaR

:egnaR:egnaR C°08+otC°04–

:egnaR

:tceffE:tceffE

:tceffE:tceffE lacipyt%50.0±

:tceffE

:yticapaCriA eeS

:ylppuSriA riatnemurtsnI

,detalugerdnaderetlif,ylno

5ebtsuM.gisp04-02

retaerg)raB43.0(gisp

gisptuptuomumixamnaht

:noitpmusnoCriA 51.0

)rh/gk3.0(.xam,mfcs

6rofycaruccadetats

erutarepmeTtneibmA

)F°671+otF°04–(

erutarepmeTtneibmA

C°08+dnaC°0neewteb

%1.0,)F°671+otF°23+(

,lacipyt%1.0±;xam

C°0otC°04–neewteb

%51.0,)F°23+otF°04–(

mumixam

:oreZtuptuO orezstsujdA

napsfo%01±ot

:napStuptuO stsujdA

napsfo%01±otnaps

snoitcennoC

)retemaid

srotacidnIsrotacidnI

srotacidnIsrotacidnI

:DEL gnittimethgildeR

srotacidnI

thgieWthgieW

thgieWthgieW

thgieW

snoitcennoCtupnI :

)00-202-361n/p

detnuomtnorfelbavomeR

.GWA41-22,skcolblanimret

:snoitcennoCtuptuO .ni8/1

raerromottob,elamefTPN

lanoitpohtiwstinunonoitacol

kcolbgnitnuomcitamuenp

:noitcennoCylppuS .ni8/1

raerromottob,elamefTPN

lanoitpohtiwstinunonoitacol

kcolbgnitnuomcitamuenp

:skcaJtseTtnerruC tupnI

,T+delebal(kcajtsettnerruc

stpecca;noitarbilacrof)T–

x.aid).ni080.0(mm2

enohpgnol).ni05.0(mm7.21

ebdluohsseldnah(sgulppit

ni).ni05.0(mm21nahtssel

:skcaJtseTcitamuenP

erusserptuptuosrotinoM

roF(noitarbilacgnirud

redro,relpuoctsetcitamuenp

foecneserpsetacidniedoid

langistupnilacirtcele

)smarg7.835(secnuo91

Figure 1. IPT Step Response

17

15

13

11

PSIG

9

7

5

3

50 100 150 200 250 300 350

0

MILLISECONDS

Specifications subject to change

Figure 2. IPT Air Capacity

4

3

AIR CAPACITY

(SCFM)

2

1

4 8 12 16 20 24 28 32 36

15 PSIG

7 PSIG

OUTPUT AT 100%

(PSIG)

The Interface Solution Experts

30 PSIG

Page 22

Page S-2

IPT

TPIAM02-4 otni

Supplement

tinU tupnI tuptuO

573 Ω 052( Ω rof

AM21-4

AM02-21AM02-21

AM02-21AM02-21

AM02-21

elbaliava

)DELtuohtiwstinu

oslasegnarmotsuC

:yficeps,gniredronehW ]gnisuoH[noitpO-noitangiseDsseccA-/erusserPylppuS/tuptuO/tupnI/tinU

:elpmaxerebmunledoM ]NID[SPE-1AF-/ISP04-02/GISP51-3/AM02-4/TPI

noitamrofnIgniredrO

ylppuS

erusserPerusserP

erusserPerusserP

erusserP

GISP02-0

GISP51-3GISP51-3

GISP51-3GISP51-3

GISP51-3

GISP6.61-3GISP6.61-3

GISP6.61-3GISP6.61-3

GISP6.61-3

GISP81-3GISP81-3

GISP81-3GISP81-3

GISP81-3

GISP71-1GISP71-1

GISP71-1GISP71-1

GISP71-1

GISP03-6GISP03-6

GISP03-6GISP03-6

GISP03-6

GISP72-3GISP72-3

GISP72-3GISP72-3

GISP72-3

RAB1-2.RAB1-2.

RAB1-2.RAB1-2.

RAB1-2.

APK001-02APK001-02

APK001-02APK001-02

APK001-02

2MCGK1-2.2MCGK1-2.

2MCGK1-2.2MCGK1-2.

2MCGK1-2.

APM01.-20.APM01.-20.

APM01.-20.APM01.-20.

APM01.-20.

tuptuOesreveR

GISP0-02

GISP3-51GISP3-51

GISP3-51GISP3-51

GISP3-51

GISP3-6.61GISP3-6.61

GISP3-6.61GISP3-6.61

GISP3-6.61

GISP3-81GISP3-81

GISP3-81GISP3-81

GISP3-81

GISP1-71GISP1-71

GISP1-71GISP1-71

GISP1-71

GISP6-03GISP6-03

GISP6-03GISP6-03

GISP6-03

GISP3-72GISP3-72

GISP3-72GISP3-72

GISP3-72

RAB2.-1RAB2.-1

RAB2.-1RAB2.-1

RAB2.-1

APK02-001APK02-001

APK02-001APK02-001

APK02-001

2MCGK2.-12MCGK2.-1

2MCGK2.-12MCGK2.-1

2MCGK2.-1

APM20.-01.APM20.-01.

APM20.-01.APM20.-01.

APM20.-01.

elbaliavaoslasegnarmotsuC

ISP04-02

RAB8.2-4.1RAB8.2-4.1

RAB8.2-4.1RAB8.2-4.1

RAB8.2-4.1

GK8.2-4.1GK8.2-4.1

GK8.2-4.1GK8.2-4.1

GK8.2-4.1

APK082-041APK082-041

APK082-041APK082-041

APK082-041

APM82.-41.APM82.-41.

APM82.-41.APM82.-41.

APM82.-41.

sseccA

snoitangiseDsnoitangiseD

snoitangiseDsnoitangiseD

snoitangiseD

1-SelbaTeeS SPE- dednetxE

snoitpO gnisuoH

NID munimulaelyts-NID

ecnamrofreP

snoitacificepS

)RIS(ro

ITW erusolcnethgit-retaW

P* semoctinusetacidni)xiffus(

.g.e( PITW )

mm23nostnuomgnisuoh

dna)53005NE(epyt-G

)22005NE(taHpoTmm53

citamuenpagnisusliar

tinu-itlumrokcolbgnitnuom

)RIR(redaehylppusria

.noitinifedR3AMENrep

ssecca01AF-ro

)noitangised

,9AF-,8AF-,7AF-seriuqer(

-Udnaetalpesabahtiwdeppiuqe

epiphcni-2anognitnuomrofstlob

Table S-1. Access Designations

tupnItnerruC

noitacoLnoitacoL

noitacoLnoitacoL

noitacoL

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

tnorF

mottoB

raeR

mottoB

raeR

mottoB

raeR

enoN

enoN

enoN

enoN

mottoB

raeR

dnatuptuOcitamuenP

*noitacoLylppuS*noitacoLylppuS

*noitacoLylppuS*noitacoLylppuS

*noitacoLylppuS

skcolbgnitnuomhtiwstinunoylnoelbacilppA*

tseTcitamuenP

noitacoLkcaJnoitacoLkcaJ

noitacoLkcaJnoitacoLkcaJ

noitacoLkcaJ

enoN

enoN

tnorF

tnorF

enoN

enoN

enoN

tnorF

enoN

tnorF

tnorF

tnorF

tnerruCdnaDEL

skcaJtseTskcaJtseT

skcaJtseTskcaJtseT

skcaJtseT

seY

seY

seY

seY

enoN

enoN

seY

seY

enoN

enoN

enoN

enoN

sseccA

snoitangiseDsnoitangiseD

snoitangiseDsnoitangiseD

snoitangiseD

1AF2AF3AF4AF5AF6AF7AF8AF9AF-

01AF11AF21AF-

The Interface Solution Experts

Page 23

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty , be prepared to giv e us a Purchase Order n umber when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a ) A note listing the symptoms that indicate the unit needs repair

b ) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Tel: (818) 894-7111 • FAX: (818) 891-2816

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

© 2006 Moore Industries-International, Inc.

United States • info@miinet.com

Australia • sales@mooreind.com.au

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...