Page 1

April 2016

170-746-00D

Field-Mount

Current-to-Pressure Transmitter

IPH

Field-Mount

Current-to-Pressure Transmitter

IPHIPH

IPHIPH

IPH

All product names are registered trademarks of their respective companies.

Page 2

IPH

Table of Contents

Introduction.....................................................................................................

Description ...................................................................................................................... 1

Specifications .................................................................................................................. 1

Ordering Information....................................................................................................... 2

11

1

11

Calibration .......................................................................................................

Necessary Equipment..................................................................................................... 2

Preparing for Calibration ................................................................................................. 2

Calibration Process ......................................................................................................... 4

Installation.......................................................................................................

Phase One: Mounting ..................................................................................................... 6

Phase Two: Electrical Connections................................................................................. 6

Phase Three: Pneumatic Connections............................................................................ 6

Operation.........................................................................................................

Maintenance ....................................................................................................

Necessary Equipment..................................................................................................... 7

22

2

22

66

6

66

77

7

77

77

7

77

Disassembling the IPH.................................................................................................... 7

Cleaning the Subassembly.............................................................................................. 7

Changing the Pneumatic Block ....................................................................................... 8

Re-assembly ................................................................................................................. 10

Troubleshooting............................................................................................

1010

10

1010

Page 3

IPH

Introduction

This is the users’ manual for Moore Industries’ IPH

Current-to-Pressure Transmitter. It contains all of the

information that is needed to configure, install, operate,

maintain, and troubleshoot the IPH. If you would like

additional assistance, call one of our STAR centers.

The following guidelines are used in this manual:

WARNING

could injure the operator.

Caution

damage or destroy the unit.

Note

condition, or operation of the unit.

Description

The IPH is Moore Industries’ rugged and compact

Field-Mount Current-to-Pressure (I/P) Transmitter. It is

designed to meet NEMA 4X and IP55 requirements, is

watertight, dust-tight, and resistant to corrosion and

chemicals. These qualities make the IPH the ideal

transmitter for extended use in harsh situations.

- Hazardous procedure or condition that

- Hazardous procedure or condition that could

- Information that is helpful for a procedure,

The 2-wire (loop-powered) IPH accepts a 4-20mA input

from a DCS, PLC or PC-based control system. It

converts the current signal to a pneumatic signal

(3-15psig, 0.2-1 Bar, 20-100 kPa, etc.), providing

precise proportional control of valves, actuators, and

other pneumatically-controlled devices. Reverse

pneumatic outputs (15-3psig, 1-0.2 Bar, 100-20 kPa,

etc.) are also available.

The IPH is available with an optional coalescing

filter/regulator that combines an air filter, a miniature

supply line regulator, and a pressure gauge that reads

in both psi (0-60) and Bars (0-4).

Model/Serial Number. Moore Industries tracks all

their IPH units with a system of model numbers and

serial numbers. Please be prepared to provide these

numbers if you need service information or assistance.

The IPH serial and model numbers can be found on

the instrument’s metal tag.

Specifications

Performance

Specifications and information subject to change without notice.

Accuracy: Less than

0.5% of span including the

combined effects of

linearity, hysteresis, and

repeatability-defined as

independent linearity per

SAMA standard PMC 20.1-

1973. (For 3-27psig, error

will not exceed 1% of

span)

Step Response: 0.3 seconds into 100ml (6 cu. in.)

at 90% of output span

Supply Pressure Effect:

Maximum 0.3%/1.4psig

(0.3%/0.1BAR)

Air Consumption:

0.1SCFM (dead-ended)

Air Capacity: 1.4 SCFM

maximum

Performance

(continued)

Ambient

Temperature

Maximum Input: 150%

of input span without

damage

RFI/EMI Effect: With

field strengths of 10 volts

per meter, at frequencies

of 20-500MHz, it has less

than ±0.1% of span

change (standard)

Mounting Position

Effect: Negligible, unit

mounts in any position,

but should be calibrated

in final orientation

Range: –40 to +60°C

(–40 to +140°F)

Effect: Less than ±0.1%

of input span per °C over

above range (0.005%/°F)

Adjustments

Connections

Weight

Zero: Multiturn screw

adjusts zero to ±3% of

span

Span: Multiturn potentiometer fully adjustable to

100% of output span

Pneumatic: 1/4-inch

NPT female for both supply air and output air. Air

supply also has an additional (normally plugged)

port for optional filter/

regulator (-FR1 option)

Electrical: WDNS and

WDNA, 1/2-inch NPT female; WDMS and WDMA,

M20 x 1.5 female

993 grams

(2lb, 3oz)

The Interface Solution Experts 1

Page 4

IPH

Ordering Information

Unit Input Output Supply Pressure Options Housing

IPH

Current-toPressure

Transmitter

When ordering, specify: Unit / Input / Output / Supply Pressure / Option [Housing]

Model number example: IPH / 4-20MA / 3-15PSIG / 20PSI / -FR1 [WDNS]

4-20MA

into 260

ohms,

nominal

3-15PSIG

3-27PSIG

15-3PSIG

20-100KPA

.2-1BAR

.2-1KGCM2

*The unit’s output must match the

supply pressure to its right.

20PSI

35PSI

20PSI

140KPA

1.4BAR

1.4KGCM2

-FR1 Combines a

coalescing filter, a

miniature supply line

regulator, and a

pressure gauge that

reads in both psi (0-

60) and Bars (0-4)

-ISF FM approved

Intrinsically Safe

-ISE PTB/CENELEC

Intrinsically Safe

-NE CENELEC

Type N

WDNS Aluminum body with PBT polyester cover; NPT

pneumatic ports and NPT electrical entry port

WDNA Aluminum body with aluminum cover; NPT

pneumatic ports and NPT electrical entry port

WDMS Aluminum body with PBT polyester cover; NPT

pneumatic ports and metric electrical entry port

WDMA Aluminum body with aluminum cover; NPT

pneumatic ports and metric electrical entry port

NOTE: Add “P” suffix to the model housing designator for 2-inch pipe

mounting hardware (e.g., WDNSP, WDMSP)

Calibration

Every IPH is fully tested and calibrated at the factory

prior to shipment. Before installation, however, your

IPH’s should be bench-checked to verify proper

operating levels and to set the desired unit zero and

unit span. Calibration should be conducted in an

appropriate testing environment.

Necessary Equipment

Table 1 lists the equipment required to calibrate the

IPH. This equipment is not supplied by Moore

Industries, but should be available in most labs or

maintenance areas.

Table 1. IPH Calibration Equipment

Equipment Specifications

Current So urce

Cali brated, adj ustable. Must be capabl e of di scret e ou t p ut levels withi n t h e appropri ate, rated range

for the unit un der test; 4-20 or 10-50 mA. Accuracy of ±0.1%

Preparing for Calibration

To prepare the IPH for calibration, remove the

screw-on cap and connect the unit to your calibration

equipment as shown in Figure 1 on page 3, which

shows the calibration setup.

Unit Connections and Controls. The IPH has two

labeled terminals on its faceplate, located under the top

protective cover of the housing. The terminal labeled

“+I” is for connection of the positive current input, and

the terminal labeled “–I” is for negative connections.

DC Multimeter

Air Supply

Air Pressure Gauges

Pneumati c Test Load

Screwdriver

2 The Interface Solution Experts

Calibrated. Accuracy of ±0.1% (optional equipment)

Filtered, regulated, instrument-quality.

Two calibra ted gauges; #1 with accuracy of ±2%, #2 with accur acy of ±0.1%.

Calibrated. Volume of appr oximately 120 ml (75 in3), per IE C spec #770.

Slotted-tip. Head width of 5 mm (0.1875 in), maximum.

Page 5

IPH

The two IPH controls are also located inside the unit

housing under the screw-on cap. They consist of a

mechanical adjustment screw and an electronic

potentiometer, each accessed through the front panel.

They are labeled “zero” and “span”. The zero adjustment screw mechanically provides a control range for

zero offsets of ±3 percent of rated unit span.

The span pot electronically adjusts unit full-scale

output to 100 percent of rated span. It requires approximately 22 turns to move its wiper from one

extreme to the other, clockwise for maximum or

counterclockwise for minimum span. It is equipped

with a slip clutch to prevent damage if the adjustment is

turned beyond the wiper stop.

Note: Always use clean, dry, instrument air when

calibrating or operating the IPH.

All pneumatic lines used in calibration and operation

must be “blown down” (purged) prior to connection to

the IPH. Any condensation or oil residue in the lines, if

introduced into the pneumatic chambers of the IPH,

may result in poor unit performance.

Calibration Steps:

(See Figure 1)

1. Orient IPH vertically or horizontally based on

how it will be positioned in the application.

2. With zero air input (supply off), connect 1/4-inch

pneumatic tubing between the appropriate output

port of the regulated instrument air supply and the

calibrated pressure gauge #1 (accuracy of ±2% of

span). Connect another hose from the pressure

gauge to the port labeled “IN” on IPH.

3. Connect 1/4-inch pneumatic tubing between the

IPH port labeled “OUT” and the appropriate port of

pressure gauge #2 (accuracy of ±0.1% of span),

then from gauge #2 to the appropriate pneumatic

load.

4. Run current source wiring through conduit opening

in housing, and to front panel of IPH.

5. Connect positive lead of adjustable current source

to +I terminal of IPH. Connect negative source

lead to –I IPH terminal. A dc multimeter may also

be connected to verify level of current input.

Figure 1. IPH Calibration Setup

PRESSURE GAUGE #2

(ACCURACY ±0.1%)

PNEUMATIC

TEST LOAD

OUTPUT

PORT

IPH

SPAN

ZERO

CURRENT TO

PRESSURE TRANSMITTER

INPUT

PORT

+I

DC

MULTIMETER

+

-I

_

_

ADJUSTABLE

CURRENT

SOURCE

+

PRESSURE GAUGE #1

(ACCURACY ±0.2%)

REGULATED

INSTRUMENT

AIR SUPPLY

The Interface Solution Experts 3

Page 6

IPH

6. When connections are complete, apply 4mA of

input current. (0% of total current)

7. Apply appropriate filtered, instrument-quality air to

supply line: 20 or 35 psi (40 kPa, or 1.4 bar).

Verify appropriate supply pressure by checking

Supply Pressure field of unit model number.

8. Set span pot to approximately mid-scale (22 turns

in either direction, then approximately 11 turns in

the opposite direction).

9. Set zero adjustment screw fully clockwise, then

five turns counterclockwise.

10. Allow approximately 30 seconds for calibration

setup to stabilize.

Calibration Process

To perform the recommended bench-check for the

IPH, first perform the setup as described in the preceding section. The calibration procedure consists of a

basic check and adjustment of unit zero and span,

based on the reading of pressure gauge #2 (accuracy

of ±0.1%).

Table 2 lists the values to be used during calibration.

Refer to the table when performing the following:

1. Check unit zero setting. Monitor reading of

pressure gauge #2 (output), and turn zero adjust

screw counterclockwise to lower output, clockwise

to raise output. Set zero adjust screw so that

pressure output is at 0% of appropriate range

(±3%) when 0% input is applied.

2. Check unit span setting. Increase input to 100% of

rated span (20 mA).

3. Monitor reading of pressure gauge #2 (output), and

adjust span pot so that reading is at 100% of

appropriate pressure range for your unit.

Check the values listed in Table 2.

4. Repeat steps 1 through 3 until IPH outputs 0% of

rated pressure range at 0% current input, and

100% of output pressure range at 100% current

input.

5. Verify the accuracy of your adjustments by inputting the appropriate percent of span levels listed in

table 2.

Table 2. IPH Calibration Values

At

0% of

Rated Inpu t

IPH Output

Configuration

3-15 psig 3 psi 15 psi 6 psi 9 psi 12 psi

15-3 psig 15 psi 3 psi 12 psi 9 psi 6 psi

0.2- 1 ba r 0.2 bar 1 bar 0.4 bar 0.6 bar 0.8 bar

1-0. 2 ba r 1 bar 0.2 bar 0.8 bar 0.6 bar 0.4 bar

3-27 psig 3 psi 27 psi 9 psi 15 psi 21 psi

3-16.6 psig 3 psi 16.6 psi 6.4 psi 9.8 psi 13.2 psi

20-100 kPa 20 kPa 100 kPa 40 kPa 60 kPa 80 kPa

Range

(4mA)

Adjust Zero

until Gauge

#2 Reads:

At

100% of

Rated Inpu t

Range (20mA)

Adjust Sp an

until Gauge #2

Reads:

Verif y by Applying

25% of Rated Input

Range (8mA)

Gauge #2 will

Read:

Verif y by Applying

50% of Rated Input

Range (12mA)

Gauge #2 will

Read:

Verif y by Applying

75% of Rated Input

Range (16mA)

Gauge #2 will

Read:

100-20 kPa 100 kPa 20 kPa 80 kPa 60 kPa 40 kPa

4 The Interface Solution Experts

Page 7

Figure 2. IPH Current-to-Pressure Transmitter Housing Dimensions

CONDUIT WIRE ENTRY

METRIC (M20 x 1.5)

OR NPT (1/2-14)

143 mm

(5.6 in)

85 mm

(3.4 in)

THREADS

-FR1 OPTION

(COALESCING

FILTER/REGULATOR

AND PRESSURE GAUGE)

IPH

SCREW-ON CAP

21 mm

(0.8 in)

51 mm

(2.0 in)

1/4 NPT

FEMALE

PNEUMATIC

OUTPUT

PORT

119 mm

OUT

(4.7 in)

33 mm

(1.3 in)

53 mm

(2.1 in)

IN

1/4 NPT FEMALE

PNEUMATIC

INPUT PORT

(UNUSED PORT IS

PLUGGED)

140 mm

(5.5 in)

WITH

-FR1 OPTION

SLIP-ON DRAIN

CONNECTION FOR

1/4-INCH FLEXIBLE TUBING

0.36 DIA. (9.15mm)

MOUNTING HOLES (2)

91 mm

(3.6 in)

157 mm

(6.2 in)

1/4 NPT PNEUMATIC

INPUT PORT FOR OPTIONAL

-FR1 FILTER/REGULATOR/GAUGE

36 mm

(1.4 in)

23 mm

(0.9 in)

INSTRUMENT

TAG

UNIVERSAL MOUNTING BRACKET

(SURFACE OR PIPE MOUNT;

VERTICAL OR HORIZONTAL)

72 mm

(2.9 in DIA.)

9.7 mm

(0.38 in DIA.)

69 mm

(2.7 in)

69 mm

(2.7 in)

89 mm

(3.5 in)

NOTE:

For NEMA4X and IP55 Installations, the unit must be mounted

vertically or within 45 degrees of vertical.

The Interface Solution Experts 5

Page 8

IPH

Installation

The installation of the IPH is carried out in three

phases. The first phase is the physical mounting of the

unit. Next is the electrical connections phase, and

finally, pneumatic connections can be made. It is

strongly recommended that IPH’s be installed in this

order. It is also strongly suggested that each unit be

calibrated according to the instructions in this manual

before being placed into service.

The IPH may be installed at any angle: either surfacemounted or attached to pipe or round conduit. When

deciding on the placement of the IPH unit, make sure

to consider the possibility of needing to: access the

front panel, check the fittings, read the -FR1 Option

gauge, or drain the filter.

Closed Loop/Open Loop. The IPH should be

installed in a closed loop. A closed loop is the best

way to measure a control variable. It also helps

determine if a deviation from a desired value exists and

provides feedback for actuator loading pressure.

An open loop has limitations that are not consistent

with precise control. Long term drift of the loop dynamics, load fluctuations that require constant adjustments

of the actuator loading pressure, and performance

quality variations due to inconsistencies between

operating personnel are all problems commonly

associated with open loops. A controlled variable

cannot be directly measured in an open loop; this

prevents compensating adjustments to the system

input.

Phase Two: Electrical Connections

To complete the electrical connections, route the wiring

through the conduit port to the terminal block, then use

a slotted-tip screwdriver with a maximum head width of

3 mm (0.125 inch) to loosen the terminal screws.

The terminals are comprised of compression-screw

sockets that accommodate 22-14 AWG wiring.

Connect positive lead (+) to terminal labeled “+

negative lead (–) to terminal labeled “–I”. Tighten the

terminal screws until snug.

Use shielded, twisted-pair wiring for low-level input.

Ground the shielding wire as close as possible to the

installed IPH.

I”, and

Phase Three: Pneumatic Connections

To complete the final phase of installation, the pneumatic connections, connect the supply line to the

1/4-inch NPT female port labeled “IN”. Connect the

output line to the 1/4-inch NPT female port labeled

“OUT”.

Seal all fittings with Teflon® tape, or equivalent. Always

“blow down” (purge) all tubing and the controlled

device before connecting the IPH.

Filters. The IPH requires filtered, dry, regulated,

instrument-quality air to prevent clogging and to ensure

extended periods of maintenance-free operation.

Moore Industries suggests the following levels of

filtering protection:

Phase One: Mounting

Figure 2 gives the IPH’s outline dimensions. The

illustration also gives the dimensions of the available

-FR1 Option hardware, which is recommended for

most installations.

After placing the IPH in the desired location and

orientation, secure the housing with the optional pipe

mounting hardware or other appropriate fasteners.

If you have further questions on how to mount the IPH,

contact your Moore Industries Sales Representative for

assistance.

NOTE:

For NEMA4X and IP55 Installations, the unit must be

mounted vertically or within 45 degrees of vertical.

6 The Interface Solution Experts

• Pre-filter – A general purpose “rough” filter, used

to reduce particulate matter to 5 microns in size.

Also removes bulk liquids. Although not required,

this filter is especially recommended to protect the

0.01 micron final filter when used.

• Final Filter – A second, final filter is recommended, to remove particulate matter in sizes

down to 0.01 micron. This filter removes virtually

all condensable liquids from the air stream as well.

• Filter/Regulator Module Option – A combined

filter/regulator assembly, the -FR1 Option, offered

as an accessory for the IPH, removes particles

down to 0.01 micron, supplying regulated, instrument-quality air to the unit. This space-saving

module is affixed to the IPH supply port, and

comes with a pressure gauge scaled in both psi

(0-60) and bars (0-4).

Page 9

IPH

Operation

Once the IPH unit’s calibration has been checked or

adjusted and the unit has been installed properly, the

IPH operates unattended with the exception of the

minor maintenence procedures that are described in

the next section.

Remember that if an IPH is installed in an open loop, it

may appear to drift over extended periods of time

because of the lack of corrective feedback.

If the unit is determined to be the cause of a loop

irregularity, carry out the maintenance procedure in the

next section of this manual. If problems persist, refer

to the Troubleshooting Section.

Instrument-quality Air. Air from the application

continuously flows through the IPH during operation.

Depending upon the purity of the air supply, the unit’s

internal assembly may have to be removed and

cleaned to ensure continued optimum performance.

Initially, random checks can help establish a satisfactory maintenance interval geared to the user’s air

supply cleanliness. Refer to the next section for

instruction on the disassembly and cleaning of the IPH.

this equipment is not available, your facility may not be

qualified to perform the operations described in this

section. Contact Moore Industries’ Customer Service

Department for more information.

Disassembling the IPH

To disassemble the IPH for maintenance/cleaning,

unscrew the protective top cover, then unscrew the two

screws from the base and remove the unit.

Take the internal assembly out of the housing by

pulling straight out, away from housing base. Apply

steady pull, disengaging the pneumatic fittings from

their ports in the housing base. Do not disassemble

the pneumatic block at this time.

Separate the faceplate from the transducer by removing the screws on both sides of the plate assembly.

Cleaning the Subassembly

1. Place subassembly on work surface with zero

screw and span pot down.

2. Use syringe to fill Orifice #1 with trichloroethane

(TCE). See Figure 3.

Maintenance

Before beginning IPH maintenance, the unit must be

removed from its application.

Warning: It is strongly recommended that the

maintenance procedures be performed in a clean,

controlled environment, such as a technicians’

bench, a laboratory, etc. Several internal parts are

small and precision-machined and can be easily lost

or damaged if an attempt is made to perform

maintenance in the field.

After maintenance, each IPH should be recalibrated

before it is returned to service. Refer to the Calibration

Section of this manual for instructions.

Necessary Equipment

To perform the basic maintenance procedure for the

IPH, refer to Table 3, which lists the required

equipment. These materials are not supplied by Moore

Industries, but should be available in maintenance

areas prepared to perform this type of procedure. If

3. Clean nozzle air passage by gently passing

cleaning wire back and forth through opening in

subassembly base.

4. Soak several small strips of clean paper in TCE.

5. Set the subassembly on its side and slide one strip

between the nozzle and the flapper. Carefully

apply slight pressure to flapper until it rests against

nozzle with soaked paper in between.

6. Maintain pressure while pulling paper out. Repeat

with other strips of paper until no residue is transferred to paper.

7. Inspect air passage O-ring. If damaged, contact

Moore Industries’ Customer Service Department

for replacement.

8. Use instrument air supply to dry and generally

“blow out” subassembly. Put small amount of

alcohol in air passage and set subassembly aside.

The Interface Solution Experts 7

Page 10

IPH

Cleaning the Pneumatic Block

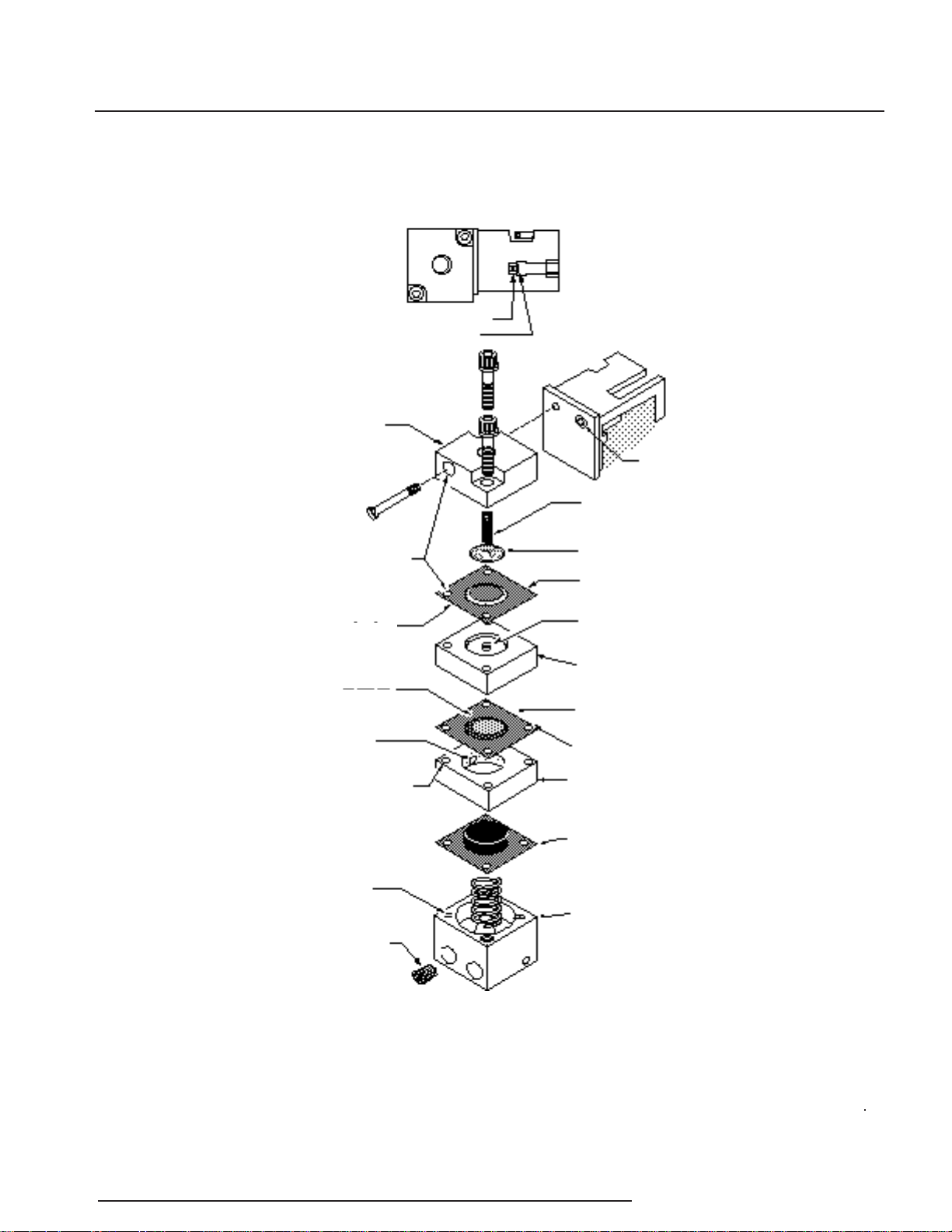

Refer to Figure to disassemble the IPH pneumatic

block, and when performing the following:

1. Place block on work surface with its two sockethead screws facing up. Use a screwdriver to mark

one side of the block with several small scratches

for use when re-assembling parts.

2. Dip cleaning wire in TCE and use it to clean orifice

#1, the air passage between block and mechanical

subassembly.

3. Remove two screws that hold the pneumatic block

together. Separate section #1 from block.

4. Use swabs dipped in TCE to clean internal surfaces and to remove any dirt particles or oil. Flush

all parts with alcohol after cleaning.

5. Push cleaning wire dipped in TCE through the

small orifices on underside of section #1, in the

Table 3. IPH Maintenance Equipment

center opening, and along the outside edge. Use a

syringe filled with alcohol to flush the openings.

Set section #1 aside.

6. Remove spring, disk, and diaphragm from top of

section #2. Inspect each for deterioration and dirt.

Use compressed air to blow off all parts. Flush

orifice with alcohol after cleaning.

7. If necessary, remove diaphragm from bottom

surface of section.

8. Push cleaning wire dipped in TCE through brass

fitting in center of section.

9. Clean small orifices along edge of section (top and

bottom) with cleaning wire and flush with alcohol

syringe.

10. Use swabs dipped in TCE to clean all surfaces.

11. Repeat cleaning/flushing procedure for orifices and

surfaces of section #3.

Equipment Specifications/Notes

Instrum ent-Qua lity Air

or Nitrogen Supply

White, B ond Paper Clean, undyed, and unlaminated.

Cotton Swabs Clean, general-utility swabs for use in cleaning surfa ces and absorbin g excess

Trichloroethan e

(TCE)

Isopropyl Alcohol Clean, general-purpose flushing solution.

Syringe For injecting alcohol into small orifices.

Screwdriver Slotted-tip. Head width of 5 mm (0.1875 in), maximum.

Probe T echnic i a n’s tool f o r ma nipulat i on of very s m all parts .

Cleaning Wire 0.005-inch diameter, maximum.

Reduced to between 20 and 30 psig, and fitted with a hose and fine tip or nozzle.

solvent and alcohol.

Rho-T r on - TPC-400 or equivalent.

Hex Keys One 3/32 in, minimu m length 5.5 in. Ball-t ipped head re com m ended;

Removeable

Thread-locking Compound

8 The Interface Solution Experts

One 5/ 32 in, stan da r d; One 4 mm, s t a ndard

Loctite® #242 or equivalent removable threadlocker.

Page 11

Figure 3. IPH Internal Assemblies

IPH

PNEUMATIC

BLOCK

SECTION #1

HOLE

ROLL IS UP

ROLL IS DOWN

HOLE

MECHANICAL

SUB-ASSEMBLY

NOZZLE

FLAPPER

ORIFICE #1

UPPER SPRING

(HEAVY GAUGE WIRE)

PLASTIC DISK

UPPER RUBBER

DIAPHRAGM

BRASS

FITTING

SECTION #2

MIDDLE RUBBER

DIAPHRAGM

HOLE

RESTRICTOR

HOLE

SUPPLY

SCREEN

SECTION #3

LOWER RUBBER

DIAPHRAGM/DISK

SECTION #4

The Interface Solution Experts 9

Page 12

IPH

12. Remove integrated diaphragm/fitting from section

#4.

13. Repeat cleaning/flushing procedure for orifices and

surfaces.

14. Check to make sure that the spring is in good

condition.

15. Locate the supply port air filter screen on the

pneumatic block.

16. Remove filter screen with needle, and flush with

TCE. Rinse with alcohol and set aside to dry.

Re-assembly

1. Dry all parts of the pneumatic block and the

mechanical subassembly with the specified air or

nitrogen supply. Make sure all parts are clean and

dry.

2. Use the scratch markings made earlier to make

sure that each section of pneumatic block is

oriented properly, then use small socket-head

screws to secure re-assembled block. Tighten

screws to between 35 and 45 Nm of torque (26 to

33 ft/lbs).

3. Line up pin on section #1 of pneumatic block with

hole on base plate of mechanical subassembly.

4. Place a small amount of thread-locker on the

threads of the head screw used to hold the pneumatic block and mechanical subassembly together,

and secure two subassemblies to each other with

the screw. Make sure screw is as tight as possible.

Drain Check. System filters have automatic drains

that depend on the fluctuation of system pressure to

induce drainage. A stable system may not drain

efficiently.

Check periodically for clogs and drain system’s filters

by pushing the drainage valve with a small probe or

wire.

Troubleshooting the IPH

Many components of the IPH have been thermally

aged, tested, and selected using a computer-aided

design program. This usually makes field repair

unnecessary.

It is therefore recommended that any properly maintained unit found to be performing below specifications

be returned to the factory in accordance with the

instructions found on the back cover of this manual.

If a problem is suspected with the IPH, review the

following steps:

1. Verify that bench instruments used to take measurements have the proper range and accuracy

and are within current certification period limits.

2. If a change in the relationship between the input

and output is detected, attempt a re-calibration of

the IPH.

3. If the response time lengthens, or if the span

drops, this may indicate a blockage due to air

supply contamination. Follow the instructions in

the Maintenance Section of this manual.

5. Place mounting bracket over subassembly and

pneumatic block and screw the bracket onto the

subassembly.

6. Slide internal assembly into housing, being careful

not to crimp or pinch the current wiring, and mate

fittings in housing with ports on pneumatic block of

internal assembly. Press down until locked into

place.

7. Reseat the IPH and screw it in.

8. Calibrate unit. Refer to Calibration Section of this

manual for detailed instructions.

10 The Interface Solution Experts

The Zero Adjust Screw. This screw has a flange to

prevent its being turned too far counterclockwise

during adjustment. Forcing the screw past the point at

which its flange comes into contact with the unit front

panel could disengage it from the internal assembly.

If this happens, disassemble the IPH as described in

the Maintenance Section of this manual.

Visually inspect the screw, and if serviceable, hold

down the flapper arm and turn the screw clockwise

until its pin is in a position to hold the arm.

Refer to the Calibration Section of this manual, and

recalibrate unit.

Page 13

IPH

IPH:

Current-to-Pressure Transmitter

Appendix A: Intrinsic Safety

This page contains the installation diagram for the IPH

carrying the intrinsically safe option. It also includes

guidelines for setting up zener barriers necessary in

these types of applications.

REVISION

DRAWING NUMBER

CB

G.E. 09/00

100-100-53 B

ECO 13163

REVISED BY DATE BY APPROVAL

NOTICE RE PROPRIETARY INFORMATION: This drawing and the inform-

ation contained herein are the proprietary property of Moore Industries-

International, Inc. (MII) and should not be reproduced or disclosed to any

third party without the written consent of an authorized officer of MII.

= 30 VDC

i

U

or

Entity Parameters

max

V

(Power/Loop, +PS & -PS):

ITTER

SM

AN

E TR

R

T TO

ESSU

EN

R

PR

R

U

C

= 85 mA

= 0.6375 W

= 0 µF

i

i

i

I

P

or

or

max

I

max

C

P

ELEC IN

cable

cable

+ C

+ L

i

i

= 5 mH

³ C

³ L

i

o

o

L

C

or

or

a

a

L

C

L

These diagrams must be used to augment the installation instructions earlier in this manual for units that are

to operate in areas requiring intrinsically safe instrumentation.

t

t

or V

or I

oc

sc

³ V

³ I

i

i

I

U

or

or

max

max

I

V

PNEU IN

PNEU OUT

CSA International

Class I, Div. 2, Groups A-D.

Class II, Div. 1, Groups E, F & G.

Hazardous 'Classified' Locations/Areas:

Intrinsically Safe: Class I, Div. 1, Groups A-D.

II 1G EEx ia IIC.

CENELEC/ATEX

Class II, Div. 2, Groups F & G. Class III.

Intrinsically Safe:

£ +60˚C

amb.

Environmental Protection: IP65 & NEMA 4X

-I

+I

No modifications are permitted

SPAN

ZERO

GROUND

CURRENT TO

PRESSURE TRANSMITTER

Non-Hazardous Safe Area

(3)

-PS

+PS

(2)

Apparatus

Associated

Barrier or other

(1)

Apparatus

Unspecified

Hazardous (Classified) Locations - FM (US NEC 500):

Intrinsically Safe System

Current-to-Pressure T ransmitter

CONTROL DRAWING

Field Installation Diagram:

For Hazardous 'Classified' Locations.

TITLE

09/00

IPH,

09/00

09/00

CATEGORY

Current-to-Pressure Transmitter

Current-to-Pressure Transmitter

IPH:

IPH:

Gus H. Elias

DRAWN

CHECKED

/mm

= ±inch

(UNLESS NOTED)

TOLERANCES

DO NOT SCALE DRAWING

DECIMALS.X.XX

W.Ho

ENGINEER

/2.54

/0.76

= ±.1

= ±.03

NONE

Gus H. Elias

SCALE

/0.25

= ±.010

= ± 30'

=+.003-.002/+.08-.05

ANGLES:

.XXX

HOLES:

CERTIFIED PRODUCT

Non-Incendive: Class I, Div. 2, Groups A-D.

T Code: T6 @ 60˚C Maximum Operating Ambient

Class II, Div. 2, Groups F & G and Class III, Div. 2.

Intrinsically Safe: Class I,II,III; Div. 1; Groups A-G.

Exceed 1 W

Ground/Earth Path

Resistance Must Not

Temperature. Range: -40˚C £ T

exceed 30 VDC & the output current (Isc, It or Io) must not exceed 85 mA. Also, it must be installed per the manufacturer's guidelines.

be approved by the "specific" (CSA/EECS/FM/LCIE/SAA/SIRA/TUV, etc..) certifying agency for I.S. connections in: "Class I-III, Division 1, Groups

be in accordance to 'ANSI-P12.6' (Installation of I.S. Systems for Hazardous 'Classified' Locations) and the National Electric Code 'ANSI/NFPA 70' . Also, a

be used when installed in Class II and Class III environments. For CSA applications, adhere to the 'Canadian Electric Code C22.1' most current publication on I.S. installation

Substitution of components may impair the Intrinsic Safety of the unit. DO NOT open the unit when either energized or when an explosive gas atmoshpere is present. Disconnect power

drawing.

This is a controlled 'Related' or 'Schedule'

without the notification and final approval of

or the Certifying Agency (schedule dwgs.).

the Q.A. Certification Engineer (related dwgs.)

Notes:

(1) Apparatus which is unspecified except that it must not be supplied from, or contain under normal or abnormal conditions a source of potential with respect to earth in excess of 250 VRMS or 250 VDC

which is considered to be the Safe Area's maximum voltage.

(2) The Barrier or other Associated Apparatus must

A Shunt Zener Barrier is NOT required for Non-Incendive (or Class I, Division 2 or Type N) installations.

A-G" locations. The output voltage (Voc, Vt or Vo) must not

4- For FM applications, installation must

(3) The combined Capacitance and Inductance of the inter-connecting cables and the PC Prog. Transmitters must not exceed the values indicated on the Associated Apparatus.

dust-tight conduit seal must

before servicing. Also read, understand and adhere to the manufacturer's installation and operating procedures.

guidelines. For CENELEC/ATEX applications, adhere to 'BS5345 or EN 60079-14:1997' or any equivalent, most current and pertaining publication on I.S. installation guidelines.

5- Warning:

The Interface Solution Experts 11

Page 14

GUIDELINES AND CERTIFICATIONS

Low Voltage Directive

When installing any Moore Industries product, always follow all local regulations and standards for

grounding, shielding, and safety. The following

grounding and wiring practices must be followed in

order for the unit(s) to meet the requirements set

fourth in the EMC directives EN50082-2 and

EN55011.

Grounding

If the unit has a metal case it is to be grounded.

(DIN rail mounted units should be mounted on a

grounded rail).

Wiring

Twisted shielded wire should be used for all input

and output signals. The shields are to be grounded

at the units, to earth ground (safety ground). The

un-shielded part of the in/output wires should be no

longer than 2 inches.

CE Certification-related Guidelines

The following guidelines must be followed in order

to comply with EN61010-1 (Low Voltage Directive).

These items affect the AC version of the IPH. If

these products are to be used in a non-CE environment, this directive may be disregarded.

WARNING:

If this unit is used in a manner not specified by

Moore Industries, the protection provided by the

equipment may be impaired.

Switches and Circuit Breakers

A switch or circuit breaker must be wired in series

with the AC power conductors. The switch or circuit breaker used must be located within three

meters of the unit.

WARNING:

Terminals on this unit may be connected to

hazardous voltages. Before making ANY

connections to this unit, ALL hazardous voltages

must be de-energized.

The circuit breaker or switch will only remove

power to the unit, hazardous voltages may still be

connected to other terminals on the unit.

Installation Category

All of Moore Industries’ terminals are rated CAT II,

except those with the -RF option. These terminals

are rated CAT I.

Equipment Ratings

The IPH does not generate hazardous voltages,

rather, it accommodates a current input, and generates a pressure output. Products connected to

the IPH should be designed to receive these inputs.

Supply Wiring

All power connections should be made with the

proper wire.

The end of each conductor should be stripped no

more than 8mm. The end of the stripped wire

should be tinned with solder, or inserted into a ferrule and crimped before being placed into a terminal block.

Conductors connected to screw-type connections

should have a ring-lug or spade-lug crimped onto

the wire end.

Page 15

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty , be prepared to giv e us a Purchase Order n umber when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a ) A note listing the symptoms that indicate the unit needs repair

b ) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Tel: (818) 894-7111 • FAX: (818) 891-2816

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

© 2006 Moore Industries-International, Inc.

United States • info@miinet.com

Australia • sales@mooreind.com.au

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...