Page 1

Demand Moore Reliability

No. 226-710-00A

September 2018

HART to Ethernet Gateway System

HES

SYI

User’s Manual

All product names are registered trademarks of their

respective companies.

Page 2

Demand Moore Reliability

Customer Support

Moore Industries is recognized as the industry leader in delivering top quality to its customers in products

and services. We perform a sequence of stringent quality assurance checks on every unit we ship. If any

Moore Industries product fails to perform up to rated specications, call us for help. Our highly skilled sta of

trained technicians and engineers pride themselves on their ability to provide timely, accurate, and practical

answers to your process instrumentation questions. Our headquarters and other facilities phone numbers

are listed below.

There are several pieces of information that can be gathered before you call the factory that will help our

sta get the answers you need in the shortest time possible. For fastest service, gather the complete model

and serial number(s) of the problem unit(s) and the job number of the original sale.

Locations

World Headquarters Europe Australia

16650 Schoenborn Street

North Hills, California

91343-6196, U.S.A.

Tel: (818) 894-7111

Fax: (818) 891-2816

E-mail: info@miinet.com

TOLL FREE: 1-800-999-2900

www.miinet.com

China

Room 402, No. 57,

Lane 651, Xipu Road,

Xinqiao Town, Songjiang District,

Shanghai, 201612, P. R. China

Tel: 86-21 62491499

Fax: 86-21 62490635

E-mail: sales@mooreind.sh.cn

www.miinet.com/cn

1 Lloyds Court, Manor Royal, Crawley

W. Sussex RH10-9QU

United Kingdom

Tel: 01293 514488

Fax: 01293 536852

FREE PHONE: 0800 525107

sales@mooreind.com

www.miinet.com/uk

Guido Gezellestraat 106

BE-2630 Aartselaar

Belgium

Tel: 03/448.10.18

Fax: 03/440.17.97

info@mooreind.be

Dutch: www.miinet.com/dbe

French: www.miinet.com/fbe

Burg Meslaan 98

4003 CD Tiel

The Netherlands

Tel: (0)344-617971

Fax: (0)344-615920

sales@mooreind.nl

www.miinet.com/nl

Sydney, NSW

3/1 Resolution Drive

Caringbah, New South Wales 2229

Australia

Tel: (02) 8536-7200

Fax: (02) 9525-7296

sales@mooreind.com.au

www.miinet.com/au

Perth, WA

6/46 Angove Street

North Perth, Western Australia 6006

Australia

Tel: (08) 9228-4435

Fax: (08) 9228-4436

sales@mooreind.com.au

www.miinet.com/au

www.miinet.com

www.miinet.com Moore Industries-International, Inc.

Page 3

Safety Messages

Please read this manual in its entirety. It should answer most of your questions. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before installing, using, or maintaining

this product. Should you still have questions please visit our web site at www.miinet.com or contact any of our sales/

support oces nearest you.

Your safety and the safety of others is very important. We have provided many important safety messages in this

manual. Please read these messages carefully. These safety messages alert you to potential hazards that could hurt

you or others or render damage to units.

All Moore Industries instrumentation should only be used for the purpose and in the manner described in this manual.

If you use this product in a manner other than that for which it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

Each safety message is associated with a safety alert symbol. These symbols are found in the throughout the manual.

The denition of these symbols is described below:

Pay particular attention wherever you see the following symbols:

Note – Information that is helpful for a procedure, condition or

operation of the unit.

Caution – Hazardous procedure or condition that could damage or

destroy the unit.

Warning – Hazardous procedure or condition that could injure the

operator.

Qualied Personnel

The Moore Industries’ product/systems described in this manual may be operated only by personnel qualied for the

specic task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualied personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these Moore Industries’ products/systems.

Proper use of Moore Industries products

Moore Industries’ products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Moore Industries’ . Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient

conditions must be complied with. The information in the relevant documentation must be observed.

We have reviewed the contents of this publication to ensure consistency with the hardware and/or software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions. Specications and

information are subject to change without notice.

All product and company names are trademarks™ or registered® trademarks of their respective holders. Use of them

does not imply any aliation with or endorsement by them unless otherwise specied.

www.miinet.com Moore Industries-International, Inc.

Page 4

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Contents

HES Quick Start Guide ........................................................................................................... 6

Section 1 - Introduction .............................................................................................................. 7

Overview ................................................................................................................................ 7

Features ................................................................................................................................. 7

Model Numbers and Options .................................................................................................. 8

Understanding How the HES Retrieves and Stores HART Field Device Data ......................... 9

Section 2 – Calibration and Bench Check .................................................................................15

Calibration .............................................................................................................................15

Bench Check .........................................................................................................................15

Configuring the HES Ethernet Settings ..................................................................................15

Section 3 – Wiring and Installation ............................................................................................23

Terminal Designations ...........................................................................................................23

Dimensions ...........................................................................................................................24

Installation .............................................................................................................................25

Mounting ...............................................................................................................................25

Electrical Connections ...........................................................................................................25

Installation Category ..............................................................................................................25

User Configurable Hardware .................................................................................................26

Section 4 – HES Configuration ..................................................................................................29

FDT Frame Application ..........................................................................................................29

FDT/DTM Software Installation ..............................................................................................29

Basic Setup ...........................................................................................................................32

Network Configuration ...........................................................................................................32

Connecting to the HES Using MIIP ........................................................................................35

HART Inputs Settings ............................................................................................................42

MODBUS/TCP Settings .........................................................................................................48

HES System Settings ............................................................................................................51

Downloading the Configuration File to the HES (DTM) ..........................................................56

Built-in HTTP Web Server .....................................................................................................58

Section 5 - MODBUS Register Definitions .................................................................................65

www.miinet.com [4] Moore Industries-International, Inc.

Page 5

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HES MODBUS Register Defin itions .......................................................................................65

HART Field Device Register s ................................................................................................66

Section 6 – Operation and Maintenance ...................................................................................78

Operation ..............................................................................................................................78

HES Status Information .........................................................................................................78

Maintenance ..........................................................................................................................88

Section 7 – Application ..............................................................................................................89

Leveraging Existing Networks ...............................................................................................89

HES Installation in Remote Oil & Gas Tank Battery ...............................................................90

Diagnostics Help Improve Process Uptime ............................................................................91

Section 8 - Specifications ..........................................................................................................92

HES Specifications ................................................................................................................92

Section 9 – Ordering Infor mation ..............................................................................................93

Ordering Information ..............................................................................................................93

Warranty ...................................................................................................................................94

www.miinet.com [5] Moore Industries-International, Inc.

Page 6

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HES Quick Start Guide

The HES is ready to install and is set up either with your specified configuration or the default

configuration.

After programming your HES, Ethernet Gateway System, install the unit into your application

using the connection diagrams and terminal designation table located in this manual.

HART Input Settings:

For each HART input Primary Master, 1 HART Field Device with address 0, Normal

mode, 1 retry, polling with command 3, additional status off

Factory Default User Configuration for MODBUS:

Mapping = By variable

Compressed unused devices = OFF

Compressed CMD3/CMD9 Variables = OFF

Floating Point Word Order = Standard LSW

Number of Decimal Places = 0

Failed HART Device’s Register Value = Hold Last Value

HES System Settings:

ID tag=blank

Descriptor = blank

Message = blank

PV=DV66

SV=DV68

TV=DV70

QV=DV72

Network Default Configuration:

DHCP = ON

Name = HES

Location = TBD

MODBUS TCP connections = 4

HART-IP connections = 4

Security Jumpers Set To:

Network configuration = Read / Write

User configuration = Read / Write

www.miinet.com [6] Moore Industries-International, Inc.

Page 7

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Section 1 - Introduction

The Moore Industries’ HES HART® to Ethernet Gateway System converts signals from wired

HART devices to Ethernet MODBUS/ TCP and HART-IP. This manual contains information

needed to install, operate and maintain this product.

Overview

Description

The flexible HES HART to Ethernet Gateway System converts signals from wired HART devices

to Ethernet MODBUS TCP/IP. The robust HES is the perfect economical way to process data

and instrument diagnostics from multiple connected smart HART instruments via MODBUS

TCP/IP by allowing greater process uptime through acquisition of process variable data and

instrument diagnostics, enabling timely and effective analysis of a process.

The HES HART to Ethernet Gateway System is available with 1 or 4 HART input channels. It

supports up to 16 field devices per channel (in multidrop mode) for a total of 64 Field Devices on

4 channels, configurable for Primary or Secondary Master, support for retries, BURST mode

and HART Command 3 or 9.

The Ethernet output supports up to four MODBUS/TCP and four HART-IP connections. A builtin web server provides quick and easy viewing of HES and device status, HART field device

variable data and its MODBUS register address using any web browser. Configuration is

available using PACTware and the associated DTMs.

Features

Available with multiple channels. 1 or 4 HART channels to support up to 16 or 64 HART

devices.

Single HART channels: Up to 16 HART devices in digital multidrop mode, or one device in a

standard point-to-point 4-20mA loop configuration.

4 HART channels: Up to 16 on each of four multidrop HART networks to HES transmits to IIoT

systems over Internet or Intranet to control systems, asset manager and historians.

HART Multiplexer Capability. Multiplex up to 64 HART instruments with dynamic and device

variables and diagnostic bits that you want to capture in your asset management system over

your industrial Ethernet network.

Works with HART compatible devices. The HES communicates with HART 5, 6 and 7 smart

multivariable mass flow, pressure, pH and temperature transmitters, coriolis, magnetic,

ultrasonic and vortex flow meters and more.

Monitor up to 8 variables per device plus instrument diagnostics. Using the Field Device

Status byte data, the HES reads diagnostic data including smart device configuration changed;

www.miinet.com [7] Moore Industries-International, Inc.

Page 8

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

primary and non-primary variables out of limits; primary variable analog output fixed and more

HART status data. It can also be configured to read the Additional Status from the Field Devices

(using command 48).

Network configuration. Supports DHCP or fixed IP address, subnet mask and gateway

settings (NAC client), au to

Security. Two layer security. User and Network configuration can be independently write

protected using hardware jumpers (see Section 3) and the number of connections

(MODBUS/TCP and HART-IP) can be set by the user (see Section 5).

Easy MODBUS mapping selection. Provided by variable or by device grouping.

Simple to Configure. Configure over HART-IP, using PACTware or other FDT host and

supplied DTM. Easy to use menus provide full configuration of HES, HART channel

communications and MODBUS data.

Webpage monitoring and status. A built-in web server in the HES provides quick and easy

viewing of HES and HART field device status, HART device variable data and its MODBUS

register address using any web browser.

negotiation and auto MDIX.

Operating power. 9-30DC

Model Numbers and Options

The following section provides details of the Moore Industries model number and the available

options for the HES.

Moore Industries uses the model and serial numbers of our instruments to track information

regarding each unit that we sell and service. If a problem occurs with your instrument, check for

a tag affixed to the unit listing these numbers. Supply the Customer Support representative with

this information when calling.

Moore Industries model numbers for HES is structured as follows:

HES/4HART/ETH/9-30DC/-MB [DIN]

Unit/Input/Output/Power/-Options [Housing]

Refer to Section 10 Ordering Information for a quick reference table of ordering information.

www.miinet.com [8] Moore Industries-International, Inc.

Page 9

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

INPUTS:

Accepts a HART digital protocol input directly from a smart HART transmitter.

HART - Single HART channel input supporting up to 16 HART devices.

4HART - Four HART channel inputs supporting up to 64 HART devices.

OUTPUT:

ETH

HES has Ethernet Output that supports 10/100 Mbps Cat 5/6 Ethernet communications.

POWER:

9-30DC

Accepts any power input range of 9-30Vdc.

OPTIONS:

-MB

HES has MODBUS/TCP Output. This option must be specified.

HOUSING:

[DIN]

DIN-style aluminum housing mounts on 35mm Top Hat DIN-rail (EN50022).

Dynamic and Device Variables

Before setting up the HES, or incorporating the unit in your application, Moore Industries

suggests that all users take a few moments to become familiar with the different HART revisions

and variables available in their HART field devices.

Understanding How the HES Retrieves and Stores HART Field Device Data

HART Revisions

HART field devices are compliant to a certain HART revision. Most field devices released within

the last twenty years support HART revisions 5, 6 or 7. Each new revision of HART offers

different features and capabilities but all field devices, regardless of revision, still support

backwards compatibility with HART masters and handheld communicators. The HES, acting as

a HART master, communicates with all HART field devices that contain HART revision 5, 6 or 7.

It is important to verify what revision of HART the field device contains to ensure that the HES is

configured correctly.

HART Dynamic and Device Variables

HART devices can provide a significant amount of data in addition to the primary variable, which

is embedded onto the 4-20mA loop. In addition to diagnostic and status bits and bytes, there are

www.miinet.com [9] Moore Industries-International, Inc.

Page 10

HES User Manual

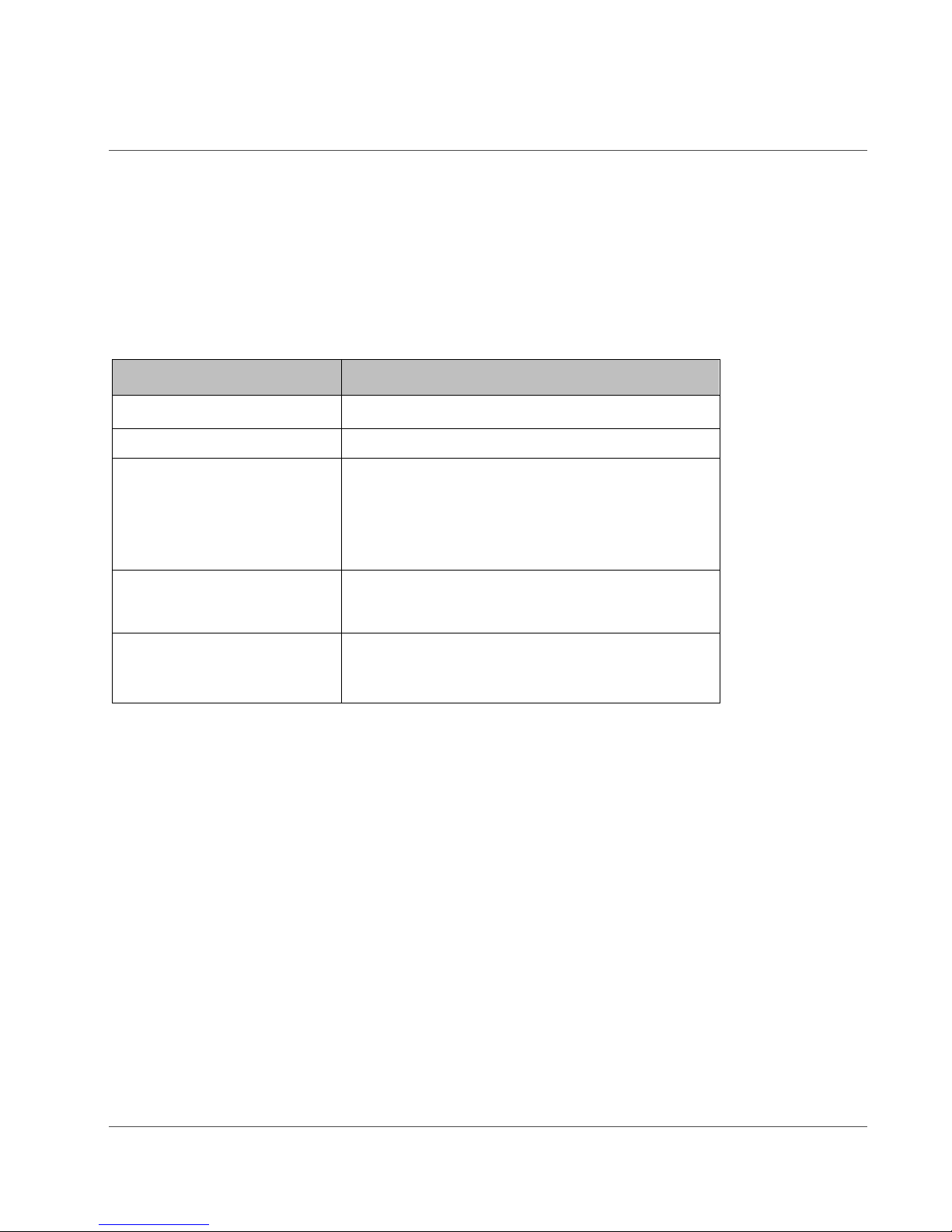

DV

Description

242

(Optional) Battery Voltage

243

(Optional) Battery life

244

Percent Range

245

Loop Current

246

Primary Variable (PV)

247

Secondary Variable (SV)

248

Tertiary Variable (TV)

249

Quaternary Variable (QV)

HART to Ethernet Gateway System 226-710-00A

September 2018

two types of HART variables that you can retrieve from HART devices – Dynamic Variables and

Device Variables.

All of the HART field device HART Variables are IEEE 754 Floating Point values and are

retrieved by the HES from the field device by utilizing HART Command 03 or Command 09.

Dynamic Variables consist of the Primary Variable (PV), Secondary Variable (SV), Tertiary

Variable (TV) and Quaternary Variable (QV). These variables can be obtained from the field

device using HART Command 03 or 09.

Device Variables may also be used in more sophisticated or multivariable HART field devices to

provide additional process, diagnostic or status related information. Device Variables are only

available in HART 6 and 7 revision field devices and are read using HART Command 09. Each

field device can define up to 240 Device Variables (HART 7) numbered consecutively from 0 to

239. The Device Variable Codes are unique to each field device and may be defined in the

operation manual or obtained from the manufacturer. In addition, the following Device Variable

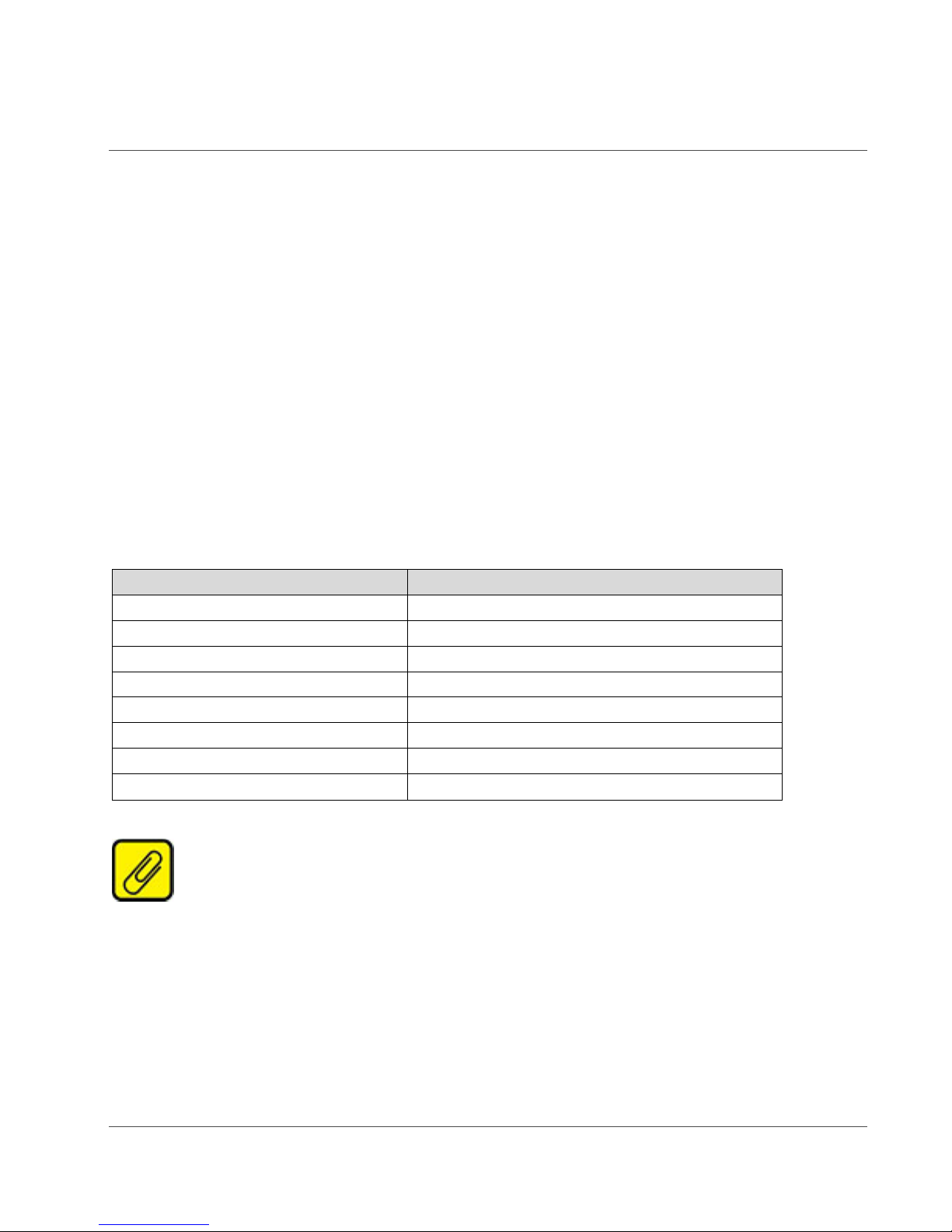

Codes are defined in the HART specification (see table 1.1).

Table 1.1. HART Additional Device Variables

NOTE: On some HART field devices the Dynamic Variables - PV, SV, TV and QV, can

be assigned and represented as any of the Device Variables.

www.miinet.com [10] Moore Industries-International, Inc.

Page 11

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HES as a HART Master

The HES can be configured as a Primary or Secondary HART master and polls up to 16 field

devices on each of its four channels (total of 64 field devices maximum per HES). The HES

supports HART Commands 03 and 09 for the reading of Dynamic and Device Variables.

Additionally the HES supports HART Command 48 which reads the field device’s Additional

Status data. The HART revision of the field device will determine how it supports these

commands. Below is a brief summary of which HART Commands are supported by each HART

Revision.

HART 5 Devices support HART Command 03 only.

Using HART Command 03, the HES will read the Dynamic Variables, i.e. PV, SV, TV, QV and

loop current from the field device.

HART 6 Devices support HART Command 03 and Command 09.

Using HART Command 03, the HES will read the Dynamic Variables and loop current from the

field device. Using Command 09, the HES can read up to 4 four Device Variables from the field

device. To use Command 09, the number of Device Variables and each Device Variable Code

from the specific field device need to be specified.

HART 7 Devices support HART Command 03 and Command 09.

Using HART Command 03, the HES will read the Dynamic Variables and loop current from the

field device. Using Command 09, the HES can read up to eight Device Variables from the field

device. To use Command 09, the number of Device Variables and each Device Variable Code

from the specific field device need to be specified.

All HART revisions support t h e Additional Status Command 48.

For multivariable and more complex HART field devices, where data is required from more than

eight Device Variables, the field device can be polled multiple times by the HES with each poll

specifying up to eight unique Device Variables. For example, if you wanted Device Variables 225 from a specific field device, you could configure the HES to poll that same f ield device using

HART Command 09 three times specifying eight unique Device Variables in each poll.

HES as a HART Field Device

The HES acts as both a HART Master (reading up to 64 field devices across four channels) and

as a HART Field Device. As a HART Field Device, it is HART 7 compliant and has both

Dynamic and Device Variables, which can be read via MODBUS/TCP, HART-IP or can be

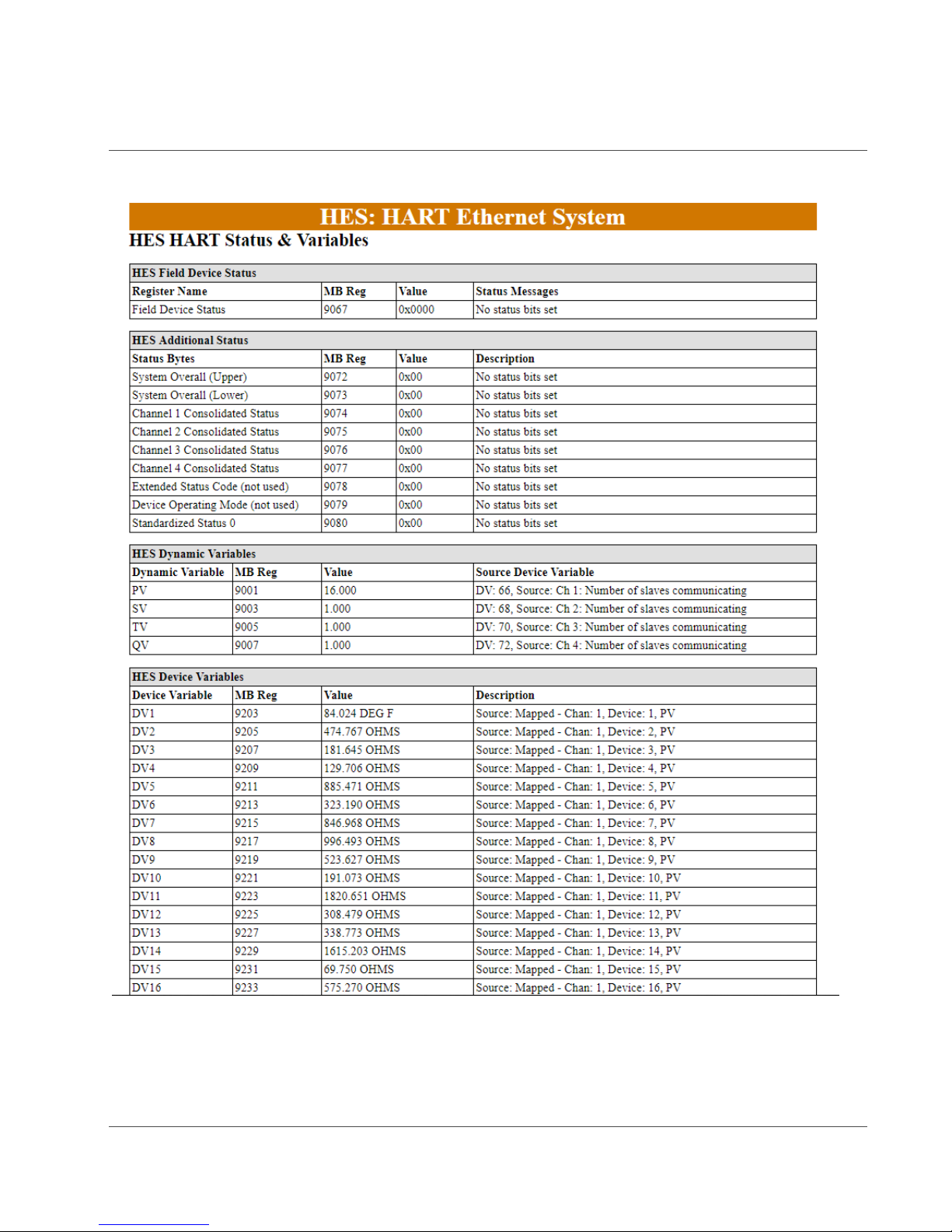

viewed on the HES’ webpage. See figure 1.1

www.miinet.com [11] Moore Industries-International, Inc.

Page 12

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Figure 1.1. HES HART Status & Variables webpage

www.miinet.com [12] Moore Industries-International, Inc.

Page 13

HES User Manual

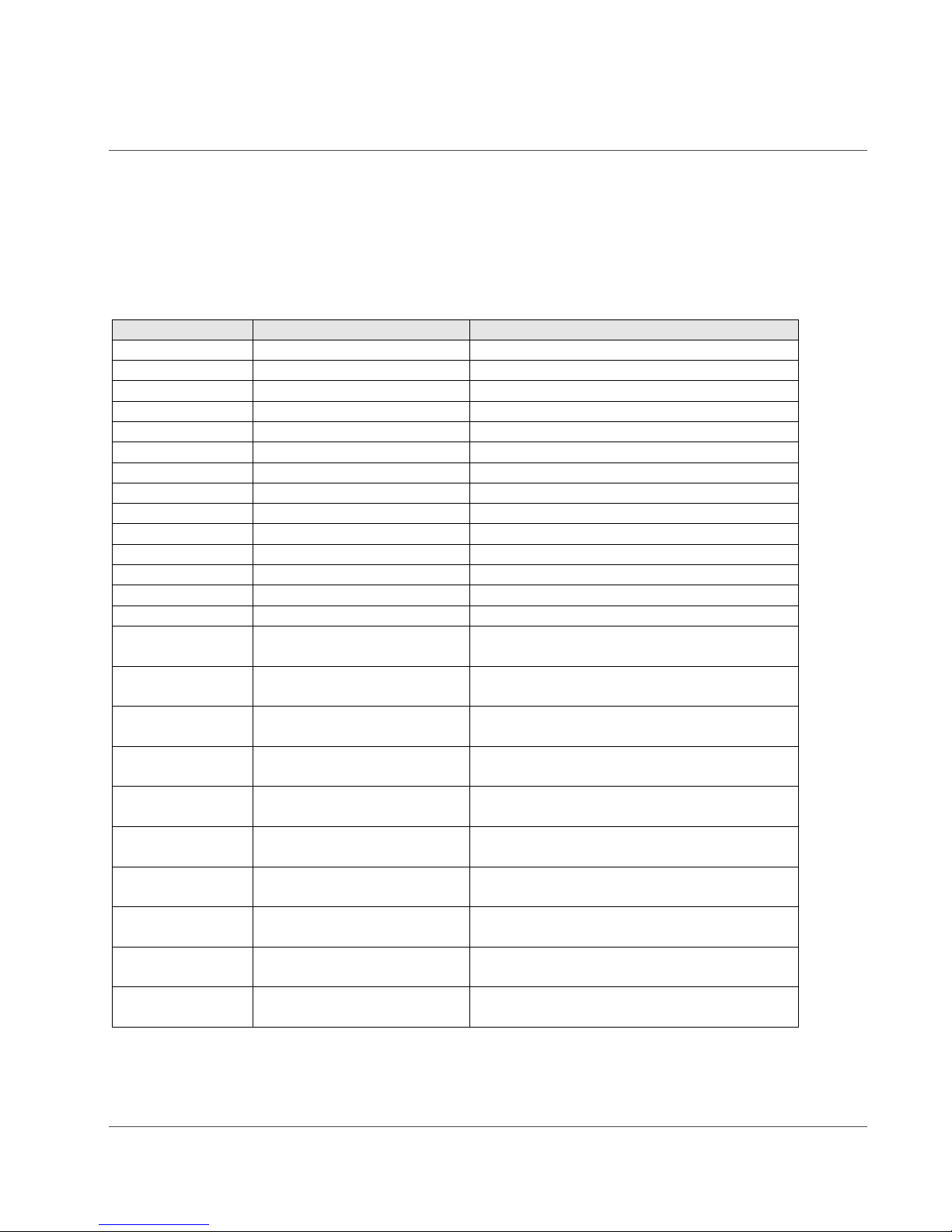

DV Code

Name

Description

1

FieldDevData

Ch1, Device 1, PV

2

FieldDevData

Ch1, Device 2, PV

----------------

----------------

thru

16

FieldDevData

Ch1, Device 16, PV

17

FieldDevData

Ch2, Device 1, PV

----------------

----------------

thru

32

FieldDevData

Ch2, Device 16, PV

33

FieldDevData

Ch3, Device 1, PV

----------------

----------------

thru

48

FieldDevData

Ch3, Device 16, PV

49

FieldDevData

Ch4, Device 1, PV

----------------

----------------

thru

63

FieldDevData

Ch4, Device 15, PV

64

FieldDevData

Ch4, Device 15, PV

65

ch1 num configured

Number of field devices channel 1 is

configured to poll

66

ch1 w/ comms

Number of field devices channel 1 is

communicating with

67

ch2 num configured

Number of field devices channel 2 is

configured to poll

68

ch2 w/ comms

Number of field devices channel 2 is

communicating with

69

ch3 num configured

Number of field devices channel 3 is

configured to poll

70

ch3 w/ comms

Number of field devices channel 3 is

communicating with

71

ch4 num configured

Number of field devices channel 4is

configured to poll

72

ch4 w/ comms

Number of field devices channel 4 is

communicating with

73

total configured

Total number of field devices the HES is

configured to poll

74

total w/ comms

Total number of field devices the HES is

communicating with

HART to Ethernet Gateway System 226-710-00A

September 2018

The HES has 74 defined Device Variables (see default assignments in table 1.2). DV1-64 are

assigned by default to represent the PV of each device (1-16) on each HES channel (1-4).

However, any of these 64 Device Variables can be re-configured to represent any variables of

the connected HART field devices. DV65-74 are fixed Device Variables that include information

on HES channel and device communications.

Table 1.2. HES HART Device Variables

www.miinet.com [13] Moore Industries-International, Inc.

Page 14

HES User Manual

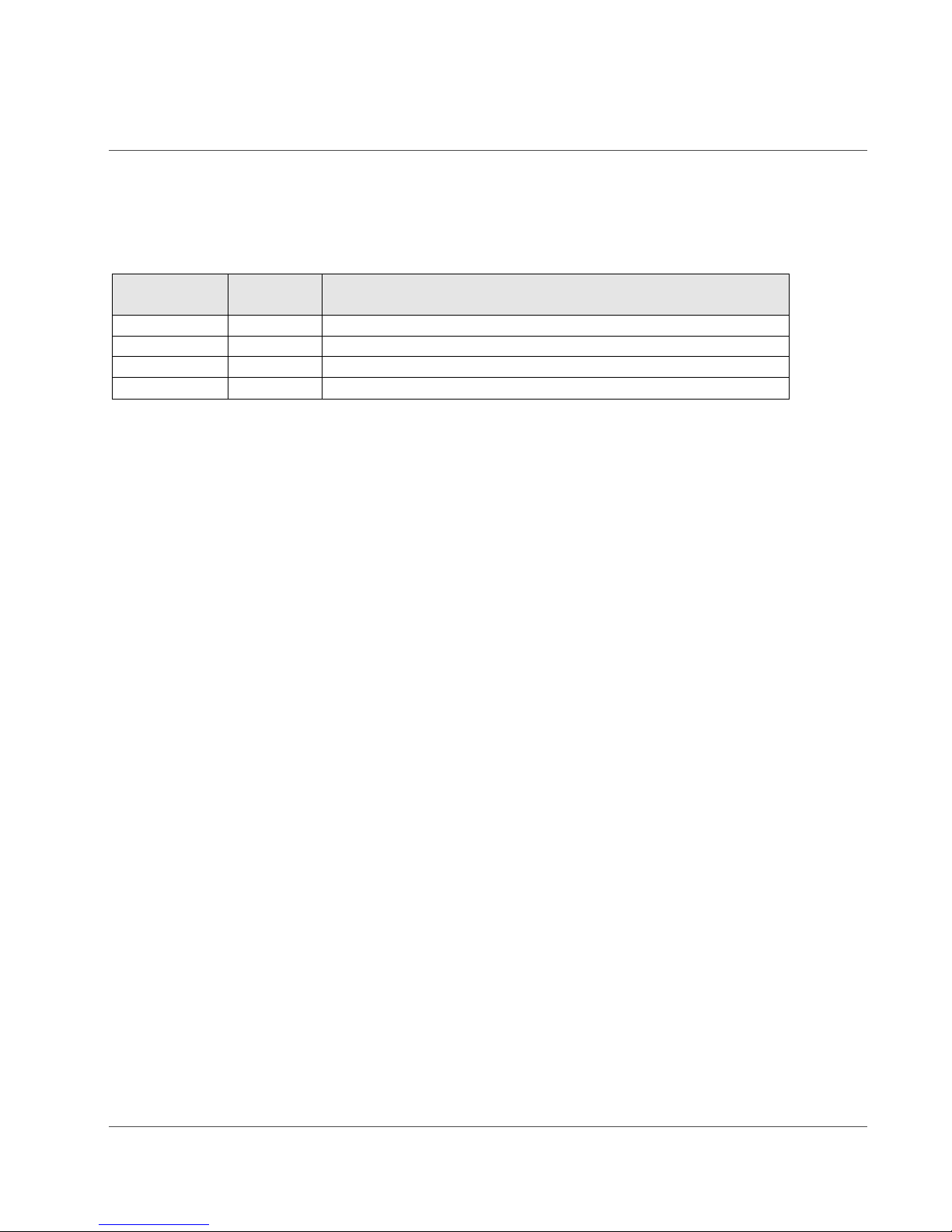

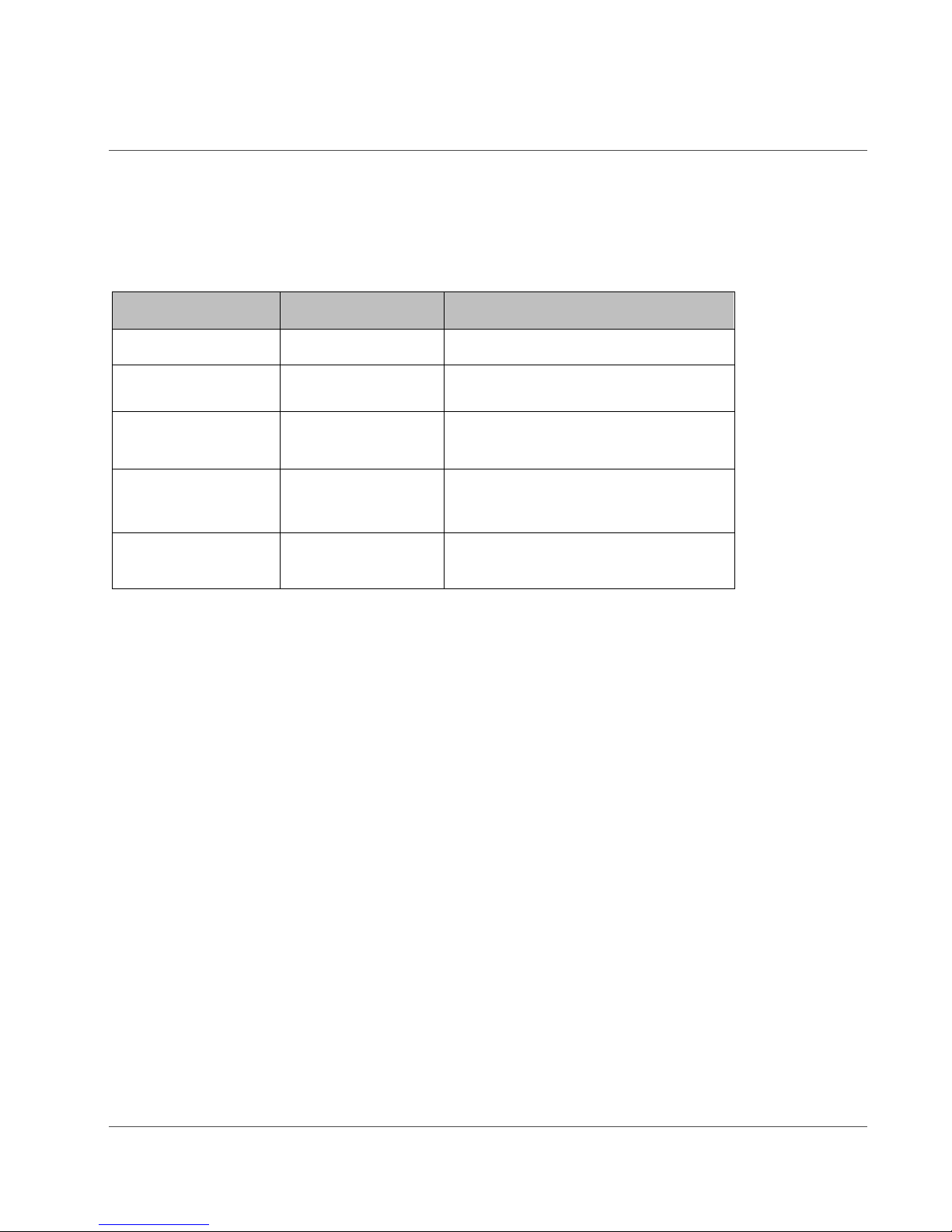

Dynamic

Variable

DV Code

Description

PV

DV66

Number of field devices channel 1 is communicating with

SV

DV68

Number of field devices channel 2 is communicating with

TV

DV70

Number of field devices channel 3 is communicating with

QV

DV72

Number of field devices channel 4 is communicating with

HART to Ethernet Gateway System 226-710-00A

September 2018

The Dynamic Variables are assigned by default as shown below, but any of the HES’ 74 Device

Variables can be assigned to any of the Dynamic Variables - PV, SV, TV and QV, when

configuring the device. The Loop Current value of the HES is set to NaN (Not a Number).

Table 1.3. HES HART Dynamic Variable Defaults

HES MODBUS Data

The HES provides access to both HART field device data, HES device data and additional

status information.

For each field device, the following information is made available to the MODBUS memory map:

Dynamic Variables (PV, SV, TV, QV) plus Loop Current or Device Variables (1-8)*

Variables’ Quality Stamps

Status and Additional Status** Information

Configuration Data – Serial number, Tag, HART revision, Manufacture and Device Type

Code, EGU, PV Upper & Lower Range

There are various options to organize and compress the HART field device data within the

MODBUS memory map. Compression allows each group of data within the memory map to be

organized in a contiguous manner, which optimizes and minimizes the number of MODBUS

master polling records. The default setting organizes the HART field device data by variable

type and uses no compression.

For the HES, the following information is available within the MODBUS memory map:

System Information (Overall status, information, diagnostics, security, configuration

errors)

Channel status

Dynamic Variables (PV, SV, TV, QV)

Device Variables (1-64)

Variables’ Quality Stamps

Once the HES is fully configured, the HES web pages can be referenced to confirm the

MODBUS registers used for all data.

*2 sets of registers are provided for the device data, one set is 32 bit floating point and the other set is 16 bit integer

values

**The Acquire Additional Status setting needs to be enabled for the channel in the HES

www.miinet.com [14] Moore Industries-International, Inc.

Page 15

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Section 2 – Calibration and Bench Check

Calibration

As the Input signals and Output data are in a digital format, no calibration is necessary.

Bench Check

We strongly recommend that you initially configure and test the HES on your bench prior to

installing it on your HART loop(s).

Your first task would be to configure the IP address for your HES.

Configuring the HES Ethernet Settings

Configuring your HES for your local area network (LAN) is the first step in this process. Our

Network Address Configuration (NAC) Client software will help you configure the HES properly.

Begin by installing the NAC Client software onto your PC.

Installing the NAC Client

To install the software, insert the Interface Solution Configuration Tools and Installation Manuals

CD into the CD drive of a Windows® equipped PC. Open the CD/Configuration Software and

Tools, navigate to Ethernet NAC Client Software and run the Moore NAC program, then use the

setup program to install the NAC Client. The setup program may require you to upgrade certain

Windows® components before it will install.

Fixed Network Settings or DHCP

To use the HES on a given Ethernet network, three settings must be configured – IP address,

gateway and subnet mask. The HES comes with DHCP (Dynamic Host Configuration Protocol)

enabled, allowing the network settings to be acquired automatically when the HES is connected

to a network with a DHCP server. If connected to a network without a DHCP server, fixed

network settings must be configured in the HES.

NOTE: If the HES is using DHCP at start up, the network address information

displayed in the list box is how it is currently configured. When you double-click to open the Edit

window, the network settings boxes are disabled. You cannot set the IP address, subnet mask

or gateway address manually if DHCP is enabled.

CAUTION: The use of DHCP introduces the possibility of change or loss of IP

address, caused by DHCP server outages or configuration specifics, or by an untimely power

outage to the HES (i.e. coincident with DHCP lease expiration). Use of fixed network settings in

the HES is recommended. This avoids these potential problems.

www.miinet.com [15] Moore Industries-International, Inc.

Page 16

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

To access the network settings of any HES, run the NAC Client on a PC connected to the same

network as the HES or, if no network is available, connect an Ethernet cable between the

Ethernet port of the HES and PC.

1. Start the NAC Client by clicking on the icon in the Start Menu.

2. Once the program is running, click “Find All”. If more than one HES is on the network,

the NAC Client will list them a ll.

3. Either use the serial number to identify the HES, or simply disconnect the network cable

from the HES in question, click “Find All” again and determine which HES disappeared

from the list.

Figure 2.1. NAC Client showing HES default setting with DHCP enabled.

To change the network settings for the HES, double-click on the HES that you want to change.

This will open a second window where you can view and chang e all network settings. Click OK

when you are fini shed.

If you receive an error, you may have an incorrect setting in the network window.

Figure 2.2 – NAC Client showing HES with DHCP disabled and showing a user specific IP

address.

www.miinet.com [16] Moore Industries-International, Inc.

Page 17

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Verifying the HES Ethernet Connection

To test the HES Ethernet connection, open a web browser (for example Internet Explorer) and

type the IP address of the station into the address bar. If you are successful, you will see a web

page entitled “HES: HART Ethernet System”.

Testing your HES

To test that your HES is operating properly you will need the following:

Table 2.1. Assembling the Necessary

Device

HART Load

Power

Personal

HART Field Device

MODBUS/TCP Host

Resistor

Supply

Computer

Specifications

250 – 1100 ohm s

9 – 30Vdc

Microsoft Windows based PC; 16Mb free

20MB free disk space on hard drive;

Windows 7 or

Ethernet

Internet Explorer (or other web browser)

At least one HART device to be used to test the

functionality of the HES

To be used to verify the transfer of data from the

HART Field Device to the MODBUS/TCP Host

Equipment

10

cable

RAM;

Microsoft

www.miinet.com [17] Moore Industries-International, Inc.

Page 18

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Front Panel LEDs

The front panel of the single channel HES has two LEDs, Ready and Channel 1.

The front panel of the four channel HES has five LEDs, Ready and Channels 1 - 4.

Table 2.2. LED Meanings

LED

Color

Description

Ready

Channel X (1, 2, 3, 4)

RED

Initializing on power up or Unit

GREEN

RED

GREEN

RED/GREEN

System OK

Initializing, Fault or No

communication

Channel OK and HART

communication

Some but not all field devices

responding to

HART

with all field

polling

Fault

devices

www.miinet.com [18] Moore Industries-International, Inc.

Page 19

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

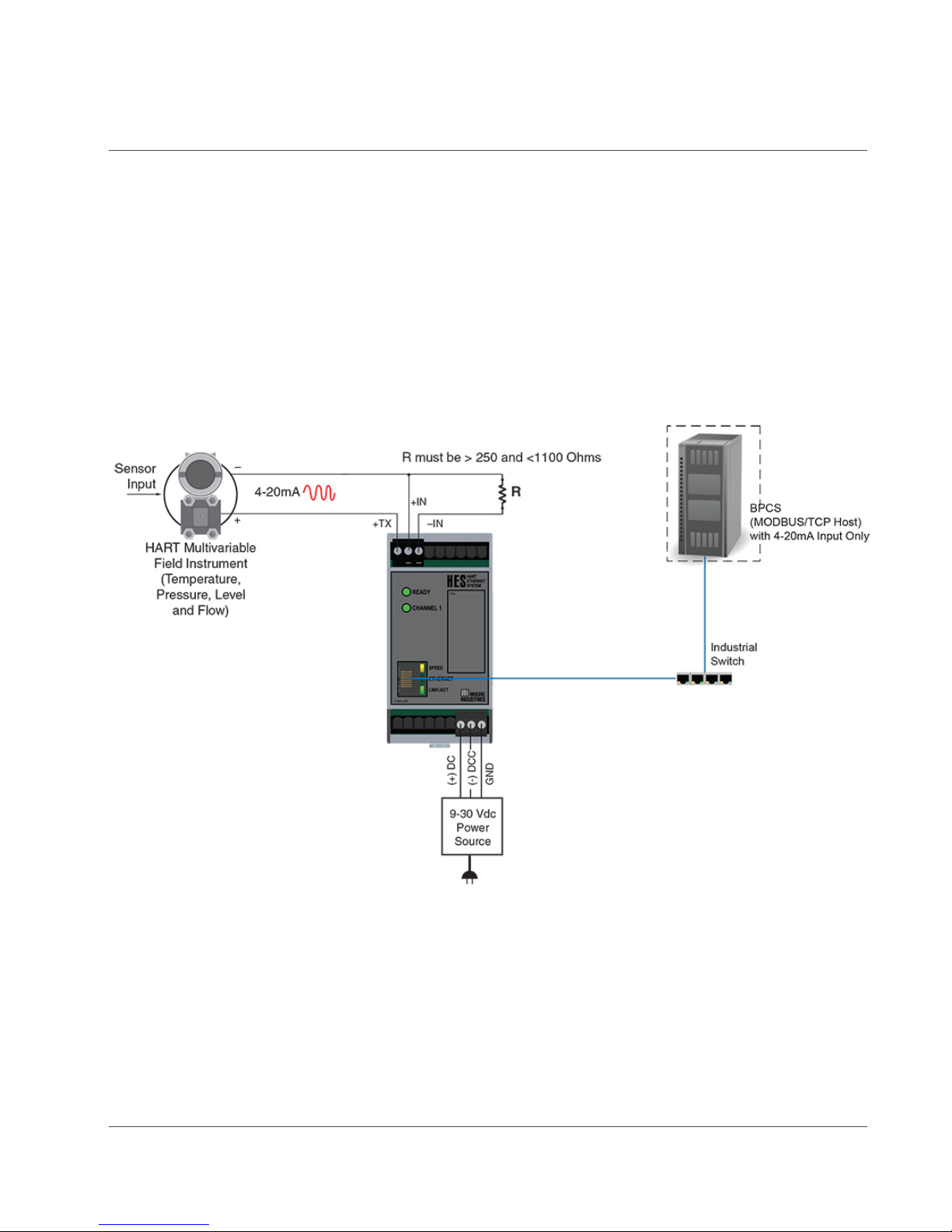

Wiring your HES

For your testing, your HART Field Device can be powered either by the HES, or by a separate

power source.

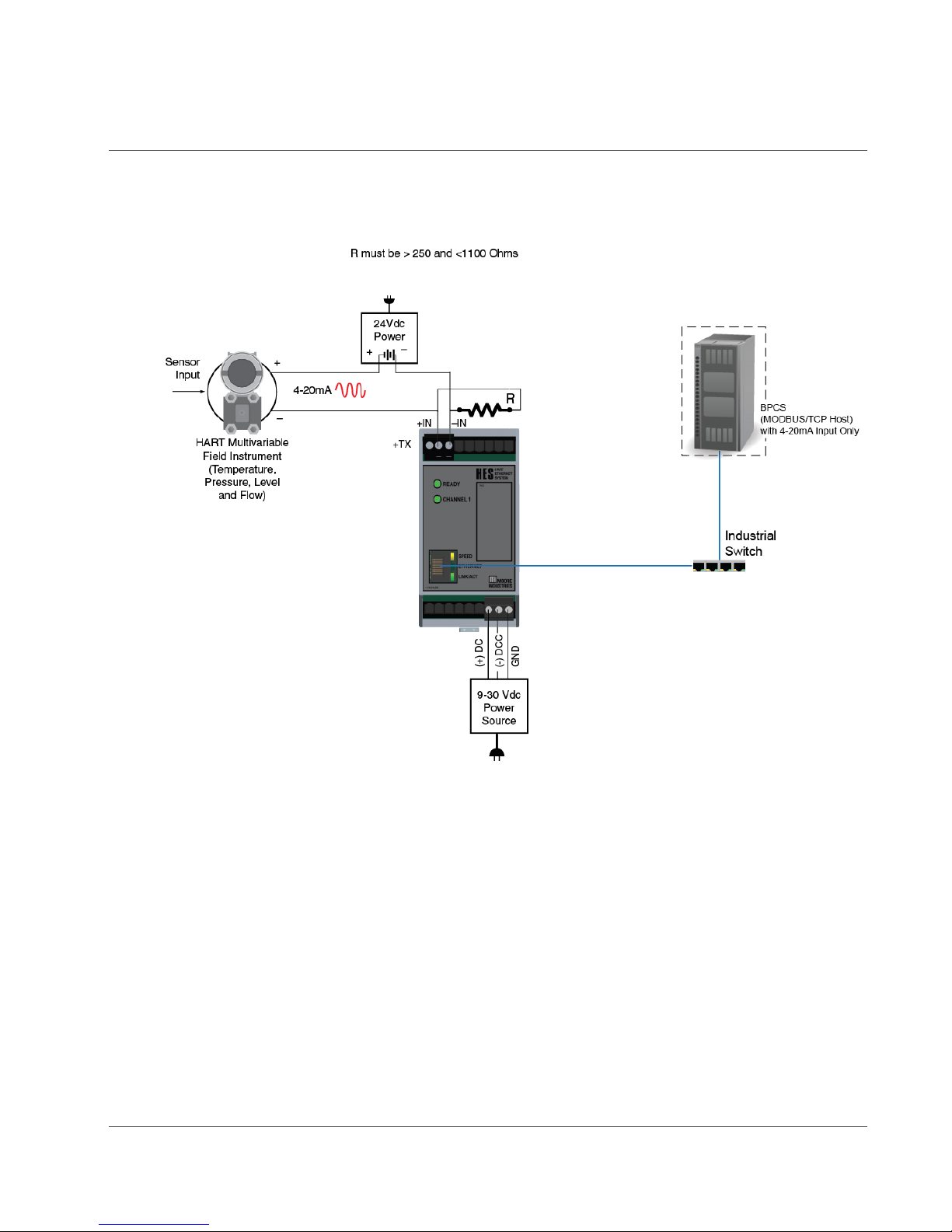

See Figure 2.3 for connecting your HART Field Device to the HES by using the HES to provide

power to the HART Field Device. Note that this method is only applicable to testing on Channel

1 of the HES. Only Channel 1 has the transmitter excitation (TX) terminal.

See Figure 2.4 for connecting your HART Field Device using an external power source to

provide power to the HART Field Device.

Figure 2.3. Connecting a HART Field Device to the HES

www.miinet.com [19] Moore Industries-International, Inc.

Page 20

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Figure 2.4. Powering your HART Field Device by Using an External Power Source.

Testing Channel 1

By default, Channel 1 of the HES is configured to poll one device at HART address 0, so set up

your HART field device for HART address 0. Connect it to the input of the HES by following the

wiring diagram of either Figure 2.3 (using the HES TX terminal to power your HART field device)

or Figure 2.4 (using an external power source to power your HART field device). If everything is

correct, you should observe a green indication on the LED adjacent to Channel 1 on the front

panel of the HES.

You can now use your MODBUS/TCP Host to verify that the HES is passing MODBUS data

correctly. First , use your PC to view the HES web page for the IP address that you provided

earlier in this bench test procedure. View the System Status Registers for Channel 1 and look

at the Register Name “Detected Devices”. The value in the register should be 0x001 that

implies Device 1 is present.

www.miinet.com [20] Moore Industries-International, Inc.

Page 21

HES User Manual

Channel 1

Register Name

MB Reg

Value

Status

Ch 1 Consolidated

Status

9566

0x0010

(4) One or more Devices have Device

Malfunction Bit Set

Detected Devices

9569

0x0001

(0) Device 1 is Present

Devices Not

Producing Data

9571

0x0000

No status bits set

Channel 1

Device

MB Reg

Status

Status Message

Channel 1, Device 1

4225

Field Device Status

(4) More Status

4545

Additional Status

Not Read

Channel 1, Devices 2 to 16 are not polled.

HART to Ethernet Gateway System 226-710-00A

September 2018

If you see a value of 0x000 press the F5 key on your keyboard to update the web page. When

you see the 0x001 value then your HES is successfully communicating with your MODBUS

Host via Ethernet (see Table 2.3).

Table 2.3. System Status Registers for Channel 1

Now you can verify that HART data is passing from your HART device, through the HES, and

on to your MODBUS/TCP Host (even though your HART Field Device is not connected to your

process).

Go to the page entitled Field Device HART Status and observe the registers for Channel 1. You

should be able to see status information for Channel 1, Device 1 similar to the Table 2.4.

Table 2.4. Status Information for Channel 1, Device 1

Addr: 0

Tag: TAG4

Note that the Field Device Status in this example shows a code of (4) for More Status Available

and a code of (7) for Device Malfunction. This data is being transmitted by the HART Field

Device and is being successfully read by the HES. To ensure that this data is being

successfully passed along to your MODBUS/TCP Host you will have to use your MODBUS/TCP

Host to read Register 4225. Please see Figure 2.5 and notice that register 4225, bit position 4

shows a 1, and register 4225, bit position 7 also shows a 1. This proves that the HART data is

being successfully passed from your HART Field Device, through the HES, and on to your

MODBUS/TCP Host without er r or .

Available

(7) Device

Malfunction

www.miinet.com [21] Moore Industries-International, Inc.

Page 22

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Figure 2.5. MODBUS Register Information

If you have an HES with a single HART channel then your testing is now complete. If you have

an HES with four HART channels, you can now proceed to test the remaining three channels.

The major difference will be in the way the HART loop is powered (by an external power source)

as shown in Figure 2.4.

www.miinet.com [22] Moore Industries-International, Inc.

Page 23

HES User Manual

Top Terminals (Left to Right)

T1

T2

T3

Input Single

TX

+IN

-IN

Top (Left to Right)

T1

T2

T3

T4

T5

T6

T7

T8

T9

Input Four

Channel

TX

+IN

-IN

+IN

-IN

+IN

-IN

+IN

-IN

Channel 1

Channel 2

Channel 3

Channel 4

Bottom Terminals (Left to Right)

B1

B2

B3

Power 9-30VDC

(+)DC

(-)DCC

GND

HART to Ethernet Gateway System 226-710-00A

September 2018

Section 3 – Wiring and Installation

Instructions in this section and others may require special precautions to ensure the safety of

the personnel performing the operations. Notes, Cautions and Warnings that may cause

potential safety issues are indicated throughout this manual by symbols, please refer to the

Safety Message Page.

Terminal Designations

The following figures (3.1-3.4) are the terminal designation information for both the single and

four channel HES.

Figure 3.1. Top Terminal Configuration for Single Channel HES

Channel

Figure 3.2. Top Terminal Configuration for Four Channel HES

Figure 3.3. Bottom Terminal Configuration for Single and Four Channel HES

www.miinet.com [23] Moore Industries-International, Inc.

Page 24

HES User Manual

Abbreviation

Meaning

TX

Power for 2-Wire transmitter

+IN

Positive input

–IN

Negative input

(+)DC

Positive power input

(–)DCC

Negative power input

GND

Ground

HART to Ethernet Gateway System 226-710-00A

September 2018

Figure 3.4. Key for Figures for 3.1 – 3.3

NOTE: Terminal blocks can accommodate 14-22 AWG solid wirin g. Tighten terminals

to four inch-pounds (maximum).

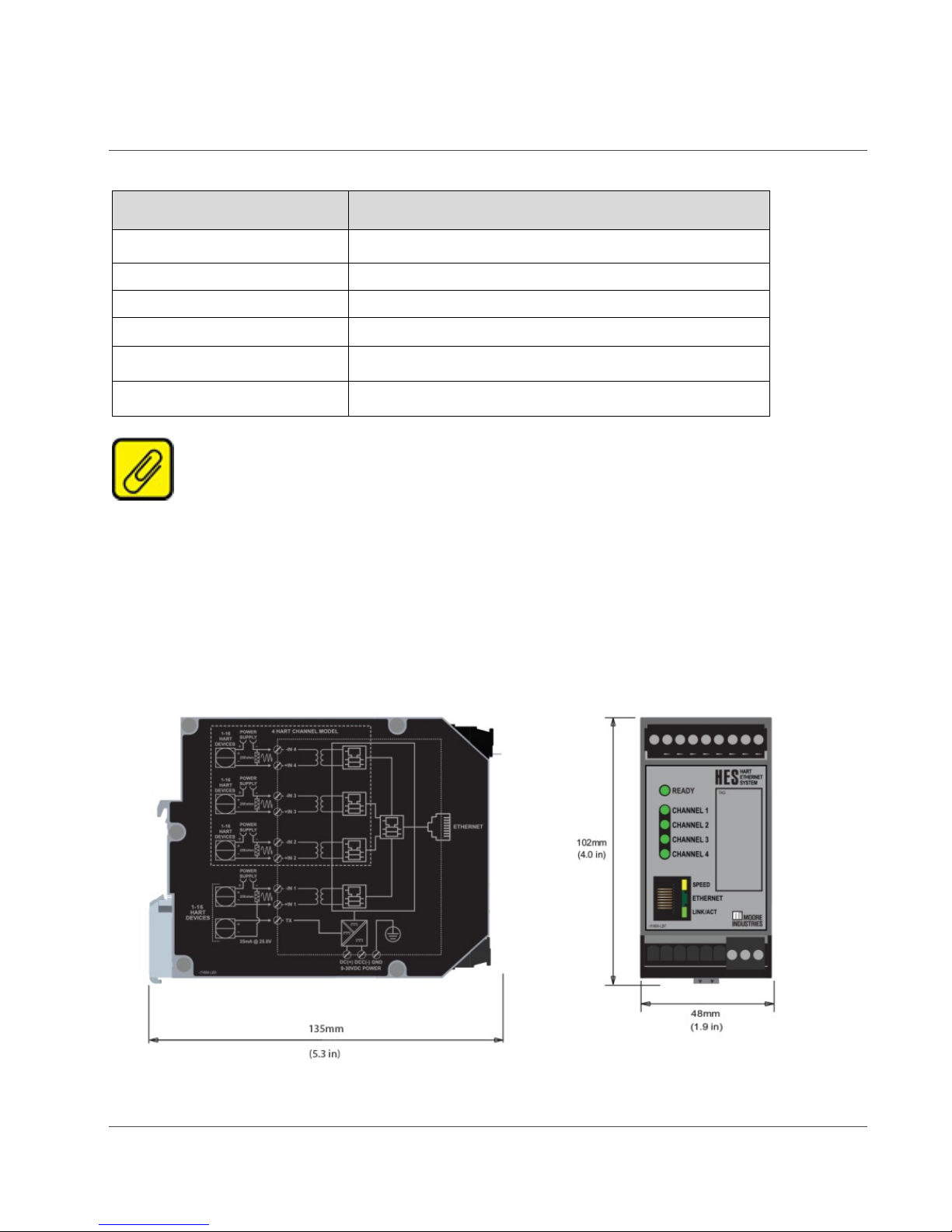

Dimensions

Dimensions are the same for the 1 channel and 4 channel. See figure 3.5.

Figure 3.5. HES Dimensions

www.miinet.com [24] Moore Industries-International, Inc.

Page 25

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Installation

Installation consists of physically mounting the unit, grounding the instrument, and completing

the electrical connections.

Mounting

The HES is designed to snap easily onto 35mm Top Hat (EN50022) DIN rails.

Electrical Connections

When installing any Moore Industries product, always follow all local regulations and standards

for grounding, shielding, and safety.

Installation Category

All terminals are rated CAT 1.

Equipment Ratings

The HES does not generate hazardous voltages, it provides a low current (4-20mA) input or

Ethernet output. Products connected to the HES should be designed to receive this type of

input.

Input

The HES has a choice or either 1 or 4 channels HART inputs with the ability to individually

configure each channel as either a Primary, Secondary, or Disabled Master. Each channel

supports up to 16 HART devices in digital multidrop mode, or can support just one device in a

standard point-to-point 4-20mA loop configuration.

Four channel configuration can support up to 64 total HART devices for high density

installations. The HES communicates with all HART 5, 6 and 7 devices including smart valves,

multivariable flowmeters, pressure, pH, level, and temperature transmitters and more.

A transmitter excitation power supply on Channel 1 only: 25.8Vdc ±3%@35mA; capable of

powering multiple HART field devices configured as multidrop model. (See figures 3.1 – 3.4)

Output

The HES offers a standard one RJ45 connector for Ethernet.

Protective Earth Conductor

The Protective Earth Conductor shall be of equal or larger size wire than the other two power

conductors. The Protective Earth Conductor shall be the first conductor connected to the unit

when the unit is being wired. It shall be the last conductor removed when the unit is being unwired.

www.miinet.com [25] Moore Industries-International, Inc.

Page 26

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Recommended Ground Wiring Practices

Moore Industries recommends the following ground wiring practices:

Any Moore Industries product in a metal case or housing should be grounded. The protective

earth conductor must be connected to a system safety earth ground before making other

connections. All input signals to, and output signals from, Moore Industries’ products should be

wired using a shielded, twisted pair wiring technique. Shields should be connected to an earth

or safety ground. For the best shielding, the shield should be run all the way from the signal

source to the receiving device (see Note below). The maximum length of unshielded input and

output signal wiring should be 2 inches.

NOTE: Some of Moore Industries’ instruments can be classified as receivers (IPT2,

IPX2, etc.) and some can be classified as transmitters (TRX, TRY, etc.) while some are both a

receiver and a transmitter (SPA2, HIM, etc). Your shield ground connections should be

appropriate for the type of signal line being shielded. The shield should be grounded at the

receiver and not at the signal source.

CE Conformity

Installation of any Moore Industries’ products that carry the CE marking must adhere to the

guidelines in the Recommended Ground Wiring Practices section in order to meet the EN 61326

requirements set forth in the applicable EMC directive.

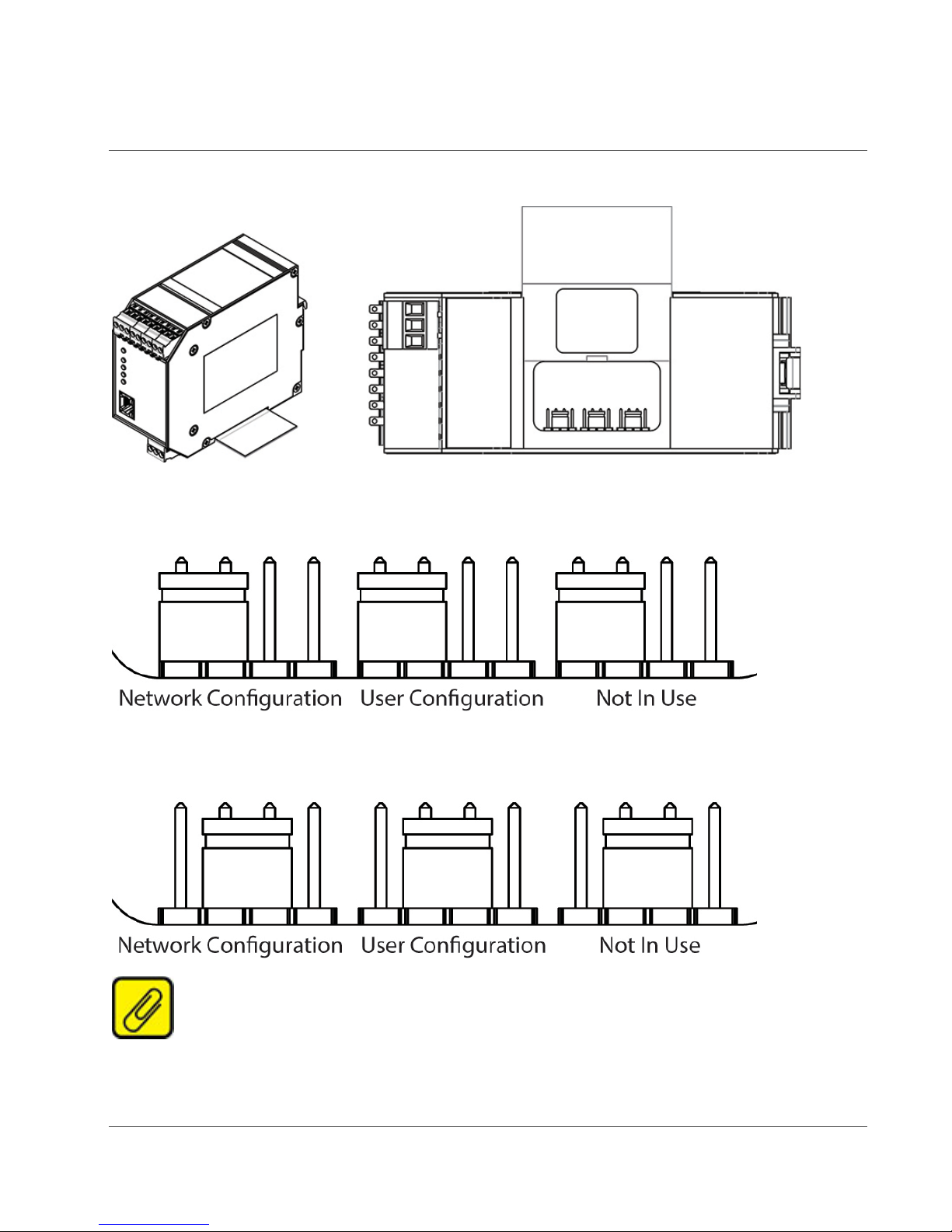

User Configurable Hardware

The HES has access to internal security jumpers with the ability to set them to read only (see

figures 3.6, 3.7.A, and 3.7.B). The jumpers are accessed by a sliding panel on the bottom of the

device (see figure 3.7).

Security jumpers are set by default to:

• Network configuration = Read / Write

• User configuration = Read / Write

CAUTION: Please power down unit before accessing the jumpers.

www.miinet.com [26] Moore Industries-International, Inc.

Page 27

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Figure 3.6. Jumpers Access Located on the Bottom of the HES under a Sliding Panel

Figure 3.7.A HES Jumper Configuration for Read/Write

Figure 3.7.B HES Jumper Configuration for Read Only

NOTE: For jumper configuration change to take effect, the HES will need to be power

cycled (turn power off and back on).

www.miinet.com [27] Moore Industries-International, Inc.

Page 28

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

To check, click on the HES System Settings, in the HES DTM software, upload the

configuration, select HES System Settings and scroll down, see figure 3.8.

Figure 3.8. View of Status of HES Network Configuration Jumper

NOTE: The jumper settings are also viewable on the HES Home webpage in the

Security table.

www.miinet.com [28] Moore Industries-International, Inc.

Page 29

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Section 4 – HES Configuration

Four different pieces of software are required for configuring your HES. They are available on

the Moore Industries’ CD shipped with the HES or for download from Moore Industries’ web site

at http://www.miinet.com/

• PACTware v. XXX (Download the latest version) or any FDT frame application

• Moore Industries MIIP Communications DTM

• Moore Industries’ HES Device DTM

• Moore Industries’ Network Address Configuration (NAC) Client

For users who already have an FDT Frame Application, all the following information is still

relevant except for the PACTware installation. For more information on FDT/DTM please refer

to www.fdtgroup.org.

FDT Frame Application

Moore Industries has always provided proprietary software to configure and operate our field

instruments to the full extent. The HES will require the use of an FDT frame application, which

allows configuration and adjustment of any and all field instruments, which have a DTM. For

users who do not already have an FDT frame application, Moore Industries provides

PACTware.

. The software required includes:

An FDT frame application, such as PACTware, is a PC program, which interfaces with individual

software modules for instrument operation. This interface is regarded as the FDT; the individual

software modules for instrument adjustment are called DTMs (Device Type Manager). This

confi gurati on makes u ser-friendly adjustments possible because the interface for instrument

adjustment is optimally adapted to each instrument.

When installing the version of PACTware supplied by Moore Industries, the installation will

include three communication DTMs. They are a HART Communication DTM, and two

proprietary communication DTMs. The MISP DTM stands for Moore Industries Serial Port and

the MIIP DTM stands for Moore Industries Internet Protocol. The HES only uses the MIIP DTM.

FDT/DTM Software Installation

In order to get started you will need to either install the PACTware software and DTMs or just

install the DTMs (if you already have an FDT frame application installed). All the files you need

can be found on our website www.miinet.com.

The PACTware installer file will ins tall PACTware and all requir e d communication DTMs. The

HES and other device DTMs need to be installed separately (see below).

PACTware_vxxx_FDT_DTM_Installation_Moore_Industries.exe

When you run the installer, you will have the option to select which components you want to

install.

www.miinet.com [29] Moore Industries-International, Inc.

Page 30

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

NOTE: xxx is the current version of software. Download the latest version of all

software to assure compatibility.

To Install PACTware

Click on installer and follow prompts.

You will find individual DTM installers on the website and Moore Tools CD in Comms and

Device folders. Use these to install or update the Moore Industries DTMs.

Figure 4.1. PACTw are Ready for MIIP DTM Installation

Moore Industries MIIP DTM Installation

To communicate with the HES you will need to install the MIIP DTM. The MIIP DTM can be

found on the Moore Industries Configuration Tools CD, or from our website www.miinet.com.

To install simply locate file, double click file and follow on screen instructions to install.

NOTE: The MIIP Communications DTM: Is a Moore Industries Internet Protocol, which

allows communication via Ethernet.

Moore Industries HES Device DTM Installation

File is named: HES_PC_Configuration_Software_Moore_Industries

www.miinet.com [30] Moore Industries-International, Inc.

Page 31

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

To install simply locate file on the CD or download from the web site, double click file and follow

on screen instructions to install.

Once you have installed all the necessary DTMs on your system, you are now ready to launch

the FDT frame application (PACTware) and configure your device.

www.miinet.com [31] Moore Industries-International, Inc.

Page 32

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Basic Setup

Once the HES is powered up and the software is loaded, a simple setup is all that is needed to

get started with a laptop, CAT 5 Ethernet cable with RJ45 connection (see figure 4.2). The HES

supports Auto MDIX (Medium Dependent Interface), which means that either a straight through

Ethernet patch cable or crossover cable can be used for commissioning and configuration.

Figure 4.2. HES connection to PC for Configuration

Network Configuration

The HES comes default from the factory set to DHCP. Configuring the HES for your local area

network (LAN) is the first step in this process. Our Network Address Configuration (NAC) Client

software will help you configure the HES properly. Begin by installing the NAC Client software

onto your PC.

Installing the NAC Client

To install the software, insert the Interface Solution Configuration Tools and Installation Manuals

CD into the CD drive of a Windows® equipped PC. The NAC client software available in the

Resources Area on the Moore Industries website or on the CD included with your product.

Run the Moore NAC program, then use the setup program to install the NAC Client. The setup

program may require you to upgrade certain Windows® components before it will install.

www.miinet.com [32] Moore Industries-International, Inc.

Page 33

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Fixed Network Settings or DHCP

To use the HES on a given Ethernet network, three settings must be configured– IP address,

gateway and subnet mask. The HES comes with DHCP (Dynamic Host Configuration Protocol)

enabled, allowing the network settings to be acquired automatically when the HES is

connected to a network with a DHCP server. Change the DHCP to a static IP. The number can

be obtained from your system administrator. NAC client should always be used initially and

DHCP should not be set permanently.

NOTE: If the HES is using DHCP at start up, the network address information

displayed in the list box is how the server is currently configured. When you double-click to open

the Edit window, the network settings boxes are disabled. You cannot set the IP address,

subnet mask or gateway address manually if DHCP is enabled.

CAUTION: The use of DHCP introduces the possibility of change or loss of IP

address, caused by DHCP server outages or configuration specifics, or by an untimely power

outage to the HES (i.e. coincident with DHCP lease expiration). Use of fixed network settings in

the HES is recommended, and avoids these potential problems.

Change Network Settings

To access the network settings of the HES, run the NAC Client on a PC connected to the same

network as the HES or, if no network is available, connect a network cable between the

Ethernet ports of the HES and PC. No cross over cable is necessary.

1. Start the NAC Client by clicking on the icon in the Start Menu

2. Once the program is running, click F in d All

3. If more than one HES is on the network, the NAC Client will list them all.

4. Disconnect the network cable from the HES in question, click Find All again and

determine which HES disappeared from the list.

www.miinet.com [33] Moore Industries-International, Inc.

Page 34

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

To Change the Network Settings for a HES

1. Double click on the HES that you want to change. This will open a second window where

you can view and change all network settings.

2. Set Static IP Using NAC Client.

3. Click OK when you are finished.

Power the HES on and off.

www.miinet.com [34] Moore Industries-International, Inc.

Page 35

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Connecting to the HES Using MIIP

Once you have installed all the necessary DTMs on your system, connected your HES to an

Ethernet Network, and you know the IP address of the HES (use the NAC client for the IP), you

are now ready to launch the FDT frame application (PACTware) and configure your device.

1. Click on the “PACTware” Icon to launch the software.

2. Right Click on Host PC, select “Add Device”

3. Select the “MII MIIP Communications DTM” from the pop up window.

a. Click OK.

www.miinet.com [35] Moore Industries-International, Inc.

Page 36

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

4. To be able to configure the HES, you will need to set its IP address in the MIIP DTM.

a. Right click on the MII MIIP Communications DTM and select “Parameters”

www.miinet.com [36] Moore Industries-International, Inc.

Page 37

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

2. Enter the IP for the HES, Click ”Apply”

a. You have assigned the IP using the NAC client, you want to use it to talk to the

HES

b. Click “Apply”

Add Device

1. Right click on the DTM listed under Project (where the IP was just set)

www.miinet.com [37] Moore Industries-International, Inc.

Page 38

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

2. Select “Add Device”

3. In the pop up window, select “HES”.

www.miinet.com [38] Moore Industries-International, Inc.

Page 39

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Display HES Configuration

1. Right click on the HES and select “Parameter”

2. Right click on the “HES” (selected DTM), and select “Connect”

www.miinet.com [39] Moore Industries-International, Inc.

Page 40

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

A green box will appear around the connection symbols showing the device is connected.

3. Load the parameters from the device to see the current device settings.

a. Right click on the HES, select “Load From Device”

b. A window will appear while loading the information

www.miinet.com [40] Moore Industries-International, Inc.

Page 41

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

4. The HART Inputs screen will be displayed

For HES Default Settings, please refer to the HES Quick Start Guide. Default values for each

parameter are also shown below in [ ] (on the following pages).

www.miinet.com [41] Moore Industries-International, Inc.

Page 42

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HART Inputs Settings

HART Inputs - Channel Settings

Each channel has identical settings. Channel 1 is shown as an example.

• HES Master Mode [Primary] - The user can select Primary Master, Secondary

Master, or Disabled. Choose Disabled when a channel has no devices hooked up to it or

you want to disable the HART monitoring on that channel.

• Operation

o Acquire Additional Status [off] - The field devices all produce device specific

Additional Status bytes (25 maximum) as defined by the HART standard. If

configured and available, the HES will read the field device additional status

bytes. These are displayed on the ‘Field Device HART Status ’ webpage and can

also be found in the MODBUS registers (see MODBUS registers section).

www.miinet.com [42] Moore Industries-International, Inc.

Page 43

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

o Burst Mode [off] - The HES supports enhanced broadcast messaging more

commonly referred to as burst mode for one field device per channel. When set

to burst mode, the field device will proactively send out messages instead of

waiting for the HART master to request them. This enables event driven

communication (high, low, deviation of signal or change in status) and/or timed

communication to the master. Burst slot is enabled when the user selects Burst

Mode. Select the Device number in the pull down menu.

NOTE: The HART field device needs to be configured for Burst with the same burst

confi gurati on (Command 3 or 9) as the HES.

• Number of Retries [1] – The number of times the HES will try a HART field device that

isn’t responding before declaring a communications error for that Field Device.

• HART Devices – Channel X

o Number of HART Devices [1] – the number of devices (up to 16) chosen on a

channel will equal the number of polling device addresses available (not grayed

out).

o Device Y Polling Address - This is the HART Polling Address for the selected

field device, enter a number from 0-63.

www.miinet.com [43] Moore Industries-International, Inc.

Page 44

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

NOTE: The pencil icon means you have not saved or applied the change.

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

HART Field Device Settings

First, select the device you want to configure from the pull down list.

• Polling Address - This is the HART Polling Address, as entered on the Channel

Configuration screen. It is read-only on the Field Device Settings screen.

• Polling Command [Command 3] - This is used to select the HART command for

retrieving Dynamic or Device Variables. See Section 1 Introduction, Dynamic and Device

Variable for more information.

o Command 3 - Used for retrieving PV, SV, TV, QV and loop current from the field

device.

o Command 9 - Command 9 is supported by HART 6 or 7 devices. Selecting this

command requires the user to define the number of Device Variables (DVs) and

each DV code to be read.

www.miinet.com [44] Moore Industries-International, Inc.

Page 45

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Configure Using Command 9

1. Select the number of “Device Variables” on the channel you are configuring

2. Enter Device Variable codes for the data to be read from connected HART devices

3. Click “Apply”

www.miinet.com [45] Moore Industries-International, Inc.

Page 46

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Copy Device Settings to a Different Channel

If you have a number of devices with the same settings, this feature helps to speed up

configuration.

1. Set up 1 device with your command settings

2. Go to the channel and device you want to copy the setting to and scroll to the bottom of

the Device Setting

3. Select “Copy HART Field Device Settings From” and choose the Device you want to

copy from in the pull down menu

4. Click “Copy”

5. Click “Apply”

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

www.miinet.com [46] Moore Industries-International, Inc.

Page 47

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Default Device Settings

Use “Set to Default” to set a particular device to the default configuration.

1. Click on the channel then the “HART Field Device Settings” you want to change t o

default

a. Select the device you wish to default

2. Click on the “Default“ Button under “Default HART Field Device Settings”

3. Click “Apply”

Please remember to download to your device, refer to Saving the Configuration File to the

HES at the end of this section.

www.miinet.com [47] Moore Industries-International, Inc.

Page 48

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

MODBUS/TCP Settings

1. Select MODBUS/TCP in the selection pane

2. Configure the various options, which control how Field Device data is placed in

MODBUS registers, and how errors are handled.

3. Click “Apply”

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

MODBUS Mapping Configuration

Allows the mapping of the HART field device variables to MODBUS registers. See Section 5 for

details on MODBUS Register definitions and HART field device registers.

Mapping Mode [By Variable Type]

• By Variable Type – Organize by Variable Type (Primary Variable1 (PV1), Primary

Variable 2 (PV2), Primary Variable 3 (PV3), etc.)

• By Device Type - Organize by Device Type (Primary Variable (PV1), Secondary

Variable (SV1), Tertiary Variable (TV1), Quaternary (QV1) etc.)

www.miinet.com [48] Moore Industries-International, Inc.

Page 49

HES User Manual

HES Modbus map - Device Data by Variable

IO Channel

CHANNEL 1 1 1 1 1 1

DEVICE 1 2 3 4 5 6

Paramete r Type

Group(s)

Float D ata

PV float32

Float D yn Vars A

1 3 5 7 9 11

SV float32 Float D yn Vars A

109 111 113 115 117 119

TV f loat32 Float Dyn Vars A

217 219 221 223 225 227

QV float32 Float Dyn Vars A

325 327 329 331 333 335

Loop Current

float32

Float D yn Vars B

513 515 517 519 521 523

POR

float32

Float D yn Vars B

621 623 625 627 629 631

RESERVED float32 Float D yn Vars B

729 733 737 741 745 749

Var1 float32

Float D ev Vars

1025 1027 1029 1031 1033 1035

Var2 float32

Float D ev Vars

1133 1135 1137 1139 1141 1143

Var3 float32

Float D ev Vars

1241 1243 1245 1247 1249 1251

Var4 float32

Float D ev Vars

1349 1351 1353 1355 1357 1359

Var5 float32

Float D ev Vars

1457 1459 1461 1463 1465 1467

Var6 float32

Float D ev Vars

1565 1567 1569 1571 1573 1575

Var7 float32

Float D ev Vars

1673 1675 1677 1679 1681 1683

Var8 float32

Float D ev Vars

1781 1783 1785 1787 1789 1791

Integer Data

PVInteger fixed point

Int D yn Vars A

2049 2050 2051 2052 2053 2054

SVInteger fixed point

Int D yn Vars A

2103 2104 2105 2106 2107 2108

TVInteger fixed point Int D yn Vars A

2157 2158 2159 2160 2161 2162

QVInteger fixed point

Int D yn Vars A

2211 2212 2213 2214 2215 2216

LoopCurrentInteger fixed point Int Dyn Vars B

2305 2306 2307 2308 2309 2310

PO R Integer fixed point

Int D yn Vars B

2359 2360 2361 2362 2363 2364

RESERVED Int Dyn Vars B

2413 2415 2417 2419 2421 2423

Var1 Integer fixed point Int D ev Vars

2561 2562 2563 2564 2565 2566

Var2 Integer fixed point Int D ev Vars

2615 2616 2617 2618 2619 2620

Var3 Integer fixed point Int D ev Vars

2669 2670 2671 2672 2673 2674

Var4 Integer fixed point Int D ev Vars

2723 2724 2725 2726 2727 2728

Var5 Integer fixed point Int D ev Vars

2777 2778 2779 2780 2781 2782

Var6 Integer fixed point Int D ev Vars

2831 2832 2833 2834 2835 2836

Var7 Integer fixed point Int D ev Vars

2885 2886 2887 2888 2889 2890

Var8 Integer

fixed point Int D ev Vars

2939 2940 2941 2942 2943 2944

Quality

RESERVED

Quality

3073 3081 3089 3097 3105 3113

Var1 Quality

Quality Stamp - see S

Quality Dev Vars

3585 3586 3587 3588 3589 3590

Var2 Quality

Quality Stamp - see

Quality Dev Vars

3639 3640 3641 3642 3643 3644

Var3 Quality

Quality Stamp - see S

Quality Dev Vars

3693 3694 3695 3696 3697 3698

Var4 Quality

Quality Stamp - see S

Quality Dev Vars

3747 3748 3749 3750 3751 3752

Var5 Quality

Quality Stamp - see S

Quality Dev Vars

3801 3802 3803 3804 3805 3806

Var6 Quality

Quality Stamp - see S

Quality Dev Vars

3855 3856 3857 3858 3859 3860

Var7 Quality

Quality Stamp - see S

Quality Dev Vars

3909

3910 3911 3912 3913 3914

Var8 Quality

Quality Stamp - see S

Quality Dev Vars

3963

3964 3965 3966 3967 3968

HES Modbus map - Device Data by Variable with CMD3/9 Compressi on

IO Channel Data

CHANNEL 1 1 1 1 1 1

DEVICE 1 2 3 4 5 6

Paramete r Type Group(s)

Float Data

PV/Dev Var 1 f loat32 Float Dev Vars

1 3 5 7 9 11

SV/ Dev Var 2 float32 Float Dev Vars

109 111 113 115 117 119

TV/ Dev Var 3 float32 Float Dev Vars

217 219 221 223 225 227

QV/ Dev Var 4

float32 Float Dev Vars

325 327 329 331 333 335

Dev Var 5

float32 Float Dev Vars

433 435 437 439 441 443

Dev Var 6 float32 Float Dev Vars

541 543 545 547 549 551

Dev Var 7 float32 Float Dev Vars

649 651 653 655 657 659

Dev Var 8 float32 Float Dev Vars

757 759 761 763 765 767

Integer Data

PV/Dev Var 1 Integer fixed point Int Dev Vars

2049 2050 2051 2052 2053 2054

SV/ Dev Var 2 Integer fixed point Int Dev Vars

2103 2104 2105 2106 2107 2108

TV/ Dev Var 3 Integer fixed point Int Dev Vars

2157 2158 2159 2160 2161 2162

QV/ Dev Var 4 Integer fixed point Int Dev Vars

2211 2212 2213 2214 2215 2216

Dev Var 5 Integer

fixed point Int Dev Vars

2265 2266 2267 2268 2269 2270

Dev Var 6 Integer

fixed point Int Dev Vars

2319 2320 2321 2322 2323 2324

Dev Var 7 Integer fixed point Int Dev Vars

2373 2374 2375 2376 2377 2378

Dev Var 8 Integer fixed point Int Dev Vars

2427 2428 2429 2430 2431 2432

Quality

RESERV ED

Quality

3073 3081 3089 3097 3105 3113

Var1 Quality

Quality Stamp - see S

Quality Dev Vars

3585 3586 3587 3588 3589 3590

Var2 Quality

Quality Stamp - see

Quality Dev Vars

3639 3640 3641 3642 3643 3644

Var3 Quality

Quality Stamp - see S

Quality Dev Vars

3693 3694 3695 3696 3697 3698

Var4 Quality

Quality Stamp - see S

Quality Dev Vars

3747 3748 3749 3750 3751 3752

Var5 Quality

Quality Stamp - see S

Quality Dev Vars

3801 3802 3803 3804 3805 3806

Var6 Quality

Quality Stamp - see S

Quality Dev Vars

3855 3856 3857 3858 3859 3860

Var7 Quality

Quality Stamp - see S

Quality Dev Vars

3909 3910 3911 3912 3913 3914

Var8 Quality

Quality Stamp - see S

Quality Dev Vars

3963 3964 3965 3966 3967 3968

HART to Ethernet Gateway System 226-710-00A

September 2018

Mapping Options

• Compress Unused Devices [off] – Remove unused device visibility; this will eliminate

empty devices

• Compress CMD3/CMD9 Variable [off] – Compress MODBUS map data device

variables for command 3 and command 9; applies to float data, integer data, and quality

Figure 4.4. Example of MODBUS Compress CMD3/CMD9

This illustrates that in non compressed mode PV and Var1 will be in different MODBUS

registers but with CMD3/CMD9 compression on, either PV (for CMD3) or Var1 (for CMD9) will

be in the same register.

MODBUS Settings

Floating Point Word Order: [Standard LSW]

• Standard LSW – Least significant word; this stores the most significant bits in the

second register and the least significant bits in the first register

• Swapped MSW – Most significant word; will reverse the order, storing the most

significant bits in the first register and the least significant bits in the second register

www.miinet.com [49] Moore Industries-International, Inc.

Page 50

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Number of Decim al Pla ces: [0]

• Number of places possible = 0-3

MODBUS Fail Response: [Hold Last Value]

Failed HART Dev ice’ s Reg ister Valu e:

• Hold Last Value - Use the last received value upon lost communication with the

Field Device or upon receiving invalid data

• Preset Value - Use the Preset Value Box to add a custom value; go to a pre-defined

value upon lost communication with the Field Device or upon receiving invalid data;

for example use 777 for errors

• Set to NaN – set to not a number (a special numeric data type value representing an

undefined value in floating-point calculations) upon lost communication with the Field

Device or upon receiving invalid data.

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

www.miinet.com [50] Moore Industries-International, Inc.

Page 51

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HES System Settings

Use the System Settings to add a T ag, Desc riptor, or Message, and to review Device Property

information.

Scrolling down allows the user to see the current Security Settings (for jumper configuration

options please see Section 3 – Wiring and Installation)

www.miinet.com [51] Moore Industries-International, Inc.

Page 52

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

As a HART Field Device, the HES is HART 7 compliant and has both Dynamic and Device

Variables which can be read via MODBUS/TCP, HART-IP or can be viewed on the HES'

webpage. The HES allows users to map HES and field device data to both the Dynamic and

Device Variables.

HES Dynamic Variable Mapping

To map Dynamic Variables, click on “HES Dynamic Variable Mapping”

www.miinet.com [52] Moore Industries-International, Inc.

Page 53

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Map the listed variable (PV, SV, TV, and QV) to any of the HES Device Variables (1-74) in the

pull down list. When done click “Apply.”

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

www.miinet.com [53] Moore Industries-International, Inc.

Page 54

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

HES Device Variable Mapping

Map specific Device Variables for the HES to a specific variable (in a specific device,) so they

can be mapped as HES Dynamic Variables, and can be viewed on the HES web page.

1. Select “HES Device Variable Mapping”

2. Choose which device variable to edit

3. Select channel you want to map to, including device as well as the variable itself. For

example choose PV for primary variable

4. Click “Apply”

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

www.miinet.com [54] Moore Industries-International, Inc.

Page 55

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Network Security

Two-layer security is standard on the HES. There is a hardware level, which can make the

network configuration read only (see User Configurable Hardware section for details) as well as

the ability to limit the number of active connections.

Modbus TCP connections = 4 HART-IP connections = 4

For more secure network environments, the number of active MODBUS/TCP connections can

be limited to just one. This will ensure that there are not multiple unauthorized or undesired

MODBUS/TCP hosts polling the HES. If only the web server pages or HART-IP are going to be

used, you can set the number of MODBUS/TCP connections to zero preventing any MODBUS

hosts from connecting to the HES.

To set the number of allowed HART IP or MODBUS TCP connections to the HES:

1. Click on “Network Security” in the selection pane.

2. Choose the number of HART-IP connections (1-4) in the pull down menu

3. Choose the number of MODBUS TCP Connections (0-4)

4. Click “Apply”

Please remember to download to your device, refer to Saving the Configuration File to the HES

at the end of this section.

www.miinet.com [55] Moore Industries-International, Inc.

Page 56

HES User Manual

HART to Ethernet Gateway System 226-710-00A

September 2018

Downloading the Configuration File to the HES (DTM)

Once you have finished configuring your unit, remember to download the new settings to your

HES. To save the configuration to the HES:

1. When connected to the HES, Right click on the HES

2. Select “Store to Device”

3. A window will appear while saving the configur ation to the HES

Saving the Configuration File to a Location

1. Click on the “File Menu”

2. Select “Save As”

3. Select a location to save and name the file

4. Select “Save”

Print the HES [DIN] Configuration

1. Click on the “File Menu”

2. Select “Print”

3. Follow the prompts