Page 1

May 2016

920091D

TG300

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

Page 2

Table of Contents

Introduction ............................................................................................................................................. 3

About this Manual ............................................................................................................ 3

DIN Units

Device Coupler Enclosures

.......................................................................................................................... 3

.............................................................................................. 3

Specifications ................................................................................................. 4

Dimensions

Installation

Wiring Connections

Device Coupler Hook-Up .................................................................................................6

DISCONN Key

Recommended Ground Wiring Practices

CE Conformity

..................................................................................................... 4

....................................................................................................... 6

........................................................................................ 6

.................................................................................................................. 7

......................................................................... 7

.................................................................................................................. 8

Testing and Troubleshooting ......................................................................... 8

Operation

Maintenance ..................................................................................................................... 9

......................................................................................................... 9

Customer Support .......................................................................................... 9

Control Drawing

............................................................................................ 11

Page 3

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

Introduction

Device Couplers provide easy and practical

mechanisms for implementing fieldbus systems.

TRUNKGUARD Series 300 Device Couplers (TG300)

simplify the use of fieldbus devices in Zone 1 by

allowing “live” access for maintenance and eliminating

the need for Exd junction boxes.

The TG300 Series offers our patented Automatic

Segment Termination feature and a key-operated

magnetic interlock which permits one spur at a time to

be de-energized and worked on without shutting down

the entire segment.

TRUNKGUARD Device Couplers provide electronic

and fully auto-resetting spur short-circuit protection

that prevents a segment failure that maybe caused by

a short circuit to any field device. Utilizing a unique

“Fold-Back” technique, any spur that attempts to draw

more than 48mA is automatically switched off and not

permitted any current flow until the fault is removed.

With removal of the spur short circuit, TRUNKGUARD

automatically reconnects the spur to the fieldbus

segment within 20 microseconds.

The Automatic Segment Termination feature

eliminates segment failure from under or over

termination which is generally the most common

cause for delay in starting up fieldbus projects. The

auto-terminator also assures that local parts of a

segment will continue to function even if there is a

downstream cable break.

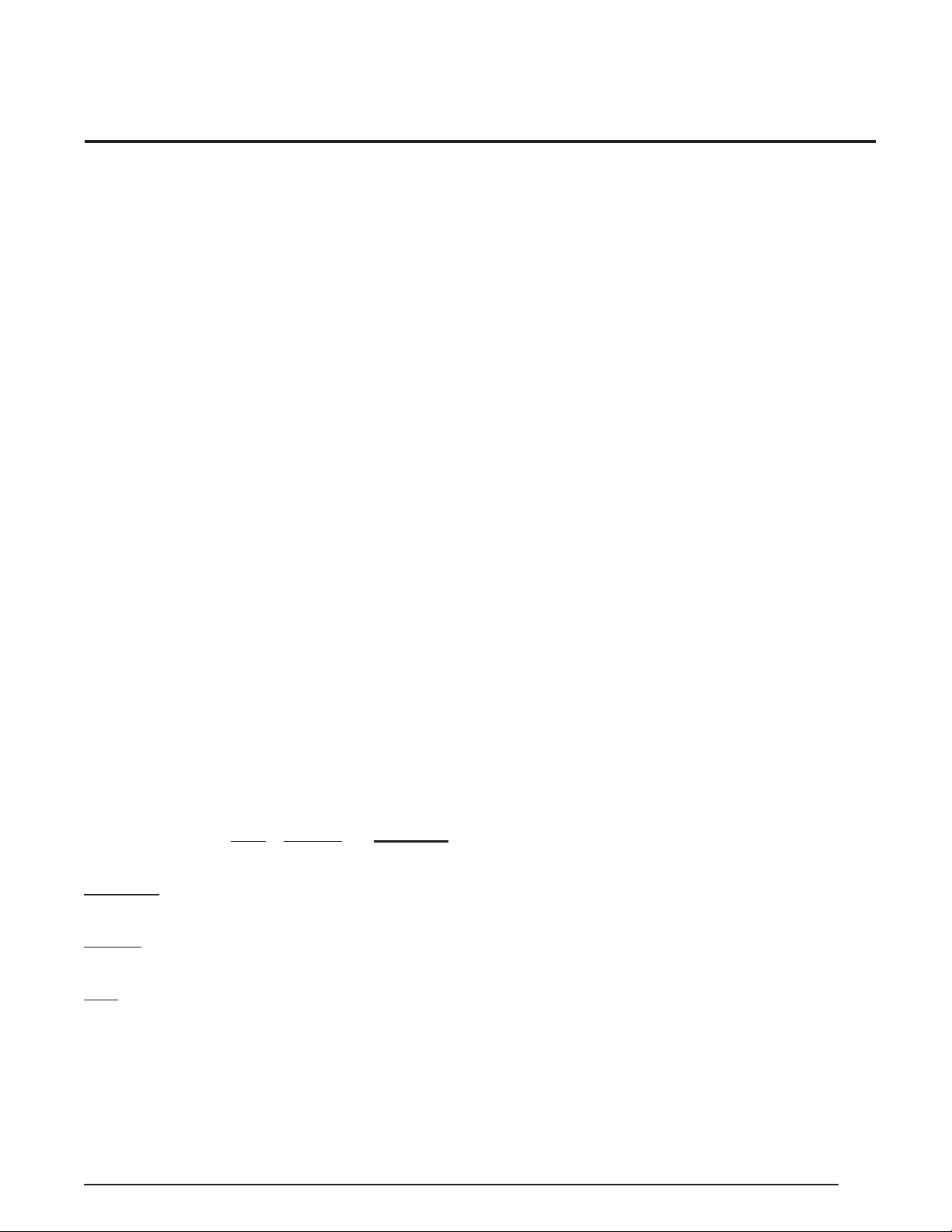

DIN Units

TG300-DIN units are designed to fit onto a 32mm

(EN50035) G-type and 35mm (EN50022) Top Hat

DIN-rail and may be mounted at any angle and in

such a way as to allow easy access to terminal

receptacles and to keep LEDs visible. These units are

not weatherproof and outdoor placement will require

an external enclosure. Any enclosure which meets

the requirements of the location in relation to electrical

and mechanical safety may be used.

For Zone 1 applications an external enclosure is

required. The enclosure and glands must be certified

for increased safety and suitable for Zone 1 use,

IP64 protection minimum. All MooreHawke TG300

enclosures are suitable for Zone 1.

Device Coupler Enclosures

Standard enclosures are available in GRP (Glass

Reinforced Polyester with side-entry cable glands).

These enclosures provide IP66/NEMA Type 4X

protection.

Standard cable glands are nickel-plated brass, and

can be ordered for use with un-armored or armored

cable. Compound seal glands (for cable with inter-core

spaces, i.e., unfilled cable), and quick connect plugs

and sockets are also available. Field devices are

individually connected directly to terminals via spur

cables through a variety of cable gland options.

About this Manual

Wherever you see a “Note”, “Caution” or “WARNING”

pay particular attention.

WARNING - Hazardous procedure or condition that

could injure the operator.

Caution - Hazardous procedure or condition that could

damage or destroy the unit.

Note - Information that is helpful for a procedure,

condition, or operation of the unit.

Installation

The enclosure should be mounted to a flat surface

using the internal mounting holes or via external

3

Page 4

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

FAULT

NORMAL

DEENERGISED

ACTIVE AUTO

TERMINATOR

KEY PARK

+-S+-S+-S+-S+-S+-S

TRUNK IN

TRUNK OUT

SPUR 4

SPUR 3SPUR 2SPUR 1

Moore Inductries-International, Inc., CA 91343, USA

G

TG304-DIN

TRUNKGUARD

FAULT

NORMAL

DEENERGISED

ACTIVE AUTO

TERMINATOR

+-S+-S

TRUNK OUT

SPUR 8

4-Spur: 98mm (3.85 in)

8-Spur: 178mm (7.03 in)

82mm

(3.23 in)

52mm

(2.04 in)

Specifications

Communications

FOUNDATION

Performance

fieldbus™ H1 and

PROFIBUS PA

Performance

Supply Voltage:

10 to 32Vdc

Maximum Segment

Current: 800mA

Maximum Quiescent

Current:

TG304: 13mA@32V

5mA@16VFB

;

FB

TG308: 23mA@32VFB;

10mA@16V

* 3mA less with -MT option

FB

Maximum Spur Output

Current: I

Spur Short Circuit Load:

=5mA (32V), 3mA (16V)

I

Ssc

Spur Voltage Drop:

=48mA

Slim

0.7V@20mA

Maximum Voltage Drop

Trunk IN to OUT: 0.7V

Terminator: 100Ω/1µF

(Internal Automatic

Segment Termination is

standard; For manual

*Auto-terminator function not applicable with -MT option.

(continued)

Indicators

Terminals

termination, specify

the -MT option with

the MooreHawke

model number (e.g.

TG308-DIN-MT). Also

separately specify a

TRK-TERM Trunk

Terminator for mounting

on the final device

coupler in the segment.)

Spur: GREEN (normal)

RED (fault)

YELLOW

(de-energized)

Auto-Terminator:

YELLOW LED is ON

when auto-termination

is activated

Type: EEx e approved

terminals with IP30

shrouds and fillers

Wire Size: Handles

sizes between

0.8-2.5mm

2

/12-24AWG

Cable Glands

(Device

Couplers with

Enclosures)

Ambient

Conditions

Type:

Armored/Unarmored

Material:

Nickel-plated brass

Operating:

-40°C to +70°C

(-40°F to +158°F)

Storage:

-40°C to +85°C

(-40°F to +185°F)

Relative Humidity:

0-95%,

non-condensing

Surge Protection:

EN61326, EN61000-4-5

1KV (1.2/50µsec)

RFI/EMI Immunity:

10V/m@80-1000MHz,

1kHz AM (IEC61326)

Vibration:

(EN 60068-2-6): 1g max

acceleration,10-150Hz

Shock:

(EN 60068-2-27): 15g

max. acceleration, 11ms

Figure 1. DIN-Rail Mounting Installation Dimensions

4

Page 5

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

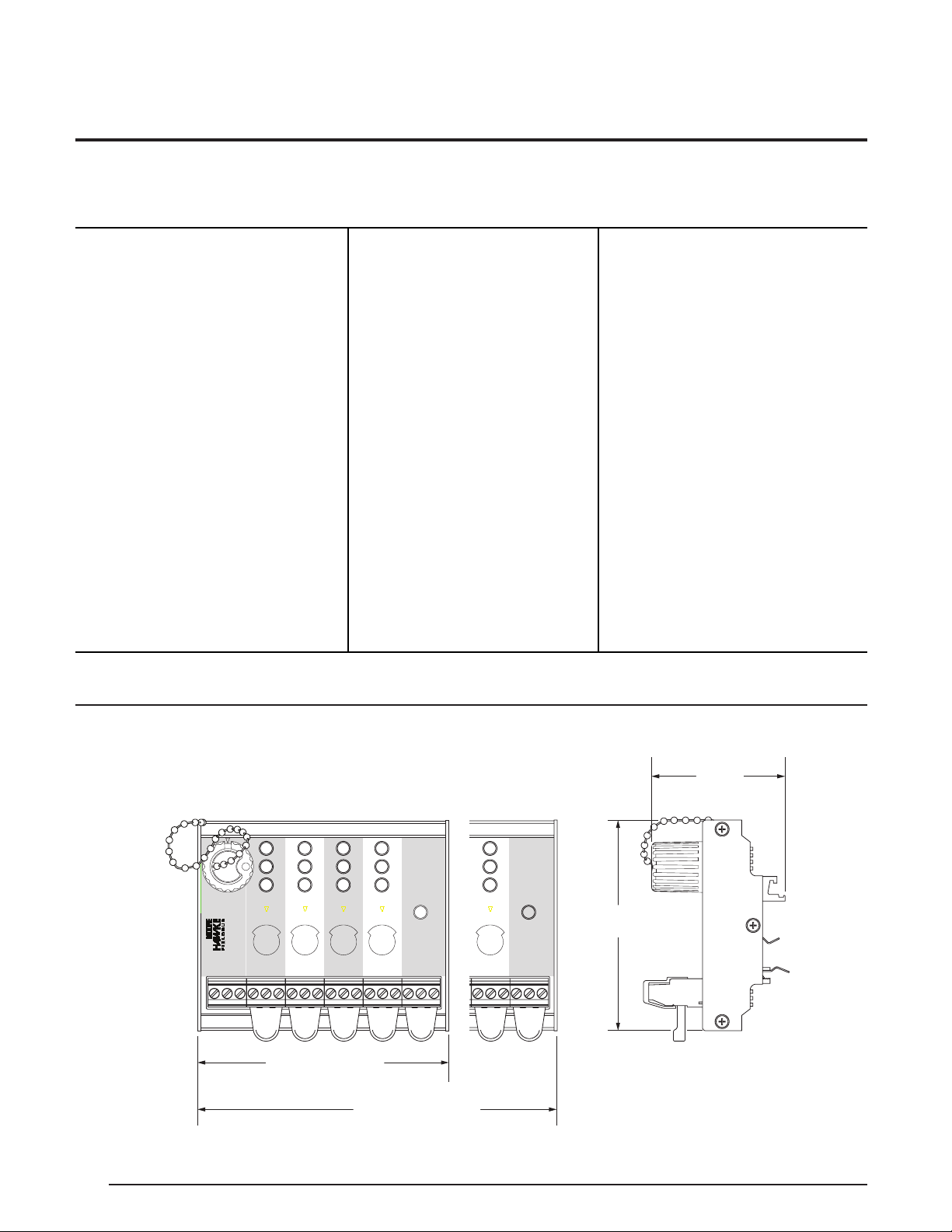

Figure 2. GRP (Glass Reinforced Polyester) Enclosure Installation Dimensions

8-Spur Model

4-Spur Model

OUT

IN

1234

250mm

(9.85 in)

200mm

(7.87 in)

120mm

(4.72 in)

255mm

(10.04 in)

235mm

(9.25 in)

OUT

IN

1234

5678

255mm

(10.04 in)

235mm

(9.25 in)

250mm

(9.85 in)

200mm

(7.87 in)

120mm

(4.72 in)

Shows TG338-B-*

Fitted with M20 glands

(Hawke International 501/UNIV/453)

5

Page 6

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

KEY PARK

FAULT

NORMAL

DEENERGISED

ACTIVE AUTO

TERMINATOR

+

_

S

+

_

S

+

_

S

+

_

S

+

_

S

+

_

S

SPUR 1 SPUR 2 SPUR 4SPUR 3

Device

Exd

Spur Wiring

120m maximum

TRUNK

IN

TRUNK

OUT

EEx me

IIC

T5

Exe

Enclosure

Exd/e

Cable Glands

Key

*

mounting feet (where supplied), in a location where

the risk of external mechanical damage is minimized.

Cable type and cable glands should be selected in

accordance with the intended Zone of installation.

Cables should be brought to the device coupler in

such a way as to prevent external water from running

into the cable entry position. For cables coming

vertically down to a device coupler, it is good practice

to continue down past the device coupler and return

upwards to the cable entry position. All cables should

be supported within 250mm (9.84 in) of the cable

entry position by a cable tray or other support. This is

particularly important with armored cable.

Once the installation and wiring has been completed,

the terminal covers and shrouds (if removed) must be

replaced and the enclosure should be properly closed

and secured.

LEDs indicate the status of each spur as either

“Normal” (GREEN), “Fault” (RED) or “De-Energized”

(YELLOW). “Normal” shows that the spur has voltage

for device operation and that spur current is within

limits. “Fault” indicates that the short circuit protection

has been activated for that spur.

WARNING:

No access is permitted to TRUNK IN

or TRUNK OUT terminals while the

segment is powered.

Use of the DISCONN Key to physically de-energize an

individual spur, allows wiring activity without affecting

other devices on the segment, even in the hazardous

area. The “De-Energized” (YELLOW) LED can only be

activated if the DISCONN Key interlock has operated

correctly, providing a positive indication of safety for

temporary wiring access. The DISCONN Key can be

locked in position, if required. Wiring terminals have

shrouds and fillers to ensure all live parts are covered

to IP30, and these must be refitted before returning

the unit into service.

Wiring Connections

TG300 units have terminals for either four or eight

hazardous area devices, as well as TRUNK IN and

TRUNK OUT terminals. For multiple TRUNKGUARD

units, TRUNK OUT can be looped into any adjacent

TRUNK IN. Segment termination is automatically

provided by the final active TG300 unit. No additional

or external fieldbus terminator is required.

All wiring connections are made directly to Exe

terminals. Cables should be stripped to expose no

more than 8mm (0.31 in) of conductor and inserted

into bootlace ferrules for full insertion into the terminal

opening so that no conductor remains exposed.

Terminals are originally supplied fitted with non-

conducting shrouds and terminal entry fillers. These

components are designed to prevent accidental

Caution:

contact with live parts, and should be retained

for further use. Unused terminals must have the

shrouds/entry fillers restored before the unit is

*Auto-terminator function not applicable with -MT option.

6

energized in the hazardous area.

Segment connections (TRUNK IN and TRUNK OUT)

Figure 4. Typical TG300 Series Device Coupler Hook-Up

Page 7

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

may be made only while the trunk is de-energized

or under normal Zone 1 working practices (typically,

under local supervision by gas detectors, etc). Spur

connections can be made while the TG300 unit is

energized only if the DISCONN Key is activated

and only the YELLOW LED is ON for that spur.

Alternatively, the whole segment should be deenergized.

Recommended Ground Wiring Practices

Moore Industries recommends the following ground

wiring practices:

• Any MooreHawke product in a metal case or

housing should be grounded.

If the GREEN LED is ON at the same time as the

YELLOW LED is ON, the segment has not been

de-energized and no wiring work is permitted

without removing power to that segment. If the RED

LED is ON, then follow the steps in the Testing and

Troubleshooting section.

Field devices should be certified/approved for use

in hazardous areas (e.g. EEx d in Zone 1) and

are typically connected using armored, braided or

toughened-sheath cabling. MooreHawke cable glands

are EEx d and EEx e approved, but need to be sized

for the appropriate armored or toughened cable.

Earth continuity plates are provided, bonded to an

external earth stud.

DISCONN Key

The DISCONN Key contains the magnet used

to operate the magnetic interlock which permits

individual fieldbus devices to be de-energized and

worked on without de-powering the entire segment.

You must have the DISCONN Key fully inserted into

the spur receptacle for the spur to be de-energized.

• The protective earth conductor must be

connected to a system safety earth ground

before making any other connections.

• The maximum length of unshielded input and

output signal wiring should be 2 inches.

• Some local electrical codes or facility

practices may require the Shield to be

connected to Ground at more than one

location. Follow proper local guidelines.

Fieldbus segment cable Shields for spurs and

trunks are gathered together in the device coupler

and then wired through the trunk cable to the next

device coupler and eventually to the fieldbus power

conditioner. Single point Grounding is recommended

for segment shields. Grounding of the segment shield

usually occurs at the power conditioner.

7

Page 8

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

CE Conformity

Then

If

Check polarity of TRUNK IN

Check that voltage at TRUNK IN is >10V

Check for short circuits in the trunk cable

Check that the segment power supply is operating correctly

If

Then

Disconnect that individual spur using DISCONN key

Check for a short circuit on that spur cable

Check for a core-to-shield fault on that spur cable

Locate and repair any spur fault before reconnecting that spur

All LEDs are OFF

Any red LED is

ON

Installation of any Moore Hawke products that

carry CE marking must adhere to the guidelines in

Recommended Ground Wiring Practices section in

order to meet the EN 61326 requirements set forth in

applicable EMC directive.

ATEX Installation Drawing

The installation diagrams located in the back of this

manual must be used to augment the installation

instructions described earlier in this manual for units

that are to operate per ATEX requirements.

Testing and Troubleshooting

Testing of the TG300 series should only be performed

in the safe area. Refer to Table 1 regarding LED

indications of fault conditions.

In the safe area, the following tests may be applied:

1. Apply fieldbus power supply of 10-30Vdc

to TRUNK-IN with no other trunk or spur wiring

connected.

Normal indications include:

GREEN LEDs: ON

YELLOW LEDs: OFF

RED LEDs: OFF

Active Auto Terminator LED: ON*

2. Insert DISCONN Key in to each spur one at a

time, switch key position and check that the YELLOW

LED turns ON, and the GREEN LED turns off.

Remove DISCONN Key and place in Key Park.

3. Check the Auto-Terminator* by putting a load

(1kohm, minimum) across the TRUNK OUT terminals.

The YELLOW LED should turn OFF.

Table 1. LED Indications

8

*Auto-terminator function not applicable with -MT option.

Caution:

Do not short any terminals if power conditioner output

can be more than 800mA.

Page 9

TRUNKGUARD™ Series Fieldbus Device Couplers

(Zone 1 Locations)

TG300

Operation

Each spur has three LEDs indicating the following

states: Normal, Fault and De-Energized.

During normal operation, the GREEN LEDs should be

ON for all spur connections.

If any RED LED(s) are ON, the affected spur(s) have

fault(s) in external wiring or field device(s). Please

refer to the Testing and Troubleshooting section..

Maintenance

The TG300 series contain no user serviceable parts.

Non-functioning units should be returned to Moore

Industries for replacement or repair.

WARNING:

Substitution of components may impair

the device coupler, wiring and field device

suitability for hazardous area applications.

Use the DISCONN Key to de-energize that spur,

remove the wiring and then re-energize it by removing

the DISCONN Key. This spur now has no device

connected, and the GREEN LED should turn ON with

the RED LED turning OFF. Use this to confirm a fault

in the spur wiring or field device.

Segment termination is automatically provided by

the last TG300 unit connected in the segment, and

operation is indicated by a YELLOW LED labeled

Active Auto Terminator*.

Note:

When returning non-functioning units only

the DIN-Rail mounted electronics should be

returned. It is normally prudent to retain the

enclosure, glands, and connectors with their

terminals attached when a device coupler is

changed out in the field.

TG300 enclosures have weatherproof seals on

enclosure lids and on cable glands; these should be

periodically inspected to verify correct operation. Any

significant water entry should be investigated and

corrected in order to prevent malfunction.

In high humidity environments, it may be appropriate

to have enclosure breathers fitted so that internal

condensation does not lead to equipment malfunction.

Customer Support

If service assistance is ever required for an instrument

in your application, refer to the back cover of this

manual for the telephone numbers to MooreHawke

Customer Service Department.

If possible, make a note of the model number of the

unit before calling. For fastest assistance, have the

following available: serial number, job number or

purchase order number.

*Auto-terminator function not applicable with -MT option.

9

Page 10

Page 11

RETURN PROCEDURES

• www.miinet.com

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

China • sales@mooreind.sh.cn

Tel: 86-21-62491499 • FAX: 86-21-62490635

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information

is needed. The repaired equipment, or its replacement, will be returned to you in accordance

with the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY

WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY

OR OF FITNESS FOR A PARTICULAR PURPOSE) WITH RESPECT TO

ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY

DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING

OR TRADE USAGE, AND ANY BUYER OF GOODS OR SERVICES FROM

THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES

IMPLIED BY CUSTOM OR USAGE IN THE TRADE OF THE BUYER AND

OF THE COMPANY, AND THAT ANY PRIOR DEALINGS OF THE BUYER

WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS

THE GOODS OR SERVICES IN ANY WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY

AGREES WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE

REMEDIES FOR BREACH OF ANY WARRANTY CONCERNING THE

GOODS OR SERVICES SHALL BE FOR THE COMPANY, AT ITS OPTION,

TO REPAIR OR REPLACE THE GOODS OR SERVICES OR REFUND THE

PURCHASE PRICE. THE COMPANY SHALL IN NO EVENT BE LIABLE

FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES EVEN IF THE

COMPANY FAILS IN ANY ATTEMPT TO REMEDY DEFECTS IN THE GOODS

OR SERVICES , BUT IN SUCH CASE THE BUYER SHALL BE ENTITLED

TO NO MORE THAN A REFUND OF ALL MONIES PAID TO THE COMPANY

BY THE BUYER FOR PURCHASE OF THE GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY

BY THE COMPANY SHALL BE BARRED UNLESS THE COMPANY

RECEIVES FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED

DEFECT OR BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE

ON WHICH THE BUYER COULD REASONABLY HAVE DISCOVERED

THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE

BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER

ANY LATER THAN TWELVE MONTHS FROM THE EARLIEST DATE ON

WHICH THE BUYER COULD REASONABLY HAVE DISCOVERED THE

ALLEGED DEFECT OR BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries (“The Company”)

will at its option replace, repair or refund the purchase price for any of its

manufactured products found, upon return to the Company (transportation

charges prepaid and otherwise in accordance with the return procedures

established by The Company), to be defective in material or workmanship.

This policy extends to the original Buyer only and not to Buyer’s customers

or the users of Buyer’s products, unless Buyer is an engineering contractor

in which case the policy shall extend to Buyer’s immediate customer only.

This policy shall not apply if the product has been subject to alteration,

misuse, accident, neglect or improper application, installation, or operation.

THE COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

© 2013 Moore Industries-International, Inc.

Specifications and Information subject to change without notice.

Loading...

Loading...