Page 1

May 2016

221-703-00 E

240 Milliamp

DIN-style Power Supply

DPS

240 Milliamp

DIN-style Power Supply

DPS

Page 2

Table of Contents

Introduction 1

Description 1

Calibration 3

Installation 5

Troubleshooting 7

HR.

DELIVERY

48

United States/Canada

TOLL FREE

1-800-999-2900

United Kingdom

FREE PHONE

0800 525107

Australia

TOLL FREE

008 251928

Ask for the STAR Center

16650 Schoenborn Street

Sepulveda, California 91343, U.S.A.

Tel: (818) 894-7111 • Tlx: 65-1322

FAX: (818) 891-3297

CONNECT (MacNet): MIISEPULVEDA

18 Royce Road, Crawley

W. Sussex RH10-2NX, United Kingdom

Tel: 0293 514488 • Tlx: 87667

FAX: 0293 36852

3/18 Resolution Drive, Caringbah

New South Wales 2229, Australia

Tel: (02) 525-9177 • Tlx: 790-75914

FAX: (02) 525-7296

Moore Industries’ STAR Center has a

wide variety of quality instrumentation

in stock and ready to ship.

• Signal Transmitters

• Temperature Transmitters

• P/I and I/P Converters

• Isolators and Converters

• Indicators and Displays

• Alarm Trips

• Integrators and Totalizers

• Power Transducers

• Instrument Power Supplies

• Racks, Rails and Enclosures

Most instruments can be customized

to meet your needs. Even then, you’ll

never have to wait more than a few days.

Moore Industries

CENTER

* Support, Technical Assistance, and Repair (our Quick-Ship Facility)

*

Page 3

DPS

Introduction

The DPS 240 is Moore Industries’ 240 milliamp (mA)

DIN-style Power Supply. It is a highly accurate, adjustable unit, most often used to power 2-wire transmitters. It is also ideal for use with data

communications

modules like Moore Industries’ Link Converter Module

(LCM), or Redundant Link Module (RLM).

Unit features include continuous short circuit and

short-term overload protection, input/output isolation,

and a derated circuit design for added dependability.

This manual contains the description, specifications,

calibration information, and installation procedures for

the DPS 240.

Description

The DPS 240 is a compact unit; particularly wellsuited for use in industrial environments where available installation space is at a premium. It is enclosed

in a standard, DIN-style, aluminum housing designed to be installed on a standard “G-rail” (not included). This rail can then be mounted on a wall, in a

rack, or in a NEMA enclosure. Each DPS 240 is capable of powering twelve 4-20 mA loops.

The front panel of the the unit features potentiometers

for adjustment of voltage and current limit, test jacks

for auxiliary connection of calibration equipment, and

a red LED indicator that lights when dc output is

present.

The terminal blocks, three for input and eight for output, can be set into either the front or rear panel, according to customer specification.

The unit is available in 24- or 42-Vdc output configurations. A potentiometer on the front panel allows for

adjustment of the output ±5.0%.

Input voltage can also be specified by the customer,

and is available set to 117, 220, or 240 Vac, 50/60

Hz.

The equipment specifications for the DPS 240

are listed in table 1.

Serial Number. A complete, serial-number-depen-

dent history is kept on every unit that Moore Industries sells and services. For service information,

provide the factory with the serial number of the unit

that requires

attention. The serial number is stamped on a label,

and affixed to the side panel.

Model Number. Moore Industries’ model numbers

identify the type of instrument, functional characteristics, any options ordered, and the housing type. The

model number reflects the way the unit was configured when it originally left the factory. It is all that is

needed to identify the operational characteristics of

the power supply. The number appears on the same

label as the serial number.

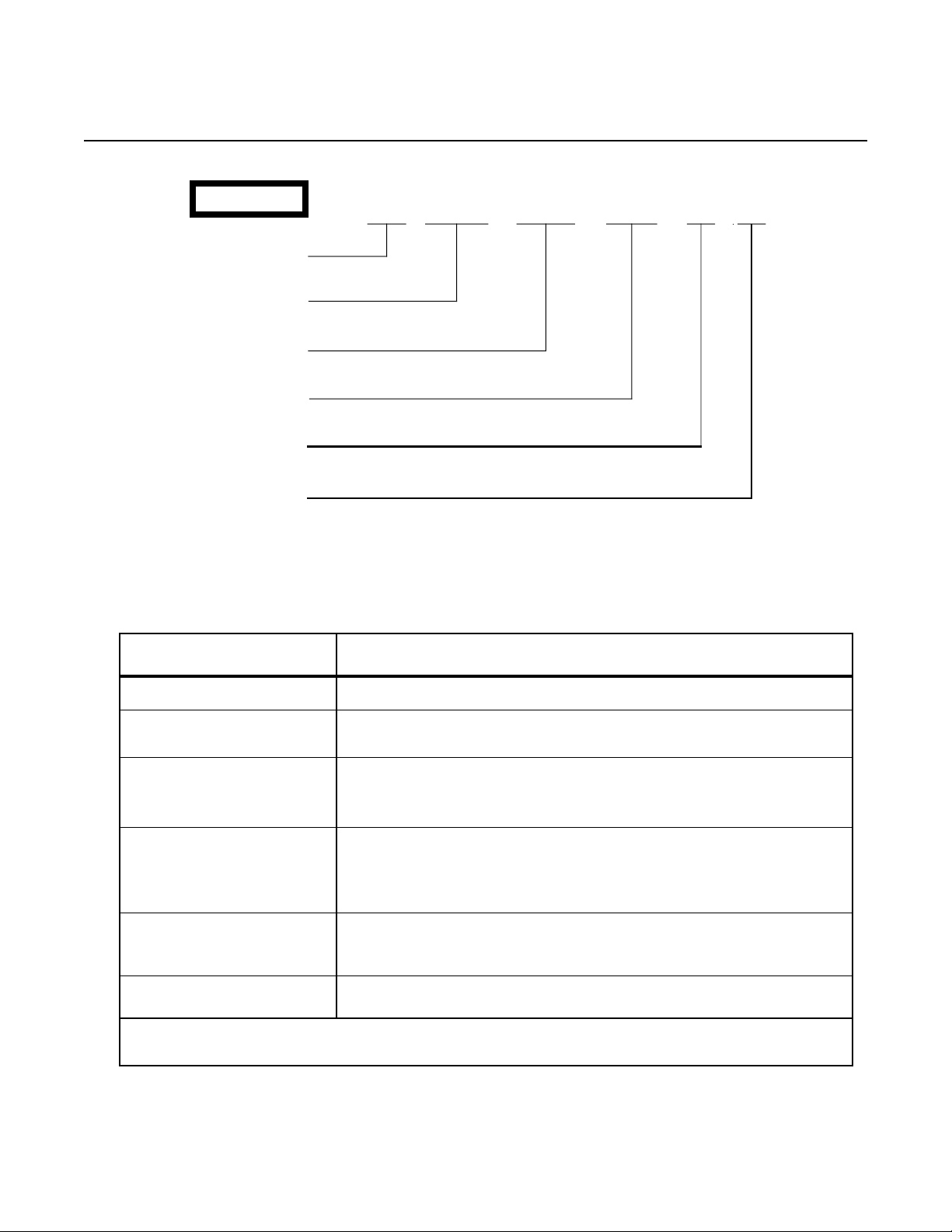

The following example outlines the significance of

each field in a typical DPS 240 model number.

Page 1

Page 4

DPS

EXAMPLE

Unit Type

OutPut Voltage

Current

Power

Options(s)

Housing

DPS / 24VDC / 240 MA / 117AC/ -FA / [DIN]

Table 1. DPS 240 Equipment Specifications

Characteristics

Input Power

Input Frequency

Output

Performance Efficiency

Environmental Conditions

Weight

NOTE: Refer to the Installation Section of this manual for unit dimensions.

Specifications

117, 220, or 240 Vac (factory-configured according to customer requirement)

48 to 62 Hz

Supply Type: Linear

24 or 42 Vdc, 240 mA (factory-configured according to customer requirement),

adjustable ±5.0% with front panel potentiometers

Regulation: 0.5% maximum, low line to high line

70% typical, rated at full load

Load: 1.0% maximum, no load to full load

Ripple: 50 mV peak-to-peak, maximum

Isolation: Input/Output/Unit Housing = 1100 Vrms

Ambient Temperature Operating Range: 0 to +70 °C (+32 to +158 °F)

Effect on Unit: ±0.03% per °C over the range specified

765 grams (1 pound, 11 ounces)

Page 2

Page 5

DPS

Calibration

Each power supply is calibrated and checked at the

factory to ensure proper performance before shipping.

However, output values for each unit should be

checked by the user on-site before the equipment is

placed into service.

Indicators

There is a red LED indicator on the front panel of the

DPS 240, which lights when the unit is producing dc

output. The indicator, labeled “OUTPUT ON”, goes

out if a short circuit, overload, or any other unacceptable condition occurs during operation.

Controls

The unit’s front panel has two multiturn potentiometers labeled “VOLTAGE ADJUST” and “CURRENT

LIMIT”. Voltage adjust allows the user to set dc output to ±5.0% of the rated value. Using the current

limit potentiometer, the user can calibrate the unit so

that the output voltage stays within the specified

range, even when input varies ±10%. This protects

the DPS 240 from possible damage due to overheating.

Refer to table 1 for the equipment specifications of

the DPS 240.

Calibration Equipment

Table 2 lists the equipment required to calibrate the

DPS 240. This equipment must be provided by the

user.

Equipment

Adjustable ac Power Source

Voltmeter

Milliammeter

Variable Power Resistor

Screwdriver, slotted

Table 2. Calibration Equipment

Description

Variac or equivalent; capable of 105-264 Vac output

Accurate to 0.01 millivolt

Accurate to 1.0 milliamp

Powerstat, or equivalent; capable of output load of 175ý

Head measuring less than 2.54 mm (0.1 inch) in width

Page 3

Page 6

DPS

Calibration Setup

Calibration should be performed in a laboratory setting. This will allow the user to control input variables,

and to monitor changes in the output more easily.

Figure 1 depicts the correct calibration setup for the

DPS 240.

Before beginning to the calibration itself, connect the

unit as shown, and set the load to 100 ohms for

24Vdc units, or 175 ohms for 42 Vdc units.

ADJUSTABLE

AC POWER

SOURCE

GND AC ACC

Apply the appropriate ac power to the setup (117, 220,

or 240 Vac). The specifications table and the model

number printed on the serial tag list the acceptable

input power levels for the unit being calibrated.

When power is applied, the front panel “OUTPUT ON”

LED will light, indicating the presence of dc output.

+

VOLTMETER

–

+

MILLIAMMETER

–

GND AC ACC + DC OUT – DC OUT

POWER

DPS

VOLTAGE ADJUST

CURRENT LIMIT

OUTPUT ON

+T

T

SUPPLY

LOAD

Figure 1. DPS 240 Calibration Setup

Page 4

Page 7

DPS

Calibration Procedure

To calibrate the DPS 240:

1. Turn CURRENT LIMIT potentiometer fully clockwise.

2. Vary setting of VOLTAGE ADJUST potentiometer

from fully clockwise to fully counterclockwise.

Note output reading at each extreme. Available

voltage range will equal ±5.0% of unit’s rated output voltage (23.8 to 25.2 Vdc for 24-Vdc models,

or 39.9 to 44.1 Vdc for 42-Vdc models).

3. Use VOLTAGE ADJUST potentiometer to set output voltage to maximum specified for the unit being calibrated, ±10 millivolts (24, or 42 Vdc, as

appropriate).

4. Reset load to 91ý, or until the milliammeter reads

264 mA (+10% of the maximum rated current output for the DPS 240).

5. Turn CURRENT LIMIT potentiometer counterclockwise until output voltage drops to 23.88 Vdc

for 24 Vdc units, or 41.79 Vdc for 42 Vdc units

(99.5% of appropriate nominal output level ).

6. Reset load so that current output is 240 mA.

7. Short the output.

Red “OUTPUT ON” LED on unit’s front panel will

go out.

8. Hold short circuit in place for 1 minute, then remove it. Observe that the LED turns on, and that

output voltage quickly returns to rated nominal,

±10 mV (23.88 Vdc for 24-Vdc units, or 41.79 Vdc

for 42-Vdc units).

9. Remove load. Observe that output voltage drop is

less than 100 mV.

12. Use VOLTAGE ADJUST potentiometer to select

output voltage desired. Disconnect voltmeter from

terminal blocks, and re-connect leads to “+T” and

“–T” test jacks on front panel of DPS 240.

13. Verify that reading at these test jacks is the same

as for terminal block connections.

14. Remove ac input, and dismantle test setup.

The unit is now calibrated and ready to be placed into

service.

Installation

Installing the DPS 240 consists of physically mounting

the device, and then completing the necessary electrical connections.

Mounting

Although the DPS 240 is designed to employ convection cooling, it is advised to mount it on a surface

made of material that can serve as a heat sink. Care

should also be taken to locate the DPS 240 in an area

that is protected from dust, moisture, and corrosive

atmospheres.

Figure 2 shows the outline dimensions of the DPS

240.

To mount the unit, the DIN rail should be positioned so

that the smaller of its two flanges is toward the top

(see figure 2).

Tilt the unit slightly backward, and insert the spring

flanges on the back panel under the top flange of the

DIN rail. Push inward and down until the DPS 240

snaps into place.

10. Re-apply load. Set it so that current output is 240

mA. Note output voltage reading at this setting.

11. Vary input voltage ±10%. Observe that voltage

varies less than 0.5%, low-line to high-line.

To remove the unit, pull outward (from the bottom)

and up.

Page 5

Page 8

DPS

66mm

(2.59 in)

80mm

(3.15 in)

OPTIONAL

ENGRAVED TAG

FOR CUSTOMER I.D.

Figure 2. Outline Dimensions for the DPS 240

Electrical Connections

Figure 3 shows the front panel of the DPS 240 in detail, and depicts its electrical connection in a typical

application.

For information on the Moore Industries products that

typically work with the DPS 240, contact your local

sales representative, or Moore Industries’ Customer

Service Department.

94mm

(3.89 in)

9mm

(0.35 in)

SPRING

FLANGE

93mm

(3.65 in)

103mm

(4.05 in)

32mm

(1.28 in)

TS-32

G-RAIL

15mm

(0.59 in)

strip 5/16 to 3/8 inches of the insulation from the end

of the wire.

To connect the DPS 240, loosen the clamping screw

of the appropriate terminal, and insert the uninsulated

end of the wire into the socket. Tighten the screw

while holding the wire in place. Finally, tag the wire

for identification. Once supplied with the appropriate

ac power, the DPS 240 will begin to operate.

The use of 14-22 AWG insulated copper wire is recommended in connecting the DPS 240 terminals.

To avoid transients and stray pick-ups, it is recommended that twisted conductors be used when running close to other services. To ensure good contact,

Page 6

Page 9

DPS

AC POWRER

SOURCE

117, 220,

OR

240 VAC

GND AC ACC

DPS

VOLTAGE ADJUST

CURRENT LIMIT

OUTPUT ON

T

+

T

+ DC OUT

– DC OUT

POWER

SUPPLY

+

2-WIRE TRANSMITTER

–

+

CURRENT-DRIVEN

DEVICE

–

GND AC ACC + DC OUT – DC OUT

Figure 3. Typical Connection of the DPS 240

Troubleshooting

If a problem develops with the performance of the

DPS 240, use the front panel test jacks to verify the

proper output voltage. The probes should be 2.03 mm

(0.08 in) in diameter, and 12.7 mm (0.50 in) long,

maximum.

Connect a voltmeter to the appropriate test jacks, and

re-adjust the output using the two adjustment potentiometers, VOLTAGE ADJUST and CURRENT LIMIT.

If problems continue, remove and recalibrate the

unit. Refer to the Calibration section of this manual.

Any units found to be performing below specifications should be immediately returned to the factory

for service. Instructions for return of the equipment

are on the back cover of this manual. Customers

may also contact Moore Industries’ Customer Service Department at 1-800-999-2900 for assistance.

Page 7

Page 10

NO TES

Page 11

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.© 2005 Moore Industries-International, Inc.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...