Page 1

May 2016

DCA

Direct Current Alarm

USER’S MANUAL

No. 192-701-00 K

© 2012 by Moore Industries-International, Inc.

Page 2

Table of Contents

Introduction 1

Description 1

Calibration 4

Installation 19

Maintenance 22

HR.

DELIVERY

48

United States/Canada

TOLL FREE

1-800-999-2900

United Kingdom

FREE PHONE

0800 525107

Australia

TOLL FREE

008 251928

Ask for the STAR Center

16650 Schoenborn Street

Sepulveda, California 91343, U.S.A.

Tel: (818) 894-7111 • Tlx: 65-1322

FAX: (818) 891-2816

CONNECT (MacNet): MIISEPULVEDA

1 Lloyds Court, Manor Royal, Crawley

W. Sussex RH10-2QU, United Kingdom

Tel: 0293 514488 • Tlx: 87667

FAX: 0293 536852

3/18 Resolution Drive, Caringbah

New South Wales 2229, Australia

Tel: (02) 525-9177 • Tlx: 790-75914

FAX: (02) 525-7296

Moore Industries’ STAR Center has a

wide variety of quality instrumentation

in stock and ready to ship.

• Signal Transmitters

• Temperature Transmitters

• P/I and I/P Converters

• Isolators and Converters

• Indicators and Displays

• Alarm Trips

• Integrators and Totalizers

• Power Transducers

• Instrument Power Supplies

• Racks, Rails and Enclosures

Most instruments can be customized

to meet your needs. Even then, you’ll

never have to wait more than a few days.

Moore Industries

CENTER

* Support, Technical Assistance, and Repair (our Quick-Ship Facility)

*

Page 3

Page 1

DCA

Introduction

Moore Industries’ Direct Current Alarm (DCA) is a

highly versatile, fully adjustable device that is factoryconfigured to accept either current or voltage input.

The unit’s internal relays are tripped when input

deviates from a customer-set “safe” range defined by

adjustable trip points. The DCA is ideal for use in an

alarm system, where it may be used to activate a

warning device, or to drive an analog indicator.

This manual provides a brief description of the DCA,

including its physical characteristics and options; a

table of performance and operating specifications; a

set of procedures for calibrating the unit; instructions

for installation, including physical mounting and

electrical connections; and finally, information on

basic maintenance and troubleshooting.

Notes, Cautions, and Warnings are included as a

means of identifying those practices that may present

unnecessary inconveniences (notes), result in damage to the unit (cautions), or cause injury (warnings).

bination of single, dual, high, low, fail-safe, or non-failsafe alarm relays. The following paragraphs describe

each of these configurations.

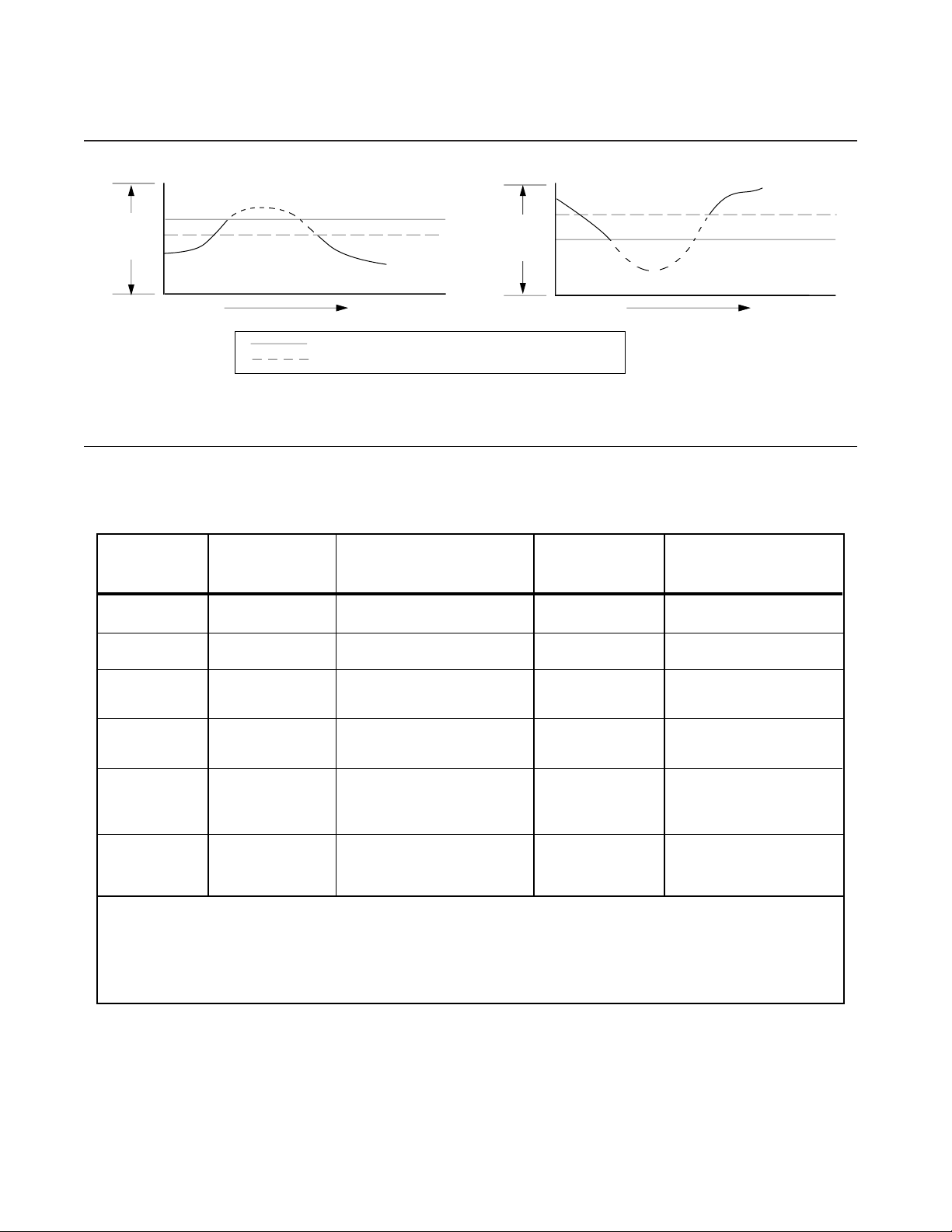

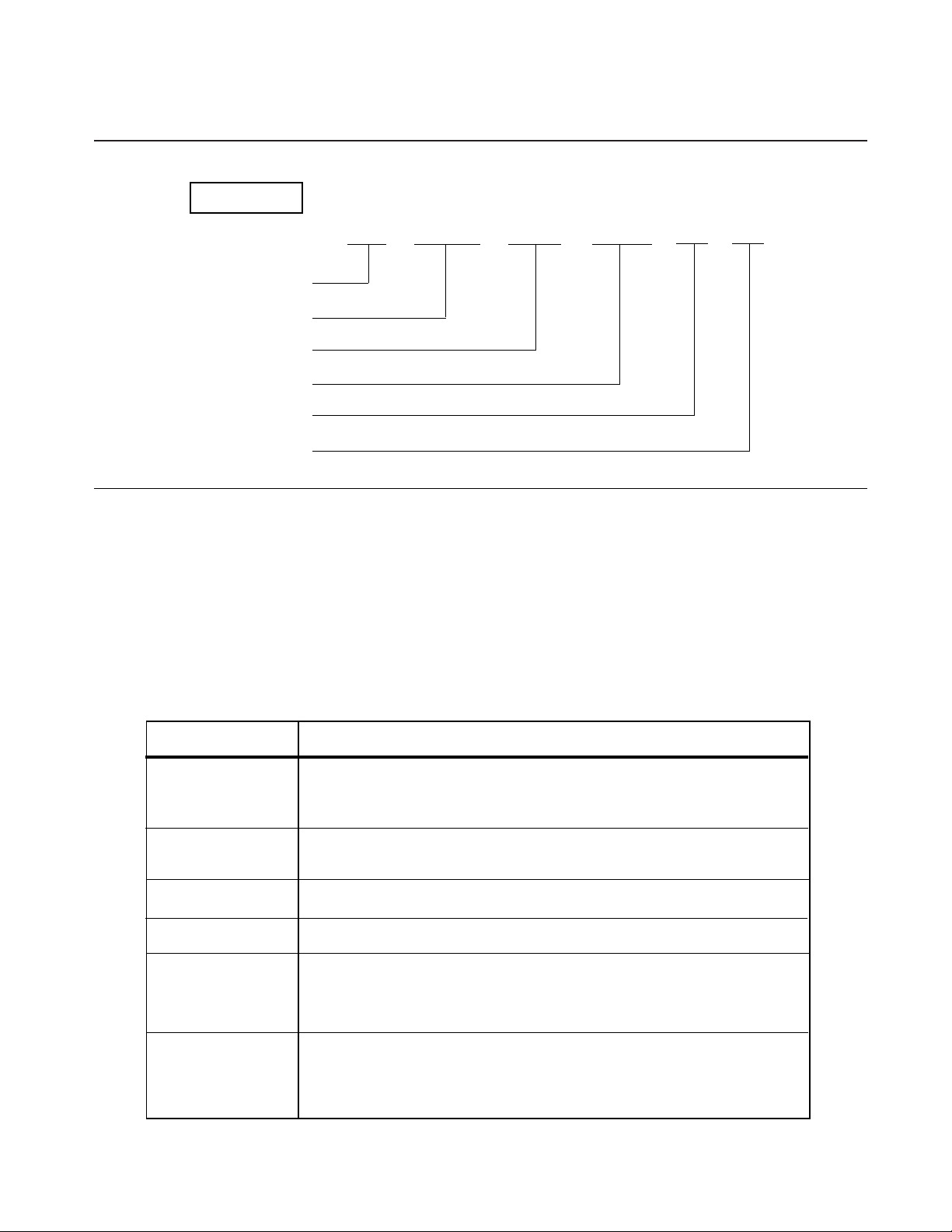

High Alarm/Low Alarm. A DCA configured as a high

alarm is tripped when the input increases, and

reaches a customer-set trip point. A low alarm unit is

tripped by a decreasing input that drops below a

customer-set trip point.

Figure 1 illustrates the concept.

Fail-safe/Non-fail-safe. A fail-safe unit’s relay is

energized when input is within a “safe” range, i.e. is

normal, or not in an alarm condition. When the input

goes into an alarm condition, reaching a trip point or

losing power, the relay of a fail-safe DCA is deenergized.

Conversely, a non-fail-safe unit’s relay is de-energized

when input is within the customer-specified “safe”

range, and is energized when the input reaches the

trip point setting.

Figure 1 also depicts the action of fail-safe relays.

Description

The DCA comes in either Moore Industries’ standard

(STD) or plug-in card (PC) housing.

The STD unit can be used with a variety of mounting

options, including those suitable for use with explosion-proof and NEMA enclosures.

PC-style DCA’s are designed for use with Moore

Industries’ multi-position card racks; the surface

mounted SMR, or the rack mounted RMR.

Both STD and PC DCA’s are available with either

single or dual alarm configurations. The relays used

are single-pole/double-throw, form C. There are a

number of input ranges and alternate relay ratings

available.

Operationally, the unit can be ordered with any com-

Controls and Indicators

Every type and configuration of DCA comes with

potentiometers (pots) to set the alarm trip points of

each installed relay. Additional pots for controlling

unit dead band are available as an option, and precision ten-turn vernier scales can be used instead of

the standard pots.

Trip point pots afford full 0- to 100-percent adjustability over the unit’s specified span.

Each installed relay is wired to a front panel LED,

which lights when the relay is energized. Depending

upon the type of relay ordered, i.e. fail-safe/non-failsafe, a lit LED can indicate either an “alarm” or a “nonalarm” input condition.

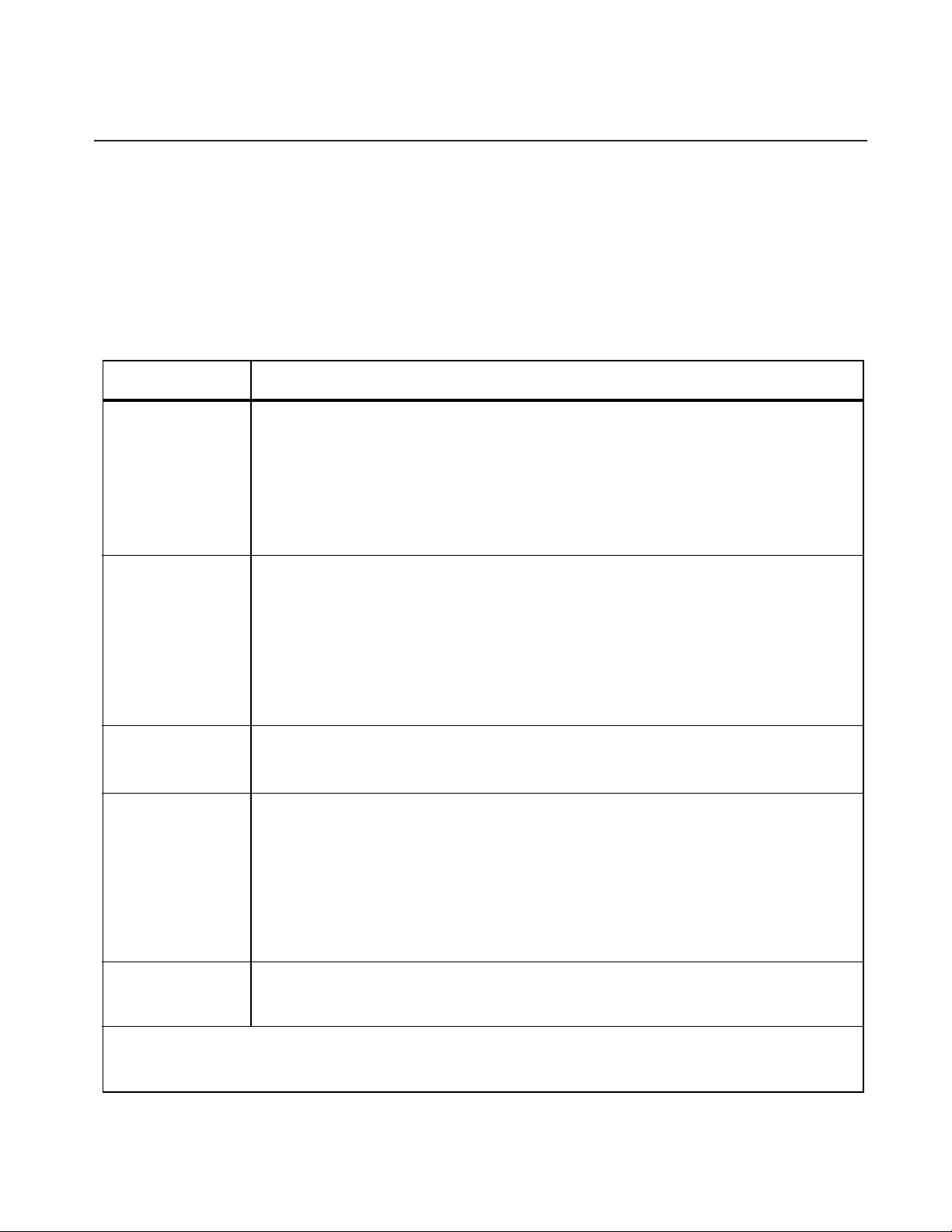

Table 1 summarizes the alarm type/LED status

options for the available types of DCA.

Page 4

Page 2

DCA

100 %

ANALOG

INPUT

VALUE

0 %

Model Number

Designator

HIGH-ALA RM DCA

TIME

100 %

TRIP POINT

DEAD BAND

RESET

FAIL-SAFE R ELAY ENERGIZED , LED ON

FAIL-SAFE R ELAY DE-ENERGIZED, LED OFF

ANALOG

INPUT

VALUE

0 %

LOW-ALARM DCA

RESET

DEAD BAND

TRIP POINT

TIME

Figure 1. High - and Low-alarm Relay Configurations

Table 1. DCA Alarm Types

This Unit is...

S Single Alarm - - Only one relay installed

This Unit signals an

“Alarm” condition when...

Its LED will be...

Relay(s)

D Dual Alarm - - Two relays are installed

H1 High Fail-Safe

H2 High NON-Fail-Safe

L1 Low Fail-Safe

L2 Low NON-Fail-Safe

Input increases, and exceeds

Trip Point. (See Note 2).

Input increases, and exceeds

Trip Point. (See Note 2).

Input decreases, and drops

below Trip Point

(See Note 2)

Input decreases, and drops

below Trip Point

(See Note 2)

OFF in alarm

ON in Non-alarm

ON in Alarm,

OFF in Non-alarm

OFF in alarm

ON in Non-alarm

ON in Alarm,

OFF in Non-alarm

DE-energized in alarm

Energized in Non-alarm

Energized in Alarm,

DE-energized in Non-alarm

DE-energized in alarm

Energized in Non-alarm

Energized in Alarm,

DE-energized in Non-alarm

NOTES: 1. Older DCA’s may use X1 for H1, X2 for H2, X3 for L1, and X4 for L2.

2. The “UPPER” and “LOWER” labeling on the DCA front panel is for reference only.

Configurations where “LOWER” terminals and pots pertain to the unit’s high alarm, for

example, are quite possible.

3. Relays in fail-safe alarms are DE-energized in the event of power loss to the unit.

Page 5

Page 3

DCA

Table 2 lists the performance and operational specifications for the unit.

Table 2. DCA Performance and Operational Specifications

Characteristic

Input

Output

Specifications

Current: 1-5 mA @ 200Ω nominal input impedance

4-20 mA @ 50Ω nominal input impedance

10-50 mA @ 20Ω nominal input impedance

Selectable Current (SC) comes with three load resistors for selecting1-5, 4-20, or

10-50 mA (See Note 1)

Voltage: 0.25-1.25 V @ 1MΩ, minimum (See Note 2)

1-5 V @ 1MΩ, minimum

Consult factory for dual input and special range options.

Factory-configured with one (Single DCA) or two (Dual DCA) single pole/double throw

(SPDT), form C, mechanical relays rated for 5 A @ 117 Vac non-inductive, or 28 Vdc.

User selects Normally Open (NO), Normally Closed (NC), or any combination of NO/NC

configurations during installation. Fail-safe/Non-fail-safe configuration factory-set. Refer to

table 1 for available combinations.

Options

Each DCA is configured according to customer

requirements. The paragraphs on the following pages

highlight some of the options available.

Power

Performance

Environmental

Ratings

NOTES: 1. One of the available resistors MUST be installed.

2. Requires extra engineering when used with some option combinations.

3. DPDT not available with some enclosures and option combinations.

Double pole/double throw (DPDT), form 2C and 7.5 A relays available as options.

(See Note 3)

24 or 45 Vdc ±10%, 5 watts nominal

100, 117, 200, 220, or 240 Vac ±10%, 50/60 Hz

AC power inputs not available with PC-style housing

Repeatability: Trip point settings repeat within ±0.1% of span.

Dead Band: 1% of span, standard. Adjustable Dead Band Option available.

Alarm Response: 50 milliseconds for step change of 1% of span.

Line Voltage Effect: ±0.005% per 1% line voltage change (ac or dc).

Isolation: No galvanic path between input, output, and power.

Accuracy: Front panel potentiometers capable of setting trip points from 0 to 100% of

span. Lockable, scaled vernier dials optional.

Effect of Ambient Temperature on Performance: Less than ±0.018% per °C through the

specified range (Less than ±0.01% per °F)

Ambient Operating Temperature: –18 to 65 °C (0 to 150 °F)

Page 6

Page 4

DCA

For a complete list of available options, and for

information on other housings, mounting hardware,

and enclosures, contact your Moore Industries Sales

Representative.

AD Option —

Front panel potentiometers vary dead band 1- to 20percent of span (nominal), 1- to 50-percent of span

(AD50), or 1- to 100-percent (AD100) of span. (AD

Option not available with some option combinations).

AR Option —

factory for output delays of 1 to 5, 10, 15, 20, 25, or

30 seconds, according to customer specification.

DA Option —

condition when the difference between two inputs

exceeds adjustable percent of full span. Requires DI

Option or 2X input. (Not available with some option

combinations.)

DI Option —

to operate as two, single-alarm units. Standard DI

unit provides a high alarm for one input and a low

alarm for the other. (DI Option not available with

some option combinations).

DPDT Option —

Relays. Contact 5 amps at 28 Vdc, or 117 Vac noninductive. (DPDT Option not available with some

option combinations).

Externally-adjustable Dead Band.

Response Time Delay. Set by the

Deviation Input. Unit signals alarm

Dual Input. Configures dual-alarm DCA

Double Pole, Double Throw/Form 2C

TX Option

at 30 Vdc @ 25 mA.

7.5A Option —

UL at 7.5 amps, 28 Vdc or 120 Vac.

Model/Serial Number. Moore Industries uses a

system of unit model and serial numbers to keep

track of factory configuration and options for each

DCA shipped and serviced.

The example outlines the significance of each field of

information in a typical DCA model number. Refer to

table 1 for an explanation of the relay configuration

codes used.

If service information or assistance for a DCA is

needed, make a note of the unit’s model and serial

number before contacting Moore Industries’ Customer

Service Department. Our highly skilled technicians

will be happy to assist you.

STD units’ serial and model numbers are located on

an L-shaped metal tag at the top of the connection

terminal strips. On PC DCA’s, the numbers are

located on an adhesive label affixed to the side of the

front panel.

— Two-wire Transmitter Excitation. Rated

7.5 amp Relay(s). Rated by CSA and

Calibration

FU Option

PC-style unit. Use of the FU Option with the STD

housing requires special engineering.

HS Option

@ 117 Vac non-inductive, 2A @ 28 Vdc. Meets

requirements for installation in Class I, Division 2

locations.

MR Option —

button for single- and dual-alarm units. In place of

dead band, MR-equipped units return to normal only

when the process input returns to non-alarm state

the external reset push button is pressed.

TT Option —

multiturn potentiometers for setting and locking trip

points. Includes front panel ZERO potentiometer for

appropriate offsets.

— Power Fuse. 400 mA rated fuse on

— Hermetically Sealed Relays. Rated 1A

Manual Reset. External reset push

and

Lockable Vernier Dial. Front panel,

Every DCA shipped from the factory is manufactured

and tested according to Moore Industries’ exacting

standards for product quality. A bench check of basic

unit operations is recommended, however, in order to

identify any damage to the unit that may have occurred during shipping. This also allows the user to

effect operational adjustments to trip point settings

and unit dead band, if available.

It is recommended that the procedures in this section

be carried out at a technician’s bench or in a similar

lab environment. This is the safest means of making

adjustments to trip point values; isolated from the

intended DCA application.

The calibration of the DCA consists basically of

setting trip points and dead bands based on the

resistance across the unit contact-closure terminals

as measured by an ohmmeter. With relay contacts

closed, resistance is negligible. With relay contacts

open, resistance is infinite.

Page 7

EXAMPLE

Unit Type

Input

Relay Configuration

Power

Options(s)

Housing

Page 5

DCA

DCA / 4-20MA / DH1L1 / 117AC / -AD [STD]

Basic Calibration Setup

The equipment listed in table 3 is needed for calibrating the DCA. These items are not supplied with the

unit, but should be available in most testing labs.

Table 3. DCA Calibration Equipment

Equipment Specifications

Voltage

Voltage or

Current Source

Current Source

Power Source

Ohmmeter Accuracy of ±1%, minimum.

Screwdriver Slotted-tip with head width no greater than 2.54 mm (0.01 in).

Wire Jumpers

(required for

AR-equipped

DCA’s ONLY)

or

Calibrated, adjustable unit, capable of output at discrete levels in the

appropriate range, with the rated impedance for the unit being calibrated.

EDC Models MV105, MV155, or equivalent.

AC or dc power input appropriate for the type of DCA being calibrated.

Refer to table 2, earlier in this manual.

Temporary jumper wiring suitable for shorting AR Option diodes so that the

alarm delay may be defeated while adjusting the unit’s trip point settings.

Be sure to use calibrated test equipment when

performing the bench check and calibration of the

DCA. The use of inaccurate test equipment may

result in unreliable settings for the unit’s trip point(s),

etc.

Extender Card

(optional for use

with PC-style

DCA’s ONLY)

Moore Industries’ part number 350-513-00.

Page 8

Page 6

DCA

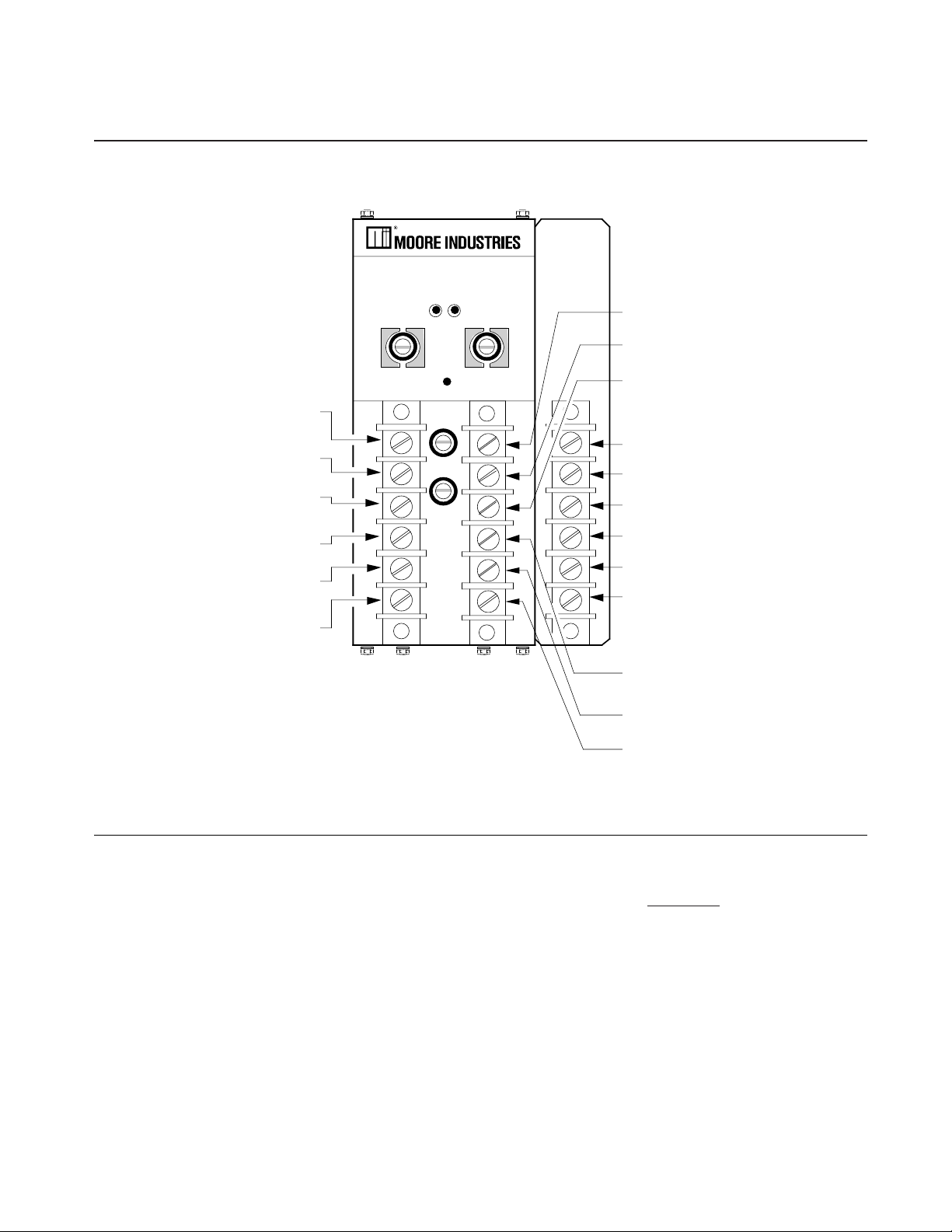

Setup for the STD DCA. Figure 2 shows the labeling

used on the front panel of the STD DCA. Figure 3

shows the terminals on a unit equipped with DPDT

relays.

CDC URRENT

DCA

UPPER RELAY NORM ALLY

OPEN — UNO

COMMON — COM

UPPER RELAY NORM ALLY

CLOSED — UNC

ALARM

UPPER LOWER

ZERO

U PPER

D EADBAN D

LOWER

To access the connection terminals for a DCA in the

basic extruded housing (STD, AB, etc.), use a screw

driver to remove the securing screw from the protective plastic cover on the unit front panel. With the

screw removed, the cover can be removed by hand,

revealing the terminals and the labels depicted in the

illustrations in this manual.

LNO —

LOW ER R ELAY N ORM ALLY OPEN

COM — COMMON

LNC —

LOWER RELAY NORMALLY CLOSED

ACC — –DC

AC — +DC

GND

NOTES: 1. Each uni t i s factor y- configured for ac or dc pow er .

2. Each unit is factor y-c onfi gur ed for specifi c cur r ent or voltage input.

Figure 2. STD DCA Terminal Locations

OPTION — +TX FOR TRANSMITTER

EXCITATION, +REF FOR D EVIATION ALARM

+IN — CURRENT OR VOLTAGE +INPUT

-IN — CURRENT OR VOLTAGE -INPUT

Page 9

UPPER RELAY #1 NOR MALLY

OPEN — UNO1

COMMON — COM

UPPER RELAY #1 NOR MALLY

CLOSED — UNC1

ACC — –DC

AC — +DC

GND

DC CURRENT

DCA

ALARM

UPPER LOWER

ZERO

U PPER

D EADBAN D

LOWER

Page 7

DCA

UN O2 — UPPER RELAY #2

NORM ALLY OPEN

COM — COMMON

UNO2 — UPPER RELAY

#2 NORMALLY CLOSED

LNO1 — LOWER RELAY #1

NORMALLY OPEN

COM — COMMON

LNC1 — LOWER RELAY #1

NORMALLY CLOSED

LNO2 — LOWER RELAY #2

NORMALLY OPEN

COM — COMMON

LNC2 — LOWER RELAY #2

NORMALLY CLOSED

OPTION — +TX FOR

TRANSMITTER EXCITATION,

+R EF FOR D EVIATION ALARM

Figure 3. STD DCA w/DPDT Option Terminal Locations

Figure 4 shows the labeling for a STD DCA equipped

with the DI Option. Note that both inputs share the “–

IN” terminal.

+IN — CURRENT

OR VOLTAGE +INPUT

-IN — CURRENT

OR VOLTAGE -INPUT

WARNING

To guard against accidental electric

shock, it is recommended that the protec-

tive plastic cover be re-installed over the

terminal strip of the STD DCA before

applying power to the calibration setup.

Page 10

Page 8

DCA

Setup for the PC DCA. There are two methods of

carrying out the calibration setup connections on the

PC DCA. Most often the unit is installed in one of

Moore Industries’ card racks, and the calibration

equipment is connected to the appropriate rack

terminal strip.

Figure 5 illustrates the PC DCA installed in the

surface mounted card rack, the SMR. Figure 6 shows

the terminal strip labeling for rack units when the DCA

is equipped with the DI Option.

As an alternative to using the card rack, individual PC

DCA’s can be checked with Moore Industries’ Process Power Supply, the PPS, equipped with its CT

Option. The CT-equipped PPS accepts the connection strip of the PC DCA in a connector built into its

side panel. The PPS front panel provides access to

terminal strips similar to those used on the card

racks.

Whether using the card rack or the PPS/CT combination, note that the DC power connections are not

made directly to the unit, but to the terminal strips of

either the card rack or the PPS. DC power is supplied

to the DCA at its pins 8 and 9

NOTE

The “UPPER” and “LOWER” labeling used

on the DCA is for reference purposes only.

The trip point pots allow for adjustments through 100percent of span. It is therefore possible for the

connections to the “LOWER” labeled alarm section to

be configured as a “high alarm”, and the “UPPER”

section to be configured as a “low alarm”.

NOTE

The LED’s DO NOT always indicate an

alarm condition; rather, they light to show

that their complimentary relay is ener-

gized. It is possible for a DCA to be

configured such that the LED’s are lit

when input is in a “non-alarm” state.

ACC — –DC

AC — +DC

GND

LNO —

LOWER RELAY NORMALLY OPEN

COM — COMMON

LNC —

LOWER RELAY NORMALLY CLOSED

+IN U P — UPPER

CURRENT/VOLTAGE +INPUT

+IN LOW — LOW ER

CURRENT/VOLTAGE +INPUT

-IN — NEGATIVE INPUT

Figure 4. STD DCA with DI Option Terminal Locations

Page 11

Page 9

DCA

-DC

+DC

GND

PC

DCA

1

INTERNAL RACK SLOT

AND CONNECTOR

15

PC DCA

COMPONENT SIDE

SMR

MOUNTING

FLANGES

NOTES :

7

LNO - LOWER RELAY NORMALLY OPEN

ONE POWER

CONNECTION

PER R ACK

ONE TER MINAL

STR IP PER

CARD POSITION

Rack is shown wi th protective cover s removed.1.

2.

Power is not appl i ed to eac h PC connector strip, but to the rack ter m i nal strip.

Power is supplied to the PC DCA at i ts pins 8 (-D C ) and 9 (+DC).

4

LNC - LOWER RELAY NORMALLY CLOSED

2

COM - COMMON

OPTION — +TX, +REF

5

3

+IN — CURRENT OR VOLTAGE + INPUT

10

-IN — CURRENT OR VOLTAGE - INPUT

UN O - UPPER RELAY NORMALLY OPEN

13

1

UNC - UPPER RELAY NORMALLY CLOSED

15

COM - COMMON

Figure 5. Terminals Labeling, the PC DCA in the SMR

Page 12

Page 10

DCA

ONE TER MINAL

STR IP PER

CARD POSITION

7

LNO - LOWER RELAY NORMALLY OPEN

4

LNC - LOWER RELAY NORMALLY CLOSED

2

COM - COMMON

5

+IN — UPPER ALARM CURENT OR VOLTAGE +INPUT

3

+IN — LOWER ALARM CURRENT OR VOLTAGE + INPUT

-IN — CURRENT OR VOLTAGE - INPUT

10

13

UN O - UPPER RELAY NORMALLY OPEN

1

UNC - UPPER RELAY NORMALLY CLOSED

15

COM - COMMON

Figure 6. PC DCA with DI Option Terminal Locations

Setup of DCA’s in Explosion-proof Enclosures.

The DCA in an explosion-proof enclosure (EX) incorporates a modification of the STD housing where

the connection terminals are replaced with pins on the

unit bottom panel. These pins are inserted in a

terminal block permanently mounted inside the base

of the explosion-proof enclosure.

To effect the calibration connections, unscrew the top

of the enclosure and pull the DCA up and out of the

enclosure base, exposing the terminal block. Figure 7

shows the block and its labeling. Figure 8 shows the

labeling used for units equipped with the DI Option.

Use the appropriate terminal locations figure to

connect the calibration equipment to the terminal

block in the enclosure base. Then re-connect the

DCA by aligning the pins on the bottom of the unit

housing with the holes in the terminal block. Press

down until the unit is seated firmly in the enclosure

base.

CAUTION

The EX DCA housing fits into the terminal

block in its correct orientation only. Note

the position of the connection “key”.

Attempting to “force” the unit in when the

pins are not aligned with the correct holes

will bend the pins.

Basic Calibration Hookup. Use the terminal locations figure that is appropriate for the type of DCA

being checked, and connect the equipment described

in the calibration equipment table as shown in the

calibration hookup diagram, figure 9.

Set all low alarm pots fully counterclockwise. DCA

pots are equipped with slip clutches to prevent

damage in the event of over-turning. A slight change

in torque may be felt when a wiper stop is reached. If

unable to sense the stop, set pot 15 turns counterclockwise.

Page 13

Page 11

DCA

NORMALLY OPEN — LNO

NORMALLY CLOSED — LNC

EXCITATION, +REF FOR D EVIATION ALARM

CURRENT OR VOLTAGE

CURRENT OR VOLTAGE

LOWER RELAY

COMMON — COM

LOWER RELAY

+INPUT — +IN

-INPUT — -IN

Figure 7. DCA in an Explosion-proof Enclosure Terminal Locations

NORMALLY OPEN — LNO

LOWER RELAY

7

8

9

OPTION — +TX FOR TRANSMITTER

10

11

12

7

`

6

6

5

4

3

2

1

GND

+DC — AC

–DC — ACC

UNC — UPPER RELAY

NORMALLY CLOSED

COM — COMMON

UN O — UPPER RELAY

NORMALLY OPEN

GND

COMMON — COM

NORMALLY CLOSED — LNC

UPPER ALARM CURRENT OR

VOLTAGE +INPUT — +IN UPP

LOWER ALARM CURRENT OR

VOLTAGE -INPUT — +IN LOW

CURRENT OR VOLTAGE

LOWER RELAY

-INPUT — -IN

8

9

10

11

12

5

4

3

2

1

+DC — AC

–DC — AC C

UNC — UPPER RELAY

NORMALLY CLOSED

COM — COMMON

UN O — UPPER RELAY

NORMALLY OPEN

Figure 8. DCA with DI Option in an Explosion-proof Enclosure Terminal Locations

Page 14

Page 12

DCA

APPROPRIATE

CALIBR ATED

ADJUSTABLE

CURRENT

VOLTAGE SOURCE

NOTES: Check unit m odel number for appr opi ate input sour c e.

1.

2.

3.

OR

(SEE NOTE 1)

Check unit m odel number for appr opr i ate power source.

X = U for upper or L for lower. Connect ohmmeter to " N O" for ter m i nals of normally open r el ay, to

NC for normally closed. “#” is used in DPDT- equipped units to refer to the number of the al ar m

output, as i n U NO1 and LN C2.

+

–

+IN

–IN

POWER SOURCE

Figure 9. The DCA Calibration Setup

Special Considerations for AR-equipped DCA’s.

Units equipped with the AR Option are factory-set for

specific alarm delay times ranging from 1 to 30

seconds (refer to Options listing). The AR is set and

fully calibrated according to customer requirements

before unit shipment.

The delay in an AR-equipped DCA’s transition from

normal to alarm condition makes the calibration of trip

points difficult, and a temporary disabling of the option

is therefore recommended during the calibration

procedures.

To defeat the AR Option, diodes on PC1 of the DCA

must be shorted. There is a diode for each installed

relay.

DCA’s in the STD housing must be partially disassembled to access the AR diode(s). See figure10.

Figures 11 and 12 show the location of the diodes on

the various types of AR-equipped DCA.

Access to the AR diode(s) on PC-style DCA’s may be

difficult if the unit being calibrated is already installed

in its rack. Moore Industries offers an Extender Card

accessory for calibrating units under these circumstances.

XNO#

DCA

+

+

VDC or VAC

(SEE NOTE 2)

COM

XNC#

–

–

The Extender, P/N 350-513-00, mates with the

connector on the PC-style DCA, and then plugs in to

the rack so that the unit is clear of the rack front,

allowing for access to the diode(s).

OHM METER

(SEE NOTE 3)

Calibration Procedures

Before beginning the actual calibration of the DCA,

check the unit’s model number to verify that the

correct power supply and input simulator is being

used. Make sure that the appropriate connections are

made as shown in the figures of the preceding

section.

Using the Calibration Procedures. The Calibration

Procedures section is divided into subsections that

describe first low alarm, then high alarm trip point

setting. The procedure for calibrating the DCA dead

band, for units equipped with the AD Option, should

be conducted after the trip points are set.

If the DCA to be calibrated is equipped with the TT

Option, skip to and complete the procedure in the

section entitled “Calibrating DCA’s Equipped with the

TT Option”.

Page 15

Page 13

DCA

FRONT PANEL

Figure 10. STD DCA Disassembly

FOR DUAL-ALARM

PC DCA SHORT AROUND

TH ESE DIODES

RELAY

CONNECTOR

PINS

RELAY

FOR SINGLE-ALARM

PC DCA SHORT AROUND

THIS DIODE

Figure 11. AR Option Diodes on the PC DCA

Page 16

Page 14

DCA

LED’S

PC2

PC1

RELAY

Figure 12. AR Option Diodes on PC1 of the STD DCA

RELAY

FOR SINGLE ALARM

STD DCA SH OR T

AROUND THIS DIODE

FOR DUAL ALARM STD

DCA SHORT AROUND

TH ESE DIODES

Setting Low-Alarm Trip Points. Remember that the

“UPPER” and “LOWER” labeling on the DCA is for

reference purposes only. The DCA can be ordered

without low alarms, as in a “high/high” configuration.

Dual alarm units can be ordered with either one or

both relays configured as low alarms, and DPDTequipped DCA’s may be configured with any combination of high/low alarms.

Refer to the unit’s model number to determine the

alarm configuration, and perform the following procedure for each installed low alarm.

1. Check model number to verify correct power

input, and apply 117 or 240 Vac; 24 or 45 Vdc, as

appropriate.

2. Make sure that ohmmeter in calibration setup is

connected to appropriate -NO or -NC terminals, as

desired.

3. Apply 100% of application’s input span (current or

voltage, as appropriate) to DCA.

If low alarm is configured as fail-safe, L1 in model

number, verify that appropriate LED for that alarm

is lit. LED for non-fail-safe low alarm, L2 in model

number, will not be lit.

4. Note ohmmeter reading.

In a low alarm, 100% input is a non-alarm condition. If connected to XNO and COM terminals (

= U or L, UPP or LOW; NO = normally open),

Resistance across the terminals in a fail-safe

alarm is zero. In a non-fail-safe alarm resistance will be near infinite.

If connected to XNC and COM terminals, resistance is infinite in fail-safe, zero in non-fail-safe

alarms.

X

Page 17

Page 15

DCA

5. Set input to desired low alarm trip point level.

6. Turn appropriate low alarm adjustment pot (may

be labeled “UPPER” or “LOWER”) slowly clockwise. Observe LED and ohmmeter, and stop

turning at exact point where relay changes state.

Vary pot setting slightly above and below trip

point to “zero in” on exact setting.

If low alarm is configured as fail-safe, L1 in model

number, verify that appropriate LED for low alarm

is not lit. LED for non-fail-safe low alarm, L2 in

model number, will be lit.

7. Verify desired setting by varying input above and

below trip point level (from step 6) and observing

both LED and ohmmeter to confirm change of

relay state at, and below trip point setting.

NOTE

Units equipped with any Manual Reset

Option have external push buttons that

must be pressed to reset the relays once

they have been tripped.

Setting High-Alarm Trip Points. Remember that the

“UPPER” and “LOWER” labeling on the DCA is for

reference purposes only. The DCA can be ordered

without high alarms, as in a “low/low” configuration.

Dual alarm units, on the other hand, can be ordered

with either one or both relays configured as high

alarms.

3. Apply 0% of application’s input span (current or

voltage, as appropriate) to DCA.

If high alarm is configured as fail-safe, H1 in

model number, verify that appropriate LED for that

alarm is lit. LED for non-fail-safe low alarm, H2 in

model number, will not be lit.

4. Note ohmmeter reading.

In a high alarm, 0% input is a non-alarm condition. If connected to XNO and COM terminals

(X= U or L, UPP or LOW; NO = normally open),

Resistance across the terminals in a fail-safe

alarm is zero. In a non-fail-safe alarm resistance will be near infinite.

If connected to XNC and COM terminals, resistance is infinite in fail-safe, zero in non-fail-safe

alarms.

5. Set input to desired high alarm trip point level.

6. Turn appropriate high alarm adjustment pot (may

be labeled “UPPER” or “LOWER”) slowly clockwise. Observe LED and ohmmeter, and stop

turning at exact point where relay changes state.

Vary pot setting slightly above and below trip

point to “zero in” on exact setting.

If high alarm is configured as fail-safe, H1 in

model number, verify that appropriate LED for that

alarm is not lit. LED for non-fail-safe high alarm,

H2 in model number, will be lit.

Refer to the unit’s model number to determine the

alarm configuration, and perform the following procedure for each installed high alarm.

1. Check model number to verify correct power

input, and apply 117 or 240 Vac; 24 or 45 Vdc, as

appropriate.

2. Make sure that ohmmeter in calibration setup is

connected to appropriate -NO or -NC terminals, as

desired.

7. Verify desired setting by varying input above and

below trip point level (from step 6) and observing

both LED and ohmmeter to confirm change of

relay state at, or above trip point setting.

NOTE

Units equipped with any Manual Reset

Option have external push buttons that

must be pressed to reset the relays once

they have been tripped.

Page 18

Page 16

DCA

Setting the Dead Band. See figure 1 for a graphic

representation of the DCA dead band. The dead band

may be thought of as an “area” around a trip point in

which the alarm will not reset.

In a scenario using a high-alarm DCA as an example,

the unit will signal an alarm at its trip point, and will

continue to signal an alarm as long as the input is

above that point.

Without an adjustable dead band, the relay will reset

when the input drops below the trip point. When

equipped with the AD Option, however, no reset will

occur until the input continues to drop to the dead

band setting, presumably some percentage of span

below the trip point.

To set the DCA dead band:

1. Make sure dead band pots are turned fully

counterclockwise. Set trip points for installed

alarms as described in preceding section. Connect ohmmeter to UPPER alarm section to set

UPPER dead band, or to LOWER section for

setting LOWER dead band.

For Example

A single, high-alarm DCA rated for 4-20 mA input is

required to have a 25% dead band around its 14 mA

trip point setting. To calculate the input level needed

to set the desired dead band, subtract 25% of 16 mA

(span) from 14 mA:

The result, 10 mA, is the level of input to be applied in

step 2. The DCA in this example will signal an alarm

condition when the input reaches or exceeds 14 mA,

but will not reset until the input drops below 10 mA.

Calibrating TT-equipped Units. Lockable, multiturn

trip point adjustment pots on the front panel of each

TT-equipped DCA are set at the factory so that “0.00”

on the dial is equal to 0% of the application’s rated

input span. “10.00” is equal to 100% of span. The

accuracy of these settings is ±0.5% of the rated

span.

:

Trip point setting in mA = 14

– 25% of input span in mA = 16(0.25)

14 – 4 = 10

2. Apply input at the dead band setting level.

Typically, this will be lower than trip point for high

alarms, or higher than trip point for low alarms.

3. Turn appropriate dead band pot slowly clockwise,

observing LED and ohmmeter.

4. Set pot (stop turning) at exact point at which relay

changes state.

5. Verify desired setting by varying input above and

below trip point, observing both LED and ohmmeter to confirm appropriate change of relay state.

Unit will “trip” at trip point setting, and will not

reset until input returns past dead band setting.

The DCA dead band can be expressed as a percentage of the unit’s factory-configured span.

Calibration of DCA’s with this option consists of two

procedures. First, the internal, Full-Scale Adjust

(FSA) potentiometer(s) must be set (this involves

some disassembly of the STD DCA). Then, the unit

zero, trip points, and dead band (if so-equipped), must

be set.

Figure 13 shows the location of the STD DCA FSA

potentiometers. Figure 14 shows the location of the

pots on the PC-style unit. Refer to figure 10 when

disassembling the unit in STD housing, and refer to

figures 13 or 14 while executing the procedure.

NOTE

The following procedure assumes that the

DCA being calibrated has its “UPPER”

alarm section configured as a high alarm,

and its “LOWER” alarm section configured

as a low alarm. If this is not the case for

your DCA, interchange references to

“UPPER” and “LOWER”, as appropriate.

Page 19

LED’S

Page 17

DCA

RELAY

PC1

Figure 13. Location of the FSA Potentiometers on the STD DCA PC1

RELAY

LOWER FULL-SCALE

ADJUSTMENT POT

(DUAL ALARMS ONLY)

UPPER FULL-SCALE

ADJUSTMENT POT

FRONT PANEL

FU LL-SCALE AD JU STMENT

(SINGLE ALARM ONLY)

Figure 14. Location of the FSA Potentiometers on the PC DCA

UPPER FULL-SCALE

ADJUSTM ENT

(DUAL ALARM ON LY)

CONNECTOR

PINS

LOW ER FULL- SC ALE

ADJUSTM ENT (D UAL ALARM ON LY)

Page 20

Page 18

DCA

1. With the hookup described in the Calibration

Setup Section complete, disable AR Option as

described in section titled “Calibrating ARequipped DCA’s”. Connect ohmmeter to “UPPER” alarm terminals first.

2. Verify that all pots are set fully counterclockwise,

to 0.00.

NOTE

Steps 3 through 10 apply to high alarms.

Skip to step 11 to calibrate the ten-turn

dials on low alarms.

3. Apply 0% of appropriate input from application.

Refer to unit’s model number and specifications

listing in table 2.

4. Turn ZERO pot clockwise until both “UPPER” and

“LOWER” alarms trip.

5. Apply 100% input to setup.

6. Turn “UPPER” and “LOWER” pots clockwise to

10.0 setting.

7. Turn internal FSA pots fully counterclockwise.

High alarm will change state. Disregard low alarm

at this time.

8. Turn FSA pot for “UPPER” alarm slowly clockwise, observing ohmmeter and appropriate front

panel LED.

9. Set FSA pot (stop turning) at exact point at which

high alarm is tripped. If high alarm is configured

as fail-safe, H1 in the unit model number, verify

that appropriate LED for high alarm is not lit. The

LED for a non-fail-safe high alarm, H2 in the

model number, will be lit.

12. Turn “LOWER” FSA pot slowly clockwise, observing ohmmeter and appropriate front panel LED.

13. Set FSA pot (stop turning) at exact point at which

low alarm is tripped.

If low alarm is configured as fail-safe, L1 in the

unit model number, verify that appropriate LED for

low alarm is not lit.

The LED for a non-fail-safe low alarm, L2 in the

model number, will be lit.

14. Alternate the input between its rated 0 and 100%

level, verifying the setting of the unit’s front panel

pots (0.00 at 0% input, 10.00 at 100% input).

Readjust both FSA pots as necessary.

Calibrating DA -equipped Units. If ordered, the

Deviation Alarm Option allows the user to set alarm

trip points based on the difference between two

inputs. This difference is expressed as a percentage

of total input span, and unit relays are “tripped”

whenever process input varies, more than (high alarm)

or less than (low alarm) the set percentage.

To calibrate DA-equipped DCA’s, a second input

source will be needed. Refer to table 3, and use two

of the appropriate sources as specified.

Refer to figures 2 through 8 as appropriate, to determine which of the unit terminals is used for the

second, reference input connection.

Finally, refer to the setup shown in figure 9, and add

the connection for the second input source as follows:

“+REF” is used for positive reference input, and the

negative connection for both inputs is common, the “–

IN”.

To calibrate DA-equipped DCA’s:

10. Disconnect ohmmeter, and reconnect it to

“LOWER” alarm section of DCA.

11. With input at 100%, and ohmmeter connected to

“LOWER” alarm section of unit, turn appropriate

“LOWER” FSA pot fully clockwise. Note that low

alarm trips.

1. With setup complete as described in preceding

paragraph, and all pots set fully counterclockwise,

determine percentage of rated input span that is

to serve as difference between reference input

and input #2.

2. Set reference input to 50% of rated span.

Page 21

Page 19

DCA

3. Set input #2 to desired percentage above or below

reference.

4. Set trip points as appropriate, using UNC pot for

UPPER normally closed alarm, UNO pot for

UPPER normally open; LNC for LOWER normally

closed, and LNO for LOWER normally open.

Base settings on input #2.

Units factory-configured as high alarms will “trip”

when input #2 exceeds the desired difference.

Low alarms “trip” when input #2 falls below

desired difference.

For Example:

A DA-equipped DCA is rated for two, 4-20 mA inputs

(“2X” in the model number). The application calls for

an alarm condition when input #2 varies more than

25% of span from the reference input.

Span = 16 mA

25% of 16 = 4 mA

The reference input is set to 50% of rated span, or 12

mA. Input #2 is set 25% higher, 16 mA.

Installation

Installing the DCA is typically accomplished by

physically mounting the unit, then effecting the

electrical connections.

Mounting

Figures 15 and 16, respectively, show the outline

dimensions of the DCA in the STD and the PC

housing styles. The drawing of the STD housing

includes the dimensions of the U-bracket, typically

included with that type of DCA, and also of the side

housing used for DCA’s equipped with the DPDT

option.

Always try to install the DCA in an area relatively free

of dust, excessive moisture, or corrosives.

Contact your Moore Industries Sales Representative

for information on other types of DCA housings,

enclosures, and mounting hardware.

The trip point pots are turned clockwise until relays

change state.

Regardless of how the reference input is varied, from

4 to 20 mA, as long as input #2 is likewise varied at a

50% offset, the alarms are not “tripped”.

However, if the reference is at 12 mA and input #2 is

at 20 mA, the high-alarm relay will indicate an alarm

condition. Likewise, if the reference is at 12 mA and

input #2 is at 14 mA, the low-alarm relay will indicate

an alarm.

Making Electrical Connections

Figure 17 illustrates the installation hookup for the

unit. Refer to the terminal location figures in the

Calibration Section when making the electrical

connections associated with installing the DCA.

Though there is no special wiring required for standard

connections, the use of shielded, twisted wiring is

recommended for all low-level signals, or where

connecting leads are run close to other services such

as power wiring. Ground the shield wire as close to

the DCA as possible in the installation.

Page 22

Page 20

DCA

9.5 mm

(0.38 in)

167 mm

(6.56 in)

6.4 mm

(0.25 in)

76.2 mm

(3.00 in)

66 mm

(2.60 in)

DC CURRENT

ALARM

DCA

UPPER LOWER

ZERO

COVER

63.3 mm

(2.49 in)

95 mm

(3.75 in)

102 mm

(4.00 in)

76.2 mm

(3.00 in)

63.5 mm

(2.50 in)

186 mm

(7.31 in)

154 mm

(6.08 in)

Figure 15. STD DCA Outline Dimensions, Including DPDT Option

When making the electrical connections for units in

explosion-proof enclosures, route the wiring through

the conduit hubs in the enclosure with enough slack

to reach the appropriate terminal.

Units in oil- or water-tight NEMA enclosures require

the use of Myer Scru-Tite (or equivalent) fittings to

maintain the enclosure integrity when routing wiring

conduit to or from the DCA.

WARNINGS

Do not apply power to the DCA until all

connections are secure. The uncovered

power input terminals of ac-powered STD

DCA’s present an electric shock hazard.

Always turn off the power to the unit

before servicing.

Page 23

Page 21

DCA

CURRENT

OR VOLTAGE

SOURCE

NOTES: 1.

Figure 16. PC DCA Outline Dimensions

(SEE NOTE 2)

+OUT

–OUT

+IN

–IN

DCA

XNO

COM

XNC

+

–

+

–

VDC or VAC

POWER SOURCE

(SEE NOTE 1)

Check the m odel num ber for pow er source r equirements.

2.

X=U for upper al ar m secti on, high or low , or L for lower alarm sec ti on,

high or low .

NO=norm ally open

NC=normally closed

ALARM

INDICATOR

Figure 17. DCA Installation Hookup

Page 24

Page 22

DCA

PC DCA’s slide into card slots in Moore Industries’

nineteen-inch card racks, the SMR and RMR. Each

DCA has individual contacts on its rear edge that

mate with an edge connector at the back of the rack.

Maintenance

Once the DCA is properly calibrated and installed, it

will operate indefinitely. No further adjustments

should be necessary, unless the unit is moved, or the

process input changes.

It is recommended that the unit terminals be checked

periodically for signs of oxidation or looseness.

If a problem develops with the performance of the

DCA, remove the unit from service and recalibrate.

Refer to the Calibration Section of this manual for

instructions.

Any units found to be performing below specifications

after a recalibration should be returned to the factory

immediately. Instructions for unit return can be found

on the back cover of this manual.

Customers may also contact the friendly folks in

Moore Industries’ Customer Service Department at 1800-999-2900 for technical assistance.

Page 25

August 1992

DCA

Direct Current Alarm

SUPPLEMENT

To Manual No. 192-701-00 G

Purpose

This supplement is being distributed to users of

Moore Industries' Direct Current Alarm (DCA) to inform them of corrections/additions to the current

manual since its release date. These changes will

be incorporated in the manual during its next revision.

Corrections

The wording of the second paragraph of step 4 of the

"Setting Low-Alarm Trip Points" (page 14) and "Setting High-Alarm Trip Points" (page 15) calibration

procedures should read:

In a low alarm, 100% input is a non-alarm condition. If connected to XNO and COM terminals (X =

U or L (upper or lower); NO = normally open). Resistance across these terminals in a fail-safe alarm is

near zero

infinite

. In a non-fail-safe alarm, resistance will be

.

It is important to understand that the "normal" condition of these relays refers to the

de-energized

terminal labeling is true when power is removed from

the unit or when the unit is operating and the LED is

NOT lit. Since each LED illuminates only while the

corresponding relay is

not lit its corresponding relay is de-energized.

So, regardless if the DCA is configured for fail-safe

or non-fail-safe operation, each relay's normally-open

or normally-closed contact states are true as labeled

only when the relay is de-energized.

state of the relay. This means that the

energized

non-energized

, when the LED is

or

Addition

The hookup connections for units configured with the

TX Opton are not provided in the Installation Section

of the user's manual. For units with the TX Option,

connect the positive output lead from the external

equipment to the +TX terminal on the DCA, and connect the minus output lead from the external equipment to the +IN terminal of the DCA. Do not use the

-IN when installing DCA's with the TX Option.

Page 26

Supplement

Page S-1

Low Voltage Directive

The following guidelines must be followed in order to

comply with EN 61010-1 (Low Voltage Directive).

These items affect the AC versions of the following

products: DCA, DPS-240, DPS1200, ECA, ECS,

ECT, FCA, FDT, IST, PIT-4W, PWT, RBA, SCT,

SMP, SPA-CE. If these products are to be used in

a non-CE environment, this supplement may

be disregarded.

WARNING:

If this unit is used in a manner not specified

by Moore Industries, the protection provided

by the equipment may

be impaired.

Switches and Circuit Breakers

A switch or circuit breaker must be wired in series

with the AC power conductors. This switch or circuit

breaker must be located within three meters of

the unit.

WARNING:

Terminals on this unit may be connected to

hazardous voltages. Before making ANY

connections to this unit, ALL hazardous

voltages must be de-energized.

The circuit breaker or switch will only remove power

to the unit, hazardous voltages may still be connected to other terminals on the unit.

Equipment Ratings

Moore Industries transmitters do not generate hazardous voltages. They measure voltage or current

inputs, and generate low voltages and currents

(<42Vdc and <50mAdc). Products connected to

Moore Industries transmitters should be designed to

receive these inputs.

Moore Industries alarms do not generate any hazardous voltages. Alarm contacts are wired in series

with power sources and their intended loads.

The correct load should be selected for the

power source.

Supply Wiring

All power connections shall be made with 14 or 16

AWG (.083mm or .064mm) wire.

The end of each conductor should be stripped no

more than 8mm. The end of the stripped wire should

be tinned with solder or inserted into a ferrule and

crimped before being placed into a terminal block.

Conductors connected to screw type connections

must have a ring or spade lug crimped on the end of

the wire.

Protective Earth Conductor

The Protective Earth Conductor shall be of equal or

larger size wire than the other two power conductors.

The Protective Earth Conductor shall be the first

conductor connected to the unit when the unit is being wired. It shall be the last conductor removed

when the unit is being un-wired.

Installation Category

All terminals are rated CAT II, except for terminals

with the -RF option. These terminals are

rated CAT I.

The Interface Solution Experts

Page 27

Page S-2

Supplement

Maximum Working Voltage

Table 1-s shows the maximum working voltage for

Moore Industries’ low voltage products.

Table 1-s. Maximum Working Voltage

epyTtupnI gnikroWmumixaM

DTRdna,elpuocomrehT,tlovilliMcdV84

stupnIegatloVCDcdV84

stupnIegatloVCAcaV462

stuptuOgolanAcdV84

stcatnoCyaleRcaV462

slanimreTrewoPcaV711caV921

slanimreTrewoPcaV042caV462

stuptuOerusolCtcatnoCcdV03

egatloVegatloV

egatloVegatloV

egatloV

Accessories

Contact Moore Industries for information on suitable

accessories for our products.

Mounting

When mounting the unit or installing it into an application, ensure that the unit can be easily removed

for maintenance or repairs.

Cleaning and Maintenance

Maintenance on Moore Industries’ products is limited

to keeping the unit clean and the wire terminals free

of oxidation. This is best accomplished by installing the unit in an area protected from dust, heat,

moisture, and corrosive atmospheres. Yearly visual

inspections should be performed to ensure that the

unit is clean and the electrical connections are in

good repair.

Symbols

Table 2-s shows the symbols used on Moore Industries’ products, the corresponding IEC/ISO symbol,

and its definition.

Table 2-s. Symbols on Moore Industries’ Products

OSI/CEI

lobmySlobmyS

lobmySlobmyS

lobmyS

deificepStoN

deificepStoN

erooMerooM

erooMerooM

erooM

tcudorPtcudorP

tcudorPtcudorP

tcudorP

SP+

SP–

CCD

CA

CCA

CDroCAtnerruCgnitanretlAdnatceriD

DNG

NI+

NI–

TUO+

TUO–

nolobmyS

seirtsudnIseirtsudnI

seirtsudnIseirtsudnI

seirtsudnI

noitinifeD

tnerruCtceriD

tnerruCgnitanretlA

lanimreThtraEdetcetorP

lanimreTrotcudnoCevitcetorP

ronoitalusnielbuodyb

tnelaviuqe(noitalusnidecrofnier

)635CEIfoIIssalCot

roflaunameeS(noituaC

)noitamrofni

tupnIevitisoP

tupnIevitageN

tuptuOevitisoP

tuptuOevitageN

tuohguorhtdetcetorptnempiuqE

Replacement of

Consumable Materials

No consumable materials are used in the Moore

Industries products covered by EN 61010-1.

deificepStoN

deificepStoN

deificepStoN

deificepStoNXTnoitaiticxErettimsnarT

ON

CN

MC

ONU

CNU

ONL

CNL

The Interface Solution Experts

nepOyllamroN

desolCyllamroN

nommoC

nepOyllamroNreppU

desolCyllamroNreppU

nepOyllamroNrewoL

desolCyllamroNrewoL

Page 28

RETURN PROCEDURES

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping

container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is

needed. The repaired equipment, or its replacement, will be returned to you in accordance with

the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR TRADE USAGE, AND

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES IMPLIED BY CUSTOM OR

USAGE IN THE TRADE OF THE BUYER AND OF THE COMPANY, AND THAT

ANY PRIOR DEALINGS OF THE BUYER WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS THE GOODS OR SERVICES IN ANY

WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY AGREES

WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONCERNING THE GOODS OR SERVICES

SHALL BE FOR THE COMPANY, AT ITS OPTION, TO REPAIR OR REPLACE

THE GOODS OR SERVICES OR REFUND THE PURCHASE PRICE. THE

COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES EVEN IF THE COMPANY FAILS IN ANY ATTEMPT

TO REMEDY DEFECTS IN THE GOODS OR SERVICES , BUT IN SUCH CASE

THE BUYER SHALL BE ENTITLED TO NO MORE THAN A REFUND OF ALL

MONIES PAID TO THE COMPANY BY THE BUYER FOR PURCHASE OF THE

GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY THE

COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES

FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED DEFECT OR

BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE ON WHICH THE

BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE BUYER ANY LATER THAN

TWELVE MONTHS FROM THE EARLIEST DATE ON WHICH THE BUYER

COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR

BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries ("The Company") will

at its option replace, repair or refund the purchase price for any of its manufactured products found, upon return to the Company (transportation charges

prepaid and otherwise in accordance with the return procedures established

by The Company), to be defective in material or workmanship. This policy

extends to the original Buyer only and not to Buyer's customers or the users

of Buyer's products, unless Buyer is an engineering contractor in which case

the policy shall extend to Buyer's immediate customer only. This policy shall

not apply if the product has been subject to alteration, misuse, accident, neglect or improper application, installation, or operation. THE COMPANY

SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Tel: (818) 894-7111 • FAX: (818) 891-2816

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

© 2006 Moore Industries-International, Inc.

United States • info@miinet.com

Australia • sales@mooreind.com.au

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

Tel: 86-21-62491499 • FAX: 86-21-62490635

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

Specifications and Information subject to change without notice.

China • sales@mooreind.sh.cn

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Loading...

Loading...