Page 1

Demand Moore Reliability

No. 700-701-96A

February 2018

BULLET WirelessHART® Adapter

BULLET

SYI

User’s Manual

All product names are registered trademarks of their

respective companies.

Page 2

User’s Manual

224-790-00J

December 2017

Customer Support

Moore Industries is recognized as the industry leader in delivering top quality to its customers in

products and services. We perform a sequence of stringent quality assurance checks on every

unit we ship. If any Moore Industries product fails to perform up to rated specications, call us for

help. Our highly skilled sta of trained technicians and engineers pride themselves on their ability

to provide timely, accurate, and practical answers to your process instrumentation questions. Our

headquarters and other facilities phone numbers are listed below.

There are several pieces of information that can be gathered before you call the factory that will

help our sta get the answers you need in the shortest time possible. For fastest service, gather

the complete model and serial number(s) of the problem unit(s) and the job number of the original

sale.

Australia

Sydney, NSW

3/1 Resolution Drive

Caringbah, New South Wales

2229

Australia

Tel: (02) 8536-7200

Fax: (02) 9525-7296

sales@mooreind.com.au

www.miinet.com/au

Perth, WA

6/46 Angove Street

North Perth, Western Australia

6006

Australia

Tel: (08) 9228-4435

Fax: (08) 9228-4436

sales@mooreind.com.au

www.miinet.com/au

Demand Moore Reliability

Bullet

WirelessHART® Adapter

Customer Support

Locations

World Headquarters

16650 Schoenborn Street

North Hills, California

91343-6196, U.S.A.

Tel: (818) 894-7111

Fax: (818) 891-2816

E-mail: info@miinet.com

TOLL FREE: 1-800-999-2900

www.miinet.com

China

Room 806, Block 2,

Lotus International Plaza

No. 7866 Hu Min Road,

Min Hang District,

Shanghai, 201102, P. R. China

Tel: 86-21 62491499

Fax: 86-21 62490635

E-mail: sales@mooreind.sh.cn

www.miinet.com/cn

Europe

1 Lloyds Court, Manor Royal,

Crawley

W. Sussex RH10-9QU

United Kingdom

Tel: 01293 514488

Fax: 01293 536852

FREE PHONE: 0800 525107

sales@mooreind.com

www.miinet.com/uk

Guido Gezellestraat 106

BE-2630 Aartselaar

Belgium

Tel: 03/448.10.18

Fax: 03/440.17.97

info@mooreind.be

Dutch: www.miinet.com/dbe

French: www.miinet.com/fbe

Burg Meslaan 98

4003 CD Tiel

The Netherlands

Tel: (0)344-617971

Fax: (0)344-615920

sales@mooreind.nl

www.miinet.com/nl

www.miinet.com Moore Industries-International, Inc.

www.miinet.com

- 2 -

Page 3

Warranty Disclaimer

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

China • dho@mooreind.sh.cn

Tel: 86-21-62491499 • FAX: 86-21-62490635

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

Moore Industries (“The Company”) makes no express, implied or statutory warranties (including any warranty of merchantability or

of tness for a particular purpose) with respect to any goods or services sold by the company. The company disclaims all warranties

arising from any course of dealing or trade usage, and any buyer of goods or services from the company acknowledges that there

are no warranties implied by custom or usage in the trade of the buyer and of the company, and that any prior dealings of the buyer

with the company do not imply that the company warrants the goods or services in any way.

Any buyer of goods or services from the company agrees with the company that the sole and exclusive remedies for breach of any

warranty concerning the goods or services shall be for the company, at its option, to repair or replace the goods or services or refund

the purchase price. The company shall in no event be liable for any consequential or incidental damages even if the company fails

in any attempt to remedy defects in the goods or services , but in such case the buyer shall be entitled to no more than a refund of all

monies paid to the company by the buyer for purchase of the goods or services.

Any cause of action for breach of any warranty by the company shall be barred unless the company receives from the buyer a

written notice of the alleged defect or breach within ten days from the earliest date on which the buyer could reasonably have

discovered the alleged defect or breach, and no action for the breach of any warranty shall be commenced by the buyer any later

than twelve months from the earliest date on which the buyer could reasonably have discovered the alleged defect or breach.

Return Policy

For a period of thirty-six (36) months from the date of shipment, and under normal conditions of use and service, Moore Industries

(“The Company”) will at its option replace, repair or refund the purchase price for any of its manufactured products found, upon

return to the Company (transportation charges prepaid and otherwise in accordance with the return procedures established by

The Company), to be defective in material or workmanship. This policy extends to the original Buyer only and not to Buyer’s

customers or the users of Buyer’s products, unless Buyer is an engineering contractor in which case the policy shall extend to

Buyer’s immediate customer only. This policy shall not apply if the product has been subject to alteration, misuse, accident, neglect

or improper application, installation, or operation. THE COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number to verify the warranty status for you

over the phone. Be sure to include the RMA number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when you call. In most cases, we will be

able to quote you the repair costs at that time. The repair price you are quoted will be a “Not To Exceed” price, which means

that the actual repair costs may be less than the quote. Be sure to include the RMA number on all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sufficient packing material and carefully pack the equipment in a sturdy shipping container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries representative will contact the person

designated on your documentation if more information is needed. The repaired equipment, or its replacement, will be returned to

you in accordance with the shipping instructions furnished in your documentation.

Specifications and Information subject to change without notice.© 2017 Moore Industries-International, Inc.

Page 4

Instruction Manual

Marking

Bullet WirelesHART Adapter

WHA-BLT-F9D0-N-A0-GP-1

table 1

Pepperl+Fuchs GmbH

Lilienthalstraße 200, 68307 Mannheim, Germany

table 2

Validity

Specific processes and instructions in this instruction manual require

special provisions to guarantee the safety of the operating personnel.

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location. Observe Directive 1999/92/EC in relation to

hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, ECtype-examination certificates, certificates, and control drawings if

applicable (see datasheet) are an integral part of this document. You can

find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change.

Please refer only to the most up-to-date version, which can be found under

www.pepperl-fuchs.com.

Intended Use

The device is only approved for appropriate and intended use. Ignoring

these instructions will void any warranty and absolve the manufacturer

from any liability.

Use the device only within the specified ambient temperature range.

The device is used in control and instrumentation technology

(C&I technology) for wireless data transfer from HART devices.

Take the intended use of the connected devices from the corresponding

documentation.

Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the

instruction manual.

Do not mount the device at locations where an aggressive atmosphere

may be present.

Do not mount a damaged or polluted device.

Avoid electrostatic charges which could result in electrostatic discharges

while installing or operating the device.

The usage of 2400 MHz equipment is bound to local restrictions. Ensure

that local restrictions allow usage of this device before commissioning.

Observe the tightening torque of the screws.

The device provides a grounding terminal to which an equipotential

bonding conductor with a minimum cross section of 4 mm² must be

connected.

Mark permanently the selected type of protection for your specified

application. Use the tick box on the nameplate for that. It is forbidden to

change this marking afterwards.

Ensure that the degree of protection is not violated by the conduit.

Use seals that are suitable for the specified application.

Requirements for Cables and Connection Lines

Install cables and cable glands in a way that they are not exposed to

mechanical hazards.

Protect cables and cable glands from tensile load and torsional stress or

use certified cable glands.

Unused cables and connection lines must be either connected to terminals

or securely tied down and isolated.

Requirements for Cable Glands

Only use cable glands that are suitably certified for the application.

Only use cable glands with a temperature range appropriate to the

application.

For cable glands only use incoming cable diameters of the appropriate

size.

Ensure that the degree of protection is not violated by the cable glands.

Operation, Maintenance, Repair

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

When the device is in operation, maintain at all times a distance of at least

20 cm to the device antenna. This also applies to any other person in the

vicinity of the device.

Delivery, Transport, Disposal

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the

ones you ordered.

Keep the original packaging. Always store and transport the device in the

original packaging.

Store the device in a clean and dry environment. The permitted ambient

conditions must be considered, see datasheet.

Disposing of device, packaging, and possibly contained batteries must be

in compliance with the applicable laws and guidelines of the respective

country.

DOCT-5061 / 2016-04 1 / 1

Page 5

Instruction Manual

Marking

Bullet WirelesHART Adapter

WHA-BLT-F9D0-N-A0-Z0-Ex1

EC-Type Examination Certificate: FM 11 ATEX 0019 X

II 1 G Ex ia IIC T6/T5 Ga

II 1 D Ex ia IIIC T95 °C Da

Certificate: FM 11 ATEX 0068 X

II 3 G Ex nA IIC T6/T5 Gc

FM approval: CoC3040786(C)

Class I, Zone 0, (A)Ex ia IIC T6/T5 Ga

Class I, Zone 2, (A)Ex nA IIC T6/T5 Gc

Class I, Zone 20, (A)Ex ia IIIC T95°C Da

Class I, Division 1, Groups A - D

Class II, Division 1, Groups E - G

Class III

Class I, Division 2, Groups A - D

IECEx approval: IECEx FMG 11.0010X

Ex ia IIC T6/T5 Ga

Ex nA IIC T6/T5 Gc

Ex ia IIIC T95°C Da

table 1

Pepperl+Fuchs GmbH

Lilienthalstraße 200, 68307 Mannheim, Germany

table 2

Validity

Specific processes and instructions in this instruction manual require

special provisions to guarantee the safety of the operating personnel.

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location. Observe Directive 1999/92/EC in relation to

hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, ECtype-examination certificates, certificates, and control drawings if

applicable (see datasheet) are an integral part of this document. You can

find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change.

Please refer only to the most up-to-date version, which can be found under

www.pepperl-fuchs.com.

Intended Use

The device is only approved for appropriate and intended use. Ignoring

these instructions will void any warranty and absolve the manufacturer

from any liability.

Use the device only within the specified ambient temperature range.

The device is used in control and instrumentation technology

(C&I technology) for wireless data transfer from HART devices.

Take the intended use of the connected devices from the corresponding

documentation.

Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the

instruction manual.

Do not mount the device at locations where an aggressive atmosphere

may be present.

Do not mount a damaged or polluted device.

Avoid electrostatic charges which could result in electrostatic discharges

while installing or operating the device.

If the device has already been operated in general electrical installations,

the device may subsequently no longer be installed in electrical

installations used in combination with hazardous areas.

Observe the installation instructions according to IEC/EN 60079-14.

Connection or disconnection of energized non-intrinsically safe circuits is

only permitted in the absence of a potentially explosive atmosphere.

If circuits with type of protection Ex i are operated with non-intrinsically

safe circuits, they must no longer be used as circuits with type of

protection Ex i.

The usage of 2400 MHz equipment is bound to local restrictions. Ensure

that local restrictions allow usage of this device before commissioning.

Observe the respective peak values of the field device and the associated

apparatus with regard to explosion protection when connecting intrinsically

safe field devices with intrinsically safe circuits of associated apparatus

(verification of intrinsic safety). Also observe IEC/EN 60079-14 and

IEC/EN 60079-25.

Keep the separation distances between all non-intrinsically safe circuits

and intrinsically safe circuits according to IEC/EN 60079-14.

Observe the compliance of the separation distances between two

adjacent intrinsically safe circuits according to IEC/EN 60079-14.

If no Lo and Co values are specified for the simultaneous appearance of

lumped inductances and capacitances, the following rule applies.

l

The specified value for Lo and Co is used if one of the following

conditions applies:

l

The circuit has distributed inductances and capacitances only, e. g., in

cables and connection lines.

l

The total value of Li (excluding cable) of the circuit is < 1 % of the

specified Lo value.

l

The total value of Ci (excluding cable) of the circuit is < 1 % of the

specified Co value.

l

A maximum of 50 % of the specified value for Lo and Co is used if the

following condition applies:

The total value of Li (excluding cable) of the circuit is ≥ 1 % of the

specified Lo value.

The total value of Ci (excluding cable) of the circuit is ≥ 1 % of the

specified Co value.

l

The reduced capacitance for gas groups I, IIA, and IIB must not exceed

the value of 1 µF (including cable). The reduced capacitance for

gas group IIC must not exceed the value of 600 nF (including cable).

Provide a transient protection. Ensure that the peak value of the transient

protection does not exceed 140 % of the rated voltage.

Observe the tightening torque of the screws.

The device provides a grounding terminal to which an equipotential

bonding conductor with a minimum cross section of 4 mm² must be

connected.

Observe the grounding requirements for type of protection Ex i according

to IEC/EN 60079‑14.

The associated apparatus must provide a characteristic which is limited by

a resistor.

Mark permanently the selected type of protection for your specified

application. Use the tick box on the nameplate for that. It is forbidden to

change this marking afterwards.

The device contains aluminum. Thereby the device is considered to

constitute an ignition hazard by impact effect or friction. Avoid impact

effect or friction during mounting and operating.

Ensure that the degree of protection is not violated by the conduit.

Use seals that are suitable for the specified application.

Requirements for Cables and Connection Lines

Observe the permissible cable type and cable length given in the

respective hazardous area certificate.

Regarding the verification of intrinsic safety, observe the maximum

permissible external capacitance of this device and the other devices in

the circuit.

External capacitance C

o

22 µF

table 3

Install cables and cable glands in a way that they are not exposed to

mechanical hazards.

Protect cables and cable glands from tensile load and torsional stress or

use certified cable glands.

Unused cables and connection lines must be either connected to terminals

or securely tied down and isolated.

Requirements for Cable Glands

Only use cable glands that are suitably certified for the application.

Only use cable glands with a temperature range appropriate to the

application.

For cable glands only use incoming cable diameters of the appropriate

size.

Ensure that the degree of protection is not violated by the cable glands.

Operation, Maintenance, Repair

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

When the device is in operation, maintain at all times a distance of at least

20 cm to the device antenna. This also applies to any other person in the

vicinity of the device.

Delivery, Transport, Disposal

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the

ones you ordered.

Keep the original packaging. Always store and transport the device in the

original packaging.

Store the device in a clean and dry environment. The permitted ambient

conditions must be considered, see datasheet.

Disposing of device, packaging, and possibly contained batteries must be

in compliance with the applicable laws and guidelines of the respective

country.

DOCT-5165 / 2016-04 1 / 1

Page 6

Instruction Manual

Marking

Bullet WirelesHART Adapter

WHA-BLT-F9D0-N-A0-Z1-1

EC-Type Examination Certificate: FM 12 ATEX 0021 X

II 2 G Ex db IIC T6/T5 Gb

II 2 D Ex tb IIIC T95°C Db

FM approval: Coc3041762(C)

Class I, Zone 1, (A)Ex db IIC T6/T5 Gb

Class I, Zone 21, (A)Ex tb IIIC T95°C Db

Class I, Division 1, Groups A - D

Class II, Division 1, Groups E - G

Class III

IECEx approval: IECEx FMG 12.0005X

Ex db IIC T6/T5 Gb

Ex tb IIIC T95°C Db

table 1

Pepperl+Fuchs GmbH

Lilienthalstraße 200, 68307 Mannheim, Germany

table 2

Validity

Specific processes and instructions in this instruction manual require

special provisions to guarantee the safety of the operating personnel.

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location. Observe Directive 1999/92/EC in relation to

hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, ECtype-examination certificates, certificates, and control drawings if

applicable (see datasheet) are an integral part of this document. You can

find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change.

Please refer only to the most up-to-date version, which can be found under

www.pepperl-fuchs.com.

Intended Use

The device is only approved for appropriate and intended use. Ignoring

these instructions will void any warranty and absolve the manufacturer

from any liability.

Use the device only within the specified ambient temperature range.

The device is used in control and instrumentation technology

(C&I technology) for wireless data transfer from HART devices.

Take the intended use of the connected devices from the corresponding

documentation.

Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the

instruction manual.

Do not mount the device at locations where an aggressive atmosphere

may be present.

Do not mount a damaged or polluted device.

Avoid electrostatic charges which could result in electrostatic discharges

while installing or operating the device.

If the device has already been operated in general electrical installations,

the device may subsequently no longer be installed in electrical

installations used in combination with hazardous areas.

Observe the installation instructions according to IEC/EN 60079-14.

The usage of 2400 MHz equipment is bound to local restrictions. Ensure

that local restrictions allow usage of this device before commissioning.

Provide a transient protection. Ensure that the peak value of the transient

protection does not exceed 140 % of the rated voltage.

Observe the tightening torque of the screws.

The device provides a grounding terminal to which an equipotential

bonding conductor with a minimum cross section of 4 mm² must be

connected.

Mark permanently the selected type of protection for your specified

application. Use the tick box on the nameplate for that. It is forbidden to

change this marking afterwards.

The device contains aluminum. Thereby the device is considered to

constitute an ignition hazard by impact effect or friction. Avoid impact

effect or friction during mounting and operating.

Ensure that the degree of protection is not violated by the conduit.

Use seals that are suitable for the specified application.

Requirements for Cables and Connection Lines

Install cables and cable glands in a way that they are not exposed to

mechanical hazards.

Protect cables and cable glands from tensile load and torsional stress or

use certified cable glands.

Unused cables and connection lines must be either connected to terminals

or securely tied down and isolated.

Requirements for Cable Glands

Only use cable glands that are suitably certified for the application.

Only use cable glands with a temperature range appropriate to the

application.

For cable glands only use incoming cable diameters of the appropriate

size.

Ensure that the degree of protection is not violated by the cable glands.

Operation, Maintenance, Repair

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

When the device is in operation, maintain at all times a distance of at least

20 cm to the device antenna. This also applies to any other person in the

vicinity of the device.

Delivery, Transport, Disposal

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the

ones you ordered.

Keep the original packaging. Always store and transport the device in the

original packaging.

Store the device in a clean and dry environment. The permitted ambient

conditions must be considered, see datasheet.

Disposing of device, packaging, and possibly contained batteries must be

in compliance with the applicable laws and guidelines of the respective

country.

DOCT-5166 / 2016-04 1 / 1

Page 7

1 Introduction................................................................................. 5

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

1.1 Contents................................................................................................ 5

1.2 Target Group, Personnel...................................................................... 5

1.3 Symbols Used ...................................................................................... 6

2 Product Specifications............................................................... 7

2.1 Use and Application............................................................................. 7

2.2 Indicators and Operating Elements ................................................... 8

2.3 Scope of Delivery................................................................................. 8

2.4 Storage and Disposal .......................................................................... 9

3 Configuration ............................................................................ 10

3.1 Wired Configuration........................................................................... 10

3.2 Configuration via Device Type Manager (DTM)............................... 11

3.2.1 HART Communication DTM............................................................. 12

3.2.2 Adapter DTM ................................................................................... 14

3.2.3 Online and Offline Parameterization (DTM)...................................... 15

3.2.4 Setup Wizard ................................................................................... 16

3.2.5 Power............................................................................................... 18

3.2.6 Wireless........................................................................................... 20

3.2.7 Wired ............................................................................................... 21

3.2.8 4 ... 20 mA........................................................................................ 23

3.2.9 Burst Settings .................................................................................. 24

3.2.10 Event Notification ............................................................................. 26

3.2.11 Time................................................................................................. 27

3.2.12 Adapter Info ..................................................................................... 28

3.2.13 Battery Info....................................................................................... 29

3.2.14 Alerts ............................................................................................... 30

3.2.15 Device Status................................................................................... 33

3.2.16 Communications.............................................................................. 34

3.2.17 Maintenance .................................................................................... 35

3.2.18 Device Info....................................................................................... 37

3.3 Configuration via Device Description (DD) ..................................... 37

Page 8

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

User's Manual, December 2017

4 Installation................................................................................. 40

4.1 Mounting Considerations ..................................................................40

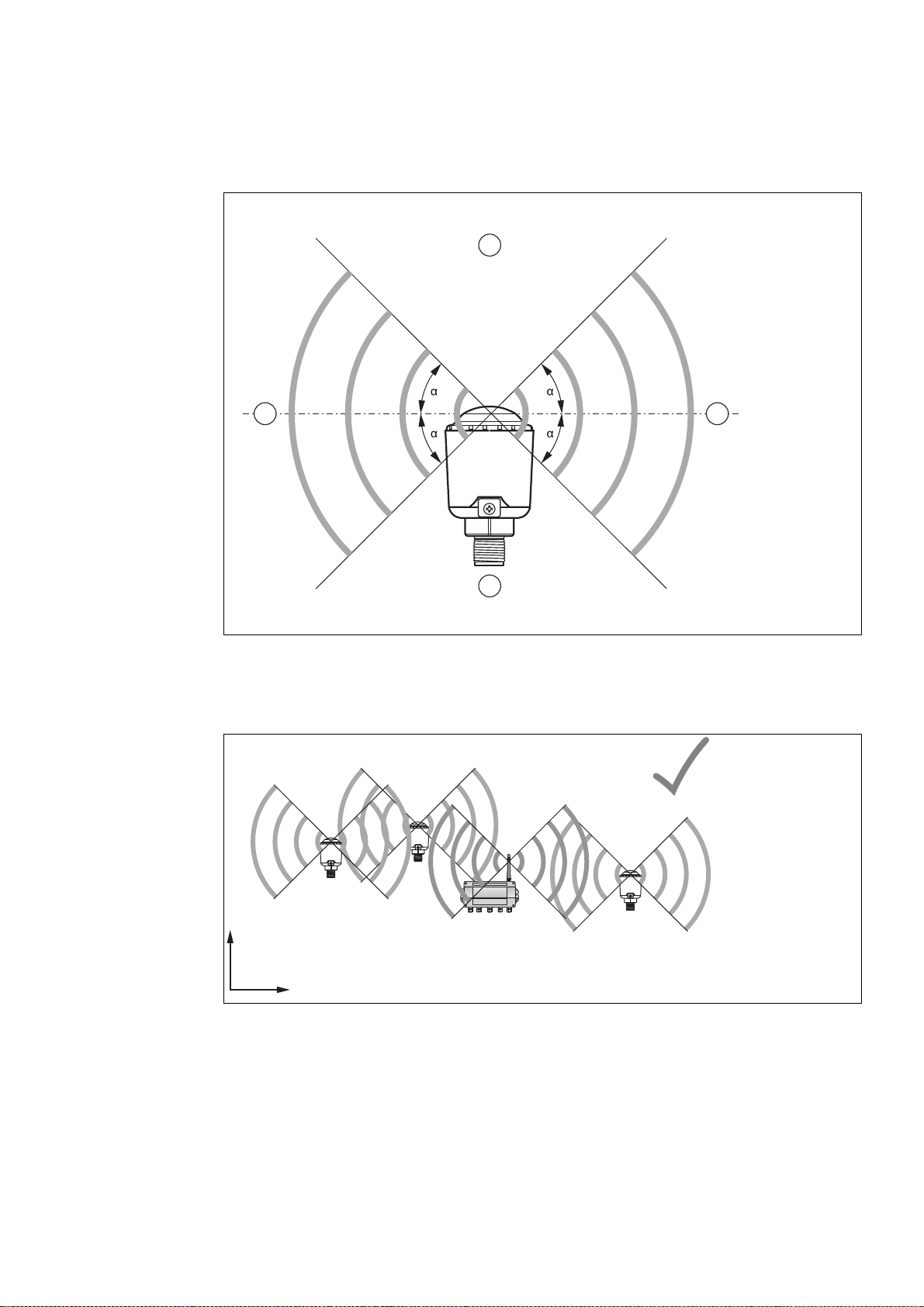

4.1.1 Positioning the Device ......................................................................40

4.1.2 Examples for Good and Poor Positioning ......................................... 41

4.1.3 Installation Options........................................................................... 42

4.2 Explosion-Hazardous and Non-Explosion Hazardous Areas ........43

4.3 Wiring ..................................................................................................43

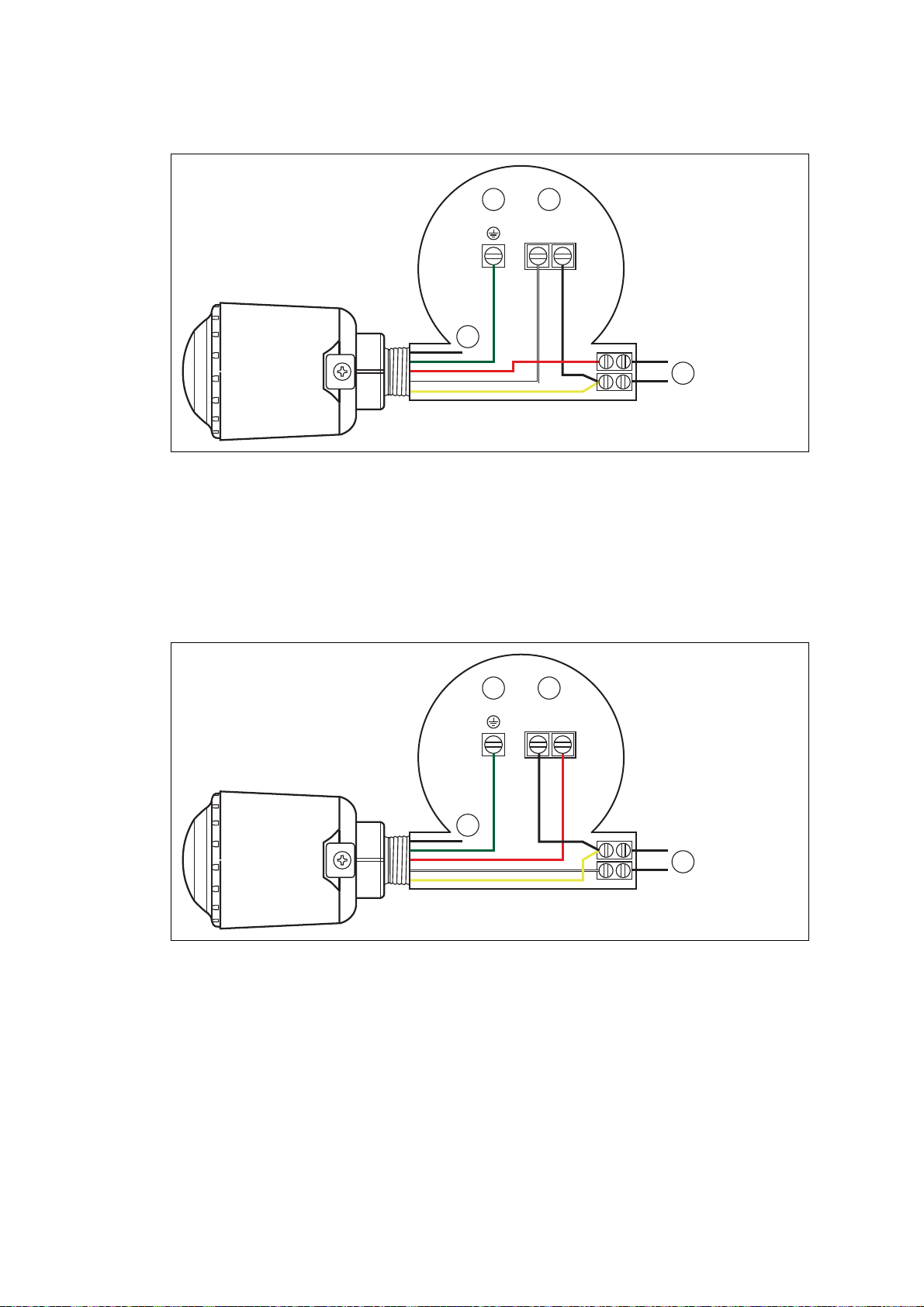

4.3.1 Field Wiring ...................................................................................... 43

4.3.2 Grounding ........................................................................................44

4.4 Installation on Field Device ............................................................... 46

4.5 Installation as Stand-Alone Router ................................................... 49

4.6 Multidrop Mode................................................................................... 52

5 Operation................................................................................... 52

5.1

6 Troubleshooting........................................................................

Control Drawings & Certifications........................................

7

HART Variables ...................................................................................52

53

59

Page 9

1Introduction

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

1.1 Contents

This document contains information that you need in order to use your product throughout the

applicable stages of the product life cycle. These can include the following:

■ Product identification

■ Delivery, transport, and storage

■ Mounting and installation

■ Commissioning and operation

■ Maintenance and repair

■ Troubleshooting

■ Dismounting

■ Disposal

Note!

You can obtain detailed BULLET part number and

ordering information from the BULLET data sheet which

is available for download from the Moore Industries web

site, www.miinet.com.

1.2 Target Group, Personnel

2015-12

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

5

Page 10

1.3

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages in instances, whenever dangers may arise from your actions. It

is mandatory that you observe these warning messages for your personal safety and in order to

avoid property damages.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

6

2015-12

Page 11

2 Product Specifications

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

2.1 Use and Application

The Bullet WirelessHART Adapter enables up to 8 HART field devices or analog field devices

(with no HART capability) to communicate with host applications by means of WirelessHART

technology. The adapter can be attached directly to a spare connection of a field device or

anywhere on the 4 ... 20 mA current loop. Once a HART field device is equipped with an

adapter, it communicates its primary variable (PV) over the existing wire and simultaneously

communicates the primary variable (PV), secondary variable (SV), tertiary variable (TV),

quaternary variable (QV) as well as diagnostic and alarm data over the WirelessHART network.

The adapter can be supplied by the existing current loop or by an external power supply, such

as, a battery.

■ When loop powered, the adapter saves users the long-term cost of battery maintenance,

replacement and disposal programs. The patent pending StepVolt

TM

technology enables

you to set the insertion voltage in steps from 1 ... 2.5 V.

■ When battery powered, the adapter provides battery power management by switching the

attached field devices on and off as needed.

2015-12

The device is used in control and instrumentation technology (C&I technology) for wireless data

transfer from HART devices.

The device is only approved for appropriate and intended use. Ignoring these instructions will

void any warranty and absolve the manufacturer from any liability.

Protection of the personnel and the plant is not ensured if the device is not being used

according to its intended use.

Take the intended use of the connected devices from the corresponding documentation.

Use the device only within the specified ambient and operating conditions.

The usage of 2400 MHz equipment is bound to local restrictions. Ensure that local restrictions

allow usage of this device before commissioning.

7

Page 12

Country Guideline

1

2

3

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Bulgaria General authorization required for outdoor use

Italy If used outside of own premises, general

Japan The device is granted pursuant to the

Latvia The outdoor usage of the 2.4 GHz band

Norway May be restricted in the geographical area

Romania

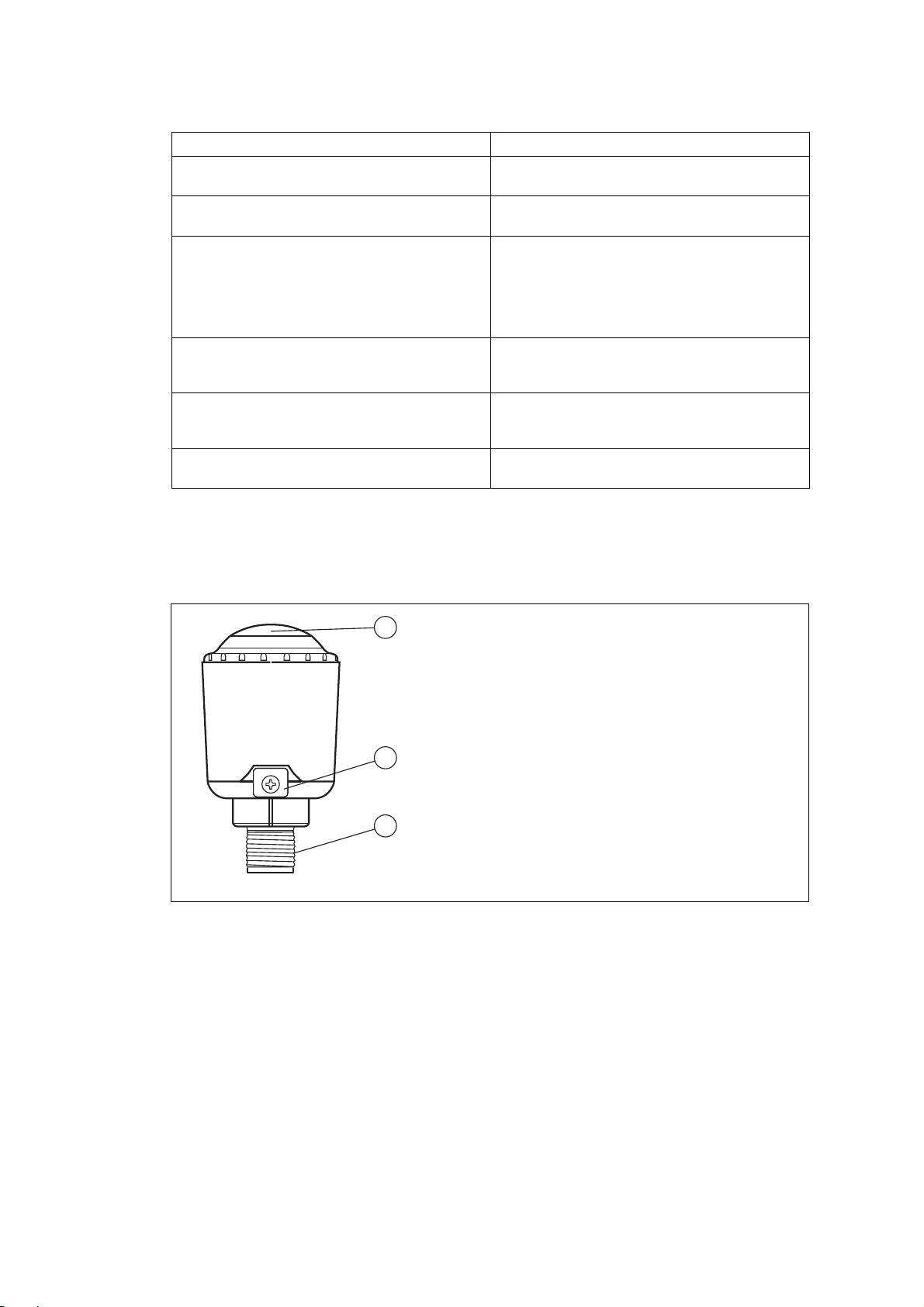

2.2 Indicators and Operating Elements

The adapter has both a radio interface to communicate with the WirelessHART network and a

wired HART interface to communicate with HART field devices and analog field devices (with

no HART capability) on the 4 ... 20 mA current loop.

and public service.

authorization is required.

Japanese Radio Law and the Japanese

Telecommunications Business Law.

The device must not be modified (otherwise

the granted designation number will become

invalid).

requires an authorization from the Electronic

Communications Office.

within a radius of 20 km from the center of NyAlesund.

Use on a secondary basis. Individual license

required.

2.3 Scope of Delivery

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the ones you ordered.

8

1. Encapsulated antenna

2. Grounding point

3. Male ½ inch NPT thread for installation on field device

■ Bullet WirelessHART

®

Adapter

11010z-x0M0

z = 0,1,2 and x=8 or P

Refer to data sheet for more

information

2015-12

Page 13

2.4 Storage and Disposal

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Keep the original packaging. Always store and transport the device in the original packaging.

Store the device in a clean and dry environment. The permitted ambient conditions

(see datasheet) must be considered.

Disposing of device, packaging, and possibly contained batteries must be in compliance with

the applicable laws and guidelines of the respective country.

2015-12

9

Page 14

3 Configuration

mA

+

-

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

3.1 Wired Configuration

Configure the adapter on the shop floor using a wired connection prior to its installation in the

field.

1. Define basic settings, such as, wireless communication parameters and identification parameters using a HART modem.

2. Make the adapter join the WirelessHART network.

3. Once the adapter has joined the WirelessHART network, configure the burst settings and

other application settings using a HART modem.

4. Disconnect the HART modem and install the adapter in the field.

Caution!

Loss of type of protection

If circuits with type of protection Ex i are operated with non-intrinsically safe circuits, they must

no longer be used as circuits with type of protection Ex i.

When configuring an adapter with type of protection Ex i, use a HART modem with type of

protection Ex i to communicate with the adapter.

Caution!

Damage due to overcurrent

A current that exceeds the operating specifications of the device can cause damage to the

device.

Ensure that the supplied current never exceeds 32 V DC.

Setup for Wired Configuration

1. Connect the black conductor (Direct Power) to the positive terminal (+) of the power supply

and the white conductor (Return) to the negative terminal (-) of the power supply.

2. Connect the HART modem to the yellow conductor (HART) and white conductor (Return) of

the adapter. The HART connection is polarity independent.

3. Make sure the red conductor (Loop Power) of the adapter is not connected to the power

supply or ground connection.

4. Turn on the power supply. Make sure the adapter is supplied with 7 ... 32 V DC.

10

The adapter is ready to be configured.

2015-12

Page 15

3.2

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Configuration via Device Type Manager (DTM)

Once the adapter is connected to a HART modem, you can configure the adapter using a

PC that has an FDT frame application installed, for example, PACTwareTM. Furthermore,

the HART communication DTM and the DTM of the adapter must be installed on the PC.

Install Components

1. Download the latest version of PACTware, from http://www.miinet.com/ and the

HART communication DTM and the DTM of the adapter on the BULLET product

page.

2. and the HART communication DTM and the DTM of the adapter at http://

www.miinet.com/InterfaceSolutionDownloadCenter/Products.aspx?product=244

Create New Project?

1. Start PACTware.

2. Select File > New or click Create New Project.

A new, unnamed project appears in the main window. The project initially consists of the

entry HOST PC.

Update Device Catalog

1. Select View > Device Catalog.

The Device Catalog window opens.

2. Click Update Device Catalog to update the device catalog.

3. Click Ye s to continue.

The device catalog has been updated and newly installed components, such as the

HART communication DTM and the DTM of the adapter have been integrated into the

catalog.

2015-12

11

Page 16

3.2.1 HART Communication DTM

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

A communication DTM is an interface between the FDT frame application and the DTM of the

device.

For the PC to communicate with the device via the HART modem, a HART communication

DTM has to be added to the PACTware project.

Add HART Communication DTM

1. Select HOST PC in the project view of your PACTware project.

2. Choose Device > Add device or click the Add device icon on the toolbar.

The Device for window appears.

Figure 3.1 Device selection

3. Select HART communication.

4. Click OK.

The HART communication DTM is added to the project.

Figure 3.2 Project view

5. To edit the parameters, double-click the HART communication DTM.

The parameter window appears.

12

2015-12

Page 17

Figure 3.3 Parameter window

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

6. Set the parameters according to the following table.

7. Click OK to save the changes and to close the parameter window.

Parameter Description Default

Communication

interface

Set this parameter to HART modem. HART

modem

Port Select the COM port that your HART modem is connected to. COM1

Master The adapter is configured as a primary master. Therefore the

device used to configure the adapter should be configured as

Primary

Master

secondary master.

Set this parameter to Secondary Master.

Preamble Number of preambles for HART communication. 5

Number of

The number of retries in case of an error. 3

communication

retries

Start address Defines the address range, in which the HART communication

End address 0

DTM searches for HART devices connected to the HART

modem.

0

The default polling address of the adapter is 15.

Communication

timeout

If no communication takes place during this time frame, the

connection is reestablished unless the number of

2

communication retries is used up.

Multimaster and

Enables support for multiple masters and burst mode. Activated

Burst mode

support

2015-12

13

Page 18

3.2.2 Adapter DTM

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

After you have added a communication DTM, add the adapter DTM to the PACTware project.

Add Adapter DTM

1. In the project view, right-click the HART communication DTM.

Figure 3.4 Project view

2. To add the adapter DTM, choose Add device from the context menu.

The Device for window opens.

Figure 3.5 Device selection

3. Select Bullet HART DTM.

4. Click OK.

The adapter is added to the project. Now you can configure the adapter as if you had a

wired connection.

Figure 3.6 Project view

5. Right-click the adapter DTM.

6. Select Additional Functions > Communication.

7. Select the polling address 15 and click Apply.

2015-12

14

Page 19

Figure 3.7 Set polling address

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

8. Click Close.

3.2.3 Online and Offline Parameterization (DTM)

The concept of online and offline parameterization applies only to configuration via DTM and

PAC Twa re .

■ Offline Parameterization (not connected to device)

If there is no active connection to the device, you can edit and save the data that is stored

locally in PACTware. You can transfer the local data to the device, as soon as a connection

to the device has been established.

■ Online Parameterization (connected to device)

If there is an active connection to the device, you can directly edit the data that is stored

on the device. Parameter changes are immediately stored on the device.

Note!

Data that is edited and stored on the device during online parameterization is not automatically

synchronized with the offline data in the PACTware project. If you change device parameters in

online mode, the data in PACTware differs from the data on the device. To make sure the data in

PACTware matches the data on the device after online parameterization, load the data from the

device into the PACTware project.

Offline Parameterization

1. Right-click the device in the PACTware project view.

2. Choose Parameter > Offline Parameterization.

The window containing the offline data record appears.

3. Modify a parameter by typing in a new value or choosing a new value from the drop-down

list.

4. To accept the new value, press Enter.

5. After all parameter changes have been made, save your project by choosing File > Save.

6. To write the new offline configuration to the device, right-click the device in the project view

and choose Connect.

A connection to the device is established.

7. Right-click the device again and choose Store to device.

The new configuration is stored in the device.

2015-12

15

Page 20

Online Parameterization

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Note!

Some options are only available during online parameterization. These options are pointed out

in the relevant sections.

1. Right-click the device in the PACTware project view.

2. Select Connect.

A connection to the device is established.

3. Right-click the device in the PACTware project view.

4. Select Parameter > Online Parameterization.

The window containing the online data opens and the data is read from the device.

5. Modify a parameter by typing in a new value or choosing a new value from the drop-down

list.

6. To accept the new value, press Enter.

The new value is stored in the device immediately.

7. After all parameter changes have been made, you can load the online configuration into the

PACTware project. To do this, right-click on the device entry in the project view and choose

Load from device.

8. Save your project by choosing File > Save.

3.2.4 Setup Wizard

The setup wizard enables you to define basic parameters, such as, network ID and join key.

Note!

This submenu is available only during online parameterization.

Run Setup Wizard

1. Right-click the adapter DTM.

2. Select Connect.

16

Figure 3.8 Connect to device

2015-12

Page 21

3. To edit the parameters, double-click the adapter DTM.

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

The Online Parameterization window opens with the Adapter Overview screen.

Figure 3.9 Adapter Overview

4. Select Setup Wizard.

Figure 3.10 Setup Wizard

2015-12

5. The setup wizard enables you to define the tag, the long tag, the way the adapter is

supplied, as well as the network settings.

For more information on the available options, see the following chapters.

17

Page 22

3.2.5 Power

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

This submenu enables you to define the way the adapter is supplied.

Note!

This submenu is available only during online parameterization.

Figure 3.11 Power options

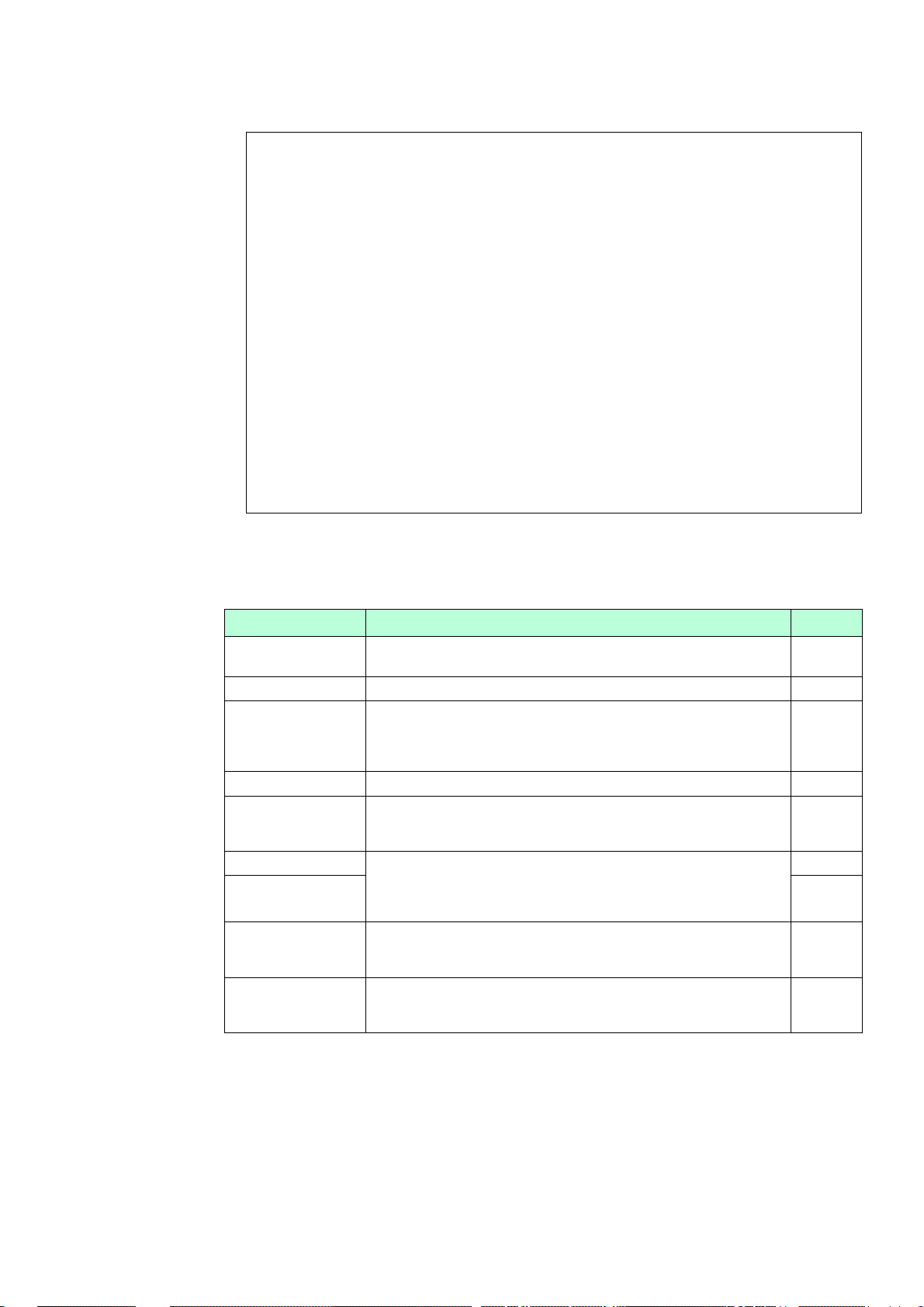

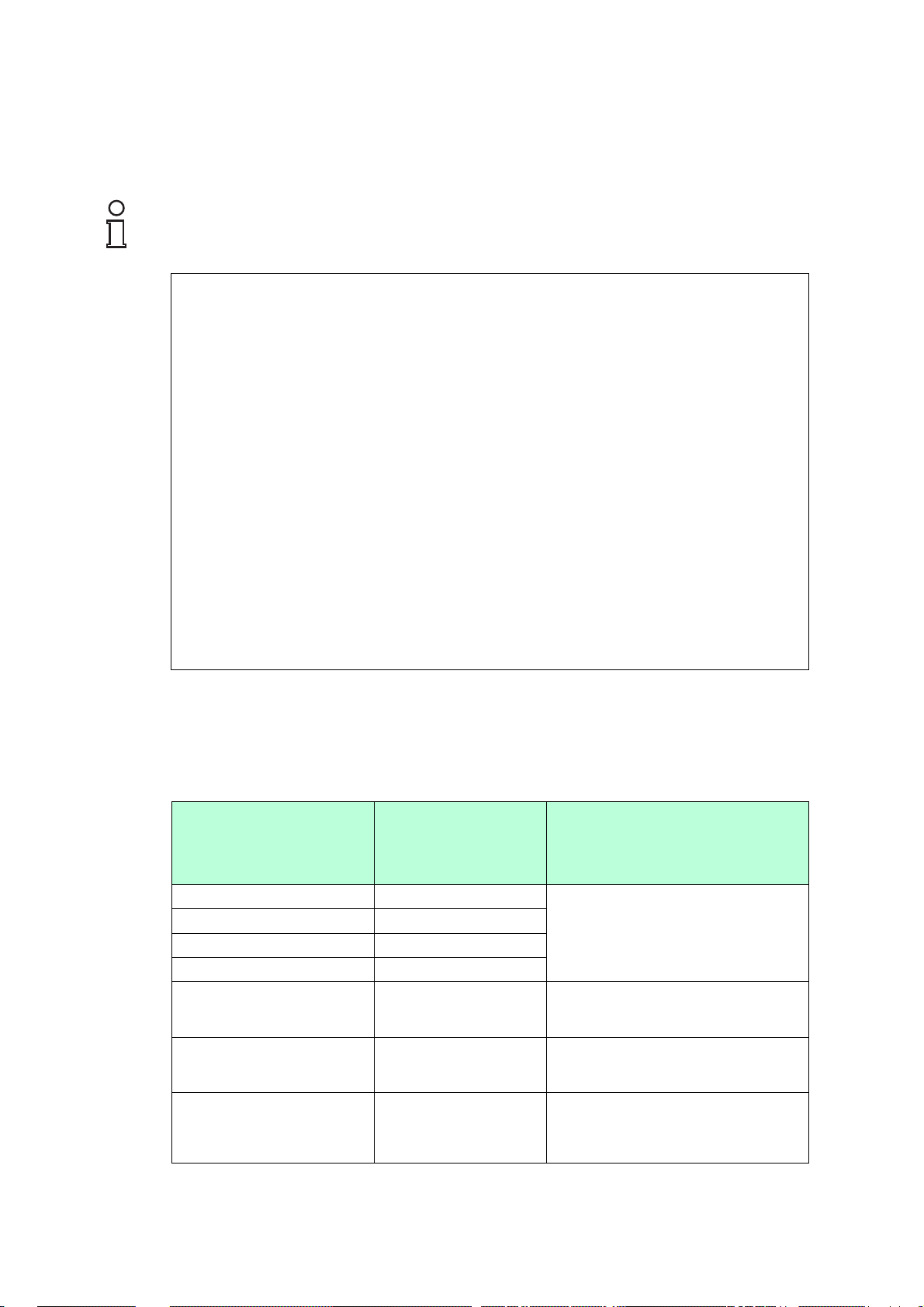

Adapter Power Setting

By default, the adapter is loop powered with an insertion voltage drop of 1 V DC.

The following options are available.

WirelessHART Packets

per Second

(as reported by HART

Option

command 777)

Loop Powered - 1.0 V 4.25

Loop Powered - 1.5 V 12.65

Loop Powered - 2.0 V 19.66

Loop Powered - 2.5 V 26.66

Direct Powered - Max

101.40 Provides maximum bandwidth,

Bandwidth

Direct Powered - Power Save 26.66 Limits the number of WirelessHART

Direct Powered - Battery 26.66 Assumes that the power supply is a

Description

Ste pVoltTM settings when loop

powered

assuming the powers supply supplies

32 V

data packets, assuming the power

supply is limited

battery and enables the battery

management functions, such as,

battery life calculations and alerts

18

2015-12

Page 23

The adapter can be supplied by an external DC powers supply and wired in series with the

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

4 ... 20 mA current loop at the same time. If the adapter is configured in any of the Direct

Power options and wired in series with the current loop, there will be an insertion voltage drop

of 1.0 V DC.

Warning!

Field device failure due to insufficient power supply

TM

If the adapter has an internal failure and stops regulating the StepVolt

value, the maximum

insertion voltage drop can rise up to 4.935 V DC.

Note!

The adapter will power up and operate with any configuration. This enables you to change the

configuration of an incorrectly configured device. However, you should change the power

options before the adapter joins the WirelessHART network. Once the adapter joins the

WirelessHART network it might reset itself due to insufficient power supply.

Field Device Power Control

If the adapter is directly powered by an external current source, the adapter can activate a

terminator of 250 between the HART and the RETURN conductors. In some installations this

can eliminate the need for an external terminator.

The Field Device Power Control option allows you to control the power supply for the field

devices by switching them on and off. The following options are available.

■ Off

Power supply for field devices is switched off.

■ On

Power supply for field devices is switched on.

■ Switching

Power supply for field devices is automatically switched on and off by the adapter.

When Switching is enabled, the adapter switches the field devices on and off as needed. This

can be used to switch off a field device between measurements, of example, if the field device

is supplied by a limited power supply, such as, a battery.

When used in combination with burst mode, the adapter schedules measurements from the

field devices, and turns them on when a scheduled measurement is needed. After all

measurements have been read from the field devices, the adapter turns off the supply for the

field devices.

Note that the Field Device Turn On Time must be sufficiently long, in order to obtain accurate

measurements from the field devices. Otherwise, the field device may not have enough time to

power up, initialize and respond with a correct measurement value before the power supply is

switched off again.

The Field Device Idle Time is the duration for which a field device remains powered after an

unscheduled event. Such events could be a HART query from a handheld or the detection of

another HART master trying to communicate with the field device. This option prevents the

adapter from switching off the field device when another master communicates with the field

device.

2015-12

Field Device On Estimated Percent displays the estimated time that the field device is

supplied during normal operation. The calculation is based on the Field Device Turn On Time

and the burst mode settings of the adapter.

19

Page 24

Field Device Cutoff Enable enables the adapter to turn off the power supply for field devices

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

when the power of the power supply drops below the value that is defined in the Field Device

Cutoff Voltage field. To use this option, Field Device Power Control must be set to On or

Switching.

Note that there is a built-in 0.5 V hysteresis for the Field Device Cutoff Voltage.

Note!

Battery-Powered Operation

If the adapter is loop powered, the adapter and field devices are continuously powered on. If

the adapter is directly powered, the adapter can switch the field devices on and off, which

results in a prolonged battery life.

In order to manage the battery power, the Field Device Power Control option must be set to

On. This enables you to define the Field Device Turn On Time and Field Device Idle Time

as required by the field device for correct operation and as required by the application.

See chapter 3.2.13

3.2.6 Wireless

This submenu enables you to define the network settings for joining the WirelessHART

network.

Note!

This submenu is available only during online parameterization.

Figure 3.12 Wireless options

Wireless Connection

The Network ID is the identifier of the WirelessHART network to join.

The Join Key is a 32 character hexadecimal password that is used to access the

WirelessHART network.

20

2015-12

Page 25

The Join Mode defines when the adapter should connect itself to the WirelessHART network.

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

The following options are available.

■ Don't attempt to join

Do not connect to the WirelessHART network.

■ Join Now

Manually connect to the WirelessHART network.

■ Attempt to join immediately on powerup or reset

Automatically connect to the WirelessHART network.

Danger!

Explosion hazard

If the emitted power level is too high, a potentially explosive atmosphere can ignite

■ Respect the limitations for explosion-hazardous areas.

■ Respect local restrictions for usage of 2400 MHz equipment. If in doubt, consult your

national regulations expert.

The Radio Output Power defines the power level of the radio transmitter. This option can be

set to either 0dBm (1.3 mW) or +10 dBm (10 mW).

Radio Upgrade

If Over the Air Upgrade is enabled, the device data can be updated over the WirelessHART

network.

3.2.7 Wired

This submenu enables you to define the settings for communicating with HART field devices.

Note!

This submenu is available only during online parameterization.

2015-12

Figure 3.13 Wired options

21

Page 26

HART

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

The Master Mode defines whether the adapter acts as a primary or a secondary master when

communicating with HART field devices.

The Retry Count defines how often the adapter retries to communicate with HART field

devices as a HART master.

The Polling Address defines the HART polling address that is used to communicate with the

adapter over a wired HART connection, for example, using a HART modem.

Sub-Device Scan

When Sub-Device Scan On Power-up is enabled, the adapter scans the 4 ... 20 mA current

loop for HART field devices on power-up and after a reset. The HART field devices that have

been detected are added to the list of sub-devices and can be accessed over the

WirelessHART network.

We recommend, that you leave this option enabled. If disabled, the host must support scanning

for sub-devices or you must initiate the scan manually by clicking Scan for Devices.

Furthermore, each time the adapter is powered-up or reset, the list of sub-devices is lost and

the network must be rescanned.

Note!

The scan for sub-devices is performed only during power-up or reset of the adapter. If an

additional field device is added to the current loop while the adapter is in normal operation, you

must reset the adapter or initiate the scan manually by clicking Scan for Devices to detect the

new field device.

Scan Start Address designates the first HART polling address that is used when scanning for

sub-devices.

Scan Stop Address designates the last HART polling address that is used when scanning for

sub-devices.

If Sub-Device Time Sync is enabled, the adapter can synchronize the sub-device time with

the WirelessHART network time for HART devices supporting HART 7 or greater. If the subdevice does not support a real-time clock, this option has no effect. Synchronization is

performed once a day.

22

2015-12

Page 27

3.2.8 4 ... 20 mA

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

When the adapter is connected to an analog field device (with no HART capability), the adapter

can measure the current on the 4 ... 20 mA current loop. The adapter can convert the

measured value into another engineering unit and communicate the result as primary variable

(PV) over the WirelessHART network.

Note!

This submenu is available only during online parameterization.

Figure 3.14 4 ... 20 mA options

4...20mA

PV Units defines the unit that the primary variable (PC) is reported as.

The PV Linearization Mode enables you to define different linearization tables for the

measured values. The following options are available.

■ Linear

A basic linear calculation will be performed to convert the measured values. The PV

Upper Range Value and the PV Lower Range Value correspond to the 4 ... 20 mA

points.

■ Special Curve

This option enables you to define individual linearization tables. Click PV Linearization

Ta b l e to enter data pairs for mapping a current value of the 4 ... 20 mA current loop to

another engineering unit. The table must have at least two data pairs and can have up to

32 pairs.

PV Damp defines the attenuation value in seconds that is applied to the PV.

If the current on the 4 ... 20 mA current loop exceeds the Upper Fault Current, the adapter

sets a HART loop current alarm.

If the current on the 4 ... 20 mA current loop falls below the Lower Fault Current, the adapter

sets a HART loop current error.

2015-12

23

Page 28

If the current on the 4 ... 20 mA current loop exceeds the Upper Limit of Proportional Range,

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

the adapter sets a HART loop current warning.

If the current on the 4 ... 20 mA current loop falls below the Lower Limit of Proportional

Range, the adapter sets a HART loop current warning.

3.2.9 Burst Settings

Burst settings enable the adapter to publish data in regular intervals without being polled by a

host.

Note!

This submenu is available only during online parameterization.

24

Figure 3.15 Burst options

Auto Burst

When automatic configuration is enabled, the adapter automatically configures the burst

messages for the adapter and all of the connected sub-devices.

The Automatic Update Rate enables you to define a fixed update rate. The following options

are available.

■ Off

Disable automatic configuration of burst settings.

■ 1 ... 32 seconds

Select an update rate between 1 and 32 seconds in which all of the burst messages will

be published to the WirelessHART gateway.

■ 1 ... 60 minutes

Select an update rate between 1 and 60 minutes in which all of the burst messages will be

published to the WirelessHART gateway.

Select the commands that will be used for automatic configuration from the Automatic

Commands drop-down list.

2015-12

Page 29

Click Apply Auto Burst to enable automatic configuration.

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Note!

If automatic configuration is enabled while a manual configuration has already been activated,

the manual configuration is overwritten.

If a manual configuration is activated while an automatic configuration has already been

enabled, the automatic configuration is disabled.

Manual Burst

To define the burst settings manually, double-click a row in the Manual Burst table. In the

Burst Message Setting window you can define the commands, trigger options, and update

periods for each burst message.

2015-12

Figure 3.16 Burst Message Setting window

Click Apply Manual Burst to activate the manual configuration.

25

Page 30

3.2.10 Event Notification

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

The adapter detects and logs different event messages. This submenu enables you to activate

or deactivate selected standard events and device-specific events.

Note!

This submenu is available only during online parameterization.

Figure 3.17 Event notification options

Select Event Status in the navigation area on the left, to see the current status of the selected

events.

26

Figure 3.18 Event status overview

2015-12

Page 31

3.2.11 Time

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

This submenu displays the current time of the internal clock of the adapter as well as the

uptime of the adapter.

Note!

This submenu is available only during online parameterization.

Figure 3.19 Current time and uptime

2015-12

27

Page 32

3.2.12 Adapter Info

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

This submenu enables you to define the identification parameters to identify the adapter within

the WirelessHART network.

Note!

This submenu is available only during online parameterization.

Figure 3.20 Adapter identification options

Adapter Information

The Ta g identifies the field device within the process plant. Enter up to 8 characters.

The Long Tag identifies the device in a WirelessHART network. Enter up to 32 characters.

The Descriptor contains a description of the device. Enter up to 16 characters.

The Message field enables you to define a device-specific message. Enter up to 32

characters.

The Final Assembly Num field enables you to enter an identifier for the connected field

device.

The Date field enables you to enter a date. Use the following date format dd/mm/yyyy.

The Country field enables you to define the country of installation.

The SI Unit Control field enables you to select whether you want to use only SI units, for

example, for converting a current value on the 4 ... 20 mA current loop into another engineering

unit.

The Electronics Temperature field enables you to define whether you want to use the

Celsius, Fahrenheit, or Kelvin scale for temperatures.

Write Protected

If Write Protected is enabled, the configuration of the adapter cannot be changed. The factory

default setting is Disabled. If you changed this option, click Apply to apply the current setting.

28

2015-12

Page 33

3.2.13 Battery Info

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

If the adapter is supplied by an external battery, this submenu enables you to define basic

battery settings and to monitor battery consumption.

To determine the remaining battery life, the adapter employs the battery voltage and the battery

coulomb discharge rate. Both variables are continuously monitored.

Note!

This submenu is available only during online parameterization.

Figure 3.21 Battery options

Battery Settings

Enter the capacity of the battery in mAh in the Battery Capacity field. This value is used by the

Coulomb algorithm to determine the remaining battery life in days.

If the voltage falls below the Battery Low Voltage, the power status is set to Low and the

remaining battery life is set to 25 days or less. This value is used as an independent check

beside the Coulomb algorithm.

If the voltage falls below the Battery Critical Voltage, the power status is set to Critical and

the remaining battery life is set to 0 days. This value is used as an independent check beside

the Coulomb algorithm.

Enter the date of the battery change in the Battery Changed Date field. Use the following date

format dd/mm/yyyy. The battery counter is reset on this date.

2015-12

29

Page 34

Battery Stats

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

WirelessHART defines 3 power status levels for battery powered devices.

1. Nominal

The power supply is operating correctly.

2. Low

The power supply should be exchanged when the low indication is set.

3. Critical

The power supply should be exchanged immediately. Otherwise, an interruption of the

power supply will happen in the immediate future.

The current battery ratings are displayed below the Power Status.

3.2.14 Alerts

The adapter detects and logs system events when something has occurred that could affect

system operation. All alerts are mapped into HART command 48 status bits.

Note!

This submenu is available only during online parameterization.

Figure 3.22 Alerts

30

2015-12

Page 35

Alerts are divided into active and historic alerts.

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

■ Active alerts are displayed on the Active tab. The condition that caused the alert is still

present. Active alerts cannot be cleared. A corrective action must be taken to eliminate

the alert, for example, if the power status of an external battery is Low, the battery must be

exchanged to clear the alert.

■ Historic alerts are displayed on the History tab. The condition that caused the alert is no

longer present, or the alert is a one-time event. The Start Date and Start Tim e indicate

when the condition first occurred and the Stop Date and Stop T i me indicate when the

condition stopped, or the last time that the condition was detected.

Click Clear to eliminate the alert history.

Alerts

Alert Description Corrective Action

Direct Power Out of Range The adapter is configured for

direct power (external power

Check the external power

supply.

supply) and the voltage on the

input is out of range.

Loop Power Out of Range The adapter is configured to

be loop powered and the

Check the current on the

4 ... 20 mA current loop.

voltage on the input is out of

range.

Temperature Out of Range The Electronics

Te m pe r a tu r e is out of range.

See chapter 3.2.14

Power Mode Misconfigured The power supply detected on

the inputs does not match the

Check whether the adapter is

used within the specified

ambient conditions.

Check the power options. See

chapter 3.2.5

configuration.

Watchdog Reset The microprocessor inside of

the adapter has experienced a

watchdog reset event.

Stack Overflow The microprocessor inside of

the adapter has experienced a

stack overflow event.

Duplicate HART Master

Detected

A HART master has been

detected that has the same

master type as the adapter.

This prevents the adapter form

communicating with the

connected sub-devices.

HART Devices Count

Exceeded

A HART master has been

detected that has the same

master type as the adapter.

This prevents the adapter form

communicating with the

connected sub-devices.

HART Sub-Device Lost A sub-device has stopped

communicating with the

adapter and has been

dropped from the sub-device

Clear the alert. Report the

event to customer support.

Clear the alert. Report the

event to customer support.

Check the Master Mode of

the adapter. If using a HART

Handheld, make sure it is not

set for the same master type

as the adapter. See chapter

3.2.7

Check the Master Mode of

the adapter. If using a HART

Handheld, make sure it is not

set for the same master type

as the adapter. See chapter

3.2.7

If the sub-device was removed

intentionally, clear the alert.

Otherwise, check the wiring of

the sub-device.

list.

2015-12

31

Page 36

Alert Description Corrective Action

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

Burst Packets are Being

Dropped

One or more burst data

packets have been dropped.

Check whether the

WirelessHART network has

granted the requested

bandwidth for the burst

messages. If not, you can

either adjust the

WirelessHART network

settings or adjust the burst

times of the adapter.

If the burst messages were

intended for the connected

sub-devices, make sure there

are no other HART masters on

the connection, as these can

cause burst message delays.

Field Device Power Control This alert is set, whenever

Field Device Power Control

is set to Switching and the

Field Device On Estimated

Percent is 100 because the

burst settings keep the subdevice always powered on.

If the Switching option is not

required, change this option.

Otherwise, reduce the burst

times for the connected subdevice and check the variation

of the Field Device On

Estimated Percent value.

See chapter 3.2.5

Wireless Capacity Denied The WirelessHART network

has denied a request for

wireless bandwidth.

Burst Message Configuration

Issue

A burst message is configured

to a command that is not

supported by the selected

sub-device.

Wired Device in Burst Mode A connected sub-device is

configured for wired burst

Check the burst settings and

reduce the requested

bandwidth.

Change the command

number of the burst message

to a command that is

supported by the sub-device.

Disable wired burst mode of

the connected sub-device.

mode, which may conflict with

burst settings of the adapter.

Adapter Failed to Join the

Network

Radio Malfunction The radio module inside the

Variable Simulation One or more of the device

Field Device Cutoff Occurred This alert is set, whenever

The adapter has failed to join

the WirelessHART network.

adapter is malfunctioning.

variables are being simulated.

Field Device Cutoff Enable

Check the network ID and join

key. See chapter 3.2.6

Report this issue to

Customer Support.

Check the simulation settings

for the variables.

Check the external power

supply.

is enabled and the voltage of

the external power supply

drops below the Field Device

Cutoff Voltage. See chapter

3.2.5

Low Battery This alert is set, whenever the

Replace the external battery.

adapter is configured to use

an external battery and the

battery voltage drops below

the Battery Low Voltage or

the calculated remaining

battery life is 25 days or less.

32

2015-12

Page 37

3.2.15 Device Status

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.

This submenu provides a detailed overview of all device data.

Note!

This submenu is available only during online parameterization.

Figure 3.23 Device status overview

2015-12

33

Page 38

3.2.16 Communications

BULLET

BULLET WirelessHART® Adapter

User's Manual, December 2017

700-701-96A

www.miinet.com

Moore Industries-International, Inc.