Page 1

5 5 5

5 5 5

CHLORINATION/DECHLORINATION

CONTROLLER USER'S MANUAL

M555 V8, M

ARCH

201

7

Page 2

page

TABLE OF CONTENTS............................................................................. i

FIGURE LIST ........................................................................................... iii

CHAPTER 1

GENERAL INFORMATION ............................................................... 1

555 Control Modes ............................................................................ 1

555 Operation ................................................................................... 2

Order Code, Packaging Information .................................................. 2

Where To Go Next ............................................................................ 2

Text Formatting in This Manual ......................................................... 2

CHAPTER 2

BASIC INTERFACE .......................................................................... 5

Displays ............................................................................................ 5

Icons (Lit) .......................................................................................... 6

Keys .................................................................................................. 6

CHAPTER 3

HARDWARE SET UP ....................................................................... 7

Hardware Input Types ....................................................................... 7

The Process Variable ........................................................................ 7

The Remote Setpoint ........................................................................ 8

Mechanical Relays ............................................................................ 8

Accessing and Changing Jumpers .................................................... 9

Adding and Changing Output Modules ............................................ 10

Special Communications Module .................................................... 12

Contents

About This Manual:

Throughout this User’s Manual

information appears along the

margins, in the form of NOTEs,

CAUTIONs and WARNINGs, usually

in boldface. Please heed these

safety and good practice notices for

the protection of you and your

equipment.

CHAPTER 4

INSTALLATION .............................................................................. 13

Mounting the Controller ................................................................... 13

Wiring for Input and Outputs ........................................................... 14

AC Power Input ...................................................................... 14

Process Variables .................................................................. 15

Digital Inputs........................................................................... 17

Output Modules ...................................................................... 18

Remote Setpoint ..................................................................... 21

Serial Communications ........................................................... 21

CHAPTER 5

SOFTWARE CONFIGURATION..................................................... 23

Menus ............................................................................................. 23

Parameters ..................................................................................... 24

Configuration and Operation ........................................................... 24

Where to Go Next ........................................................................... 25

Software Menus and Parameters .................................................... 27

CONFIG ................................................................................. 27

CONTROL.............................................................................. 31

FLOW INPT. ........................................................................... 32

CUST.LINR. ........................................................................... 34

RSDL. INPT. .......................................................................... 35

SETPOINT ............................................................................. 36

REM. INPUT .......................................................................... 37

OUTPUT ................................................................................ 38

RETRANS. ............................................................................. 41

ALARMS ................................................................................ 43

555 User's Manual Table of Contents i

Page 3

Contents

page

POWER-UP ........................................................................... 47

SECURITY ............................................................................. 47

SER. COMM........................................................................... 48

TUNING ................................................................................. 49

Parameter Value Charts.................................................................. 51

CHAPTER 6

APPLICATIONS .............................................................................. 59

A. Flow Pacing Mode ...................................................................... 59

B. Residual Chlorine Loop Mode ..................................................... 61

C. Compound Loop Mode ............................................................... 64

D. Dechlorination Mode ................................................................... 67

E. Alarms ........................................................................................ 70

F. Slidewire Position Proportioning Output ...................................... 74

G. Staged Outputs ........................................................................... 75

H. Retransmission ........................................................................... 75

I. Digital Inputs ............................................................................... 76

J. Remote Input .............................................................................. 78

K. Integral Setting ............................................................................ 79

L. Tuning Tips ................................................................................. 80

M.Input Linearization ...................................................................... 83

N. Security ...................................................................................... 84

O. Process Variable Reading Correction ......................................... 85

P. Serial Communications ............................................................... 86

Q. Lag ............................................................................................. 87

APPENDIX A

ERROR HANDLING ..................................................................... A-1

Troubleshooting ............................................................................ A-1

Error Messages ............................................................................ A-2

APPENDIX B

CALIBRATION .............................................................................. B-1

Analog Input (V and mA) Calibration ............................................. B-1

Milliamp Output Calibration ........................................................... B-3

Reset Menu Data .......................................................................... B-4

Hardware Scan ............................................................................. B-4

Slidewire Test ............................................................................... B-5

Quick Calibration Procedure ......................................................... B-5

APPENDIX C

SPECIFICATIONS ........................................................................ C-1

APPENDIX D

FLOWCHARTS ............................................................................. D-1

Set Up and Tuning Mode Menus and Parameters ........................ D-1

APPENDIX E

GLOSSARY .................................................................................. E-1

APPENDIX F

ISOLATION BLOCK DIAGRAM .................................................... F-1

APPENDIX G

PARTS LIST ................................................................................. G-1

ii Table of Contents 555 User's Manual

Page 4

Figure.............Title ............................................................................ Page

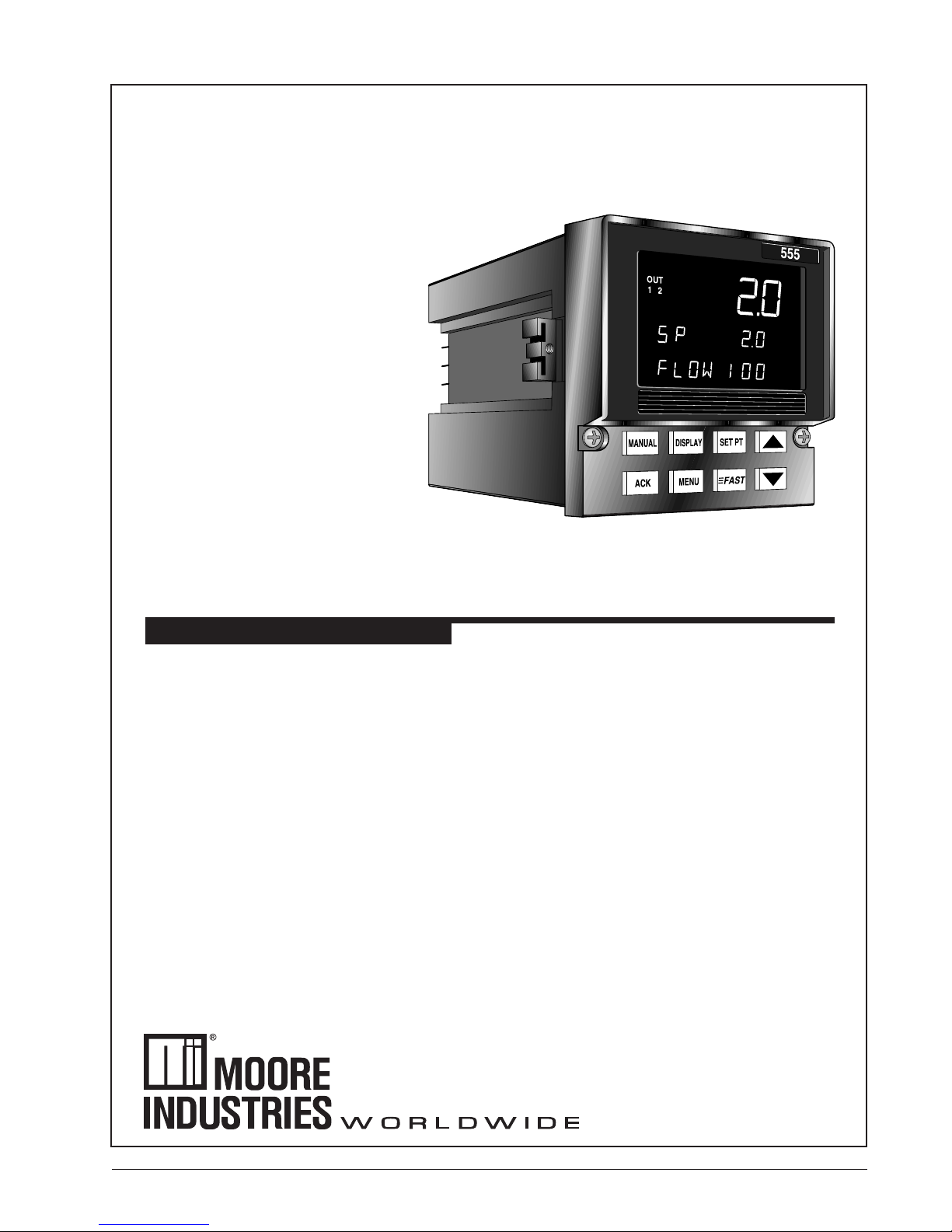

Figure 1.1 ........ The 555 Chlorination/Dechlorination Controller................. 1

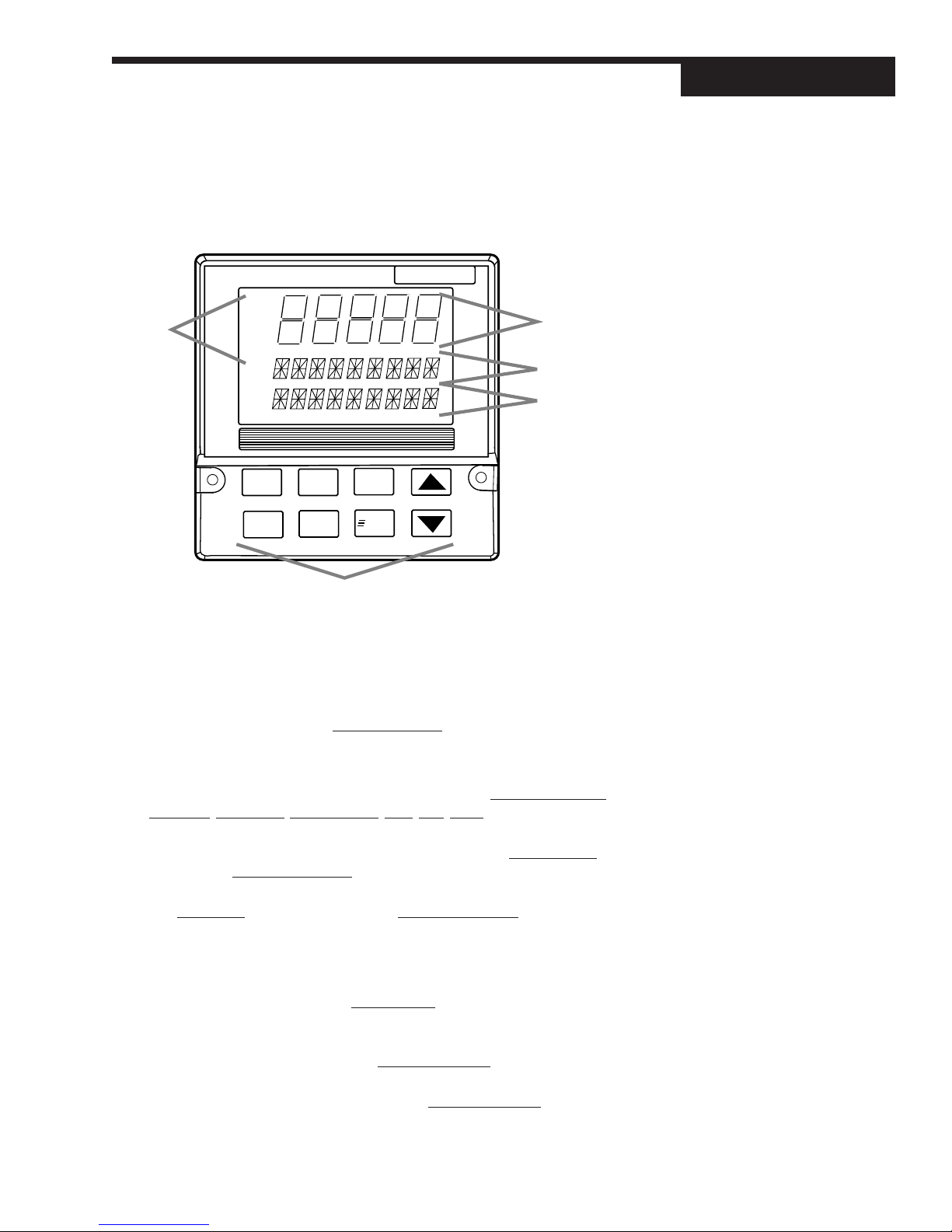

Figure 2.1 ........ 555 Operator Interface ...................................................... 5

Figure 3.1 ........ Accessing the 555 Circuit Boards ..................................... 7

Figure 3.2 ........ The Microcontroller Circuit Board,

The Option Board, and the Power Supply Board ............... 8

Figure 3.3 ........ Output Module ................................................................ 11

Figure 3.4 ........ Install Communications Module onto the

Microcontroller Board ...................................................... 12

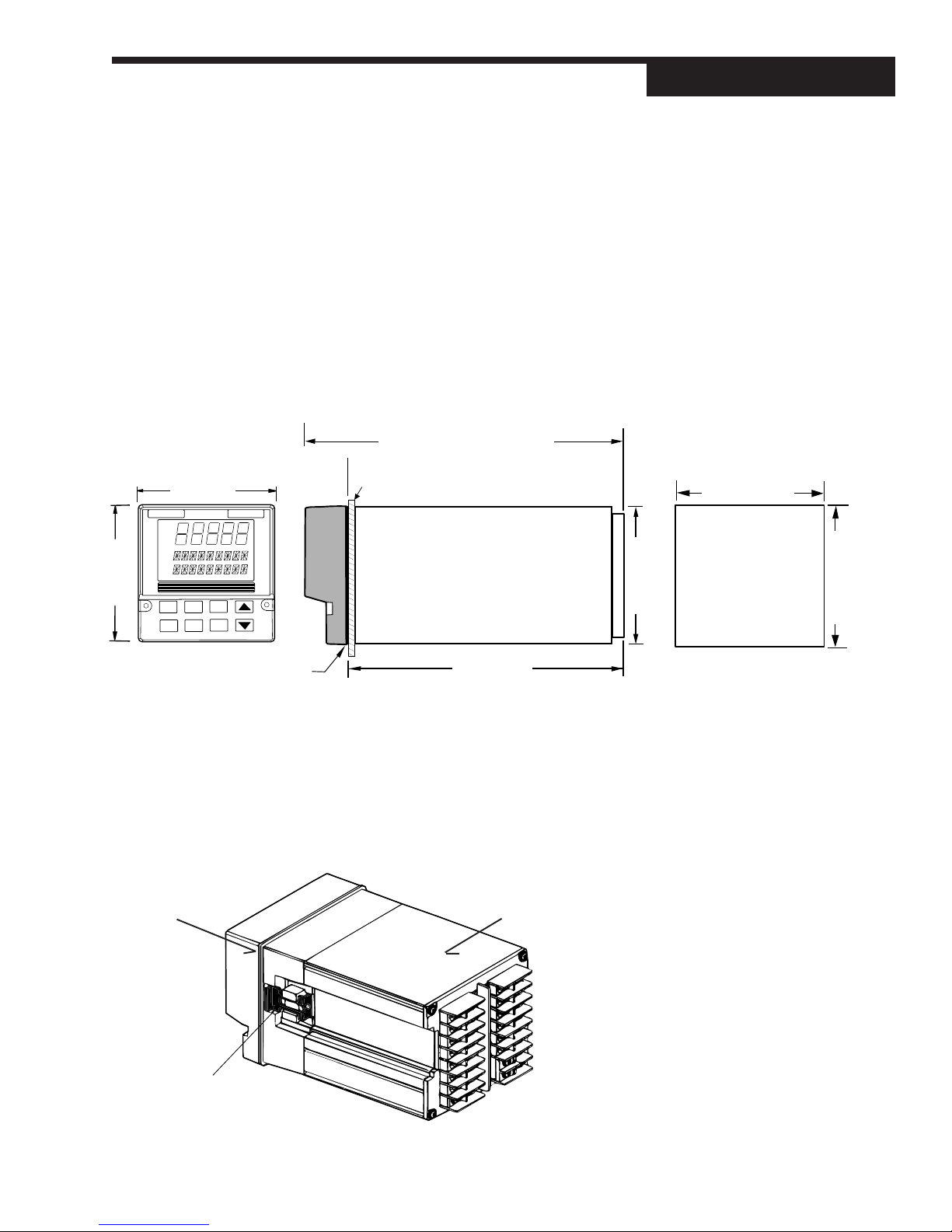

Figure 4.1 ........ Controller Dimensions. .................................................... 13

Figure 4.2 ........ Insert Mounting Clips ...................................................... 13

Figure 4.3 ........ 555 Input and Output Wiring Options .............................. 14

Figure 4.4 ........ AC Power Input Wiring .................................................... 15

Figure 4.5 ........ PV Voltage Input Wiring .................................................. 15

Figure 4.6 ........ PV mA Input with External Power Supply Wiring ............. 16

Figure 4.7 ........ PV mA Input with Internal Power Supply and

2-Wire Transmitter Wiring ................................................ 16

Figure 4.8 ........ PV mA Input with Internal Power Supply and

4-Wire Transmitter Wiring ................................................ 17

Figure 4.9 ........ Digital Input Wiring with a Switch or Relay ...................... 17

Figure 4.10 ...... Digital Input Wiring with an Open Collector ..................... 18

Figure 4.11 ...... Mechanical Relay Output Wiring ..................................... 18

Figure 4.12 ...... Solid State Relay Output Wiring ...................................... 19

Figure 4.13 ...... DC Logic Output and Milliamp Output Wiring ..................19

Figure 4.14 ...... Position Proportioning Output

with Slidwire Feedback Terminals ................................... 20

Figure 4.15 ...... Remote Setpoint Terminals ............................................. 21

Figure 4.16 ...... Serial Communications Terminals ................................... 21

Figure 5.1 ........ Menus, Parameters and Values ...................................... 23

Figure 5.2 ........ Independent vs. Dependent Parameters ......................... 24

Figure 5.3 ........ Operation and Configuration Flowchart ...........................24

Figure 6.1 ........ Flow Pacing Control ........................................................ 59

Figure 6.2 ........ Residual Chlorine Loop Control ...................................... 61

Figure 6.3 ........ Compound Loop Control ................................................. 64

Figure 6.4 ........ Dechlorination Control .................................................... 67

Figure 6.5 ........ Alarm Examples .............................................................. 73

Figure 6.6 ........ Residual Control Responses .......................................... 81

Figure 6.7 ........ Square Root Linearization Formula................................. 83

Figure 6.8 ........ Custom Linearization Curve............................................ 84

Figure 6.9 ........ Compound Loop Flow Pacing with Lag Times ................. 87

Figure B.1 ........ Calibration Menu Flowchart .......................................... B-1

Figure B.2 ........ Microcontroller Circuit Board ......................................... B-2

Figure B.3 ........ PV1 & PV2 Calibration Wiring ....................................... B-2

Figure B.4 ........ Milliamp Output Calibration Wiring ................................ B-3

Figure B.5 ........ Output Module Menu Cycle ........................................... B-4

Figure B.6 ........ Slidewire Calibration Wiring .......................................... B-5

Contents

555 User's Manual Table of Contents iii

Page 5

Contents

iv Table of Contents 555 User's Manual

Page 6

CHAPTER 1

GENERAL INFORMATION

General Information

Figure 1.1

The 555 Chlorination/Dechlorination

Controller

Automatic and accurate control of chlorine in potable and waste water is

more important than ever due to health and regulatory concerns. Poor

control can lead to failure of biomonitoring tests, leading to an even more

costly “Toxicity Reduction Evaluation.” The 555 is a cost effective way to

upgrade chlorination and dechlorination processes in an easy to use,

rugged 1/4 DIN size package. The 555 can be easily set up to handle flow

proportional control, residual control, compound loop control with lag times,

and dechlorination with sulfur dioxide.

Designed with the needs of the water and wastewater industry in mind, the

555 offers features that set it apart from the competition. The front panel is

NEMA 4X rated for protection from water and corrosion. The vacuum fluorescent display is bright and crisp, offering the best readability in all light

conditions. All prompts are displayed in easy to understand terms, with two

fully alphanumeric displays. An extra large third display is dedicated to

indicating one of the measured variables. When performing Compound Loop

Flow Pacing control, the 555 clearly displays both flow rate and residual

chlorine level simultaneously. The sturdy rubber keys are large and backlit

with excellent tactile feel.

The 555 is designed to quickly integrate with your flow transmitters and

residual analyzers through straightforward menu configuration selections.

555 CONTROL MODES

FLOW PACING MODE: control mode for adding chlorine to and/or removing

chlorine from the water, based on flow rate with no feedback.

RESIDUAL CHLORINE MODE: control mode for adding chlorine to the water

based on residual level as the process variable.

COMPOUND LOOP MODE: control mode for adding chlorine based on a

combination of both flow pacing and residual level.

DECHLORINATION MODE: the control output for adding SO2 to the water

based on a combination of both flow pacing and residual chlorine level.

555 User's Manual Chapter 1 1

Page 7

General Information

555 OPERATION

There are 3 operation “modes” for the 555 controller:

OPERATING, the default mode of the controller. While the 555 is “operating,”

you can change dosage setpoints, select manual control and change output level,

acknowledge alarms and monitor conditions.

SET UP, sometimes referred to as “configuration.” In set up, you configure the

basic functions of the instrument such as input and output assignments, alarm

types and special functions.

TUNING, where you configure control function parameters for Residual and

Compound Loop control. Use the tuning function periodically to optimize the

performance of the 555.

Refer to Chapter 5, and Figure 5.3, to view the relationship between these 3

modes.

ORDER CODE, P A CKAGING INFORMATION

Compare the product number on your controller (the label on top of the controller) with the order code on the next page. From this number you can confirm the

options on your 555.

In the controller packaging, you should have received:

• one 555 controller

• one 555 User’s Manual

• 555 mounting hardware

• one sheet engineering unit adhesive labels

• one rear terminal label

WHERE TO GO NEXT

• To become more familiar with the 555 interface, continue to Chapter 2.

• For important hardware installation guidelines, see Chapters 3 and 4.

• For a detailed description of all the software menus and parameters of the

555, follow through Chapter 5. Appendix D can be used as a basic guideline

to these parameters.

TEXT FORMA TTING IN THIS MANU AL

Feature Format

KEYS SET PT DISPLAY

or

SET PT DISPLAY

ICONS OUT, ALM

MENUS CONFIG., TUNING,

PARAMETERS CYCLE TM:1, MIN.OUT2

PARAMETER VALUES OFF, SETPOINT, LAST OUT.

DISPLAY MESSAGES TOO HOT, OUT%,

2 Chapter 1 555 User's Manual

Page 8

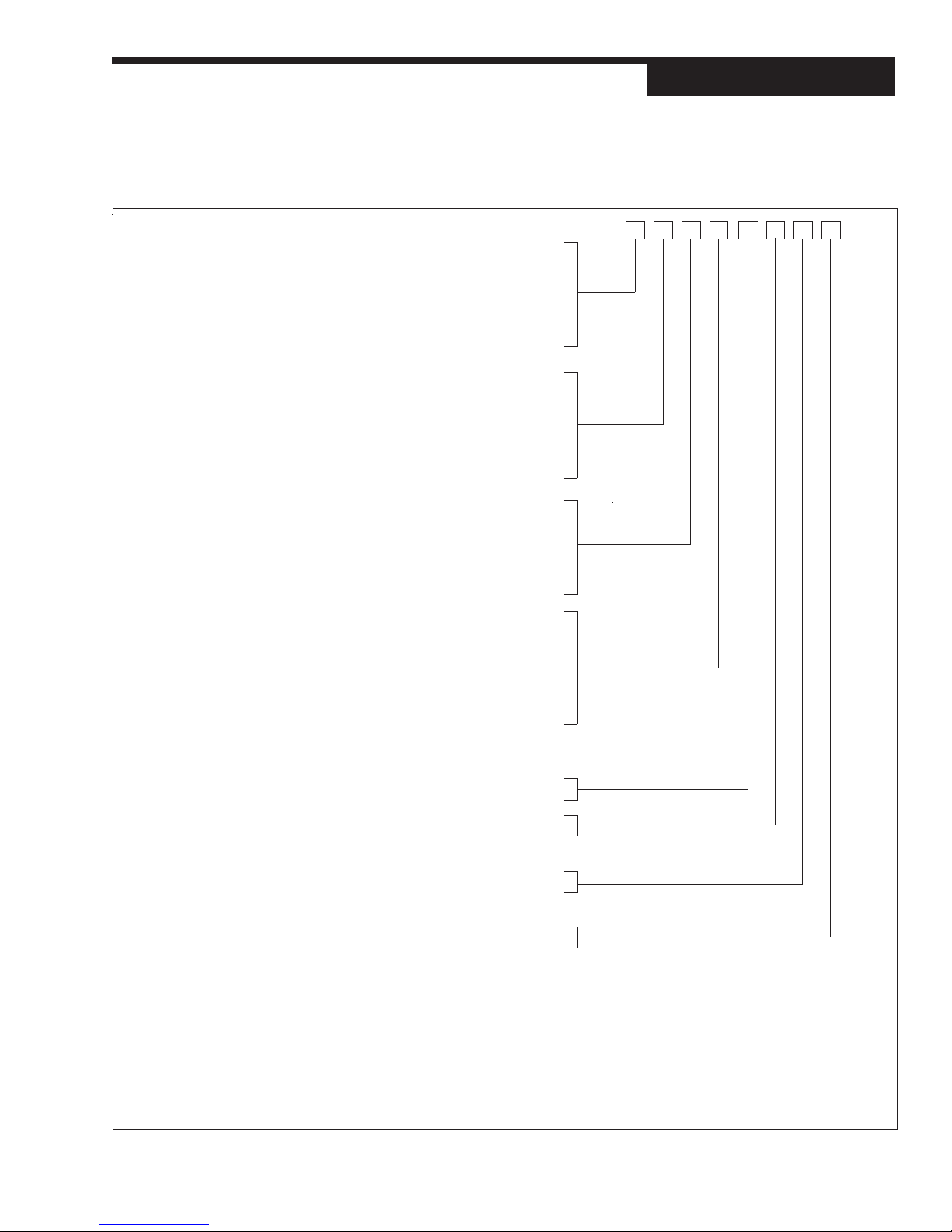

ORDER CODE

General Information

OUTPUT 1 —

CONTROL

OUTPUT 2 —

CONTROL,

ALARM,

OR

RETRANSMISSION

OUTPUT 3 —

ALARM,

OR

RETRANSMISSION

OUTPUT 4 —

ALARM,

RETRANSMISSION,

OR LOOP POWER

None .......................................................... 0

Mechanical relay (5 amp) ........................... 1

Analog (milliamp) ....................................... 2

Solid state relay (triac) (1 amp) ...................3

DC logic (SSR drive) .................................. 4

None .......................................................... 0

Mechanical relay (5 amp) ........................... 1

Analog (milliamp) ....................................... 2

Solid state relay (triac) (1 amp) ...................3

DC logic (SSR drive) .................................. 4

None .......................................................... 0

Mechanical relay (5 amp) .......................... 1

Analog (milliamp) ....................................... 2

Solid state relay (triac) (1 amp) .................. 3

DC logic (SSR drive) ................................. 4

None .......................................................... 0

Mechanical relay (0.5 amp, 24 V) .............. 1

Analog (milliamp) ....................................... 2

Solid state relay (triac) (0.5 amp, 24 V) ..... 3

DC logic (SSR drive) ................................. 4

Loop power................................................ 5

B

0 0555 -

Optional Inputs

ENTER “0” IF

OPTIONAL

NOT DESIRED

INPUT

Slidewire feedback for

position proportioning

output ........................................................ A

Remote setpoint (Standard) ....................... B

Five digital inputs (for vacuum alarm and

stand by mode) .......................................... D

SERIAL

COMMUNICATIONS

ENTER

“0” IF

RS-485 serial

communications......................................... S

COMMUNICATIONS

NOT

DESIRED

Note 1: Capability for position proportioning output is specified by ordering 555-11xxAxxx00, 555-33xxAxxx00,

or 555-44xxAxxx00. (Slidewire not required for velocity proportioning.) Note 2: Up to two outputs may be

used for alarms. Note 3: All outputs are interchangeable modules. Note 4: The mechanical relay and solid

state relay modules are derated to 0.5 amp at 24 Vac when used as the fourth output.

555 User's Manual Chapter 1 3

Page 9

General Information

4 Chapter 1 555 User's Manual

Page 10

CHAPTER 2

BASIC INTERF A CE

Interface

Icons

OUT

1 2

ALM

1 2

555

Displays:

1st

2nd

3rd

MANUAL

ACK

DISPLAY

MENU

SET PT

FAST

Keys

DISPLAYS

Refer to Chapter 6 for details on the interface functions for specific modes.

1st Line (five 7-segment digits)

• Always displays a (primary) process variable, with value/units depending

on the individual mode.

2nd Line (nine 14-Segment Digits)

• Under “normal” operating conditions, displays process dosage or

setpoints, deviations, output values, lags, trim, pace, etc., depending upon

the mode.

• When configuring the 555 (in any mode), displays the menu names and

subsequent parameter names.

• When using a ramping setpoint that is actively ramping, alternates between

the target SP (SP2, RSP) and the ramping setpoint (which causes

RAMPING to show in the third display).

• When using the slidewire option, displays the actual valve position.

3rd Line (nine 14-Segment Digits)

• For dual PV modes shows the alternate PV, whether it is flow or residual

level. To switch the display positions of the primary and secondary PV,

press FAST + DISPLAY.

• If alarms occur, this line will show alarm messages alternating with any

other messages.

• During configuration, this line shows the parameter value in the menu

system.

Figure 2.1

555 Operator Interface

555 User's Manual Chapter 2 5

Page 11

Interface

OUT OUT OUT

1212

ALM ALM ALM

1212

PV2

ICONS (LIT)

OUT1 Indicates the output is at a level greater than 0%, or “activated” (for time

OUT2 Indicates the second output (SO

ALM1 Indicates the respective alarm (one) is active.

ALM2 Indicates the respective alarm (one) is active.

PV2 Indicates that the flow input (PV2) is in the 1st display.

KEYS

FAST: Has no independent function - press to modify the function of another

key (see below).

MANUAL : Press to toggle between manual and automatic control. When lit,

indicates that the unit is under manual control.

FAST+MANUAL : Press to transfer controller from manual to automatic control

when setting up bumpless transfer dosage values. Refer to Chapter 6 for more

information about bumpless transfer and dosage values.

SET PT : Press to select the active SP. When lit, indicates that a setpoint other

than the primary (e.g., RSP, SP2) is active.

DISPLAY

DISPLAY

MANUAL

MANUAL

+

SET PT

proportioning or a digital output).

2

staging or slidewire output is active.

) of the duplex flow pacing mode,

FAST

FAST

FAST

FAST

DISPLAY

DISPLAY

+

+

+

+

▲

▲

▼

▼

MENU

MENU

DISPLAY : Press to step through the values (SP, %OUT, DOSAGE, etc.) to be

shown in the 2nd display.

FAST+DISPLAY : Allows user to switch display positions of the PV1 (residual)

and PV2 (flow) between the 1st and 3rd displays.

▲▲

▲ : Press to advance to previous value or parameter

▲▲

FAST+

▼▼

▼ : Press to advance to next value or parameter

▼▼

FAST+

ACK : Press to acknowledge (an) alarm(s). When lit, indicates that there is an

acknowledgeable alarm.

MENU : Press to access the Tuning Menu, and its parameters. When lit, indicates

that the controller is in Set Up mode (in the configuration menus).

FAST+MENU : Press to access the Set Up menus. Use MENU to access the

parameters of the software menus. When lit, indicates that the controller is in

Set Up mode (in the configuration menus).

▲▲

▲ : Press to scroll through values at a faster rate.

▲▲

▼▼

▼ : Press to scroll through values at a faster rate.

▼▼

6 Chapter 2 555 User's Manual

Page 12

CHAPTER 3

HARDW ARE SET UP

Hardware

The configuration of the hardware in your controller determines the available

outputs as well as the type of input signal. Your 555 controller comes factory

set with the following:

• All the specified modules and options installed. (For more details, refer to

the order code in Chapter 1.)

• Process variable, setpoint and/or valve position inputs set to accept a

milliamp input

• Relay outputs set to normally open

To alter the factory configuration of your 555, you will need to access the 555

circuit boards, and locate the jumpers and output modules on the circuit boards

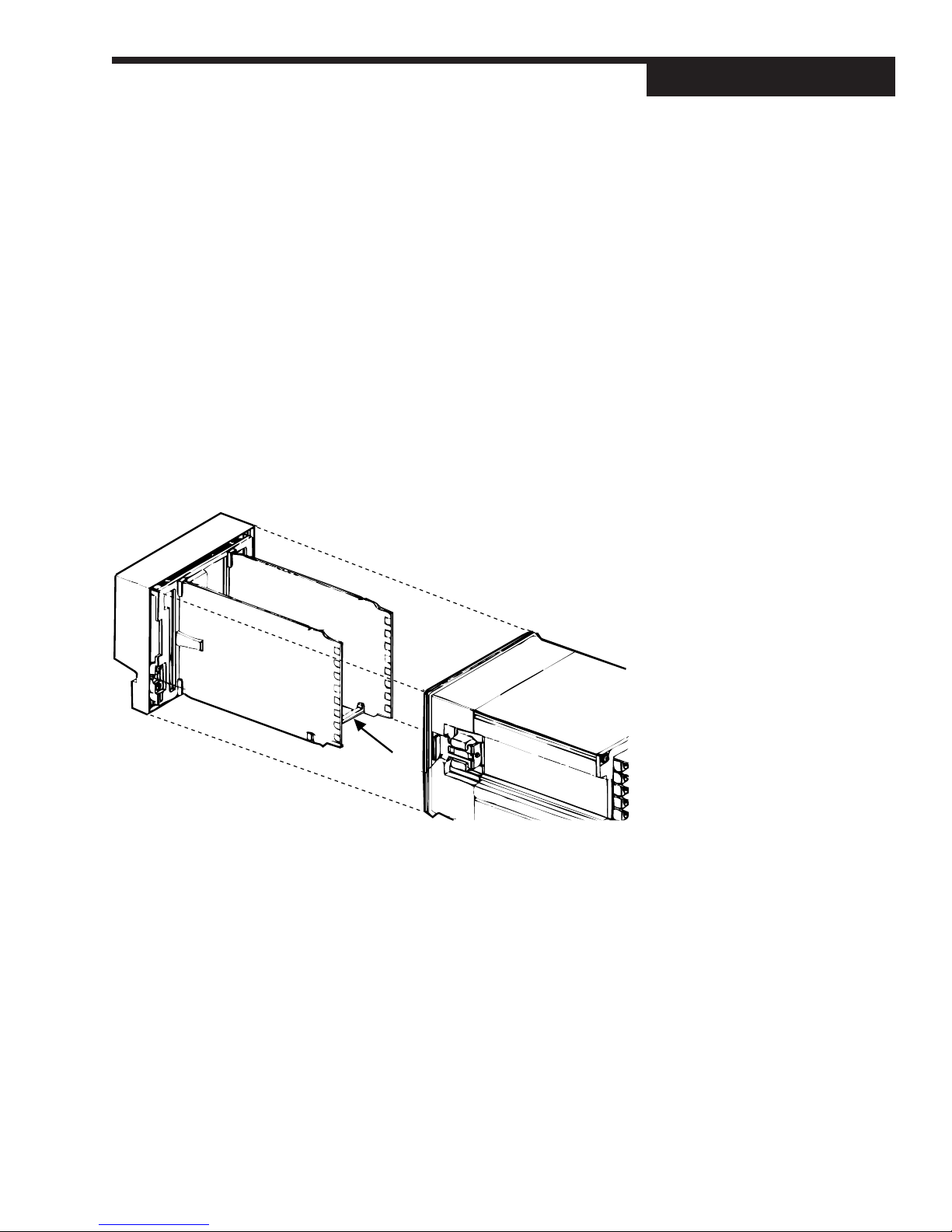

(see Figure 3.1):

1. With power off, loosen two front screws, and remove them.

2. Slide the chassis out of the case by pulling firmly on the bezel.

MICROCONTROLLER

BOARD

POWER SUPPLY

BOARD

NOTE:

If you would like your controller

configured at the factory, please

consult an application engineer.

NOTE:

Your hardware configuration will

influence the available software

options as discussed in Chapter 3.

Figure 3.1

Accessing the 555 Circuit Boards

OPTION

BOARD

A detailed view of the circuit boards appears in Figure 3.2.

After configuring the hardware, or if you do not need to make any changes, con-

tinue your process set up as needed.

HARDW ARE INPUT TYPES

The Process Variable

The 555 accepts both voltage and milliamp process variable signals. You must

set a jumper location to specify the type of input signal. You set the particular

range in the software (see Chapter 5 for software menus, or Chapter 6 for applications).

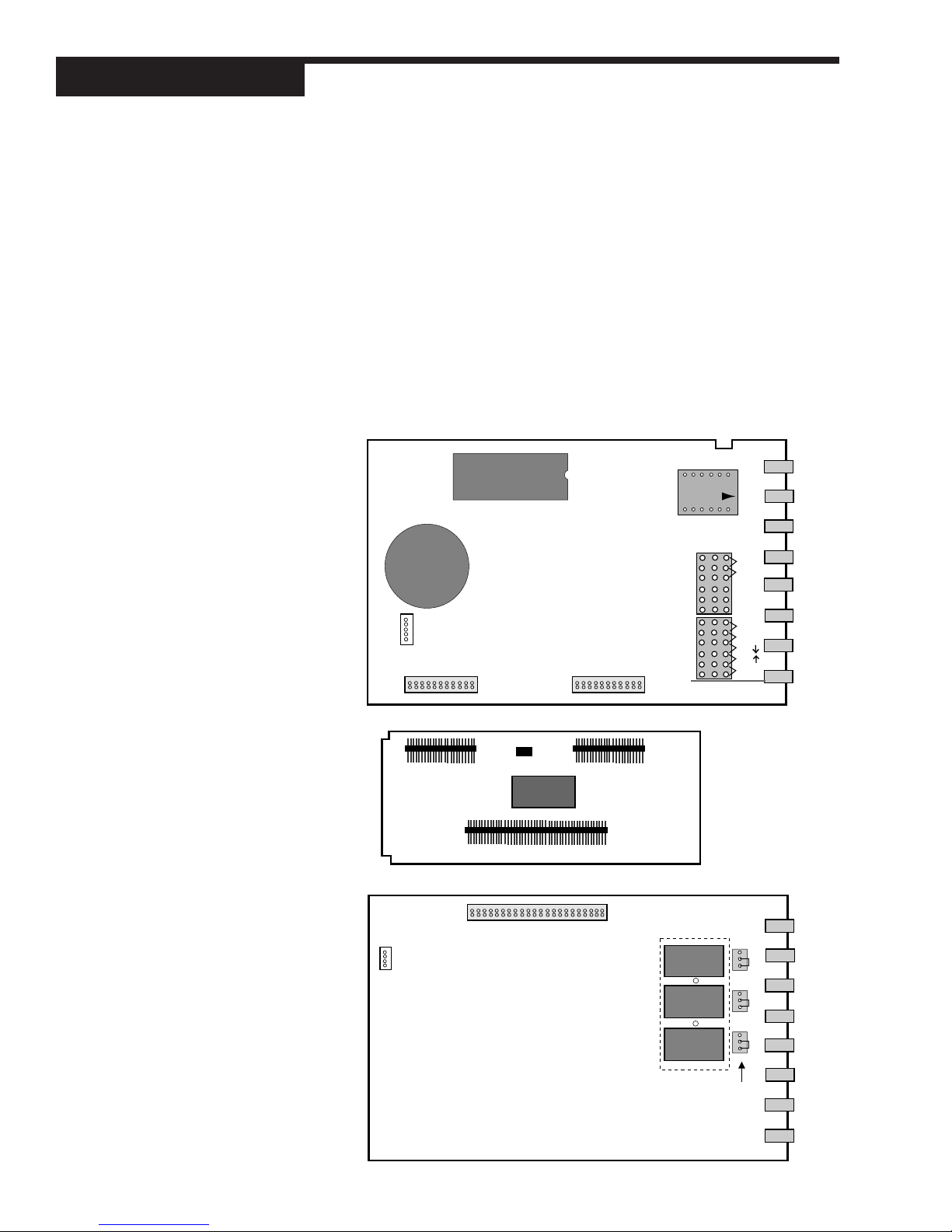

The jumpers for the process variable are located on the Microcontroller Circuit

Board (see Figure 3.2). The factory default is Milliamp. Locations are marked

as follows:

V Voltage

MA Milliamp

555 User's Manual Chapter 3 7

NOTE:

Any changes you make to the output

modules will render the code on the

product label invalid.

Page 13

Hardware

BATTERY

EPROM

Figure 3.2

(from the top) The Microcontroller

Circuit board, The Option Board,

and the Power Supply Board

The Remote Setpoint

Figure 3.2 shows the location of the remote setpoint jumper. The factory default

is Milliamp. Choose from the following settings:

V Voltage

MA Milliamp

Mechanical Relays

There are three output module sockets on the Power Supply Circuit Board,

and one output module on the Option Board (see Figure 3.2). The mechanical relay on the Power Supply Board may be configured for either normally

open (NO) or normally closed (NC). A jumper located next to each socket de-

termines this configuration. All the relay outputs are factory set to NO

(normally open).

EPROM

Comm Module

TB2

BATTERY

5-Pin Connector

Female 22-Pin ConnectorFemale 22-Pin Connector

V

MA

V

MA

TC

TC

RTD

2ND

PV1

TB1

8 Chapter 3 555 User's Manual

Male 22-Pin

Connector

4-Pin Connector

Output 4

4

Female 44-Pin Connector

Male 22-Pin

Connector

Male 44-Pin

Connector

Module

Retention

Plate

over Outputs 1,2,3

3

2

1

NO J3 NC

NO J2 NC

NO J1 NC

Jumpers

NO and NC

Page 14

ACCESSING AND CHANGING JUMPERS

Follow these instructions to change jumpers for the Process Variable, Remote

Setpoint and Digital Inputs:

Equipment needed: Needle-nose pliers (optional)

Phillips screwdriver (#2)

Wrist grounding strap

1. With power off, loosen two front screws, and remove them.

2. Slide the chassis out of the case by pulling firmly on the bezel.

3. Use Figure 3.2 to help you locate the jumper connector that you intend to

change.

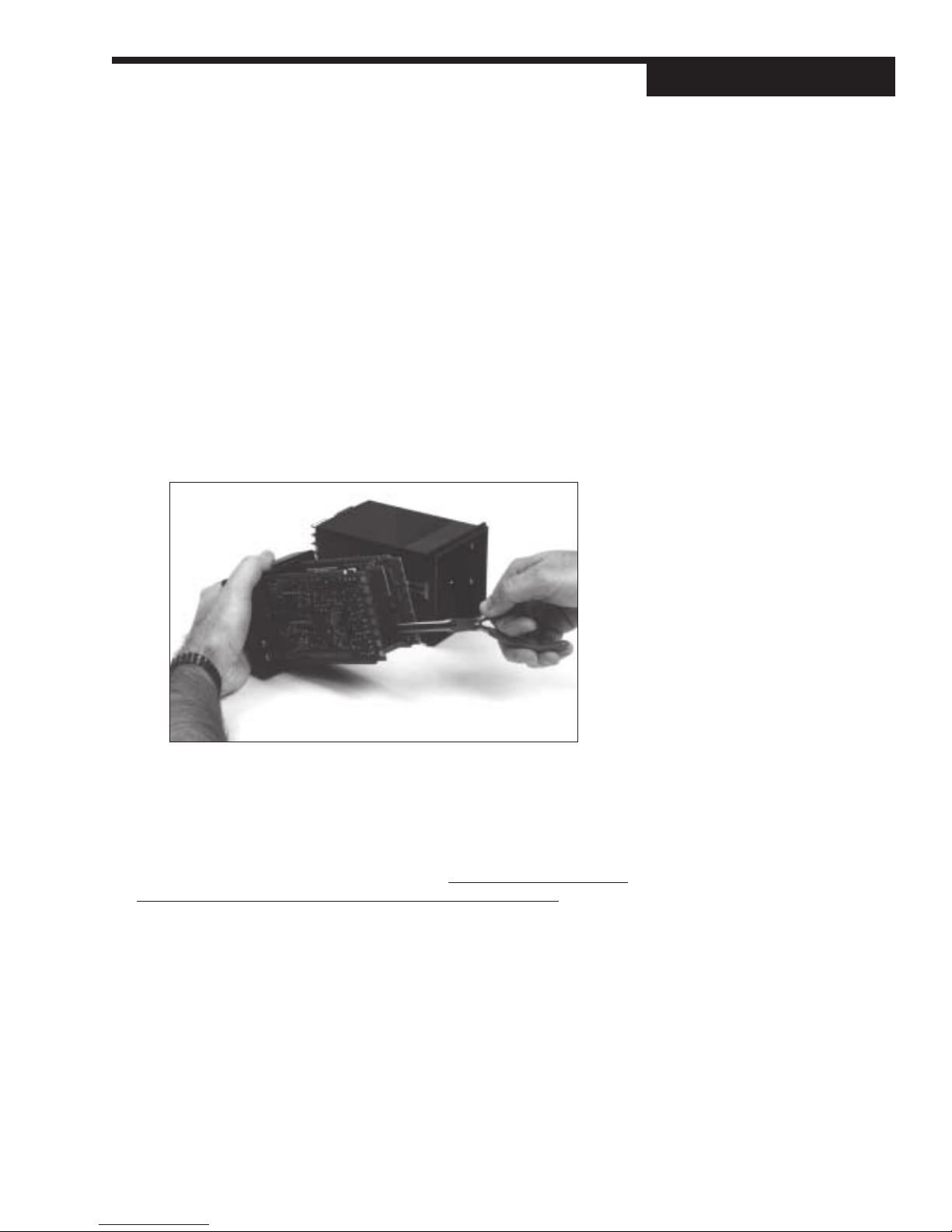

4. Using either your fingers or the needle nose pliers, pull straight up on the

connector and remove it from its pins, as shown in Photo 4. Be careful not

to bend the pins.

Hardware

4. Remove Jumpers

5. Find the new location of the jumper connector (again, refer to Figure 3.2).

Carefully place it over the pins, then press connector straight down. Make

sure it is seated firmly on the pins.

6. Make any other jumper changes as needed.

modules, please refer to the next section, starting with Step #3.

7. To reassemble the controller, properly orient the chassis with board opening on top. Align the circuit boards into the grooves on the top and bottom of

the case. Press firmly on the front face assembly until the chassis is all the

way into the case.

If you have difficulty sliding the chassis in all the way, make sure you have

removed the screws (they can block proper alignment), and that the chassis is properly oriented.

8. Carefully insert and align screws. Tighten them until the bezel is seated firmly

against the gasket. Do not overtighten.

555 User's Manual Chapter 3 9

If you need to alter output

Page 15

Hardware

ADDING AND CHANGING OUTPUT MODULES

The 555 has provisions for four output modules. A controller ordered with

output module options already has the modules properly installed. Follow

these instructions to add modules, change module type(s) or change module

location(s).

Equipment needed: Wrist grounding strap

Phillips screwdriver (#2)

Small flat blade screwdriver

Wire cutters

1. With power off, loosen two front screws, and remove them.

2. Slide the chassis out of the case by pulling firmly on the bezel.

3. Use a flat screwdriver to carefully pry apart the clips that hold the front

face assembly to the chassis, as in Photo 3. Separate the printed circuit

board assembly from the front face assembly. Use care not to break the

clips or scratch the circuit boards.

4. As shown in Photo 4, use your hands, or the flat screwdriver, to carefully

pry apart the smaller Option board and the Power Supply board (the one

with 3 modules).

5. If you need to change modules 1, 2 or 3:

Output modules 1, 2, and 3 are firmly held in place by a retention plate

and tie wrap. Carefully snip the tie wrap with a wire cutter. To prevent

damage to the surface mount components, ALWAYS snip the tie wrap on

TOP of the Retention Plate, as shown in Photo 5.

Remove the retention plate.

3. Pry Clips

10 Chapter 3 555 User's Manual

4. Separate Boards

5. Remove Retention Plate

Page 16

6. If you need to change module 4:

Output Module 4 (on the Option board) is also held in place by a tie wrap.

Snip tie wrap to remove module as shown in Photo 6.

7. Figure 3.3 shows a representation of an output module. Inspect your

module(s) to make sure that the pins are straight.

8. To install any module, align its pins with the holes in the circuit board, and

carefully insert the module in the socket. Press down on the module until

it is firmly seated; refer to Photo 8.

Hardware

Figure 3.3

Output Module

6. Snip Tie Wrap

9. Replace tie wraps for all the modules (the Retention Plate and Output

Module 4) with new ones before you reassemble.

Failure to use the tie wraps may result in loosening of the module and

eventual failure. All separately ordered modules should come with a tie

wrap. Extra sets of tie wraps are available by ordering Part #555-665.

10.Rejoin the circuit boards by aligning the pins of their connectors, then

squeezing the board(s) together. Make sure that all three printed circuit

boards are properly seated against one another; check along side edges

for gaps. Make sure the cable assemblies are not pinched.

11.To reattach the board assembly to the front face assembly, align the

boards (with the open area on top) into the slots of the font face assembly. The clips should snap into place.

12.To reassemble the controller, properly orient the chassis with board

opening on top. Align the circuit boards into the grooves on the top and

bottom of the case. Press firmly on the front face assembly until the

chassis is all the way into the case.

If you have difficulty sliding the chassis in all the way, make sure you

have removed the screws (they can block proper alignment), and that the

chassis is properly oriented.

13.Carefully insert and align screws. Tighten them until the bezel is seated

firmly against the gasket. Do not overtighten.

8. Add/Change Module

NOTE: For greatest accuracy,

calibrate all milliamp modules added

for retransmission as per the

instructions in Appendix B.

SPECIAL COMMUNICA TIONS MODULE

555 User's Manual Chapter 3 11

Page 17

Hardware

A special communications module is available for the 555; see order code in

Chapter 1 for details.

Equipment needed: Wrist grounding strap

Phillips screwdriver (#2)

Small flat blade screwdriver

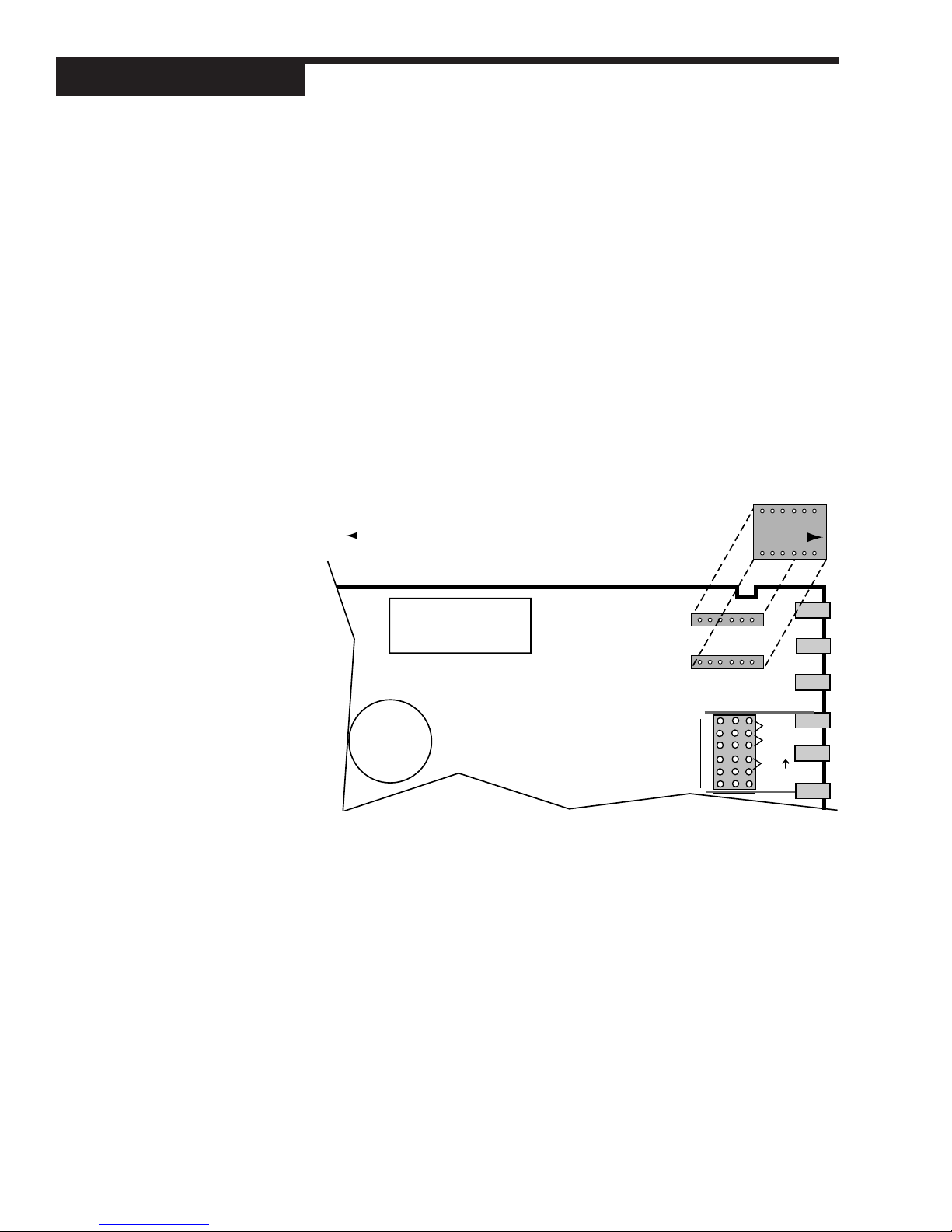

1. Before you install the communications module, set up the hardware wiring

for your application. See Chapter 4 for details.

2. With power off, loosen two front screws, and remove them.

3. Slide the chassis out of the case by pulling firmly on the bezel. Do not detach

the board assembly from the front face of the controller.

4. Orient the Communications Module with the arrow pointing towards the rear

of the 555 unit, and attach it to Connectors P1 and P2 as shown in Figure

3.4.

5. To reassemble the controller, properly orient the chassis with board open-

Insert module onto connectors.

Make sure arrow on module

points toward rear terminals.

Figure 3.4

Install Communications Module onto

Microcontroller Board

Front of controller

(circuits boards still attached to front face)

EPROM

P2

P1

TB2

(REMOTE SP

BATTERY

OR

DIGITAL INPUT)

CONFIGURATION

ing on top. Align the circuit boards into the grooves on the top and bottom of

the case. Press firmly on the front face assembly until the chassis is all the

way into the case.

If you have difficulty sliding the chassis in all the way, make sure you have

removed the screws (they can block proper alignment), and that the chassis is properly oriented.

6. Carefully insert and align screws. Tighten them until the bezel is seated firmly

against the gasket. Do not overtighten.

V

MA

TC

2ND

12 Chapter 3 555 User's Manual

Page 18

CHAPTER 4

INSTALLA TION

MOUNTING THE CONTROLLER

The front face of the 555 is NEMA 4X rated. To obtain a waterproof seal between the controller and the instrument panel, follow these directions:

1. The 555 fits in a standard 1/4 DIN cutout. You may mount your 555 in any

panel with a thickness from 0.06 in. to 0.275 in. (1.5mm to 7.0mm).

2. Figure 4.1 shows controller and panel dimensions. The panel cutout must

be precise, and the edges free from burrs and waves.

7.180 (182.37) OVERALL LENGTH

1.180 (29.97)

3.770 (95.76)

PANEL

Installation

Figure 4.1

Controller Dimensions

3.622 (92.00) MIN.

3.653 (92.80) MAX.

OUT

1 2

ALM

1 2

3.770 (95.76)

6.000 (152.40)

SIDE

FRONT

BEZEL

GASKET

3. Place a new bezel gasket around the controller case, starting at the back of

controller. Then, slide the gasket up against the back of the bezel. To ensure a good seal, always use a fresh gasket.

4. With the bezel gasket in place, insert the 555 into the panel cutout from the

front of the panel. The case of the controller must be centered in the cutout.

5. From behind the panel, insert the mounting clips (one on each side), as

shown in Figure 4.2.

3.585 (91.06)

CUTOUT

Figure 4.2

Insert Mounting Clips

3.622 (92.00) MIN.

3.653 (92.80) MAX.

MOUNTING BRACKET

(1 EA. SIDE)

BEZEL

555 User's Manual Chapter 4 13

Slide

gasket on

from this

end.

HOUSING

Page 19

Installation

6. Gradually tighten the mounting bracket screws with a long Phillips screw

driver (#2). Make sure the screws are secure, and check the bezel gasket

for a tight, even seal.

7. If you have difficulty with any of the mounting requirements, apply a bead of

caulk or silicone sealant behind the panel around the perimeter of the case.

WIRING FOR INPUT AND OUTPUTS

555 controllers are thoroughly tested, calibrated and “burned in” at the factory,

so your controller is ready to install. Before you begin wiring your system, read

this section thoroughly and take care in planning your system. A properly designed system can help prevent problems such as electrical noise disturbances

and dangerous extreme conditions.

Special Notes:

1. For improved electrical noise immunity, install the 555 as far away as possible from motors, relays and other similar noise generators.

2. Do not run low power (sensor input) lines in the same bundle as AC power

lines. Grouping these lines in the same bundle can create electrical noise

interference.

3. All wiring and fusing should conform to the National Electric Code and to

any locally applicable codes.

4. An excellent resource about good wiring practices is the IEEE Standard No.

518-1982 and is available from IEEE, Inc., 345 East 47th Street, New York,

NY 10017, (212) 705-7900.

Rear terminal diagrams on the next pages are guides for wiring the different

types of inputs and outputs for the 555. Remember that the installed output

modules (Chapter 3) determine which inputs and outputs are available, and your

software set up (Chapter 5) will determine how your instrument controls.

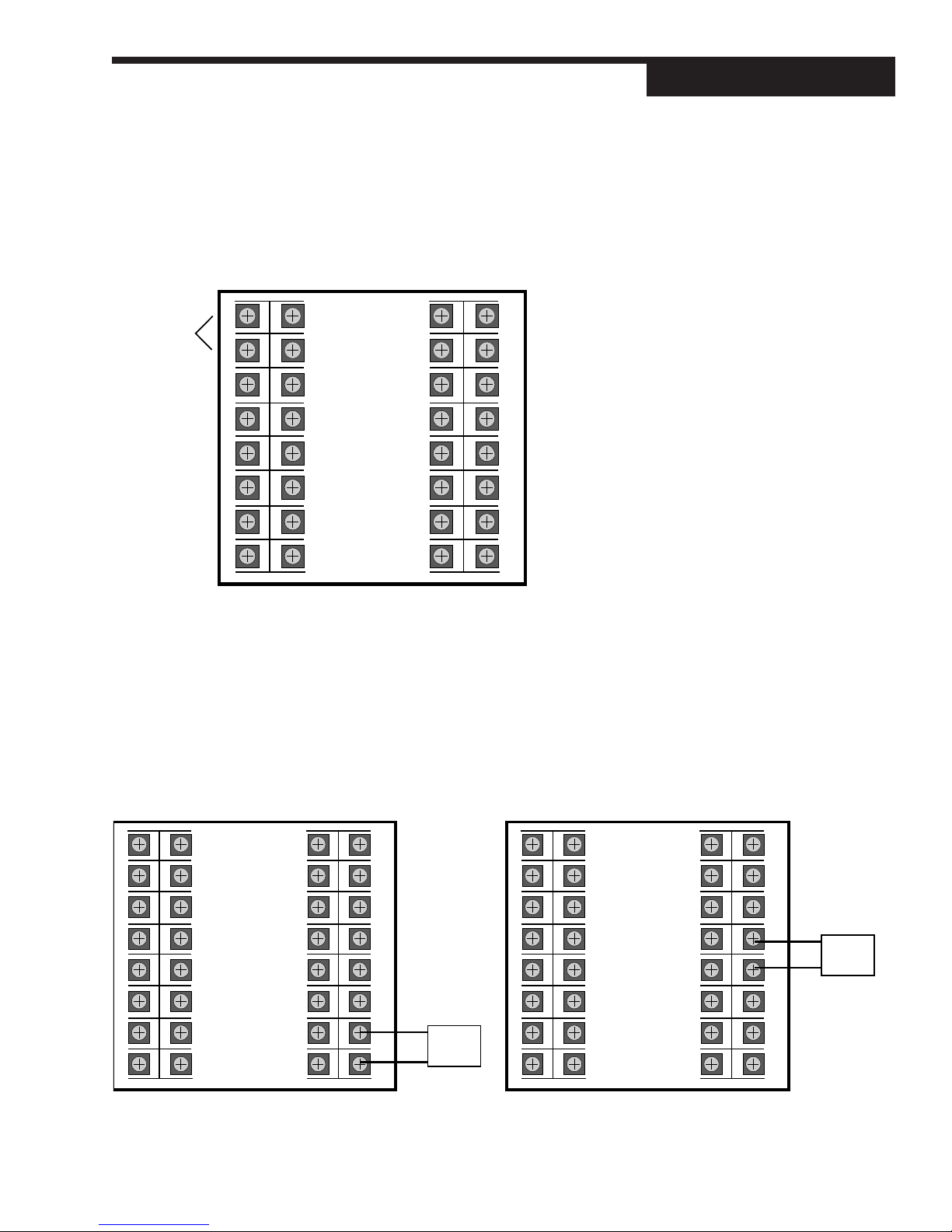

Figure 4.3

555 Input and Output Wiring

Digital Inputs Option (if installed)Slidewire Option Input

Options

AC Power

Flow Pacing, Residual, Compound Loop:

CL2 valve output (4-20mA or Relay)**

Dechlorination:

SO2 valve output (4-20mA or Relay)**

Dual Flow Pacing:

SO2 valve output (4-20mA or Relay)**

Alarm Relay/Retransmission:

2nd staged output (4-20mA)**

2nd slidewire output (relay)**

Alarm Relay/ Retransmission**

** Outputs 1, 2, 3 and 4 must be filled

with appropriate modules. See Chapter 3.

LINE

NEUTRAL

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

1

2

3

4

5

6

7

8

Alarm Relay/ Retransmission**

9

10

11

12

13

14

15

16

EARTH

GND

S/W

CCW

S/W2

S/W3

RSP–

RSP+

OUT 4–

OUT 4+

DIN

17

GND

DIN 1

18

DIN 2

19

DIN 3

20

DIN 4

21

DIN 5

22

N/A

23

N/A

24 32

Remote Set Point Option Input

25

26

27

28

29

30

31

N/A

RS485–

RS485+

PV2–

PV2+

N/A

PV1–

PV1+

RS485 Com

(if installed)

Flow signal input

4-20mA from transmitter

CL2 signal input

4-20mA from analyzer

14 Chapter 4 555 User's Manual

Page 20

AC P ower Input

Installation

Terminals 1 and 2 are for POWER. Terminal 9 is earth ground. Use a 0.5

Amp, 250 V fast-acting fuse in line with your AC power connection.

AC LINE

AC NEUTRAL

1

2

7

8

Screws must be tight to ensure electrical connection

9

16

EARTH

GND

17

25

31

24 32

Process V ariables

Note:

On the actual 555, the only

terminals with printed numbers are

those shown in Figure 4.4.

Figure 4.4

AC Power Input Wiring

The 555 uses up to two process variables depending on the control mode:

PV1 is for Cl

residual level, and PV2 is for flow (rate). Each PV signal can be

2

either voltage or milliamp input.

1. Voltage Input (Figure 4.5)

• PV1 uses terminals 31 and 32 connected to a transmitter.

• PV2 uses terminals 28 and 29 connected to a transmitter.

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

24 32

PV1–

PV1+

–

Transmitter

+

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

9

10

11

12

13

14

15

16

Figure 4.5

PV Voltage Input Wiring

17

18

19

20

21

22

23

25

26

27

28

29

30

31

PV2–

PV2+

24 32

–

Transmitter

+

555 User's Manual Chapter 4 15

Page 21

Installation

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

17

18

19

20

21

22

23

24 32

31

30

29

28

27

26

25

Screws must be tight to ensure electrical connection

2-wire

transmitter

–

+

Input power can come from

a loop power module in

Output 2 (terminals 5 & 6),

Output 3 (terminals 7 & 8), or

Output 4 (terminals 15 & 16).

Transmitter output can

be connected to

PV1 (temrinals 31 & 32) or

PV2 (temrinals 28 & 29)

OUT 4–

OUT 4+

OUT 3–

OUT 3+

OUT 2–

OUT 2+

PV1–

PV1+

PV2–

PV2+

Figure 4.6

PV mA Input with External Power

Supply Wiring

2. Milliamp Input + External Power Supply (Figure 4.6)

• PV1 Milliamp Input with an external power supply uses terminals 31

and 32 with a 2-wire transmitter.

• PV2 Milliamp Input with an external power supply uses terminals 28

and 29 with a 2-wire transmitter.

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

24 32

Figure 4.7

PV mA Input with Internal Power

Supply and 2-wire Transmitter

Wiring

PV1–

PV1+

External Power

Supply

–

Transmitter

–

1

2

3

4

5

6

+

+

7

8

Screws must be tight to ensure electrical connection

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 32

3. Milliamp Input + Internal (loop) Power Supply

If internal loop power is desired, a loop power module must be installed

in Output 2, 3 or 4. See Chapter 1 for details on your controller’s installed

options. See also Chapter 3 for module installation details.

2-wire Transmitter (Figure 4.7)

• PV1: terminals 31 and 32 with the loop power module output terminals, and a 2-wire transmitter.

• PV2: terminals 28 and 29 with the loop power module output terminals, and a 2-wire transmitter.

25

26

27

28

29

30

31

PV2–

PV2+

External Power

Supply

–

Transmitter

–

+

+

16 Chapter 4 555 User's Manual

Page 22

4-wire Transmitter (Figure 4.8)

• PV1: terminals 31 and 32 with the loop power module output terminals, and a 4-wire transmitter.

• PV2: terminals 28 and 29 with the loop power module output terminals, and a 4-wire transmitter.

Installation

Input power can come from

a loop power module in

Output 2 (terminals 5 & 6),

Output 3 (terminals 7 & 8), or

Output 4 (terminals 15 & 16).

Ð

Power for

transmitter

+

PV2–

PV2+

PV1–

PV1+

Ð

4-20mA

output from

transmitter

+

Transmitter output can

be connected to

PV1 (temrinals 31 & 32) or

PV2 (temrinals 28 & 29)

Input

OUT 2–

OUT 2+

OUT 3–

OUT 3+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

OUT 4–

OUT 4+

17

18

19

20

21

22

23

25

26

27

28

29

30

31

24 32

Screws must be tight to ensure electrical connection

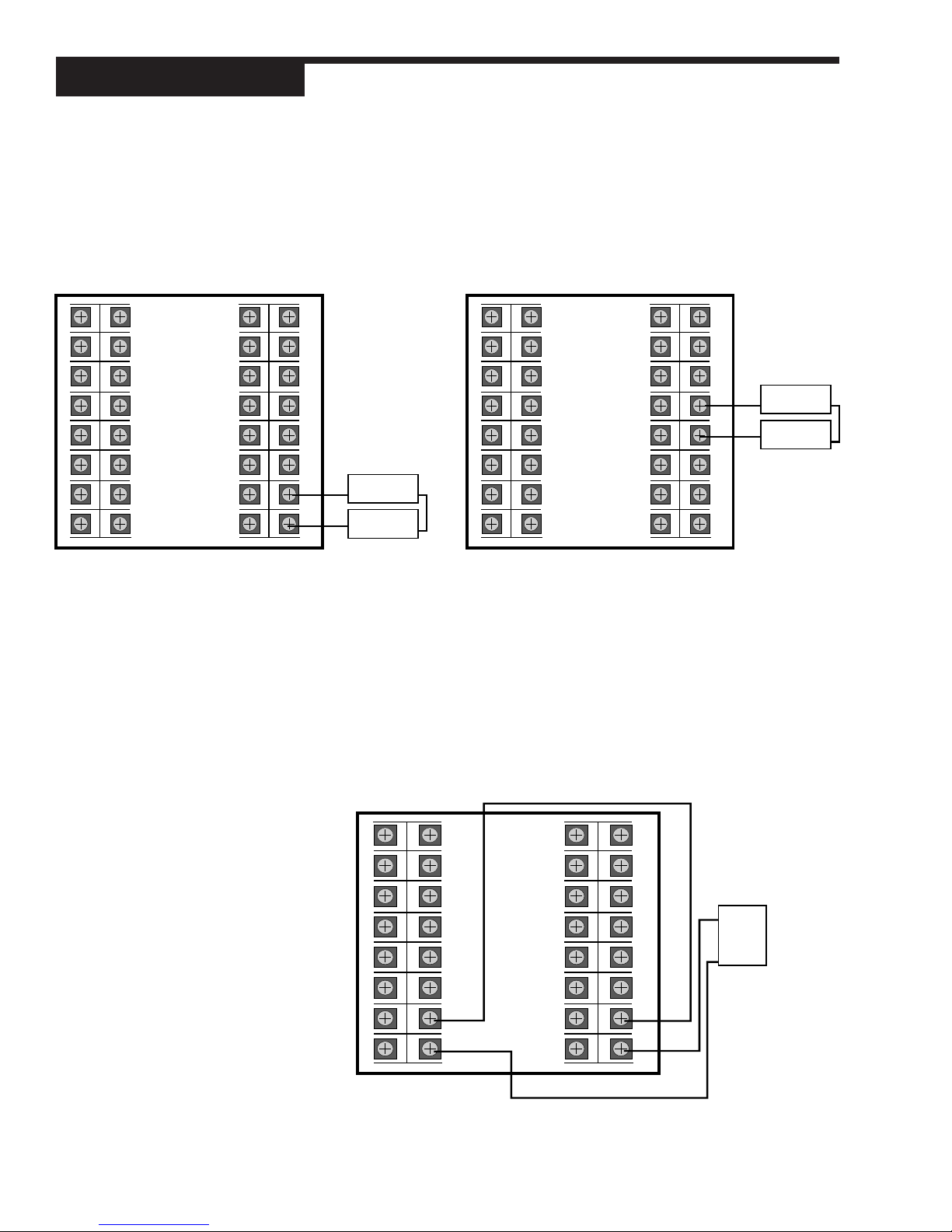

Digital Inputs

Digital inputs can be activated in three ways: a switch (signal type) - the recommended type, closure of a relay, or an open collector transistor.

Digital inputs are only functional when that option is installed (via hardware).

The controller detects the hardware type, and supplies the appropriate software

menu.

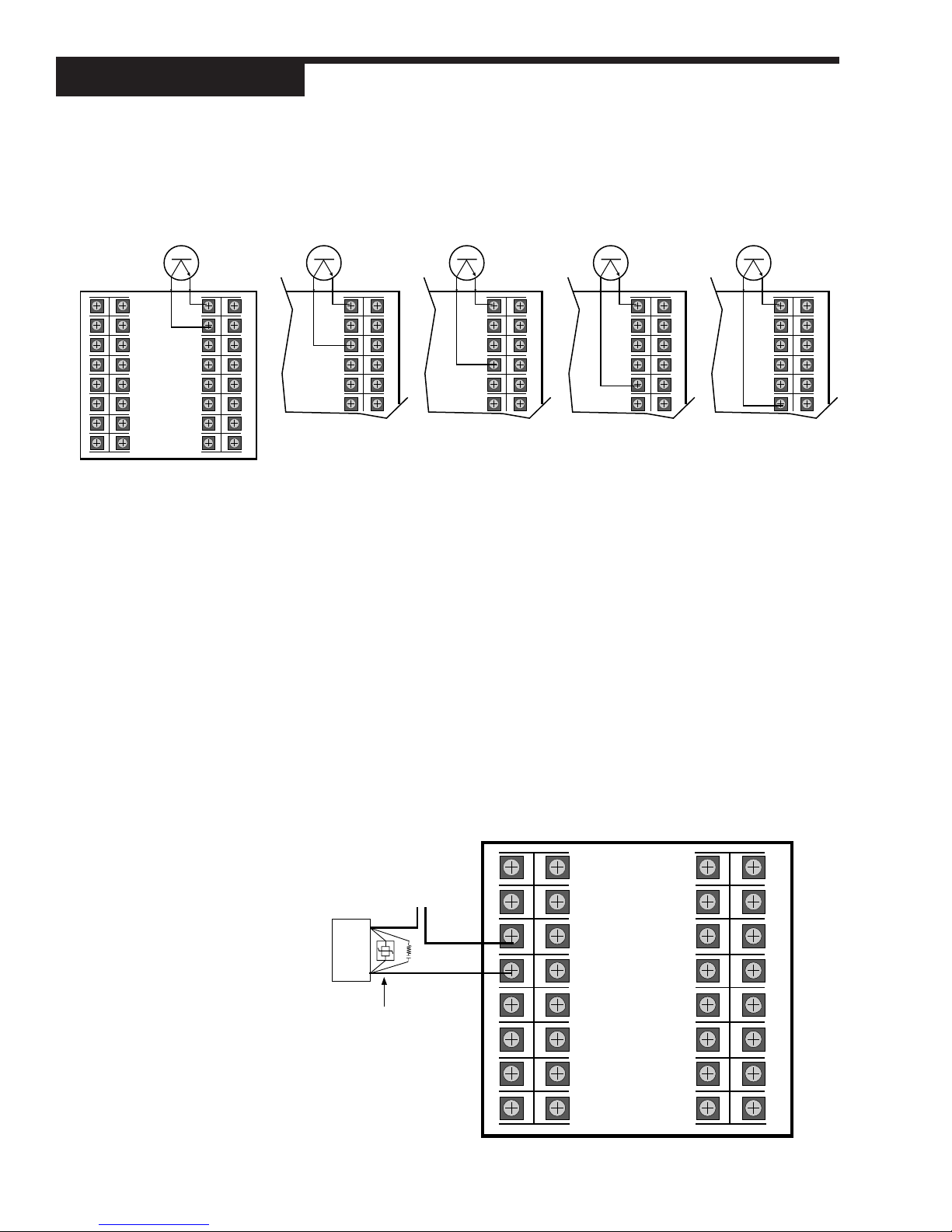

1. Digital Inputs with a switch or relay

Wire the switch/relay between terminal 17 and the specific digital input

terminal (Figure 4.9).

Figure 4.8

PV mA Input with Internal Power

Supply and 4-wire Transmitter Wiring

NOTE:

There are 14 contact types for the up

to 5 digital inputs - refer to Chapter 6

for a complete discussion.

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22

23

24 32

9

10

11

12

13

14

15

16

25

26

27

28

29

30

31

555 User's Manual Chapter 4 17

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

Figure 4.9

Digital Input Wiring with a Switch or

Relay

Page 23

Installation

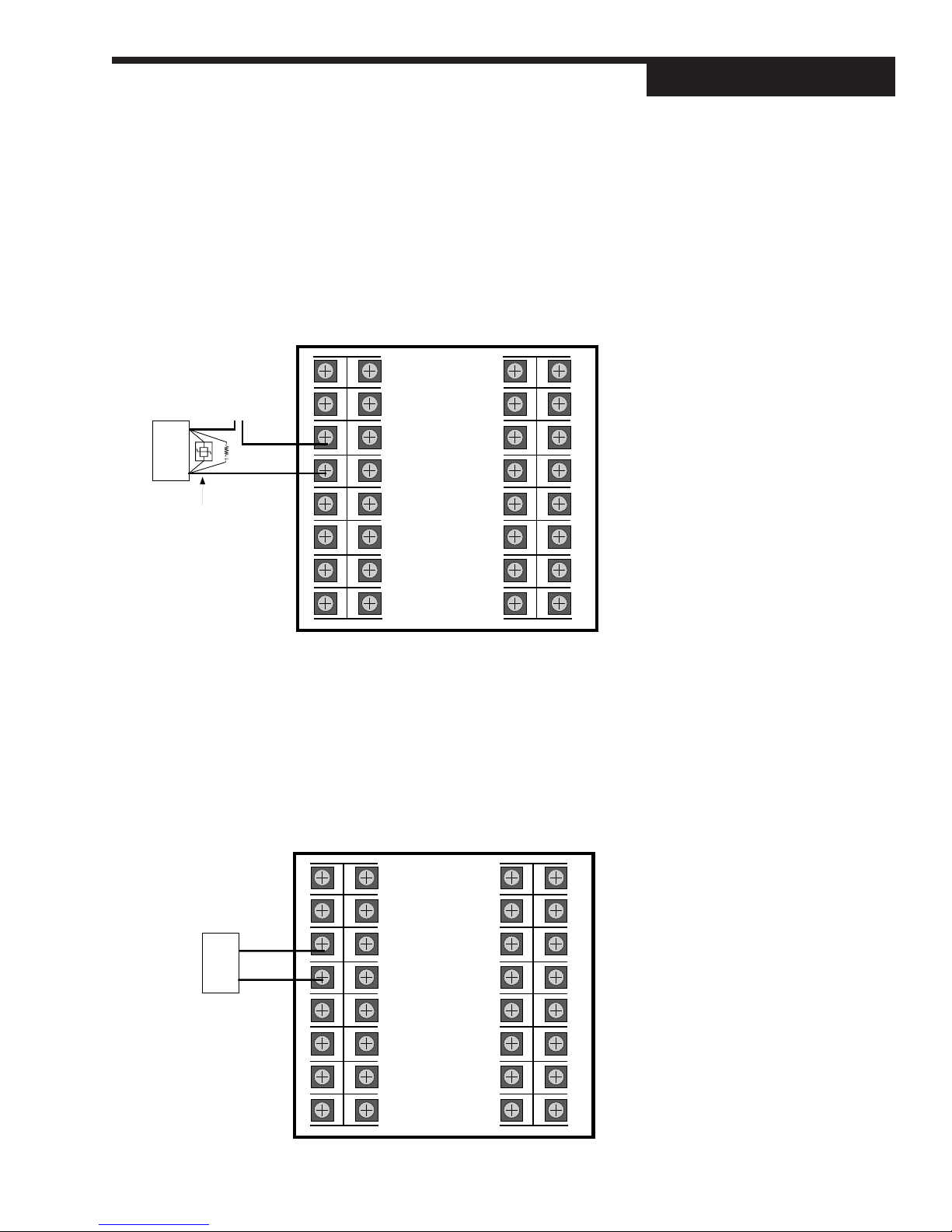

Figure 4.10

Digital Input Wiring with an Open

Collector (transistor)

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22

23

24 32

9

10

11

12

13

14

15

16

25

26

27

28

29

30

31

2. Digital Inputs with an Open Collector

An open collector is also called a transistor. Wire the transistor between

terminal 17 and the specific digital input terminal (Figure 4.10)

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

17

18

19

20

21

22 30

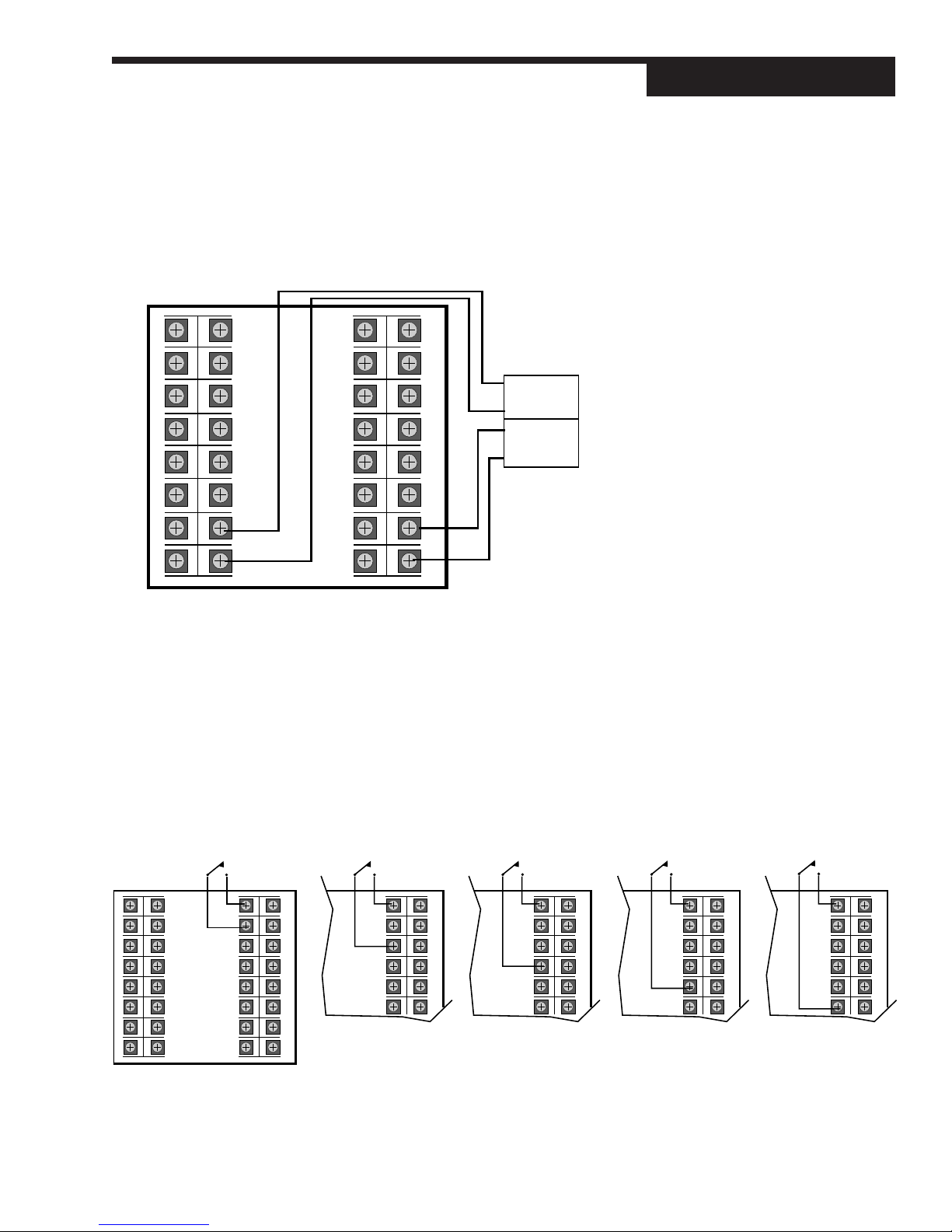

Output Modules

Output modules are used for control, alarms and retransmission (the wiring is

the same). There are three digital types — Mechanical Relay, Solid State Relay

(Triac), DC Logic (SSR Drive) — and one Analog type (Milliamp).

To identify which modules (if any) are installed on your 555, compare the product order code in Chapter 1 against the code on top of your controller. If you

want to change the configuration of the modules, refer to Chapter 3.

Wire using the corresponding output terminals (examples show Output 1).

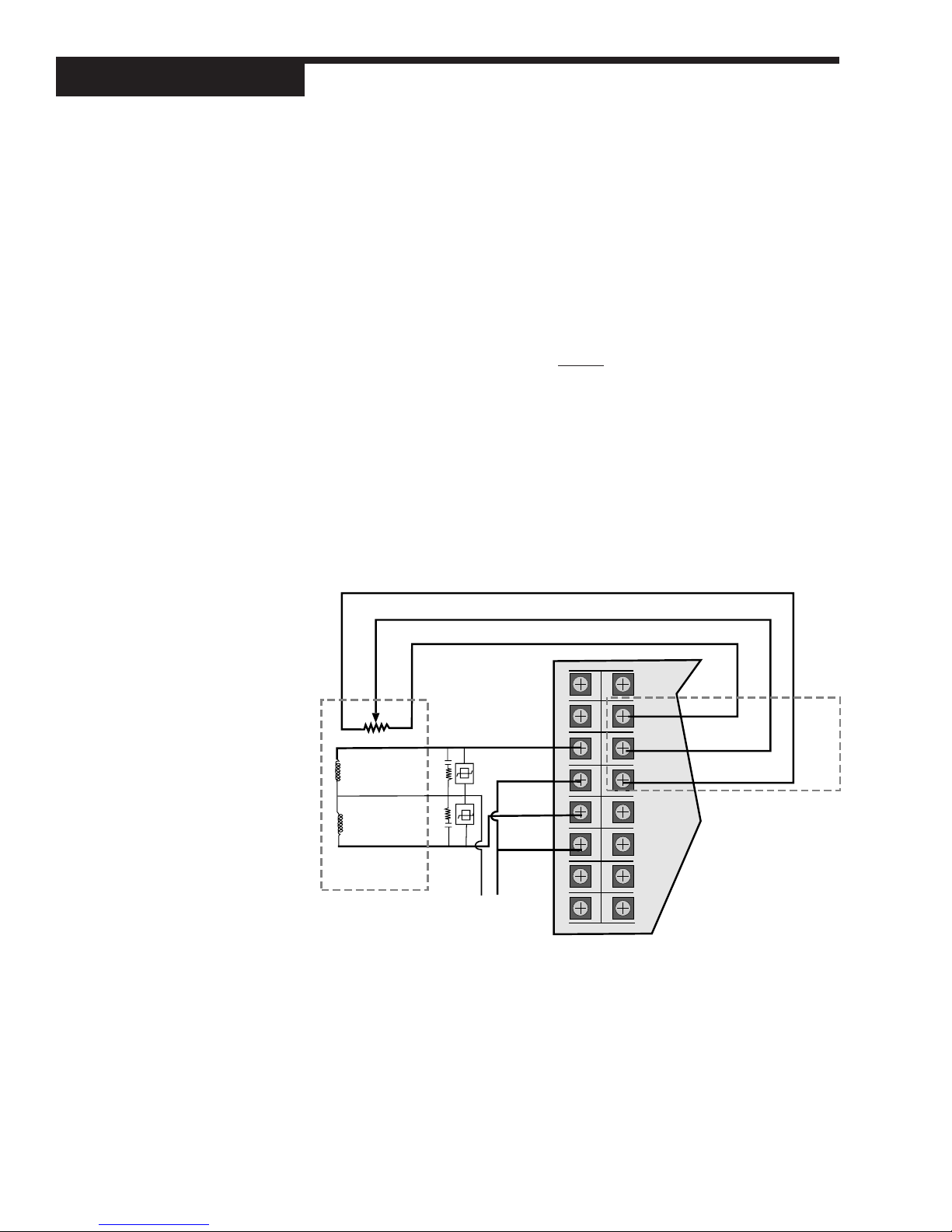

1. Mechanical Relay Output (Figure 4.11)

• Output 1 is always the Control output.

• Output Slots 1 and 2 together will allow for duplex flow pacing mode

control (again, only as time-proportioned outputs).

•“Staging” outputs is not allowed.

• Output Slots 2, 3 and/or 4 can be used for alarms (up to two). However, Output 2 is not available for alarms when using “duplex” control (i.e., duplex flow pacing, staging, or slidewire).

25

26

27

28

29

Figure 4.11

Mechanical Relay Output

Wiring

18 Chapter 4 555 User's Manual

Output 1 uses terminals 3 & 4

Output 2 uses terminals 5 & 6

Output 3 uses terminals 7 & 4

Output 4 uses terminals 15 & 16

Line Power

Load

Recommend use of

both MOV and snubber

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

OUT 4–

OUT 4+

17

18

19

20

21

22

23

25

26

27

28

29

30

31

24 32

Screws must be tight to ensure electrical connection

Page 24

2. Solid State Relay (Triac) Output (Figure 4.12)

• Output 1 is always the Control output.

• Output Slots 1 and 2 together will allow for duplex flow pacing mode

control (again, only as time-proportioned outputs).

•“Staging” outputs is not allowed.

• Output Slots 2, 3 and/or 4 can be used for alarms (up to two); however, Output 2 is not available for alarms when using “duplex” control (i.e., duplex flow pacing, staging, or slidewire).

Output 1 uses terminals 3 & 4

Output 2 uses terminals 5 & 6

Output 3 uses terminals 7 & 4

Output 4 uses terminals 15 & 16

Line Power

–

Load

+

Recommend use of

both MOV and snubber

OUT 1–

OUT 1+

OUT 2–

OUT 2+

1

2

3

4

5

6

9

10

11

12

13

14

17

18

19

20

21

22

25

26

27

28

29

30

Installation

Figure 4.12

Solid State Relay Output Wiring

OUT 3–

7

OUT 3+

8

Screws must be tight to ensure electrical connection

15

16

OUT 4–

OUT 4+

23

24 32

3. DC Logic (SSR Drive) Output (Figure 4.13)

• Output 1 is always the Control output.

• Output Slots 1 and 2 together will allow for duplex flow pacing mode

control (again, only as time-proportioned outputs).

•“Staging” outputs is not allowed.

• Output Slots 2, 3 and/or 4 can be used for alarms (up to two); however, Output 2 is not available for alarms when using “duplex” control (i.e., duplex flow pacing, staging, or slidewire).

Output 1 uses terminals 3 & 4

Output 2 uses terminals 5 & 6

Output 3 uses terminals 7 & 4

Output 4 uses terminals 15 & 16

–

Load

+

OUT 1–

OUT 1+

OUT 2–

1

2

3

4

5

9

10

11

12

13

17

18

19

20

21

31

25

26

27

28

29

Figure 4.13

DC Logic Output and Milliamp

Output Wiring

OUT 2+

6

OUT 3–

7

OUT 3+

8

Screws must be tight to ensure electrical connection

555 User's Manual Chapter 4 19

14

15

16

OUT 4–

OUT 4+

22

23

30

31

24 32

Page 25

Installation

4. Milliamp (analog) Output (Figure 4.13)

• Output 1 is always the Control output.

• Output Slots 1 and 2 together allow for duplex flow pacing mode or

output “staging.”

• Output Slots 2, 3 and/or 4 can be used for retransmission (up to two).

However, Output 2 is not available when using duplex flow pacing,

staging or slidewire control.

5. Loop Power

• Any unused output slot (except for Output 1) may be used to hold a

loop power module, when needed to supply voltage for a transducer.

• Output 1 is always the Control output.

• Refer to Figure 4.7 for a diagram of Loop Power.

6. Position Proportioning Output (with Slidewire Feedback)

• Output Slots 1 and 2 with mechanical or solid state relay modules,

plus the slidewire option, will allow for electrical control valve actuators (motorized CCW/CW) to operate as the control output (see Figure 4.14).

Figure 4.14

Position Proportioning Output with

Slidewire Feedback Terminals

CW

Slidewire Wiper 0–1050

CCW

1

2

CCW

3

CCW

Winding

CW

Winding

ELECTRIC MOTOR

ACTUATOR

Actuator Supply Current

Screws must be tight to ensure electrical connection

COM

CW

COM

4

5

6

7

8

9

10

11

12

13

14

15

16

CCW

Slidewire Wiper

CW

ELECTRIC

ACTUATOR OUTPUT

20 Chapter 4 555 User's Manual

Page 26

Remote Setpoint

If you have the remote setpoint option, use terminals 13 and 14 to connect your

remote setpoint signal (Figure 4.15).

1

2

9

10

17

18

25

26

–

RSP

Source

+

Installation

Figure 4.15

Remote Setpoint Terminals

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

11

12

13

14

15

16

RSP–

RSP+

19

20

21

22

23

27

28

29

30

31

24 32

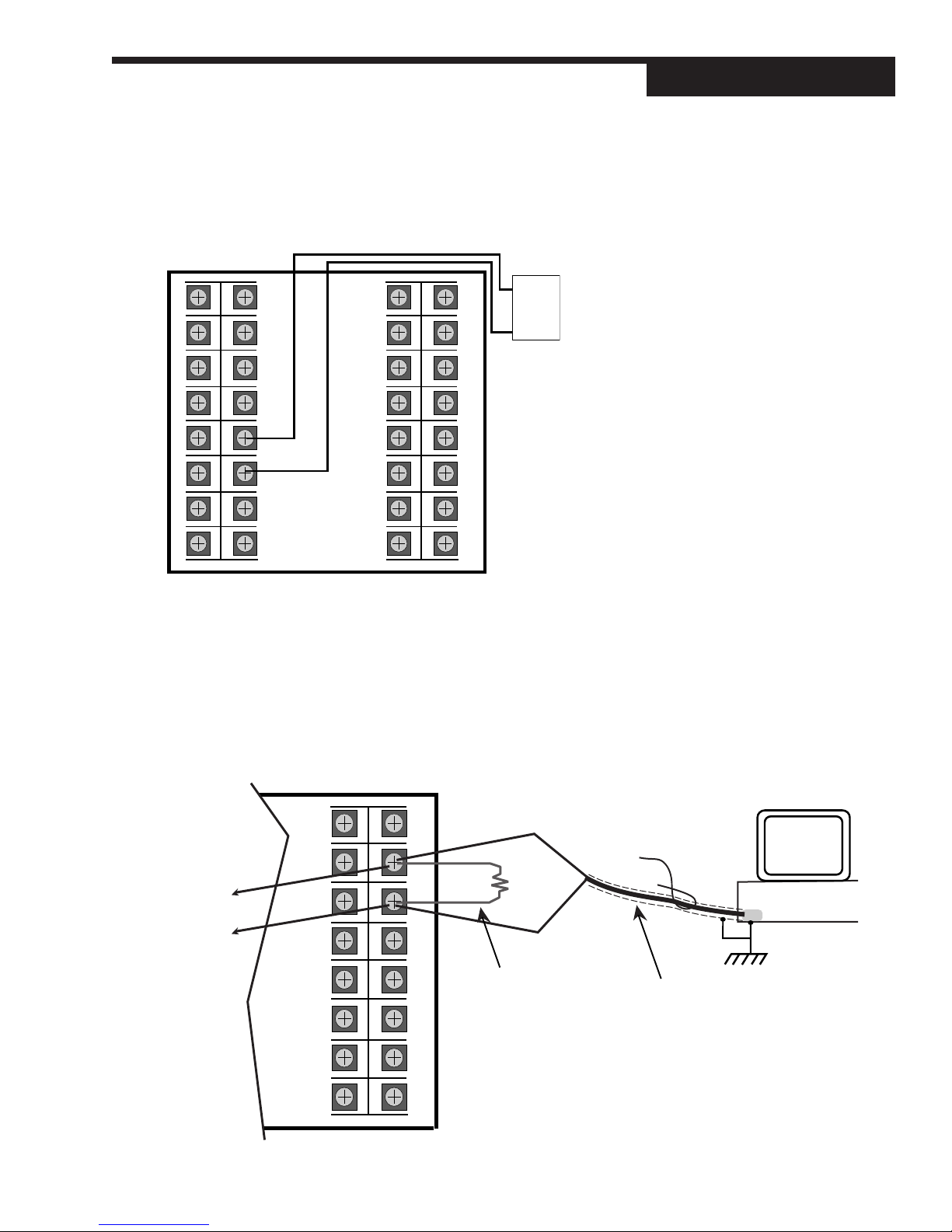

Serial Communications

If you have this option, use terminals 26 and 27 as shown in Figure 4.16.

A twisted shielded pair of wires should be used to interconnect the host and

field units. Belden #9414 foil shield or #8441 braid shield 22-gauge wire are

acceptable for most applications. The foil shielded wire has superior noise

rejection characteristics. The braid shielded wire has more flexibility. The

17

18

To Comm – terminal

of next device

To Comm + terminal

of next device

19

20

21

22

23

24 32

Screws must be tight to ensure electrical connection

555 User's Manual Chapter 4 21

25

26

27

28

29

30

31

RS485–

RS485+

Use a 60 to 100 ohm

terminating resistor

connected to the two

data terminals of the

final device on the line

Comm –

Twisted, shielded

Comm +

This shield needs to be connected continuously, but only tied to one

ground at the host. Failure to follow these proper wiring practices

could result in transmission errors and other communications

problems.

Figure 4.16

Serial Communications Terminals

PC or

other

RS-485

port

host

Page 27

Installation

maximum recommended length of the RS-485 line is 4000 feet. Termination resistors are required at the host and the last device on the line. Some

RS-485 cards/converters already have a terminating resistor. Use a

RS-232/RS-485 converter, Part #500-485. The communication protocol is

asynchronous bidirectional half-duplex, therefore the leads are labeled

Comm + and Comm–.

22 Chapter 4 555 User's Manual

Page 28

CHAPTER 5

SOFTW ARE CONFIGURATION

The software configuration menus of the 555 contain user-selected variables that

define the action of the controller. Read through this section before making any

parameter adjustments to your controller.

Software Configuration

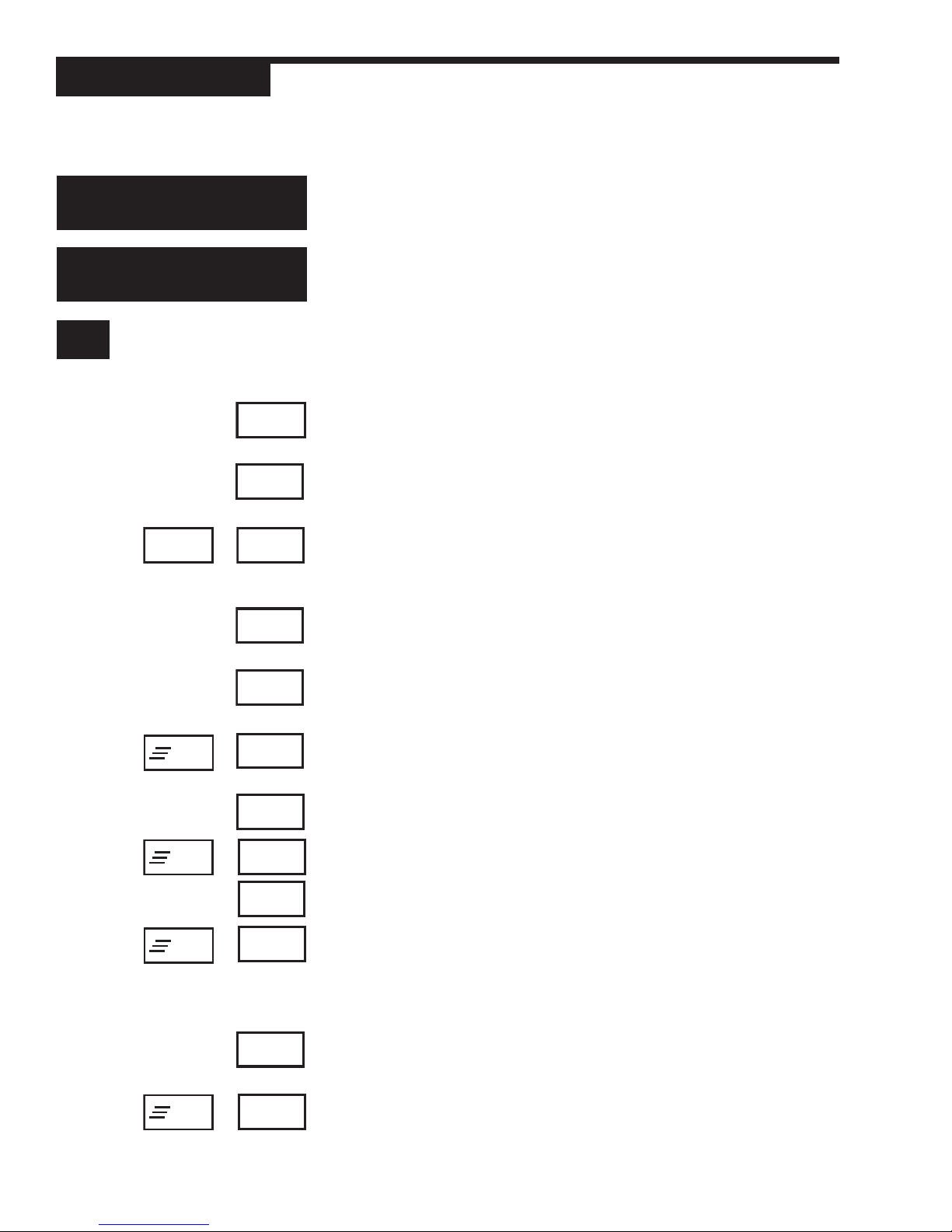

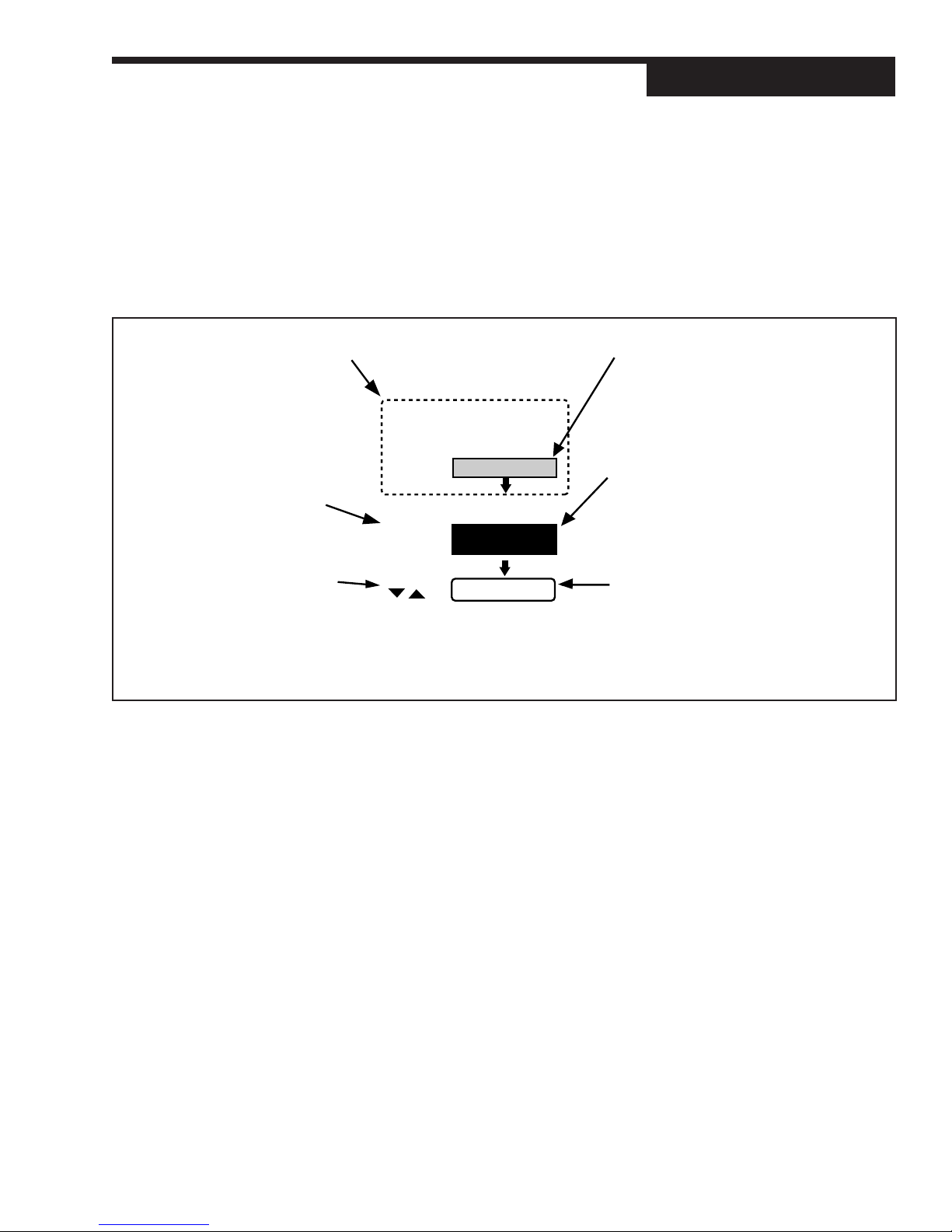

Figure 5.1

Menus, Parameters and Values

When initially setting up the

controller, cycle through all the

parameters in each Menu.

Press the MENU+FAST to

advance to the next Menu.

Press MENU to advance to the

next parameter (this also sets the

value for the current parameter.

Use arrow keys to selects a value).

press:

MENU/FAST

CONFIG.

press:

MENU

INDICATOR

Use the arrows keys to enter

numerical values, and/or move

through the selection group.

press:

NONE

press MENU/FAST

Go to next Menu Block:

MENUS

In Set Up mode, there are 13 sets of options that control different aspects of 555

operation; in Tuning mode, there is one. Each set of options is called a menu. As

you traverse the two modes, the menu names appear in the 2nd display.

CONFIG Mode selection and input/output hardware assignments

CONTROL Control options

FLOW INPT. Flow data input (PV2) options

CUST. LINR. Linearization curve options for PV2 input.

RSDL. INPT. Residual Cl2 data input (PV1) options

SETPOINT Controller setpoint options

REM. INPUT Remote Setpoint input options

OUTPUT Output options

RETRANS. Retransmission output options

ALARMS Alarm options

POWER-UP Power Up values configuration

SECURITY Security functions

SER.COMM. Serial Communications options (requires comm. board)

and

TUNING Tuning parameters configuration

This is a Menu.

Its name will show in the 2nd display.

This is a Parameter.

Its names show in the 3nd display.

In this manual, when the appearance

of a parameter is dependent upon

other hardware/software options, the

background is black. When the

appearance of a paramter is dependent

on those options,the background is

white.

This is a Value.

The numbers/values that correspond to

your particular hardware/software

options will show in the 3rd display.

The graphics in this chapter show the

default (factory)setting.

IMPORTANT!!

All software changes occur in real time;

always perform set up functions under

Manual operation.

555 User's Manual Chapter 5 23

Page 29

Software Configuration

PARAMETERS

Independent

Parameter

CONFIGURE

UNLOCKED

Figure 5.2

Independent vs. Dependent

Parameters

NOTE:

Changing the value of one parameter

may affect the value or status of another.

Dependent

Parameter

RSP TYPE

(D)

MANUAL to switch

between automatic and

manual operating controls

DISPLAY or SET PT

Within each menu are parameters for particular control functions. You select

values for each parameter depending on the specific application. Use the MENU

key to access parameters for a particular menu; the parameter name will replace the menu name in the 2nd display, and the parameter value will show in

the 3rd display.

This chapter outlines all the available parameters for the 555. Some parameters

are independent of any special configuration you apply, and others are depen-

dent on the individual configuration. This manual displays these two types of

parameters differently; refer to Figure 5.2. A special feature of the 555, called

Smart Menus, determines the correct parameters to display for your configu-

ration, so not all the listed parameters will appear.

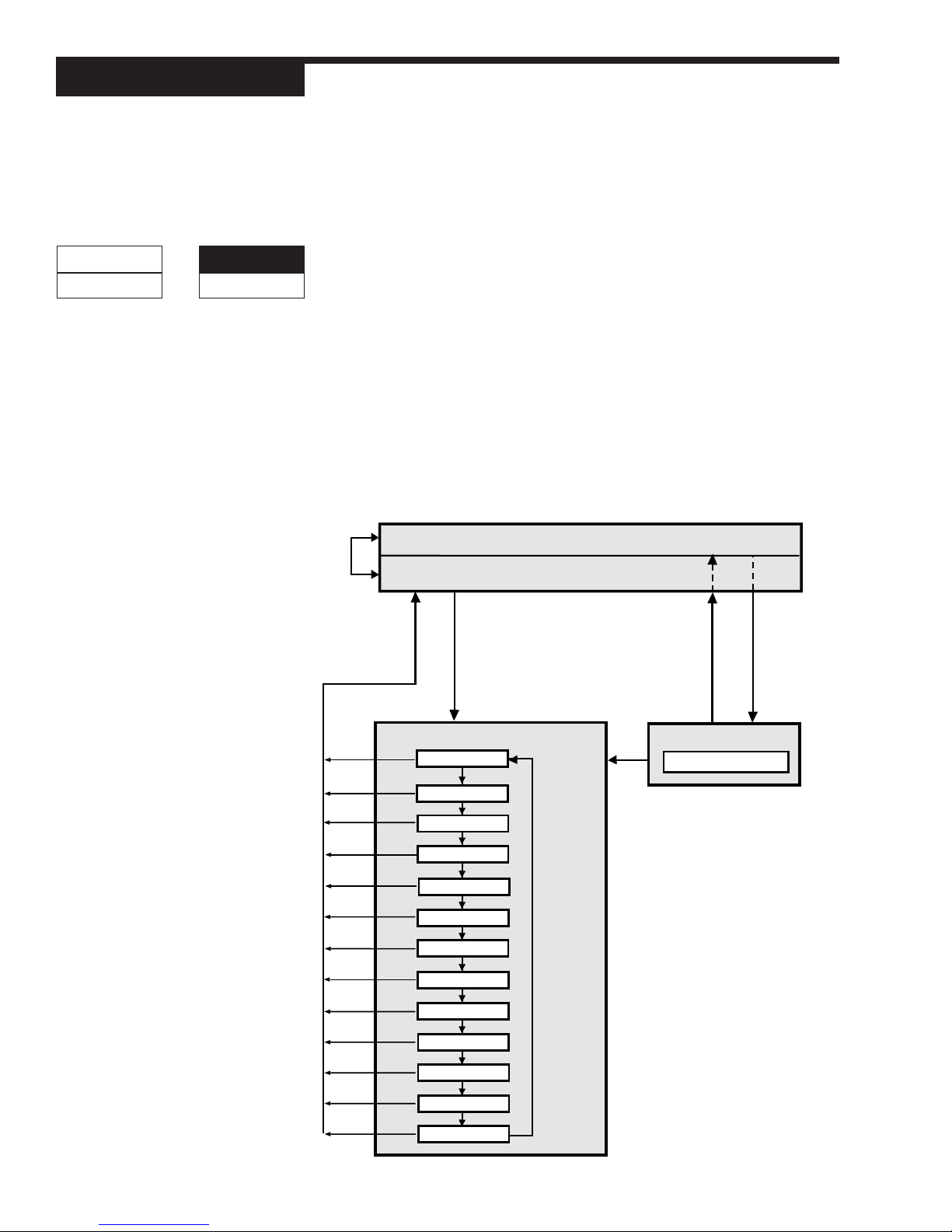

CONFIGURA TION AND OPERATION

Figure 5.3 shows the relationships among the different modes of the 555 and

the configuration menus:

AUTOMATIC control

MANUAL control

DISPLAY or SET PT

to return to manual

operating control

to restore

operating display

FAST + MENU

to access set up menus

MENU

to access

tuning menu

Figure 5.3

Operation and Configuration Flowchart

13 set up menus

CONFIG.

CONTROL

FLOW INPT.

CUST.LINR.

RSDL. INPT.

SETPOINT

REM. INPUT

OUTPUT

RETRANS.

ALARMS

POWER-UP

SECURITY

SER.COMM.

FAST

+

MENU

to move

from menu

to menu

FAST + MENU

to access

set up menus

1 tuning menu

TUNING

24 Chapter 5 555 User's Manual

Page 30

• Set Up menus can only be accessed from manual control. To transfer the

555 from automatic to manual control, press MANUAL.

• To access the set up menus, press FAST+MENU.

• To advance to the next menu, press FAST+MENU.

• Tuning mode (and the TUNING menu) can be accessed from either auto-

matic or manual control. To access the tuning menu, press MENU .

• To access the parameters for a particular menu, press MENU.

▲▲

• To select a parameter value, use

next parameter, or FAST+MENU to advance to the next menu.

• To return controller to manual control, press DISPLAY or SET PT.

• To transfer the controller from manual to automatic control when setting up

bumpless transfer dosage values, press FAST+MANUAL.

A key to these functions appears at the bottom of every page in the menu section

of this chapter.

▼▼

▲ and

▼. Press MENU to advance to the

▲▲

▼▼

WHERE T O GO NEXT

• For information about all the software menus and parameters, continue reading

this chapter. Refer to Appendix D for a quick-reference flowchart of all menus

and parameters.

• For information about the installed options on your 555, look at the product

label on top of the controller, and compare it to the order code in Chapter 1.

• To alter the output module and jumper configuration of your controller, see

Chapter 3.

• To mount your controller and configure the wiring of the 555 for inputs and

outputs, see Chapter 4.

• To set up the 555 control modes, and other applications, see Chapter 6.

Software Configuration

555 User's Manual Chapter 5 25

Page 31

Software Configuration

26 Chapter 5 555 User's Manual

Page 32

SOFTW ARE MENU AND P ARAMETERS

Software Configuration

CONFIG.

1. CTRL. MODE

Selects the main operating mode of the controller.

• FLOW PACE

• RESIDUAL

D COMPOUND

• DECHLOR

2. OUT. MODE

Selects the control output mode of the controller.

D STANDARD Fixed value if different modules in slots 1 and

2, slot 2 is empty, or 2 digital outputs with no

slidewire option

• STAGED Only available if analog modules in slots 1 and 2.

• SLIDEWIRE Only available if digital modules in slots 1 and

2 and slidewire option installed)

• DUAL OUT. Only available if 2 analog or 2 digital modules

in slots 1 and 2 with flow pacing mode

3. LINE FREQ.

Defines the AC line frequency, so that the input sampling rate will be optimized for common mode noise rejection.

D 60 HZ.

• 50 HZ.

CONFIG

CTRL. MODE

COMPOUND

OUT . MODE

STANDARD

LINE FREQ.

60 HZ.

4. OUTPUT 2

Selects use for an existing output in slot 2 (not for control or loop power).

D OFF

• ALM.RLY.: ON (digital only)

• ALM.RLY.: OFF (digital only)

• RETRANS. (analog only)

• COMM. ONLY

OUTPUT 2

OFF

5. OUTPUT 3

Selects use for an existing output in slot 3 (not for control or loop power).

D OFF

• ALM.RLY.: ON (digital only)

• ALM.RLY.: OFF (digital only)

• RETRANS. (analog only)

• COMM. ONLY

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

555 User's Manual Chapter 5 27

DISPLAY

+

FAST MENU

MENU

▲▲

▲

▲▲

▼▼

▼

▼▼

OUTPUT 3

OFF

MENU

DISPLAY

Page 33

Software Configuration

6. OUTPUT 4

OUTPUT 4

OFF

7. ANLG.RNG.:1

aNLG.RNG.: 1

4-20 MA

Selects use for an existing output in slot 4 (not for control or loop power).

D OFF

• ALM.RLY.: ON (digital only)

• ALM.RLY.: OFF (digital only)

• RETRANS. (analog only)

• COMM. ONLY

Selects the range of operation for an existing mA output in slot 1.

• 0 – 20mA

D 4 – 20mA

ANLG.RNG.: 2

4-20 MA

ANLG.RNG.: 3

4-20 MA

ANLG.RNG.: 4

4-20 MA

CONT A CT 1

MANU A L

8. ANLG.RNG.: 2

Selects the range of operation for an existing mA output in slot 2.

• 0 – 20mA

D 4 – 20mA

9. ANLG.RNG.: 3

Selects the range of operation for an existing mA output in slot 3.

• 0 – 20mA

D 4 – 20mA

10. ANLG.RNG.: 4

Selects the range of operation for an existing mA output in slot 4.

• 0 – 20mA

D 4 – 20mA

11. CONTACT 1

Selects the use for the existing digital input 1.

• REM. INPUT

D MANUAL

• 2ND. SETPT.

• 2ND. INT.

• ALARM ACK.

• INT. INHBT.

• LOCK MAN.

• STANDBY

• LO VACUUM

• HI VACUUM

• UP KEY

• DOWN KEY

• DISP. KEY

• MENU KEY

• FAST KEY

• COMM. ONLY

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

28 Chapter 5 555 User's Manual

DISPLAY

FAST MENU

+

MENU

▲

▲▲

▲▲

▼▼

▼

▼▼

MENU

DISPLAY

Page 34

12. CONTACT 2

Selects the use for the existing digital input 2.

D REM. INPUT

• MANUAL

• 2ND. SETPT.

• 2ND. INT.

• ALARM ACK.

• INT. INHBT.

• LOCK MAN.

• STANDBY

• LO VACUUM

• HI VACUUM

• UP KEY

• DOWN KEY

• DISP. KEY

• MENU KEY

• FAST KEY

• COMM. ONLY

Software Configuration

CONT A CT 2

REM. INPUT

13. CONTACT 3

Selects the use for the existing digital input 3.

• REM. INPUT

• MANUAL

D 2ND. SETPT.

• 2ND. INT.

• ALARM ACK.

• INT. INHBT.

• LOCK MAN.

• STANDBY

• LO VACUUM

• HI VACUUM

• UP KEY

• DOWN KEY

• DISP. KEY

• MENU KEY

• FAST KEY

• COMM. ONLY.

CONT A CT 3

2ND.SETPT.

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

555 User's Manual Chapter 5 29

DISPLAY

+

FAST MENU

MENU

▲▲

▲

▲▲

▼▼

▼

▼▼

MENU

DISPLAY

Page 35

Software Configuration

14. CONTACT 4

CONT A CT 4

2ND. INT .

Selects the use for the existing digital input 4.

• REM. INPUT

• MANUAL

• 2ND. SETPT.

D 2ND. INT.

• ALARM ACK

• INT. INHBT.

• LOCK MAN.

• STANDBY

• LO VACUUM

• HI VACUUM

• UP KEY

• DOWN KEY

• DISP. KEY

• MENU KEY

• FAST KEY

• COMM. ONLY

CONT A CT 5

ALARM. A CK.

REMOTE IN.

OFF

15. CONTACT 5

Selects the use for the existing digital input 5.

• REM. INPUT

• MANUAL

• 2ND. SETPT.

• 2ND. INT.

D ALARM ACK.

• INT. INHBT.

• LOCK MAN.

• STANDBY

• LO VACUUM

• HI VACUUM

• UP KEY

• DOWN KEY

• DISP. KEY

• MENU KEY

• FAST KEY

• COMM. ONLY

16. REMOTE IN.

Defines the value of the remote setpoint feature.

D OFF

• SETPOINT

• CL2 DOSE

• SO2 DOSE

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

30 Chapter 5 555 User's Manual

DISPLAY

FAST MENU

+

MENU

▲

▲▲

▲▲

▼▼

▼

▼▼

MENU

DISPLAY

Page 36

Software Configuration

CONTROL

Available only for Residual or Compound Loop Mode.

1. FIXED LAG

Sets the fixed lag term used for computing the total lag.

R 0 to 14400 seconds

D0

2. VARBL. LAG

(Compound Loop mode)

Sets the variable lag term used for computing the total lag.

R 0 to 14400 seconds

D0

3. MAX. LAG

(Compound Loop mode)

Sets the maximum limit for the total lag calculation.

R 0 to 14400 seconds

D 14400

4. MIN. TRIM

(Compound Loop mode)

Sets the minimum amount of correction that can be applied to the current flow

pacing output level.

R –100 to 100%

D –100%

CONTROL

FIXED LA G

0

V ARBL. L AG

0

MAX. LA G

14400

MIN. TRIM

-100%

5. MAX. TRIM

(Compound Loop mode)

Sets the maximum amount of correction that can be applied to the current flow

pacing output level.

R –100 to 100%

D 100%.

MAX. TRIM

100%

6. FLOW ONLY

(Compound Loop mode)

Determines whether to allow flow pacing only control or remain under

automatic control if the residual signal is lost (see RSDL REST. in the

RSDL.INPT. menu).

D DISABLED

• ENABLED

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

555 User's Manual Chapter 5 31

DISPLAY

+

FAST MENU

MENU

▲▲

▲

▲▲

▼▼

▼

▼▼

FLO W ONL Y

DISABLED

MENU

DISPLAY

Page 37

Software Configuration

RSDL. ONLY

disabled

FLO W INPT .

PV TYPE

4-20 mA

7. RSDL. ONLY

(Compound Loop mode)

Determines whether to allow residual only control (i.e., remain under auto-

matic control) if the flow signal is lost (see FLOW REST. in the FLOW INPT.

menu).

D DISABLED

• ENABLED

FLO W INPT .

Available only when a flow signal is used (Flow Pacing, Compound Loop or

Dechlorination Mode).

1. PV TYPE

Selects the type of PV being used for the flow input.

If jumper is set to volts:

D 1 – 5V

• 0 – 5V

• 0 – 100mV

• 0 – 60mV

• 0 – 30mV

• 0 – 10mV

• ± 25mV

If jumper is set to mA:

D 4 – 20mA

• 0 – 20mA

DECIMAL

XXXXX

LINEARIZE

NORMAL

LO W RANGE

0

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

32 Chapter 5 555 User's Manual

DISPLAY

2. DECIMAL

Selects position of the decimal point in the engineering units display of flow.

D XXXXX

• XXXX.X

• XXX.XX

• XX.XXX

• X.XXXX

3. LINEARIZE

Selects the type of linearization used for the flow input.

D NORMAL

• SQR. ROOT

• CUSTOM

4. LOW RANGE

Sets the value in engineering units corresponding to the low flow input value.

R –9999 to 99999

D0

+

FAST MENU

MENU

▲

▲▲

▲▲

▼▼

▼

▼▼

MENU

DISPLAY

Page 38

5. HI RANGE

Sets the value in engineering units corresponding to the high flow input value.

R –9999 to 99999

D 1000

6. FILTER

Sets the amount of filtering to be used for the flow input.

R 0 to 120 seconds

D0

7. PV OFFSET

Sets a constant offset to be applied to the flow input.

R –9999 to 99999

D0

8. PV GAIN

Sets a constant gain to be applied to the flow input.

R 0.100 to 10.000

D 1.000

9. FLOW BRK.

Defines percentage of (first) output upon switching to Manual control due to a

flow signal break signal.

R -5% to 105%

D0%

10. FLOW BRK.2

(Dual Flow Pacing mode)

Defines percentage of second output upon switching to Manual control due to

a flow signal break signal.

R -5% to 105%

D0%

Software Configuration

HI RANGE

1000

FILTER

0

PV OFFSET

0

PV GAIN

1.000

FLO W BRK.

0%

FLO W BRK.2

0%

11. FLOW REST.

(Flow Pacing mode, Dechlorination mode, and Compound Loop mode with

Residual Only control disabled)

Defines type of control mode after flow signal is restored.

D LAST MODE

• MANUAL

• AUTOMATIC

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

555 User's Manual Chapter 5 33

DISPLAY

+

FAST MENU

MENU

▲▲

▲

▲▲

▼▼

▼

▼▼

FLO W REST.

LAST MODE

MENU

DISPLAY

Page 39

Software Configuration

CUST.LINR.

1ST . INPUT

LO W RANGE

1ST . PV

0

XTH. INPUT

LO W RANGE

XTH. PV

0

CUST.LINR.

Available only if a flow signal is used (Flow Pacing, Compound Loop or Dechlorina-

tion mode) with LINEARIZE set to CUSTOM.

Defines a custom linearization curve for the Flow input (PV2). Points 1 and 15 are

fixed to the low and high end of the input range (respectively) and only require you

to set a corresponding PV value. Points 1 through 14 (the X points) require you to

set both the input and the PV.

You do not have to use all 15 points. Whenever the Xth INPUT becomes the high

end of the range, that will be the last point in the linearization table.

Refer to Chapter 6 for more details.

1. 1st. INPUT

Sets the flow input value for Point 1.

R LOW RANGE to HIGH RANGE based on FLOW PV TYPE

D LOW RANGE

2. 1st. PV

Sets the engineering units value for Point 1.

R –9999 to 99999

D0

3. Xth. INPUT

Sets the flow input value for Point X (X = 2 to 14).

R LOW RANGE to HIGH RANGE based on FLOW PV TYPE

D LOW RANGE

4. Xth. PV

Sets the engineering units value for Point X (X = 2 to 14).

R –9999 to 99999

D0

15TH. INPUT

LO W RANGE

15TH. PV

0

Access Set Up Return to Operation Next menu Next parameter Next value Access Tuning Return to Operation

+

FAST MENU

34 Chapter 5 555 User's Manual

DISPLAY

FAST MENU

29. 15th. INPUT

Sets the flow input value for Point 15.

R LOW RANGE to HIGH RANGE based on FLOW PV TYPE

D LOW RANGE

30. 15th. PV

Sets the engineering units value for Point 15.

R –9999 to 99999

D0

+

MENU

▲

▲▲

▲▲

▼▼

▼

▼▼

MENU

DISPLAY

Page 40

Software Configuration

RSDL. INPT.

Available only if a residual chlorine signal is used (Compound Loop or Dechlorination mode).

1. PV TYPE

Selects the type of PV being used for the residual chlorine input.

If jumper set to volts

D 1 – 5V

• 0 – 5V

• 0 – 100mV

• 0 – 60mV

• 0 – 30mV

• 0 – 10mV

• ± 25mV

If jumper set to mA:

D 4 – 20mA

• 0 – 20mA

2. DECIMAL

Selects the position of the decimal point in the engineering units display of residual value.

D XXXXX

• XXXX.X

• XXX.XX

• XX.XXX

• X.XXXX

RSDL. INPT.

PV TYPE

4-20 mA

DECIMAL

XXXXX

3. LOW RANGE

Sets the value in engineering units corresponding to the low residual input

value.

R –9999 to 99999

D0

LO W RANGE

0

4. HI RANGE