Page 1

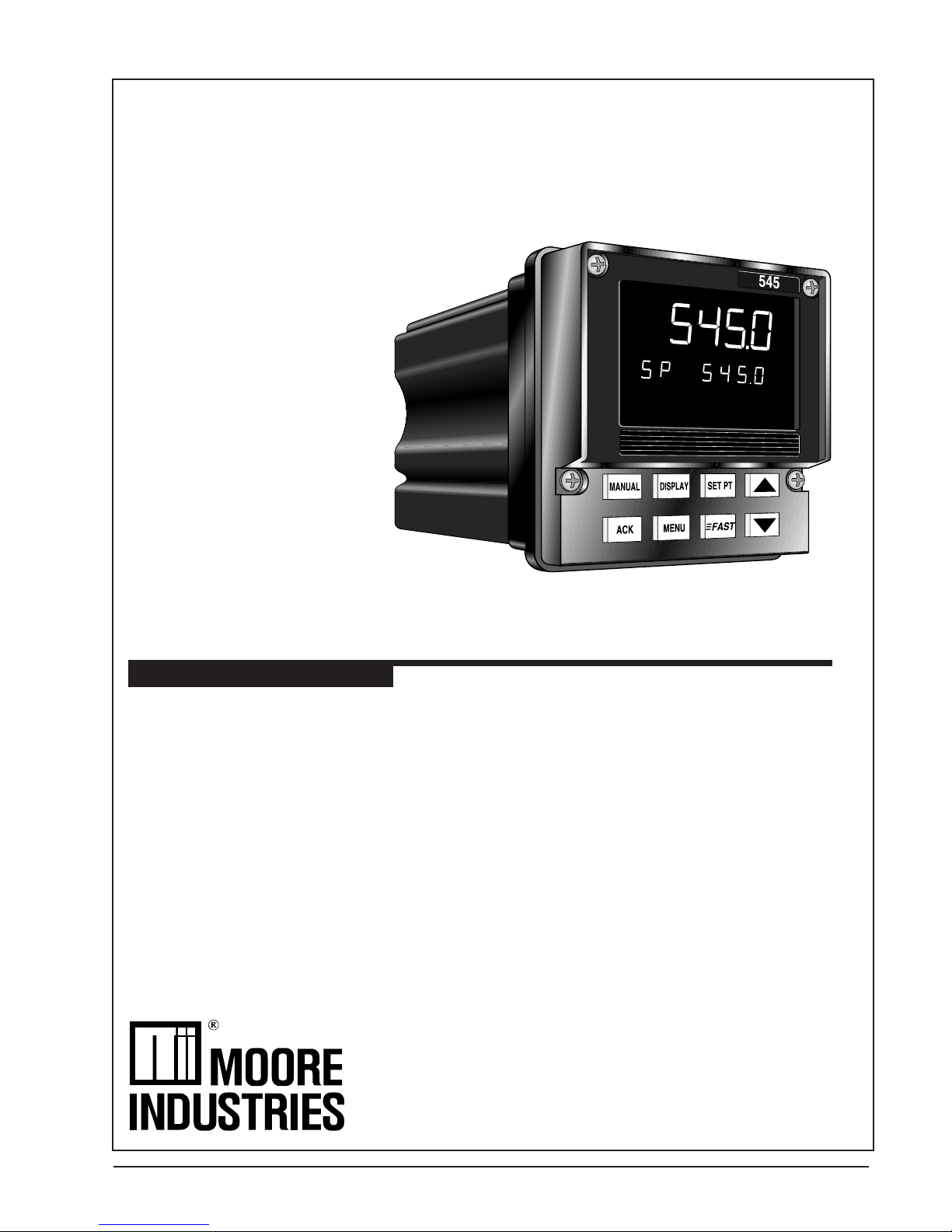

5 4 5

5 4 5

1/4 DIN PROCESS CONTROLLER

USER’S MANUAL

M545 V 8, MA

RCH 2 017

Page 2

Table of Contents

Table of Contents

CHAPTER 1

INTRODUCTION ............................................................................... 1

545 Modes ......................................................................................... 2

Order Code, Packaging Information ..................................................... 2

Where To Go Next .............................................................................. 2

Text Formatting in This Manual ............................................................ 2

CHAPTER 2

CONTROLLER OPERATION ............................................................ 5

Displays ............................................................................................. 5

Icons ................................................................................................. 5

Keys .................................................................................................. 6

Basic Operation Procedures ............................................................... 7

Alarm Operation ................................................................................. 8

CHAPTER 3

INSTALLATION AND WIRING ........................................................ 11

Mounting the Controller ..................................................................... 11

Wiring .............................................................................................. 12

AC Power Input ....................................................................... 12

Process Variable Input ............................................................. 13

Digital Input(s) ......................................................................... 16

Remote Setpoint Option ........................................................... 16

Output Modules ....................................................................... 17

Serial Communications ............................................................ 19

PAGE

About This Manual:

Throughout this User’s Manual

information appears along the

margins, in the form of NOTEs,

CAUTIONs and WARNINGs, usually

in boldface. Please heed these

safety and good practice notices for

the protection of you and your

equipment.

CHAPTER 4

HARDWARE CONFIGURATION ..................................................... 21

Hardware Input Types ...................................................................... 21

Accessing and Changing Jumpers .................................................... 23

Adding and Changing Output Modules ............................................... 24

Special Communications Module ...................................................... 26

CHAPTER 5

SOFTWARE CONFIGURATION ...................................................... 27

Menus ............................................................................................. 27

Parameters ...................................................................................... 28

Configuration and Operation ............................................................. 29

Where to Go Next ............................................................................. 29

Text Formatting in This Manual .......................................................... 29

Step-by-Step Guide to Set-Up Parameters ......................................... 30

CONFIG.................................................................................. 30

PV INPUT ............................................................................... 35

CUST. LINR. ........................................................................... 37

CONTROL .............................................................................. 38

ALARMS ................................................................................. 41

REM. SETPT. .......................................................................... 45

RETRANS............................................................................... 46

SELF TUNE ............................................................................ 48

SPECIAL ................................................................................ 49

545 User's Manual Table of Contents i

Page 3

Table of Contents

Step-by-Step Guide to Set-Up Parameters (continued)

SECURITY.............................................................................. 51

SER. COMM. .......................................................................... 52

Parameter Value Charts ................................................................... 54

CHAPTER 6

TUNING .......................................................................................... 63

Overview ......................................................................................... 63

TUNING Parameter Guide ................................................................ 64

TUNING Value Chart ........................................................................ 68

Self Tune Messages and Troubleshooting ......................................... 70

CHAPTER 7

APPLICATIONS .............................................................................. 71

A. Control Type ................................................................................ 71

B. Alarms ......................................................................................... 72

C. Duplex Control ............................................................................. 76

D. Slidewire Position Proportioning Control ........................................ 81

E. Velocity Position Proportioning Control .......................................... 82

F. Staged Outputs ............................................................................ 83

G. Retransmission ............................................................................ 83

H. Digital Inputs ................................................................................ 84

I. Remote Setpoint ............................................................................ 88

J. Multiple Setpoints .......................................................................... 88

K. Multiple Sets of PID Values ........................................................... 89

L. Powerback ................................................................................... 90

M. Self Tune—POWERTUNE

®

........................................................................ 90

N. Ramp-to-Setpoint ......................................................................... 96

O. Input Linearization ........................................................................ 97

Thermocouple and RTD Linearization ....................................... 97

Square Root Linearization ........................................................ 97

Custom Linearization ............................................................... 98

P. Load Line ..................................................................................... 98

Q. Security ....................................................................................... 99

R. Reset Inhibition .......................................................................... 100

S. Process Variable Reading Correction .......................................... 100

T. Serial Communications ............................................................... 101

U. Cascade Control ........................................................................ 102

V. Ratio Control .............................................................................. 104

Ratio Control with One Wild Stream ........................................ 104

Ratio Control with Combined Discharge Monitoring .................. 105

W. Feed Forward/Feedback Control ................................................ 107

X. Lag Time .................................................................................... 108

Fixed Lag .............................................................................. 108

Variable Lag .......................................................................... 109

PAGE

ii Table of Contents 545 User's Manual

Page 4

APPENDIX 1

MENU FLOWCHARTS .................................................................. A-1

APPENDIX 2

PARTS LIST .................................................................................. A-3

APPENDIX 3

TROUBLESHOOTING .................................................................. A-5

APPENDIX 4

CALIBRATION .............................................................................. A-7

Preparation for all Input Calibrations ................................................. A-8

Thermocouple Cold Junction Calibration ........................................... A-9

Analog Milliamp Input Calibration ...................................................... A-9

Milliamp Output Calibration ............................................................ A-10

Reset Menu Data .......................................................................... A-11

Hardware Scan ............................................................................. A-12

Slidewire Test ............................................................................... A-12

Quick Calibration Procedure .......................................................... A-12

Table of Contents

PAGE

APPENDIX 5

SPECIFICATIONS ........................................................................A-13

APPENDIX 6

GLOSSARY ................................................................................. A-17

APPENDIX 7

ISOLATION BLOCK DIAGRAM ...................................................A-23

545 User's Manual Table of Contents iii

Page 5

Table of Contents

List of Figures

FIGURE DESCRIPTION PAGE

2.1 ................. Operator Interface ............................................................... 5

2.2 ................. Before and After Acknowledging an Alarm ............................ 9

3.1 ................. Instrument Panel & Cutout Dimensions ............................... 11

3.2 ................. Attaching Mounting Collar .................................................. 11

3.3 ................. Terminal Assignments ....................................................... 12

3.4 ................. AC Power Input Terminals ................................................. 13

3.5 ................. Process Variable Terminals ............................................... 13

3.6 ................. PV1 and PV2 Wiring for Milliamp, RTD and Voltage Inputs ... 14

3.7 ................. PV1 and PV2 Wiring for Milliamp Inputs

with Internal and External Power Supply ............................. 15

3.8 ................. Digital Input Wiring with a Switch or Relay ........................... 16

3.9 ................. Digital Input Wiring with an Open Collector .......................... 16

3.10 ............... Remote Setpoint Terminals ................................................ 16

3.11 ............... Mechanical Relay Output Wiring ......................................... 17

3.12 ............... SSR Relay Output Wiring ................................................... 17

3.13 ............... DC Logic Output Wiring ..................................................... 18

3.14 ............... Milliamp Output Wiring ....................................................... 18

3.15 ............... Position Proportioning Output Wiring .................................. 18

3.16 ............... Serial Communications Terminals ...................................... 19

4.1 ................. Location of Printed Circuit Boards ....................................... 21

4.2 ................. The Microcontroller Circuit Board, the Option Board,

and the Power Supply Board .............................................. 22

4.3 ................. Representation of Module .................................................. 25

4.4 ................. Install Communications Module .......................................... 26

5.1 ................. Parts of the Menu Block ..................................................... 27

5.2 ................. Independent vs. Dependent Parameters ............................. 28

5.3 ................. Configuration Flowchart ..................................................... 28

6.1 ................. Access the Tuning Menu Block .......................................... 63

7.1 ................. Alarm Examples ................................................................ 75

7.2 ................. Duplex With Reverse and Direct Acting Outputs .................. 77

7.3 ................. Duplex With Direct and Reverse Acting Outputs .................. 77

7.4 ................. Duplex With Two Reverse Acting Outputs ........................... 78

7.5 ................. Duplex With a Gap Between Outputs .................................. 78

7.6 ................. Duplex With Overlapping Outputs and Output Limits ............ 79

7.7 ................. Duplex With Various Relative Gain Settings ........................ 79

7.8 ................. Duplex With One ON/OFF Output ...................................... 80

7.9 ................. Duplex With Two ON/OFF Outputs..................................... 80

7.10 ............... Staged Outputs Example ................................................... 83

7.11 ............... Combinations of Closed Digital Inputs ................................. 84

7.12 ............... Pretune TYPE 1, 2 and 3 with Adaptive Tune....................... 93

7.13 ............... Noise Band Calculation Example ........................................ 94

7.14 ............... Noise Band Values for Temperature Inputs ......................... 95

7.15 ............... Deadtime and Time Constant ............................................. 95

7.16 ............... Square Root Linearization Formula .................................... 97

7.17 ............... 15-point Linearization Curve ............................................... 98

iv Table of Contents 545 User's Manual

Page 6

FIGURE DESCRIPTION PAGE

7.18 ............... Load Line Example............................................................ 99

7.19 ............... Cascade Control of Product Temperature -

Functional View ............................................................... 102

7.20 ............... Cascade Control of Produce Temperature -

Wiring View ..................................................................... 103

7.21 ............... The Functions of Cascade Control ................................... 103

7.22 ............... Ratio Control in Mixing Application “Wild Stream” -

Wiring View ..................................................................... 104

7.23 ............... Ratio Control in Mixing Application “Controlled Stream” -

Functional View ............................................................... 105

7.24 ............... Ratio Control in Mixing Application “Controlled Stream” -

Wiring View ..................................................................... 106

7.25 ............... Feed Forward Control in Mixing Application -

Wiring View ..................................................................... 107

7.26 ............... Feed Forward Control in Mixing Application -

Functional View ............................................................... 107

7.27 ............... Fixed and Variable Lag Example -

Compound Loop Chlorine Control .................................... 108

A4.1 ............... 545 Rear Terminals for Calibration ....................................... 7

A4.2 ............... Flowchart Calibration Menus ............................................... 7

A4.3 ............... Jumper Locations on the Microcontroller Circuit Board .......... 8

A4.4 ............... Input Calibration Wiring ....................................................... 8

A4.5 ............... Thermocouple/Cold Junction Calibration Wiring ................... 9

A4.6 ............... Analog mA Input Calibration Wiring .................................... 10

A4.7 ............... Analog mA Input Jumper Positions ..................................... 10

A4.8 ............... Milliamp Output Calibration Wiring ..................................... 11

A4.9 ............... Output Module Menu Cycle ............................................... 11

A4.10 ............. Slidewire Test Wiring ......................................................... 12

Table of Contents

545 User's Manual Table of Contents v

Page 7

Table of Contents

vi Table of Contents 545 User's Manual

Page 8

CHAPTER 1

INTRODUCTION

Introduction

From its surge-resistant power supply to its rugged construction, the 545

process controller is designed to ensure the integrity of your process with

maximum reliability — hour after hour, day after day. The isolated inputs

and outputs guard against the dangers of electrical interference, the front

face meets NEMA 4X standards for watertight operation and exposure to

corrosive environments, and the solid metal housing and sturdy rubber keys

enhance durability and ESD protection.

The 545 has been engineered to be the industry’s most user–friendly

process controller. With three digital display areas — two offering up to 9

characters of true alphanumerics — the 545 effectively eliminates the

cryptic messages that could confuse even the most experienced operator.

The bright, crisp display is vacuum fluorescent, and offers much better

readability than any other display technology. Additional operator–friendly

features include: custom programmable alarm messages, illuminated keys,

and an easy to use menu system.

The 545 is the most accurate instrument in its class. With a sampling rate of

eight times per second, it is ideal for demanding pressure and flow applications. The 545 also offers two universal process inputs and modular, field

interchangeable outputs that allow more flexibility than ever before. With

two independent full feature control loops, the 545 can take the place of two

PID controllers; additionally, preprogrammed functions can be called for

cascade, ratio and feed forward applications.

The 545 uses foreground and background loops that facilitate straight

forward operator interface in any of the dual loop modes. It also offers

sophisticated control algorithms, including heuristic adaptive tuning, split

range and duplex outputs (control), and open or closed loop electric actuator control (velocity control).

Thank you for selecting the dual

loop Process Controller. The 545 is

user-configurable for any of the

following functions:

• Two independent PID loops

• Single Station Cascade Control

• Single Station Ratio Control

• Feed Forward Control

Specifications and information subject to change without notice.

545 User's Manual Chapter 1 1

Page 9

Introduction

545 MODES

There are three operating modes for the 545 controller:

OPERATION, the default mode of the controller. When the 545 is operating,

you can change setpoints, select manual control and change output level,

acknowledge alarms and monitor conditions.

SET UP, also referred to as configuration. Here you set up the basic functions of the instrument such as input and output assignments, alarm types

and special functions

TUNING, where you configure function parameters for Proportional, Integral

and Derivation (PID) control. Use this mode periodically to optimize the

control performance of the instrument.

ORDER CODE, PACKAGING INFORMATION

Comparing the product number to the ordering code on page 3 to determine

the outputs and options installed on the 545. The product number is printed

on the label on the top of the controller case.

Included with the 545 are:

• a 545 User’s Manual

• mounting hardware

• 1 sheet engineering unit adhesive labels

WHERE TO GO NEXT

• To become more familiar with the 545 interface, continue to Chapter 2.

• For important hardware installation guidelines, see Chapters 3 and 4.

• For a detailed description of all the software menus and parameters of

the 545, follow through Chapter 5 and 6. Appendix 1 can be used as a

guide to these parameters.

TEXT FORMATTING IN THIS MANUAL

Feature Format

KEYS SET PT DISPLAY

or

SET PT DISPLAY

ICONS OUT, ALM

MENUS CONFIG., TUNING,

PARAMETERS CYCLE TM:1, MIN.OUT2

PARAMETER VALUES OFF, SETPOINT, LAST OUT.

DISPLAY MESSAGES TOO HOT, OUT%

2 Chapter 1 545 User's Manual

Page 10

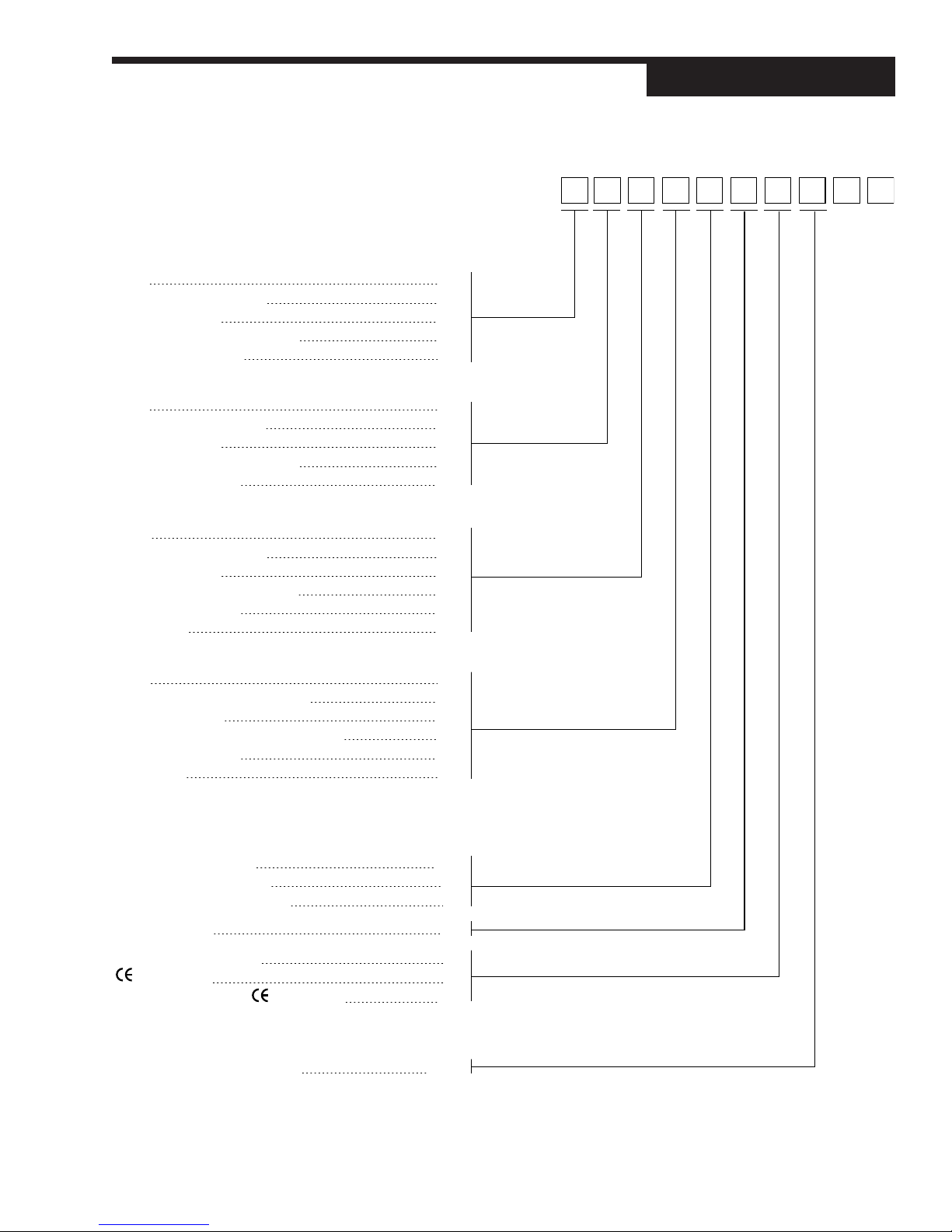

Order

Output 1: Control Code

None 0

Mechanical Relay (5 amp) 1

Analog (milliamp) 2

Solid State Relay (triac) (1 amp) 3

DC Logic (SSR drive) 4

Output 2: Control, Alarm, or Retransmission

None 0

Mechanical Relay (5 amp) 1

Analog (milliamp) 2

Solid State Relay (triac) (1 amp) 3

DC Logic (SSR drive) 4

Output 3: Control, Alarm, Retransmission, or Loop Power

None 0

Mechanical Relay (5 amp) 1

Analog (milliamp) 2

Solid State Relay (triac) (1 amp) 3

DC Logic (SSR drive) 4

Loop Power 5

Output 4: Control, Alarm, Retransmission, or Loop Power

None 0

Mechanical Relay (0.5 amp, 24 V) 1

Analog (milliamp) 2

Solid State Relay (triac) (0.5 amp, 24 V) 3

DC Logic (SSR drive) 4

Loop Power 5

Options

Enter “0” if not desired

Slidewire Feedback for Position

Proportioning Output A

24 VAC/24VDC Operation F

Slidewire and 24 VAC/24VDC G

Remote Setpoint B

Set of Five Digital Inputs D

Certification H

Five Digital Inputs and Certification J

Serial Communications

Enter “0” if not desired

RS-485 Serial Communications S

545 – 00

Introduction

Note 1: Capability for position proportioning output with slidewire feedback is specifed by ordering 545-11xxAxxx00, 545-33xxAxxx00,

or 545-44xxAxxx00. (Slidewire not required for velocity proportioning.)

outputs are interchangeable modules.

when used as the fourth output.

545 User's Manual Chapter 1 3

Note 4: The mechanical relay and solid state relay modules are derated to 0.5 amp at 24 Vac

Note 2: Up to three outputs may be used for alarms. Note 3: All

Page 11

Introduction

4 Chapter 1 545 User's Manual

Page 12

CHAPTER 2

CONTROLLER OPERATION

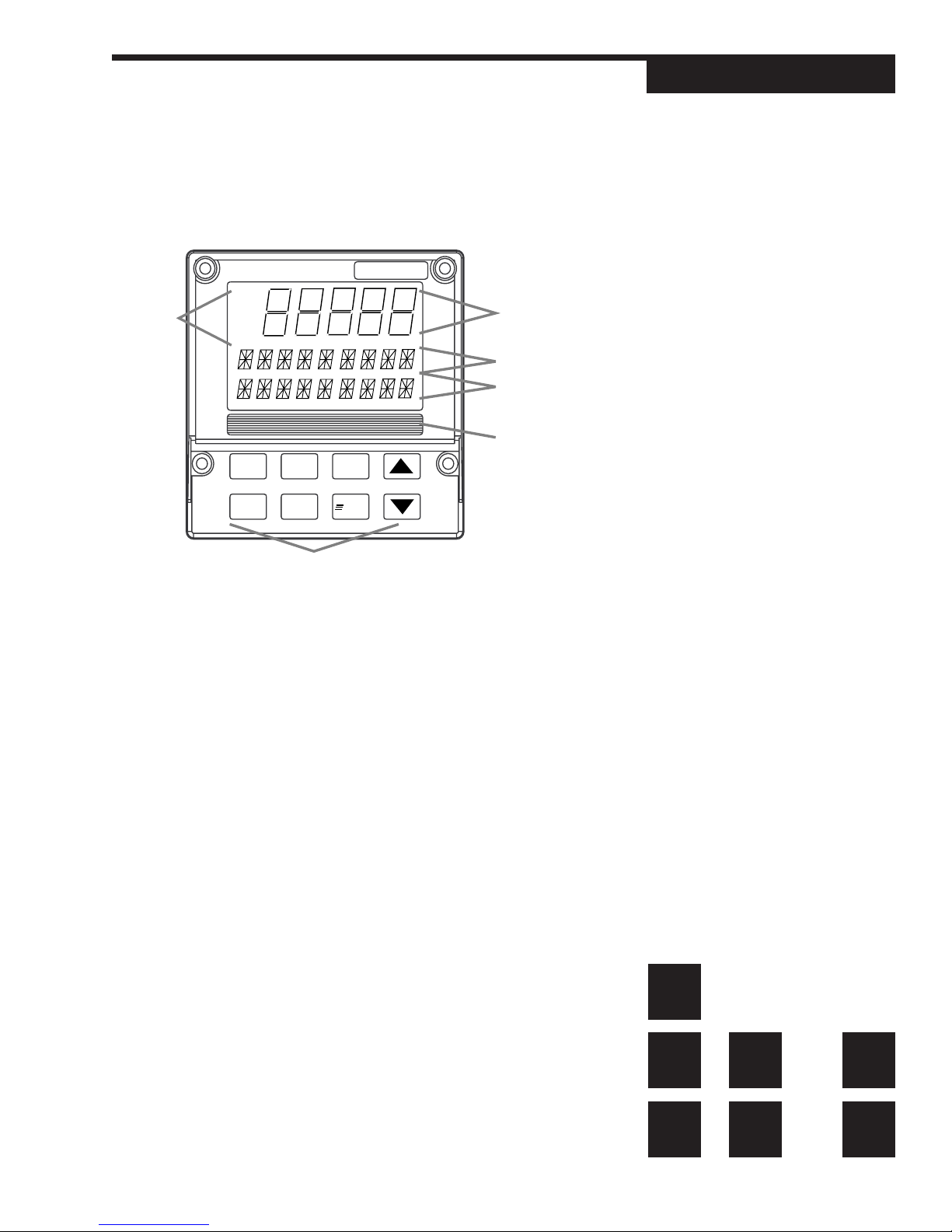

Basic Interface

Icons

PV2

OUT

1 2

ALM

1 2

545

Displays:

1st

2nd

3rd

Location for

MANUAL DISPLAY SET PT

identification

label

ACK MENU FAST

Keys

DISPLAYS

The display strategy of the 545 Process Controller is the same for all control

modes: Dual Loop, Cascade, Ratio and Feed Forward.

1st Display (five 7-segment digits)

• For the process variable value.

2nd Display (nine 14-segment digits)

• For the setpoint, deviation, output value or valve position (if available).

• In TUNING or SET UP mode, for the parameter name.

• Upon power up, indicates the current setpoint.

3rd Display (nine 14-segment digits)

• Name of current foreground loop

• For alarm messages, errors, etc.

• In TUNING or SET UP mode, for the value or choice of parameter shown in

the 2nd display.

Figure 2.1

Operator Interface

ICONS (LIT)

PV2 Loop 2 is in the foreground (on display); Loop 1 is in the background.

OUT1 For this output, either the relay output is energized or the analog

output is greater than 0%.

OUT2 For this output, either the relay output is energized or the analog

output is greater than 0%.

If control output is analog, indicates the output is greater than 0%.

ALM 1 The respective alarm (one) is active.

ALM 2 The respective alarm (two) is active.

ALM An alarm is active but no output is assigned.

545 User's Manual Chapter 2 5

PV2

OUT OUT OUT

1212

ALM ALM ALM

1212

Page 13

Basic Interface

KEYS

FAST

+

FAST

MANUAL

SET PT

DISPLAY

DISPLAY

▲▲

▲

▲▲

FAST: Has no independent function. Press to modify the function of another

key (see below).

MANUAL: Press to toggle between manual and automatic control.

When lit, indicates the unit is under manual control.

SET PT: Press to select the active setpoint.

In SET UP or TUNING mode, press to return controller to OPERATION mode.

When lit, indicates that a setpoint other than the local SP1 is active.

DISPLAY: Press to toggle through values in the 2nd display for setpoint, ramping setpoint (if available), deviation, output. background PV, lag (if available)

and valve position (if available).

In SET UP or TUNING mode, press to return controller to OPERATION mode

(with display showing current setpoint).

When lit, Loop 2 is in the foreground.

FAST+DISPLAY: Toggles between the background loop and foreground loop.

▲▲

▲ : Press to increase the value or selection of displayed parameter.

▲▲

FAST

FAST

▲

+

▼

+

▼

ACK

FAST+

▼▼

▼ : Press to decrease the value or selection of displayed parameter.

▼▼

FAST+

ACK: Press to acknowledge (an) alarm(s).

▲▲

▲ : Press to scroll through values at a faster rate.

▲▲

▼▼

▼ : Press to scroll through values at a faster rate.

▼▼

When lit, indicates there is an acknowledgeable alarm.

MENU

MENU : In OPERATION Mode, press to access the TUNING mode and menu.

In Set Up or Tuning mode, press to advance through a menu’s parameters. (Use

FAST+MENU to advance to the next menu.)

When lit, indicates the controller is in SET UP mode.

MENUFAST

+

FAST+MENU: Press to access the Set Up menus.

In SET UP mode, press to advance through menus. (Use MENU by itself to ac-

cess the parameters of a particular menu.)

6 Chapter 2 545 User's Manual

Page 14

BASIC OPERATION PROCEDURES

A Quick Explanation of Dual Loop Operation

Upon power up, Loop 1 is in the foreground (displayed), and Loop 2 is in the

“background” (hidden). Set up changes only affect the foreground loop; to make

changes to the operation of the background loop, it must be brought to the foreground.

The controller helps the user identify the foreground and background loops with

the following:

• When Loop 2 is in foreground DISPLAY key and the PV2 icon are lit

• The third display will show a message identifying the foreground loop.

Use the following as a quick guide to key operating functions of your 545. Most

of these procedures will affect whichever loop is in the foreground at the time

you execute the procedures. Those that are specified by the word GLOBAL will

affect both loops (the whole controller).

To switch the foreground and background loops

1. Press FAST+DISPLAY.

To select /change a setpoint

1. Use DISPLAY key to toggle display to Set Point.

2. Use SET PT key to toggle to active setpoint.

Before the newly selected setpoint is made active, there is a two-second de-

lay to prevent any disruptive bumps. If the setpoint displayed is ramping,

RAMPING will show the 3rd display.

▲▲

3. To change value, press

To change from auto to manual control (bumpless transfer)

1. When in automatic control, press the MANUAL key at any time, except while

in the TUNING mode.

2. The MANUAL key will light in red, and the 2nd display will immediately change

to indicate current output level.

To change from manual to auto

1. When in manual control, press MANUAL at any time except while in the

TUNING or SET UP mode.

2. The 2nd display will not change, and the MANUAL key will no longer be lit

once control changes.

To change manual output values

1. Make sure the controller is under manual control.

2. Use the DISPLAY key to toggle 2nd display to output level.

▲▲

3. Use the

▼ ▼

▲ or

▼ key to change the value.

▲▲

▼ ▼

To override security

If a locked operation is attempted, SECURITY appears in the 2nd display for

two seconds.

▲▲

1. Use the

the 3rd display. The starting value is 0.

Note: Two seconds of key inactivity will clear the display.

2. If the code is correct, CORRECT appears in the 3rd display. The display will

clear after two seconds, allowing full access.

▼▼

▲ and

▼ keys to quickly enter the security code, which will show in

▲▲

▼▼

▲ or

▲▲

▼ ▼

▼ .

▼ ▼

Basic Interface

NOTE:

See the glossary in Appendix 6 for

explanation of

setpoint

Chapter 7.

. Also refer to the section in

ramping

and

target

545 User's Manual Chapter 2 7

Page 15

Basic Interface

4. If code is incorrect, INCORRECT appears in the 3rd display. INCORRECT

will disappear after two seconds, and a new security code can then be entered.

5. The controller will revert back to full security lock after one minute of key inactivity.

To display control output value

1. Toggle DISPLAY key until the 2nd display shows OUT followed by the out-

put percentage. This value is the PID output.

• In duplex applications, this value does not directly refer to the output

signal (refer to the Chapter 7 section on Duplex Control for details.)

• For on/off outputs, the output value shown is either ON or OFF.

• For duplex applications with two on/off outputs, the OUT tag is not shown.

In this case, the status of both outputs is shown in the following manner:

1:ON 2:OFF (1 and 2 are the respective outputs).

To display the active PID set

1. Select the desired foreground loop (hold FAST, press DISPLAY).

2. Press MENU to reach Tuning Mode.

3. In TUNING Mode, press MENU to reach the correct Menu parameter.

4. The active PID set will have an asterisk (*) on both sides of the value.

NOTE:

All alarms are software alarms unless

tied to an output relay in the SET UP

mode. See Chapter 5 and Chapter 7 for

more details on alarms.

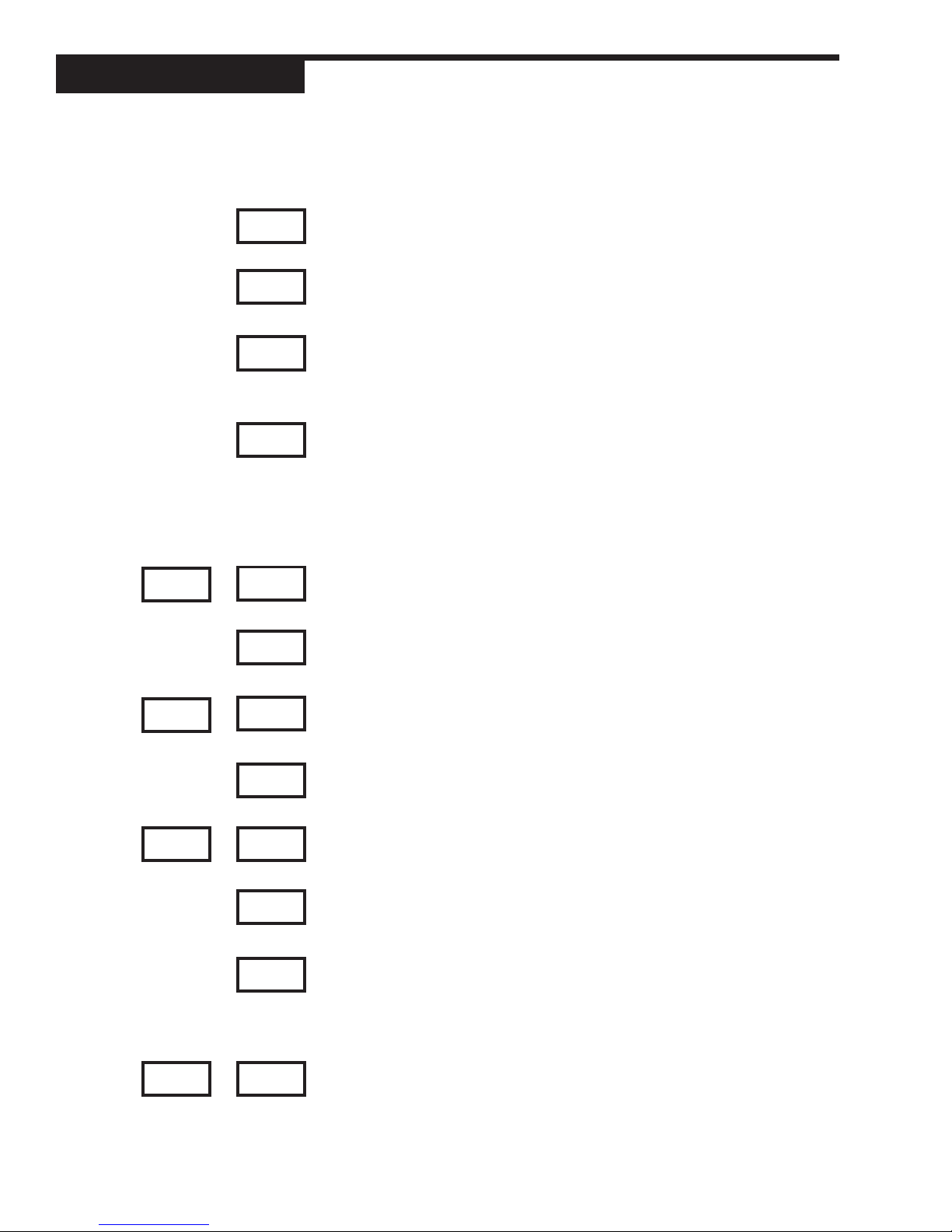

ALARM OPERATION

Alarms may be used in systems to provide warnings of unsafe conditions. All

545 operators must know how the alarms are configured, the consequences of

acknowledging an alarm, and how to react to alarm conditions.

Alarm Indication

Depending on how the system is configured, the 545 indicates an alarm

condition(s) for the foreground loop by:

• Lit icons ALM 1 and/or ALM 2

• Lit ACK key

• Displayed alarm message

The 545 indicates an alarm condition(s) for the background loop by:

• Showing the (user defined) message for one or both alarms in the third display

(alternate displays for simultaneous alarms).

To acknowledge an alarm(s):

An acknowledgeable alarm has both a lit icon and a lit ACK key.

A non-acknowledgeable alarm has only a lit icon.

Figure 2.2 demonstrates acknowledging an alarm.

1. If the alarm is in the background, bring that loop forward using

FAST+DISPLAY.

2. To acknowledge Alarm 1, press ACK once.

3. To acknowledge Alarm 2, press ACK twice.

4. If both alarms are activated, press ACK once to acknowledge Alarm 1, then

again to acknowledge Alarm 2.

5. The message and alarm icon disappear.

8 Chapter 2 545 User's Manual

Page 16

Basic Interface

BEFORE

OUT

1

ALM

1

MANUAL DISPLAY SET PT

ACK MENU FAST

545

MANUAL DISPLAY SET PT

AFTER

OUT

1

ACK MENU FAST

545

Latching Alarms

If an alarm is set up to be latching (for details, see Chapter 5) then, in general,

it must be acknowledged in order to clear the alarm and release the relay (if

applicable). A non-latching alarm will clear itself as soon as the process leaves

the alarm condition.

Limit Sequence

An alarm can be configured to be both latching and non-acknowledgeable. In

this case, the alarm is acknowledgeable only after the process has left the alarm

condition. This is similar to the function of a limit controller.

More on Alarms

For more details on how to set up alarms and for examples of various ways alarms

can be set up, refer to the section on Alarms in Chapter 7.

NOTE:

Powering down the 545 acknowledges/

clears all latched alarms. When powering

up, all alarms will be reinitialized.

Figure 2.2

Before and After Acknowledging an

Alarm

545 User's Manual Chapter 2 9

Page 17

Basic Interface

10 Chapter 2 545 User's Manual

Page 18

CHAPTER 3

INSTALLATION AND WIRING

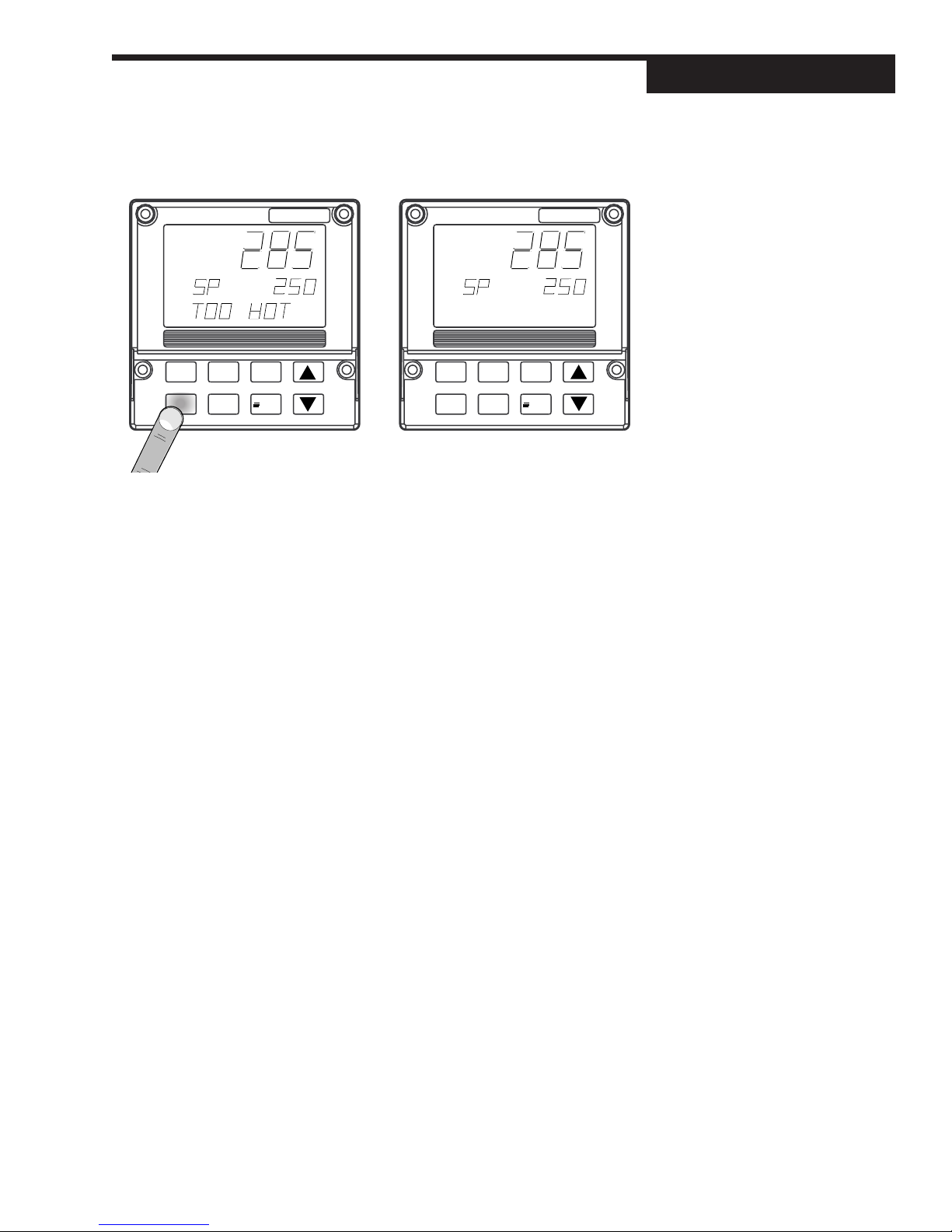

MOUNTING THE CONTROLLER

The 545 front face is NEMA 4X rated (waterproof). To obtain a waterproof

seal between the controller and the panel, follow these directions:

1. The 545 fits in a standard 1/4 DIN cutout. Mount the 545 in any panel

with a thickness from .06 in. to .275 in. (1.5 mm to 7.0 mm).

2. Figure 3.1 shows the controller and panel dimensions. The panel cutout

must be precise, and the edges free from burrs and waves.

7.180 (182.37) OVERALL LENGTH

3.770 (95.76)

PV2

OUT

1 2

ALM

1 2

545

PANEL

1.180 (29.97)

Installation

Figure 3.1

Instrument Panel & Cutout

Dimensions

3.622 (92.00) MIN.

3.653 (92.80) MAX.

3.622 (92.00) MIN.

3.653 (92.80) MAX.

3.770 (95.76)

MANUAL DISPLAY SET PT

ACK MENU FAST

FRONT

BEZEL

GASKET

6.000 (152.40)

SIDE

3. Place bezel gasket around the controller case (starting at the back of

controller). Then, slide the gasket against the back of the bezel.

4. With the bezel gasket in place, insert the 545 into the panel cutout from

the front of the panel.

5. Slide the mounting collar over the back of the case, as shown in

Figure 3.2. The collar clip edges will lock with matching edges on the

controller case.

Mounting Clip

3.585 (91.06)

CUTOUT

Figure 3.2

Attaching Mounting Collar

Front Panel

Mounting Collar

545 User's Manual Chapter 3 11

Collar Screws (1 of 4)

Page 19

Installation

AUTION !

C

The enclosure into which the 545

Controller is mounted must be

grounded.

WARNING!

Avoid electrical shock. Do not

connect AC power wiring at the

source distribution panel until all

wiring connections are complete.

6. Insert the four mounting collar screws from the rear of the collar. Gradually tighten the screws (using a Phillips #2 screwdriver) to secure the

controller against the panel.

7. If there is difficulty with any of the mounting requirements, apply a bead of

caulk or silicone sealant behind the panel around the perimeter of the case.

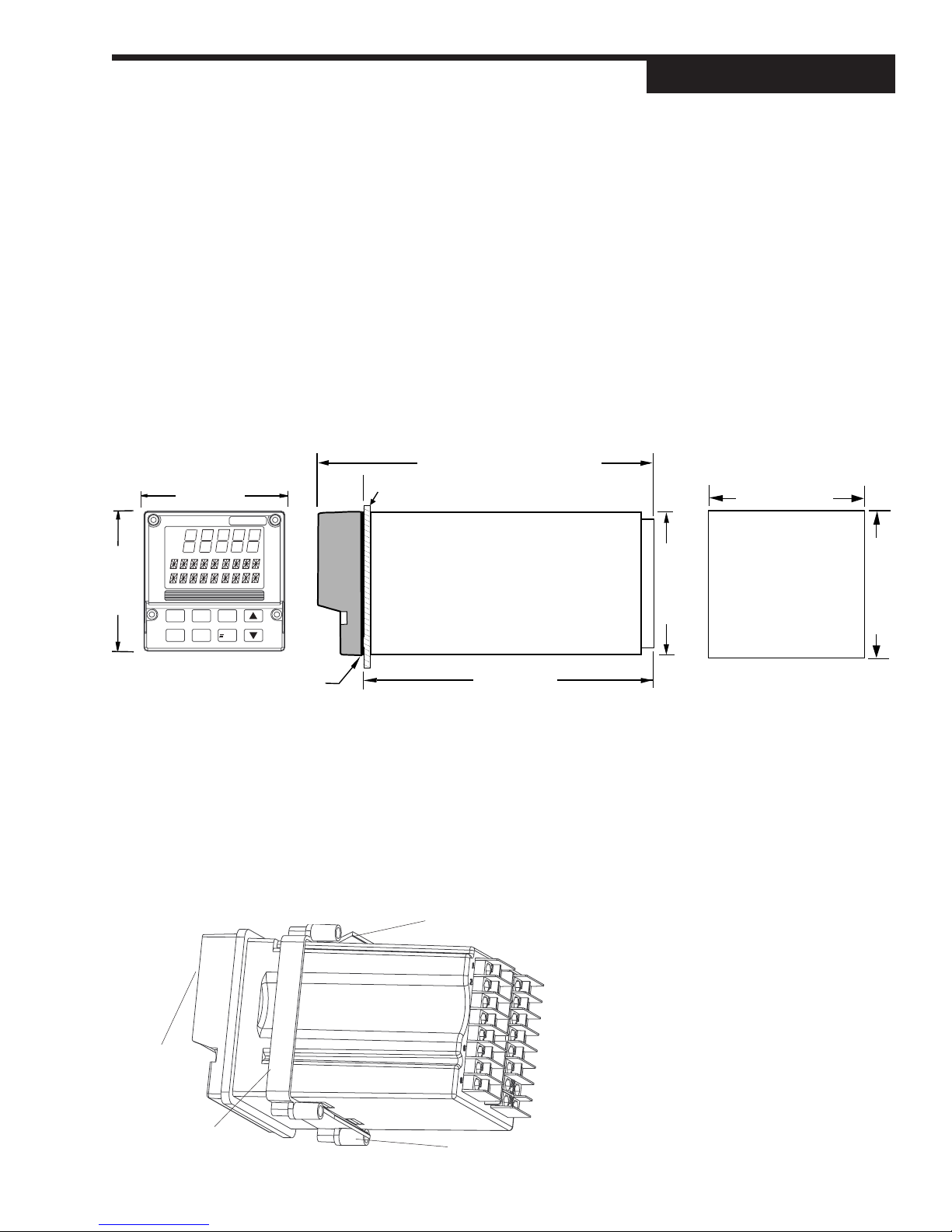

WIRING

Our 545 controllers are thoroughly tested, calibrated and “burned in” at the factory, so the controller is ready to install. Before beginning, read this chapter thoroughly and take great care in planning a system. A properly designed system

can help prevent problems such as electrical noise disturbances and dangerous extreme conditions.

1. For improved electrical noise immunity, install the 545 as far away as possible from motors, relays and other similar noise generators.

2. Do not run low power (sensor input) lines in the same bundle as AC power

lines. Grouping these lines in the same bundle can create electrical noise

interference.

3. All wiring and fusing should conform to the National Electric Code and to

any locally applicable codes.

4. An excellent resource about good wiring practices is the IEEE Standard No.

518-1982 and is available from IEEE, Inc., 345 East 47th Street, New York,

NY 10017, (212) 705-7900.

Diagrams on the next three pages serve as guides for wiring different types of

process inputs. The shaded areas on the diagrams show which rear terminals

are used for that type of wiring.

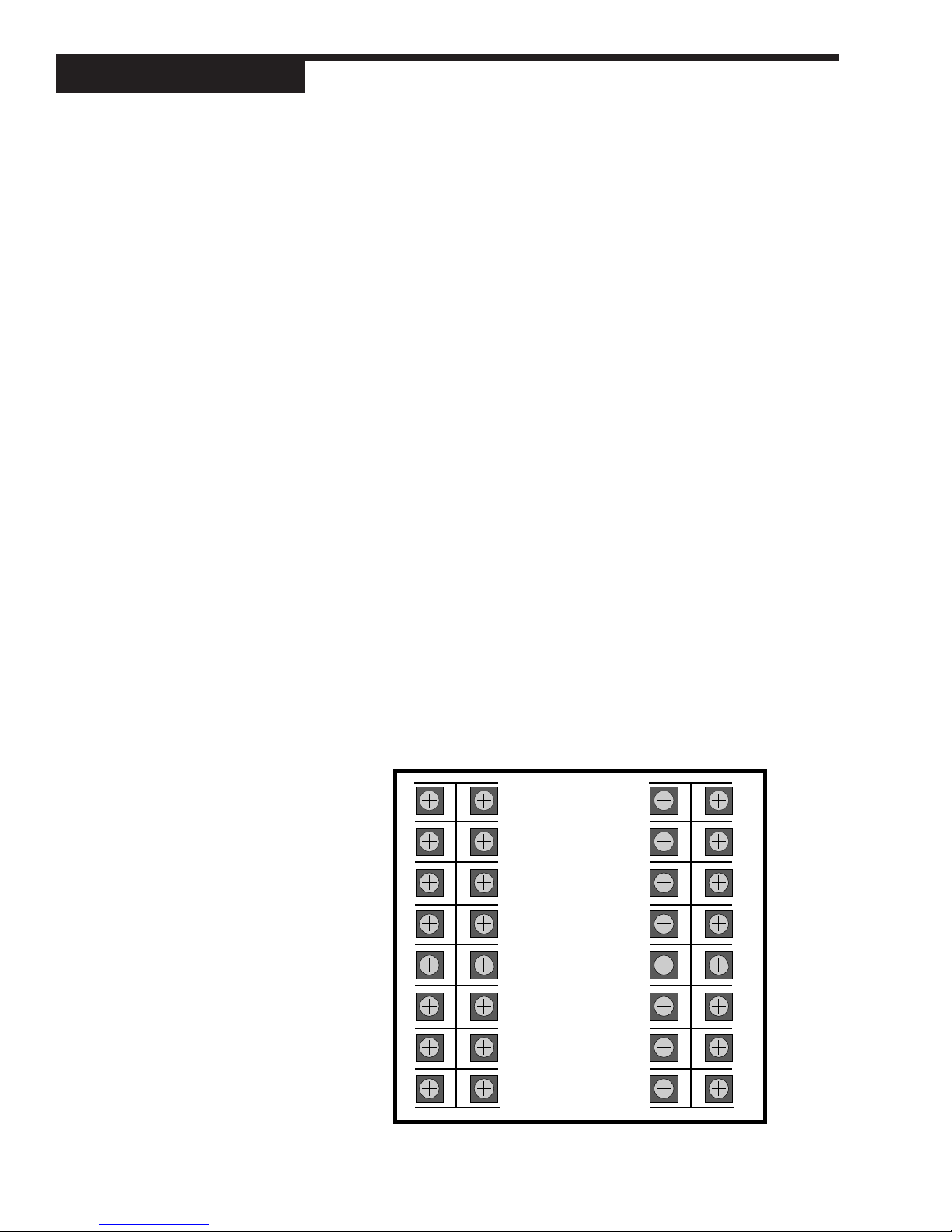

Figure 3.3

Terminal Assignments

Actual 545 device only has top and

bottom numbers of each column of

terminals marked.

WARNING!

Electric Shock Hazard! Terminals 1

and 2 carry live power. DO NOT touch

these terminals when power is on.

WARNING!

Terminal 9 must be grounded to avoid

potential shock hazard, and reduced

noise immunity to your system.

AC Power Input

LINE

1

NEUTRAL

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

2

3

4

5

6

7

816

TOP (as viewed from back of controller)

EARTH

917

GND

S/W

10

CCW

S/W 2

11

S/W 3

12

RSP–

13

RSP+

14

OUT 4–

15

OUT 4+

DIN

GND

DIN 1

18

DIN 2

19

DIN 3

20

DIN 4

21

DIN 5

22

COLD

23

JUNC–

COLD

24 32

JUNC+

25

26

27

28

29

30

31

(NOT

USED)

COMM–

COMM+

PV2–

PV2+

RTD 3RD

PV1–

PV1+

12 Chapter 3 545 User's Manual

Page 20

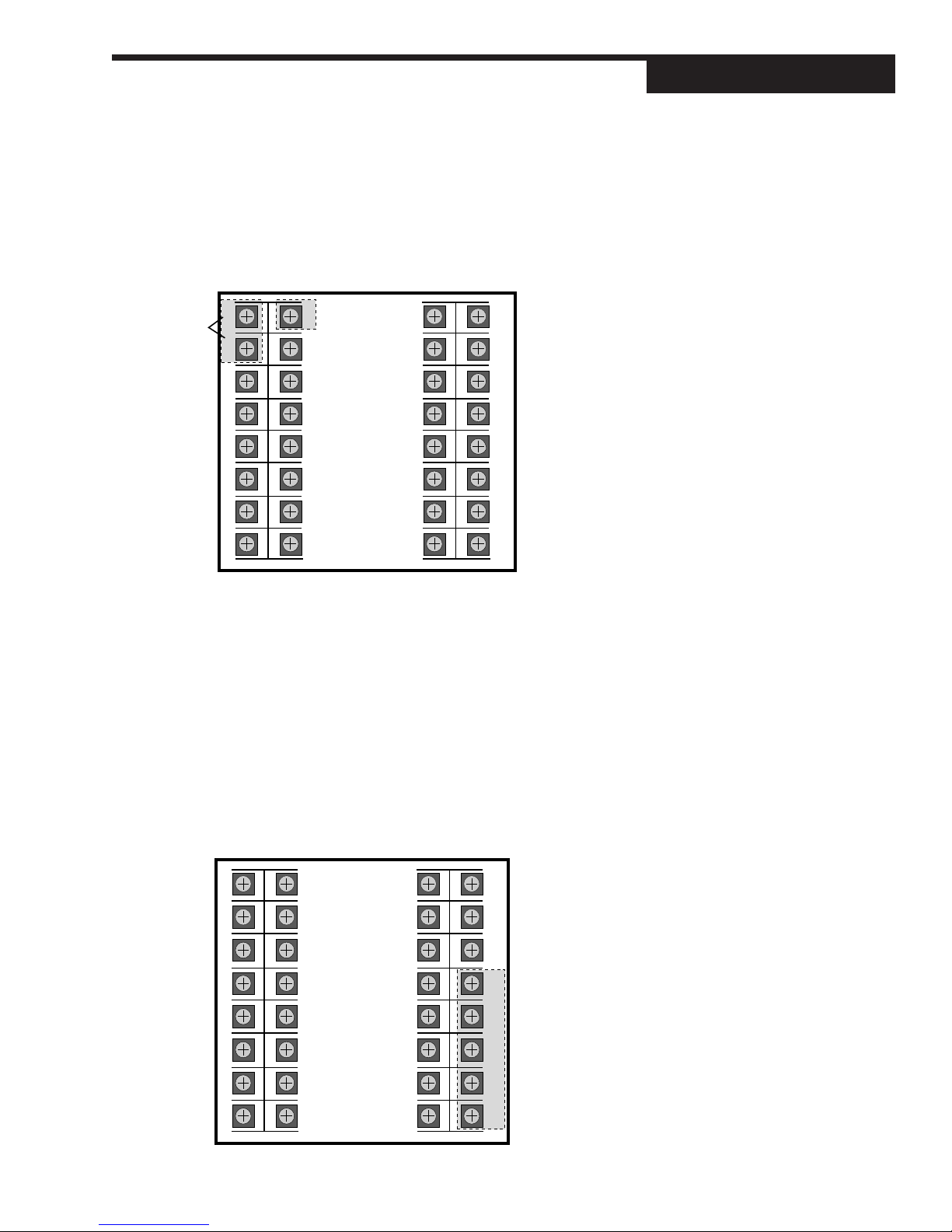

Terminals 1 and 2 are for power. Terminal 9 is the earth ground.

Use a 0.5 Amp, 250 V, fast-acting fuse in line with your AC power connection.

Process Variable Input

TOP

Installation

POWER

1

2

3

4

5

6

7

816

Screws must be tight to ensure good electrical connection

The 545 accommodates the following types of process variable inputs:

• Thermocouple Input

• RTD Input

• Voltage Input

• Milliamp Input with External Power Supply

• Milliamp Input with Internal Power Supply

Each type of input can be wired for PV1 (terminals 31 and 32) or for PV2 (termi-

nals 28 and 29).

EARTH/

917

GROUND

10

11

12

13

14

15

18

19

20

21

22

23

25

26

27

28

29

30

31

24 32

Figure 3.4

AC Power Input Terminals

CAUTION!

Do not run low power (sensor input)

lines in the same bundle as AC power

lines. Grouping these lines in the same

bundle can create electrical noise

interference.

Digital Input(s)

1

2

3

4

5

6

7

917

10

11

12

13

14

15

816

545 User's Manual Chapter 3 13

TOP

25

18

19

20

21

22

23

26

27

28

29

30

31

24 32

Figure 3.5

Process Variable Terminals

PV 2–

PV 2+

RTD 3rd

PV 1–

PV 1+

Page 21

Installation

–

+

THERMOCOUPLE INPUT

28

29

NOTE:

Typically, in the U.S., negative leads

are red.

Figure 3.6

PV1 and PV2 Wiring for Milliamp,

RTD and Voltage Inputs.

For PV1 For PV2

THERMOCOUPLE INPUT

30

–

31

+

32

2-WIRE RTD

30

31

32

3-WIRE RTD

Third leg

of RTD

30

31

32

Jumper wire

RTD

Same color

2-WIRE RTD

3-WIRE RTD

28

29

30

Jumper wire

28

29

30

Third leg of RTD

RTD

RTD

Same

color

14 Chapter 3 545 User's Manual

4-WIRE RTD

Same color

–

Transmitter

+

Same color

Third leg

of RTD

30

31

32

DO NOT connect 4th leg

VOLTAGE INPUT

–

31

+

32

4-WIRE RTD

VOLTAGE INPUT

28

29

30

28

29

Same color

Third leg

of RTD

–

–

+

+

Do NOT

connect

4th leg

Transmitter

Page 22

For PV1 For PV1

Installation

MILLIAMP INPUT

2-wire transmitter with

separate power supply

–

External +

Power Supply

28

29

– Transmitter +

MILLIAMP INPUT

2-wire transmitter with

loop power supply

15

16

31

32

2-wire

transmitter

+

+

–

+

–

–

MILLIAMP INPUT

4-wire transmitter with

loop power supply

–

–

15

16

31

32

+

–

+

Input power

for transmitter

+

4-20 mA output

–

from transmitter

+

MILLIAMP INPUT

2-wire transmitter with

separate power supply

External

–

Power Supply

31

32

–

Transmitter

MILLIAMP INPUT

2-wire transmitter with

loop power supply

15

16

28

29

2-wire

transmitter

+

+

–

+

–

–

MILLIAMP INPUT

4-wire transmitter with

loop power supply

–

–

15

16

28

29

+

–

+

Input power

for transmitter

+

4-20 mA output

–

from transmitter

+

Figure 3.7

PV1 and PV2 Wiring for Milliamp

Inputs with Internal and External

+

+

Power Supply

NOTE:

To use loop power, there must be a

loop power module is installed in the

3rd or 4th output socket. Compare the

controller product number with the

order code in Chapter 1 to determine

if the 545 has a loop power module

installed. To install a loop power

module, refer to Chapter 4

.

545 User's Manual Chapter 3 15

Page 23

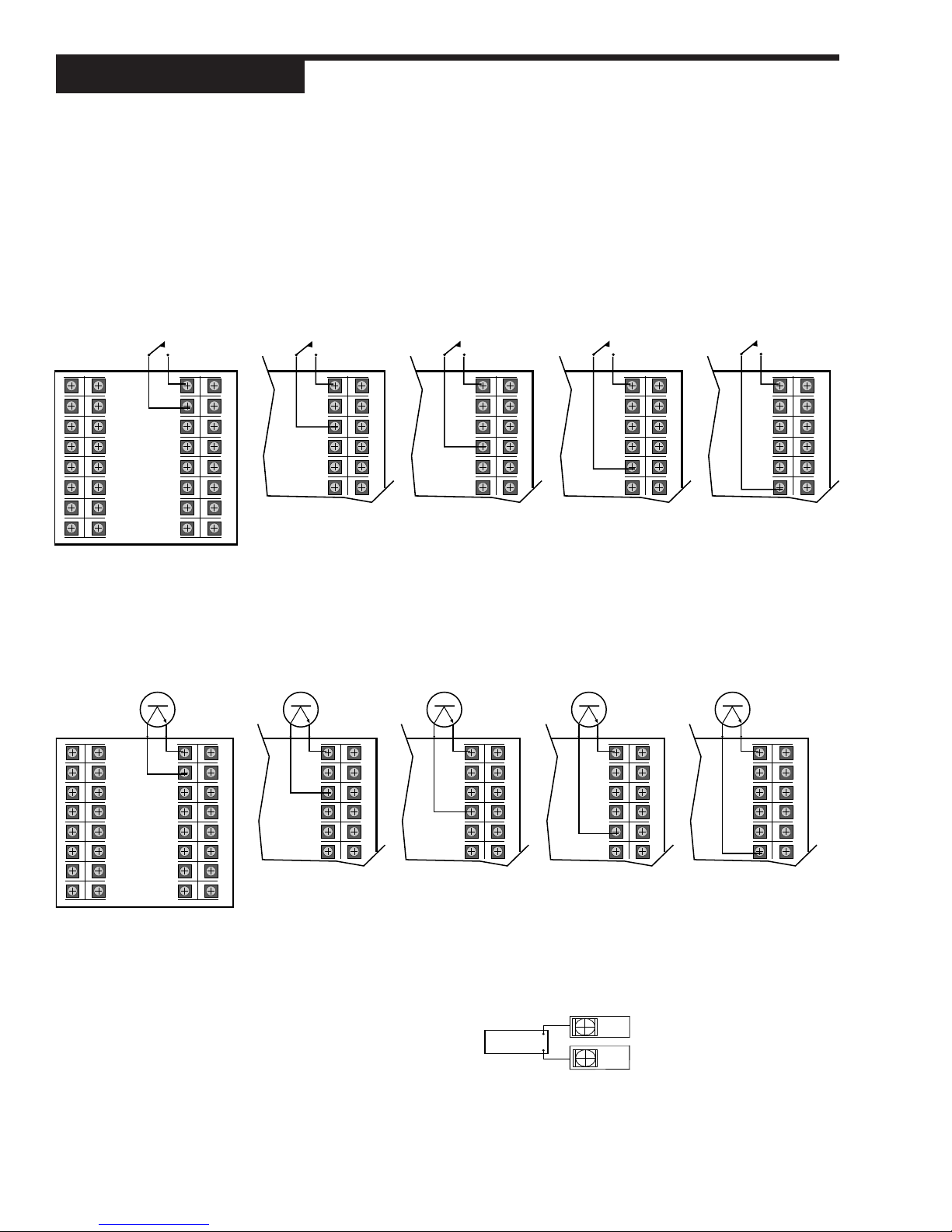

Installation

Figure 3.8

Digital Input Wiring with a Switch or

Relay

Digital inputs can be activated in three ways: a switch (signal type), closure of

a relay, or an open collector transistor. Digital inputs are only functional when

that option is installed (via hardware). The controller detects the hardware and

supplies the appropriate software menu.

1. Digital Inputs with a switch or relay

Wire the switch/relay between terminal 17 and the specific digital input

terminal (Figure 3.8).

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22

23

24 32

9

10

11

12

13

14

15

16

25

26

27

28

29

30

31

Figure 3.9

Digital Input Wiring with an Open

Collector

1

2

3

4

5

6

7

8

Screws must be tight to ensure electrical connection

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22

23

24 32

9

10

11

12

13

14

15

16

25

26

27

28

29

30

31

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

DIN

17

18

19

20

21

22 30

25

26

27

28

29

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

2. Digital Inputs with an Open Collector

An open collector is also called a transistor. Wire the transistor between

terminal 17 and the specified digital input terminal (Figure 3.9)

17

18

19

20

21

22 30

25

26

27

28

29

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22 30

25

26

27

28

29

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

Remote Setpoint Option

17

18

19

20

21

22 30

17

18

19

20

21

22 30

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

DIN

DIN

GND

DIN 1

DIN 2

DIN 3

DIN 4

DIN 5

17

18

19

20

21

22 30

17

18

19

20

21

22 30

25

26

27

28

29

25

26

27

28

29

25

26

27

28

29

25

26

27

28

29

Figure 3.10

Remote Setpoint Terminals

16 Chapter 3 545 User's Manual

Use terminals 13 and 14 to connect the remote setpoint signal.

Source

–

–

+

+

13

14

Page 24

Installation

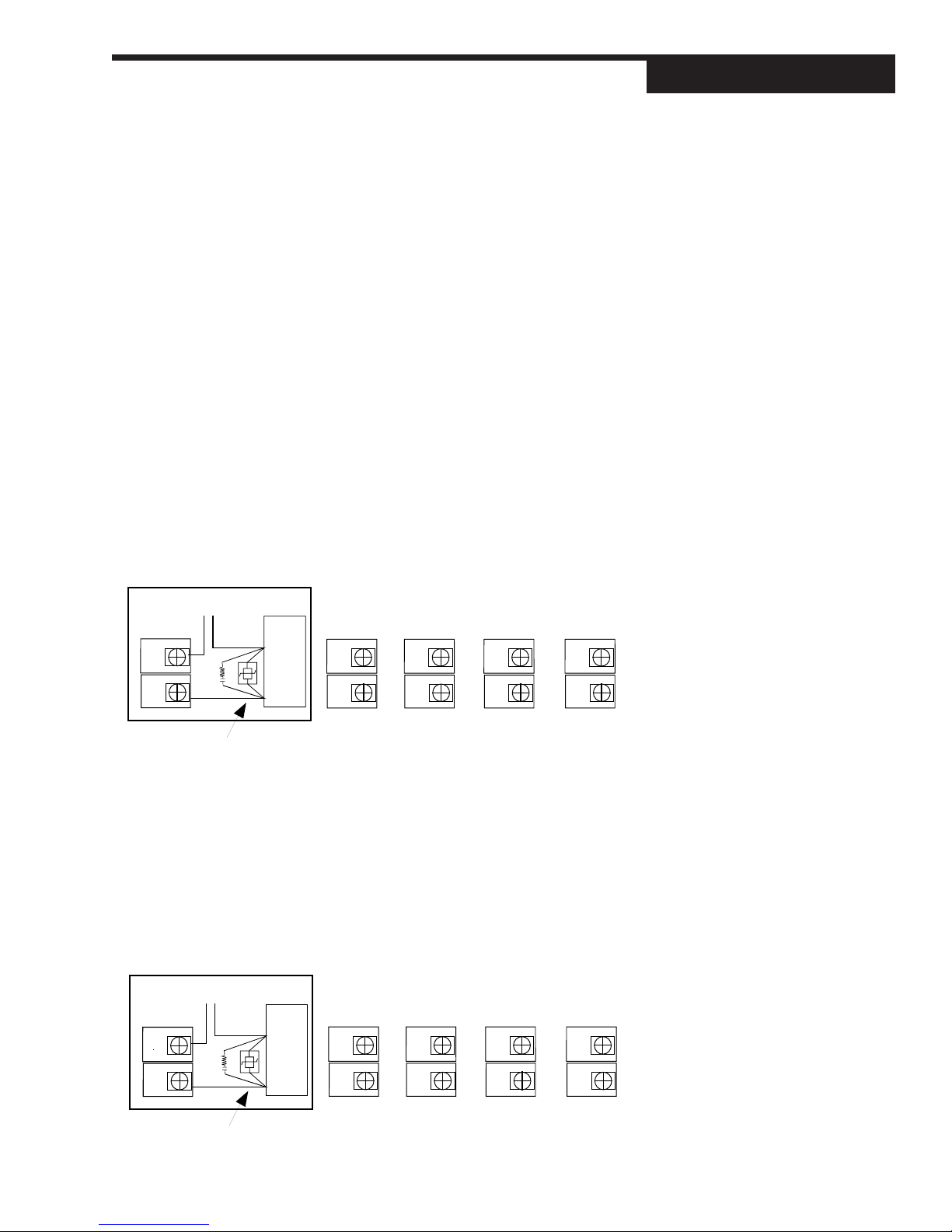

OUTPUT MODULES

The 545 output modules are used for control, alarms and retransmission. The

four output module types are: Mechanical Relay, Solid State Relay (Triac),

DC Logic (SSR Drive) and Analog (Milliamp).

To install these modules, plug them into any of the four output sockets on the

printed circuit boards (refer to Chapter 4). The wiring is the same whether the

modules are used for control, alarm or retransmission.

The diagrams on the next two pages are a guide for properly connecting the

various outputs. To find out which module(s) have been installed in the controller, compare the product number on the controller label with the section Order

Code in Chapter 1. This section also includes a diagram of how to wire a position proportioning output, a special application using two mechanical or two solid

state relays.

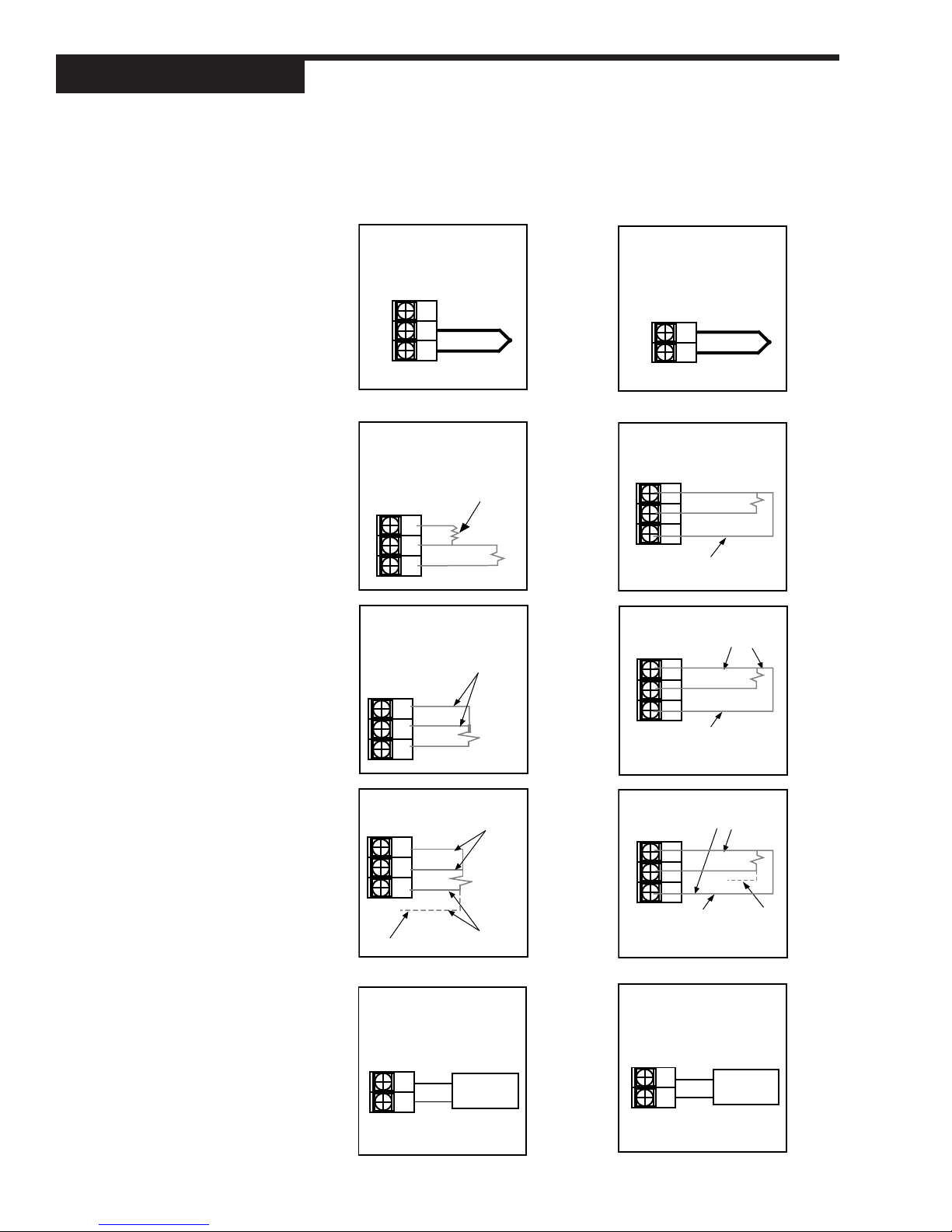

1. Mechanical Relay Output

• Output 1 is always Control 1.

• Outputs 1, 2 and 3 are jumper selectable for normally open and normally closed on the power supply circuit board.

• Output 4 is always configured for normally open and has reduced

voltage and current ratings (see Specifications).

Line Power

Terminals used

with Output

Module 1

Terminals used

with Output

Module 2

Terminals used

with Output

Module 3

Terminals used

with Output

Module 4

NOTE:

Refer to Figure 4.2 for location of the

corresponding jumpers.

Second input jumper connector on the

option board must be in either

mA

(milliamp) or V (voltage) position.

3

Load

4

Recommend use of both MOV and snubber

3

4

2. Solid State Relay (Triac) Output

• Output 1 is always Control 1.

• Respective jumper J1, J2 or J3 must be set to normally open for SSR

(Triac) output.

• Output 4 is always configured for normally open and has reduced

voltage and current ratings (see Specifications).

3

4

Line Power

-

+

-

Load

+

Terminals used

with Output

Module 1

3

4

5

6

Terminals used

with Output

Module 2

5

6

7

8

Terminals used

with Output

Module 3

7

8

15

16

Terminals used

with Output

Module 4

15

16

Figure 3.11

Mechanical Relay Output Wiring

Figure 3.12

SSR Relay Output Wiring

Recommend use of both MOV and snubber

545 User's Manual Chapter 3 17

Page 25

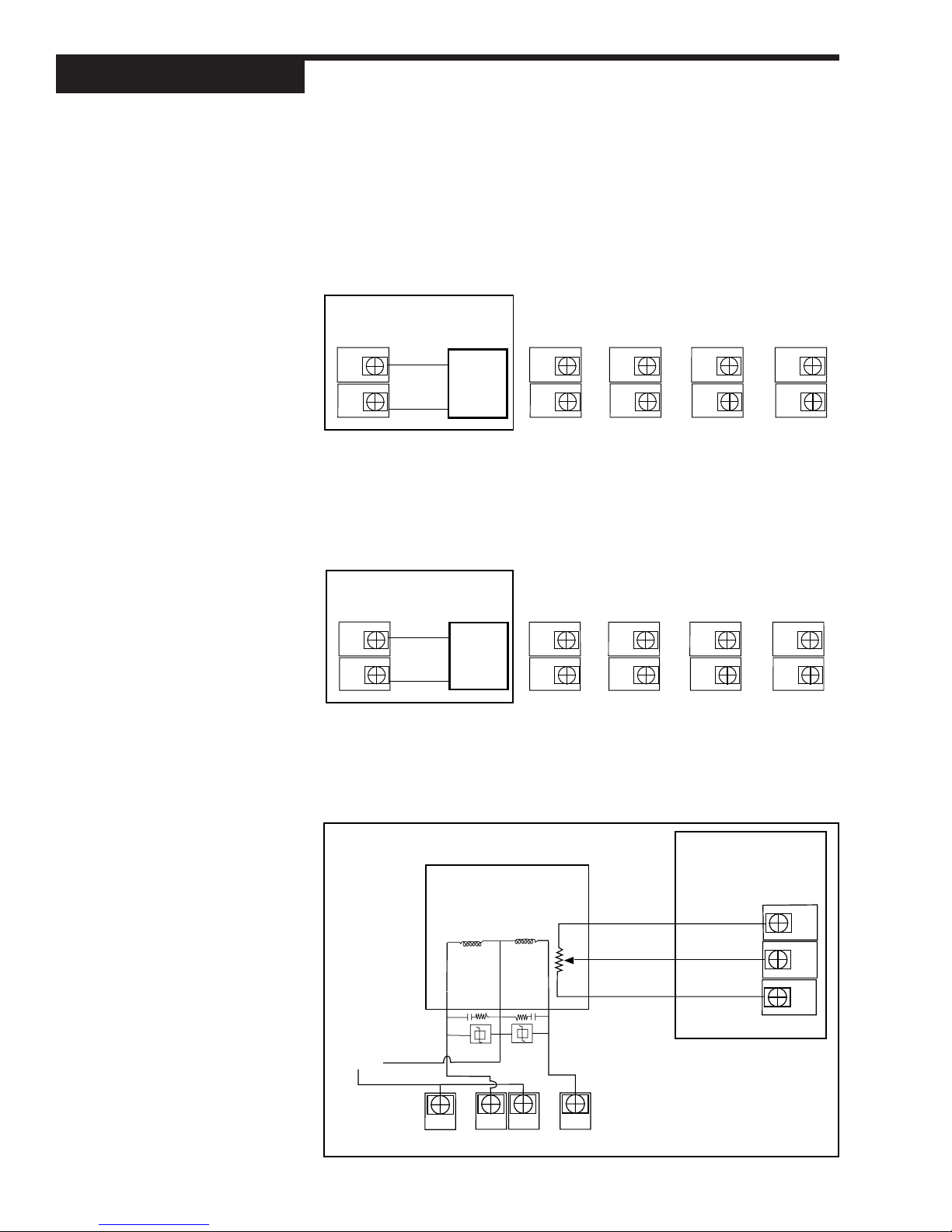

Installation

Figure 3.13

DC Logic Output Wiring

3. DC Logic (SSR Drive) Output

• Output 1 is always Control 1.

• Respective jumper J1, J2 or J3 must be set to normally open for DC

Logic output.

• Output 4 is always configured for normally open.

Figure 3.14

Milliamp Output Wiring

Terminals used

with Output

Module 1

3

_

4

+

_

Load

+

3

4

Terminals used

with Output

Module 2

5

6

Terminals used

with Output

Module 3

7

8

Terminals used

with Output

15

16

4. Milliamp Output

• Output 1 is always Control 1.

• Respective jumper J1, J2 or J3 must be set to normally open for

Milliamp output.

Terminals used

with Output

Module 1

Terminals used

with Output

Module 2

Terminals used

with Output

Module 3

Terminals used

with Output

_

3

Load

4

+

3

4

5

6

7

8

15

16

Module 4

Module 4

5. Position Proportioning Output

Figure 3.15

Position Proportioning Output

Wiring

18 Chapter 3 545 User's Manual

(with or without Slidewire Feedback)

Electric Motor Actuator

CCW

Winding

Actuator

Supply

Current

3

COMCWCCW

CW

Winding

4

5

COM

CCW

Slidewire

Wiper

0–1050 Ohm

CW

6

POSITION

PROPORTIONING

OUTPUT

10

11

12

Page 26

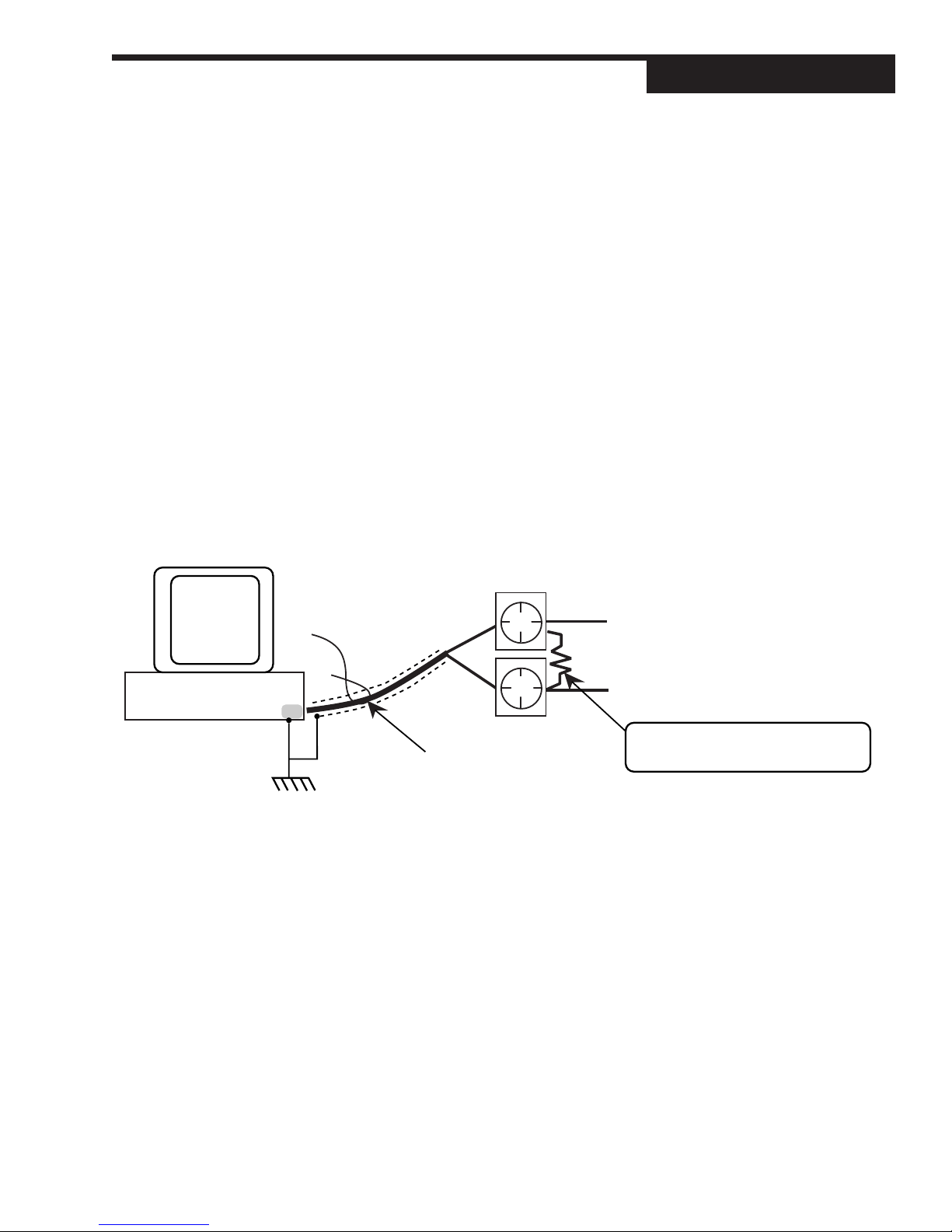

• Mechanical relay or solid state relay modules must be installed in

PC

or other host

545

Terminals

RS-485

port

Twisted, shielded

To "Comm –" terminal of

next Moore Industries device

To "Comm +" terminal of

next Moore Industries device

Comm +

Comm –

Use a 60 to 100 Ohm terminating resistor

connected to the two data terminals of

the final device on the line.

CAUTION

The shield needs to be connected continuously

but only tied to one ground at the host.

Failure to follow these proper wiring practices

could result in transmission errors and other

communications problems.

26

27

output sockets 1 and 2.

• When using velocity control (no slidewire feedback), there are no connections at terminals 10, 11 and 12.

• Use of the slidewire feedback is optional

Serial Communications

A twisted shielded pair of wires should be used to interconnect the host and

field units. Belden #9414 foil shield or #8441 braid shield 22-gauge wire are

acceptable for most applications. The foil shielded wire has superior noise

rejection characteristics. The braid shielded wire has more flexibility. The

maximum recommended length of the RS 485 line is 4000 feet. Termination

resistors are required at the host and the last device on the line. Some RS

485 cards/converters already have a terminating resistor. We recommend

using RS-232/RS-485 converter (Product #500-485). The communication

protocol is asynchronous bidirectional half-duplex, hence the leads are

labelled

Comm +

and

Comm –

.

Installation

Figure 3.16

Serial Communications Terminals

545 User's Manual Chapter 3 19

Page 27

Installation

20 Chapter 3 545 User's Manual

Page 28

CHAPTER 4

HARDWARE CONFIGURATION

Hardware configuration determines the available outputs as well as the type of

input signal. The 545 controller comes factory set with the following:

• All specified module and options installed (for details, refer to the Order Code

in Chapter 1).

• Process variable and remote setpoint set to accept a milliamp input.

• Relay outputs set to normally open.

Alter the factory configuration of the 545, requires accessing the circuit boards,

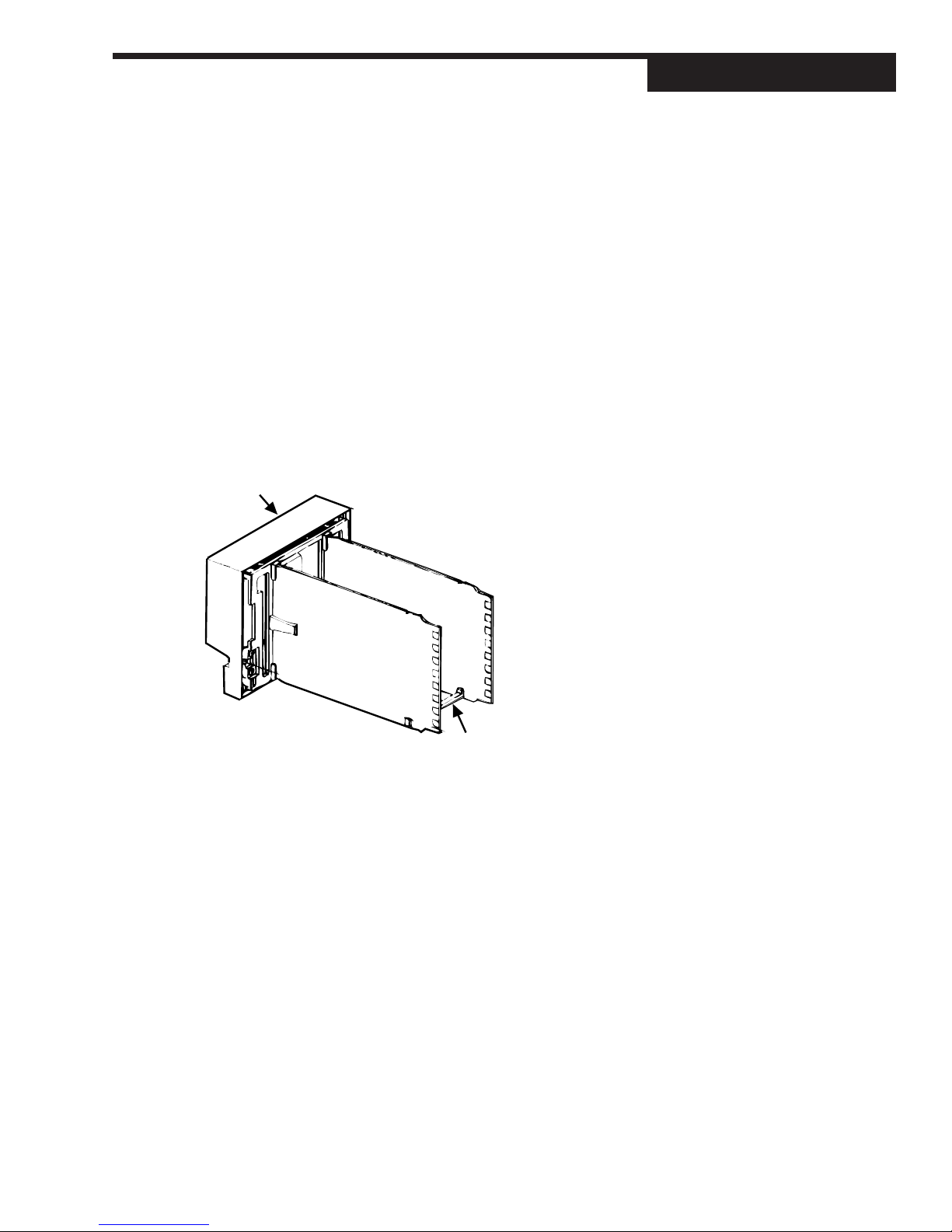

and locating the jumpers and output modules (see Figure 4.1).

1. With the power off, loosen the four front screws, and remove them.

2. Slide chassis out of the case by pulling firmly on the bezel.

FRONT FACE

Hardware Configuration

NOTE:

Hardware configuration of the

controller is available at the factory;

Consult an application engineer for

details.

MICROCONTROLLER

BOARD

POWER SUPPLY

BOARD

OPTION BOARD

A detailed view of the circuit boards appears in Figure 4.2.

After configuring the hardware, or if no changes are necessary, continue setting

up the process as needed.

HARDWARE INPUT TYPES

The Process Variable

The 545 accepts several different types of process variable signals. Set a jumper

location to specify the type of input signal. Set the signal range in the software

(see Chapter 5 for software menus, or Chapter 7 for applications).

The jumpers for the process variable are located on the Microcontroller Circuit

Board (see Figure 4.2). The factory default is Milliamp. Locations are marked

as follows:

V Voltage

MA Milliamp

TC ▼ Thermocouple with downscale burnout

TC ▲ Thermocouple with upscale burnout

RTD RTD

Figure 4.1

Location of Printed Circuit Boards for

Hardware Configuration

NOTE:

Thermocouple downscale and

upscale burnout offers a choice in

which direction the controller would

react in the event of thermocouple

failure. For example, in heat

applications, typically, it is desirable

to fail upscale (TC ▲) so that the

system does not apply more heat.

545 User's Manual Chapter 4 21

Page 29

Hardware Configuration

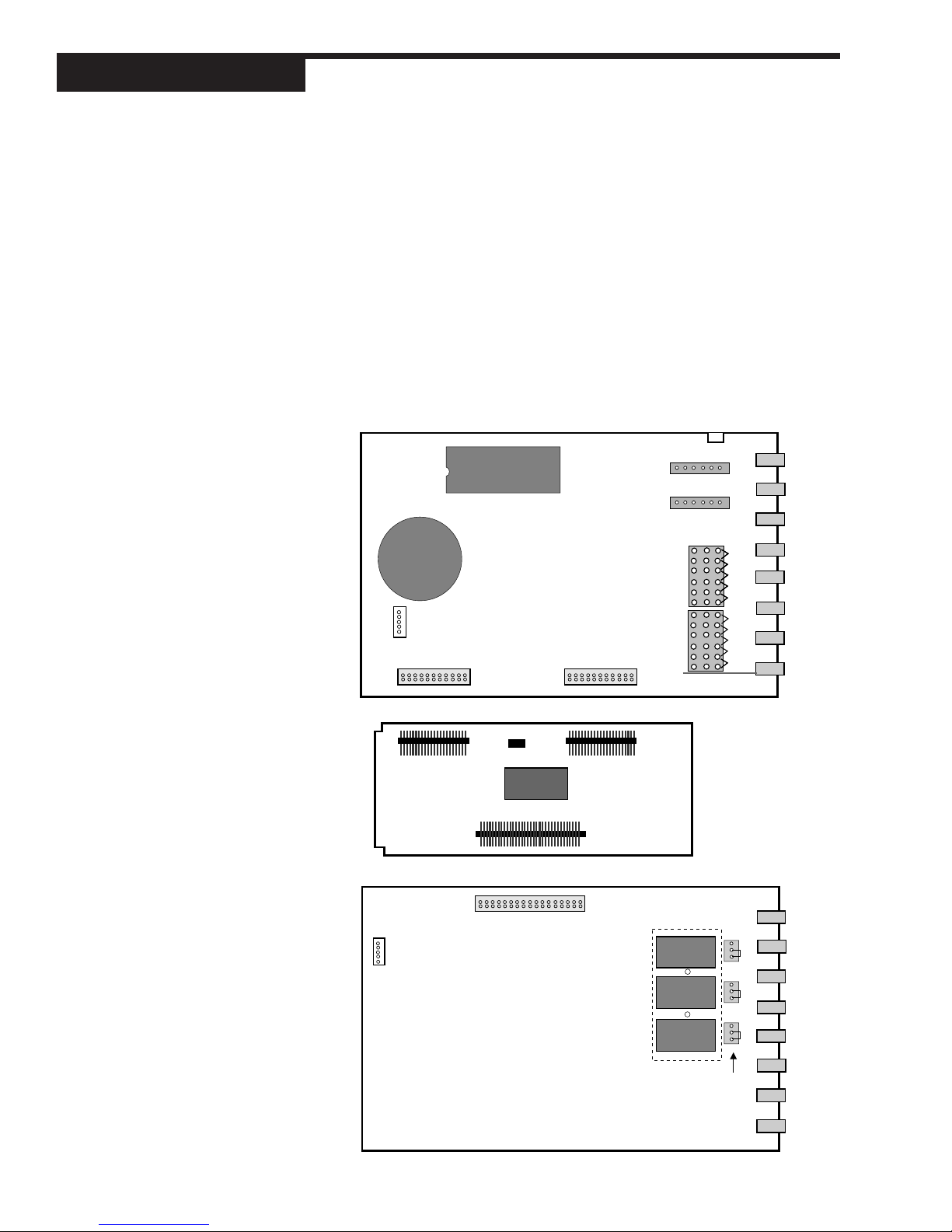

BATTERY

EPROM

NOTE:

Changing the jumpers means moving

the jumper connector. The jumper

connector slips over the pins,

straddling two rows of pins. The

printed circuit boards are labeled next

to the jumpers.

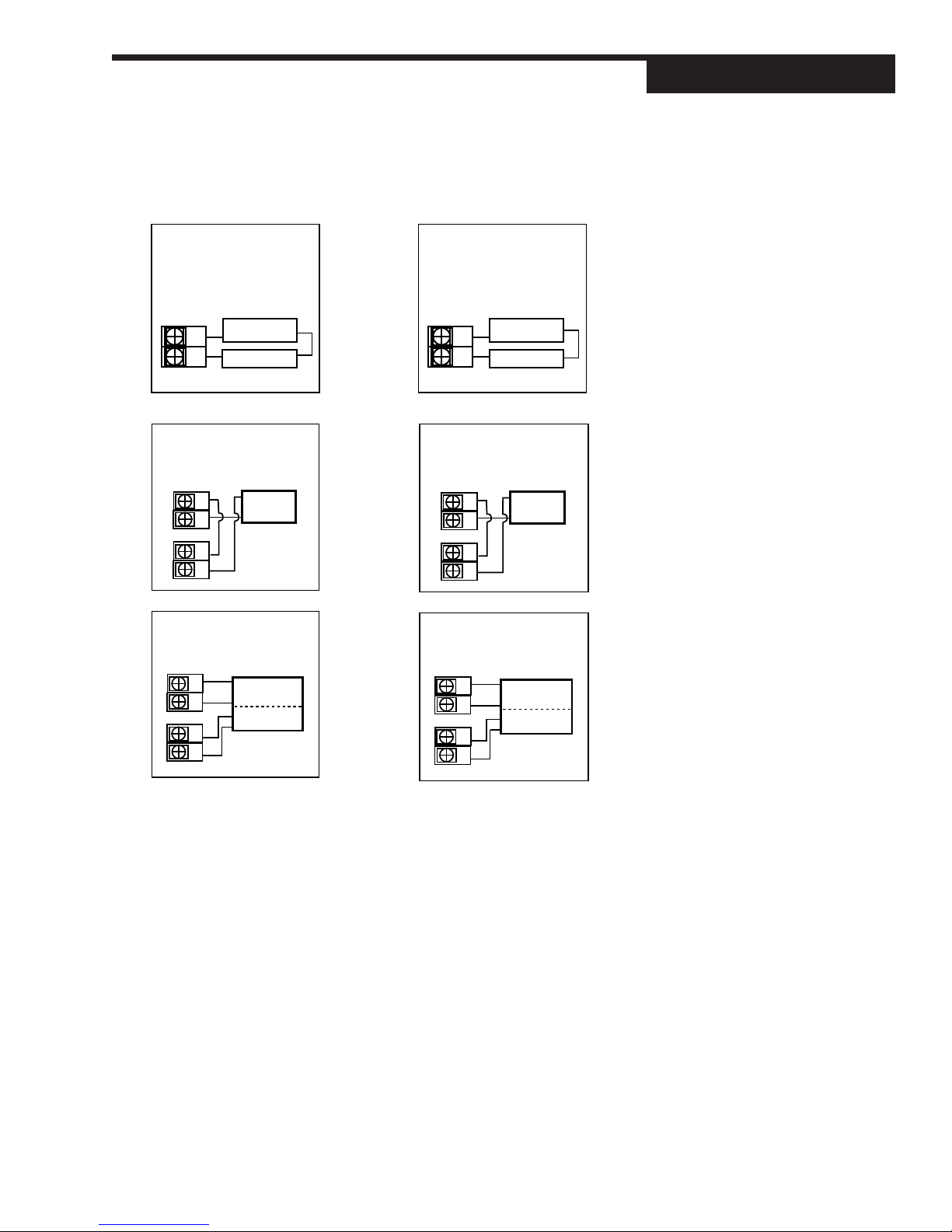

Figure 4.2

(from the top) The Microcontroller

Circuit Board, the Option Board, and

the Power Supply Board

The Remote Setpoint

Figure 4.2 shows the location of the remote setpoint jumper. The factory default is milliamp. Choose from the following settings:

V Remote setpoint with voltage signal (jumper removed)

mA Remote setpoint with milliamp signal (jumper installed)

Mechanical Relays

There are three output module sockets on the Power Supply Circuit Board, and

one output module on the Option Board (see Figure 4.2). The mechanical relay

on the Power Supply Board may be configured for either normally open (NO) or

normally closed (NC). A jumper located next to each socket determines this configuration. All relay output are factory set to NO (normally open).

EPROM

BATTERY

5-Pin Connector

Female 22-Pin ConnectorFemale 22-Pin Connector

P1

P2

V

V

V

MA

MA

MA

TC

TC

TC ▼

TC

TC

TC ▲

RTD

RTD

RTD

V

MA

TC ▼

TC ▲

RTD

TB2

2ND

PV1

TB1

Male 22-Pin

Connector

5-Pin Connector

Remote Setpoint Jumper

Output 4

4

Female 34-Pin Connector

Male 22-Pin

Connector

Male 34-Pin

Connector

Module

Retention

over Outputs 1,2,3

Plate

3

2

1

NO J3 NC

NO J2 NC

NO J1 NC

Jumpers

NO and NC

22 Chapter 4 545 User's Manual

Page 30

Hardware Configuration

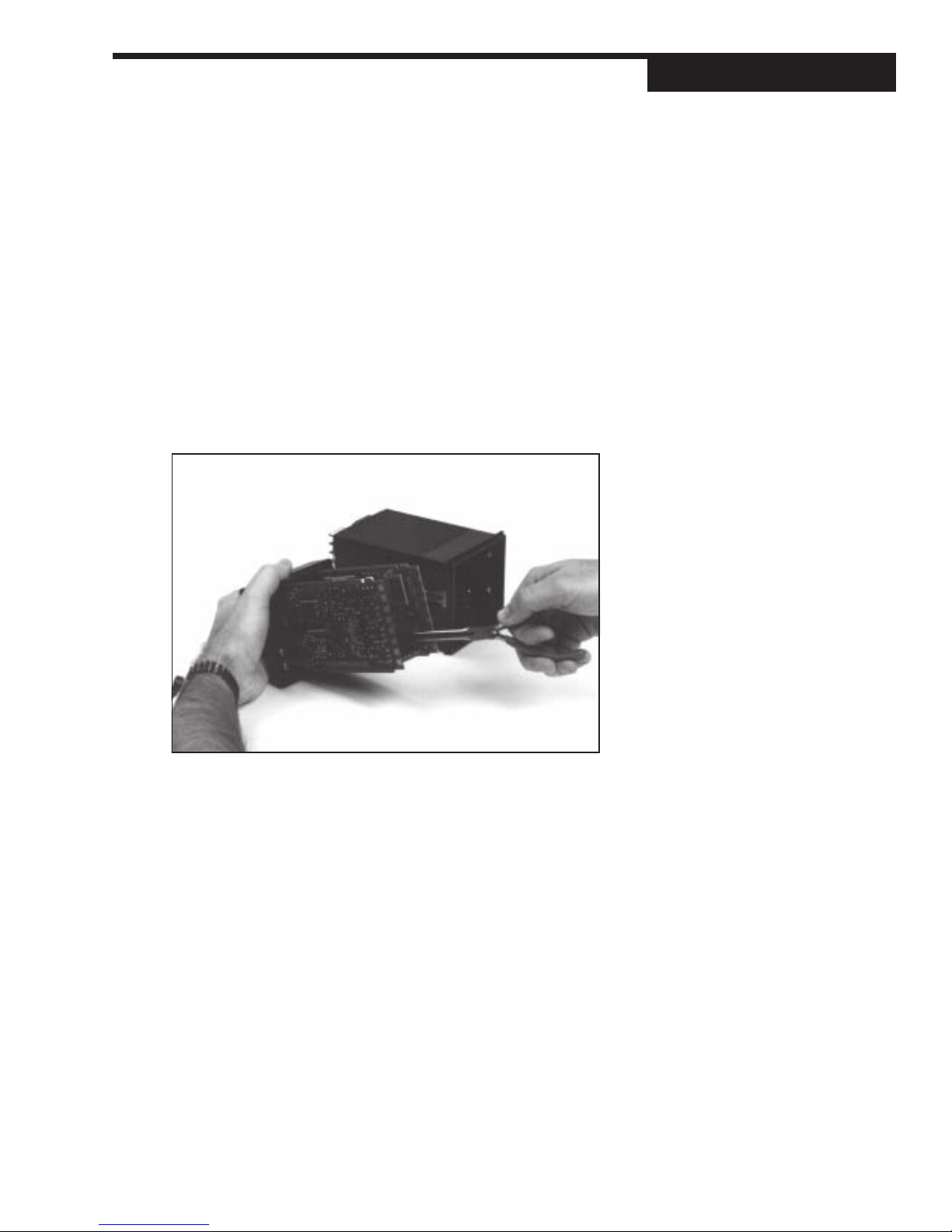

ACCESSING AND CHANGING JUMPERS

Follow these instructions to change jumpers for the Process Variable, Remote

Setpoint and Digital Inputs:

Equipment needed: Needle-nose pliers (optional)

Phillips screwdriver (#2)

Wrist grounding strap

1. With power off, loosen two front screws, and remove them.

2. Side the chassis out of the case by pulling firmly on the bezel.

3. Use Figure 4.2 to locate the jumper connector to change.

4. Using the needle nose pliers (or fingers), pull straight up on the connector

and remove it from its pins, as shown in Photo 2. Be careful not to bend the

pins.

Caution!!

Static discharge can cause damage

to equipment. Always use a wrist

grounding strap when handling

electronics to prevent static

discharge.

2. Remove Jumpers

5. Find the new location of the jumper connector (again, refer to Figure 3.2).

Carefully place it over the pins, then press connector straight down. Make

sure it is seated firmly on the pins.

6. Make any other jumper changes as needed. To alter output modules 1,

please refer to the next section, starting with Step #3.

7. To reassemble the controller, properly orient the chassis with board opening on top. Align the circuit boards into the grooves on the top and bottom of

the case. Press firmly on the front face assembly until the chassis is all the

way into the case.

If it is difficult to slide the chassis in all the way, make sure the screws have

been removed (they can block proper alignment), and that the chassis is

properly oriented.

8. Carefully insert and align screws. Tighten them until the bezel is seated firmly

against the gasket. Do not overtighten.

545 User's Manual Chapter 4 23

Page 31

Hardware Configuration

ADDING AND CHANGING OUTPUT MODULES

The 545 has provisions for four output modules. A controller ordered with output

module options already has the modules properly installed. Follow these instructions to add modules, change module type(s) or change module location(s).

Equipment needed: Wrist grounding strap

1. With power off, loosen two front screws, and remove them.

2. Slide the chassis out of the case by pulling firmly on the bezel.

3. Use a flat screwdriver to carefully pry apart the clips that hold the front face

4. As shown in Photo 4, carefully pry apart, using hands or a small flat screw-

5. To change modules 1, 2 or 3:

Phillips screwdriver (#2)

Small flat blade screwdriver

Wire cutters

assembly to the chassis, as in Photo 3. Separate the printed circuit board

assembly from the front face assembly. Use care not to break the clips or

scratch the circuit boards.

driver, the smaller Option board and the Power Supply board (the one with

3 modules).

Output modules 1, 2, and 3 are firmly held in place by a retention plate and

tie wrap. Carefully snip the tie wrap with a wire cutter. To prevent damage to

the surface mount components, ALWAYS snip the tie wrap on TOP of the

Retention Plate, as shown in Photo 5.

Remove the retention plate.

3. Pry Clips

24 Chapter 4 545 User's Manual

4. Separate Boards

5. Remove Retention Plate

Page 32

6. To change module 4:

Output Module 4 (on the Option board) is also held in place by a tie wrap.

Snip tie wrap to remove module as shown in Photo 6.

7. Figure 4.3 shows a representation of an output module. Inspect the

module(s) to make sure that the pins are straight.

8. To install any module, align its pins with the holes in the circuit board, and

carefully insert the module in the socket. Press down on the module until it

is firmly seated; refer to Photo 7.

Hardware Configuration

Figure 4.3

Representation of Module

7. Add/Change Module6. Snip Tie Wrap

9. Replace tie wraps for all the modules (the Retention Plate and Output Module 4) with new ones before reassembling the controller.

Failure to use the tie wraps may result in loosening of the module and eventual failure. All separately ordered modules should come with a tie wrap. Extra

sets of tie wraps are available by ordering Part #545-665.

NOTE: For greatest accuracy, calibrate all milliamp modules added for

retransmission as per the instructions in Appendix 2.

10. Rejoin the circuit boards by aligning the pins of their connectors, then squeezing the board(s) together. Make sure that all three printed circuit boards are

properly seated against one another; check along side edges for gaps. Make

sure the cable assemblies are not pinched.

11. To reattach the board assembly to the front face assembly, align the boards

(with the open area on top) into the slots of the font face assembly. The clips

should snap into place.

12.To reassemble the controller, properly orient the chassis with board opening on top. Align the circuit boards into the grooves on the top and bottom of

the case. Press firmly on the front face assembly until the chassis is all the

way into the case.

If it is difficult to slide the chassis in all the way, make sure the screws have

been removed (they can block proper alignment), and that the chassis is

properly oriented.

13. Carefully insert and align screws. Tighten them until the bezel is seated firmly

against the gasket. Do not overtighten.

545 User's Manual Chapter 4 25

Page 33

Hardware Configuration

Insert module onto connectors

Front of controller

(circuits boards still attached to front face)

2ND

REMOTE SP

CONFIGURATION

TB2

EPROM

BATTERY

P2

P1

V

MA

TCs

RTD

TCt

SPECIAL COMMUNICATIONS MODULE

A special communications module is available for the 545; see order code in

Chapter 1 for details.

Equipment needed: Wrist grounding strap

1. Before installing the communications module, set up the hardware wiring

2. With power off, loosen two front screws, and remove them.

3. Slide the chassis out of the case by pulling firmly on the bezel. Do not detach

4. Orient the Communications Module as shown, and attach it to Connectors

Phillips screwdriver (#2)

Small flat blade screwdriver

for the application. See Chapter 4 for details.

the board assembly from the front face of the controller.

P1 and P2 as shown in Figure 4.4.

Figure 4.4

Install Communications Module

onto Microcontroller Board

5. To reassemble the controller, properly orient the chassis with board opening

on top. Align the circuit boards into the grooves on the top and bottom of the

case. Press firmly on the front face assembly until the chassis is all the way

into the case.

If it is difficult to slide the chassis in all the way, make sure the screws have

been removed (they can block proper alignment), and that the chassis is

properly oriented.

6. Carefully insert and align screws. Tighten them until the bezel is seated firmly

against the gasket. Do not overtighten.

26 Chapter 4 545 User's Manual

Page 34

CHAPTER 5

SOFTWARE CONFIGURATION

The software configuration menus of the 545 contain user-selected variables that

define the action of the controller. Read through this section before making any

parameter adjustments to the controller.

When initially setting up the

controller, cycle through all the

parameters in each Menu.

Press the MENU+FAST to

advance to the next menu.

Press MENU to advance to the

next parameter (this also sets

the value for the current

parameter. Use arrow keys to

select a value).

Use the arrows keys to

enter numerical values,

and/or move through the

selection group.

press:

MENU/FAST

CONFIG.

press:

MENU

INDICATOR

press:

press MENU/FAST

Go to next Menu Block:

(D)

This is a Menu.

Its name will show in the 2nd display.

This is a menu Parameter.

The name shows in the 3rd display.

In this manual, independent parameters

appear as white text on black, and

dependent parameters appear as black

This is a parameter Value.

These values appear in the 3rd display,

replacing the parameter name.

In this manual, parameter graphics

indicate the default (factory) setting.

If the default value is dependent on other

variables, (D) is shown.

Software Configuration

Figure 5.1

Parts of the Menu Block

MENUS

In SETUP mode, there are 12 sets of options that control different aspects of 545

operation; in TUNING mode, there is one. Each set of options is called a menu.

When traversing the two modes, the menu names appear in the 2nd display.

Most of the menus are loop dependent, that is, each loop has its own set of

parameters for that menu. Three of the menus are global, that is, one set of

parameters applies to both loops.

CONFIG (Global) Mode selection and input/output hardware assignments

PV INPUT Process variable input options

CUST. LINR. Linearization curve options for PV input.

CONTROL Control options

ALARMS Alarm options

REM. SETPT. (Global) Controller remote setpoint options

RETRANS. (Global) Retransmission output options

SELF TUNE Self tune algorithm options

SPECIAL Special feature options

SECURITY (Global) Security functions

SER.COMM. (Glob al) Serial Communications options (requires comm. board)

and

TUNING Tuning parameters configuration (see Chapter 6)

CAUTION!

All software changes occur in real time;

always perform set up functions under

manual operation.

NOTE:

For information about the Tuning

menu/mode, refer to Chapter 6. For

more information about set up

parameters and 545 applications,

refer to Chapter 7.

545 User's Manual Chapter 5 27

Page 35

Software Configuration

FAST

DISPLAY

TUNE PT.

AUTOMATIC

CONTACT 1

MANUAL

Figure 5.2

Independent vs. Depedent

Parameters

Figure 5.3

Configuration Flowchart

MANUAL

OPERATION

+

or

to return to

OPERATION

mode

for Loop 1

SET UP mode

PARAMETERS

Within each menu are parameters for particular control functions. Select val-

ues for each parameter depending on the specific application. Use the MENU

key to access parameters for a particular menu; the parameter name will replace the menu name in the 2nd display, and the parameter value will show in

the 3rd display.

This chapter outlines all the available parameters for the 5 45. Some parameters

are independent of any special configuration, and others are dependent on

the individual configuration. This manual displays these two types of parameters differently; refer to Figure 5.2. A special feature of the 545, called Smart

Menus, determines the correct parameters to display for the specific configuration, so not all the listed parameters will appear.

+

to move background loop to displayed loop

for

TUNING mode

TUNING

or

for

OPERATION mode

SET UP

CONFIG

PV INPUT

CUST. LINR.

CONTROL

ALARMS

for Loop 1

SET UP mode

+

to toggle through

menu blocks

in SET UP mode

+

SET UP

mode

for

TUNING mode

OPERATION mode

SET UP

CONFIG

PV INPUT

CUST. LINR.

CONTROL

ALARMS

REM. SETPT.

RETRANS.

SELF TUNE

SPECIAL

SECURITY

SER. COMM.

or

for

TUNING

+

for Loop 2

SET UP mode

+

to toggle through

menu blocks

in SET UP mode

MANUAL

OPERATION

or

to return to

OPERATION

for Loop 2

mode

+

LOOP 2

REM. SETPT.

RETRANS.

SELF TUNE

SPECIAL

SECURITY

SER. COMM.

LOOP 1

28 Chapter 5 545 User's Manual

Page 36

CONFIGURATION AND OPERATION

Figure 5.3 shows the relationships among the different modes of the 545 and

the configuration menus:

• Parameter changes can only be made to the loop in the foreground

(Loop 1 upon power up). To bring the background loop into the foreground

to view and make changes, hold down FAST and press DISPLAY.

• SET UP menus can only be accessed from manual control. To transfer the

545 from automatic to manual control, press MANUAL.

• To access the SET UP menus, hold down FAST and press MENU. The

MENU key will illuminate; and CONFIG will appear in the 2nd display.

• To access the parameters for a particular menu, press MENU.

▲▲

• To select a parameter value, use

next parameter, or FAST+MENU to advance to the next menu.

• To advance to the next menu, press FAST+MENU.

• TUNING mode (and the TUNING menu) can be accessed from either automatic or manual control. To access the tuning menu, press MENU .

• To return controller to manual control, press DISPLAY or SET PT.

A key to these functions (as shown below) appears at the bottom of every page

in the menu section of this chapter.

▼▼

▲ and

▼. Press MENU to advance to the

▲▲

▼▼

Software Configuration

Access Set Up Next menu Next p arameter Next value Access Tuning Retur n to Operation Switch Loops

+

FAST MENU

MENU MENU

+

▲ ▼

MENU

DISPLAYFAST

+

FAST DISPLAY

WHERE TO GO NEXT

• For information about all the software menus and parameters, continue reading this chapter. Refer to Appendix 1 for a

quick-reference flowchart of all menus and parameters.

• For information about the installed options on the 54 5, compare the product label on top of the controller to the order code

in Chapter 1.

• To mount the controller and configure the wiring of the 545 for inputs and outputs, see Chapter 3.

• To alter the output module and jumper configuration, see Chapter 4.

• For more information about the Tuning function of the 545, see Chapter 6.

• For more information about application for the 545, see Chapter 7.

TEXT FORMATTING IN THIS MANUAL

Feature Format

KEYS SET PT DISPLAY

or

SET PT DISPLAY

ICONS OUT, ALM

MENUS CONFIG., TUNING,

PARAMETERS CYCLE TM:1, MIN.OUT2

PARAMETER VALUES OFF, SETPOINT, LAST OUT.

DISPLAY MESSAGES TOO HOT, OUT%

545 User's Manual Chapter 5 29

Page 37

Software Configuration

STEP-BY-STEP GUIDE TO SETUP PARAMETERS

CONFIG.

CTRL. TYPE

ONE LOOP

LOOP1 OUT

STANDARD

LOOP2 OUT

STANDARD

CONFIG.

For configuring the input and output hardware assignments. (GLOBAL)

1. CTRL. TYPE

Defines the fundamental controller setup.

D ONE LOOP Single PV, Single Control Output

• DUAL LOOP Two PV, with Control Output for each

• RATIO Two loops with Set Points rationed

• CASCADE Two PV with single Control Output

• FFWD.SUM Single loop control, 2nd PV added to or subtracted from output value

• FFWD.MULT Single loop control, 2nd PV multiplies output

value

2. LOOP1 OUT

Defines standard configuration for Loop 1.

D STANDARD Standard control output

• DUPLEX Duplex outputs (Refer to Chapter 7)

• STAGED Staged outputs (Refer to Chapter 7)

• POS.PROP. Position proportioning control output

3. LOOP2 OUT

Defines standard configuration for Loop 2.

D STANDARD Standard control output

• DUPLEX Duplex outputs (Refer to Chapter 7)

• STAGED Staged outputs (Refer to Chapter 7)

• POS.PROP. Position proportioning control output

• NONE Allows second loop to function as an indicator

LINE FREQ.

60 HZ

OUTPUT:2

OFF

Access Set Up Next menu Next parameter Next value Access Tuning Return to Operation Switch Loops

+

FAST MENU

30 Chapter 5 545 User's Manual

MENU MENU

+

4. LINE FREQ

Specifies the power source frequency

D 60 Hz

• 50 Hz

5. OUTPUT:2

Defines the function of the second output.

D OFF Completely deactivates output

• ALM.RLY:ON

• ALM.RLY:OFF

• RETRANS. Retransmission

• COMM. ONLY Output addressable only through communications

▲ ▼

MENU

DISPLAYFAST

FAST

+

DISPLAY

Page 38

6. OUTPUT:3

Defines the function of the third output.

D OFF Completely deactivates output

• ALM.RLY:ON

• ALM.RLY:OFF

• RETRANS. Retransmission

• COMM. ONLY Output addressable only through communications

Software Configuration

OUTPUT:3

Off

7. OUTPUT:4

Defines the function of the fourth output.

D OFF Completely deactivates output

• ALM.RLY:ON

• ALM.RLY:OFF

• RETRANS. Retransmission

• COMM. ONLY Output addressable only through communications

8. ANLG. RNG.:1

Defines the output signal for the first output.

D 4–20mA

• 0–20mA

• 20-4mA

• 20-0mA

9. ANLG. RNG.:2

Defines the output signal for the second output.

D 4–20mA

• 0–20mA

• 20-4mA

• 20-0mA

OUTPUT:4

OFF

ANLG.RNG.:1

4-20mA

ANLG.RNG.:2

4-20mA

10. ANLG. RNG.:3

Defines the output signal for the third output.

D 4–20mA

• 0–20mA

• 20-4mA

• 20-0mA

11. ANLG. RNG.:4

Defines the output signal for the fourth output.

D 4–20mA

• 0–20mA

• 20-4mA

• 20-0mA

Access Set Up Next menu Next parameter Next value Access Tuning Retur n to Op eration Switch Loops

+

FAST MENU

545 User's Manual Chapter 5 31

+

MENU MENU

▲ ▼

ANLG.RNG.:3

4-20mA

ANLG.RNG.:4

4-20mA

+

MENU DISPLAYFAST

FAST

DISPLAY

Page 39

Software Configuration

12. CONTACT 1

CONTACT 1

L1.MAN

Defines the operation of the first digital input, for Loop 1.

D L1. MAN. Trips the controller to manual control

• L1.2ND. SP. Makes the second setpoint active

• L1. 2ND. PID. Makes the second set of PID values active

• L1. ALARM ACK. Acknowledges alarms

• L1. RST. INH. Deactivates the reset term

• L1. D.A./R.A. Switches the control action

• L1. NO. A/T Suspends the adaptive tune function

• L1. LCK. MAN Locks controller in manual control

• UP KEY Remote

• DOWN KEY Remote

▲▲

▲ function

▲▲

▼▼

▼ function

▼▼

• DISP KEY Toggle between SP DEV or OUT%

• FAST KEY Actives FAST key

• MENU KEY Activates MENU key

• COMM. ONLY Status readable only through communications

• L1.SP. 1-4 Assigns the first two digital inputs to select

setpoints 1 through 4 via BCD signal

• L1. REM. SP. Makes the remote setpoint active

CONTACT 2

L1.REM.SP

13. CONTACT 2

Defines the operation of the second digital input, for Loop 1.

• L1. MAN. Trips the controller to manual control

• L1.2ND. SP. Makes the second setpoint active

• L1. 2ND. PID. Makes the second set of PID values active

• L1. ALARM ACK. Acknowledges alarms

• L1. RST. INH. Deactivates the reset term

• L1. D.A./R.A. Switches the control action

• L1. NO. A/T Suspends the adaptive tune function

• L1. LCK. MAN Locks controller in manual control

• UP KEY Remote

• DOWN KEY Remote

• DISP KEY Toggles between SP DEV or OUT%

• FAST KEY Actives FAST key

• MENU KEY Activates MENU key

• COMM. ONLY Status readable only through communications

D L1. REM. SP. Makes the remote setpoint active

▲▲

▲ function

▲▲

▼▼

▼ function

▼▼