Moore Inductries IPH2, IPX2 User Manual

2

2

December 2016

170-775-00G

IPH

& IPX

Current-to-Pressure

(I/P) Transmitters

Transmitters

Current-to-Pressure

(I/P)

2

& IPX

2

IPH

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

Table of Contents

Introduction .........................................................................................................3

The IPH2 & IPX2 ..................................................................................................3

Specications .....................................................................................................4

IPX2 Dimensional Diagram .................................................................................5

IPH2 Dimensional Diagram ................................................................................6

Calibration ...........................................................................................................7

Necessary Equipment and Calibration Preparation .............................................................7

Calibration Process .......................................................................................................... 7-9

Installation .........................................................................................................10

Phase One: Mounting ........................................................................................................10

Phase Two: Electrical Connections ....................................................................................10

Phase Three: Pneumatic Connections ...............................................................................11

Hazardous Location Applications ................................................................... 12

Operation ...........................................................................................................13

Maintenance ...................................................................................................... 13

Troubleshooting the IPH2 & IPX2 .....................................................................14

2

IPX

Customer Service ............................................................................................. 15

Intrinsically Safe Diagram................................................................................16

Return Procedures .......................................................................................... 19

Replacement Modules .............................................................................14

2 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Introduction

This users’ manual for Moore Industries’ IPH2 and

IPX2 Current-to-Pressure Transmitters contains all

of the information that is needed to calibrate, install,

operate, maintain, and troubleshoot this family of

transmitters.

The following guidelines are used in this manual:

WARNING - Hazardous procedure or condition that

could injure the operator.

Caution - Hazardous procedure or condition that could

damage or destroy the unit.

Note - Information that is helpful for a procedure,

condition, or operation of the unit.

About this Manual

Wherever you see a “WARNING”, “Caution”

or “Note” pay particular attention.

WARNING - Hazardous procedure or condition that

could injure the operator.

Caution - Hazardous procedure or condition that could

damage or destroy the unit.

Note - Information that is helpful for a procedure,

condition, or operation of the unit.

IPH2 & IPX

The rugged IPH2 and IPX2 Current-to-Pressure (I/P)

Transmitters are designed specically for extended

duty in harsh eld environments. Being Type

3X/4X- and IP56/IP66-rated, the extruded aluminum

housings, for both the IPH2 and IPX2, oer water

and dust protection and are also highly resistant to

corrosion and chemicals. In addition, while the air and

natural gas versions of the IPX2 are explosion-proof,

the later oers an increased ingress protection of IP66.

These 2-wire (loop-powered) transmitters convert

a current signal to a pneumatic signal so that an

electronic-based system such as a DCS, PLC, or PC

can control a pneumatic actuator, valve, or damper

drive. Available models accept a wide range of current

inputs (4-20mA, 4-12mA, and 12-20mA) and provide a

proportional pneumatic signal (3-15psig, 0.2-1Bar,

20-100kPA, etc.). A reverse pneumatic output option

is available for the IPH2. Reverse output is switch

selectable on new versions of the IPX2 (introduced in

2013).

The high-performance line of I/P transmitters

utilizes an internal feedback loop to ensure accurate

operation. The feedback loop consists of an internal

pressure transducer that samples the unit’s output

pressure and compares it to the input signal. This

allows the unit’s output to track the input signal. Other

I/P transmitters, such as our original IPT, IPH and IPX

models, rely solely on mechanical positioning.

Since the feedback loop requires power to operate,

when there is no input power to the unit, the pneumatic

output will be shut o. Units that use mechanical

positioning only, will typically still have a pneumatic

output when power is removed. By example, a unit

(IPT, IPH and IPX) with an output range of 15 - 3PSIG

will output approximately 18PSIG when the input

signal is removed. This is not an issue except for

those users that rely on this elevated output (18PSIG)

to maintain a valve’s position upon the unexpected

loss of input signal (4-20mA). In such cases, the IPT2,

IPH2 and IPX2 units react dierently by shutting o the

pneumatic output.

Both units are available with an optional coalescing

lter/regulator that combines an air lter and miniature

supply line regulator with a pressure gauge that reads

in both psi and Bars.

2

Demand Moore Reliability 3

2

IPH

&

IPX

Current-to-Pressure

(I/P) Transmitters

Specifications

2

Performance

Accuracy: <±0.25% of span

including the combined eect

of linearity, hysteresis and

repeatability (between

0 and 3psig output, error will

not exceed ±1.0% of span)

Stability: Not to degrade

from stated accuracy for six

months

Step Response: <0.2

seconds into 100ml load

3

(6 in

) from 10% to 90% of

span; Not guaranteed below

3psig output

Supply Pressure Eect:

Negligible from 20-40psig,

steady pressure

Air Capacity:

5.0SCFM minimum (20psig

supply, 0psig output)

Relief Capacity: 2.5SCFM

minimum (15psig output)

Air Supply: Instrument air

only, 20-40psig.

Gas Supply with -NG1 or

-NG2 Option: 17-40psig.

Same cleanliness as

instrument air. H

exceed 20ppm

Maximum Input: 80psig

without damage for units with

output pressure rating of

>15psig; 45psig without

damage for units with output

pressure rating of ≤ 15psig

S not to

2

Performance

(Continued)

Voltage Drop:

5V, maximum

Air Consumption

(Dead-ended):

At 3-15psig output 20psig

supply, average steady state

consumption* of 4.7SCFH

(min 4.2SCFH@ 3psig, max

5.2SCFH@15psig);

40psig supply, max 9SCFH

@15psig output;

40psig supply, max 10SCFH

@30psig output

Natural Gas Consumption

(Dead-ended):

At 3-15psig output 20psig

supply, average steady state

consumption* of 5.7SCFH,

(min 5.1SCFH@ 3psig, max

6.2SCFH@15psig);

17psig supply, max 5.9SCFH

@15psig output;

40psig supply, max 12SCFH

@30psig output;

Mounting Position Eect:

Negligible, unit can be

mounted in any position;

refer to user manual for

special conditions of use with

natural gas supply or outdoor

environments.

Ambient

Conditions

Adjustment

Weight

*Average ow rate determined at 9 psig output

Operating & Storage

Range:

-40°C to +85°C

(-40°F to +185°F)

Ambient Temperature

Eect: <±0.025% of

span/°C, maximum from

-20°C to 80°C;

<±0.1% of span/°C,

maximum

RFI/EMI Eect:

<±0.25% of span change

at in eld strengths of

10V/m@ frequencies of

20-1000MHz

Vibration Eect: Meets

ANSI/ISA-75 13.01-1996

(R2007) 5.3.5 as follows:

5-15Hz, 2mm peak-topeak; 15-150Hz, 1g;

150-2000Hz, 0.5g

Relative Humidity:

0-100%, non-condensing

Zero & Span: Screw

adjusts zero or span by

±10% minimum, noninteractive

2

IPH

: 1.14kg (2.5 lbs)

IPX2: 2.4kg (5.3 lbs)

Specifications and information subject to change without notice.

4 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

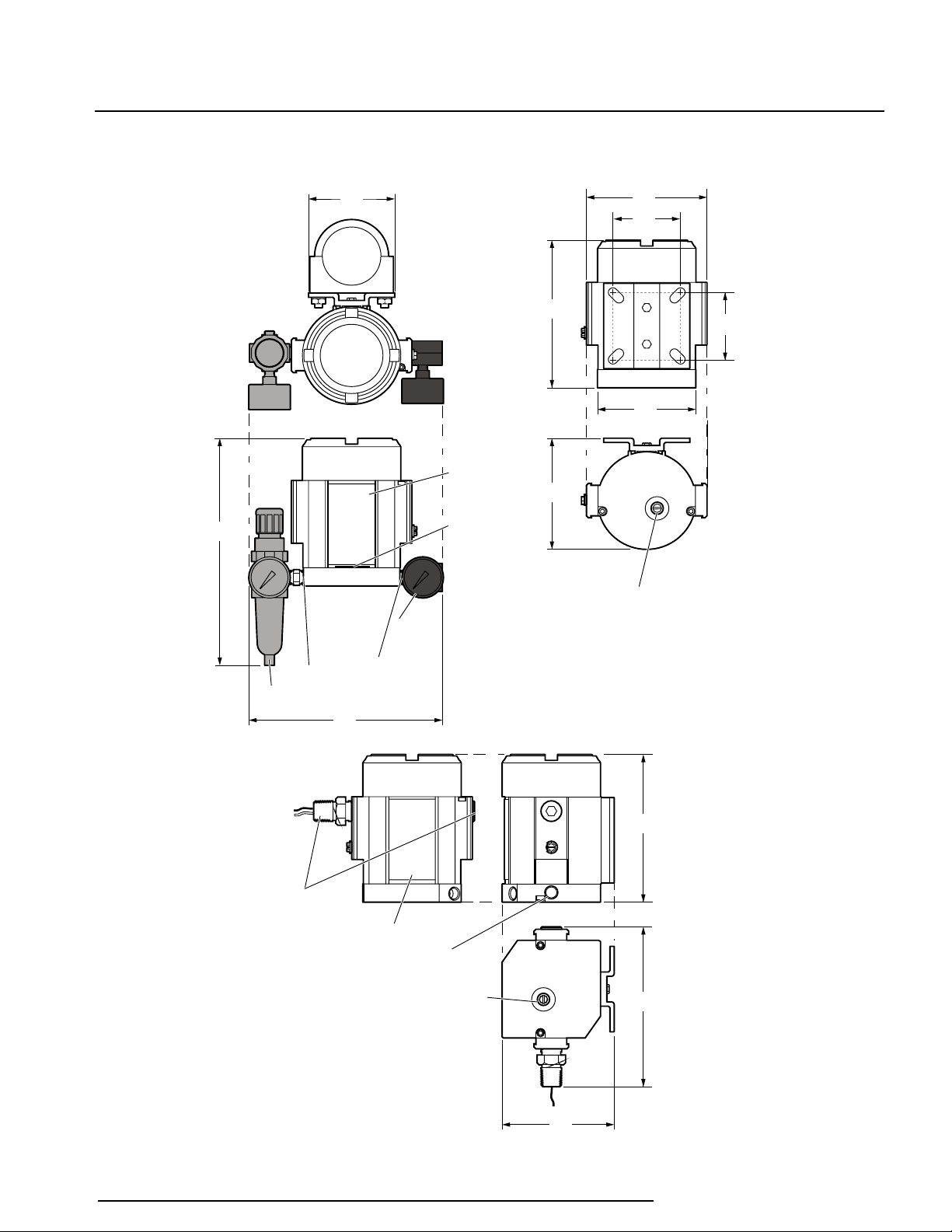

Figure 1. IPX 2 Current-to-Pressure Transmitter Housing Dimensions

VENT

OUT

OUT

Instrument Tag

Manual override &

filter holder

Both side fittings are

permanently attached.

Do not attempt to remove.

(They may be installed on

either side of the unit by

the factory)

Natural gas vent (-NG option)

See Pneumatic Connections section

166

(6.5)

117

(4.6)

154

(6.1)

Manual override &

filter holder

125

(4.9)

70

(2.8)

70

(2.8)

154

(6.1)

102

(4.0)

117

(4.6)

-FR1 Option

-GA Option

Instrument

Tag

Pneumatic

input port

1/4 NPT

female

Pneumatic

output port

1/4 NPT

female

Open vent

(air model only)

200

(7.9)

239

(9.4)

89

(3.5)

NG

Option

Demand Moore Reliability 5

2

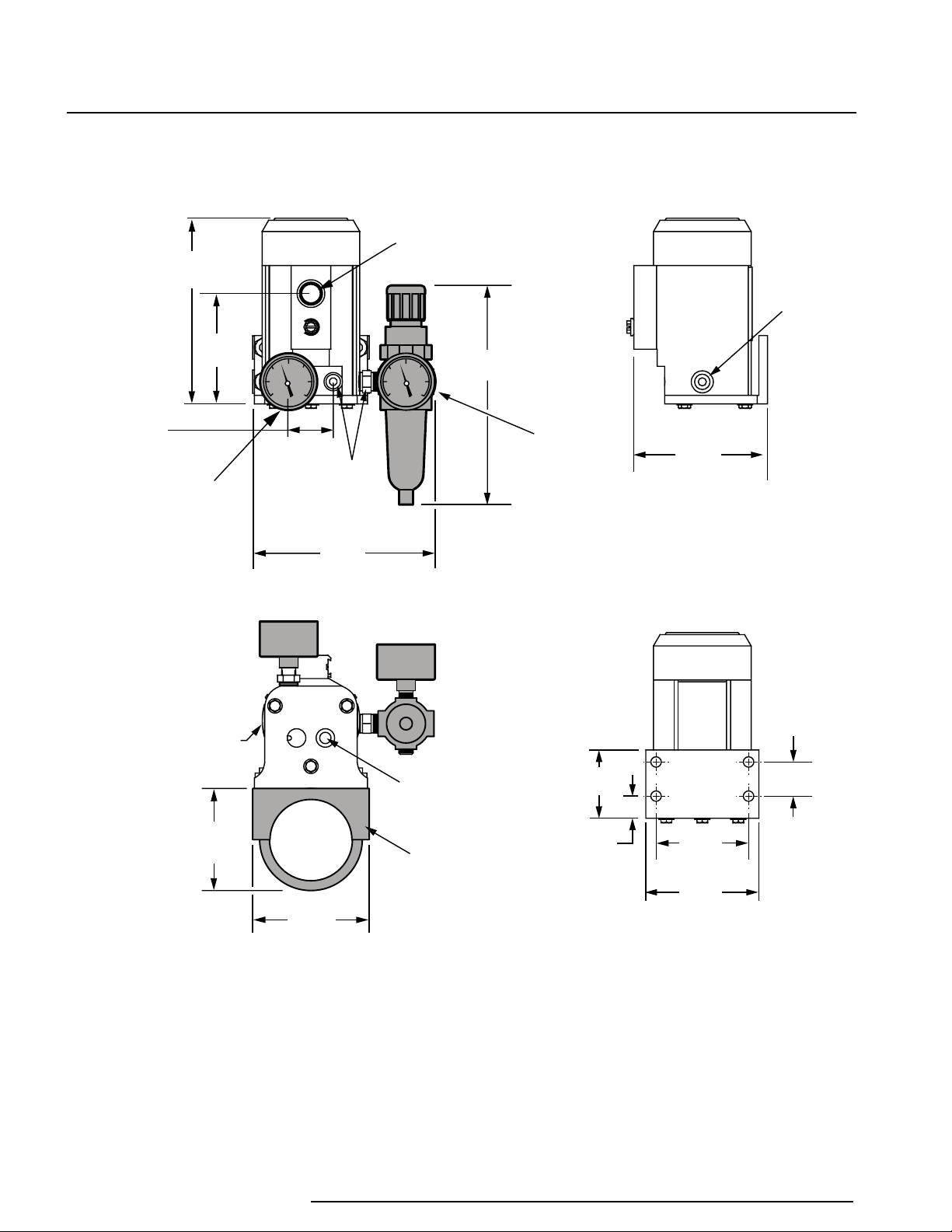

33mm

(1.3 in)

1/4 NPT FEMALE

PNEUMATIC OUTPUT

PORT (COVERED BY

OPTIONAL –GA

OUTPUT GAUGE)

137mm

(5.4 in)

86mm

(3.4 in)

MANUAL OVERRIDE

& FILTER HOLDER

72mm

(2.9 in DIA.)

76mm

(3.0 in)

REF.

69mm

(2.7 in)

16mm

(0.65 in)

51mm

(2.0 in)

83mm

(3.3 in)

1/4 NPT

FEMALE

PNEUMATIC

INPUT

PORT

163mm

(6.4 in)

135mm

(5.3 in)

WITH –FR1 OPTION

1/4 NPT FEMALE

PNEUMATIC INPUT

PORT (UNUSED PORT

IS PLUGGED)

CONDUIT WIRE ENTRY

METRIC (M20 x 1.5)

OR NPT (1/2-14)

THREADS

99mm

(3.9 in)

-P OPTION

2 INCH PIPE

MOUNTING

BRACKET

1/4 NPT

PNEUMATIC

INPUT PORT

FOR OPTIONAL

–FR1 FILTER/

REGULATOR/

GAUGE

76mm

(3.0 in)

25mm

(1.0 in)

IPH

&

2

IPX

Current-to-Pressure

(I/P) Transmitters

Figure 2. IPH 2 Current-to-Pressure Transmitter Housing Dimensions

6 Demand Moore Reliability

Loading...

Loading...