2

2

December 2016

170-775-00G

IPH

& IPX

Current-to-Pressure

(I/P) Transmitters

Transmitters

Current-to-Pressure

(I/P)

2

& IPX

2

IPH

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

Table of Contents

Introduction .........................................................................................................3

The IPH2 & IPX2 ..................................................................................................3

Specications .....................................................................................................4

IPX2 Dimensional Diagram .................................................................................5

IPH2 Dimensional Diagram ................................................................................6

Calibration ...........................................................................................................7

Necessary Equipment and Calibration Preparation .............................................................7

Calibration Process .......................................................................................................... 7-9

Installation .........................................................................................................10

Phase One: Mounting ........................................................................................................10

Phase Two: Electrical Connections ....................................................................................10

Phase Three: Pneumatic Connections ...............................................................................11

Hazardous Location Applications ................................................................... 12

Operation ...........................................................................................................13

Maintenance ...................................................................................................... 13

Troubleshooting the IPH2 & IPX2 .....................................................................14

2

IPX

Customer Service ............................................................................................. 15

Intrinsically Safe Diagram................................................................................16

Return Procedures .......................................................................................... 19

Replacement Modules .............................................................................14

2 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Introduction

This users’ manual for Moore Industries’ IPH2 and

IPX2 Current-to-Pressure Transmitters contains all

of the information that is needed to calibrate, install,

operate, maintain, and troubleshoot this family of

transmitters.

The following guidelines are used in this manual:

WARNING - Hazardous procedure or condition that

could injure the operator.

Caution - Hazardous procedure or condition that could

damage or destroy the unit.

Note - Information that is helpful for a procedure,

condition, or operation of the unit.

About this Manual

Wherever you see a “WARNING”, “Caution”

or “Note” pay particular attention.

WARNING - Hazardous procedure or condition that

could injure the operator.

Caution - Hazardous procedure or condition that could

damage or destroy the unit.

Note - Information that is helpful for a procedure,

condition, or operation of the unit.

IPH2 & IPX

The rugged IPH2 and IPX2 Current-to-Pressure (I/P)

Transmitters are designed specically for extended

duty in harsh eld environments. Being Type

3X/4X- and IP56/IP66-rated, the extruded aluminum

housings, for both the IPH2 and IPX2, oer water

and dust protection and are also highly resistant to

corrosion and chemicals. In addition, while the air and

natural gas versions of the IPX2 are explosion-proof,

the later oers an increased ingress protection of IP66.

These 2-wire (loop-powered) transmitters convert

a current signal to a pneumatic signal so that an

electronic-based system such as a DCS, PLC, or PC

can control a pneumatic actuator, valve, or damper

drive. Available models accept a wide range of current

inputs (4-20mA, 4-12mA, and 12-20mA) and provide a

proportional pneumatic signal (3-15psig, 0.2-1Bar,

20-100kPA, etc.). A reverse pneumatic output option

is available for the IPH2. Reverse output is switch

selectable on new versions of the IPX2 (introduced in

2013).

The high-performance line of I/P transmitters

utilizes an internal feedback loop to ensure accurate

operation. The feedback loop consists of an internal

pressure transducer that samples the unit’s output

pressure and compares it to the input signal. This

allows the unit’s output to track the input signal. Other

I/P transmitters, such as our original IPT, IPH and IPX

models, rely solely on mechanical positioning.

Since the feedback loop requires power to operate,

when there is no input power to the unit, the pneumatic

output will be shut o. Units that use mechanical

positioning only, will typically still have a pneumatic

output when power is removed. By example, a unit

(IPT, IPH and IPX) with an output range of 15 - 3PSIG

will output approximately 18PSIG when the input

signal is removed. This is not an issue except for

those users that rely on this elevated output (18PSIG)

to maintain a valve’s position upon the unexpected

loss of input signal (4-20mA). In such cases, the IPT2,

IPH2 and IPX2 units react dierently by shutting o the

pneumatic output.

Both units are available with an optional coalescing

lter/regulator that combines an air lter and miniature

supply line regulator with a pressure gauge that reads

in both psi and Bars.

2

Demand Moore Reliability 3

2

IPH

&

IPX

Current-to-Pressure

(I/P) Transmitters

Specifications

2

Performance

Accuracy: <±0.25% of span

including the combined eect

of linearity, hysteresis and

repeatability (between

0 and 3psig output, error will

not exceed ±1.0% of span)

Stability: Not to degrade

from stated accuracy for six

months

Step Response: <0.2

seconds into 100ml load

3

(6 in

) from 10% to 90% of

span; Not guaranteed below

3psig output

Supply Pressure Eect:

Negligible from 20-40psig,

steady pressure

Air Capacity:

5.0SCFM minimum (20psig

supply, 0psig output)

Relief Capacity: 2.5SCFM

minimum (15psig output)

Air Supply: Instrument air

only, 20-40psig.

Gas Supply with -NG1 or

-NG2 Option: 17-40psig.

Same cleanliness as

instrument air. H

exceed 20ppm

Maximum Input: 80psig

without damage for units with

output pressure rating of

>15psig; 45psig without

damage for units with output

pressure rating of ≤ 15psig

S not to

2

Performance

(Continued)

Voltage Drop:

5V, maximum

Air Consumption

(Dead-ended):

At 3-15psig output 20psig

supply, average steady state

consumption* of 4.7SCFH

(min 4.2SCFH@ 3psig, max

5.2SCFH@15psig);

40psig supply, max 9SCFH

@15psig output;

40psig supply, max 10SCFH

@30psig output

Natural Gas Consumption

(Dead-ended):

At 3-15psig output 20psig

supply, average steady state

consumption* of 5.7SCFH,

(min 5.1SCFH@ 3psig, max

6.2SCFH@15psig);

17psig supply, max 5.9SCFH

@15psig output;

40psig supply, max 12SCFH

@30psig output;

Mounting Position Eect:

Negligible, unit can be

mounted in any position;

refer to user manual for

special conditions of use with

natural gas supply or outdoor

environments.

Ambient

Conditions

Adjustment

Weight

*Average ow rate determined at 9 psig output

Operating & Storage

Range:

-40°C to +85°C

(-40°F to +185°F)

Ambient Temperature

Eect: <±0.025% of

span/°C, maximum from

-20°C to 80°C;

<±0.1% of span/°C,

maximum

RFI/EMI Eect:

<±0.25% of span change

at in eld strengths of

10V/m@ frequencies of

20-1000MHz

Vibration Eect: Meets

ANSI/ISA-75 13.01-1996

(R2007) 5.3.5 as follows:

5-15Hz, 2mm peak-topeak; 15-150Hz, 1g;

150-2000Hz, 0.5g

Relative Humidity:

0-100%, non-condensing

Zero & Span: Screw

adjusts zero or span by

±10% minimum, noninteractive

2

IPH

: 1.14kg (2.5 lbs)

IPX2: 2.4kg (5.3 lbs)

Specifications and information subject to change without notice.

4 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

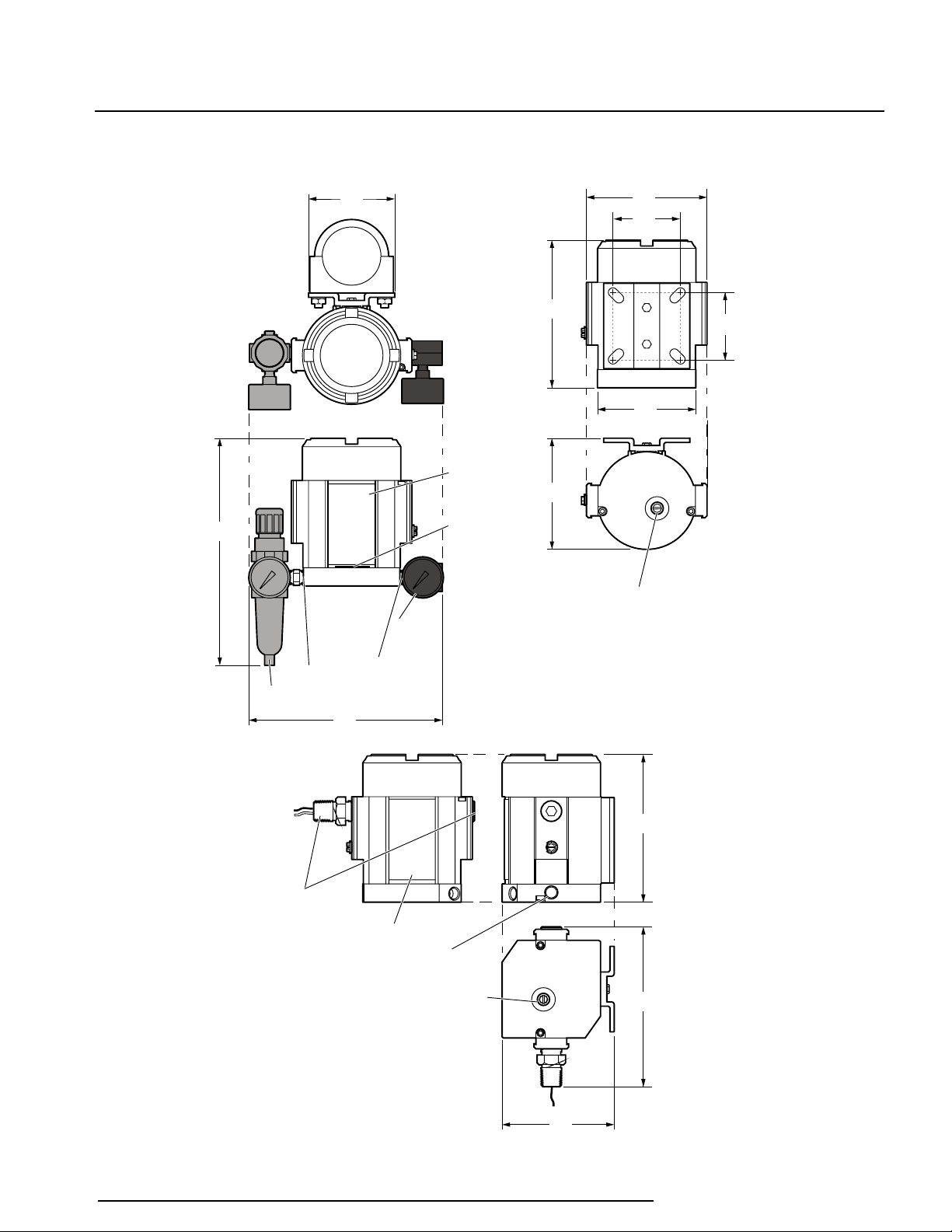

Figure 1. IPX 2 Current-to-Pressure Transmitter Housing Dimensions

VENT

OUT

OUT

Instrument Tag

Manual override &

filter holder

Both side fittings are

permanently attached.

Do not attempt to remove.

(They may be installed on

either side of the unit by

the factory)

Natural gas vent (-NG option)

See Pneumatic Connections section

166

(6.5)

117

(4.6)

154

(6.1)

Manual override &

filter holder

125

(4.9)

70

(2.8)

70

(2.8)

154

(6.1)

102

(4.0)

117

(4.6)

-FR1 Option

-GA Option

Instrument

Tag

Pneumatic

input port

1/4 NPT

female

Pneumatic

output port

1/4 NPT

female

Open vent

(air model only)

200

(7.9)

239

(9.4)

89

(3.5)

NG

Option

Demand Moore Reliability 5

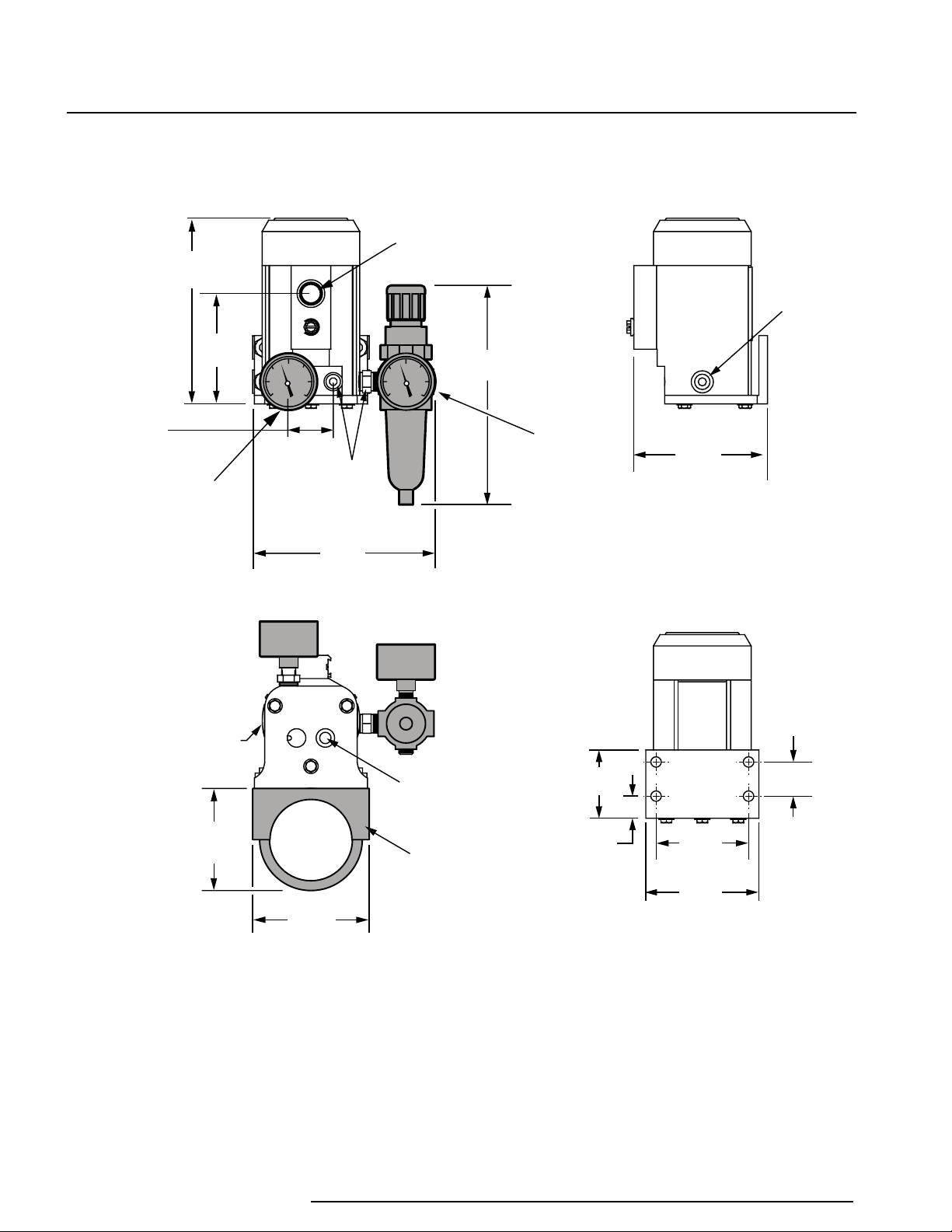

2

33mm

(1.3 in)

1/4 NPT FEMALE

PNEUMATIC OUTPUT

PORT (COVERED BY

OPTIONAL –GA

OUTPUT GAUGE)

137mm

(5.4 in)

86mm

(3.4 in)

MANUAL OVERRIDE

& FILTER HOLDER

72mm

(2.9 in DIA.)

76mm

(3.0 in)

REF.

69mm

(2.7 in)

16mm

(0.65 in)

51mm

(2.0 in)

83mm

(3.3 in)

1/4 NPT

FEMALE

PNEUMATIC

INPUT

PORT

163mm

(6.4 in)

135mm

(5.3 in)

WITH –FR1 OPTION

1/4 NPT FEMALE

PNEUMATIC INPUT

PORT (UNUSED PORT

IS PLUGGED)

CONDUIT WIRE ENTRY

METRIC (M20 x 1.5)

OR NPT (1/2-14)

THREADS

99mm

(3.9 in)

-P OPTION

2 INCH PIPE

MOUNTING

BRACKET

1/4 NPT

PNEUMATIC

INPUT PORT

FOR OPTIONAL

–FR1 FILTER/

REGULATOR/

GAUGE

76mm

(3.0 in)

25mm

(1.0 in)

IPH

&

2

IPX

Current-to-Pressure

(I/P) Transmitters

Figure 2. IPH 2 Current-to-Pressure Transmitter Housing Dimensions

6 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Calibration

Every IPH2 and IPX2 is fully tested and calibrated at the

factory prior to shipment. However, before installation,

your IPH2 or IPX2 should be bench-checked to verify

the desired unit zero and unit span. Calibration should

be conducted in an appropriate testing environment.

Necessary Equipment

Table 1 lists the equipment required to calibrate

the unit. This equipment is not supplied by Moore

Industries, but should be available in most labs or

maintenance areas.

Table 1. IPH 2 & IPX 2 Calibration Equipment

Adjustable current source

DC Multimeter

Instrument air supply

Air pressure gauge #1

Air pressure gauge #2

Pneumatic load

Equipment

4-20mA output

Accurate to ±0.05%

Filtered

Accurate to ±2%

Accurate to ±0.1%

Volume of 7.5 cubic inches

(approx. 120 milliliters)

Description

Note:

Always use clean, dry, instrument air when

calibrating or operating the IPH 2 or IPX 2.

All pneumatic lines used in calibration and operation

must be “blown down” (purged) prior to connection to

the unit. Any condensation or oil residue in the lines,

if introduced into the pneumatic chambers of the unit,

may result in poor unit performance.

Calibration Process

To perform the recommended bench-check for the

IPH2 or IPX2, rst perform the setup as described in

the next section. See Figures 3 and 4 for illustrations

of the Calibration Setup, then follow the steps under

Calibration Setup and Calibrating the IPH2 or IPX2.

Calibration Setup

1. Connect 1/4-inch pneumatic tubing between the

appropriate output port of the regulated instrument

air supply and the pressure gauge #1 (accuracy

of ±2% of span). Connect another tube from the

pressure gauge to the port labeled “IN” on IPH2 or

IPX2.

Preparing for Calibration

To prepare the IPH2 or IPX2 for calibration, remove

the screw-on cap and connect the unit to your

conguration equipment as shown in Figures 3 and 4.

Unit Connections and Controls. The IPH2 and IPX2

each have two labeled terminals on their faceplate,

located under the top protective cover of the housing.

The terminal labeled “+PS” is for connection of the

positive current input, and the terminal labeled “–PS”

is for the negative connection.

The two controls are also located inside the unit

housing under the screw-on cap. They consist of

two potentiometers, each accessed through the front

panel. They are labeled “zero” and “span”. The zero

potentiometer provides a control range for osets of

±10% of rated unit span, while the span potentiometer

adjusts unit full-scale output to 100 percent of rated

span.

Each potentiometer requires approximately 20 turns

to move its wiper from one extreme to the other:

clockwise for maximum, or counterclockwise for

minimum values. Each is equipped with a slip clutch

to prevent damage if the adjustment is turned beyond

the wiper stop.

2. Connect 1/4-inch pneumatic tubing between the

port labeled “OUT” and the appropriate port of

pressure gauge #2 (accuracy of ±0.1% of span),

then from gauge #2 to the appropriate pneumatic

load.

3. Run current source wiring through conduit opening

in housing, and to the front panel of the IPH2 or

IPX2. (Not necessary for IPX2 –NG models.)

4. Connect positive lead of adjustable current source

to the +PS terminal of unit. Connect negative

source lead to the –PS terminal. (For IPX2 –NG,

connect the positive lead of the current source

to the red wire, and the negative lead of current

source to the black wire.) A multimeter may also

be connected to verify level of current input.

5. When connections are complete, apply an input

current of 0% of span. (i.e. 4mA for a 4-20mA unit)

6. Apply appropriate ltered, instrument-quality air to

supply line: 20 or 35psi (1.4Bar to 2.4Bar). Verify

appropriate supply pressure by checking Supply

Pressure eld of unit model number.

7. Allow approximately 30 seconds for calibration

setup to stabilize.

Demand Moore Reliability 7

2

ZERO

2

-PS

+PS

SPAN

+

_

PNEUMATIC

TEST LOAD

REGULATED

INSTRUMENT

AIR SUPPLY

PRESSURE GAUGE #1

(ACCURACY ±2%)

PRESSURE GAUGE #2

(ACCURACY ±0.1%)

ADJUSTABLE

CURRENT

SOURCE

DC

MULTIMETER

+

_

OUTPUT

PORT

INPUT

PORT

IPH

&

IPX

Current-to-Pressure

(I/P) Transmitters

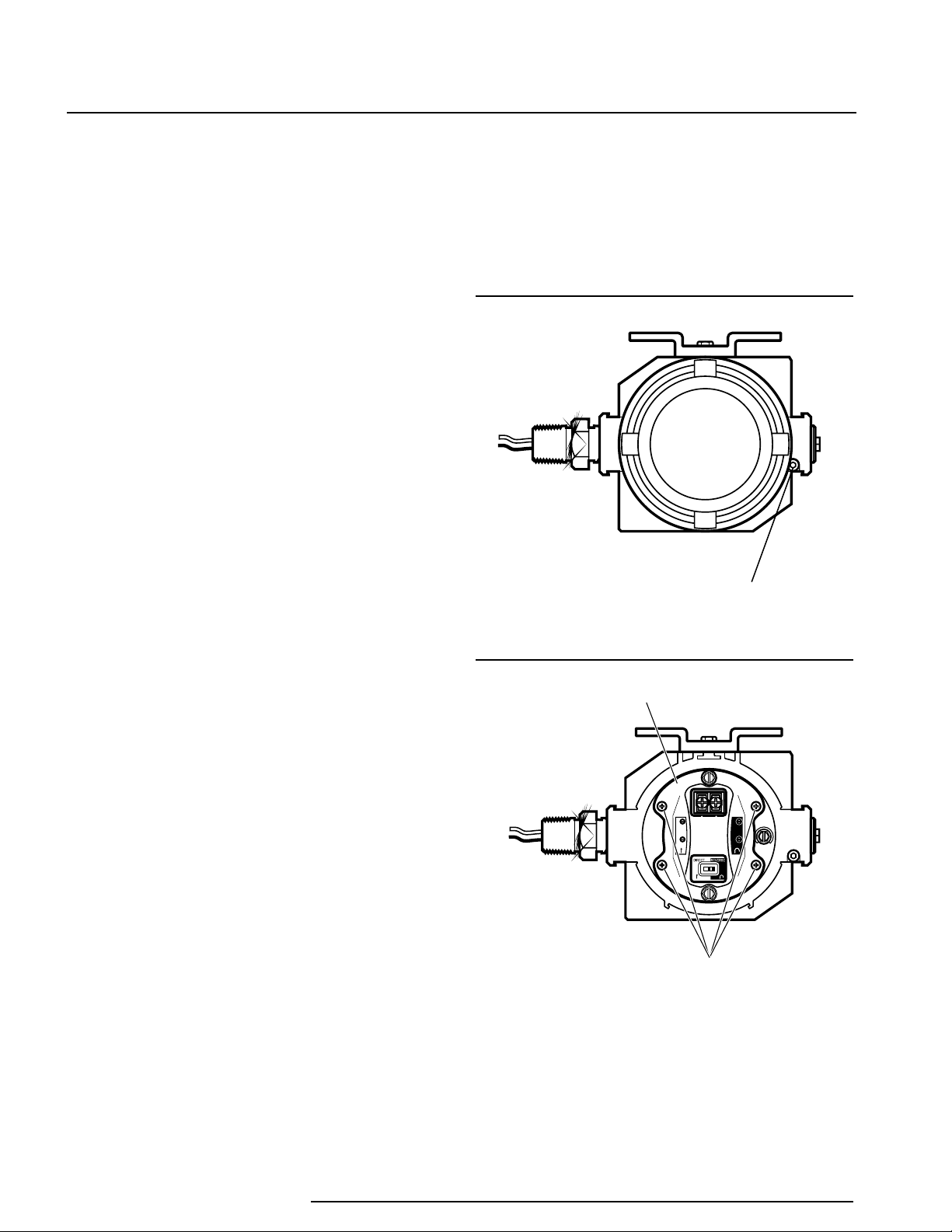

Figure 3. IPH 2 Calibration Setup

2

Figure 4. IPX 2 Calibration Setup

PRESSURE GAUGE #1

(ACCURACY ±2%)

REGULATED

INSTRUMENT

AIR SUPPLY

NOTE: This shows the new version

of IPX2 introduced in 2013. Previous

versions of IPX2 do not have a direct/

reverse switch and only have one set of

potentiometers. (similar to IPH2 in

Figure 3)

8 Demand Moore Reliability

INPUT

PORT

PS (+) PS (-)

SPAN

ZERO

SELECTABLE OUTPUT

IPX

2

OUTPUT

PORT

SPAN

ZERO

PRESSURE GAUGE #2

_

+

ADJUSTABLE

CURRENT

SOURCE

(ACCURACY ±0.1%)

PNEUMATIC

TEST LOAD

+

_

DC

MULTIMETER

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Calibrating the IPH2 or IPX

This calibration procedure consists of a basic check

and adjustment of unit zero and span, based on the

reading of pressure gauge #2. To calibrate a direct

output unit, perform the following:

1. For IPX2 new versions (introduced in 2013) only,

check switch is set to “Direct”- see Figure 5.

2

10. Monitor reading of pressure gauge #2 (output),

and adjust span potentiometer so that reading is

at 0% of span for your unit (i.e. 3 psi for a 3-15 psi

unit).

11. Repeat steps 8 through 10 until the unit outputs

100% of rated pressure range at 0% current input,

and 0% of output pressure range at 100% of span.

2. Check unit zero setting. Monitor reading of

pressure gauge #2 (output), and turn zero

potentiometer counterclockwise to lower output,

clockwise to raise output. Set zero potentiometer

so that pressure output is at 0% of span when a

current input of 0% of span is applied. (i.e. 3psi for

a 3-15psi unit)

3. Check unit span setting. Increase input to 100%

of rated span (i.e. 20mA for a 4-20mA unit).

4. Monitor reading of pressure gauge #2 (output),

and adjust span potentiometer so that reading is at

100% of span for your unit (i.e. 15psi for a 3-15psi

unit).

5. Repeat steps 1 through 4 until the unit outputs 0%

of rated pressure range at 0% current input, and

100% of output pressure range at 100% of span.

6. Verify the accuracy of your adjustments by

inputting 0%, 25%, 50%, and 75% of span inputs,

and monitoring the output.

To calibrate a reverse output unit, perform the

following:

12. Verify the accuracy of your adjustments by

inputting 0%, 25%, 50%, and 75% of span inputs,

and monitoring the output.

Note:

New versions of the IPX2 (introduced in 2013) have

a selectable output switch. Be sure to set this switch

to the required output mode, direct or reverse, and

use the corresponding set of pots accordingly.

See Figure 5.

Figure 5. IPX 2 Output Switch

Adjustable Direct

Potentiometers

PS (+) PS (-)

SPAN

ZERO

SELECTABLE OUTPUT

SPAN

2

IPX

ZERO

Selectable Output

Switch

Adjustable Reverse

Potentiometers

2

7. For IPX

check switch is set to “Reverse” - see Figure 5.

8. Check unit zero setting. Monitor reading of

pressure gauge #2 (output), and turn zero

potentiometer counterclockwise to lower output,

clockwise to raise output. Set zero potentiometer

so that pressure output is at 100% of span when a

current input of 0% of span is applied. (i.e. 15 psi

for a 3-15 psi unit).

9. Check unit span setting. Increase input to 100%

of rated span (i.e. 20mA for a 4-20mA unit).

new versions (introduced in 2013) only,

Demand Moore Reliability 9

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

Installation

The installation of the IPH2 or IPX2 is carried out in

three phases: the physical mounting of the unit, the

electrical connections phase, and the pneumatic

connections phase. It is strongly suggested that each

unit be calibrated according to the instructions in this

manual before being placed into service.

Installation in hazardous ‘Classied’ locations and

potentially explosive atmospheres must adhere to the

instructions in the Hazardous Location Applications

section which can be found at the end of this

Installation section.

Phase One: Mounting

Figures 1 and 2 give the dimensions of the IPX2 and

IPH2, respectively. The illustrations also give the

dimensions of the available option hardware, which is

recommended for most installations. After placing the

unit in the desired location and orientation, secure the

housing with the optional pipe mounting hardware or

other appropriate fasteners.

The IPH2 or IPX2 will operate when installed at any

angle–either surface-mounted or attached to pipe or

round conduit. However, there are other considerations

in selecting the ideal mounting position. If the IPH2 is

in an area which may be exposed to rain or water, it

should be mounted within 45° of vertical. In natural

gas applications, where liquid remnants are possible

in the supply, the vent port of the IPX2 needs to be

in a position that would allow for sucient draining.

Please also consider the requirements in Pneumatics

Connections on the next page before determining the

ideal mounting conguration.

Phase Two: Electrical Connections

To complete the electrical connections, route the wiring

through the conduit port to the terminal block, then

use a screwdriver to loosen the terminal screws. (Not

necessary for IPX2 –NG1 or –NG2 installation.)

For all units except the IPX2 –NG1 or –NG2, connect

positive lead (+) to the +PS terminal, and negative

lead (–) to the –PS terminal. Tighten the terminal

screws until snug.

Caution:

When connecting the IPX 2 Natural Gas (–NG1 or

–NG2) model, use an appropriately certied conduit

box and wire connectors. Do not attempt to remove

the seal tting, as it is necessary for natural gas

certication. Connect the positive lead (+) to the red

wire from the seal tting, and the negative lead (–) to

the black wire from the seal tting.

Use shielded, twisted-pair wiring for low-level input.

Ground the shielding wire as close as possible to the

installed unit.

Recommended Ground Wiring

Practices

Moore Industries recommends the following ground

wiring practices:

• Any Moore Industries product in a metal case

or housing should be grounded.

• The protective earth conductor must be

connected to a system safety earth ground

before making other connections.

• All input signals to, and output signals

from, Moore Industries’ products should be

wired using a shielded, twisted pair wiring

technique. Shields should be connected to an

earth or safety ground.

• For the best shielding, the shield should be

run all the way from the signal source to the

receiving device. (see Note below)

• The maximum length of unshielded input and

output signal wiring should be 2 inches.

Note:

Some of Moore Industries’ instruments can be

classied as receivers (IPT2, IPX2, etc.) and some

can be classied as transmitters (TRX, TRY, etc.)

while some are both a receiver and a transmitter

(SPA2, HIM, etc). Hence, your shield ground

connections should be appropriate for the type

of signal line being shielded. The shield should

be grounded at the receiver and not at the signal

source.

CE Conformity

Installation of any Moore Industries’ products that carry

the CE marking must adhere to the guidelines in the

Recommended Ground Wiring Practices section in

order to meet the EN 61326 requirements set forth in

the applicable EMC directive.

10 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Phase Three: Pneumatic Connections

To complete the nal phase of installation, connect the

supply line to the ¼-inch NPT female port labeled “IN”.

Connect the output line to the ¼-inch NPT female port

labeled “OUT”. All tubing must have at least 6mm

(¼-inch) inside diameter or the maximum ow will be

limited.

Note:

Seal all ttings with Teon® tape, or equivalent.

Always “blow down” (purge) all tubing and the

controlled device before connecting the IPH2 or IPX2.

Manual Override Screw

If you are in a potentially explosive environment and

do not want to apply electric power to the unit with

the cover removed, the pneumatic installation may

be tested by loosening the manual override screw on

the bottom of the unit. The output pressure will go to

the supply pressure. Be sure to tighten the manual

override screw after test.

WARNING:

IPX 2 units installed in a natural gas application must

have the natural gas vent properly connected. Follow

the directions below to install an IPX 2 with –NG1 or

–NG2 options into a natural gas application.

Natural Gas Applications

Customers using the IPX2 with –NG1 or –NG2 options

to regulate a sweet natural gas application (H2S levels

are not to exceed 20ppm) must also make the vent

port connections. Connect the Natural Gas Vent

(shown in Figure 1) to a device prepared to receive

natural gas. After connection, the ttings, cover, and

lter/test screw should be tested for leaks.

For an outdoor system, ventilation should consist of a

weather-proofed connection between the transmitter

exhaust and a riser, six feet above the transmitter

and control valve assembly. The riser should be

shepherd-crooked to prevent rain or incident water

from accumulating at the base. In accordance with

local safety regulation, an in-line ame arrestor should

be applied to the riser to prevent ash back to the

transmitter from an external, spontaneous ame

source.

For an indoor system, ventilation must consist of

a leak-proof connection from the exhaust of the

transmitter to a process vent. The process vent

should already be dedicated for natural gas excursions

and should conform to all standards for aring or

after-burn, and ame arrest, as dictated by local

environmental and safety regulations.

Indoor natural gas operations are typically monitored

to maintain safety conformance outside the lower

and upper explosion limits (LEL and UEL). To add

a natural gas operated transmitter in these cases,

consideration should be made as to the extent of

natural gas leak detection legacy to the installed

transmitter. Placement of the transmitter should be

such that detection and alarming surround any critical

connections between the transmitter and the natural

gas process.

If the natural gas driven transmitter is to be installed

indoors with no legacy monitoring capabilities,

additional consideration must be made to ensure the

operating area is well-ventilated and the transmitter

can be exhausted to process vent. Furthermore,

monitoring with remote annunciation within LEL and

UEL should be projected as an upgrade to the facility,

concurrently with this installation. The transmitter

installation must adhere to local environmental and

safety regulations.

WARNING:

IPX 2 units installed in a natural gas application must

have the natural gas vent properly connected. Failure

to do so may result in an explosion. The –FR1 option

should not be used with a ammable gas because it

has a vent to atmosphere. A lter-regulator without a

vent may be used. For natural gas certication to be

valid, the vent system must be able to maintain <1psig.

Filters. The IPH2 and IPX2 requires ltered, dry,

regulated, instrument-quality air to prevent clogging

and to ensure extended periods of maintenance-free

operation. Moore Industries suggests the following

levels of ltering protection:

• Pre-lter – A general purpose “rough” lter, used

to reduce particulate matter to 5 microns in size.

Also removes bulk liquids. Although not required,

this lter is especially recommended to protect the

0.01 micron nal lter when used.

• Final Filter – A second, nal lter is recommended

to remove particulate matter in sizes down to

0.01 micron. This lter removes virtually all

condensable liquids from the air stream as well.

• Filter/Regulator Module Option – A combined

lter/regulator assembly, the -FR1 Option, oered

as an accessory for either the IPH2 or IPX2,

removes particles down to 0.01 microns, supplying

regulated, instrument-quality air to the unit. This

space-saving module is axed to the supply port,

and comes with a pressure gauge scaled in both

psi (0-60) and Bars (0-4).

Demand Moore Reliability 11

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

Hazardous Location Applications

This section contains important information regarding

installation of IPX2 in hazardous locations.

Classication of the area and installation of the

IPX2 should be done in accordance with applicable

electrical codes such as the United States National

Electrical Code (NEC), and/or any other equivalent/

applicable internationally adopted standards and

installation codes (CEC & IEC).

Refer to the Special Conditions outlined below before

proceeding with installation.

Safety Concerns

For your safety, read the following information carefully

before proceeding with installation.

WARNING:

EXPLOSION HAZARD –

For Division 2 Hazardous locations. DO NOT

Disconnect equipment when a ammable

atmosphere is present.

WARNING:

Substitution of components is not allowed, as it may

impair the intrinsic safety (Zones 0 & 1, Division 1)

of the unit and/or the non-incendive/Type N (Division

2, Zone 2) circuit. DO NOT open the unit when

either energized or when an explosive gas/dust

atmosphere is present. Disconnect power before

servicing. Read and understand the Manufacturer’s

installation and Operating procedures, and adhere

to all applicable electrical codes, safety instructions

and regulations.

Special Conditions of Use

The following instructions must be adhered to when

the Model IPX2 is used in hazardous locations and

potentially explosive atmospheres.

cCSAus Installations

Intrinsically Safe Applications

Class I, Div. 1 & 2, Groups A, B, C & D

Class II & III, Div 1 & 2, Groups E, F, & G

Class1, Zone 0, AEx ia IIC, Ex ia IIC

The Model IPX2 shall be supplied by a Class 2 or

SELV Limited Circuit as dened by CAN/CSA # 1010.1

Annexes F.2.1 and H.

The Model IPX2 must be installed by drawing

100-100-78.

Explosion/Flame Proof Applications

Class I, Division 1, Groups A, B, C & D

Class II & III, Div 1 & 2, Groups E, F, & G

Class I, Zone 1, AEx d IIC, Ex d IIC

The Model IPX2 shall be supplied by a Class 2 or

SELV Limited Circuit as dened by CAN/CSA # 1010.1

Annexes F.2.1 and H.

Nonincendive, Type n Applications

Class I, Division 2, Groups A B, C & D

Class1, Zone 2, AEx nA IIC, Ex nA IIC

The Model IPX2 shall be supplied by a Class 2 or

SELV Limited Circuit as dened by CAN/CSA # 1010.1

Annexes F.2.1 and H.

Avertissement:

Ouvrir le circuit avant d’enlever le couvercle. La

substitution de composants peut compromettre la

sécurité intrinséque. Un scellement doit être installé

à moins de 457mm du boîtier. En Classe 1,

Division 2, ce produit doit être installé conformément

170-775-00.

12 Demand Moore Reliability

Installation of Model IPX2 with the –NG Option in

a Class I, Division 2 classied area requires the

use of wiring and venting methods applicable for

Class I, Division 1 Hazardous ‘Classied’ Locations.

Venting the IPX2 with the –NG Option to an approved

continuous ignition are system, or to a Class I,

Division 1 Hazardous ‘Classied’ Area which provides

minimum back-pressure to the device, must be

utilized. Vent piping and electrical conduits must

be designed and installed using approved good

engineering practices.

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

European Union Installations

(ATEX 2014/34/EU Directive)

Intrinsically Safe Applications - Zone 0

II 1 G Ex ia IIC T4 Ga

be protected from impact.

Intrinsically Safe Applications

Certicate No.: ANZEx 09.3000X

Standards:

AS/NZS 60079.0:2005 Explosive atmospheres -

Equipment - General requirements

The enclosure is manufactured from 6063-T5

Aluminum alloy. In rare cases, ignition sources due

to impact and friction sparks could occur. This shall

be considered during installation, particularly if the

equipment is installed in a Zone 0 location.

The IPX2 has the the following safety parameters when

input terminals are connected to a linear, resistive

barrier:

Ui = 30Vdc, Ii = 110mA, Pi = 0.825W, Ci = 720pF, Li =

5.12µH.

The IPX2 is to be installed per Field Installation

Drawing, 100-100-78.

Flame Proof Applications - Zone 1

II 2 G Ex d IIC T4 Gb

II 2 D Ex tb IIIC T127˚C Db

The stopping plugs must not be used with a thread

adapter/reducer.

Model IPX2 with the –NG Option (Natural Gas as the

input medium) is excluded.

Type n Applications - Zone 2

II 3 G Ex nA IIC

On installation, the Model IPX2 shall be provided with

supply transient protection external to the apparatus

such that the voltage at the supply terminals of the

IPX2 does not exceed 119V peak or 119Vdc.

Model IPX2 with the –NG Option (Natural Gas as the

input medium) is excluded.

AS/NZS 60079.11:2006 Explosive atmospheres -

Equipment protection by intrinsic safety ‘i’

Type n Applications

Certicate No.: ANZEx 09.3000X

Standards:

AS/NZS 60079.0:2005 Explosive atmospheres -

Equipment - General requirements

AS/NZS 60079.15:2006 Explosive atmospheres -

Equipment protection by type of protection ‘n’

Operation

Once the unit has been congured and installed, it

operates unattended with the exception of the minor

maintenance procedures that are described in the next

section.

If the unit is determined to be the cause of a loop

irregularity, carry out the maintenance procedure in the

next section of this manual. If problems persist, refer

to the Troubleshooting Section.

Instrument-quality Air. Air from the application

continuously ows through the IPH2/IPX2 during

operation. Depending upon the purity of the air

supply, the unit’s internal assembly may have to be

removed and cleaned to ensure continued optimum

performance.

Initially, random checks can help establish a

satisfactory internal maintenance geared to the user’s

air supply cleanliness. Refer to the next section for

instruction on the disassembly and cleaning of your

unit.

Australia New Zealand ANZEx

Installations

When the apparatus is used in a Zone 0 environment

it is a condition of safe use that the apparatus shall

Maintenance

For most applications, no maintenance outside of

routine inspection and calibration of the IPH2 or IPX2

will be necessary. These units are designed to work

unattended for up to six months with little change in

accuracy.

Demand Moore Reliability 13

2

Locking screw

IPX

2

SELECTABLE OUTPUT

PS (+) PS (-)

ZERO

SPAN

ZERO

SPAN

Mounting screws

Electronic module

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

Troubleshooting

the IPH2 & IPX2

If a problem is suspected with the IPH2 or IPX2, review

the following steps:

1. Verify that bench instruments used to take

measurements have the proper range and

accuracy and are within current certication period

limits.

2. If a change in the relationship between the input

and output is detected, attempt a re-calibration of

the unit.

3. If the response time lengthens, or if the span

drops, check the system for a blockage due

to air supply contamination. Please refer to

Maintenance section for details of replacing lters,

electronic modules and drain checking.

If the unit needs to be returned for service, the

complete valve assembly can be removed from

the housing for replacement without disturbing the

connections to the housing. Contact customer service

for details.

the recovery of the unit, by allowing any accumulated

liquid to drain out more eectively. To remove the

module follow these steps:

1. Use a 3mm Allen wrench to unlock the cover.

Drive the Allen screws clockwise until the cover

is allowed to rotate freely. Remove the cover by

accessing the locking screw shown in Figure 6.

Figure 6. Unlocking the IPX 2 Cover

2. Use a Phillips head screw driver to remove the

four module mounting screws shown in Figure 7.

Drain Check

System lters (not IPX2/IPH2 lters) have automatic

drains that depend on the uctuation of system

pressure to induce drainage. A stable system may not

drain eciently. Check periodically for clogs and drain

system’s lters by pushing the drainage valve with a

small probe or wire.

IPX2 Replacement Modules*

*This applies only to new versions of the IPX2

introduced in 2013.

In abnormal operating conditions in which a slug

(liquid) is present in the IPX2 air/ gas supply, the

electronic module may be removed. This can help in

Figure 7. Removing Mounting Screws

3. Carefully, pull the module from the housing. The

pneumatic stem, found on the bottom of the

module, is fragile; handle with care. See Figure 8.

14 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Figure 8. Removing Module from Housing

Item P/N Description Qty

1 208-876-00 Module 1

1

Barrier

plate

Customer Service

Moore Industries is recognized as the industry leader

in delivering top quality to its customers in products

and services. We perform a battery of stringent

quality assurance checks on every unit we ship. If any

Moore Industries product fails to perform up to rated

specications, call us for help. Our highly skilled sta

of trained technicians and engineers pride themselves

on their ability to provide timely, accurate and practical

answers to your process instrumentation questions.

Factory phone numbers are listed on the back cover of

this manual.

If problems involve a particular IPH2/IPX2, there are

several pieces of information that can be gathered

before you call the factory that will help our sta get

the answers you need in the shortest time possible.

For fastest service, gather the complete model and

serial number(s) of the problem unit(s) and the job

number of the original sale.

4. Inspect the module and the barrier plate for any

signs of contamination. Remove any excess liquid

and allow to dry before replacing. The electronic

module is not eld-serviceable. If irreparable

damage is found, it may be replaced. See Data

Sheet for ordering information.

5. To re-assemble, replace the module using locating

pins (see step 3), tighten the 4 module screws

(see step 2), replace the cover and secure with the

locking screw (step 1).

6. Recalibrate the unit before returning to service.

Refer to the Calibration Section of this manual for

instructions.

Demand Moore Reliability 15

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

16 Demand Moore Reliability

IPH

2

&

IPX

2

Current-to-Pressure

(I/P) Transmitters

Demand Moore Reliability 17

2

IPH

Current-to-Pressure

(I/P) Transmitters

&

2

IPX

18 Demand Moore Reliability

RETURN PROCEDURES

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

China • sales@mooreind.sh.cn

Tel: 86-21-62491499 • FAX: 86-21-62490635

United Kingdom • sales@mooreind.com

Tel: 01293 514488 • FAX: 01293 536852

To return equipment to Moore Industries for repair, follow these four steps:

1. Call Moore Industries and request a Returned Material Authorization (RMA) number.

Warranty Repair –

If you are unsure if your unit is still under warranty, we can use the unit’s serial number

to verify the warranty status for you over the phone. Be sure to include the RMA

number on all documentation.

Non-Warranty Repair –

If your unit is out of warranty, be prepared to give us a Purchase Order number when

you call. In most cases, we will be able to quote you the repair costs at that time.

The repair price you are quoted will be a “Not To Exceed” price, which means that the

actual repair costs may be less than the quote. Be sure to include the RMA number on

all documentation.

2. Provide us with the following documentation:

a) A note listing the symptoms that indicate the unit needs repair

b) Complete shipping information for return of the equipment after repair

c) The name and phone number of the person to contact if questions arise at the factory

3. Use sucient packing material and carefully pack the equipment in a sturdy shipping container.

4. Ship the equipment to the Moore Industries location nearest you.

The returned equipment will be inspected and tested at the factory. A Moore Industries

representative will contact the person designated on your documentation if more information is needed. The repaired equipment, or its replacement, will be returned to you in accordance with the shipping instructions furnished in your documentation.

WARRANTY DISCLAIMER

THE COMPANY MAKES NO EXPRESS, IMPLIED OR STATUTORY WARRANTIES (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE) WITH RESPECT TO ANY

GOODS OR SERVICES SOLD BY THE COMPANY. THE COMPANY DISCLAIMS ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING

OR TRADE USAGE, AND ANY BUYER OF GOODS OR SERVICES FROM

THE COMPANY ACKNOWLEDGES THAT THERE ARE NO WARRANTIES

IMPLIED BY CUSTOM OR USAGE IN THE TRADE OF THE BUYER AND

OF THE COMPANY, AND THAT ANY PRIOR DEALINGS OF THE BUYER

WITH THE COMPANY DO NOT IMPLY THAT THE COMPANY WARRANTS

THE GOODS OR SERVICES IN ANY WAY.

ANY BUYER OF GOODS OR SERVICES FROM THE COMPANY

AGREES WITH THE COMPANY THAT THE SOLE AND EXCLUSIVE REMEDIES FOR BREACH OF ANY WARRANTY CONCERNING THE GOODS

OR SERVICES SHALL BE FOR THE COMPANY, AT ITS OPTION, TO

REPAIR OR REPLACE THE GOODS OR SERVICES OR REFUND THE

PURCHASE PRICE. THE COMPANY SHALL IN NO EVENT BE LIABLE

FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES EVEN IF THE

COMPANY FAILS IN ANY ATTEMPT TO REMEDY DEFECTS IN THE GOODS

OR SERVICES , BUT IN SUCH CASE THE BUYER SHALL BE ENTITLED

TO NO MORE THAN A REFUND OF ALL MONIES PAID TO THE COMPANY

BY THE BUYER FOR PURCHASE OF THE GOODS OR SERVICES.

ANY CAUSE OF ACTION FOR BREACH OF ANY WARRANTY BY

THE COMPANY SHALL BE BARRED UNLESS THE COMPANY RECEIVES FROM THE BUYER A WRITTEN NOTICE OF THE ALLEGED

DEFECT OR BREACH WITHIN TEN DAYS FROM THE EARLIEST DATE

ON WHICH THE BUYER COULD REASONABLY HAVE DISCOVERED

THE ALLEGED DEFECT OR BREACH, AND NO ACTION FOR THE

BREACH OF ANY WARRANTY SHALL BE COMMENCED BY THE

BUYER ANY LATER THAN TWELVE MONTHS FROM THE EARLIEST

DATE ON WHICH THE BUYER COULD REASONABLY HAVE DISCOVERED THE ALLEGED DEFECT OR BREACH.

RETURN POLICY

For a period of thirty-six (36) months from the date of shipment, and under

normal conditions of use and service, Moore Industries (“The Company”)

will at its option replace, repair or refund the purchase price for any of its

manufactured products found, upon return to the Company (transportation

charges prepaid and otherwise in accordance with the return procedures

established by The Company), to be defective in material or workmanship.

This policy extends to the original Buyer only and not to Buyer’s customers

or the users of Buyer’s products, unless Buyer is an engineering contractor

in which case the policy shall extend to Buyer’s immediate customer only.

This policy shall not apply if the product has been subject to alteration,

misuse, accident, neglect or improper application, installation, or operation.

THE COMPANY SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

Specications and Information subject to change without notice.© 2016 Moore Industries-International, Inc.

Loading...

Loading...