Class 10000 Heavy Duty

Series 12

Installation Instructions

MOORE FANS LLC, MARCELINE, MO 64658

TMC 911 REV A (JUN/17)

PHONE (660) 376-3575 FAX (660) 376- 2909

www.moorefans.com

EMAIL info@moorefans.com

INSTALL HUB AND AIR SEAL

Hub installation instructions:

The aluminum bushing is lubricated and pre-installed in the hub at the factory, no further lubrication is required prior to installation. DO NOT apply lubricant between the bushing bore and the shaft. Leave slight play between the bushing and hub to fa-

cilitate installation on the shaft. Place the hub/bushing on the shaft. Insert the key, and tighten the setscrew to secure the hub and

key to the shaft. Now begin sequentially tightening the socket head cap screws (approximately 2-3 turns per cap screw initially)

to firmly engage the bushing in the hub and seat the bushing on the shaft. Once the bushing/hub is firmly seated on the shaft,

continue tightening the cap screws sequentially until the specified torque of 50 FT-LBS (6.9 M-KG) is reached.

DO NOT over-tighten cap screws as this could cause damage to the hub.

FAN HUB

(grease on bushing bore taper)

BUSHING TAPER

(grease on this surface)

CAP SCREWS

(grease on threads and

underside of head)

BUSHING

Caution:

If bushing is expected to see frequent oscillating loads

(Greater than 50% of nominal expected Static Torque),

Fan should be operated for approximately 15 minutes

and then re-torque bushing cap screws.

INSTALL AND ADJUST BLADES

BLADE

ROD END

BLADE BOLT

NOTE: MOUNTING BOLT

SUPPLIED WITH GREASE ON

THREADS AND CONICAL FACE

BEFORE INSTALLING BLADES. . . .

Check to see that the hub is level. If the drive shaft is not truly vertical,

causing the hub to be cocked, it will be difficult to adjust blade angles

accurately. Eccentric rotation of the fan can also cause serious vibration

problems. If misalignment, vibration or unbalance in the system is present, it

will be more easily identified and corrected at this time.

Moore fan blades are carefully balanced to the same moment at

the factory.

Proper installation, with particular attention to

tightening bolts to the specified torque, is essential to

maintain the design integrity of these units.

Install one blade: Clean any dirt or grease from the rod

end and the surfaces of the mounts. Align the rod end hole with

the holes in the mounts and insert the blade mounting bolt first

through the mount with the recess to accept the bolt head, then

through the rod end hole and screw the bolt into the second

mount lightly. The blade mounting bolt is supplied from the

factory with grease on the threads and conical face. Do NOT

clean the grease from the bolt.

Complete the installation of one blade by holding

the blade so that the blade extends straight out from the rod

end. Holding the blade in this position, tighten the bolt

using a torque wrench set to 200 ft-lb (27.6 m-kg) making

sure the rod end and the mounts seat.

After installing the first blade, manually rotate the fan

to be sure the blade clears the ring or throat at all points. When

the blade is held in alignment with the rod end (that is, straight

outward from the hub), it should clear the fan ring by a

distance adequate to provide for any relative motion between

the fan wheel and the ring. Excess clearance between the blade

tips and the ring, however, should be avoided to prevent

backflow which seriously reduces fan efficiency. If clearance

is excessive, the diameter may be adjusted at this time.

Install the remaining blades so that they are identical

with the first blade. Torque all bolts to 200 ft-lbs (27.6 m-

kg).

.25” MAX Clamp Bolts

Hubs are shipped from the factory with the rod end set for the blade angle indicated by the design performance. A change in blade

angle is sometimes necessary, however, to adjust to actual site conditions. Failure to adjust the blade angle when required may

result in blade or motor overload.

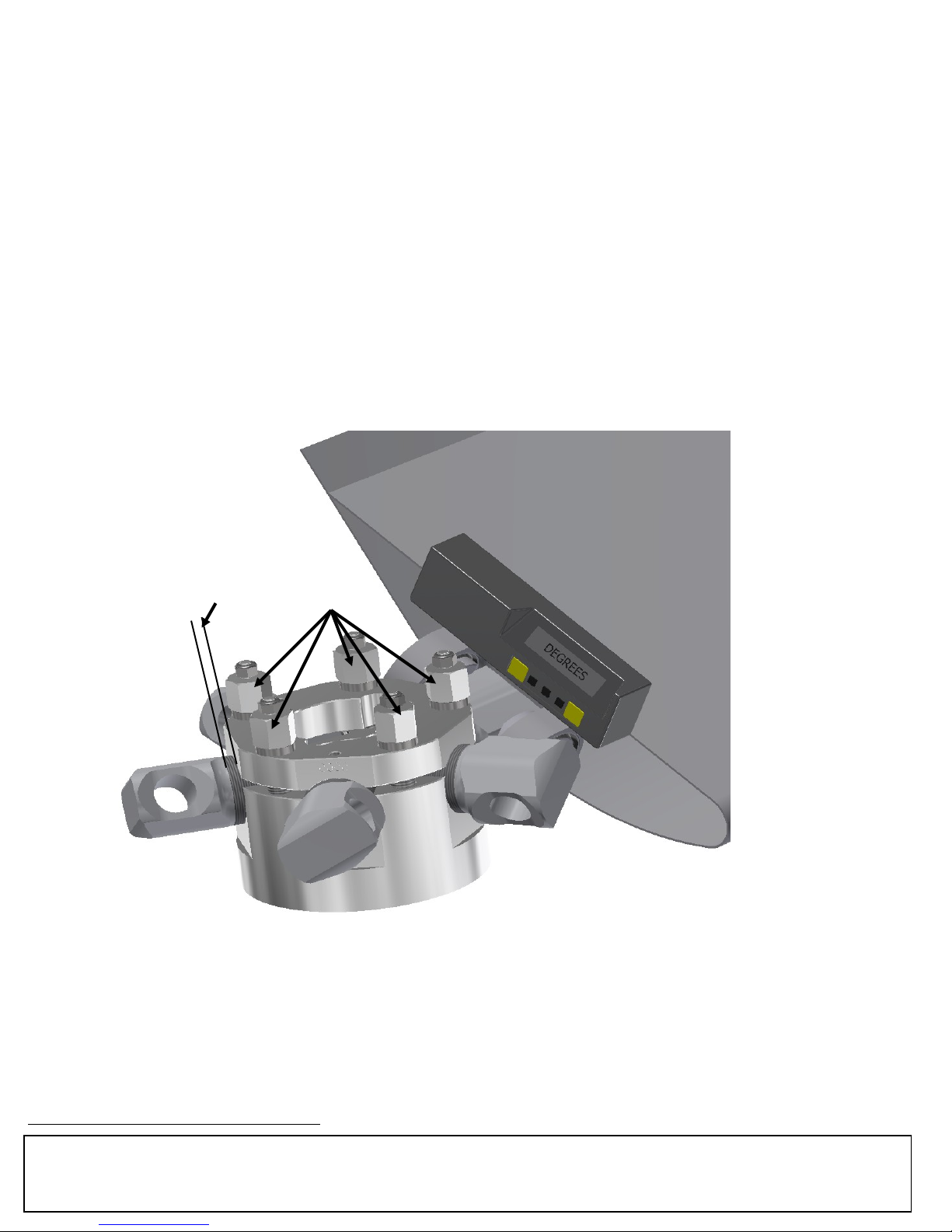

To adjust, loosen the Clamp Bolts just enough to allow the blade to be turned. Place an inclinometer on the flat surface of

the root section as shown in the illustration above. Turn the blade until the desired angle is achieved.. Make a permanent record

of the final angle selected and take care that all blades on the fan are set at the same angle. A typical adjustment may be +/- 3°

from design angle (+/- .5° tolerance blade to blade). The maximum recommended blade angle is 30°. Please consult the

factory if it is desired to go above this.

Retighten the Clamp Bolts To 60 FT-LBS (8.3 M-KG).

Recheck each blade angle after tightening.

WARNING: The fan is designed to consume the horsepower stated on the Fan Specification Sheet. Too great an increase in

blade angle can cause serious blade overload which will stall the blades. In this condition, the fan will actually deliver less air

and blade life may be shortened.

ADJUST DIAMETER IF REQUIRED

At times it may be necessary to adjust the fan diameter to

suit a particular ring. To do so, loosen the clamp bolts so

that the rod end can be rotated in the clamp block. One

complete revolution will increase or decrease the radius of

the fan by 1.5 mm (.06 in). Take care that the blade is

returned to exactly the factory-set angle unless it is intended

that the blade loading be

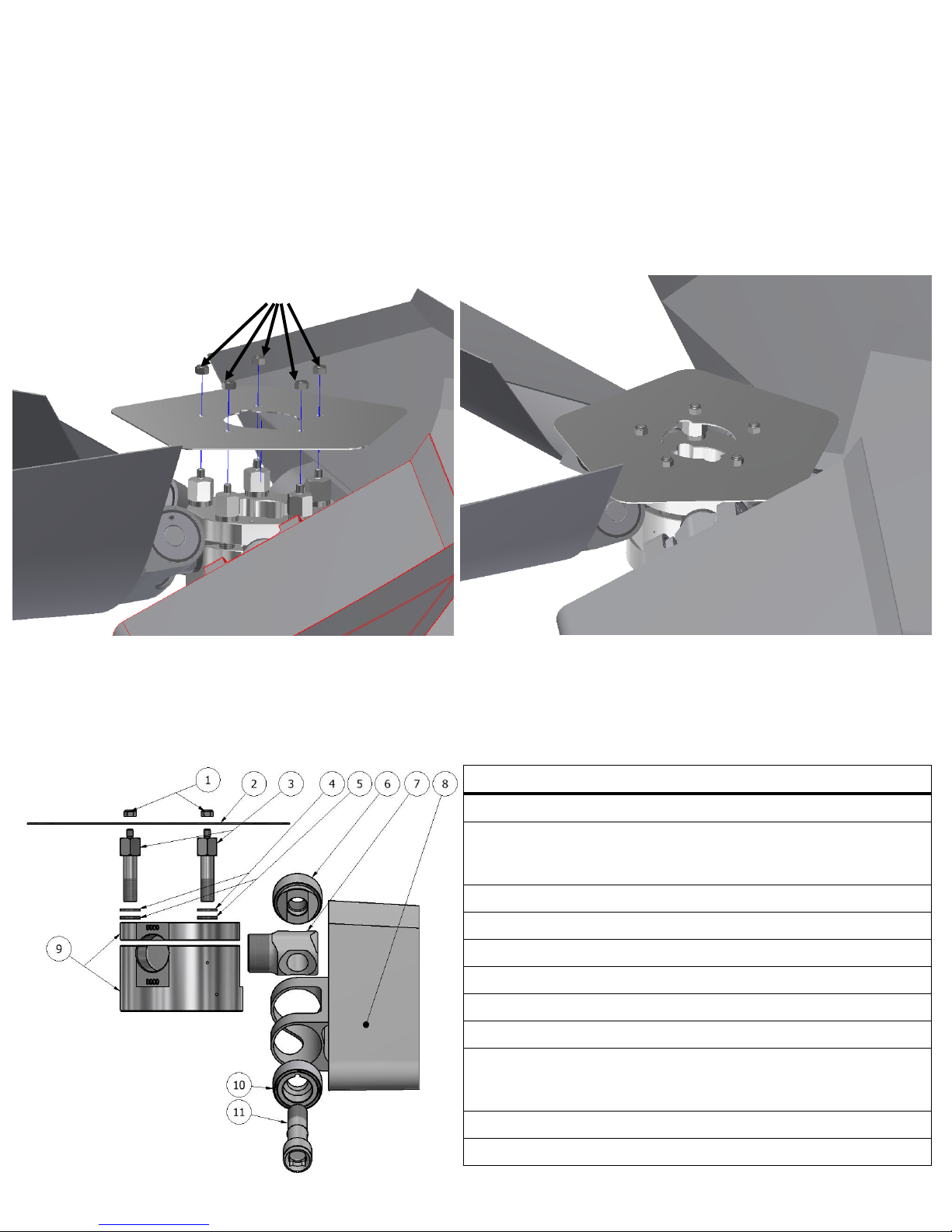

INSTALL AIR SEAL

AIR SEAL NUTS

changed as discussed in the previous section. A match mark

may be made at a point on the threads and the clamp block

before turning to assure that exactly one revolution is made.

Tighten the clamp bolts to 60 FT-LBS. Maximum adjustment

possible is +0" -.25” (6.35 mm) radially (.5” on diameter). No

more than .25" (6.35 mm) of rod end threads can remain

outside the clamp block.

**Fans with ATEX tips do not have any inward diameter

adjustment.

To install an air seal:

Align notches in air seal with bushing bolts and place

on to mounting studs.

Carefully tighten lock nuts to 50 lb-in (5.6 N-m)

PARTS LIST

ITEM PART # DESCRIPTION

1

2

3

4

5

6

7

8

9

P5122 LOCKNUT

P114

P117

P118

P7110 CLAMP BOLT

P1501 LOCK WASHER

P120 FLAT WASHER

P271 THREADED MOUNT

P7109 ROD END

CONTACT SALES FAN BLADE

P1144

P1152

P1153

3 BLADE AIRSEAL

4 BLADE AIRSEAL

5 BLADE AIRSEAL

3 BLADE HUB

4 BLADE HUB

5 BLADE HUB

MOORE FANS LLC, MARCELINE, MO 64658

TMC 911 REV A (JUN/17)

10

11

PHONE (660) 376-3575 FAX (660) 376- 2909

www.moorefans.com

P272 BORED MOUNT

P119 BLADE BOLT

EMAIL info@moorefans.com

Loading...

Loading...