SSX / SST

Safety Series Isolator and Splitter

Demand Moore Reliability

SSX/SST

Safety Series Isolator and Splitter

User’s Manual

206-792-00G

May 2016

www.miinet.com

SSX/SST

Safety Series Isolator and Splitter

Customer Support

Moore Industries is recognized as the industry leader in delivering top quality to its customers in products

and services. We perform a sequence of stringent quality assurance checks on every unit we ship. If any

Moore Industries product fails to perform up to rated specications, call us for help. Our highly skilled staff of

trained technicians and engineers pride themselves on their ability to provide timely, accurate, and practical

answers to your process instrumentation questions. Our headquarters and other facilities phone numbers

are listed below.

Customer Support

There are several pieces of information that can be gathered before you call the factory that will help our

staff get the answers you need in the shortest time possible. For fastest service, gather the complete model

and serial number(s) of the problem unit(s) and the job number of the original sale.

Locations

User’s Manual

206-792-00G

May 2016

Demand Moore Reliability

World Headquarters

16650 Schoenborn Street

North Hills, California

91343-6196, U.S.A.

Tel: (818) 894-7111

Fax: (818) 891-2816

E-mail: info@miinet.com

TOLL FREE: 1-800-999-2900

www.miinet.com

China

Room 806, Block 2,

Lotus International Plaza

No. 7866 Hu Min Road,

Min Hang District,

Shanghai, 201102, P. R. China

Tel: 86-21 62491499

Fax: 86-21 62490635

E-mail: sales@mooreind.sh.cn

www.miinet.com/cn

Europe

1 Lloyds Court, Manor Royal,

Crawley

W. Sussex RH10-9QU

United Kingdom

Tel: 01293 514488

Fax: 01293 536852

FREE PHONE: 0800 525107

sales@mooreind.com

www.miinet.com/uk

Drie Eikenstraat 362

B-2650 Edegem

Belgium

Tel: 03/448.10.18

Fax: 03/440.17.97

info@mooreind.be

Dutch: www.miinet.com/dbe

French: www.miinet.com/fbe

Burg Meslaan 98

4003 CD Tiel

The Netherlands

Tel: (0)344-617971

Fax: (0)344-615920

sales@mooreind.nl

www.miinet.com/nl

Australia

Sydney, NSW

3/1 Resolution Drive

Caringbah, New South Wales

2229

Australia

Tel: (02) 8536-7200

Fax: (02) 9525-7296

sales@mooreind.com.au

www.miinet.com/au

Perth, WA

6/46 Angove Street

North Perth, Western Australia

6006

Australia

Tel: (08) 9228-4435

Fax: (08) 9228-4436

sales@mooreind.com.au

www.miinet.com/au

www.miinet.com

www.miinet.com Moore Industries-International, Inc.

- 2 -

User’s Manual

SSX/SST

206-792-00G

May 2016

Safety Series Isolator and Splitter

Safety Messages

Please read this manual in its entirety. It should answer most of your questions. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before installing, using, or maintaining

this product. Should you still have questions please visit our web site at www.miinet.com or contact any of our sales/

support ofces nearest you.

Your safety and the safety of others is very important. We have provided many important safety messages in this

manual. Please read these messages carefully. These safety messages alert you to potential hazards that could hurt

you or others or render damage to units.

All Moore Industries instrumentation should only be used for the purpose and in the manner described in this manual.

If you use this product in a manner other than that for which it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

Each safety message is associated with a safety alert symbol. These symbols are found in the throughout the manual.

The denition of these symbols is described below:

Pay particular attention wherever you see the following symbols:

Note – Information that is helpful for a procedure,

condition or operation of the unit.

About this Manual

Caution – Hazardous procedure or condition that

could damage or destroy the unit.

Warning – Hazardous procedure or condition that

could injure the operator.

Qualied Personnel

The Moore Industries’ product/systems described in this manual may be operated only by personnel qualied for the

specic task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualied personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these Moore Industries’ products/systems.

Proper use of Moore Industries products

Moore Industries’ products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Moore Industries’ . Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient

conditions must be complied with. The information in the relevant documentation must be observed.

We have reviewed the contents of this publication to ensure consistency with the hardware and/or software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions. Specications and

information are subject to change without notice.

All product and company names are trademarks™ or registered

does not imply any afliation with or endorsement by them unless otherwise specied.

®

trademarks of their respective holders. Use of them

- 3 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

User’s Manual

206-792-00G

May 2016

Table of Contents

Section 1 - Introduction 6

Overview....................................................................................................................6

Description

2-Wire, Loop Powered SSX ......................................................................................................... 6

CONTENTS

4-Wire Line/Mains Powered SST and SST Splitter

................................................................................................................ 6

..................................................................... 6

Model Numbers and Options ...................................................................................8

SSX 2-Wire Loop Powered Safety Isolator / Signal Convertor .................................................... 9

SST 4-Wire Line/Mains Powered Safety Isolator/Signal Convertor

(Single Output Channel)

SST 4-Wire Line/Mains Powered Safety Isolator Splitter

(Two Output Channels)

................................................................................................................ 10

..................................................................................................................11

Section 2 - Calibration and Bench Check 13

Calibration ............................................................................................................... 13

Calibration Procedure - SSX and SST Single Output Channel ................................................. 14

SPAN and ZERO Adjustments - SSX and SST Single Output Channel

Calibration Procedure - SST Splitter (Two Output channels)

SPAN and ZERO Adjustments - SST Splitter

............................................................................ 16

.................................................... 16

Bench Check ........................................................................................................... 18

Bench Check Procedure ............................................................................................................ 19

.................................... 14

Section 3 - Installation and Wiring 24

Terminal Designations ...........................................................................................24

Dimensions

Electrical Connections ............................................................................................................... 27

Installation Category

Installation in Hazardous Locations ..................................................................... 29

Special Conditions of Use ........................................................................................................ 29

www.miinet.com Moore Industries-International, Inc.

.............................................................................................................25

.................................................................................................................. 27

- 4 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Table of Contents

Section 4 - Operation and Maintenance 30

Operation .................................................................................................................30

Maintenance

Section 5 - Applications 31

Isolate and Pass Critical HART Data ....................................................................31

Isolate and Power a 2-Wire Transmitter

Isolation of Safety Systems

“Sharing” or “Splitting” Process Signals

Solve “Bucking” Power Supplies and Filter HART

Solving 4-Wire Transmitter Problems

Duplicate Signal to Two Legacy Systems

Section 6 - SSX/SST in SIS 38

............................................................................................................ 30

...............................................................32

................................................................................... 33

............................................................34

.............................................35

...................................................................36

............................................................ 37

CONTENTS

Functional Safety Description ............................................................................... 38

Failure Rate Data

Product life

Conguration

Process Safety Time

Input Types

Broken Wire Detection

Proof Test Procedure

Repair and Replacement........................................................................................39

.............................................................................................................. 38

..............................................................................................................39

....................................................................................................38

.......................................................................................................... 38

..............................................................................................39

........................................................................................... 39

.............................................................................................39

Section 7 - Specications 41

Section 8- Ordering Information 42

Warranty Disclaimer 43

- 5 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Section 1 - Introduction

The Moore Industries’ Safety Series Isolators (SSX and SST) are designed and manufactured to

provide a high level of availability for safety critical applications and for use as a component part

of a safety instrumented system.

This manual contains information needed to install, operate and maintain this product. When

the SSX or SST are used in a SIL rated safety application, please refer to Section 6 SSX/SST

in Safety Instrumented Systems. Safety and failure rate data for the SSX and SST are in the

SECTION 1

SSX/SST FMEDA report (Moore Industries’ Document No: 700-702-36), which is available upon

request.

Overview

As part of the Moore Industries’ FS Functional Safety Series, the exida® approved, SIL 3

capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and

Splitters provide galvanic isolation and signal conversion for your SIS (Safety Instrumented

System) needs. These units protect and enhance loops and also pass valuable HART® data

from the eld transmitter to host systems and vice-versa.

User’s Manual

206-792-00G

May 2016

Description

2-Wire, Loop Powered SSX

The SSX is a 2-wire isolator /signal convertor, drawing power from the output side of the loop.

Typically, this is from a secondary receiving device such as a DCS or PLC. The SSX will also

pass through a HART signal on its input or optionally can block the signal on its output.

4-Wire Line/Mains Powered SST and SST Splitter

The SST is a 4-wire unit powered by 24DC, 117AC or 230AC. It is designed for applications

where line/mains power is readily available, such as the back of a panel or inside of a control

room. It passes through a HART signal on its input or optionally can block the signal on its

output. The SST can also provide 24V power to a 2-wire, output-loop powered instrument which

eliminates the need for an additional power supply.

The SST Splitter takes one input and creates two identical, completely isolated outputs.

Additionally, the SST can function as a HART splitter that passes valuable HART data to one or

both of the SST’s independent outputs. This is especially important when asset management

systems need to maintain a digital HART connection with critical valves or instruments for

diagnostic monitoring or calibration record keeping.

www.miinet.com Moore Industries-International, Inc.

- 6 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Single- and Multiple-Unit Instrument Enclosures

Designed to meet NEMA 4X and IP66 ratings, the R-BOX is the perfect solution for protecting the

SST/SSX in field and control room applications. Rugged and versatile, it delivers a high impact

structure and resistance to ultraviolet rays and chemicals. The R-BOX mounts on a pipe, panel

or surface, and comes in a variety of widths to economically accommodate several SSTs or

SSXs. It features a pre-installed mounting rail; customizable conduit entry options; a clear cover

and a secure locking mechanism (See Figure 1.1). For more information, see the R-BOX Field-

Mount Enclosure datasheet.

Figure 1.1. Available in a variety of widths, our R-BOX field-mount instrument enclosure is designed to protect DIN-rail

instruments in even the most rugged environments

SECTION 1

SSX and SST Applications

Please refer to Section 5: Applications for examples of typical SSX and SST applications

- 7 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Model Numbers and Options

The following section provides details of the Moore Industries model number and the available

options for the SSX and SST.

Moore Industries model numbers or SSX/SST are structured as follows:

SSX / 4-20MA / 4-20MA / 12-42DC / -IZ250 [DIN]

User’s Manual

206-792-00G

May 2016

SECTION 1

Unit / Input / Output / Power / -Options [Housing]

Refer to Section 8 Ordering Information for a quick reference table of ordering information.

Further details are provided for each model starting on next page.

www.miinet.com Moore Industries-International, Inc.

- 8 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

SSX 2-Wire Loop Powered Safety Isolator / Signal Convertor

INPUT

4-20MA

The standard input of the SSX is 4-20mA into 100 ohms.

There are two options available that will change the input resistance. The – IZ250 option

will increase the input resistance to 250 ohms and the -0HART option (no HART pass-

through) will change the input resistance to 65 ohms.

1-5V

The SSX can also be ordered for use with a 1-5Vdc input (non-HART). The input

impedance for this application is 1 Megohm.

Note: Input resistance specifies the resistance seen by the DC signal. Since the HART signal

is AC, it will see the input resistance plus the internal HART transformer (70 ohms) plus any

termination resistance in the loop.

OUTPUT

4-20MA

Isolated 4-20mA into 0-600 ohms (with 24Vdc series loop voltage), with HART digital data

pass-through.

Note: There is no HART digital data pass-through at the output when the -0HART option is

chosen or when the 1-5V Input is chosen.

SECTION 1

POWER

12-42DC

The SSX is a 2-wire, loop powered instrument. It is powered either by an external 12-

42Vdc power supply, or by a DCS (or PLC) input channel that provides power (12-42Vdc)

to the loop.

OPTIONS

-IZ250

This option increases the input resistance to 250 ohms. (4-20mA input units only)

-0HART

With this option the instrument is configured for no HART pass-through. (4-20mA input

units only)

HOUSING

[DIN]

Universal DIN-style housing mounts on a 32mm G-type rail (EN 50035) or on 35mm Top

Hat rail (EN50022).

[FLB]

Flange mount bracket for wall mounting.

- 9 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

SST 4-Wire Line/Mains Powered Safety Isolator/Signal Convertor

(Single Output Channel)

INPUT

4-20MA

The standard input of the SST is 4-20mA into 100 ohms.

There are two options available that will change the input resistance. The –IZ250 option

SECTION 1

Note: Input resistance specifies the resistance seen by the DC signal. Since the HART signal

is AC, it will see the input resistance plus the internal HART transformer (70ohms) plus any

termination resistance in the loop.

OUTPUT

will increase the input resistance to 250 ohms and the -0HART option (no HART pass-

through) will change the input resistance to 65 ohms.

1-5V

The SST can also be ordered for use with a 1-5Vdc input (non-HART). The input

impedance for this application is 1 Megohm.

4-20MA

Isolated 4-20mA into 0-1000 ohms, with HART digital data pass-through.

User’s Manual

206-792-00G

May 2016

Note: There is no HART digital data pass-through at the output when the -0HART option is

chosen or

when the 1-5V Input is chosen.

POWER

24DC

117AC

230AC

The SST is a 4-wire, line/mains powered instrument. The voltage choice should be

specified at the time that the instrument is ordered. It can be powered by either 24Vdc (+/-

10%), 117Vac, 50/60Hz (+/- 10%) or 230Vac, 50/60Hz (+/- 10%). The SST with one output

channel consumes 3 watts maximum.

OPTIONS

-IZ250

This option increases the input resistance to 250 ohms. (4-20mA input units only)

-0HART

With this option the instrument is configured for no HART pass-through.

(4-20mA input units only)

HOUSING

[DIN]

Universal DIN-style housing mounts on a 32mm G-type rail (EN 50035) or on 35mm Top

Hat rail (EN50022).

[FLB]

Flange mount bracket for wall mounting

www.miinet.com Moore Industries-International, Inc.

- 10 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

SST 4-Wire Line/Mains Powered Safety Isolator Splitter

(Two Output Channels)

INPUT

4-20MA

The standard input of the SST is 4-20mA into 100 ohms.

There are three options available that will change the input resistance. The –IZ250 option

will increase the input resistance to 250 ohms, the -0HART option (no HART pass-through)

will change the input resistance to 65 ohms, and the -2HART option (HART pass-through

for both output channels) will change the input resistance to 135 ohms

Note: Input resistance specifies the resistance seen by the DC signal. Since the HART signal

is AC, it will see the input resistance plus the internal HART transformer (70 ohms) plus any

termination resistance in the loop. For -2HART option this will be the input resistance plus 140

ohms plus the termination resistances in both output loops.

1-5V

The SST can also be ordered for use with a 1-5Vdc input (non-HART). The input

impedance for this application is 1 Megohm.

OUTPUT

2X4-20MA

Two isolated 4-20mA channels into 0-600 ohms, with HART digital data pass through on

one output channel only (Output ”A”).

The -2HART option will provide isolated two isolated 4-20mA channels into

0-600 ohms, with HART digital data pass-through on both output channels.

If the –EP (External Power) option is selected both outputs will be powered by external

voltage sources connected in series.

SECTION 1

Note: There is no HART digital data available at the output when the -0HART option is chosen or

when the 1-5V Input is chosen.

POWER

24DC

117AC

230AC

The SST is a 4-wire, line/mains powered instrument. The voltage choice should be

specified at the time that the instrument is ordered. It can be powered by either 24Vdc (+/-

10%), 117Vac, 50/60Hz (+/- 10%) or 230Vac, 50/60Hz (+/- 10%). The SST with two output

channels consumes 5 watts maximum.

- 11 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

OPTIONS

-IZ250

This option increases the input resistance to 250 ohms. (4-20mA input units only)

-0HART

With this option the instrument is configured for no HART pass-through. (4-20mA input

units only)

SECTION 1

-2HART

With this option the instrument is configured for HART pass-through on both output

channels. (4-20mA input units only)

-EP

With this option both output channels will be powered by an external source.

-RO

With this option both output channels will be the reverse of the input eg. 4mA input would

be represented as 20mA on both outputs.

HOUSING

[DIN]

Universal DIN-style housing mounts on a 32mm G-type rail (EN 50035) or on 35mm Top

Hat rail (EN50022).

[FLB]

Flange mount bracket for wall mounting.

User’s Manual

206-792-00G

May 2016

www.miinet.com Moore Industries-International, Inc.

- 12 -

User’s Manual

Current/Voltage

Calibrator

Adjustable, calibrated to an accuracy of ±0.025% (Fluke Model 725, or similar)

Calibrated, regulated 24Vdc (±10%) source, nominal, for SSX or dc-powered SST;

calibrated, regulated 117Vac or 230Vac (±10%) source, nominal, for ac-powered SST

250 ohm with ±0.01% precision; required only if using a Voltmeter to calibrate the analog

output from the SST/SSX (voltage drop across the precision resistor; 4-20mA=1-5V)

Calibrated to an accuracy of ±0.025%, or better; such as Fluke Model 725, or similar

Standard (blade) head; head width 2.5mm (0.1in), maximum width

Device

Specifications

Power Supply

Load Resistor

Multimeter

Screwdriver

All referenced product names are the sole property of their respective manufacturers

.

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Section 2 - Calibration and Bench Check

It is recommended that you perform a bench check on your instruments prior to installing them in

your application.

Calibration

We recommend that you check the calibration every year and re-calibrate only when necessary.

To calibrate the SSX or the SST, set up the equipment listed in Table 1 as shown in Figures 2.2

thru 2.4, as appropriate.

Table 1. Calibration Equipment for the SSX and SST

SECTION 2

- 13 -

www.miinet.comMoore Industries-International, Inc.

SPAN

Potentiometer

Adjustment

ZERO

Potentiometer

Adjustment

SPAN

Potentiometer

Adjustment

ZERO

Potentiometer

Adjustment

SPAN

Potentiometer

Adjustments

ZERO

Potentiometer

Adjustments

SSX/SST

Safety Series Isolator and Splitter

Calibration Procedure - SSX and SST Single Output Channel

Current Input Units

1. Apply the appropriate power to the unit being calibrated.

2. Set the INPUT simulator to 4mA.

3. Adjust the ZERO potentiometer (pot) on the SSX or SST front panel until the meter in the

calibration setup reads 1V, ±0.02V.

SECTION 2

4. Adjust the INPUT to 20mA.

5. Adjust the SPAN pot on the SSX or SST front panel until the meter in the calibration setup

reads 5V, ±0.02V.

Note: SPAN and ZERO adjustments are non‑interactive as long as zero is set rst.

Voltage Input Units

1. Apply the appropriate power to the unit being calibrated.

2. Set the INPUT simulator to 1V.

3. Adjust the ZERO potentiometer (pot) on the SSX or SST front panel until the meter in the

calibration setup reads 1V, ±0.02V.

4. Adjust the INPUT to 5V.

5. Adjust the SPAN pot on the SSX or SST front panel until the meter in the calibration setup

reads 5V, ±0.02V.

User’s Manual

206-792-00G

May 2016

SPAN and ZERO Adjustments - SSX and SST Single Output Channel

Figure 2.1. SPAN and ZERO adjustments - SSX and SST Single Output Channel

www.miinet.com Moore Industries-International, Inc.

- 14 -

Moore industries-International, Inc.

User’s Manual

250ohm

4-20mA = 1-5V

VOLTMETER

+–

CURRENT/

VOLTAGE

CALIBRATOR

+

–

117 or

230Vac

+

–

24Vdc

Power

OR

250ohm

24Vdc

+

–

4-20mA = 1-5V

VOLTMETER

+

–

CURRENT/

VOLTAGE

CALIBRATOR

+

–

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Figure 2.2. Setting up to Calibrate the SSX

SECTION 2

Figure 2.3. Setting up to Calibrate the SST (Single Output Channel)

- 15 -

www.miinet.comMoore Industries-International, Inc.

SPAN

Potentiometer

Adjustments

ZERO

Potentiometer

Adjustments

SSX/SST

Safety Series Isolator and Splitter

Calibration Procedure - SST Splitter (Two Output channels)

Current Input Units

1. Apply the appropriate power to the unit being calibrated.

2. Set the INPUT simulator to 20mA.

3. Adjust the SPAN pot on the SST Splitter front panel until the meter in the calibration setup

reads 5V, ±0.02V (1V, ±0.02V for -RO option units).

SECTION 2

4. Adjust the INPUT to 4mA.

5. Adjust the ZERO potentiometer (pot) on the SST Splitter front panel until the meter in the

calibration setup reads 1V, ±0.02V (5V, ±0.02V for -RO option units).

6. Re-check SPAN at 20mA, adjust if needed; re-check ZERO.

7. Repeat steps 2 to 6 for the second output channel.

Note: SST Splitter SPAN and ZERO adjustments are non‑interactive as long as span is set rst.

Voltage Input Units

1. Apply the appropriate power to the unit being calibrated.

2. Set the INPUT simulator to 5V.

3. Adjust the SPAN pot on the SST Splitter front panel until the meter in the calibration setup

reads 5V, ±0.02V (1V, ±0.02V , for -RO option units).

4. Adjust the INPUT to 1V.

5. Adjust the ZERO potentiometer (pot) on the SST Splitter front panel until the meter in the

calibration setup reads 1V, ±0.02V (5V, ±0.02V for -RO option units).

6. Re-check SPAN at 20mA, adjust if needed; re-check ZERO.

7. Repeat steps 2 to 6 for the second output channel.

User’s Manual

206-792-00G

May 2016

SPAN and ZERO Adjustments - SST Splitter

Figure 2.4. SPAN and ZERO adjustments - SST Splitter

www.miinet.com Moore Industries-International, Inc.

- 16 -

Moore industries-International, Inc.

User’s Manual

-EP Option Wiring

250ohm

VOLTMETER

+–

250ohm

OUTPUT A

OUTPUT A

4-20mA = 1-5V

250ohm

VOLTMETER

+–

OUTPUT B

OUTPUT B

4-20mA = 1-5V

+

–

VOLT

METER

VOLT

METER

DC

SUPPLY

12-42V

+

–

+

–

250ohm

CURRENT/

VOLTAGE

CALIBRATOR

+

–

CURRENT/

VOLTAGE

CALIBRATOR

+

–

117 or 230Vac

+

–

24Vdc

Power

24Vdc

Power

24Vdc

Power

OR

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Figure 2.5. Setting up to Calibrate the SST Splitter (Two Output Channels)

SECTION 2

- 17 -

www.miinet.comMoore Industries-International, Inc.

Use your HART slave device(s) that will be used for your final installation.

HART Communicator Model 275 or equivalent. Device used should be capable

of reading a valid HART signal (and 4-20mA analog signal).

Calibrated, regulated 24Vdc (±10%) source, nominal, for SSX or dc-powered SST;

calibrated, regulated 117Vac or 230Vac (±10%) source, nominal, for ac-powered SST

250 ohm with ±0.01% precision; required only if using a Voltmeter to calibrate the analog

output from the SST/SSX (voltage drop across the precision resistor; 4-20mA=1-5V)

Calibrated to an accuracy of ±0.025%, or better; such as Fluke Model 725, or similar

Standard (blade) head; head width 2.5mm (0.1in), maximum width

Device

Specifications

HART Slave

Device

HART

Communicator

Power Supply

Load Resistor

Multimeter

Screwdriver

All referenced product names are the sole property of their respective manufacturers

.

SSX/SST

Safety Series Isolator and Splitter

Bench Check

If you are using HART devices in conjunction with your SSX or SST we highly recommend that

you perform a bench check of the devices prior to installing them in the eld. Doing this will

ensure that they are operating within your expectations or requirements.

Table 2. Bench Check Equipment for the SSX and SST

SECTION 2

User’s Manual

206-792-00G

May 2016

www.miinet.com Moore Industries-International, Inc.

- 18 -

Moore industries-International, Inc.

User’s Manual

Smart

HART

Transmitter

(Loop-powered)

–

+

4-20mA + HART

24Vdc

Power

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

+–

DCS,

PLC, etc.

*

+

–

DCS,

PLC, etc.

*

+

–

OPTIONAL

HART

COMMUNICATOR

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250 ohms resistor should be added

in the loop.

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Bench Check Procedure

SSX Bench Check

1. Connect your SSX as shown in Figure 2.6.

2. Using your HART Communicator verify that you can read HART data on the Input side of

the SSX.

3. Using your HART Communicator verify that you can read HART data on the Output side of

the SSX.

Note: If your SSX has the -0HART option verify that there is no HART data on the Output side of

the SSX.

4. With your HART Communicator connected to the Output side of the SSX send a HART

command to your HART slave device to verify that the HART signal will pass from the

SSX’s Output side to the SSX’s Input side (except units with the -0HART option).

5. Remove the power supply from the Output side of the SSX and verify that the HART signal

is still active on the Input side.

Figure 2.6. Bench Check setup for the SSX

SECTION 2

- 19 -

www.miinet.comMoore Industries-International, Inc.

Smart

HART

Transmitter

(powered)

+ –

+

+INTX

–

4-20mA + HART

OPTIONAL

HART

COMMUNICATOR

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

117 or 230Vac

+

–

24Vdc

Power

OR

DCS,

PLC, etc.

*

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250 ohms resistor should be added

in the loop.

SSX/SST

Safety Series Isolator and Splitter

SST (Single Output Channel) Bench Check

1. Connect your SST (Single Output Channel) as shown in Figure 2.7, 2.8 or 2.9.

2. Using your HART Communicator verify that you can read HART data on the Input side of

the SST.

3. Using your HART Communicator verify that you can read HART data on the Output side of

the SST.

SECTION 2

Note: If your SST (Single Output Channel) has the -0HART option verify that there is no HART

data on the Output side of the SST.

4. With your HART Communicator connected to the Output side of the SST send a HART

command to your HART slave device to verify that the HART signal will pass from the

SST’s Output side to the SST’s Input side (except units with the -0HART option).

5. Remove the power supply from the SST and verify that the HART signal is still active on

the Input side (except when using the TX terminal to power your HART slave device).

Figure 2.7. Bench Check Setup for SST (when using the SST -TX terminal to power your HART transmitter)

User’s Manual

206-792-00G

May 2016

www.miinet.com Moore Industries-International, Inc.

- 20 -

Moore industries-International, Inc.

User’s Manual

+

Smart

HART

Transmitter

(powered)

+

–

++

––

4-20mA + HART

OPTIONAL

HART

COMMUNICATOR

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

117 or 230Vac

+

–

24Vdc

Power

24Vdc

Power

OR

DCS,

PLC, etc.

*

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250 ohms resistor should be added

in the loop.

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Figure 2.8. Bench Check Setup for SST (HART transmitter powered by PLC)

Smart

HART

Transmitter

(powered)

OPTIONAL

HART

COMMUNICATOR

–

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

+ –

PLC, etc.

DCS,

4-20mA + HART

*

+

DCS,

*

PLC, etc.

–

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250 ohms resistor should be added

in the loop.

–

24Vdc

Power

+

OR

117 or 230Vac

SECTION 2

Figure 2.9. Bench Check Setup for SST (HART transmitter powered by an external power supply)

- 21 -

www.miinet.comMoore Industries-International, Inc.

Smart

HART

Transmitter

(Loop-powered)

+

–

4-20mA + HART

OPTIONAL

TX +IN

HART

COMMUNICATOR

Output A

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

117 or 230Vac

+ –

+

–

OPTIONAL

HART

COMMUNICATOR

+

–

24Vdc

Power

OR

DCS,

PLC, etc.

*

DCS,

PLC, etc.

*

Output B

+ –

DCS,

PLC, etc.

*

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250 ohms resistor should be added

in the loop.

SSX/SST

Safety Series Isolator and Splitter

SST Splitter (Two Output Channel) Bench Check

1. Connect your SST Splitter (Two Output Channels) as shown in Figure 2.10, 2.11 or 2.12.

2. Using your HART Communicator verify that you can read HART data on the Input side of

the SST.

3. Using your HART Communicator verify that you can read HART data on Output A of the

SST.

SECTION 2

Note: If your SST (Two Output Channels) has the -0HART option verify that there is no

HART data on either Output channel of the SST Splitter. Conversely, if your SST (Two Output

Channels) has the -2HART option verify that you can read the HART data on Output A and

Output B).

4. With your HART Communicator connected to the Output side of the SST send a HART

command to your HART slave device to verify that the HART signal will pass from the

SST’s Output side to the SST’s Input side (except units with the -0HART option).

5. Remove the power supply from the SST and verify that the HART signal is still active on

the Input side (except when using the TX terminal to power your HART slave device).

User’s Manual

206-792-00G

May 2016

Figure 2.10. Bench Check Setup for SST Splitter with TX (when using the SST -TX terminal to power your HART

transmitter)

www.miinet.com Moore Industries-International, Inc.

- 22 -

Moore industries-International, Inc.

User’s Manual

+

Smart

HART

Transmitter

(Loop-powered)

+

+

–

4-20mA + HART

OPTIONAL

HART

COMMUNICATOR

OPTIONAL

OPTIONAL

HART

COMMUNICATOR

4-20mA + HART

117 or 230Vac

+ –

+

–

24Vdc

Power

OR

–

24Vdc

Power

OUTPUT A

DCS,

PLC, etc.

*

HART

COMMUNICATOR

+ –

OUTPUT B

DCS,

PLC, etc.

*

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250ohms resistor should be added

in the loop.

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Figure 2.11. Bench Check Setup for SST Splitter (HART transmitter powered by PLC)

Smart

HART

Transmitter

(Loop-powered)

HART

COMMUNICATOR

HART

COMMUNICATOR

4-20mA + HART

OPTIONAL

OPTIONAL

+

–

OPTIONAL

HART

COMMUNICATOR

OUTPUT A

OUTPUT B

+ –

DCS,

PLC, etc.

+ –

DCS,

PLC, etc.

4-20mA + HART

*

*

DCS,

*

PLC, etc.

–

*Each set up can only have

2 HART Masters, one designated

as primary and one as secondary.

For the HART signal to operate,

there needs to be a loop resistance

of 250 to 1100 ohms. If a HART

Master does not have an integral

termination resistor, then a

250ohms resistor should be added

in the loop.

–

24Vdc

Power

+

OR

SECTION 2

117 or 230Vac

Figure 2.12. Bench Check Setup for SST Splitter (HART transmitter powered by an external power supply)

- 23 -

www.miinet.comMoore Industries-International, Inc.

DC

+OUT

-OUT

DCC

GND

TX

-IN

+IN

Top View

Bottom View

SST

DC

TX

+IN

-IN

INPUT

DC(+)

DCC(-)

GND

24VDC

POWER

24VDC

POWER

CASE

OUTPUT

+OUT

-OUT

AC

+OUT

-OUT

ACC

GND

TX

-IN

+IN

B4

T1 T2 T3 T4 T5 T6

B1 B2 B3B4

T1 T2 T3 T4

B1 B2 B3 B5 B6 B4

T1 T2 T3 T4 T5 T6 T1 T2 T3 T4 T5 T6 T7 T8 T1 T2 T3 T4 T5 T6 T7 T8

B1 B2 B3 B5 B6 B4B1 B2 B3 B5 B6 B7 B8 B4B1 B2 B3 B5 B6 B7 B8

Top View

Bottom View

SST

AC

TX

+IN

-IN

INPUT

AC

ACC

GND

VAC

POWER

CASE

OUTPUT

+OUT

-OUT

AC

+OUT A

-OUT A

+OUT B

-OUT B

ACC

GND

TX

-IN

+IN

SST

SPLITTER

AC

Top View

TX

+IN

-IN

INPUT

Bottom View

AC

ACC

GND

VAC

POWER

CASE

OUTPUT

AB

+OUT

-

OUT

OUTPUT

+OUT

-OUT

DC

DCC

GND

SST

SPLITTER

DC

Top View

Bottom View

DC(+)

DCC(-)

GND

CASE

+OUT A

-OUT A

+OUT B

-OUT B

TX

-IN

+IN

TX

+IN

-IN

INPUT

OUTPUT

+OUT

-OUT

OUTPUT

+OUT

-OUT

+IN

-IN

+PS

-PS

SSX

Top View

Bottom View

+IN

-IN

INPUT

OUTPUT

+PS

-

PS

LOOP POWERED

AB

SSX/SST

Safety Series Isolator and Splitter

Section 3 - Installation and Wiring

Instructions in this section and others may require special precautions to ensure the safety of the

personnel performing the operations. Notes, Cautions and Warnings that may cause potential

safety issues are indicated throughout this manual by symbols, please refer to Page 3 of this

manual to view and familiarize yourself with these safety message symbols.

The SSX and SST housings accommodate both 32mm, DIN-style G-rail (EN50035) and 35mm

SECTION 3

Top Hat rail(EN50022). Figure 3.2, Figure 3.3, and Figure 3.4 show the dimensions of the

housing for each type of isolator.

Note: Make sure to calibrate and bench check the instruments prior to installation. Also,

install all instruments in their intended application and on their rail before making any electrical

connections. Allow enough room for pivoting instruments vertically on the rail for removal in

applications involving multiple banks of SSXs and/or SSTs.

Terminal Designations

User’s Manual

206-792-00G

May 2016

Figure 3.1. Terminal Designations

www.miinet.com Moore Industries-International, Inc.

- 24 -

User’s Manual

25mm

(.99in)

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Dimensions

Figure 3.2. Dimensions of Aluminum DIN-Housed SSX Isolator

136mm

REF.

REF.

C

REF.

L

53mm

(2.1 in)

47mm

(1.8 in)

(5.3 in)

REF.

131mm

(5.1 in)

124mm

(4.8 in)

119mm

(4.7 in)

100mm

(3.94 in)

SECTION 3

Figure 3.3. Dimensions of Aluminum DIN-Housed SST Isolator

136mm

REF.

REF.

C

REF.

L

53mm

(2.1 in)

47mm

(1.8 in)

(5.3 in)

REF.

131mm

(5.1 in)

124mm

(4.8 in)

119mm

(4.7 in)

100mm

(3.94 in)

35mm

(1.38in)

- 25 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Figure 3.4. Dimensions of Aluminum DIN-Housed SST Splitter

136mm

REF.

(5.3 in)

REF.

131mm

(5.1 in)

119mm

(4.7 in)

45mm

(1.78in)

User’s Manual

206-792-00G

May 2016

SECTION 3

REF.

REF.

C

L

53mm

(2.1 in)

47mm

(1.8 in)

Figure 3.5. The SST Splitter and the SST and SSX Isolators mounted with the FLB flange bracket and the bracket’s

dimensions.

23mm

(0.9 in)

11mm

(0.4 in)

18mm

(0.7 in)

9mm

(0.4 in)

2 mm

(0.1 in)

124mm

(4.8 in)

100mm

(3.94 in)

143mm

(5.6 in)

121mm

(4.8in)

Ø6mm

(Ø0.3 in)

www.miinet.com Moore Industries-International, Inc.

- 26 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Electrical Connections

When installing any Moore Industries product, always follow all local regulations and standards

for grounding, shielding, and safety.

WARNING: Terminals on this unit may be connected to hazardous voltages. Before making ANY

connections to this unit, always remove power from the loop or instrument power terminals.

Installation Category

All terminals are rated CAT I.

Equipment Ratings

The SSX and SST do not generate hazardous voltages, they provide a low current (4-20mA) or

voltage (1-5V) input and a 4-20mA output. Products connected to the SSX or SST should be

designed to receive this type of input.

WARNING: If this unit is used in a manner not specified by Moore Industries, the protection

provided by the equipment may be impaired.

Switches and Circuit Breakers

For SST AC powered units, a switch or circuit breaker must be wired in series with the AC power

conductors. The switch or circuit breaker used must be located within three meters of the unit.

SECTION 3

The circuit breaker or switch will only remove power to the unit, hazardous voltages may still be

connected to other terminals on the unit.

117Vac, 230Vac, and 24Vdc Supply Wiring

All power connections should be made with 14 or 16 AWG (2mm2 or 1.3mm2) wire.

The end of each conductor should be stripped no more than 0.25in (7mm). The end of the

stripped wire should be tinned with solder, or inserted into a ferrule and crimped before being

placed into a terminal block.

Tighten the screws on the terminal block to 4.4 - 5.3 lbf

•

in (0.5 - 0.6 N•m).

Input/Output Wiring

The Input/Output connections can be made with 14 to 24 AWG (2.5mm2 to 0.2mm2) wire.

The end of each conductor should be stripped no more than 0.25in (7mm).

Tighten the screws on the terminal block to 4.4 - 5.3 lbf•in (0.5 - 0.6 N•m).

Protective Earth Conductor

The Protective Earth Conductor shall be of equal or larger size wire than the other two power

conductors.

The Protective Earth Conductor shall be the first conductor connected to the unit when the unit is

being wired. It shall be the last conductor removed when the unit is being un-wired.

- 27 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Recommended Ground Wiring Practices

Moore Industries recommends the following ground wiring practices:

• Any Moore Industries product in a metal case or housing should be grounded.

• The protective earth conductor must be connected to a system safety earth ground before

making other connections.

• All input signals to, and output signals from, Moore Industries’ products should be wired

SECTION 3

using a shielded, twisted pair wiring technique. Shields should be connected to an earth or

safety ground.

• For the best shielding, the shield should be run all the way from the signal source to the

receiving device. (see Note below)

• The maximum length of un-shielded input and output signal wiring should be 2 inches.

Note: Some of Moore Industries’ instruments can be classified as receivers (IPT2, IPX2, etc.)

and some can be classified as transmitters (TRX, TRY, etc.) while some are both a receiver and

a transmitter (SPA2, HIM, etc). Hence, your shield ground connections should be appropriate for

the type of signal line being shielded. The shield should be grounded at the receiver and not at

the signal source.

User’s Manual

206-792-00G

May 2016

CE Certification-related Guidelines

The grounding and wiring practices described above must be followed in order for the unit(s) to

meet the requirements set forth in EMC standard EN61326.

The Low Voltage Directive also applies to AC powered versions of the SST. In order to comply

with EN61010-1 (Low Voltage Directive) all guidelines in this section must be followed.

www.miinet.com Moore Industries-International, Inc.

- 28 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Installation in Hazardous Locations

This section contains important information regarding installation of the SSX/SST in Hazardous

Area Locations.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C & D or non-hazardous

locations only. Field wiring shall be rated for 85˚C.

WARNING:

Explosion Hazard. Do not disconnect while circuit is live unless area is known to be nonhazardous.

AVERTISSEMENT:

Risque d’explosion. Ne pas débrancher tant que le circuit est sous tension, à moins qu’il ne

s’agisse d’un emplacement non dangereux.

WARNING:

Explosion Hazard. Substitution of components may impair suitability for Class I, Division 2.

AVERTISSEMENT:

Risque d’explosion. La substitution de composants peut rende ce materiel inacceptable pour les

emplacements de Classe I, Division 2.

SECTION 3

Special Conditions of Use

The following instructions must be adhered to when the SSX/SST is used in hazardous locations

and potentially explosive atmospheres.

The SSX/SST shall be installed in compliance with the enclosure, mounting, spacing and

segregation requirements of the ultimate application.

- 29 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Section 4 - Operation and Maintenance

When the SSX or SST are used in a SIL rated safety application, please refer to the Safety

Instrumented Systems section of this manual before operating your unit.

Operation

Once calibrated, installed, and supplied with the correct power, the SSX/SST begins to

SECTION 4

operate immediately. Depending upon environmental conditions, it can be expected to operate

unattended for extended periods of time.

Maintenance

Moore Industries recommends that the calibration of this instrument should be checked every

year and re-calibrated only when necessary. In addition, we suggest a quick check for terminal

tightness and general unit condition. Always adhere to any site requirements for programmed

maintenance.

User’s Manual

206-792-00G

May 2016

www.miinet.com Moore Industries-International, Inc.

- 30 -

User’s Manual

Asset

Management

System

+

+

+

–

–

+

–

–

+

24V

+

IN

4-20mA + HART

4-20mA + HART

LOOP

POWERED

SSX

HART Valve Positioner

4-20mA

Logic Solver

(e.g. Safety System

or DCS)

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Section 5 - Applications

This section provides some examples of typical applications for the SSX and SST.

Isolate and Pass Critical HART Data

When HART data is required for diagnostics, maintenance or calibration the SSX is able to isolate

and pass HART data from the transmitter to the host system (See Figure 5.1).

Figure 5.1. The SSX passes HART data to asset management systems or other host control and monitoring systems.

SECTION 5

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250 ohms resistor should

be added in the loop.

- 31 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Isolate and Power a 2-Wire Transmitter

In addition to isolation, the SST can also provide 24V power to a 2-wire, output-loop powered

instrument. This eliminates the need for an additional power supply (See Figure 5.2).

Figure 5.2. The standard -TX Transmitter Excitation of the SST allows it to supply loop power to a 2-wire transmitter.

User’s Manual

206-792-00G

May 2016

SECTION 5

DCS or

Asset

Management

System

TX = 24V

+ +OUT

ISOLATED

4-20mA

–

–OUT

NON-ISOLATED

+IN

TX

4-20mA

NON-ISOLATED

2-WIRE

XMITTER

+

–

–

24Vdc

Power

+

OR

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250 ohms resistor should

be added in the loop.

www.miinet.com Moore Industries-International, Inc.

117 or 230Vac

- 32 -

User’s Manual

24V

IN

Logic Solver

(e.g. Safety System

or DCS)

Safety Instrumented

Function

Non-Safety Function

24V

IN

DCS or

Asset

Management

System

2-Wire HART Transmitter

+PS

-PS12

34

TDZ

ADDR

0

602.78

DEG C

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Isolation of Safety Systems

Use the SSX to isolate your SIF (Safety Instrumented Function) from your basic process control

system. While power for the SSX is derived from the output side of the loop, disconnection

or loss of power will not affect the input loop’s signal integrity. This allows maintenance to be

performed on the non-critical side of the loop (See Figure 5.3).

The SSX has a negligible impact on the SIF since only the input circuit failures need to be

considered. Dangerous failures for the SSX in this application are <5FITS (See FMEDA report for

specific failure rates of all models and configurations).

Figure 5.3. The SSX provides area isolation for your safety system and still allows maintenance on the output side of the

loop.

SECTION 5

Caution: Sensor for the Safety System shall not be the same sensor for controlling the non

safety process. Thus the DCS or Asset Management System can only be used for monitoring the

Safety System Sensor.

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250 ohms resistor should

be added in the loop.

- 33 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

“Sharing” or “Splitting” Process Signals

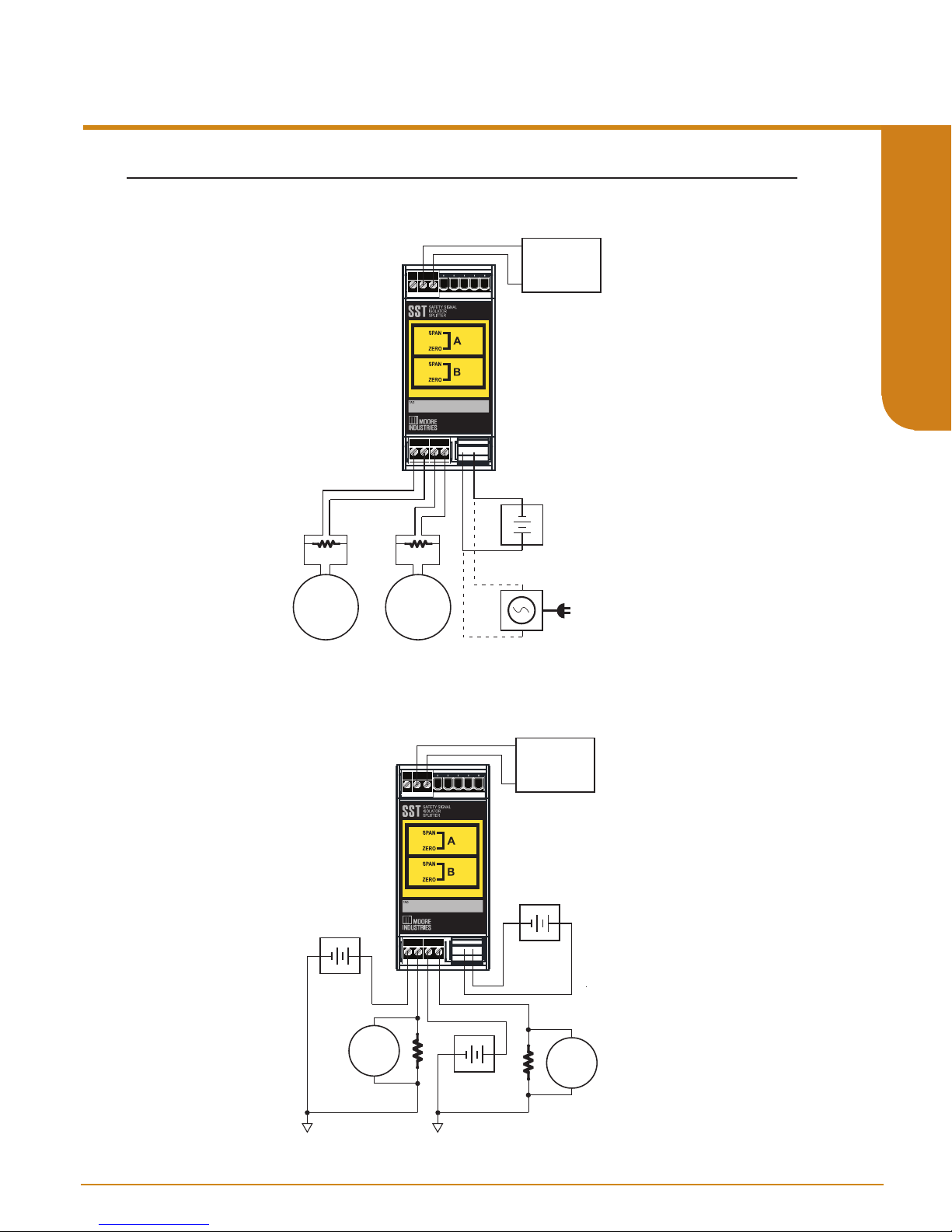

When isolation is also required in the safety loop, an SST splitter can be used. The SST Splitter

takes one input and creates two identical, completely isolated outputs to two separate monitoring

or control devices. Additionally, the SST functions as a HART splitter that passes valuable

HART data to one or both of the SST’s independent outputs. This is especially important when

asset management systems need to maintain a digital HART connection with critical valves or

instruments for diagnostic monitoring or calibration record keeping. This also makes it very

SECTION 5

convenient when using HART handhelds, modems or programming devices to configure remote

field transmitters from control rooms (See Figure 5.4).

In this example HART is blocked in the SIF on output B (default). If HART pass-through is

required on both outputs, the -2HART option needs to be ordered.

Figure 5.4. The SST Splitter takes one process signal and delivers two completely isolated signal outputs. HART data

can be passed to one or both outputs.

2-Wire DP

Transmitter

User’s Manual

206-792-00G

May 2016

–

4-20mA w/ HART

Safety Instrumented

Function

Non-Safety Function

x655 xigoLx655 xigoL

PLC

POWER

+

4-20mA w/ HART

–

+

A +OUT

ISOLATED

TX

A –OUT

+IN

B – OUT

B +OUT

–

24Vdc

Power

+

OR

–

+

Logic Solver

(e.g. Safety System

or DCS)

117 or 230Vac

Caution: Sensor for the Safety System shall not be the same sensor for controlling the non

safety process. Thus the DCS or Asset Management System can only be used for monitoring the

Safety System Sensor.

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250 ohms resistor should

be added in the loop.

www.miinet.com Moore Industries-International, Inc.

- 34 -

User’s Manual

+24V +PS -PS

+

24V

+IN –IN

–

+

4-20mA w/ HART

–

ISOLATED

4-20mA

SIS or PLC

4-Wire HART Transmitter

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Solve “Bucking” Power Supplies and Filter HART

When two devices (such as a 4-wire HART transmitter and a DCS) are trying to source power

to the same loop, the result is a non-functioning loop. When neither of the devices can be

eliminated, the solution is an SSX. It can operate with powered inputs from both sides, thus

restoring normal operations to the loop while also passing any HART signals. Sometimes older

DCS and PLC input cards have trouble with HART signals. When this problem arises you can

order the SSX with option code -0HART and the SSX will filter the HART signal (See Figure 5.5).

Figure 5.5. The SSX solves bucking power supplies. Also, when used with the -0HART option, the SSX acts as a current

isolator that stops a HART signal from reaching a PLC, DCS or other receiving device.

SECTION 5

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250 ohms resistor should

be added in the loop.

- 35 -

www.miinet.comMoore Industries-International, Inc.

SIS LOGIC

SOLVER

+

–

4-20mA + HART

4-20mA + HART

4-Wire HART Transmitter

HART

COMMUNICATOR

117 or 230Vac

+

–

24Vdc

Power

OR

+

–

-IN+IN

+

24V

SSX/SST

Safety Series Isolator and Splitter

Solving 4-Wire Transmitter Problems

Figure 5.6 shows how to use the 4-Wire SST to provide the same kind of power supply isolation

in applications that call for the use of 4-wire transmitters.

Figure 5.6. Connecting the SST to provide power supply isolation for 4-wire transmitters

SECTION 5

User’s Manual

206-792-00G

May 2016

Note: For the HART signal to operate, there needs to be a loop resistance of 250 to 1100 ohms.

If a HART Master does not have an integral termination resistor, then a 250ohms resistor should

be added in the loop.

www.miinet.com Moore Industries-International, Inc.

- 36 -

User’s Manual

SIS LOGIC

SOLVER

+24

–

+ PS

– PS

+24 –

110 or 220Vac

+

–

24Vdc

Power

OR

HART

COMMUNICATOR

2-Wire HART Transmitter

+PS

-PS 1 2

3 4

TDZ

ADDR

0

602.78

DE G C

DCS or

Asset

Management

System

TX +IN

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Duplicate Signal to Two Legacy Systems

When there are two systems which need to read the same analog signal from an instrument,

the SST Splitter can be used. Sometimes older systems want to source power to the instrument

and also have trouble with HART signals. In this case, the SST splitter can be used with -EP and

-0HART options. The SST can power a HART instrument using TX power, reads the input and

provides duplicate 4-20mA signals on each of its outputs. Each output sinks power and filters out

the HART signal.(See Figure 5.7).

Figure 5.7. Connecting the SST Splitter with -EP and -0HART options

SECTION 5

- 37 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Section 6 - SSX/SST in Safety Instrumented

Systems

The SSX/SST is designed for use as an element of a safety instrumented system as dened by

IEC61508-4 para 3.4.1 as a Type A device.

This user manual contains all of the information needed to congure, install, operate and

SECTION 6

maintain this product. For safety applications the SSX/SST must only be used in accordance

with this information and the restrictions and limitations as detailed below.

Functional Safety Description

The SSX/SST has been certified, by exida ® to IEC61508:2010 for systemic integrity up to SIL 3

and random integrity up to SIL2 in a low demand application. This means that the SST and SSX

are approved for single use in Safety Instrumented Systems (SIS) up to SIL2 for Hardware Fault

Tolerance (HFT) of zero (0).

Note: When used in monitor mode, where only the input circuit is part of the safety function (see

Figure 5.3), the SST and SSX may be used in SIS up to SIL3.

User’s Manual

206-792-00G

May 2016

Failure Rate Data

The SSX/SST FMEDA report (Moore Industries’ Document No: 700-702-36) provides the failure

data (including PFD and SFF) required for calculations to use the SSX/SST as part of a Safety

Instrumented System.

Product life

The product life of the SSX/SST is 50 years (based on worst case component life data).

However, IEC 61508-2, section 7.4 states that a useful lifetime based on experience has more

weight than the calculated figures; Note 3 in the section comments that the useful lifetime of a

transmitter is most often within 8 to 12 years.

Installation

No special installation is required in addition to the standard installation practices in this user

manual. Refer to the specifications table of this user manual for ambient conditions and required

power input.

Configuration

The SSX/SST is a passive device that requires no user conguration. For SIL1 and SIL2

applications, it can be connected directly to the safety system to monitor the loop. The input

circuit design is such that its failure will not compromise the safety function of the system.

The following considerations and restrictions will apply when using the SSX/SST in a safety

application:

For non-safety systems, the accuracy of the SSX/SST is 0.1% of span. For safety

systems, up to 3% of span is considered safe.

www.miinet.com Moore Industries-International, Inc.

- 38 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Process Safety Time

Process safety time is the minimum time from the initiation of a hazardous event to the point

where the hazardous event is unavoidable. Any safety function designed to either prevent the

event or at least mitigate its effect must be capable of performing its specied safety function in a

time period very much less than the process safety time.

The SSX/SST has a characteristic response time (end to end) of <100mSec.

Input Types

The SSX/SST can be ordered to accept 4-20mA or 1-5V. It is the end user’s responsibility to

ensure that the chosen device connected to the SSX/SST’s input is compatible.

Broken Wire Detection

When the input to an SSX (2 Wire) is broken, the output is driven to <3mA. When the input to an

SST (4 Wire) is broken, the output will be driven to <1mA.

Proof Test Procedure

It is normal practice with SIS that the components undergo periodic proof tests to expose

dangerous faults that are not detected by internal diagnostic tests. Thus, this section species

how the dangerous undetected faults determined during the FMEDA can be detected during

proof testing.

SECTION 6

Calculation of the required proof test interval can be made using data in the FMEDA report

(Moore Industries’ Document No: 700-702-36).

A proof test interval of 3 years is recommended for a single SSX/SST used in a typical SIL 2

low demand application (15% of the SIL band being allocated to the SSX/SST). The proof tests

described in Table 2 are designed to cover all possible dangerous undetected faults that can be

detected without opening the unit. Proof Test coverage: SSX 71%, SST 88%, and SST Splitter

84%.

Periodically testing the SSX/SST, using the proof test steps outlined below, the cumulated

PFDAVG value can be reduced to a smaller but non-zero value. To completely test for

all possible dangerous undetected faults, the unit must be sent back to the factory for a

comprehensive proof test inspection.

Repair and Replacement

The SSX/SST is not intended to be repaired on site and has no components needing

maintenance or regular replacement. On device failure, the SSX/SST should be returned to

Moore Industries World Headquarters in North Hills, CA U.S.A for repair and refurbishment (refer

to Returns Procedures at the end of this manual).

WARNING: The SSX/SST is a certied Safety component. Repair or replacement of any

component without authorization from Moore Industries will invalidate any remaining warranty

and the IEC61508 certication.

- 39 -

www.miinet.comMoore Industries-International, Inc.

User’s Manual

206-792-00*

0D\

Step Action

1. Bypass the safety DCS/PLC or take other appropriate action to avoid a false trip.

2. Remove power source, then disconnect all wires from the SSX. Using an ohmmeter,

measure the resistance between the case and all exposed pins on the front. Verify that

the measured resistance is greater than 1 MΩ. This tests for shorts between the power

or ground to the case

3. Connect SSX input in series to DCS/PLC to Transmitter loop. Be sure to observe polarity.

4. Connect SSX output in series with 250Ω resistor and 24Vdc power supply. Be sure to

observe polarity.

5. Connect DVM across 250Ω Resistor.

6. Perform 5 point linearity test on input to output with input range of 4-20mA (or 1-5V for

Voltage input conguration). Verify that accuracy is within +/-0.5% of span at each step.

7. Increase input current to 35mA. Verify that output remains under 30mA.

8. Open Input and verify that output drop below 3mA.

9. Disconnect SSX from Test equipment and restore Safety System connections to state

prior to testing.

SSX/SST

Safety Series Isolator and Splitter

Table 2. SSX/SST proof test steps

SSX (2-Wire)

Step Action

1. Bypass the safety DCS/PLC or take other appropriate action to avoid a false trip.

2. Remove power source, then disconnect all wires from the SSX. Using an ohmmeter,

measure the resistance between the case and all exposed pins on the front. Verify that

SECTION 6

the measured resistance is greater than 1 MΩ. This tests for shorts between the power

or ground to the case

3. Connect SSX input in series to DCS/PLC to Transmitter loop. Be sure to observe polarity.

4. Connect SSX output in series with 250Ω resistor and 24Vdc power supply. Be sure to

observe polarity.

5. Connect DVM across 250Ω Resistor.

6. Perform 5 point linearity test on input to output with input range of 4-20mA (or 1-5V for

Voltage input conguration). Verify that accuracy is within +/-0.5% of span at each step.

7. Increase input current to 35mA. Verify that output remains under 30mA.

8. Open Input and verify that output drop below 3mA.

9. Disconnect SSX from Test equipment and restore Safety System connections to state

prior to testing.

SST (4-Wire)

Step Action

1. Bypass the safety DCS/PLC/Transmitter or take other appropriate action to avoid a false trip.

2. Remove power source, disconnect all wires from the SST. Using an ohmmeter, measure the

resistance between the case and all exposed pins on the front. Verify that the measured

resistance is greater than 1 MΩ with the exception of the CASE GND pin which should have

0Ω resistance. This tests for shorts between the power or ground to the case and veries

that ground is connected to case.

3. Connect SST input in to loop powered Transmitter using SST TX and +IN. Be sure to

observe polarity.

4. Connect SST output in series with 250Ω resistor and 24Vdc power supply.

5. Connect DVM across 250Ω Resistor.

6. Perform 5 point linearity test on input to output with input range of 4-20mA (or 1-5V for

Voltage input conguration). Verify that accuracy is within +/-0.5% of span at each step.

7. Increase input current to 35mA. Verify that output remains under 30mA.

8. Open Input and verify that output drop below 1mA.

9. Disconnect SSX from Test equipment and restore Safety System connections to state prior

to testing.

www.miinet.com Moore Industries-International, Inc.

- 40 -

User’s Manual

206-792-00G

May 2016

SSX/SST

Safety Series Isolator and Splitter

Section 7 - Specications

Performance

Accuracy: ±0.1% of span;

Functional Safety Accuracy

Stability: ±0.2% of reading per

year

Isolation: Continuous:

SSX: 500Vrms between Input,

Output and Case; SST: 500Vrms

Between Input, Output, Case and

Powe r

Tested To: SSX: 1500Vrms

between Input, Output and Case

for 1 minute; SST: 1500Vrms

between Input, Output, Case

and DC Power for 1 minute

(2300Vrms from AC Power to

Input, Output and Case for 1

minute)

Response Time (analog

output): 100msec max. to 99%

of output

Input Resistance: 100 ohms

standard; 250 ohms with -IZ250

option

Input Overrange Protection:

250% of full scale

Ripple: <10mV when measured

across 250 ohm resistor

Burden: 1V maximum for

current; 1 Mohm minimum for

voltage.

Load Effect:

0.01% of span from 0-100%

of rated output (current only)

Power Supply: SST: 24DC

±10%; 117AC 50/60HZ, ±10%;

230AC 50/60HZ, ±10%; SSX:

12-42DC

Power Consumption:

SST: Single channel: 3 watts

max.; Dual output channel: 5

watts max.

Performance

(contnued)

Ambient

Conditions

Adjustments

Weight

Power Supply Rejection:

Exceeds 90db for current

input units

Load Capability:

SSX:

Vs – 12Vdc

20mA

SST: 1000 ohms

SST-Splitter: 600 ohms per

channel

Output Current Limiting: 25mA

typical; 30mA max.

Voltage Limit (for -EP only):

30Vdc max

Temperature Range:

Operating: -40°C to +85°C (-40°F

to +185°F); Storage: -40°C to

+85°C (-40°F to +185°F)

Temperature Effect: ±0.007%

of span/°C typical; ±0.015% of

span/°C max

Relative Humidity: 5-95%

non-condensing

RFI/EMI Protection: Less than

+/- 0.1% of span error when

tested at 20V/m @ 20-1000MHz

Common Mode Rejection:

Exceeds 95dB at 60Hz with a

limit of 1500Vrms

Type: Front panel pots

Span: ±2%

Zero: ±2%

SST:

DC: 12oz (340g)

AC: 17oz (482g)

SSX Splitter:

DC: 15oz (425g)

AC: 20oz (567g)

SSX Splitter:

8oz (227g)

SECTION 7

- 41 -

www.miinet.comMoore Industries-International, Inc.

SSX/SST

Safety Series Isolator and Splitter

Section 8- Ordering Information

The SSX/SST ordering information is detailed below.

User’s Manual

206-792-00G

May 2016

Unit

SST

4-wire,

Line-

SECTION 8

(Mains)

Powered,

Safety

Isolator and

Splitter

SSX

2-wire,

LoopPowered,

Safety

Isolator

Input Output

4-20MA

4-20MA into

100 ohms

with HART

digital data

superimposed

1-5V* into

1 Mohm

4-20MA

4-20MA into

100 ohms

with HART

digital data

superimposed

1-5V* into

1 Mohm

4-20MA

Isolated,

4-20MA into

1000 ohms (with

24Vdc, 117Vac,

or 230Vac power);

HART digital data

superimposed

2X4-20MA

into 600 ohms per

channel (available

with 4-20MA input

only); HART digital

data superimposed

on Channel A only

4-20MA

Isolated,

4-20MA into

600 ohms (with

24Vdc, power);

HART digital data

superimposed

Power Options

24DC ±10%

117AC 50/60HZ,

±10%

230AC 50/60HZ,

±10% 3 watts

maximum for single

channel models;

5 watts maximum

for dual output

channel models

12-42DC

-IZ250** Increases

the input resistance

to 250 ohms

-EP*** External

power, output stage

powered by external

source (both Outputs)

-0HART

No HART signal

pass-through

-2HART***

HART signal

pass-through on both

channels

-RO*** Reverse

Output (both

channels)

-IZ250** Increases

the input resistance

to 250 ohms

-0HART

No HART

signal pass-through

Housing

DIN Universal DIN-style housing

mounts on 32mm G-type rail

(EN50035) or on 35mm Top

Hat rail (EN50022)

FLB Flange bracket with

top/bottom mounting holes

When ordering, specify: Unit / Input / Output / Power / -Option [Housing]

Model number examples:

SSX / 4-20MA / 4-20MA / 12-42DC / -IZ250 [DIN]

*HART Pass Through not available for 1-5V Input models

**-IZ250 only available for 4-20mA Input models

***-EP, -RO and -2HART only available for 2X4-20mA Output models

SST / 4-20MA / 2X4-20MA / 24DC / -EP [DIN]

Accessories

Part Number

700-702-35

FMEDA Report consistent with IEC 61508-2:2010 providing the information necessary to design a Safety Instrumented

System (One copy provided free with each order Upon Request)

www.miinet.com Moore Industries-International, Inc.

- 42 -

Warranty Disclaimer

United States • info@miinet.com

Tel: (818) 894-7111 • FAX: (818) 891-2816

Australia • sales@mooreind.com.au

Tel: (02) 8536-7200 • FAX: (02) 9525-7296

Belgium • info@mooreind.be

Tel: 03/448.10.18 • FAX: 03/440.17.97

The Netherlands • sales@mooreind.nl

Tel: (0)344-617971 • FAX: (0)344-615920

China • sales@mooreind.sh.cn

Tel: 86-21-62491499 • FAX: 86-21-62490635

United Kingdom • sales@mooreind.com