IPT-DIN

Current-to-Pressure Transmitter

January 2005

Description

The IPT-DIN Current-to-Pressure Transmitter accepts

a 4-20mA input signal and is capable of supplying a 315psig (or 15-3psig) pneumatic output signal, as well

as a number of other pneumatic signals typically used

in I/P-type process control applications. Available in a

compact, aluminum housing that is only 40mm wide,

the IPT unit can be conveniently snapped onto any

standard mounting rail or a Moore Industries pneumatic header rack for use in high-density control room

and factory installations. This versatile transmitter will

interface with just about any kind of process control

instrumentation including chart recorders, data

loggers, panel meters, multiplexers, controllers and

computers.

The IPT offers infinite resolution, output volume

up to 1.4SCFM, and air consumption as low as

0.1SCFM. Intrinsically safe units are available as an

option, and the transmitter itself can be enclosed in a

water-proof box. A front panel LED that varies in

intensity with the level of the pneumatic signal indicates input current, and complete RFI protection is

provided as a standard feature. To save time during

calibration and maintenance procedures, operation of

the IPT can be monitored using an optional pneumatic

test jack located on either the front or rear panel of the

unit. Within certain limitations, the customer may

select the location of the test jack, as well as the

locations of electrical input and pneumatic output

connections, by specifying the appropriate access

designation listed in Table 1.

Data Sheet 5.10

The IPT-DIN pneumatic mounting block (left) allows the

unit to be easily snapped onto a DIN rail for high density

installation

Features

• Plug-in connections. Mounting block and optional

removable terminal block (-RTB) allow unit to be

taken out of service without use of tools.

• Vibration resistant. High-technology sensor is

insensitive to shock and vibration; unit may be

installed in any position.

• Self-sealing connection. Mounting block and

supply headers contain self-sealing valves which

offer quick release and no air loss.

• Accessory air filters available. Moore Industries

offers a series of air filters designed to protect the

IPT transmitter from plugging or corrosion.

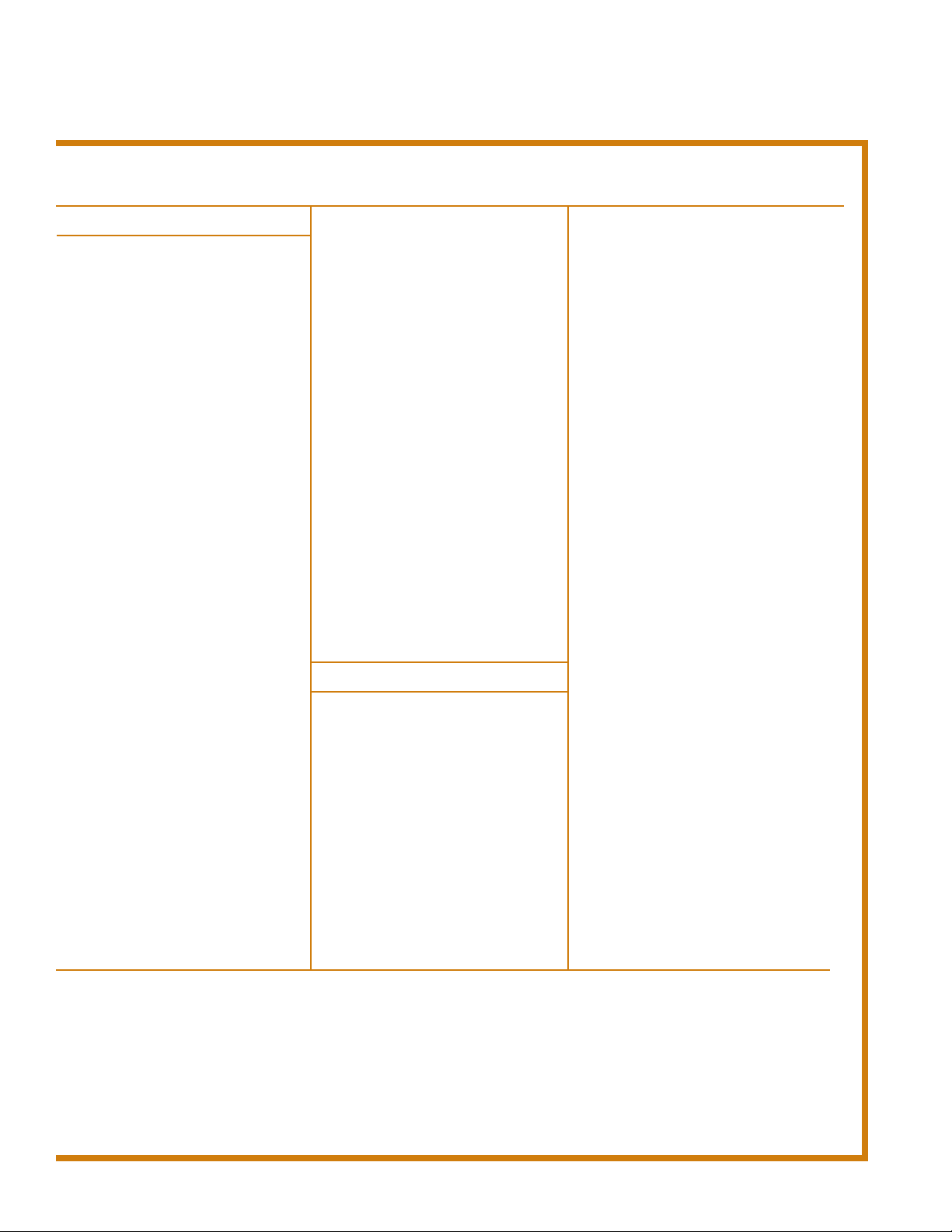

A typical IPT-DIN application

CONTROL

R

A

D

I

A

T

O

R

©2005 Moore Industries-International, Inc.

170-710-01M

VALVE

ENGINE

20psi

3-15psig

RTD

RESISTANCE BULB

TRANSMITTER

I/P

RBX

4-20mA

4-20mA

PLC

Certifications

Canadian Standards Association (CSA)

General (Ordinary) Location –

ATEX Approvals by:

TUV – Intrinsically Safe:

EEx ia IIC, T6

Standards Association of Australia (SAA)

Intrinsically Safe – Exia IIC; T6

Type N – Exn IIC; T6; IP65

CE Conformant – EMC Directive 89/336/EEC,

EN 61326; Low Voltage Directive 73/23/EEC,

EN 61010

NRTL/C

Page 1

IPT-DIN

Current-to-Pressure Transmitter

Specifications

Charcateristics

Front Panel

Adjustments

Performance

When ordering, specify: Unit Type / Input / Output / Supply Pressure / -Access Designation -Option [Housing]

Model number example: IPT / 4-20MA / 3-15PSIG / 20PSI / -FA1 -RTB [DIN]

Output Zero: Adjusts zero

to ±3% of span

Output Span: Fully

adjustable to 100%.

+T, –T: Electrical test

jacks for calibration;

accept 2mm (.080 in) dia.

x 12.7mm (.50 in) long

phone tip plugs (handles

should be less than 8mm

(.32 in) in diameter)

Accuracy: Less than 0.5%

of span including the

combined effects of

linearity, hysteresis and

repeatability–defined as

independent linearity per

SAMA standard PMC

20.1-1973. (For 3-27psig

or 10-50mA, error not to

exceed 1% of span).

Step Response: 0.3

seconds into 100 ml. (6 cu.

in) at 90% of span

Supply Pressure Effect:

Maximum 0.3% / 1.4psig

(0.3% / 0.1bar)

Mounting Position

Effect: Negligible–unit can

be mounted in any

position, but should be

calibrated in final orientation

Shock and Vibration

Effect: Less than 0.5% for

acceleration up to 10g's

and frequency up to 80Hz

RFI Effect: Negligible

Ambient Temperature

Effect: Less than 0.1%/°C

(0.055%°F)

Ambient Temperature

Range: -40°C to +85°C

(-40°F to +185°F).

LED: When lit (red),

indicates presence of

electrical input signal

Performance

(Continued)

Connections

Weight

Air Capacity: 1.6SCFM,

minimum

Air Supply: Instrument air

only, filtered and regulated. 20psig nominal;

30psig without damage.

For 3-27psig output,

35psig supply only

Air Consumption:

Deadended 0.08SCFM

(0.2 kg/hr.)

Input Connections:

Screw clamp type, front or

rear mounted, 22-14 AWG

Output Connections: 1/8

inch NPT female, bottom

or rear location on units

supplied with optional

pneumatic mounting block

Supply connection: 1/8

inch NPT female, bottom

or rear location on units

with optional pneumatic

mounting block

20 ounces (.57 kg.)

Ordering Specifications

Unit

IPT-DIN

Input

4-20MA 4-20mA into

280 ohms (into 200 ohms

for Intrinsically Safe

versions)

Output

.2-1 BAR .2-1bar

3-15PSIG 3-15psig

3-27PSIG 3-27psig

15-3PSIG 15-3psig,

reverse-acting

20-100KPA 20-100kPa

Supply

Pressure

Access

Designations

Options

Housings

20PSI 20psi

35PSI 35psi for 3-27psig

140KPA 140kPa

Refer to Table 1

-FMEDA Unit comes with

Failure Modes, Effects

and Diagnostic Analysis

(FMEDA) data for

evaluating the instrument

for suitability of use in a

safety-related application

-ISE TUV approved

intrinsically safe when

used with an approved

barrier.

-ISA SAA approved

intrinsically safe when

used with an approved

barrier; Australia, requires

-FA3 access designation

-RTB Removable terminal

block connector (not

available with XIP)

DIN Aluminum case with

rail-mount housing. Must

use either a pneumatic

mounting block or air

supply header (RIR) or

(SIR).

NOTE: For NEMA 4X

(water-tight, dust-tight

and corrosion-resistant)

protection with CSA, FM,

see IPF Current-toPressure Transmitter

data sheet.

NOTES:

1. When ordering IPTs, specify access designation -FA7 or -FA8

for use with SIR, Surface Mounted Rack; specify -RA7, -RA8 or

-RA9 for use with RIR Rack Mounted Rack.

2. Pneumatic mounting blocks are 35.31mm (1.390 in) wide. Use

of a 4.32mm (.170 in) wide gage between them when installing

on a rail provides uniform spacing in a minimum rail length.

Page 2

3. Specify length when ordering mounting rail (see Figure 2).

4. For specifications of accessory air filters, refer to appropriate

data sheet.

Specifications and information subject to change without notice. Printed in U.S.A.

IPT-DIN

Current-to-Pressure Transmitter

Figure 1. IPT-DIN Outline and Installation Dimensions

Front Access

Pneumatic

Test Jack Option

Red LED "ON"

When Input

Current is Present

Electrical Test Jack

(Calib.) For

2.03mm (0.8 in) Dia.

Phone Tip Plug

9.7mm

(.38 in)

39.4mm

(1.55 in)

CURRENT/PRESSURE

IPT

TRANSMITTER

ZERO

SPAN

INPUT

+T -T

20mm

(.78 in)

FRONT VIEW

+I -I

Front Access

Electrical

Connections

(-FA Series)

ZERO ADJ.

SPAN ADJ.

4.8mm

(.189 in)

SIDE VIEW

Figure 2. Mounting Rail Dimensions

(G-rail EN 50035-G32) P/N 800-124-24

15mm

(.59 in)

10.16mm

(.40 in)

10.7mm

(.42 in)

99.06mm

(3.90 in)

124.46mm

(4.90 in)

Bottom Access

Location for

Pneumatic Input,

1/8 NPT

32mm

(1.26 in)

16.5mm

(.65 in)

11.5mm

(.45 in)

9.4mm

(.37 in)

MTG. RAIL

REF.

(3.35 in)

(.32 in)

Pneumatic Input,

85.1mm

8mm

Rear Access

Location for

1/8 NPT

6mm

(.24 in)

Rear Access

Input Connections

(-RA Series)

Pneumatic Supply

Coupler may be

Removed to Clear

Filter by Sliding

Clip Sideways

REAR VIEW

Rear Access

Pneumatic Output

Test Jack Option

Table 1. Access Designations

Electrical Input Pneumatic Output Pneumatic Test Access

Location Supply Location* Jack Location Designation

Front Bottom None -FA1

Front Rear None -FA2

Front Bottom Front -FA3

Front Rear Front -FA4

Front (no mtg. block) None -FA7

Front (no mtg. block) Front -FA8

Rear Rear None -RA1

Rear Bottom None -RA2

Rear Rear Front -RA3

Rear Bottom Front -RA4

Rear Rear Rear -RA5

Rear Bottom Rear -RA6

Rear (no mtg. block) None -RA7

Rear (no mtg. block) Front -RA8

Rear (no mtg. block) Rear -RA9

* Applicable only on units with mounting blocks

C

Screws may Project

L

6.35mm (.25 in)

Without Interference

Page 3

IPT-DIN

Current-to-Pressure Transmitter

Figure 3. Optional Header Racks

RIR,10-Position 19-Inch

Rack Mounted Rack

SIR, 5-,10-, or 15-Position Surface Mounted Rack

(Shown with 15-Position Rack)

NOTE:

1. For rack- or surface-mounting, the IPT can be ordered

with Moore Industries Rack-Mounted Header (RIR) pr

Surface-Mounted Header (SIR). Both the RIR and SIR

racks eliminate the need for an interlocking mounting

block and rail. Each header unit supplies air to the IPT

using only one air supply pipe.

Figure 4. Pneumatic Test Coupler

P/N 163-202-00

6.35mm (.25 in)

Lock

Compression Fitting

NOTE:

1. The pneumatic test coupler is used to monitor output

pressure during calibration on units with an optional

pneumatic test jack.

Dia. Plastic Tubing

(Not Supplied)

Figure 5. Removable Terminal Block (-RTB) Option

Screws

Input Wires

Removable

Portion

(Plug)

NOTES:

1. The -RTB option adds a 2-piece wire connector to the

IPT. This allows the input wiring to be unplugged

without the use of tools and maintains polarity.

2. The plug has screw-clamp connections and accepts

22-14 AWG wire.

23mm

(.90 in)

Fixed

Portion

IPT

Page 4

Loading...

Loading...