TSM24P

Integrated Step-Servo Motor

User Manual

Rev. 1.0

AMP & MOONS’ Automation

TSM24P User Manual

Contents

1 Introduction .................................................................................. 5

1.1 Features ............................................................................................. 5

1.2 Block Diagram

1.3 Safety Instructions

...................................................................................6

.............................................................................7

2 Getting Started ............................................................................ 8

2.1 Installing Software .............................................................................8

2.2 Mounting the Hardware

2.3 Choosing a Power Supply

2.3.1 Voltage ..................................................................................................9

2.3.2 Regeneration Clamp ..............................................................................9

2.3.3 Current .................................................................................................10

.....................................................................8

.................................................................9

3 Installation/Connections ............................................................ 12

3.1 Connecting the Power Supply .........................................................12

3.2 Connecting the TSM24P Communications

3.2.1 Connecting to the PC using RS-232 ....................................................13

3.3 Inputs and Outputs ..........................................................................14

3.3.1 Connector Pin Diagram ........................................................................14

3.3.2 X1/STEP and X2/DIR High Speed Digital Inputs .................................16

...................................... 13

3.3.3 X3/EN and X4/AR Digital Inputs ...........................................................17

3.3.4 Programmable Outputs ........................................................................18

4 Drive Conguration .................................................................... 19

4.1 Quick Tuner Toolbar .........................................................................19

4.1.1 Open, Save and Print ...........................................................................19

4.1.2 Restore .................................................................................................20

4.1.3 Alarm History ........................................................................................20

4.1.4 LED Flashing ........................................................................................20

4.1.5 Drive & Revision ...................................................................................20

4.1.6 Communication ....................................................................................21

4.1.7 Servo On/Off ........................................................................................21

4.1.8 Alarms ..................................................................................................21

4.1.9 Upload & Download ..............................................................................21

4.2 Basic Conguration ..........................................................................22

4.2.1 Maximum Currents ...............................................................................22

4.2.2 Digital Input Filter .................................................................................22

Rev. 1.0

0012072012

4.2.3 Electronic Gearing ................................................................................22

4.2.4 Positioning Error Fault .........................................................................22

2

+86-400-820-9661

TSM24P User Manual

4.2.5 Maximum Speed ..................................................................................23

4.2.6 Maximum Acceleration ........................................................................23

4.3 Position Mode ..................................................................................24

4.3.1 Basic Conguration .............................................................................24

4.3.2 Position Control - Digital .......................................................................25

4.3.3 I/O Denition - Digital ...........................................................................26

5 Tuning - Sampling ...................................................................... 27

5.1 Velocity Control Loop (V Loop) ........................................................ 27

5.1.1 Gain: The Velocity Proportional Term (VP) ...........................................28

5.1.2 IntegGain: The Velocity Integral Term (VI) ............................................28

5.1.3 FF Gain: Acceleration Feed-forward Term (KK) ...................................28

5.1.4 PID Filter: Torque Command Filter Term (KC) ......................................28

5.2 Position Control Loop ......................................................................29

5.2.1 Gain: The Position Proportional Term (KP) ..........................................29

5.2.2 The Position Integral Term (KI) - Not Implemented ..............................29

5.2.3 Deri Gain: The Derivative Term (KD) ....................................................29

5.2.4 Deri Filter: Torque Command Filter Term (KE) .....................................30

5.3 Notch lter ........................................................................................ 30

5.3.1 Frequency: Notch Filter Center Frequency ..........................................30

5.3.2 BandWidth: Notch Filter Frequency Bandwidth ....................................30

5.4 Getting Ready for Tuning ................................................................. 31

5.5 Tuning the Velocity Loop

5.5.1 Entering a Sample Move ......................................................................32

5.5.2 Performing a Move ...............................................................................32

5.5.3 Adjusting tuning parameters ................................................................. 33

5.5.4 Adding in the FF Gain (KK) parameter .................................................35

5.5.5 Filter parameter ....................................................................................35

5.5.6 Verify the Drive Current ........................................................................36

5.5.7 Finishing up

..........................................................................................36

..................................................................32

5.6 Tuning the Position loop ..................................................................36

5.6.1 Entering a Sample Move ......................................................................36

5.6.2 Performing a Move ...............................................................................37

5.6.3 Adjusting the Gain (KP) and Deri Gain (KD) parameters .....................37

5.6.4 The Deri Filter (KE) parameter .............................................................37

5.6.5 Filter parameter (again) ........................................................................37

5.6.6 Verify the Drive Current ........................................................................37

5.6.7 Finishing up ..........................................................................................37

5.7 Using Auto Trigger Sampling ...........................................................38

+86-400-820-9661

3

0012072012

Rev. 1.0

TSM24P User Manual

5.7.1 Setting up Auto Trigger .........................................................................38

5.8 Setting the Notch lter .....................................................................39

6 SCL Test & Monitor .................................................................... 40

6.1 SCL Test ..........................................................................................40

6.2 Move Testing

6.2.1 Jog Move ..............................................................................................40

6.2.2 Single Move ..........................................................................................41

6.2.3 Homing .................................................................................................41

.................................................................................... 40

6.3 Motion Status ................................................................................... 41

6.4 Monitor

6.5 I/O Status

6.6 Alarm

6.7 Drive Status

............................................................................................. 42

......................................................................................... 42

................................................................................................ 42

.....................................................................................43

7 Troubleshooting ......................................................................... 44

8 Reference Materials

8.1 Mechanical Outlines (Unit:mm) ........................................................45

8.2 Torque-Speed Curves

8.3 Technical Specications

8.4 SCL Command Reference

.................................................................. 45

...................................................................... 45

................................................................... 46

.............................................................. 47

9 Contacting MOONS’ .................................................................. 49

Communication

Model

TSM24P-3AG

RS-232

Rev. 1.0

0012072012

4

+86-400-820-9661

TSM24P User Manual

1 Introduction

Thank you for selecting the MOONS’ TSM24P Integrated Motor.The

TSM line of integrated step-servo motors combines servo technology

with an integrated motor to create a product with exceptional feature

and broad capability. We hope our commitment to performance, quality

and economy will result in a successful motion control project.

1.1 Features

• Programmable, Digital servo driver and motor in an integrated

package

• Operates from a 12 to 70 volt DC power supply

• Control Modes:

* Position Control

* Digital Signal type

Step & Direction

CW & CCW pulse

A/B Quadrature (Encoder Following)

• Communications:

* RS-232

• 5000 line (20,000 counts/rev) encoder feedback

• Available torque:

* TSM24P-3AG: Up to 2.4 Nm Continuous(3.0 Nm Boost)

• I/O:

* 4 optically isolated digital inputs, with adjustable bandwidth digital noise rejection lter,5 to

24 volts

* 3 optically isolated digital outputs, 30V/100 mA max.

* Differential encoder outputs (A±, B±, Z±), 26C31 line driver, 20 mA sink or source max

• Technological advances:

* Full servo control, Closed loop

* Efcient, Accurate, Fast, Smooth

* Intelligent, Compact

+86-400-820-9661

5

Rev. 1.0

0012072012

TSM24P User Manual

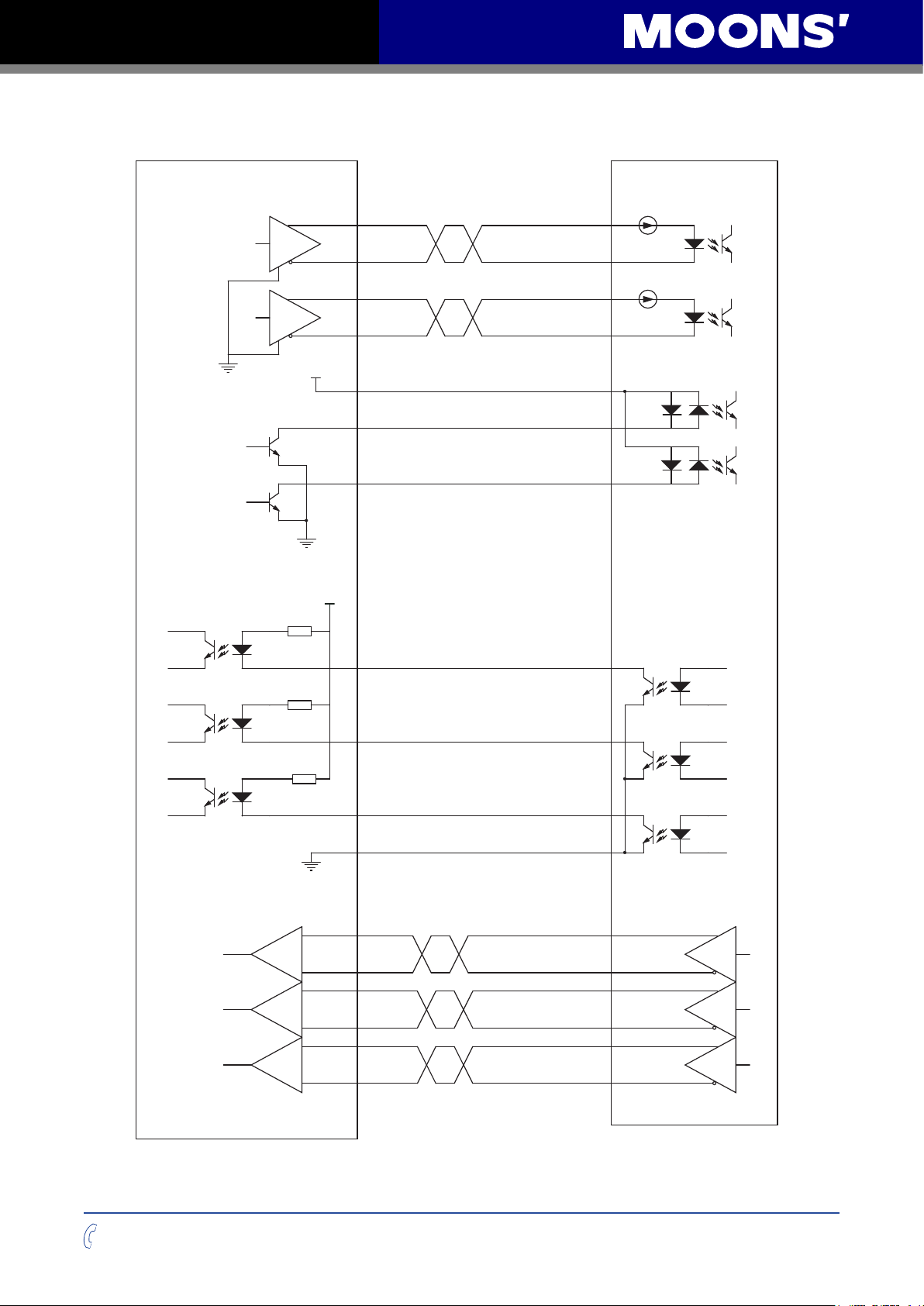

1.2 Block Diagram

TSM24P

Block Diagram

12-70 VDC

External

Power Supply

RS-232

TX, RX, GND, +5V

X1/STEP

X2/DIR

X3/EN

X4/AR

Y1/ALARM

Y2/IN POSITION

Y3/BRAKE

A+

A -

B+

Z+

B -

+

-

Z-

Conn

Power

Conn

Comm

I/O Connector

RS-232

Optical

Iso

Optical

Iso

Line

Driver

Digital

Filter

Software

Filter

5 Volt DC

Power Supply

3.3VDC

Internal

Logic

Supply

DSP

Driver

Controller

Voltage

Temp

Det.

Status

MOSFET

PWM

Power

Amplifier

Over

Current

Det.

motor

encoder

Rev. 1.0

0012072012

6

+86-400-820-9661

TSM24P User Manual

1.3 Safety Instructions

Only qualied personnel should transport, assemble, install, operate, or maintain this equipment.

Properly qualied personnel are persons who are familiar with the transport, assembly, installation,

operation, and maintenance of motors, and who meet the appropriate qualications for their jobs.

To minimize the risk of potential safety problems, all applicable local and national codes regulating

the installation and operation of equipment should be followed. These codes may vary from area

to area and it is the responsibility of the operating personnel to determine which codes should be

followed, and to verify that the equipment, installation, and operation are in compliance with the

latest revision of these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. MOONS’ does not guarantee the products described in this publication

are suitable for a particular application, nor do they assume any responsibility for product design,

installation, or operation.

Read all available documentation before assembly and operation. Incorrect handling of the

products referenced in this manual can result in injury and damage to persons and machinery. All

technical information concerning the installation requirements must be strictly adhered to.

It is vital to ensure that all system components are connected to earth ground. Electrical safety is

impossible without a low-resistance earth connection.

This product contains electrostatically sensitive components that can be damaged by incorrect

handling. Follow qualied anti-static procedures before touching the product.

During operation keep all covers and cabinet doors shut to avoid any hazards that could possibly

cause severe damage to the product or personal health.

During operation, the product may have components that are live or have hot surfaces.

Never plug in or unplug the Integrated Motor while the system is live. The possibility of electric

arcing can cause damage.

Be alert to the potential for personal injury. Follow recommended precautions and safe operating

practices emphasized with alert symbols. Safety notices in this manual provide important

information. Read and be familiar with these instructions before attempting installation, operation,

or maintenance. The purpose of this section is to alert users to the possible safety hazards

associated with this equipment and the precautions necessary to reduce the risk of personal injury

and damage to equipment. Failure to observe these precautions could result in serious bodily

injury, damage to the equipment, or operational difculty.

+86-400-820-9661

7

Rev. 1.0

0012072012

TSM24P User Manual

2 Getting Started

The following items are needed:

• A 12 - 70 volt DC power supply, see the section below entitled “Choosing a Power Supply” for

help in choosing the right one

• A small at blade screwdriver for tightening the connectors (included)

• A PC running Microsoft Windows 2000, XP, Vista, or Windows 7

• The MOONS’ CD (included)

• A MOONS’ programming cable (included)

2.1 Installing Software

Before utilizing the TSM24P Integrated Step-Servo Motor and Step-Servo Quick Tuner Software in

an application, the following steps are necessary:

• Install the Step-Servo Quick Tuner software from the CD.

• Connect the drive to the PC using the programming cable.

• Connect the drive to the power supply. See instructions below.

• Launch the software by clicking Start...Programs...MOONS’.

• Apply power to the drive.

• The software will recognize the drive and display the model and rmware version. At this point,

it is ready for use.

2.2 Mounting the Hardware

As with any step motor, the TSM24P must be mounted so as to provide maximum heat sinking

and airow. Keep enough space around the Integrated Motor to allow for airow.

• Never use the drive where there is no airow or where other devices cause the

surrounding air to be more than 40°C (104°F).

• Never put the drive where it can get wet.

• Never use the drive where metal or other electrically conductive particles can

inltrate the drive.

• Always provide airow around the drive.

Rev. 1.0

0012072012

8

+86-400-820-9661

TSM24P User Manual

2.3 Choosing a Power Supply

The main considerations when choosing a power supply are the voltage and current requirements

for the application.

2.3.1 Voltage

The TSM24P is designed to give optimum performance between 24 and 48 Volts DC. Choosing

the voltage depends on the performance needed and motor/drive heating that is acceptable and/or

does not cause a drive over-temperature. Higher voltages will give higher speed performance but

will cause the TSM24P to produce higher temperatures. Using power supplies with voltage outputs

that are near the drive maximum may signicantly reduce the operational duty-cycle.

The extended range of operation can be as low as 10 VDC minimum to as high as 75 VDC

maximum. When operating below 18 VDC, the power supply input may require larger capacitance

to prevent under-voltage and internal-supply alarms. Current spikes may make supply readings

erratic. The supply input cannot go below 10 VDC for reliable operation. Absolute minimum power

supply input is 10 VDC. If the Input supply drops below 10 VDC the low voltage alarm will be

triggered. This will not fault the drive.

Absolute maximum power supply input is 75 VDC at which point an over-voltage alarm and fault

will occur. When using a power supply that is regulated and is near the drive maximum voltage

of 75 VDC, a voltage clamp may be required to prevent over-voltage when regeneration occurs.

When using an unregulated power supply, make sure the no-load voltage of the supply does not

exceed the drive’s maximum input voltage of 75 VDC.

2.3.2 Regeneration Clamp

If a regulated power supply is being used, there may be a problem with regeneration. When a

load decelerates rapidly from a high speed, some of the kinetic energy of the load is transferred

back to the power supply, possibly tripping the over-voltage protection of a regulated power

supply, causing it to shut down. This problem can be solved with the use of a MOONS’ RC880

Regeneration Clamp. It is recommended that an RC880 initially be installed in an application. If

the “regen” LED on the RC880 never ashes, the clamp is not necessary.

LEDs

Green - Power

Red - Regen on

RC880 Regen Clamp

+86-400-820-9661

9

Rev. 1.0

0012072012

TSM24P User Manual

2.3.3 Current

The maximum supply currents required by the TSM24P are shown in the charts below at different

power supply voltage inputs. The TSM24P power supply current is lower than the winding currents

because it uses switching ampliers to convert a high voltage and low current into lower voltage

and higher current. The more the power supply voltage exceeds the motor voltage, the less

current will be required from the power supply.

It is important to note that the current draw is signicantly different at higher speeds depending

on the torque load to the motor. Estimating how much current is necessary may require a good

analysis of the load the motor will encounter.

TSM24P-3AG 24V Power

3.5

3

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

TSM24P-3AG 48V Power

3.5

3

2.5

2

1.5

Torque(N.m)

1

0.5

0

0 10 20 30 40 50

Speed(RPS)

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Rev. 1.0

0012072012

10

+86-400-820-9661

TSM24P User Manual

3.5

3

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

TSM24P-3AG 70V Power

Speed(RPS)

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

+86-400-820-9661

11

Rev. 1.0

0012072012

TSM24P User Manual

3 Installation/Connections

3.1 Connecting the Power Supply

Use 16 to 20-gauge wire to connect the TSM24 to a power supply. It contains an internal fuse

connected to the “+” terminal that is not user replaceable. If a user serviceable fuse is desired,

install a 10 amp fast acting fuse in line with the “+” power supply lead.

Be careful not to reverse the wires. Reversing the connection may open the internal

fuse on the drive and void the warranty.

Power Supply

V- V+

-

To Power Supply+

To Power Supply-

To Earth Ground

RC880

Vin

+

+

Vout

-

V- V+

TSM

MOONS' offers two matched power supplies for use with the TSM24P.

A 24VDC, 150W(P/N MF150A24AG-V) and a 48VDC 320W(P/N MF320A48AG-V).

These power supplies have current over load capability making them ideal for use.

(To use with a switch power supplier, a RC880 regen must be connected in system)

The RC880 regeneration clamp is for use where regeneration from the motor may cause damage

to the drive. In these cases the RC880 is connected between the drive and power supply and

absorbs regenerated energy.

Rev. 1.0

0012072012

12

+86-400-820-9661

TSM24P User Manual

3.2 Connecting the TSM24P Communications

The TSM24P comes with a cable that will provide the interface to an RS-232 port through a DB9

style connector.

3.2.1 Connecting to the PC using RS-232

Locate the TSM24P within 2.5 meters of the PC. Plug the DB9 connector of the communication

cable that came with the drive into the serial port of the PC. Plug the small end into the crimp style

connector on the TSM24P . Secure the cable to the PC with the screws on the DB9 connector.

Note: If the PC does not have an RS-232 serial port, a USB Serial Converter will be needed.

You can contact MOONS’ to buy a USB to RS-232 converter.

The RS-232 circuitry does not have any extra electrical “hardening” and care should be taken

when connecting to the RS-232 port as hot plugging could result in circuit failure.

GND

TX

+5V

RX

+86-400-820-9661

13

Rev. 1.0

0012072012

TSM24P User Manual

3.3 Inputs and Outputs

TSM24P drives include 4 digital inputs

X1/STEP & X2/DIR are high-speed 5-24 volt logic digital inputs for commanding position.

Quadrature signals from encoders can also be used.

X3/EN and X4/AR are 5-24 volt logic digital inputs. X3/EN is used for motor enable/disable. X4/AR

is used for alarm reset.

3.3.1 Connector Pin Diagram

27 28

ENC A+

ENC B+

ENC Z+

NC

Y3/BRAKE

Y1/ALARM

NC

NC

NC

XCOM

NC

X3/SERVO ON

X2/DIR+

X1/STEP+

ENC AENC BENC ZNC

YCOM

Y2/IN POSITION

NC

NC

NC

NC

NC

X4/ALARM RESET

X2/DIRX1/STEP-

1 2

Rev. 1.0

0012072012

14

+86-400-820-9661

TSM24P User Manual

DrivesUser Control

1 X1/STEP+

2 X1/STEP-

3 X2/DIR+

4 X2/DIR-

0VDC

5-24VDC

0VDC

9 XCOM

5 X3/SERVO ON

6 X4/ALARM RESET

Under 30V

17 Y1/ALARM

18 Y2/IN POSITION

19 Y3/BRAKE

+86-400-820-9661

0VDC

15

20 YCOM

23 ENC Z+

24 ENC Z-

25 ENC B+

26 ENC B-

27 ENC A+

28 ENC A-

Rev. 1.0

0012072012

TSM24P User Manual

3.3.2 X1/STEP and X2/DIR High Speed Digital Inputs

The TSM24 drives include two high-speed inputs: X1/STEP and X2/DIR. They accept 5 to 24 volt

single-ended or differential signals, up to 2 MHz. Typically these inputs connect to an external

controller that provides step & direction command signals. You can also connect a master encoder

to the high-speed inputs for “following” applications. Or you can use these inputs with Wait

Input(WI), Feed to Sensor(FS), Seek Home(SH) and other SCL or Q commands.

The diagrams below show how to connect the STEP & DIR Inputs to various commonly used

devices.

+5v to +24v out

Indexer

DIR

DIR+

DIR-

with

Sinking

Outputs

STEP

STEP+

STEP-

Connecting to Indexer with Sinking Outputs

DIR

DIR+

Indexer

with

Sourcing

COM

STEP

DIR-

STEP+

Outputs

STEP-

Connecting to Indexer with Sourcing Outputs

DIR+

DIR+

Indexer

with

Differential

DIR-

STEP+

DIR-

STEP+

Outputs

STEP-

STEP-

TSM24

TSM24

TSM24

Rev. 1.0

0012072012

Master

Encoder

5 - 24

volt DC

Power

Supply

Connecting to Indexer with Differential Outputs

Many high-speed indexers have differential outputs

A+

A-

STEP+

STEP-

TSM24

B+

B-

DIR+

DIR-

Wiring for Encoder Following

+

direction switch

DIR+

DIR-

TSM24

run/stop switch

(closed = run)

STEP+

STEP-

Using Mechanical Switches

16

+86-400-820-9661

TSM24P User Manual

Connecting a PNP type Proximity Sensor to an Input

3.3.3 X3/EN and X4/AR Digital Inputs

The TSM24 drives include two single ended inputs: X3/EN and X4/AR. They can be used with

sourcing or sinking signals, 5 to 24 volts. This allows connection to PLCs, sensors, relays and

mechanical switches. Because the input circuits are isolated, they require a source of power. If

you are connecting to a PLC, you should be able to get power from the PLC power supply. If you

are using relays or mechanical switches, you will need a 5-24 V power supply.

What is COM?

“Common” is an electronics term for an electrical connection to a common voltage. Sometimes

“common” means the same thing as “ground”, but not always. In the case of the TSM24 drives, if

you are using sourcing (PNP) input signals, then you will want to connect COM to ground (power

supply -). If you are using sinking (NPN) signals, then COM must connect to power supply +.

Note: If current is owing into or out of an input, the logic state of that input is low or closed. If no

current is owing, or the input is not connected, the logic state is high or open.

The diagrams below show how to connect the inputs to various commonly used devices.

5 - 24

volt DC

Power

+

Switch or Relay

(closed = logic low)

XCOM

TSM24

Supply

-

X3/X4

Connecting the Input to a Switch or Relay

5 - 24

volt DC

Power

Supply

+

+

NPN

Proximity

-

Sensor

-

output

XCOM

TSM24

X3/X4

Connecting an NPN type Proximity Sensor to an Input

output

X3/X4

TSM24

5 - 24

volt DC

Power

+

+

PNP

Proximity

Sensor

-

Supply

-

XCOM

+86-400-820-9661

17

Rev. 1.0

0012072012

TSM24P User Manual

3.3.4 Programmable Outputs

The TSM24P drives feature three optically isolated digital outputs (Y1 to Y3). Y1, Y2 and Y3 share

a common terminal YCOM.

• Y1 can be set to signal a fault condition.

• Y2 can be set to indicate when the motor is moving or to indicate whether the motor is in

position.

• Y3 can be set to control a motor brake, or to provide an output frequency proportional to motor

speed (tach signal) or to provide a timing output (50 pulses/rev)

These outputs can also be turned on and off by program instructions like Set Output (SO). The

output can be used to drive LEDs, relays and the inputs of other electronic devices like PLCs and

counters. Diagrams of various connection types follow.

Do not connect the outputs to more than 30 volts. The current through each output terminal

must not exceed 100mA.

5 - 24

volt DC

Power

Supply

PLC

+

Load

-

Connecting a Sinking Output

5 - 24VDC

Power Supply

-

COM

IN

Connecting a Sourcing Output

+

relay

Y1

TSM24

YCOM

Y2

TSM24

YCOM

Rev. 1.0

0012072012

5 - 24

volt DC

Power

Supply

+

1N4935 suppresion diode

-

Driving a Relay

18

Y3

TSM24

YCOM

+86-400-820-9661

TSM24P User Manual

4 Drive Conguration

Step-Servo Quick Tuner is the PC based software application used to congure, and perform

servo tuning, drive testing and evaluation of the TSM. System servo control gains, drive

functionality, and I/O conguration are set with Quick Tuner. It also contains an oscilloscope

function to help set the servo control gains.

4.1 Quick Tuner Toolbar

4.1.1 Open, Save and Print

In addition to exchanging settings with a drive, the Step-Servo Quick Tuner software can also save

& load settings using the PC’s hard drive.

The Open button brings up a dialog box showing all the Step-Servo Quick T

drive.

When a large number of identical machines are being built it is useful to be able to exactly

duplicate each set-up. When development of one machine is completed and the motion control is

working correctly, it can be saved to a le. When the next machine is built, the set-up le may be

opened and downloaded to that drive. One of the advantages of programmable, digital control is

this easy duplication of system settings.

With the Save button a set-up can be saved to the hard drive. Long le names may be used just

as with other 32 bit Windows programs, such as Microsoft Word or Excel.

The Print button allows a hard copy of a program to be printed on any system printer. The

standard Windows printer dialog is used, allowing the choice of typical printer settings.

+86-400-820-9661

19

uner les on the hard

Rev. 1.0

0012072012

TSM24P User Manual

4.1.2 Restore

The Restore button will reset all parameters in the drive to the ones set by the factory (defaults).

Note - as this will erase all parameters that have been changed, it may be desired to save them to

a le rst.

4.1.3 Alarm History

The TSM stores a log of previous alarm conditions viewable in the Alarm History. When an alarm

occurs, the drive stores the information on which alarm conditions were triggered. As a fault may

trigger more than one alarm condition, the drive stores all of them for reference. This information

can then be viewed in the Alarm History dialog to help with drive and system problem solving. The

drive stores up to 8 sets of alarm conditions. The Alarm History dialog can also be used to clear

the Alarm History.

4.1.4 LED Flashing

Clicking on this button will bring up a screen where the LED

ashing for certain warnings can be masked. Alarm fault conditions

are not allowed to be masked and will always be indicated by the

drive’s LEDs. Masking alarm warnings only prevents the indication

of the alarm by the LEDs. The alarm warning will still be set in the

Alarm status code and in the Alarm History. See section 7 on

“Troubleshooting” below for an explanation of these codes.

4.1.5 Drive & Revision

When Step-Servo Quick Tuner is connected to an TSM Integrated

Motor the drive model, sub-model, and rmware revision are

automatically indicated. If working ofine (no drive is connected),

the Drive model and sub-model can be selected from the drop

down lists. The model and sub-model information is found on the

label of the TSM integrated motor.

Rev. 1.0

0012072012

20

+86-400-820-9661

TSM24P User Manual

4.1.6 Communication

When the Step-Servo Quick Tuner is connected to an TSM Integrated Motor

the drive model and sub-model will cause the communications to be set to

the proper type (RS-232 or RS-485). If Step-Servo Quick Tuner is unable to

connect to the TSM Integrated Motor, manually selecting the communications

type may help establish the connection.

Port

The correct COM port may need to be selected. When the software is loaded, it looks for the

rst available COM port, but may not always nd the one connected to the drive. After a specic

COM port has been selected this setting is saved when the Step-Servo Quick Tuner is closed. If

the saved COM port is available next time Quick Tuner is started it will be automatically selected

Select the port from the drop-down list. If the port exists and is not already in use, the software will

use it to communicate with the TSM.

Uses Check Sum

The TSM Integrated Motor supports using a check sum in the communication protocol. For more

reliable communications this option can be selected. Checksum is used automatically when the

TSM is being congured, tuned or operated in the target environment. This can prevent mis-

information being sent to or received back from the drive.

4.1.7 Servo On/Off

The Enable button energizes the motor and tells it to be ready to accept motion

commands. The Disable button cuts the current to the motor and it will not be

able to execute motion commands.

The Enable button must be used to re-enable motor operation after a fault

condition has occured. Before the enable can be used the alarm fault condition must be cleared.

See Alarm Reset below.

4.1.8 Alarms

Indicator

When a fault occurs the Alarm indicator will ash red, a warning will trigger a

ashing orange signal. Green indicates there is no alarm condition.

Alarm Reset

The Alarm Reset button will clear the alarm and return the signal to green if the alarm condition

can be cleared. In some cases an alarm condition can be persistent and other action may be

required to remedy the condition.

4.1.9 Upload & Download

The Upload button allows the complete set up and tuning parameters from an TSM to be copied

to Quick Tuner. Later these settings can be saved to a PC le (see “File Saving” above). It is very

important to perform an upload from a congured drive so that its conguration is not accidentally

over-written.

The Download button is used to copy settings from Quick Tuner to the drive. Each time the

download button is clicked, all conguration settings will be downloaded to the drive.

+86-400-820-9661

21

Rev. 1.0

0012072012

TSM24P User Manual

4.2 Basic Conguration

The Control Mode of TSM24P is Position Mode.

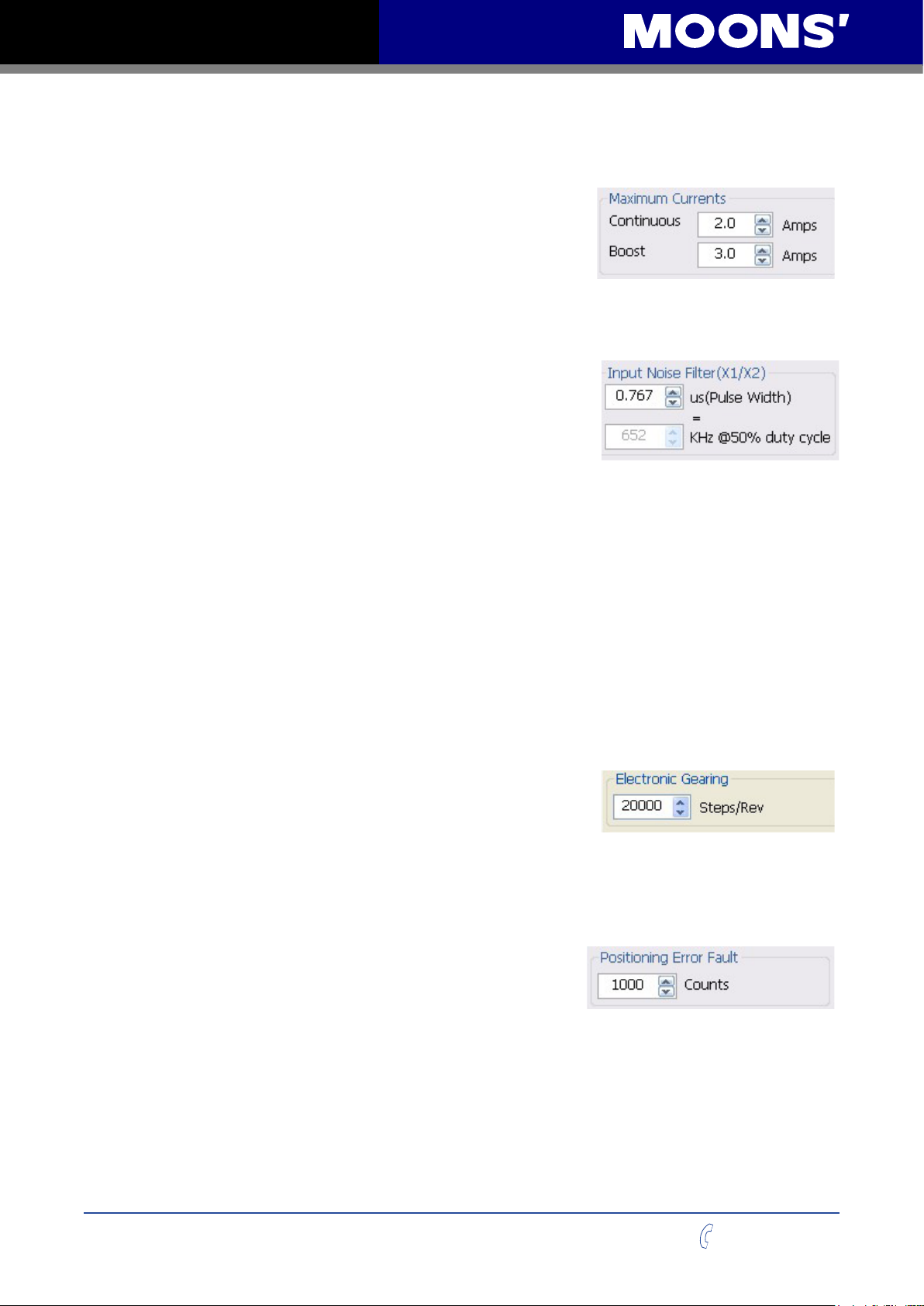

4.2.1 Maximum Currents

Continuous - The current that can be sustained indenitely.

Boost - An TSM drive can provide a momentary current boost.

This allows for greater acceleration rates than would otherwise

be possible. To assure reliable motor operation, the drive

automatically ramps the current down after one second so that the average current does not

exceed the motor’s rating.

4.2.2 Digital Input Filter

The Digital Input Filter is a hardware lter designed to

remove noise content from the digital inputs. The Digital Filter

is programmable and can be set from a minumum of 0.067

microseconds pulse width to a maximum of 12.867 microseconds.

The lter setting is applied to all three of the digital inputs - X1/

STEP, X2/DIR, and Input #3 (EN).

This is a pulse width lter but the frequency can be calculated by multiplying the pulse time by 2

and then dividing 1 by that number - 1 / (P*2). This assumes that the frequency input is a 50%

duty cycle. Quick Tuner automatically calculates the frequency and displays it on the screen.

The Digital Input Filter is most useful when the drive is used in the Pulse & Direction type of the

Position Control Mode. The purpose of the lter is to prevent noise pulses from being added

to the step count. Setting the lter value just above the maximum intended input frequency will

help prevent noise pulses from being added to the step count. This may require some degree of

experimentation with the value so that the noise is removed but not the actual step pulse.

NOTE: Low frequency lter values will cause a lag in the system response.

4.2.3 Electronic Gearing

Generally, we recommend using the default setting 20000 steps/

rev. With Electronic Gearing drive response to incoming step

pulses can be adjusted. This is very useful when a step motor

drive is being replaced with a step-servo system, as the TSM

can have the same number of steps/revolution as the stepper.

For example, TSM24P can be programmed to operate at 200 steps/rev, like a full step drive. If

the system is working in degrees, the drive can be programmed to operate at 36,000 steps/rev

resulting in an even number of steps (100) per degree.

4.2.4 Positioning Error Fault

Positioning error is the difference, in encoder counts, between

the actual position and the commanded position of the motor.

A small amount of positioning error is a normal part of a stepservo system. In the event of a broken wire, a failed sensor, the

motor encounting a physical obstruction, or operator error, a position error fault limit can prevent

damage to the system. Anytime the position error (as reported by the encoder) exceeds this set

limit, the drive is disabled and a fault alarm occurs.

Rev. 1.0

0012072012

22

+86-400-820-9661

TSM24P User Manual

The fault limit can be set as low as 10 encoder counts, or as high as 32000. During initial tuning

of the system, this value should be set high so that the drive doesn’t shut down while the tuning

parameters are being adjusted. Once the drive is properly tuned and the expected amount of error

during normal operation is known, an appropriate fault limit can be set. For example, with Quick

Tuner’s oscilloscope function set to plot position error, sample moves using the maximum speed

and acceleration planned for use in an application should be executed. If the maximum position

error is 50 counts, the fault limit could safely be set at 100.

4.2.5 Maximum Speed

The maximum speed allowable may also be set. If the maximum speed is set below the speed a

command signal demands, the nal speed achieved will be the speed set in the Maximum Speed

parameter.

Note: Maximum Speed only works with Velocity mode. In Torque mode the Peak Torque

and Continuous Torque need to be set to proper values that will limit over-speed conditions

potentionally occurring in an application.

4.2.6 Maximum Acceleration

This sets the maximum level of acceleration for the motor.

Even if the command input tries to demand a higher level of

acceleration, the drive will only accelerate at the set maximum level. This value is also used as

a quick stop when meeting with limit sensor or other stop command such as the ST (Stop) or SK

(Stop and Kill) SCL commands.

+86-400-820-9661

23

Rev. 1.0

0012072012

TSM24P User Manual

4.3 Position Mode

The Position control mode is used with digital command input signal.

4.3.1 Basic Conguration

This mode requires the setting of Maximum Currents, Digital Input Filter, Electronic Gearing,

Positioning Error Fault, and Maximum Acceleration that will appear to the left of the Control

Mode box when this option is checked.

refer to the section 4.2 above in Page26 for help in parameter setting

Smoothing Filter - Filters the change in the position command to cause a smoother movement of

the motor. A lower lter value will result in much smoother motion but will cause a lag in response.

When using smaller EG values, smaller lter values may be necessary for acceptable operation.

Rev. 1.0

0012072012

24

+86-400-820-9661

TSM24P User Manual

4.3.2 Position Control - Digital

This mode is for systems where the position of the motor is determined by a digital input signal in

the form of pulses.

Digital Settings

Input Noise Filter - The digital inputs used in this mode are very high speed and can be sensitive

to external electrical noise. The Input Noise Filter sets a hardware circuit to lter out unwanted

noise that can cause extra steps. As a general rule, the lter frequency should be set to double

that of the desired maximum input frequency. If the frequency is set too low it may cause loss of

step counts. When setting this value the performance over the whole range of desired speeds

should be considered.

Digital Signal Types - There are three types available:

• Pulse & Direction - accepts signals such as those generated by a step motor controller. The

frequency of the pulses fed into X1/STEP determines the speed. The direction of rotation is

determined by the signal fed into X2/DIR - with either an ON or an OFF signal commanding

clockwise motion.

• CW & CCW Pulse - The motor will move CW or CCW depending on which input the pulse is

fed into. Either X1/STEP or X2/DIR can be used for CW rotation.

• A/B Quadrature - sometimes called “Slave Mode”. The motor will move according to signals

fed to the drive from a master encoder. This encoder can be mounted to a rotating mechanism

on a machine or it can be another motor in the system. Rotation direction is determined by

which input is “leading” the other.

+86-400-820-9661

25

Rev. 1.0

0012072012

TSM24P User Manual

4.3.3 I/O Denition - Digital

Options for X3/EN are:

• Servo On when closed - the motor has no power when the input is open

• Servo On when open - the motor has no power when the input is closed

• Not used, generic programmable input

Options for X4/AR are:

• Reset alarm when closing - an alarm or fault can be cleared by closing the input

• Reset alarm when opening - an alarm or fault can be cleared by opening the input

• Not used, generic programmable input

Options for Y1 are:

• Closed on fault - the output will close if a fault occurs

• Open on fault - the output will open if a fault occurs

• Not used - generic programmable output

Options for Y2 are:

• Closed when motor is moving - The output is closed when motor is moving

• Open when motor is moving - The output is open when motor is moving

• The output is closed when position error less than setting

• The output is open when position error less than setting

• Not used - generic programmable output

Options for Y3 are:

• Closed to release brake - the output controls a fail safe brake relay

• Open to release brake - the output opens to release the brake

• Tach out - the output produces pulses relative to the motor position

• Timing out -the output produces 50 pulses / rev

• Not used - generic programmable output

Rev. 1.0

0012072012

26

+86-400-820-9661

TSM24P User Manual

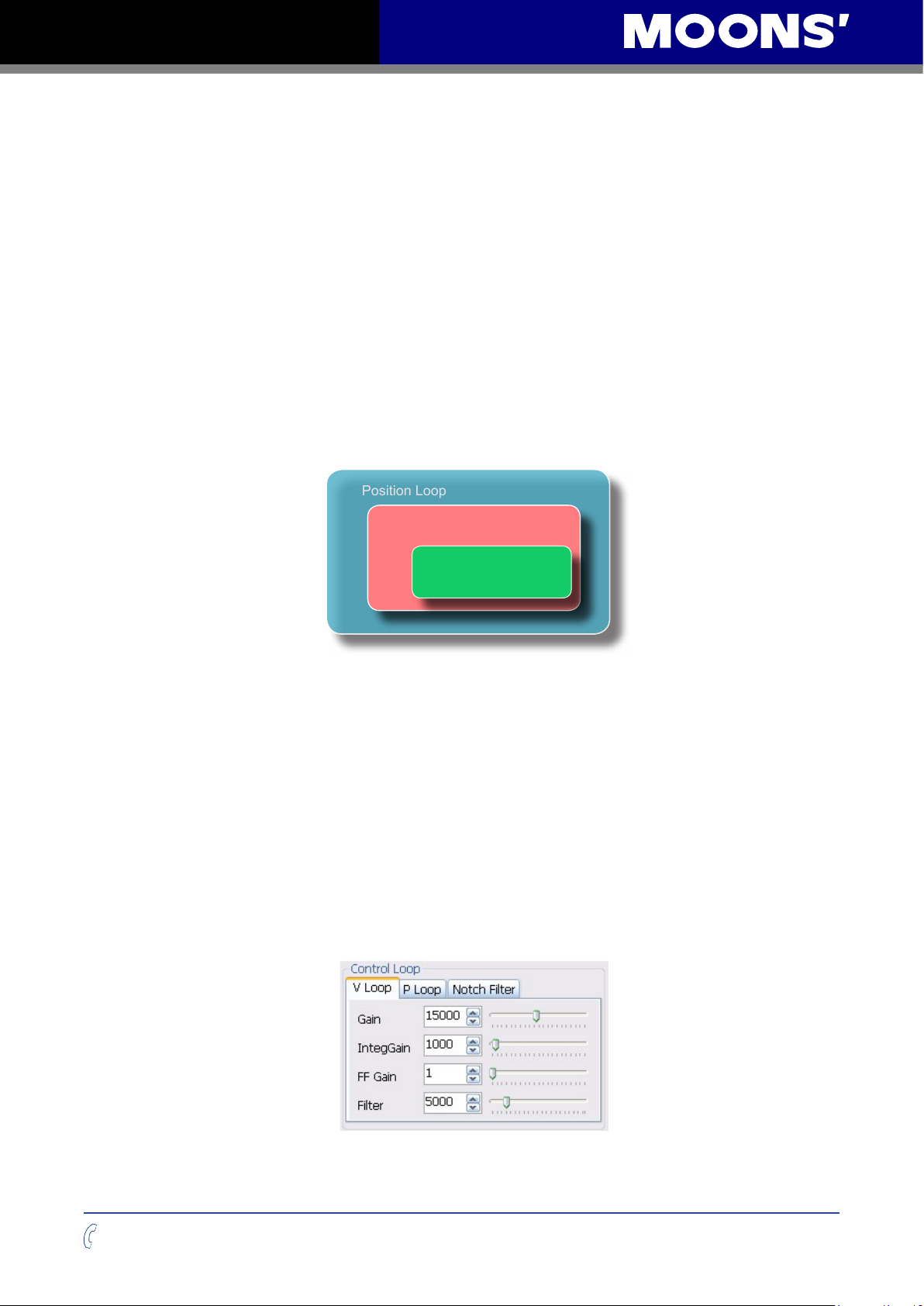

Position Loop

5 Tuning - Sampling

Being a servo motor, the TSM Integrated Motor employs sophisticated algorithms and electronics

for controlling the torque, velocity and position of the motor to achieve a well behaved operation of

the load.

Because the motor encoder continuously tells the drive what the motor is doing, the drive can

alter the current applied to the motor until the motor achieves the desired operation. This is called

“closed loop control.”

One of these loops controls the amount of current going to the motor. This loop requires no

adjustment other than specifying the maximum current the motor can handle without overheating.

The TSM employs two control loops for the actual motor motion. The rst is a Velocity Loop which

is designed to control only the speed of the motor. The second is a Position Loop that controls the

count position of the motor. As shown in the drawing below, the Current Loop is contained in the

Velocity Loop, and the Velocity Loop is contained in the Position Loop. Knowing this is important

as good Position Loop control requires rst tuning the Velocity Loop. As mentioned above, Current

Loop tuning is not required as it is already optimized for the motor.

Velocity Loop

Current Loop

5.1 Velocity Control Loop (V Loop)

The Velocity Control Loop is designed to operate the motor in a velocity-only type of servo

control. This means that it can control the speed of the motor but cannot cause the motor to

follow a command position. The Jog commands available in the drive can use this loop only for

operation, the advantage of this is good stability even with very high inertia loads. The JM (Jog

Mode) command is available to set this feature or it can be congured when selecting the Velocity

Control Mode. Selecting the Speed Only control type setting causes the Velocity Loop alone to be

used in the various Jog or Velocity control functions. JM2 (Jog Mode 2) does the same. Position

over time control type adds in the Position control loop for precise position control during the

move and when stopped, JM1 (Jog Mode 1) also congures this setting.

The Velocity Control Loop has four terms that can be congured for optimum performance with

a given load. This loop can be set and tuned independent of the Position Control Loop. These

control terms are described below.

+86-400-820-9661

27

Rev. 1.0

0012072012

TSM24P User Manual

5.1.1 Gain: The Velocity Proportional Term (VP)

The simplest part of the Velocity Loop is the proportional, or VP, term. The drive applies current

to the motor in direct proportion to the error. For example, if a motor is not moving, and the shaft

is turned by hand or some other force, the drive will increase the motor current until the motor

returns to “0” speed. The faster the motor is moved from “0” velocity, the more the opposing torque

will increase. The VP term (also called VP gain) governs how much torque will be applied for a

given amount of velocity error (Vn). In general, more load inertia or load friction, requires more

torque and therefore a higher VP gain. The torque provided by the VP term is:

T = VP * Vn

5.1.2 IntegGain: The Velocity Integral Term (VI)

In the previous example, applying the VP term alone will not result in perfect velocity control. If

one ounce-inch of torque were applied to the motor, it would move at a slower speed. The VP term

will increase the motor torque until it is producing as much torque as the force attempting to move

it. The motor may slow down or even stop moving but there will still be error. The VI term adds up

all the error the velocity calculation has reported and produces a torque that is added to the torque

command from the VP term. The equation for this is:

T = VP * Vn + VI∑(V)

In the example, the VP term allowed the motor to reach equilibrium at a speed where the applied

torque equaled the torque of the VP term. Thus, the error was not zero. But the VI term continues

adding up the error and increasing the torque until the motor returns to the true target position.

5.1.3 FF Gain: Acceleration Feed-forward Term (KK)

Larger loads typically generate larger load Inertia. These larger inertias can be more easily

controlled by anticipating the system’s torque need. The Acceleration Feed-forward term does this

by adding an acceleration value to the Torque command. The acceleration value is derived from

the Trajectory Calculation during the acceleration and deceleration phase. As can be seen in the

equation below this increased Torque command is added with the VP and VI torque command

values:

T = KK * A + VP * Vn + VI∑(V)

5.1.4 PID Filter: Torque Command Filter Term (KC)

This nal term in the Velocity control loop can be considered an over-all lter term. In fact this term

is always used even when the drive has been placed in the Torque Control Mode where only the

Current control loop is active. The lter is a very simple single-pole low pass lter that is used to

limit the high frequency response of the Velocity and therefore the Position control loops.

Rev. 1.0

0012072012

28

+86-400-820-9661

TSM24P User Manual

5.2 Position Control Loop

The Position Control Loop is designed to provide the typical positioning control for a servo

system. All positioning type operations use this loop including when operating in the Pulse &

Direction Position Control Mode. The Position loop can also be used in the Velocity Control

Mode when the Position over time control type option is selection or the Jog Mode is JM=1.

The Position Control Loop has three terms that can be congured for optimum performance with

the given load. These control terms are described below:

5.2.1 Gain: The Position Proportional Term (KP)

The simplest part of the Position loop is the proportional, or KP, term. The drive applies current

to the motor in direct proportion to the position error. For example, if a motor is not moving, and

the shaft is turned by hand or some other force, the drive will increase the motor current until the

motor returns to the commanded target position (rest position). The farther the motor is moved

from its target position, the more the torque will increase. The KP term (also called KP gain)

governs how much torque will be applied for a given amount of error (Un). In general, more load

inertia or load friction, requires more torque and therefore a higher KP gain.

Because of the topology of the control loops, the Position Control Loop output is actually a

velocity command that indirectly affects the Torque command to the motor. The Velocity command

provided by the P term is:

V = VP * Un

5.2.2 The Position Integral Term (KI) - Not Implemented

There is no KI term as it is not required because of the Velocity loop which contains an Integrator

term. Any position error will taken up and corrected for in the Velocity loop.

5.2.3 Deri Gain: The Derivative Term (KD)

A motor run with a pure PI controller would overreact to small errors, creating even larger errors

and becoming unstable. By predicting what a motor will do ahead of time, the large errors and

instability can be avoided. The derivative term determines this by analyzing the rate of change

of the position error and including that in the torque calculation. For example, if the motor has a

position error, but the rate of change of the error is decreasing, torque is lowered. The formula

used here is:

V = KP * Un + KD * (Un – (Un-1))

where:

Un is the error in encoder counts

Un-1 is the error of the previous sample

+86-400-820-9661

29

Rev. 1.0

0012072012

TSM24P User Manual

5.2.4 Deri Filter: Torque Command Filter Term (KE)

A derivative control term can be rather noisy and even though it is effective in damping the

positioning control, it can cause objectionable audible or observable noise to the system. The lter

is a very simple single-pole low pass lter that is used to limit this high frequency noise and make

the system quieter and more stable.

5.3 Notch lter

For additional ltering, an over-all notch lter is added to the current command signal. This lter

is similar to the PID Filter in that it is active even when the driveis being used in Torque Control

Mode. Notch lters are typically used to lter at a particular frequency when there is a resonant

component in the mechanical system that may oscillate at that frequency. Couplers between the

motor and the load can commonly do this which may result in a control problem. When gains are

increased to improve performance the system may resonate in an uncontrollable manner. The

Notch Filter allows gain reduction at only the problematic resonant frequency, allowing the over-all

gain to be set higher for better system control.

The notch lter has two parameters that are described below. The notch lter can only be

congured though the Quick Tuner interface where the Quick Tuner software calculates the lter

constants used by the drive.

5.3.1 Frequency: Notch Filter Center Frequency

This denes the center frequency - the frequency where the most gain reduction occurs. For now,

nding the center frequency is a bit of a guessing game and different frequencies can be tried until

the system resonance is eliminated.

5.3.2 BandWidth: Notch Filter Frequency Bandwidth

This denes the frequency span where the signal is reduced by at least 3dB. For example if the

center frequency is set to 400Hz and the bandwidth to 200 the signal will be reduced by 3dB

starting at 300hz. It will have the greatest reduction at 400Hz, and then will be greater than 3dB

above 500Hz. When setting the notch lter a chart is displayed that provides an indication of the

ltering that will be accomplished.

Rev. 1.0

0012072012

30

+86-400-820-9661

TSM24P User Manual

5.4 Getting Ready for Tuning

Before testing a servo-system a few more parameters need to be entered. These include the Max

Speed, Acceleration and Distance (or time) requirements of the sample move. The proper prole

shape of the move is needed to operate the load in the same way as what will be expected during

online operation. Accelerating the load quickly may induce signicant ring into the motion prole.

Accelerating slower and going to a higher velocity can minimize the ringing. The best prole for

a given move is sometimes arrived at more through experimentation than hard calculation. Step-

Servo QuickTuner provides easy entry of the prole parameters plus a display of the prole for

verication.

The mechanical system should be set up as close to the

nal conguration as possible so that the tuning represents

what will be expected. The critical components include the

coupler, mechanical interface ,and similar frictional and

inertial loads. As tuning can sometimes be an uncontrolled

process where the mechanical system can be damaged,

care must be taken to minimize this possibility. This could

include having limit sensors or mechanical stops that help

to prevent such damage.

Step-Servo Quick Tuner contains a sampling Oscilloscope

that will display of variety of measurements of an executed

move. Two plots can be displayed at one time and contain

the real-time information about the move performance.

Before performing the test move, make sure the desired

move information is selected. This can include the typical

information such as Actual Speed or Position Error but also can include the Supply Voltage so

that the power supply can be monitored for proper voltage during the move.

+86-400-820-9661

31

Rev. 1.0

0012072012

TSM24P User Manual

5.5 Tuning the Velocity Loop

5.5.1 Entering a Sample Move

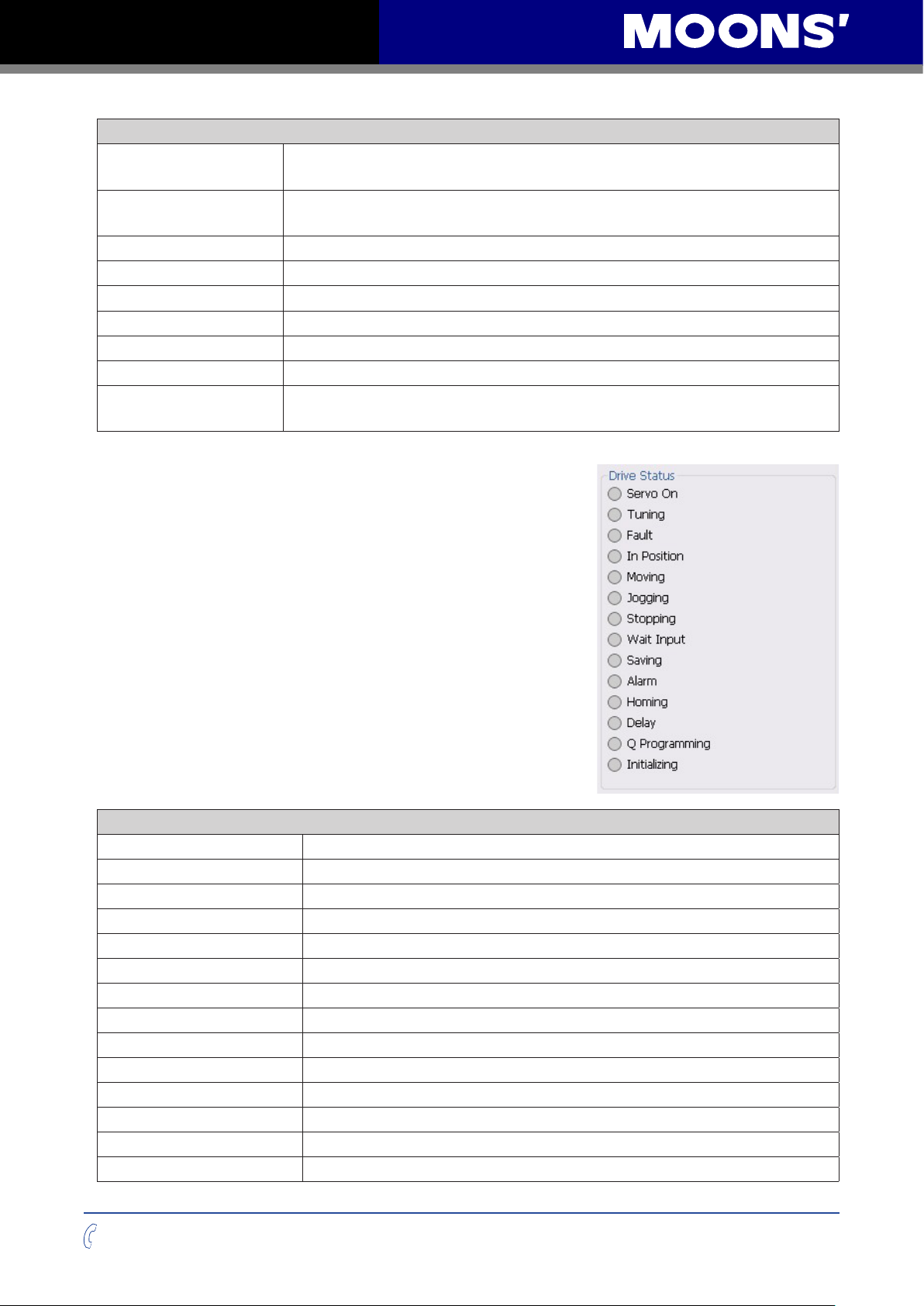

Start by selecting the V Loop tab in the Control Loop dialog section. This will cause the

Sampling to perform moves that are based on Time and operates the drive in the Speed Only

Velocity mode.

Now parameters may be entered for a Velocity based move.

Plot 1 & Plot 2: two different values can be selected

for viewing in the scope window, in this case Actual

Speed and Velocity Error are selected. These are

typical values for Velocity tuning.

Sample Move: move prole values are entered in

the Sample Move section. This example sets a move

Time of 200ms at a Jog Speed of 20 rev/sec and an

Accel/Decel rate of 300 rev/s/s. In the window to the

right of the Sampling data entry section the Desired

Prole will be displayed. This provides a visual

reference of what the expected move will look like.

Plot Zoom: the length of the plot values that are

displayed can be set from 1 to 5 times the prole

length.

Dir: the direction of the move can be set to cw, ccw

or alternate. These directions refer to the motor shaft

as viewed from the front of the motor. Alternate toggles the direction after each move. Start with a

known direction before switching to toggle.

Sample Once: after the Start button is clicked, a single move is performed, the motor stops, and

the results will be displayed.

Sample Continuously: after the Start button is clicked, the move will be repeated and the results

displayed until the Stop button is clicked. During continuous sampling the tuning gains can be

changed at any time and will be updated automatically. This enables more dynamic adjustment of

the gains for speeding up the tuning process.

5.5.2 Performing a Move

Once the move settings are correct the mechanism to be moved shold also be checked to ensure

it is ready to move. It is especially important to make sure the direction is set correctly. In some

cases it is wise to select alternate to avoid running the mechanism into a hard stop. Select the

Sample Once button. Click the Start button and observe the results.

If problems occurred during the move an Alarm indicating a Fault or Warning may be displayed

and need to be cleared. The drive may be left disabled until the Alarm is cleared and the Enable

button is clicked.

Note: Clicking the Alarm Reset button and then the Enable button will clear a fault and

enable the drive.

Now the motion parameters will need to be adjusted to achieve the desired move prole. The

move can be repeated by clicking the Start button. If the drive continues to fault it is possible the

maximum current or position error parameters are being exceeded. These can be set in the Drive

Conguration tab.

The current setting can be checked by selecting Current in one of the Plot lists and clicking Start

again to see what current is being required of the drive during a move. The current prole of the

move will be displayed and may give a clue as to why a fault is occurring.

Rev. 1.0

0012072012

32

+86-400-820-9661

TSM24P User Manual

5.5.3 Adjusting tuning parameters

The two primary parameters for a Timed move are the Proportional (VP) & Integral (VI) gain

parameters of the velocity loop.

Starting with these two terms is a good way to begin tuning as they are the minimum required

terms in Velocity Loop tuning. The FF Gain is not required but adds to the tuning, this will be

discussed later.

Note 1: The Disable button in the Menu bar of the Step-Servo Quick Tuner window under the

label Servo will disable the motor should a serious problem occur.

Note 2: The Gain values can be changed at any time during the tuning process. When the StepServo Quick Tuner software detects a change in the value it will automatically download the new

value. The Download button in the upper right of the window does not need to be clicked.

Once a successful move has been accomplished (no fault occurs) the motor is ready for tuning.

Adjust the VP and VI parameters and observe the results. VP and VI shold be adjusted at the

same time and in small increments. The following two gures shows responses with different VP

and VI settings.

This rst plot is performed with the default tuning values and no load added to the motor.

The second plot is performed with higher gain values for the VP (25000) and VI (3000), as can be

seen the velocity error decreases as the gains are increased.

To get a good comparison between different plots where the gains have been changed, turn off

the Auto Scale by clearing that check box below the plot screen. When auto scaling is turned off,

the difference can be seen more clearly.

+86-400-820-9661

33

Rev. 1.0

0012072012

TSM24P User Manual

Rev. 1.0

0012072012

34

+86-400-820-9661

TSM24P User Manual

5.5.4 Adding in the FF Gain (KK) parameter

The Acceleration Feed Forward (KK) applies more current to the motor to help compensate

for high inertia in the system. In a servo system more current is typically required during the

acceleration and deceleration phases of the move prole.

A reduction in the Velocity Error peak values should then be seen. As seen in this plot with the KK

set to 3000 the peaks in the Velocity error have been reduced. With loads that have greater inertia

this can provide a signicant improvement.

NOTE: The FF Term (KK) is not available when operating in the Pulse & Direction Control

Mode. Setting this value will have no effect.

If the Velocity Error goes too positive during acceleration, the adjustment was too large and the

value should be adjusted in smaller amounts until there is as near to zero error as possible. The

Rescale button next to the Auto Scale may be clicked at any time to re-scale the plot on the new

Velocity Error value.

5.5.5 Filter parameter

Step-servo has a control loop lter for special situations where the motor may resonate or may

have signicant audible noise. This lter is designed as a low pass type for the control loop output.

When a system is subject to mechanical resonance, this low pass lter can be set below the

natural frequency of the system so that the control loop output does not excite the resonance.

With a large inertial load, the gain parameters, especially the VP and VI terms, may need to be set

high to get a good response. The lter may then need to be decreased in value (lower frequency)

to prevent ringing or oscillation. The default of 15000 works well in many cases but can be

increased or decreased with little risk.

+86-400-820-9661

35

Rev. 1.0

0012072012

TSM24P User Manual

5.5.6 Verify the Drive Current

The amount of drive current can be veried at any time during the tuning process to make sure the

current supplied to the motor is not being limited by the drive. If too much current is being required

changes may be made to the move prole. Select Current in one of the Plot selection lists and

repeat the move, from this the current can be evaluated.

5.5.7 Finishing up

If the TSM will only be operated in a Velocity Control Mode with a Speed only Control Type, the

tuning is complete. The Position Loop (P Loop) does not need to be tuned as it is not used. After

verifying the drive current, the Notch Filter may be the only setting still needing adjusting. See

section 5.8 on “Setting the Notch Filter”.

If the TSM will be operated in a Position Control Mode, proceed to section 5.6 ”Tuning the

Position Loop” below.

See Section 5.7 below on “Using Auto Trigger Sampling” for tuning the TSM while using an

external Pulse & Direction controller.

5.6 Tuning the Position loop

5.6.1 Entering a Sample Move

Select the P Loop tab in the Control Loop dialog section.

This will cause the Sampling to do moves that are based

on distance and operates the drive in the Point to Point

Positioning mode.

Now the parameters for a Position based move can be

entered. There is one consideration that must be addressed

here. If the TSM is being operated in the Position Control

Mode with a Pulse & Direction Digital Signal Type setting

and being commanded by, for example, an external Pulse and Direction controller, the Auto

Trigger option may be used to capture and plot the move. See Section 5.6 on “Using the Auto

Trigger Sampling” for more details on this feature.

Plot 1 & Plot 2: two different values can be selected for

viewing in the scope window, in this case Actual Speed

and Position Error are selected. For Position tuning these

are typical values.

Sample Move: move prole values are entered in the

Sampling section. This example sets a move Distance of

3.00 revs at a Max Speed of 20,000 rev/sec and an Accel/

Decel rate of 300 rev/s/s. In the window to the right of the

Sampling data entry section the Desired Prole will be

displayed. This provides a visual reference of what the

expected move will look like.

Plot Zoom: the length of the plot values that are displayed

can be set from 1 to 5 times the prole length.

Dir: the direction of the move can be set to cw, ccw

or alternate. These directions refer to the motor shaft as viewed from the front of the motor.

Alternate toggles the direction after each move. Start with a known direction before switching to

toggle.

Sample Once: after the Start button is clicked, a single move is performed, the motor stops, and

the results will be displayed.

Rev. 1.0

0012072012

36

+86-400-820-9661

TSM24P User Manual

Sample Continuously: after the Start button is clicked, the move will be repeated and the results

displayed until the Stop button is clicked. During continuous sampling the tuning gains can be

changed at any time and will be updated automatically. This enables more dynamic adjustment of

the gains for speeding up the tuning process.

5.6.2 Performing a Move

Once the move settings are correct the mechanism to be moved shold also be checked to ensure

it is ready to move. It is especially important to make sure the direction is set correctly. In some

cases it is wise to select alternate to avoid running the mechanism into a hard stop. Select the

Sample Once button. Click the Start button and observe the results.

If problems occurred during the move an Alarm indicating a Fault or Warning may be displayed

and need to be cleared. The drive may be left disabled until the Alarm is cleared and the Enable

button is clicked.

Note: Clicking the Alarm Reset button and then the Enable button will clear a fault and

enable the drive.

Now the motion parameters will need to be adjusted to achieve the desired move prole. The

move can be repeated by clicking the Start button. If the drive continues to fault it is possible the

maximum current or position error parameters are being exceeded. These can be set in the Drive

Conguration tab.

The current setting can be checked by selecting Current in one of the Plot lists and clicking Start

again to see what current is being required of the drive during a move. The current prole of the

move will be displayed and may give a clue as to why a fault is occurring.

5.6.3 Adjusting the Gain (KP) and Deri Gain (KD) parameters

Adjust the KP and KD parameters and observe the results. Increasing the KP may improve the

positioning performance, but it may also cause the system to be more unstable. To counter this

the KD can be increased. The KD parameter is important: too little gain will cause the system

to oscillate; too much gain may cause the system to squeal from a high frequency oscillation. If

a very springy coupler is used between the motor and load, the KD parameter may need to be

reduced until the system is stable or the Notch Filter may need to be used to reduce the system

gain at the sensitive frequency where it oscillates.

5.6.4 The Deri Filter (KE) parameter

With a large inertial load, the KP and KD gain parameters may need to be set high to get good

response. The lter may then need to be decreased in value (lower frequency) to prevent ringing

or decrease the derivative noise.

5.6.5 Filter parameter (again)

Sometimes it may also be necessary to adjust the output lter when gain values increase. The

lter frequency may then need to be decreased in value to prevent ringing or oscillation.

5.6.6 Verify the Drive Current

The amount of drive current can be veried at any time during the tuning process to make sure the

current supplied to the motor is not being limited by the drive. If too much current is being required

changes may be made to the move prole. Select Current in one of the Plot selection lists and

repeat the move, from this the current can be evaluated.

5.6.7 Finishing up

After verifying the drive current, the Notch Filter may be the only setting still needing adjusting.

See section 5.8 on “Setting the Notch Filter”.

+86-400-820-9661

37

Rev. 1.0

0012072012

TSM24P User Manual

5.7 Using Auto Trigger Sampling

In cases where an external controller is used to perform move proles, such as in the Position

Control Mode using Pulse & Direction input, the Auto Trigger will allow the Sampling to collect

data and display the move prole.

This sampling technique is different in that it is not triggered by the start of a move prole as the

drive cannot know when the move is actually started (remember the controller is external). Instead

the Auto Trigger waits for a predened set of conditions to tell it when to start collecting the move

prole data.

5.7.1 Setting up Auto Trigger

When using Auto Trigger, the primary effort is to select the conditions that will trigger the

sampling. Begin by selecting the desired trigger value in the Plot 1 list. This selection is what is

monitored by the Auto Trigger, Plot 2 is not monitored.

In the Auto Trigger tab the displayed text will indicate the value to be used and the conditions to

trigger the capture of the selected value. In the example to the right, the capture will begin when

Actual Speed is Above 1.000 rev/sec, the capture will Capture data for 0.300 seconds and

there will be a 10% Capture delay from the beginning of the capture to the trigger point. The

Capture delay allows viewing of the data prior to the trigger point so that a more complete prole

can be observed.

When changing Plot 1 to other selections notice that the conditions for the capture trigger will

change with it. For example, when selecting Position Error the capture will look at Counts for

determining the trigger point.

Sample Once: when the Start button is clicked the TSM drive begins continuous collection of

data. It will constantly check the data to see if the value meets the capture trigger conditions. At

the same time Quick Tuner monitors the status of the TSM to detect if the capture is complete.

When the capture is complete the data is displayed in the prole window.

Sample Continuously: when the Start button is clicked the capture is repeated each time the

trigger condition is met until the Stop button is clicked. During continuous sampling the tuning

gains can be changed at any time and will be updated automatically. This allows more dynamic

adjustment of the gains for speeding up the tuning process

NOTE: When adjusting control loop gain values remember that the FF Term (KK) has no

effect when operating in the Position – Pulse & Direction Control Mode.

Rev. 1.0

0012072012

38

+86-400-820-9661

TSM24P User Manual

5.8 Setting the Notch lter

The notch lter is used when there is a specic resonate frequency present in the system and

good performance requires that only the “bad” frequency be removed. Sometimes the resonate

frequency is low enough that it should only be removed using the notch lter. Using the standard

output lter or reducing the gain settings may compromise the system performance too much.

When performing the move proles as discussed above, a signicant resonate frequency may be

experienced visually on the plot window, audibly, or both. Finding this frequency can be a difcult

task and it is often discovered by experimentation. Change the frequency then perform sampling

moves until the resonance is reduced or removed. Keeping the bandwidth wide (maybe equal to

the center frequency) may help nd the center frequency. When the center is found, the bandwidth

may be reduced until the resonance starts to return.

+86-400-820-9661

39

Rev. 1.0

0012072012

TSM24P User Manual

6 SCL Test & Monitor

6.1 SCL Test

The SCL (Serial Command Language) Test tool is used to

send commands to the serial port of the connected drive. A

command can be entered manually in the Command window

at the bottom of the screen. The history of the sent command

and responses of the drive are displayed in the Command

History & Response window. This tool is designed to help

the user learn SCL usage prior to implementation on the

system controller. The command interface allows entry of all

supported SCL commands. Any command syntax errors that

are encountered are also displayed in the response window.

The Command History & Response window also displays

commands and responses used when operating the other

functions provided on the SCL Test & Monitor tab such as Jog

Move or Single Move.

Step-Servo Quick Tuner communicates to the connected

drive using a high baud rate of 115200 and a protocol that

includes the Checksum. These protocol settings are used to

provide high speed and reliable communications with the drive

during the conguration, tuning, or testing operations. The

response window will indicate the exact command syntax that

is being used. This means that the user will be able to see both the Checksum calculated for that

command and the Checksum provided in the response by the drive. This is a useful feature to

help the system programmer determine the proper Checksum calculation in the system controller.

An option that is not recommended is to check the Hide Checksum box (turns off the Checksum).

A user might also select hiding the Checksum so that it is not visible in the Command History &

Response window.

6.2 Move Testing

6.2.1 Jog Move

The Jog Move tool provides a window for setting the Jog Speed

(commanded velocity) in rps, and the Accel/ Decel (acceleration

to and deceleration from the set speed) in rps2. By clicking

and holding the CW Jog or CCW Jog button, the drive can be

commanded to operate at the set jogging speed. (CW Jog causes

the motor to spin in a clockwise direction as viewed from the front

(shaft side) of the motor; CCW Jog does the opposite.) This is the most basic move for testing

motor operation. Be careful as this operation is not a distance move and holding the button too

long could drive a connected mechanism to the end of its limits.

Rev. 1.0

0012072012

40

+86-400-820-9661

TSM24P User Manual

6.2.2 Single Move

The Single Move tool provides settings for the Command

Distance, Command Speed, Acceleration, Deceleration,

and Electronic Gearing for a relative or an absolute type

of move. Clicking the Absolute Move button will command

the drive to move the motor to the commanded position as

indicated by the Command Distance setting. Clicking the

Relative CW Move or Relative CCW button will cause the

drive to move the motor the set distance from its current

position. Clicking the Stop button will cause an immediate stop

of the move with the given deceleration setting.

If the TSM is connected to a system where position sensors

are also connected, the TSM can be commanded to move

to the sensor in either a CW or CCW direction. It can be

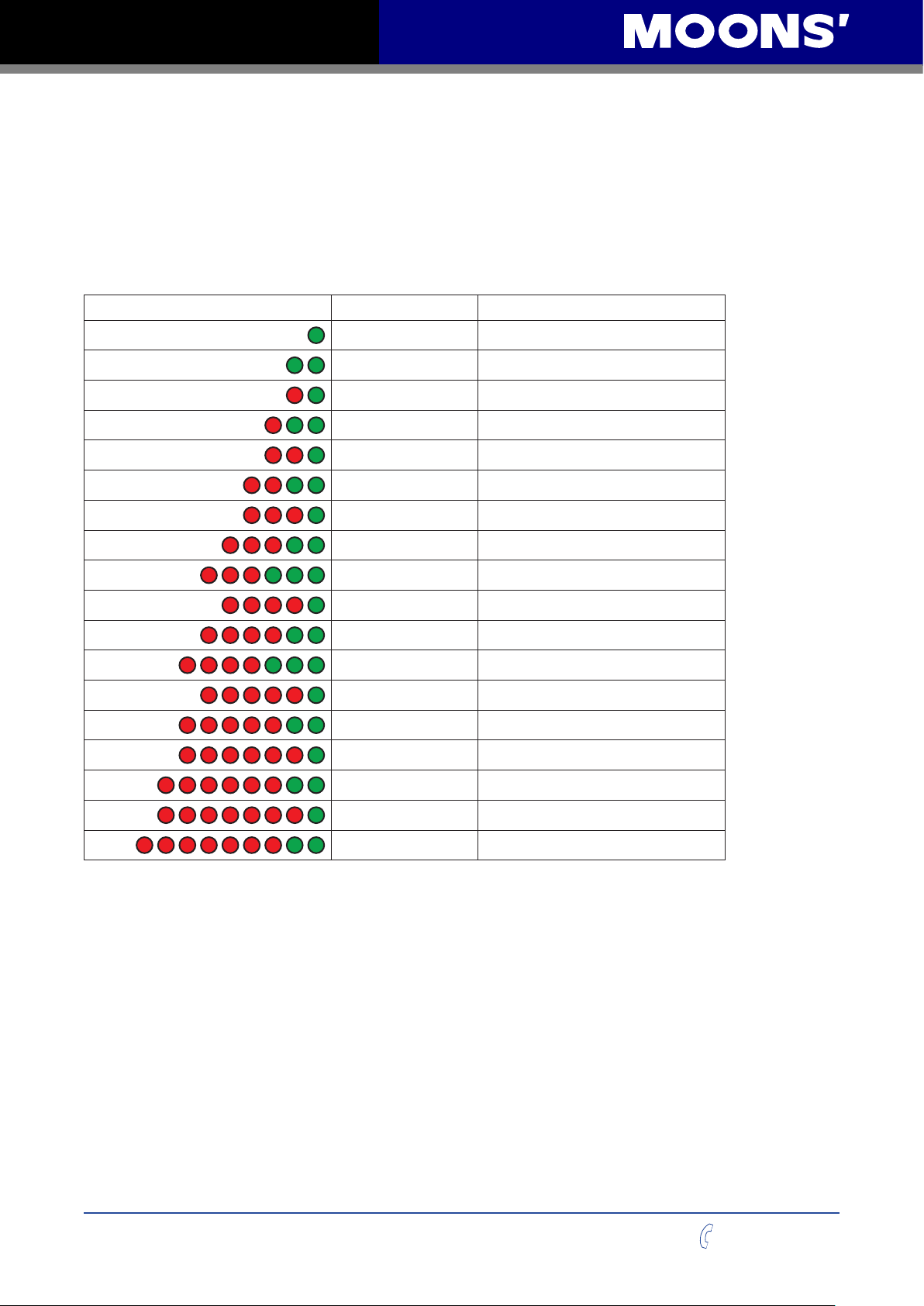

instructed to Move to Sensor #1, #2, or #3, and to Stop