SS-EC

Step-Servo EtherCAT Drive

Hardware Manual

SS03-EC-D SS05-EC-D SS10-EC-D

SHANGHAI AMP & MOONS’ AUTOMATION CO.,LTD.

Rev. 1.0

06/21/2016

SS03/05/10-EC Hardware Manual

Table of Contents

1 Introduction ......................................................................................................4

1.1 Features ................................................................................................4

1.2 Block Diagram ........................................................................................5

1.3 Safety Instructions ..................................................................................6

2 Getting Started ..................................................................................................7

2.1 Installing the Software ............................................................................7

2.2 Mounting the Drive .................................................................................8

2.3 Connecting to the PC using mini USB ...................................................8

2.4 Choosing the Right COM Port ................................................................9

2.5 Connecting the Main Power Supply .......................................................9

2.6 Connecting the Auxiliary Power Supply..................................................10

2.7 Choosing a Power Supply ......................................................................10

2.7.1 Supply Voltage .... ...................................................................10

2.7.2 Supply Current ........................................................................10

2.7.3 Auxiliary Supply Voltage (Keep Alive Function) .......................22

2.7.3.1 Keep Alive Recovery with I/O Function ...........................22

2.7.3.2 Keep Alive Recovery with the Master Controller .............22

2.8 Connecting the Motor .............................................................................23

2.9 Connecting the EtherCAT .......................................................................24

2.9.1 EtherCAT Status Indicator LEDs .............................................24

2.10 Connecting the STO .............................................................................25

2.10.1 Safety Precautions ................................................................25

2.10.2 STO Internal Circuit Diagram ................................................25

2.10.3 CN4 Connector diagram ........................................................25

2.10.4 STO Signal Denition ............................................................26

2.10.5 STO Connection Diagrams ...................................................26

3 Inputs and Outputs ............................................................................................27

3.1 Digital Inputs...........................................................................................28

3.1.1 X1, X2, X3 and X4 Digital Inputs .............................................28

3.1.2 X5, X6, X7 and X8 Digital Inputs .............................................29

3.2 Y1, Y2, Y3 and Y4 Digital Outputs .........................................................30

3.3 Analog Inputs..........................................................................................31

3.4 Encoder output .......................................................................................32

4 Control Panel (LED display and keys) ..............................................................33

4.1 Description of Control Panel...................................................................33

4.2 Mode Switch Control ..............................................................................33

4.3 LED display description ..........................................................................35

4.3.1 Decimal Point And Negative Sign Description .........................35

4.3.2 Parameter View Setting ...........................................................35

4.3.3 Parameter Save Setting ..........................................................35

4.3.4 Point To Point Motion Mode ...................................................35

4.3.5 Jog Mode .................................................................................36

4.3.6 Control Panel Lock ..................................................................36

4.4 Status Monitoring Selection Mode..........................................................36

Rev. 1.0

2016/7/30

2

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.5 Function Control Mode ...........................................................................38

4.5.1 Function Mode Description ......................................................38

4.5.2 Operation Flow Chart ..............................................................39

4.6 Parameter Setting Mode ........................................................................40

4.6.1 Parameter Setting Description ................................................40

4.6.2 Parameter Editing Examples ...................................................41

4.6.3 Parameter list ..........................................................................42

4.7 Control Panel Lock .................................................................................45

4.8 Warning And Fault Display .....................................................................45

4.9 LED Character Reference ......................................................................47

5 Reference Materials ..........................................................................................48

5.1 Drive Mechanical Outlines......................................................................48

5.2 Drive Technical Specications ................................................................49

5.3 Recommended Motors and Specications .............................................50

5.4 Motor Mechanical Outlines .....................................................................51

5.5 Torque Curves ........................................................................................54

5.6 Motor Numbering System ......................................................................56

5.7 Drive Numbering System ......................................................................56

6 Optional Accessories (Sold separately) ................... .........................................57

6.1 Cables ....................................................................................................57

6.2 Mating Connectors .................................................................................59

7 Contacting MOONS’..........................................................................................60

+86-400-820-9661

3

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

1 Introduction

Thank you for selecting the MOONS’ SS-EC Step-Servo drive and motor. The SS-EC series

combines servo technology with a stepper motor to create a product with exceptional features and

broad capability. The SS-EC drive can operate as a standard EtherCAT slave using CANopen over

EtherCAT (CoE).

1.1 Features

• Programmable, digital step-servo drive and motor package

• Operates from a 24 to 70 volt DC power supply

• CANopen over EtherCAT (CoE) with full support of CiA402. Based on the widely used

100BASE-TX cabling system and with a baud rate of 100Mbps full-duplex, EtherCAT enables

high speed and highly reliable communication

• Supported modes: Prole Position, Prole Velocity, Prole Torque, Cyclic Synchronous Position,

Cyclic Synchronous Velocity, and Homing; as well as MOONS’ own Q mode

• Dual port EtherCAT communication

• USB port for conguration

• Encoder resolution: 20000 counts/rev for AM17/23/24/34SS motor, 4096 counts/rev for AM11SS

motor

• SS03-EC output current: continuous 3A, boost 4.5A

• SS05-EC output current: continuous 5A, boost 7.5A

• SS10-EC output current: continuous 10A, boost 15A

• 8 optically isolated digital inputs, 5-24VDC high level voltage

• 4 optically isolated digital outputs, max 30V/100mA sink or source current

• 2 analog inputs, can be congured to 0-5V, 0-10V, ±5V or ±10V signal ranges

• Dierential encoder signal output (AOUT +/-, BOUT +/-, ZOUT +/-), 26C31 line driver, 20mA sink

or source current

• Keep Alive function available with an auxiliary power supply

• Front panel with 4 keys and 5 digit LED display for setting parameters

• STO function

Rev. 1.0

2016/7/30

4

+86-400-820-9661

SS03/05/10-EC Hardware Manual

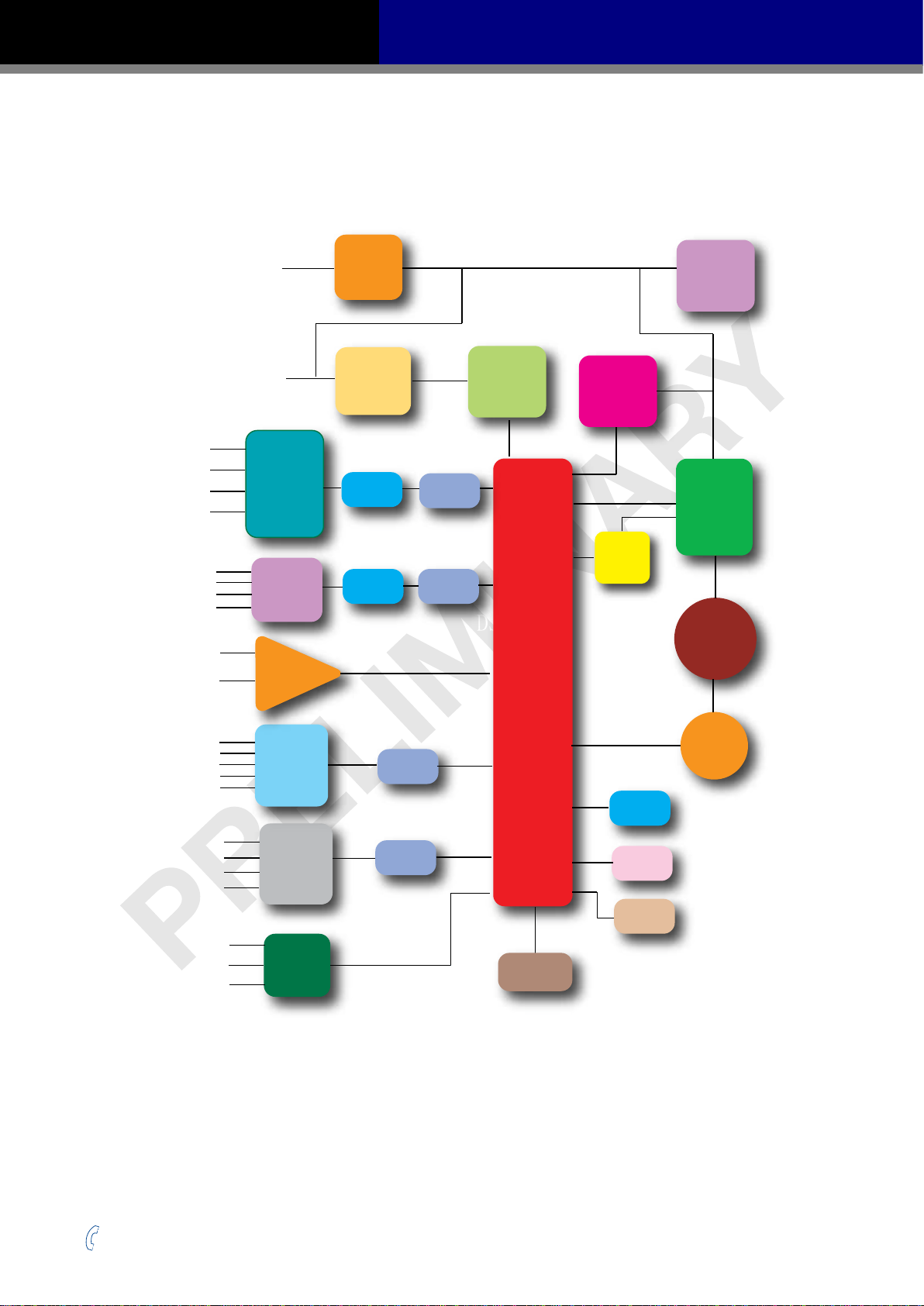

1.2 Block Diagram

SS EtherCAT Block Diagram

Power Supply

(24-70VDC)

Auxiliary Power

(12-48VDC)

X1+

X1-

X2+

X2-

X3+

X3-

X4+

X4-

ANALOG1

ANALOG2

High

Speed

Input

Optical

Isolation

Input

Optical

Isolation

Operational

Amplifter

EMC

Filter

DC Input

Power

Converter

Digital

Filter

Digital

Filter

Software

Filter

Software

Filter

DSP

Internal

Logic

Supply

DSP

Internal

Regen

Clamp

Voltage

Temp.

Det.

Mosfet

PWM

Power

Amplifier

Over

Current

Det.

Motor

X5

X6

X7

X8

XCOM

Y1+/Y2+/Y3+/Y4+/-

A+/-

B+/-

Z+/-

Single

Ended

Input

Isolation

Output

Optical

Isolation

Encoder

Output

Software

Filter

Software

Filter

Encoder

USB

EtherCAT

STO

LED

+86-400-820-9661

5

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

1.3 Safety Instructions

Only qualied personnel should transport, assemble, install, operate, or maintain this equipment.

Properly qualied personnel are persons who are familiar with the transport, assembly, installation,

operation, and maintenance of motors, and who meet the appropriate qualications for their jobs.

To minimize the risk of potential safety problems, all applicable local and national codes regulating

the installation and operation of equipment should be followed. These codes may vary from area

to area and it is the responsibility of the operating personnel to determine which codes should be

followed, and to verify that the equipment, installation, and operation are in compliance with the

latest revision of these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. MOONS’ does not guarantee the products described in this publication

are suitable for a particular application, nor do they assume any responsibility for product design,

installation, or operation.

• Read all available documentation before assembly and operation. Incorrect handling of the

products referenced in this manual can result in injury and damage to persons and machinery.

All technical information concerning the installation requirements must be strictly adhered to.

• It is vital to ensure that all system components are connected to earth ground. Electrical safety

is impossible without a low-resistance earth connection.

• This product contains electrostatically sensitive components that can be damaged by incorrect

handling. Follow qualied anti-static procedures before touching the product.

• During operation keep all covers and cabinet doors shut to avoid any hazards that could

possibly cause severe damage to the product or personal health.

• During operation, the product may have components that are live or have hot surfaces.

• Never plug in or unplug the Integrated Motor while the system is live. The possibility of electric

arcing can cause damage.

Be alert to the potential for personal injury. Follow recommended precautions and safe operating

practices emphasized with alert symbols. Safety notices in this manual provide important

information. Read and be familiar with these instructions before attempting installation, operation, or

maintenance. The purpose of this section is to alert users to the possible safety hazards associated

with this equipment and the precautions necessary to reduce the risk of personal injury and damage

to equipment. Failure to observe these precautions could result in serious bodily injury, damage to

the equipment, or operational diculty.

Rev. 1.0

2016/7/30

6

+86-400-820-9661

SS03/05/10-EC Hardware Manual

2 Getting Started

The following items are needed:

• A 24-70 volt DC power supply, see Section 2.7 “Choosing a Power Supply” for help in choosing

the right one.

• An optional 12-48 volt DC power supply for Keep Alive function

• A compatible SS motor, see Section 5.3 “Recommended Motors and Specications”

• A small at blade screwdriver for tightening the connectors (included)

• A PC running Microsoft Windows XP, Windows 7, Windows 8/10 (32-bit or 64-bit) operating

system

• A mini USB cable for conguration (not included)

• Step-ServoQuickTuner software (available from MOONS’ website)

• A CAT5 cable for EtherCAT daisy chain connection (included)

• An STO connector for CN4 connection (included)

• Optional motor extension cable

• Optional encoder extension cable

• Optional I/O cable

2.1 Installing the Software

Step-ServoQuickTuner is the PC based software application used to congure and perform servo

tuning, drive testing, and evaluation on MOONS’ step-servo products. System servo control gains,

drive functionality, and I/O conguration are set with Step-ServoQuickTuner. It also contains an

oscilloscope function to help to set the servo control gains.

• Download the Step-Servo Quick Tuner from the MOONS’ website and install it.

• Launch the software by clicking Start -- Programs -- MOONS’

• Connect the drive to the PC with the mini USB cable. Select right COM port in the software. See

Section 2.4 “Choosing the Right COM Port”.

• Connect the drive to the power supply.

• Connect the motor to the drive.

+86-400-820-9661

7

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

2.2 Mounting the Drive

Use M4 screws to securely mount the SS-EC series drive to a smooth, at metal surface that will

help to conduct heat away from the chassis. If a heat conducting surface is not available, forced

airow from a fan may be required to prevent the drive from overheating.

• Never use the drive in a place where there is no air ow or the surrounding air is

more than 40°C.

• Never put the drive where it can get wet or where metal or other electrically

conductive particle particles can get on the circuity.

• Always provide air ow around the drive. When mounting multiple SS drives near

each other, maintain at least 1.5cm of space between drives.

The connectors and other points of interest are illustrated below:

Control Panel

(LED display and keys)

Encoder Connector

Motor Connector

Power Connector

2.3 Connecting to the PC using mini USB

Mini USB

EtherCAT LINK IN

EtherCAT LINK OUT

STO

I/O Connector

Port CN2 is used to connect the drive with PC. Use Step-ServoQuickTuner software to congure

the drive and perform servo tuning and drive testing.

PIN Symbol Function

1 +5V +5V Power Supply

2 D- Data3 D+ Data+

4 - Reserved

5 GND Ground

Rev. 1.0

2016/7/30

8

+86-400-820-9661

SS03/05/10-EC Hardware Manual

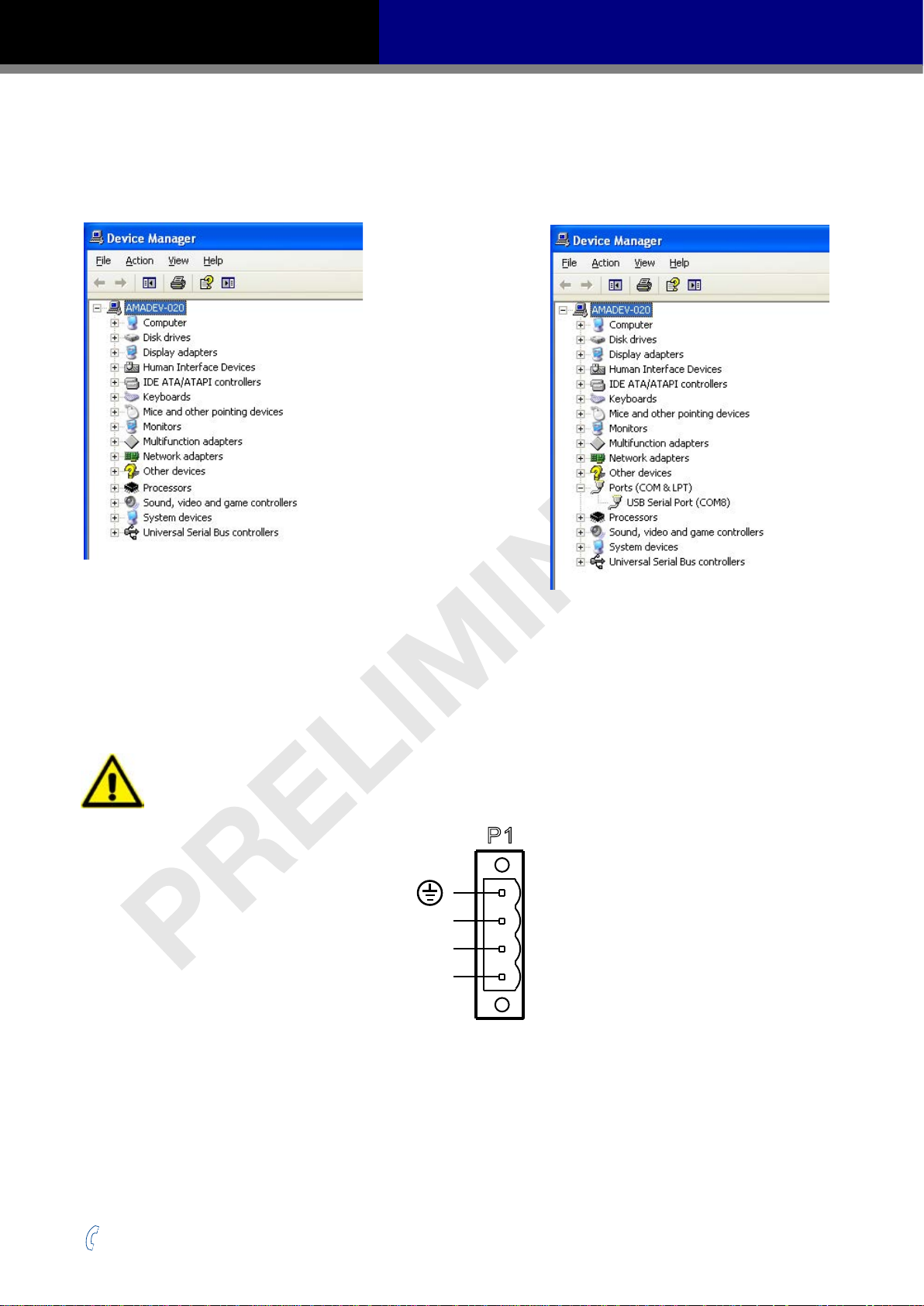

P1

V

V

AUX

-

+

2.4 Choosing the Right COM Port

Open the “Device Manager” on the PC. There may or may not be a “Ports” selection. Connect the

mini USB cable to the PC. The connected COM port should then be displayed. Choose this new

COM(n) port in the Step-Servo Quick Tuner software.

2.5 Connecting the Main Power Supply

Connect power supply “+” terminal to the drive terminal labeled “V+”.

Connect power supply “-” terminal to the drive terminal labeled “V-”.

The SS-EC accepts DC voltage ranging from 24 to 70VDC

Warning: DO NOT reverse the wires

NOTE: DO NOT apply power until all connections to the drive have been made

Power Connector

Read Section 2.7 “Choosing a Power Supply” for more details.

+86-400-820-9661

9

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

2.6 Connecting the Auxiliary Power Supply

If the Keep Alive function is needed, an auxiliary power supply is required.

Connect the auxiliary power supply “+” terminal to the drive terminal labeled “AUX”.

Connect the auxiliary power supply “-” terminal to the drive terminal labeled “V-”.

The SS-EC auxiliary Power Supply input accepts DC voltage range from 12 to 48VDC.

Warning: DO NOT reverse the wires

NOTE: DO NOT apply power until all connections to the drive have been made

2.7 Choosing a Power Supply

The main considerations when choosing a power supply are the voltage and current requirements of

the application.

2.7.1 Supply Voltage

The SS-EC is designed to give optimum performance at 24-48 volts DC. Choosing the voltage

depends on the performance needed and the motor/drive heating that is acceptable and/or does not

cause a drive over-temperature. Higher voltages will give higher speed performance but will cause

the SS-EC to produce higher temperatures. Using power supplies with voltage outputs that are near

the drive’s maximum may signicantly reduce the operational duty-cycle.

The extended range of operation can be as low as 18VDC minimum to as high as 75VDC

maximum. When operating below 18VDC, the SS-EC may become unstable. The supply input

cannot go below 18VDC for reliable operation. If the input supply drops below 18VDC the under

voltage alarm will be triggered and the drive will stop working.

Absolute maximum power supply input is 75VDC at which point an over-voltage alarm and fault

will occur. When using a power supply that is regulated and is near the drive maximum voltage of

75VDC, a voltage clamp may be required to prevent over-voltage when regeneration occurs. When

using an unregulated power supply, make sure the no-load voltage of the supply does not exceed

the drive’s maximum input voltage of 75VDC.

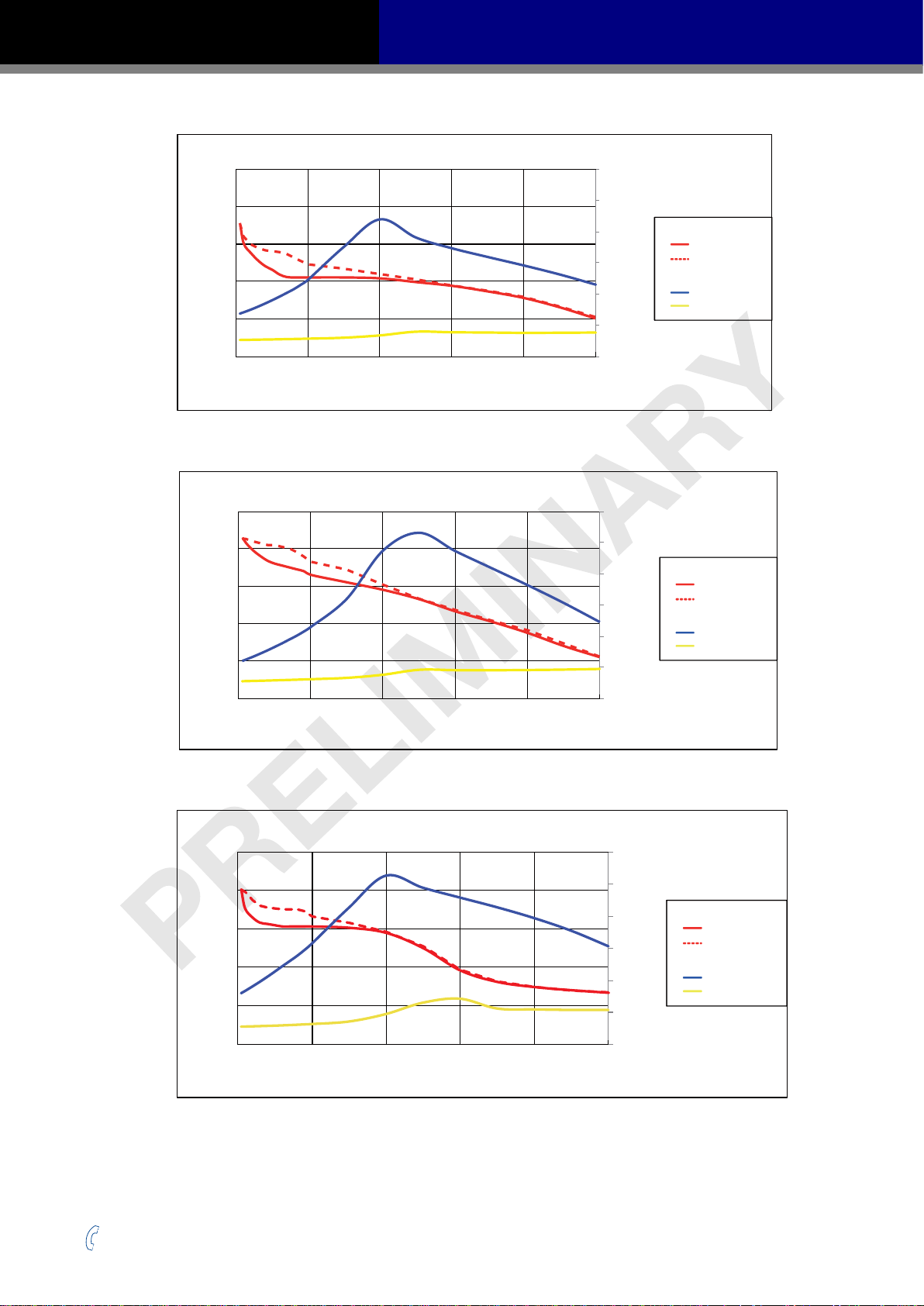

2.7.2 Supply Current

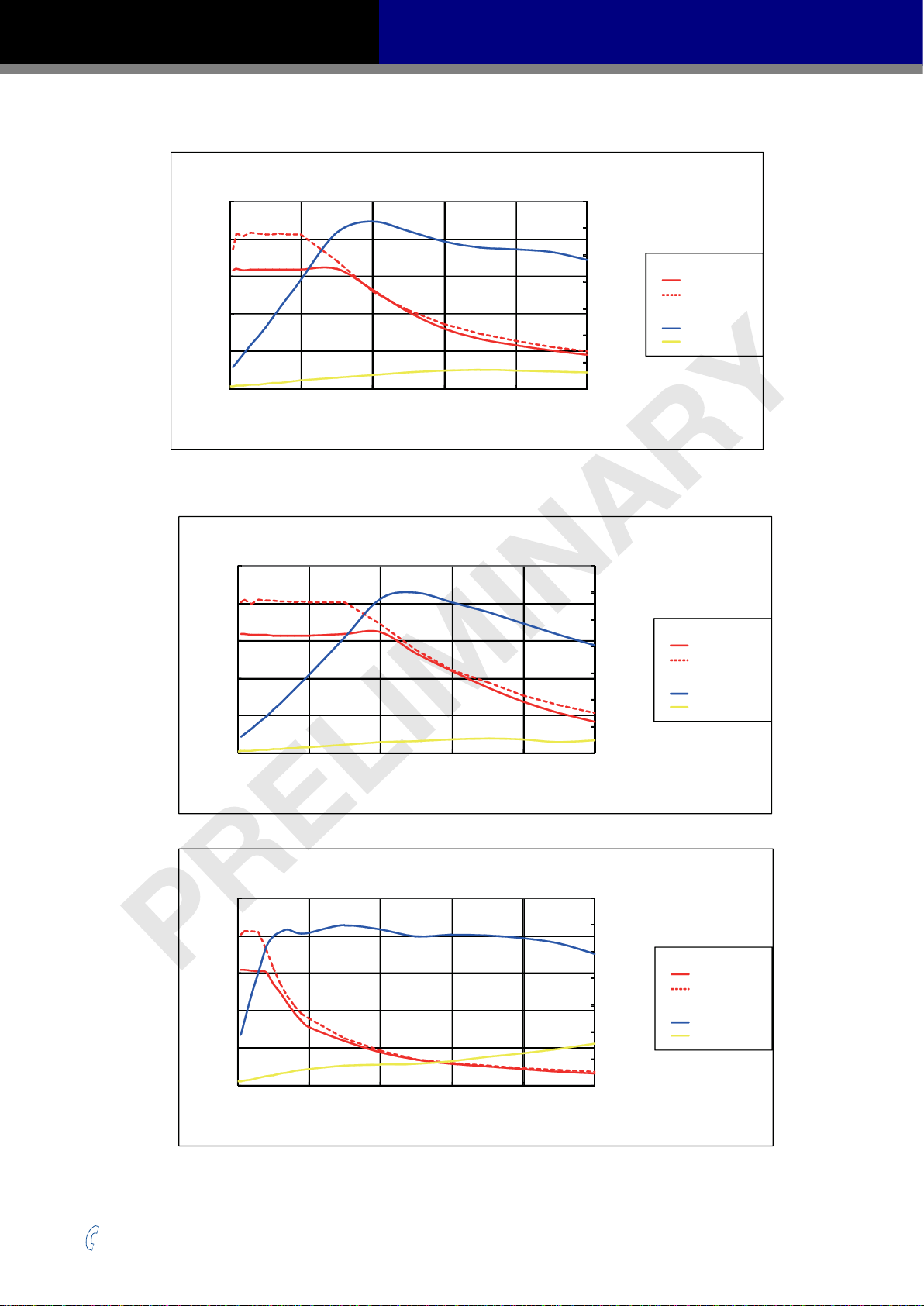

The maximum supply currents required by the SS-EC are shown in the charts below at dierent

power supply voltage inputs. The SS-EC power supply current is lower than the winding currents

because it uses switching ampliers to convert a high voltage and low current into lower voltage and

higher current. The more the power supply voltage exceeds the motor voltage, the less current will

be required from the power supply.

It is important to note that the current draw is signicantly dierent at higher speeds depending on

the torque load to the motor. Estimating how much current is necessary may require a good analysis

of the load the motor will encounter.

Rev. 1.0

2016/7/30

10

+86-400-820-9661

SS03/05/10-EC Hardware Manual

100

AM11SS1DMA 24V Power

80

60

40

Torque(mN.m)

20

0

0 10 20 30 40 50

Speed(RPS)

AM11SS2DMA 24V Power

100

80

60

40

Torque(mN.m)

20

1.2

1.0

0.8

0.6

0.4

0.2

0.0

1.2

1.0

0.8

0.6

0.4

0.2

Torque

Supply Current

Amps

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM11SS3DMA 24V Power

150

120

90

60

Torque(mN.m)

30

0

0 10 20 30 40 50

Speed(RPS)

0.0

1.2

1.0

0.8

0.6

0.4

0.2

0.0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

+86-400-820-9661

11

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

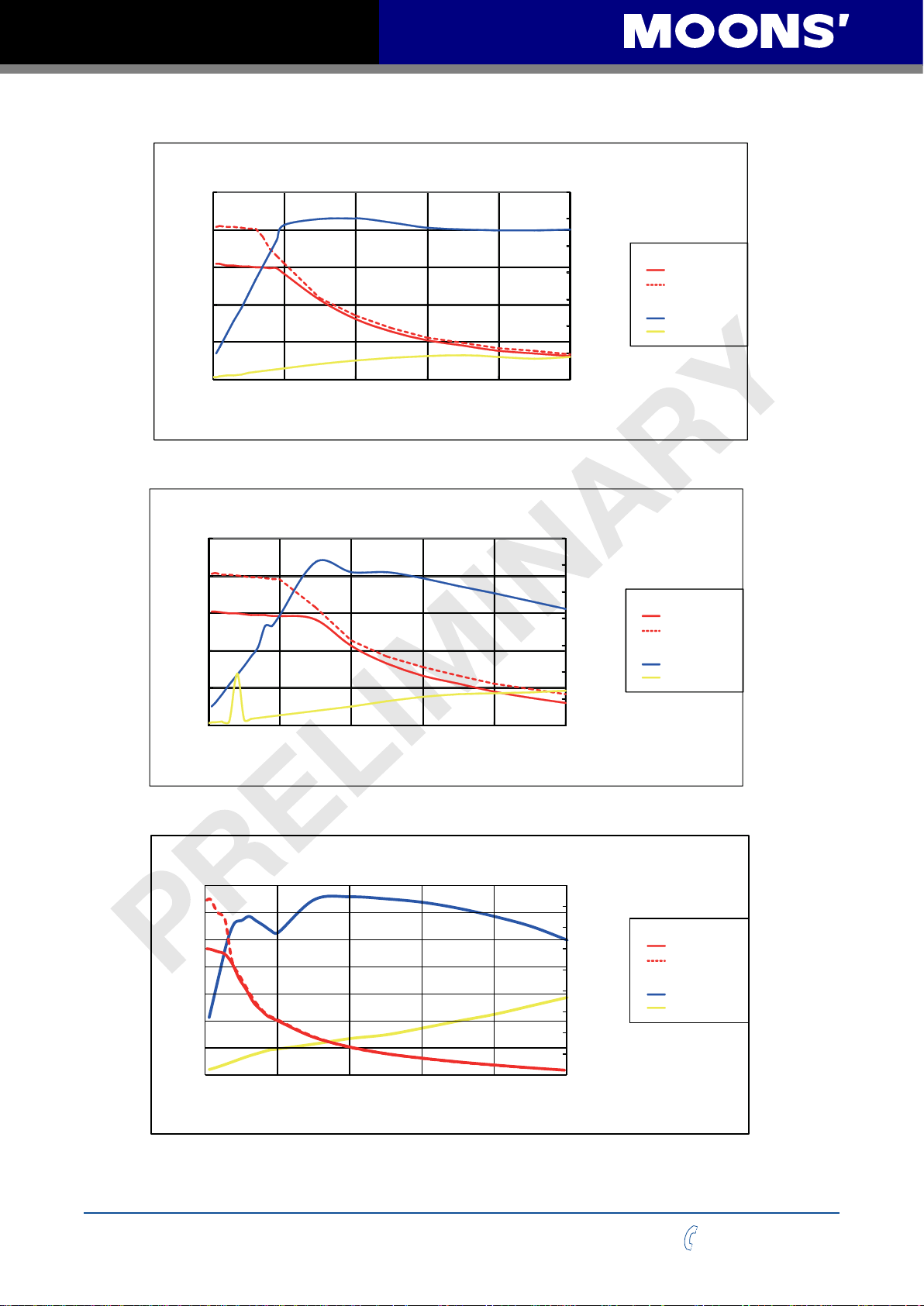

AM11SS3DMA 24V Power

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0

30

60

90

120

150

0 10 20 30 40 50

Torque(mN.m)

Speed(RPS)

Amps

Continuous

Torque

Boost

Supply Current

Full Load

No Load

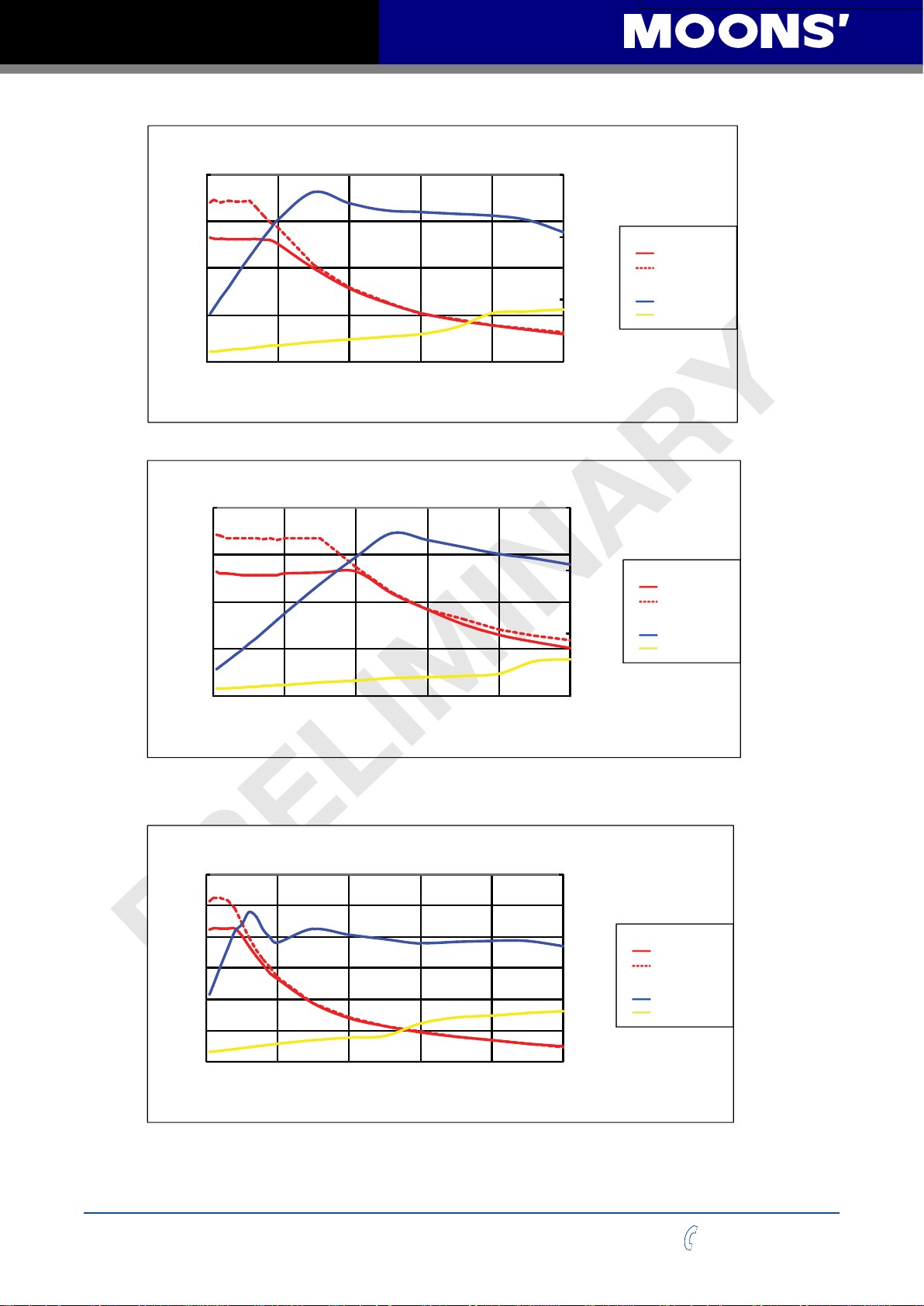

AM17SS1DG□-N 24V Power

0.4

0.3

0.2

Torque(N.m)

0.1

1.5

1

0.5

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM17SS1DG□-N 48V Power

0.4

0.3

0.2

Torque(N.m)

0.1

0

0 10 20 30 40 50

Speed(RPS)

0

1.5

1

0.5

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

0

AM17SS2DG□-N 24V Power

0.6

0.5

0.4

0.3

0.2

Torque(N.m)

0.1

0

0 10 20 30 40 50

Speed(RPS)

Rev. 1.0

2016/7/30

12

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

+86-400-820-9661

SS03/05/10-EC Hardware Manual

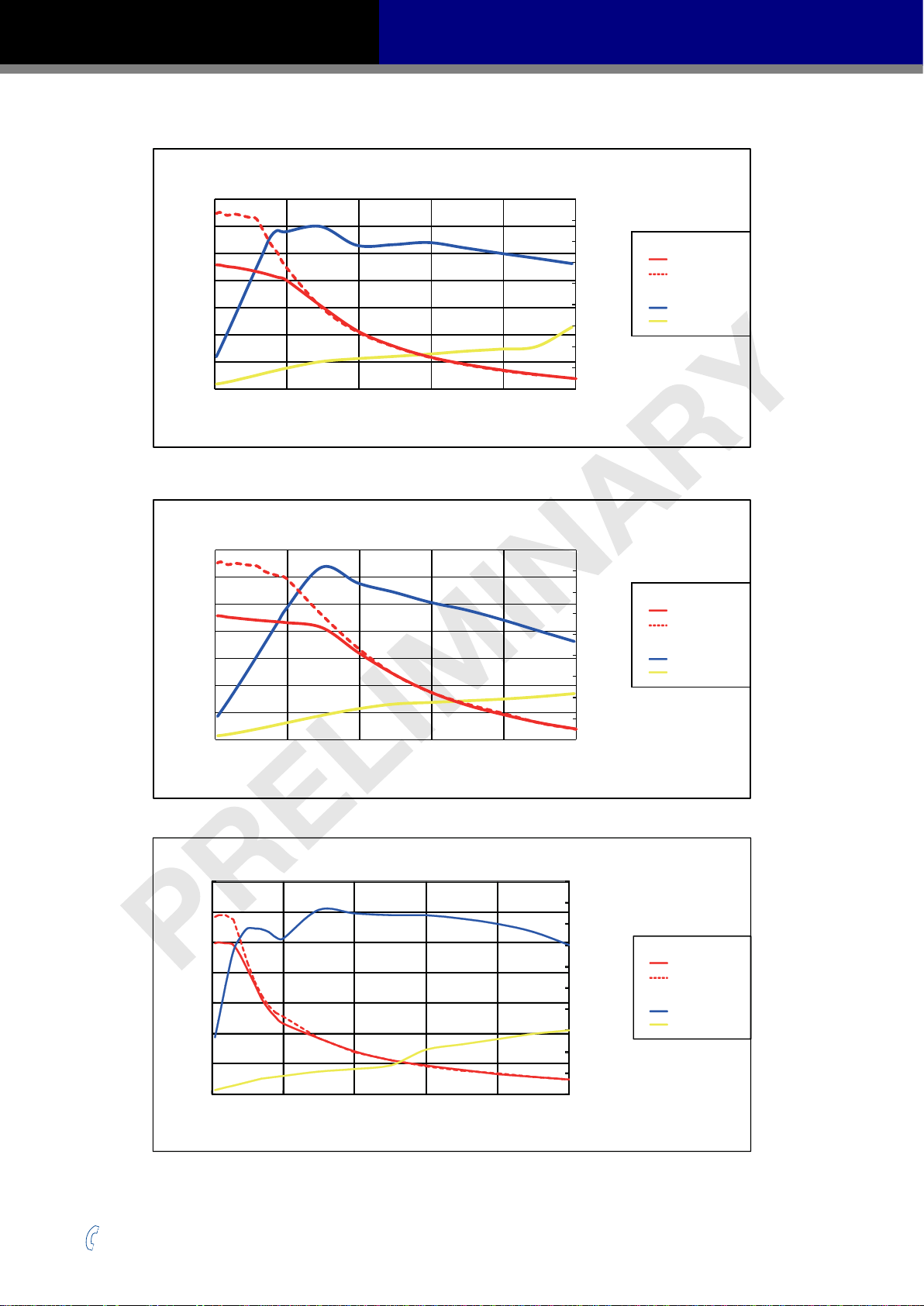

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Amps

Continuous

Torque

Boost

Supply Current

Full Load

No Load

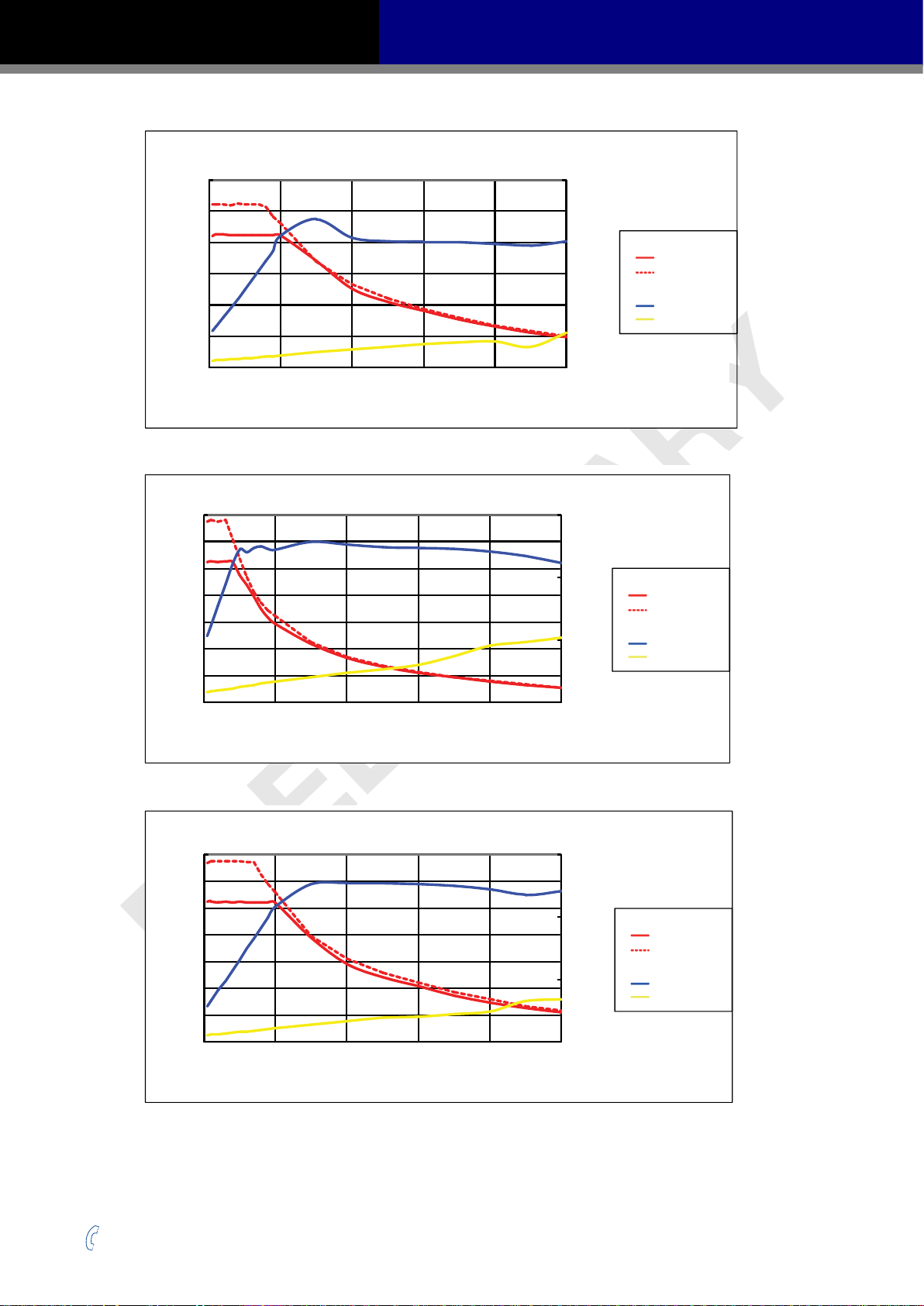

AM17SS2DG□-N 48V Power

0.6

0.5

1.5

0.4

0.3

0.2

Torque(N.m)

0.1

0

0 10 20 30 40 50

Speed(RPS)

AM17SS3DG□-N 24V Power

0.7

0.6

0.5

0.4

0.3

0.2

Torque(N.m)

0.1

1

0.5

0

1.5

1

0.5

Torque

Supply Current

Amps

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

0.7

0.6

0.5

0.4

0.3

0.2

Torque(N.m)

0.1

0

0 10 20 30 40 50

+86-400-820-9661

Speed(RPS)

AM17SS3DG□-N 48V Power

Speed(RPS)

13

0

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

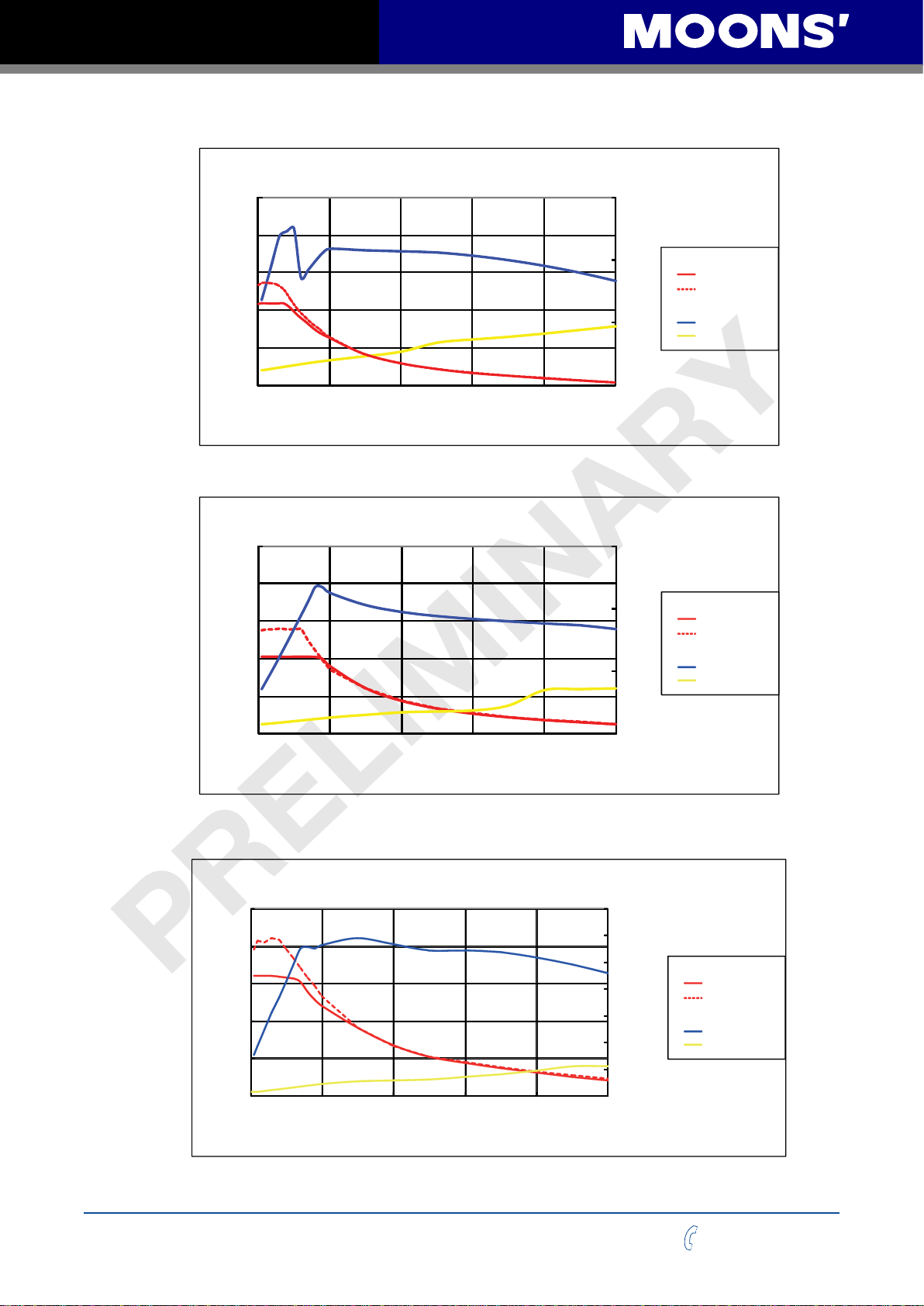

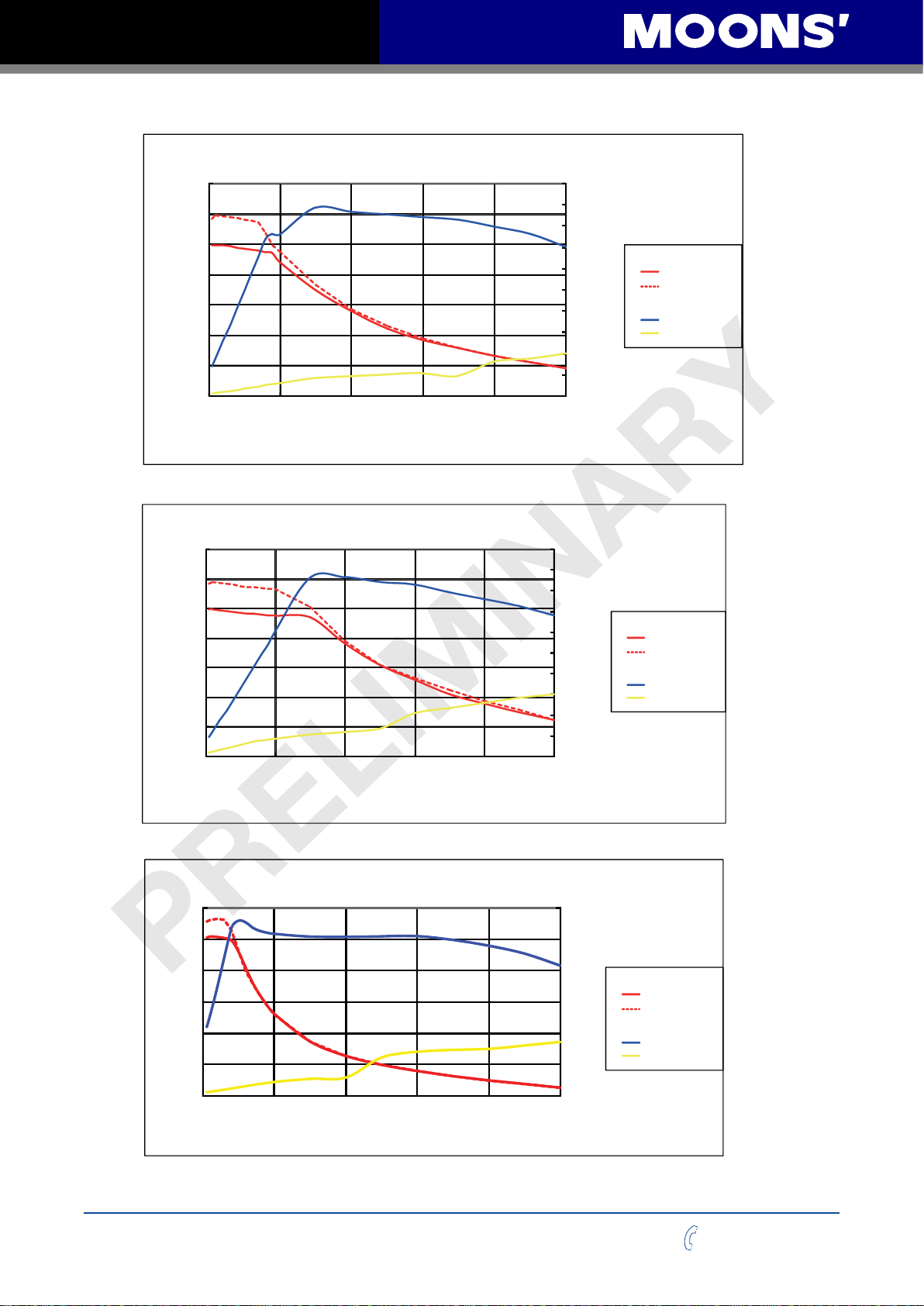

1.5

1.2

0.9

0.6

Torque(N.m)

0.3

AM17SS4DG□-N 24V Power

1.5

1

0.5

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM17SS4DG□-N 48V Power

1.5

1.2

0.9

0.6

Torque(N.m)

0.3

0

0 10 20 30 40 50

Speed(RPS)

0

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Rev. 1.0

2016/7/30

AM23SS2DG□-N 24V Power

1.5

1.2

0.9

0.6

Torque(N.m)

0.3

0

0 10 20 30 40 50

Speed(RPS)

14

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Continuous

Boost

Supply Current

Amps

Full Load

No Load

+86-400-820-9661

SS03/05/10-EC Hardware Manual

AM23SS2DG□-N 48V Power

1.5

3.5

1.2

0.9

0.6

Torque(N.m)

0.3

0

0 10 20 30 40 50

Speed(RPS)

AM23SS2DG□-N 70V Power

1.5

1.2

0.9

0.6

Torque(N.m)

0.3

3

2.5

2

1.5

1

0.5

0

3.5

3

2.5

2

1.5

1

0.5

Torque

Supply Current

Amps

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM23SS3DG□-N 24V Power

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

0

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

+86-400-820-9661

15

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

AM23SS3DG□-N 48V Power

2.5

3.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

AM23SS3DG□-N 70V Power

2.5

2

1.5

1

Torque(N.m)

0.5

3

2.5

2

1.5

1

0.5

0

3.5

3

2.5

2

1.5

1

0.5

Torque

Supply Current

Amps

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM23SS4DGA-N 24V Power

3.5

3

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

0

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Rev. 1.0

2016/7/30

16

+86-400-820-9661

SS03/05/10-EC Hardware Manual

AM23SS4DGA-N 48V Power

3.5

3

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

AM23SS4DGA-N 70V Power

3.5

3

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

AM24SS3DG□-N 24V Power

3.5

3

2.5

2

1.5

Torque(N.m)

1

0.5

0

0 10 20 30 40 50

Speed(RPS)

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

Continuous

Boost

Full Load

No Load

+86-400-820-9661

17

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

AM24SS3DG□-N 48V Power

3.5

3

2.5

2

1.5

Torque(N.m)

1

0.5

0

0 10 20 30 40 50

Speed(RPS)

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

AM24SS3DG□-N 70V Power

3.5

3

2.5

2

1.5

Torque(N.m)

1

0.5

0

0 10 20 30 40 50

Speed(RPS)

AM34SS1DGA-N 24V Power

3

2.5

2

1.5

1

Torque(N.m)

0.5

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Torque

Continuous

Boost

Supply Current

Amps

Full Load

No Load

6

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

Rev. 1.0

2016/7/30

0

0 10 20 30 40 50

Speed(RPS)

18

0

+86-400-820-9661

SS03/05/10-EC Hardware Manual

AM34SS1DGA-N 48V Power

3

6

2.5

2

1.5

1

Torque(N.m)

0.5

0

0 10 20 30 40 50

Speed(RPS)

AM34SS1DGA-N 70V Power

3

2.5

2

1.5

1

Torque(N.m)

0.5

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

0

6

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM34SS3DGA-N 24V Power

6

5

4

3

2

Torque(N.m)

1

0

0 10 20 30 40 50

Speed(RPS)

0

6

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

0

+86-400-820-9661

19

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

AM34SS3DGA-N 48V Power

6

6

5

4

3

2

Torque(N.m)

1

0

0 10 20 30 40 50

Speed(RPS)

AM34SS3DGA-N 70V Power

6

5

4

3

2

Torque(N.m)

1

5

4

3

2

1

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

0

6

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

AM34SS5DGA-N 24V Power

10

8

6

4

Torque(N.m)

2

0

0 10 20 30 40 50

Speed(RPS)

0

6

5

4

Torque

3

Amps

2

1

Continuous

Boost

Supply Current

Full Load

No Load

0

Rev. 1.0

2016/7/30

20

+86-400-820-9661

SS03/05/10-EC Hardware Manual

AM34SS5DGA-N 48V Power

10

6

8

6

4

Torque(N.m)

2

0

0 10 20 30 40 50

Speed(RPS)

AM34SS5DGA-N 70V Power

10

8

6

4

Torque(N.m)

2

5

4

3

2

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

1

0

5

4

3

2

1

Torque

Supply Current

Amps

Continuous

Boost

Full Load

No Load

0

0 10 20 30 40 50

Speed(RPS)

0

+86-400-820-9661

21

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

2.7.3 Auxiliary Supply Voltage (Keep Alive Function)

In addition to the main power supply input, the SS-EC also has an auxiliary power input (AUX

power) for Keep Alive function of the drive. When the main power supply is o, the AUX power will

keep the logic power on, allowing the drive to remember its state data (motor position, etc.). This

allows the motor to resume operation from its previous position without a homing routine when the

main power is switched back on.

If the main power is removed while the auxiliary power is still on and the drive is disabled, the drive

will show a warning. The LED display will read

power is restored, the drive will automatically clear the warning.

If the main power is removed while the auxiliary power is still on and the drive is enabled, the drive

will show a fault. The LED display will read

When the main power is restored, the drive will not automatically clear the fault. It will need to be

cleared by either the I/O alarm reset function or a clear fault command from the master controller.

2.7.3.1 Keep Alive Recovery with I/O Function

After the main power supply has been restored, the fault must be cleared. Use the alarm reset

function through input 6 (X6) if congured for alarm reset function. (See Section 3.1.2 for conguring

this input via the Step-Servo Quick Tuner software.) When an internal voltage out of range alarm

occurs, the motor is disabled. Use the servo on function through input 5 (X5), also congurable via

the software, to re-enable it.

indicating under voltage. When the main

indicating the internal voltage is out of range.

Resume motion and normal program operation.

2.7.3.2 Keep Alive Recovery with the Master Controller

After the main power supply has been restored, the fault must be cleared. The master controller

program can write 0x80 to Control Word (0x6040) to clear the fault. When an internal voltage out of

range alarm occurs, the motor is disabled. The master controller program can write 0x0F to Control

Word (0x6040) to enable the motor.

Resume motion and normal program operation.

Rev. 1.0

2016/7/30

22

+86-400-820-9661

SS03/05/10-EC Hardware Manual

P2

2.8 Connecting the Motor

The SS motors have two cables - the motor power cable, and the encoder feedback cable. Use

the optional motor extension cable and/or encoder extension cable, or make extension cables

using connector housing and crimps included in package if more length is needed. Connect the

motor power cable’s black, green, red and blue wires respectively to the drive’s A+, A-, B+ and B-

connections. Plug the encoder feedback cable into the encoder feedback connector on the drive.

DO NOT drag the motor by the cables as this may damage it.

Wire Colors

B

B

A

A

-

+

-

+

Blue

Red

Green

Black

Motor Connector

CN1

2

A-

4

B-

6

Z-

U-

V-

W-

8

10

12

14

16

GND

Encoder Feedback Connector

See Section 6 ”Optional Accessories (Sold Separately)” for cables and mating connectors.

11

13

15

1

3

5

7

9

A+

B+

Z+

+5V

NC

U+

V+

W+

+86-400-820-9661

23

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

2.9 Connecting the EtherCAT

Dual RJ-45 connectors (connection CN3) accept standard Ethernet cables and are categorized

as 100BASE-TX (100 Mb/sec) ports. CAT5 or CAT5e (or higher) cables should be used. The IN

port connects to a master, or to the OUT port of an upstream node. The OUT port connects to a

downstream node. If the drive is the last node on a network, only the IN port is used. No terminator

is required on the OUT port.

2.9.1 EtherCAT Status Indicator LEDs

The LEDs are used for indicating status of the EtherCAT. There are two Link/Activity LEDs (one for

each RJ-45 Ethernet connector) and two status LEDs (RUN and ERR).

Link/Activity Link/Activity

LED indicator codes:

LED Color Status Description

Link/Activity Green

RUN Green

ERR Red

ERR

OFF no Ethernet connection

ON Ethernet is connected

Flickering activity on line

OFF initialization state

Blinking pre-operational state

Single Flash safe-operational state

ON operational state

OFF no error

Blinking general error

Single Flash sync error

Double Flash watch dog error

RUN

Notes:

• Flickering: Rapid ashing with a period of approximately 50ms (10Hz)

• Blinking: Flashing with equal on and o periods of 200ms (2.5Hz)

• Single Flash: Repeating on for 200ms and o for 1s

• Double Flash: Two ashes with a period of 200ms followed by o for 1s

Rev. 1.0

2016/7/30

24

+86-400-820-9661

SS03/05/10-EC Hardware Manual

2.10 Connecting the STO

On the SS EtherCAT step-servo drives, the STO (Safe Torque O) function is connected via port

CN4. The STO function shuts o the motor’s current turning o the motor output torque by forcibly

turning o the signal of the drive’s power transistor. This is done internally through the STO Input/

Output signal circuit.

2.10.1 Safety Precautions

• If you want to bypass the STO function, make sure the STO connector is plugged into CN4 on

the drive correctly.

• When using the STO function, perform an equipment risk assessment to ensure that the system

conforms to the safety requirements.

• Even when the STO function is enabled, the motor may move due to external force (e.g.

gravitational force on the vertical axis). Make sure a holding brake is used in applications where

this is possible.

• When the STO function engages and the torque is removed, the motor will be “free running”,

requiring more distance until the motion stops. Make sure this will not be a safety issue.

• When the STO function operates, it will turn o the current to the motor, but it does not turn o

the power to the drive. Make sure to disconnect the power to the drive before performing any

maintenance on it.

• After the STO function is triggered, the drive will have a fault alarm status, and the motor will

remain disabled even after the STO function switch is plugged back in. To restore the system to

normal operation, clear the fault alarm, and then enable the drive and motor.

2.10.2 STO Internal Circuit Diagram

SF1+

1.5K

SF1-

1.5K

SF2+

SF2-

EDM+

EDM-

2.10.3 CN4 Connector diagram

+86-400-820-9661

25

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

2.10.4 STO Signal Denition

Signal Symbol Pin Description Control Mode

SF1+ 1

Safety Input SF1

SF1- 2

SF2+ 3

Safety Input SF2

SF2- 5

EDM+ 6

Safety Output

EDM- 4

When SF1 has no input signal, e.g.

the port is disconnected, SF1 will be

considered OFF. The upper half of the

internal power transistor will be shut o.

When SF2 has no signal input, e.g.

the port is disconnected, SF2 will be

considered OFF. The upper half of the

internal power transistor will be shut o.

Output monitor signal used to check the

safety function

Ground DGND 7, 8 +5VDC power ground

+5V power +5V 9, 10 +5VDC power supply

2.10.5 STO Connection Diagrams

Connection to safety switch

24VDC

Safety Switch

Safety Input 1

SS EtherCAT Drive

SF1+

SF1-

SF2+

Compatible with all

control modes

Safety Input 2

EDM+

Safety Output

EDM-

0VDC

Safety light connection

Safety Output

SF2-

SS EtherCAT Drive

Rev. 1.0

2016/7/30

26

+86-400-820-9661

SS03/05/10-EC Hardware Manual

3 Inputs and Outputs

The SS-EC drive’s inputs and outputs include:

• 8 optically isolated digital inputs, 5-24VDC high level voltage

• 4 optically isolated digital outputs, max 30V/100mA sink or source current

• 2 analog inputs, can be congured to 0-5V, 0-10V, ±5V or ±10V signal ranges.

• Dierential encoder signal output (AOUT +/-, BOUT +/-, ZOUT +/-), 26C31 line driver, 20mA sink

or source current

CN5

X1X2X3X4-

X6

X8

XCOM

+5V

AIN2

Y1Y2Y3-

Y4AOUTBOUT-

ZOUT-

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

X1+

X2+

X3+

X4+

X5

X7

GND

AIN1

Y1+

Y2+

Y3+

Y4+

AOUT+

BOUT+

ZOUT+

I/O Connector

+86-400-820-9661

27

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

3.1 Digital Inputs

3.1.1 X1, X2, X3 and X4 Digital Inputs

X1, X2, X3 and X4: optically isolated, dierential, 5-24VDC, minimum pulse width 250ns, maximum

pulse frequency 2MHz

• X1 can be used as general purpose input.

• X2 can be used as general purpose input.

• X3 can be used as CW limit input or general purpose input.

• X4 can be used as CCW limit input or general purpose input.

Use Step-ServoQuickTuner software for X1, X2, X3 and X4 function conguration.

The following graphs show some common connection methods for the inputs:

X1/2/3/4+

SS-EC

Drive

X1/2/3/4-

5-24

VDC

Power

Supply

+

Switch or Relay

(closed = logic Low)

-

Connecting the inputs to a switch or relay

5-24

VDC

Power

Supply

+

+

NPN

Output

-

output

–

X1/2/3/4+

X1/2/3/4-

SS-EC

Drive

Connecting the inputs to an NPN type output

Rev. 1.0

2016/7/30

5-24

VDC

Power

Supply

+

-

+

PNP

Output

–

output

X1/2/3/4+

X1/2/3/4-

SS-EC

Drive

Connecting the inputs to a PNP type output

28

+86-400-820-9661

SS03/05/10-EC Hardware Manual

3.1.2 X5, X6, X7 and X8 Digital Inputs

X5, X6, X7 and X8: optically isolated, single-ended, 5-24VDC, minimum pulse width 50μs, maximum

pulse frequency 10KHz

• X5 can be used as servo on input or general purpose input.

• X6 can be used as alarm reset input or general purpose input.

• X7 can be used as general purpose input.

• X8 can be used as general purpose input.

Because the input is an optically isolated circuit, a 5-24V power supply is needed. For example, you

can use the power supply of the PLC when you are using a PLC control system, but if you want to

connect a relay or mechanical switch to the input , you must need a power supply.

XCOM is an electronics term for a single-ended signal connection to a common voltage. In the case

of SS series, if you are using a sourcing (PNP) input signals, you need to connect XCOM to the

ground (power supply -), if you are using a sinking(NPN) input signals ,the XCOM need to connect

to the power supply +.

Use Step-ServoQuickTuner software for X5, X6, X7 and X8 function conguration.

The following graphs show some common connection methods for the inputs:

5-24

VDC

Power

Supply

+

Switch or Relay

(Closed: logic low)

-

XCOM

SS-EC

Drive

X5/X6/X7/X8

Connecting to a switch or relay

XCOM+

5-24

VDC

Power

Supply

+

NPN

Type

Output

-

output

-

X5/X6/X7/X8

SS-EC

Drive

Connecting an NPN type output to an input

+86-400-820-9661

output

5-24

VDC

Power

Supply

+

+

PNP

Type

Output

-

-

Connecting a PNP type output to an input

29

X5/X6/X7/X8

SS-EC

Drive

XCOM

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

3.2 Y1, Y2, Y3 and Y4 Digital Outputs

• Y1 can be used as an alarm signal output. It can also be used as a static in position signal

output (static, checking in position when the motor is stopped), or as a dynamic in position signal

output (dynamic, checking in position all the time).

• Y2 can be used as a tach signal output. Tach output produces pulses relative to the motor

position with congurable resolution. It can also be used as a static in position signal output

(static, checking in position when the motor is stopped), or as dynamic in position signal output

(dynamic, checking in position all the time), or as a timing signal output (50 pulses per rotation).

• Y3 can be used as a signal output to release a brake. It can also be used as a static in position

signal output (static, checking in position when the motor is stopped), or as a dynamic in position

signal output (dynamic, checking in position all the time).

• Y4 can be used as a static in position signal output (static, checking in position when the motor

is stopped), or as a dynamic in position signal output (dynamic, checking in position all the time).

Use Step-ServoQuickTuner software for Y1, Y2, Y3 and Y4 function conguration.

The following graphs show some common connection methods for the outputs:

NOTE: Do not connect the outputs to more than 30VDC power supply. And the

current of each output terminal must not exceed 100mA.

5-24 VDC

Power Supply

+ –

Y1/2/3/4+

Load

SS-EC

Drive

Y1/2/3/4-

Connecting a sinking output

5-24 VDC

Power Supply

+

–

Y1/2/3/4+

SS-EC

Drive

Y1/2/3/4-

COM

PLC

IN

Rev. 1.0

2016/7/30

Connecting a sinking output to a PLC’s input

30

+86-400-820-9661

SS03/05/10-EC Hardware Manual

Connecting a sinking output

Connecting a sinking output to a PLC’s input

SS-EC

Drive

5-24 VDC

Power Supply

+ –

Load

Y1/2/3/4-

Y1/2/3/4-

Y1/2/3/4+

Y1/2/3/4+

PLC

5-24 VDC

Power Supply

+

–

COM

IN

SS-EC

Drive

CDV 42-5

Power Supply

+ –

Y1/2/3/4+

SS-EC

Drive

Y1/2/3/4-

Connecting a sourcing output to a PLC’s input

Y1/2/3/4+

SS-EC

3.3 Analog Inputs

The SS series drive has two analog signal inputs which can accept signal range of 0-5V, 0-10V,

±5V or ±10V. The drive can be congured to operate at velocity mode or position mode that is

proportional to the analog input.

Drive

Y1/2/3/4-

COM

IN

5-24 VDC

relay

Power Supply

+ –

1N4935 suppression diode

Driving a relay

PLC

Use Step-ServoQuickTuner software to congure the input range, oset, deadband and noise

lter frequency.

The SS series provides a +5V, 100mA limit power supply that can be used to power external

devices such as potentiometer. For more precise readings use an external supply that can provide

the desired accuracy.

+5v OUT

1 - 10k

pot

Ω

AIN

GND

SS-EC

Drive

Connecting a Potentiometer to an analog input

+86-400-820-9661

31

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

3.4 Encoder output

The SS-EC drive has dierential encoder outputs (AOUT+, AOUT-, BOUT+, BOUT-, ZOUT+,

ZOUT-), with 26C31 line driver, 20 mA sink or source current max. These signals can be connected

to the motion controller to provide feedback of the motor position.

SS-EC

AOUT+

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

GND GND

A+

A-

B+

B-

Z+

Z-

Host Controller

Rev. 1.0

2016/7/30

32

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4 Control Panel (LED display and keys)

4.1 Description of Control Panel

LED Display

Mode Key

M

Up Key

Symbol Name Details

LED Display

MODE Button

UP/DOWN Button

SET Button

The LED display (5 digits, 7 segments) show the drive’s operating

condition and warning codes, parameters and settings values.

Press and hold the MODE button to change the LED display mode

a) Monitoring selection mode

b) Function selection mode

c) Parameter setting mode

When editing the parameters, press the MODE button to move the cursor

to the left and then change the parameters by using the arrow keys.

Press the UP or DOWN button to scroll through and change monitor codes,

parameter groups and various parameter settings.

Press to enter a mode

Press and hold to save parameters/settings

Set Key

S

Down Key

4.2 Mode Switch Control

(1) Press the button and the button to change modes between status monitoring,

function control, parameter setting, etc.

(2) If no warnings or faults have occurred, the drive will not go into warning and fault display mode.

(3) If any warnings are detected by the drive, the LED display will immediately switch into warning

or fault display mode. Pressing any key will switch back to the previous display mode.

(4) When no button(s) on the control panel has been pressed for 20 seconds, the display will

switch back to the previous status monitoring display mode.

(5) In monitoring selection mode, function selection mode and parameter setting mode, when

editing the parameters, press

using the

buttons.

(6) In status monitoring mode, press and hold the

the panel, press and hold the button again.

to move the cursor to the left, then change the parameters by

button to lock the control panel. To unlock

+86-400-820-9661

33

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

the SET key to confirm setting value

Control mode switch owchart:

Power On

Monitor Status

In factory default mode, it will display motor’s rotatory velocity.(*NOTE 1)

The last dot shows whether the drive is enable or disable.

Press and hold the

MODE key for 1 second

M

key for 1 second(*NOTE 4)

Press any key

Monitor Parameters

Press and hold the

MODE key for 1 second

M

Function Parameters

Press and hold the MODE

M

Drive Parameters

Configuration

Press the UP and

DOWN key to scroll

through and change

monitor status

Press the UP and

DOWN key to scroll

through and change

function selection

Press the UP and

DOWN key to scroll

through and change

parameter selection.

Press SET key back

to Monitor Status

S

Press and hold SET key to

confirm selection and execute it.

S

Press SET key enter

to value setting mode

S

Press SET key back to

Drive Parameters Configuration

mode without changing.

*NOTE(2)

Press and hold for 1 second

*Note(3)

S

NOTE:

(1) When power is applied, the drive’s display will show the customer dened monitoring

mode. In factory default mode, it will display motor’s rotary velocity.

(2) In parameter setting mode, press the

button to exit the parameter setting mode and

return to the parameter selection mode, any changes will not be saved.

(3) In parameter setting mode, press and hold the

button to conrm and apply the

current parameter setting. This will take eect immediately. However, this change will not

save to the drive’s ash. If this parameter is required for permanent use, go to function mode

“

”, and then press and hold the button to save the parameter change.

(4) When the drive is connected to the host computer with Step-Servo Quick Tuner on, the

parameter setting mode CANNOT be accessed directly on the drive’s control panel.

Rev. 1.0

2016/7/30

34

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.3 LED display description

4.3.1 Decimal Point And Negative Sign Description

LED display Description

Negative sign: when the value to be

displayed is a negative number ≥-9999,the

highest digit will display as a negative sign.

negative

sign

motor enable

sign

4.3.2 Parameter View Setting

LED display Description

4.3.3 Parameter Save Setting

LED display Description

Decimal point: when the value to be displayed

is a negative number ≤-10000, a decimal

point will be displayed.

There are only 5 digits on the LED display, when a value with

more than 5 digits needs to be displayed, it will be shown in 2

segments. When the highest digit of a value is ashing, it means

only the lower 5 digits are shown. Press

upper 5 digits.

The graph is showing ‘-12802345’

In parameter setting mode, pressing and holding the button

will save the change. ‘Saved’ will also be displayed on the LED.

In parameter setting mode when the motor is rotating, pressing

to display the

4.3.4 Point To Point Motion Mode

LED display Description

+86-400-820-9661

and holding the

the status as “busy” meaning that the current parameter cannot

be saved. Stop the motion of the motor and save the parameter

again.

When the LED display reads “P-CW” it means the motor is

rotating in a CW direction in the point-to-point mode

When the LED display reads “P-CCW” it means the motor is

rotating in a CCW direction in the point-to-point mode

35

button will cause the LED display to show

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

4.3.5 Jog Mode

LED display Description

4.3.6 Control Panel Lock

LED display Description

When the LED display reads “J--CW” it means the motor is

rotating in a CW direction in JOG mode.

When the LED display reads “J--CCW” it means the motor is

rotating in a CCW direction in JOG mode

This means the key panel is locked. Press and hold for 1

second while in status monitoring mode to lock it.

When the control panel is locked, press and hold for 1

second to unlock it.

4.4 Status Monitoring Selection Mode

To change the status monitoring type, press to enter monitoring selection mode, and then use

to make selections, and press to conrm. Steps are shown as follows:

Power ON

Default display is current motor velocity

The last decimal point is drive enable sign

Stats Display

Press Any Key

Status Monitoring

Selection

Press UP and

DOWN key

to select display

detail.

Press SET key to

select display mode

S

Rev. 1.0

2016/7/30

36

+86-400-820-9661

SS03/05/10-EC Hardware Manual

N mode selection and setting LED display Description Unit

n-00

n-01

n-02

n-03

n-04

n-05

n-06

n-07

n-08

n-09

Motor Rotation Speed RPM

Position Error counts

Pulse Counter counts

Encoder Counter counts

Command Position Counter counts

Drive Temperature x 0.1°C

DC Bus Voltage x 0.1V

SCL Address

Alarm History 1

Alarm History 2

n-10

n-11

n-12

n-13

n-14

n-15

Alarm History 3

Alarm History 4

Alarm History 5

Alarm History 6

Alarm History 7

Alarm History 8

+86-400-820-9661

37

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

4.5 Function Control Mode

In function control mode (display reads: F+parameter number), you can select functions for

preoperational mode, restart the drive, enable or disable the drive, etc. In status monitoring mode,

press and hold

for 1 second to enter function control mode. Press to select a

function, and then press and hold

F-01(CJ) excepted)

Status display

selection

Press and Hold MODE key

for 1 second

M

Function Mode

Selection

4.5.1 Function Mode Description

Function mode details are as follows:

to conrm or execute the function. (NOTE: F-00(FL) and

Press UP and

DOWN key

to select display detail.

Press and Hold Set key to

select and execute the function

S

Function mode

number

LED display Description

F-00 point to point position mode:1rps, 1rev

F-01

F-02

F-03

F-04

F-05

F-06

F-07

JOG mode:JOG speed 1rps

Restart the drive

Clear drive’s current alarm

Save parameter changes for Pxx

Motor disable

Motor enable

Activate the analog “auto oset” algorithm

F-08

Rev. 1.0

2016/7/30

Stop move and remove buered command

38

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.5.2 Operation Flow Chart

status monitoring

selection

press and hold MODE key

for 1 second

M

function selection

mode

Press UP and DOWN key

to select display detail.

F-00 point to point mode

F-01 JOG mode

Press UP and DOWN key

to select display detail.

F-02 Restart the drive

press and hold

SET key

press M key

press and hold

SET key

S

M

press M key

press and hold

SET key

press ,motor rotate

1 rev in CW direction

press ,motor rotate

1 rev in CCW direction

press to stop the motor

S

press to return back

M

NOTE: In P-P mode, rotary velocity is 1rps,

and 1 rev per time.

press ,motor rotate

in CW direction

Press ,motor rotate

in CCW direction

press stop motor

S

press to return back

M

NOTE: In JOG mode, rotary velocity is

1rps

Drive restart, and back to status

monitoring mode

Press UP and DOWN key

to select display detail.

F-03 Alarm clear

Press UP and DOWN key

to select display detail.

F-04 save parameter

Press UP and DOWN key

to select display detail.

F-05 motor disable

Press UP and DOWN key

to select display detail.

F-06 motor enable

Press UP and DOWN key

to select display detail.

S

press and hold

SET key

S

press and hold

SET key

S

display after

1 second

press and hold

SET key

S

press and hold

SET key

S

clear current drive warning

To save parameter changes for P-00

to P-98 permanently.

To disable the drive

If no alarm has occurred, enable the

drive immediately

SAVE means

success operation.

+86-400-820-9661

F-07 Analog Input Auto-offset

Press UP and DOWN key

to select display detail.

F-08 Stop move and remove

buffered command

39

press SET key

S

press SET key

S

Analog Input Auto-offset

Stop move and remove buffered

command

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

4.6 Parameter Setting Mode

4.6.1 Parameter Setting Description

The parameter setting mode (P+parameter number) allows you to select, display and edit the

necessary parameter. In function control mode, press and hold

parameter setting mode. Use

or edit the parameter. Press

to select the required parameter, and press to view

again to quit and no change will be saved. Press and hold

for 1 second to enter

for 1 second to save the parameter change. However this change will NOT be saved at the next

power on. To save the parameter PERMANENTLY, go into function control mode (F+parameter

number), and use F-04SA function.

function selection

mode

press and hold MODE key

for 1 second

M

parameter setting

selection

Press UP and DOWN key

to select display detail.

press SET key to

enter parameter editing mode

S

short press SET key

to quit

press and hold SET key

to save parameter change

S

Rev. 1.0

2016/7/30

40

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.6.2 Parameter Editing Examples

M

First digit flash

Press

Press up or down to increase or decrease value

Press

Press mode to

shift flashing digit

Press

Second digit flashing

Press

Press SET key to

enter parameter editing mode

S

M

Second digit flashing

Press

press UP or DOWN to increase or decrease value press UP or DOWN to increase or decrease value

Press

Press mode to

shift flashing digit

Press

First digit

Press

Press and hold set key

to save parameter

S

The parameter change is only saved for current

operation, it will back to original after next power up

Set display for 1 second, means save successfully

M

Press and hold mode key

Function mode selection

Press up and down key

to select display detail.

F-04 to save

parameter

Setafter 1 second

return to parameter

selection page

Press and hold set key

S

Save parameter

Saved display for 1 second

and return back to previous

page

Saved means

operation successful

+86-400-820-9661

41

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

4.6.3 Parameter list

Refer to the HostCommandReference for command details.

Parameter

Number

P00 KP position loop proportional gain

P01 KD

P02 KE

P03 VP

P04 VI

P05 -

P06 KK

P07 KC

P08 SF

P09 CM

P10 -

P11 PM

P12 JM

SCL Command

LED

Display

Function

position loop dierential gain

dierential lter

velocity loop proportional gain

velocity loop integrator gain

reserved

inertia feedforward gain

overall lter

step smoothing lter frequency

command mode

reserved

power up mode

jog mode

P13 GC

P14 CC

P15 CP

P16 -

P17 HC

P18 -

P19 VM

P20 AM

P21 JS

P22 JA

P23 JL

P24 VE

P25 AC

P26 DE

current command (torque mode)

continuous current

peak current

reserved

hard stop current

reserved

maximum velocity

maximum acceleration

jog speed

jog acceleration

jog deceleration

velocity

acceleration

deceleration

Rev. 1.0

2016/7/30

P27 VC

P28 JC

42

velocity change

velocity mode second speed

+86-400-820-9661

SS03/05/10-EC Hardware Manual

P29 - reserved

P30 -

P31 -

P32 -

P33 -

P34 -

P35 -

P36 ER

P37 -

P38 EG

P39 SZ

P40 PF

P41 PL

P42 PD

P43 PE

reserved

reserved

reserved

reserved

reserved

reserved

encoder resolution

reserved

electronic gearing

pulse mode setting

position fault limit

position limit for dynamic in position

position limit for static in position

in position timing

P44 TT

P45 AP

P46 AG

P47 AN

P48 -

P49 -

P50 AV

P51 AS

P52 -

P53 -

P54 AD

P55 AF

P56 AT

P57 SI

pulse complete timing

analog position gain

analog velocity gain

analog torque gain

reserved

reserved

analog oset value

analog scaling

reserved

reserved

analog deadband

analog lter

analog threshold

enable input usage

P58 AI

P59 DL

P60 AO

+86-400-820-9661

43

alarm reset input usage

dene limit

alarm output

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

P61 BO brake output

P62 MO

P63 BD

P64 BE

P65 FI

P66 FI

P67 FI

P68 FI

P69 -

P70 -

P71 IF

P72 PR

P73 TD

P74 BR

P75 -

motion output

brake disengage delay

brake engage delay

lter input for X5

lter input for X6

lter input for X7

lter input for X8

reserved

reserved

immediate format

protocol

transmit delay

baud rate

reserved

P76 CO

P77 -

P78 PK

P79 DD

P80 MA

P81 ZT

node id

reserved

parameter lock on control panel

default display item of LEDs

for advanced user only, not recommended

regen resistor peak time

Rev. 1.0

2016/7/30

44

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.7 Control Panel Lock

In order to prevent unauthorized or unintentional use of the key panel, a key panel lock is available

on all SS-EC drives. When the lock feature is on, no function can be changed directly on drive’s

control panel.

Status monitoring

Press and hold set key

for 1 second

If control panel is locked,

press any key will show lck

In control parameter lock mode,

press and hold set key

for 1 second will unlock

Unlock display

4.8 Warning And Fault Display

If any of the following warnings are detected by the drive when power is applied, the LED display

on the drive will immediately switch into warning or fault display mode.

If more than one warning is detected, you can scroll through by pressing the

Press

or to clear the warning display and return to the previous display mode.

Any Mode

Warning or fault alarm occurs

Bad Encoder

buttons.

Open Winding

+86-400-820-9661

If more than 1 alarm has occurred,

press Up or Down key to scroll through

the alarms

S

M

Press Set and Mode key

to exit alarm display mode

45

Previous Monitoring Mode

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

LED display Description

DriveOverTemperature

InternalVoltageBad

OverVoltage

HighsideOverCurrent

LowsideOverCurrent

OverCurrentReading

BadEncoder

OpenWinding

PositionLimit

Under Voltage

CCW Limit and CW Limit

CCW Limit

CW Limit

Current Foldback

Communication Error

Save Failed

STOActivated

RegenFailed

Blank Q Segment

Move while Disabled

NOTE: Items in bolditalic represent Drive Faults, which automatically disable the motor.

Rev. 1.0

2016/7/30

46

+86-400-820-9661

SS03/05/10-EC Hardware Manual

4.9 LED Character Reference

1 2 3 4 5 6 7 8 9 10

A B C D E F G H I J

K L M N O P Q R S T

U V W X Y Z

+86-400-820-9661

47

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

Unit:mm

5 Reference Materials

5.1 Drive Mechanical Outlines

41

150

28.5

5

139.5

R2.5

956.5

6

5

Rev. 1.0

2016/7/30

48

+86-400-820-9661

SS03/05/10-EC Hardware Manual

5.2 Drive Technical Specications

Power Amplier

Amplier Type Dual H-Bridge, 4 Quadrant

Current Control 4 state PWM at 20 KHz

SS03 Maximum continuous current 3A, boost current 4.5A (for 1.5s)

Drive auto-sets the current limitation according to the attached motor

Output Current

Power Supply

Auxiliary Power Supply External 12 - 48 volt DC power supply required

Protection Over-voltage, under-voltage, over-temp, over-current, short circuit

Microstep Resolution Software selectable from 200 to 51200 steps/rev in increments of 2 steps/rev

Encoder Resolution 20000 counts/rev for AM17/23/24/34SS motor; 4096 counts/rev for AM11SS motor

Speed Range Speeds up to 3600 rpm

Filters

Non-Volatile Storage Congurations are saved in FLASH memory on-board the DSP

Supported Protocol CoE (CiA 402 Drive prole)

Supported Modes

Synchronization SM Event, DC Sync Event

SS05 Maximum continuous current 5A, boost current 7.5A (for 1.5s)

Drive auto-sets the current limitation according to the attached motor

SS10 Maximum continuous current 10A, boost current 15A (for 1.5s)

Drive auto-sets the current limitation according to the attached motor

External 24 - 70 volt DC power supply required

Absolute maximum input voltage range 18 - 75 VDC

Controller

Programmable hardware digital noise lter, software noise lter, smoothing lter, PID lter, notch lter

Prole Position, Prole Velocity, Prole Torque, Cyclic Synchronous Position, Cyclic Synchronous

Velocity, Homing, and MOONS’ own Q mode

X1, X2, X3, X4: optically isolated, dierential, 5-24VDC, minimum pulse width 250ns,

Digital Inputs

Digital Output

Analog Input

+5V Supply Output +4.8 - 5 volts @ 100mA maximum

Communication EtherCAT and mini USB for conguration

maximum pulse frequency 2MHz

X5, X6, X7, X8: optically isolated, single-ended input, 5-24VDC

Y1, Y2, Y3, Y4: optically isolated, open collector, 30 volts, 100 mA max, maximum pulse frequency

10 KHz

AIN1, AIN2: individually single-ended or together dierential, input resolution 12-bit, software

congured as 0-5 volts, 0-10 volts, ±5 volts or ±10 volts (AIN referenced to GND)

Environment

Ambient Temperature 0 - 40°C (32 - 104°F) when mounted to a suitable heatsink

Humidity 90% non-condensing

+86-400-820-9661

49

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

5.3 Recommended Motors and Specications

Motor Part

Number

AM11SS1DMA

AM11SS2DMA 0.08 12 168

AM11SS3DMA 0.125 18 218

AM17SS1DG□-N

AM17SS2DG□-N 0.5 57 440

AM17SS3DG□-N 0.6 82 520

AM17SS4DG□-N 0.75 123 760

AM23SS2DG□-N

AM23SS4DGA-N 2.5 365 840

AM24SS3DG□-N

AM34SS1DGA-N 3.5 915 2000

AM34SS5DGA-N 8.0 2200 4200

Matching

Drive

SS03-EC-D

SS03-EC-D

or

SS05-EC-D

SS05-EC-D

SS10-EC-D

Holding

Torque

N-m G-cm

0.065 9

0.3 38

0.9 260 850

2.5 900 1650 60 90 100 130 180 270

Rotor

Inertia

Encoder

Resolution

2

counts/rev RPM g mm 0 5 10 15 20

4096

20000

Max.

Speed

3600

□: A or B, refer to motor part numbering system

Mass

118

390

Frame

Size

28 20 25 34 52 -

42 35 44 58 85 -

56 63 75 95 130 190AM23SS3DG□-N 1.5 460 1250

86 260 290 340 390 480AM34SS3DGA-N 6.0 1480 3100

Permissible Shaft Load (N)

Distance (L) from shaft end (mm)

Permissible

Thrust Load

Less than the

motor mass

Thrust Load

Overhung Load

L

Rev. 1.0

2016/7/30

50

+86-400-820-9661

SS03/05/10-EC Hardware Manual

5.4 Motor Mechanical Outlines

AM11SS

unit: mm

36

AM17SS-N

unit: mm

L

15

10

2

4.5 FLAT

5

22

28

23

4-M2.5

Depth 2.5 Min

23

28

Model L

AM11SS1DMA 43.8

AM11SS2DMA 52.9

AM11SS3DMA 64.1

L 2

B

B1

A

A1 FLAT

42.3

31

φ22

30033

4-M3 Depth 4.5Min

Model A A1 B B1 L

AM17SS1DGA-N φ6 5.5 20 15 59.5

AM17SS1DGB-N φ5 4.5 24 15 59.5

AM17SS2DGA-N φ6 5.5 20 15 65

AM17SS2DGB-N φ5 4.5 24 15 65

AM17SS3DGA-N φ6 5.5 20 15 73.5

AM17SS3DGB-N φ5 4.5 24 15 73.5

AM17SS4DGA-N φ6 5.5 20 15 89

AM17SS4DGB-N φ5 4.5 24 15 89

+86-400-820-9661

51

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

AM23SS-N

unit: mm

73.6

B

B1

A

56.3

47.14 4-φ5.1

47.14

A1 FLAT

7

L

1.6

30033

φ38.1

Model A A1 B B1 L

AM23SS2DGA-N φ8 7.5 24 20 77.5

AM23SS2DGB-N φ6.35 5.85 20 15 77.5

AM23SS3DGA-N φ8 7.5 24 20 99.5

AM23SS3DGB-N φ6.35 5.85 20 15 99.5

AM23SS4DGA-N φ8 7.5 24 20 102.5

AM24SS-N

unit: mm

77.4

B

B1

A

A1 FLAT

8

110

33

1.5

300

φ38.1

Model A A1 B B1

AM24SS3DGA-N φ10 9.5 24 20

AM24SS3DGB-N φ8 7.5 20.6 15

60

4-φ4.547.14

47.14

Rev. 1.0

2016/7/30

52

+86-400-820-9661

SS03/05/10-EC Hardware Manual

25

10

2

L

37

φ

14

13FLAT

300

102.7

38

69.6

69.6

4-6.5

86

φ73.025

AM34SS-N

unit: mm

Model L

AM34SS1DGA-N 88

AM34SS3DGA-N 117.5

AM34SS5DGA-N 147

+86-400-820-9661

53

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

5.5 Torque Curves

AM11SS1DMA

100

80

60

40

Torque(mN·m)

20

0

0 10 20 30 40 50

AM11SS3DMA

200

160

120

80

Torque(mN·m)

40

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

Continuous

Boost

24V

24V

24V

24V

Speed(rps)

AM11SS2DMA

150

120

90

60

Torque(mN·m)

30

0

0 10 20 30 40 50

Continuous

Boost

24V

24V

Speed(rps)

AM17SS1DG□-N

0.4

0.3

0.2

Torque(N·m)

0.1

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

24V 48V

24V 48V

AM17SS2DG□-N

0.6

0.5

0.4

0.3

Torque(N·m)

0.2

0.1

0

0 10 20 30 40 50

AM17SS4DG□-N

1.0

0.8

0.6

0.4

Torque(N·m)

0.2

Continuous

Boost

Speed(rps)

Continuous

Boost

24V 48V

24V 48V

24V 48V

24V 48V

AM17SS3DG□-N

0.7

0.6

0.5

0.4

0.3

Torque(N·m)

0.2

0.1

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

24V 48V

24V 48V

AM23SS2DG□-N

1.5

1.2

0.9

0.6

Torque(N·m)

0.3

Continuous

Boost

24V 48V 70V

24V 48V 70V

0

0 10 20 30 40 50

Speed(rps)

Rev. 1.0

2016/7/30

54

0

0 10 20 30 40 50

Speed(rps)

+86-400-820-9661

SS03/05/10-EC Hardware Manual

AM23SS3DG□-N

2.5

2

1.5

1

Torque(N·m)

0.5

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

24V 48V 70V

24V 48V 70V

AM24SS3DG□-N

3.5

3

2.5

2

1.5

Torque(N·m)

1

0.5

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

24V 48V 70V

24V 48V 70V

AM23SS4DGA-N

3.5

3

2.5

2

1.5

Torque(N·m)

1

0.5

0

0 10 20 30 40 50

AM34SS1DGA-N

4.0

3.0

2.0

Continuous

Boost

Speed(rps)

Continuous

Boost

24V 48V 70V

24V 48V 70V

24V 48V 70V

24V 48V 70V

Torque(N·m)

1.0

0

0 10 20 30 40 50

Speed(rps)

AM34SS3DGA-N

7.0

6.0

5.0

4.0

3.0

Torque(N·m)

2.0

1.0

0

0 10 20 30 40 50

Continuous

Boost

24V 48V 70V

24V 48V 70V

Speed(rps)

AM34SS5DGA-N

10

8.0

6.0

4.0

Torque(N·m)

2.0

0

0 10 20 30 40 50

Continuous

Boost

Speed(rps)

24V 48V 70V

24V 48V 70V

+86-400-820-9661

55

Rev. 1.0

2016/7/30

SS03/05/10-EC Hardware Manual

5.6 Motor Numbering System

AM17 SS 1 D

Frame Size

11, 17, 23, 24, 34

Step Servo

Motor Size

1 = 1 stack

2 = 2 stack

3 = 3 stack

4 = 4 stack

5 = 5 stack

Note: AM17/23/24/34SS motors matching with SS-EC drive have -N suffix

AM11SS motors matching with SS-EC drive DO NOT have -N suffix

5.7 Drive Numbering System

SS 05

Step Servo

Output Current

03 = 3A

05 = 5A

10 = 10A

-

D = DC Input

EC

-

EC = EtherCAT

G

A-N