Moons' M2DV-1D82Q, M2DV-1D82S, M2DV-3D02Q, M2DV-4D52Q, M2DV-3D02R Quick Setup Manual Manual

...

M2 Series AC Servo System

Quick Setup Guide Manual

SHANGHAI AMP & MOONS’AUTOMATION CO.,LTD.

Rev. 1.0

9/21/2015

M2 Quick Setup Guide Manaul

Safety

Only qualified persons may perform the installation procedures. The following explanations are for

things that must be observed in order to prevent harm to people and damage to property.

The M2 utilizes hazardous voltages. Be sure the drive is properly grounded.

Before you install the M2, review the safety instructions in this manual.

Failure to follow the safety instructions may result in personal injury or equipment damage.

Safety Symbols

Safety symbols indicate a potential for personal injury or equipment damage if the recommended

precautions and safe operating practices are not followed.

The following safety-alert symbols are used on the drive and in the documentat

ion:

Caution Warning. Dangerous voltage. Protective earth Caution,Hot surface

Safety Instructions

Installation

Wiring

Do not subject the product to water,corrosive or flammable gases,and combustibles.

Don’t use the motor in a place subject to excessive vibration or shock.

Never connect the motor directly to the AC power supply.

Don’t use cables soaked in water or oil.

Don’t extrude or pull-off the cable,nor damage the cables as electrical

shocks,damages may resul

Don’t block the heat dissipating holes. Please prevent

drive when mounting.

Don’t switch the power supply repeatedly.

Don’t touch the rotating shaft when the motor is running.

Don’t strike the motor when mounting as the motor shaft or encoder may be

damaged.

In order to prevent accidents, the initial trial run for servo motor should be conducted

under no load conditions (separate the motor from its couplings and belts).

Starti

ng the operation without matching the correct parameters may result in servo

drive or motor damage, or damage to the mechanical system.

Don’t touch either the drive heat sink or the motor and regenerative resister during

operation as they may become hot.

Don’t hold the motor cable during the transportation or mounting.

Don’t connect any power supplies to the U,V,W teminals.

Install the encoder cable in a separate conduit from the motor power cable to avoid

signal noise.

Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for

signal,encoder cables.

As a charge may still remain in the drive with hazardous voltage even after power has

been removed, Don’t touch the terminals when the charge led is s

Please observe the specified voltage.

Make sure both the drive and the motor connect to a class 3 ground.

Please ensure grounding wires are securely connected when power up.

any metal filings drop into the

till light.

Standards Compliance

The M2 Series AC servo drive has been designed according to standards:

* Electromagnetic compatibility * Electrical Safety: Low voltage directive

Standard EN 61800-3 (2004) Standard IEC 61800-5-1 (2007)

Rev. 1.0

4/29/2016

2

M2 Quick Setup Guide Manaul

Contens

1 Product Description ..................................................................... 5

1.1 Unpacking Check ................................................................................5

1.2 Servo Drive Model Introduction .........................................................5

1.2.1 Drive Name Plate Description ................................................................5

1.2.2 Drive Model Description ..........................................................................5

1.3 Servo Motor Model Introduction .........................................................6

1.3.1 Motor Name Plate Description ................................................................6

1.3.2 Motor Model Description .........................................................................6

1.4 Servo Drive and Servo Motor Combinations ......................................6

2 Installation ................................................................................... 7

2.1 Storage Conditions .............................................................................7

2.2 Installation Conditions .........................................................................7

2.3 Drive Dimensions(Unit: mm) ............................................................... 7

2.4 Installation Space ...............................................................................8

2.5 Motor Installation ................................................................................8

3 Connections and Wiring .............................................................. 9

3.1 Connecting to Peripheral Devices ......................................................9

3.1.1 System Conguration .............................................................................. 9

3.1.2 Servo Drive Connectors and Terminals ................................................. 10

3.1.3 Connections and Wiring Notes .............................................................. 10

3.2 Wiring Methods ................................................................................. 11

3.2.1 Single-Phase Power Supply Connection(AC220V) ............................... 11

3.2.2 Three-Phase Power Supply Connection(AC220V) ............................... 11

3.2.3 Recommend Cable Specications ........................................................12

3.3 Wiring to the Connector,P2 ............................................................... 12

3.3.1 Motor Power Cable Conguration .........................................................12

3.3.2 Motor Power Cable Connector Specications ...................................... 13

3.3.3 Wiring Diagram of Motor extend Cable .................................................13

3.4 Electromagnetic Brake .....................................................................14

3.4.1 Wiring Diagram ...................................................................................... 14

3.4.2 Notice for the Brake Motor ....................................................................14

3.4.3 The timing charts of the electromagnetic brake ....................................14

3.5 Regenerative Resister .....................................................................15

3.6 Connect to Host Computer,CN1 .......................................................15

3.7 Input and Output Signal Interface Connector,CN2 ...........................15

3

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.7.1 Input and Output Interface Diagram ......................................................16

3.7.2 Signals Description of Connector CN2 .................................................17

3.7.2.1 The Layout of CN1 Connector ............................................................17

3.7.2.2 Input Signals .......................................................................................17

3.7.2.3 Output Signals .....................................................................................19

3.7.3 Encoder Feedback Ouput .....................................................................19

3.7.3.1 A/B/Z Wiring Method ........................................................................... 19

3.7.3.2 Phase Z Open Collector Output .......................................................... 20

3.8 Encoder Connector CN3 ...................................................................20

3.8.1 Motor Encoder Feedback Cable Conguration .....................................20

3.8.2 The Layout of CN3 Connector ...............................................................20

3.8.3 Descriptions of Encoder Connector CN3 ..............................................21

3.8.4 Connect to Motor Encoder ....................................................................21

3.8.5 Specications of Encoder Connector ....................................................22

3.8.6 Wiring Diagram of Motor Encoder Extend Cable ..................................22

4 Control Block Diagram ............................................................... 23

4.1 Position Mode ...................................................................................23

4.2 Speed Mode .....................................................................................24

4.3 Torque Mode ..................................................................................... 25

5 Display and Operation ............................................................... 26

5.1 Description of Operation Panel ......................................................... 26

5.2 Key Lock ...........................................................................................26

5.3 Key Operation Flowchart ..................................................................27

6 Preoperational mode ................................................................. 28

6.1 Inspection Before Trail Tun ...............................................................28

6.2 Trail Run Procedure .......................................................................... 28

6.3 Motor Conguration Manually ........................................................... 29

6.4 Operations of JOG Mode .................................................................. 29

7 Troubleshooting ......................................................................... 30

7.1 Drive Alarm List .................................................................................30

7.2 Drive alarm reason and solutions ................................................31

8 Conguration by Personal Computer ........................................ 33

9 Appendix ................................................................................... 34

10 Contacting MOONS’ ................................................................ 35

Rev. 1.0

4/29/2016

4

M2 Quick Setup Guide Manaul

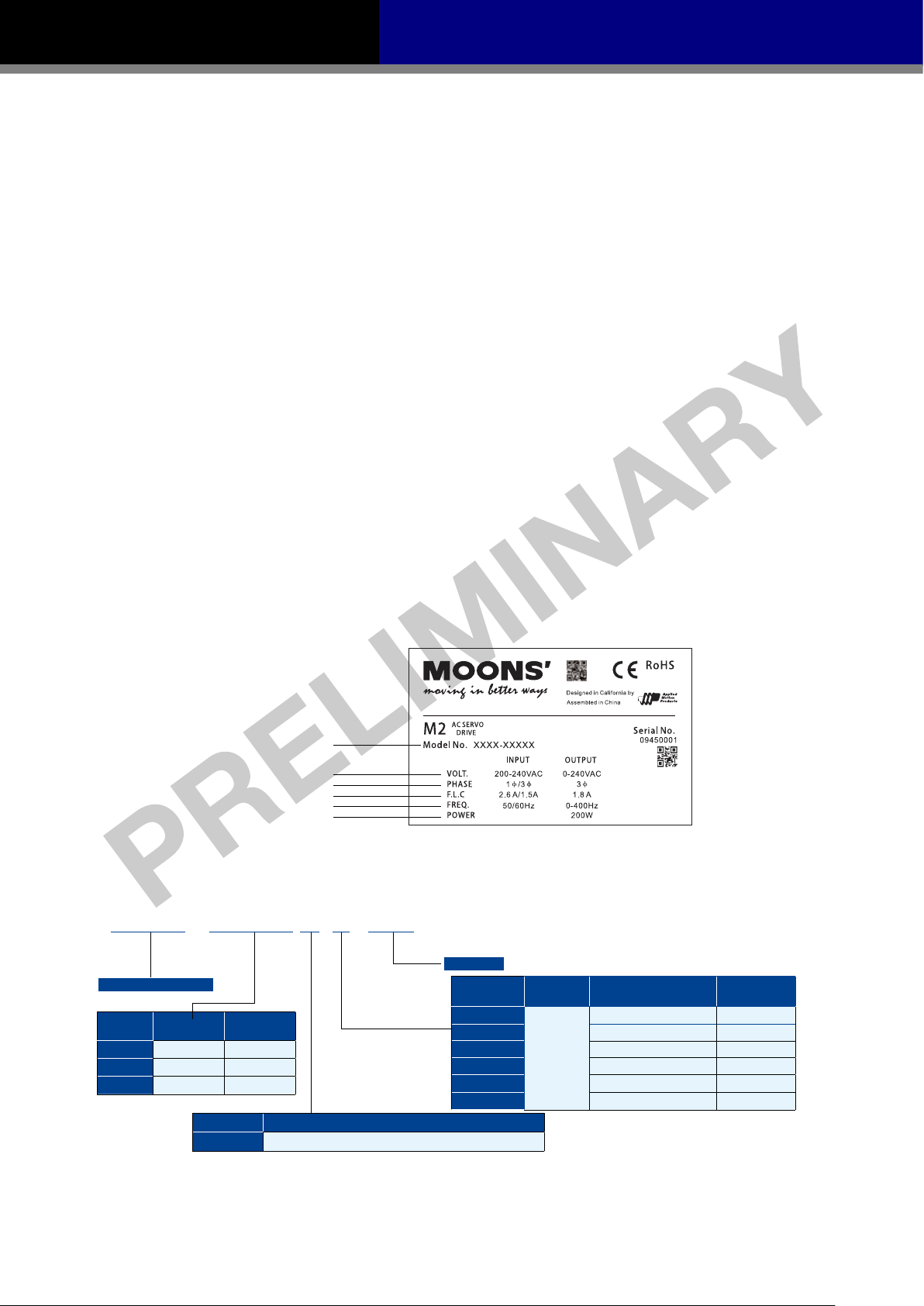

Model No.

Input/Output Voltage

Phase

Rated Current

Frequency

Rated Power

1 Product Description

1.1 Unpacking Check

Please refer to this section to confirm the model of servo drive and servo motor .

A complete and workable AC servo system should include the following parts:

1. Matched Servo drive and Servo motor

2. A power cable connect the drive to the servo motor(Option)

3. An feedback encoder cable connect the drive to the motor (Option )

4. A mini USB cable connect the port CN1 to PC for communication.(Opti

on)

5. 50-PIN connector (For I/O connections, Port CN2) Option

6. 26-PIN connector(For encoder feedback,Port CN3 ) Option

7. 6-PIN connector(IEEE1394,Option)

8. RJ-45 connectors (For RS-485 or CANopen communication,Port CN6 adn CN7)Option

9. 5-PIN connectors (For L1,L2,L3,L1C,L2C)

10. 6-PIN connector(For U,V,W,B1+,B2,B3)

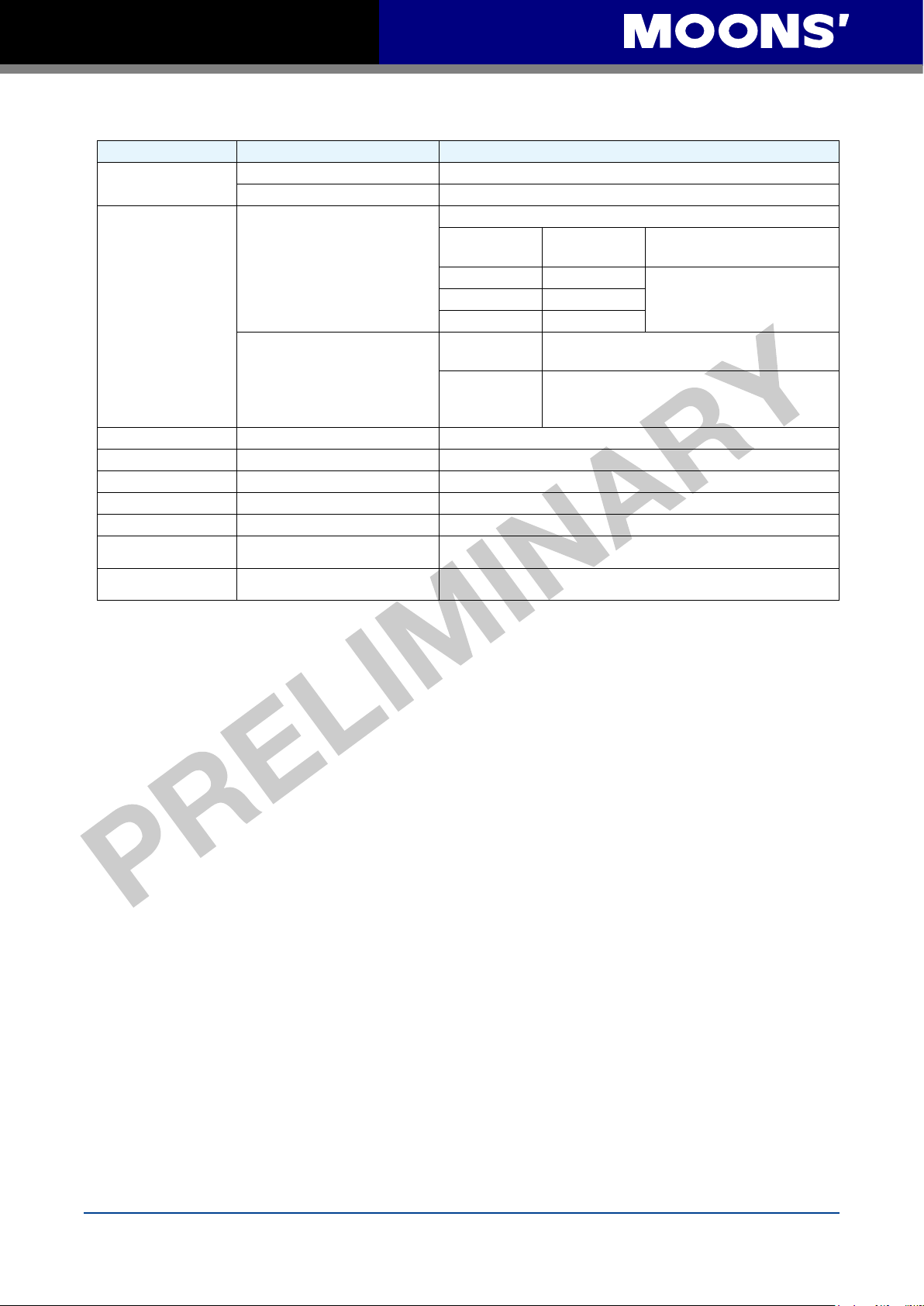

1.2 Servo Drive Model Introduction

1.2.1 Drive Name Plate Description

1.2.2 Drive Model Description

M2DV -

M2 Series AC Servo Drive

Current

Code

Continuous

Current (RMS)

1D8 1.75A 5.25A

3D0 3.00A 9.00A

4D5 4.50A 13.50A

□ □ □ 2 □

Boost

Current (RMS)

Voltage Code Input Voltage

2

Single/Three-Phases200~240VAC±10%, 50/60Hz

***

If Applicable

Communication

Type

S

Q

R

C

IP

E

5

Configuration Description Communication

Mini USB

Basic Type

Q Type

Q Type(Modbus/RTU Type)

CANopen Type

EtherNet/IP

eSCL

Type

Type

- - -

RS-232

RS-485

CANBus

EtherNet

EtherNet

4/29/2016

Rev. 1.0

M2 Quick Setup Guide Manaul

S M 04 01 A E4-K CD-N N V

**

1.3 Servo Motor Model Introduction

1.3.1 Motor Name Plate Description

Model NO.

Series NO.

Rated Torque

Input Current

Output Power

Rated Speed

1.3.2 Motor Model Description

Servo Motor

Frame Size

04-40mm

06-60mm

08-80mm

Motor Length

□40□60□

01 50W 200W

02 100W 400W

03 750W

04 1000W

80

Winding

A: 320 VDC(240 VAC)

E4: 2500 ppr Optical Encoder and Shared Commutation Tracks

1.4 Servo Drive and Servo Motor Combinations

Specificatioon

2500ppr Increment

Encoder

(9PIN AMP connector)

Rated Speed

Maximum Speed

Rated Torque

AC Servo Motor

Pulse&Direction

Type

AC

Servo

Drive

Fieldbus Type

Maximum Torque

Rated Current

Maximum Current

Rotor Inertia

Insulation Class Class B

Protection Class IP65(except shaft through hole and cable end connetor)

il Seal With Oil seal

O

USB Mini

RS-485

CAN CANopen

Ethernet

Without Brake

With Brake

(RPM) 3000

(RPM) 6000

(N•m)

(N•m)

(A)

(A)

2

Kg•m

Basic Type

Q Type

SCL

Modbus RTU

Ethernet/IP

eSCL

AC SERVO MOTOR

Model NO.SM0602AE2-KCD-NNV15

Ser NO. 12110027

Rated Torque 1.27N

Input 3ØAC 220V 2.8A

Ouput 400W

Rated Rev. 3000r/min

CD: 300mm (12") Shielded Cables with AMP 4 Pin, 6-7 Amp Motor Connector.

Shaft

K: Standard Keyway

Ecoder

50W 100W 200W 400W 750W

SM0401AE4-KCD-

NNV09

SM0401AE4-KCD-

BNV09

0.19 0.32 0.64 1.27

0.48 0.93 1.9 3.8 6.9

0.7 1.2 1.5 2.75 4.5

1.75 3.6 4.5 8.3 13.5

0.0232×10-4

*0.0298×10

(*With Brake)

M2DV-1D82S M2DV-1D82S M2DV-1D82S M2DV-3D02S M2DV-4D52S

M2DV-1D82Q M2DV-1D82Q M2DV-1D82Q M2DV-3D02Q M2DV-4D52Q

M2DV-1D82R M2DV-1D82R M2DV-1D82R M2DV-3D02R M2DV-4D52R

M2DV-1D82C M2DV-1D82C M2DV-1D82C M2DV-3D02C M2DV-4D52C

M2DV-1D82IP M2DV-1D82IP M2DV-1D82IP M2DV-3D0

M2DV-1D82E M2DV-1D82E M2DV-1D82E M2DV-3D02E M2DV-4D52E

-4

SM0402AE4-KCD-

SM0402AE4-KCD-

0.0428×10

*0.0494×10

(*With Brake)

NNV09

BNV09

·m

Code

Connections

-4

-4

Shaft Seal

SM0602AE4-KCD-

NNV09

SM0602AE4-KCD-

BNV09

0.272×10

*0.326×10

(*With Brake)

V: Shaft seal shipped with motor, but not placed on shaft

Thermal Protector

N: No Protector

Brake Option

N: No Brake

B: 24VDC Brake

Motor Model Numbers

SM0601AE4-KCD-

NNV09

SM0601AE4-KCD-

BNV09

-4

-4

0.165×10

*0.22×10

(*With Brake)

Drive Model Numbers

SM0803AE4-KCD-

NNV09

SM0803AE4-KCD-

BNV09

2.4

-4

-4

2IP M2DV-4D52IP

0.89×10

*0.97×10

(*With Brake)

-4

-4

Rev. 1.0

4/29/2016

6

M2 Quick Setup Guide Manaul

2 Installation

2.1 Storage Conditions

Some Storage suggestions are followed:

• Correctly packaged and store in a clean and dry ,avoid direct sunlight

• Store within an ambient temperature range of -20℃ to +65

• Store within a relative humidity rang of 10% to 85% and non-condensing

• Don

’t store in a place subjected to corrosive gasses

2.2 Installation Conditions

The operation ambient conditions are followed:

• Temperature range of 0℃ to 50℃. If the ambient tempera

45℃, please install the drive in a well-ventilated location

The ambient temperature of servo dive for long-term reliability should be under 45℃.

• The servo drive and motor will generate heat. If they are installed in a control panel, please

ensure sufficient space around the units for heat dissipation.

• Operation within a relative humidity rang of 5%to

• The vibration lower than 5.88m/s

2

, 10-60Hz(Do not continuously use the drive for along time at

resonance point.)

• Don

’t mount the servo drive and motor in a location subjected to corrosive gasses or

flammable gases, and combustibles.

• Please mount the servo drive and motor to a indoor electric control cabinet without liquid and

direct sunlight

• Don

’t mount the servo drive and motor in a location subjected to airborne dust.

85% and non-condensing

℃

ture of servo drive is greater than

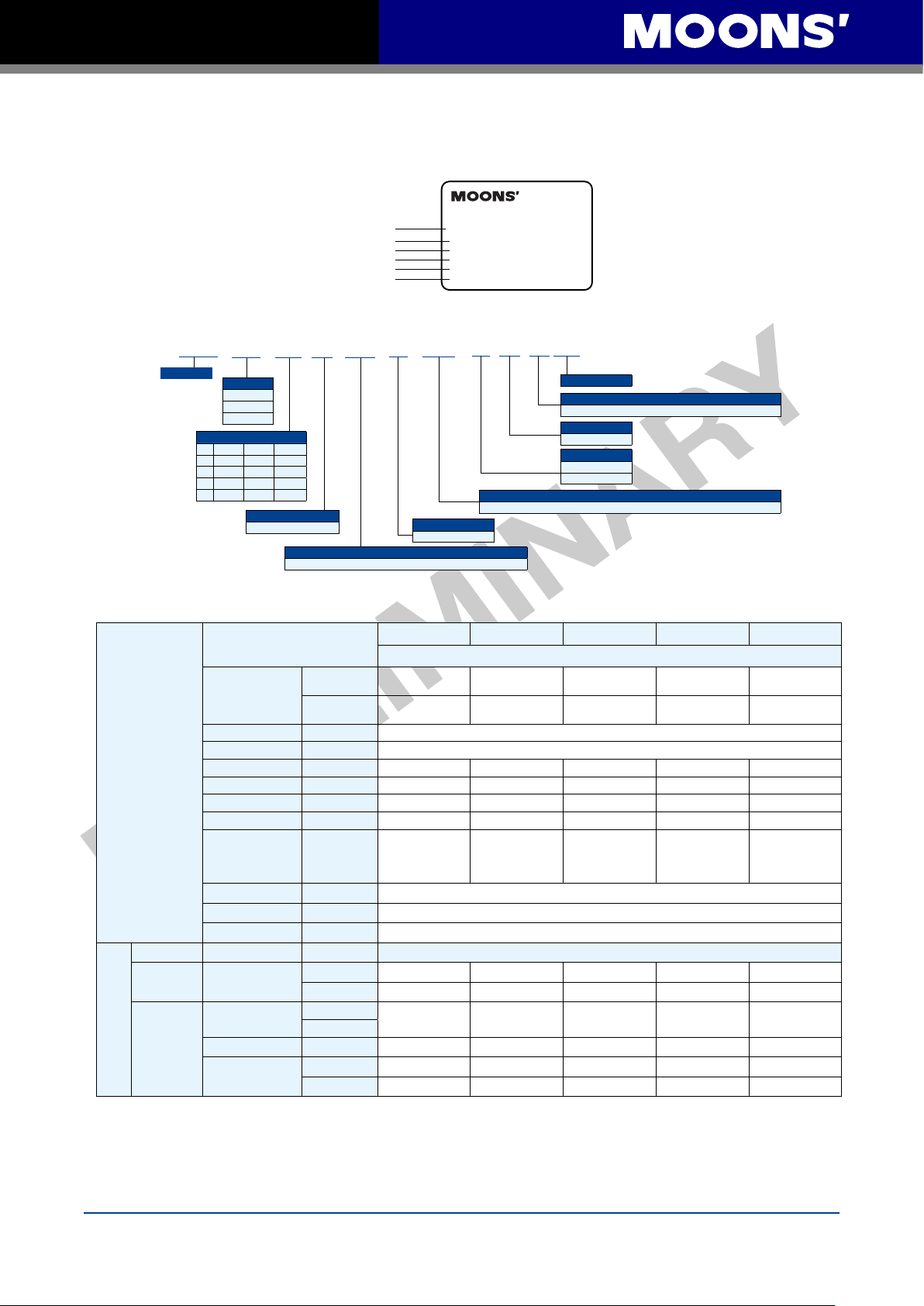

2.3 Drive Dimensions(Unit: mm)

50W、100W、200W Type

6

Ø5

5

140

5

35.5

750W Type

7.5

5

Ø5.2

140

145

150

41

150

400W Type

6

Ø5

5

140

49.5

150

5

145

55

57.5

5.2

176

65

7

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

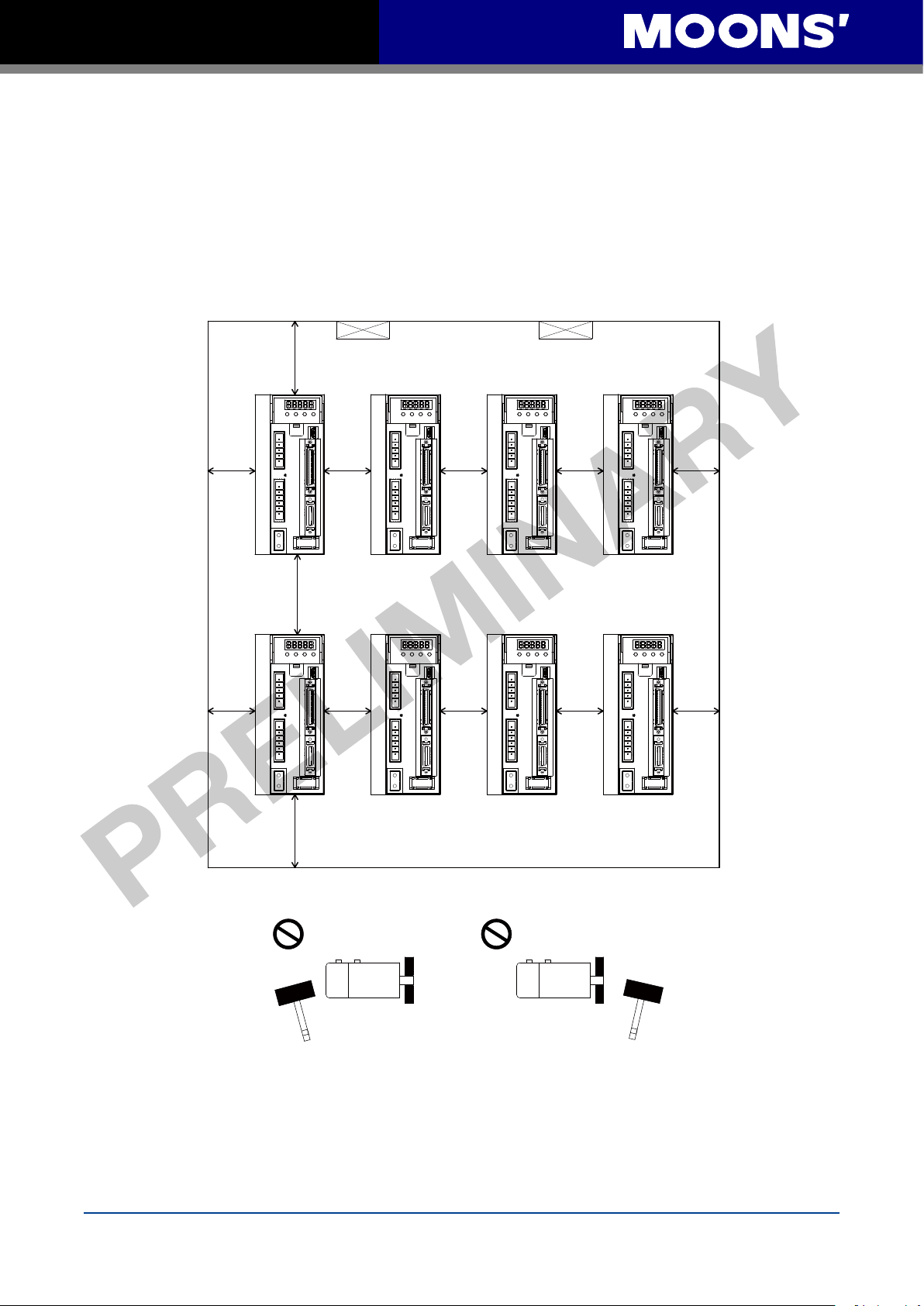

2.4 Installation Space

• Incorrect installation may result in a drive malfunction or premature failure of the drive and or

motor. Please follow the guidelines in this manual when installing the servo drive and motor.

• The M2 servo drive should be mounted perpendicular to the wall or in the control panel.

• In order to ensure the drive is well ventilated, ensure that the all ventilation holes are not

obstructed and suffic

the control panel.

• Please ensure grounding wires are securely connected

ient free space is given to the servo drive,and a cooling fan is mounted in

100mm

80mm

Fan Fan

10mm 10mm 10mm20mm

10mm 10mm 10mm20mm 20mm

20mm

100mm

2.5 Motor Installation

• Don't strike the motor when mounting as the motor shaft or encoder may be damaged.

• Don't use cables soaked in water or oil.

• Avoid a stress application to the cable outlet and connecting portion by bending

• Please use flexible cables when using cable carrier, make sure the minimum cable bending

radius is 200mm

• The shaft through hole and cable end connector is not IP65 design. Make sure to preve

liquid or oil into the motor from these parts.

Rev. 1.0

4/29/2016

8

nt any

M2 Quick Setup Guide Manaul

3 Connections and Wiring

3.1 Connecting to Peripheral Devices

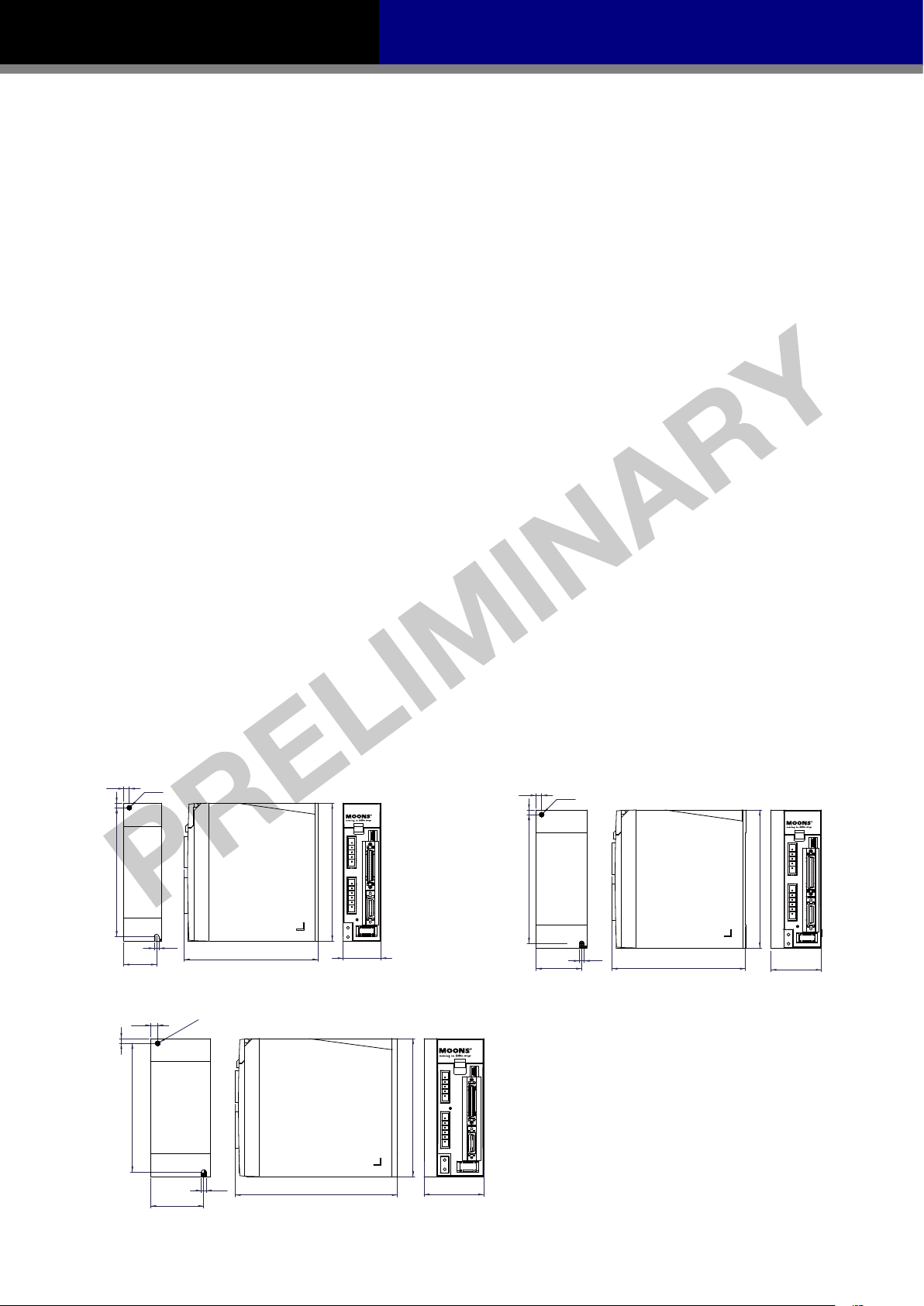

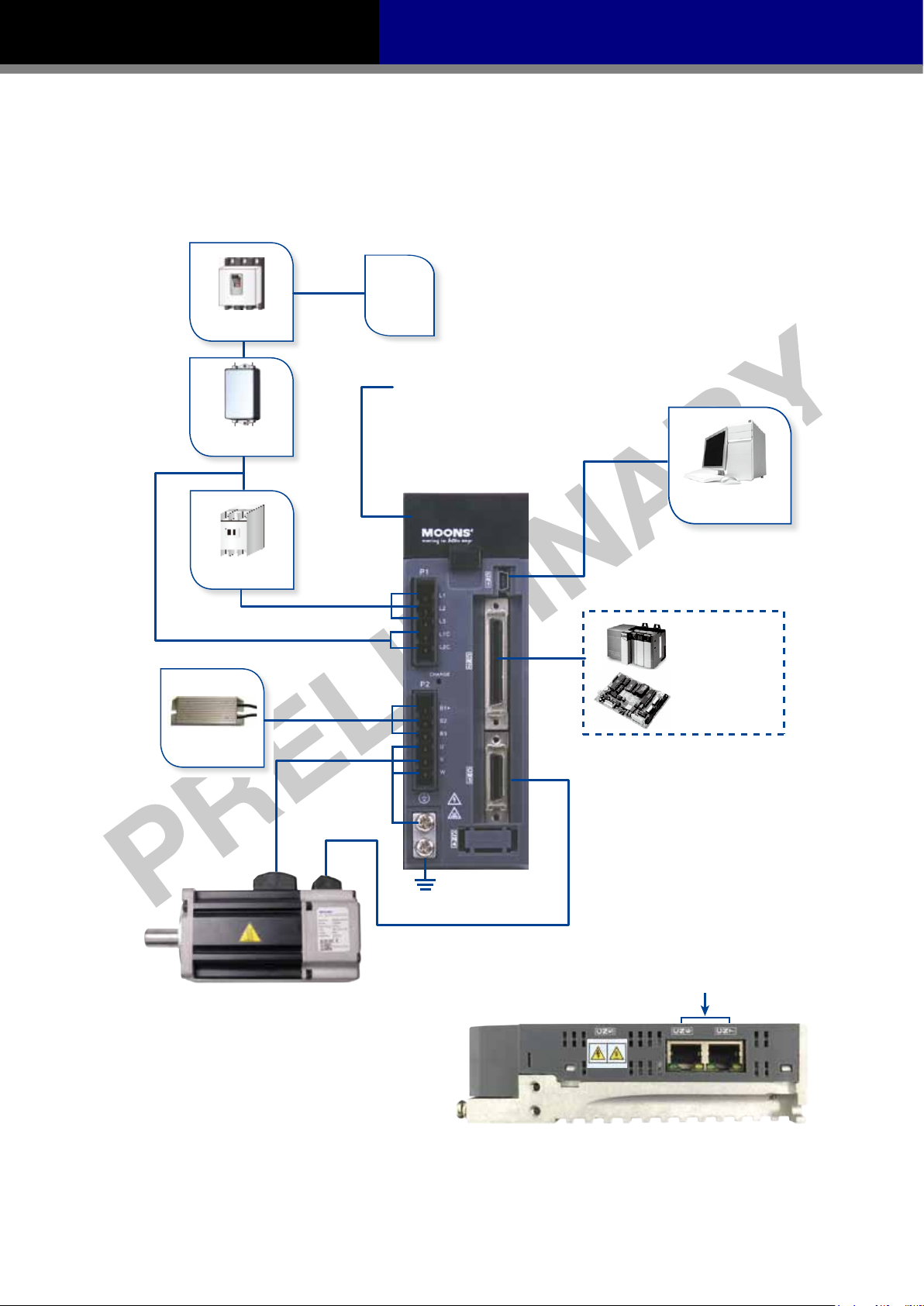

3.1.1 System Conguration

AC Power

Non Fuse Breaker

LED Display

The 5 digit,7 segment LED displays the

diver status and faults.

Operation Panel

Line Filter

(optional)

Function keys are used to perform status

display,monitor and diagnostic,function

and parameter setting.

Electromagnetic

Contactor

Regeneration

Absorbing Resistor

Main Power Input

Control Power Input

Motor Power Cable

Ground (PE)

Motor Feedback Cable

USB communication Port

(CN1)

PLC

Motion Control Card

I/O Interface

Used to connect PLC ,motion card

and other controllers.

Line Filter

AC Power Part No. Vendor

Single phase 240Vac 10ET1 Tyco

Three phase 240Vac DF300-10A-01 Dephir

CANBus, RS-485, Ethernet

Communication Port

9

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.1.2 Servo Drive Connectors and Terminals

Terminal Identification Description Details

P1

P2

CN1 Communication Port User to connect personal computer

CN2 I/O Connector Used to connect external controllers.

CN3 Encoder Feedback Connector Used to connect encoder of servo motor.

CN4 Reserved

CN5 Reserved

CN6

CN7

L1、L2、L3 Used to connect three-phase AC main circuit power

L1C、L2C Used to connect single-phase AC for control circuit power

Used to connect servo motor

U、V、W

B1+、B2、B3

Regenerative resister terninals

RS-485/CANopen

*RS-2

32 Communication Port

RS-485/CANopen

Communication Port

Terminal

Symbol

U Red

V Yellow

W Blue

Internal

Resister

External

Resister

RJ45 connector, Daisy Chain, Used for RS-485/CANopen

*RS-232 Communication Port (-Q Type Only)

RJ45 connector, Daisy Chain, Used for RS-485/CANopen

Wire color Description

Ensure the circuit is closed between B2 and

and the circuit is open between B1+ and B3.

Ensure the circuit is open between B2 and B3,

and connect the external regenerative resister

between B1+ and B2.

Communication

Connecting to three-phase

motor main circuit cable

B3,

3.1.3 Connections and Wiring Notes

• Please ensure grounding wires are securely connected, wires with more than 2.0mm2 on width

is recommended.

• Grounding method must be single point grounding.

• Ensure L1/L2/L3 and

specification range.

• Ensure U/V/W are following the order of RED/YELLOW/BULE. Wrong connections will cause

motor stop rotation, or wrong rotatory directions.

• Isolation transformer or EMI filter is recommended on drive

safety and improve its anti-interference level.

• Please setup a emergence stop circ

• Please DO NOT touch drive or motors

powered off. There are electrical charge components in the circuitry. Therefore, even power is

off, there might still be hazardous voltages within the circuitry, before its total discharge.

• Install the encoder cables in a separate conduit from the

noise. Separate the conduits by 30cm (11.8inches) above.

• Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for signal, encoder

feedback cables.

L1C/L2C are correctly wired, and voltage supply are within the

’s power supply to ensure drive’s

uitry to switch off the power supply when fault occurs.

’s connector terminals 5 minutes after drive and motor is

motor power cables to avoid signal

• The maximum length of signal input/output cable is 5m, and the maximum length of encoder

(PG) feedback cables is 15m

Rev. 1.0

4/29/2016

10

M2 Quick Setup Guide Manaul

3.2 Wiring Methods

220V AC servo drive supports single phase or three phase wiring method. Three phase wiring

method for 750W or above drives is recommended.

3.2.1 Single-Phase Power Supply Connection(AC220V)

L N E

MCCB

NF

P_on

P_off

E_stop

MC

Alarm

MC

Use external

regeneration resistor

B1+

B2

B3

regeneration resistor

Use Internal

MC

M2 Servo Drive

L1

L3

L1C

L2C

B1+

B2

B3

P1

P2

U

V

W

CN3

Alm_R

Red

Yellow

Blue

Yellow/Green

Ground

Encoder

Alm_R

3.2.2 Three-Phase Power Supply Connection(AC220V)

R

MCCB

NF

E

T

S

P_on

P_off

E_stop

MC

M

Encoder

24VDC

Alarm

MC

Use external

regeneration resistor

B1+

B2

B3

Use Internal

regeneration resistor

MC

M2 Servo Drive

L1

L2

L3

L1C

L2C

B1+

B2

B3

11

Alm_R

Red

U

Yellow

V

P2

W

CN3

Blue

Yellow/Green

Ground

Encoder

M

Encoder

Alm_R

24VDC

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

Note:

Symbol Description

MCCB Circuit Breaker

NF Noise Filter

P_on Power On Switch

P_off Power Off Switch

E_stop Emergency Stop Switch

MC Magnetic Contactor

Alm_R Alarm Relay

Alarm Alarm Relay Contactor

3.2.3 Recommend Cable Specications

• For drive’s main circuit, please use wires withstands at least 600Vac.

• Please select wires with sufficient allowance for parameters such as operating current, and

ambient temperature.

• Recommended wire selections a

Matched Servo Drive and Motor

SM0401AE4-KCD-*NV

M2DV-1D82*

M2DV-3D02* SM0602AE4-KCD-*NV

M2DV-4D52* SM0803AE4-KCD-*NV

SM0402AE4-KCD-*NV

SM0601AE4-KCD-*NV

re as follows:

Wire Diameter mm

L1/L2/L3 L1C/L2C U/V/W B1+,B3

1.25

(AWG16)

1.25

(AWG16)

1.25

(AWG16)

2.0

(AWG14)

3.5

(AWG12)

1.25

(AWG16)

1.25

(AWG16)

1.25

(AWG16)

2.0

(AWG14)

3.5

(AWG12)

2

(AWG)

1.25

(AWG16)

1.25

(AWG16)

1.25

(AWG16)

2.0

(AWG14)

3.5

(AWG12)

2.0

(AWG14)

2.0

(AWG14)

2.0

(AWG14)

2.0

(AWG14)

3.5

(AWG12

)

3.3 Wiring to the Connector,P2

3.3.1 Motor Power Cable Conguration

P2 connector Interface of the Drive

extension cable connector

Motor power

NOTE: Please refer to section 3.3.2 Motor Power Cable Connector Specications for

details

Lead wire

of the motor connector

Rev. 1.0

4/29/2016

12

M2 Quick Setup Guide Manaul

3.3.2 Motor Power Cable Connector Specications

◆ PIN Assignment

A B

View A View B

PIN 1 2 3 4

Signal U V W PE

Colour Red Yellow Blue Yellow/Green

◆ Model of Motor Connector

Type Motor Side(Plug) Plug-in(Housing)

Housing AMP 172167-1 AMP 172159-1

Crimp

AMP 170360-1 AMP 170362-1

3.3.3 Wiring Diagram of Motor extend Cable

Drive Side(P2)

(JST) S06B-F32SK-GGXR AMP 172159-1

4 U Red 1

5 V Yellow 2

6 W Blue 3

Grounding Screw PE Yellow/Green 4

Signal Colour

NOTE: Ensure U/V/W are following the order of RED-YELLOW-BULE. Wrong connections

will cause motor stop rotation, or wrong rotatory directions.

Housing: 172159-1(AMP)

Terminal: 170362-1(AMP)

Motor Side(Housing)

13

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

Servo Drive

3.4 Electromagnetic Brake

When motor drives the vertical axis, brake should be used to hold and prevent the work (moving

load) from falling by gravity while the power to servo is shut off.

NOTE: only use servo motor brake for hold the stalling status, i.e.. motor is in disable or

power off.

Never use this for “brake” purpose to stop the load in motion. Wrong use might cause

servo motor damage.

3.4.1 Wiring Diagram

24V

Relay

DC

Brake

Brake+

Brake-

Relay

R

24V

DC

3.4.2 Notice for the Brake Motor

◆When no power is applied to the electromagnetic brake, it is in locked position. Therefore, the

motor shaft will not be able to rotate.

◆The brake coil has no polarity.

◆During the brake/release action, there might be “Ka-Da” sounds occurring, this does not

effect the use of brake.

◆Specification of brakes are as follows:

Motor Power

Type 50W 100W 200W 400W 750W

Holding Torque(N•m) 0.35 2 4.5

Working Current(A) 0.25 0.38 0.61

Rated Voltage(V) 24V±10%

Release Time <25ms

Engage Time <25ms

Release Voltage(V) Release Voltage18.5VDC

3.4.3 The timing charts of the electromagnetic brake

In order to prevent damage to the brake, there are delay sequences during the brake operation.

Please be cautious with brake operation sequence.

Servo-on In Put

Motor Active

Brake Signal

Brake Action

Motion Command

Actual Motion

Brake/release delay time can be set via M servo suite software, or on the drive itself through P

function: P-68(BD) or P-69(BE) .

Rev. 1.0

4/29/2016

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Brake Release Delay

P-68 Setting

14

Brake Engage Delay

P-69 Setting

M2 Quick Setup Guide Manaul

3.5 Regenerative Resister

In M2 series AC servo drives, there is a pre-installed 40W (M2DV-4D5 model: 60W )regeneration

resistor. In some applications, he pre-installed regeneration might not be enough to absorb all

fold back current. In these cases, a larger wattage regeneration resistor needs to be connected

externally, to prevent drive from over voltage warnings.

Ensure the circuit is closed between B2 and

B3,and the circuit is open between B1+ and

B3 when using internal resister.

Ensure the circuit is opened between

B2 and B3,and connect regenerative

resister between B1+ and B2 when

using external resister.

Regeneration

Resister

• For more detailed informations on regeneration resistor selection, please refer to M2 user

manual “regeneration resistor”.

3.6 Connect to Host Computer,CN1

Port CN1 is used to connect drive with PC. Use M servo suite software to set control mode,

change parameter values, use auto-tuning function and etc.

PIN Symbol Function

1 +5V +5V Power Supply

2 D- Data -

3 D+ Data +

4

5 GND Ground

—

Reserved

3.7 Input and Output Signal Interface Connector,CN2

The CN2 port on M2 series AC servo drives is used from input/output signals. Details are shown in

table below:

8 Configurable Optically isolate general High Speed Inputs, 5-24VDC, 20mA

2 Configurable Optically isolate general Inputs

4 Configurable Optically isolate general High Speed Outputs, max 30VDC,20mA

1 Alarm Output, max 30VDC,20mA.

1 motor brake control output, max 30VDC,100mA .

2 Analog Inputs, with 12bit resolution

2 Optically isolated high speed inputs 500Hz(Open collector)

2 high speed different

4 high speed encoder feedback output(3 Line Driver A/B/Z,and 1 open collector OZ)

ial inputs 2MHz

I/O

Signals

Inputs

Digital Signal

Outputs

Analog Signal Inputs

Inputs

Pulse Signal

Outputs

15

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.7.1 Input and Output Interface Diagram

X1+

X1-

X2+

X2-

X3+

X3-

X4+

X4-

X5+

X5-

X6+

X6-

X7+

X7-

X8+

X8-

COM

X9

44

45

46

47

3

4

5

6

29

31

35

34

8

2

9

1

39

38

12

32

7

1.5K

26

1.5K

1.5K

Position

Command

PULSH1

High Speed

PULSH2

Pulse Input

SIGNH1

SIGNH2

STEP/CW

DIR/CCW

Enable

Alarm Reset

Limit Sensor

Limit Sensor

Gain Select

Control mode Switch

Dividing Switch

Analog Input

16

+

-

+

-

ANA1

Speed Command

15

DGND

18

ANA2

Torque Command

17

DGND

37

Y1+

Alarm Output

36

Y1-

11

Y2+

Motor Brake

Y2-

Y5+

Control Output

10

40

Servo Ready Output

41

Y5-

14

Y6+

In Position Output

13

Y6-

42

Y3

Torque Reached Output

43

Y4

Velocity Reached Output

33

OUT-

21

AOUT+

Encoder

Feedback

22

48

49

23

24

19

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

CZ

Output

Rev. 1.0

4/29/2016

SPD0

SPD1

SPD2

X10

X11

X12

27

1.5K

1.5K

28

1.5K

1.5K

30

1.5K

DGND

15

20

+10V User

User_GND

25

FG

50

16

M2 Quick Setup Guide Manaul

3.7.2 Signals Description of Connector CN2

3.7.2.1 The Layout of CN1 Connector

A

View AView B

B

3.7.2.2 Input Signals

M2 series AC servo drive have 12 programmable digital inputs as well as 2 analog inputs.

Each of the input can be specified with different function via parameter settings. The functions are

as follows:

◆Specified function signals: i.e. Pulse/DIR signal, motor enable/disable signals.

◆General purpose signal: In velocity mode, torque mode, Q program mode, or SCL mode,

17

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

general purpose signal has no specified functions.

Signal Symbol Pin NO. Details

X1+ 3

X1

X1- 4

This input has three functions:

Accept STEP pulse input such as pulse signals, CW pulse, A pulse in

●

position mode.

Run/Stop input in torque or velocity mode.

●

General Input.

●

X2+ 5

X2

X2- 6

X3

X3+ 29

X3- 31

X4+ 35

X4

X4- 34

X5

X6

X7

X8

X5+ 8

X5- 2

X6+ 9

X6- 1

X7+ 39

X7- 38

X8+ 12

X8- 32

X9 X9 26

X10 X10 27

X11 X11 28

X12 X12 30

COM COM 7

PULSH1 44

PULSH2 45

High-speed pulse

SIGNH1 46

inputs

SIGNH2 47

Analog input

ANA1 16

signal 1

DGND 15

Analog input

ANA2 18

signal 2

DGND 17

This input has three functions:

Accept STEP pulse input such as Direction signals,CCW pulse,

●

B pulse in position mode.

Direction input in torque or velocity mode.

●

General Input.

●

Enable/Disable input.

●

General Input.

●

Alarm Reset Input,used to reset drive alarm.

●

General Input.

●

Limit Sensor Input

●

General Input

●

Limit Sensor Input

●

General Input

●

Gain Select Input in all control mode.

●

General Input.

●

Switch Control mode between Main mode and second mode.

●

General Input.

●

Dividing Sw

●

General Input.

●

Pulse Inhibited Input. Ignore the pulse input when this input is activated

●

in position mode.

Speed Selecting Input 1 in change Speed mode.

●

General Input.

●

Speed Selecting Input 2 in change Speed mode.

●

General Input.

●

Speed Selecting Input 3 in change Speed mode.

●

General Input.

●

X9-X12 COM point.

High-speed pulse inputs(+5VDC line drive input).The max. input frequency is

2MHz.Three different pulse command can be selected:

Pulse & Direction

●

CW Pulse and CCW Pulse

●

A Quadrature B pulse

●

(NOTE:DO NOT use it with X1/X2 both. )

AS velocity command in analog velocity mode. The offset ,dead band,

●

function of analog input 1 can be set by M Servo Suit or parameters

P-51, P-55 and P-60.

Sets or requests the analog Input gain that relates to motor position

●

when the drive is in analog position command mode.

Sets or requests the gain value used in analog velocity mode.

●

General Analog Input in Q mode.

●

Digital Ground for Analog input.

AS torque com

●

analog input 2 can be set by M Servo Suit or parameters P-53,P-57 and P-61.

General Analog Input in Q mode

●

Digital Ground for Analog input.

itch,change the pulses per revolution for electronic Gearing.

mand in analog torque mode. The offset ,dead band, function of

Rev. 1.0

4/29/2016

18

M2 Quick Setup Guide Manaul

3.7.2.3 Output Signals

M2 series AC servo drive has 6 programmable digital outputs available, each of the output can be

specified with different function via parameter settings.

Signal Symbol Pin NO. Details

This output has two functions:

Alarm Output

●

General Output

●

This output has two functions:

Motor brake control output

●

General Output

●

Torque Reached Output

●

General Output

●

Moving signal output, output signal when dynamic position error less

●

than set value in position mode.

Velocity reach output. Output signal when actual speed is same as the

●

target speed and the speed ripple less than ripple range.

General Output.

●

Servo ready output. Output servo ready signal when the drive is ready

●

to be controlled and without alarm.

General Output.

●

In position signal output, output signal when in position, and the

●

position error less than set value in position mode.

Tach out output. Tach output, produces pulses relative to the motor

●

position with configurable resolution.

General Output.

●

The encoder feedback phase A line drive output.

The encoder feedback phase B line drive output.

The encoder feedback phase Z line drive output.

The encoder feedback phase Z output.(Open collector)

+10Vdc user ,max 100mA

+10Vdc user Ground

Y1

Y2

Y3

Y4

Y5

Y6

Encoder pulse

feedback Output

+10V

Output

Y1+ 37

Y1- 36

Y2+ 11

Y2- 10

Y3+ 42

Y3- 33

Y4+ 43

Y4- 33

Y5+ 40

Y5- 41

Y6+ 14

Y6- 13

AOUT+ 21

AOUT- 22

BOUT+ 48

BOUT- 49

ZOUT+ 23

ZOUT- 24

ZOUT 19

+10V Us

er 20

USER_GND 25

3.7.3 Encoder Feedback Ouput

M2 series AC servo drive can output encoder A/B/Z phase as differential output signals through

line driver. The output signal is 5V, A/B signals are 10000 pulse/rev, Z signal is 1pluse/rev.

The host must use line receiver to receive the signals. Please use twist pair wires for signal

transfers.

3.7.3.1 A/B/Z Wiring Method

Servo Drive

21

AOUT+

22

AOUT-

48

BOUT+

49

BOUT-

23

ZOUT+

24

ZOUT-

DGND

25

50

FG FG

NOTE:Please make sure the host controller and the servo drive have a same ground.

Host Controller

A+

A-

B+

B-

Z+

Z-

DGND

19

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.7.3.2 Phase Z Open Collector Output

In M2 series AC servo drive, encoder signal Z uses open collector output circuitry. Due to the

narrow bandwidth of encoder signal Z, please use high speed optocoupler circuitry for the host

receiver.

Servo Drive

CZ

19

DGND

15

3.8 Encoder Connector CN3

3.8.1 Motor Encoder Feedback Cable Conguration

驱动器CN3端

P2

B1+

B2

B3

U

V

C

N

W

3

编码器延长线连接头

24VDC

0VDC

编码器引出线编码器连接头

NOTE: Please refer to section 3.8.4 Encoder Connector Specications for details.

3.8.2 The Layout of CN3 Connector

Rev. 1.0

4/29/2016

1

2

12

13

15

14

26

25

View B

14

26

View A

1

13

A

20

B

M2 Quick Setup Guide Manaul

3.8.3 Descriptions of Encoder Connector CN3

Pin NO. Symbol Description

1 A+ Encoder A+

2 B+ Encoder B+

3 Z+ Encoder Z+

4 U+ Hall U+

5 W+ Hall W+

6 U- Hall U-

7 W- Hall W-

11 Encoder +5V Encoder power supply +5V

13 Encoder +5V Encoder power supply +5V

14 A- Encoder A-

15 B- Encoder B-

16 Z- Encoder Z-

17 V+ Hall V+

19 V- Hall V-

24 GND Encoder power supply ground

26 Shield Shield

3.8.4 Connect to Motor Encoder

A. Connect to 2500ppr Increment Encoder (9PIN AMP connector)

Servo Drive CN3

CN3

1

14

2

15

3

16

11

24

26

Motor Encoder

A+

1

A-

4

B+

2

B-

5

Z+

3

Z-

6

+5V

7

GND

8

Shield

9

A+

A-

B+

B-

Z+

Z-

+5V

GND

Shield

21

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

A

3.8.5 Specications of Encoder Connector

A. 9PIN AMP Connector

◆PIN Assignment

1 3

7

9

View A

PIN#

1

2

3

4

5

6

7

8

9

Signal Colour

U+/A+ Blue

V+/B+ Green

W+/Z+ Yellow

U-/A- Yellow/Black

V-/B- Green/Black

W-/Z- Yellow/Black

+5V Red

GND Black

Shield Shield

NOTE: HALL signal U/V/W will only appear for 1.5 seconds when encoder power is applied,

and it will switch to A/B/Z signals after.

◆Specification of 9PIN AMP Connector

Type Plug of the Motor Housing for the motor

Housing AMP 172169-1 AMP 172161-1

Crimp AMP 770835-1 AMP 770834-1

3.8.6 Wiring Diagram of Motor Encoder Extend Cable

A. Diagram of 9PIN Encoder Cable

Rev. 1.0

4/29/2016

Connect to drive

Connect to Motor

Drive Side

3M 26PIN PIN脚 AMP 172161-1

Signal Colour

A

1

3

7

9

View A

Housing for the motor

1 A+/U+ Blue 1

2 B+/V+ Green 2

3 Z+/W+ Yellow 3

14 A-/U- Yellow/Black 4

15 B-/V- Green/Black 5

16 Z-/W- Yellow/Black 6

11 +5V Red 7

24 GND Black 8

26 Shield Shield 9

22

M2 Quick Setup Guide Manaul

4 Control Block Diagram

4.1 Position Mode

Differential Pulse Signal

Controller

VDC Spec.

DGND

Open Collector Output

VDC

5-24VDC

High Speed Differential Input

44

PULSH1

45

PULSH2

46

SIGNH1

47

SIGNH2

DGND

25

FG

Control mode Switch

VDC

Pulse Inhibited Input.

High Speed Pulse Input

PULSH1

PULSH2

SIGNH1

SIGNH2

X1+

X1-

X2+

X2-

X3+

X3-

Enable Signal Input

X4+

X4-

Alarm Reset

X5+

X5-

Limit Sensor

X6+

X6-

Limit Sensor

X7+

X7-

Gain Select

X8+

X8-

COM

X9

Dividing Switch

X10

X11

X12

44

45

46

47

3

4

5

6

29

31

35

34

8

2

9

1

39

38

12

32

7

1.5K

26

1.5K

1.5K

27

1.5K

1.5K

28

1.5K

1.5K

30

1.5K

Encoder

Feedback

Output

Analog Input

16

+

ANA1

15

18

17

37

36

11

10

40

41

14

13

42

43

33

21

22

48

49

23

24

15

19

15

50

DGND

ANA2

DGND

Y1+

Y1-

Y2+

Y2-

Y5+

Y5-

Y6+

Y6-

Y3

Y4

OUT-

AOUT+

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

DGND

CZ

DGND

FG

Speed Command

Torque Command

Alarm Output

Brake Control Output

Servo Ready

In Position

Torque Reached Output

Velocity Reached Output

A+

A-

B+

B-

Z+

Z-

DGND

5-24VDC

Drive

Encoder Phase A Output

Encoder Phase B Output

Encoder Phase Z Output

Phase Z (Open Collector Output)

5-24VDC

-

+

-

Note:VDC Spec. 5~24VDC

23

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

4.2 Speed Mode

44

PULSH1

45

High Speed Pulse Input

Enable Signal Input

Alarm Reset

Limit Sensor

Limit Sensor

Gain Select

Control mode Switch

VDC

Pulse Inhibited Input.

PULSH2

SIGNH1

SIGNH2

X1+

RUN/STOP

Rotation Direction

X1-

X2+

X2-

X3+

X3-

X4+

X4-

X5+

X5-

X6+

X6-

X7+

X7-

X8+

X8-

COM

X9

X10

X11

46

47

3

4

5

6

29

31

35

34

8

2

9

1

39

38

12

32

7

1.5K

26

1.5K

1.5K

27

1.5K

1.5K

28

1.5K

1.5K

Encoder

Feedback

Output

Analog Input

16

+

-

+

-

ANA1

15

DGND

18

ANA2

17

DGND

37

Y1+

36

Y1-

11

Y2+

±10VDC

±10VDC

Alarm Output

Speed Command

Torque Command

Brake Control Output

10

Y2-

40

41

14

13

42

43

33

21

Y5+

Y5-

Y6+

Y6-

Y3

Y4

OUT-

AOUT+

Servo Ready

5-24VDC

In Position

Torque Reached Output

Velocity Reached Output

Drive

A+

Encoder Phase A Output

22

48

49

23

24

15

19

15

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

DGND

CZ

DGND

A-

B+

B-

Z+

Z-

DGND

Encoder Phase B Output

Encoder Phase Z Output

Phase Z (Open Collector Output)

5-24VDC

30

X12

Note:VDC Spec. 5~24VDC

Rev. 1.0

4/29/2016

1.5K

FG

50

24

M2 Quick Setup Guide Manaul

4.3 Torque Mode

44

PULSH1

45

RUN/STOP

PULSH2

SIGNH1

SIGNH2

X1+

X1-

X2+

X2-

X3+

X3-

X4+

X4-

X5+

X5-

X6+

X6-

X7+

X7-

X8+

X8-

COM

X9

X10

X11

46

47

3

4

5

6

29

31

35

34

8

2

9

1

39

38

12

32

7

1.5K

26

1.5K

1.5K

27

1.5K

1.5K

28

1.5K

1.5K

High Speed Pulse Input

Rotation Direction

Enable Signal Input

Alarm Reset

Limit Sensor

Limit Sensor

Gain Select

Control mode Switch

VDC

Encoder

Feedback

Output

Analog Input

16

+

-

+

-

ANA1

15

DGND

18

ANA2

17

DGND

37

Y1+

36

Y1-

11

Y2+

±10VDC

±10VDC

Alarm Output

Speed Command

Torque Command

Brake Control Output

10

Y2-

40

41

14

13

42

43

33

21

22

48

49

23

24

15

19

15

Y5+

Y5-

Y6+

Y6-

Y3

Y4

OUT-

AOUT+

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

DGND

CZ

DGND

Servo Ready

In Position

Torque Reached Output

Velocity Reached Output

A+

A-

B+

B-

Z+

Z-

DGND

5-24VDC

Drive

Encoder Phase A Output

Encoder Phase B Output

Encoder Phase Z Output

Phase Z (Open Collector Output)

5-24VDC

30

X12

1.5K

Note:VDC Spec. 5~24VDC

25

FG

50

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

5 Display and Operation

5.1 Description of Operation Panel

LED Display

MODE

UP

Symbol Name Details

LED Display

MODE Key

UP/DOWN Key

SET Key

The LCD display (5 digits, 7 segments) show the drive’s

operating condition and warning codes, parameters and

settings values.

Press and hold on mode button to switch LED display mode

a). monitoring mode

b). monitoring selection mode

c). function selection mode

d). parameter setting mode

When editing the parameters, press on MODE button can

move the cursor to the left and then change parameters by

using arrow keys.

UP and DOWN Key. Pressing the UP and DOWN key can

scroll through and change monitor codes, parameter groups

and various parameter settings.

Press to entering mode

Press and hold to save parameters/settings

SET

M

S

DOWN

5.2 Key Lock

M2 series AC servo drive has Key Lock function to prevent unexpected operation. When the key

is locked ,the panel can not be operated of set any parameters.

Monitor Status

Press and hold SET key for 1 second

The Key Lock is active.

Any key operation will display as follows:

Press and hold the SET Key for 1 second

to Unlock the panel when the Key Lock is active.

Unlock the key

Rev. 1.0

4/29/2016

26

M2 Quick Setup Guide Manaul

the SET key to confirm setting value

5.3 Key Operation Flowchart

Power On

In factory default mode, it will display motor’s rotatory velocity.(*NOTE 1)

The last dot shows whether the drive is enable or disable.

Monitor Status

Press and hold the

MODE key for 1 second

M

key for 1 second(*NOTE 4)

Press any key

Monitor Parameters

Press and hold the

MODE key for 1 second

M

Function Parameters

Press and hold the MODE

M

Drive Parameters

Configuration

Press the UP and

DOWN key to scroll

through and change

monitor status

Press the UP and

DOWN key to scroll

through and change

function selection

Press the UP and

DOWN key to scroll

through and change

parameter selection.

Press SET key back

to Monitor Status

S

Press and hold SET key to

confirm selection and execute it.

S

Press SET key enter

to value setting mode

S

Press SET key back to

Drive Parameters Configuration

mode without changing.

*NOTE(2)

Press and hold for 1 second

*Note(3)

S

*NOTE:

1) When power is applied, drive

default mode, it will display motor

2) In parameter setting mode, press set

’s display will show customer defined monitoring mode. In factory

’s rotatory velocity.

key will quit from parameter setting mode, and return

back to parameter selection mode, and changes will not be saved.

3) In parameter setting mode, press and hold set

button will confirm and save current

parameter setting. This will effect immediately, however, this change will not save to drive

If parameter is required for permanent use, please go to function mode

press and hold set

button to save the parameter change.

“

”

27

’s Flash.

, and then

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

6 Preoperational mode

When preoperational mode is working, please disconnect servo motor from any mechanical

system to prevent any damages and accidents. Please performs this operation under no load

condition.

6.1 Inspection Before Trail Tun

In order to avoid any accidents and damages to servo drive and mechanical systems, we strongly

recommend following safety checks before you turn on the drive.

1) Connection inspections

Please ensure secure wirin

CN3, communication connector CN1. Ensure wirings corrections, and wires are correctly

insulated(not short circuit) for all connectors.

Ensure ground wire from power connector P1, and motor connector P2 are securely

connected(screwing) to the shield ground.

2) Power supply inspection

gs for power connector P1, motor connector P2, Encoder connector

Check and ensure voltage supplies between L1/L2/L3,

meets drive’s power supply specifications.

Check and ensure voltage between L1C/L2C are within the correct supply voltage range.

3) Ensure secure installation of servo drive and motor.

4) Ensure no load is installed on the servo motor.

6.2 Trail Run Procedure

Step Details Description

1

Please fix and sure the motor as well

as possible

2 Please ensure the wiring between the

drive and motor is correctly.

3 Please make sure the main power

circuit wiring connect correctly.

4 Supply the Power

The LED Display will show as follows

5

without alarm:

When the alarm occurs, it will display:

1) The motor can be installed on the machine.

2) Ensure no load is installed on the servo motor.

1.Terminal U,V,W and FG must connect to Red,Yellow ,Blue and Yellow/Green

cable separately(U:Red,V:Yellow,U:Blue,FG:Yellow/Green).If not connect to the

specified cable and terminals,then the drive cannot control motor.

2.Ensure to connect e

connector correctly.

Refer to Section 3.1 Connecting to Peripheral Devices to confirm the main power

circuit wiring connect correctly.

’t supply 380VAC power supply into the servo system.

Don

1. When the power is on ,the normal display should be shown without any alarm

codes and the drive is disabled.

2. If display shows alarm codes such as r-08 and r-09.It means that the encoder

feedback connection is incorrectly. Check if the encoder wiring of servo motor is

loose or incorrect.

ncoder cable to CN2

6 User need to setup a motor

brake control circuit when using a

electromagnetic brake motor.

7 Motor Configuration Configure the correct motor that has been used with the M2 Servo Suit or the

8 JOG Trail Run without Load You can continue to do JOD trail run if all the steps above mentioned are correct.

Rev. 1.0

4/29/2016

Please refer to

operation panel.

28

Section 3.4 Electromagnetic Brake for more details.

M2 Quick Setup Guide Manaul

6.3 Motor Conguration Manually

Before JOG mode operation, M2 series AC servo drive requires motor configuration setup. To

confirm your motor specification, please refer to chapter 2.3.

For more MOONS

For example: To setup a drive for model: SM0402AE4-KCD-NNV09 motor. these are the following

steps:

Step Display Details

’ motor information, please refer to appendix 1.

1

2

3

4

5

6

7

Press into the Function Parameters mode at the Monitor Status mode

Press the and key to select F07(MC)

Press key into value setting mode.

Press

Press and hole key for 1 second to confirm motor configuration.

Parameter is effective only after the servo drive is restarted.

6.4 Operations of JOG Mode

Step Display Details

1

2

3

Press to switch the Monitor Status mode into the Drive Parameters

Configuration mode

Scroll

Press key into value setting mode

、

key to change value.

、

key to select parameter P61(SI)

4

5

6

7

8

10

11

12

13

14

9

Scroll

Press and hold key for 1 second to confirm the setting value.

Press key into the Function Operation mode.

Scroll

Press and hold SET key for 1 second, the drive will be enabled. The last dot will

light to shows the drive is enabled.

Scroll the

Press the key into JOG mode

Press the key ,the motor will rotate at CW direction with the speed 1rps.

Press the key ,the motor will rotate at CCW direction with the speed 1rps.

Press the key to stop the motor

Press the key back to the Function Operation mode.

、

key to change values.

、

key to select Function F06(MC) to enable the motor.

、

key into function F01(CJ) to run JOG mode.

29

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

7 Troubleshooting

When power is applied, if any of the following warnings are detected, the LED display of the drive

will switch into warning or fault display mode immediately.

If more than one warning is detected, you can scroll through by press

Press

m/s button will clear the warnings and back to pervious display mode.

7.1 Drive Alarm List

LED display Description Alarm type Drive status after alarm occurs

Drive over temperature Fault Servo off

Internal voltage fault Fault Servo off

Over voltage Fault Servo off

Fault Servo off

Over current

Bad hall sensor Fault Servo off

Encoder error Fault Servo off

Position error Fault Servo off

Fault Servo off

Fault Servo off

up /down button.

Low voltage Fault Servo off

Velocity limited Warning No change to drive’s staus

CW limit or CCW limit activated Warning No change to drive’s staus

CW limit is activated Warning No change to drive’s staus

CCW limit is activated Warning No change to drive’s staus

Current limit Warning No change to drive’s staus

Communication error Warning No change to drive’s staus

Parameter save failed Warning No change to drive’s staus

Phase loss of the main circuit Warning No change to drive’s staus

STO is activated Warning Servo off

Regeneration failed Warning No change to drive’s staus

Low voltage Warning No change to drive’s staus

Q program is empty Warning No change to drive’s staus

Rev. 1.0

4/29/2016

Move when the drive is disabled. Warning No change to drive’s staus

30

M2 Quick Setup Guide Manaul

7.2 Drive alarm reason and solutions

LED display Description Alarm type Processing method

Temperature of the heat sink or power

device has been risen over the specied

Drive over

temperature

Internal voltage

fault

temperature.

1. Ambient temperature has risen over

the specied temperature.

2. Over-load

Drive internal voltage failure.

1. Improve the ambient temperature and

cooling condition.

2. Increase the capacity of the driver

and motor. Set up longer acceleration/

deceleration time. Lower the load

1. Please check supply power voltage

2. Please replace the drive with a new one,

and contact MOONS

Drive DC bus volatage is too high

220V series : 420V

1. Power supply voltage has exceeded the

permissible input voltage.

Over voltage

Over current

Bad hall sensor Hall sensor fault

2. Disconnection of the regeneration

discharge resistor

3. External regeneration discharge

resistor is not appropriate and could not

absorb the regeneration energy.

4. Failure

1. Failure of servo driver (failure of the

circuit, IGBT or other components)

2. Short of the motor wire (U, V and W)

3. Burnout of the motor

4. Poor contact of the motor wire.

5. Input pulse frequency is too high.

6. Motor is over load, command output

torque is larger than speciced torque, for a

long operating time.

7. Poor gain adjustment cause motor

vibration, and abnormal nosie.

8. Machine has collided or the load has

gotten heavy. Machine has been distorted.

9. Welding of contact of dynamic braking

relay due to frequent servo ON/OFF

operations.

Measure the voltage between lines of

connector (L1, L2 and L3).

1. Enter correct voltage.

2. Measure the resistance of the internal

regeneration resistor.

3. please measure the external resistor,

Replace the external resistor if the value is ∞.

4. Please contact MOONS or replace the

driver with a new one.

1. Turn to Servo-ON, while disconnecting the

motor. If error occurs immediately, replace

with a new driver.

2. Check that the motor wire (U, V and W) is

not shorted, and check the branched out wire

out of the connector. Make a correct wiring

connection.

3. Measure the insulation resistance between

motor wires, U, V and W and earth wire. In

case of poor insulation, replace the motor.

4. Check the balance of resister between

each motor line, and if unbalance is found,

replace the motor.

5. Check the loose connectors. If they are, or

pulled out, x them securely.

6. Adjust gain value settings.

7. Measuring brake voltage

8. Check drive and motor encoder and power

wires.

9. please contact MOONS.

1. please check encoder connection

2. please check your drive motor

congurations.

Encoder error Encoder signal fault please check encoder connection.

1. Please check parameter P-43 (PF).

2. Please check drive gain value settings.

3. Please check the load factor of the

regeneration resistor, increase the capacity

of the driver and the motor, and loosen the

deceleration time

Measure the voltage between lines of

connector and terminal block L1,L2,L3.

1. Increase the power capacity. Change the

power supply.

2. please check connections between

L1,L2,L3. Please refer to 4.1.5 drive power

connection

3. please cpntact MOONS

Rev. 1.0

4/29/2016

Position error

Encoder error

Position error value exceeds the position

error range set by parameter P-43 (PF).

1. Power supply voltage is low. Instantaneous

power failure has occurred

2. Lack of power capacity...Power supply

voltage has fallen down due to inrush

current at the main power-on.

3. Failure of servo driver (failure of the circuit)

31

M2 Quick Setup Guide Manaul

Position error

CW limit or CCW

limit activated

CW limit is

activated

CCW limit is

activated

Current limit

Communication

error

Parameter save

failed

Phase loss of the

main circuit

STO is activated

Regeneration

failed

Low voltage

Motor rotary velocity exceeds parameter P-19

(VM) setting value.

CW and CCW limit is ON

CCW limit triggered

CW limit triggered

Driver’s output current exceeds setting value

P-18 (CP)

1. Load was heavy and actual torque has

exceeded the rated torque and kept running

for a long time.

2. Oscillation and hunching action due

to poor gain adjustment. Motor vibration,

abnormal noise.

3. Machine has collided or the load has

gotten heavy. Machine has been distorted.

Drive and host communication error.

Saving parameter failure.

- - - - - -

Safty torque off function is activated. Either

or both safety input 1 or 2 is ON.

Regenerative energy has exceeded the

capacity of regenerative resistor.

1. Due to the regenerative energy during

deceleration caused by a large load inertia,

converter voltage has risen, and the voltage

is risen further due to

the lack of capacity of absorbing this energy

of the regeneration discharge resistor.

2. Regenerative energy has not been

absorbed in the specied time due to a high

motor rotational speed.

Drive voltage lower than 170VDC

1) Power supply voltage is low. Instantaneous

power failure has occurred

2) Lack of power capacity...Power supply

voltage has fallen down due to inrush current

at the main power-on.

3) Failure of servo driver (failure of the

circuit)

Please check motor velocity command if it is

within the P-19 (VM) range.

1. Avoid high velocity command

2. Check the command pulse input frequency

and division/multiplication ratio.

3. Make a gain adjustment when an

overshoot has occurred due to a poor gain

adjustment.

4. Make a wiring connection of the encoder

as per the wiring diagram.

1. External limit switch is triggered.

2. Check x5 and x6 limit settings, please

refer to chapter7.1.3 Cw/ccw limit.

1. External limit switch is triggered.

2. Check x5 and x6 limit settings.

1. Make a gain re-adjustment.

2. Increase the capacity of the driver

and motor. Set up longer acceleration/

deceleration time. Lower the load.

3. Check motor wirings for U/V/W as red/

yellow/bule.

Please check wiring connection, and drive’s

communication address and baud rate

setting.

1. Please try to save again.

2. if problems is not solved, please contact

MOONS

Please conrm safety input 1 and 2 wiring

conguration.

Please check Safety sensor setting.

1. Internal resistor value is smaller than

required, cannot absorb the regeneration

energy.

2. Please check external regeneration

resistor connections.

3. Reduce rotary velocity and decrease

acceleration and deceleration value.

1) Increase the power capacity. Change the

power supply.

2) Please check l1, l2, l3 power connections,

please refer to 4.1.5 P1 drive power

connection.

3) please contact moons.

Rev. 1.0

4/29/2016

Q program is

empty

Move when the

drive is disabled.

Drive in Q mode, but Q program is empty.

Motion command is received while motor is

disabled.

32

1. Please check Q program.

2. Please check operation mode correction.

3. Please check Q program coding, make

sure no faults to stop the program running.

Please enable the motor, and send the

command again.

M2 Quick Setup Guide Manaul

8 Conguration by Personal Computer

in order to ensure servo drive and motor meets your operation requirements, we strongly

recommend customers to use “M servo suite” for following configuration setups:

1. Servo Motor model selection and configuration

2. Operational mode selection

3. Define drive

’s input/output mode

4. Apply auto tuning function on PID parameters for optimized motor performance.

Connect to Personal Computer

MODE SET

安装M2 Servo Suit设置软件

请到本公司网站下载

www.moons.com.cn

Interface of M2 Servo Suit

Configuration Steps Details

Step 1 Motor Configuration

Step 2 Select Control Mode

Step 3 Further configuration 1

Step 4 Further configuration 2

Step 5 I/O configuration

33

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

9 Appendix

LED Panel Model

Appendix 1:Motor Model Display

SM0401AE2-KCD-NNV

SM0402AE2-KCD-NNV

SM0601AE2-KCD-NNV

SM0602AE2-KCD-NNV

SM0801AE2-KCD-NNV

SM0802AE2-KCD-NNV

SM0803AE2-KCD-NNV

SM0401AE4-KCD-NNV

SM0402AE4-KCD-NNV

SM0601AE4-KCD-NNV

SM0602AE4-KCD-NNV

SM0801AE4-KCD-NNV

SM0802AE4-KCD-NNV

SM0803AE4-KCD-NNV

Appendix 2:LED Character Reference

1 2 3 4 5 6 7 8 9 10

A B C D E F G H I J

K L M N O P Q R S T

U V W X Y Z

Rev. 1.0

4/29/2016

34

M2 Quick Setup Guide Manaul

10 Contacting MOONS’

Service Center

+86-400-820-9661

35

Rev. 1.0

4/29/2016

Loading...

Loading...