Moons' M2DV-1D82Q, M2DV-1D82S, M2DV-3D02Q, M2DV-4D52Q, M2DV-3D02R Quick Setup Manual Manual

...

M2 Series AC Servo System

Quick Setup Guide Manual

SHANGHAI AMP & MOONS’AUTOMATION CO.,LTD.

Rev. 1.0

9/21/2015

M2 Quick Setup Guide Manaul

Safety

Only qualified persons may perform the installation procedures. The following explanations are for

things that must be observed in order to prevent harm to people and damage to property.

The M2 utilizes hazardous voltages. Be sure the drive is properly grounded.

Before you install the M2, review the safety instructions in this manual.

Failure to follow the safety instructions may result in personal injury or equipment damage.

Safety Symbols

Safety symbols indicate a potential for personal injury or equipment damage if the recommended

precautions and safe operating practices are not followed.

The following safety-alert symbols are used on the drive and in the documentat

ion:

Caution Warning. Dangerous voltage. Protective earth Caution,Hot surface

Safety Instructions

Installation

Wiring

Do not subject the product to water,corrosive or flammable gases,and combustibles.

Don’t use the motor in a place subject to excessive vibration or shock.

Never connect the motor directly to the AC power supply.

Don’t use cables soaked in water or oil.

Don’t extrude or pull-off the cable,nor damage the cables as electrical

shocks,damages may resul

Don’t block the heat dissipating holes. Please prevent

drive when mounting.

Don’t switch the power supply repeatedly.

Don’t touch the rotating shaft when the motor is running.

Don’t strike the motor when mounting as the motor shaft or encoder may be

damaged.

In order to prevent accidents, the initial trial run for servo motor should be conducted

under no load conditions (separate the motor from its couplings and belts).

Starti

ng the operation without matching the correct parameters may result in servo

drive or motor damage, or damage to the mechanical system.

Don’t touch either the drive heat sink or the motor and regenerative resister during

operation as they may become hot.

Don’t hold the motor cable during the transportation or mounting.

Don’t connect any power supplies to the U,V,W teminals.

Install the encoder cable in a separate conduit from the motor power cable to avoid

signal noise.

Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for

signal,encoder cables.

As a charge may still remain in the drive with hazardous voltage even after power has

been removed, Don’t touch the terminals when the charge led is s

Please observe the specified voltage.

Make sure both the drive and the motor connect to a class 3 ground.

Please ensure grounding wires are securely connected when power up.

any metal filings drop into the

till light.

Standards Compliance

The M2 Series AC servo drive has been designed according to standards:

* Electromagnetic compatibility * Electrical Safety: Low voltage directive

Standard EN 61800-3 (2004) Standard IEC 61800-5-1 (2007)

Rev. 1.0

4/29/2016

2

M2 Quick Setup Guide Manaul

Contens

1 Product Description ..................................................................... 5

1.1 Unpacking Check ................................................................................5

1.2 Servo Drive Model Introduction .........................................................5

1.2.1 Drive Name Plate Description ................................................................5

1.2.2 Drive Model Description ..........................................................................5

1.3 Servo Motor Model Introduction .........................................................6

1.3.1 Motor Name Plate Description ................................................................6

1.3.2 Motor Model Description .........................................................................6

1.4 Servo Drive and Servo Motor Combinations ......................................6

2 Installation ................................................................................... 7

2.1 Storage Conditions .............................................................................7

2.2 Installation Conditions .........................................................................7

2.3 Drive Dimensions(Unit: mm) ............................................................... 7

2.4 Installation Space ...............................................................................8

2.5 Motor Installation ................................................................................8

3 Connections and Wiring .............................................................. 9

3.1 Connecting to Peripheral Devices ......................................................9

3.1.1 System Conguration .............................................................................. 9

3.1.2 Servo Drive Connectors and Terminals ................................................. 10

3.1.3 Connections and Wiring Notes .............................................................. 10

3.2 Wiring Methods ................................................................................. 11

3.2.1 Single-Phase Power Supply Connection(AC220V) ............................... 11

3.2.2 Three-Phase Power Supply Connection(AC220V) ............................... 11

3.2.3 Recommend Cable Specications ........................................................12

3.3 Wiring to the Connector,P2 ............................................................... 12

3.3.1 Motor Power Cable Conguration .........................................................12

3.3.2 Motor Power Cable Connector Specications ...................................... 13

3.3.3 Wiring Diagram of Motor extend Cable .................................................13

3.4 Electromagnetic Brake .....................................................................14

3.4.1 Wiring Diagram ...................................................................................... 14

3.4.2 Notice for the Brake Motor ....................................................................14

3.4.3 The timing charts of the electromagnetic brake ....................................14

3.5 Regenerative Resister .....................................................................15

3.6 Connect to Host Computer,CN1 .......................................................15

3.7 Input and Output Signal Interface Connector,CN2 ...........................15

3

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.7.1 Input and Output Interface Diagram ......................................................16

3.7.2 Signals Description of Connector CN2 .................................................17

3.7.2.1 The Layout of CN1 Connector ............................................................17

3.7.2.2 Input Signals .......................................................................................17

3.7.2.3 Output Signals .....................................................................................19

3.7.3 Encoder Feedback Ouput .....................................................................19

3.7.3.1 A/B/Z Wiring Method ........................................................................... 19

3.7.3.2 Phase Z Open Collector Output .......................................................... 20

3.8 Encoder Connector CN3 ...................................................................20

3.8.1 Motor Encoder Feedback Cable Conguration .....................................20

3.8.2 The Layout of CN3 Connector ...............................................................20

3.8.3 Descriptions of Encoder Connector CN3 ..............................................21

3.8.4 Connect to Motor Encoder ....................................................................21

3.8.5 Specications of Encoder Connector ....................................................22

3.8.6 Wiring Diagram of Motor Encoder Extend Cable ..................................22

4 Control Block Diagram ............................................................... 23

4.1 Position Mode ...................................................................................23

4.2 Speed Mode .....................................................................................24

4.3 Torque Mode ..................................................................................... 25

5 Display and Operation ............................................................... 26

5.1 Description of Operation Panel ......................................................... 26

5.2 Key Lock ...........................................................................................26

5.3 Key Operation Flowchart ..................................................................27

6 Preoperational mode ................................................................. 28

6.1 Inspection Before Trail Tun ...............................................................28

6.2 Trail Run Procedure .......................................................................... 28

6.3 Motor Conguration Manually ........................................................... 29

6.4 Operations of JOG Mode .................................................................. 29

7 Troubleshooting ......................................................................... 30

7.1 Drive Alarm List .................................................................................30

7.2 Drive alarm reason and solutions ................................................31

8 Conguration by Personal Computer ........................................ 33

9 Appendix ................................................................................... 34

10 Contacting MOONS’ ................................................................ 35

Rev. 1.0

4/29/2016

4

M2 Quick Setup Guide Manaul

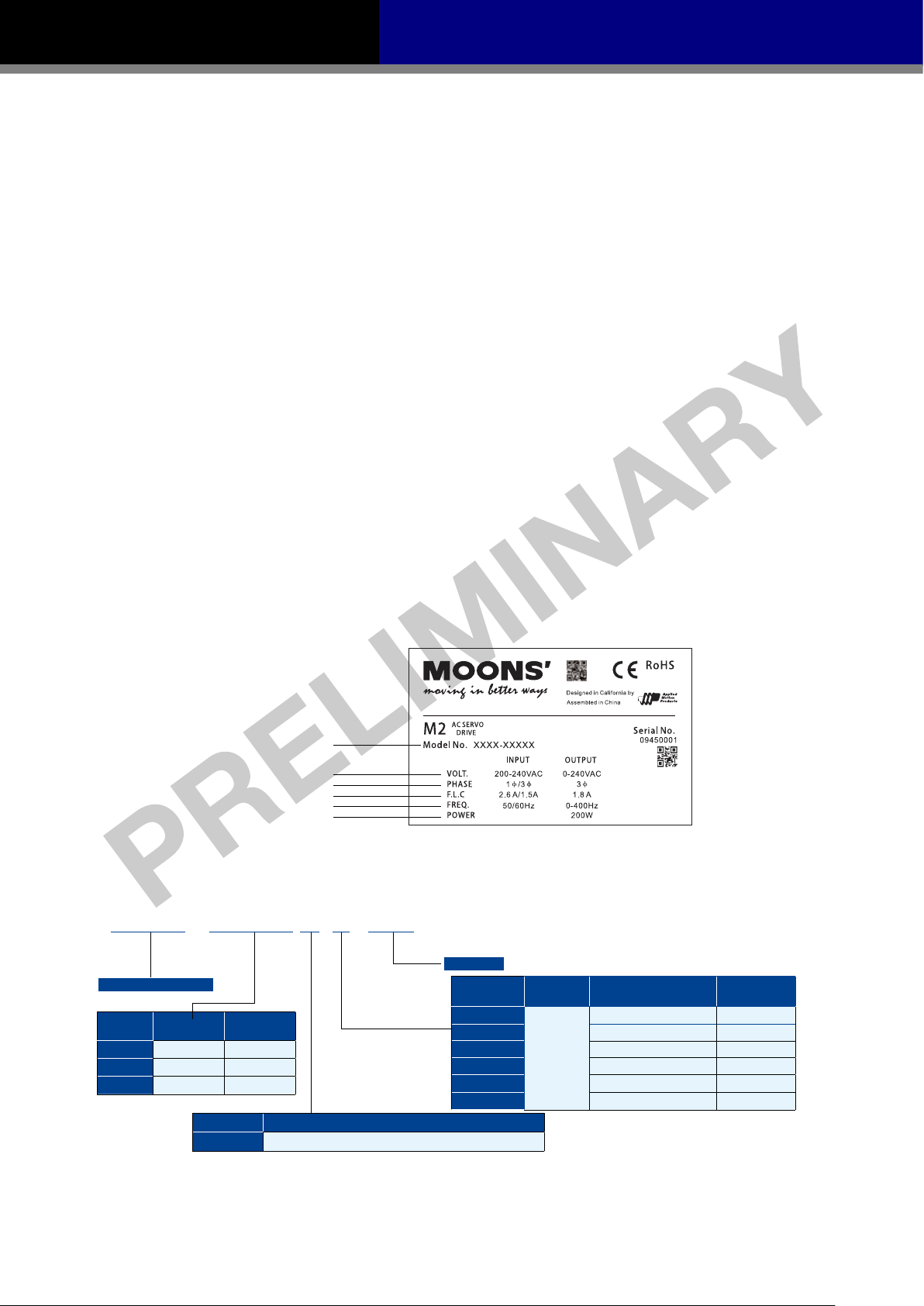

Model No.

Input/Output Voltage

Phase

Rated Current

Frequency

Rated Power

1 Product Description

1.1 Unpacking Check

Please refer to this section to confirm the model of servo drive and servo motor .

A complete and workable AC servo system should include the following parts:

1. Matched Servo drive and Servo motor

2. A power cable connect the drive to the servo motor(Option)

3. An feedback encoder cable connect the drive to the motor (Option )

4. A mini USB cable connect the port CN1 to PC for communication.(Opti

on)

5. 50-PIN connector (For I/O connections, Port CN2) Option

6. 26-PIN connector(For encoder feedback,Port CN3 ) Option

7. 6-PIN connector(IEEE1394,Option)

8. RJ-45 connectors (For RS-485 or CANopen communication,Port CN6 adn CN7)Option

9. 5-PIN connectors (For L1,L2,L3,L1C,L2C)

10. 6-PIN connector(For U,V,W,B1+,B2,B3)

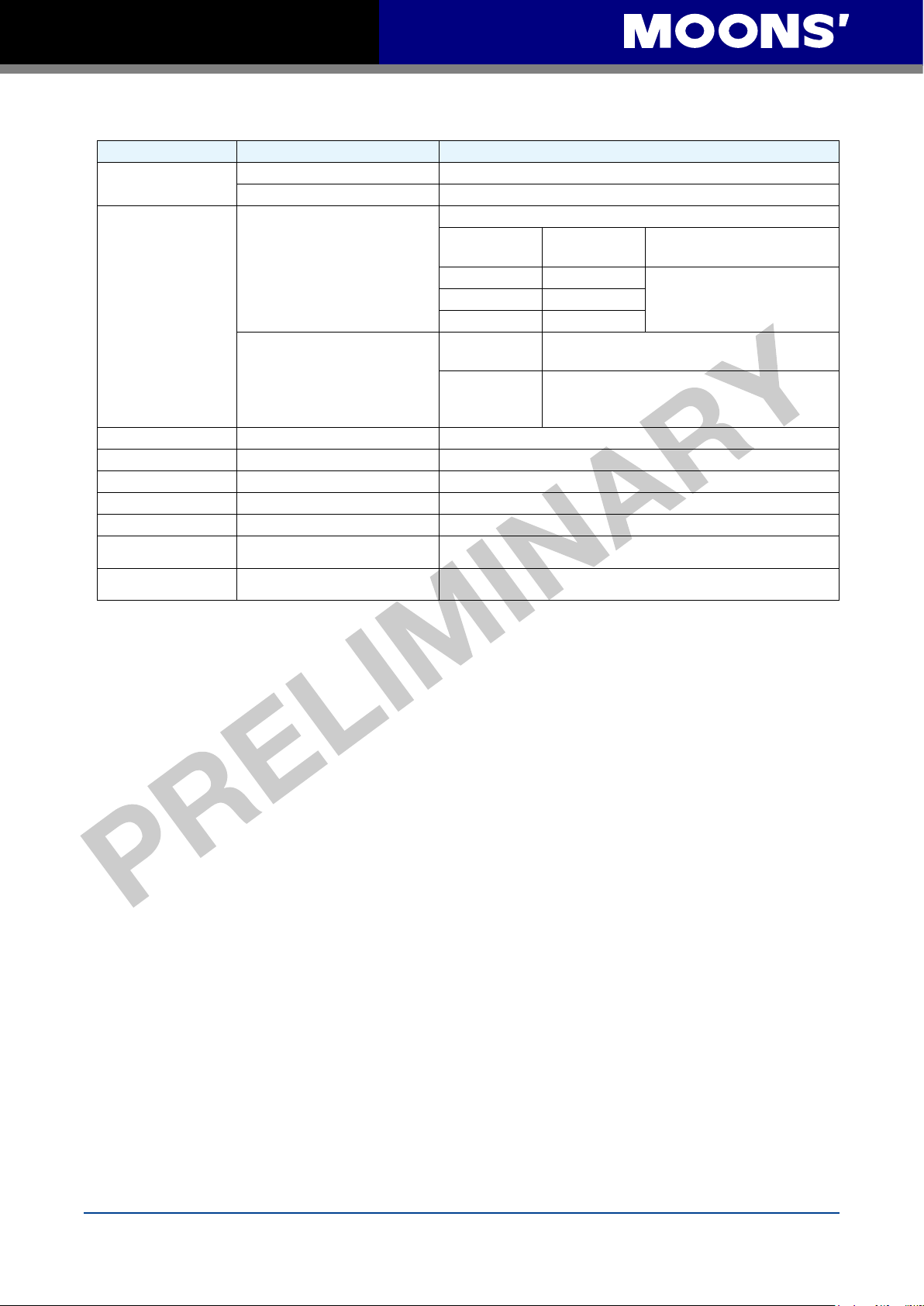

1.2 Servo Drive Model Introduction

1.2.1 Drive Name Plate Description

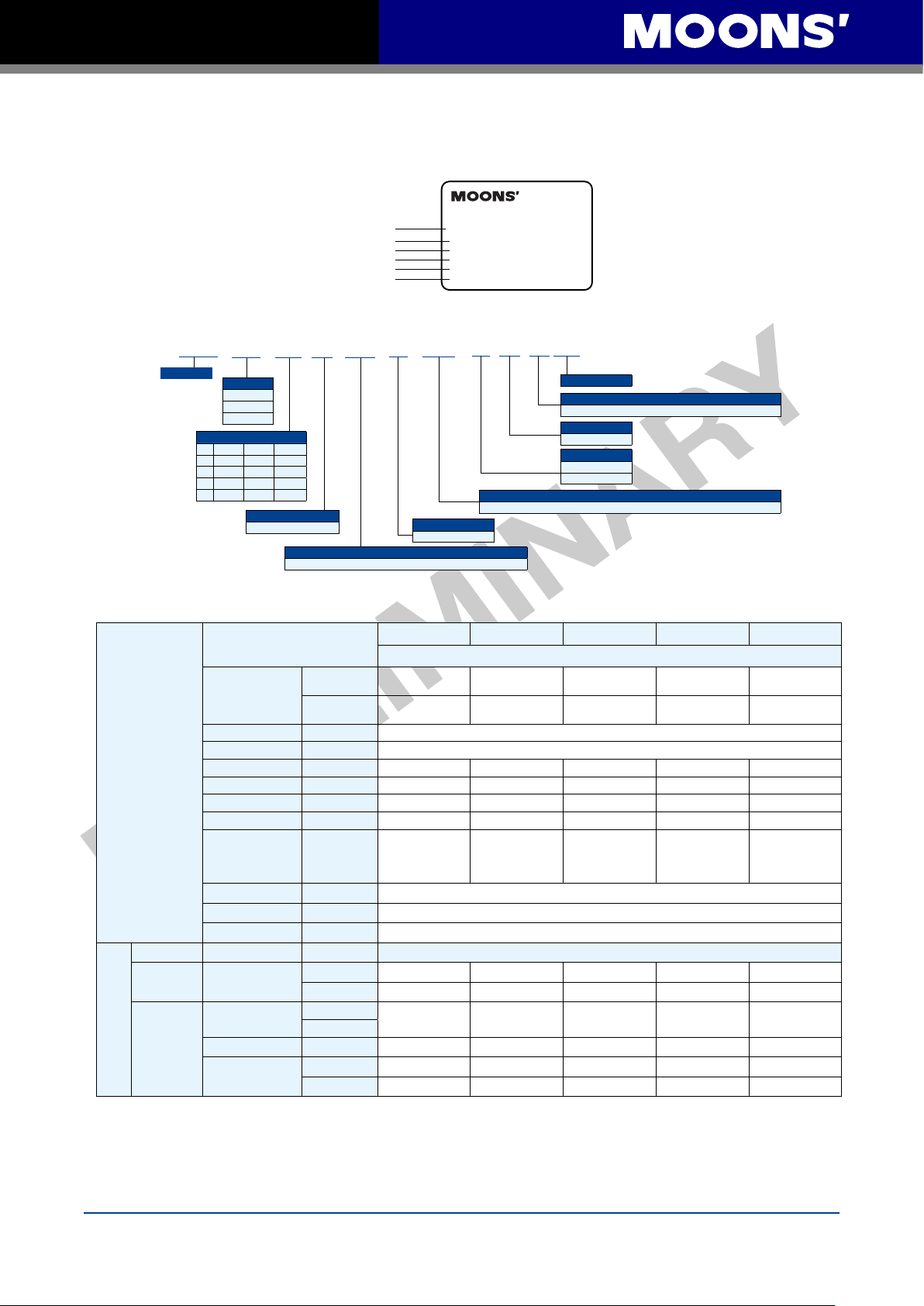

1.2.2 Drive Model Description

M2DV -

M2 Series AC Servo Drive

Current

Code

Continuous

Current (RMS)

1D8 1.75A 5.25A

3D0 3.00A 9.00A

4D5 4.50A 13.50A

□ □ □ 2 □

Boost

Current (RMS)

Voltage Code Input Voltage

2

Single/Three-Phases200~240VAC±10%, 50/60Hz

***

If Applicable

Communication

Type

S

Q

R

C

IP

E

5

Configuration Description Communication

Mini USB

Basic Type

Q Type

Q Type(Modbus/RTU Type)

CANopen Type

EtherNet/IP

eSCL

Type

Type

- - -

RS-232

RS-485

CANBus

EtherNet

EtherNet

4/29/2016

Rev. 1.0

M2 Quick Setup Guide Manaul

S M 04 01 A E4-K CD-N N V

**

1.3 Servo Motor Model Introduction

1.3.1 Motor Name Plate Description

Model NO.

Series NO.

Rated Torque

Input Current

Output Power

Rated Speed

1.3.2 Motor Model Description

Servo Motor

Frame Size

04-40mm

06-60mm

08-80mm

Motor Length

□40□60□

01 50W 200W

02 100W 400W

03 750W

04 1000W

80

Winding

A: 320 VDC(240 VAC)

E4: 2500 ppr Optical Encoder and Shared Commutation Tracks

1.4 Servo Drive and Servo Motor Combinations

Specificatioon

2500ppr Increment

Encoder

(9PIN AMP connector)

Rated Speed

Maximum Speed

Rated Torque

AC Servo Motor

Pulse&Direction

Type

AC

Servo

Drive

Fieldbus Type

Maximum Torque

Rated Current

Maximum Current

Rotor Inertia

Insulation Class Class B

Protection Class IP65(except shaft through hole and cable end connetor)

il Seal With Oil seal

O

USB Mini

RS-485

CAN CANopen

Ethernet

Without Brake

With Brake

(RPM) 3000

(RPM) 6000

(N•m)

(N•m)

(A)

(A)

2

Kg•m

Basic Type

Q Type

SCL

Modbus RTU

Ethernet/IP

eSCL

AC SERVO MOTOR

Model NO.SM0602AE2-KCD-NNV15

Ser NO. 12110027

Rated Torque 1.27N

Input 3ØAC 220V 2.8A

Ouput 400W

Rated Rev. 3000r/min

CD: 300mm (12") Shielded Cables with AMP 4 Pin, 6-7 Amp Motor Connector.

Shaft

K: Standard Keyway

Ecoder

50W 100W 200W 400W 750W

SM0401AE4-KCD-

NNV09

SM0401AE4-KCD-

BNV09

0.19 0.32 0.64 1.27

0.48 0.93 1.9 3.8 6.9

0.7 1.2 1.5 2.75 4.5

1.75 3.6 4.5 8.3 13.5

0.0232×10-4

*0.0298×10

(*With Brake)

M2DV-1D82S M2DV-1D82S M2DV-1D82S M2DV-3D02S M2DV-4D52S

M2DV-1D82Q M2DV-1D82Q M2DV-1D82Q M2DV-3D02Q M2DV-4D52Q

M2DV-1D82R M2DV-1D82R M2DV-1D82R M2DV-3D02R M2DV-4D52R

M2DV-1D82C M2DV-1D82C M2DV-1D82C M2DV-3D02C M2DV-4D52C

M2DV-1D82IP M2DV-1D82IP M2DV-1D82IP M2DV-3D0

M2DV-1D82E M2DV-1D82E M2DV-1D82E M2DV-3D02E M2DV-4D52E

-4

SM0402AE4-KCD-

SM0402AE4-KCD-

0.0428×10

*0.0494×10

(*With Brake)

NNV09

BNV09

·m

Code

Connections

-4

-4

Shaft Seal

SM0602AE4-KCD-

NNV09

SM0602AE4-KCD-

BNV09

0.272×10

*0.326×10

(*With Brake)

V: Shaft seal shipped with motor, but not placed on shaft

Thermal Protector

N: No Protector

Brake Option

N: No Brake

B: 24VDC Brake

Motor Model Numbers

SM0601AE4-KCD-

NNV09

SM0601AE4-KCD-

BNV09

-4

-4

0.165×10

*0.22×10

(*With Brake)

Drive Model Numbers

SM0803AE4-KCD-

NNV09

SM0803AE4-KCD-

BNV09

2.4

-4

-4

2IP M2DV-4D52IP

0.89×10

*0.97×10

(*With Brake)

-4

-4

Rev. 1.0

4/29/2016

6

M2 Quick Setup Guide Manaul

2 Installation

2.1 Storage Conditions

Some Storage suggestions are followed:

• Correctly packaged and store in a clean and dry ,avoid direct sunlight

• Store within an ambient temperature range of -20℃ to +65

• Store within a relative humidity rang of 10% to 85% and non-condensing

• Don

’t store in a place subjected to corrosive gasses

2.2 Installation Conditions

The operation ambient conditions are followed:

• Temperature range of 0℃ to 50℃. If the ambient tempera

45℃, please install the drive in a well-ventilated location

The ambient temperature of servo dive for long-term reliability should be under 45℃.

• The servo drive and motor will generate heat. If they are installed in a control panel, please

ensure sufficient space around the units for heat dissipation.

• Operation within a relative humidity rang of 5%to

• The vibration lower than 5.88m/s

2

, 10-60Hz(Do not continuously use the drive for along time at

resonance point.)

• Don

’t mount the servo drive and motor in a location subjected to corrosive gasses or

flammable gases, and combustibles.

• Please mount the servo drive and motor to a indoor electric control cabinet without liquid and

direct sunlight

• Don

’t mount the servo drive and motor in a location subjected to airborne dust.

85% and non-condensing

℃

ture of servo drive is greater than

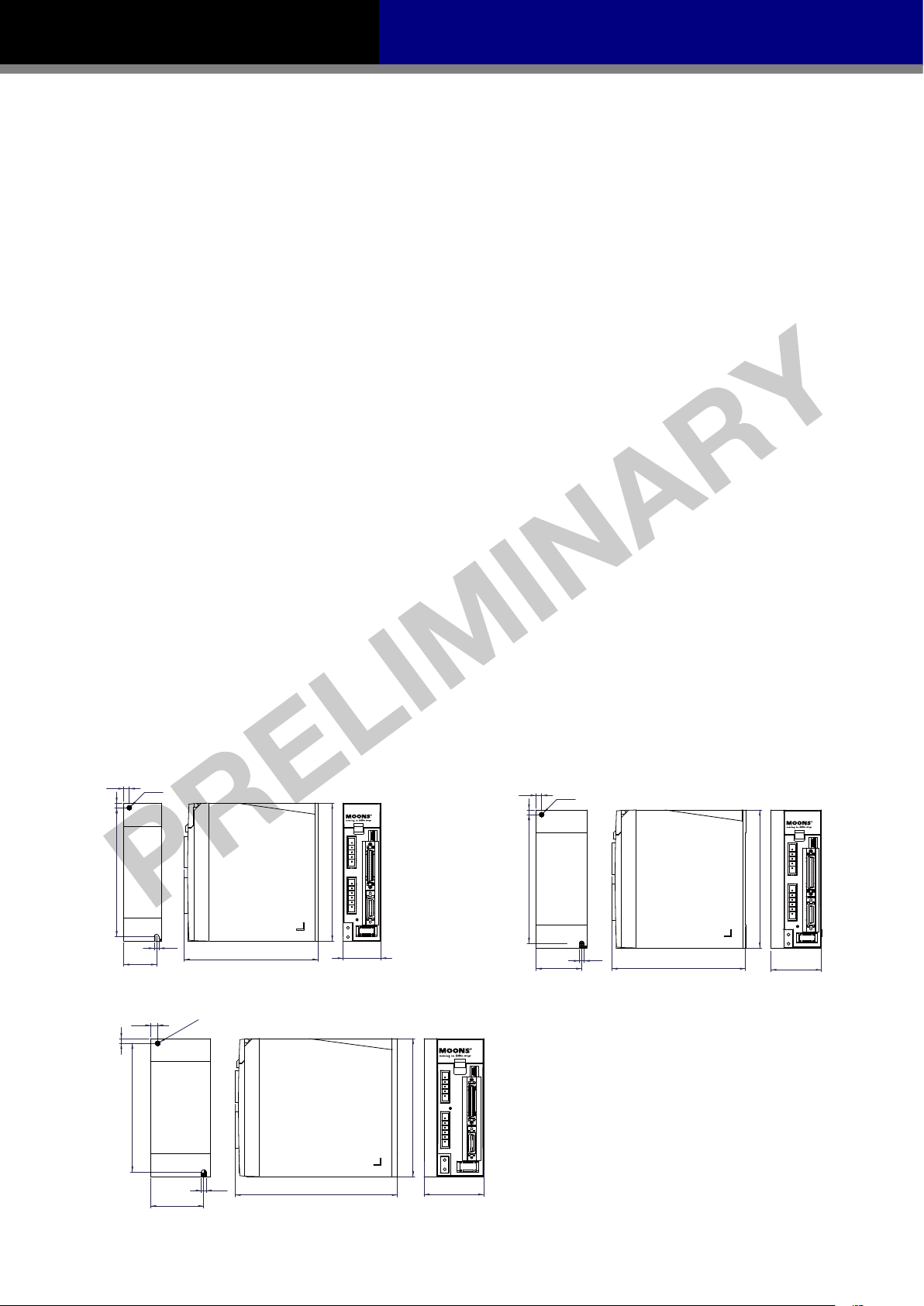

2.3 Drive Dimensions(Unit: mm)

50W、100W、200W Type

6

Ø5

5

140

5

35.5

750W Type

7.5

5

Ø5.2

140

145

150

41

150

400W Type

6

Ø5

5

140

49.5

150

5

145

55

57.5

5.2

176

65

7

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

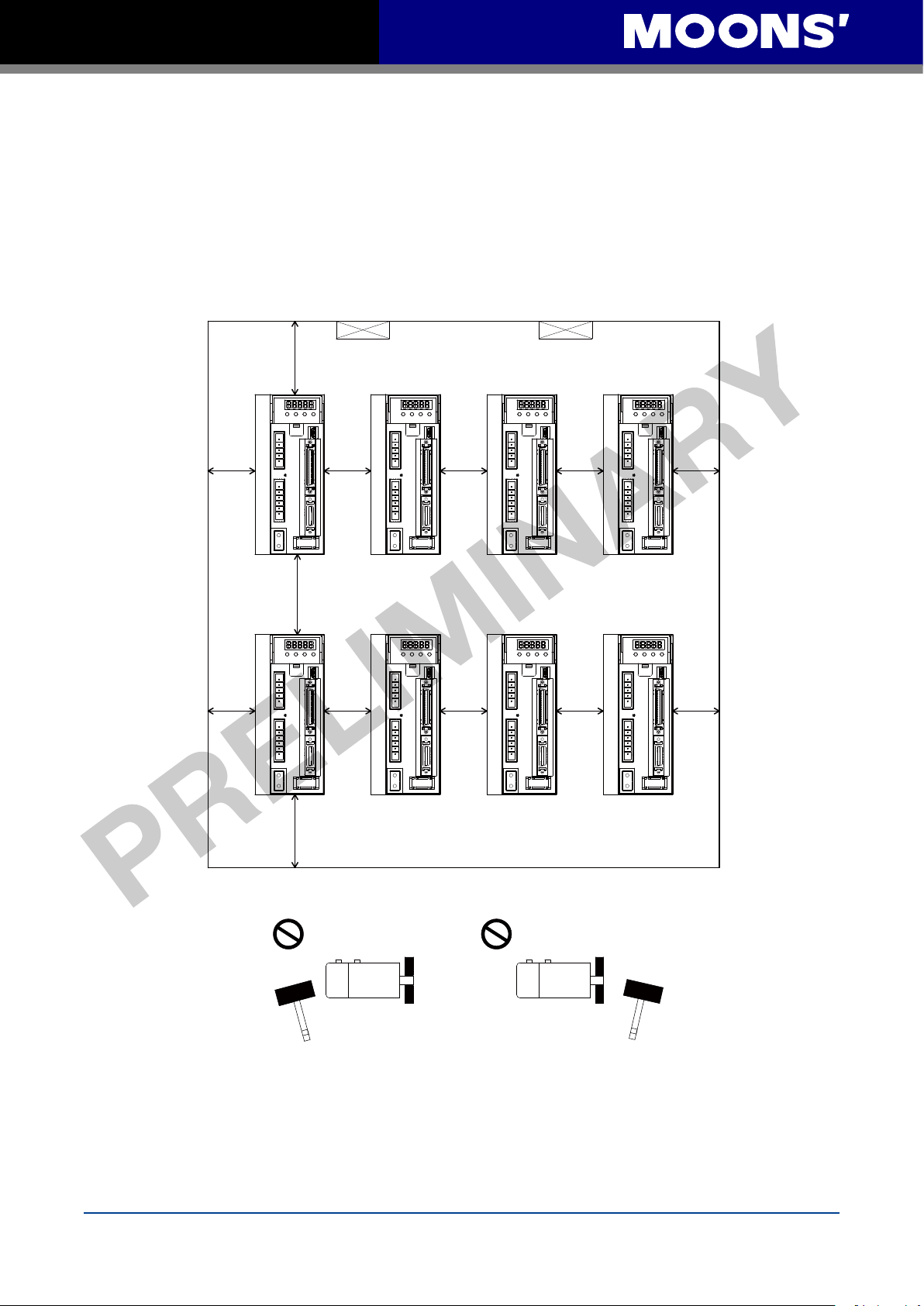

2.4 Installation Space

• Incorrect installation may result in a drive malfunction or premature failure of the drive and or

motor. Please follow the guidelines in this manual when installing the servo drive and motor.

• The M2 servo drive should be mounted perpendicular to the wall or in the control panel.

• In order to ensure the drive is well ventilated, ensure that the all ventilation holes are not

obstructed and suffic

the control panel.

• Please ensure grounding wires are securely connected

ient free space is given to the servo drive,and a cooling fan is mounted in

100mm

80mm

Fan Fan

10mm 10mm 10mm20mm

10mm 10mm 10mm20mm 20mm

20mm

100mm

2.5 Motor Installation

• Don't strike the motor when mounting as the motor shaft or encoder may be damaged.

• Don't use cables soaked in water or oil.

• Avoid a stress application to the cable outlet and connecting portion by bending

• Please use flexible cables when using cable carrier, make sure the minimum cable bending

radius is 200mm

• The shaft through hole and cable end connector is not IP65 design. Make sure to preve

liquid or oil into the motor from these parts.

Rev. 1.0

4/29/2016

8

nt any

M2 Quick Setup Guide Manaul

3 Connections and Wiring

3.1 Connecting to Peripheral Devices

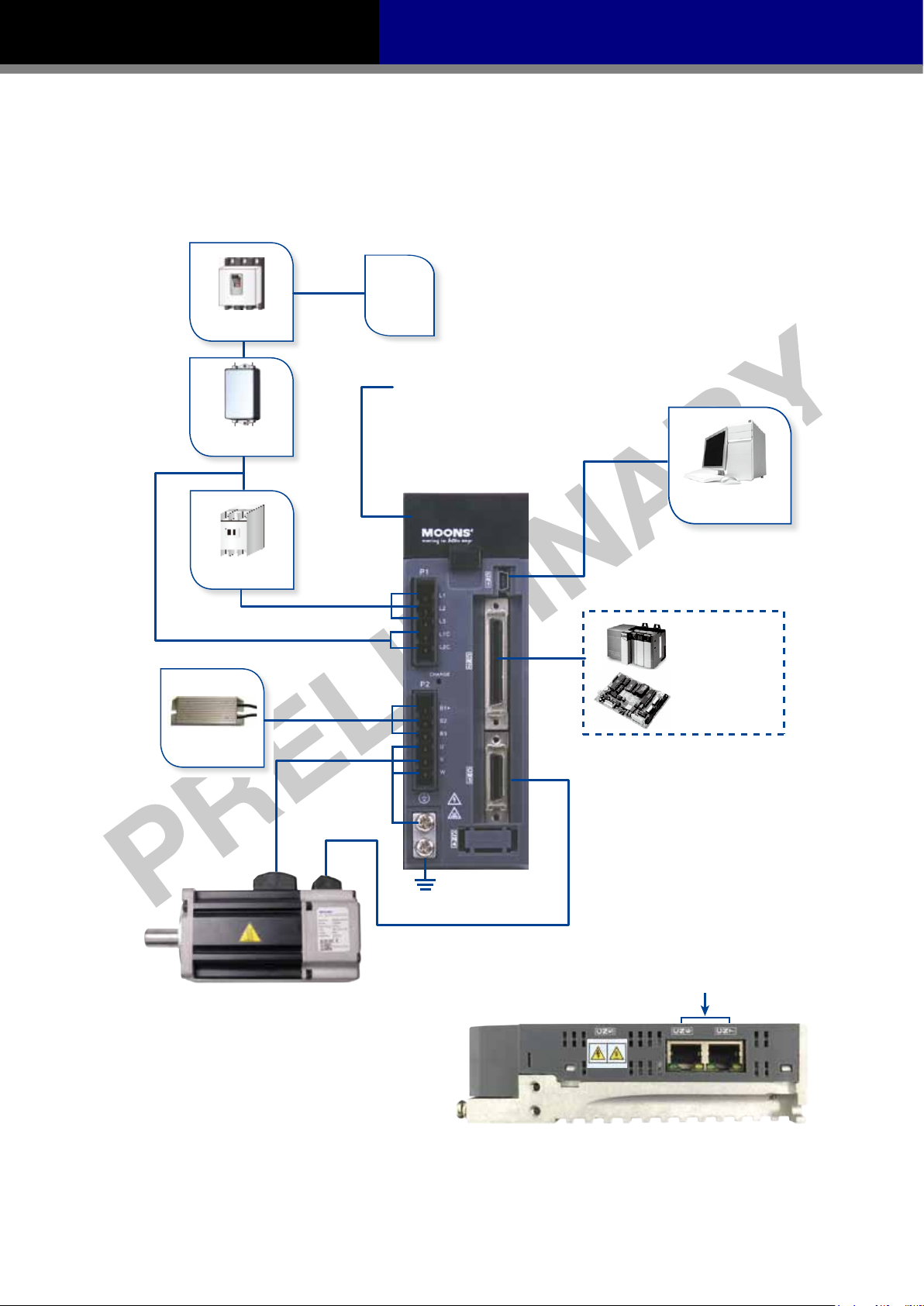

3.1.1 System Conguration

AC Power

Non Fuse Breaker

LED Display

The 5 digit,7 segment LED displays the

diver status and faults.

Operation Panel

Line Filter

(optional)

Function keys are used to perform status

display,monitor and diagnostic,function

and parameter setting.

Electromagnetic

Contactor

Regeneration

Absorbing Resistor

Main Power Input

Control Power Input

Motor Power Cable

Ground (PE)

Motor Feedback Cable

USB communication Port

(CN1)

PLC

Motion Control Card

I/O Interface

Used to connect PLC ,motion card

and other controllers.

Line Filter

AC Power Part No. Vendor

Single phase 240Vac 10ET1 Tyco

Three phase 240Vac DF300-10A-01 Dephir

CANBus, RS-485, Ethernet

Communication Port

9

Rev. 1.0

4/29/2016

M2 Quick Setup Guide Manaul

3.1.2 Servo Drive Connectors and Terminals

Terminal Identification Description Details

P1

P2

CN1 Communication Port User to connect personal computer

CN2 I/O Connector Used to connect external controllers.

CN3 Encoder Feedback Connector Used to connect encoder of servo motor.

CN4 Reserved

CN5 Reserved

CN6

CN7

L1、L2、L3 Used to connect three-phase AC main circuit power

L1C、L2C Used to connect single-phase AC for control circuit power

Used to connect servo motor

U、V、W

B1+、B2、B3

Regenerative resister terninals

RS-485/CANopen

*RS-2

32 Communication Port

RS-485/CANopen

Communication Port

Terminal

Symbol

U Red

V Yellow

W Blue

Internal

Resister

External

Resister

RJ45 connector, Daisy Chain, Used for RS-485/CANopen

*RS-232 Communication Port (-Q Type Only)

RJ45 connector, Daisy Chain, Used for RS-485/CANopen

Wire color Description

Ensure the circuit is closed between B2 and

and the circuit is open between B1+ and B3.

Ensure the circuit is open between B2 and B3,

and connect the external regenerative resister

between B1+ and B2.

Communication

Connecting to three-phase

motor main circuit cable

B3,

3.1.3 Connections and Wiring Notes

• Please ensure grounding wires are securely connected, wires with more than 2.0mm2 on width

is recommended.

• Grounding method must be single point grounding.

• Ensure L1/L2/L3 and

specification range.

• Ensure U/V/W are following the order of RED/YELLOW/BULE. Wrong connections will cause

motor stop rotation, or wrong rotatory directions.

• Isolation transformer or EMI filter is recommended on drive

safety and improve its anti-interference level.

• Please setup a emergence stop circ

• Please DO NOT touch drive or motors

powered off. There are electrical charge components in the circuitry. Therefore, even power is

off, there might still be hazardous voltages within the circuitry, before its total discharge.

• Install the encoder cables in a separate conduit from the

noise. Separate the conduits by 30cm (11.8inches) above.

• Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for signal, encoder

feedback cables.

L1C/L2C are correctly wired, and voltage supply are within the

’s power supply to ensure drive’s

uitry to switch off the power supply when fault occurs.

’s connector terminals 5 minutes after drive and motor is

motor power cables to avoid signal

• The maximum length of signal input/output cable is 5m, and the maximum length of encoder

(PG) feedback cables is 15m

Rev. 1.0

4/29/2016

10

M2 Quick Setup Guide Manaul

3.2 Wiring Methods

220V AC servo drive supports single phase or three phase wiring method. Three phase wiring

method for 750W or above drives is recommended.

3.2.1 Single-Phase Power Supply Connection(AC220V)

L N E

MCCB

NF

P_on

P_off

E_stop

MC

Alarm

MC

Use external

regeneration resistor

B1+

B2

B3

regeneration resistor

Use Internal

MC

M2 Servo Drive

L1

L3

L1C

L2C

B1+

B2

B3

P1

P2

U

V

W

CN3

Alm_R

Red

Yellow

Blue

Yellow/Green

Ground

Encoder

Alm_R

3.2.2 Three-Phase Power Supply Connection(AC220V)

R

MCCB

NF

E

T

S

P_on

P_off

E_stop

MC

M

Encoder

24VDC

Alarm

MC

Use external

regeneration resistor

B1+

B2

B3

Use Internal

regeneration resistor

MC

M2 Servo Drive

L1

L2

L3

L1C

L2C

B1+

B2

B3

11

Alm_R

Red

U

Yellow

V

P2

W

CN3

Blue

Yellow/Green

Ground

Encoder

M

Encoder

Alm_R

24VDC

Rev. 1.0

4/29/2016

Loading...

Loading...