M2 Series DC Servo System

Quick Setup Guide Manual

SHANGHAI AMP&MOONS’ AUT OMATION CO.,LTD.

1

Rev. 1.0

Introduction

About This Manual

This manual describes the M2DC Servo Drive.

It provides the information required for installation, conguration and basic operation of the M2DC

series servo drive.

This document is intended for persons who are qualied to transport, assemble, commission, and

maintain the equipment described herein.

Documentation Set for the M2DC Series Servo Drive

This manual is part of a documentation set. The entire set consists of the following:

• M2DC Quick Start Guide: Basic setup and operation of the drive

• M2DC Hardware Manual: Hardware installation, conguration and operation

• M Servo Suite Software User Manual: How to use the M Servo Suite software

Safety

Only qualied persons may perform the installation procedures. The following explanations are for

procedures that must be observed in order to prevent harm to people and damage to property.

The M2DC utilizes hazardous voltages. Be sure the drive is properly grounded.

Before you install the M2DC, review the safety instructions in this manual.

Failure to follow the safety instructions may result in personal injury or equipment damage.

Safety Symbols

Safety symbols indicate a potential for personal injury or equipment damage if the recommended

precautions and safe operating practices are not followed.

The following safety-alert symbols are used on the drive and in the documentation:

Caution Warning - Dangerous voltage

Protective earth Caution - Hot surface

2

Rev. 1.0

Safety Instructions

Installation

DO NOT subject the product to water, corrosive or ammable gases, or combustibles.

DO NOT use the motor in a place subject to excessive vibration or shock.

Never connect the motor directly to the AC power supply.

DO NOT use cables soaked in water or oil.

DO NOT extrude or pull off the cable, or damage the cables as electrical shocks or damage

may result

DO NOT block the heat dissipating holes. Prevent any metal lings from dropping into the drive

during installation.

DO NOT switch the power supply on and off repeatedly.

DO NOT touch the rotating shaft when the motor is running.

DO NOT strike the motor when during indtallation as the motor shaft or encoder may be dam-

aged.

To prevent accidents, the initial trial run for the servo motor should be conducted under a noload condition (separate the motor from its couplings and belts).

Starting system operation without rst matching the correct parameters may result in servo

drive or motor damage, or damage to the mechanical system.

DO NOT touch the drive heat sink, motor, or the regeneration resistor during operation as they

may be very hot.

DO NOT hold the motor by the cable during transportation or installation.

Wiring

DO NOT connect any power supply to the U, V, or W terminals.

Install the encoder cable in a separate conduit from the motor power cable to avoid signal

noise.

Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for signal and encoder

cables.

A hazardous voltage charge may still remain in the drive even after the power has been removed - Do not touch the terminals when the charge led is still lit.

Please observe the specied voltage(s).

Make sure both the drive and the motor connect to a class 3 ground.

Please ensure the grounding wires are securely connected before power up.

Standards Compliance

The M2DC Series Servo drive has been designed according to standards:

Electromagnetic compatibility Electrical Safety: Low voltage directive

Standard EN 61800-3 (2004) Standard IEC 61800-5-1 (2007)

3

Rev. 1.0

Table of Contents

1. Product Description ...................................................................................................................6

1.2 Servo Drive Model Introduction .........................................................................................6

1.2.1 Drive Name Plate Description ..................................................................................6

1.2.2 Drive Model Description ...........................................................................................6

1.2.3 Drive specications ..................................................................................................7

1.3 Servo Motor Model Introduction ........................................................................................8

1.3.1 Motor Name Plate Description .................................................................................8

1.3.2 Motor Model Description ..........................................................................................8

2 Installation ..................................................................................................................................9

2.1 Storage Conditions ............................................................................................................9

2.2 Installation Conditions .......................................................................................................9

2.3 Drive Dimensions (Unit: mm) ............................................................................................9

2.4 Installation Space ............................................................................................................10

2.5 Motor Installation .............................................................................................................11

3. Connections and Wiring ..........................................................................................................12

3.1 Connecting to Peripheral Devices ...................................................................................12

3.1.1 System Conguration ............................................................................................12

3.1.2 Servo Drive Connectors and Terminals .................................................................13

3.1.3 Connections and Wiring Notes ..............................................................................13

3.1.4 Wiring Methods for P1 Power Supply Connector ..................................................14

3.2 Wiring to the P2 Connector ............................................................................................15

3.2.1 Motor Power Cable Conguration ................................................................................15

3.2.2 Motor Power Cable Connector(-CD Winding ,6Amps) ..........................................15

3.2.3 Motor Extension Cable Wiring Diagram .................................................................16

3.2.4 Motor Power Cable Connector(-CF Winding,10Amps) ..........................................16

3.2.4.1 PIN Assignment ............................................................................................16

3.2.4.2 Motor Extension Cable Wiring Diagram .......................................................17

3.3 Encoder Connector CN3 .................................................................................................17

3.3.1 Motor Encoder Feedback Cable Conguration ......................................................17

3.3.2 Layout of CN3 Connector ......................................................................................18

3.3.3 Connection to Motor Encoder ................................................................................18

3.3.4 Specications of Encoder Connector .....................................................................19

3.3.5 Motor Encoder Extension Cable Wiring Diagram .................................................20

3.4 Electromagnetic Brake ....................................................................................................21

3.4.1 Wiring Diagram ......................................................................................................21

3.4.2 Brake Motor ...........................................................................................................21

3.4.3 Timing Charts of the Electromagnetic Brake .........................................................22

3.5 Regeneration Resistor ....................................................................................................22

3.6 Recommended Cable Specications ..............................................................................22

3.7 Connecting to the Host Computer - CN1 ........................................................................23

3.8 Input and Output Signal Interface Connector - CN2 .......................................................23

3.8.1 Input and Output Interface Specications and Diagram ........................................23

3.8.2 Layout of CN2 Connector ....................................................................................23

3.8.3 Signal Description of Connector CN2 ....................................................................24

3.8.3.1 Input Signals .................................................................................................25

3.8.3.2 Input Function List ........................................................................................26

3.8.3.3 Output Signals ..............................................................................................27

3.8.3.4 Output Function List .....................................................................................28

3.8.4 Encoder Feedback Output .....................................................................................29

3.8.4.1 A/B/Z Connection Diagram ...........................................................................29

3.8.4.2 Z Phase Open Collector Output ...................................................................29

3.8.5 Input Signal Interface Connector, CN2 ..................................................................30

4

Rev. 1.0

3.8.5.1 Position pulse signal input ............................................................................30

3.8.5.2 Analog Signal Input For Velocity And Torque Mode .....................................32

3.8.5.3 High Speed Input Ports X1, X2, X3, X4 ........................................................33

3.8.5.4 General Digital Input X5, X6, X7, X8 ............................................................35

3.8.5.5 X9, X10, X11, X12 Inputs with common COM Port ......................................37

3.8.6 CN2 Output Signal Specication ...........................................................................38

3.9 STO Connector ...............................................................................................................39

3.9.1 Safety Precautions .................................................................................................39

3.9.2 STO Input/Output Signals ......................................................................................39

3.9.2.1 STO Internal Circuit Diagram .......................................................................39

3.9.2.2 CN5 Connector diagram ...............................................................................40

3.9.2.3 STO Signal Denition ...................................................................................40

3.9.2.4 STO Connection Diagrams ..........................................................................41

4. Display and Operation .............................................................................................................42

4.1 Control Panel Description ...............................................................................................42

4.2 Mode Switch Control .......................................................................................................43

4.3 LED display description ...................................................................................................45

4.3.1 Decimal Point And Negative Sign Description .......................................................45

4.3.2 Parameter View Setting .........................................................................................45

4.3.3 Parameter Save Setting .........................................................................................46

4.3.4 Point To Point Motion Mode ..................................................................................46

4.3.5 Jog Mode ...............................................................................................................46

4.3.6 Control Panel Lock ................................................................................................46

4.4 Status Monitoring Selection Mode ..................................................................................47

4.5 Function Control Mode ....................................................................................................49

4.5.1 Function Mode Description ....................................................................................50

4.5.2 Operation Flow Chart .............................................................................................51

4.6 Parameter Setting Mode .................................................................................................52

4.6.1 Parameter Setting Description ...............................................................................52

4.6.2 Parameter Editing Examples .................................................................................53

4.7 Control Panel Lock ..........................................................................................................54

4.8 Warning And Fault Display ..............................................................................................54

5. Preoperational mode ...............................................................................................................56

5.1 Inspection Before Trial Run ............................................................................................56

5.2 Trial Run Procedure ........................................................................................................57

5.3 Motor Conguration .........................................................................................................58

5.3.1 Using the Drive Control Panel for conguration .....................................................58

5.3.2 Using M Servo Suite Software for conguration ....................................................59

5.4 Operations of JOG Mode ................................................................................................60

5.5 Conguration by Personal Computer ..............................................................................61

6.Drive alarm causes and solutions.............................................................................................62

7. Position Mode ..........................................................................................................................66

7.1 Digital Pulse Position Mode Connection Diagram...........................................................66

7.2 Velocity Mode Connection Diagram ................................................................................67

7.3 Analog Torque Mode Connection Diagram .....................................................................68

5

Rev. 1.0

1. Product Description

1.1 System Checklist

A complete and workable M2DC servo system should include the following parts:

A matched servo drive and servo motor (see section 2.4 for recommended combinations)

1. A power cable with a 4-PIN connector to connect P1 (V+, V-, AUX+) to supply power to the

drive

2. A motor cable with a 5-PIN connector to supply the servo motor with power from the drive and

to connect a regenerative resistor through P2 (U, V, W)

3. An encoder cable with a 26-PIN connector to connect port CN3 for encoder feedback

4. A mini USB cable to connect port CN1 to a PC for communication

5. An I/O cable with a 50-PIN connector to connect port CN2 for I/O

6. Cables with RJ-45 connectors to connect ports CN6 and CN7 for RS-485 or CANopen com-

munication

1.2 Servo Drive Model Introduction

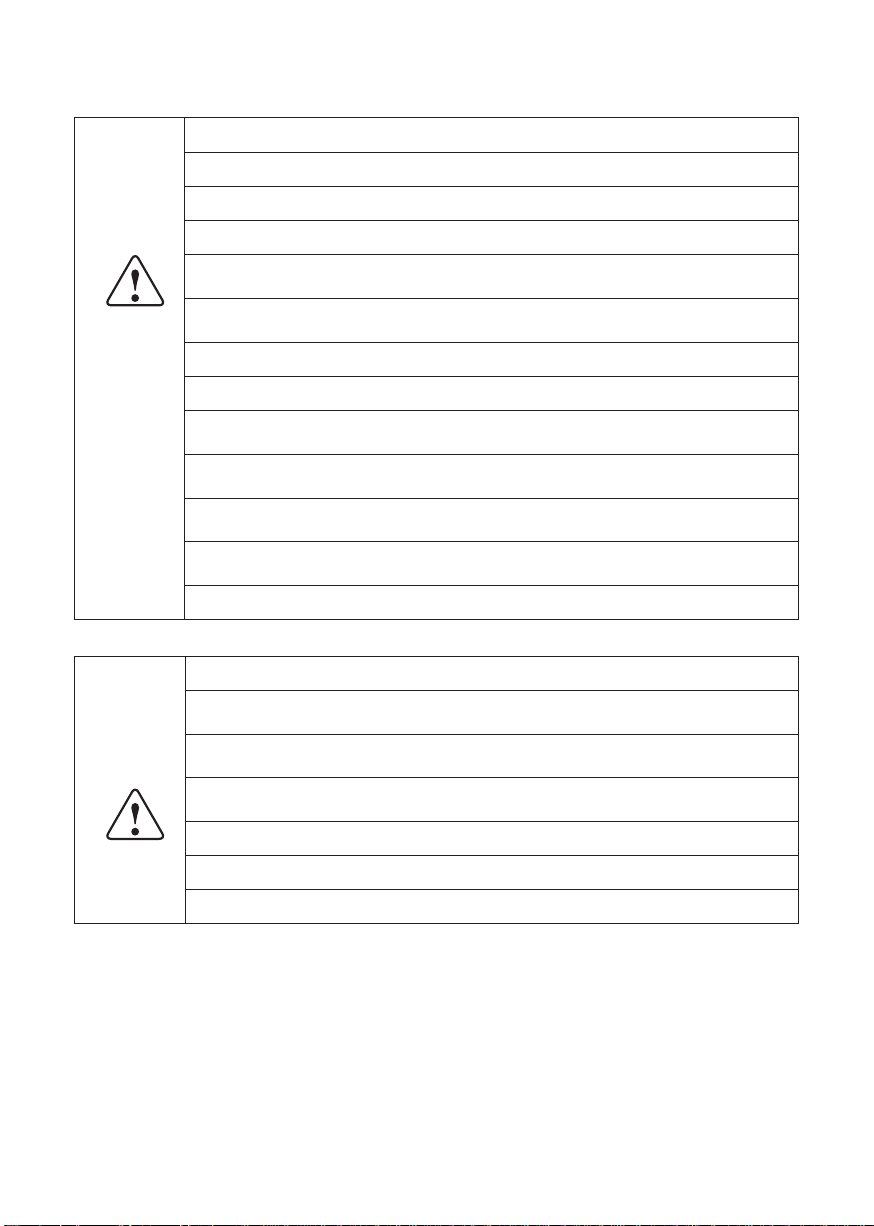

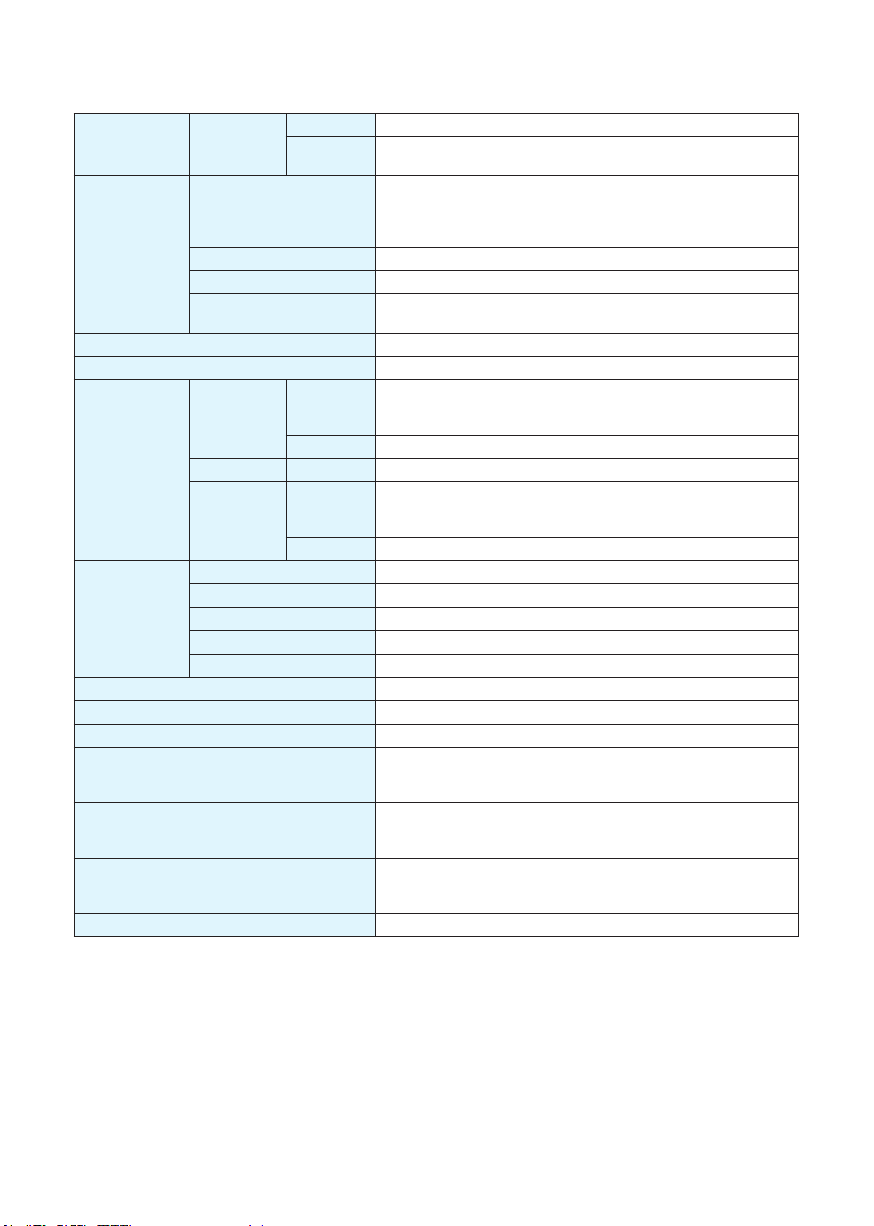

1.2.1 Drive Name Plate Description

www.moons.com.cn

Model No.

Voltage

Output Current

1.2.2 Drive Model Description

M2DC - 6D0 5 S

M2 Series DC Servo Drive

Current

Continuous

Code

Current (RMS)

6D0 6.0A 18.0A

10D 10.0A 30.0A

Voltage Code Input Voltage

5 10-60VDC

Boost

Current (RMS)

RoHS

DC SERVO

M2

DRIVE

Model No. M2DC-6D05X

VOLT. 0-60VDC20-60VDC

F.L.C

Designed in California by

Assembled in China

INPUT

Communication

Code

S

Q Q Type RS-232

R Q Type (Modbus/RTU) RS-485

C CANopen Type CANBus

D eSCL Type Ethernet

IP EtherNet/IP Type Ethernet

6

OUTPUT

6 A

***

Configuration

type

Mini USB

Serial No.

09450001

Serial No.

Customized Specification (If Applicable)

Description

Basic Type - - - - - -

Communication

type

Rev. 1.0

1.2.3 Drive specications

Input Power

Environment

I/O

Communication

Regeneration Resistor Built-in regenerative resistor (external resistor is also enabled)

M2DC-6D0

M2DC-10D

Control method IGBT PWM Sinusoidal wave drive

Encoder feedback 2500 ppr optical encoder with shared commutation signals

Control

Signal

Analog signal Input 2 inputs (12Bit A/D: 2 input)

Pulse signal

Front panel 4 keys (MODE, UP, DOWN, SET), LED (5-digit)

Dynamic Brake Built-in

Control modes

Control inputs

Control outputs

Certication RoHS, EN 61800-3:2004, EN 61800-5-1:2007

Main Circuit 20 - 60VDC

Control

Circuit

Temperature

Humidity Both operating and storage: 10 to 85%RH or less

Altitude Lower than 1000m

Vibration

Input

Output 6 optically isolated multi function outputs, 5-24VDC, 20mA

Input

Output 3 line driver outputs, 1 open collector output

Mini USB Connection with PC or 1 : 1 communication to a host.

RS-232 RS-232 communication

RS-485 RS-485 communication & Modbus/RTU

CANbus CANopen communication

Ethernet EtherNET/IP or eSCL

10- 60VDC

Ambient temperature: 0°C to 50°C (if the ambient temperature of

the servo drive is greater than 40°C, please install the drive in a

well-ventilated location)

Storage temperature: -20°C to 65°C

5.88m/s2 or less, 10 to 60Hz

(do not use continuously at resonance frequency)

8 optically isolated multi function inputs, 5-24VDC, 20mA

2 optically isolated multi function high speed inputs, 5-24VDC,

20mA

1 photocoupler input compatible with both line driver I/F and open

collector I/F

1 line receiver input compatible with line driver I/F

(1) Position mode (2) Analog velocity mode (3) Analog position

mode (4) Position mode (5) Velocity change mode (6) Command torque mode (7) Command velocity mode

(1) Servo-ON input (2) Alarm clear input (3) CW/CCW Limit (4)

Pulse& Direction or CW/CCW input (5) Gain Switch (6) Control

mode Switch (7) Pulse Inhibition (8) General Input

(1) Alarm output (2) Servo-Ready output (3) External brake release (4) Speed arrival output (5) Torque arrival output (6) Tach

out (7) General output (8) Position arrival output

7

Rev. 1.0

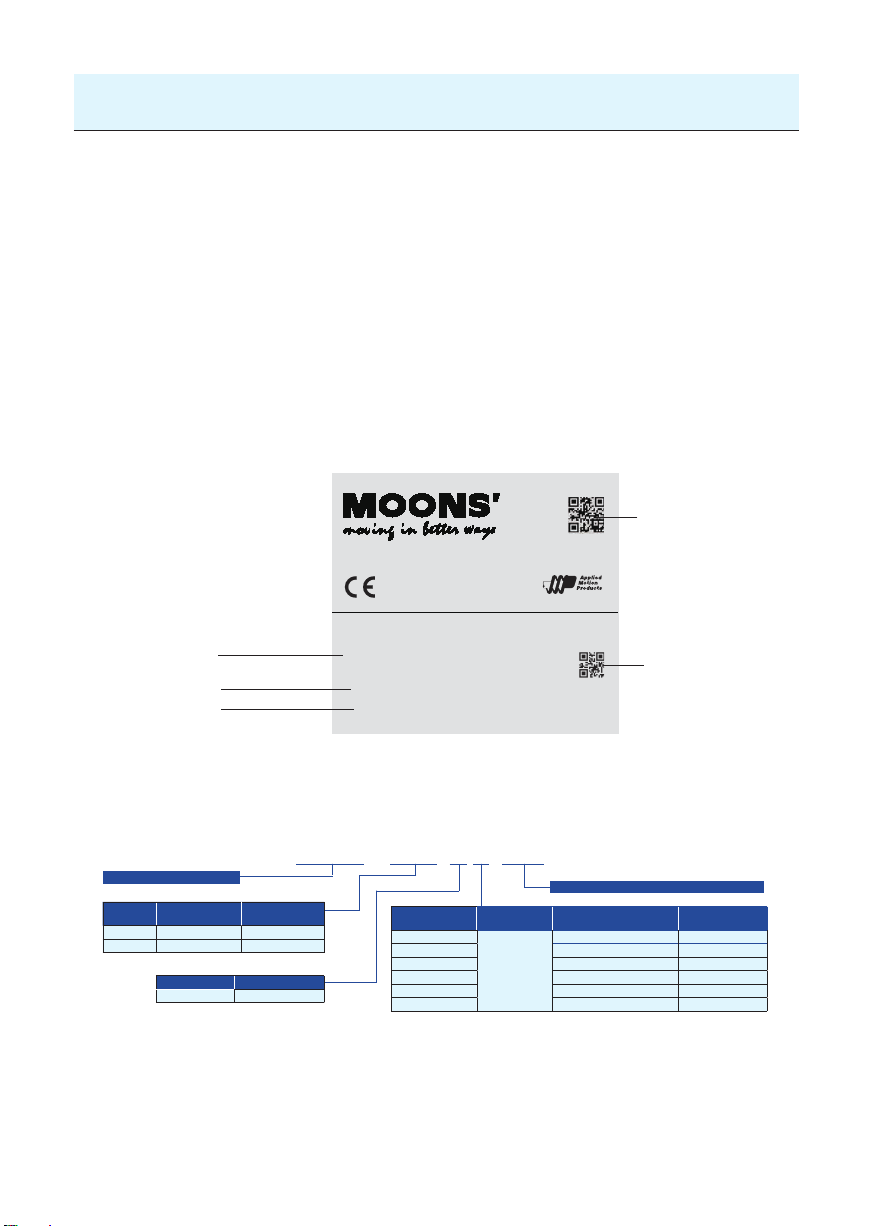

1.3 Servo Motor Model Introduction

1.3.1 Motor Name Plate Description

Mode NO.

Series NO.

Input

Ouyput Power

Rated Torque,speed

Max. Speed

Ins.Class

1.3.2 Motor Model Description

Servo Motor

Frame Size

04 40mm

06 60mm

08 80mm

Wattage code

01 60W 200W

02 100W 400W 300W

03 550W

Motor Length (mm)

40 60 80

SM06 02 F E4-KCF-NNV

300mm Shielded Cable with non-Sealed Connectors -

Input

Voltage(DC)

E 80V

F 60V

G 48V

H 36V

KCD

For Winings up to 6.5Amps

300mm Shielded Cable with non-Sealed Connectors -

KCF

For Winings 6.6 to 12.5 Amps

E4 2500 ppr optical encoder with shared commutation signals

**

Customized Specification (If Applicable)

Brake Option

N No Brake

B 24VDCBrake

Shaft and Lead/Connector Style

Feedback

8

Rev. 1.0

2 Installation

2.1 Storage Conditions

Store properly packaged in a clean and dry environment,away from direct sunlight

Store in an ambient temperature range of -10°C to +85°C

Store where the relative humidity range is 10% to 85% with non-condensing

DO NOT store in a place exposed to corrosive gases

2.2 Installation Conditions

Temperature range of 0°C to 50°C. If the ambient temperature of the servo drive is greater than 40°C,

please install it in a well-ventilated location.

The ambient temperature of the servo drive for long-term reliability should be less than 45°C.

The servo drive and motor will generate heat; if they are installed in a control panel, please

ensure sufcient space around the units for heat dissipation.

Operate where the relative humidity range is 10% to 85% and non-condensing

Install where the vibration is lower than 5.88m/s2, 10Hz-60Hz (DO NOT use the drive for extended

periods of time at the resonance point.)

DO NOT install the servo drive and motor in a location subjected to corrosive or ammable gases, or

combustibles.

Install the servo drive and motor in an indoor electric control cabinet.

DO NOT install the servo drive and motor in a location subject to airborne dust.

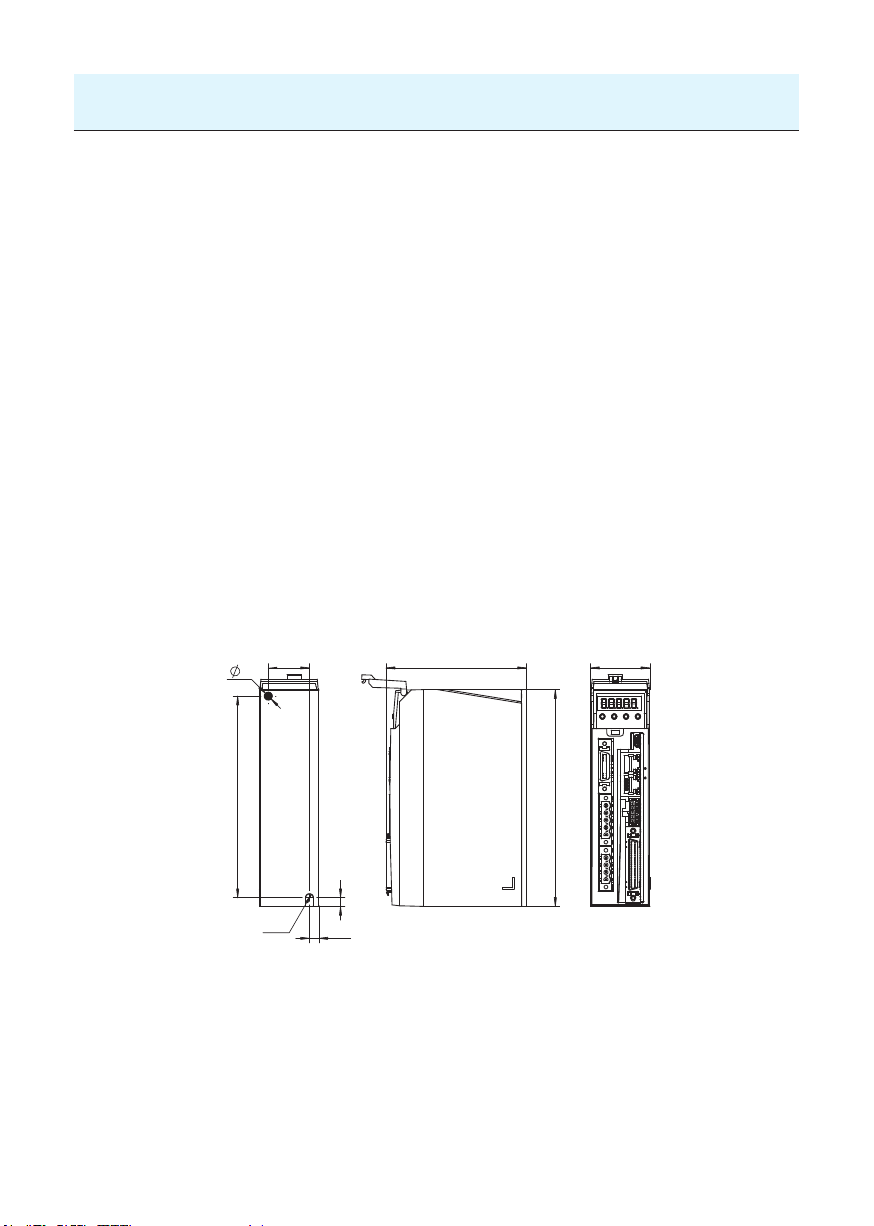

2.3 Drive Dimensions (Unit: mm)

5

139.5

28.5

R2.5

6

6.5

97

150

9

41

Rev. 1.0

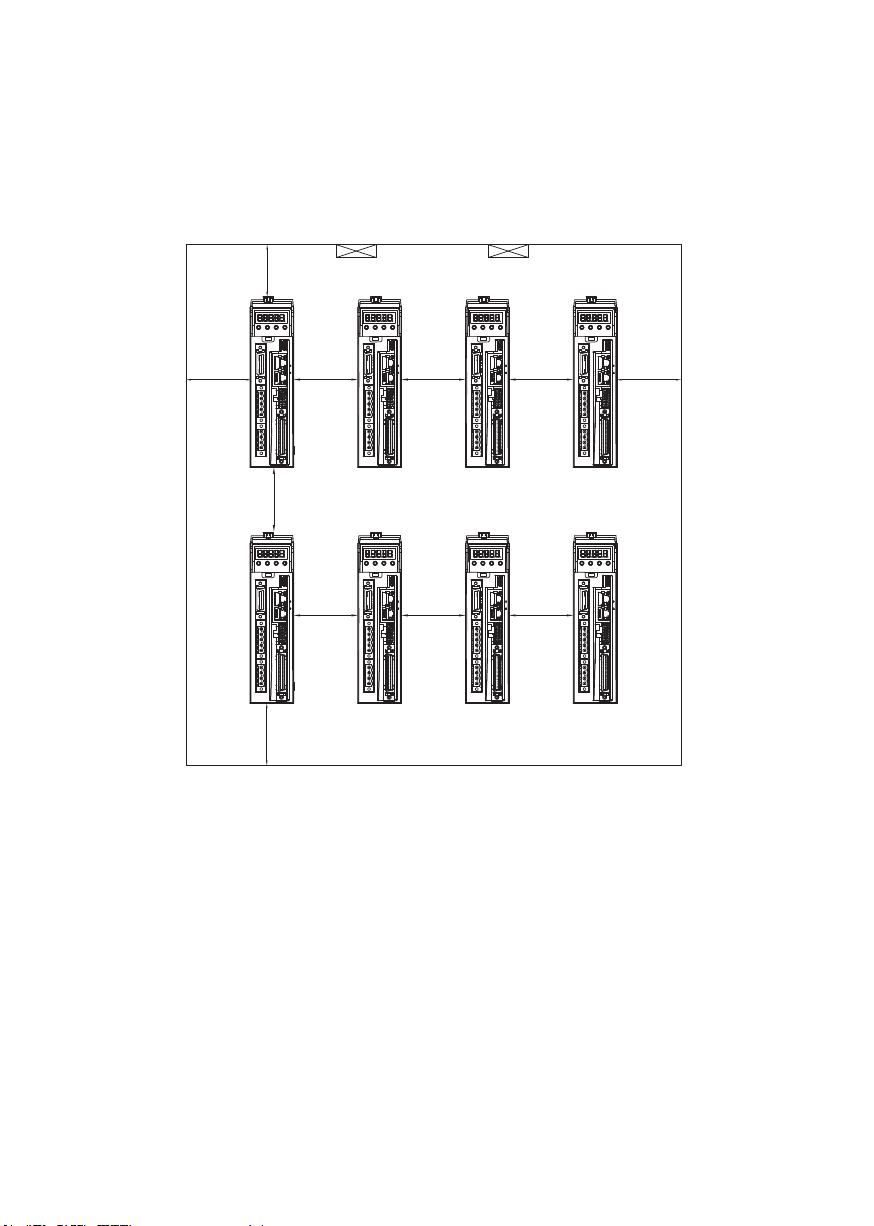

2.4 Installation Space

Incorrect installation may result in a drive malfunction or premature failure of the drive and/or motor.

Please follow the guidelines in this manual when installing the servo drive and motor.

The M2DC servo drive should be installed perpendicular to the wall or in a control panel.

In order to ensure the drive is well ventilated, make sure ventilation holes are not obstructed, there is

sufcient free space around the servo drive, and a cooling fan is mounted in the control panel.

Ensure the grounding wires are securely connected

20mm

100mm

80mm

100mm

Fan Fan

10mm

10mm

10mm 10mm

10mm

20mm

10mm

10

Rev. 1.0

2.5 Motor Installation

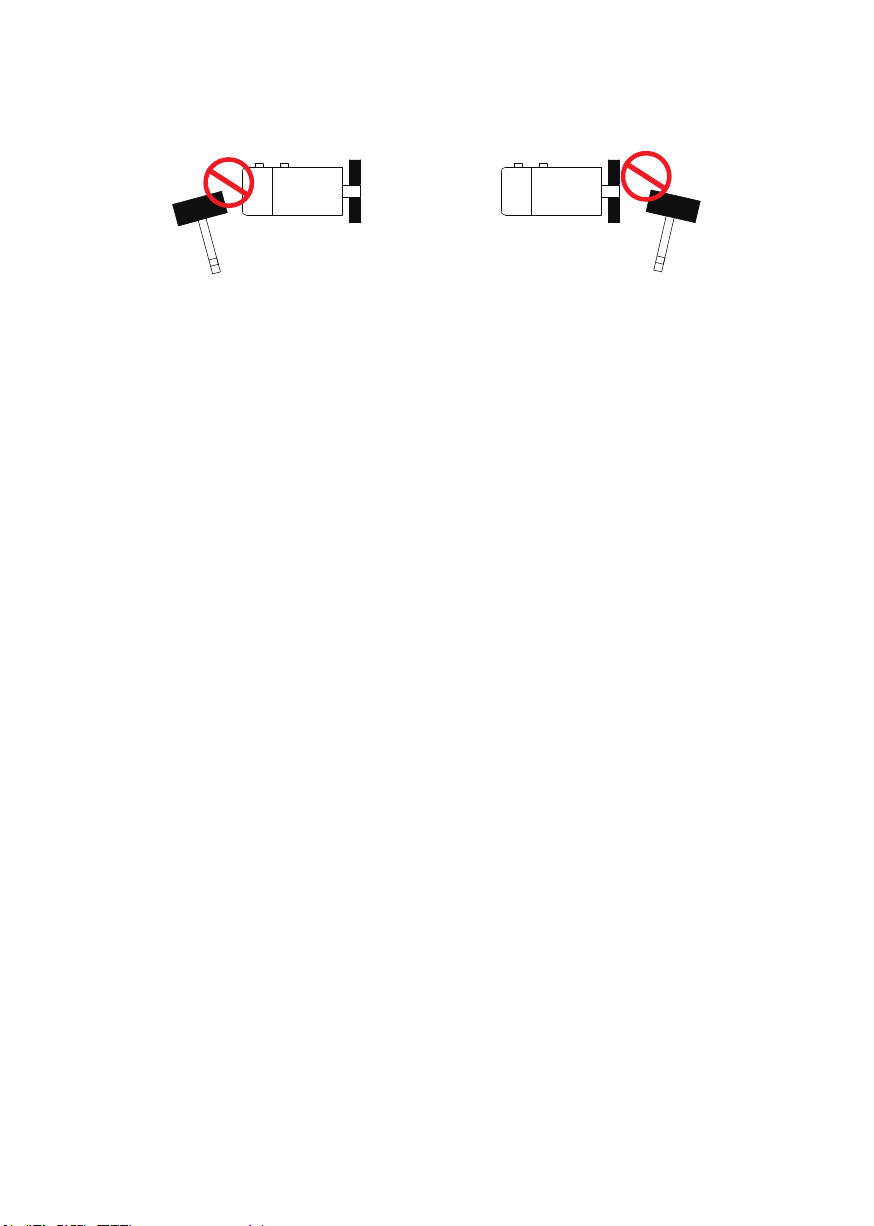

DO NOT strike the motor when installing it as the motor shaft or encoder may be damaged.

DO NOT use cables that have been soaked with water or oil.

Avoid a stress application to the cable outlet and connecting portion by bending.

Use exible cables when using a cable carrier, and make sure the minimum cable bending diameter is

200mm.

The shaft through hole and cable end connector are not IP65 designed. Be careful to prevent any

liquid or oil from getting into the motor at these areas.

11

Rev. 1.0

3. Connections and Wiring

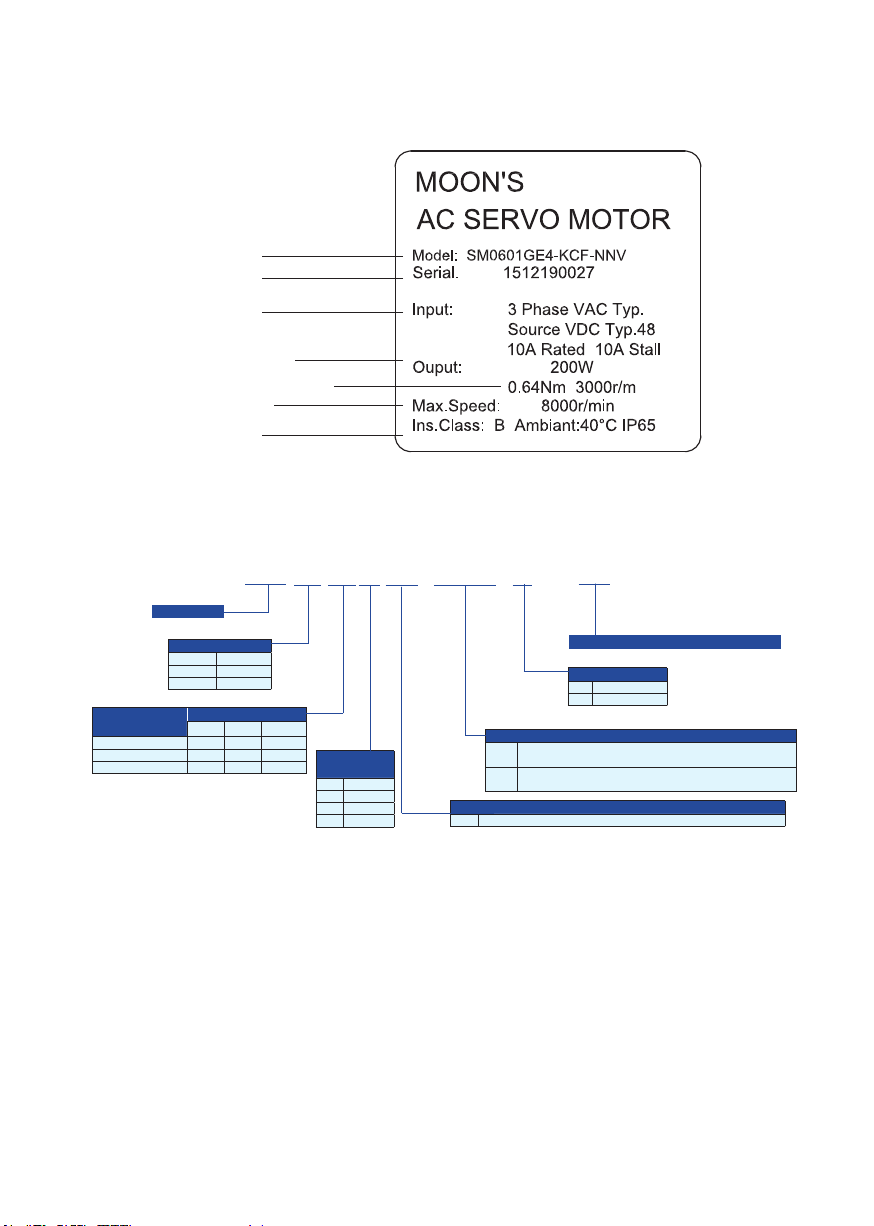

3.1 Connecting to Peripheral Devices

3.1.1 System Conguration

LED Display

The 5 digit, 7 segment LED displays

the diver status and faults.

Operation Panel

Function keys are used to perform status

display, monitor and diagnostic,

function and parameter setting.

PC/Configuration

AC

Source

AC-DC Power Supply

Motor Feedback Cable

Motor Power Cable

AUX Power

MAIN Power

USB Cable

CANBus, RS-485, Ethernet

Communication Port

STO Interface

PLC

Motion

Control Card

I/O Interface

Used to connect PLC, motion card

and other controllers.

12

Rev. 1.0

3.1.2 Servo Drive Connectors and Terminals

Terminal

Identication

Description Details

P1

P2

CN1 Communication Port

CN2 I/O Connector

CN3

Encoder Feedback Connector

CN4 Reserved

CN5 STO Connector

RS-485/CANopen Port

CN6

Ethernet Port

*RS-232 Communication

Port

RS-485/CANopen Port

CN7

Ethernet Port

Communication Port

V+, V-

AUX

U, V, W

Used to connect DC main circuit power

Used to connect an auxiliary circuit power

Ground

Used to connect servo motor

Terminal

Symbol

Wire color Description

U Red

Connects to servo motorV Yellow

W Blue

Ground

User to connect PC

Used to connect external controllers

Used to connect servo motor encoder

Used to connect STO (Safe Torque Off)

RJ45 connector, Daisy Chain, Used for RS-485/CANopen/

Ethernet

*RS-232 Communication Port (-Q Type Only)

RJ45 connector, Daisy Chain, Used for RS-485/CANopen /

Ethernet

Communication

3.1.3 Connections and Wiring Notes

• Ensure the grounding wires are securely connected. Wire with a cross section of more than

2.0mm2 is recommended.

• Grounding method must be single point grounding.

• Ensure V+ and V- are correctly wired, and voltage supplies are within the specied range.

• Auxiliary power V+ connects to drive AUX connector, auxiliary power V- connects to drive V-.

• Ensure U/V/W is wired following the order of RED/YELLOW/BLUE.

• An isolation transformer or EMI lter is recommended on drive’s power supply to ensure the

drive’s safety and improve its anti-interference level.

• Set up emergency stop circuitry to switch off the power supply when a fault occurs.

• DO NOT touch the drive or motor’s connector terminals for at least 5 minutes after the drive and

motor have been powered off. There are electrical charge components in the circuitry which discharge

slowly.

• Install the encoder cables in a separate conduit from the motor power cables to avoid signal

noise. Separate the conduits by at least 30cm (11.8 inches).

• Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for the encoder feedback

cables.

• The maximum length of the signal input/output cable should be no more 5 meters, and the en-

coder (PG) feedback cable no more than 15 meters.

13

Rev. 1.0

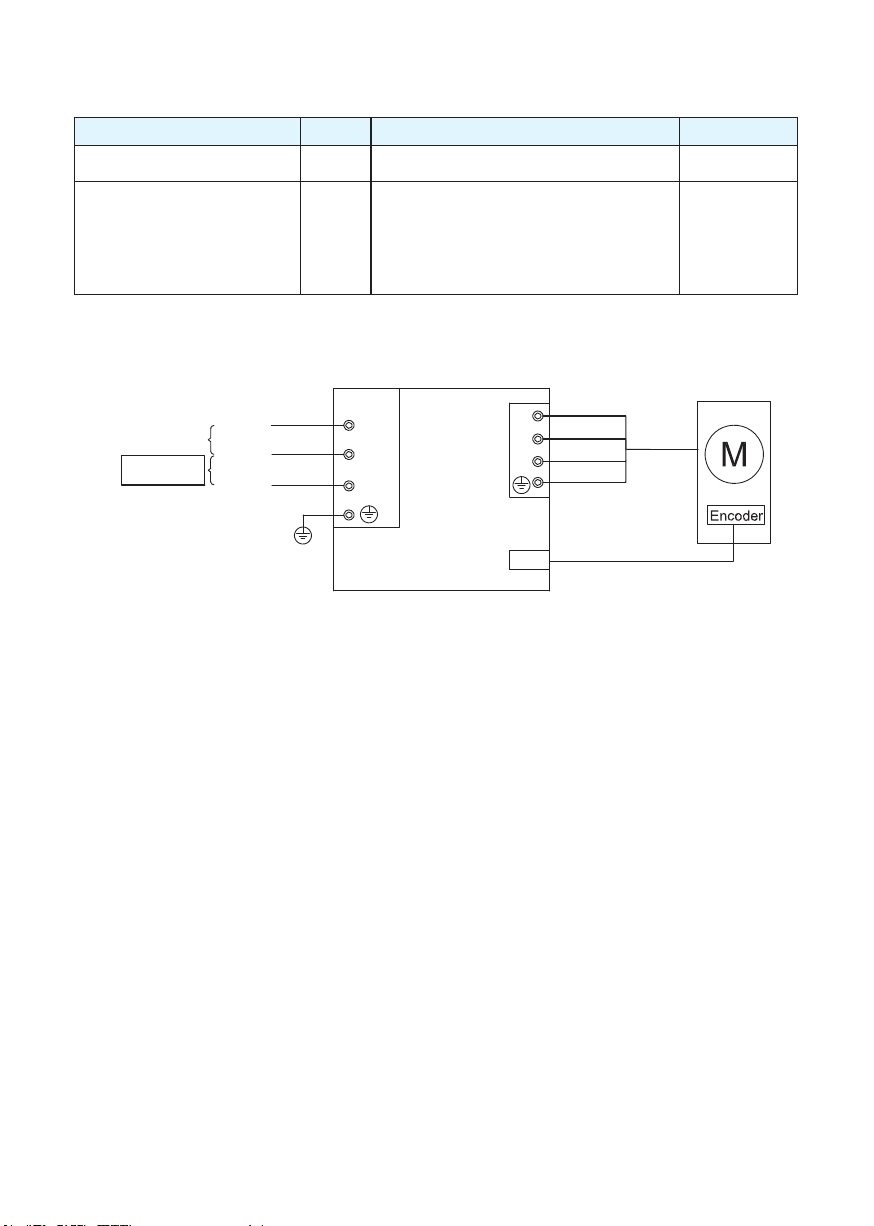

3.1.4 Wiring Methods for P1 Power Supply Connector

Power for the M2DC servo drives comes from 2 different sources

Pin Function Input Power

Main power supply V+, V- Drive’s main power input 20 - 60VDC

When the main power supply is off, the AUX

power will keep the logic circuitry alive, allow-

Control circuitry power/auxiliary

Main power

18 - 70VDC

Control circuitry/

auxiliary power

*

power

DC in+

DC GND

DC in+

AUX, V-

ing the drive to remember its current state data

(motor position, etc.) The motor is then able

to resume operation without running a homing

routine while the main power is switch-on

again.

M2DC Servo Drive

red

P2

U

V

W

CN3

yellow

blue

yellow/green

Encoder connector

V+

VAUX

P1

10 - 60VDC

*Note: For optimized motion performance, make sure the main power input voltage is higher

than the motor winding voltage by at least 2VDC.

14

Rev. 1.0

3.2 Wiring to the P2 Connector

Please follow Chart 5.3 before power up.

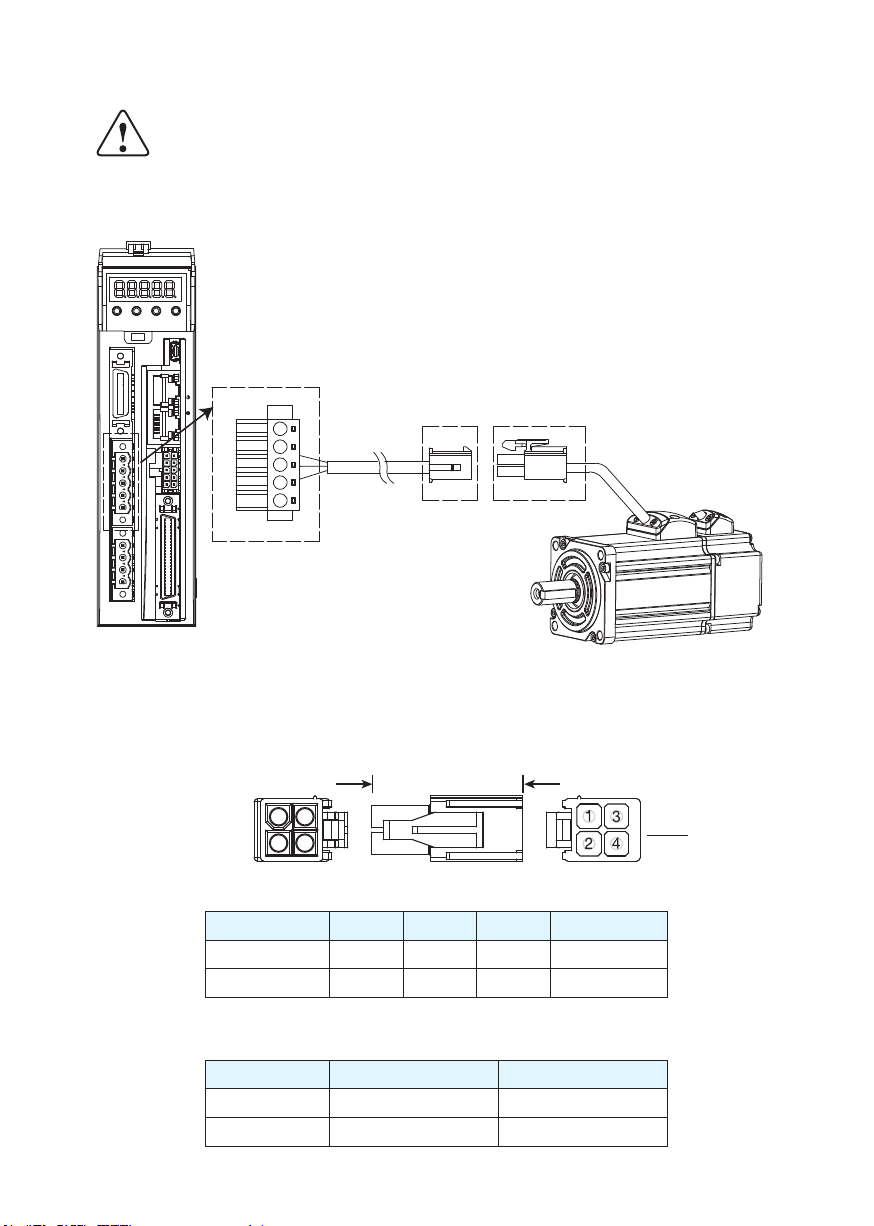

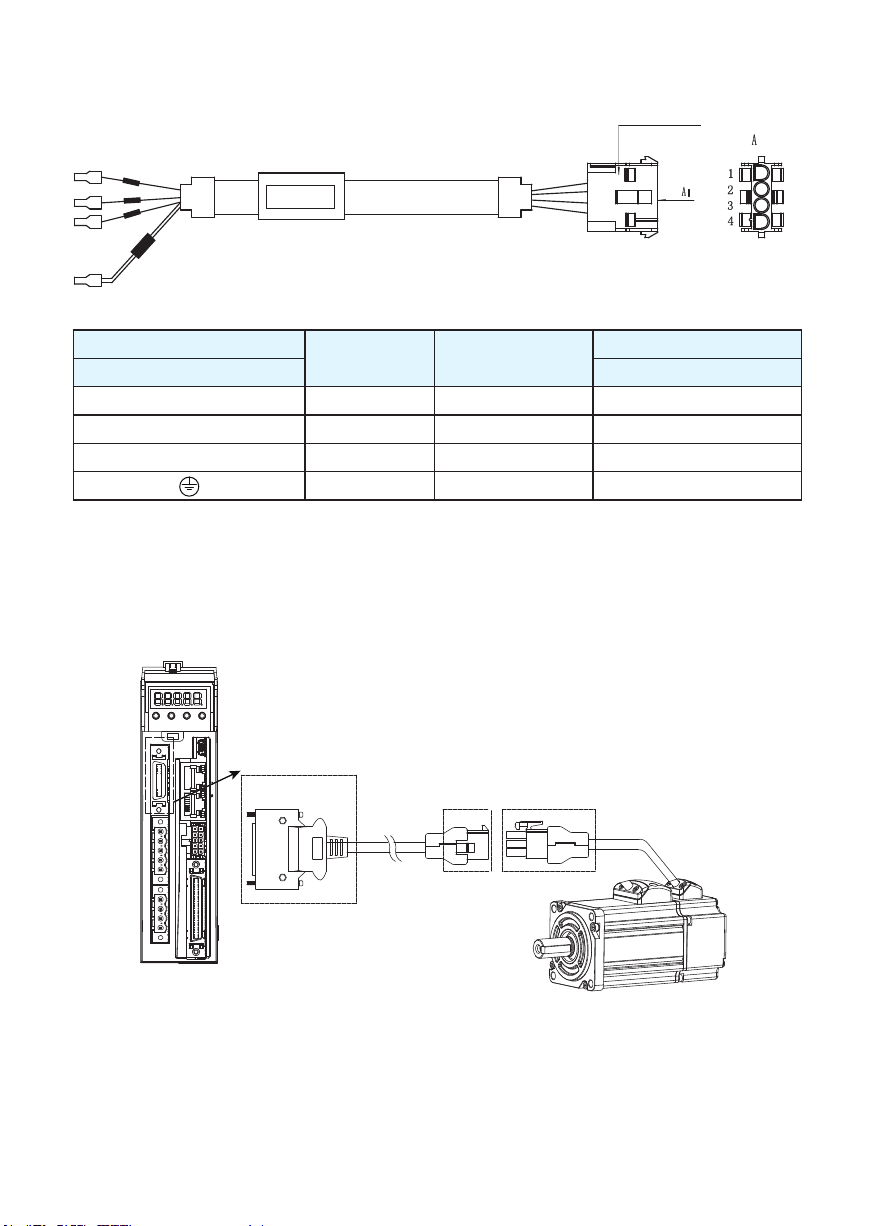

3.2.1 Motor Power Cable Conguration

P2 interface of the drive

W

V

U

Motor power

extension cable

connector

Motor

lead wire

connector

3.2.2 Motor Power Cable Connector(-CD Winding ,6Amps)

A PIN Assignment

A B

View A View B

Pin 1 2

Signal U V

Color Red Yellow

3 4

W PE

Blue Yellow/Green

B Motor Connector Specications

Type Motor side (plug) Plug-in (housing)

Housing AMP 172167-1 AMP 172159-1

Terminal AMP 170360-1 AMP 170362-1

15

Rev. 1.0

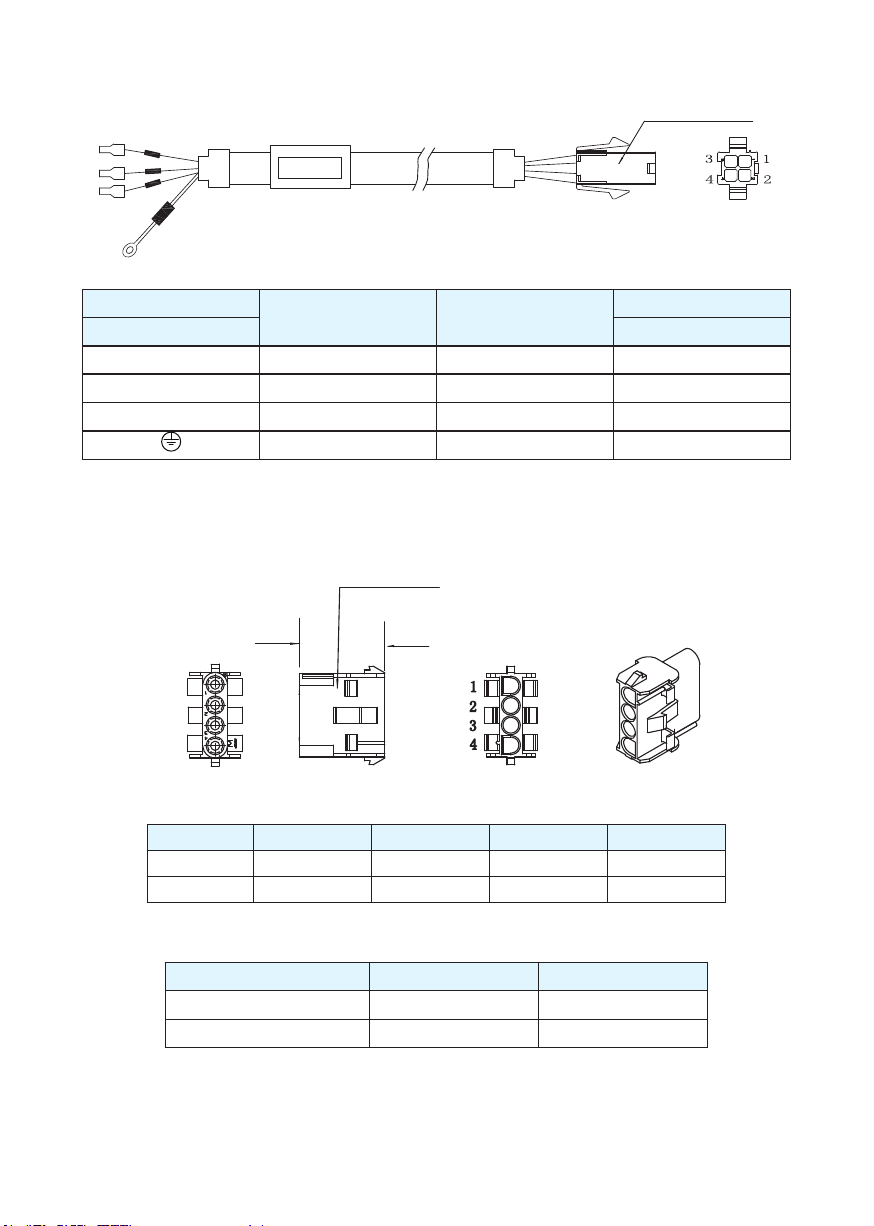

3.2.3 Motor Extension Cable Wiring Diagram

Housing: 172159-1(AMP)

Terminal: 170362-1(AMP)

Drive side (P2)

5452571(Phoenix) AMP 172159-1

U U Red 1

V V Yellow 2

W W Blue 3

Signal Color

PE Yellow/Green 4

Motor side (housing)

3.2.4 Motor Power Cable Connector(-CF Winding,10Amps)

3.2.4.1 PIN Assignment

Cover:350780-1(AMP)

Pin:350536-1(AMP)

A

A side view B side view

Pin 1 2

Signal U V

Color Red Yellow

B

3 4

W PE

Blue Yellow/Green

Motor Connector Specications

Type Motor side (plug) Plug-in (housing)

Housing AMP 350-779-1 AMP 350780-1

Terminal AMP 350218-1 AMP 350536-1

16

Rev. 1.0

3.2.4.2 Motor Extension Cable Wiring Diagram

Housing :350780-1

Terminal:350536-1

Drive side (P2)

5452571 (Phoenix) AMP 350780-1

Signal Color

U U Red 1

V V Yellow 2

W W Bleu 3

PE Yellow/Green 4

Ensure U/V/W is wired in the order of RED/YELLOW/BLUE.

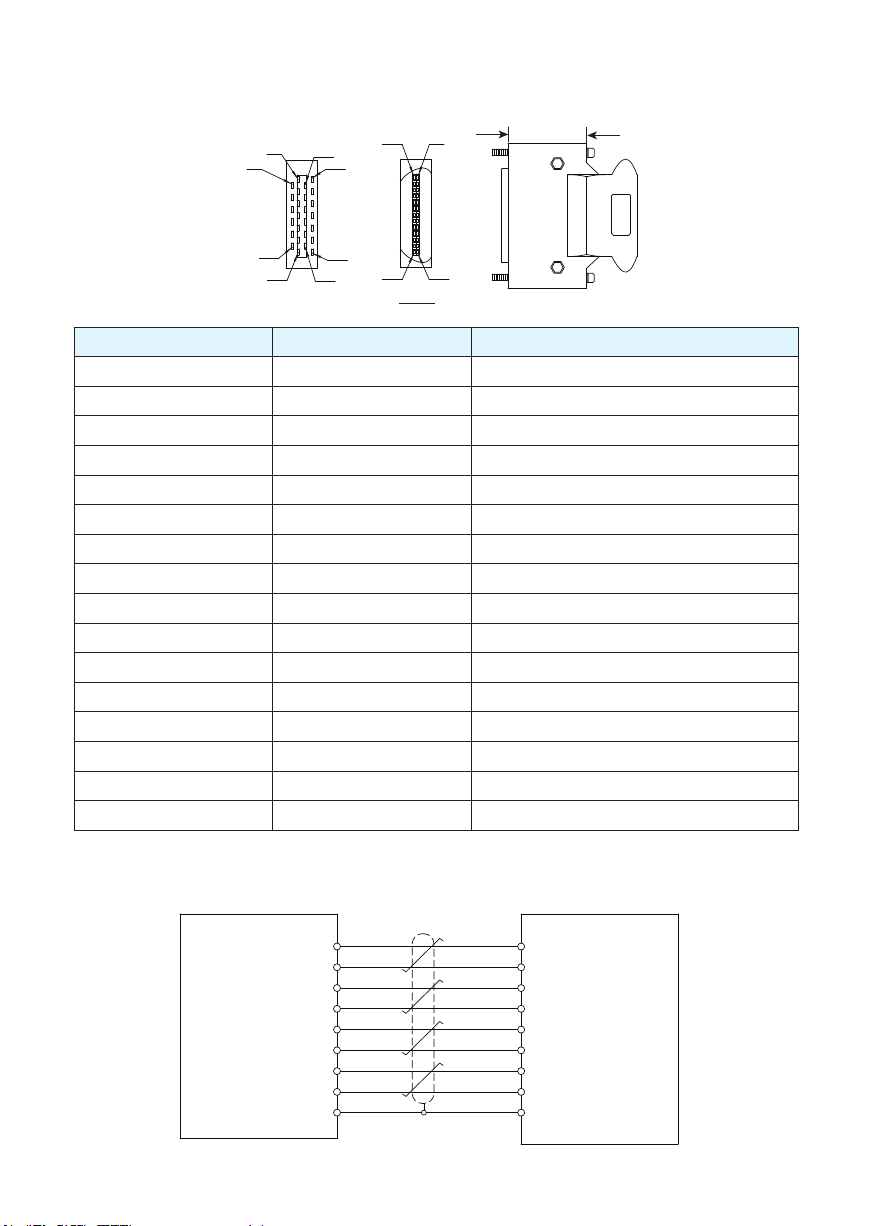

3.3 Encoder Connector CN3

3.3.1 Motor Encoder Feedback Cable Conguration

CN3 interface of the drive

Encoder

extension cable

connector

Motor encoder

connector

Motor side (housing)

17

Rev. 1.0

3.3.2 Layout of CN3 Connector

Motor Encoder

Servo Drive CN3

A+

1

A-

4

B+

2

B-

5

Z+

3

Z-

6

+5V

7

GND

8

Shield

9

1

14

2

15

3

16

11

24

26

A+

AB+

BZ+

Z+5V

GND

Shield

A

1

15

25

14

26

14

26

13

View A

1

2

12

13

View B

B

Pin NO. Symbol Description

1 A+ Encoder A+

2 B+ Encoder B+

3 Z+ Encoder Z+

4 U+ Hall U+

5 W+ Hall W+

6 U- Hall U-

7 W- Hall W-

11 Encoder +5V Encoder power supply +5V

13 Encoder +5V Encoder power supply +5V

14 A- Encoder A-

15 B- Encoder B-

16 Z- Encoder Z-

17 V+ Hall V+

19 V- Hall V24 GND Encoder power supply ground

26 Shield Shield

3.3.3 Connection to Motor Encoder

Connect to 2500ppr Increment Encoder (9PIN AMP connector)

18

Rev. 1.0

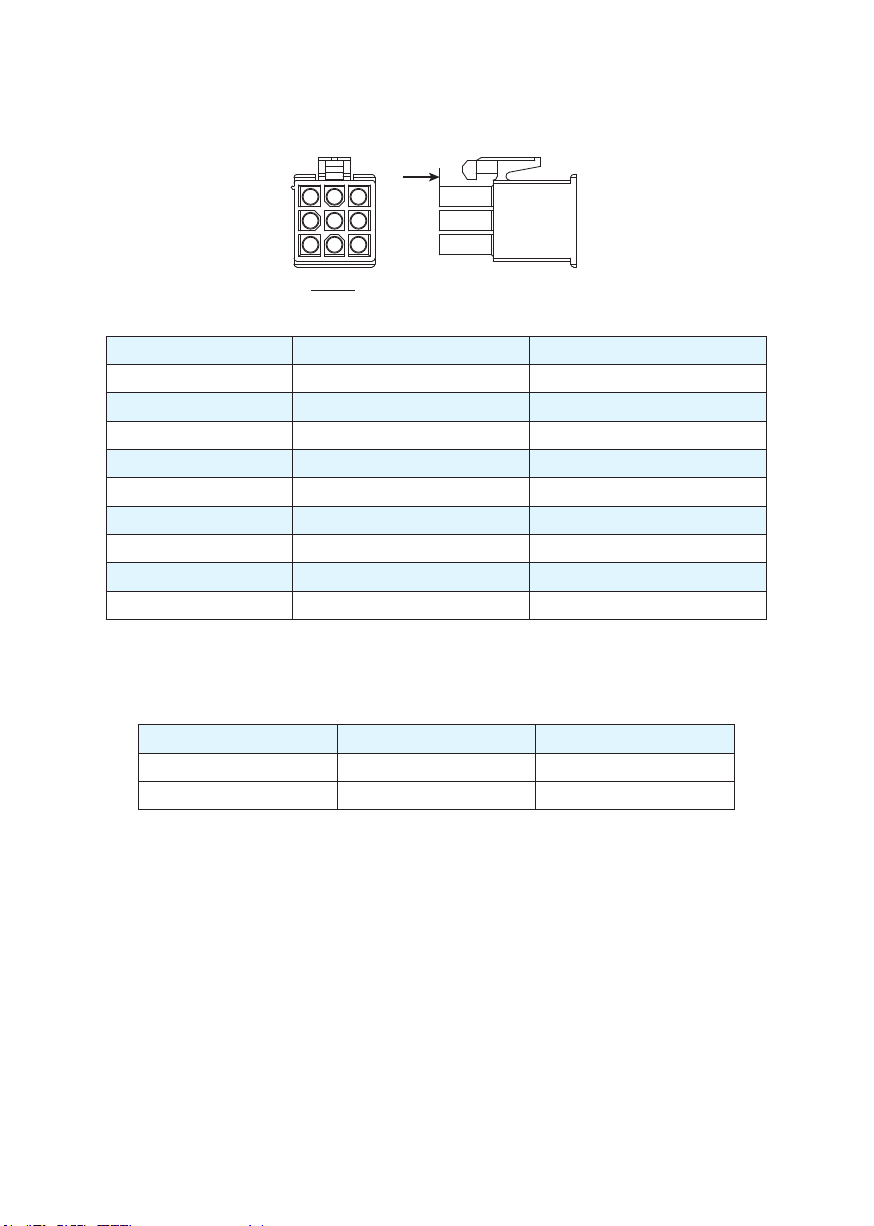

3.3.4 Specications of Encoder Connector

A. -E4 Encoder Connector PIN Assignment

A

1 3

7

9

View A

PIN# Signal Colour

1 U+/A+ Blue

2 V+/B+ Green

3 W+/Z+ Yellow

4 U-/A- Yellow/Black

5 V-/B- Green/Black

6 W-/Z- Yellow/Black

7 +5V Red

8 GND Black

9 Shield Shield

NOTE: The HALL signal U/V/W ONLY appears for short time after the encoder is powered on,

it will then covert to A/B/Z signals.

B. -E4 Encoder Connector Specications

Type Motor Plug Housing for the motor

Housing AMP 172169-1 AMP 172161-1

Terminal AMP 770835-1 AMP 770834-1

19

Rev. 1.0

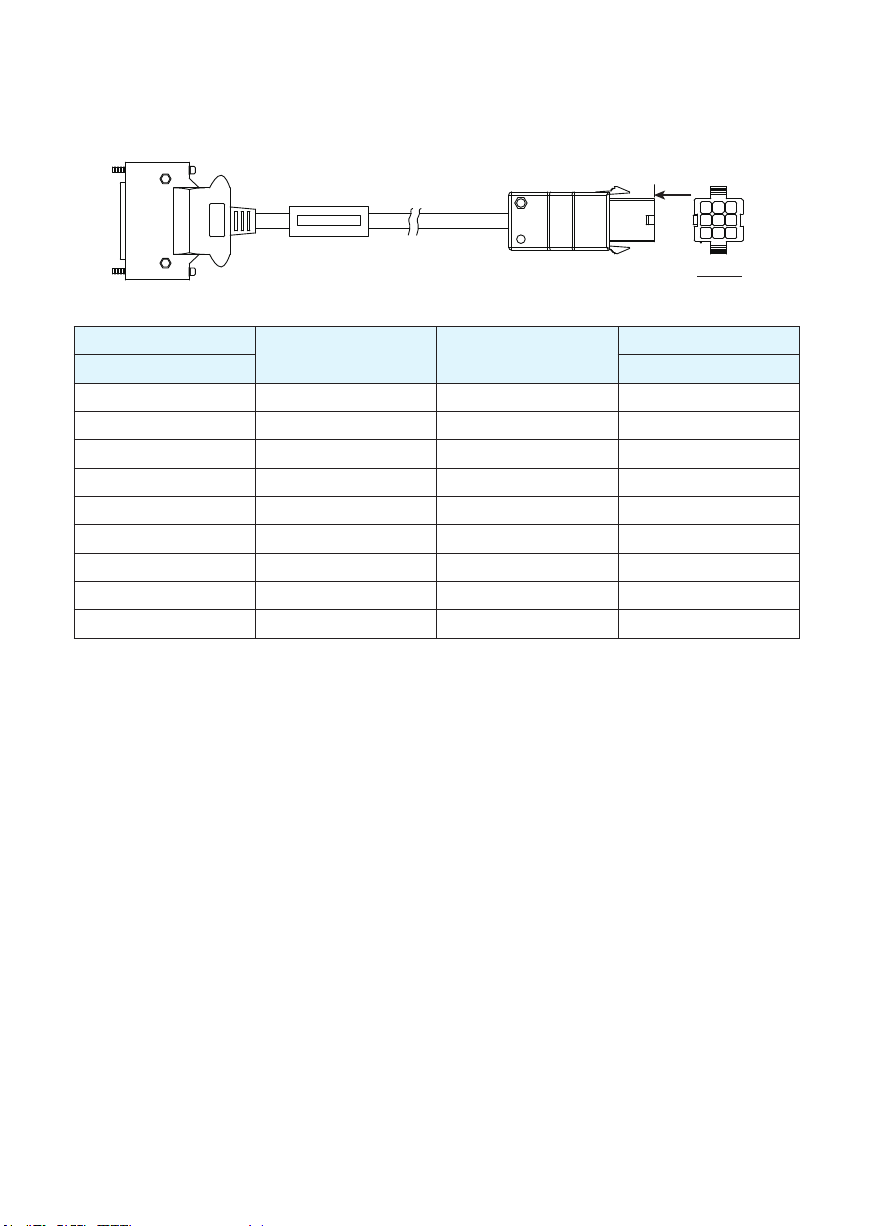

3.3.5 Motor Encoder Extension Cable Wiring Diagram

-E4 Encoder Encoder Cable Diagram

Connect to drive

Connect to Motor

A

1

3

View A

7

9

Drive Side

TYCO 3-22322346-1 AMP 172161-1

Signal Color

Housing for the motor

1 A+/U+ Blue 1

2 B+/V+ Green 2

3 Z+/W+ Yellow 3

14 A-/U- Yellow/Black 4

15 B-/V- Green/Black 5

16 Z-/W- Yellow/Black 6

11 +5V Red 7

24 GND Black 8

26 Shield Shield 9

20

Rev. 1.0

3.4 Electromagnetic Brake

When the motor drives the vertical axis, a brake should be used to hold and prevent the load from

fallingby gravity when the power is removed.

NOTE: Use only a servo motor brake for holding a load when the motor is disabled or the power

is off. Never use a servo motor brake to stop a load in motion. This may cause damage to the

servo motor.

3.4.1 Wiring Diagram

Servo Drive

Relay

Brake

Brake+

Brake-

Relay

R

24VDC 24VDC

3.4.2 Brake Motor

● When no power is applied to the electromagnetic brake, it is in a locked position. Therefore, the mo-

tor shaft will not be able to rotate.

● The brake coil has no polarity.

● During the brake/release action, you might hear a clicking sound. This is normal and does not affect

the use of brake.

● Specications of the brakes are as follows:

Motor Power

Type 60W 100W 200W 400W 550W

Holding torque (N•m) 0.35 2 4.5

Working current (A) 0.25 0.38 0.61

Rated voltage (V) 24V±10%

Release time <25ms

Engage time <25ms

Release voltage (V) Release voltage18.5VDC

21

Rev. 1.0

3.4.3 Timing Charts of the Electromagnetic Brake

In order to prevent damage to the brake, there are delay sequences during the brake operation.

Please be cautious with brake operation sequence.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Brake Release Delay

P-69 Setting

Brake Engage Delay

P-70 Setting

Servo on Input

Motor Active

Brake Signal

Brake Action

Motion Command

Actual Motion

Brake engage/disengage delay time can be set through M Servo Suite software, or on the drive

directly through the P function: P-69 (BD) or P-70 (BE).

3.5 Regeneration Resistor

In M2DC series servo drives, there is a pre-installed 20W regeneration resistor. In some applications,

the pre-installed regeneration resistor might not be enough to absorb all foldback current. In these

cases, a larger wattage regeneration resistor needs to be connected externally, to prevent drive over

voltage warnings.

3.6 Recommended Cable Specications

● Select wires with sufcient allowance for parameters such as operating current and ambient

temperature.

● Recommended wire selections are as follows:

Servo Drive And Corresponding Motor Model

M2DC-6D05 1.5 (AWG15) .75 (AWG18)

M2DC-10D5 2.5 (AWG13) 1.25 (AWG16)

22

Wire Width mm

2

(AWG)

V+/V- U/V/W

Rev. 1.0

3.7 Connecting to the Host Computer - CN1

Port CN1 is used to connect the drive with a PC. Use M Servo Suite software to set the control mode,

change parameter values, use the auto-tuning function, etc.

PIN Symbol Function

1 +5V +5V Power Supply

2 D- Data -

3 D+ Data +

4 — Reserved

5 GND Ground

3.8 Input and Output Signal Interface Connector - CN2

3.8.1 Input and Output Interface Specications and Diagram

Port CN2 on the M2DC series servo drives is used for input/output signals. Details are shown in table

below:

Inputs

Digital Signal

Outputs

I/O

Signals

Analog Signal Inputs 2 Analog inputs, with 12 bit resolution

Inputs

Pulse Signal

Outputs

8 Congurable optically isolated general inputs, 5-24VDC, 20mA

4 Congurable optically isolated high speed inputs

4 Congurable optically isolated general outputs, max 30VDC, 20mA

1 Alarm output, max 30VDC, 20mA

1 motor brake control output, max 30VDC, 20mA

2 optically isolated high speed inputs 500KHz (open collector)

2 high speed differential inputs 2MHz

4 high speed encoder feedback outputs (3 line driver A/B/Z, and 1 open

collector output Z)

3.8.2 Layout of CN2 Connector

1

2

27

26

24

50

25

49

View B

50 25

View A

126

A

B

23

Rev. 1.0

3.8.3 Signal Description of Connector CN2

44

PULSH1

45

PULSH2

SIGNH1

SIGNH2

X1+

X1-

X2+

X2-

X3+

X3-

X4+

X4-

X5+

X5-

X6+

X6-

X7+

X7-

X8+

X8-

COM

X9

X10

X11

X12

46

47

3

4

5

6

29

31

35

34

8

2

9

1

39

38

12

32

7

1.5K

26

1.5K

1.5K

27

1.5K

1.5K

28

1.5K

1.5K

30

1.5K

Position

Command

High Speed

Pulse Input

STEP/CW

DIR/CCW

Enable

Alarm Reset

Limit Sensor

Limit Sensor

Gain Select

Control mode Switch

Dividing Switch

SPD0

SPD1

SPD2

Analog Input

16

+

-

+

-

15

18

17

37

36

11

10

40

41

14

13

42

43

33

21

22

48

49

23

24

19

15

20

25

50

ANA1

Speed Command

DGND

ANA2

Torque Command

DGND

Y1+

Alarm Output

Y1-

Y2+

Motor Brake

Control Output

Y2-

Y5+

Servo-on Status Output

Y5-

Y6+

In Position Output

Y6-

Y3

Torque Reached Output

Servo Ready Output

Y4

Velocity Reached Output

OUT-

AOUT+

AOUT-

BOUT+

BOUT-

ZOUT+

ZOUT-

CZ

DGND

+10V User

User_GND

FG

Encoder

Feedback

Output

24

Rev. 1.0

3.8.3.1 Input Signals

The M2DC series servo drive has 12 programmable digital inputs as well as 2 analog inputs.

Each of the inputs can be specied with different functions via the parameter settings. The functions

are as follows:

● Specied function signals: i.e. STEP/DIR signal, motor enable/disable signals.

● General purpose signal: In velocity mode, torque mode, Q program mode, or SCL mode, it is used

as general purpose signal with no specied functions.

Signal Symbol Pin NO. Details

X1+ 3

X1

X1- 4

X2+ 5

X2

X2- 6

X3

X4

X5

X6

X7

X8

X9 X9 26

X10 X10 27

X11 X11 28

X12 X12 30

COM COM 7 X9-X12 COM point

X3+ 29

X3- 31

X4+ 35

X4- 34

X5+ 8

X5- 2

X6+ 9

X6- 1

X7+ 39

X7- 38

X8+ 12

X8- 32

This input has three functions:

● Accept STEP pulse input such as STEP signals, CW pulse, A pulse in position

mode

● Run/Stop input in torque or velocity mode

● General purpose input

This input has three functions:

● Accept STEP pulse input such as Direction signals, CCW pulse, B pulse in

position mode

● Direction input in torque or velocity mode

● General purpose input

● Enable/Disable input

● General purpose input

● Alarm reset input, used to reset drive alarm

● General purpose input

● Limit sensor input

● General purpose input

● Limit sensor input

● General purpose input

● Gain select input in pulse position mode

● General purpose input

● Switch control mode between main mode and second mode

● General purpose input

● Dividing switch, change the pulses per revolution for electronic gearing

● General purpose input

● Pulse inhibited input - ignores the pulse input when this input is activated in

position mode

● Speed selecting input 1 in change speed mode

● General purpose input

● Speed selecting input 2 in change speed mode

● General purpose input

● Speed selecting input 3 in change speed mode

● General purpose input

25

Rev. 1.0

High-

Speed

Pulse

Inputs

Analog

Input

Signal 1

Analog

Input

Signal 2

PULSH1 44

PULSH2 45

SIGNH1 46

SIGNH2 47

ANA1 16

DGND 15 Digital Ground for analog input

ANA2 18

DGND 17 Digital ground for analog input

High-speed pulse inputs (+5VDC line drive input), the maximum input frequency

2MHz.Three pulse commands available:

Pulse & Direction

●

CW Pulse and CCW Pulse

●

A Quadrature B pulse

●

(NOTE: DO NOT use with both X1 and X2)

In analog velocity control mode, the offset, dead band, and function of analog

input 1 can be set by M Servo Suite or parameters P-52, P-56 and P-61.

● Sets or requests the analog input gain that relates to motor position when the

drive is in analog position command mode

● Sets or requests the gain value used in analog velocity mode

General analog input in Q mode

●

● In analog torque control mode, the offset, dead band, and function of

input 2 can be set by M Servo Suite or parameters P-53, P-57 and P-61.

General analog input in Q mode

●

analog

3.8.3.2 Input Function List

1 2 3 4 5 6 7 8 9 10 11 12

Step ■

DIR ■

CW Limit ●

CCW Limit ●

Start/Stop ▲▼

Direction ▲▼

Servo enable ●

Alarm clear ●

Speed selection 1,2,3 ▲ ▲ ▲

Global gain selection ■

Control mode selec-

tion

Pulse encoder Reso-

lution selection

Pulse Inhabit ■

General Input ● ● ● ● ● ● ● ● ● ● ● ●

●

■

■– Position Mode ▲– Velocity Mode ▼ – Torque Mode ● – All Modes

26

Rev. 1.0

3.8.3.3 Output Signals

The M2DC series servo drive has 6 programmable digital output signals available; each of the outputs

can be specied with a different function via parameter settings.

Signal Symbol Pin NO. Details

This output has two functions:

● Alarm Output

● General purpose output

This output has two functions:

● Motor brake control output

● General purpose output

Torque Reached Output

Servo ready output

●

drive is ready to be controlled and without alarm

General purpose output

●

● Moving signal output - output signal when the dynamic posi-

tion error is less than the set value in position mode

● Velocity reach output - output signal when the actual speed

is the same as the target speed and the speed ripple less than

the ripple range

● General purpose output

enabled.

● General purpose outputY5- 41

I● n position signal output - output signal when in position,

and the position error is less than the set value in position

mode

● Tach out output - produces pulses relative to the motor position with congurable resolution

● General purpose output

● The encoder feedback phase A line drive output

● The encoder feedback phase B line drive output

● The encoder feedback phase Z line drive output

- output servo ready signal when the

Y1

Y2

Y3

Y4

Y5

Y6

Encoder pulse

feedback Output

+10V

Output

Y1+ 37

Y1- 36

Y2+ 11

Y2- 10

Y3+ 42

Y3- 33

Y4+ 43

Y4- 33

Y5+ 40 ● Servo-on Status output --output signals when the motor is

Y6+ 14

Y6- 13

AOUT+ 21

AOUT- 22

BOUT+ 48

BOUT- 49

ZOUT+ 23

ZOUT- 24

ZOUT 19 ● The encoder feedback phase Z output (open collector)

+10V User 20 +10VDC user, max 100mA

USER_GND 25 +10VDC user ground

27

Rev. 1.0

3.8.3.4 Output Function List

Output Pin Y1 Y2 Y3 Y4 Y5 Y6

Alarm Output ●

In Postion error ●

Dynamic Postion

error

Tach Out ●

Function

Brake ●

Torque Reach ●

Servo Ready ●

Servo-On Status ●

Velocity Reach ▲▼

General Output ● ● ● ● ● ●

■ – Position Mode ▲– Velocity Mode ▼ – Torque Mode ● – All Modes

■

28

Rev. 1.0

3.8.4 Encoder Feedback Output

The M2DC series servo drive can output encoder A/B/Z phase as differential output signals through

the line driver. The output signal is 5V, A/B signals are 10000 pulse/rev, Z signal is 1 pulse/rev.

The host must use the line receiver to receive these signals. Use twisted-pair wires for signal transfer.

3.8.4.1 A/B/Z Connection Diagram

Servo Drive

50

21

AOUT+

22

AOUT-

48

BOUT+

49

BOUT-

23

ZOUT+

24

ZOUT-

DGND

25

FG FG

Host Controller

A+

A-

B+

B-

Z+

Z-

DGND

NOTE: Please make sure the host controller and the servo drive are connected to a common

ground.

3.8.4.2 Z Phase Open Collector Output

On the M2 drives, encoder signal Z uses open collector output circuitry. Due to the narrow bandwidth

of encoder signal Z, please use high speed opto-coulper circuitry for the host receiver.

Servo Drive

24VDC

CZ

19

DGND

15

0VDC

29

Rev. 1.0

3.8.5 Input Signal Interface Connector, CN2

Open collector input

3

STEP+

4

STEP-

5

DIR+

6

DIR-

Controller

24VDC

0VDC

Controller

Controller

3.8.5.1 Position pulse signal input

The M2DC series servo has two high speed pulse intputs, STEP/DIR and PULSH/SIGNH. STEP/DIR

supports 5-24VDC, up to 500KHz open collector input signal or differential input signal through the line

driver. PULSH/SIGNH supports 5VDC, up to 2MHz with differential line driver input.

NOTE: STEP/DIR and PULSH/SIGNH CANNOT be used at the same time.

A. Open Collector Input Signal Diagram B. Differential Input Signal Diagram

DGND

FG FG

C. High Speed Differential Signal Input Diagram

Use ONLY 5V supply for PULSH/SIGNH input, DO NOT use 24V.

STEP+

STEP-

DIR+

DIR-

DGND

Differential Input

3

4

5

6

25

50

PULSH1

PULSH2

SIGNH1

SIGNH2

DGND

DGND

FG FG

30

Differential Input

44

45

46

47

25

50

Rev. 1.0

D. Pulse Input Description

STEP/DIR Pulse Input

When both STEP and DIR input signals are ON, the motor will rotate in one direction.

When STEP input signal is ON, and DIR input signal is OFF, the motor will rotate in the opposite direc-

tion.

The direction signal (DIR) can be congured via M Servo Suite software.

The following graph represents motor rotatation in CW direction when DIR input is ON.

Step

(PLS)

Direction

(DIR.)

Motor motion

High

Low

Single Pulse Input

Low

CW Direction

High

CCW Direction

CW/CCW Pulse

When Pulse input goes into X1, the motor will rotate in one direction.

When Pulse input goes into X2, the motor will rotate in the opposite direction.

Motor direction can be congured via M Servo Suite software.

CW pulse

CCW pulse

Motor motion

High

Low

High

Low

Dual Pulse Input

CW Direction

CCW

Direction

A/B Quadrature

In A/B Quadrature mode, the motor rotary direction is based on the leading signal between A and B.

Motor rotary direction can be congured via M Servo Suite software. Direction is dened by the leading input between X1/X2.

The following graph represents motor rotates in CW direction when X1 is leading X2.

Input A(X1)

Input B(X2)

A/B Quadrature Pulse Input

High

Low

High

Low

Motor motion

CWDirection

31

CCW

Direction

Rev. 1.0

3.8.5.2 Analog Signal Input For Velocity And Torque Mode

The M2DC series servo drive has 2 single ended analog inputs OR 1 differential analog input. The

input voltage range is -10V to +10V. Velocity and torque range can be congured via M Servo Suite

software.

Single Ended Analog Input

±10VDC

Differential Analog Input

Single Ended Analog Control Mode

ANA1(ANA2)

DGND

16(18)

15(17)

+

-

Host PC

D/A Output

DGND

Differential Analog Control Mode

16

15

18

17

DGND

+

-

+

-

32

Rev. 1.0

3.8.5.3 High Speed Input Ports X1, X2, X3, X4

High Speed Input Port

The M2DC has 4 optically isolated high speed digital inputs X1, X2, X3, and X4. These inputs allow

input voltage from 5VDC to 24VDC with maximum current of 20mA, and up to 500KHz. They can be

used for general purpose inputs, connecting sensor switch signals, PLC controllers or other types of

controller output signals.

NOTE: When the drive is in position mode, X1, X2 can ONLY be set as STEP/DIR signal.

When the drive is NOT in position mode, X1, X2 can be set as general purpose signals.

, X2, X3, X4 circuits are as follows:

X1

3

X1+

4

X1-

5

X2+

6

X2-

29

X3+

31

X3-

35

X4+

34

X4-

33

Rev. 1.0

High Speed Input Connection Diagrams

HOST controller

+5-24VDC

Power

0V

5-24VDC

X1\2\3\4+

X1\2\3\4-

0VDC

Host Sink Mode

X1\2\3\4+

X1\2\3\4-

Relay Or Switch

HOST controller

5-24VDC

0VDC

5-24VDC

NPN

Output

sensor

connection

0VDC

X1\2\3\4+

X1\2\3\4-

Host Sourcing Mode

X1\2\3\4+

X1\2\3\4-

Sensor And Switch Connection

5-24VDC

PNP

sensor

connection

Output

X1\2\3\4+

X1\2\3\4-

0VDC

NPN Sensor Connection

NPN Sensor Connection

34

Rev. 1.0

3.8.5.4 General Digital Input X5, X6, X7, X8

The M2 has 4 optically isolated general digital inputs X5, X6, X7 and X8. These inputs allow input voltage from 5VDC to 24VDC, with maximum input current of 20mA up to 5KHz. Both single ended and

differential signals are allowed.

X5, X6, X7, X8 circuits are as follows:

8

X5+

2

X5-

9

X6+

1

X6-

39

X7+

38

X7-

12

X8+

32

X8-

35

Rev. 1.0

X5, X6, X7, X8 Input Port Connection Diagrams

HOST controller

+5-24VDC

Power

0V

5-24VDC

X5\6\7\8+

X5\6\7\8-

0VDC

Host Sink Mode

X5\6\7\8+

X5\6\7\8-

Relay Or Switch

HOST controller

5-24VDC

0VDC

5-24VDC

NPN

Output

sensor

connection

0VDC

X5\6\7\8+

X5\6\7\8-

Host Sourcing Mode

X5\6\7\8+

X5\6\7\8-

Sensor And Switch Connection

PNP

sensor

connection

5-24VDC

Output

X5\6\7\8+

X5\6\7\8-

0VDC

PNP Sensor Connection

NPN Sensor Connection

36

Rev. 1.0

3.8.5.5 X9, X10, X11, X12 Inputs with common COM Port

The M2 drives also have 4 single ended optically isolated inputs connected with a single common

node named ‘COM’. These inputs can be used with sourcing or sinking signals, 12-24V. This allows for

connection to PLCs, sensors, relays and mechanical switches. Because the input circuits are isolated,

they require a source of power. If you are connecting to a PLC, you should be able to get power from

the PLC power supply. If you are using relays or mechanical switches, you will need a 12-24V power

supply.

What is COM?

“Common” is an electronics term for an electrical connection to a common voltage. Sometimes “common” means the same thing as “ground”, but not always. If you are using sinking (NPN) signals, then

COM must connect to the power supply +. If you are using sourcing (PNP) input signals, then you will

want to connect COM to ground (power supply -).

NOTE: If current is owing into or out of an input, the logic state of that input is low or closed. If no current is owing, or the input is not connected, the logic state is high or open.

X9, X10, X11, X12 circuits are as follows:

7

COM

1.5K

26

1.5K

X9

1.5K

27

1.5K

X10

1.5K

28

1.5K

X11

1.5K

30

1.5K

X12

X9, X10, X11, X12 Input Port Connection Diagrams

HOST controller

+5-24VDC

Power

0V

Sensor And Switch Connection

5-24VDC

COM

X9\10\11\12-

0VDC

Host Sink Mode

X9\10\11\12-

Relay Or Switch

1.5K

1.5K

1.5K

COM

1.5K

HOST controller

5-24VDC

0VDC

5-24VDC

NPN

Output

X9\10\11\12-

sensor

connection

0VDC

NPN Sensor Connection

Host Sourcing Mode

COM

37

1.5K

1.5K

X9\10\11\12-

COM

5-24VDC

1.5K

1.5K

PNP

sensor

connection

0VDC

Output

X9\10\11\12-

COM

1.5K

1.5K

PNP Sensor Connection

Rev. 1.0

3.8.6 CN2 Output Signal Specication

The M2DC series servo drives feature 6 optically isolated digital outputs. They can be congured via

M Servo Suite. Y1, Y2, Y5, and Y6 are differential output signals, they can be used for both sourcing

or sinking signals. Y3 and Y4 are common ground outputs that can be used for sinking signals.

Y1, Y2, Y5, Y6 circuits are as follows:

37

Y1+

36

Y1-

11

Y2+

10

Y2-

40

Y5+

41

Y5-

14

Y6+

13

Y6-

42

Y3

43

Y4

OUT-

Y1, Y2, Y5, Y6 Output Connection Diagrams

NOTE: Y1, Y2, Y3, Y4, Y5 and Y6 maximum outputs are 30VDC 30mA.

Controller

24VDC

COM

Y1/2/5/6+

IN

Y1/2/5/6-

0VDC

Opt Coupler Circuity

24VDC

Y1/2/5/6+

Y1/2/5/6-

0VDC

Connect To External Load

Y3, Y4 Connection Examples

24VDC

42

Y3

43

Y4

33

OUT-

0VDC

38

24VDC

Y1/2/5/6+

Relay

Y1/2/5/6-

0VDC

Connect To Relay Circuity

Rev. 1.0

3.9 STO Connector

On the M2DC series servo drives, the STO (Safe Torque Off) function is connected via port CN5. The

STO function shuts off the motor current turning off the motor output torque by forcibly turning off the

signal of the servo driver power transistor. This is done internally through the STO Input/Output signal

circuit.

3.9.1 Safety Precautions

• If the STO function does not trigger, make sure the STO connector is plugged into CN5 on the drive

correctly.

• When using the STO function, perform an equipment risk assessment to ensure that the system

conforms to the safety requirements.

• Even when the STO function is enabled, the servo motor may move due to external force (e.g.

gravitational force on the vertical axis). Make sure a holding brake is used in applications where this is

possible.

• When the STO function engages and removes the torque, the motor will be “free running”, requiring

more distance until the motion stops. Make sure this will not be a safety issue.

• When the STO function operates, it will turn off the current to the motor, but it does not turn off the

power to the servo drive. Make sure to disconnect the power to the drive before performing any

maintenance on it.

• After the STO function is triggered, the drive will have a fault alarm status(Alarm code: ),

and the motor will be disabled.

• After the STO signal return to normal, the drive will automatically clear the STO fault alarm, but the

motor will remain disabled . To restore the system to normal operation, re-enable is needed.

3.9.2 STO Input/Output Signals

3.9.2.1 STO Internal Circuit Diagram

SF1+

1.5K

SF1-

1.5K

SF2+

SF2-

EDM+

EDM-

39

Rev. 1.0

3.9.2.2 CN5 Connector diagram

Item Part number Vendor

Housing 43025-1000 Molex

Crimp 43030-0005 Molex

3.9.2.3 STO Signal Denition

Signal Symbol Pin Description Control Mode

SF1+ 1

Safety Input SF1

SF1- 5

SF2+ 3

Safety Input SF2

SF2- 2

Safety Output

Ground DGND 7, 8 +5VDC power ground

+5V power +5V 9, 10 +5VDC power supply

EDM+ 6

EDM- 4

When SF1 has no input signal, e.g. the port is

disconnected, SF1 will be considered OFF. The

upper half of the internal power transistor will be

shut off.

When SF2 has no signal input, e.g. the port is

disconnected, SF2 will be considered OFF. The

upper half of the internal power transistor will be

shut off.

Output monitor signal used to check the safety

function.

Compatible

with all control

modes

40

Rev. 1.0

3.9.2.4 STO Connection Diagrams

● Connection to safety switch

24VDC

Safety Switch

● Safety light curtain connection

M2 Servo Drive

Safety Input 1

Safety Input 2

Safety Output

0VDC

41

Rev. 1.0

4. Display and Operation

4.1 Control Panel Description

MODE

UP

Symbol Name Details

LED Display

MODE

UP/DOWN

SET

The LCD display (5 digits, 7 segments) shows the drive’s oper-

ating condition, warning codes, parameters, and setting values.

Press and hold MODE button to switch the LED display mode

a) Monitoring selection mode

b) Function selection mode

c) Parameter setting mode

When editing the parameters, press the MODE button to move

the cursor to the left and then change the parameters by using

the UP/DOWN buttons.

Press the UP and DOWN buttons to scroll through and change

monitor codes, parameter groups and other parameter settings.

Press to enter a mode

Press and hold to save parameters/settings

LED Display

SET

M

S

DOWN

42

Rev. 1.0

4.2 Mode Switch Control

• Pressing the button and the button changes between status monitoring, function control,

parameters setting and other modes.

• If no warnings or faults occur, the drive will not go into warning and fault display mode.

• If any warnings are detected by the drive, the LED display will switch into warning or fault display

mode immediately. Pressing Mode/Set button will switch back to the previous display mode. Press UP/

DOWN button will switch other warning or fault display.

• If no button(s) on the control panel is pressed for 20 seconds, the display will switch back to the

previous status monitoring display mode.

• In monitoring selection mode, function selection mode and parameter setting mode, to edit the

values, press to move the cursor to the left, then change parameters by using the

buttons.

• In status monitoring mode, press and hold the

button to lock the control panel. To unlock the

panel, press and hold the

button again.

43

Rev. 1.0

Control mode switch owchart:

the SET key to confirm setting value

Power On

Monitor Status

Press any key

Monitor Parameters

Press and hold the

MODE key for 1 second

M

Press and hold the

MODE key for 1 second

M

Press and hold the MODE

key for 1 second(*NOTE 4)

Function Parameters

M

Drive Parameters

Configuration

In factory default mode, the motor’s rotatory velocity will be displayed.(*NOTE 1)

The last dot shows whether the drive is enabled or disabled.

Press SET key back

to Monitor Status

S

Press the UP and

DOWN key to scroll

through and change

monitor status

Press and hold SET key to

Press the UP and

DOWN key to scroll

through and change

function selection

Press the UP and

DOWN key to scroll

through and change

parameter selection.

confirm selection and execute it.

S

Press SET key enter

to value setting mode

S

Press SET key back to

Drive Parameters Configuration

mode without changing.

*NOTE(2)

Press and hold for 1 second

*Note(3)

S

NOTE:

When power is applied, the drive’s display will show the customer dened monitoring mode.

In factory default mode, it will display the motor’s rotary velocity.

• When in parameter setting mode, pressing the

button will exit the parameter setting mode, and

return back to parameter selection mode, without saving any changes.

• When in parameter setting mode, pressing and holding the button will conrm and apply the

current parameter setting. This will take effect immediately. However, this change will not save to

drive’s ash memory. To save the parameter, go to function mode , and then press and hold

the button.

• When the drive is connected to the host computer with M Servo Suite on, the parameter setting

mode CANNOT be accessed directly on the drive’s control panel.

44

Rev. 1.0

4.3 LED display description

4.3.1 Decimal Point And Negative Sign Description

LED display Description

Negative sign: when the value to be displayed

is a negative number ≥-9999, the highest digit

will display as a negative sign.

negative

sign

motor enable

sign

Decimal point: when the value to be displayed

is a negative number ≤-10000, a decimal point

will be displayed.

4.3.2 Parameter View Setting

LED display Description

There are only 5 digits on the LED display, when a value with more

than 5 digits needs to be displayed, it will be displayed in 2 segments.

When the highest digit of a value is ashing, it means only the lower 5

digits are shown. Press to display the upper 5 digits.

The graph is displaying ‘-12802345’

45

Rev. 1.0

4.3.3 Parameter Save Setting

LED display Description

In parameter setting mode, pressing and holding the button will

save the change. ‘Saved’ will also be displayed on the LED.

In parameter setting mode when the motor is rotating and the is pressed

and held, the LED display will read “busy” meaning that the current

parameter change cannot be saved. Stop the current motor motion and

save the parameter again.

4.3.4 Point To Point Motion Mode

LED display Description

When the LED display reads “P-CW” it means the motor is rotating in a

CW direction in the point-to-point mode.

When the LED display reads “P-CCW” it means the motor is rotating in a

CCW direction in the point-to-point mode.

4.3.5 Jog Mode

LED display Description

When the LED display reads “J-CW” it means the motor is rotating in a

CW direction in JOG mode.

When the LED display reads “J-CCW” it means the motor is rotating in a

CCW direction in JOG mode.

4.3.6 Control Panel Lock

LED display Description

This means the key panel is locked. Press and hold for 1 second

while in status monitoring mode to lock.

When the control panel is locked, press and hold for 1 second to

unlock it.

46

Rev. 1.0

4.4 Status Monitoring Selection Mode

To change the status monitoring mode, press to enter monitoring selection mode, and then

use

to make selections, and press to conrm, as below:

Press Any Key

Status Monitoring

N mode selection and

setting

Power ON

Stats Display

Selection

Default display is current motor velocity

The last decimal point is drive enable sign

Press SET key to

select display mode

Press UP and

DOWN key

to select display

detail.

S

LED display Description Unit

n-00

n-01

n-02

n-03

n-04

n-05

Motor Rotation Speed RPM

Position Error Pulse

Pulse Counter counts

Encode Counter counts

Command Position Counter counts

Drive Temperature x 0.1°C

47

Rev. 1.0

n-06

DC Bus Voltage x0.1V

n-07

n-08

n-09

n-10

n-11

n-12

n-13

n-14

n-15

n-16

Node ID (Drive Address)

Fault History 1

Fault History 2

Fault History 3

Fault History 4

Fault History 5

Fault History 6

Fault History 7

Fault History 8

Differential Analog Input

0.001VDC

n-17

n-18

48

Analog Input 1

Analog Input 2

0.001VDC

0.001VDC

Rev. 1.0

4.5 Function Control Mode

In function control mode (display F+ parameter number), you can select functions for preoperational

mode, restart the drive, enable or disable the drive, etc. In status monitoring mode, press and hold

for 1 second to enter function control mode. Press to select function, and then

press and hold to conrm or execute the function. (NOTE: F-00(FL) and F-01(CJ) excepted)

Status display

selection

Press and Hold MODE key

for 1 second

M

Function Mode

Selection

Press UP and

DOWN key

to select display detail.

Press and Hold Set key to

select and execute the function

S

49

Rev. 1.0

4.5.1 Function Mode Description

Function mode details are as follows:

Function mode

number

F-00

F-01

F-02

F-03

F-04

F-05

F-06

F-07

F-08

LED display Description

point to point position mode: rotating speed is1rps; travel

distance is 1rev

JOG mode:JOG speed 1rps

Restart the drive

(F-03AR) Clear drive’s current alarm

(F-04SA) Save parameter changes for P-00 to P-98

(F-05MD) Drive disable

(F-06ME) Drive enable

(F-07MC) Select motor specication

(F-08AZ) Analog auto tunning

F-09

(F-09SK)Motion Stop/Q Stop

50

Rev. 1.0

4.5.2 Operation Flow Chart

status monitoring

selection

press and hold MODE key

for 1 second

M

function selection

mode

Press UP and DOWN key

to select display detail.

F-00 point to point mode

F-01 JOG mode

Press UP and DOWN key

to select display detail.

F-02 Restart the drive

Press UP and DOWN key

to select display detail.

F-03 Alarm clear

Press UP and DOWN key

to select display detail.

F-04 save parameter

Press UP and DOWN key

to select display detail.

F-05 motor disable

Press UP and DOWN key

to select display detail.

F-06 motor enable

press and hold

SET key

press ,motor rotate

1 rev in CW direction

press ,motor rotate

1 rev in CCW direction

press to stop the motor

press M key

press to return back

NOTE: In P-P mode, rotary velocity is 1rps,

and 1 rev per time.

press and hold

SET key

S

press ,motor rotate

in CW direction

Press ,motor rotate

in CCW direction

M

press stop motor

press to return back

press M key

NOTE: In JOG mode, rotary velocity is

1rps

press and hold

press and hold

press and hold

press and hold

press and hold

SET key

S

SET key

S

SET key

S

display after

1 second

SET key

S

SET key

S

Drive restart, and back to status

monitoring mode

clear current drive warning

To save parameter changes for P-00

to P-98 permanently.

To disable the drive

If no alarm has occurred, enable the

drive immediately

S

M

S

M

SAVE means

success operation.

F-07 motor configuration

Press UP and DOWN key

to select display detail.

Press UP and DOWN key

to select display detail.

press and hold SET key to confirm

F-08 Analog Input Auto-offset

Press UP and DOWN key

to select display detail.

F-09 Motion Stop/Q stop

51

press SET key

S

press SET key

press SET key

S

S

S

select current motor model

press to select

motor type

Analog Input Auto-offset

Stop current movement

Stop current Q program

Rev. 1.0

4.6 Parameter Setting Mode

4.6.1 Parameter Setting Description

The parameter setting mode (P+parameter number) allows you to select, display and edit the required

parameter. In function control mode, press and hold

mode. Use

Press

to select required parameter, and press to view or edit the parameter.

again to quit and no change will be saved. Press and hold for 1 second to save

for 1 second to enter parameter setting

the parameter change. However this change will NOT be saved at the next power on.

If you want to save parameter PERMANENTLY, go into function control mode (F+parameter number),

and use F-04SA function.

function selection

mode

press and hold MODE key

for 1 second

M

parameter setting

selection

Press UP and DOWN key

to select display detail.

press SET key to

enter parameter editing mode

S

short press SET key

to quit

press and hold SET key

to save parameter change

S

52

Rev. 1.0

4.6.2 Parameter Editing Examples

M

First digit flash

Press

Press up or down to increase or decrease value

Press

Press mode to

shift flashing digit

Press

Second digit flashing

Press

Press SET key to

enter parameter editing mode

S

M

Press

Press mode to

shift flashing digit

Setafter 1 second

return to parameter

selection page

Press and hold set key

S

First digit

Press

The parameter change is only saved for current

operation, it will back to original after next power up

M

Press

Press and hold mode key

Function mode selection

Press up and down key

to select display detail.

F-04 to save

parameter

Second digit flashing

Press

press UP or DOWN to increase or decrease value press UP or DOWN to increase or decrease value

Press and hold set key

to save parameter

S

Set display for 1 second, means save successfully

Save parameter

Saved means

operation successful

Saved display for 1 second

and return back to previous

page

53

Rev. 1.0

4.7 Control Panel Lock

To prevent unauthorized use of the key panel, a key panel lock is featured on all M2DC servo drives.

When the panel is locked, no function can be changed directly on drive’s control panel.

Status monitoring

Press and hold set key

for 1 second

If control panel is locked,

press any key will show lck

In control parameter lock mode,

press and hold set key

for 1 second will unlock

Unlock display

4.8 Warning And Fault Display

When power is applied, if any warnings are detected by the drive, the LED display on the drive will

switch into warning or fault display mode immediately.

If more than one warning is detected, pressing the

Press the

or button to clear the warning display and return to the previous display mode.

Any Mode

Warning And Fault Alarm Occurs

Encode Hall Failure

If More Than 1 Alarm Has Occur,

Press Up And Down Key To Scroll Through

Encode Fault

S

Press Set And Mode Key

To Return From Alarm

Display Mode

54

buttons will scroll through the warnings.

Pervious Monitoring Mode

M

Rev. 1.0

LED display Description LED display Description

Drive over temperature

Internal voltage fault

Over voltage

Over current

Bad hall sensor

Encoder error

Position error

Low voltage

Velocity limited

CW limit or CCW limit

activated

CW limit is activated

CCW limit is activated

Current limit

Communication error

Parameter save failed

STO is activated

Regeneration failed

Low voltage

Q program is empty

Motion command received

while motor in disabled

55

Rev. 1.0

5. Preoperational mode

When using preoperational mode, disconnect the servo motor from any mechanical system to prevent

damages and accidents. Preoperational mode should be used only under a no load condition.

5.1 Inspection Before Trial Run

To avoid any accidents and damages to the servo drive and mechanical systems, the following safety

checks are recommend before the drive is turned on.

• Connection inspections

- Ensure secure wiring for power connector P1, motor connector P2, encoder connector CN3,

and communication connector CN1. Check the wiring connections, and that wires are correctly

insulated (to avoid short circuits) for all connectors.

- Make sure the ground wire from power connector P1, and motor connector P2 are securely connected to the shield ground.

• Power supply inspection - Ensure the power supply to V+ and V- meet the drive’s power supply

specications.

• Check that the servo drive and motor are securely installed.

• Make sure no load is connected to the servo motor.

56

Rev. 1.0

5.2 Trial Run Procedure

Step Details Description

Install the motor securely.

1

Make sure the wiring between the drive

2

and motor is correct.

Make sure the main power circuit is

3

wired correctly.

Supply power Do not apply more than 75V power supply to the

4

If there are no alarms the LED Display

will read:

5

If an alarm occurs, it will display:

Set up a motor brake control circuit if

6

using an electromagnetic brake motor.

7 Motor Conguration

8 JOG Trial Run without load

- The motor can be installed on the machine.

- Ensure no load is installed on the servo motor.

- The terminals on connector P2 must be connected in the order of U - Red, V - Yellow, U

- Blue, FG - Yellow/Green. If the terminals are not

connected to the specied wire, the drive will not

be able to control the motor.

- Ensure the encoder cable is connected to CN2

correctly.

Refer to Section 3.1 Connecting to Peripheral

Devices to conrm the correct main power circuit

wiring.

servo system.

- When the power is on, the normal display should

be shown without any alarm codes and the drive is

disabled.

- If the display shows alarm codes such as r-08

and r-09 the encoder feedback connection is incorrect. Check the encoder wiring to the servo motor

to see if it is loose or incorrect.

- See Section 6 for a list of alarm codes.

Please refer to Section 3.4 for more details about

the Electromagnetic Brake.

Congure the drive for the correct motor through

M Servo Suite or the operation panel. See Section

5.3 Motor Conguration.

The system is ready to run JOG trial if all the

above steps are completed.

57

Rev. 1.0

5.3 Motor Conguration

Before using JOG mode, the drive needs to be properly congured for the connected motor. This can

be done through the drive control panel or the M Servo Suite software. For more details about motor

specications, refer to Section 2.3.

5.3.1 Using the Drive Control Panel for conguration

Motor information and LED display list:

LED display Motor Model Number LED display Motor Model Number

SM0401HE4-KCD-*NV SM0401EE4-KCD-*NV

SM0402FE4-KCD-*NV

SM0601GE4-KCF-*NV

SM0602FE4-KCF-*NV

SM0801GE4-KCF-*NV

SM0802EE4-KCF-*NV

To set up a drive for model: SM0402FE4-KCD-NNV motor follow these steps:

Step LED display Description

1

2

3

4

5

6