Mooney Aircraft MARK 21, M 20 C 1962, M 20 C 1963, M 20 C 1965, M 20 C 1964 Owner's Manual

MARK

21

MODEL

M

20

C

OPERATE THIS AIRCRAFT

ONLY

-

after reading

owners manual

@

with owners manual on board

@

after you are fully qualified & understand all of

the aircraft operating characteristics& limitations

OWNERS

MANUAL

DATA

INCLUDED

MOONEY

AIRCRAFT. /NC.

NOTE:

Information in the

1965

MARK

21

owner's manual

also applies

to

the

1962

through

1964

models with the

ex-

1852, 1940

thru

2207, 2209

thru

2255, 2257

thru

2296

2208,2256, 2297

thru

2622

ment

to

the

1965

MARK

21

owrrers

manual

PAR"1" DESCRIPTION AND OPERATION

OF COMPONENTS

FUEL

SYSTEM

(Reference page 3)

The fuel tank capacity of the 1962 and 1963 Mark 21 is 24

gallons per wing tank or 48 gallons total fuel. The '62 and

'63 models do not have a pull ring to drain the fuel selector

sump

from the cabin. In these models the selector sump is

drained from outside using the same procedure recommended

for draining the wing tanks. 1962 and 1963 models have a

gascolator in the nose wheel well which can be inspected and

drained from outside the aircraft.

LANDING

GEAR:

(Reference page 6)

The thumb operated safety latch for the landing gear retraction lever has not been factory installed on serial numbers

1852, 1940 through 2050.

POSITWE CONTROL SYSTEM: (Reference page 8)

The Positive Control section does not apply

to 1962, 1963

or 1964 models unless retrofit installation of the PC system

has been made.

TRIM SYSTEM: (Reference page 9)

The friction

adjsstment for the trim control wheel does not

apply to 1962 models.

FLAPS: (Reference page 9)

The 1962 and

I965 model fiaps are retracted by pulling the

release knob adjacent to the flap handle.

VACUUM

SYSTEM: (Reference page 10)

1962,

'63

and '64 models do not have a vacuum operated

cabin entry seep. These models have a manually operated

step retraction system

activated

by

a hand crank on the left

side panel near the pilot's knee. Turning

the crank clockwise

raises the step; counter

clockw

is,

lowers the step.

The vacuum regulator will maintain vacuum

between

3.5

and

5.0

inches of mercury on 1962, 1963 and 1964 models. The

vacuum warning lights for these airplanes are

see

accord-

ingly.

HEATING

AND VENTILATION SYSTEMS: (Reference pages 10

and 11)

1962 models do not have rear heat outlets. There

Ls

no left

side air scoop on 1962, 1963 or 1964 production aircraft.

Serial numbers 1852 and 1940 through 2693 do not have a

firewall-mounted radio cooling grill.

PART

II

FLIGHT

PROCEDURES

WEIGHT AND BALANCE: (Reference page 14)

1962 models are not equipped

with the utility shelf aft of the

main baggage compartment. Therefore, related weight limitation does not apply.

ENTERING THE AIRCRAFT: (Reference page

15)

Drain the fuel selector valve sump from outside the air-

craft on 1962 and 1963 models.

STARTING THE ENGINE:

(Reference page

15)

-

--

"Push to Stare" feature was installed on the ignition switch

beginning with 1963 models. On earlier aircraft, turning

the

ignition switch to "start" engages the starter and the

"shower of sparks" ignition.

COLD

WEATHER AND MANUAL STARTI* (Reference page 16

To manually start aircraft with serial numbers 1852 and 1940

through 2342 use

the

following procedures:

(1)

Turn off the "starter disconnect switch"

located on the

upper center section of the

firewall under the instrument

panel. The switch disconnects the starter so that only

the starter vibrator operates when the

magneto switch is

turned to the start position.

(2)

As the engine is "propped", hold the magneto switch in

the "start" position. This operates the starter vibrator

and furnishes retarded spark to the engine.

(3) When the engine starts, release the switch to the "both"

position and place the starter disconnect switch in the

"on" position.

Aircraft serial numbers

from 2343 may be manually started

as described on page

16.

PART

ill

SERVICE

AND

MAINTENANCE

VACUUM

STEP: (Reference page 27)

The maintenance check of the step retraction does not apply

to 1962, 1963 or 1964 models.

REQUIRED DATA

:

(Reference page

28)

The F.A .A. approved flight manual is part

of

the requird

data for

1962 and 1963 models. Placards in the aircraft and

data in the owner's manual supercede the flight manual data

for

later models.

PART

IV

PERFORMANCE

DATA

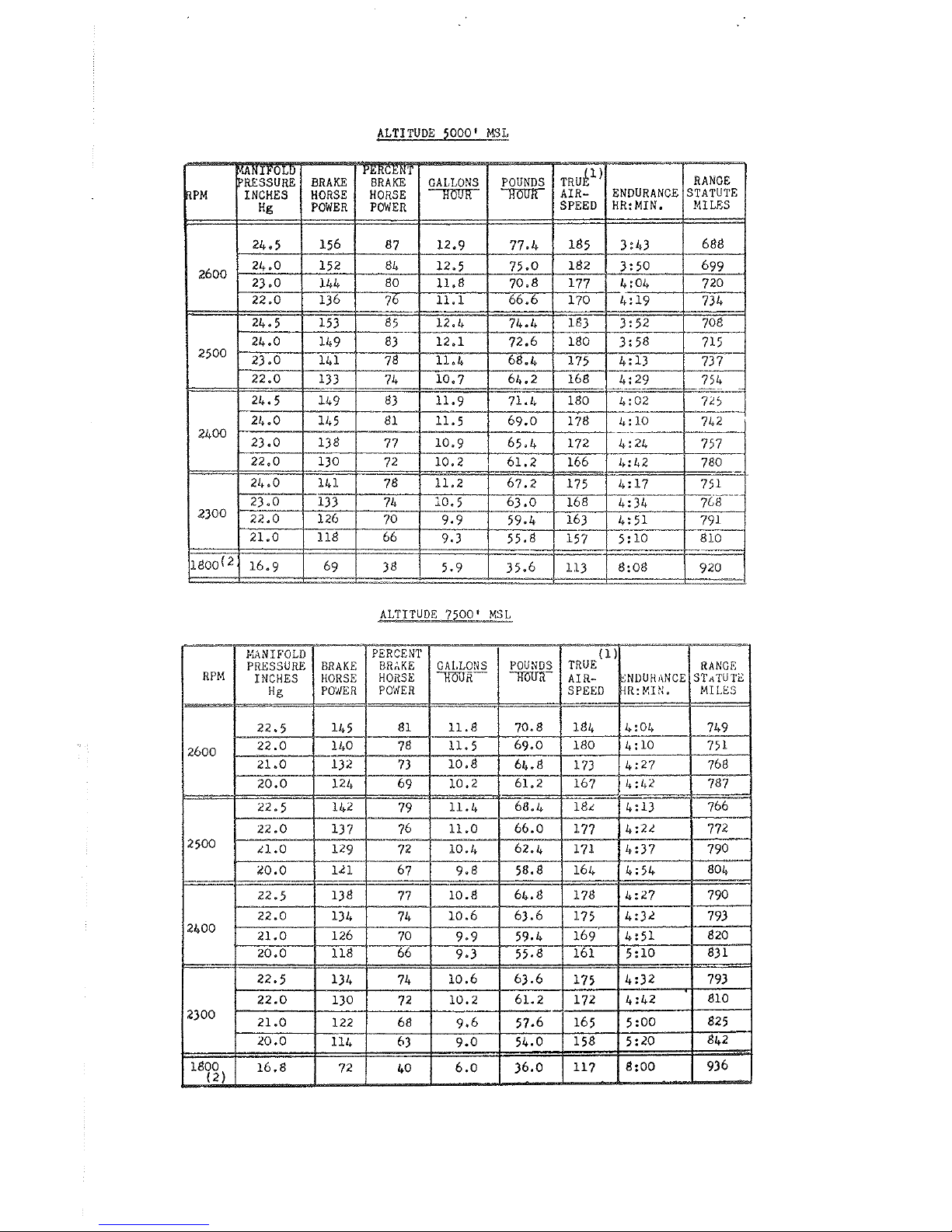

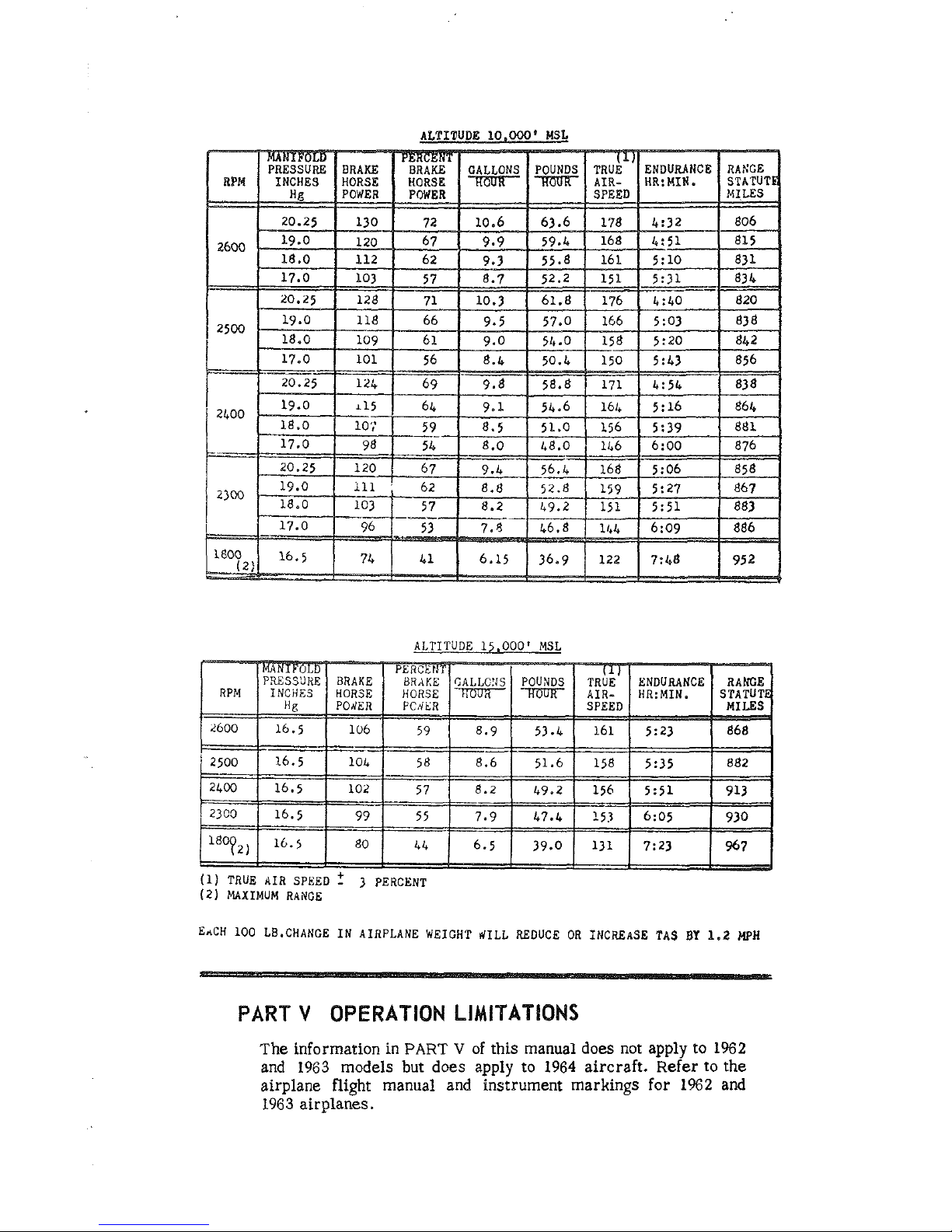

(Reference pages 29-37)

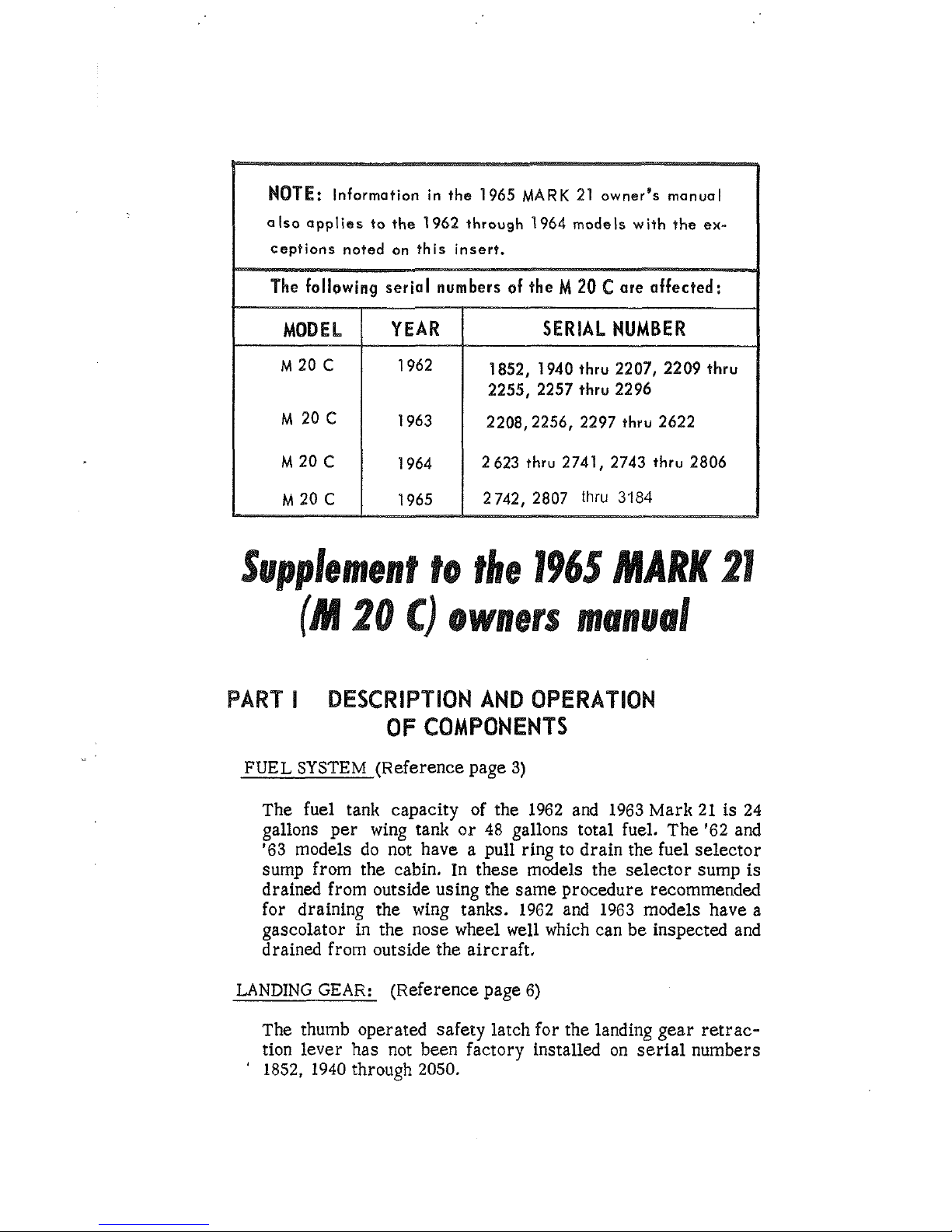

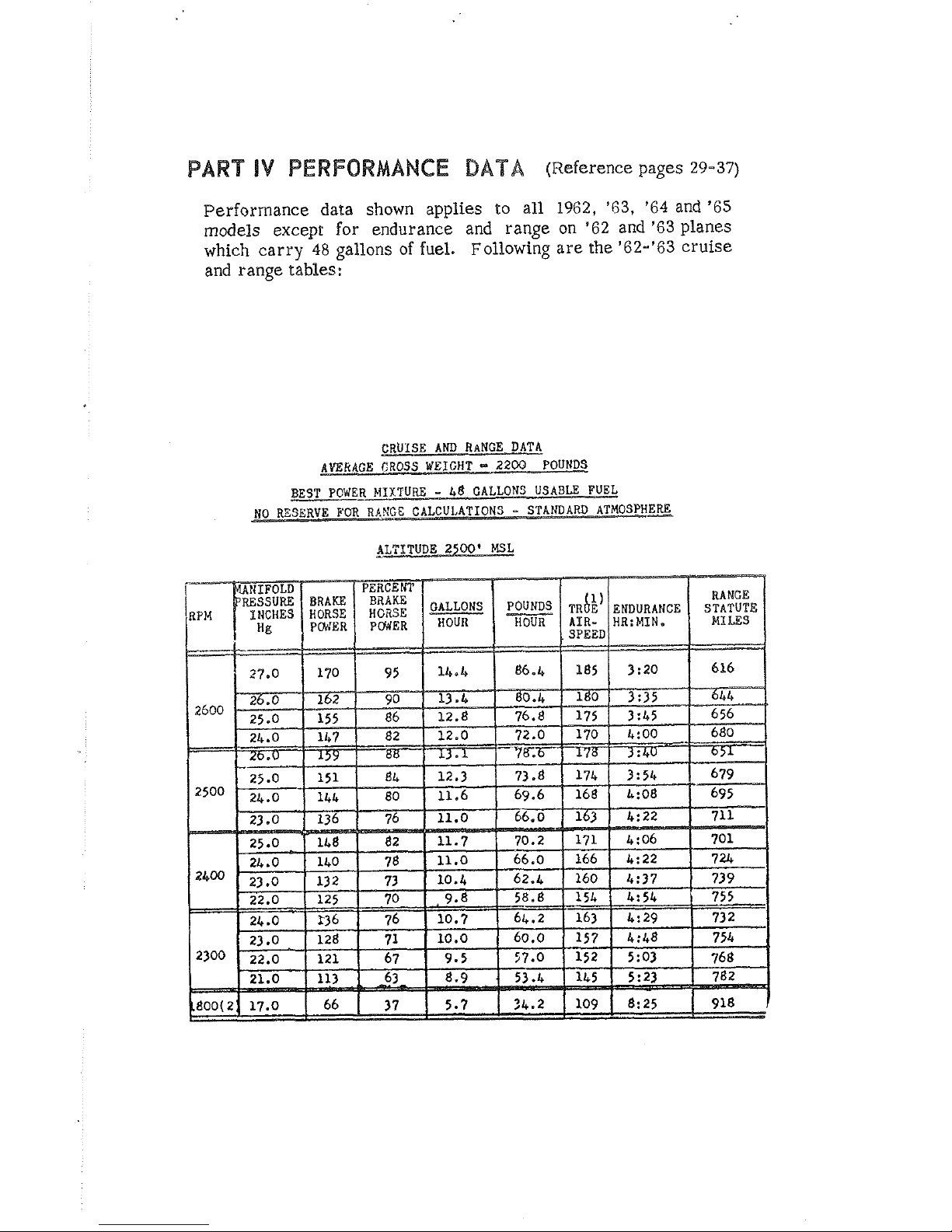

Perforrnance data shown applies to all 1962, '63, '64 and '65

models except for endurance and range on '62 and '63 planes

which carry

48

gallons of fuel. Following are

the

'62-'63 cruise

and range tables:

CRUISE

AND

RANGE DATA

AWRGGE

CROSS

WEIGHT

-

2200

POUNDS

BEST

POWER

MIXTURE

-

48

GALLONS USABLE FUEL

ALTITUDE

5000'

K3&

AETIPUDE

10,000'

MSL

I

I

I

I

I

I

J

(1)

TRUE AIR SPEED

?

3

PERCENT

(2)

MAXIMUM

RANGE

EACH

100

LB.CHANGE IN AIRPLANE WEIGHT

#ILL

REDUCE OR iNCREASE

TAS

BY

1.2

MPH

PART

V

OPERATION

LlMlTATlONS

The information in

PART

V

of this manual does not apply

to

1962

and

1963

models but does apply to

1964

aircraft. Refer to the

airplane flight manual and instrument markings for

1962

and

1963

airplanes.

OPERATE

THIS

AIRCRAFT

ONLY

-

@

after

reading

owners

manual

@

with

owners

manual

on

board

@

after

you

are

fully

qualified

81

understand

all

of

the

aircraft

operating

characteristics&

limitations

MARK

2

OWNERS

MANUAL

Thank you for choosing a hlooney

The wisdom of

your

selection of a Mooney Mark

21

will

be

proved many times as your hours in this exceptional

airplane increase.

It

takes a

long

time

and a lot

of

flying to appreciate

all of the

mauy outstanding features built into the

Mark

21.

This

owners manual

will

help you know

your

airplane

better and will make your experience with the Mark

21

more enjoyable.

Welcome

to

the rapidly growing family of blooney own-

ers.

M001VE

B8

AIRCRAFI,

INC.

LOUIS

SCHREINER

FIELD . XERRVILLE.

TEXAS

1965

MARK

21

PART

I

DESCRlPTlON

AND

OPERATBa

OF

COMPONENTS

Page

Genera

I

Propeller

Engine

Engine ignition

Fuel System

E

lectrical System

Airframe

Landing Gear

Flight Controls

Mooney Positive Control System

Trim System

Flaps

Vacuum System

Brakes

Heating and Ventilation Systems

Pictures

PART

!l

FLIGHT

PROCEDURES

General

Weight and Balance

Pre-F

light Inspection

Entering the Airplane

Starting the Engine

Cold Weather and Manual Starting

Taxiing

and Ground Operation

Pre Take-Off Check

Take-Off and

Climb

Power Changes

Cruise Procedures

Indicated Airspeed

Fuel Management

bet-Down Procedures

Carburetor

Heat

Landing Procedures

Normal Landing

Stopping

the

Engine

PART

III

SERVICE

AHD

MIHTEHANCE

Page

Genera

I

Ground Wondl ing

Propeller

Engine

Battery

Care of Interior

Care of Exterior

Windows

banding Gear

Vacuum Operated Step

Required Data

Service Letters and

Bulietins

PART

l\d

PERFORMANCEDATA

Take-Off and

Climb

Data

(Fig-

7)

Climb Performrsnee (Fig.

2)

Cruise and Range (Fig.

3)

(Fig.

3A)

(Fig,

3B)

(Fig.

3C)

(Fig.

3D)

Stall

Speed

vs.

Bonk Angle

(Fig.

4)

Maximum

Range & Glide Chart

(Fig.

5)

Landing

Dora

(Fig.

6)

PART V OPERAnING

LIMBPATBONS

Airspeed Limitations

Engine Operating

Limitations

Engine lnstrunnent Markings

Page

2

9

3

0

31

32

33

34

35

36

36

3

7

38

3

8

3

8

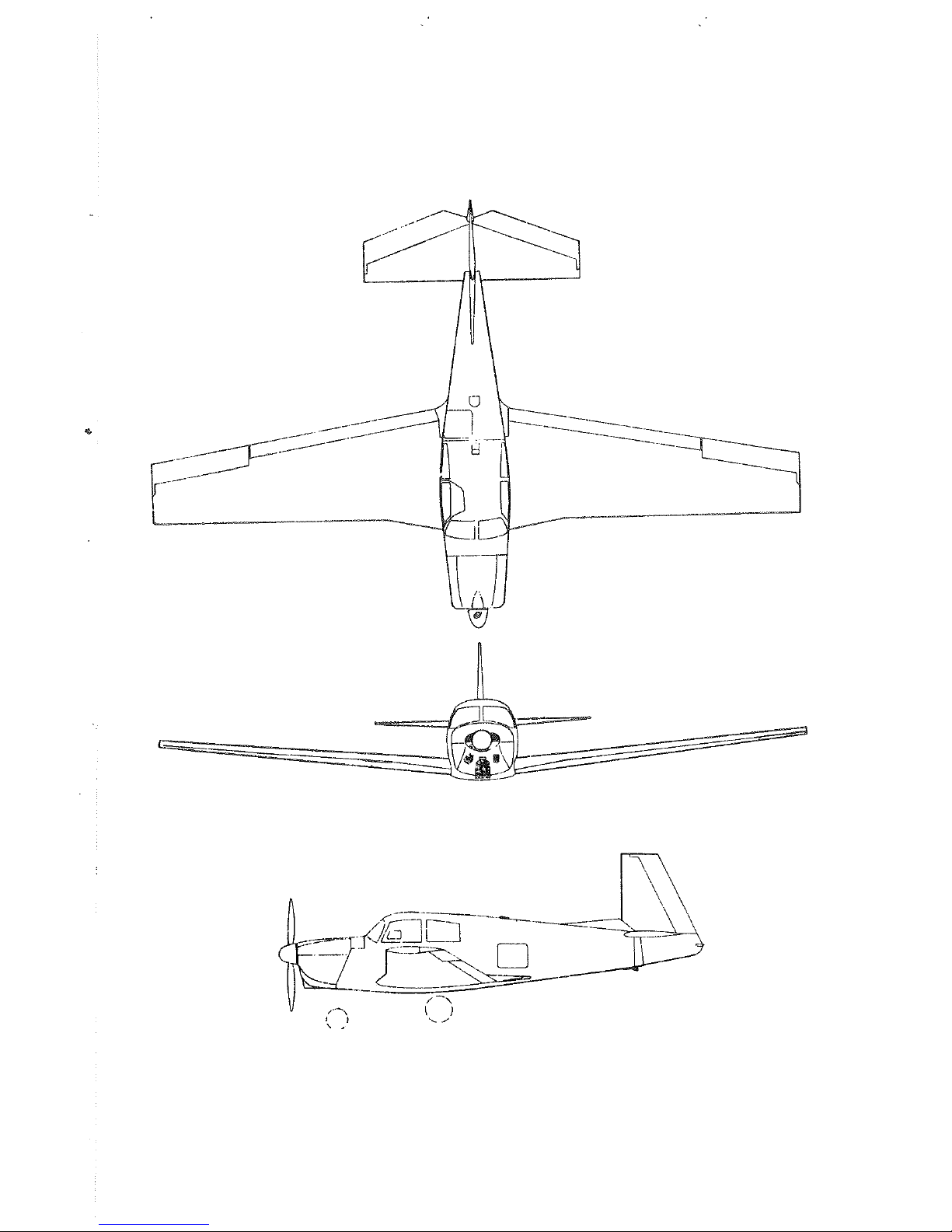

The Mark

21

is

a single engine four-place low wing, retractable

tricycle landing gear

airplane, The design and operation of this

aircraft are conventional with few exceptions, There are no

tricky or complex operational characteristics requiring unusual

or extreme piloting skill. This section

will describe some of

the components of the Mark

2%

and operating details.

PROPELLER

The Mark

2%.

uses an aluminum alloy constant sped propeller

of

74

inch diameter. The pitch of the blades is contro%ld

by

engine oil pressure which acts

to

increase or decrease blade

angle of attack and thereby control engine sped. The propeller

control in the cabin operates

the

propdler governor which

contro%s the oil pressure providd to the propeller hub. The

governor

sating functions to maintain the engine at a constant

SF&

by actuating blade angle of ;track. In essence then, the

function of the

propeller control in the cabin

is

to regulate and

maintain the rotational

sped of the engine

at

a desired setting,

The Mark

21

is powered by the Lycoming 180hp 0-360-AID

four cylinder engine. This engine uses

91/98

octane fuel. Four

rubber bushings on the aft side of the engine provide mounting

and vibration isolation. Engine manifold pressure is regulated

5y

the push-pull throttle control on the panel.

The fuel-to-air ratio (mixture) is regulated by the hexagon

shaped push-pull control located between the throttle and propeller controls in the cabin. The Mark

21

engine baffling directs

air flow over the cylinders for cooling in flight. Cowl flaps are

provided on .the lower cowling to allow more free air flow on

the ground and during low speed, high power conditions

(Leo,

climb conditions). Cowl flaps should always be open on the

ground, and prolonged engine operation on

the

ground should be

avoided to prevent engine overhearing.

A

push-pull control is

provided klow the instrument panel and to the right of the

pilot for

operation of the cowl flap.

The engine has a pressure-type wee-sump %ubsicaeion

syseern.

It has an eight quart capacity; however, as a general rule, when

the oil

level drops below six quarts, one quart

is

added. This

will maintain the oil level

between the

six

and seven wart

level.

See Pare

IPI

for tgrge of oil used and time kerween

oil

changes.

An

oil temperature thermostat, see for

180

I?*

is

located in

the oil reservoir to assure warm oil for ,311 operations. An oil

cooler

is

mounted on the lower %eft side of the cowling to pre-

vent the

oil from overheating. An oil filter mounted on the fise-

wall is available

as

optional ewipmene.

The Mark

29

ignition system

has

the following features:

1.

Two Bendix magnetos, the left mapeto being eqippd with

a

see

of retard breaker points.

2.

A

starting vibrator, located on the upper firewall, which

furnishes a shower of sparks for starting.

3.

A

switch which combines both ignition and starting functions.

4.

Shielded spark plugs and ignition harness to suppress radio

noises.

When the push-type starter switch

is

activated in the -'startD'

position, the starter vibrator sends an interrupted current

through the retard-breaker points while the right

magndo is

grounded out. The left magneto then provides a shower of sparks

to each cylinder after the piston has reached top dead center on

the compression stroke. The engine starts sooner and easier

because of this system,

FUEL

b"BSfEDIL

Fuel

is

comain4 in two imegral sealed sections in the front

part

of each wing root. Each tank will hold

26

gallons of gasoline.

These fuel tanks each have a sump drain under the wing from

which

fuel may be sampld to check for water or sediment con-

tamination. A small plastic cup with an actuator prong

is

pro-

vided to obtain

fuel samples. If water

is

present in the fuel, a

distinct line separating the water from the gasoline may be

seen through the plastic cup. Water,

king heavier, will be on

the bottom of the

cup, ad the light-colored fuel will

be

on

top.

Aluminum fuel lines feed the fidd from the tank to a two-way,

positive-setting selector valve on the

floor ahead

0%

the pilot's

seat.

The selector valve feeds fuel from one of the tanks at a

time, and

also has an "off" position for extended periods of

storage o

I-

for emergency use. The selector valve also contains

a

sump

drain which

is

actuatd by pullfrag the ring adjacent

to

the fuel valve handle, Switch the selector valve handle to the

right and left

tanks

to drain the respective %laaes.

Be

sure sump

drain returns

to

normal closed position after releasing the ring.

Fuel

is

fed from the selector valve through the electric boost

pump,

then

to

the engine driven punip and into

the

carburetor.

The electric boost pump

is

turned on for take-off and Lnding

to provide fuel pressure if the engine driven pump malfunctions.

WARNING: Under no circumsfances should aviation fuel of

a

lower grade than 91/98 octane be used. Aviation

fuels may

distinguished by their color: 80 octane

is

red, 91 octane is blue, and 100 octane

is

green. If

91/98 octane is not available,

100/130 octane gas-

oline may be used.

THE ELECTRICAL

SYS"6M

The

Mark

21

electrical system

is

provided with a 50 amp

12

volt generator and a 35 amp-hour battery which

is

located

on

the forward left side of the firewall. All electrical systems can

Loading...

Loading...